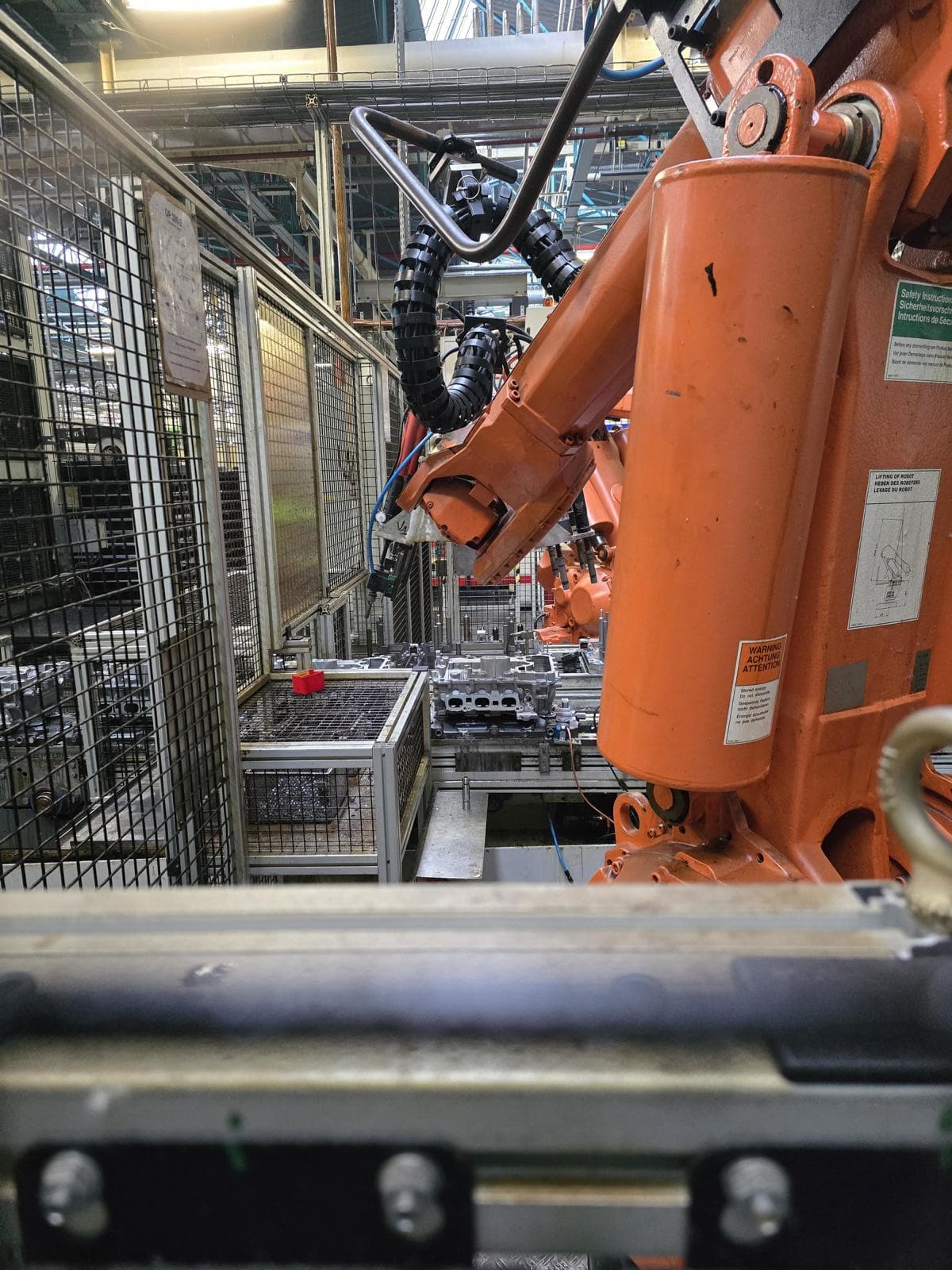

Private Treaty Sale | Stellantis Douvrin | Machining for Crankshaft, Cylinder Heads and Blocks

Starts: 13 November 2025 at 07:00 GMT

Ends: 31 March 2026 at 15:00 BST

In collaboration with Liquidity Services, Maynards offers a range of high-quality, well-maintained machinery and equipment, including CNC machines, compressors, and more, used for Crankshaft, Cylinder Heads and Cylinder Blocks manufacturing by a renowned automotive brand. The sale takes place on the Liquidity Services website.

Share:

Showing 77 of 77 lots

- LISTING 1

![Français]()

- LISTING 2830001

![Français]()

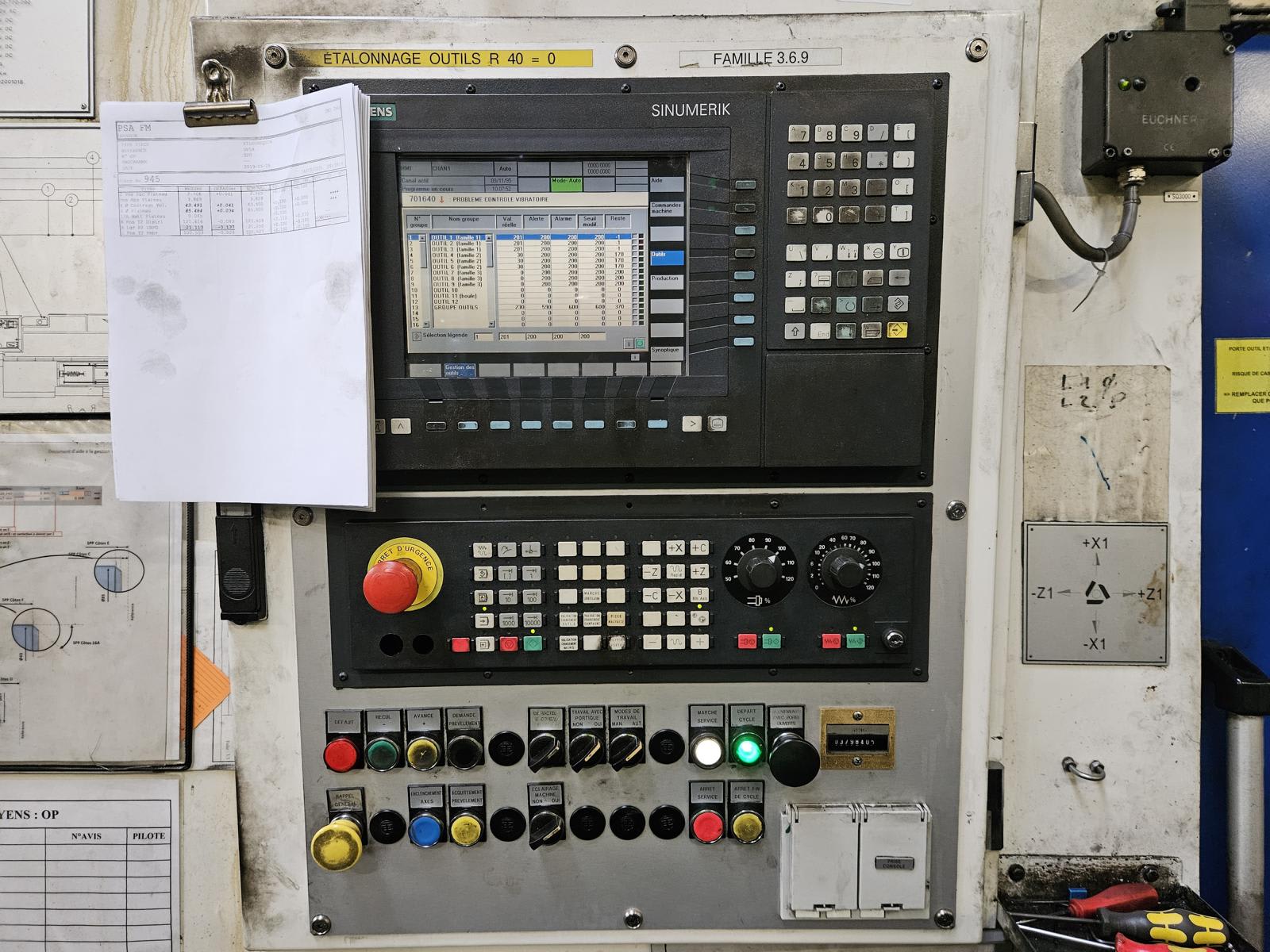

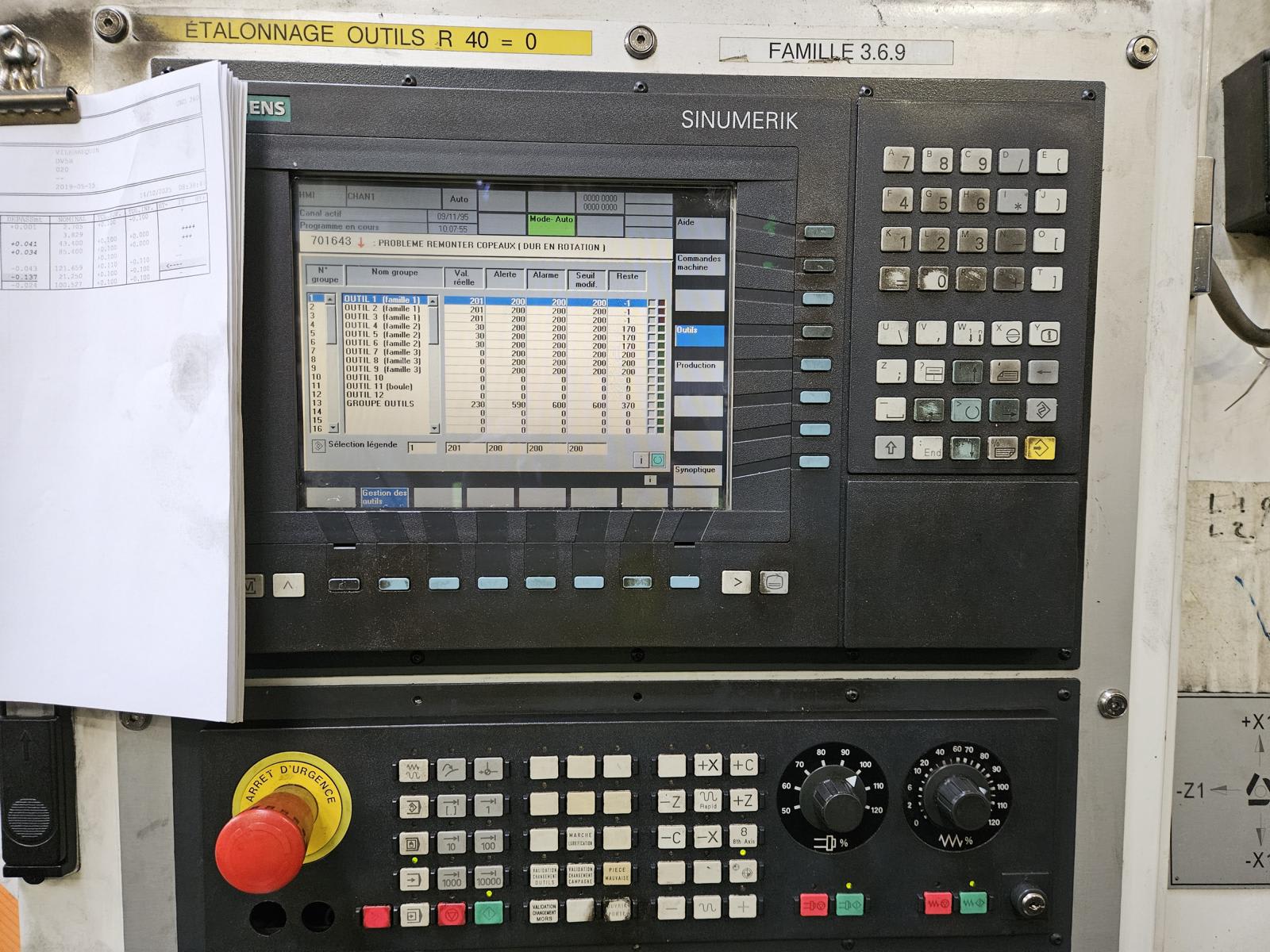

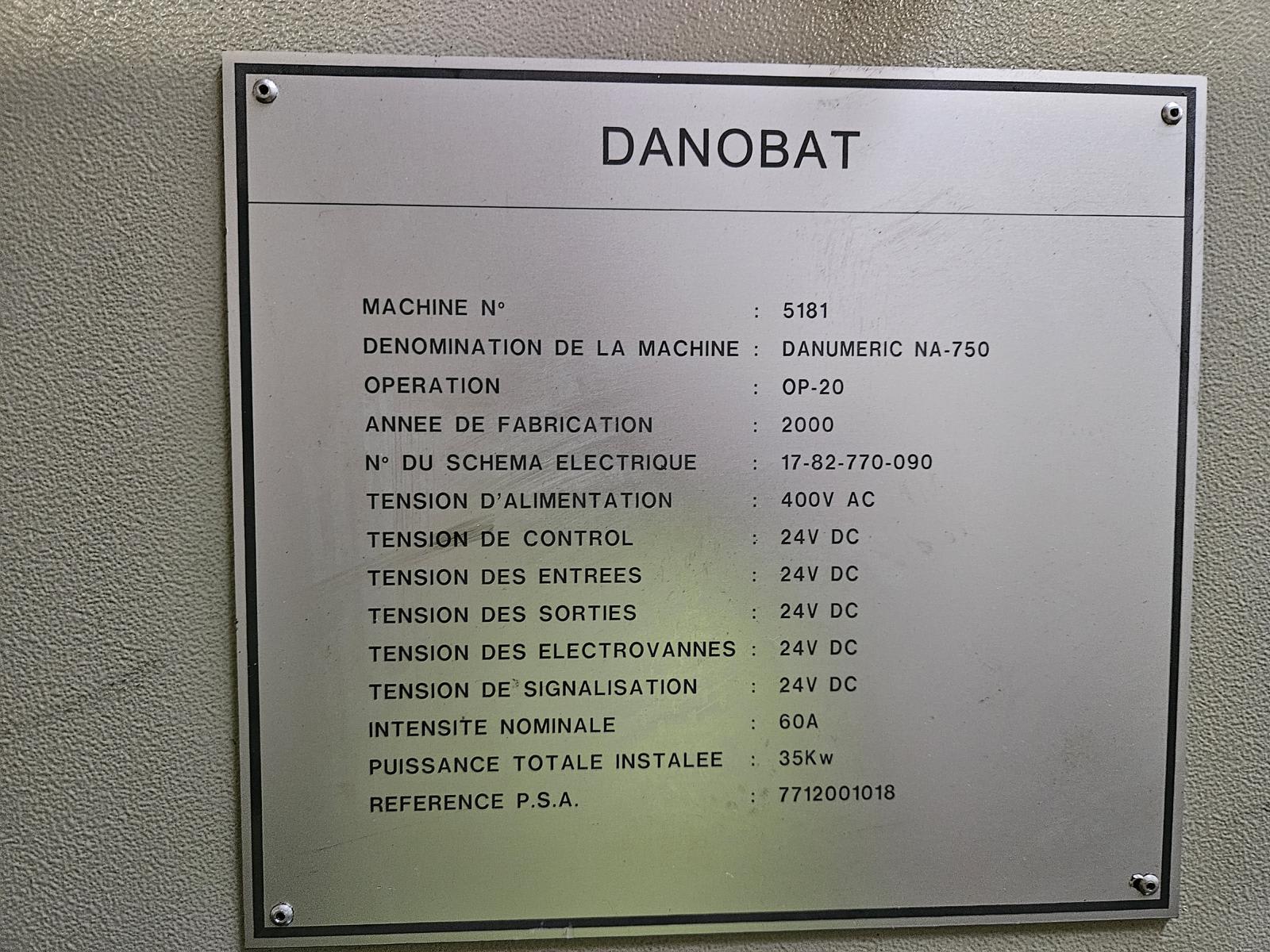

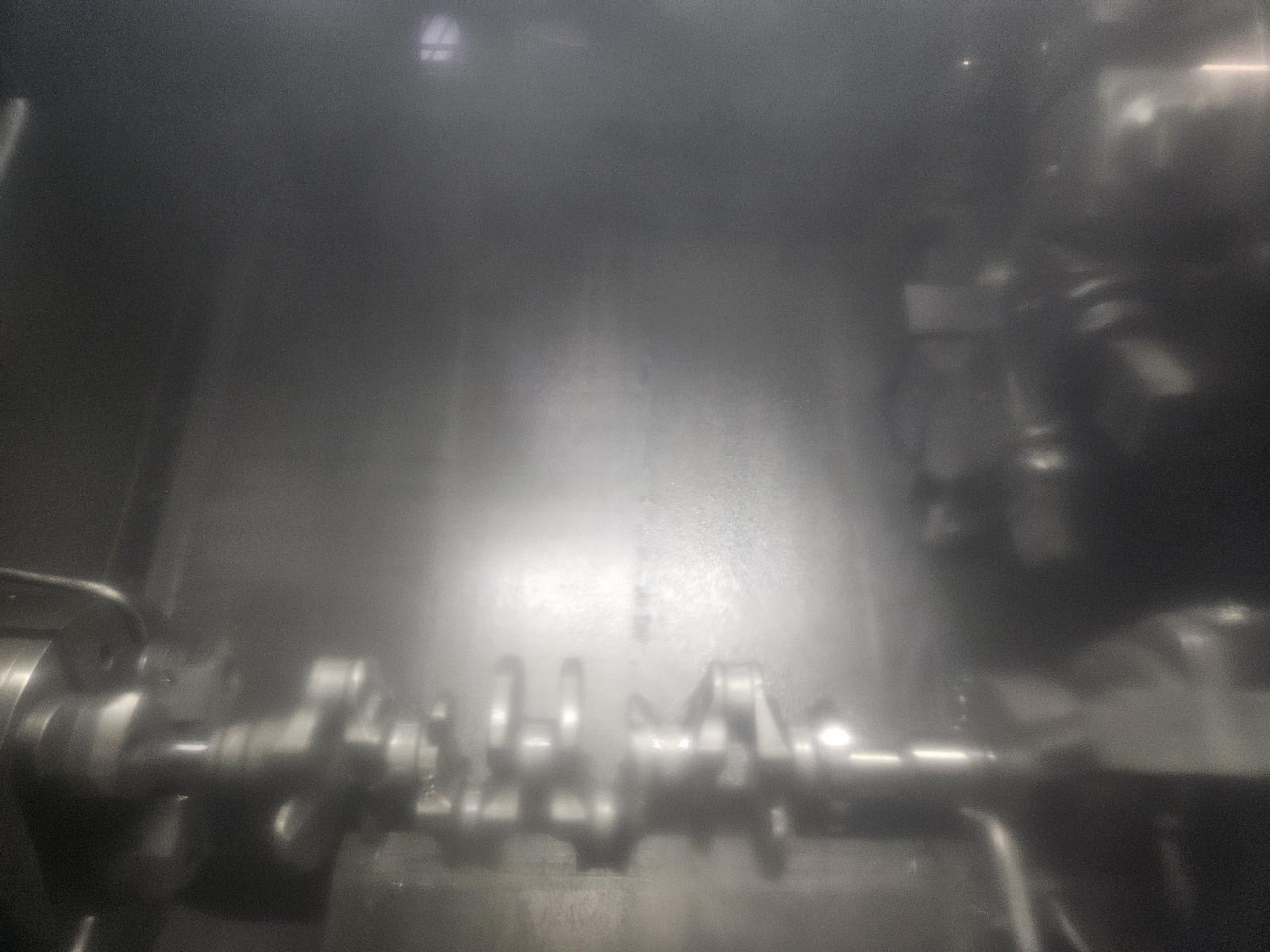

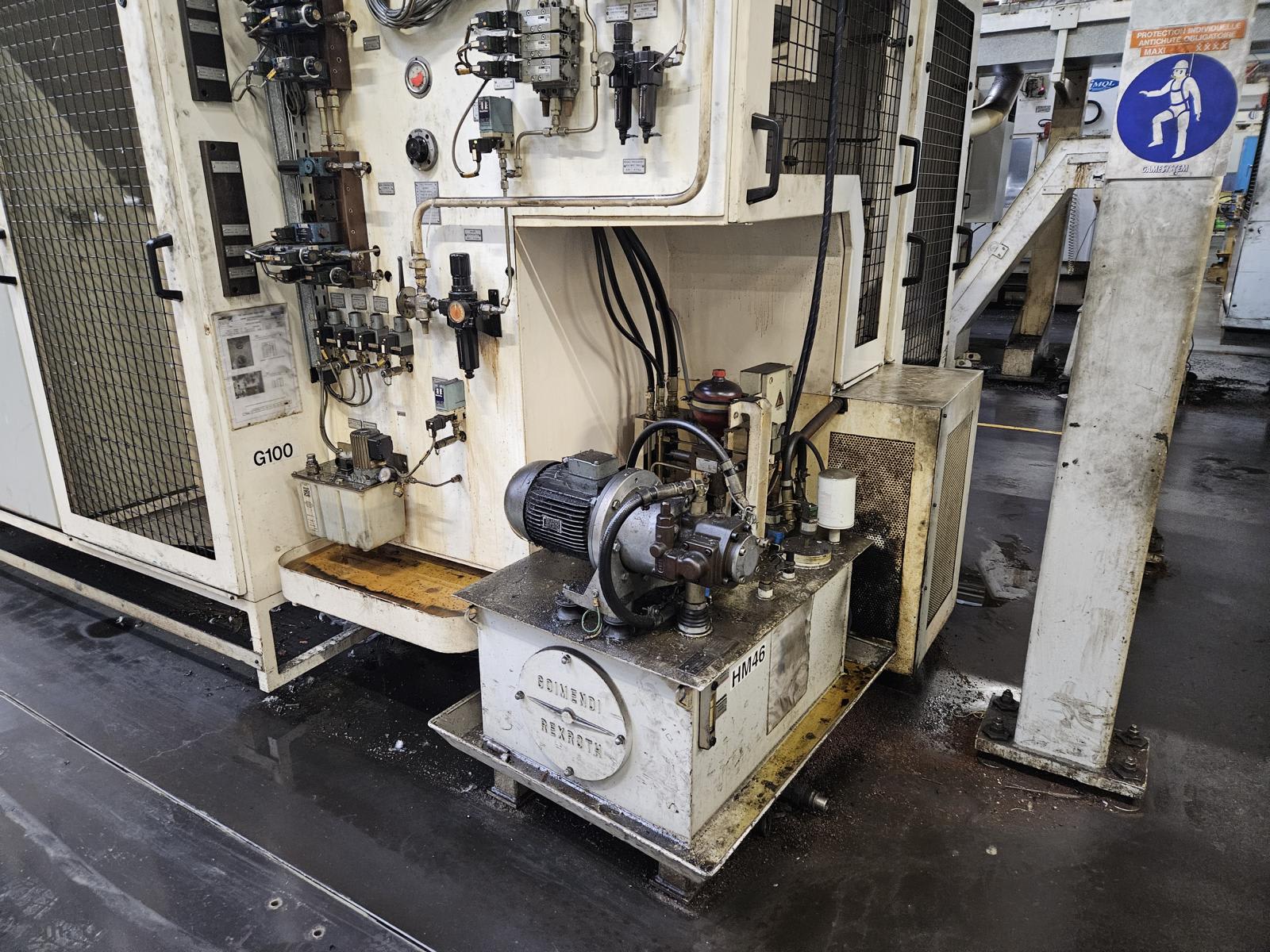

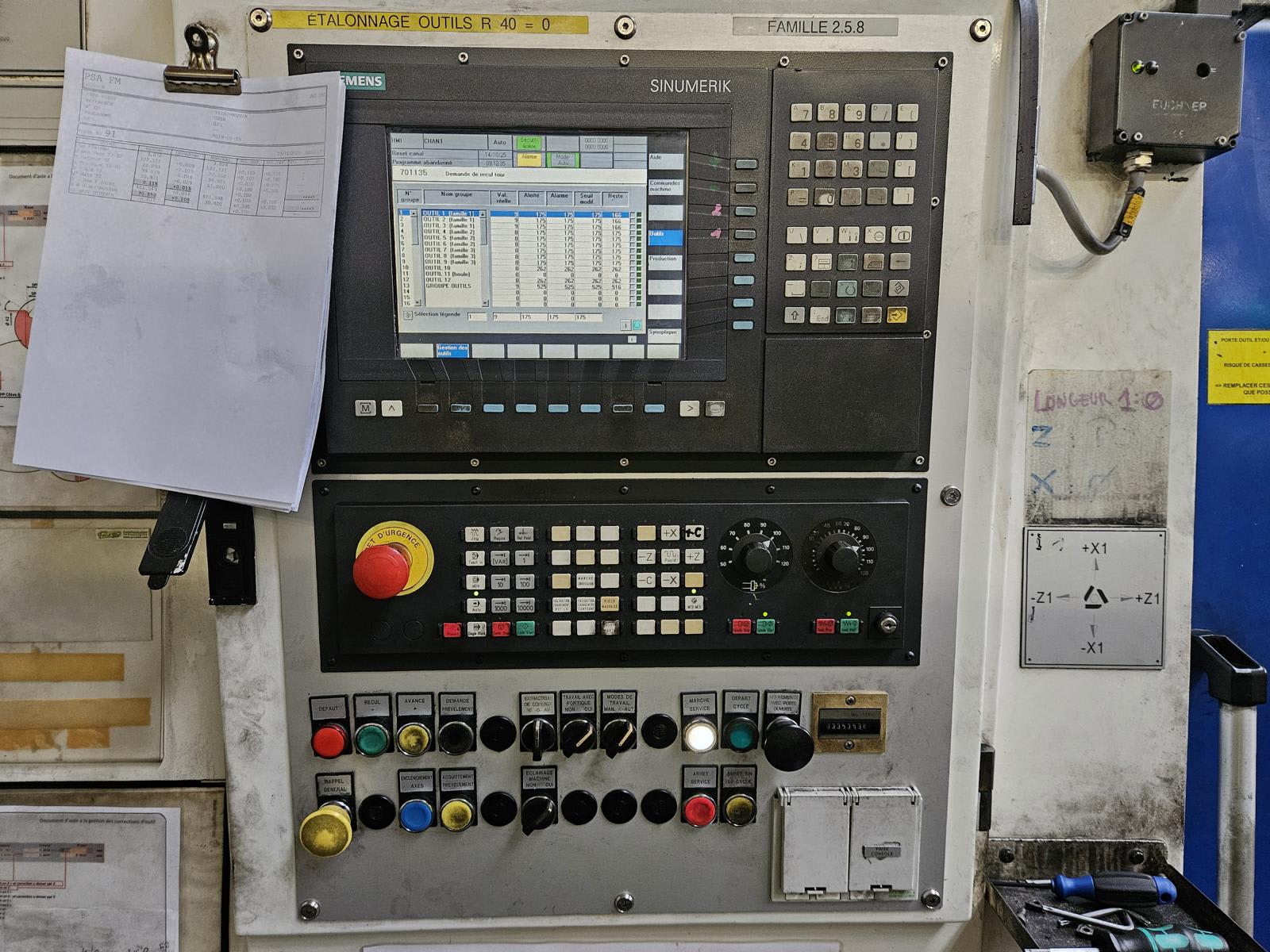

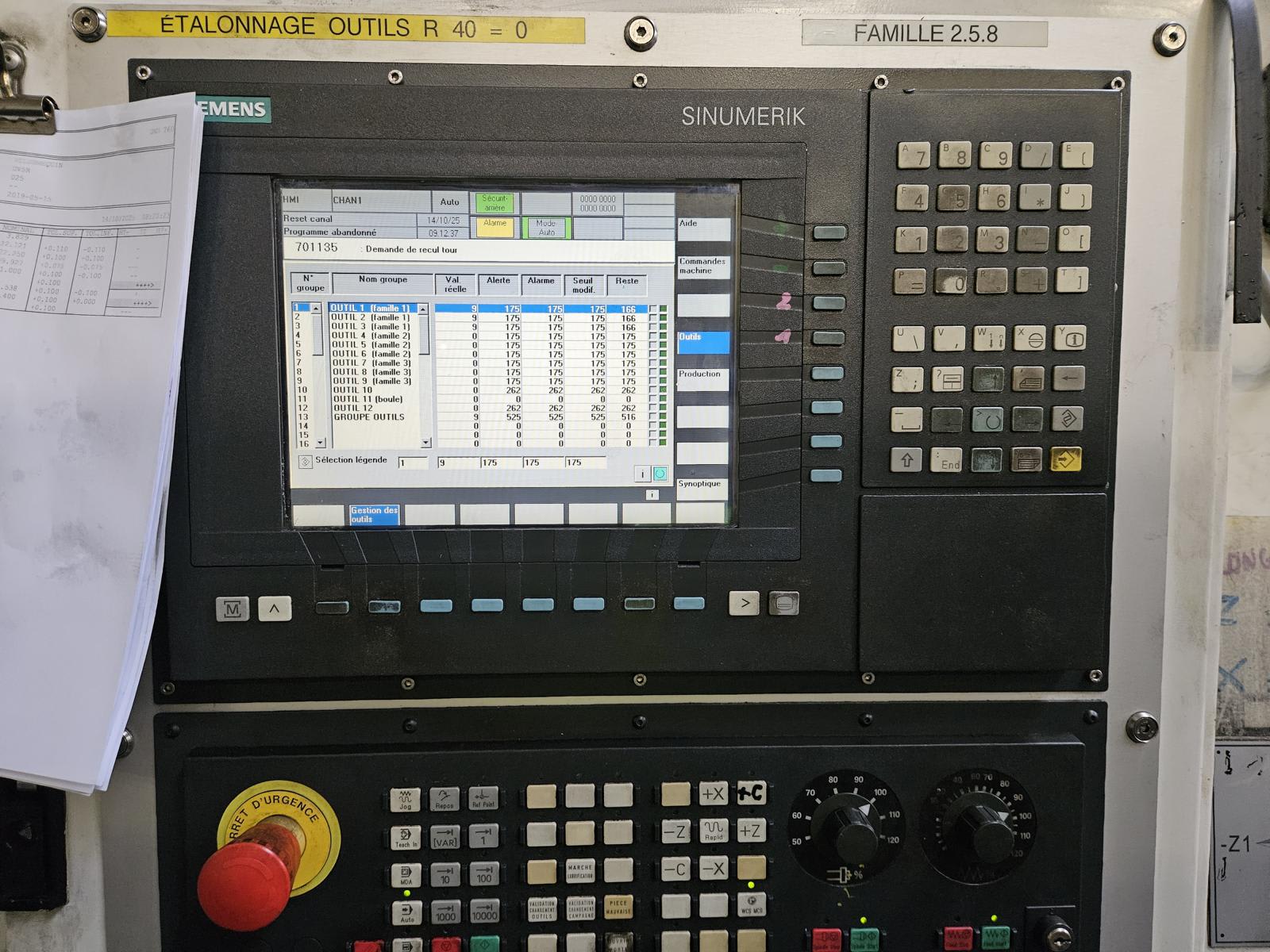

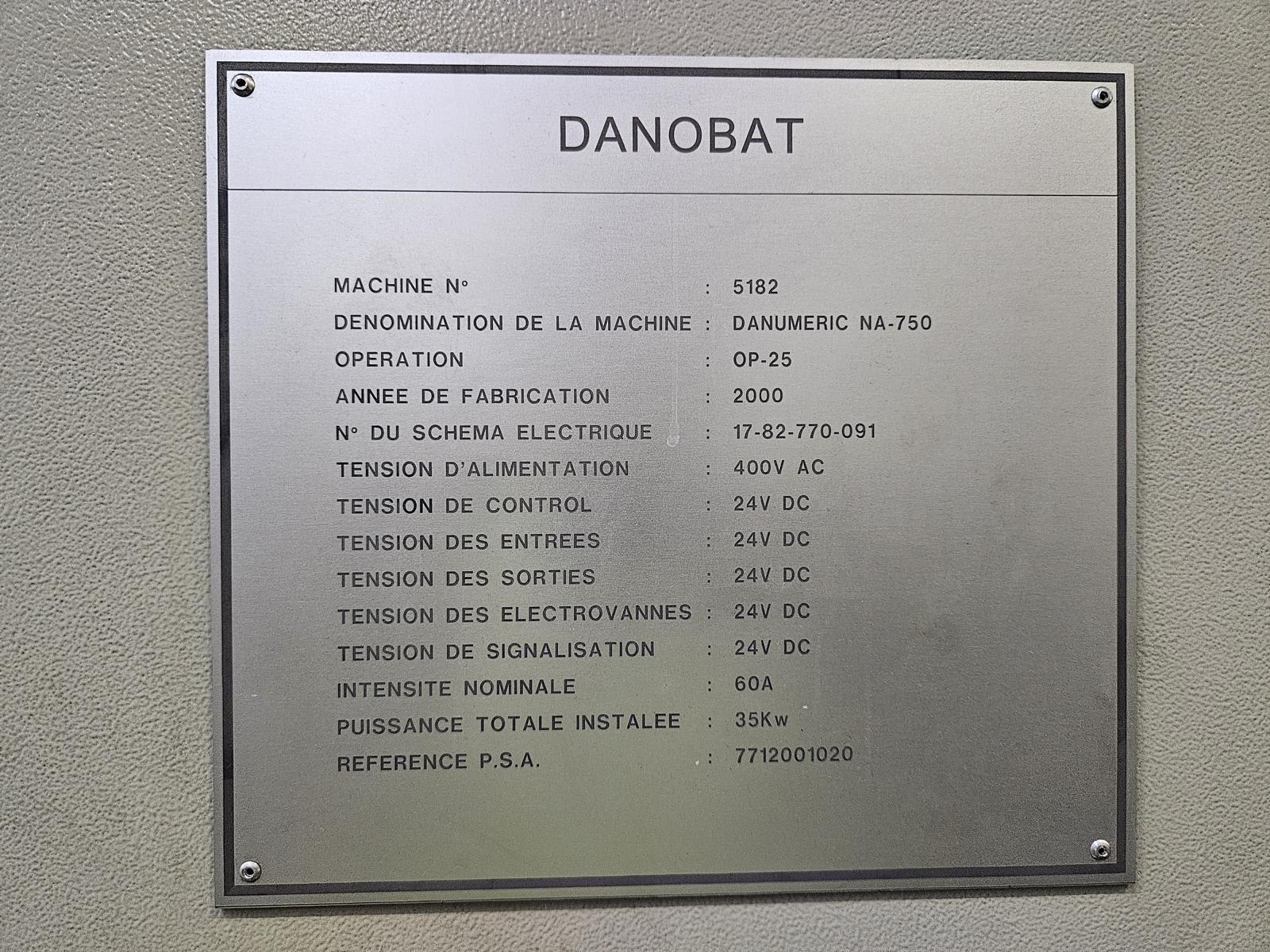

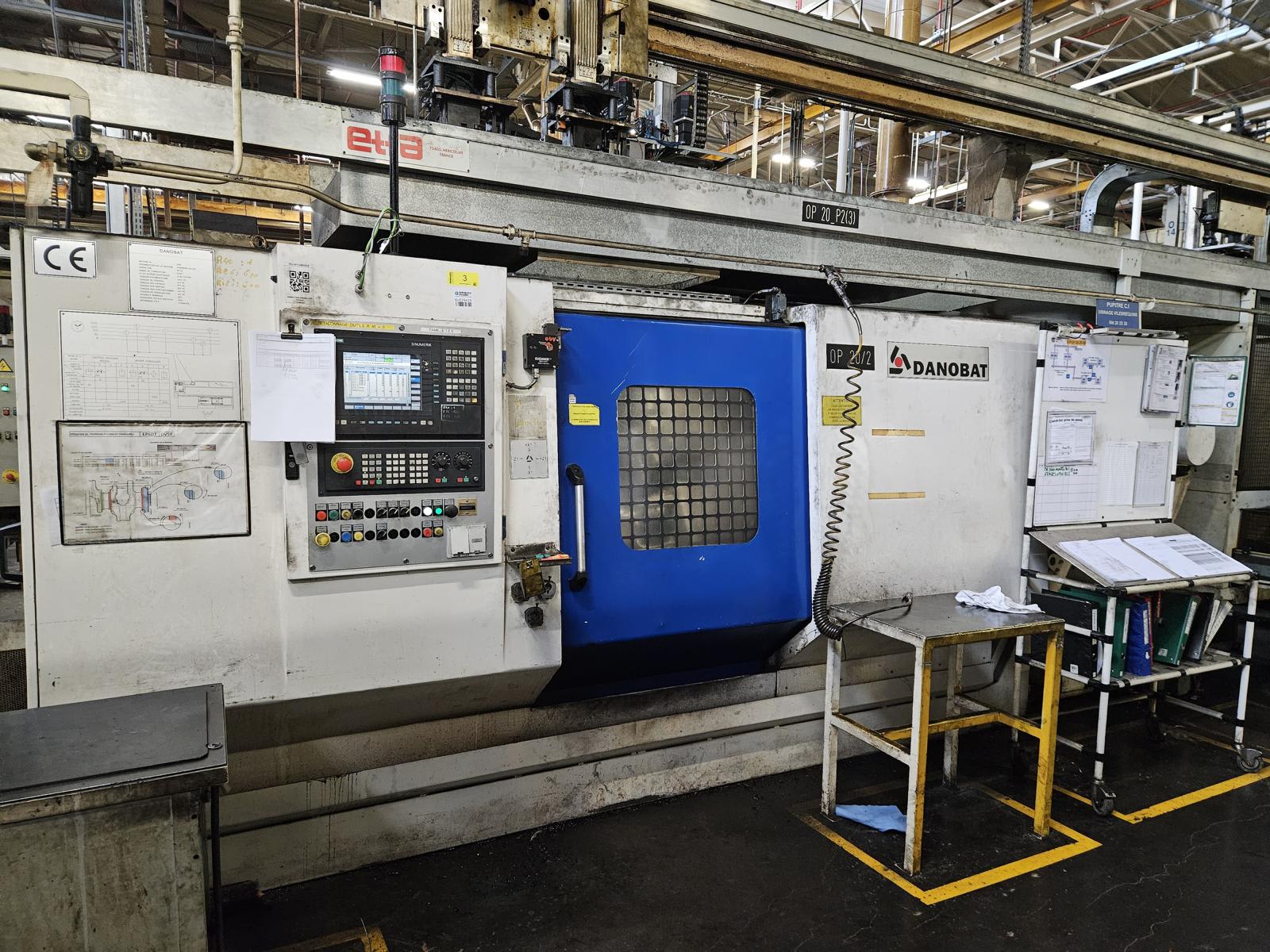

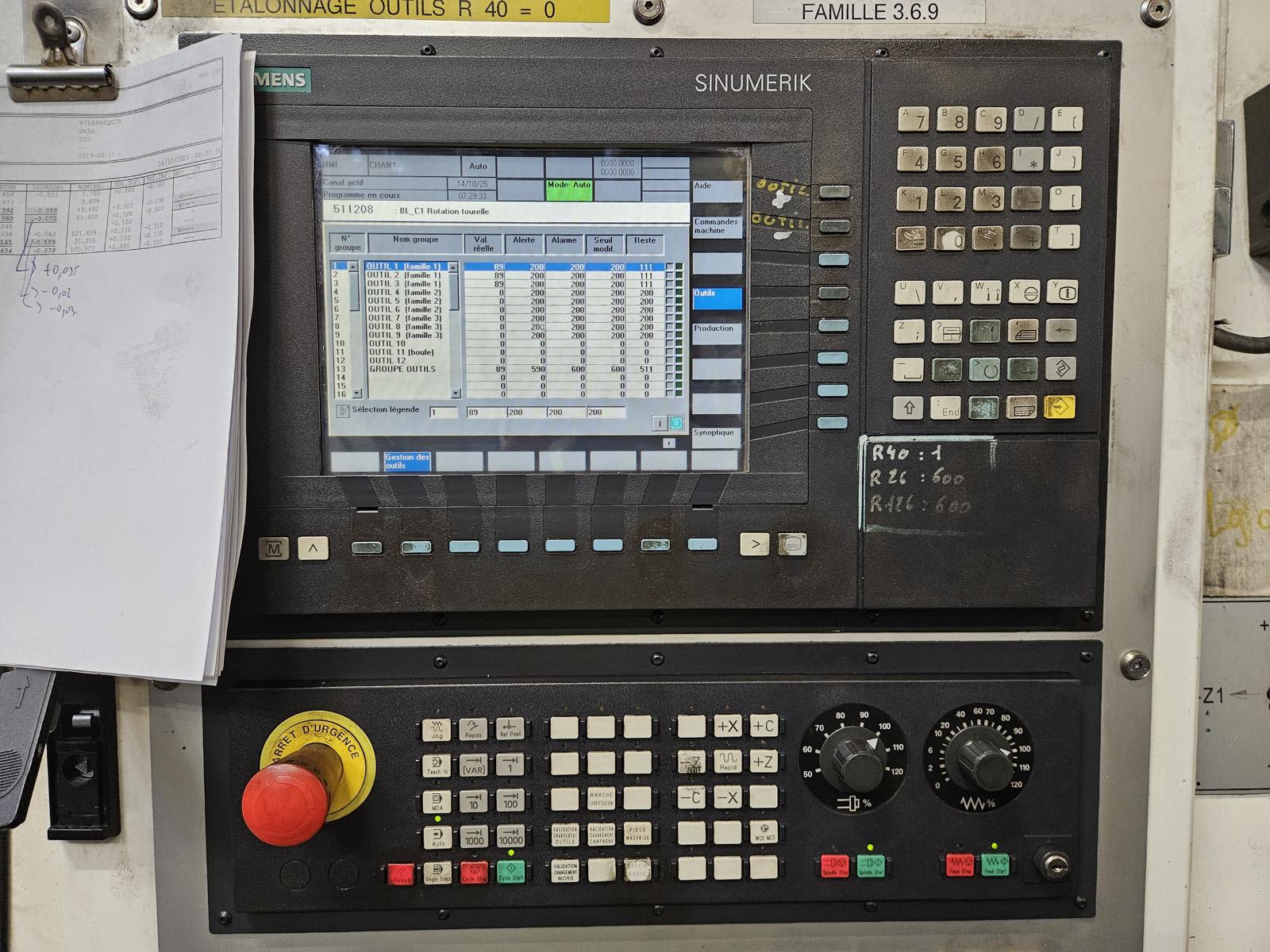

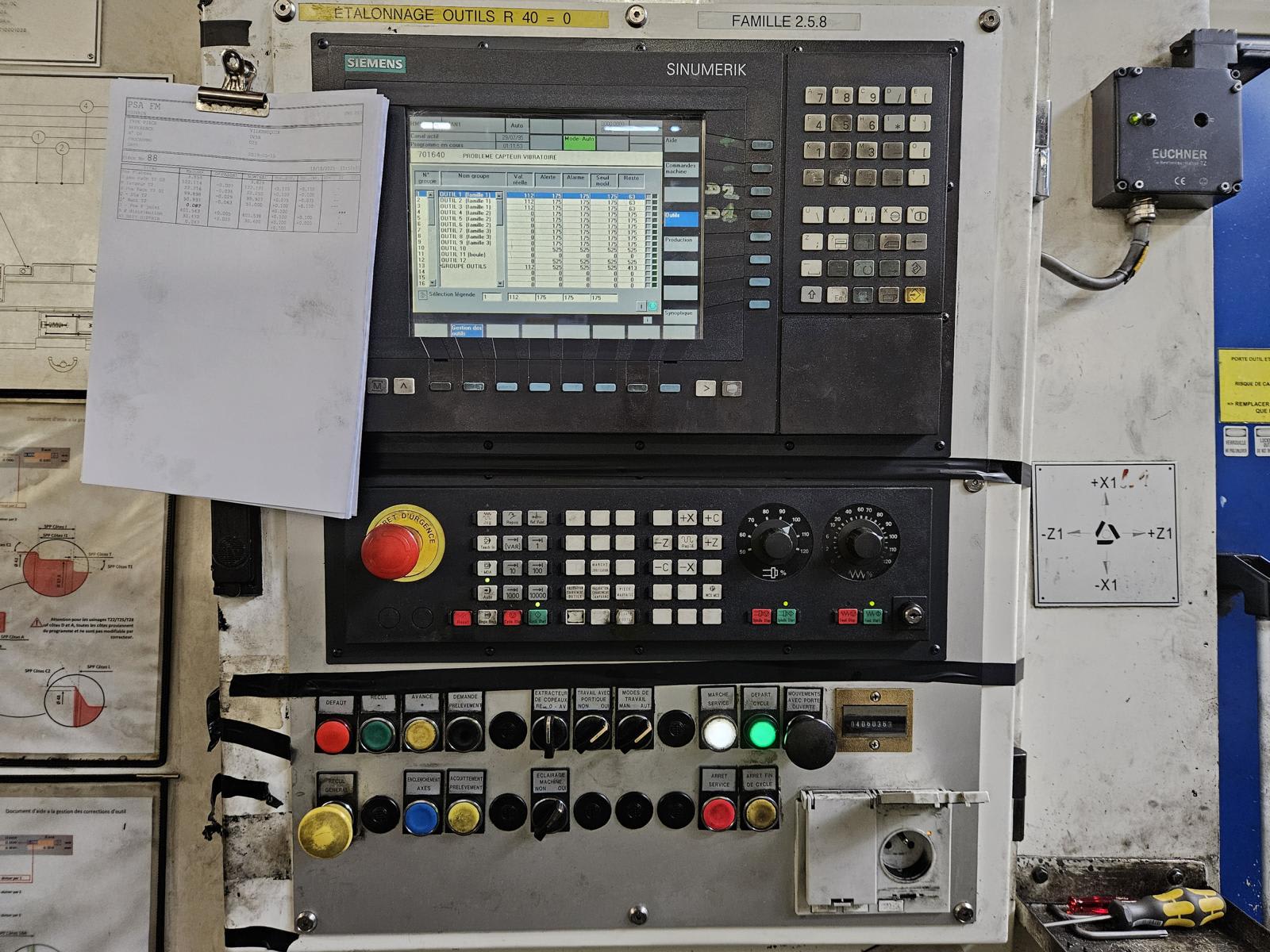

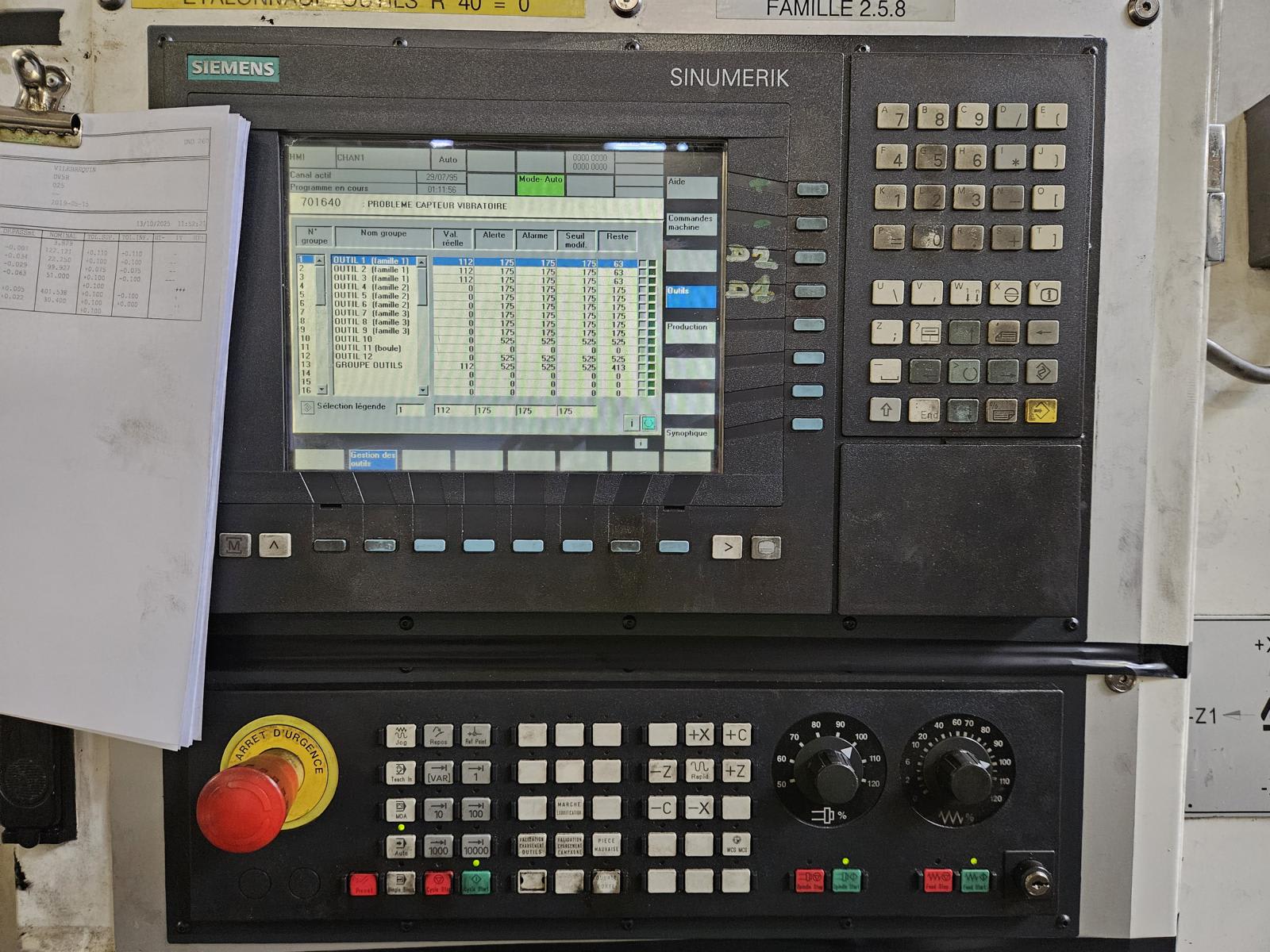

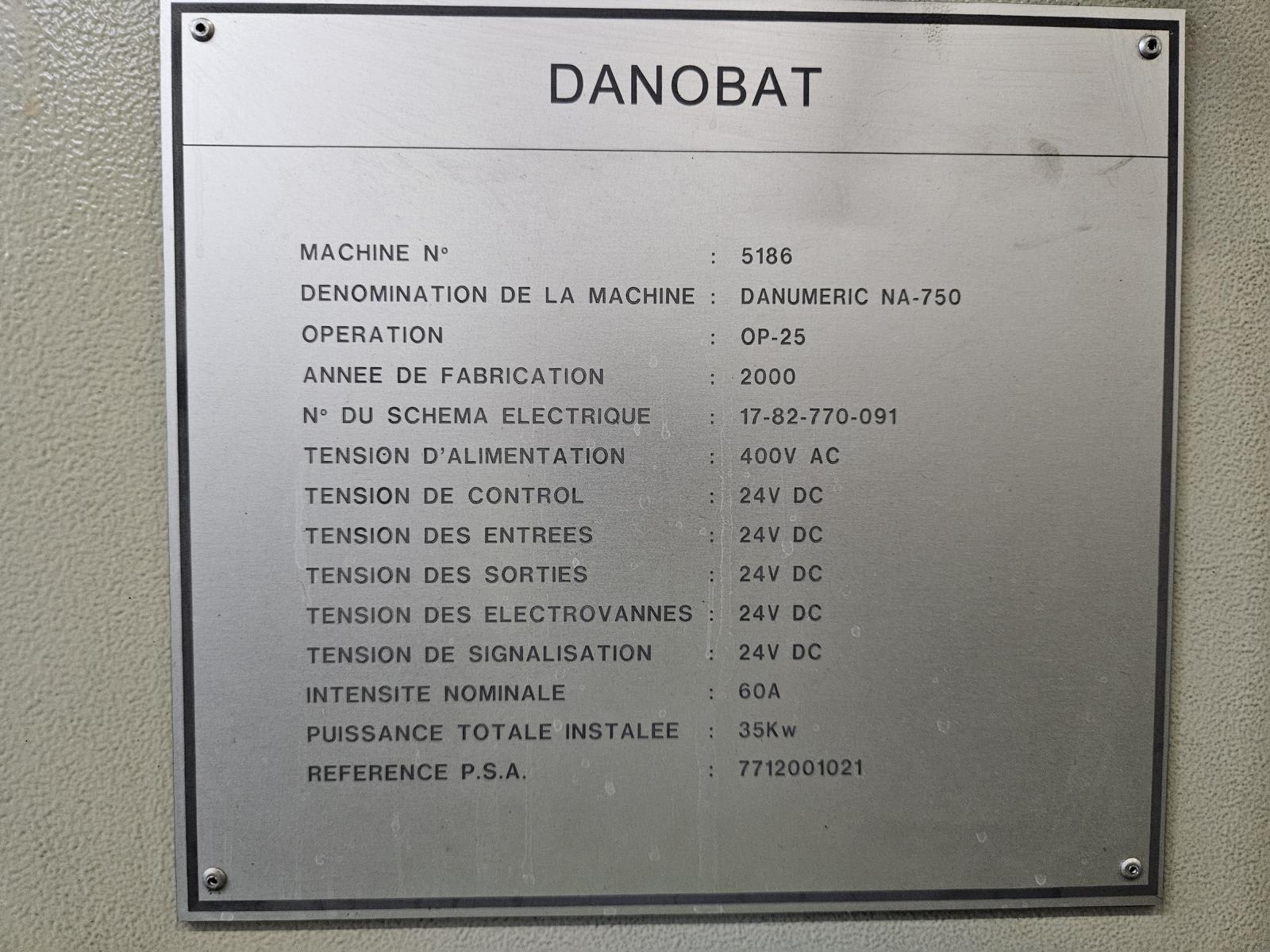

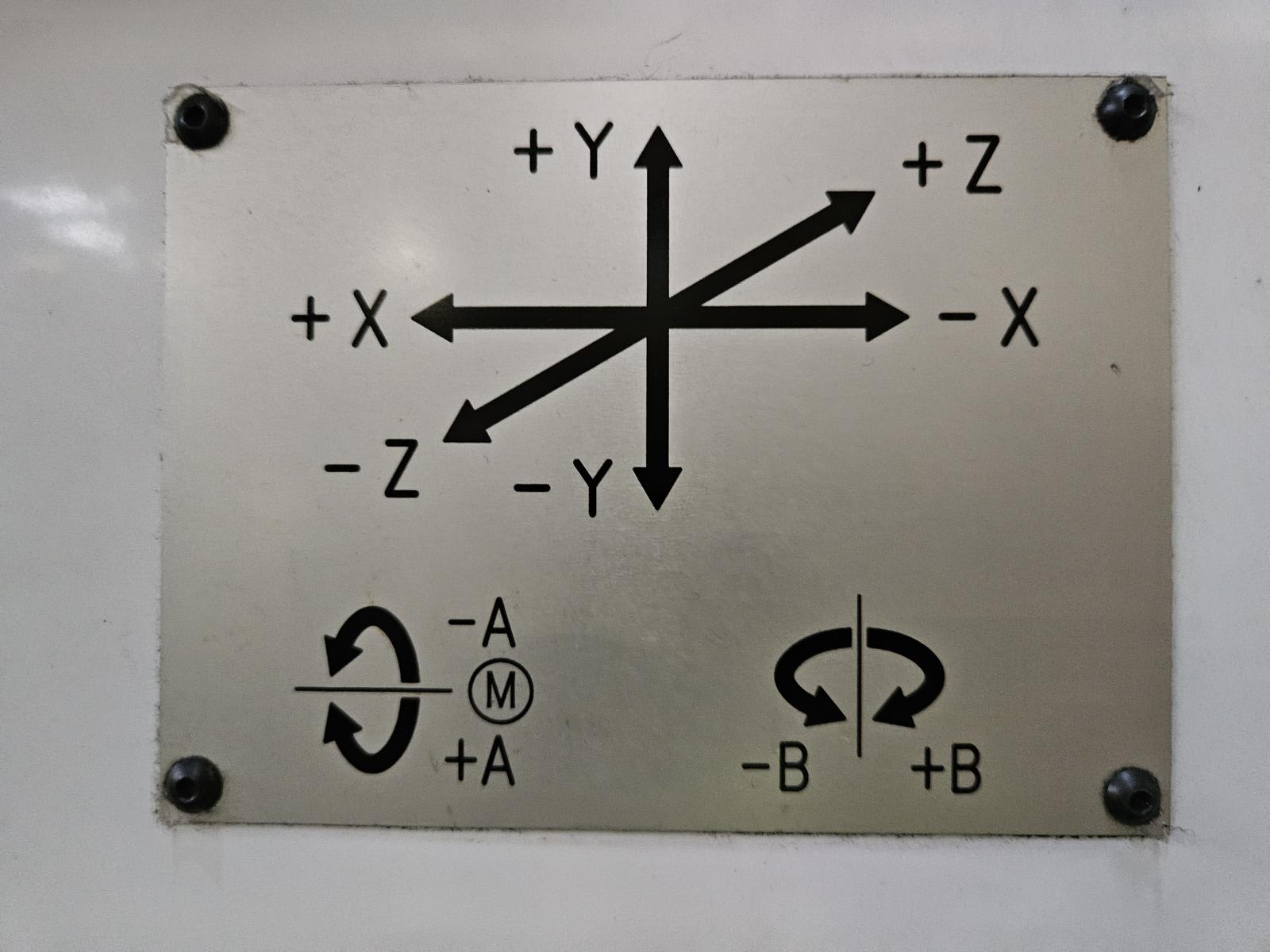

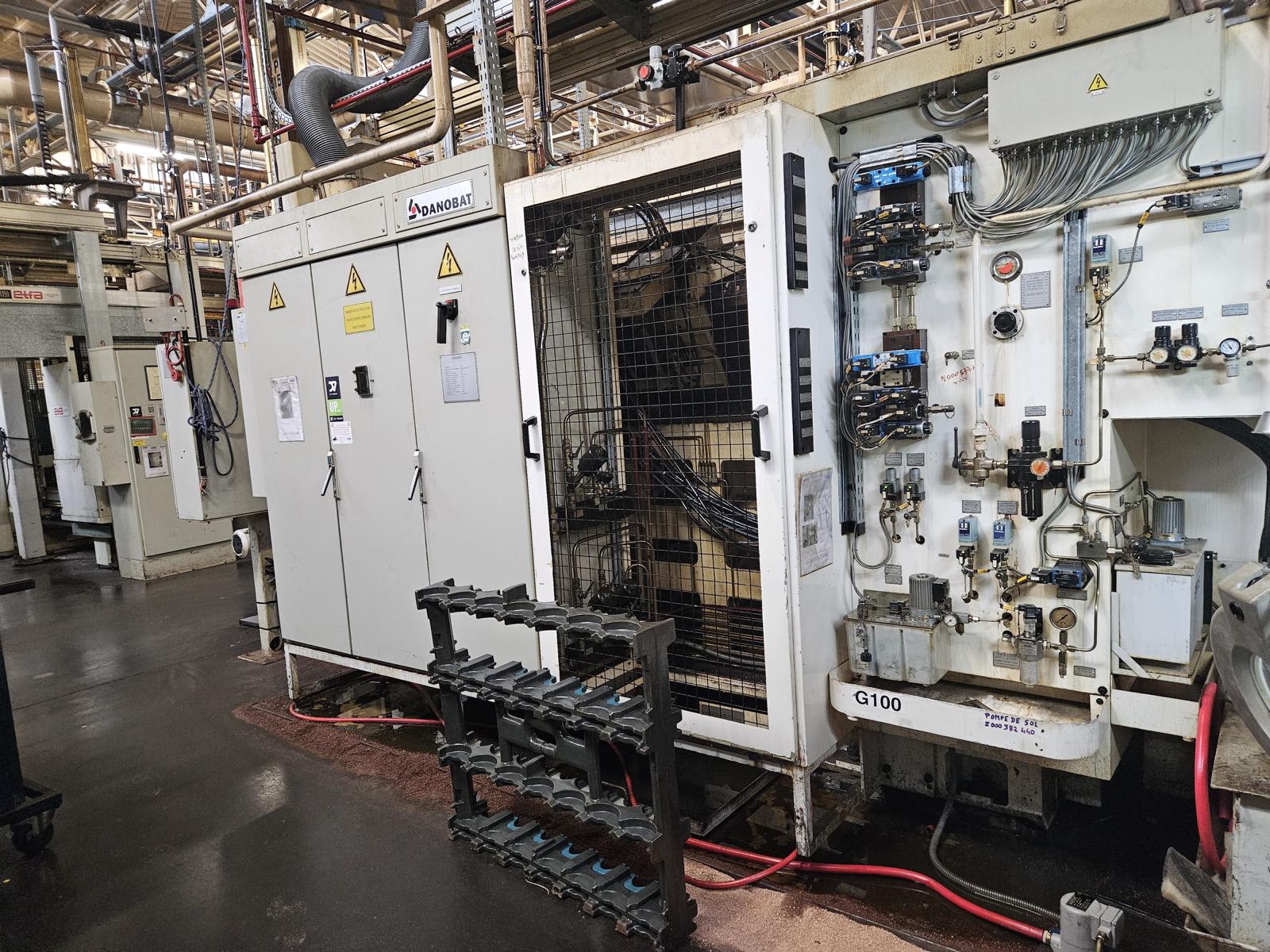

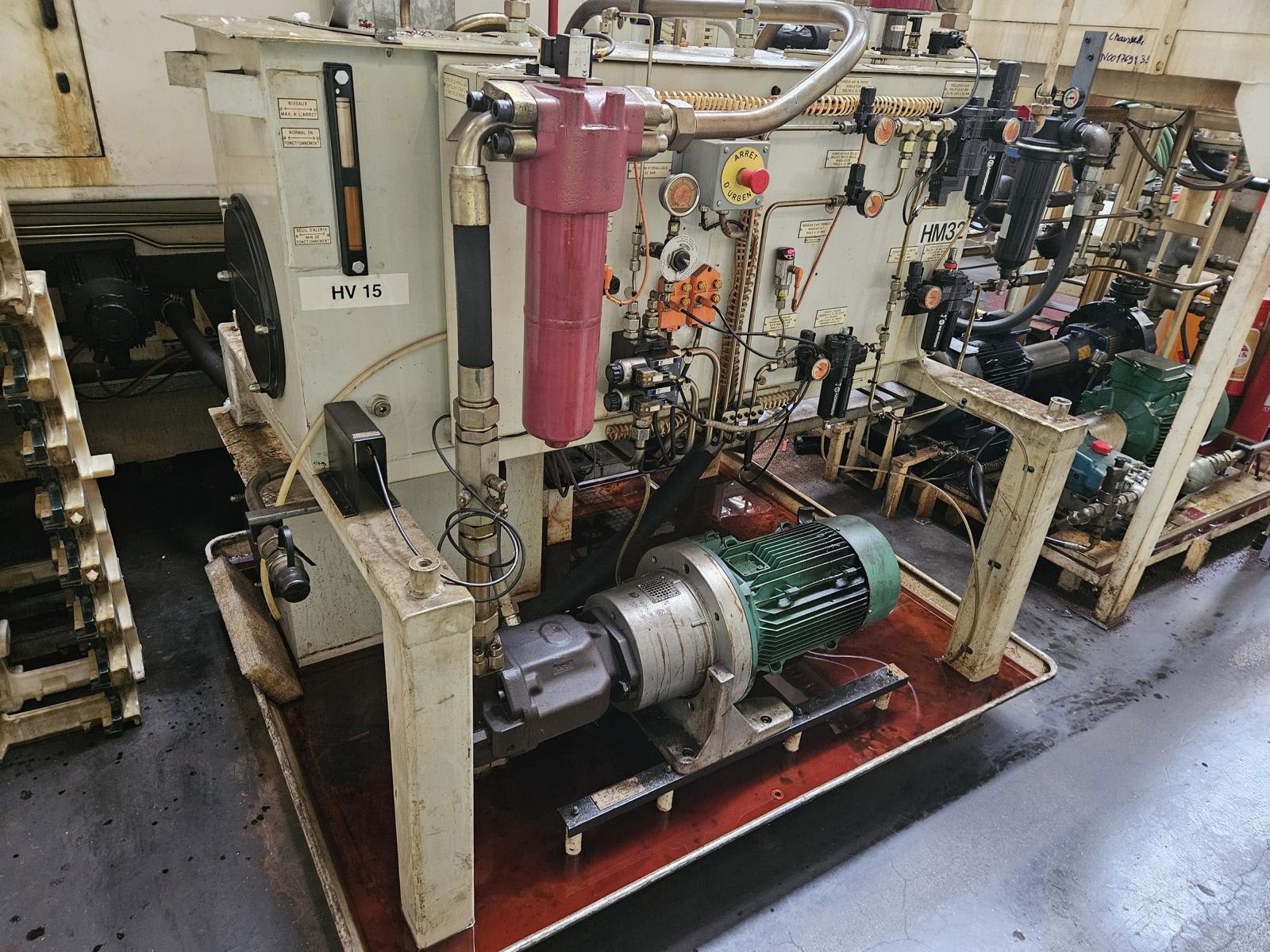

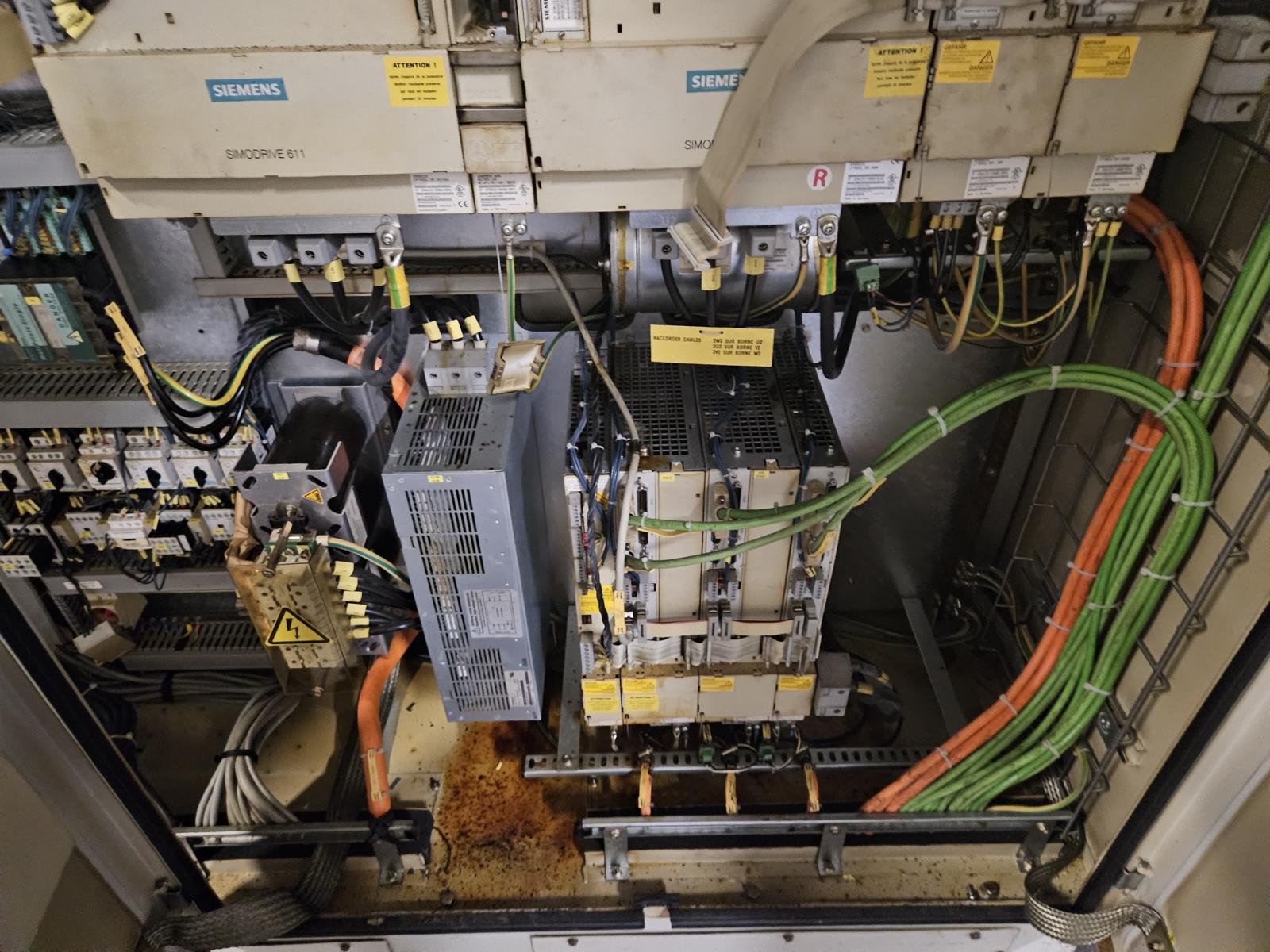

CNC Lathe DANOBAT DANUMERIC NA - 750 | 2000

max swing 700mm, X/Y 255/520mm, tailstock, 12-Pos-Tool-Turret, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 45kW, weight 12to - LISTING 2830002

