Past Auction

Online Auction | Semper SE | Processing & Packaging Equipment for Powder Food Products

Started: 11 November 2024 at 23:00 GMT

Ended: 13 February 2025 at 10:00 GMT

Semper, member of the Hero Group, will be closing its infant formula, baby food and gluten free production facility in Götene, Sweden. The Götene plant is manufacturing gruel, porridge and infant dry milk formula products. This sale features several packaging lines (as new as 2019), drum dryers, mixing lines and late model general facility equipment. Offers for complete lines will be considered immediately. Sale in conjunction with Liquidity Services.

Share:

LISTING External Webpage

LISTING External Webpage![]()

Sale On Partners Webpage

Sale has ended LISTING 2610012

LISTING 2610012![]()

Unloading and Transport Station for Powdered Food VeBE / Piab | 2017

Output: Up to 6m³ product/h (bulk density 0.5-0.6). Bag Handling: Handles bags up to 1000kg. Bag Dimensions: Used for bags measuring: 970x970x1900. Approval: OK for Atex approval. Transport (PIAB): P.P80L.P6.76.33.CBA.1A.AAL.EX2.SE. Transport Distance: 5m horizontally and 4m vertically. Air Filter: Filter for transport air Hepa 13. Material: 100% Stainless steel except pipe for incoming transport air.Sale has ended LISTING 2610009

LISTING 2610009![]()