![Français]()

CNC Lathe DANOBAT DANUMERIC NA - 750 | 2000

max swing 700mm, X/Y 255/520mm, tailstock, 12-Pos-Tool-Turret, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 45kW, weight 12to - LISTING 2830003

![Français]()

CNC Lathe DANOBAT DANUMERIC NA - 750 | 2000

max swing 700mm, X/Y 255/520mm, tailstock, 12-Pos-Tool-Turret, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 45kW, weight 12to - LISTING 2830004

![Français]()

CNC Lathe DANOBAT DANUMERIC NA - 750 | 2000

max swing 700mm, X/Y 255/520mm, tailstock, 12-Pos-Tool-Turret, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 45kW, weight 12to - LISTING 2830005

![Français]()

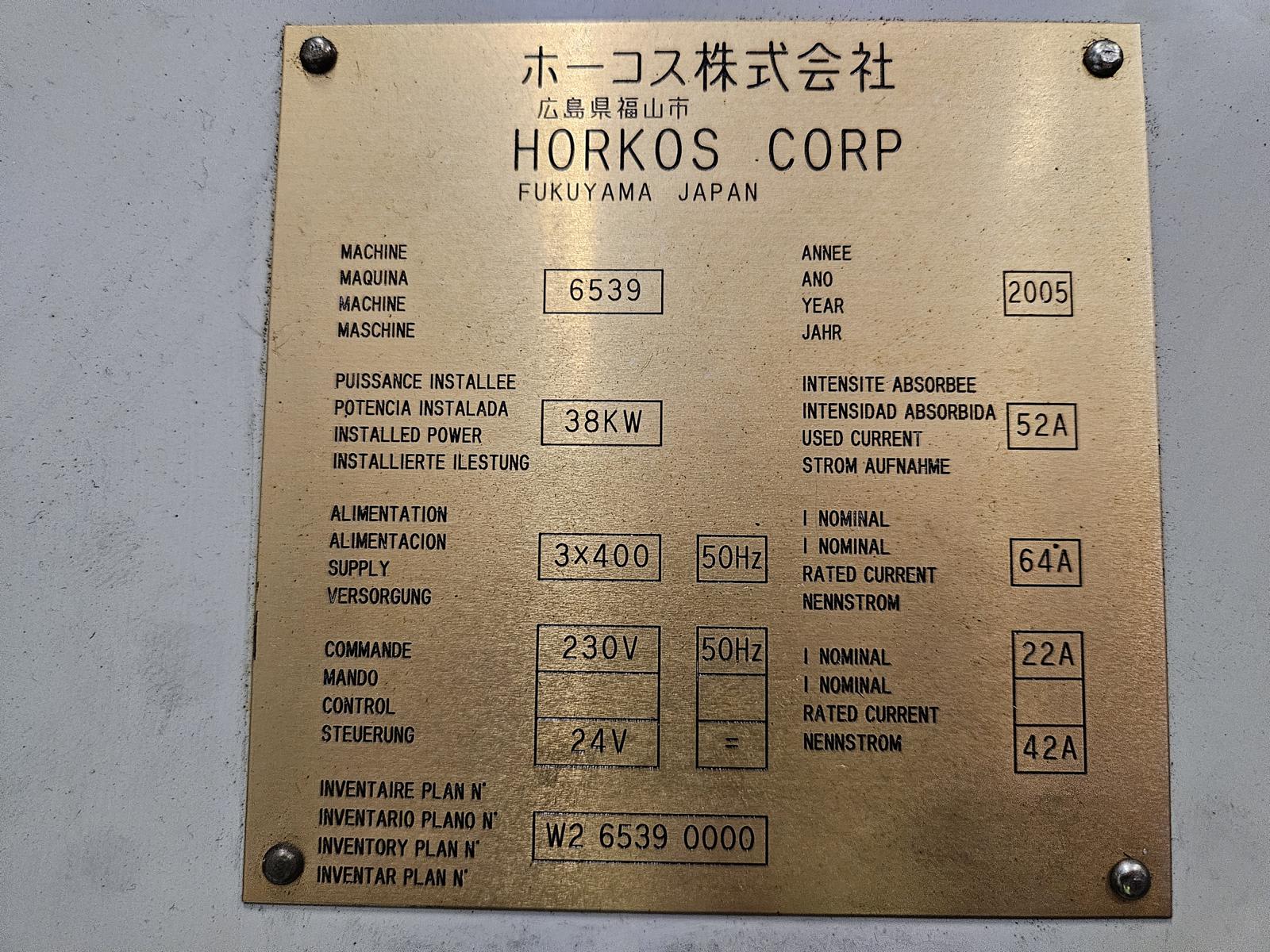

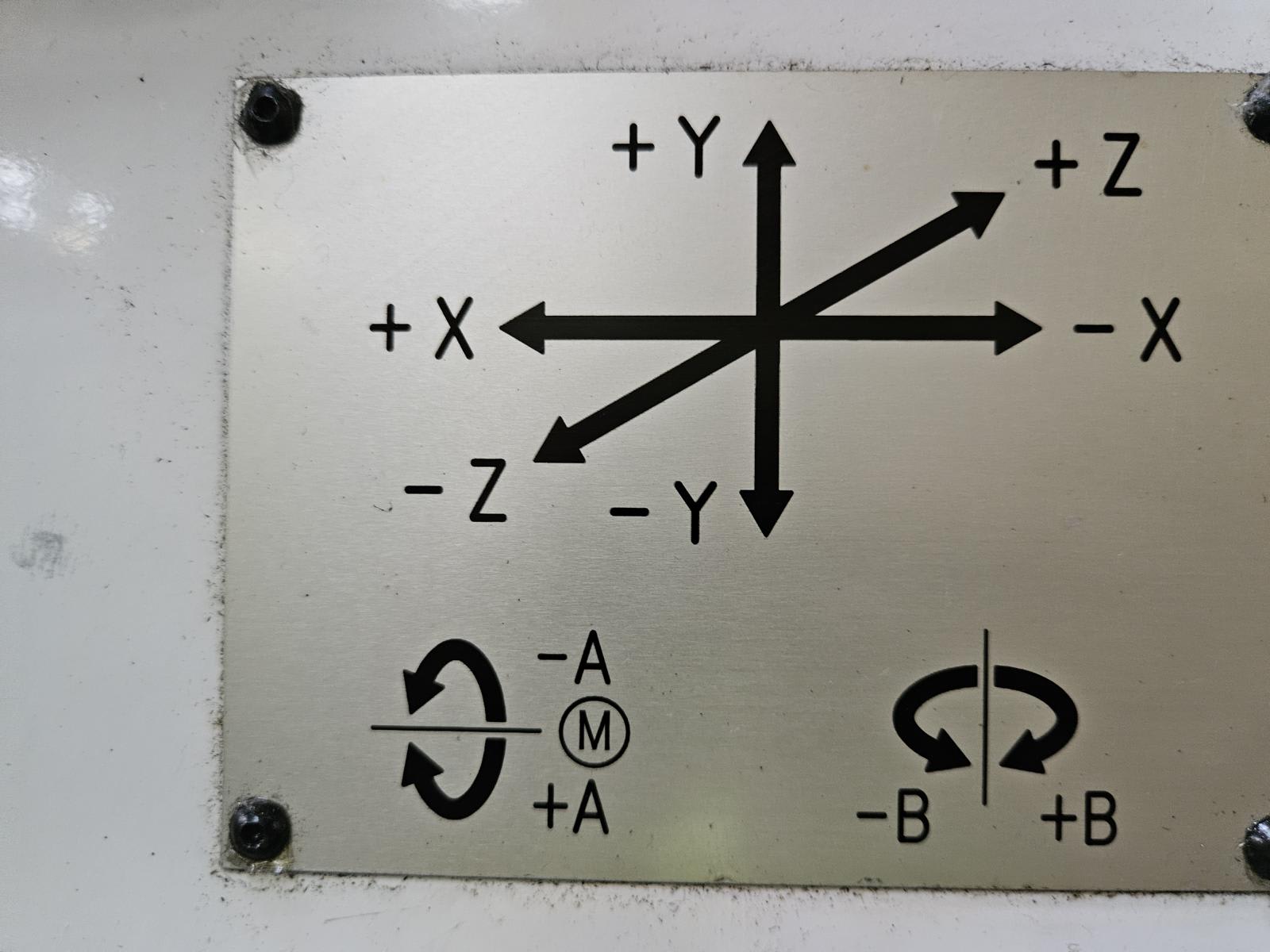

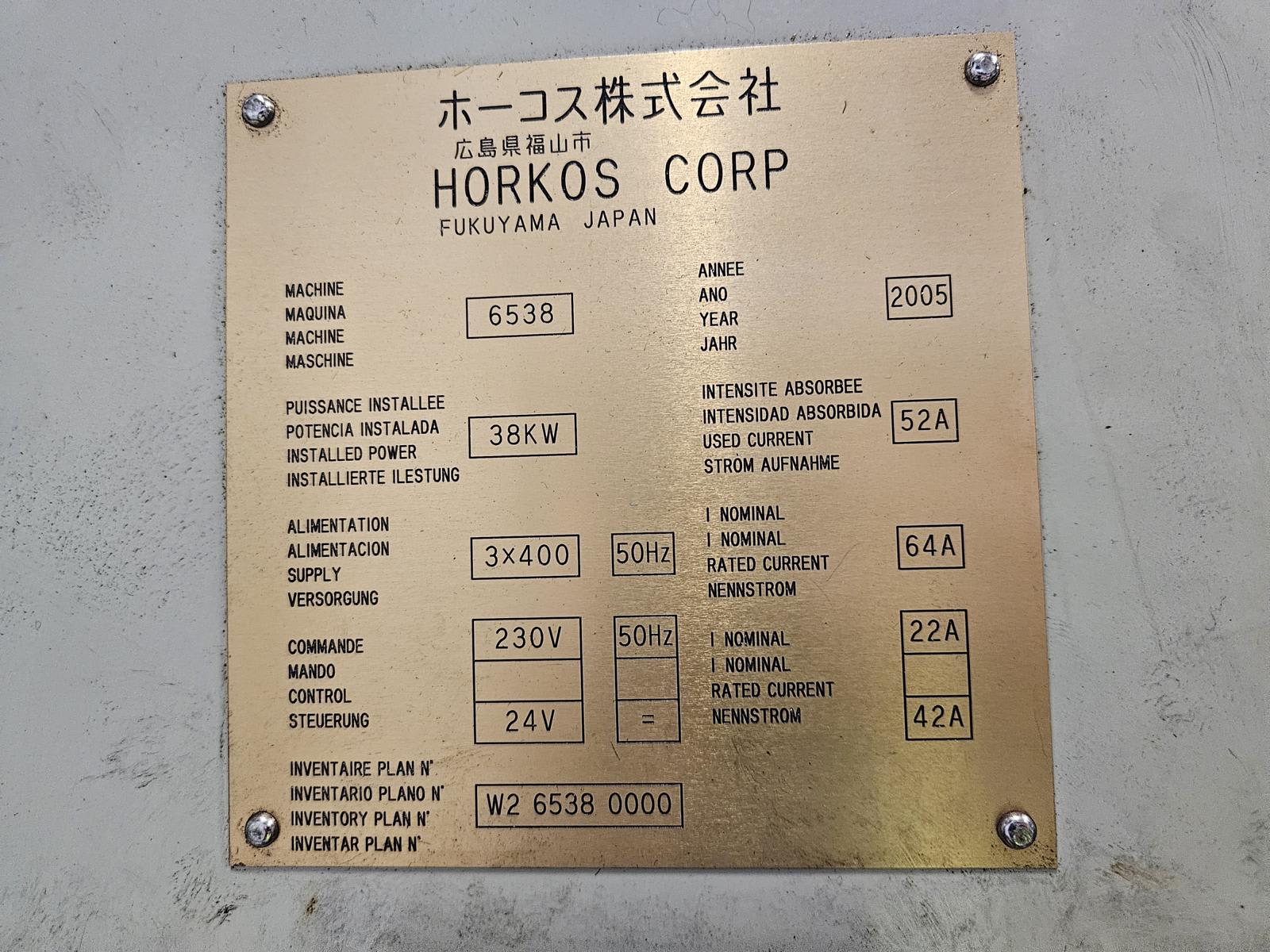

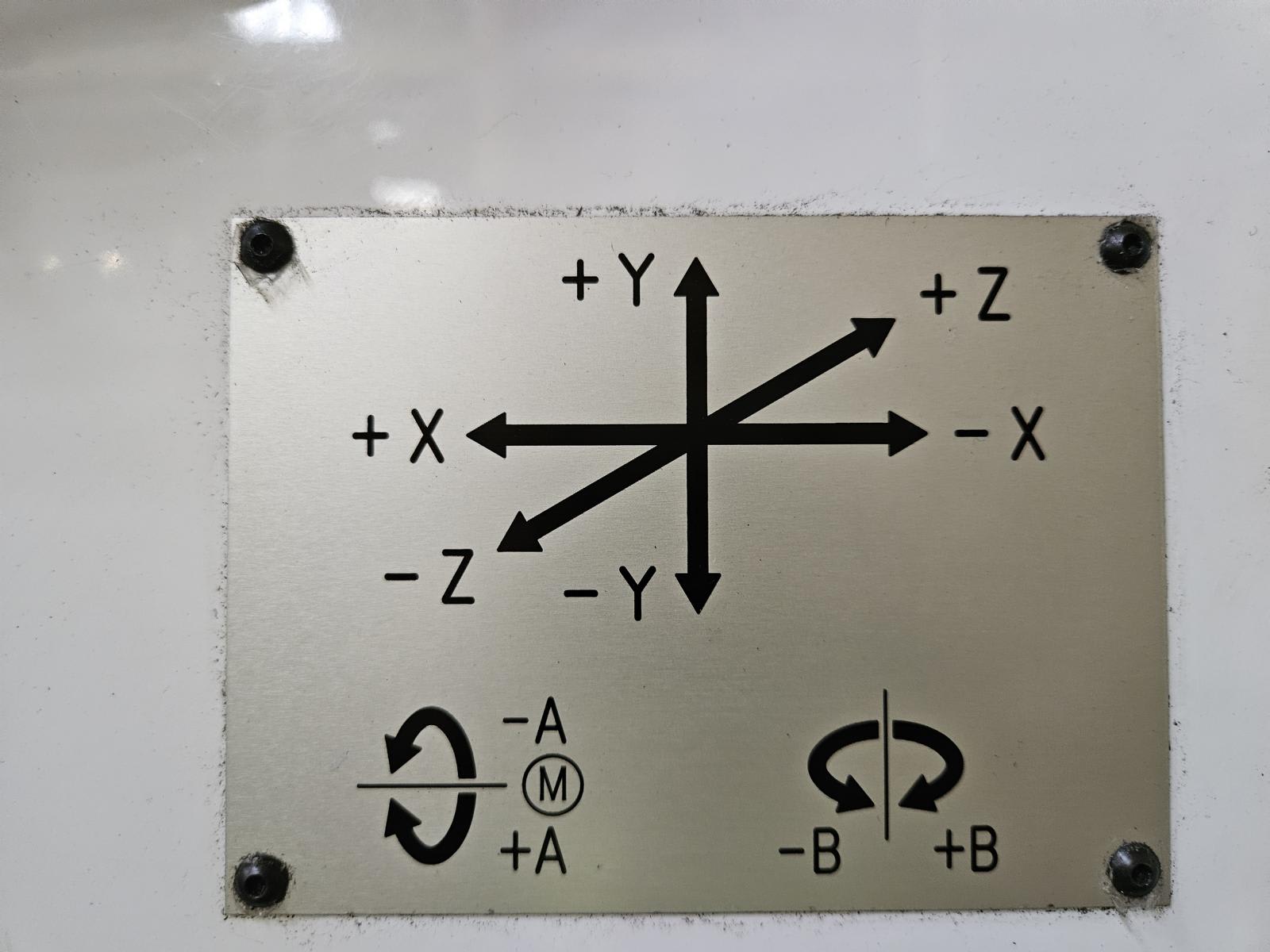

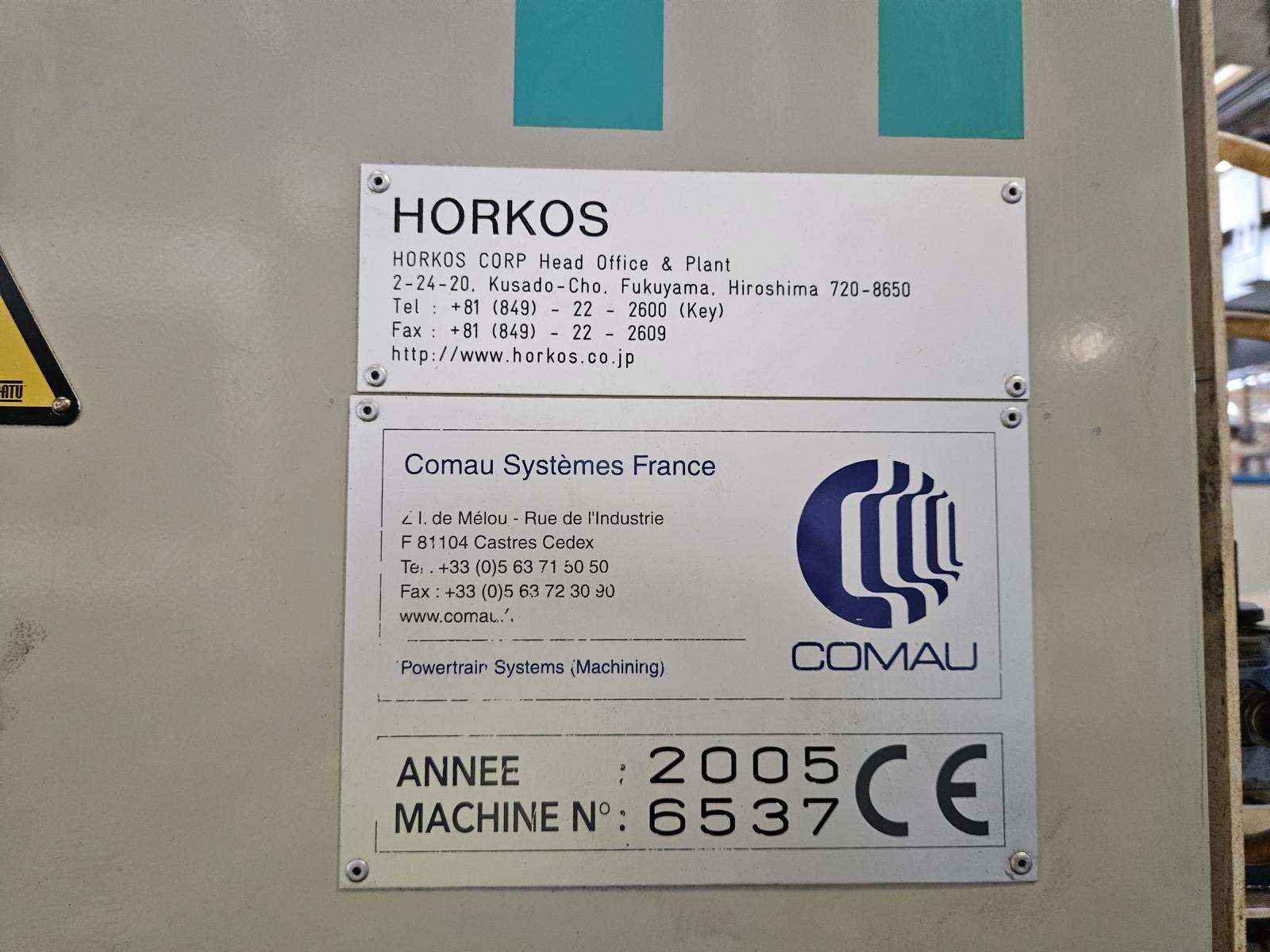

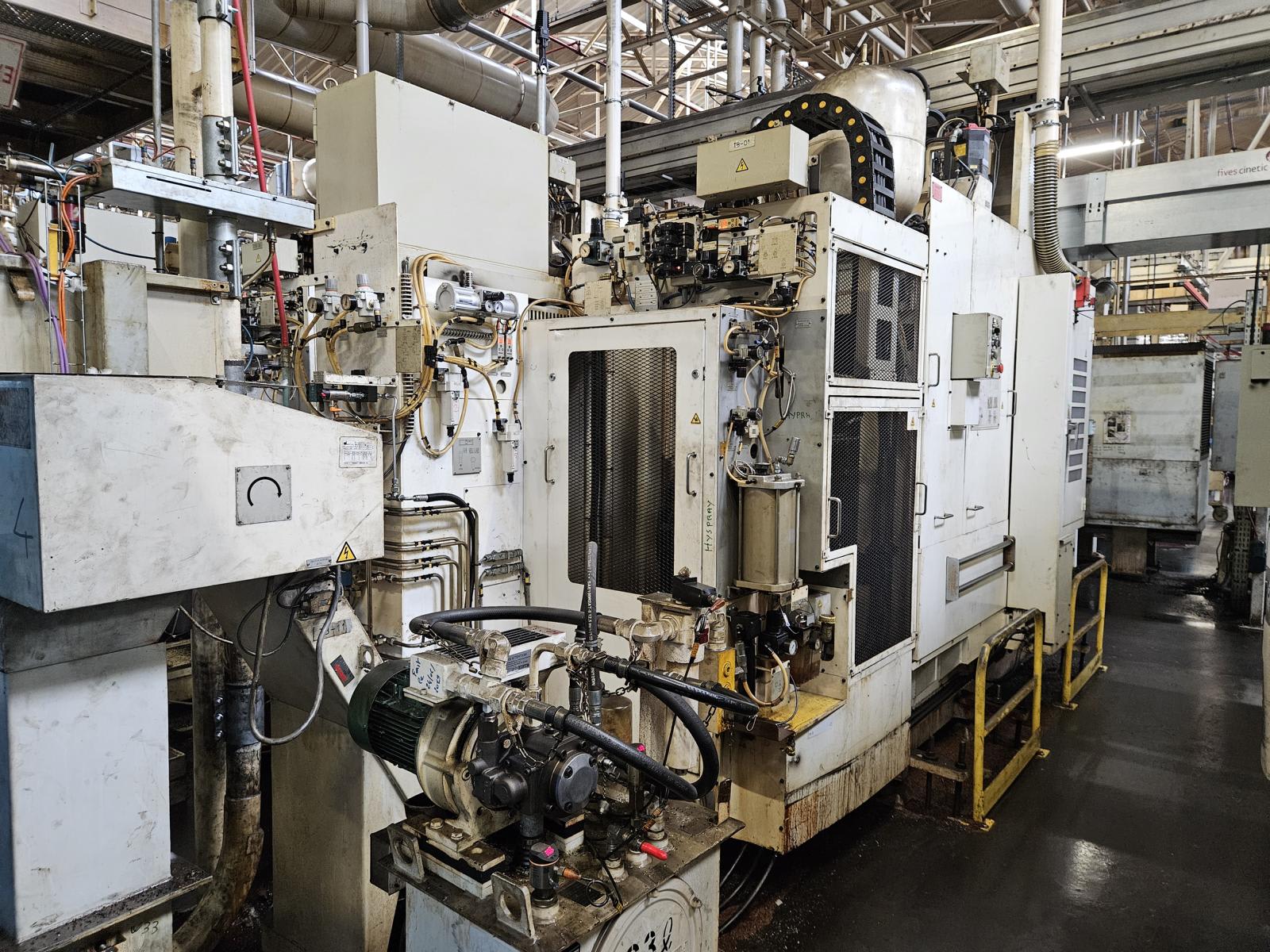

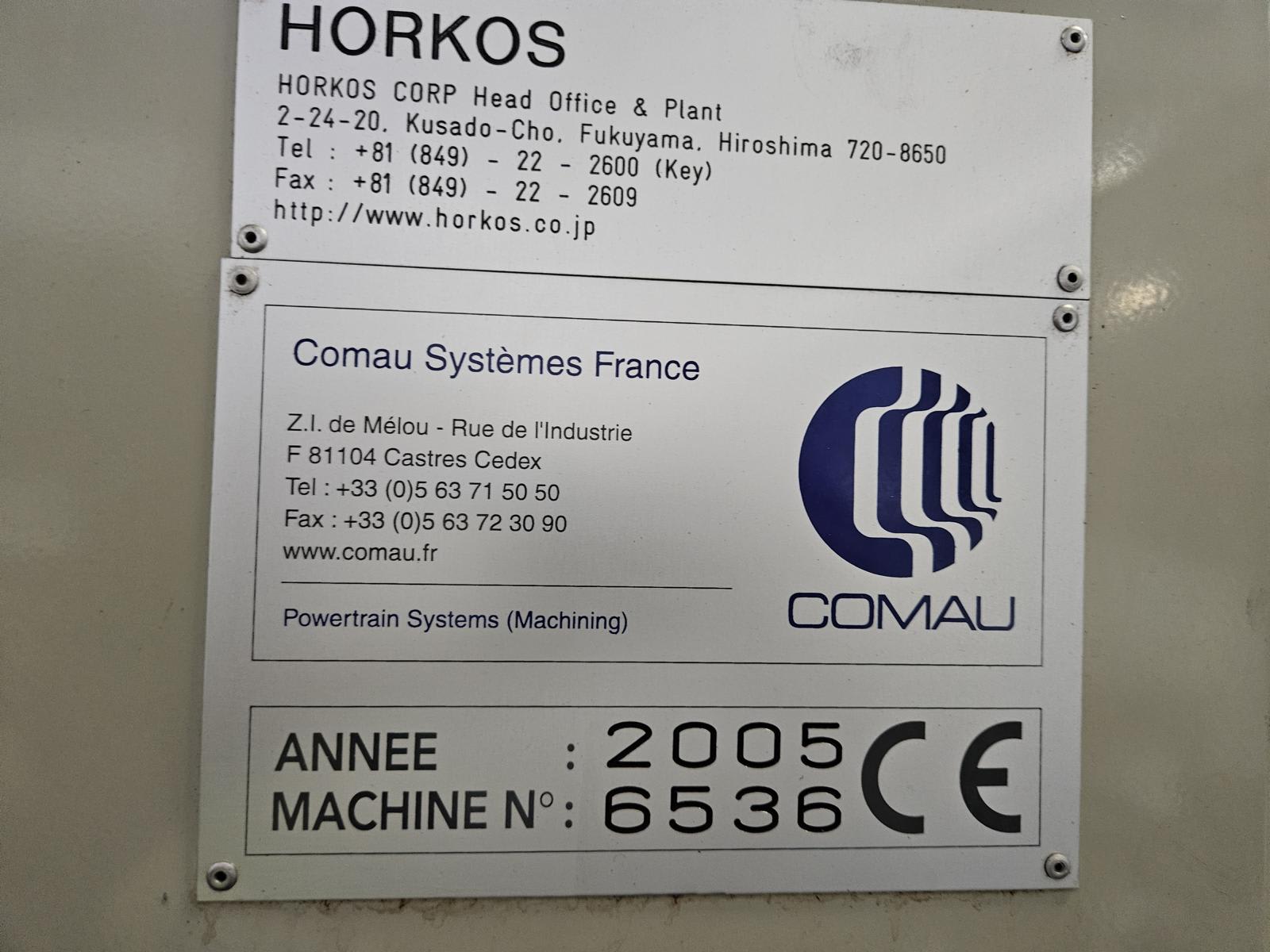

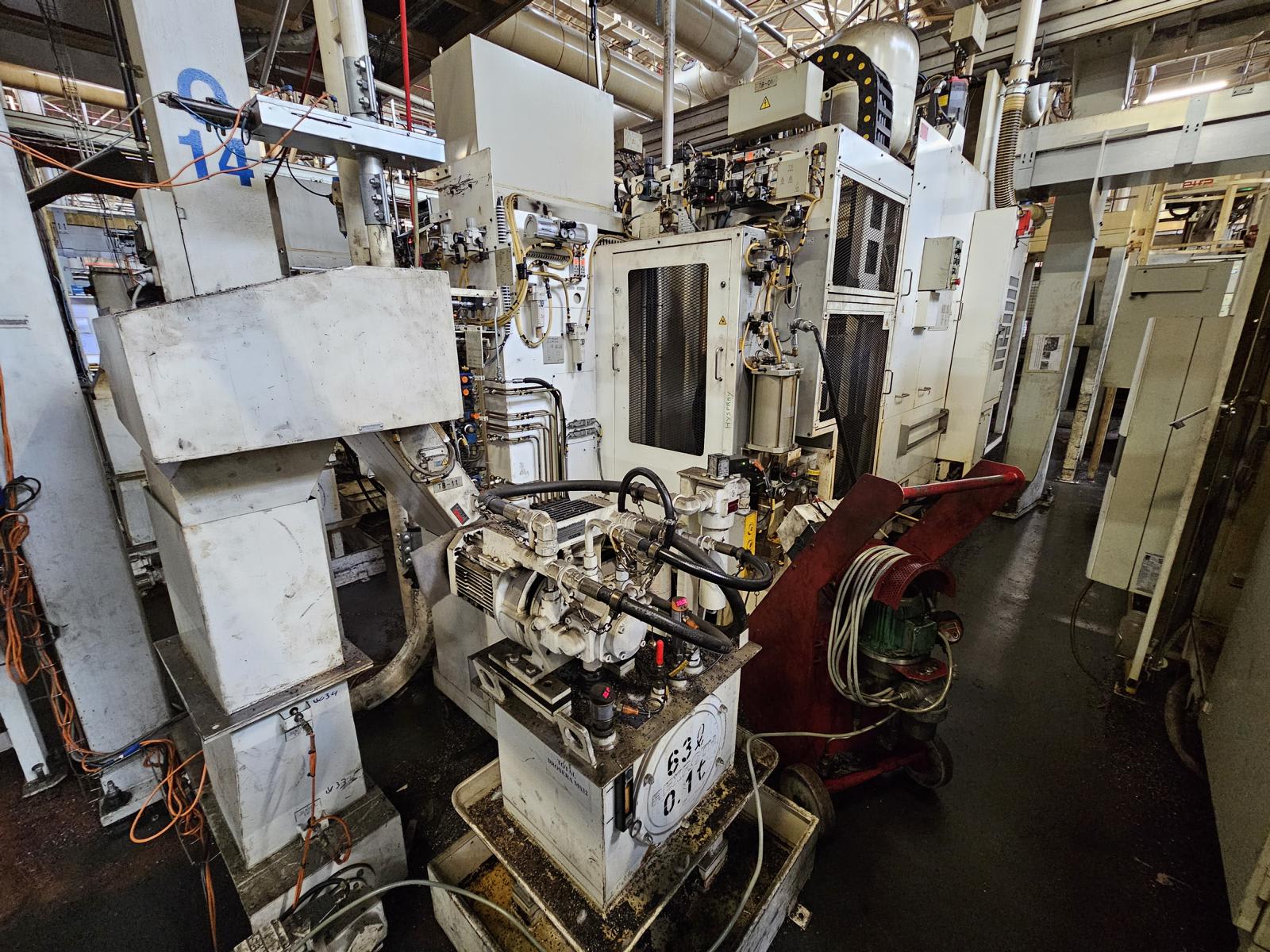

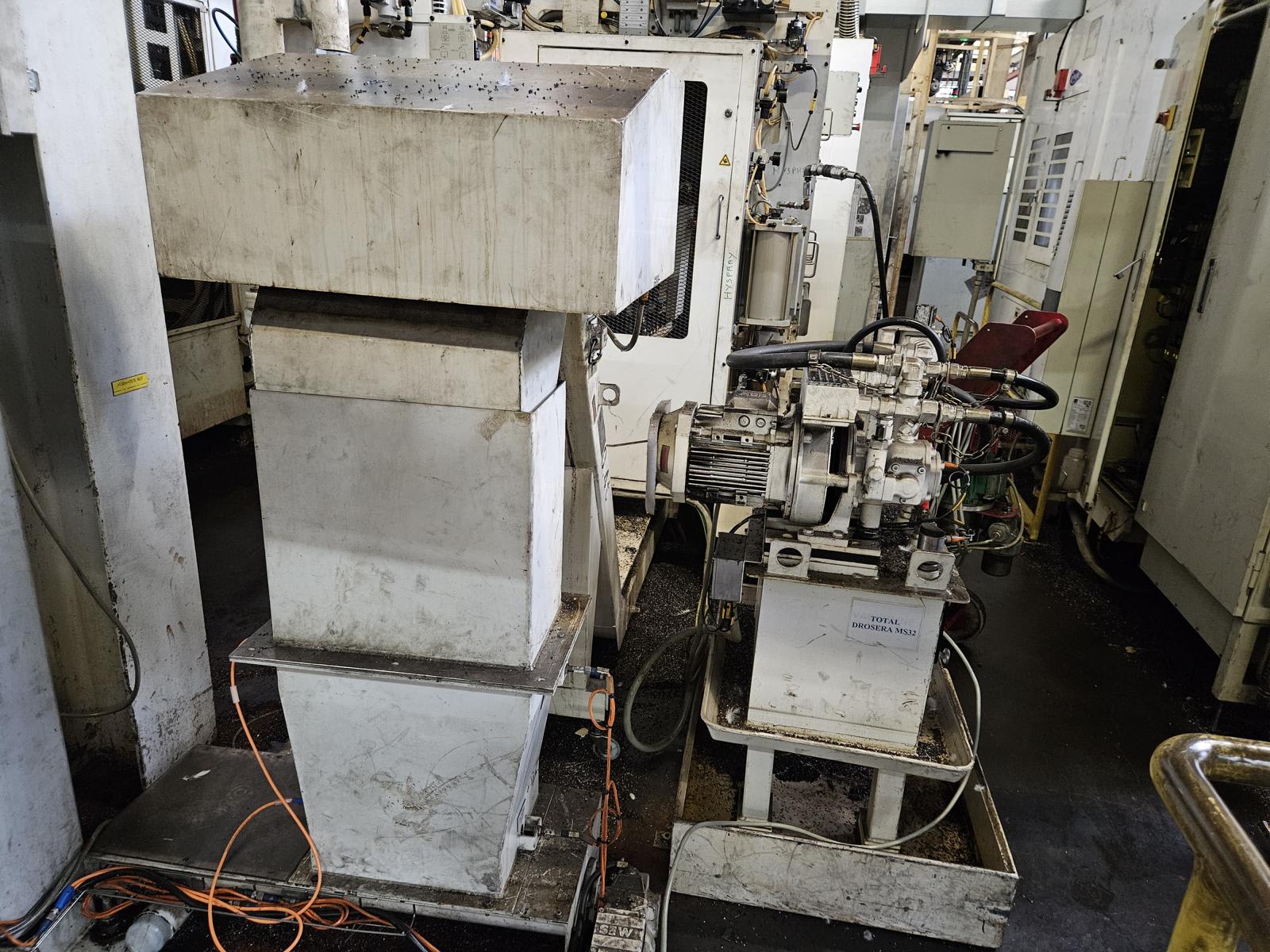

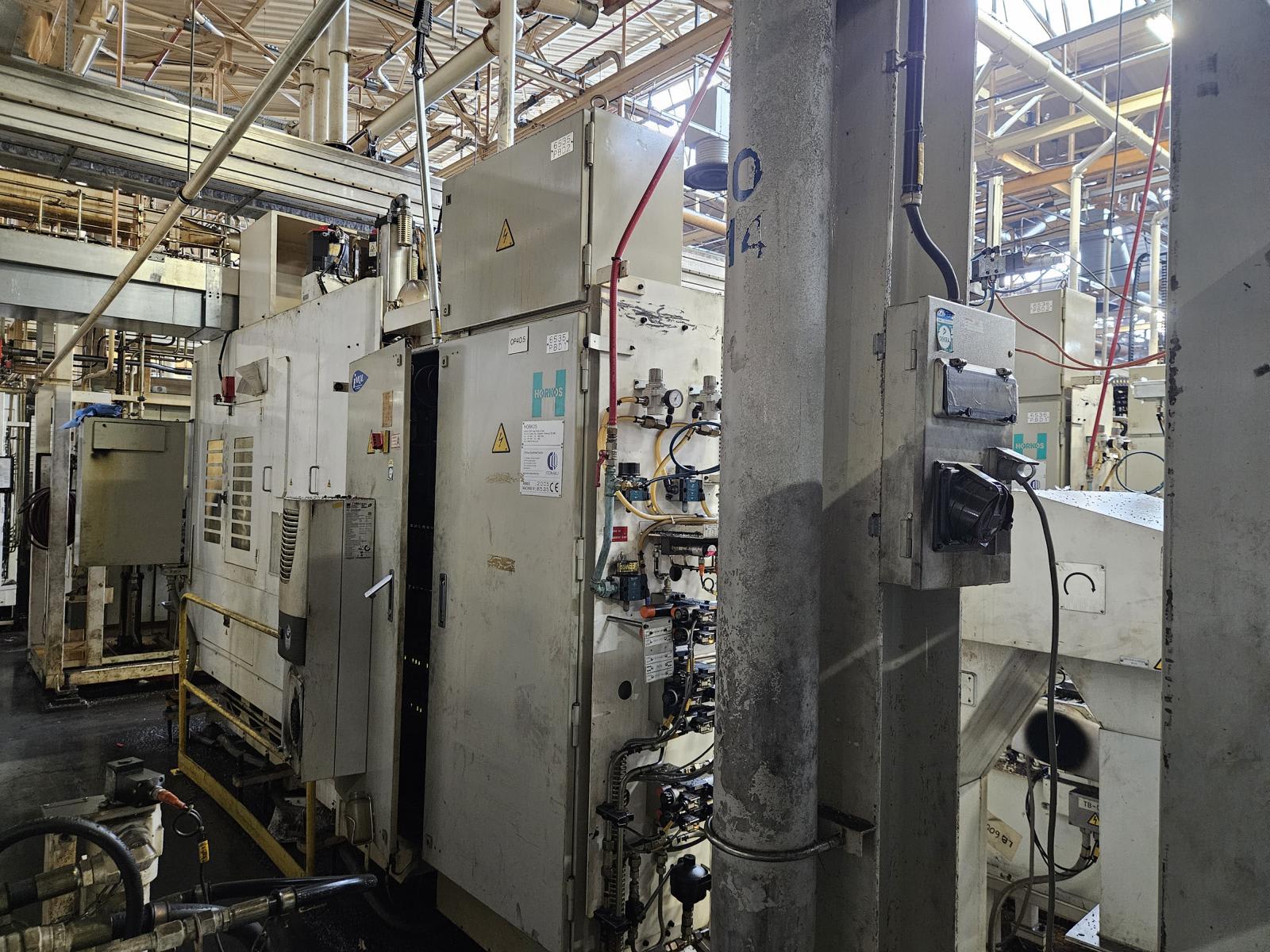

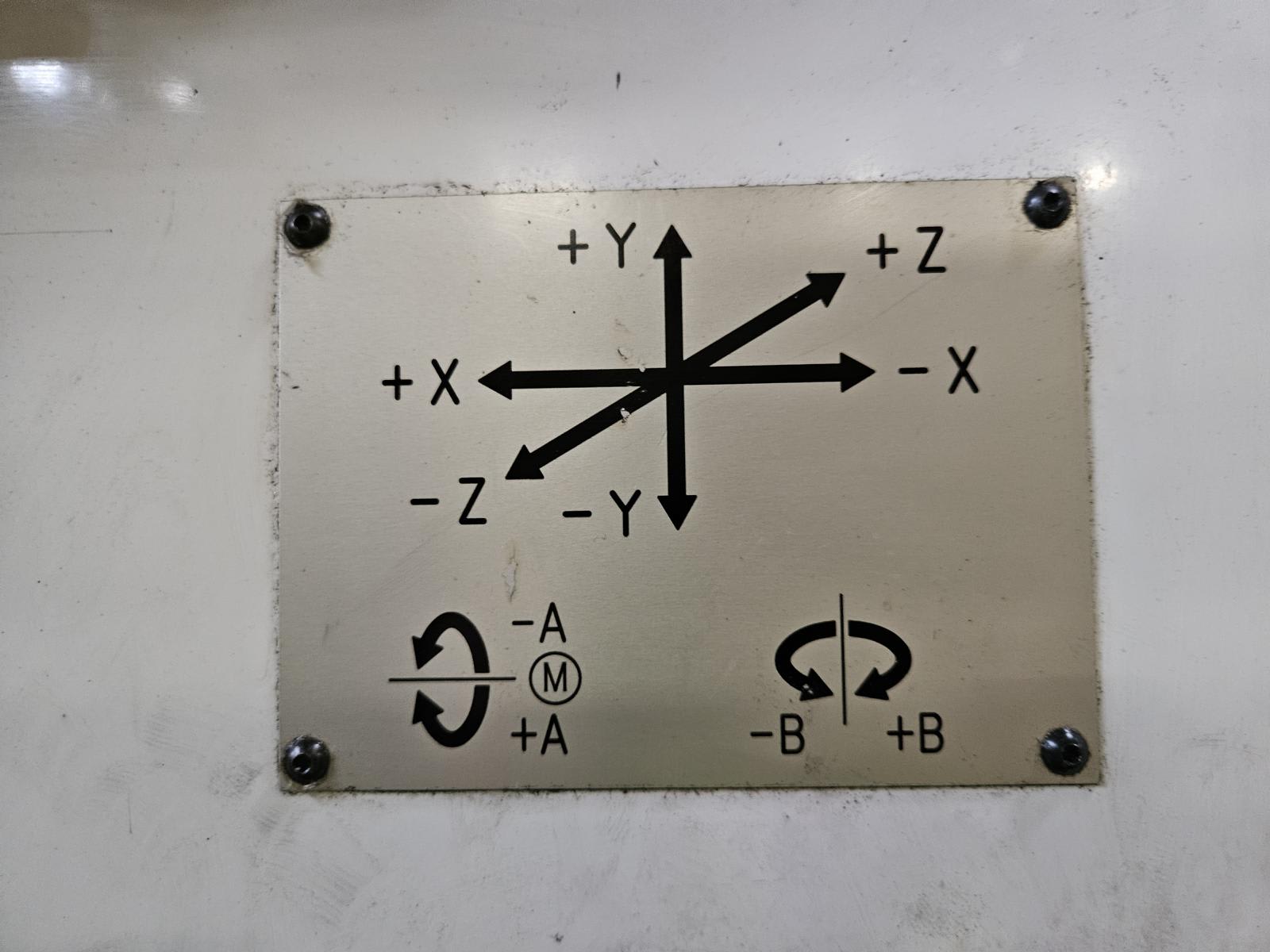

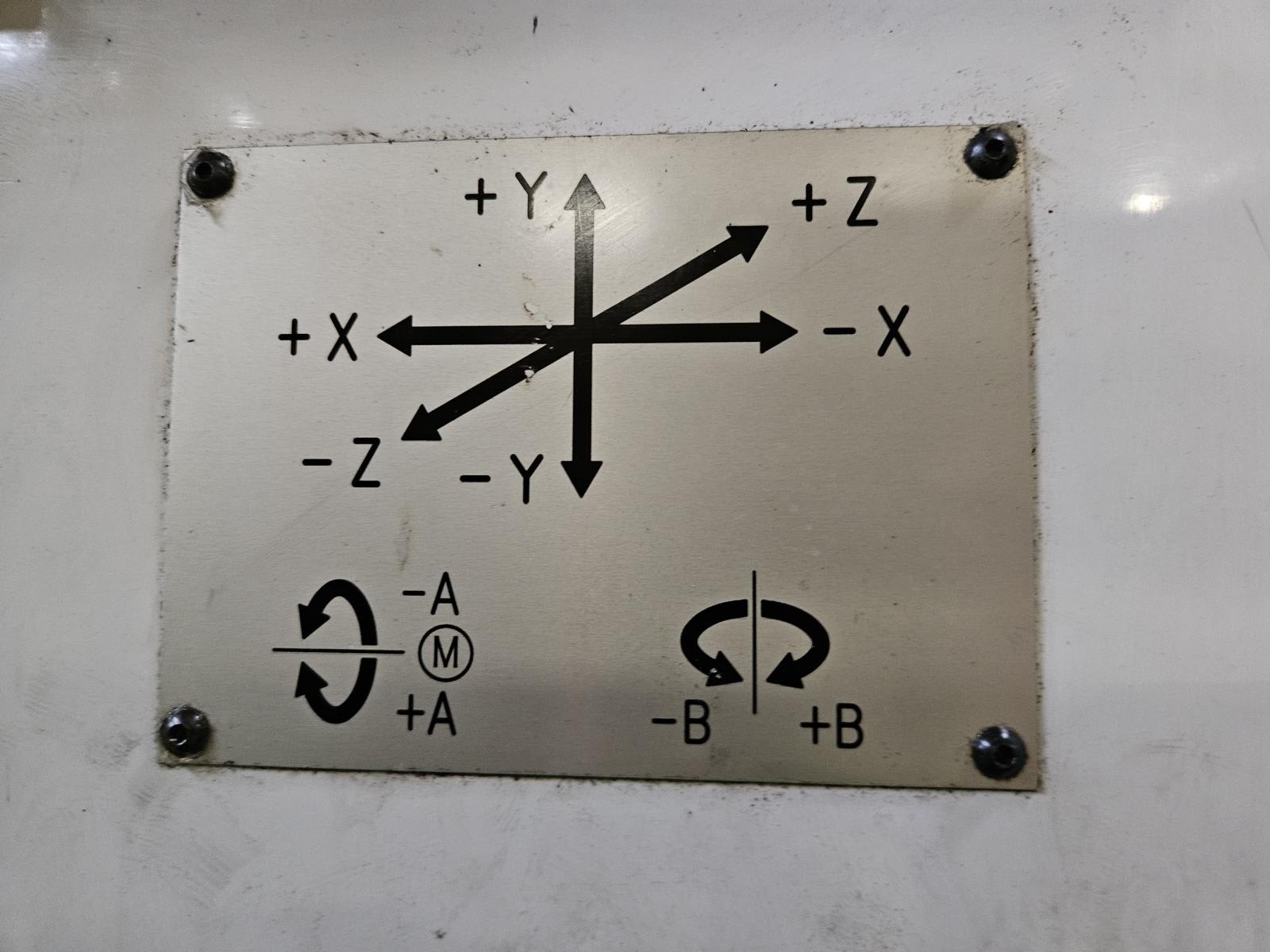

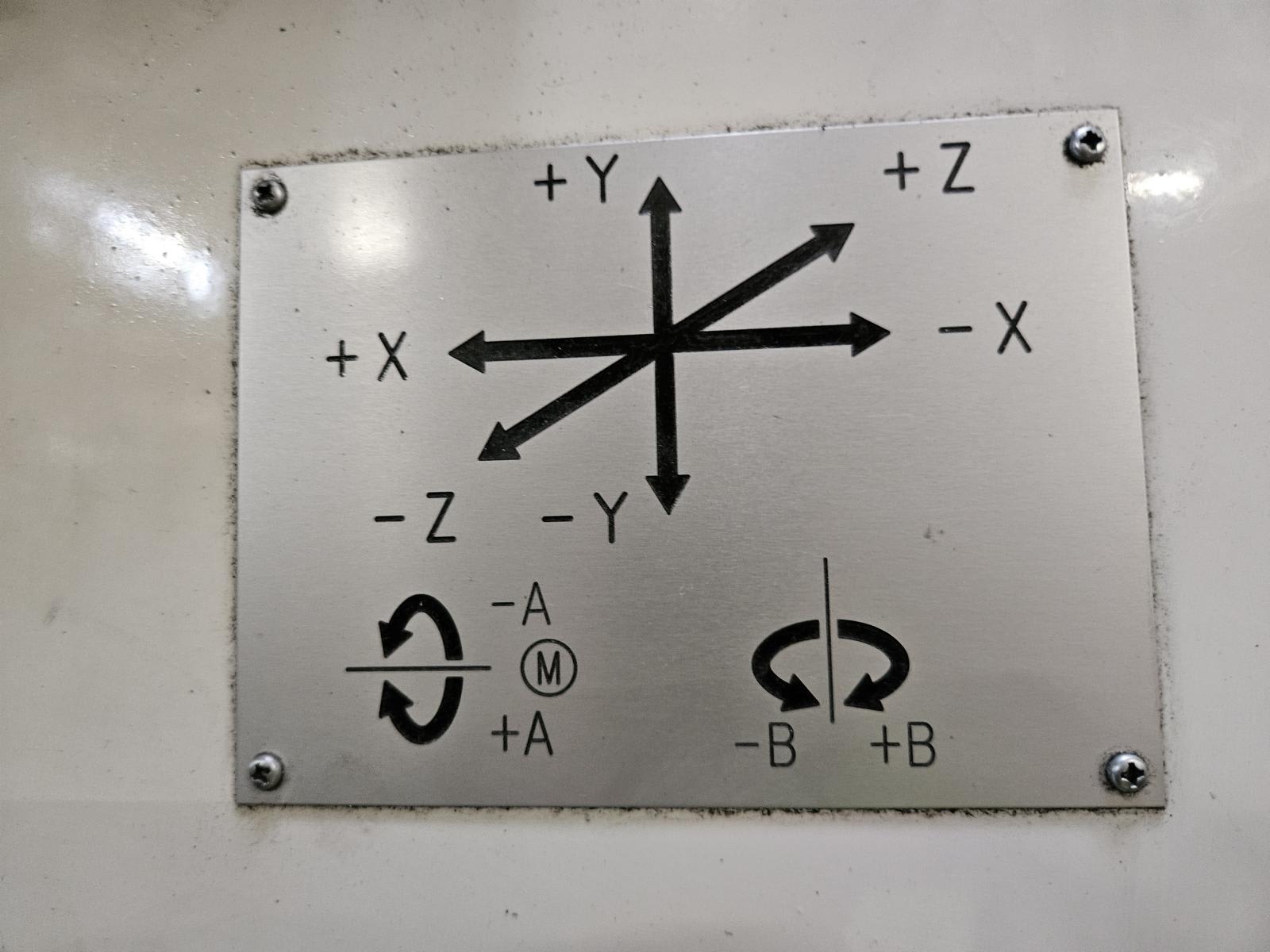

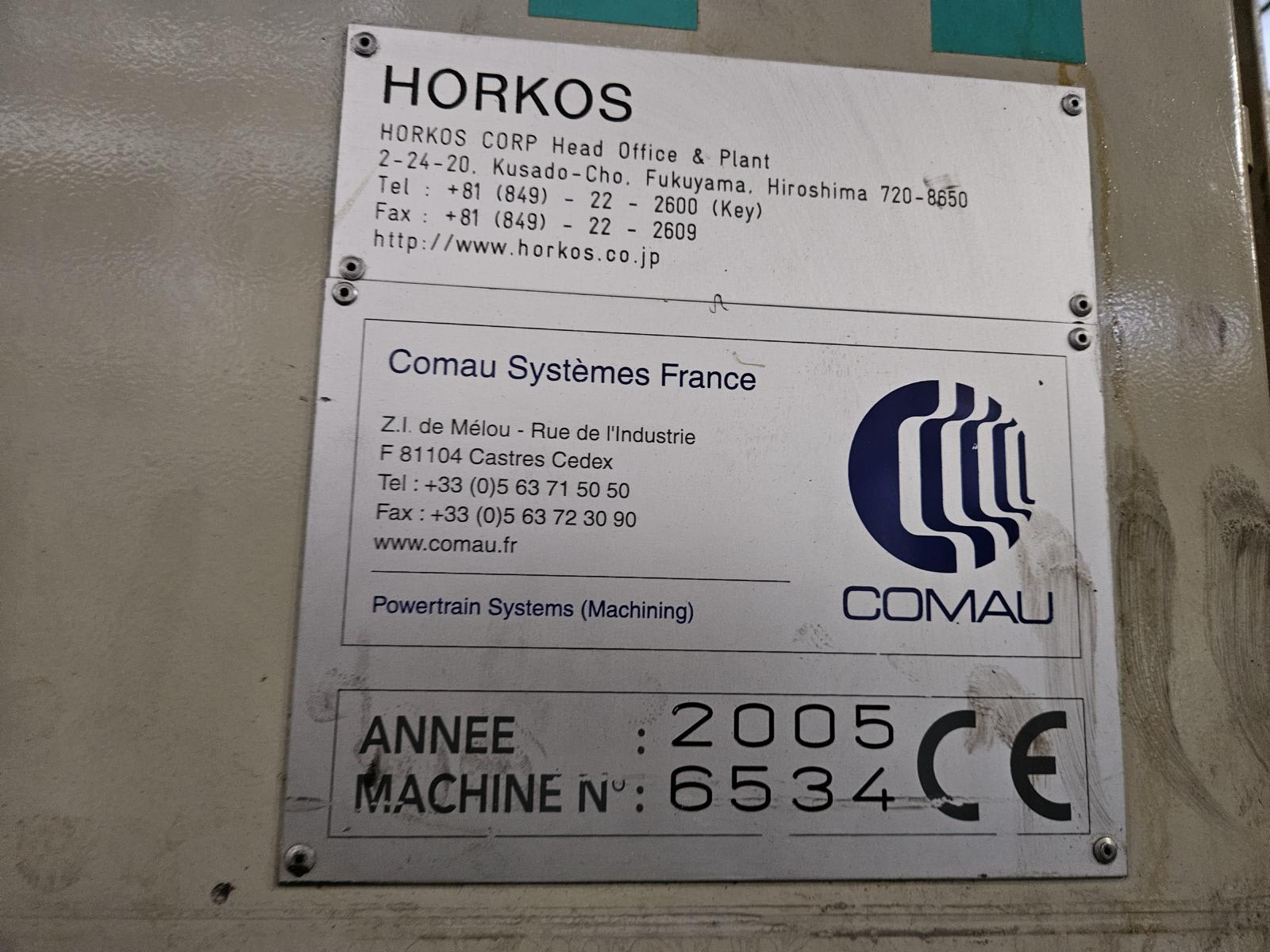

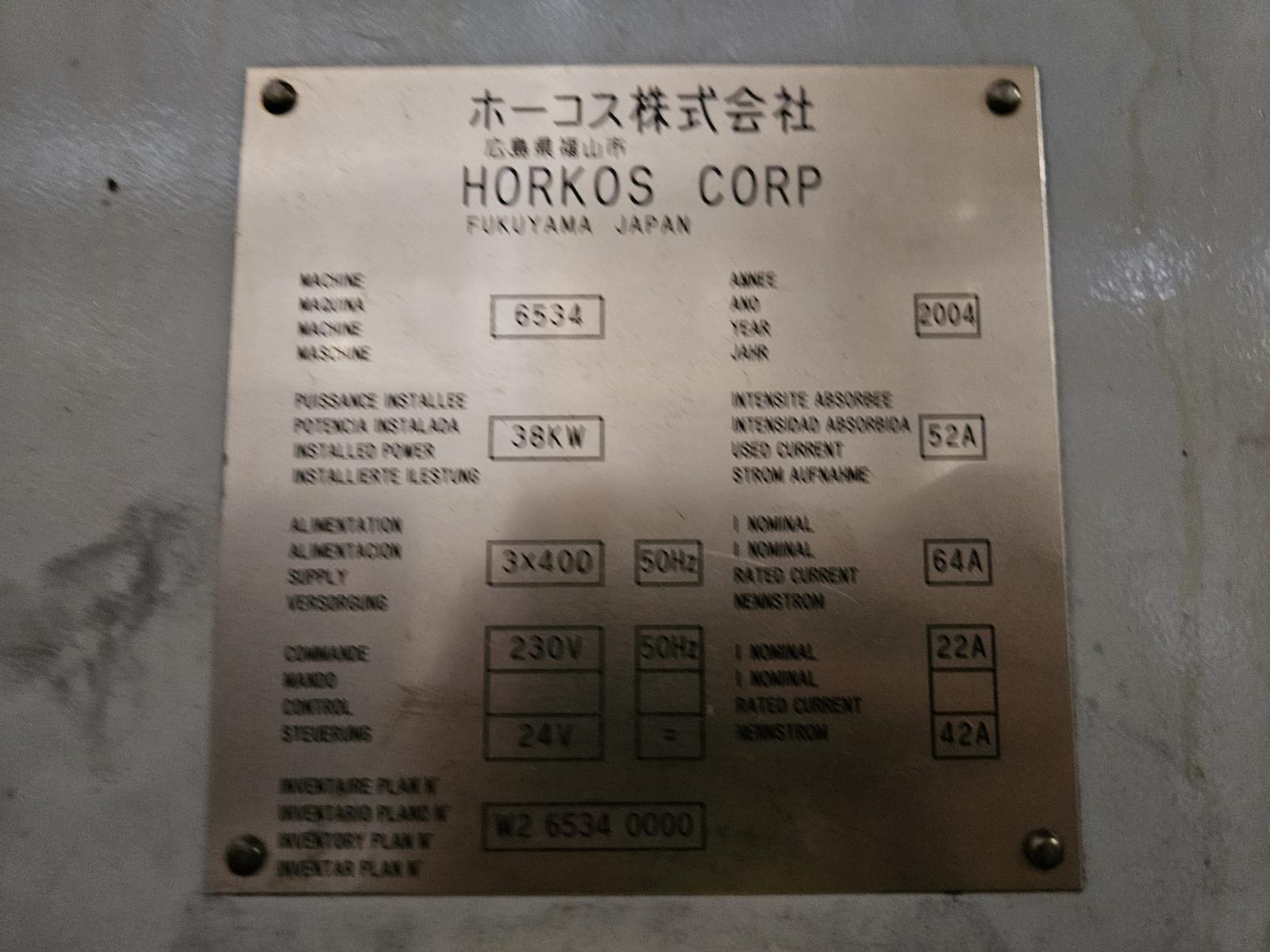

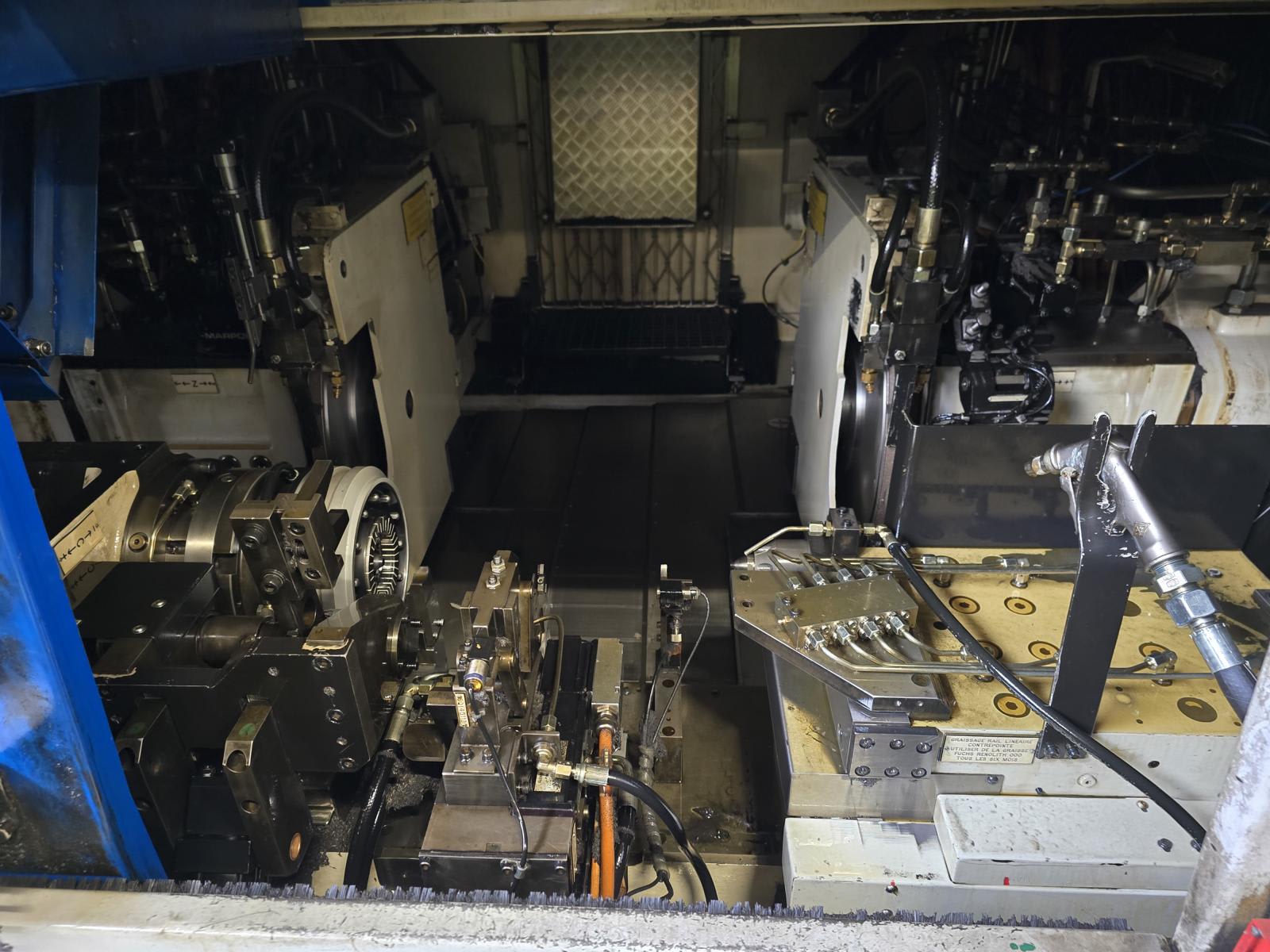

5-Axes Oil Hole Boring MC HORKOS MOH | 2005

X/Y/Z 500/150/765mm, B-Axes rotary table with A-Axes unit for part size 630 x dia 190mm, spindle 8.000rpm / HSK-63-A, 12-Pos-ATC, LxW xH, CNC GE-FANUC 160i-MB, LxWxH,ca. 2x4x3m - LISTING 2830006