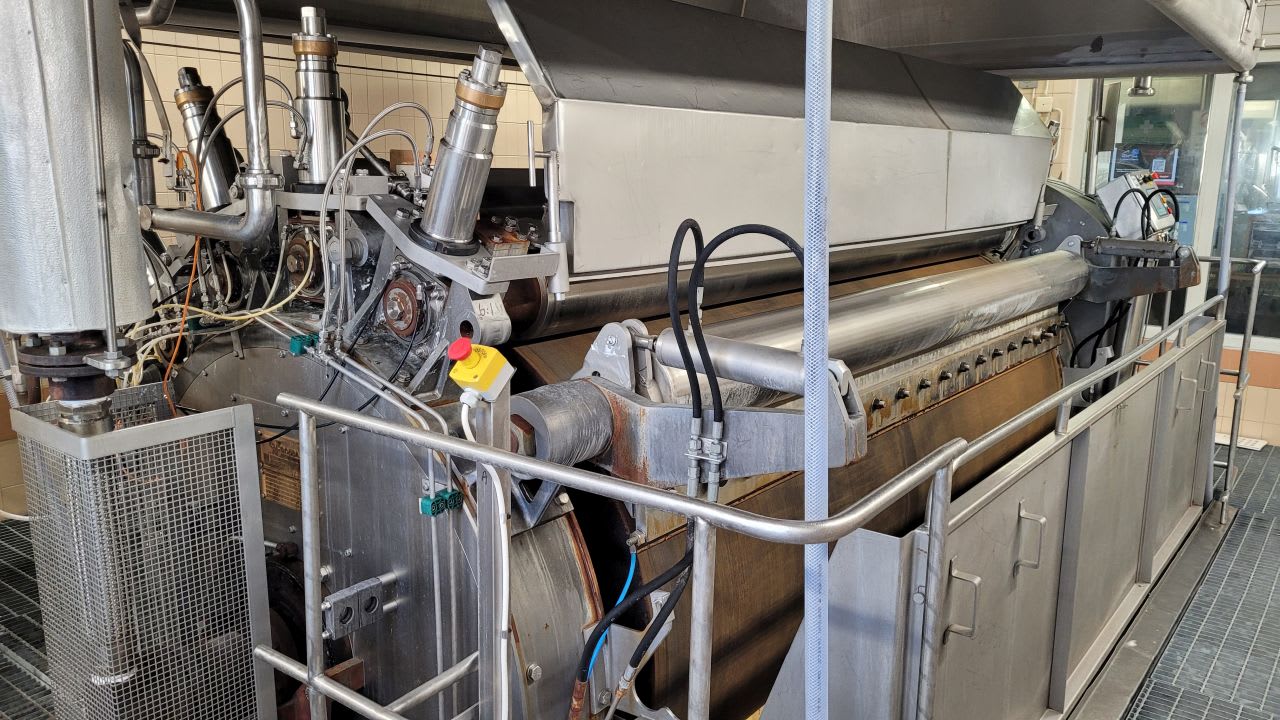

Twin Drum Dryer Andritz Gouda | 1989

Andritz Gouda drum dryer; Output 2 x 200kg / hour; size of drum Ø1500x3000mm

4 x applicator rollersSale has ended LISTING 2610001

LISTING 2610001![]()

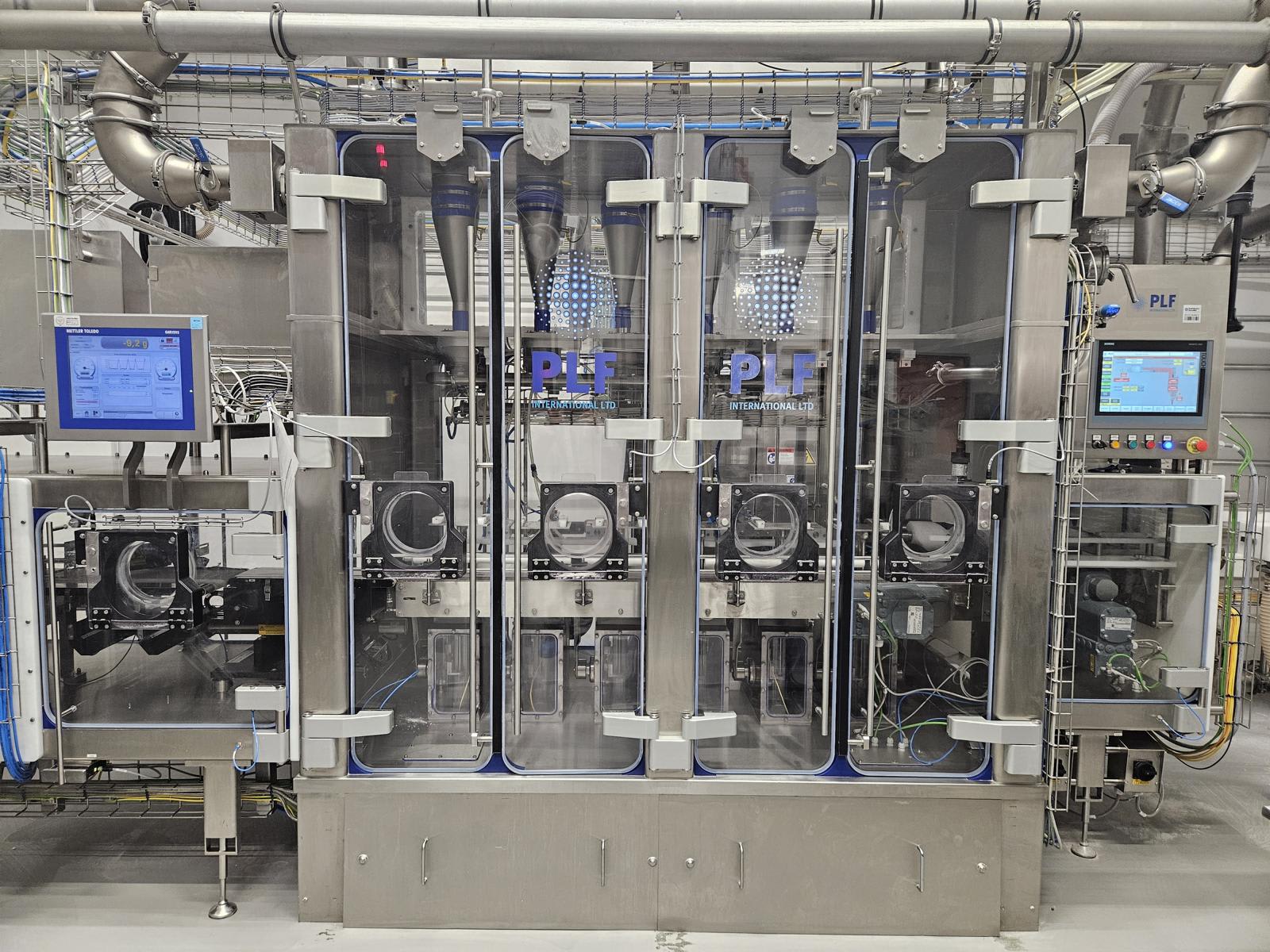

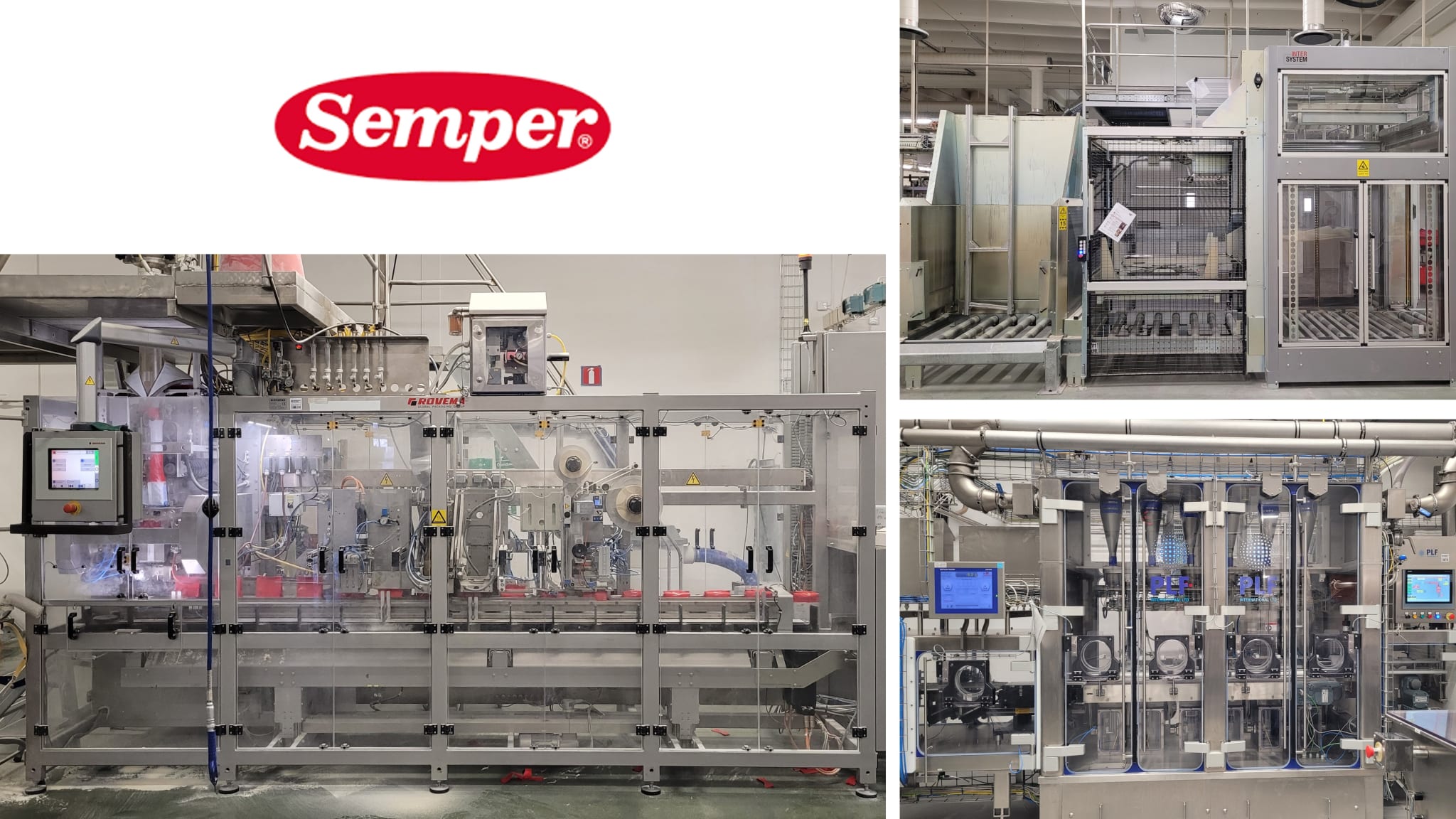

Can Filling Line PLF, Lanico, Inemur, Aylesbury Automation, Inter System, Österberg | 2019

Consumer pack line for infant formula Powder in tin cans below 1,5 % of oxygen for tin diameter 127mm + 99mm;

Line performs “high standard Infant formula packaging”. Formats cans Ø 127x153mm, Ø99x123,5mm. 127 caps both with spoon-cap and snap-cap - 99 with snap-cap. Laser prints on “blue-dot” at bottom of can.

including Can and Can-end material handling; depalletising, cleaning and UV sterilising (Inemur), handling of loose spoons (Aylesbury Automation), 360° inspection system (Eagle Vision), 6-head vacuum filler and top-up station (PLF/JBT), checkweigher (Mettler Toledo), seamer (Lanico), all enclosed in controlled N2 athmosphere, capper for spoon-cap and snap-cap (Euroflow), CO2 laser marker and vision (Markem Imaje), printer and applier (Markem Imaje). Output 2500 - 3000 cans / hourSale has ended LISTING 2610003

LISTING 2610003![]()

Flip-Top Box Filling Line Graphic Packaging Trepko | 2009

Consumer powder pack line - N2 flushed, hermetic flip top box line including; Graphic Packaging filling machine with Bosch filler (2009), hot melt unit Nordson ProBlue 4; controlled atmosphere Dust handling unit, Mettler Toledo metal detector and Xray unit, Bosch weighchecker, Markem Imaje coder. Output 3,000 bags per hour. Format: Hermetic FlipTop box.