![Français]()

5-Axes Oil Hole Boring MC HORKOS MOH | 2005

X/Y/Z 500/150/765mm, B-Axes rotary table with A-Axes unit for part size 630 x dia 190mm, spindle 8.000rpm / HSK-63-A, 12-Pos-ATC, LxW xH, CNC GE-FANUC 160i-MB, LxWxH,ca. 2x4x3m - LISTING 2830007

![Français]()

5-Axes Oil Hole Boring MC HORKOS MOH | 2005

X/Y/Z 500/150/765mm, B-Axes rotary table with A-Axes unit for part size 630 x dia 190mm, spindle 8.000rpm / HSK-63-A, 12-Pos-ATC, LxW xH, CNC GE-FANUC 160i-MB, LxWxH,ca. 2x4x3m - LISTING 2830008

![Français]()

5-Axes Oil Hole Boring MC HORKOS MOH | 2005

X/Y/Z 500/150/765mm, B-Axes rotary table with A-Axes unit for part size 630 x dia 190mm, spindle 8.000rpm / HSK-63-A, 12-Pos-ATC, LxW xH, CNC GE-FANUC 160i-MB, LxWxH,ca. 2x4x3m - LISTING 2830009

![Français]()

5-Axes Oil Hole Boring MC HORKOS MOH | 2005

X/Y/Z 500/150/765mm, B-Axes rotary table with A-Axes unit for part size 630 x dia 190mm, spindle 8.000rpm / HSK-63-A, 12-Pos-ATC, LxW xH, CNC GE-FANUC 160i-MB, LxWxH,ca. 2x4x3m - LISTING 2830010

![Français]()

5-Axes Oil Hole Boring MC HORKOS MOH | 2005

X/Y/Z 500/150/765mm, B-Axes rotary table with A-Axes unit for part size 630 x dia 190mm, spindle 8.000rpm / HSK-63-A, 12-Pos-ATC, LxW xH, CNC GE-FANUC 160i-MB, LxWxH,ca. 2x4x3m - LISTING 2830011

![Français]()