Formats: Box: W138, D73,5, H151,5Sale has ended LISTING 2610011

LISTING 2610011![]()

Pallet Wrapper Cyklop/Markem Image Cyklop Ctt 1000 - Ctt10001010+TSD | 2023

Pallet wrapper Cyklop CTT 1000; including top sheet foil application, up to 70pallets/h Sale has ended LISTING Preview

LISTING Preview![]()

Complete Production Plant for Powdered Food

Located in Sweden

Sale has ended LISTING 2610006

LISTING 2610006![]()

Automatic Blending Line Ruberg | 2001

Automatic batch blending line for powder products including: receiving filter-hopper on loadcells, 2m3 Ruberg mixer, vacuum receiving hopper with filters, funnel on blender, 4 x emptying stations for tote bins, scale for finished blend, Pedro Gil vacuum pump for vacuum transport, Weighing takes part in receiving hopper on top of blender (gain-in-weight); 4 tote bin emptying stations connected to line via augers; Funnel + cutting station on blender to ad “small ingredients” directly in blender; currently connected via Ø156mm pipes and valves; 100% stainless steel and food approved Sale has ended LISTING 2610008

LISTING 2610008![]()

Drum Dryer Andritz Gouda | 2013 (Refurbished

Andritz Gouda drum dryer; output 200kg / hour; size of drum Ø1500x3000mm; 5 x applicator rollers; incl. hydraulic unit with filter Sale has ended LISTING 2610005

LISTING 2610005![]()