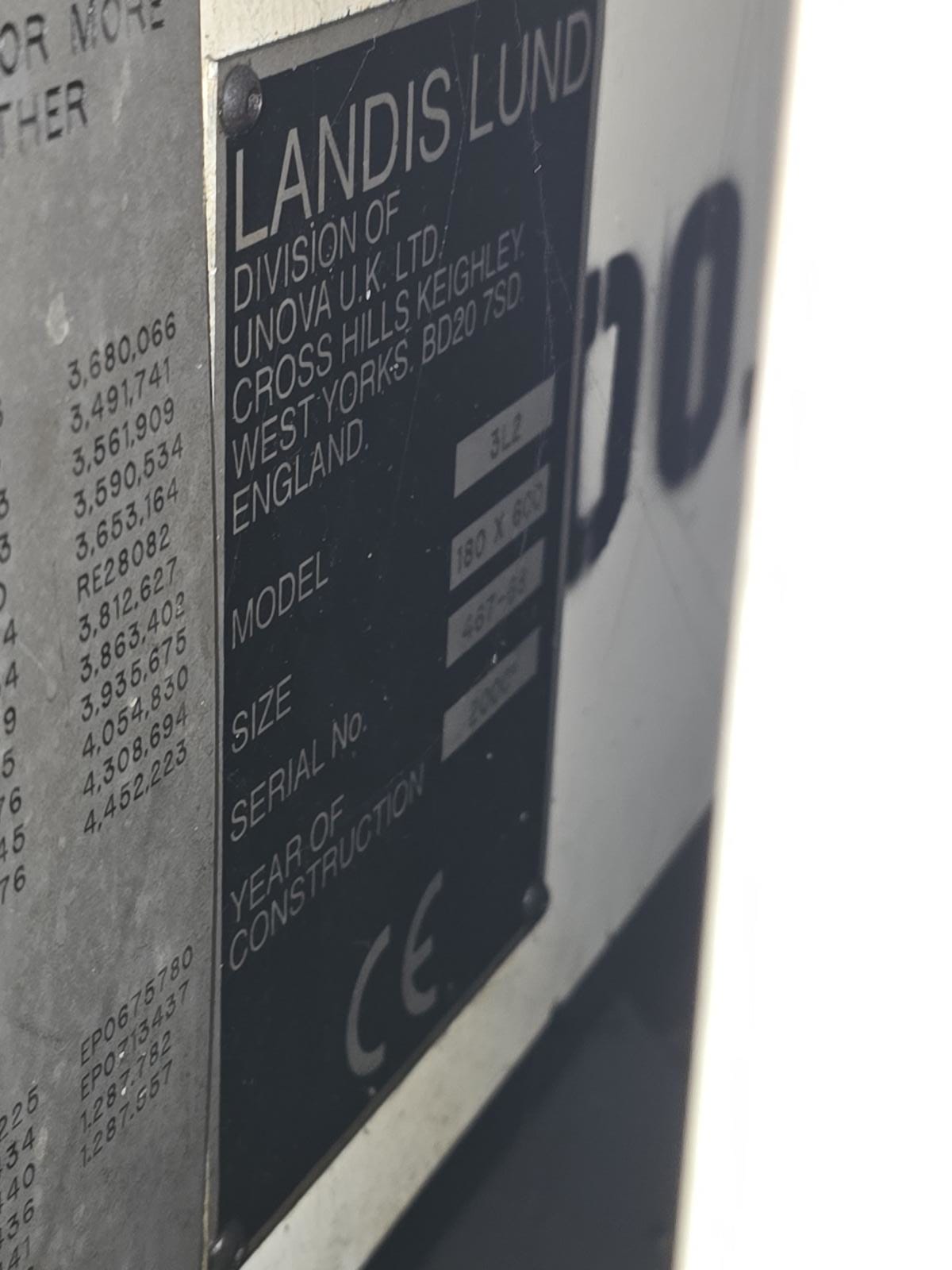

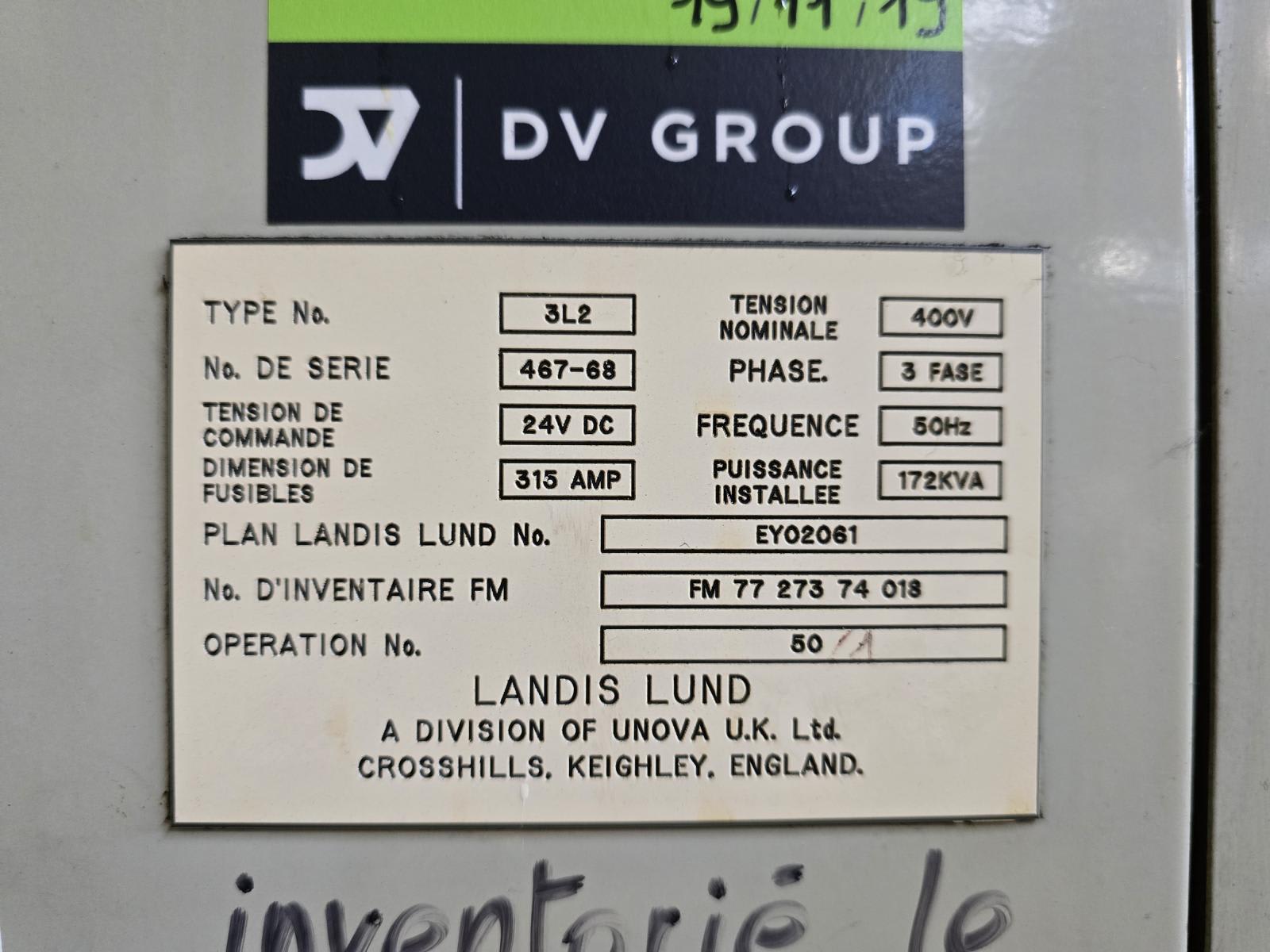

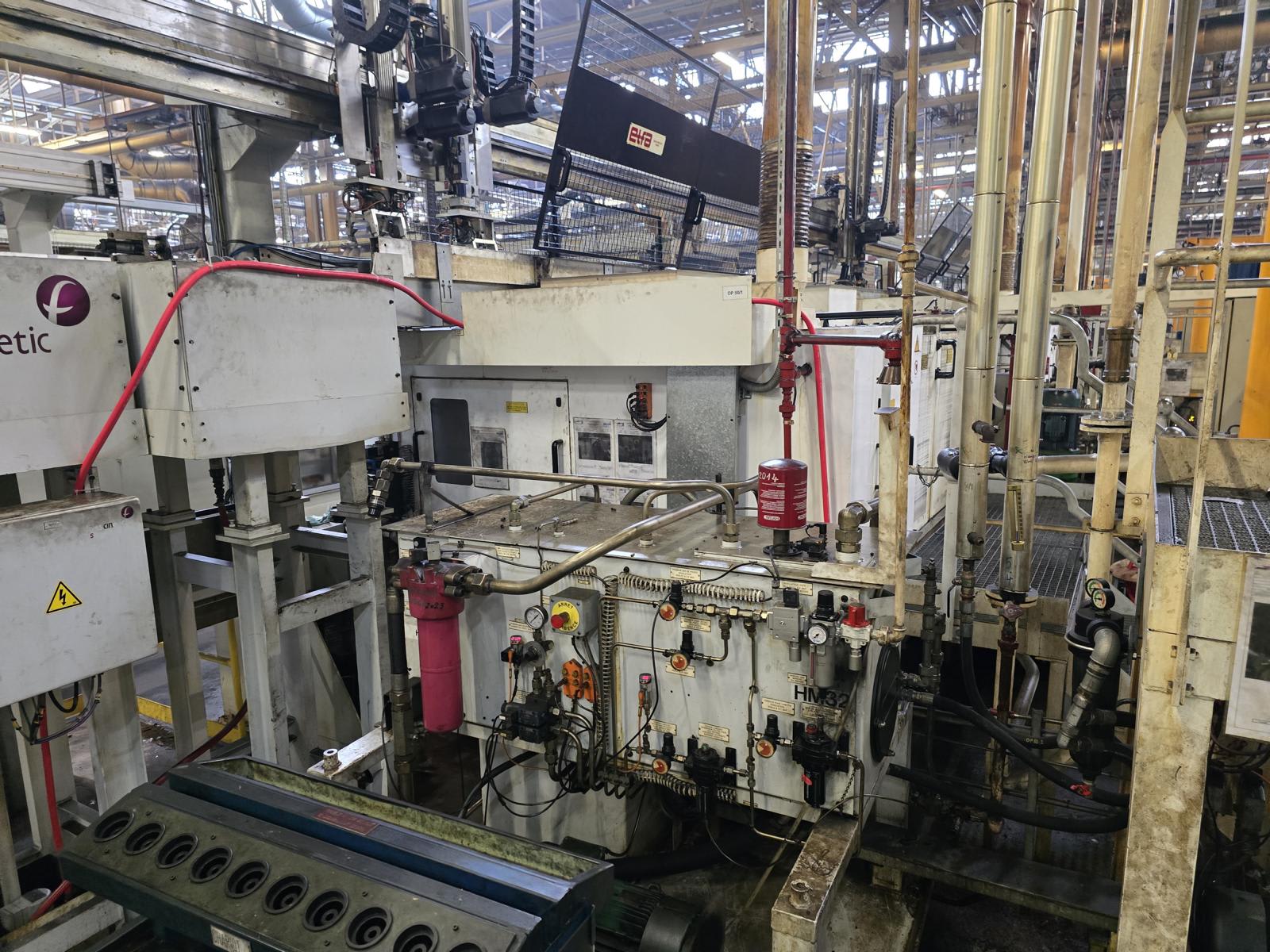

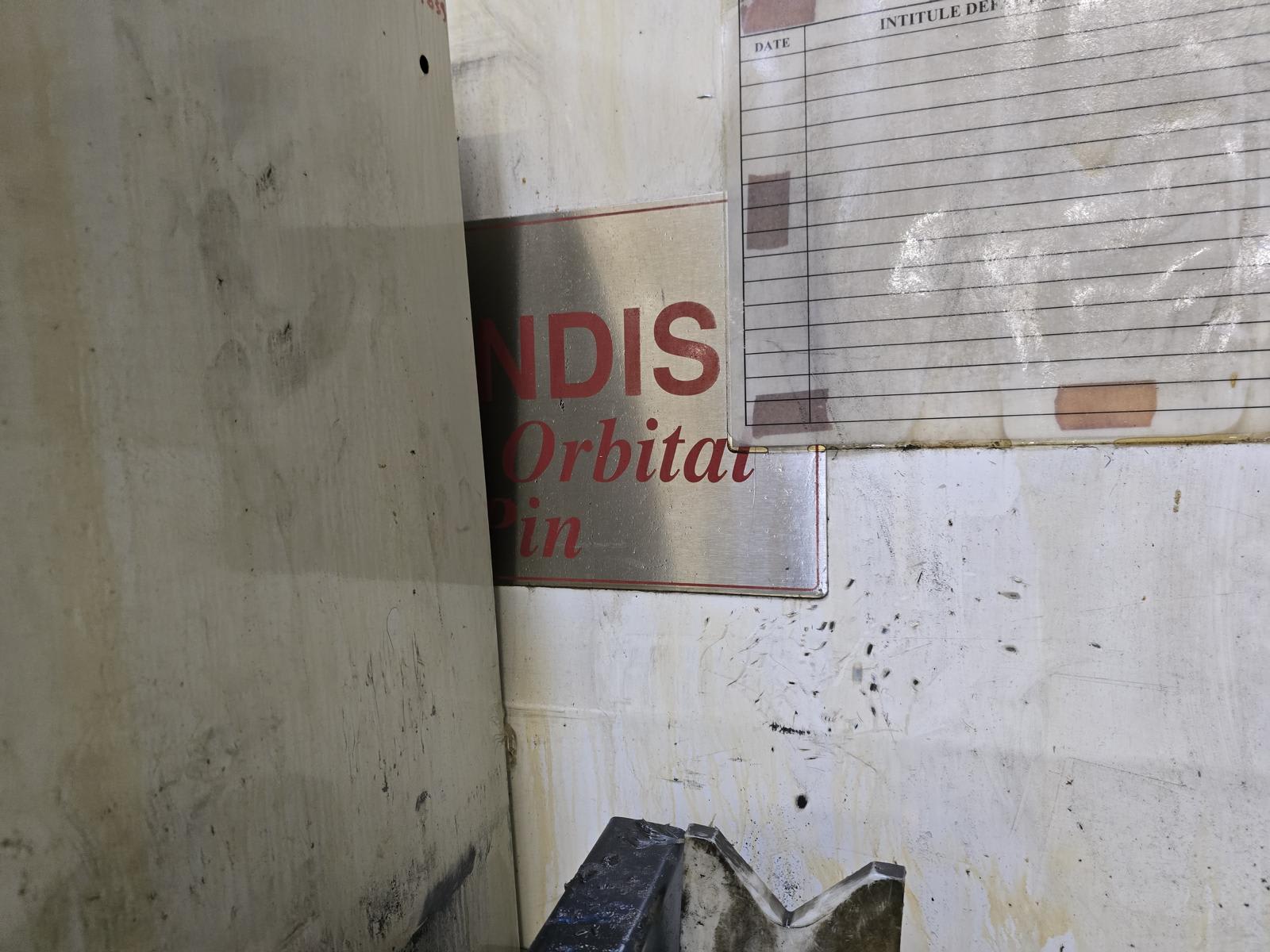

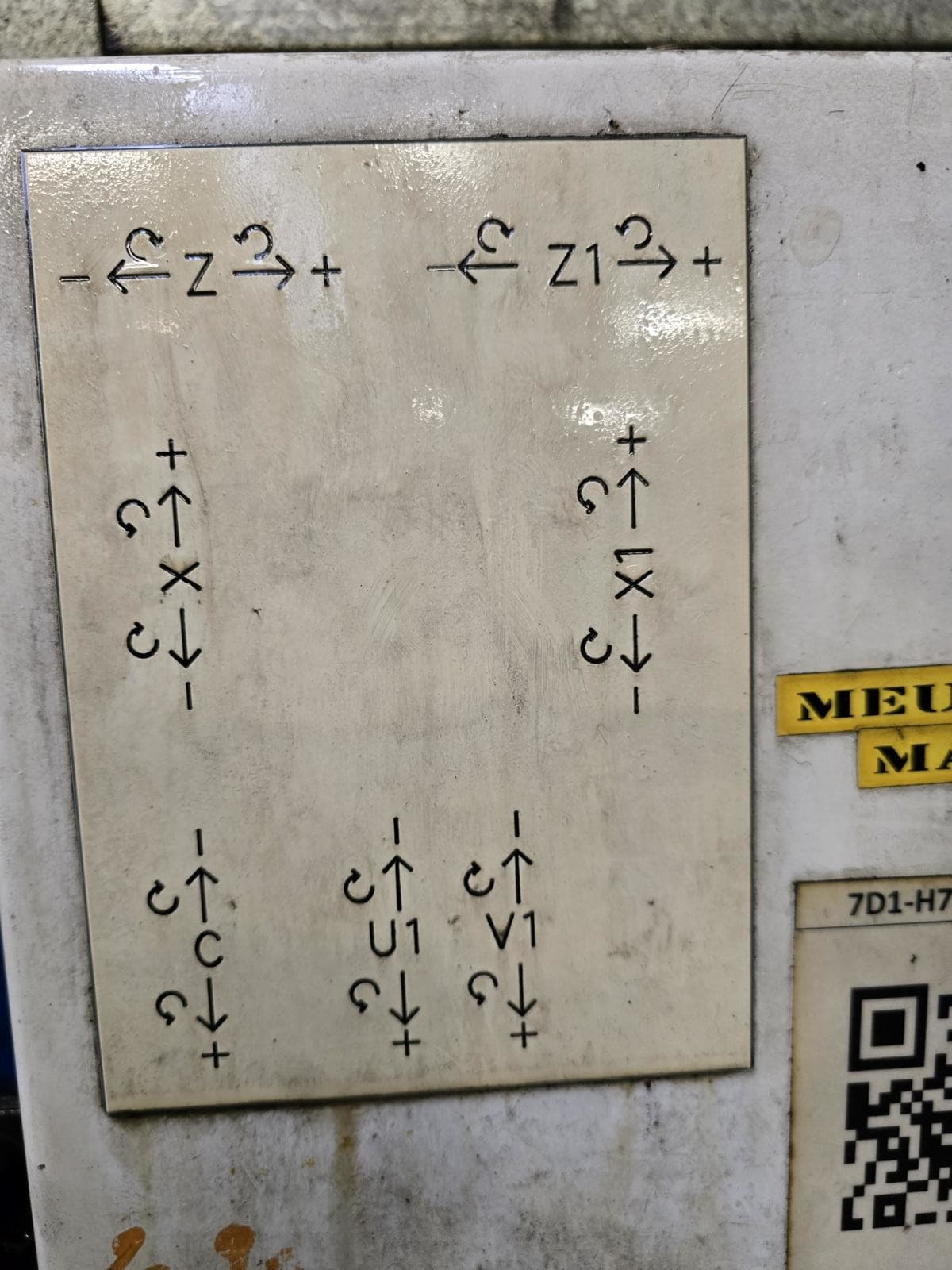

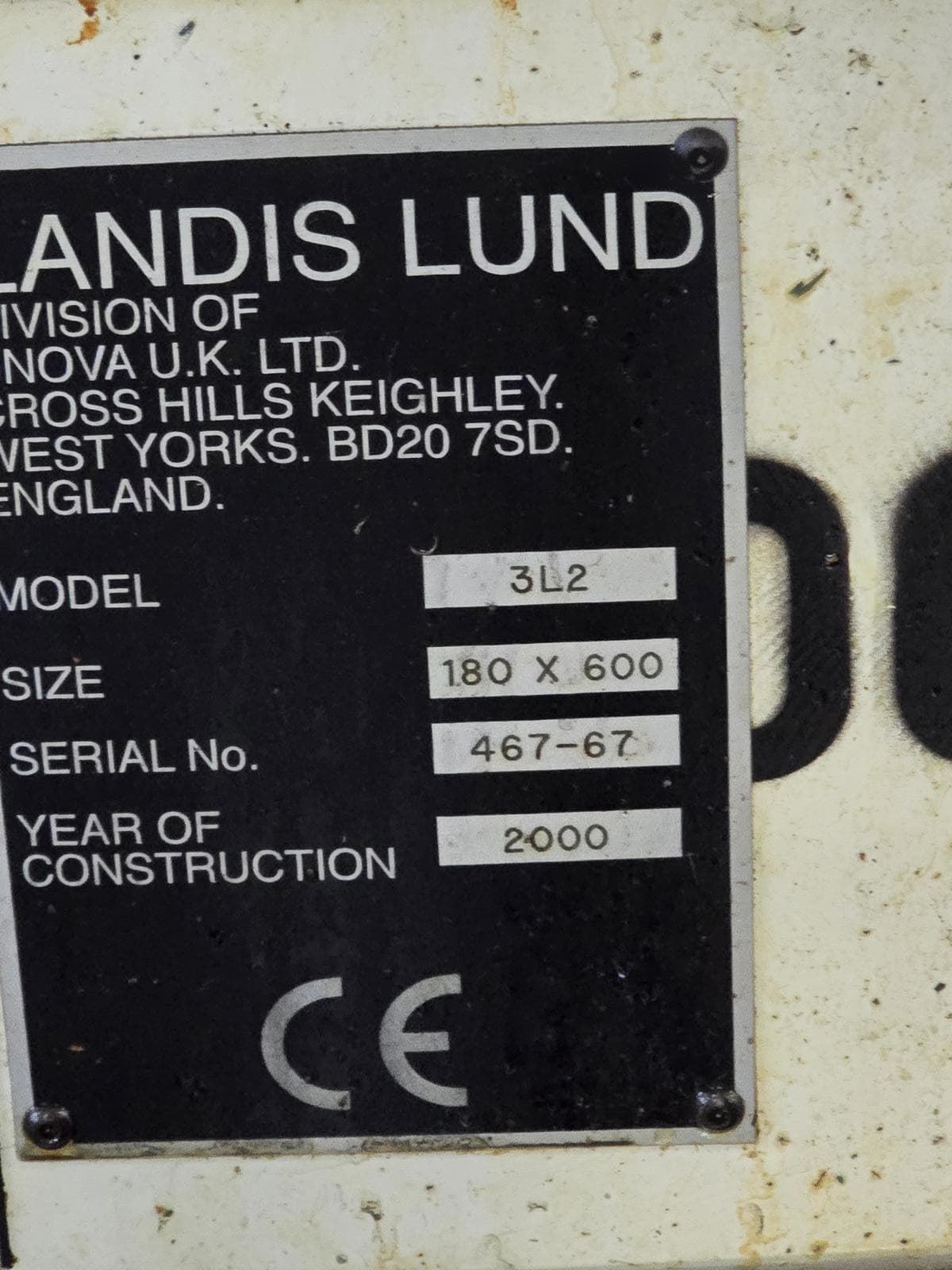

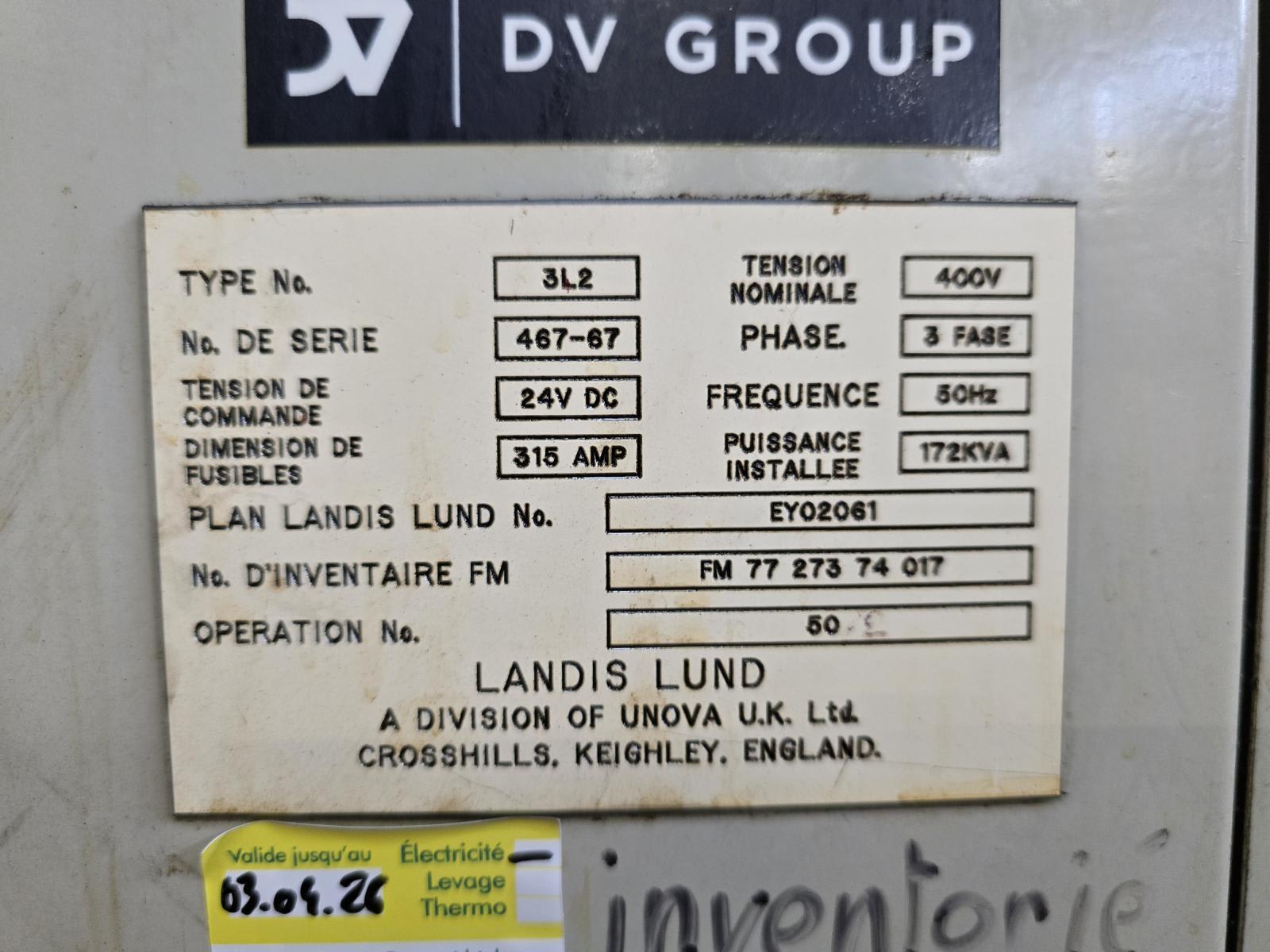

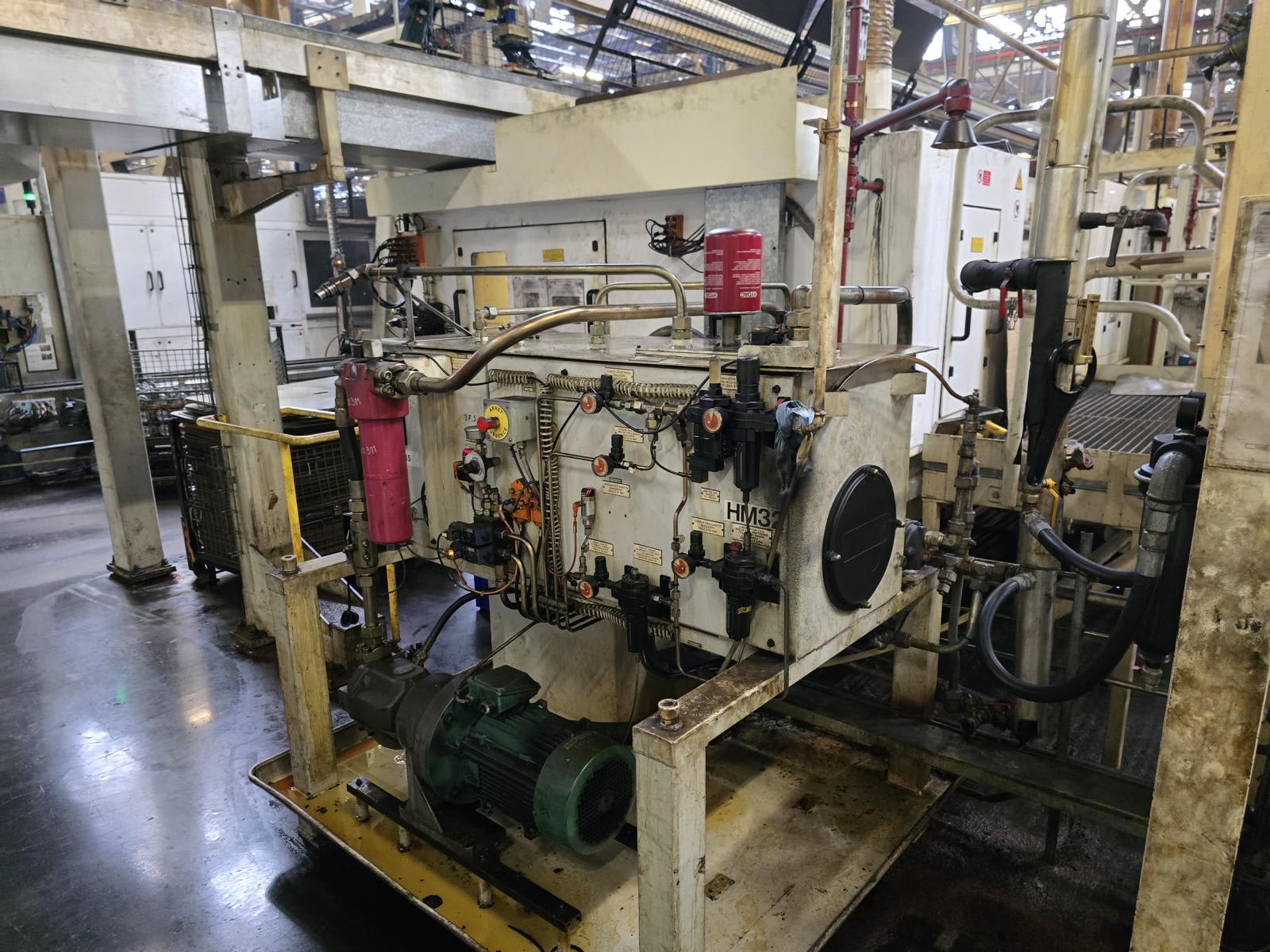

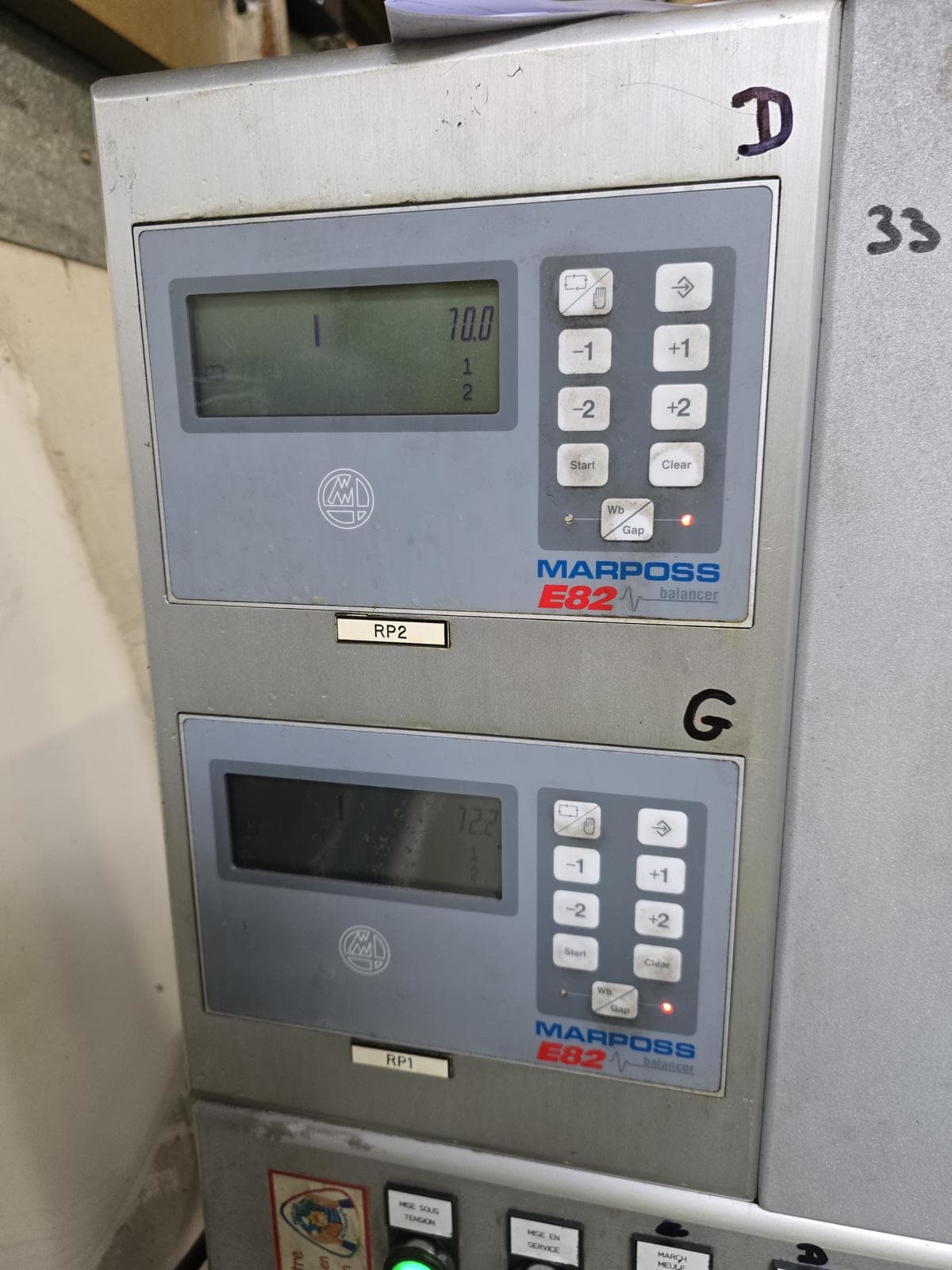

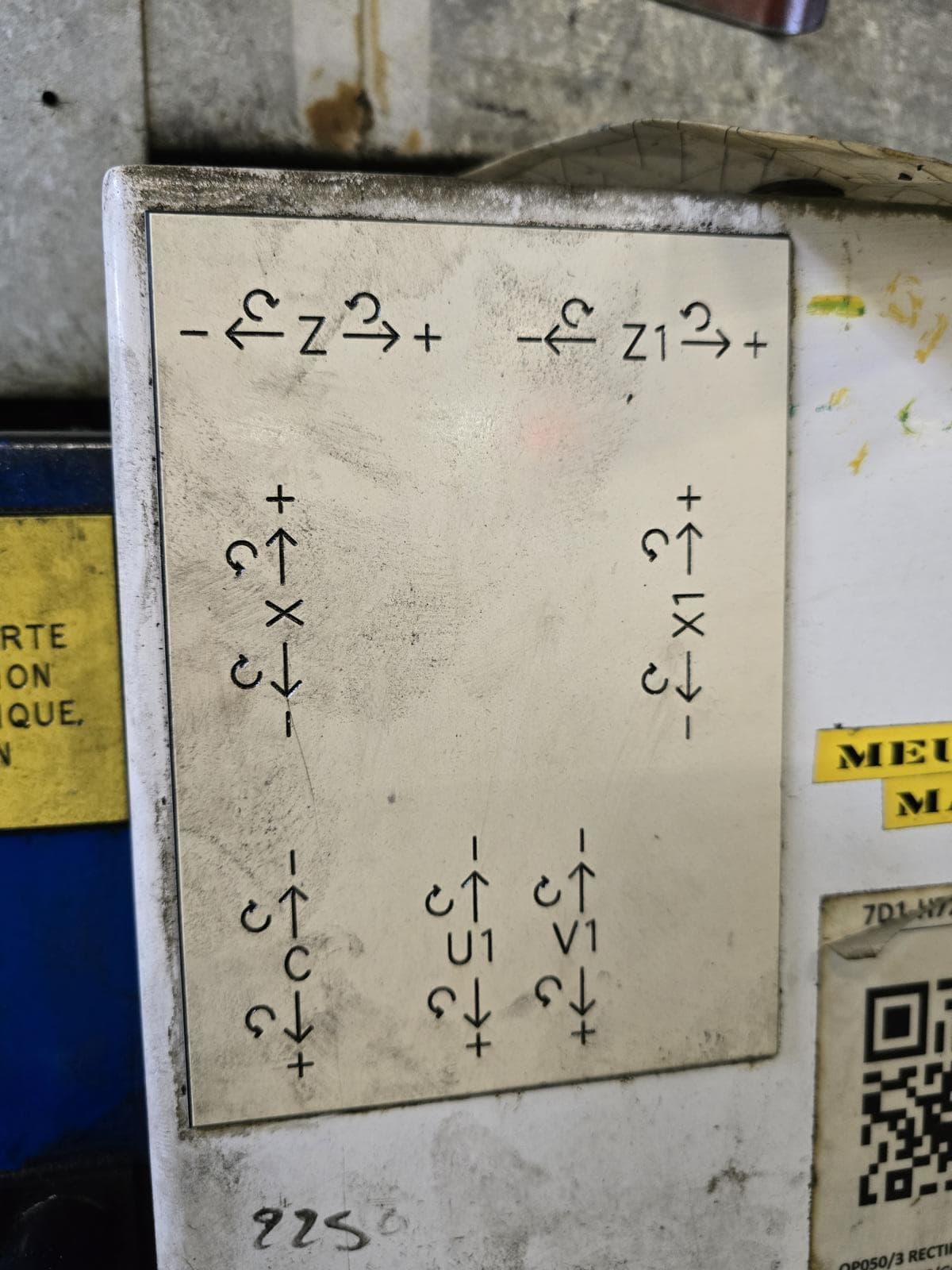

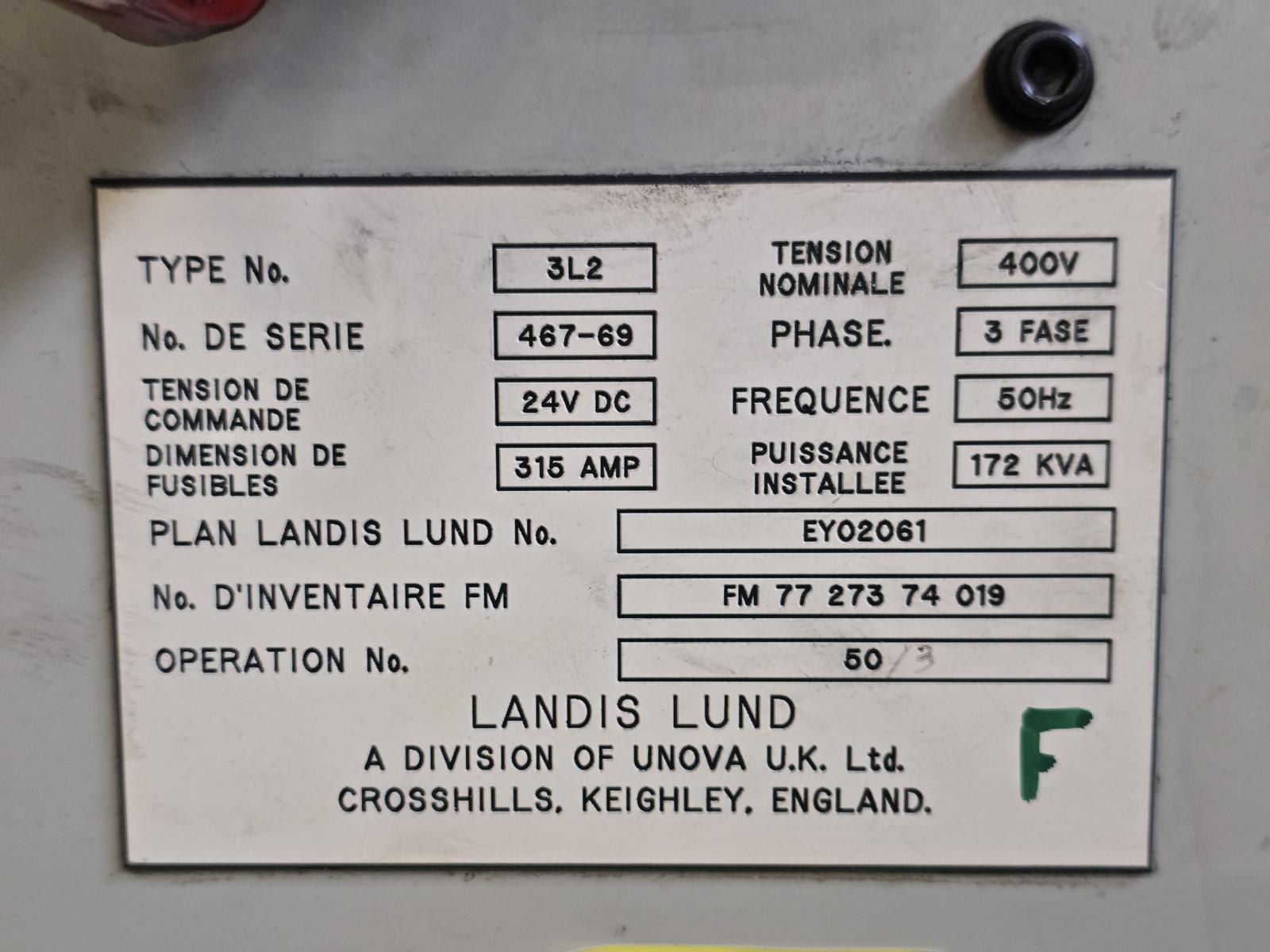

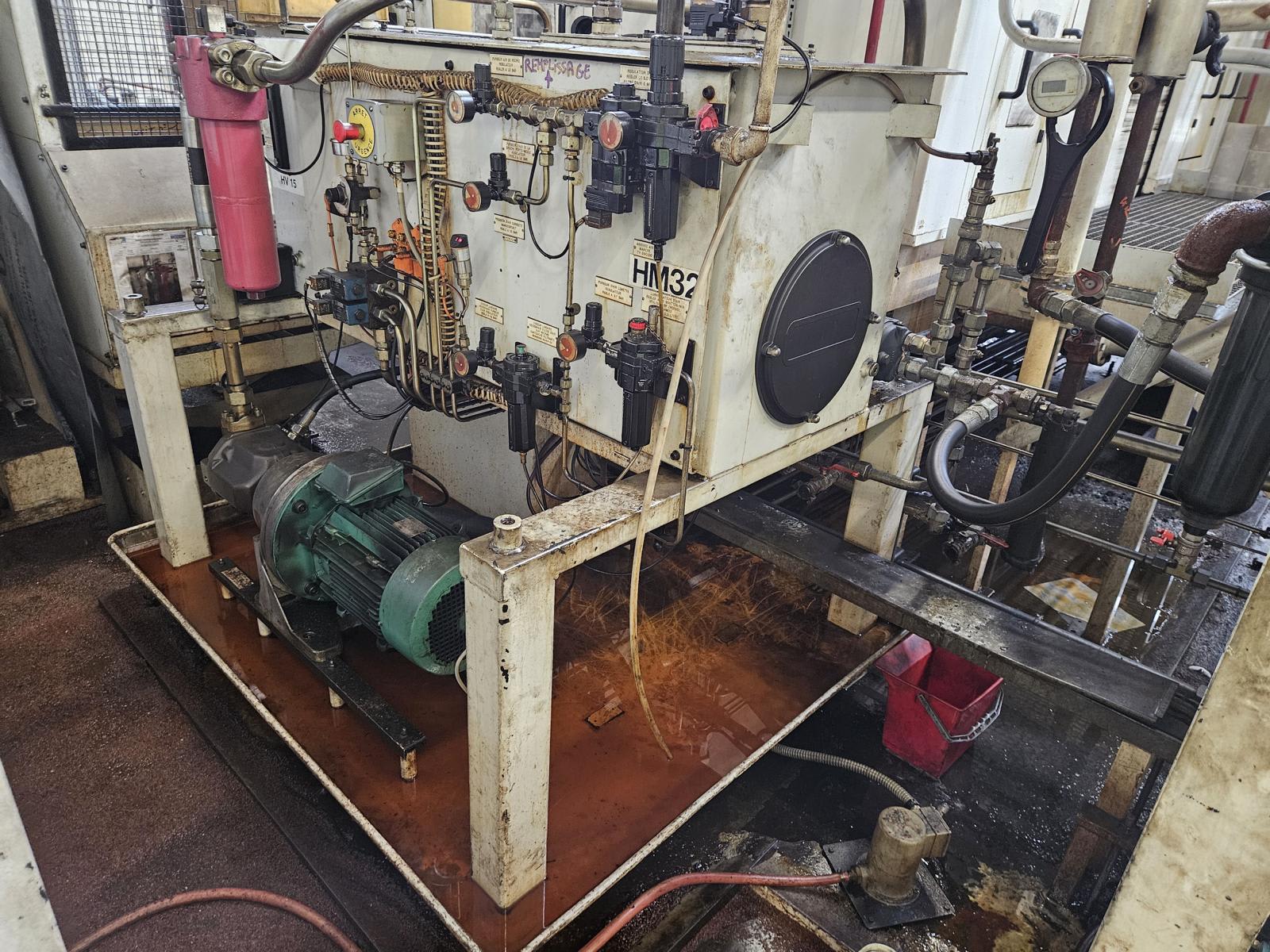

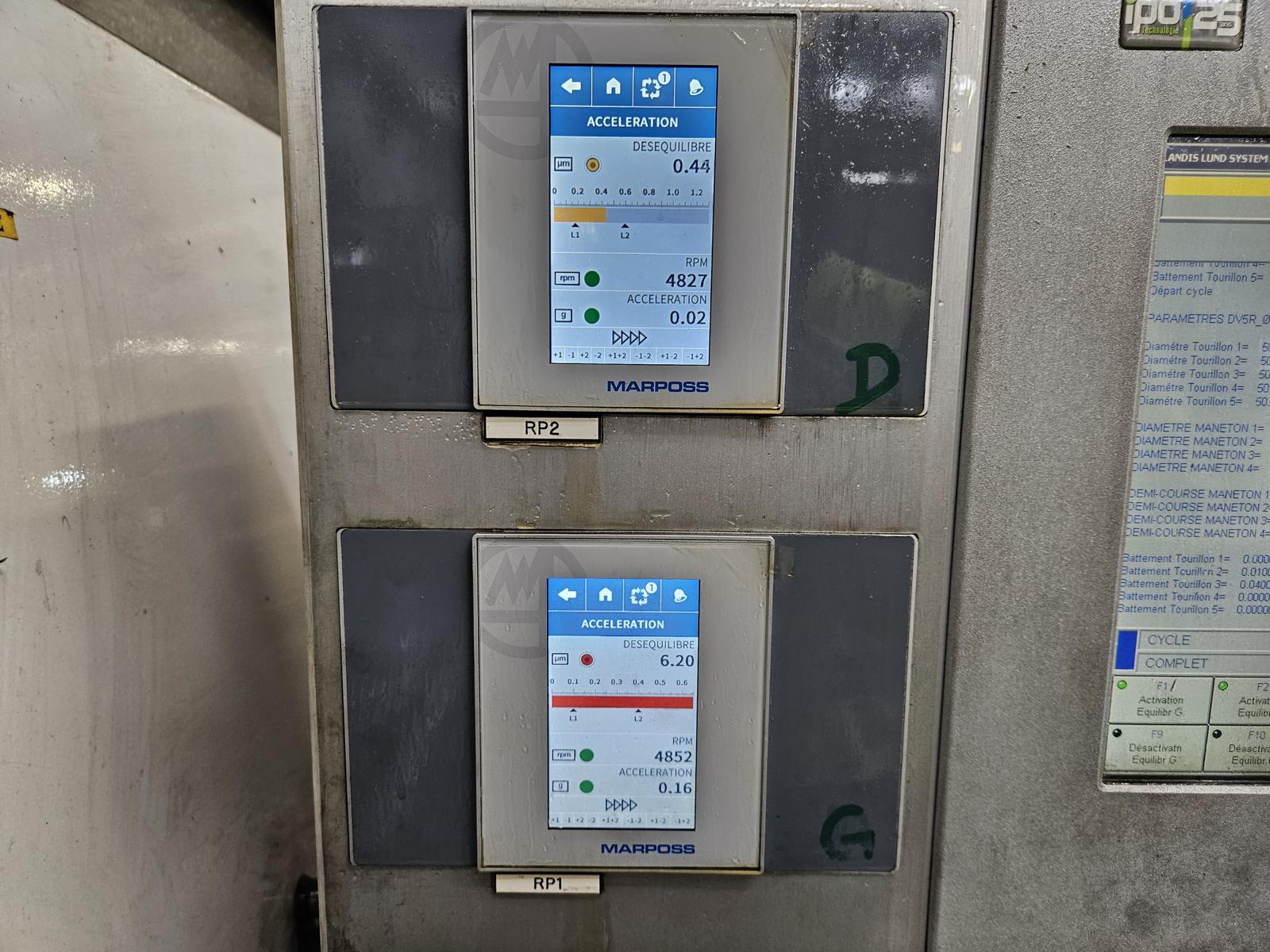

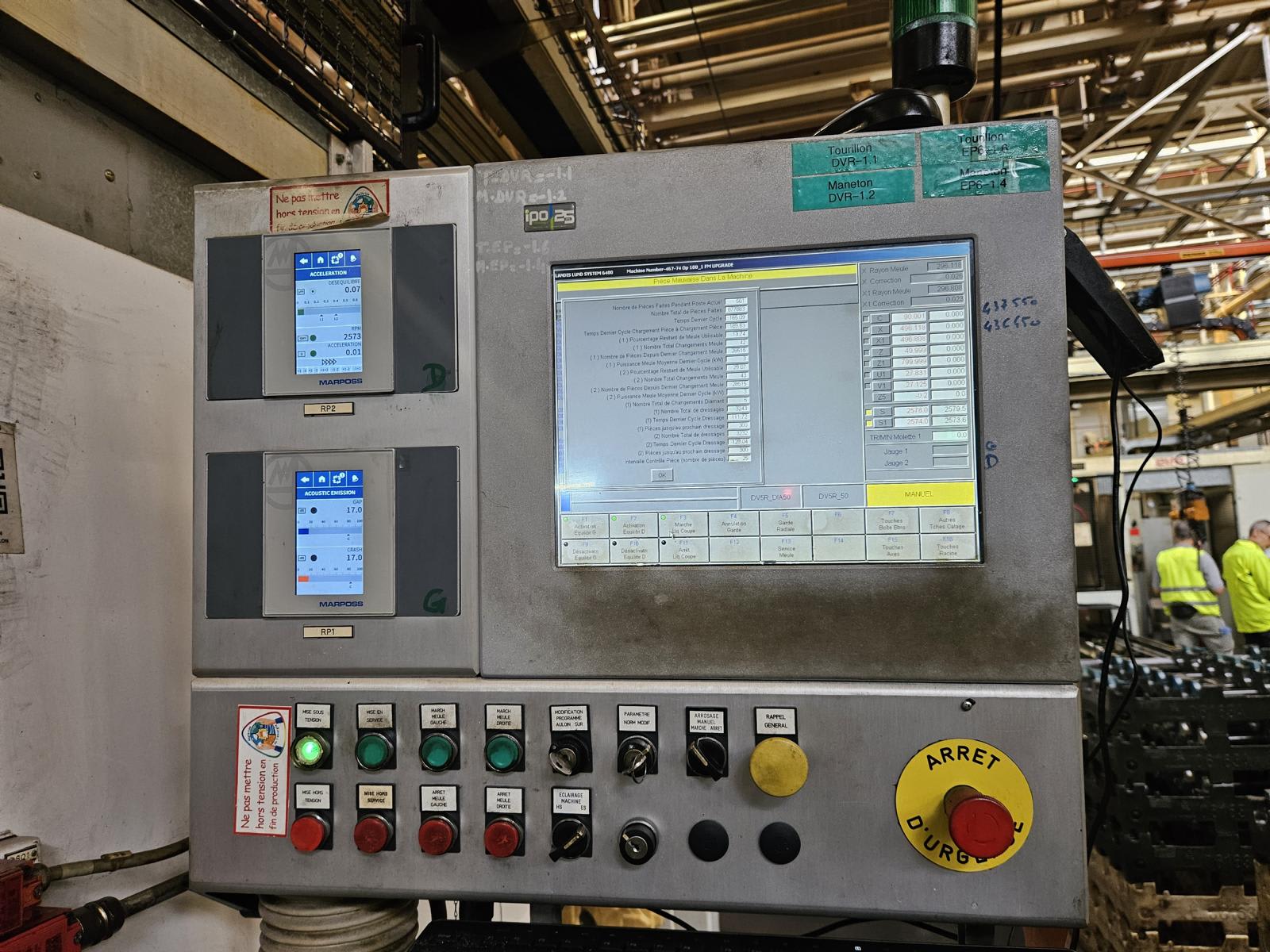

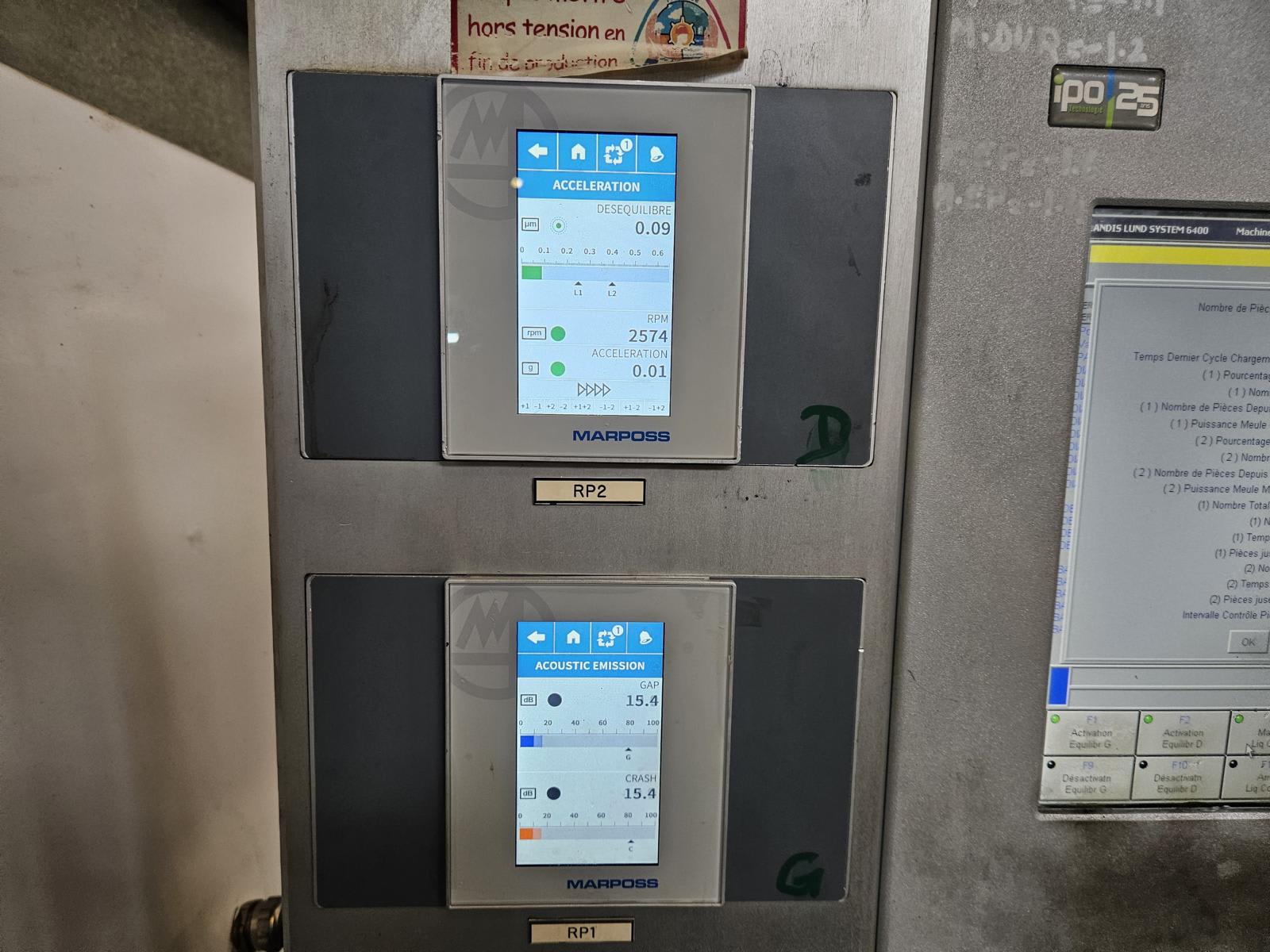

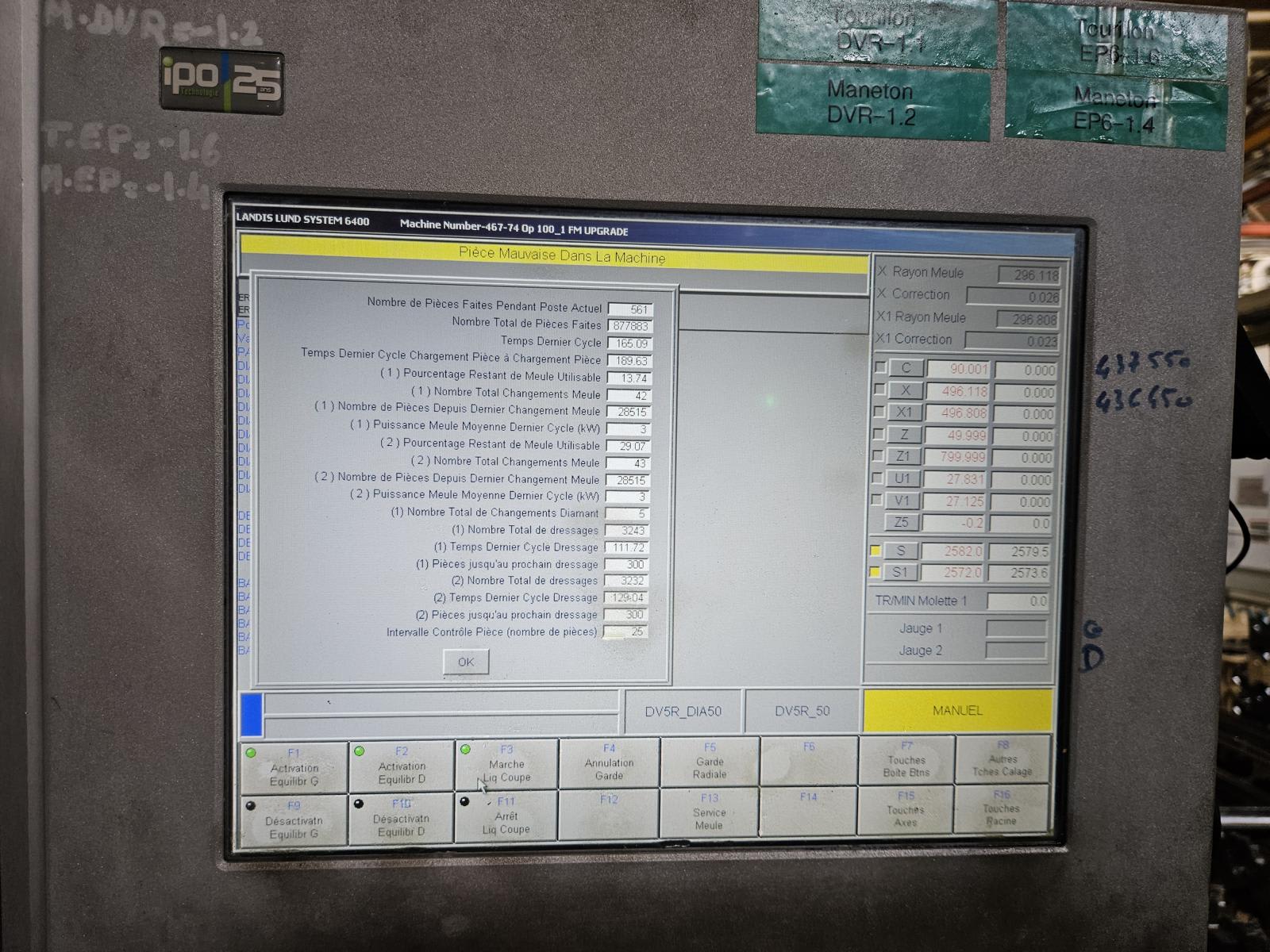

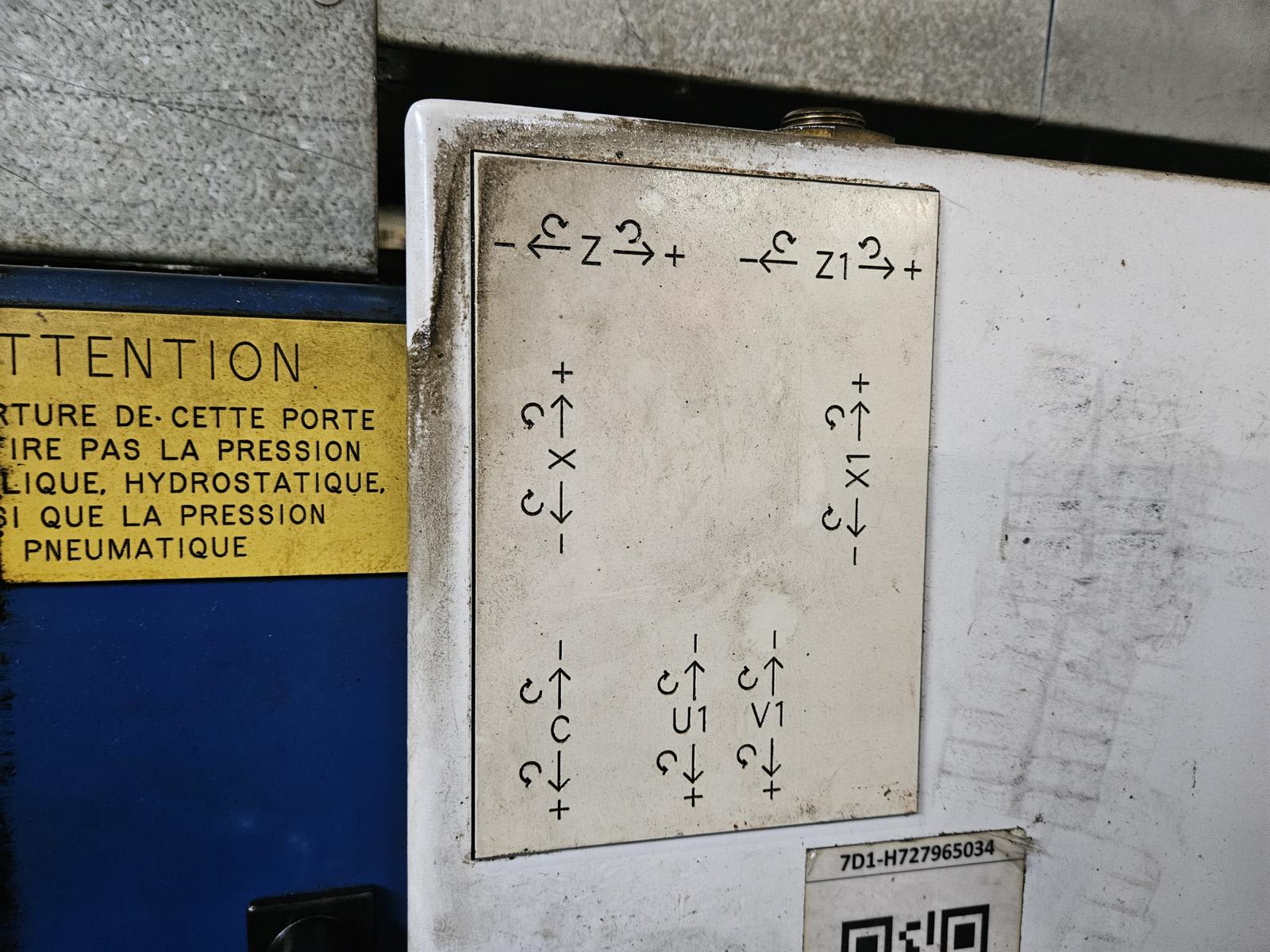

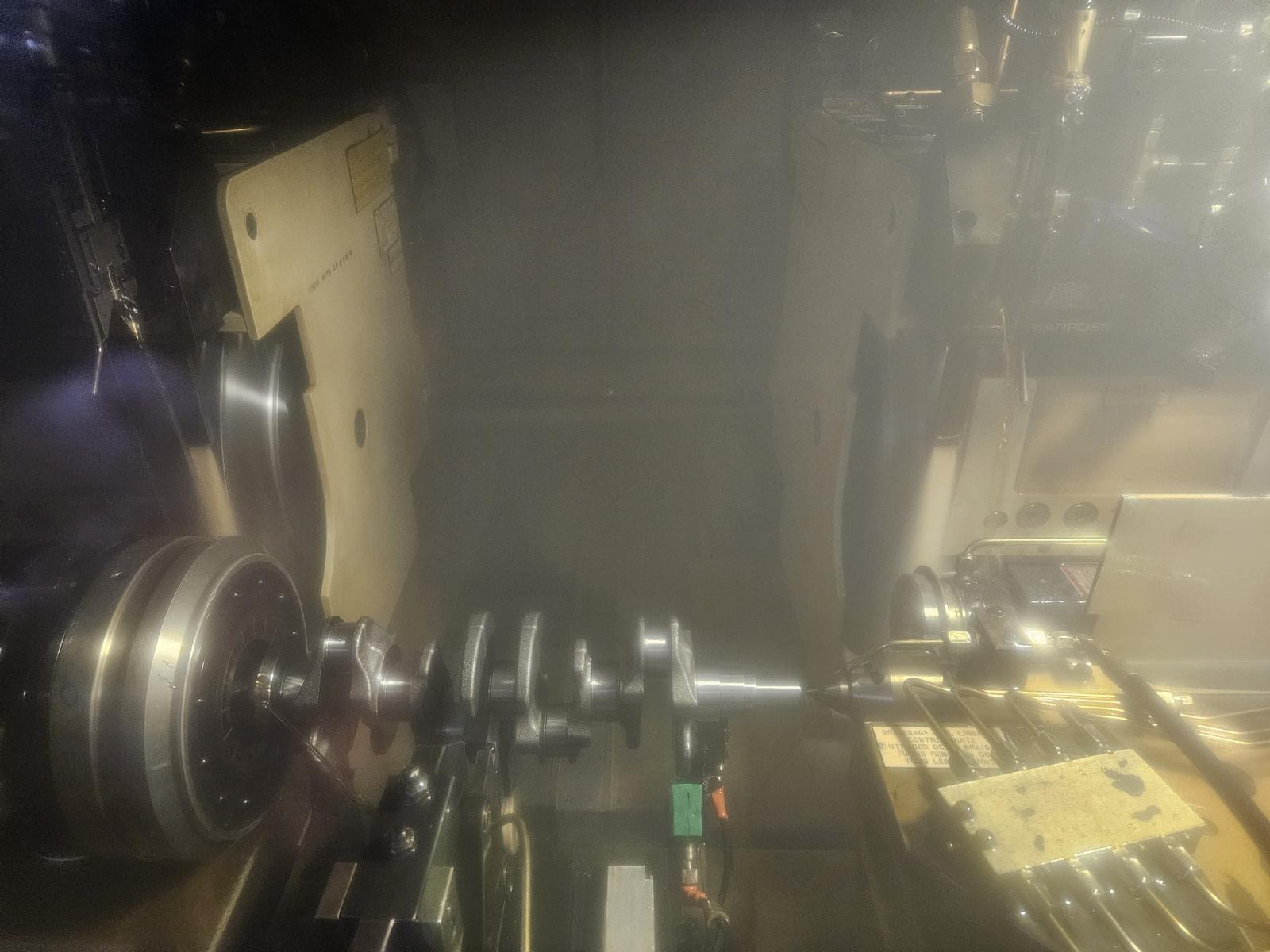

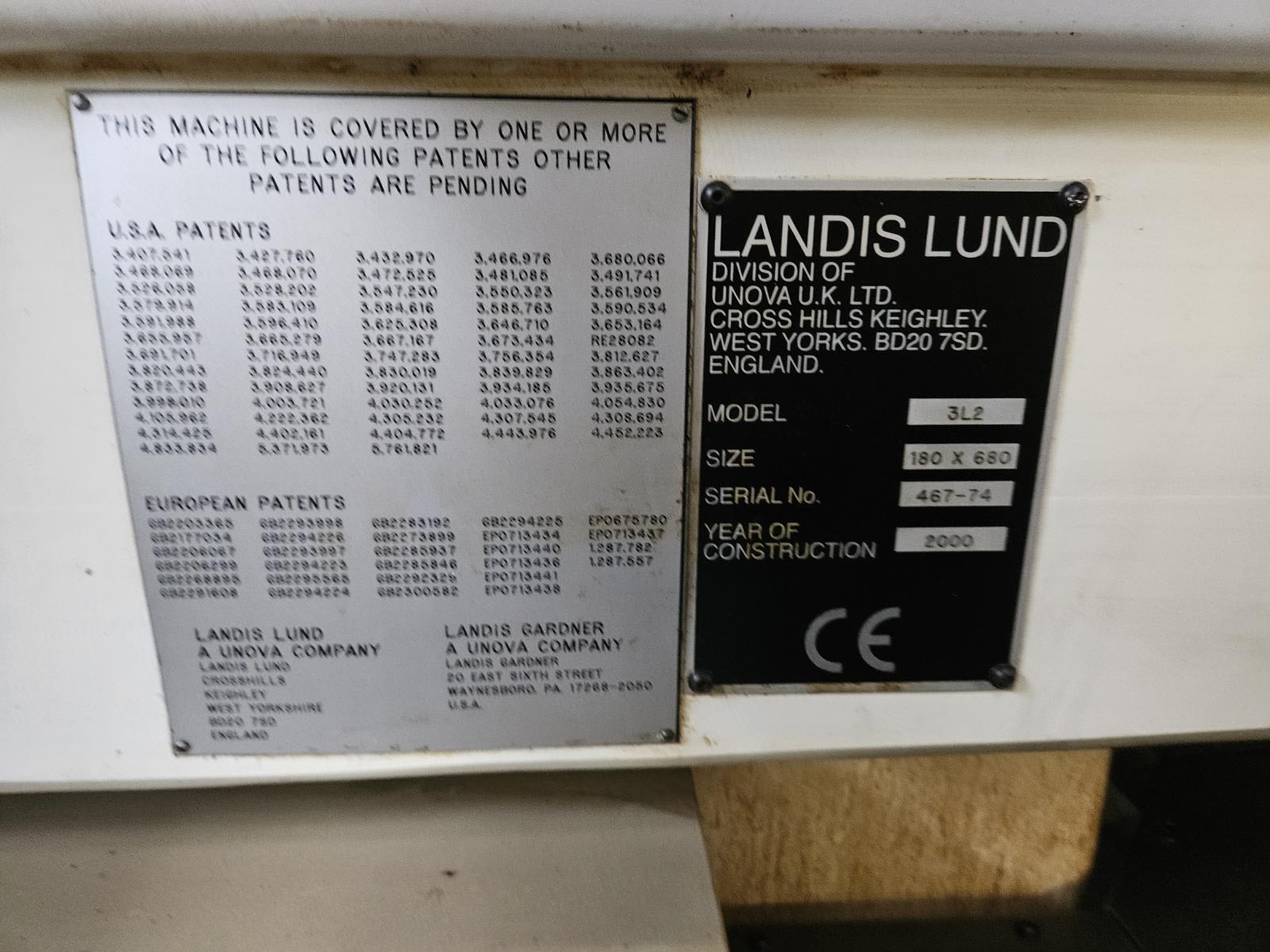

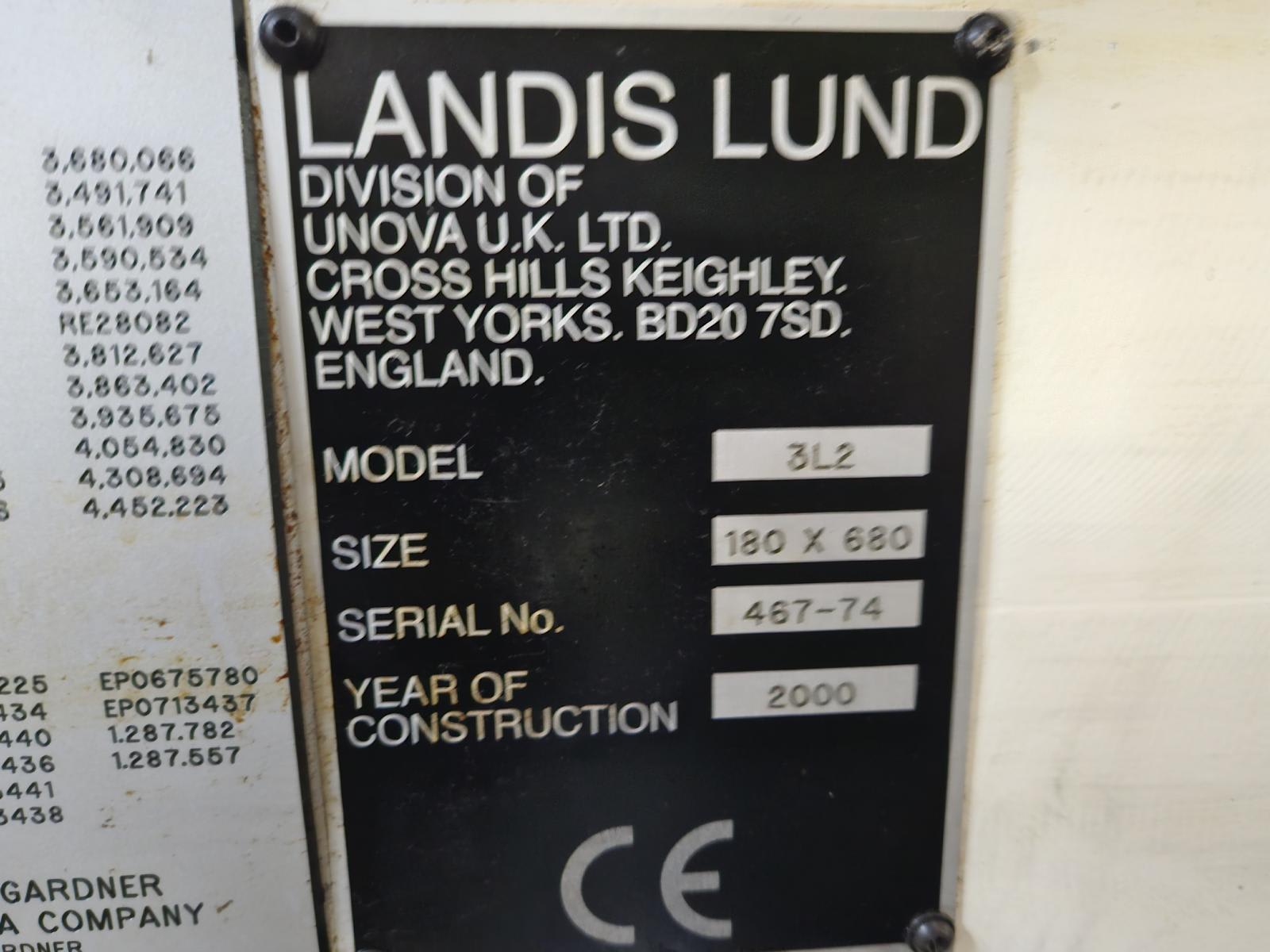

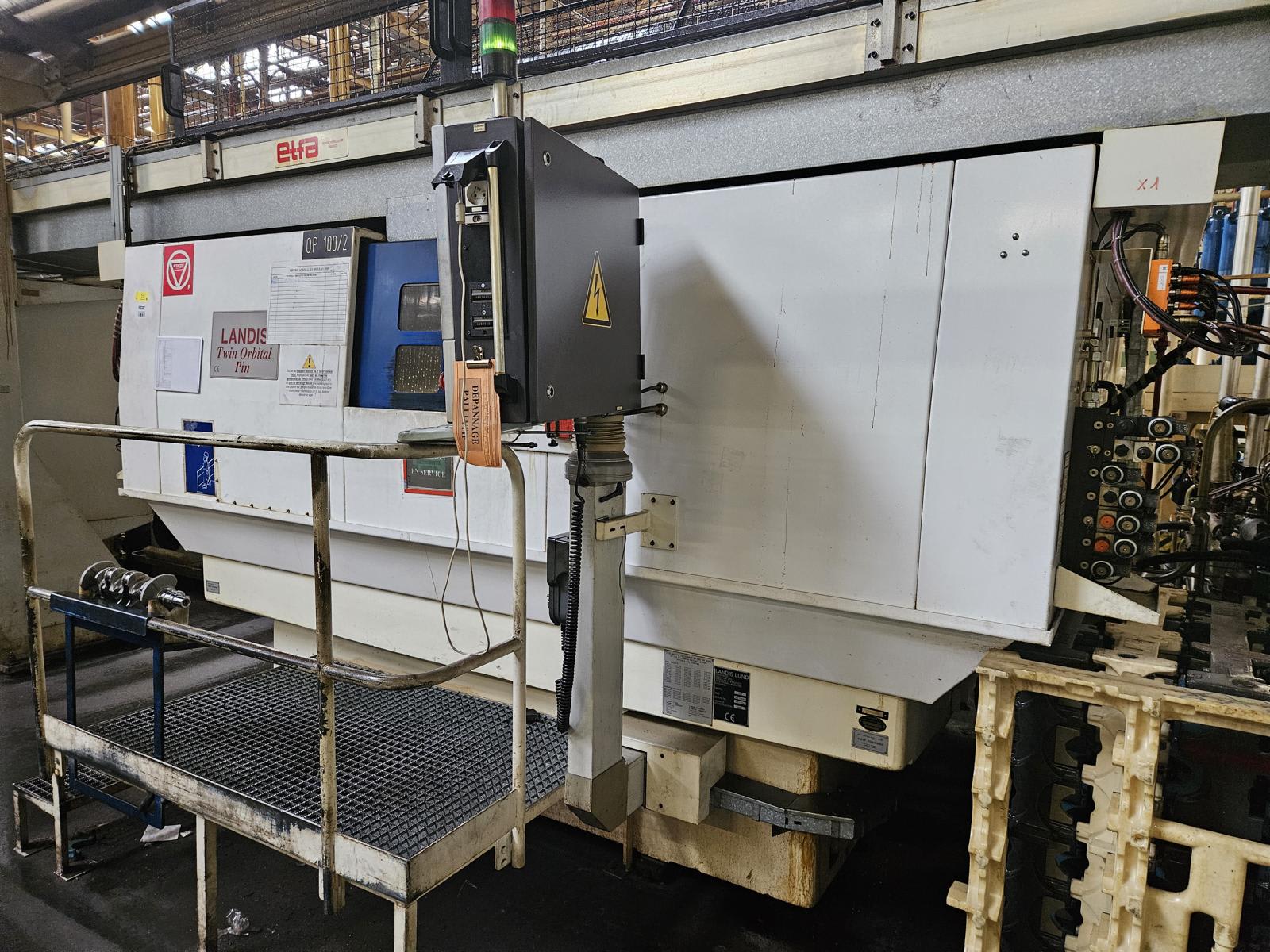

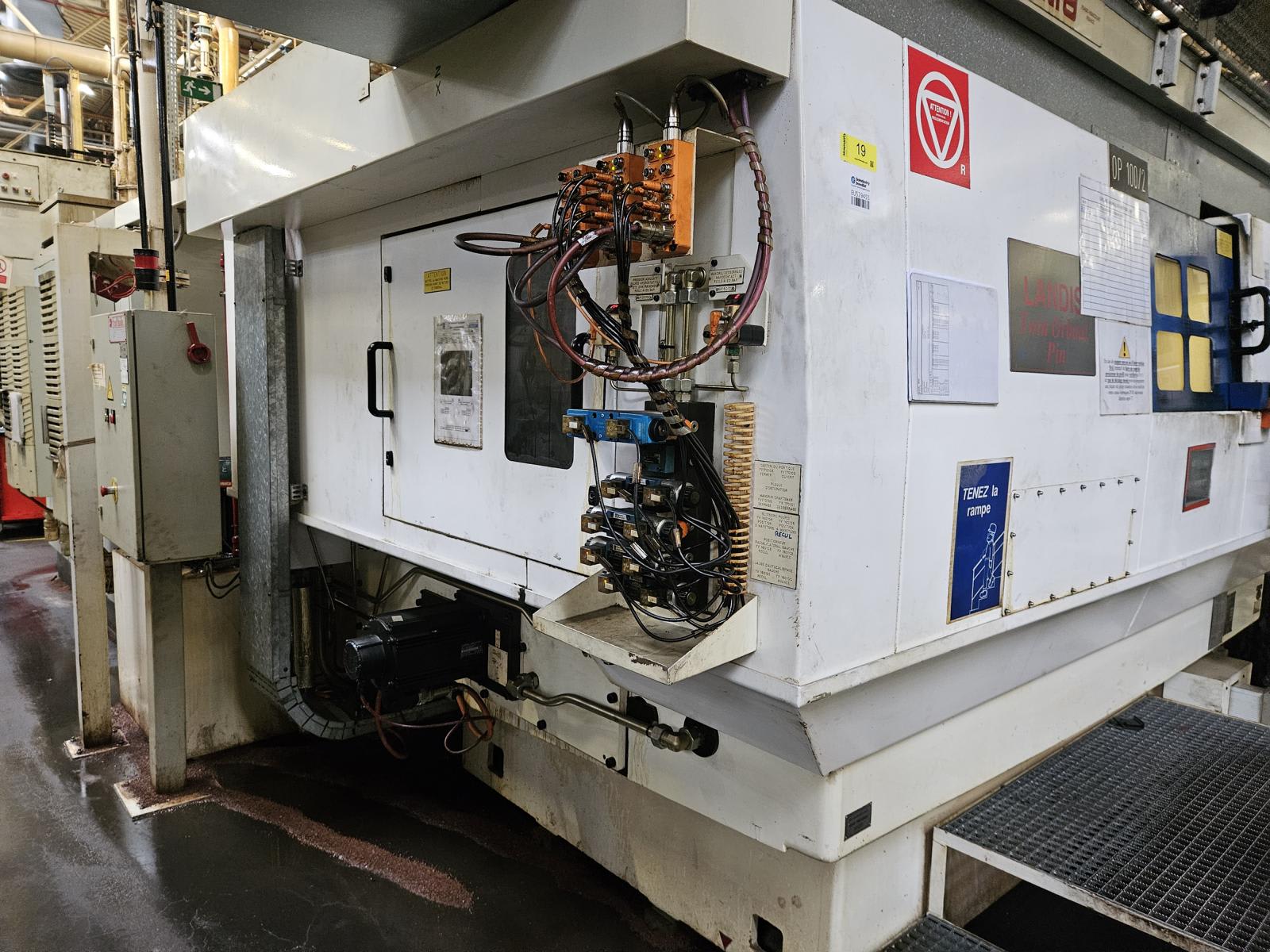

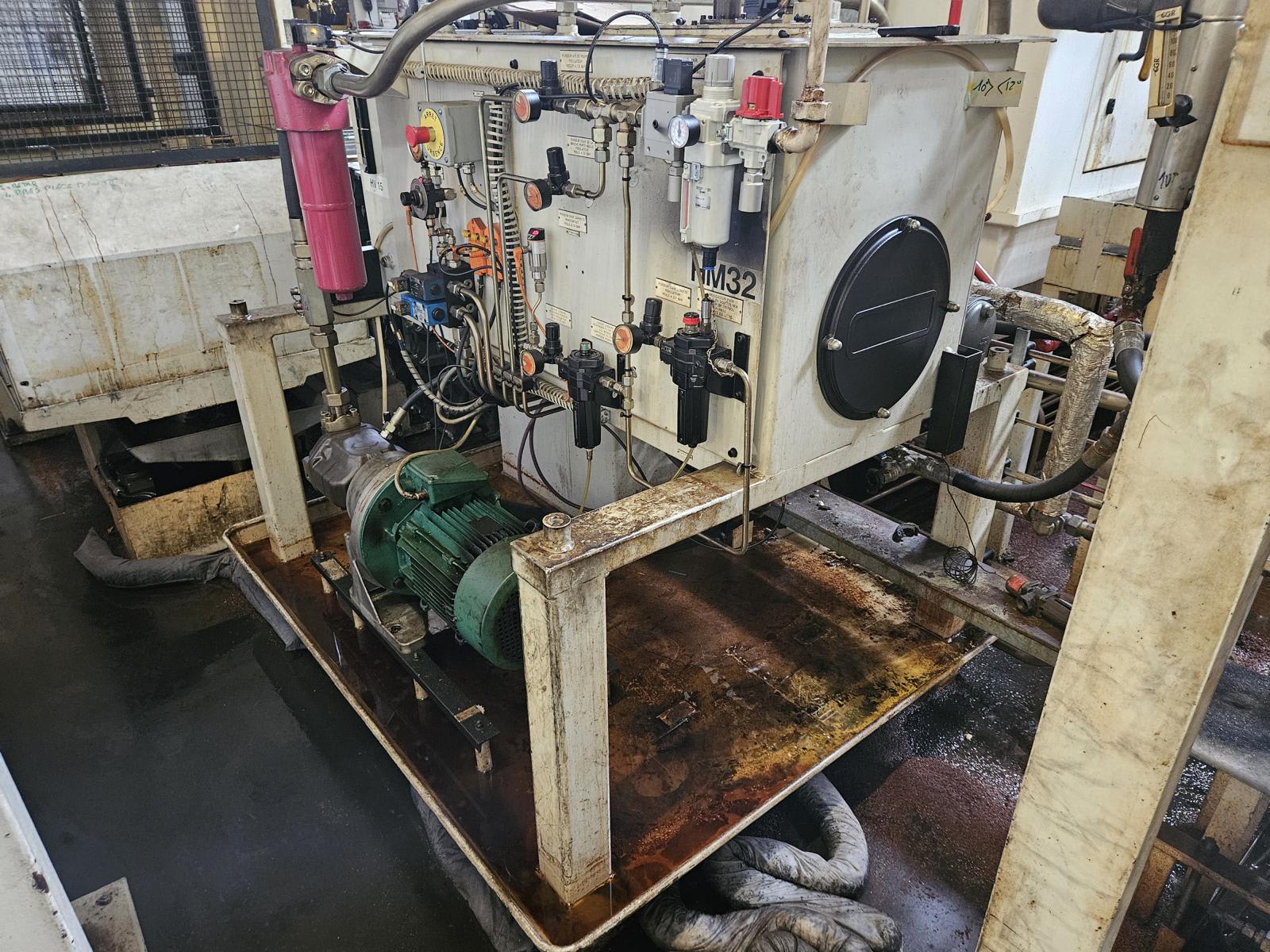

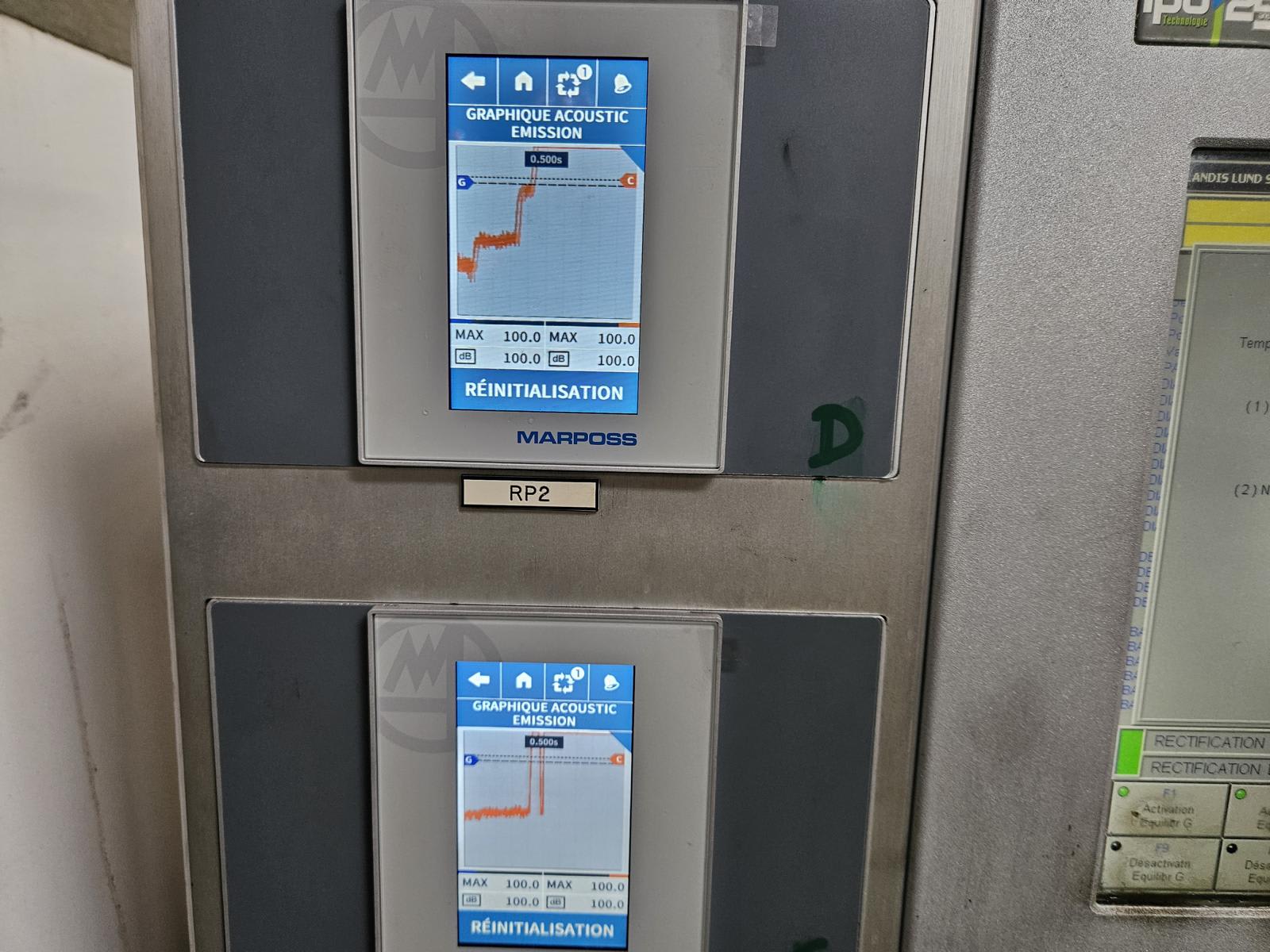

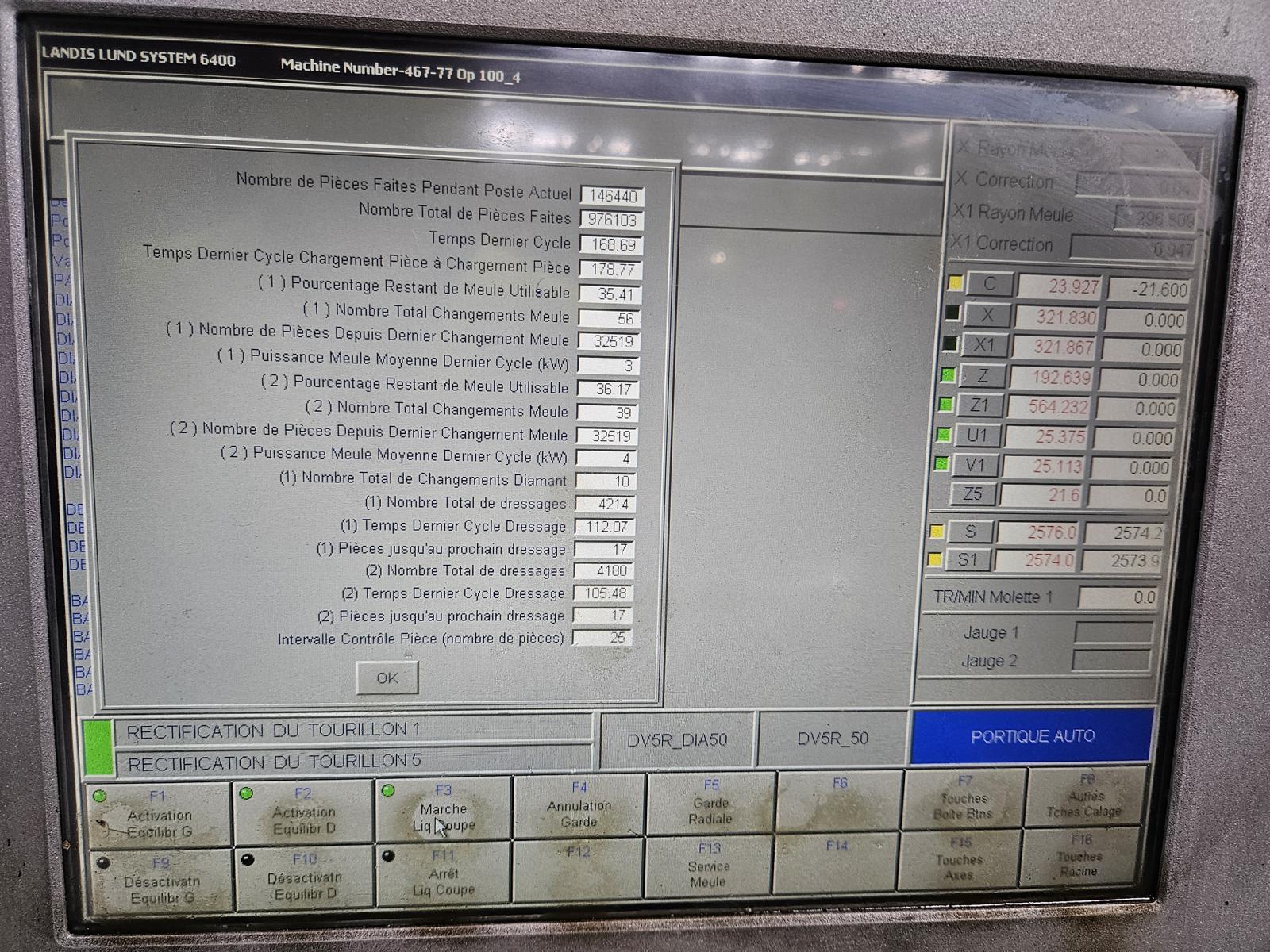

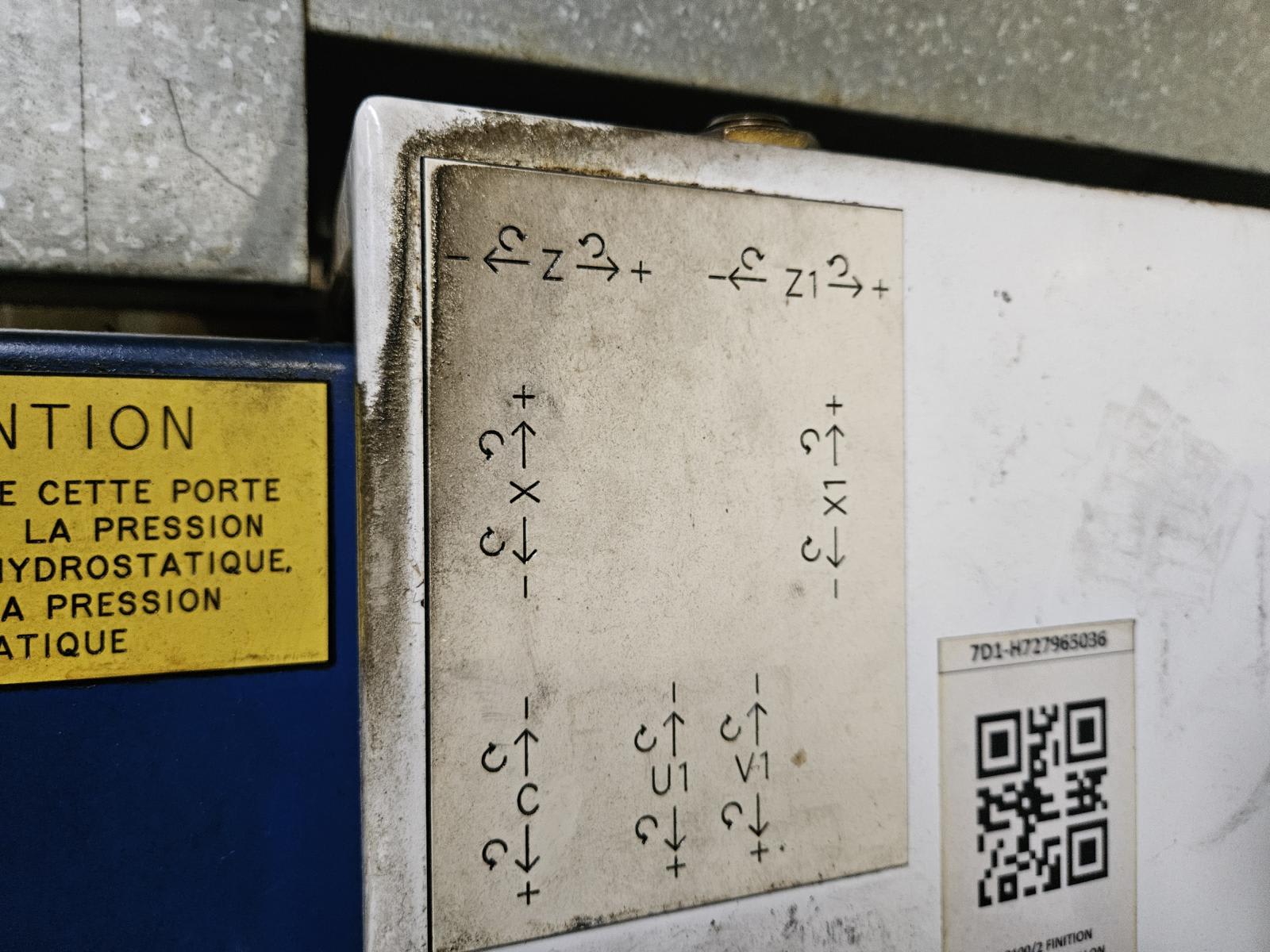

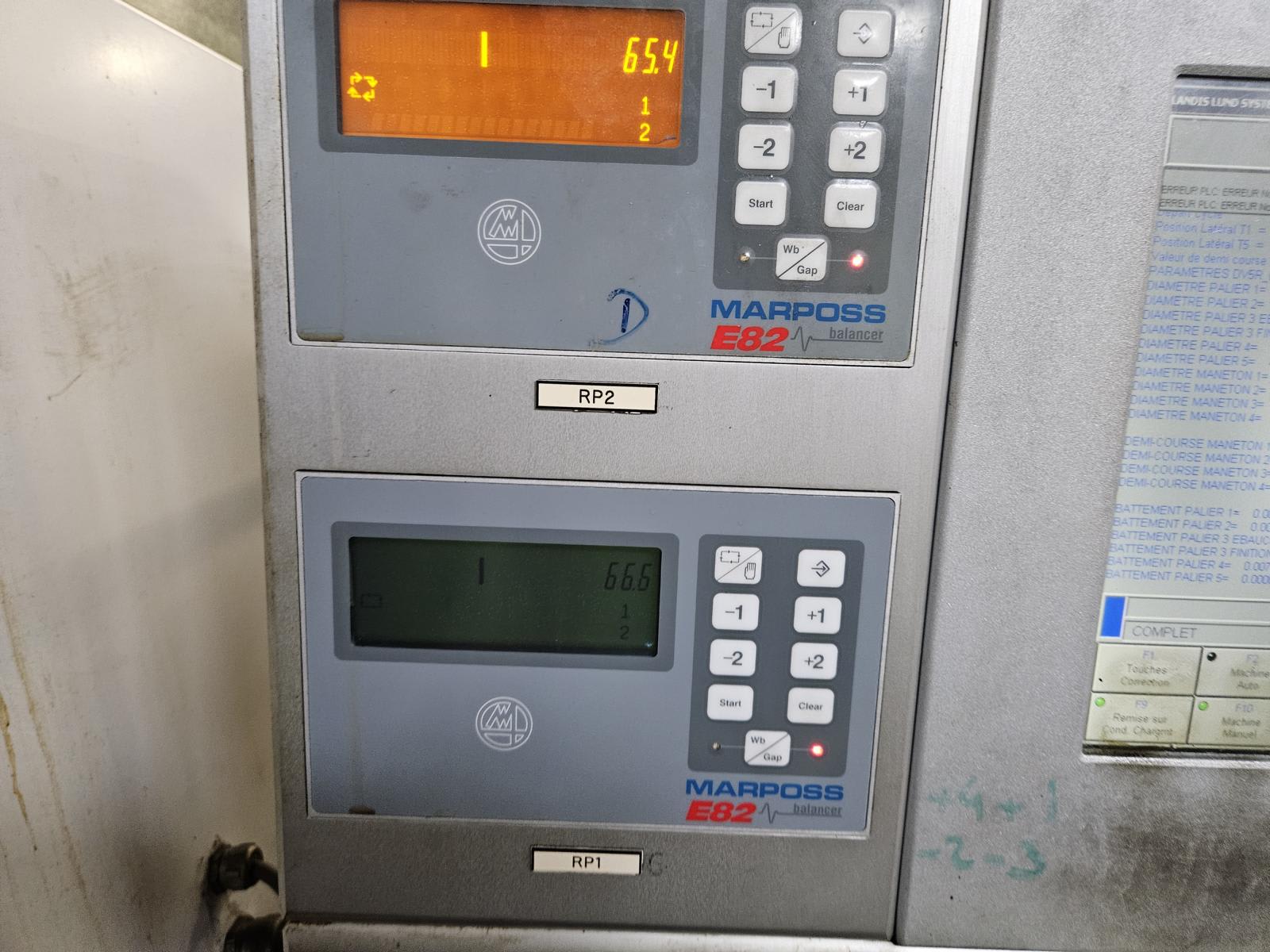

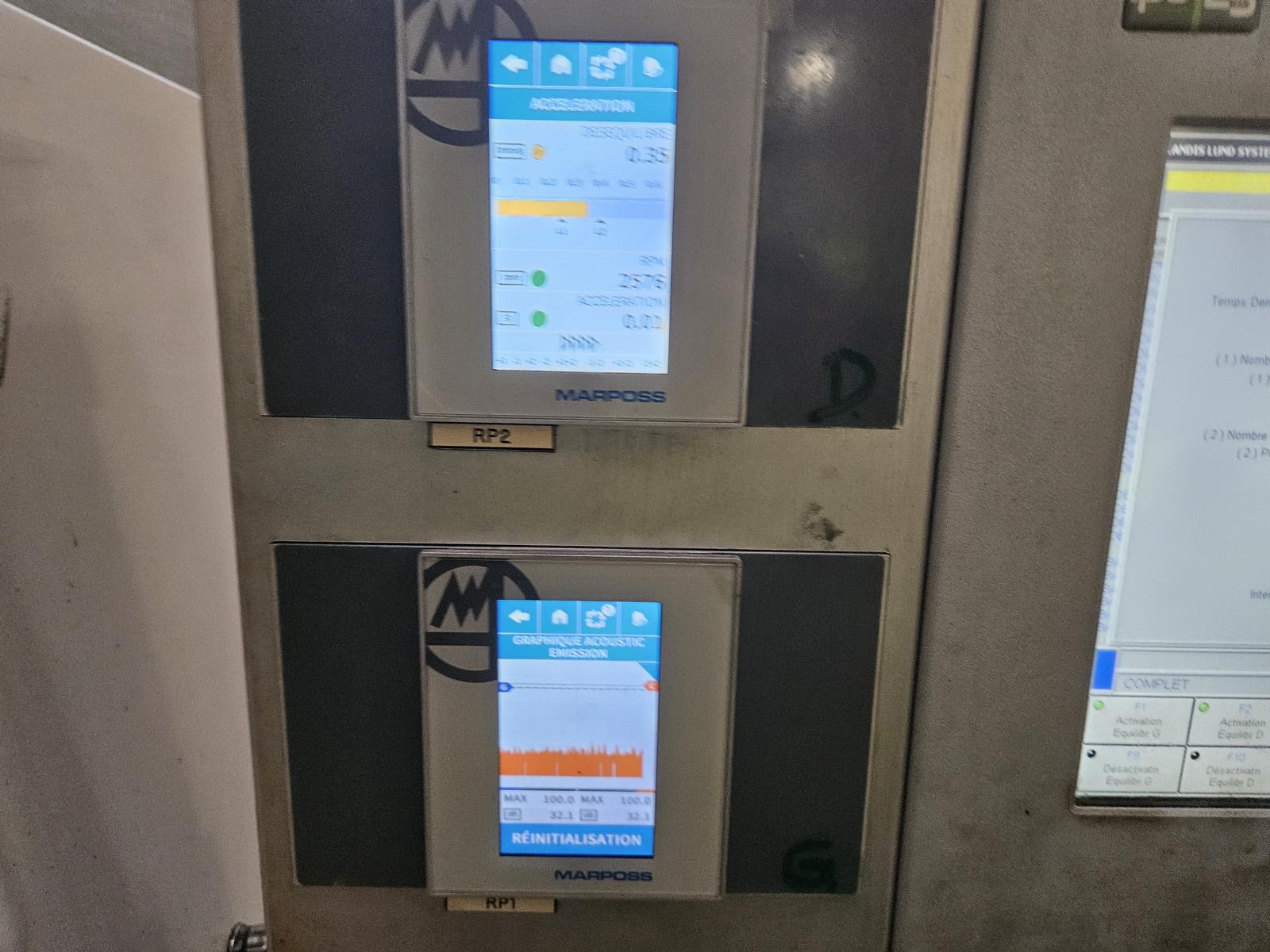

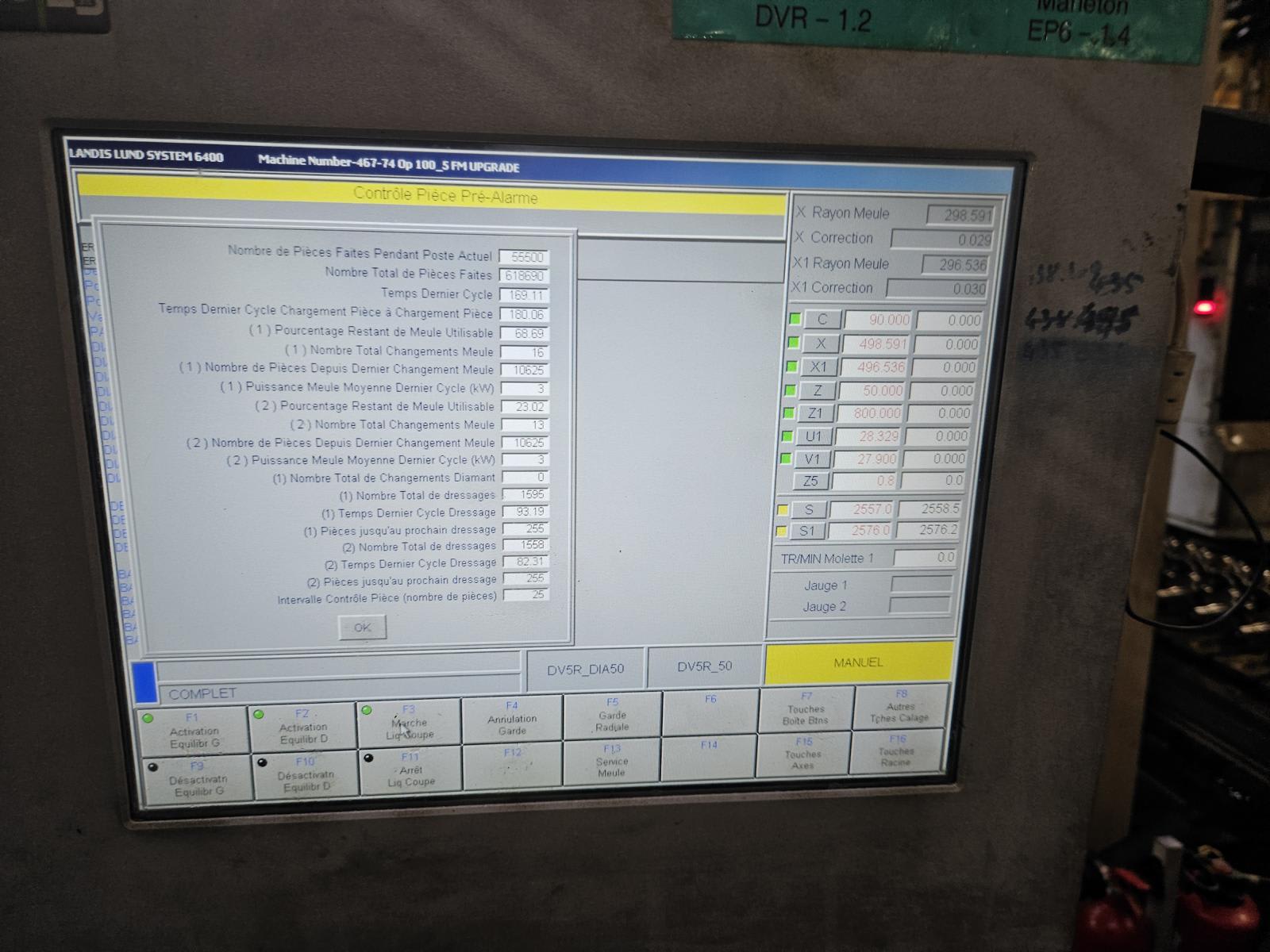

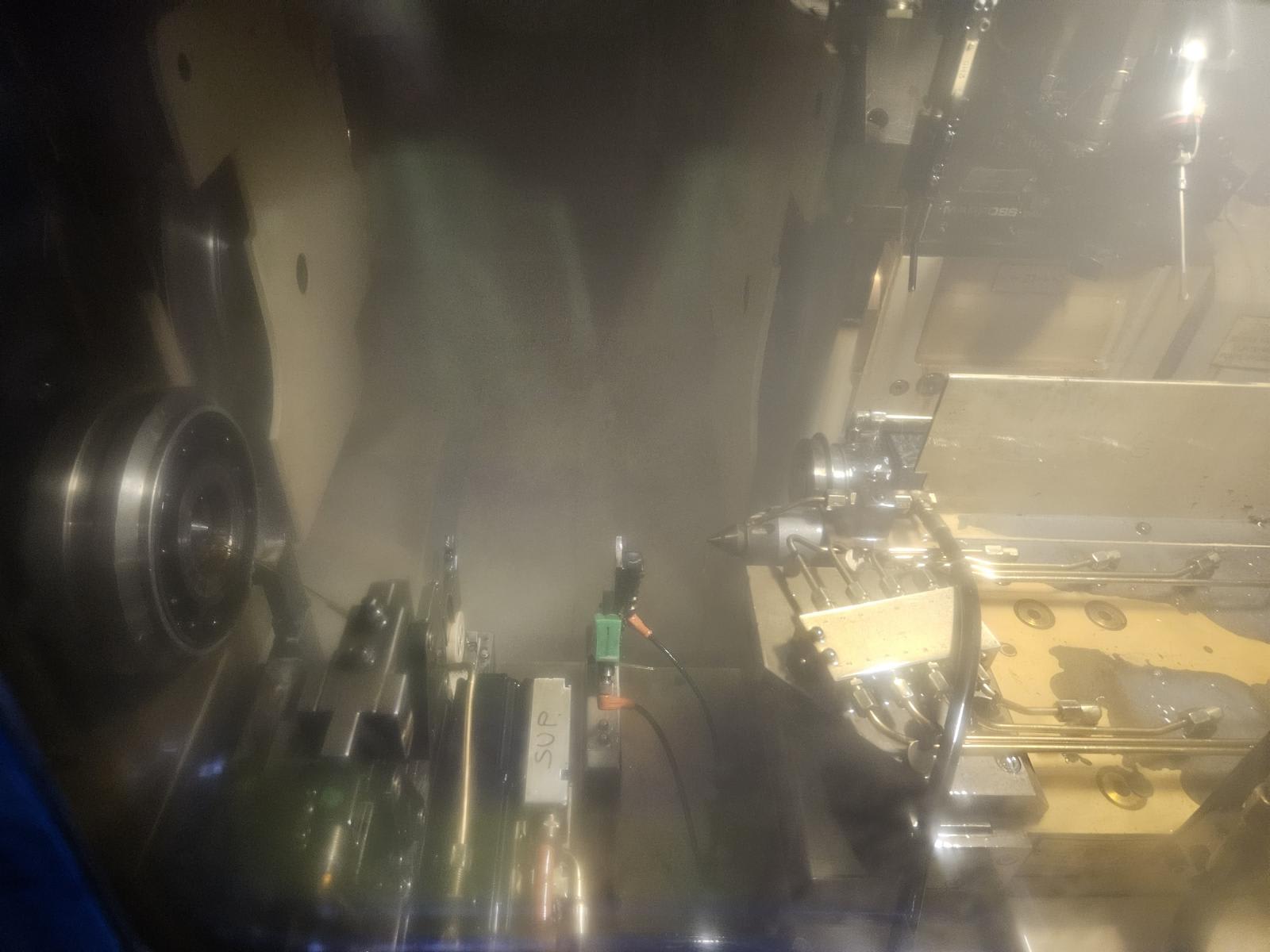

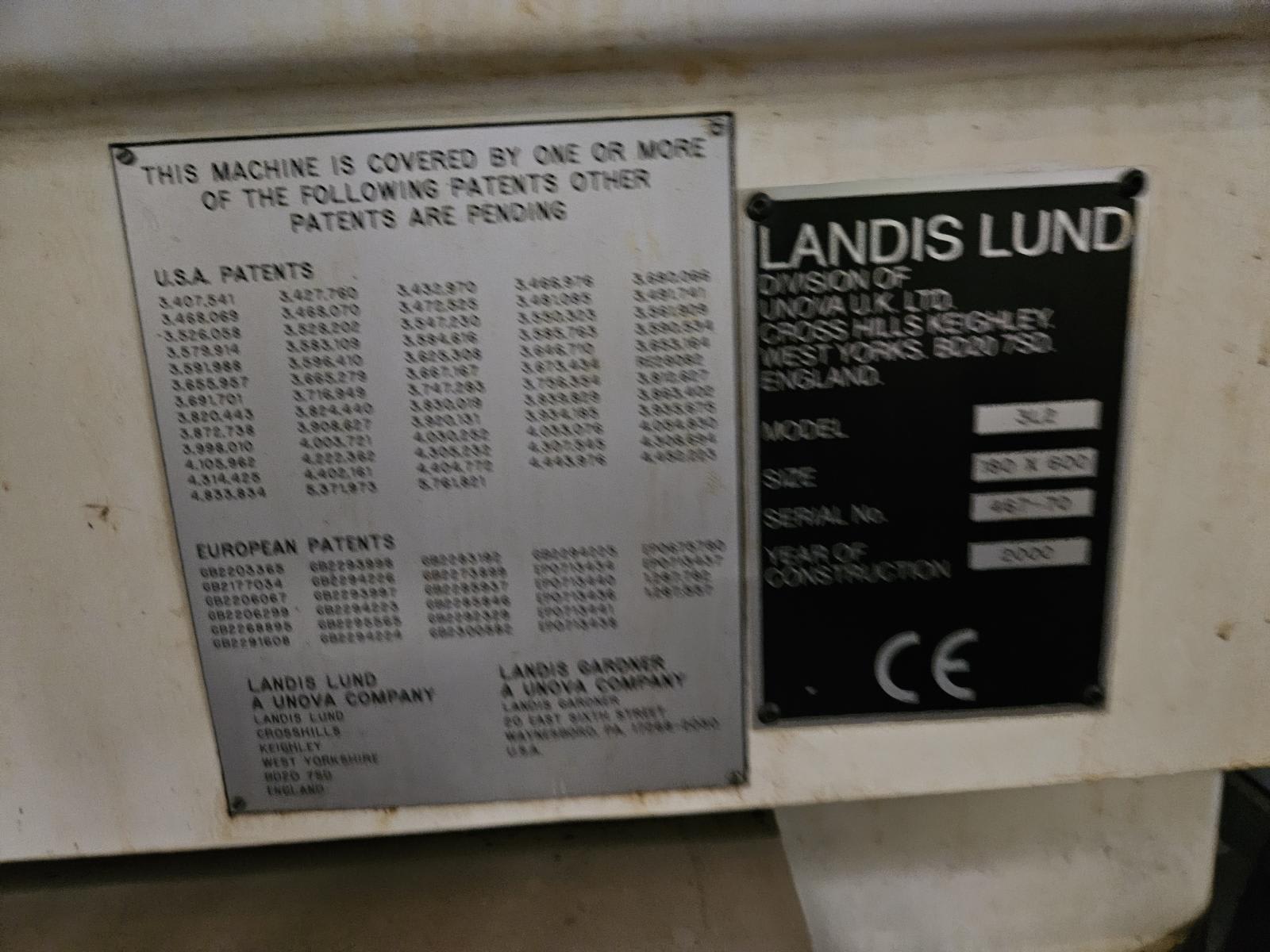

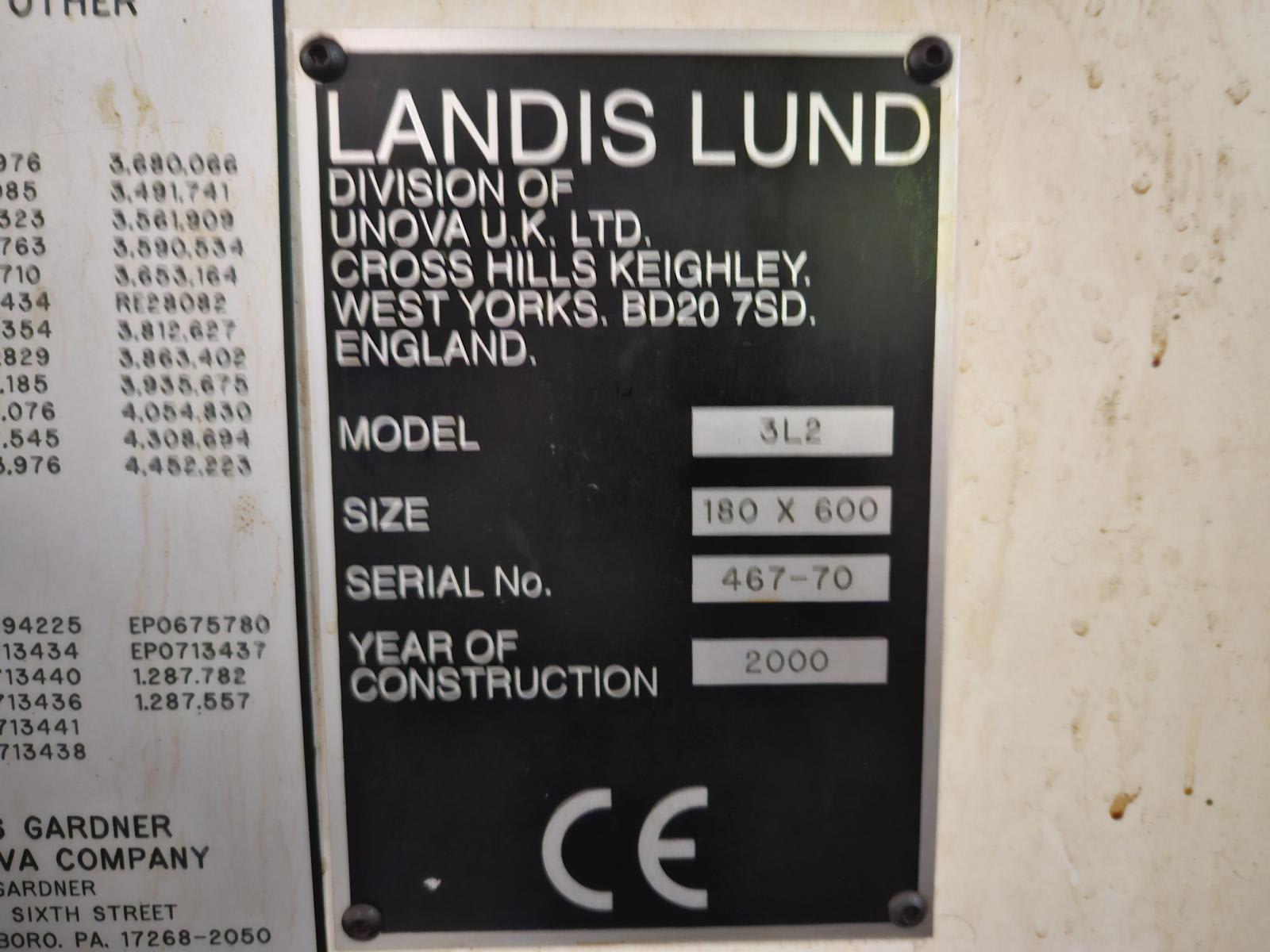

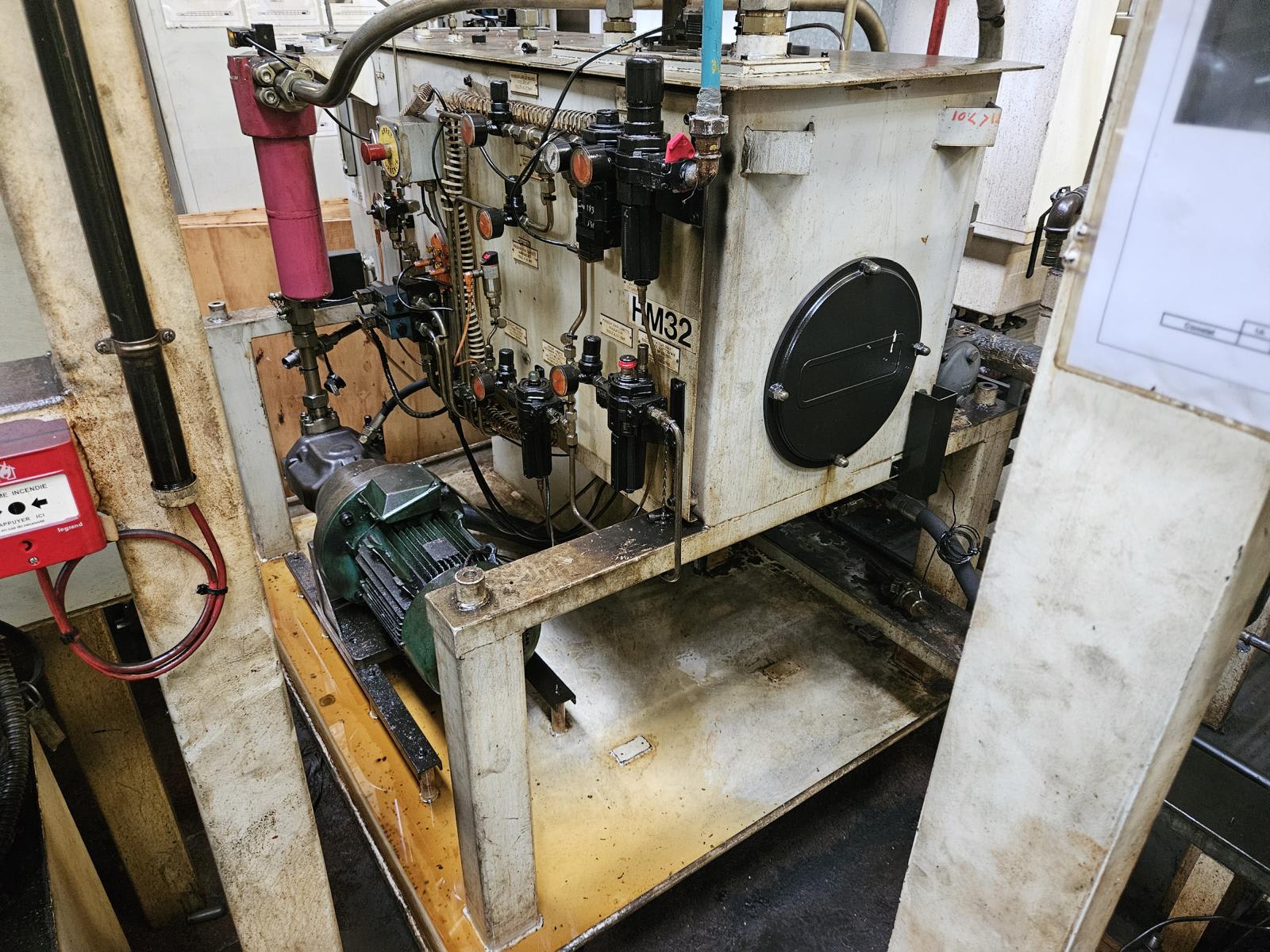

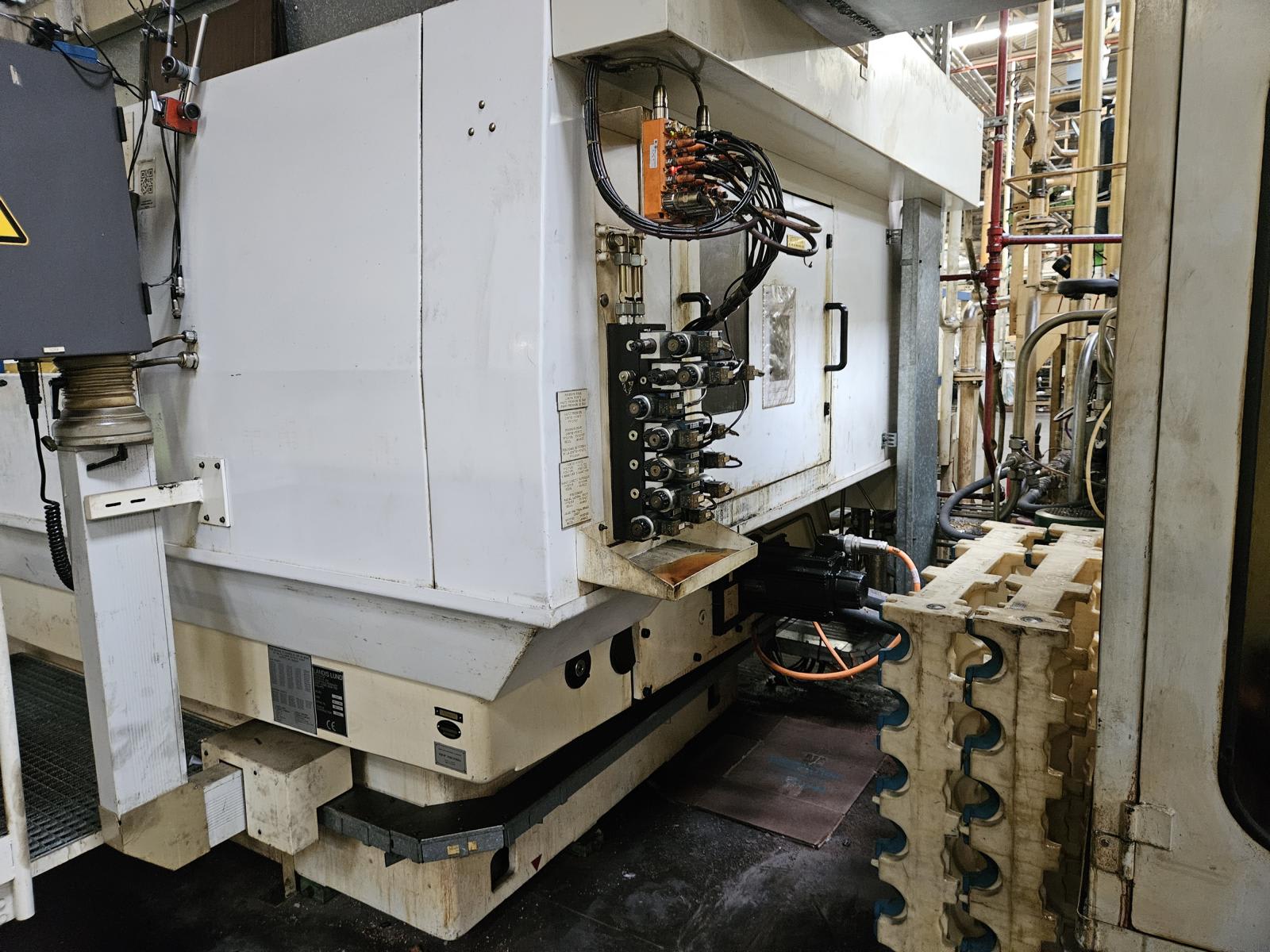

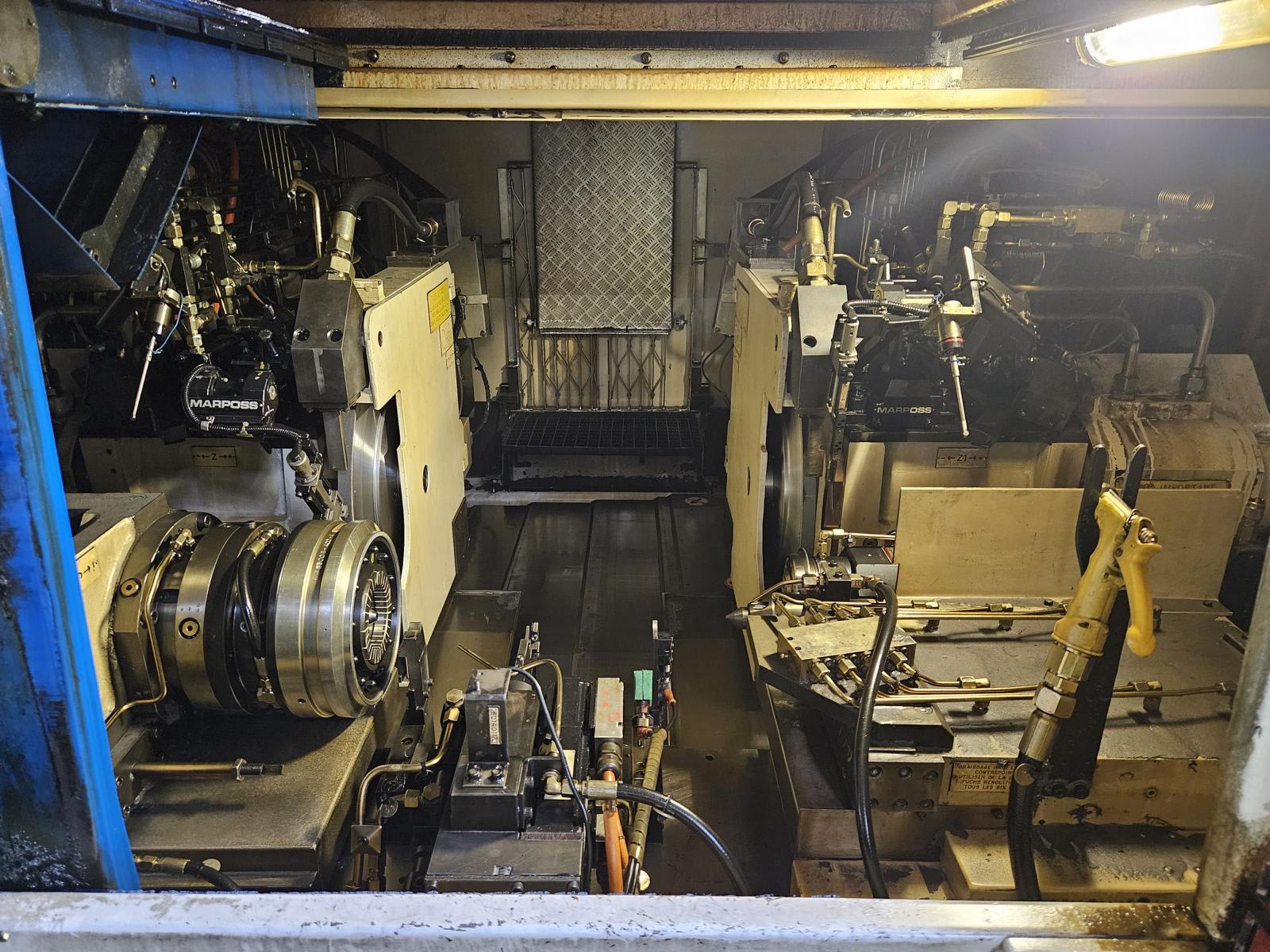

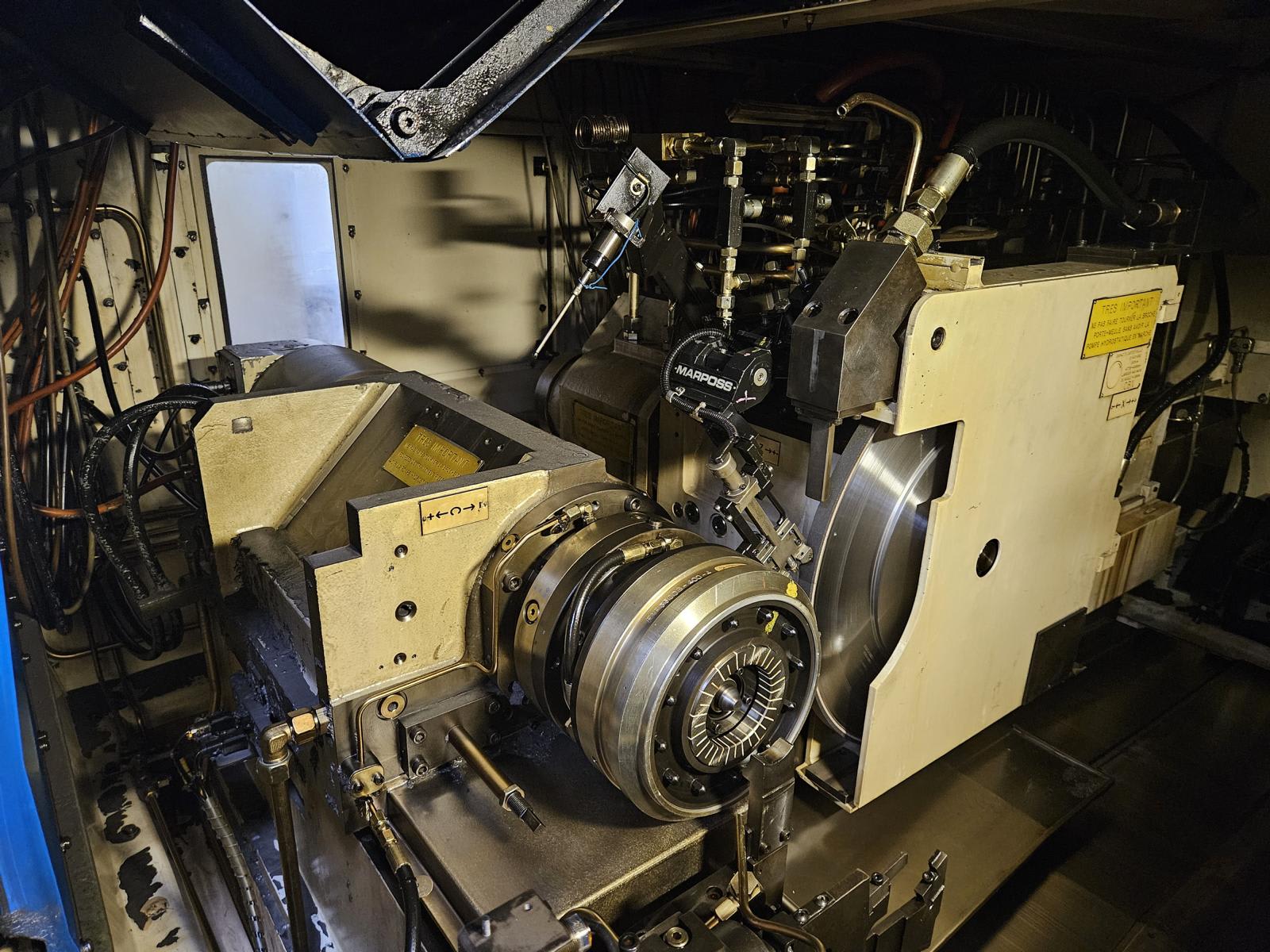

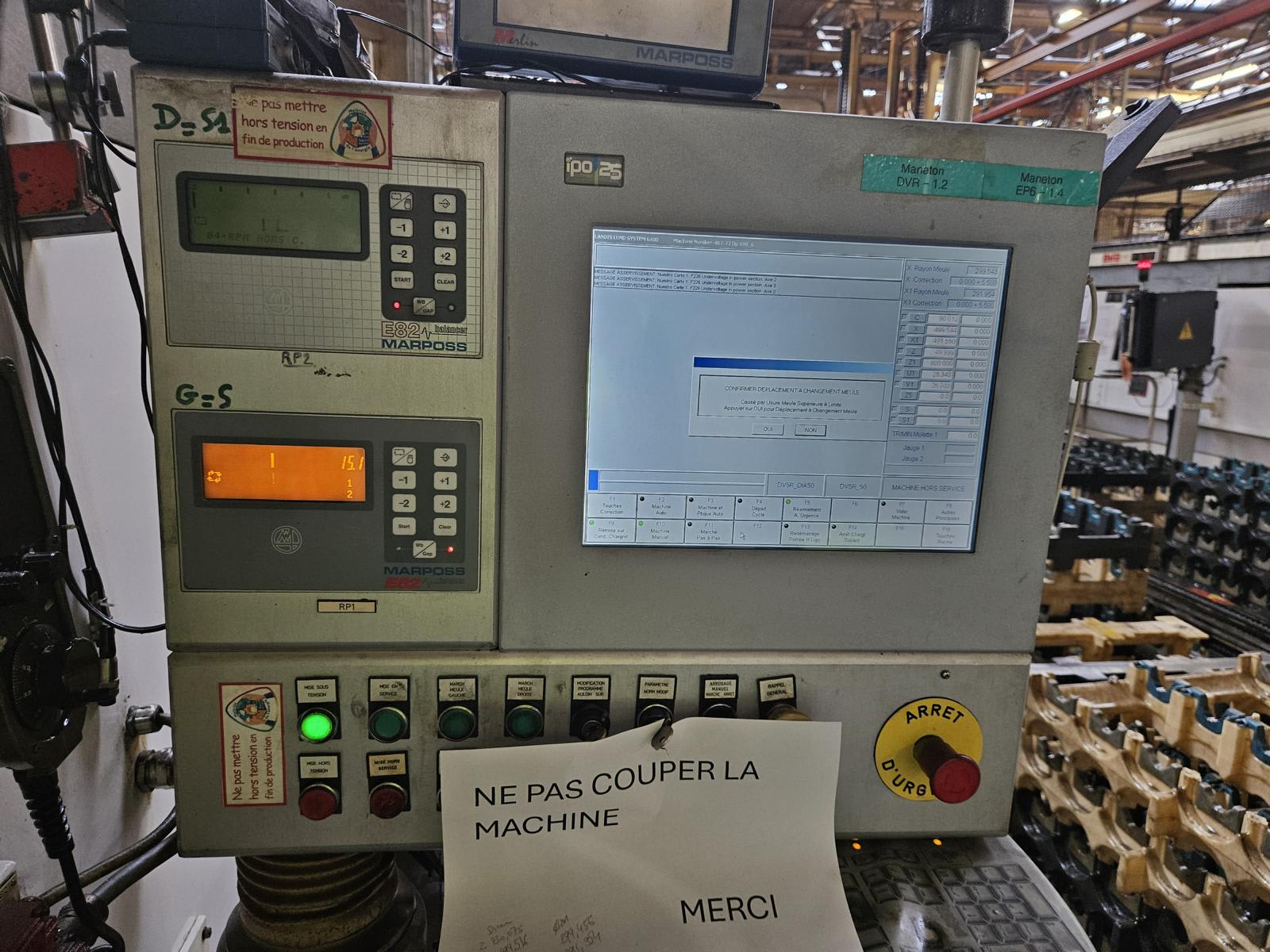

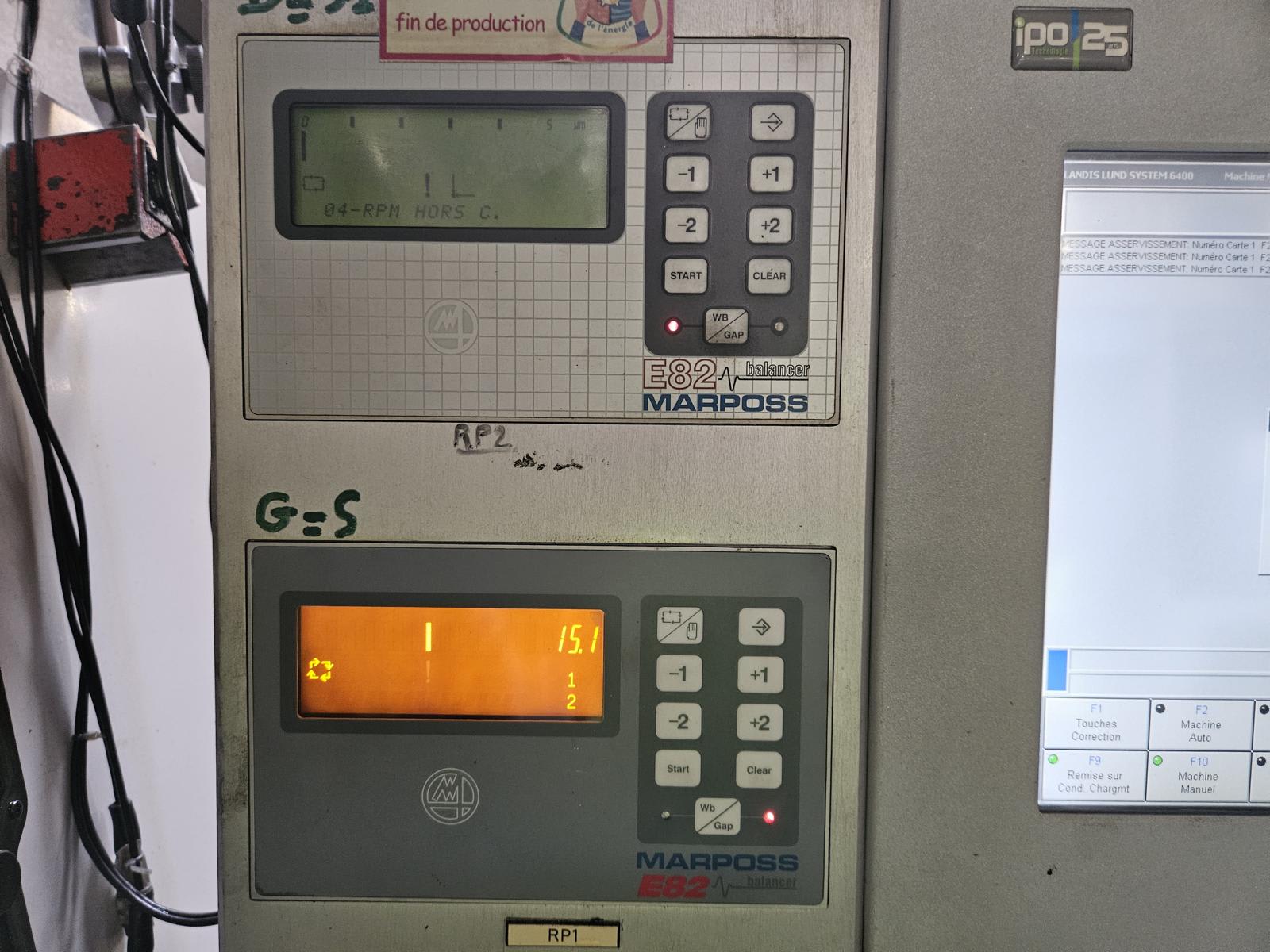

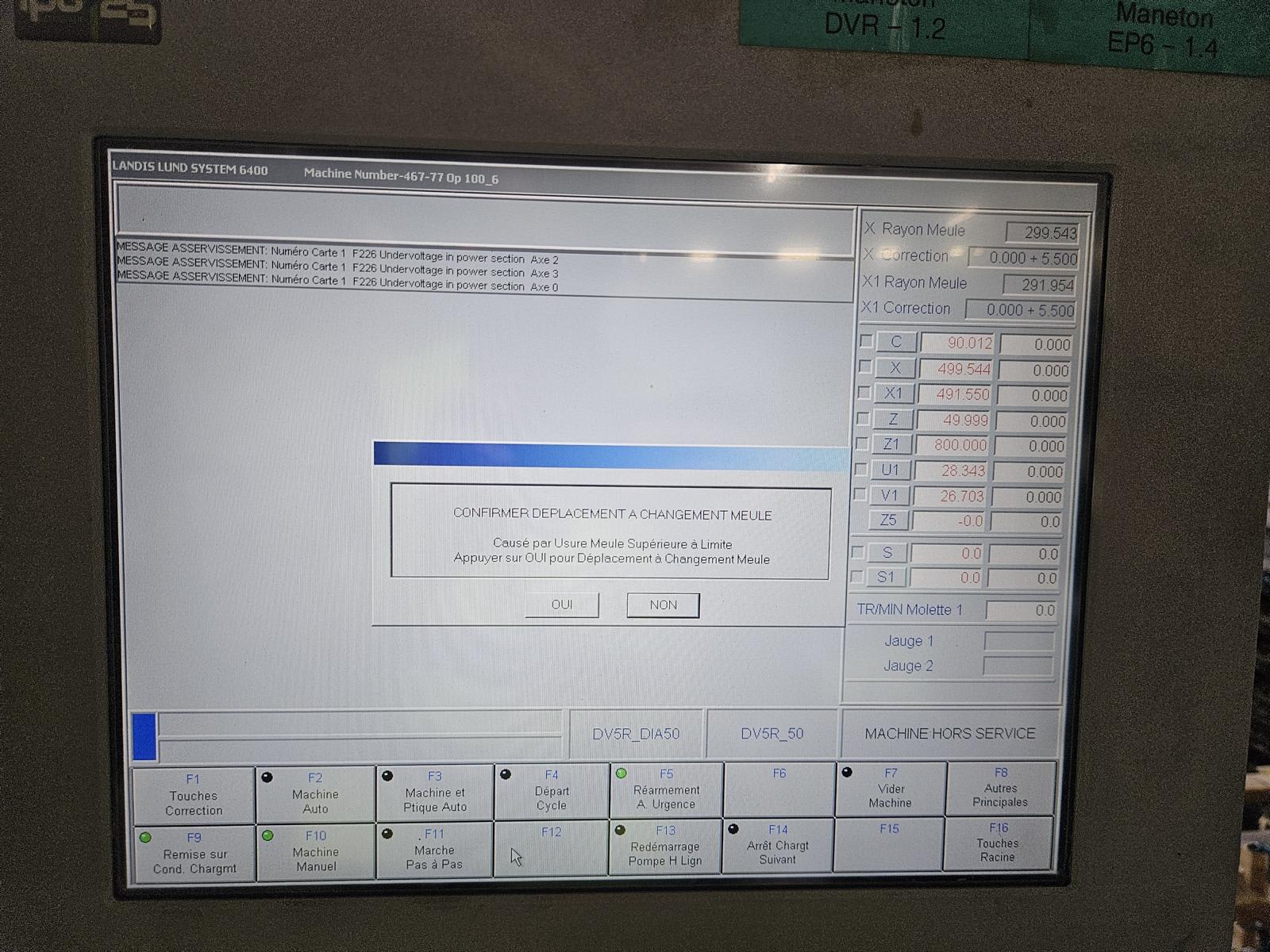

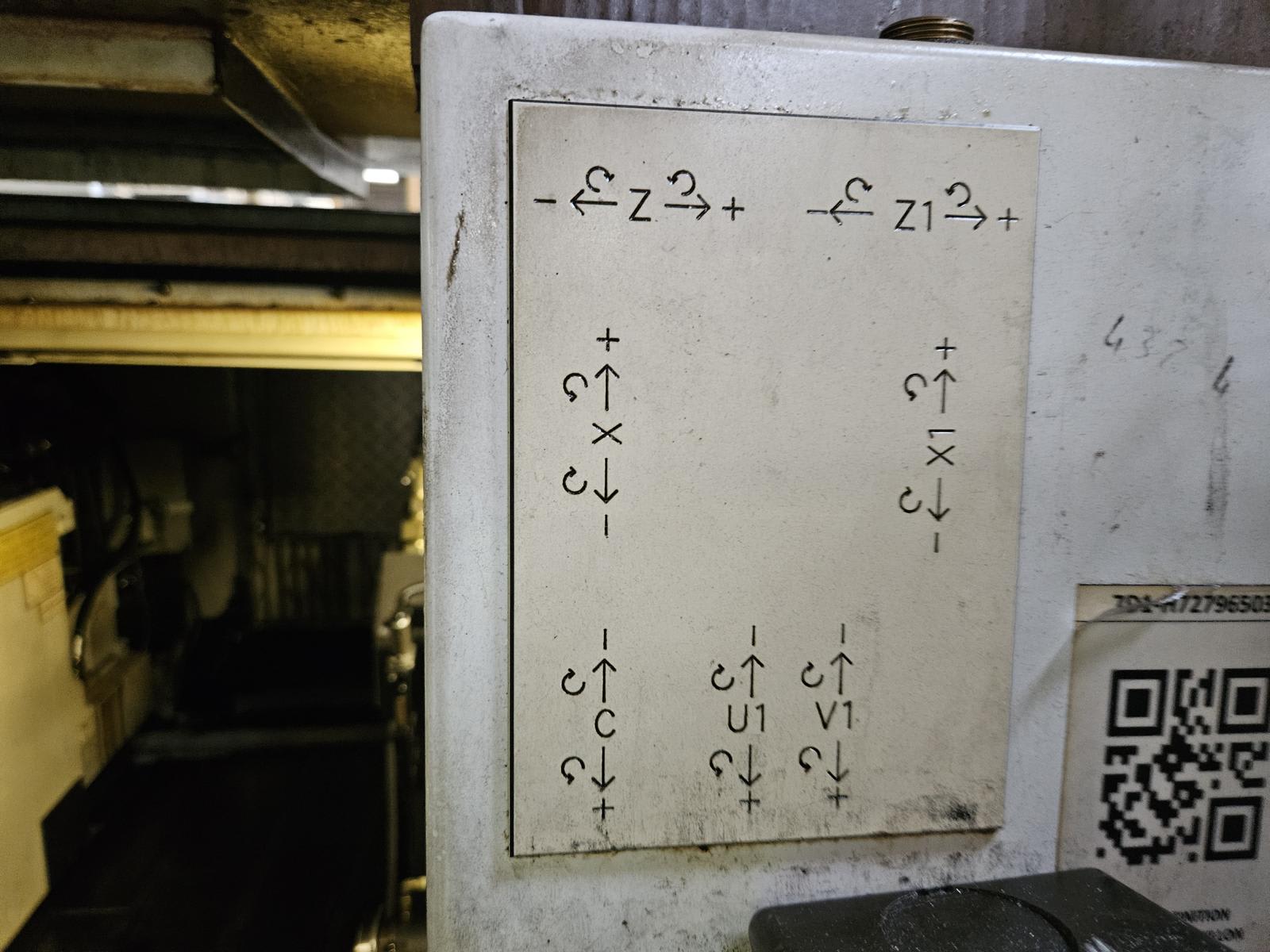

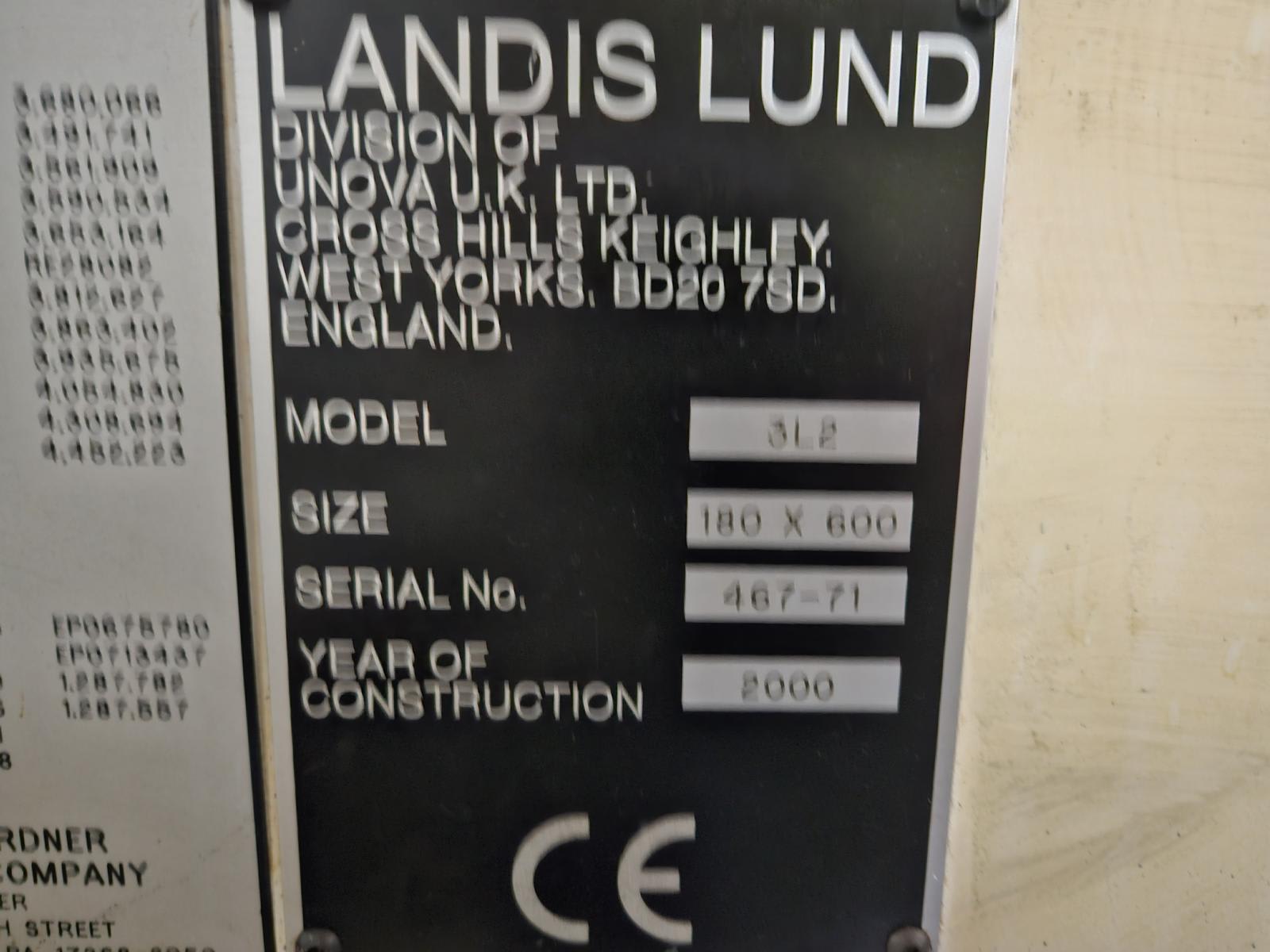

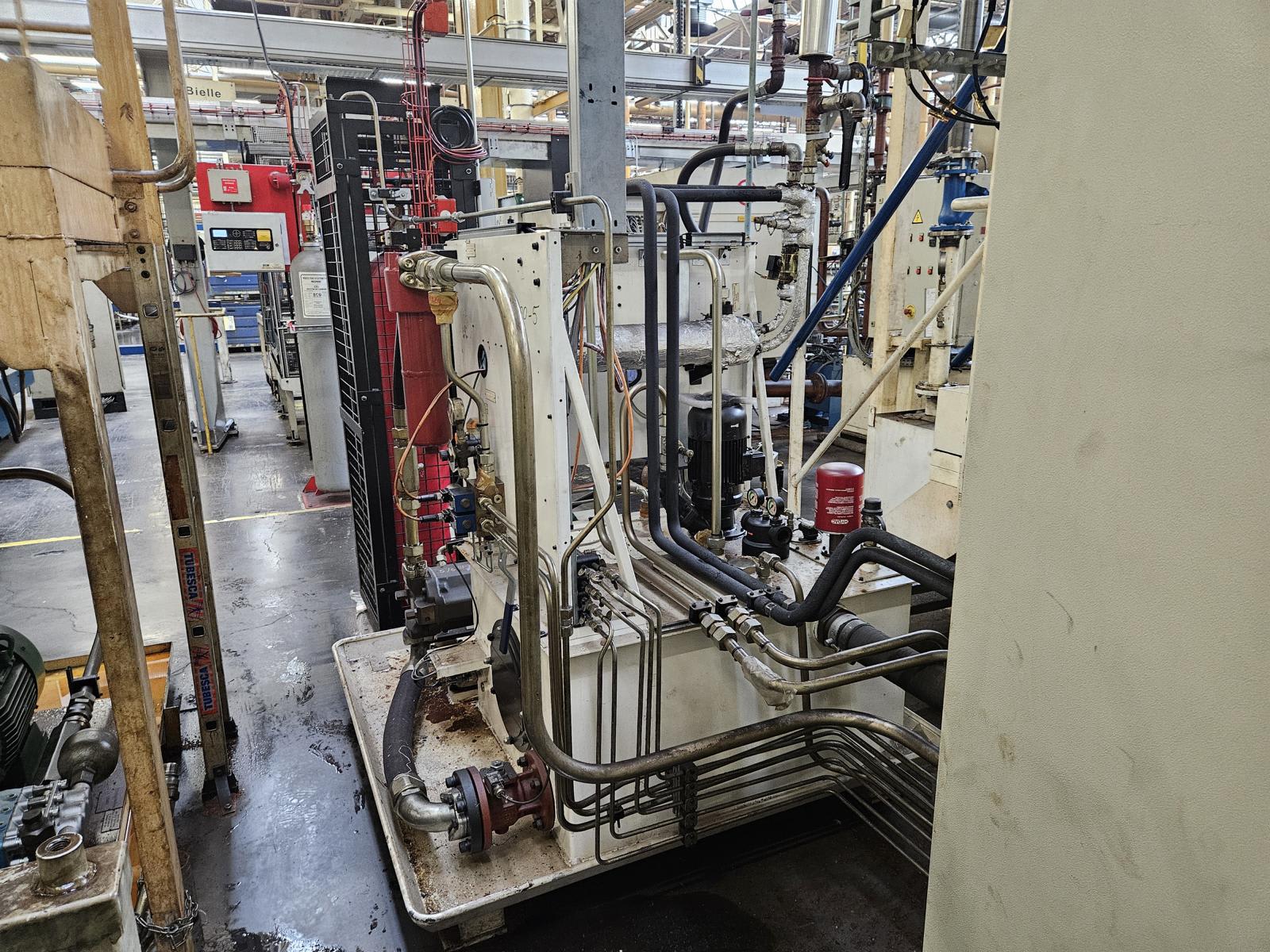

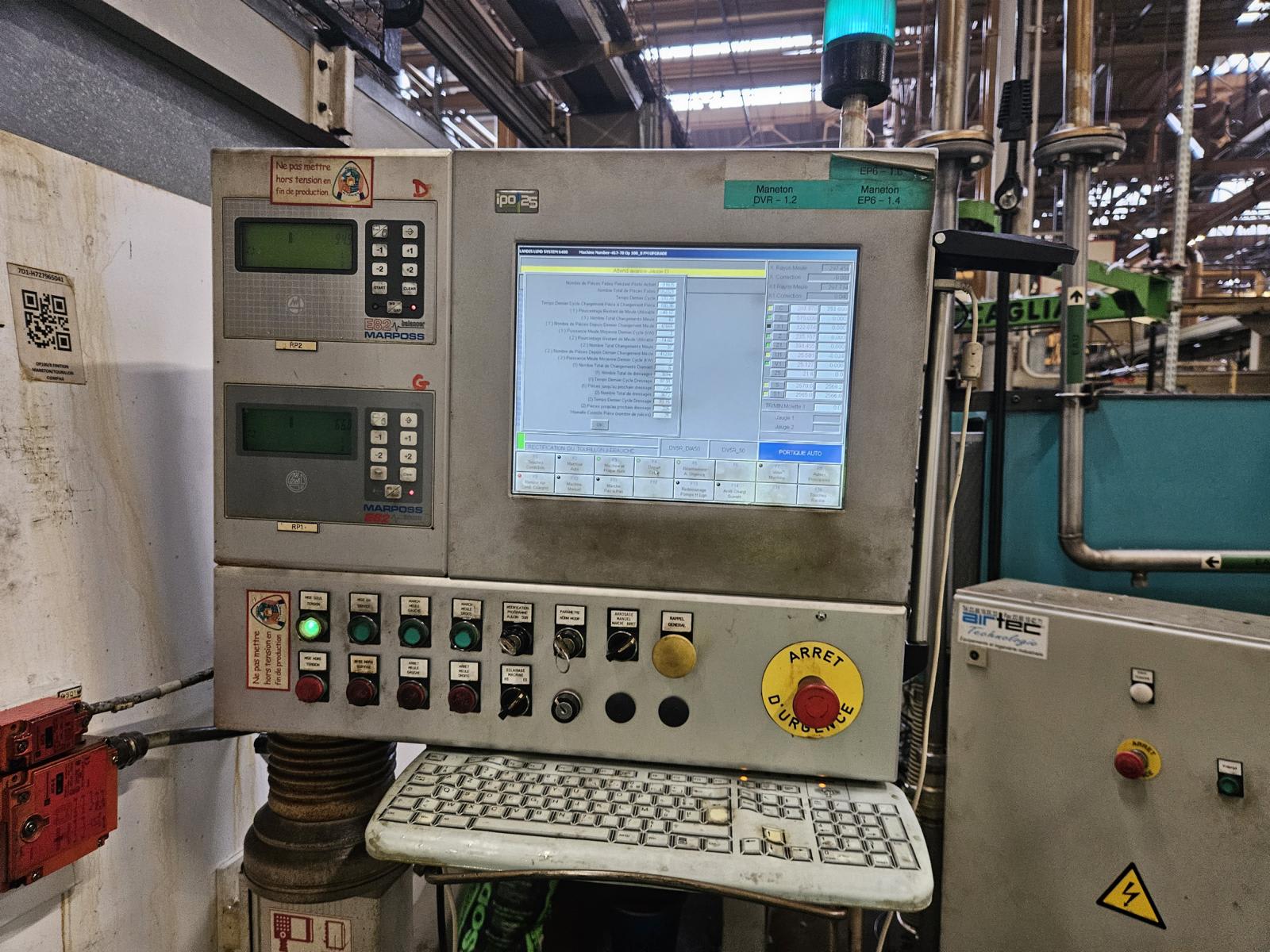

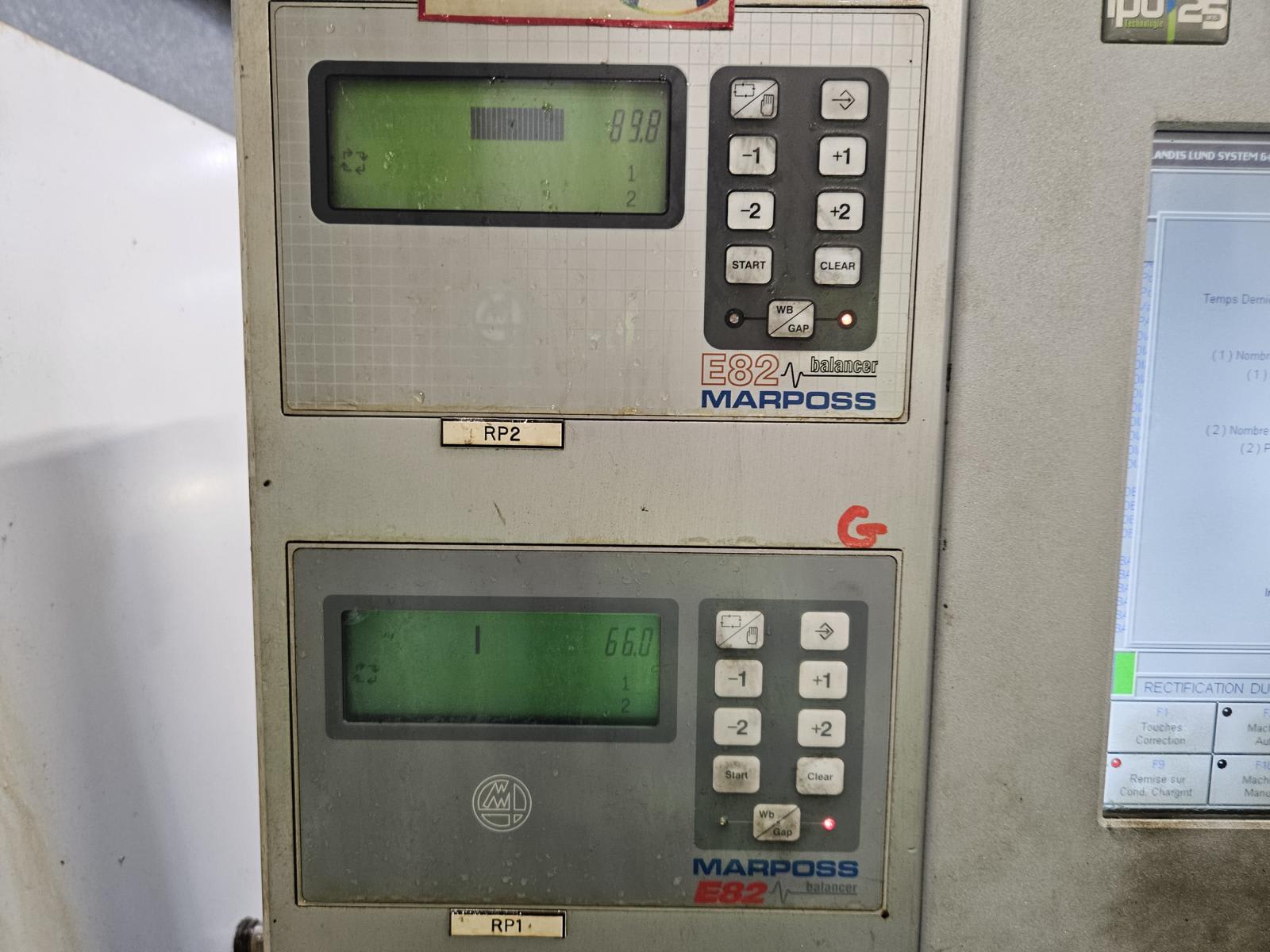

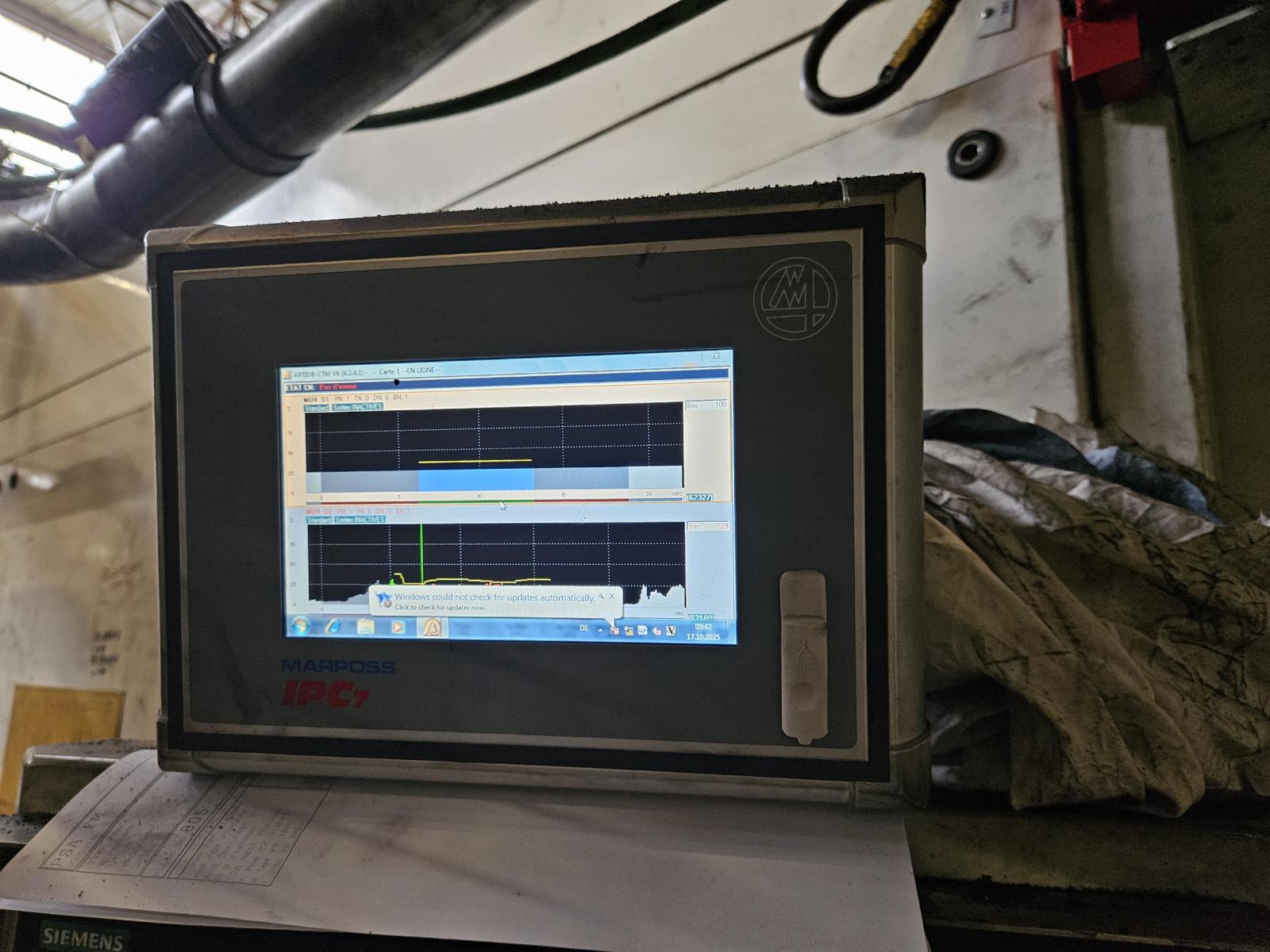

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 600 | 2000

crankshaft length 600 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830012

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 600 | 2000

crankshaft length 600 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830013

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 600 | 2000

crankshaft length 600 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830014

![Français]()