Automatic Blending Line Hosowaka (Nauta) , Aerzener Blow and Vacuum | 2001

Automatic batch blending line for powder products (cereal mixing line with Nauta mixer) including: receiving hopper on top of blender; double cone 4m3 nauta mixer, 3 x tote-bin emptiers with silos, 500kg hopper and 100kg hopper, receiving scales under mixer, Aerzener vacuum / blow compressors, output 5000kg on bulk ensity 0,45g/ml (estimated); Double cone Nauta mixer from Hosokawa 4m3; Weighing takes part in two receiving hoppers on loadcells 500kg and 100kg. They are filled via vacuum transport from silos or tote-bin stations; Weighing hoppers empty first gravimetric to hopper below, and then by blowing to receiving hopper on top of mixer. 3 tote bin emptying stations + several silos with vibrating sieves connected to line100% stainless steel and food approved; CE approved

Win CC Scada and Siemens PLC

Today the line is connected to several silos that will not become availableSale has ended LISTING 2610004

LISTING 2610004![]()

Automatic Blending Line Amixon, Anutec, Mettler Toledo | 2019

Automatic batch blending line for baby food products including: preweighed bags station on top of small Anutec premixer on loadcells, big bag emptiers on loadcells empties via vibrating ducts to main mixer, 4m3 main mixer empties in 4,5m3 hopper underneathn both on loadcells, Output: approx. 3mT/hour

State of the art 4m3 Amixon mixer equipped with 0,2m3 pre-mixer from Anutec on top.

Raws taken in gravimetrically from 3 big bag emptiers (loss-in-weight) and from manual dosing station on top of small premixer.

Mixer empties out gravimetrically in 4,5m3 hopper underneath.

Hopper empties via vacuum-transportSale has ended LISTING 2610010

LISTING 2610010![]()

Palletizing Line ABB/PIAB | 2015 (Refurbished)

ABB FlexPalletizer robot; weight approx. 1950kg; incl. control unit and handheld controller; weight approx. 250kg Formats: 1200 x 800 & 1200 x 1000 Sale has ended LISTING 2610013

LISTING 2610013![]()

Unloading and Transport Station for Powdered Food VeBE / Piab | 2013

Output: Up to 6m³ product/h (bulk density 0.5-0.6). Bag Handling: Handles bags up to 1000kg. Bag Dimensions: Used for bags measuring: 970x970x1900. Approval: OK for Atex approval. Transport (PIAB): P.P80L.P6.76.33.CBA.1A.AAL.EX.SE. Transport Distance: 10m Air Filter: Filter for transport air Hepa 13. Material: 100% Stainless steel except pipe for incoming transport air.Sale has ended LISTING 2610002

LISTING 2610002![]()

Packaging Bag Filling Line Rovema, Mettler Toeldo, Markem Imaje | 2016 (Refurbished)

Consumer powder pack -gas tight_block bottom gusseted bag bag line including; Rovema SBS 250 bagger with labeller and closing strip supply - output 2450 bages / hour (On 725 bag format). Equipped with system for controlled atmosphere (N2). Bag footprint 135x65 (Reel width 425 Sale has ended LISTING 2610007

LISTING 2610007![]()

Automatic Blending Line Ruberg | 2001

Automatic batch blending line for powder products including: receiving filter-hopper on loadcells, 2m3 Ruberg mixer, vacuum receiving hopper with filters, 5 x emptying stations for tote bins connected to line, funnel on blender, scale for filling finished blend into tote bins, Pedro Gil vacuum pump for vacuum transport, output depending on pipe lenght and raw materials, maximum output at bulk density 0,45g/ml = 3,000kg /hour

Weighing takes part in receiving hopper on top of blender (gain-in-weight); 5 tote bin emptying stations connected to the line via augers; funnel + cutting station on blender to ad “small ingredients” directly in blender; currently connected via Ø156mm pipes and valves; 100% stainless steel and food approvedSale has ended