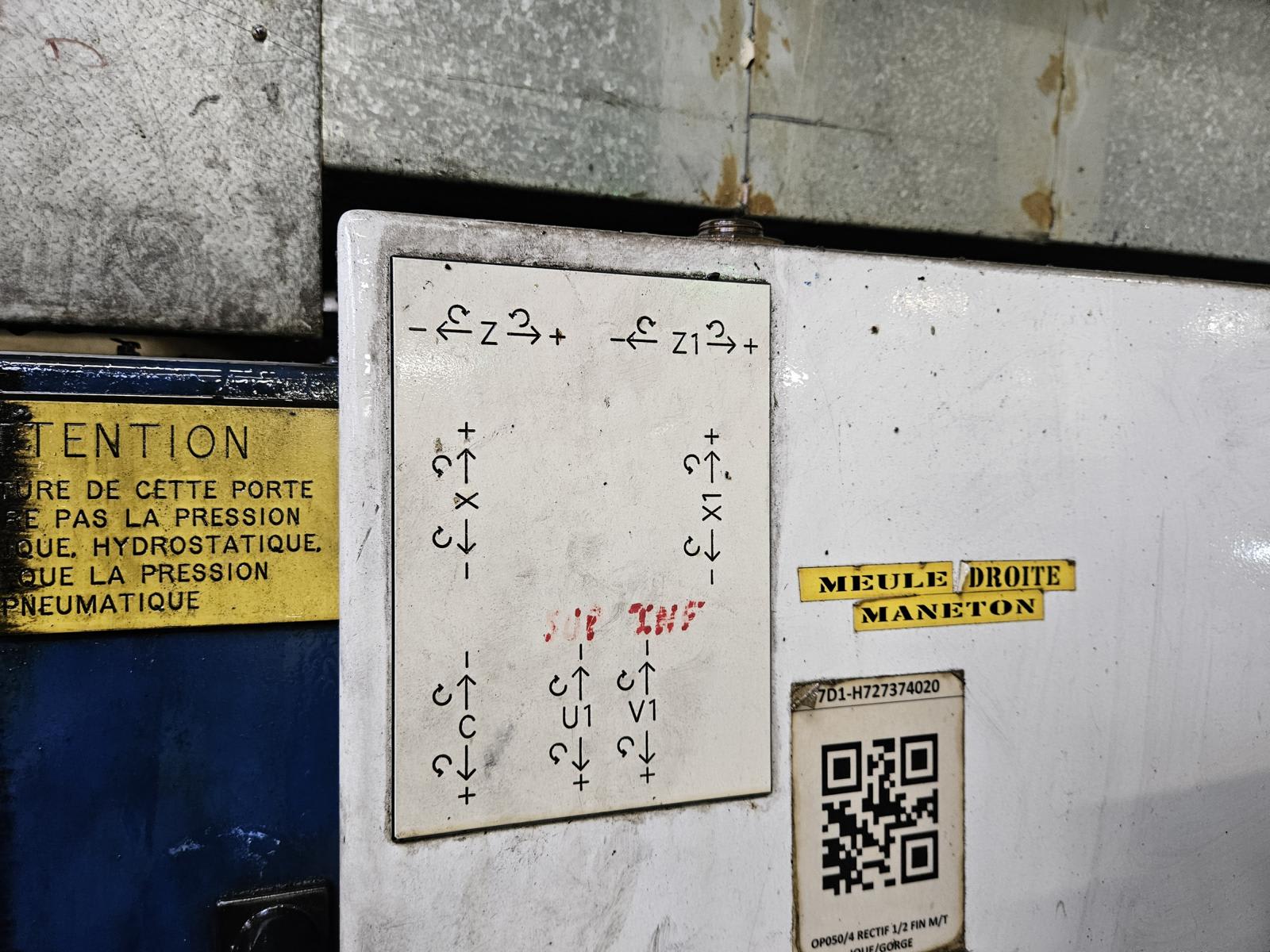

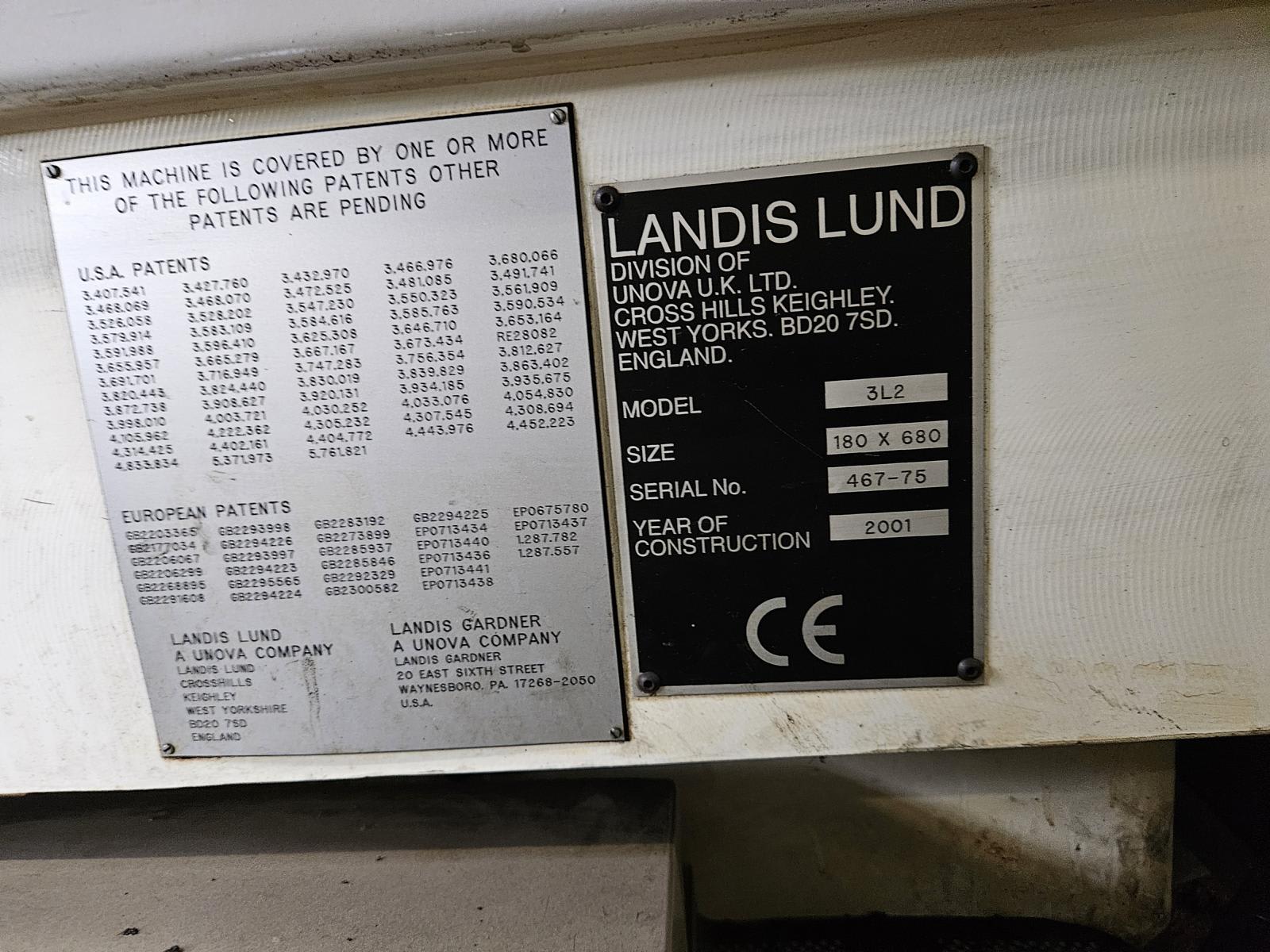

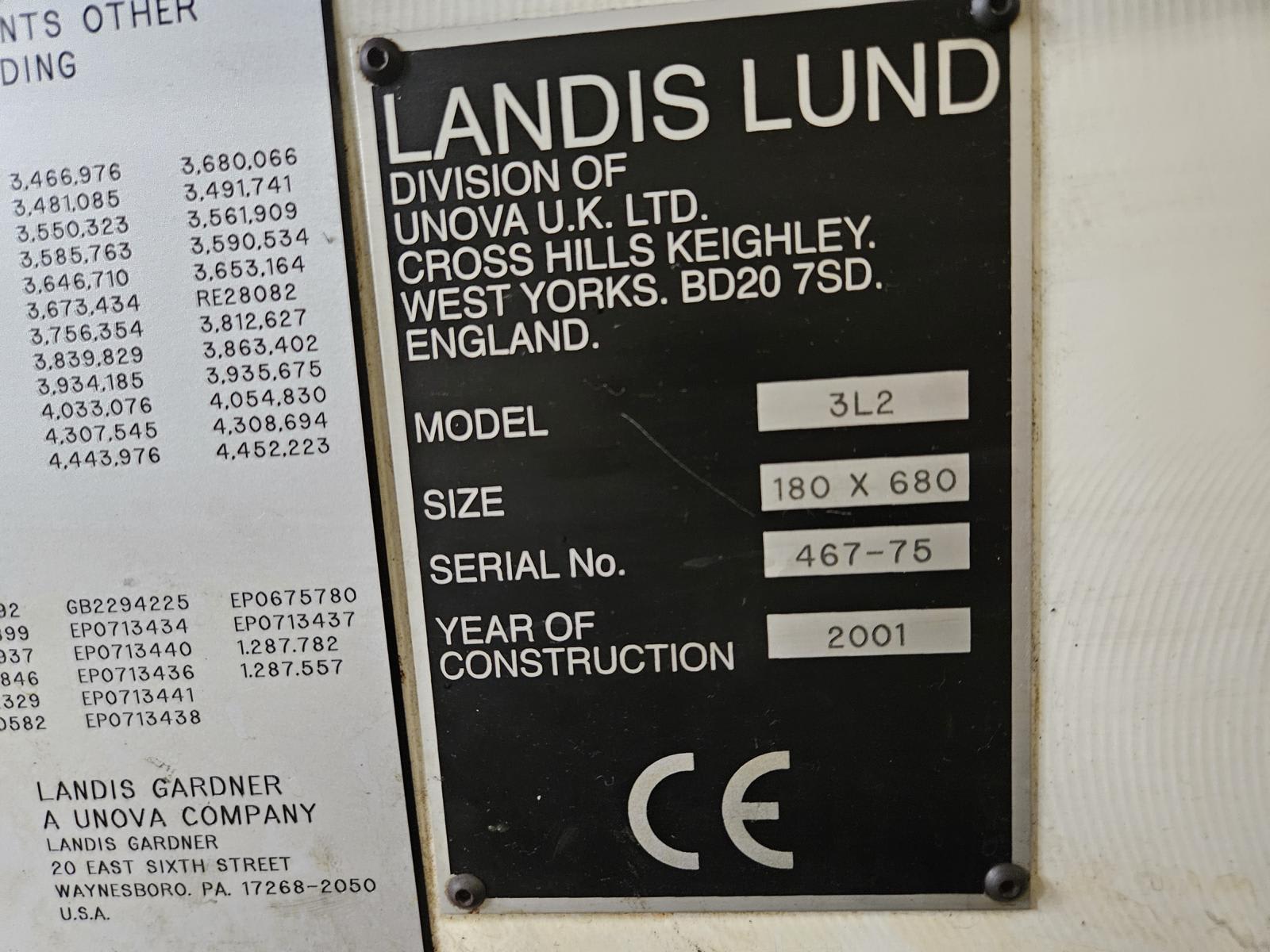

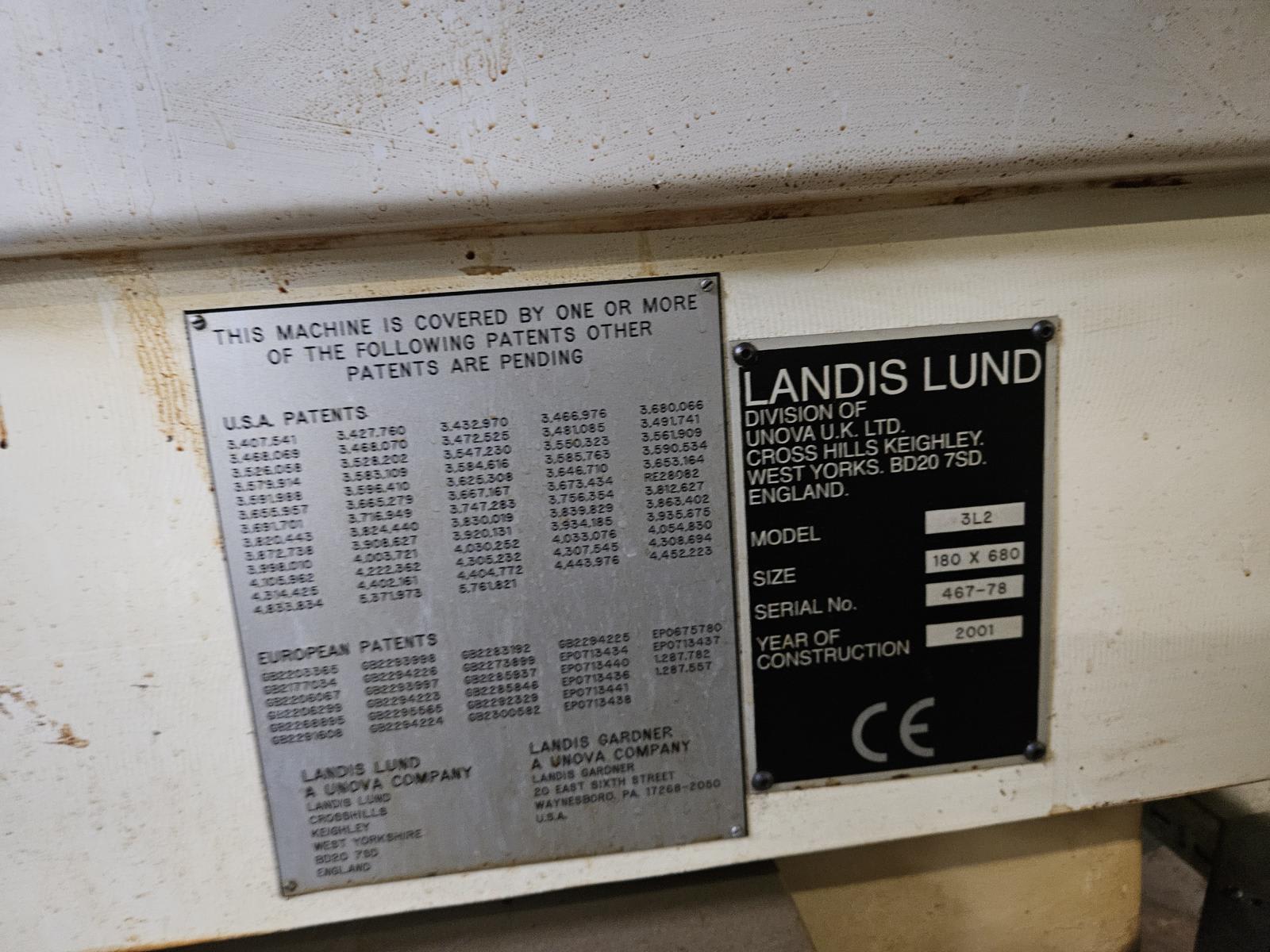

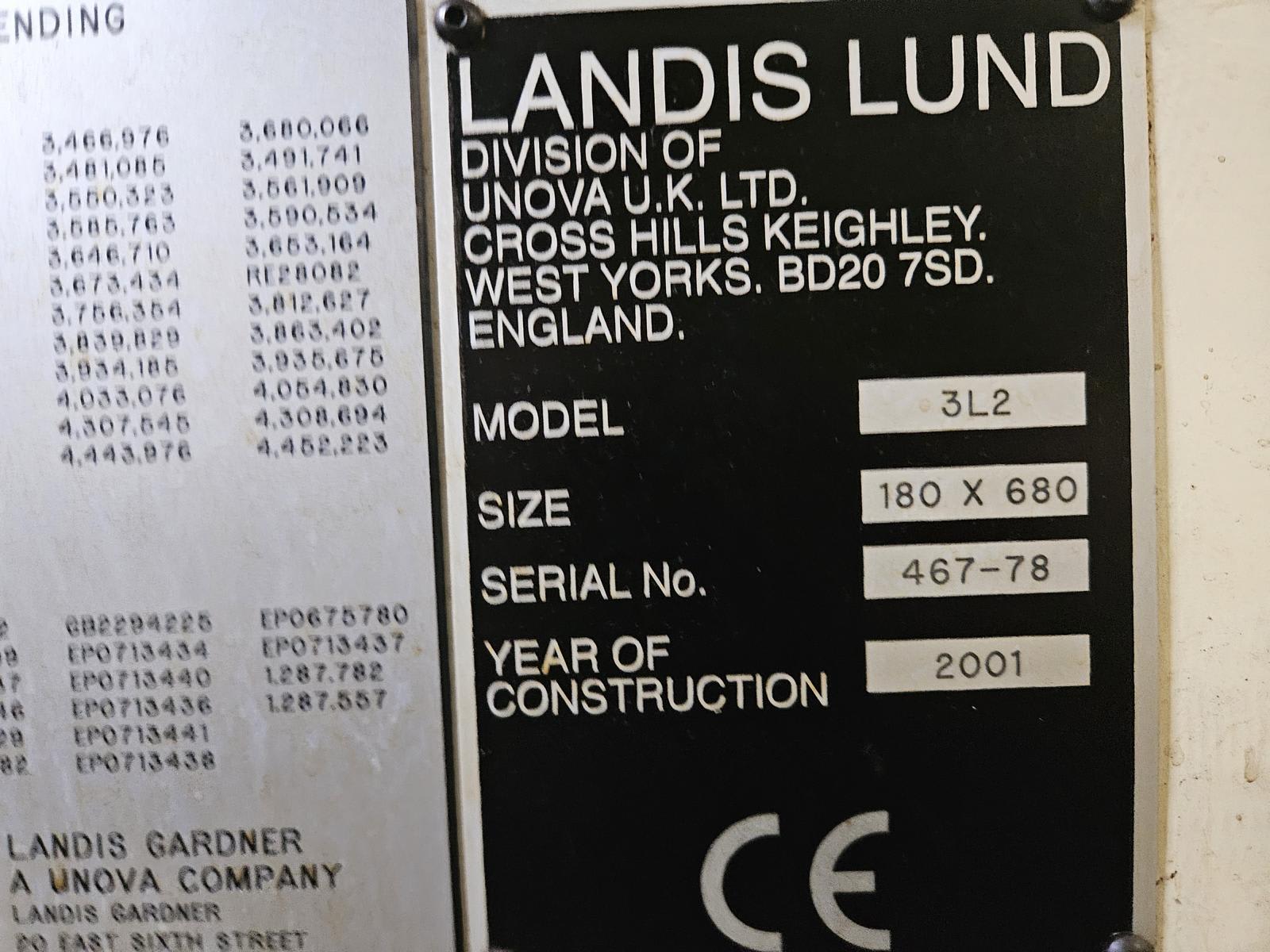

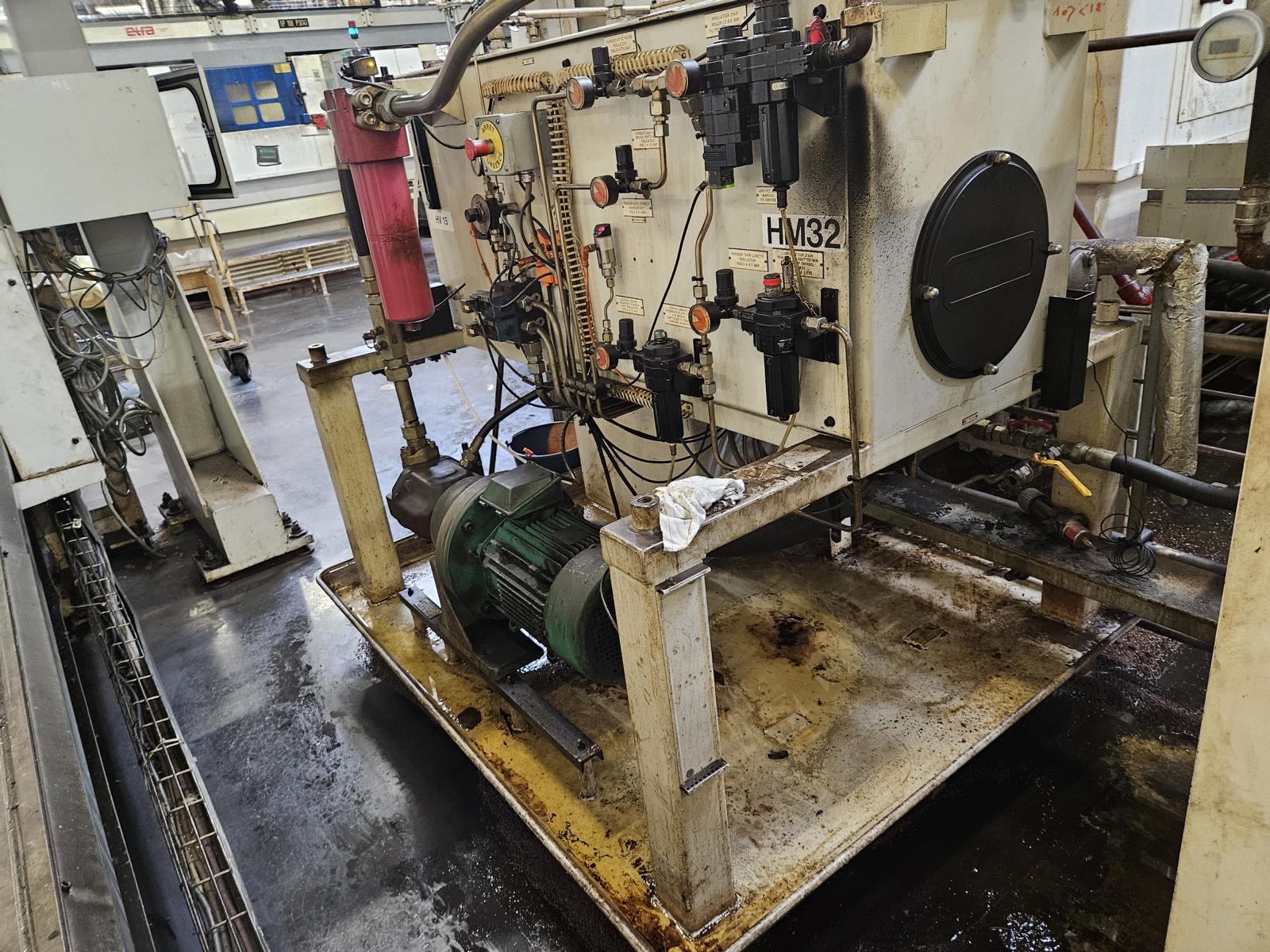

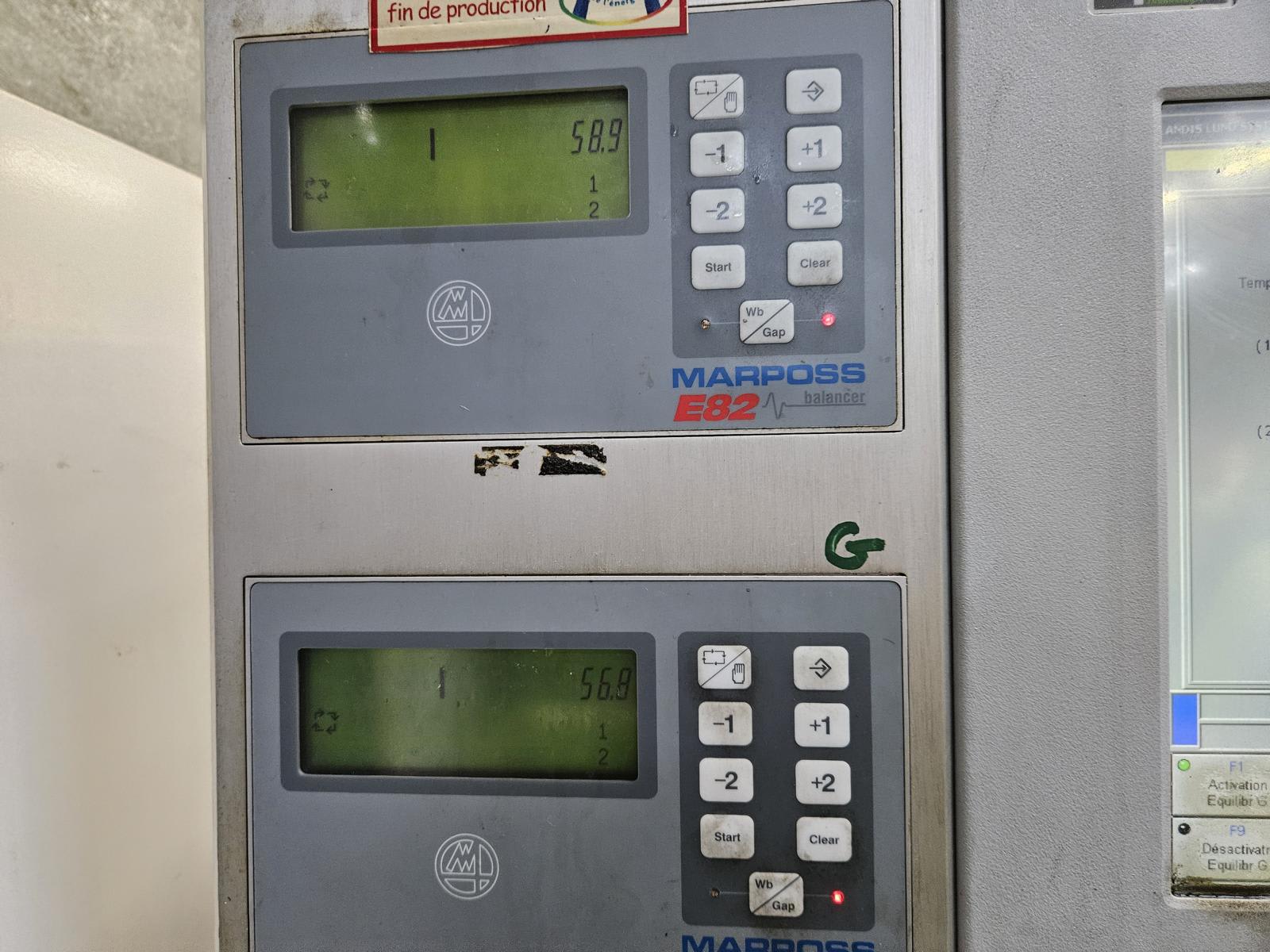

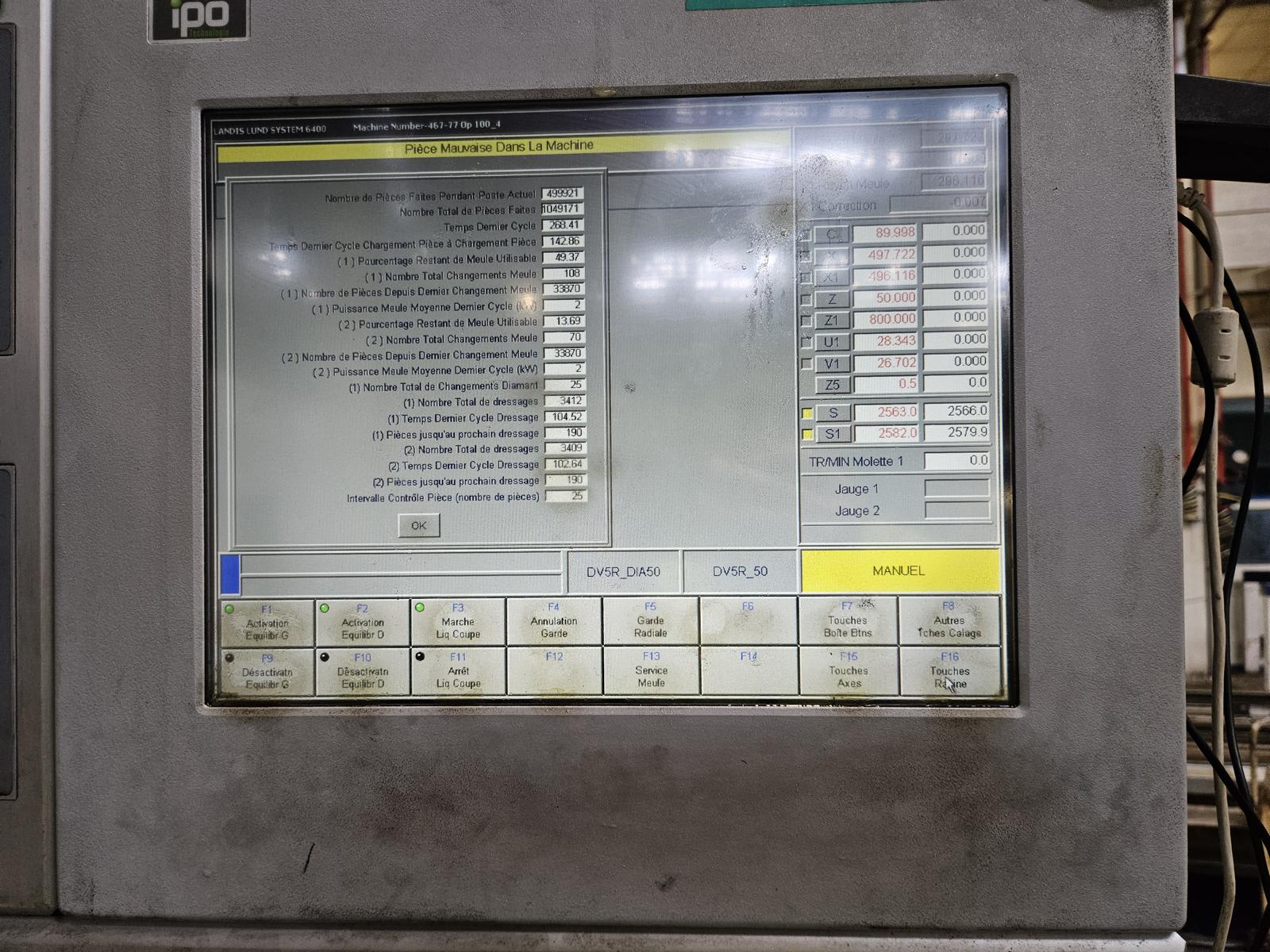

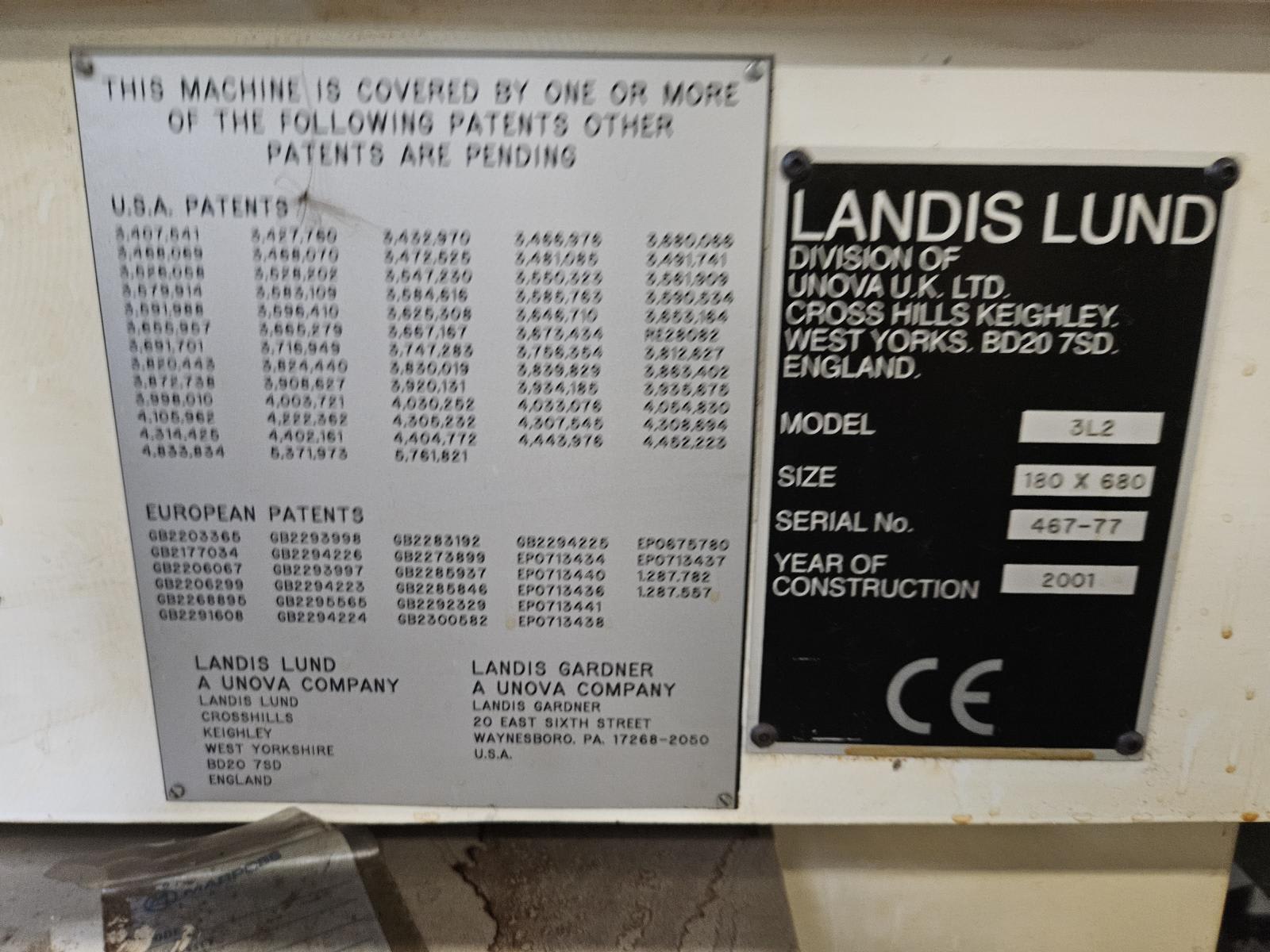

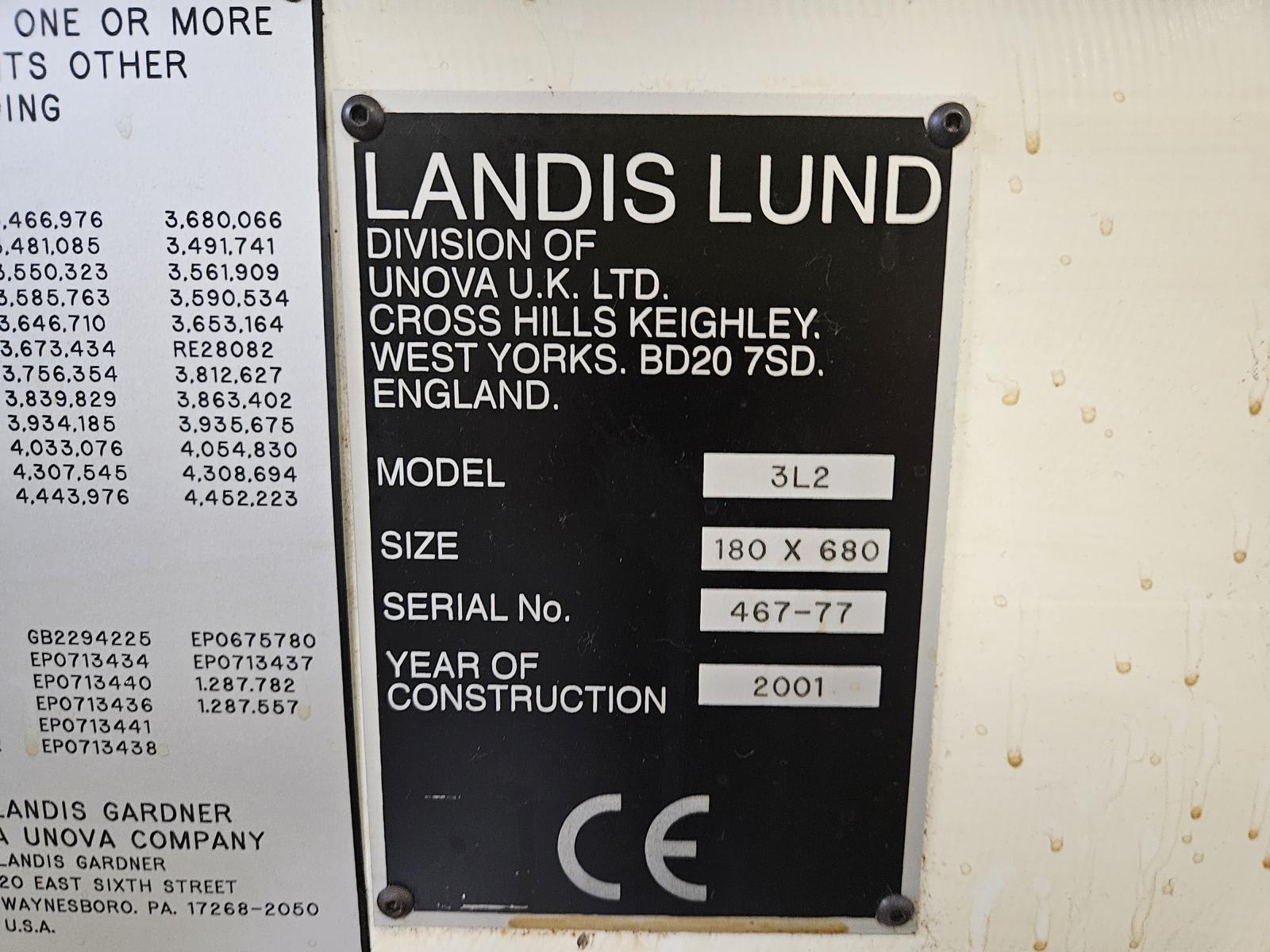

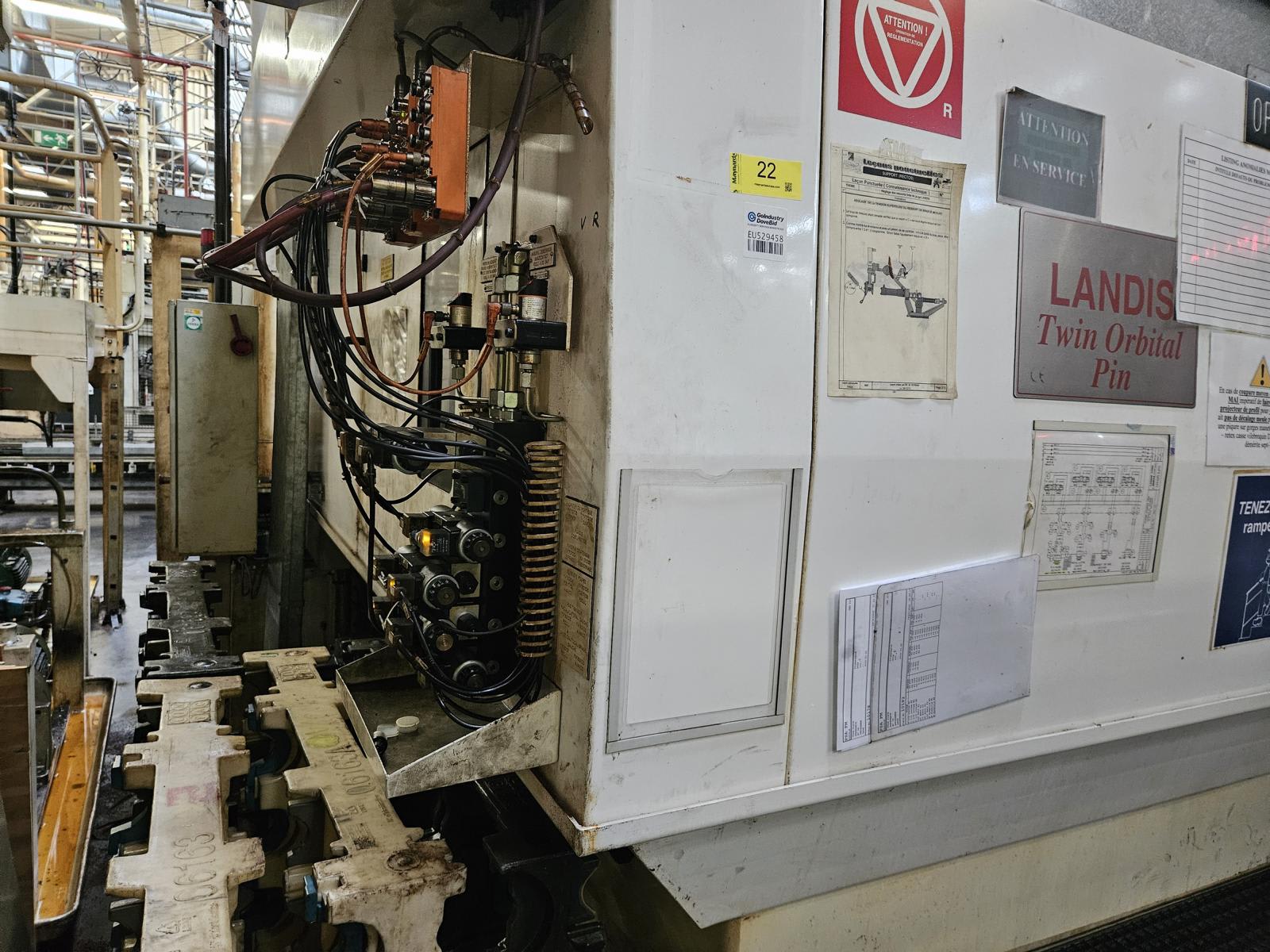

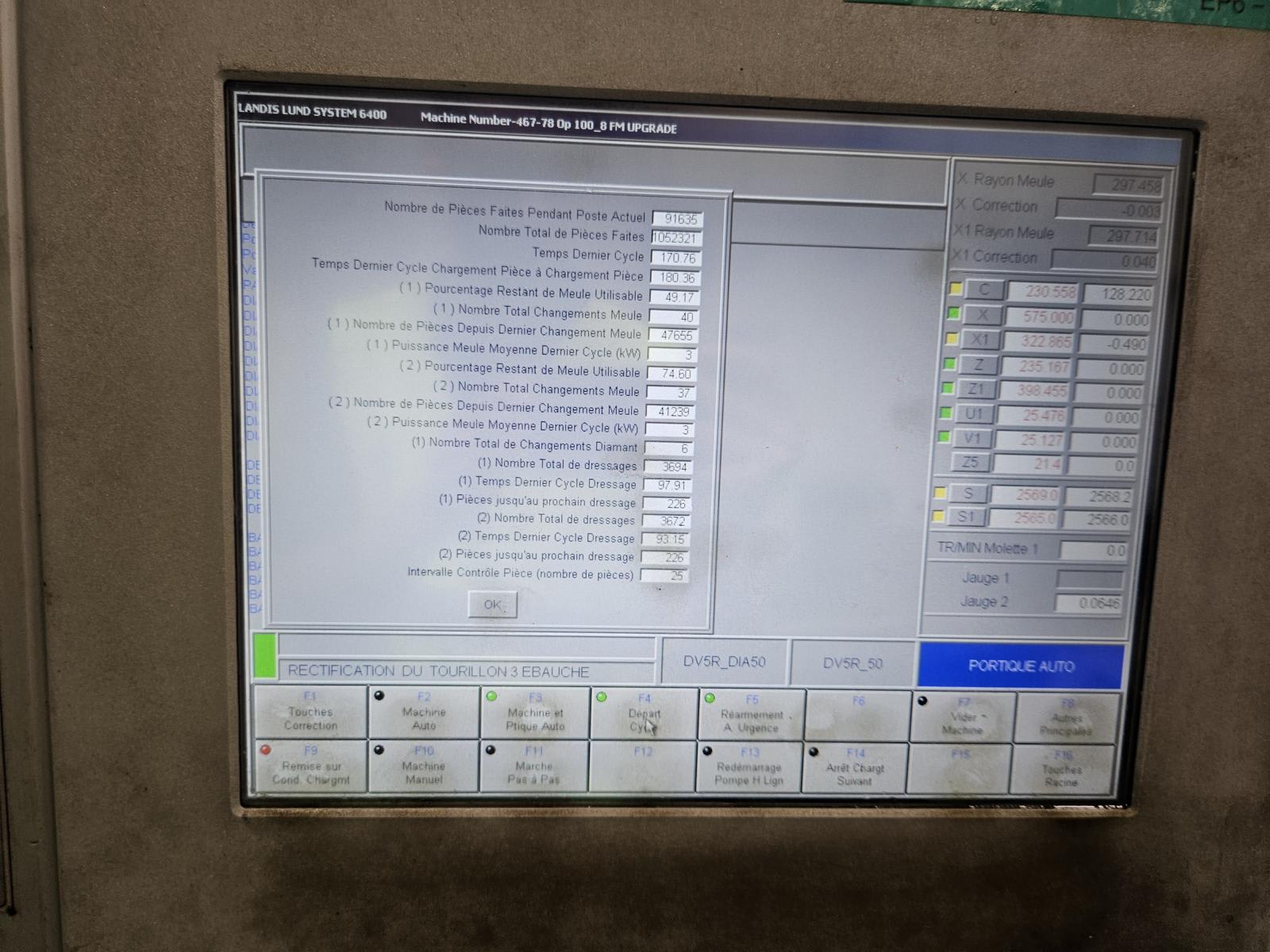

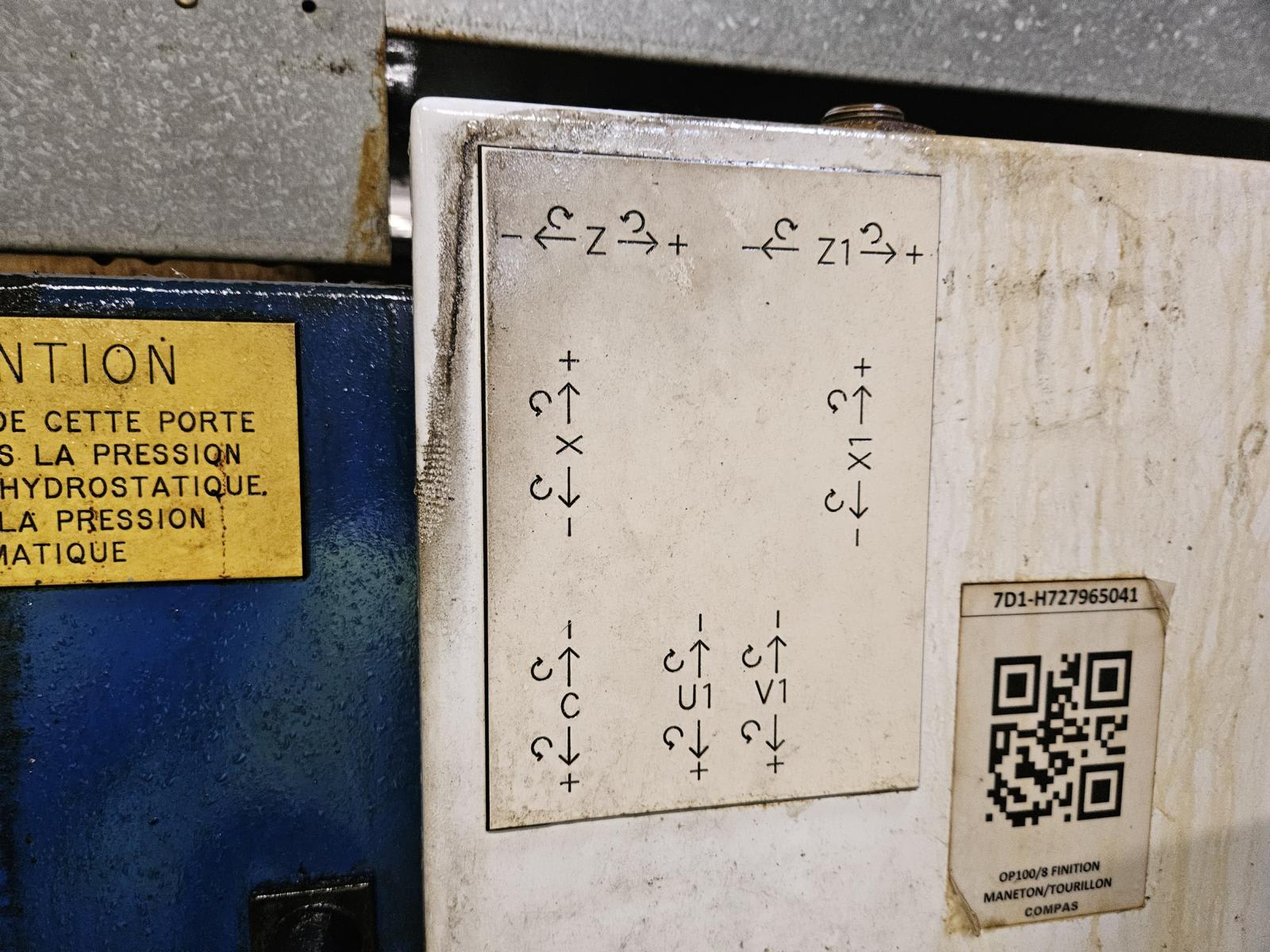

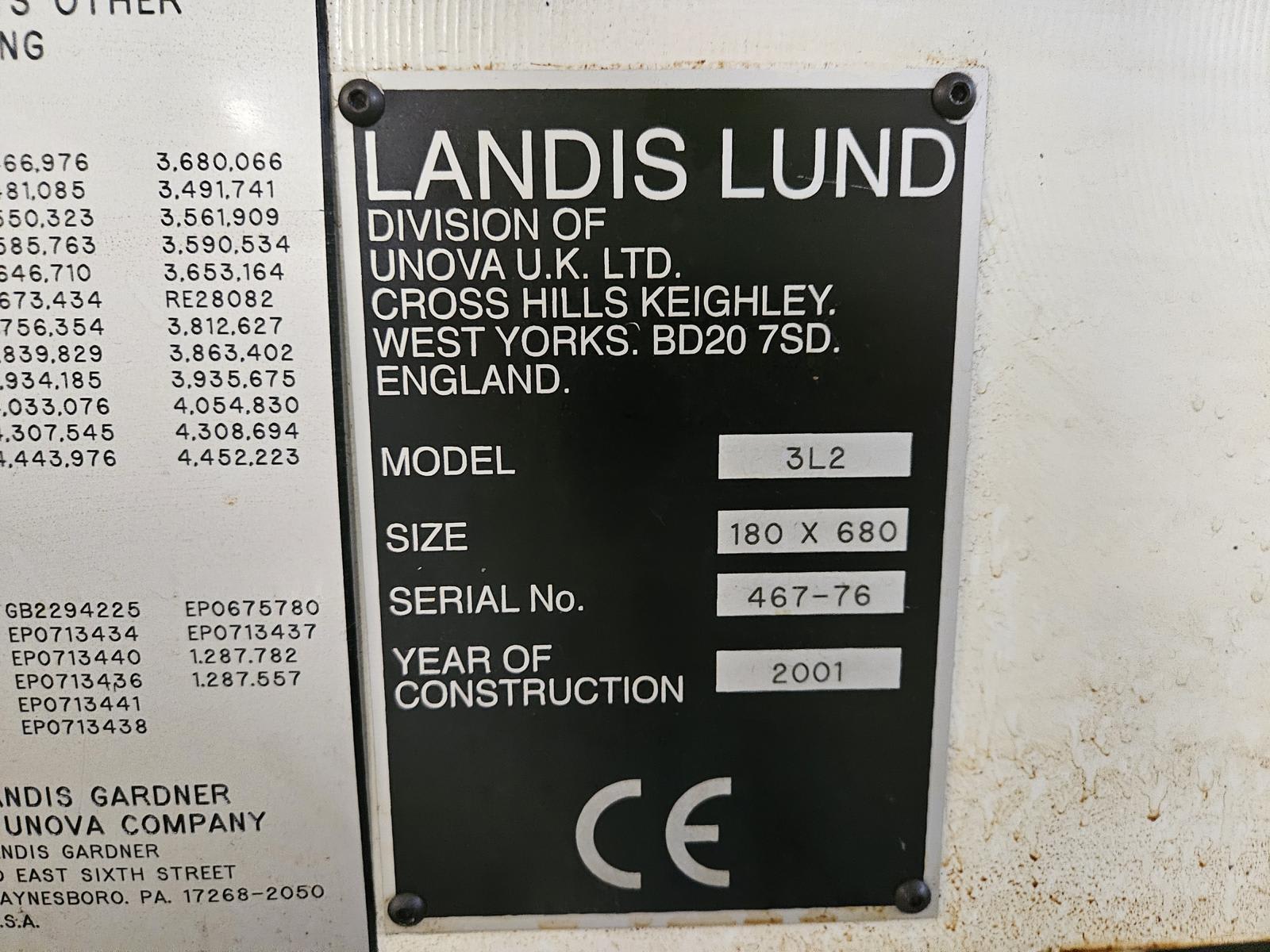

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 630 | 2001

crankshaft length 630 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830015

![Français]()

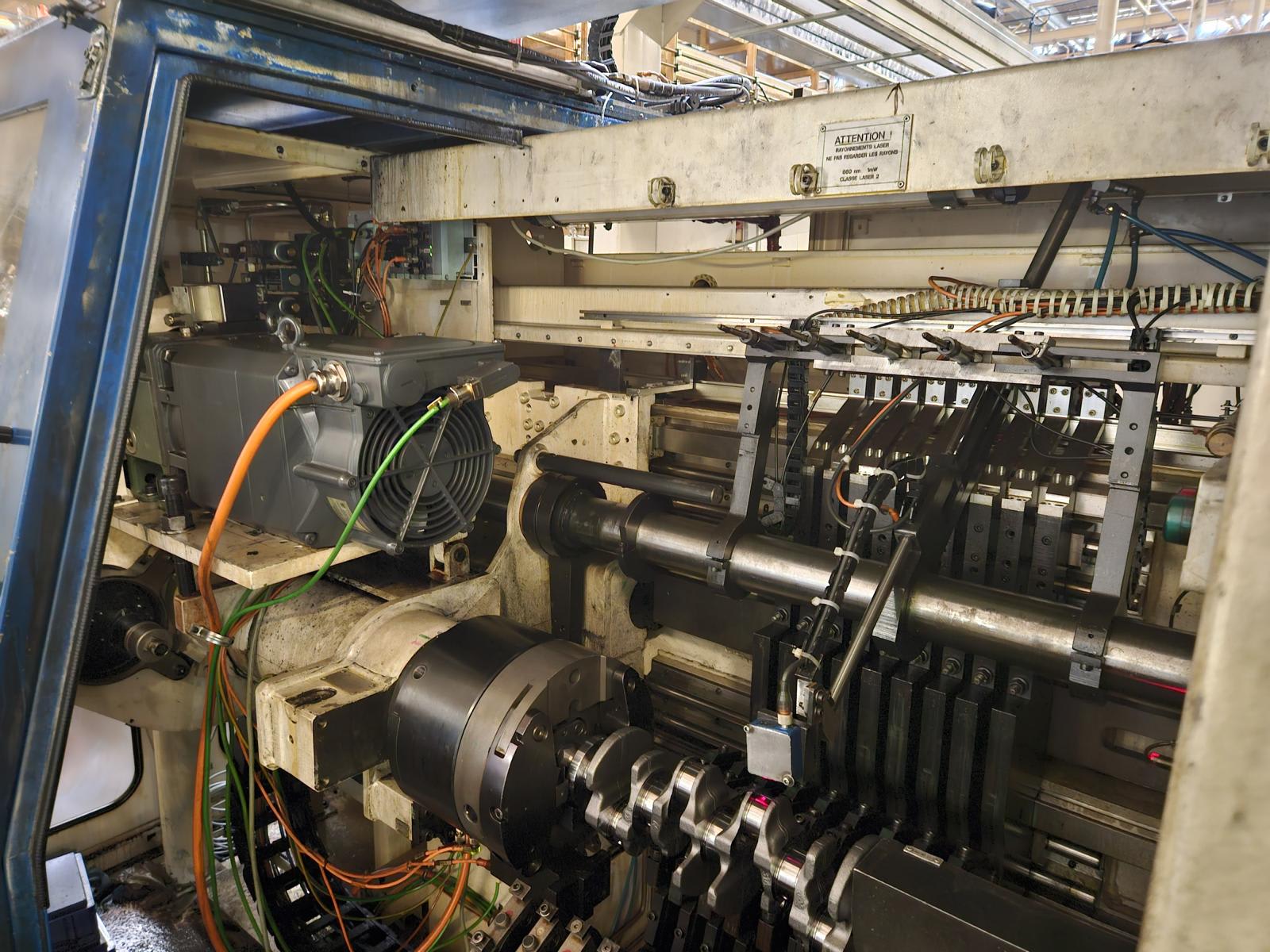

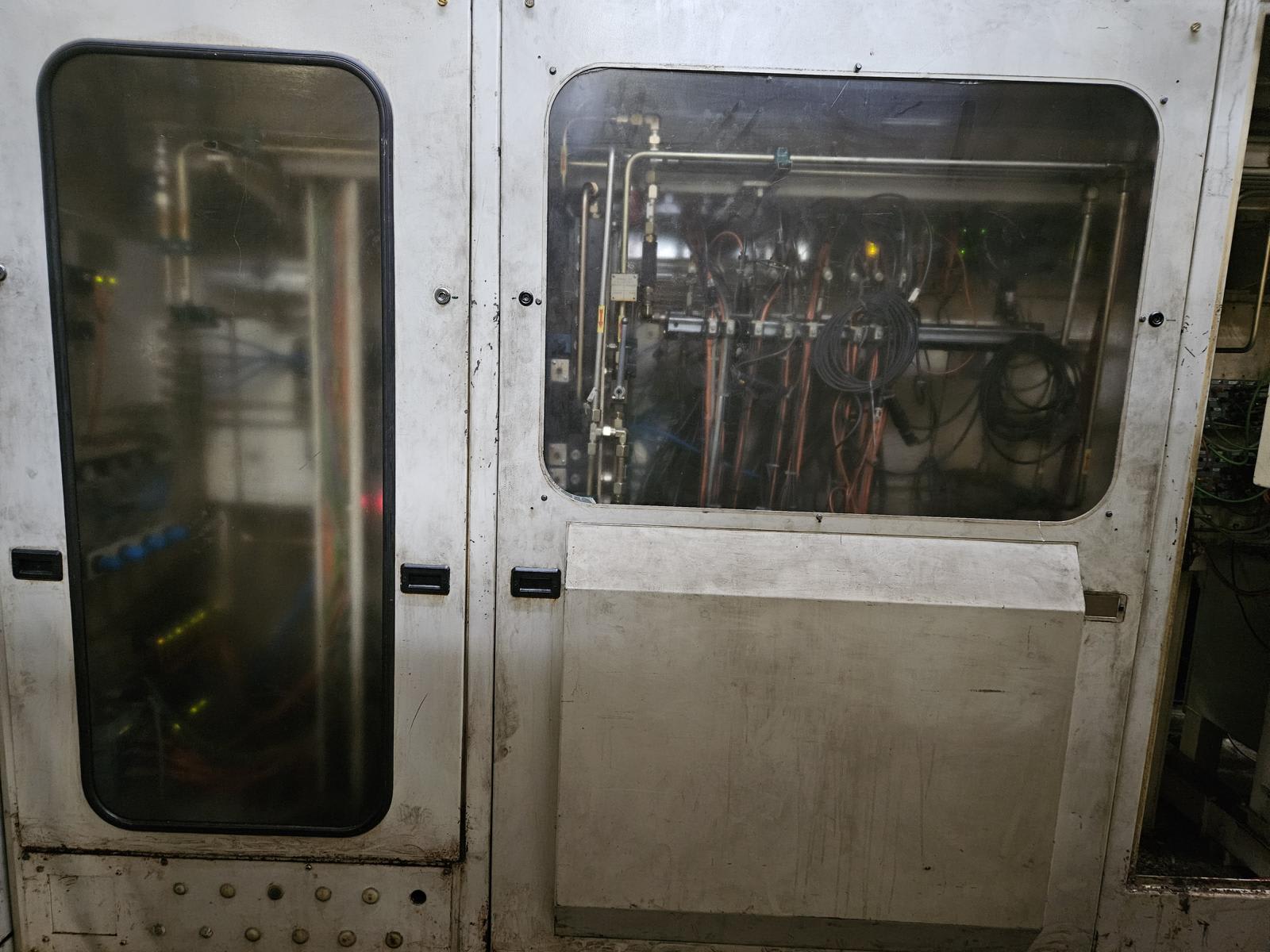

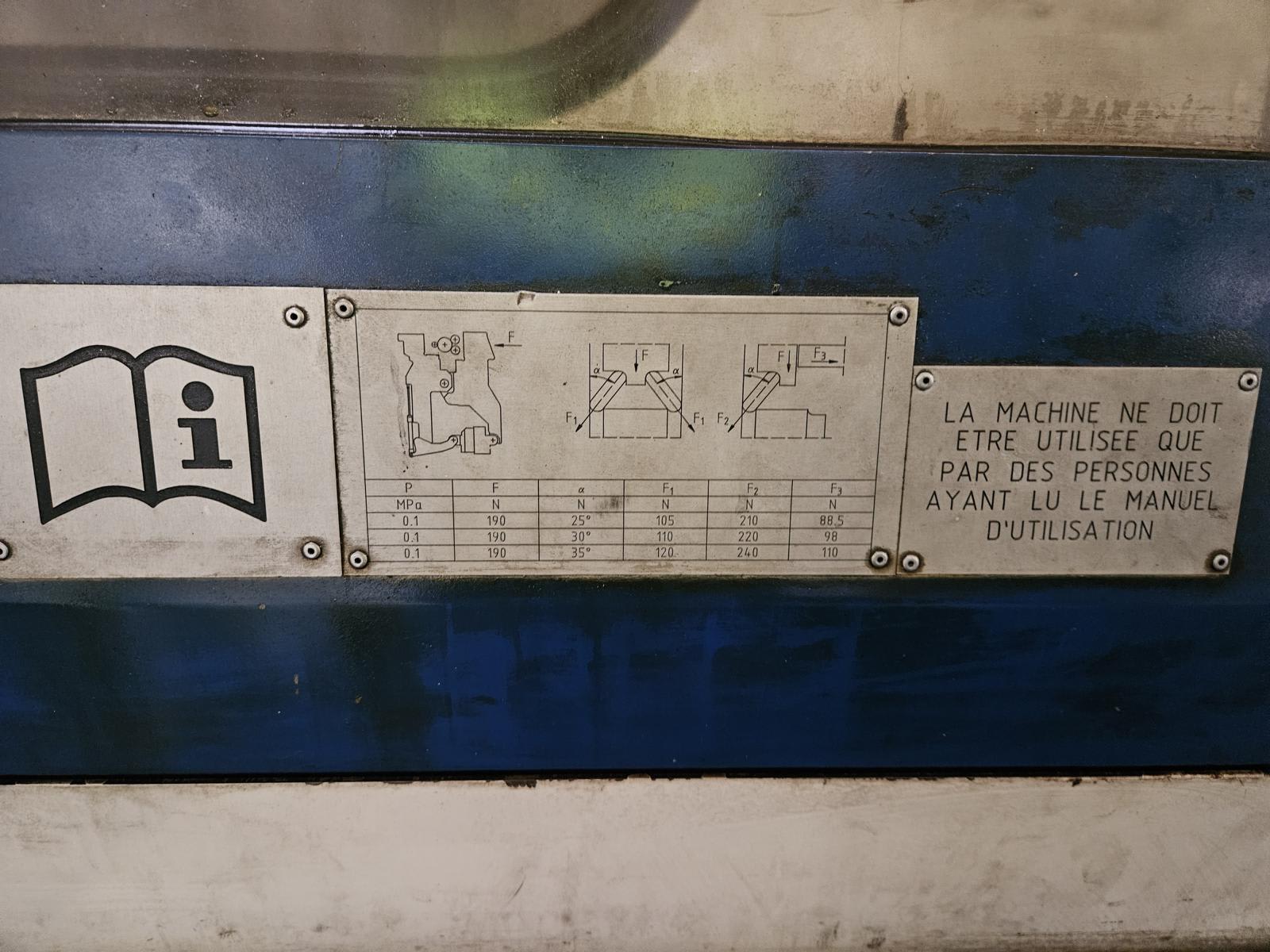

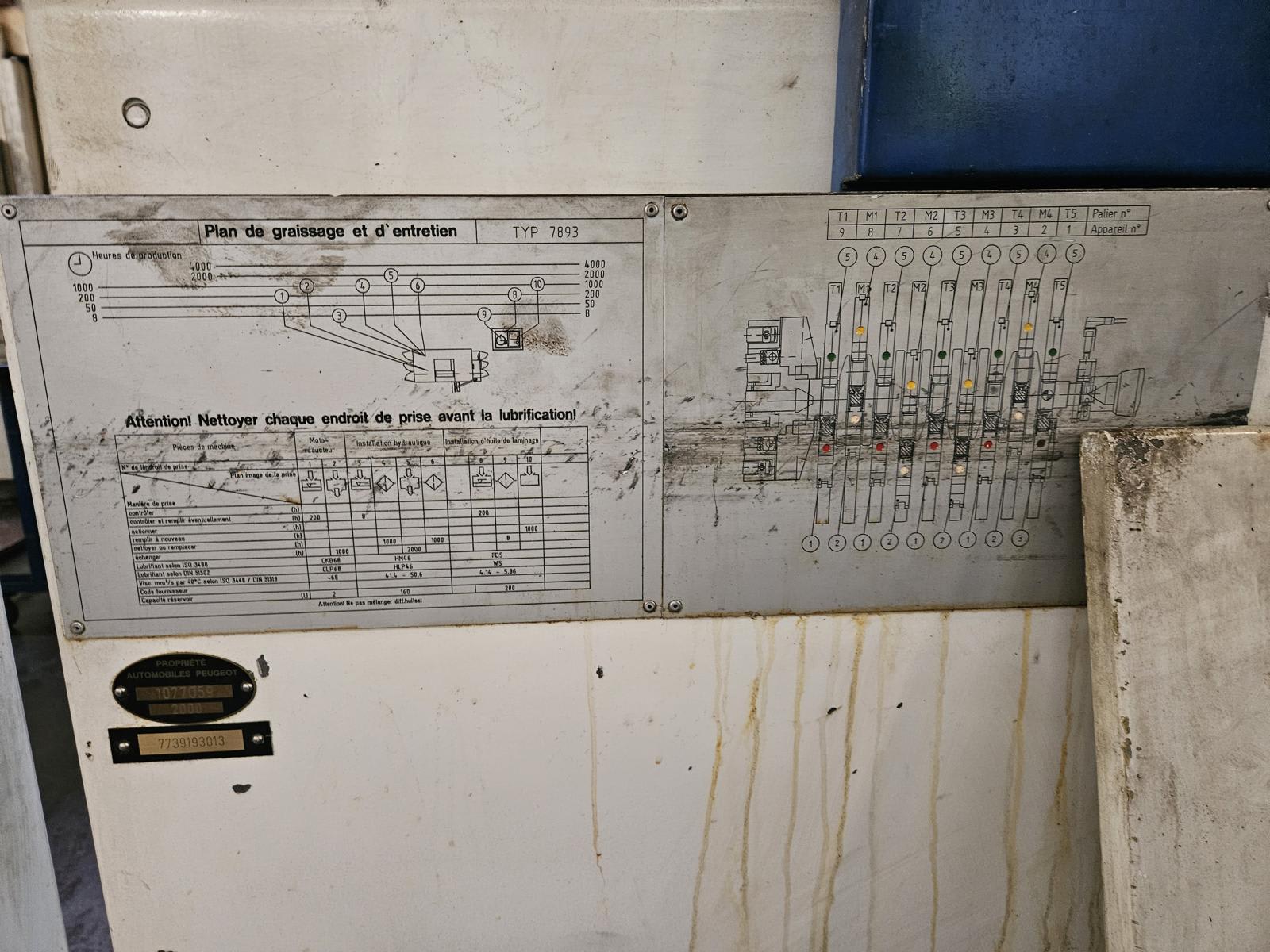

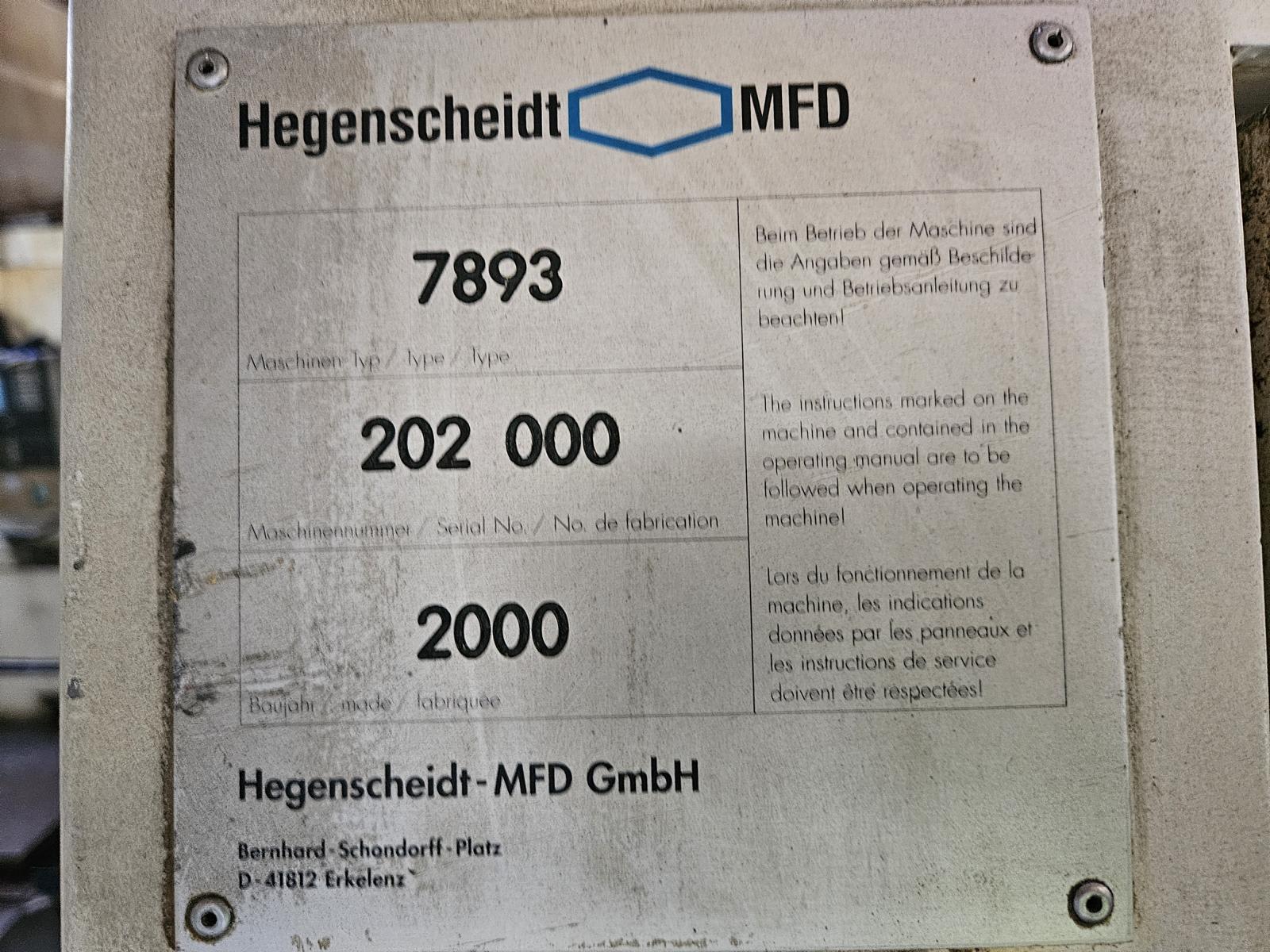

CNC Deep Rolling Machine HEGENSCHEIDT MFD 7893 | 2000

max length 920mm, max radius of counter weight (deüending on dtroke and bearing width) 195 - 270mm, max 8 main + 6 pin bearings, min/max main bearing dia 33 - 88mm, min/max pin bearing dia 30 - 84mm, max bearing width 18,5mm, max stroke 140mm, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 35kVA, weight 13to - LISTING 2830016

![Français]()

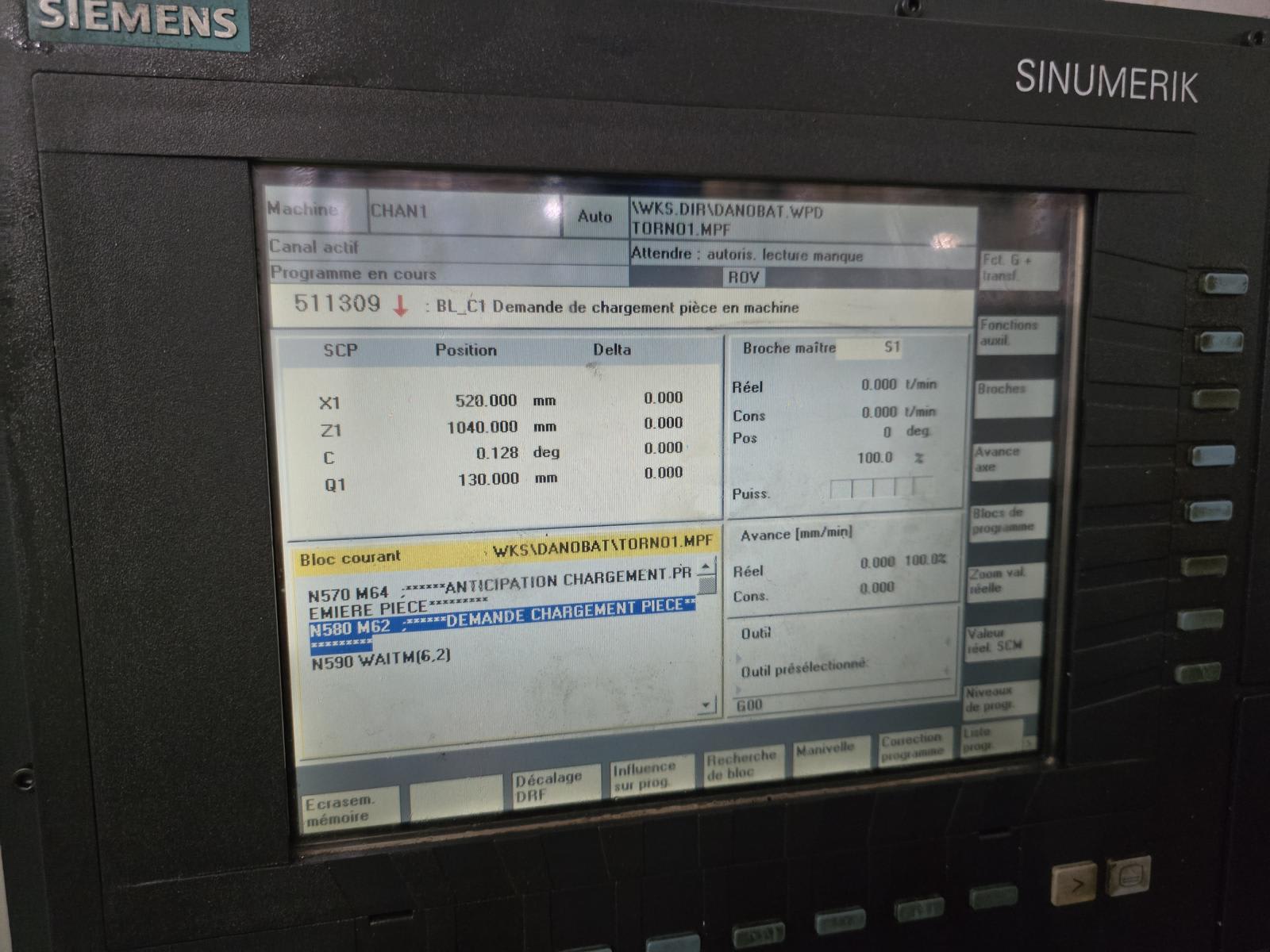

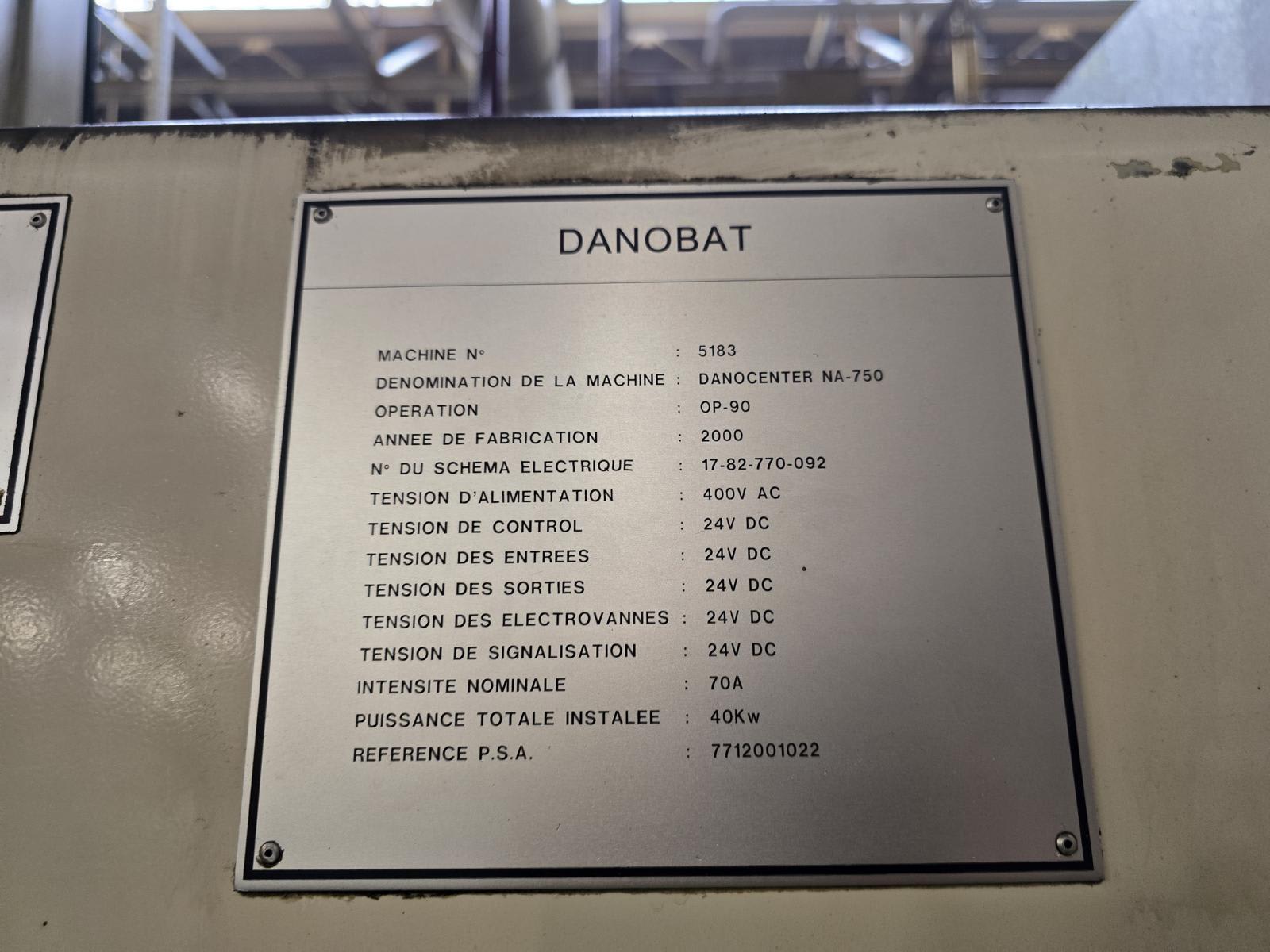

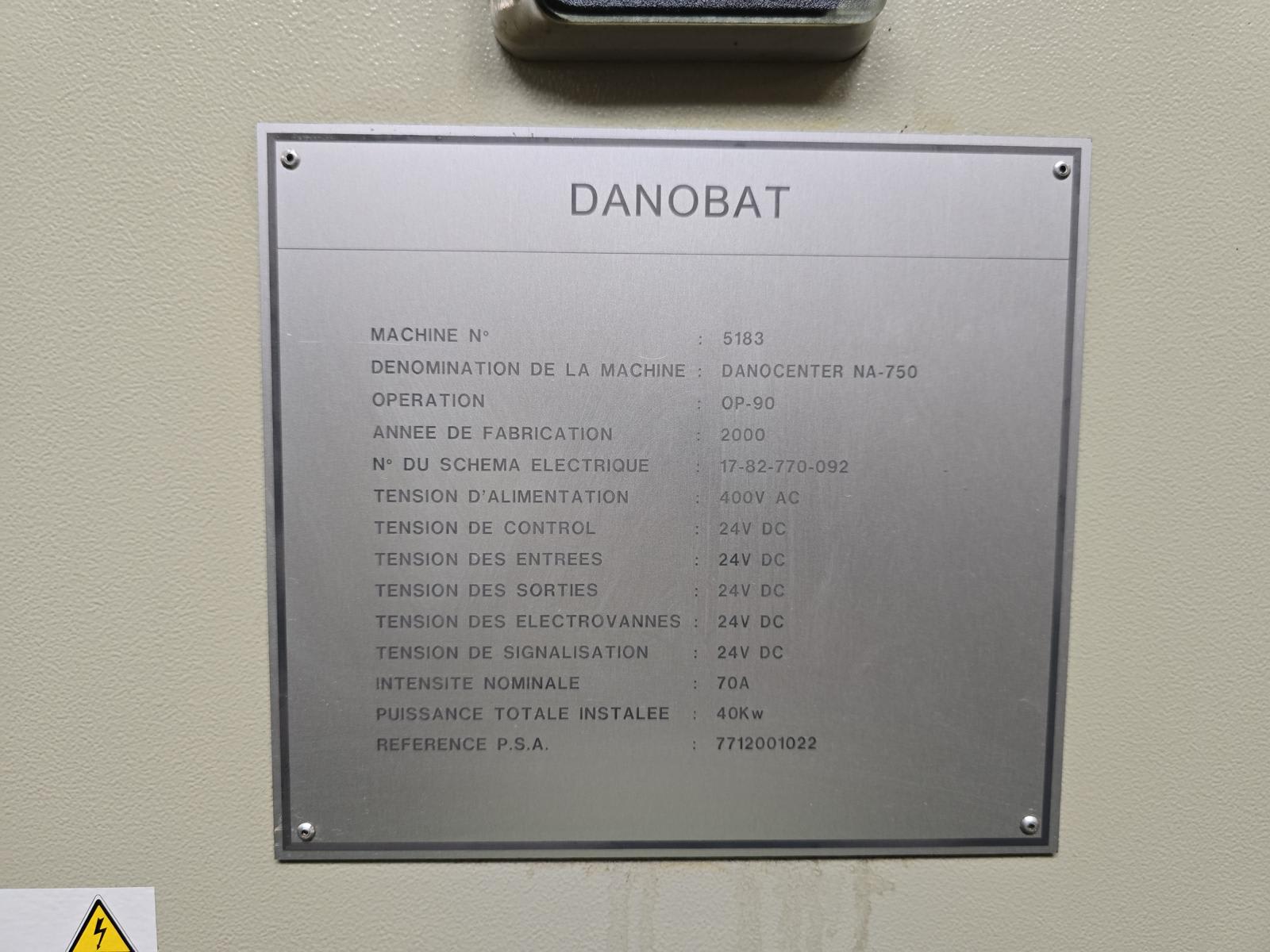

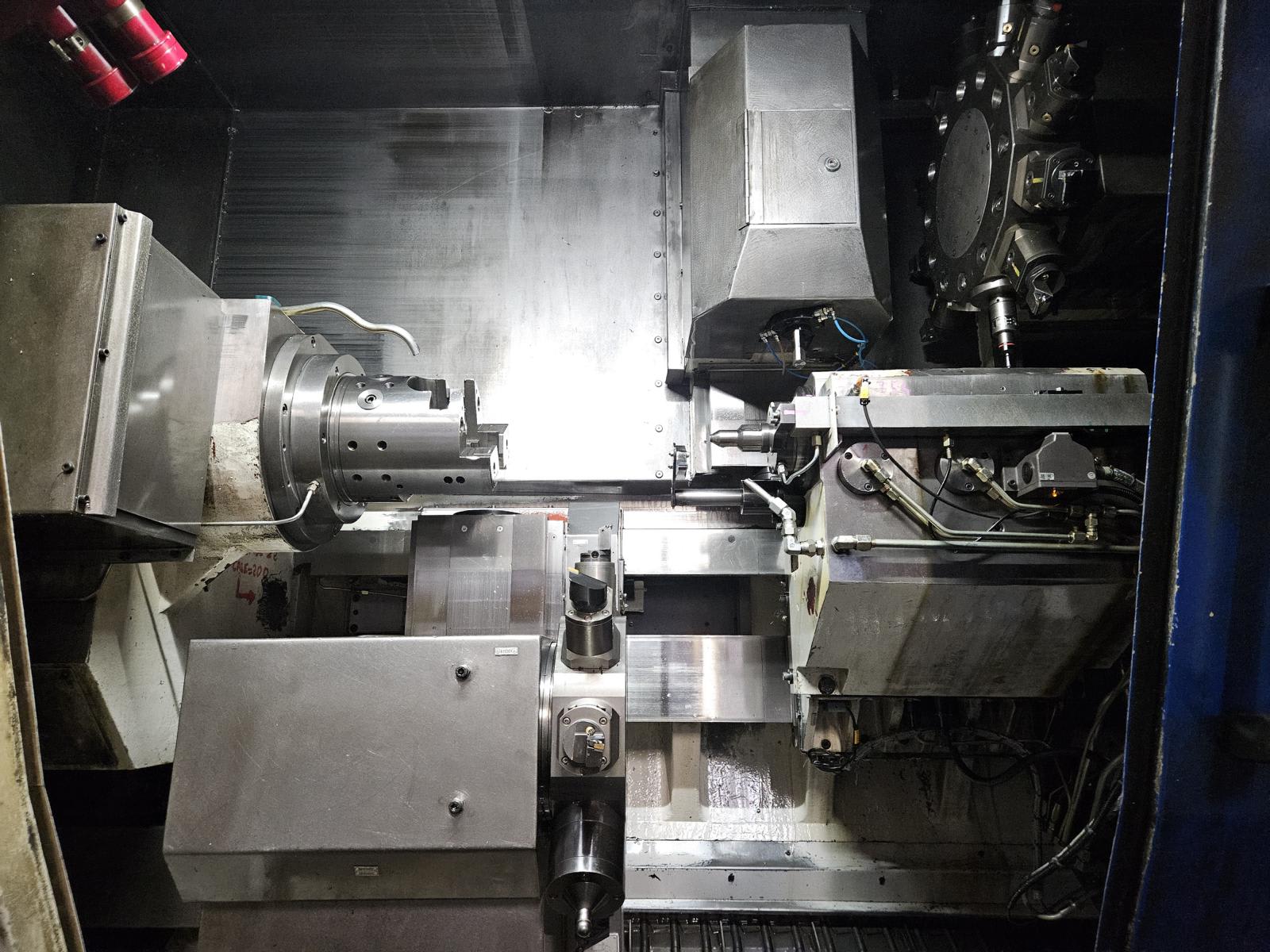

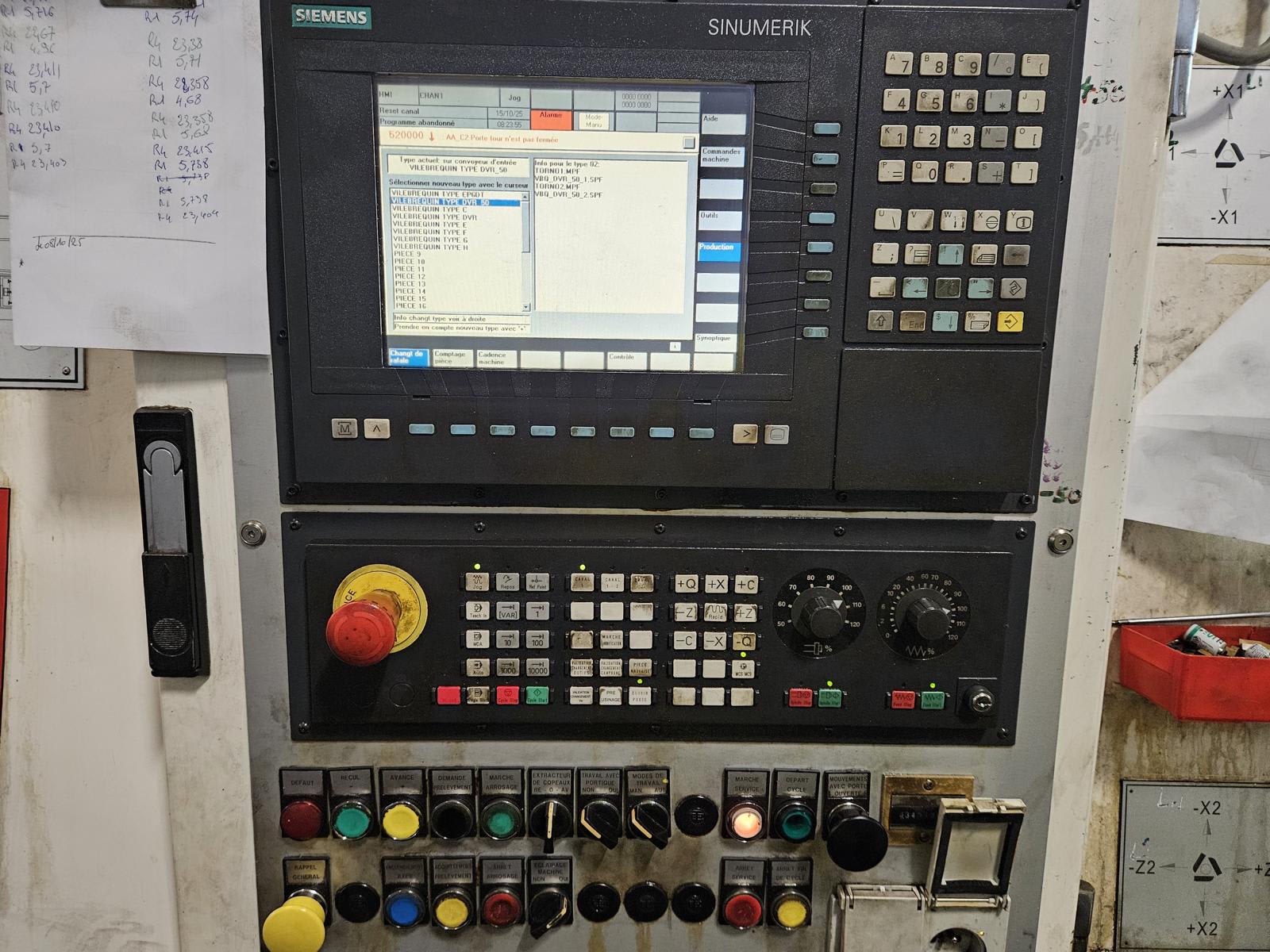

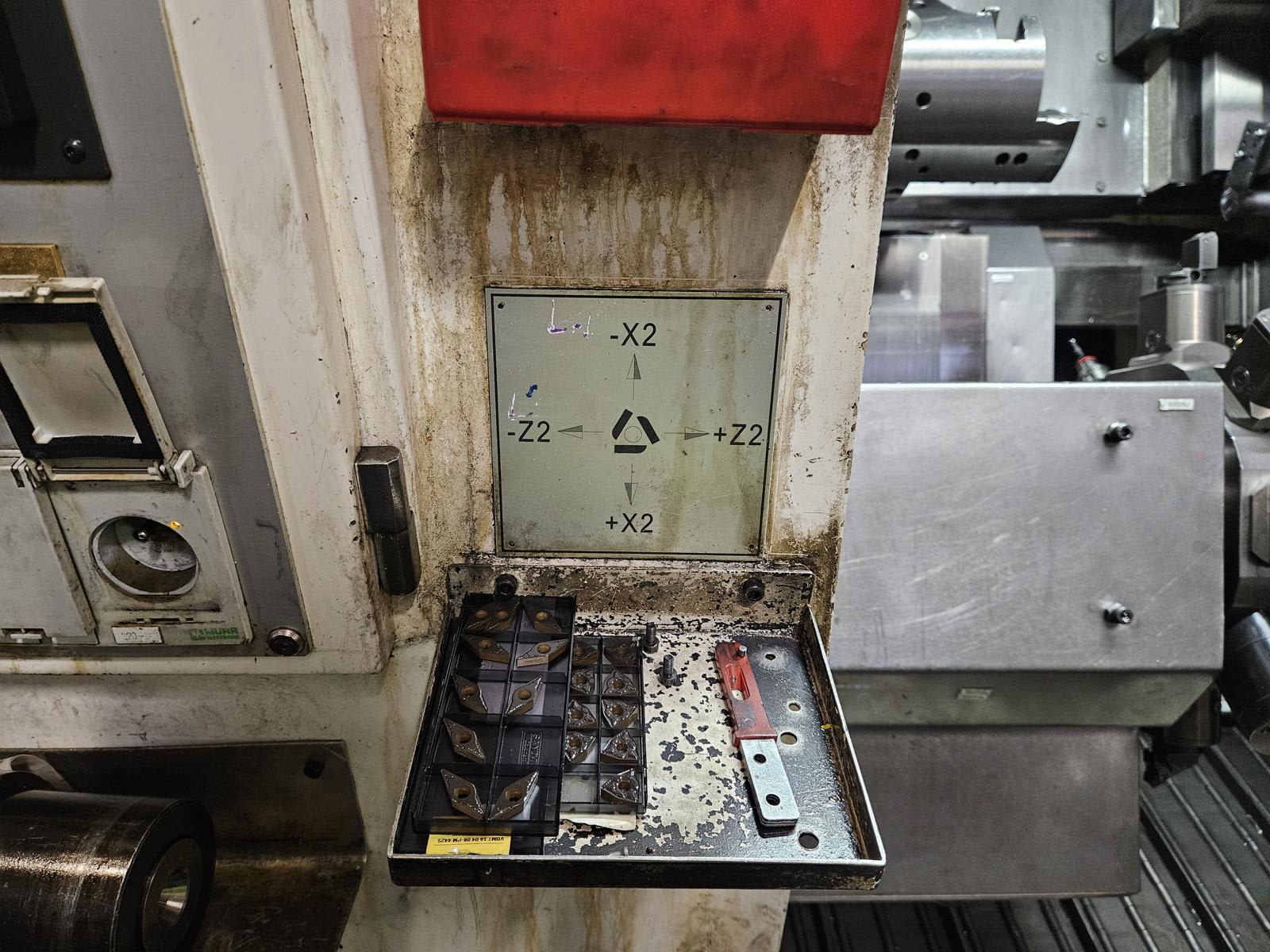

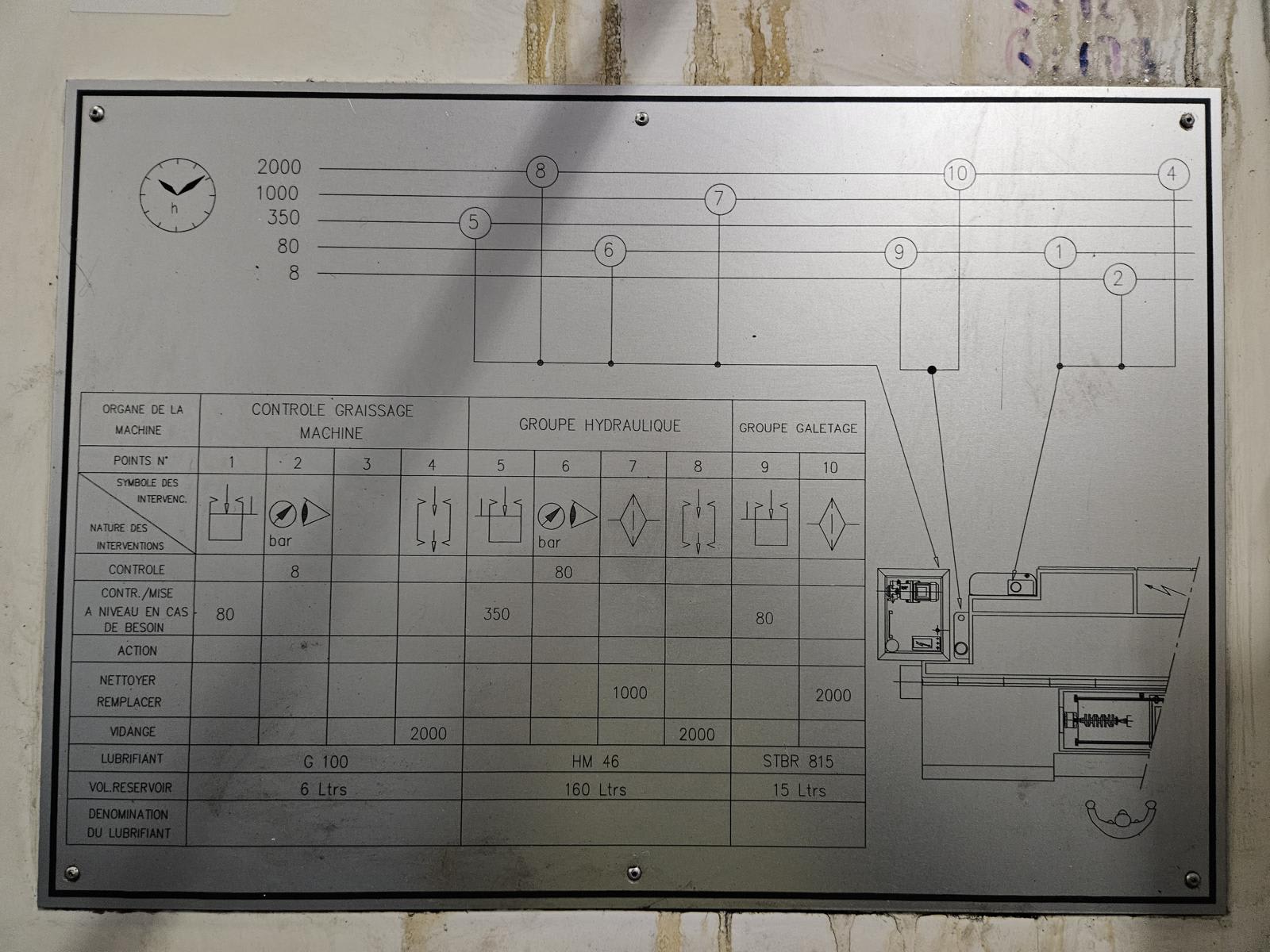

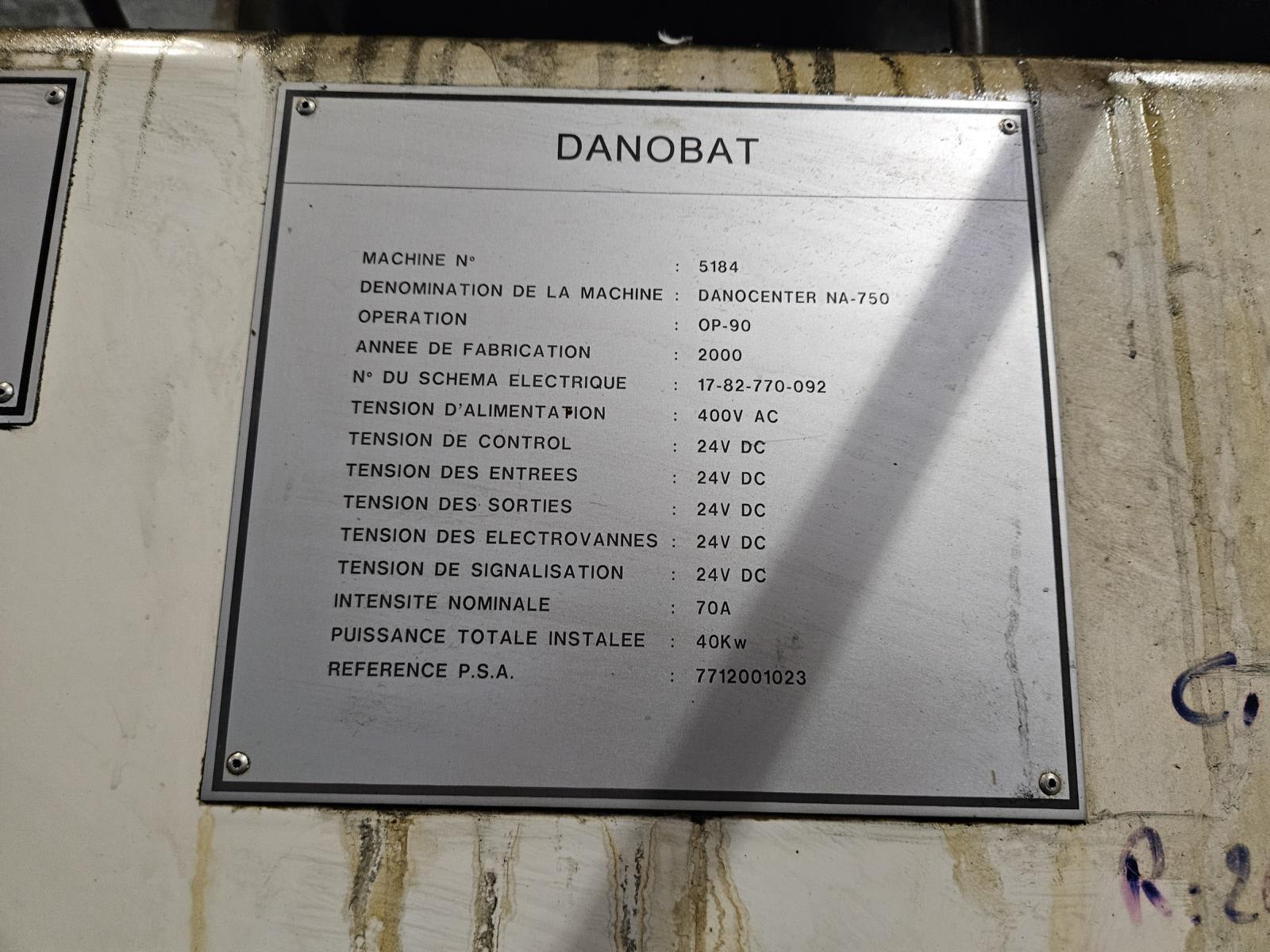

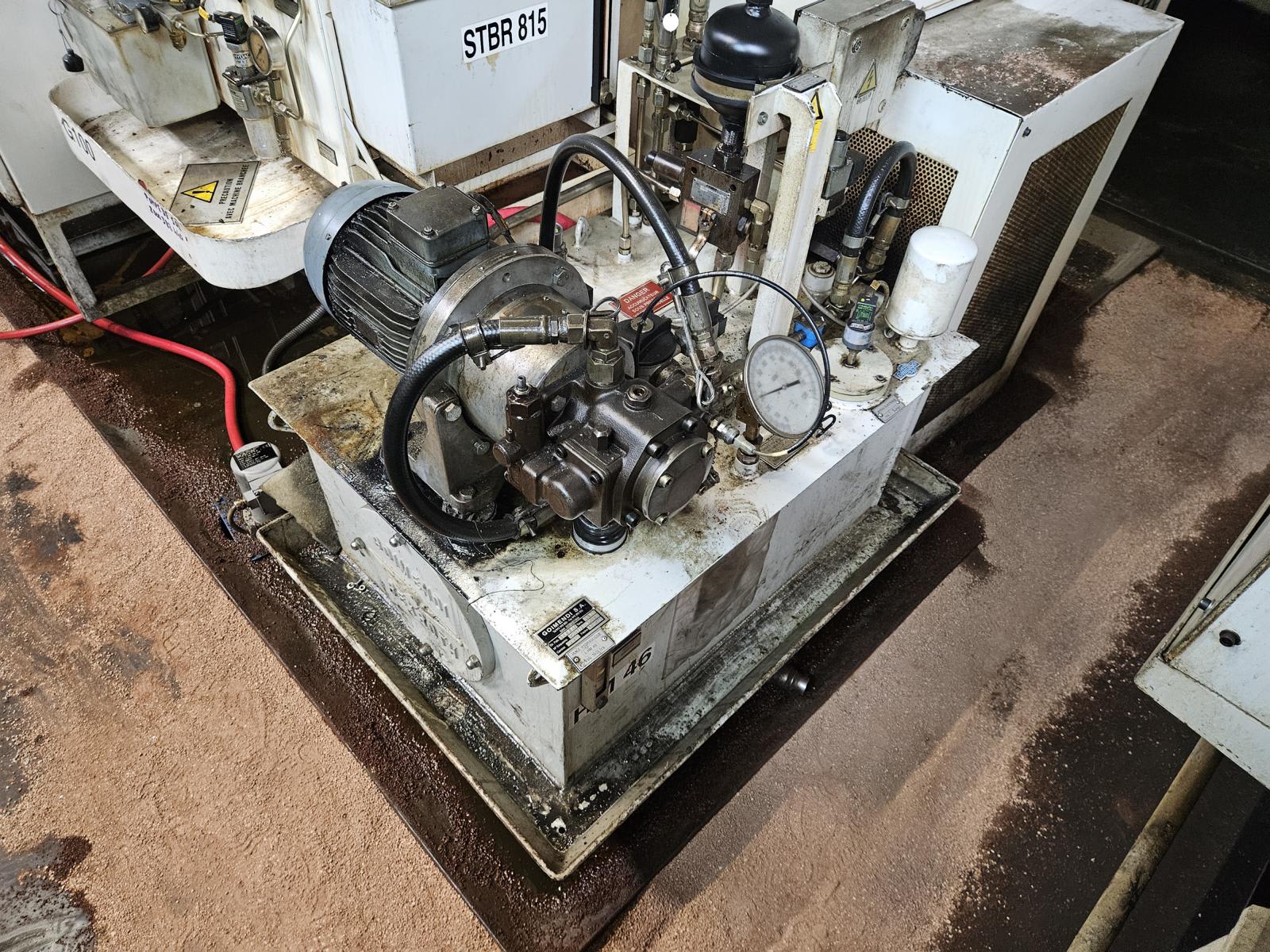

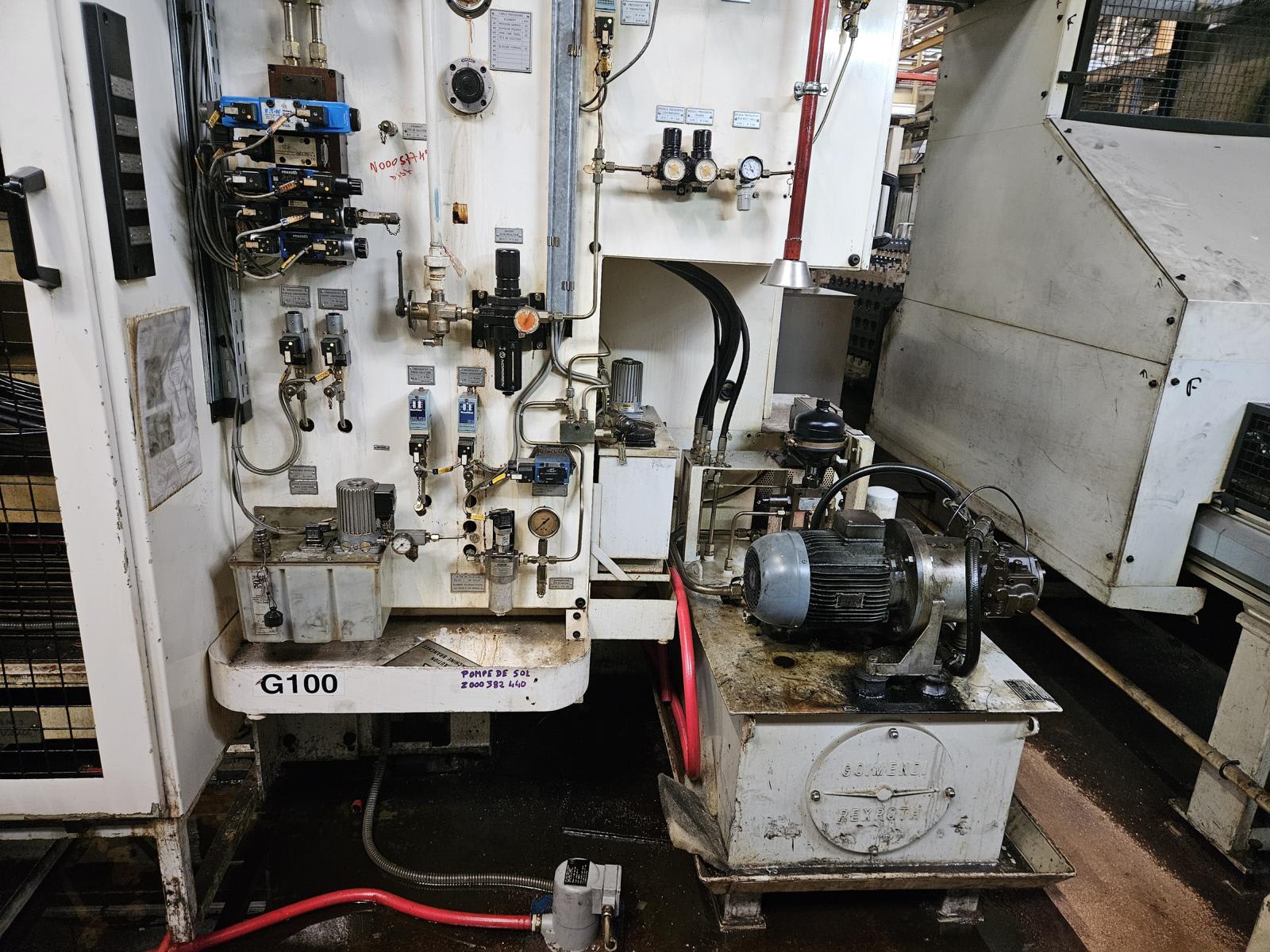

CNC Turning + Milling Center DANOBAT DANOCENTER NA-750 | 2000

max swing 700mm, X/Y 255/520mm, 12-Pos-Upper-Tool-Turret and 8-Pos-Lower-Tool-Turret with driven tooling, Measuring Head, Tailstock, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 45kW, weight 15to - LISTING 2830017

![Français]()

CNC Turning + Milling Center DANOBAT DANOCENTER NA-750 | 2000

max swing 700mm, X/Y 255/520mm, 12-Pos-Upper-Tool-Turret and 8-Pos-Lower-Tool-Turret with driven tooling, Measuring Head, Tailstock, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 45kW, weight 15to - LISTING 2830018

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 630 | 2001

crankshaft length 630 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830019

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 630 | 2001

crankshaft length 630 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830020

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 630 | 2001

crankshaft length 630 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830021

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 630 | 2001

crankshaft length 630 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830022

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 600 | 2000

crankshaft length 600 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830023

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 600 | 2000

crankshaft length 600 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830024

![Français]()

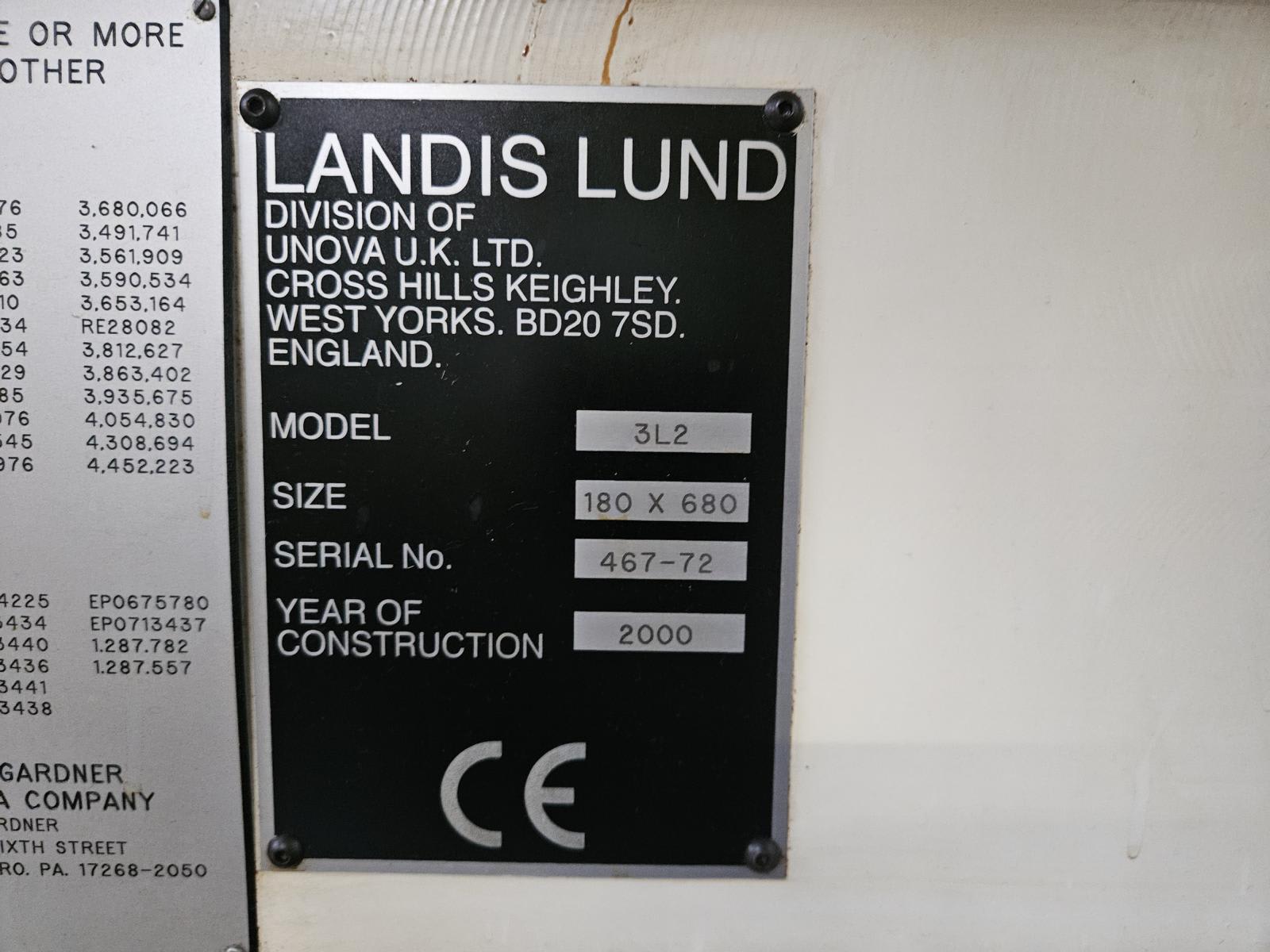

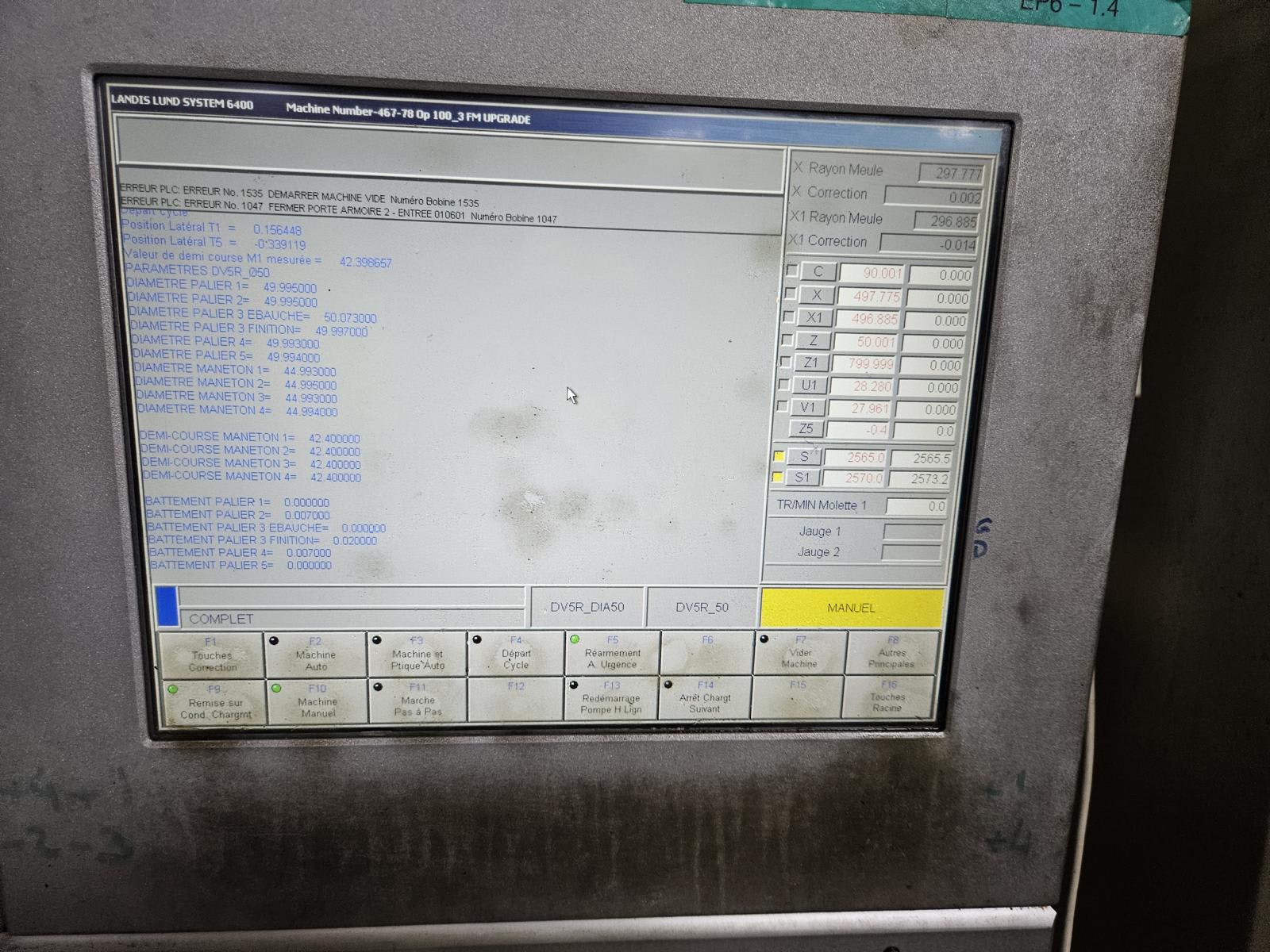

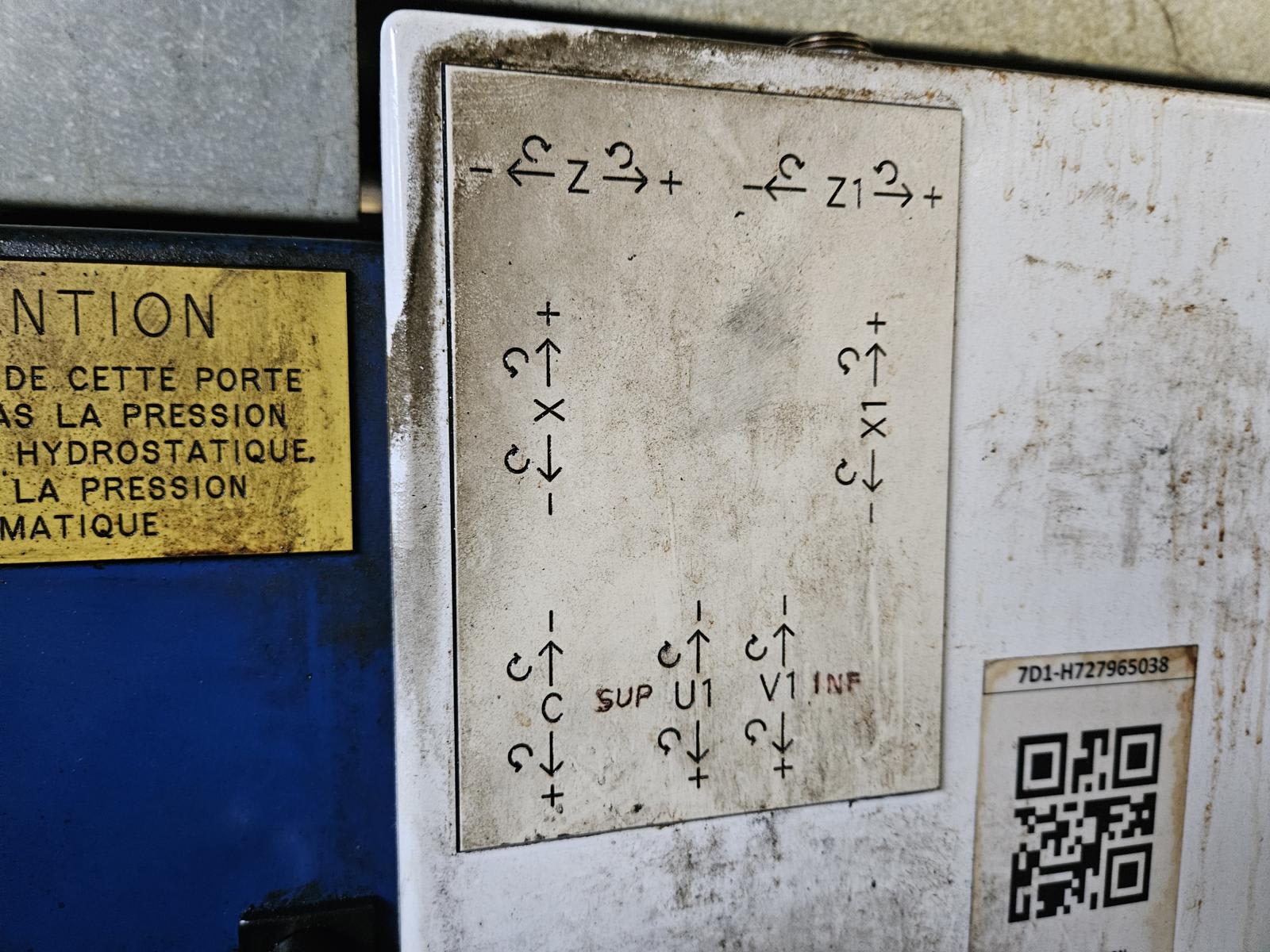

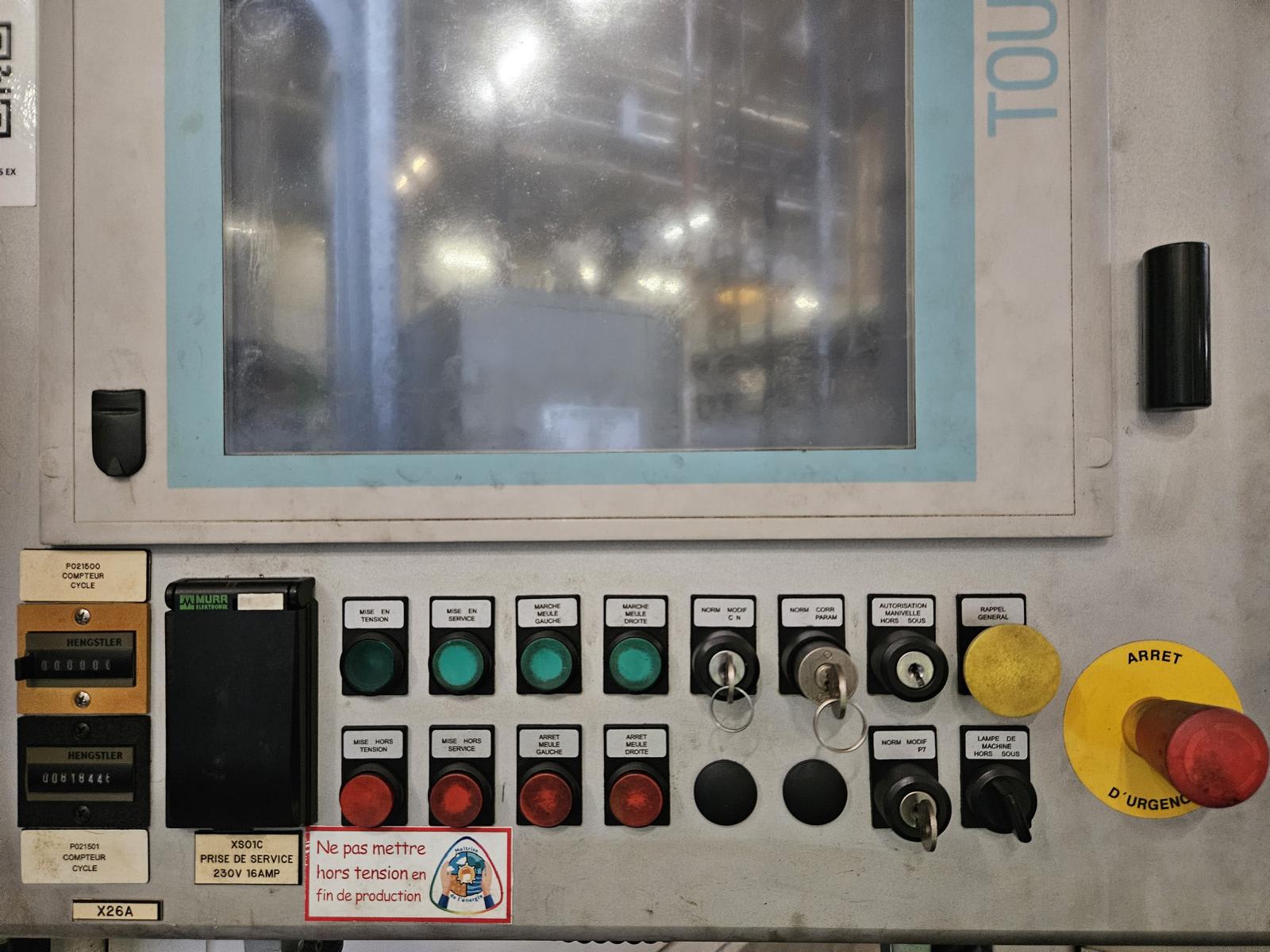

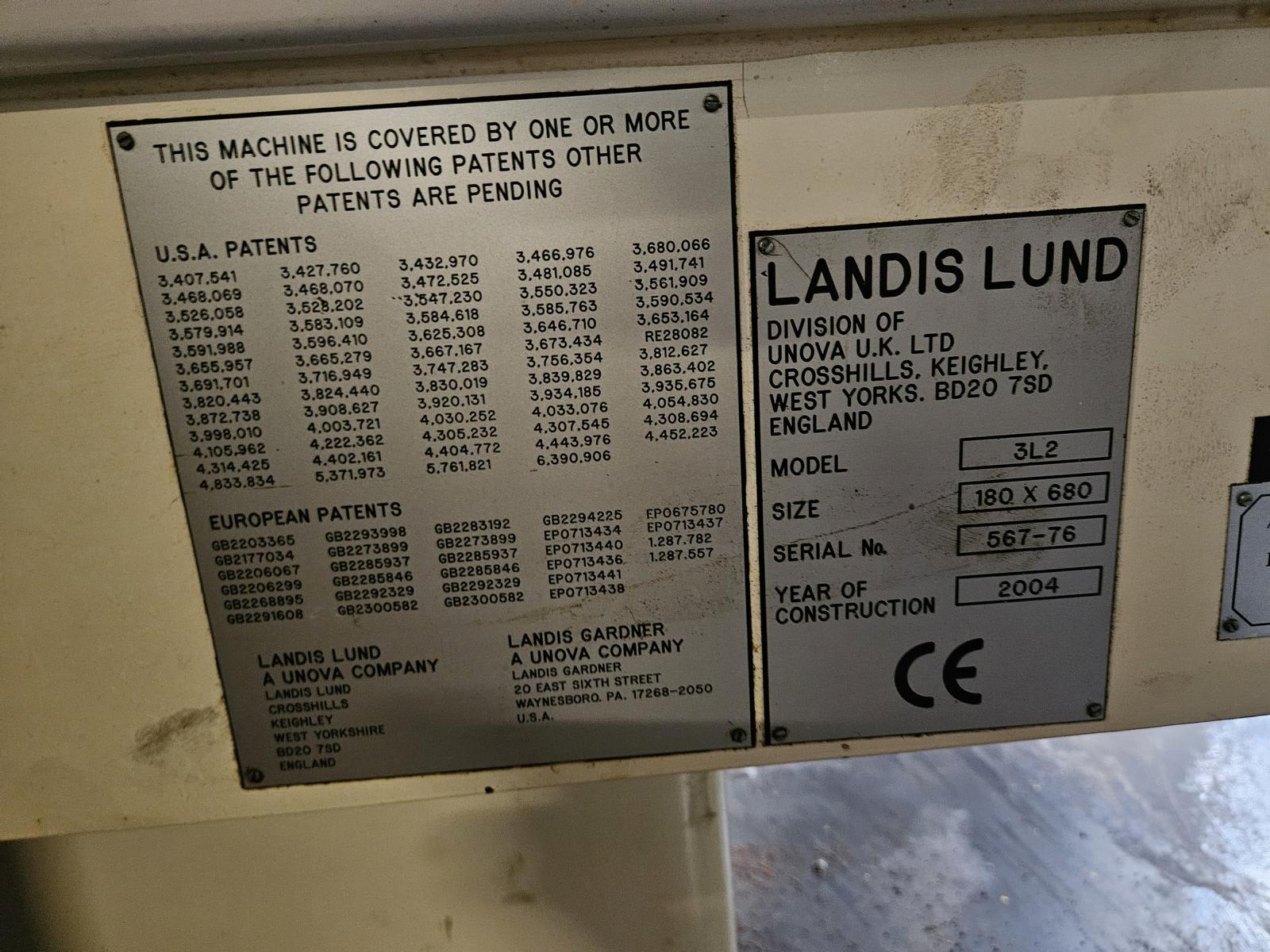

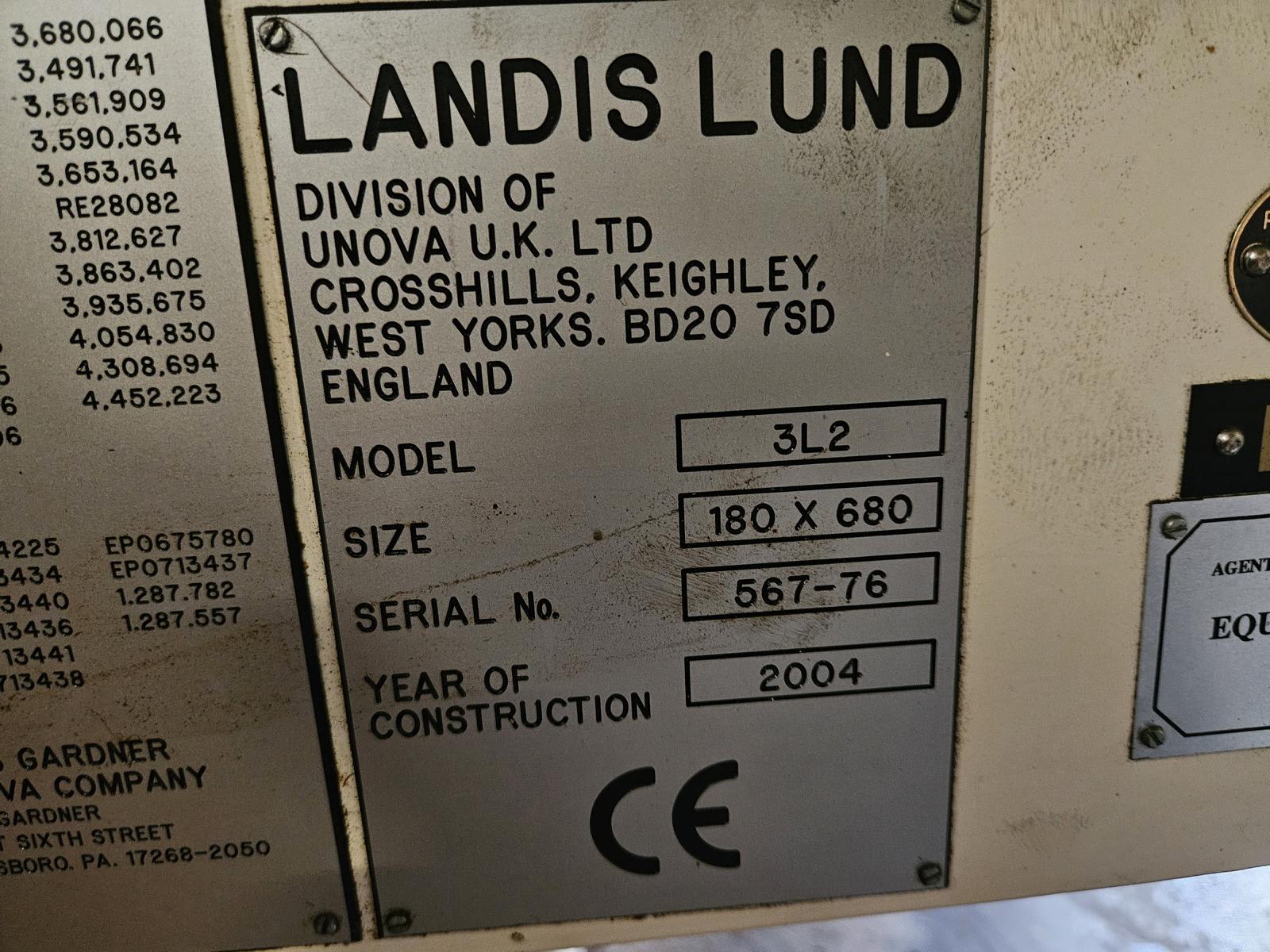

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 680 | 2004

crankshaft length 680 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400 with SIEIEMSN HMI panel, weight, ca. 16to - LISTING 2830025

![Français]()

CNC Pin Grinder LANDIS 3L2 Twin Orbital Pin 180 x 680 | 2004

crankshaft length 630 x dia 180mm, 2 grinding spindles (grinding wheel dia 400mm), MARPOSS E82 In-Process grinding wheel balancing system, CNC LANDIS 6400, weight, ca. 16to - LISTING 2830026

![Français]()

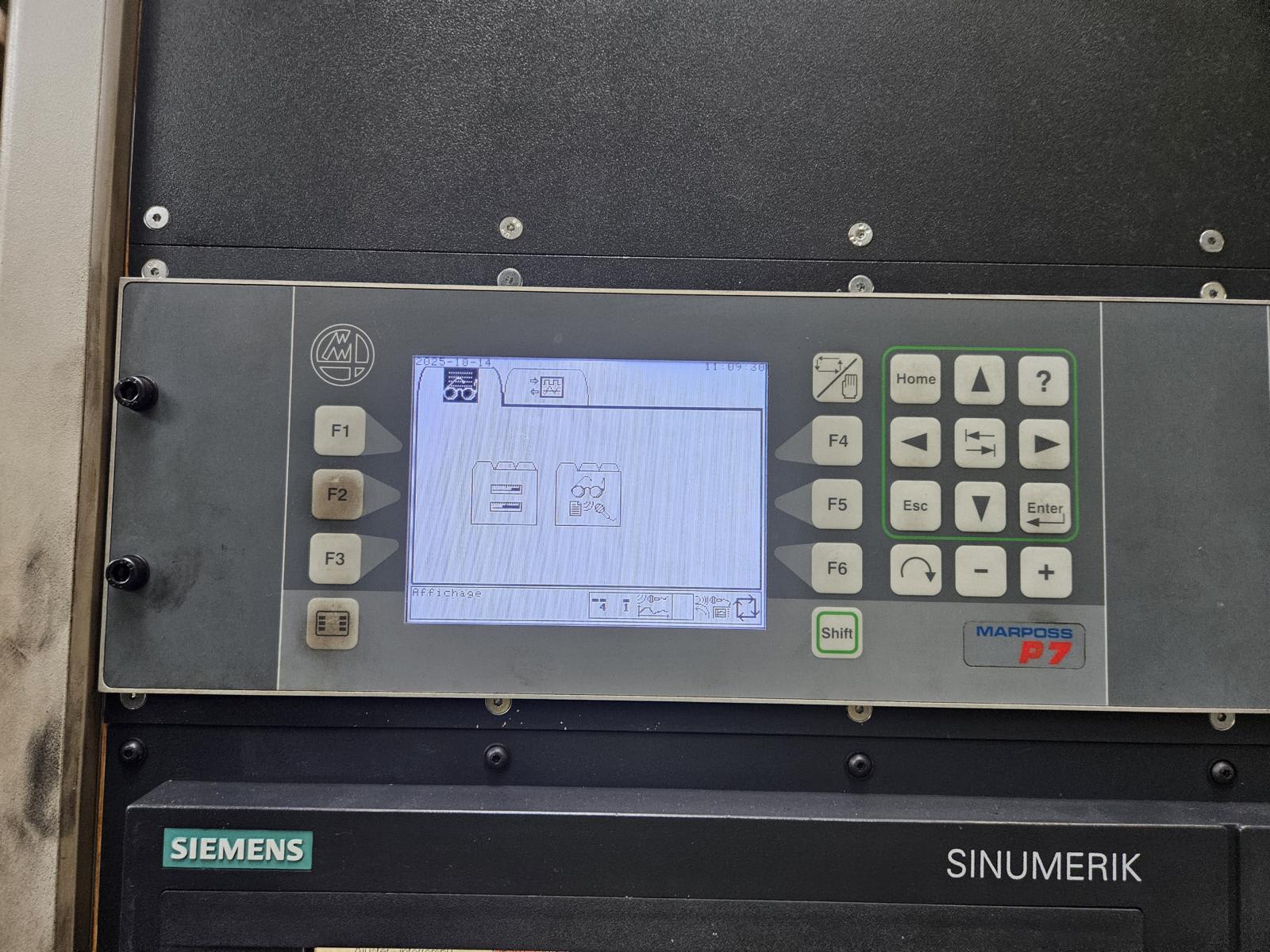

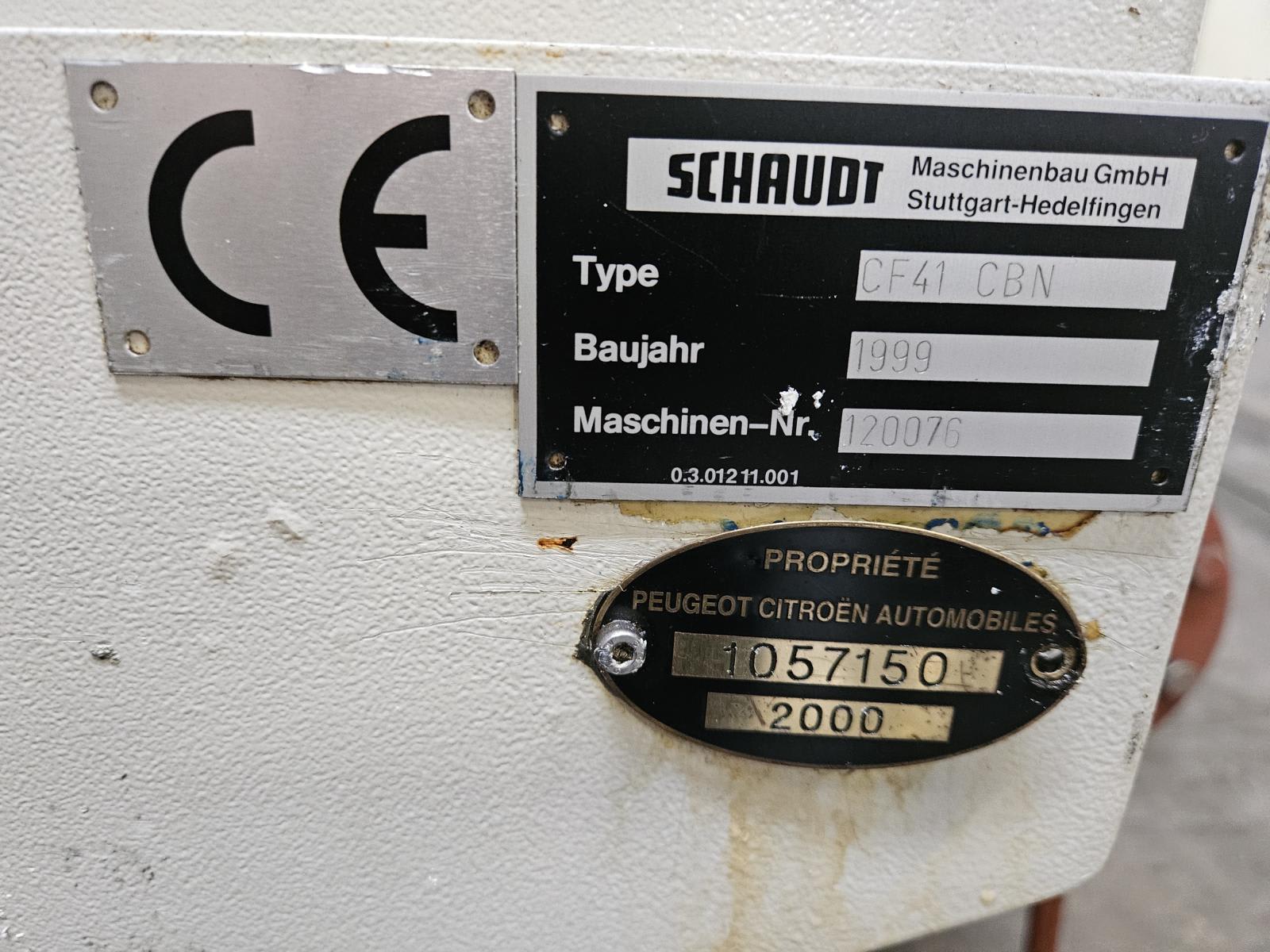

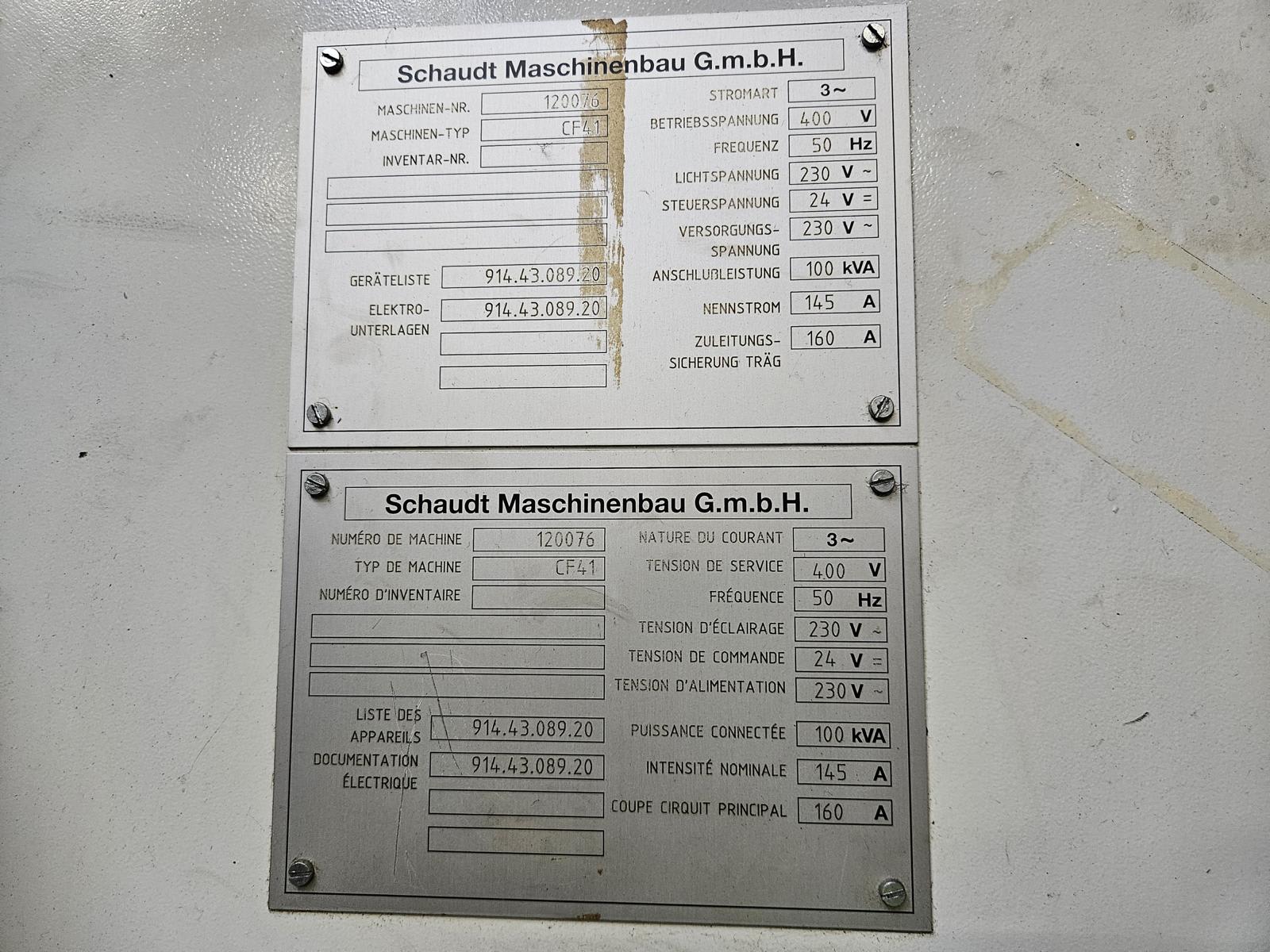

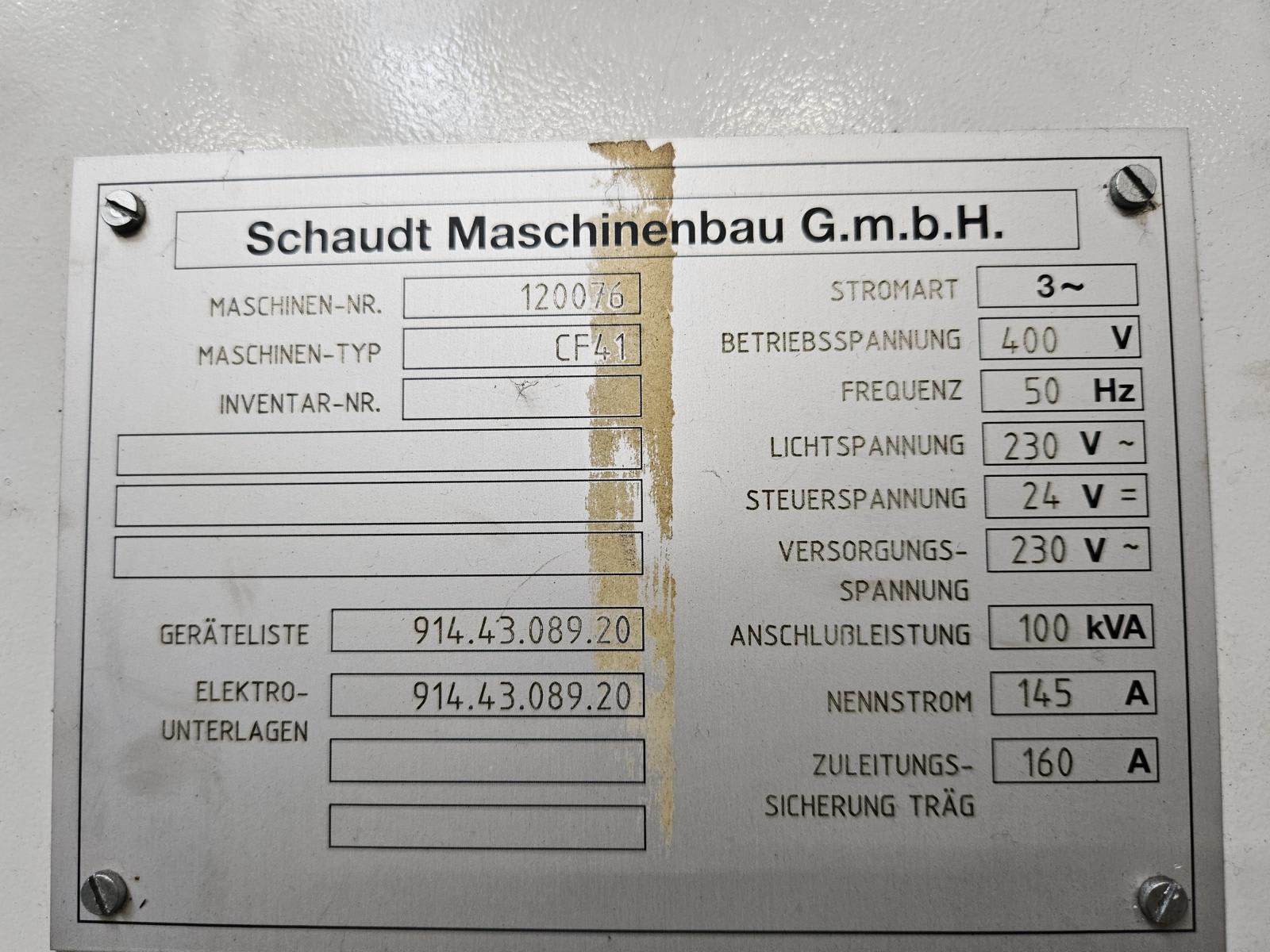

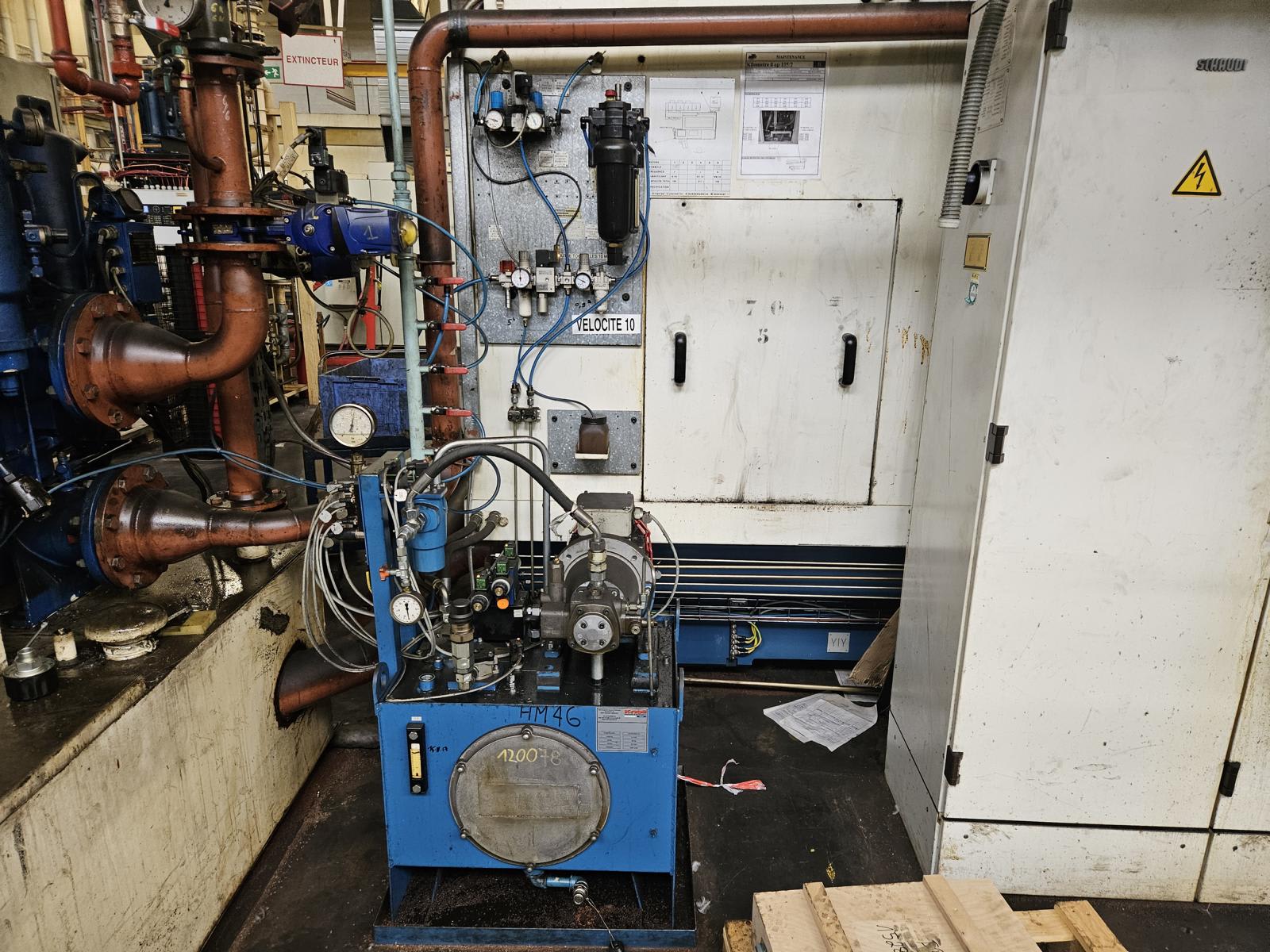

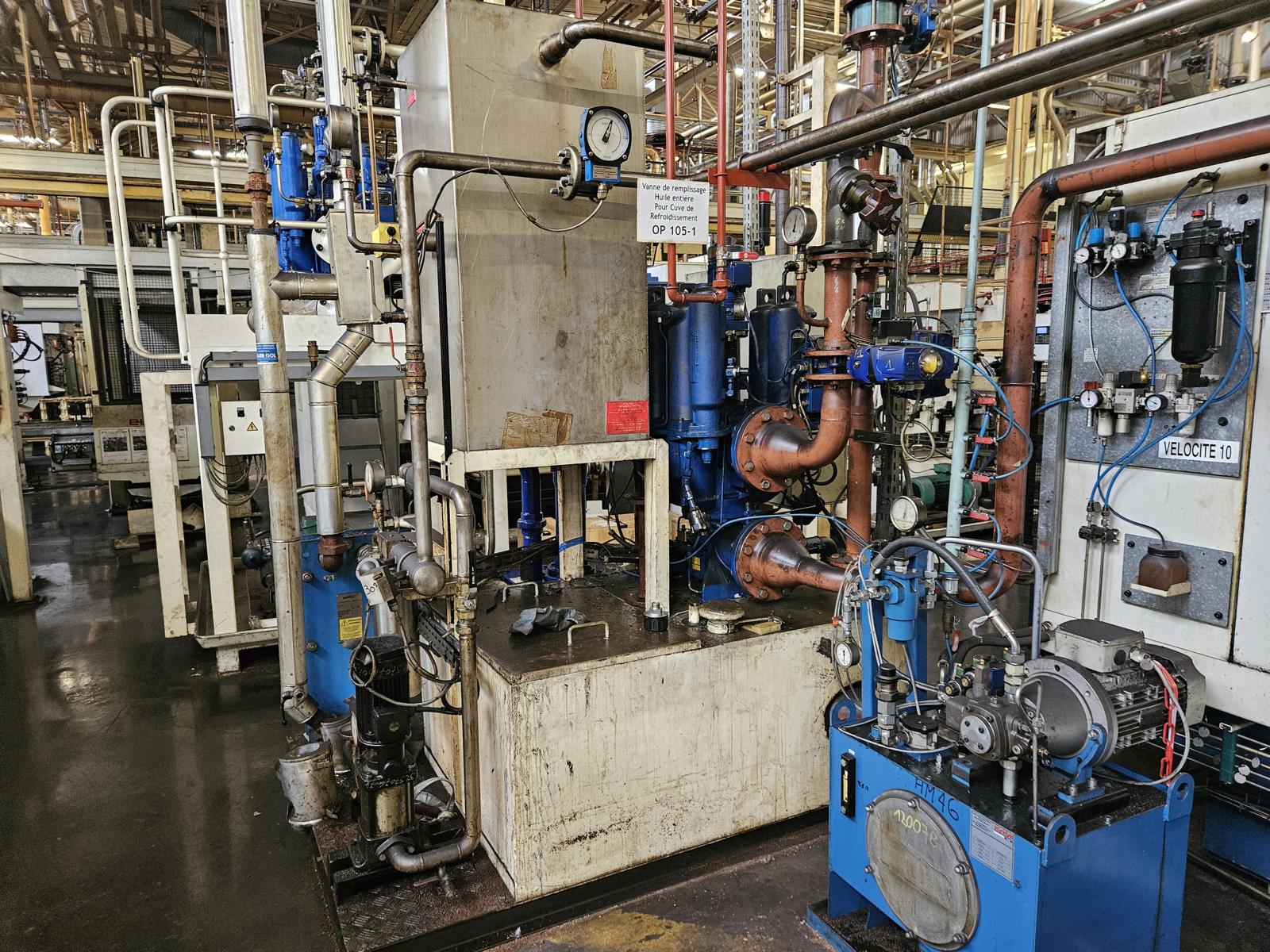

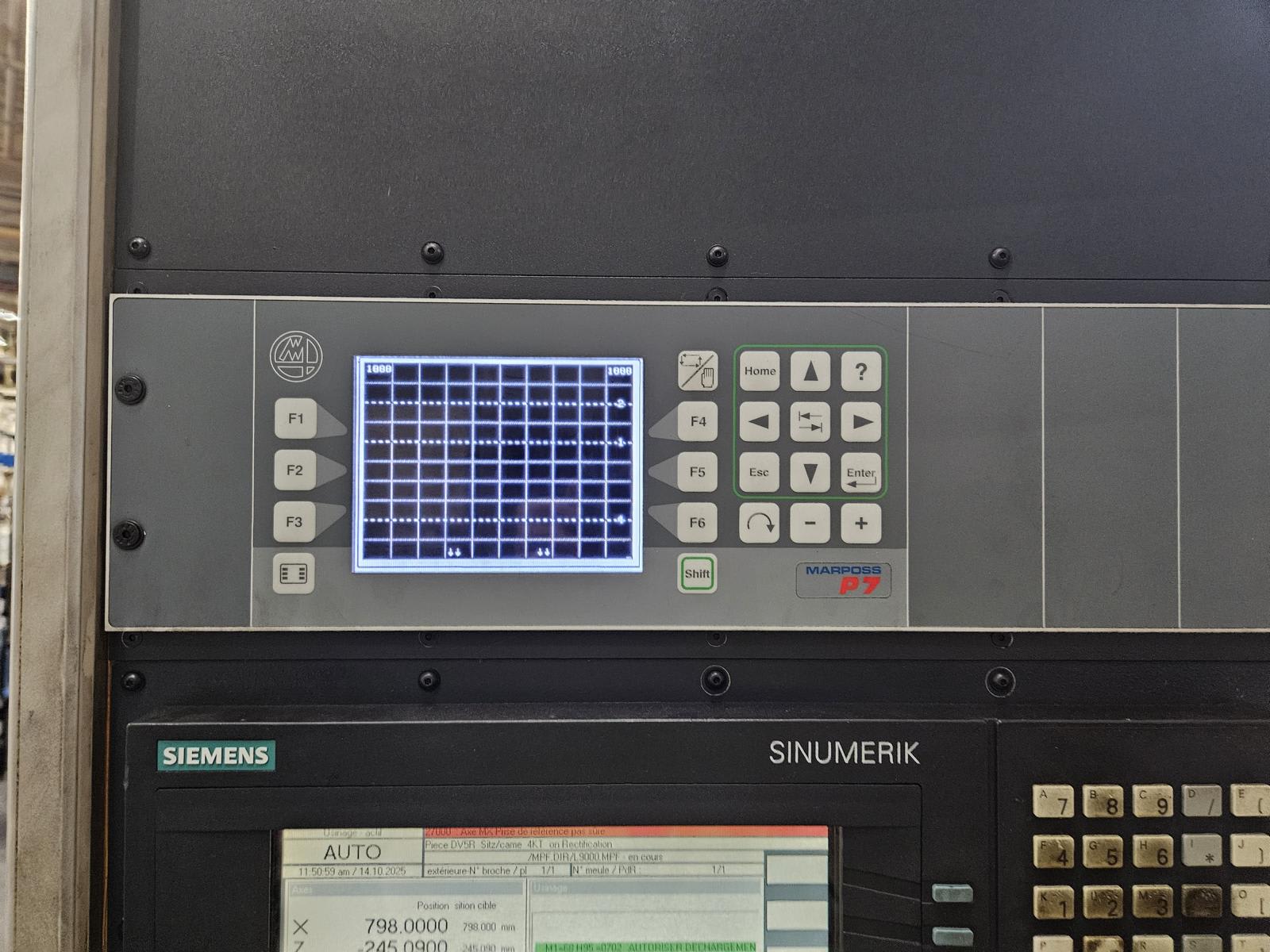

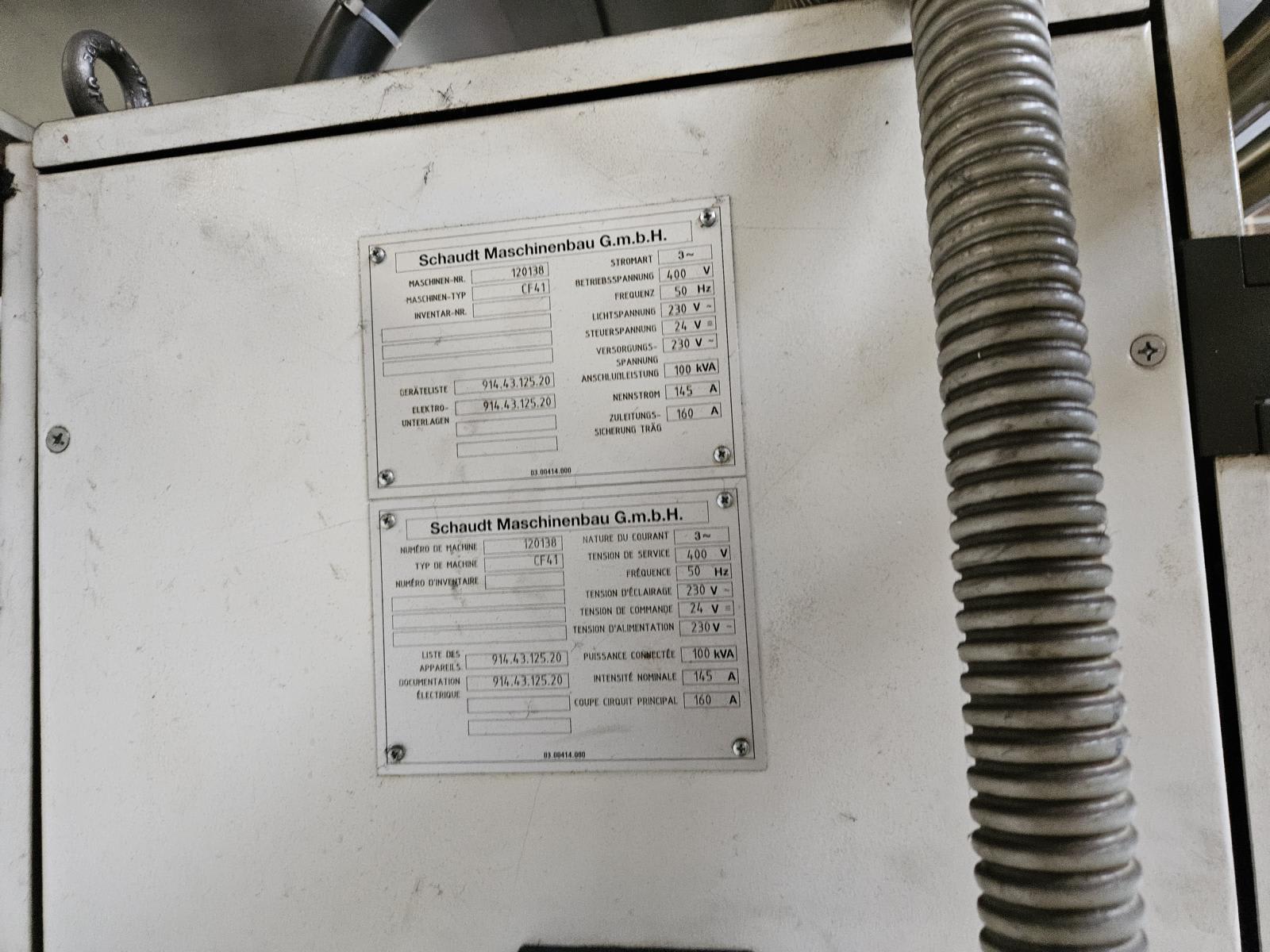

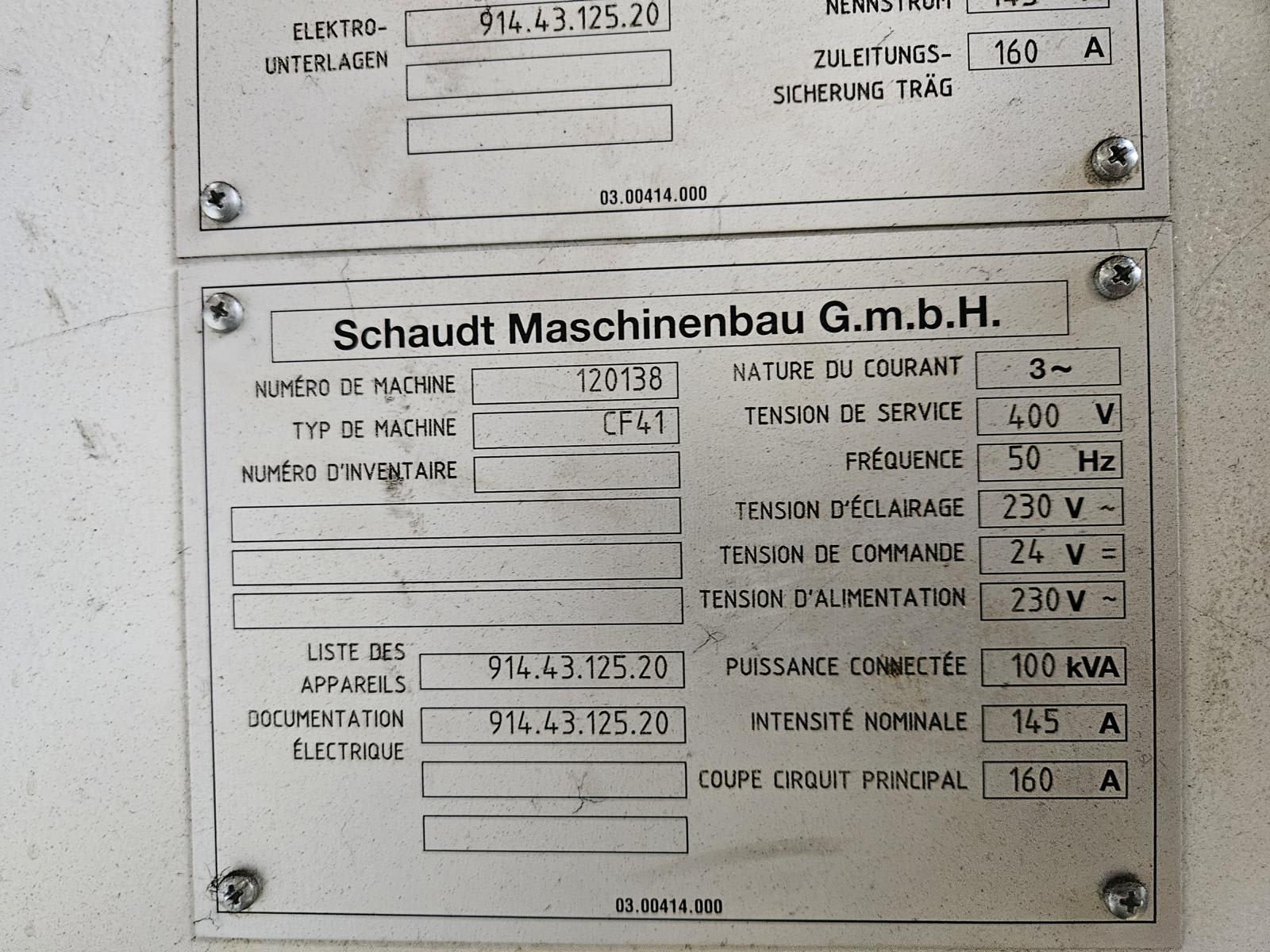

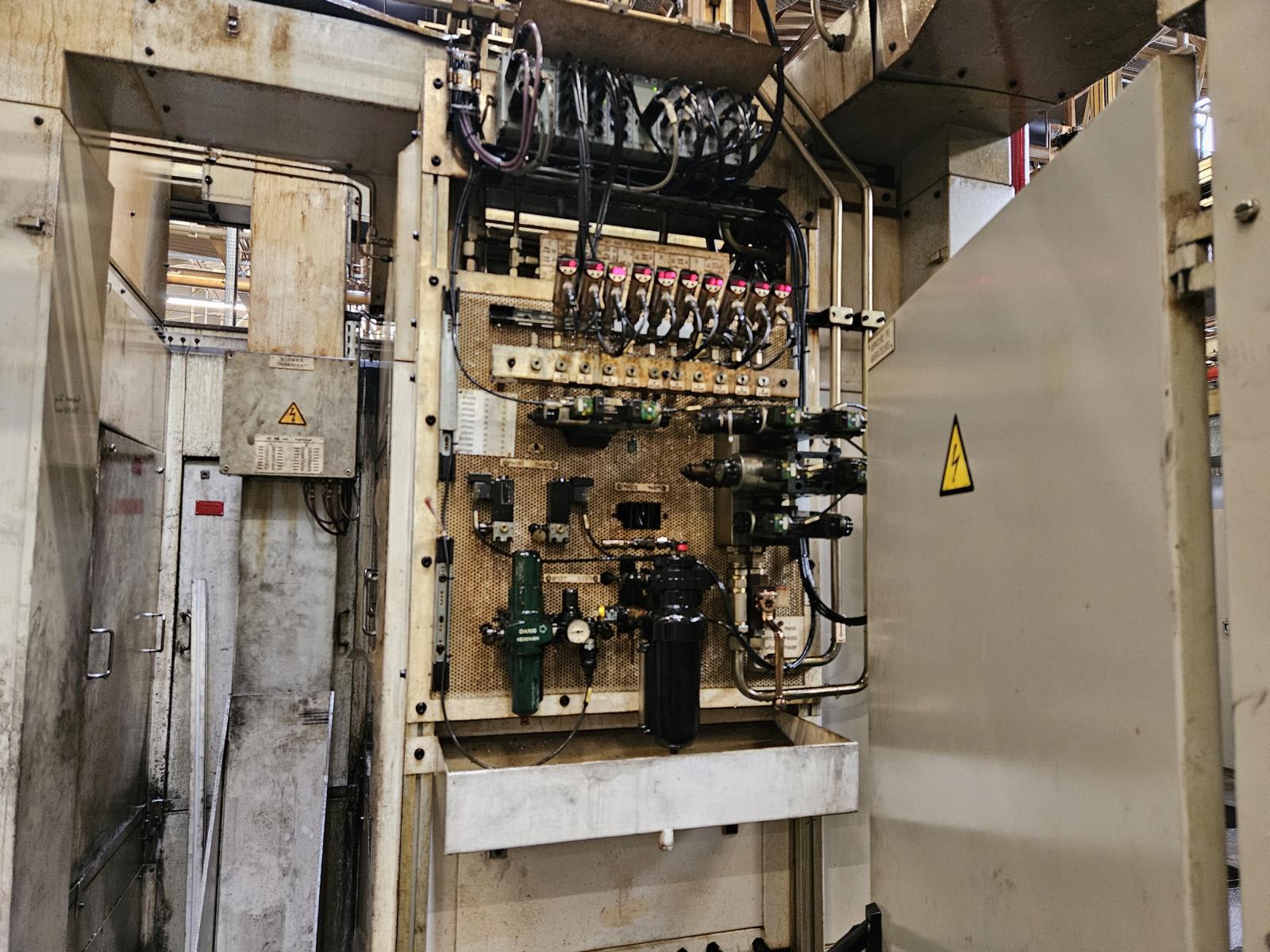

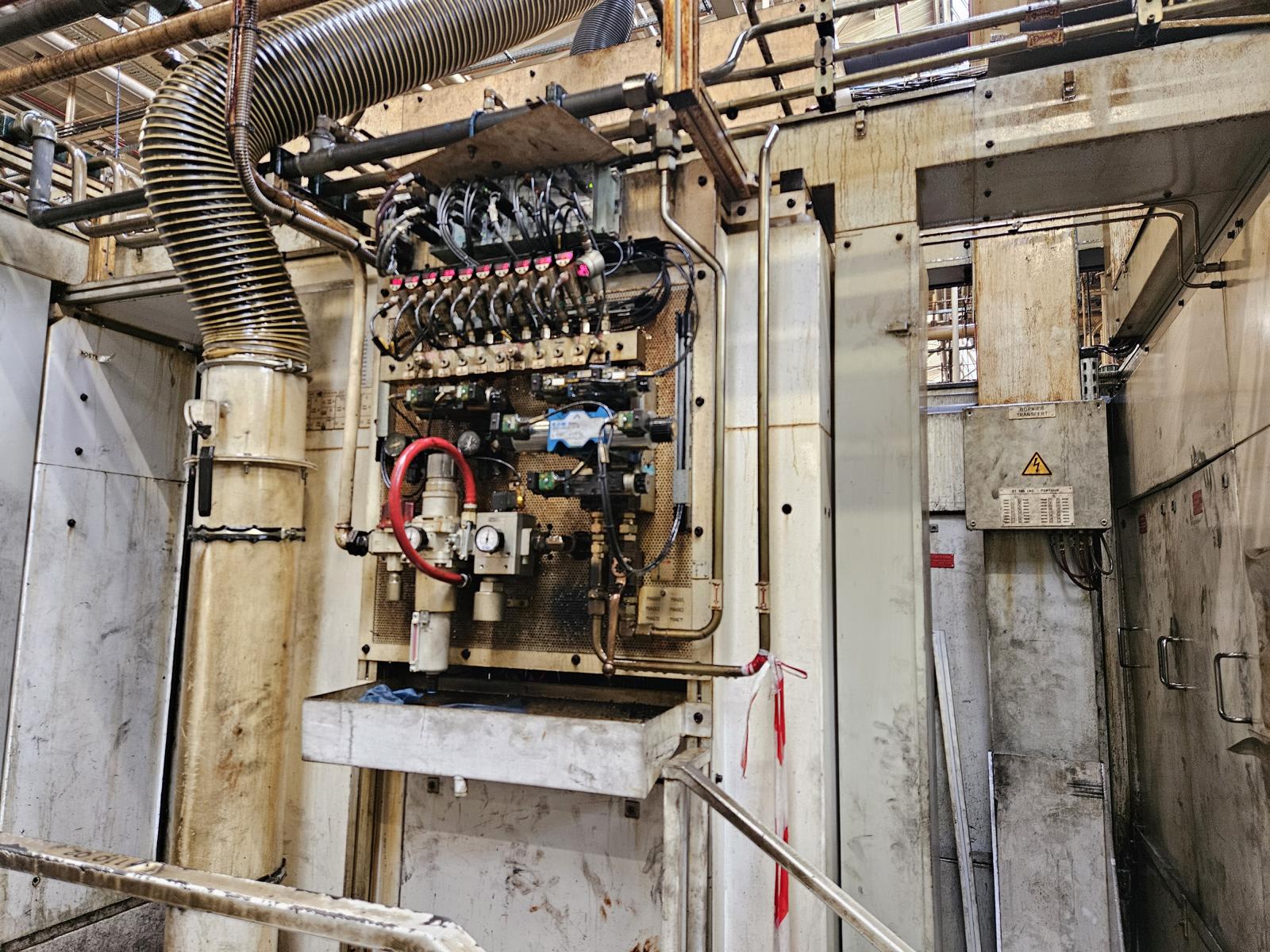

CNC Grinder SCHAUDT CF 41 CBN | 1999

center height 180mm, dia 200 x 600mm, one grinding slide / travel 150mm, CNC SIEMENS SINUMERIK 840D, LxWxH, ca. 3 x 2 x 2m, weight, ca. 6,5to - LISTING 2830027

![Français]()

CNC Grinder SCHAUDT CF 41 CBN 600 D | 2000

center height 180mm, dia 200 x 600mm, one grinding slide / travel 150mm, CNC SIEMENS SINUMERIK 840D, LxWxH, ca. 3 x 2 x 2m, weight, ca. 6,5to - LISTING 2830028

![Français]()

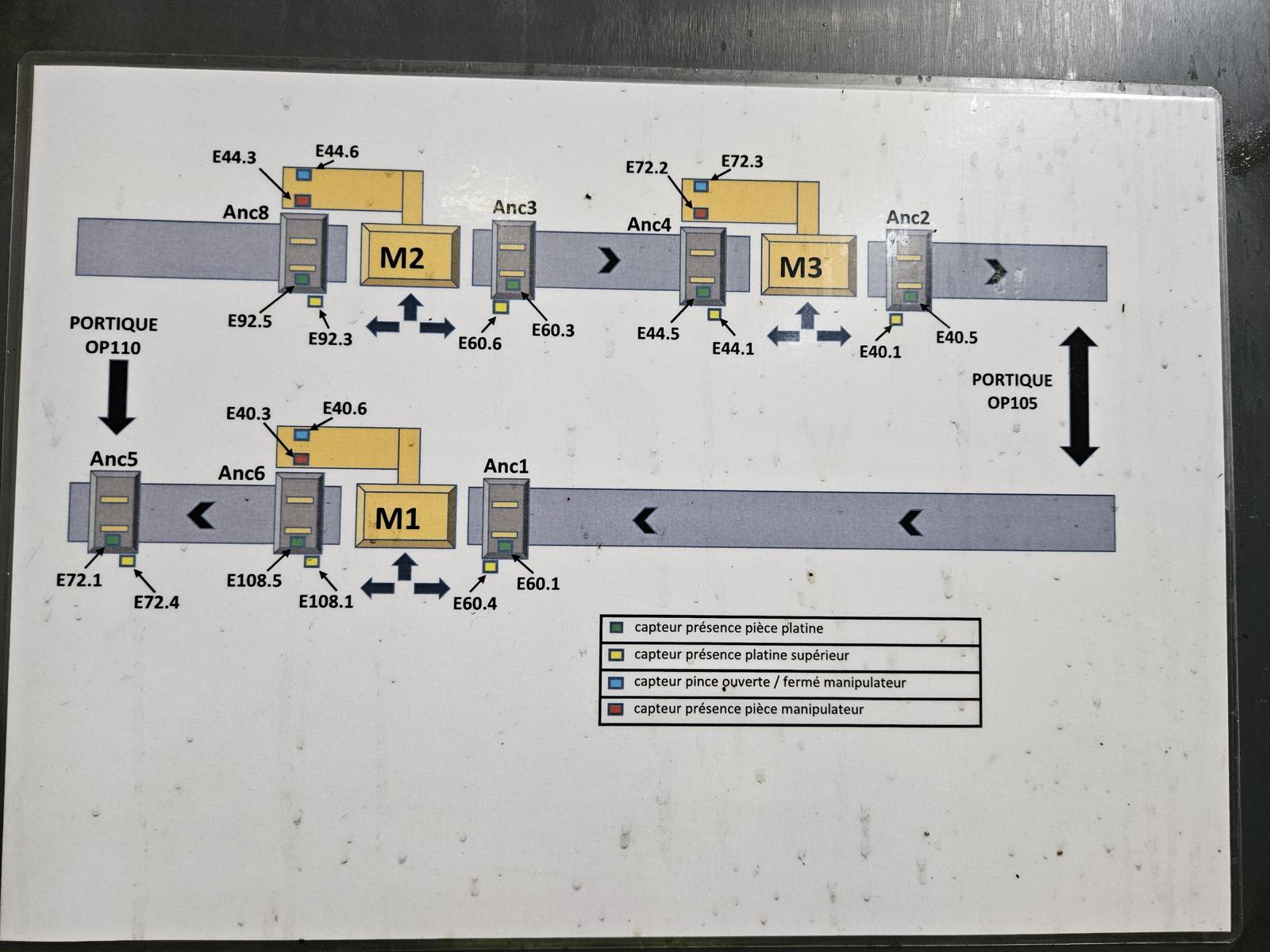

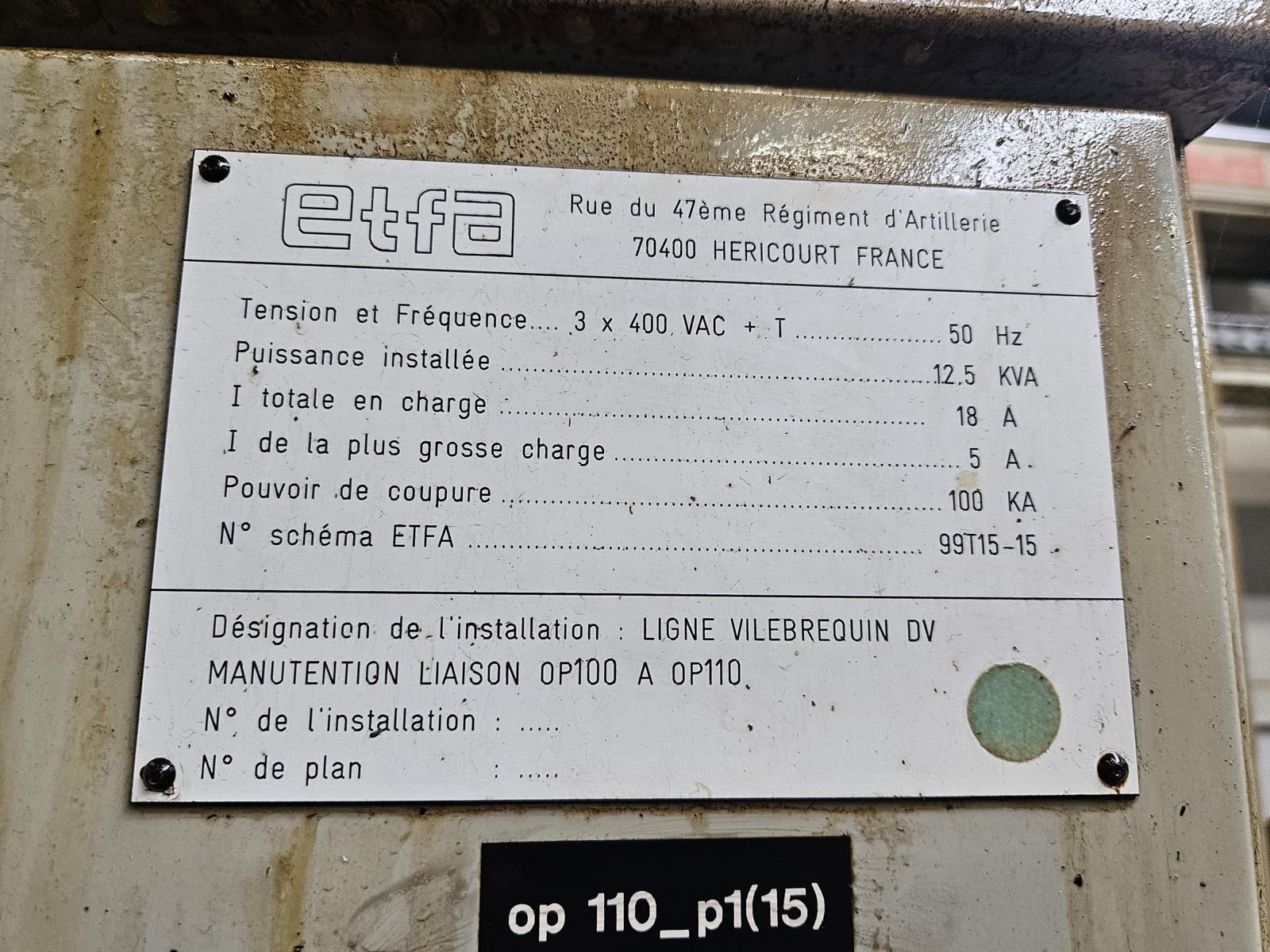

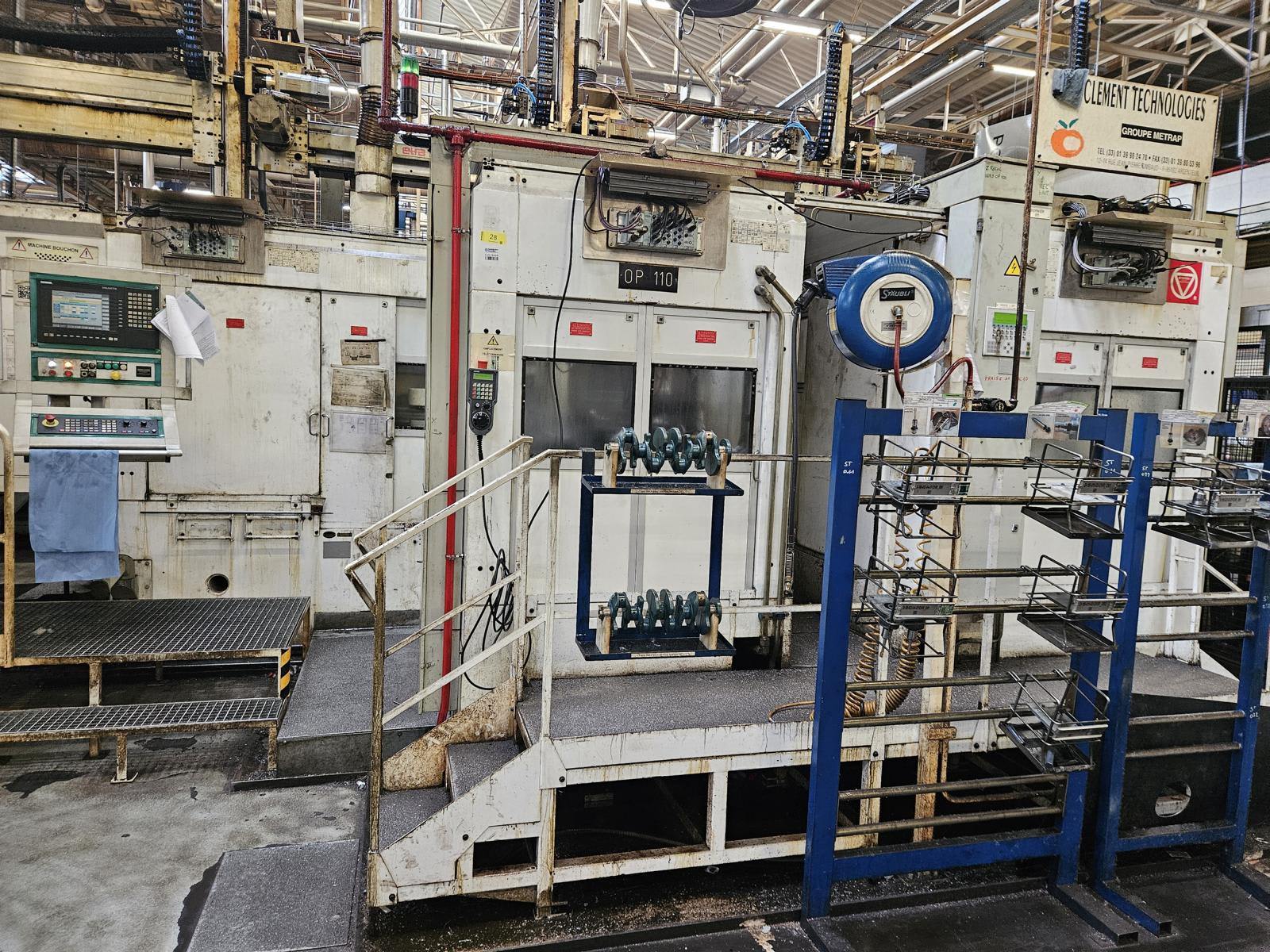

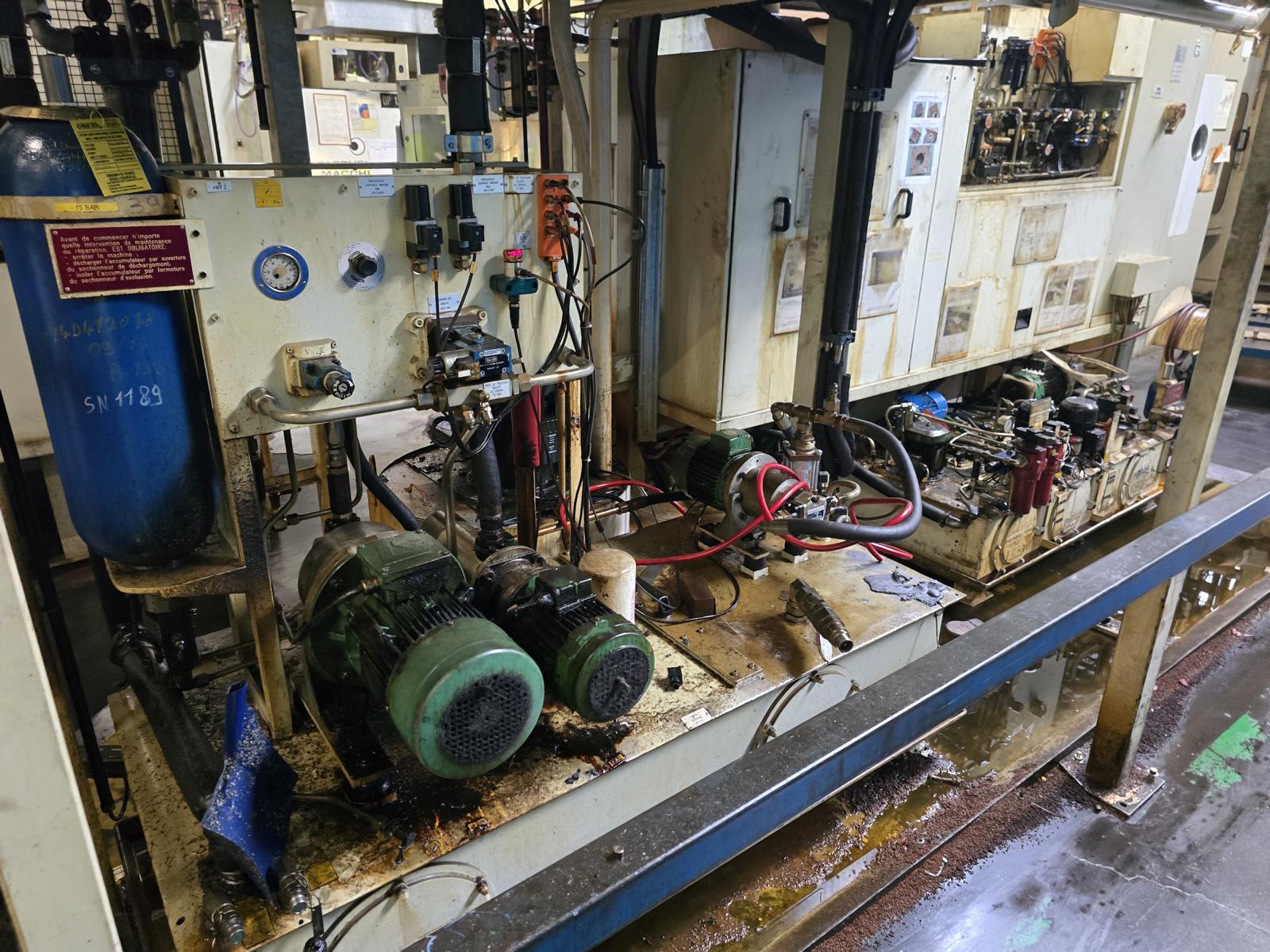

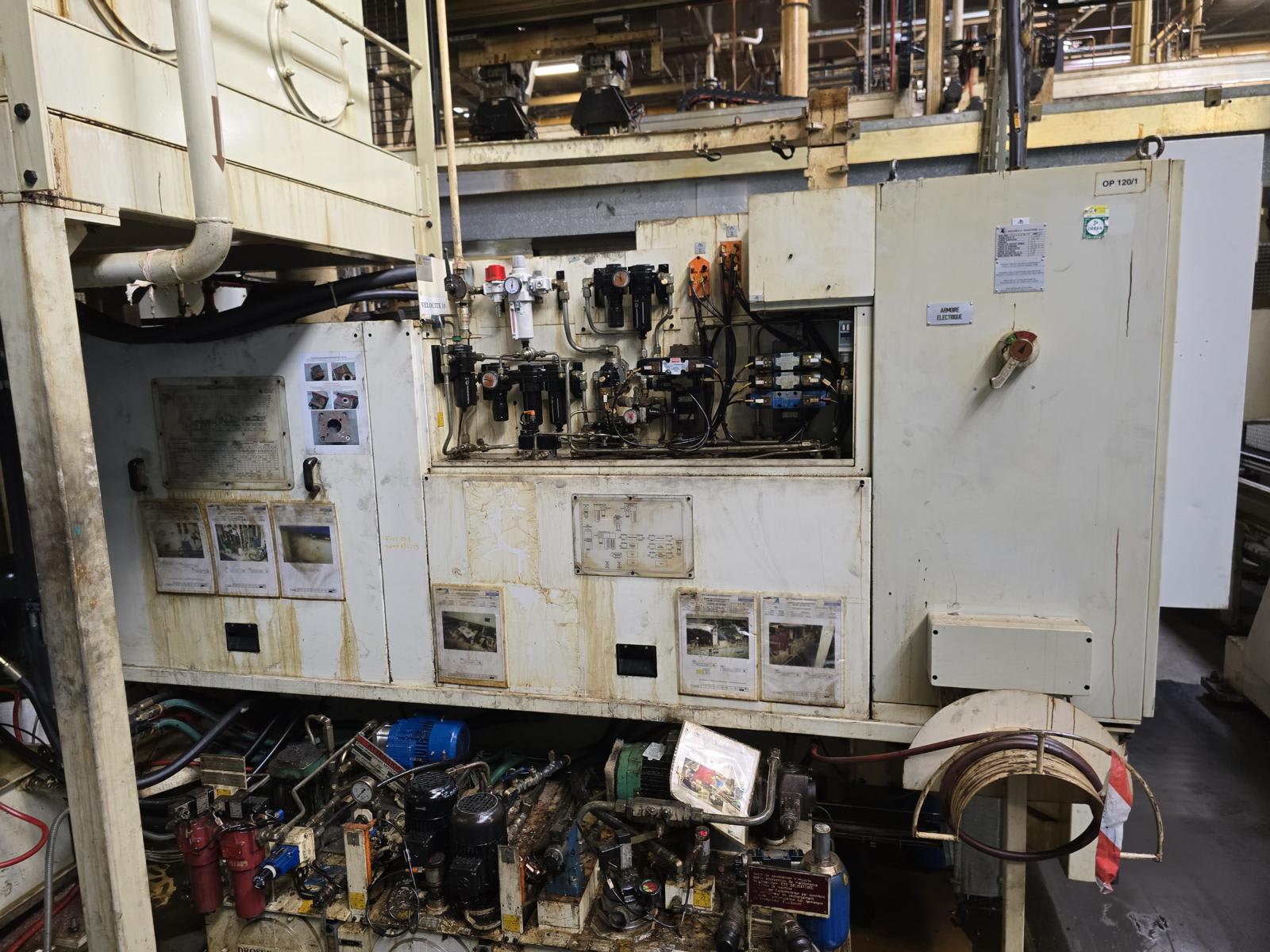

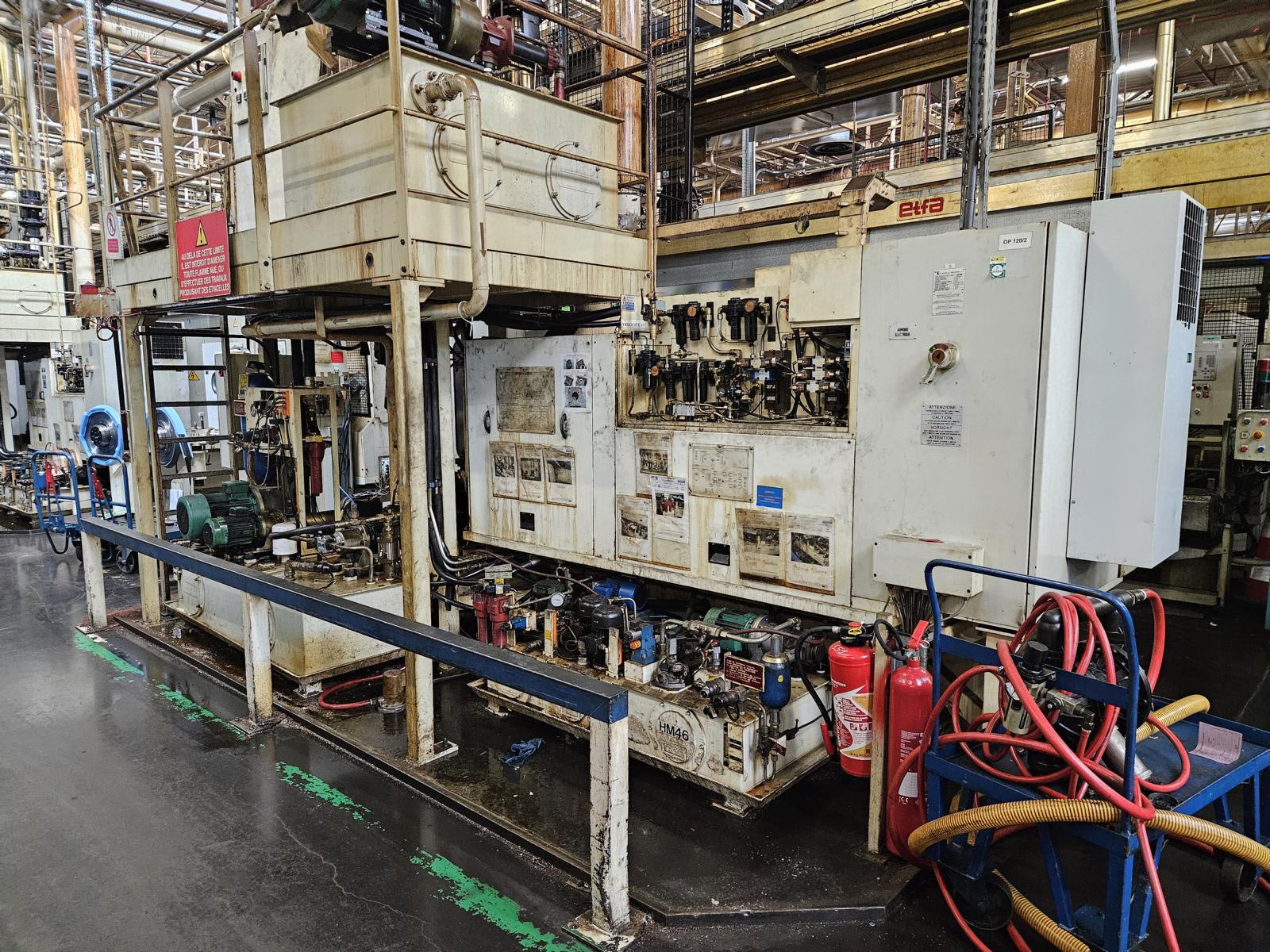

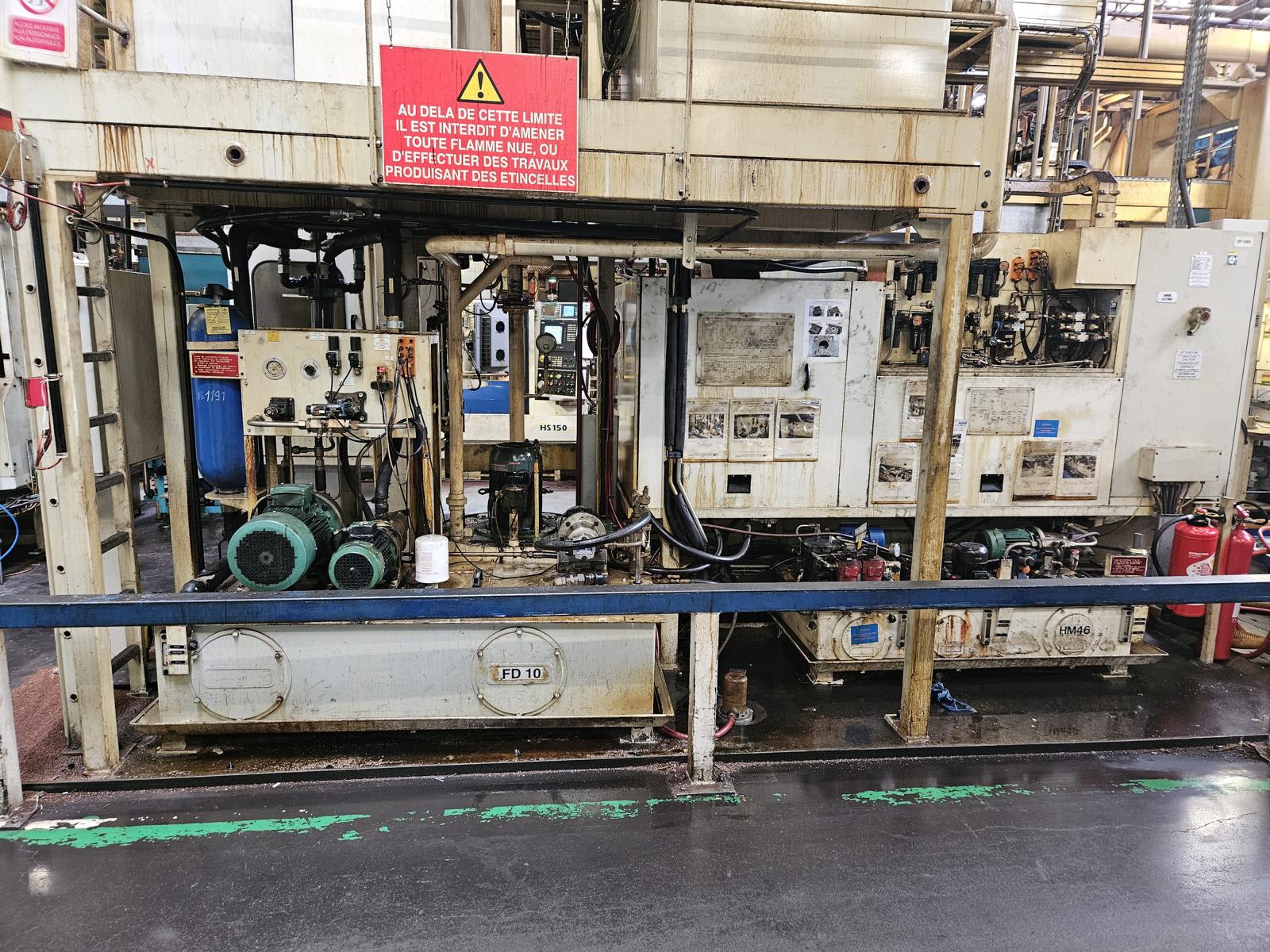

Rene Clement | 2000

crankshaft machining unit, 400V 50Hz 12,5kVA 18A, CNC SIEMENS SINUMERIK 840D - LISTING 2830029

![Français]()

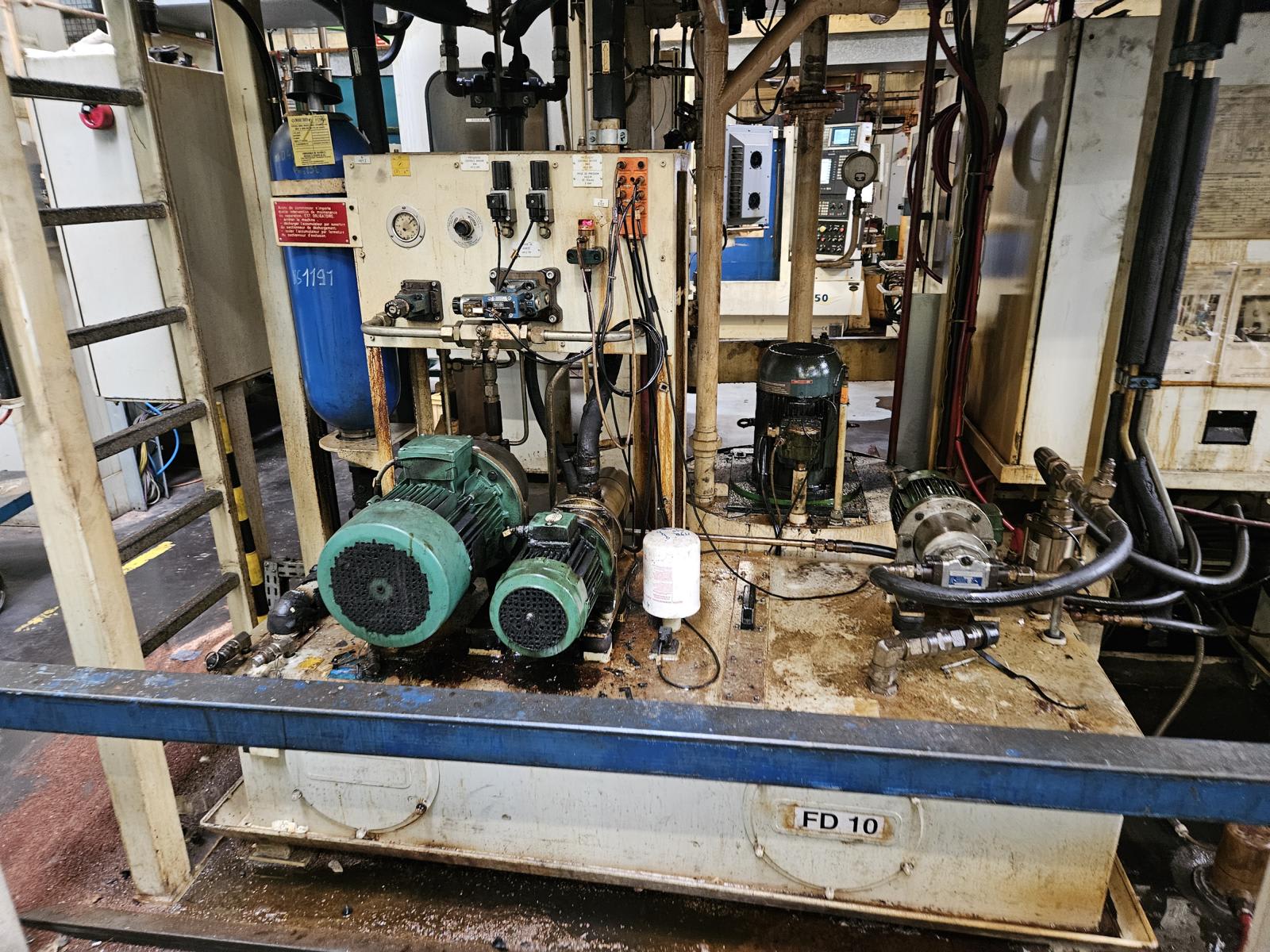

- LISTING 2830030

![Français]()

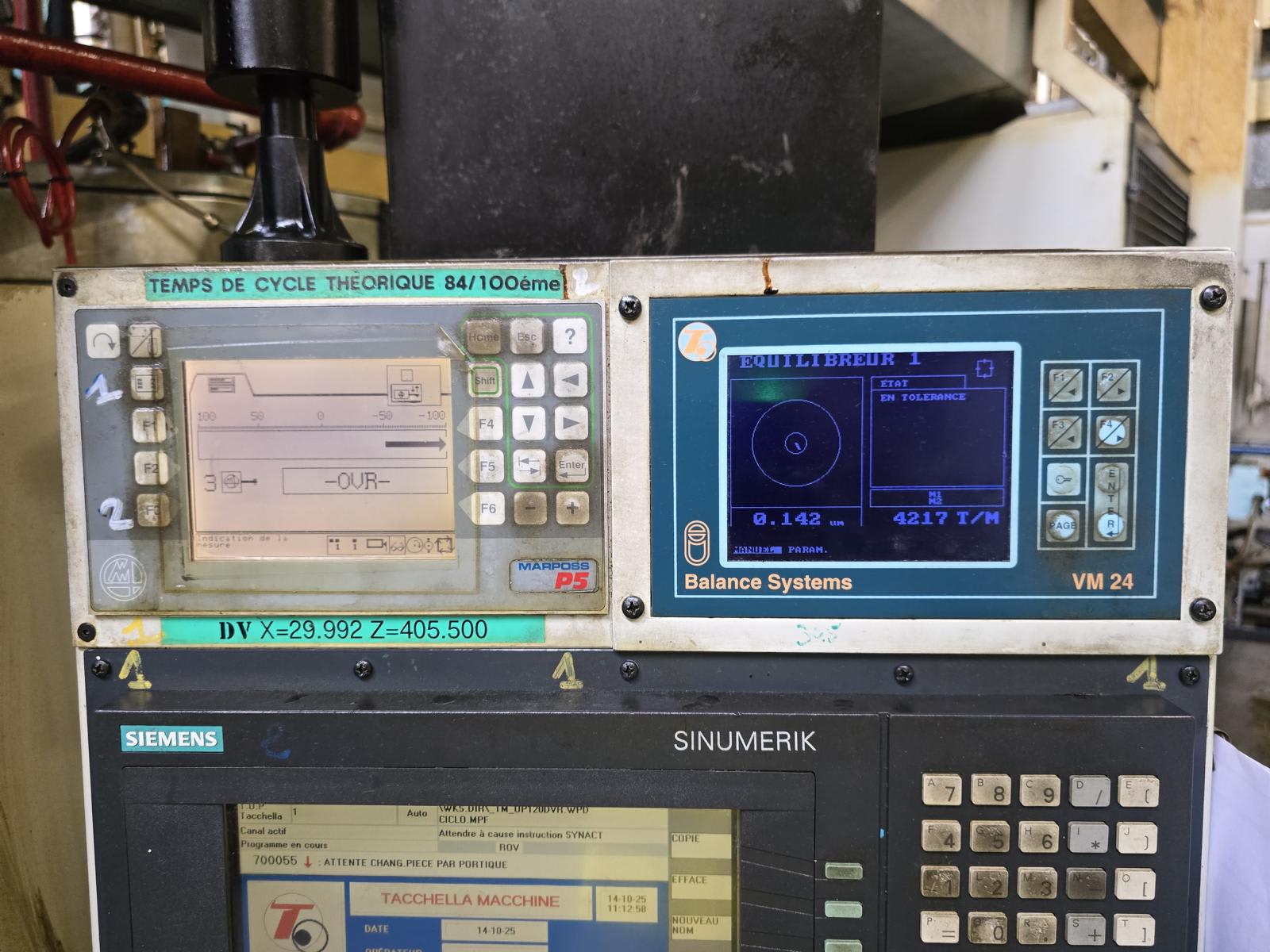

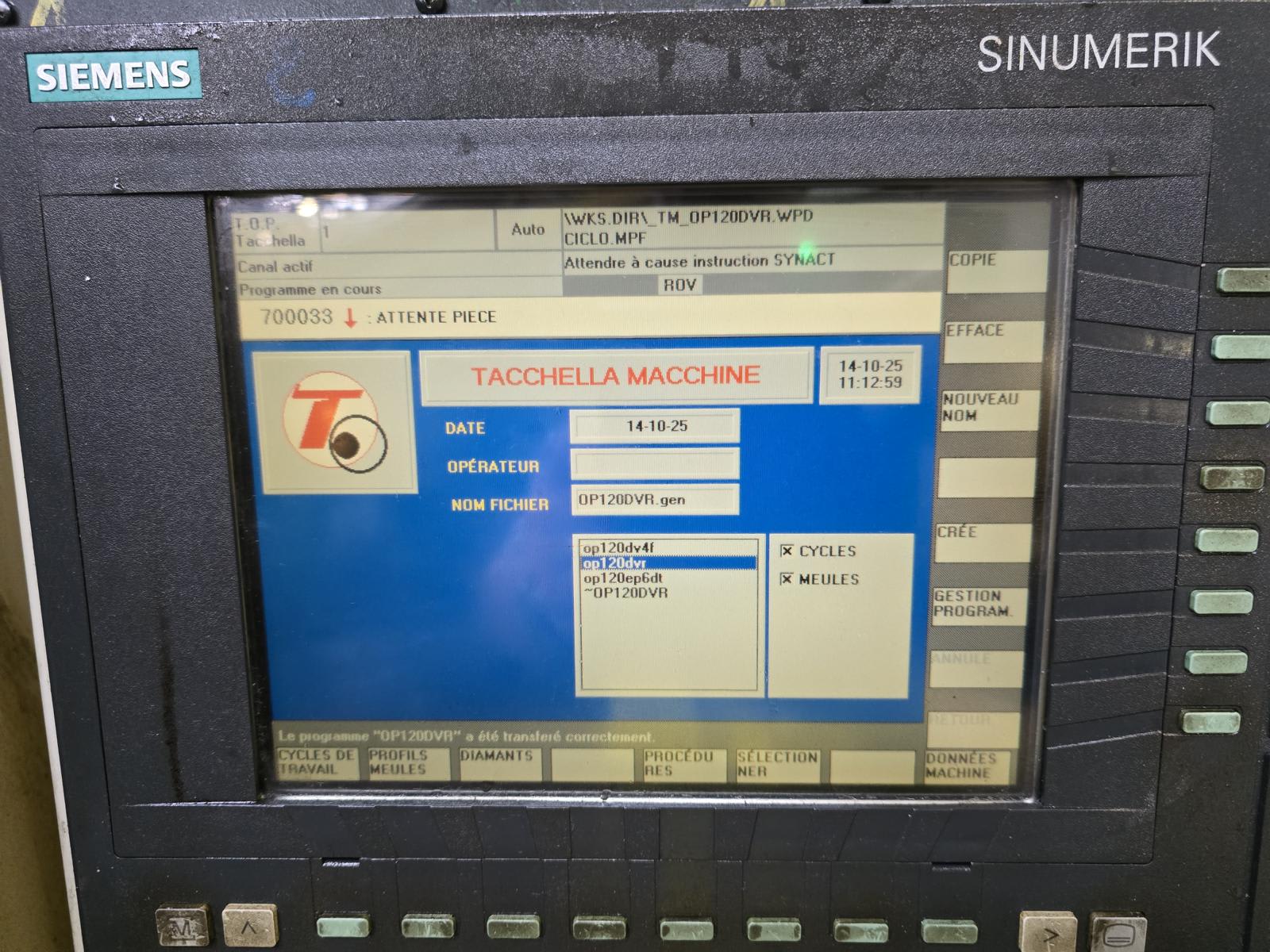

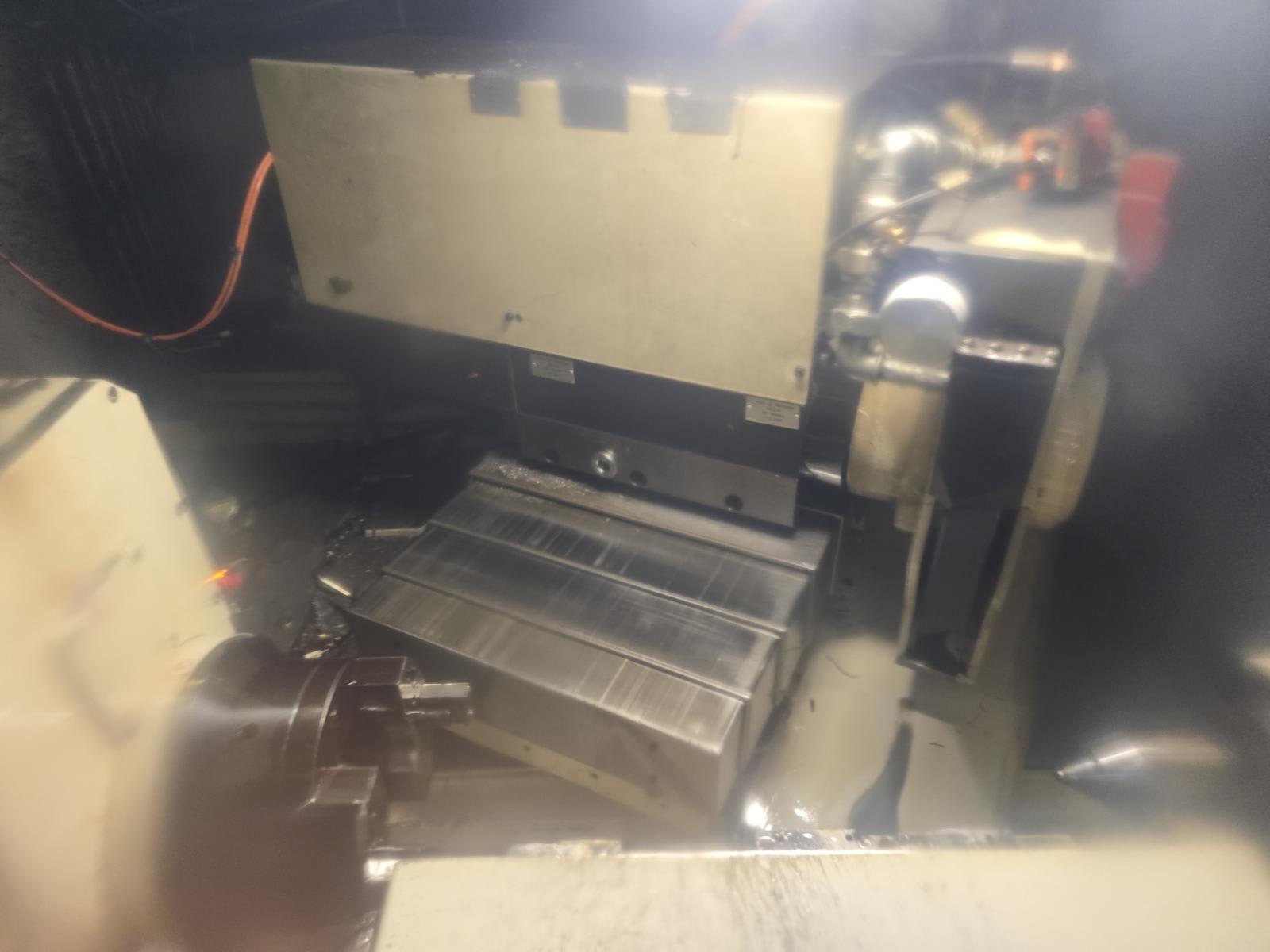

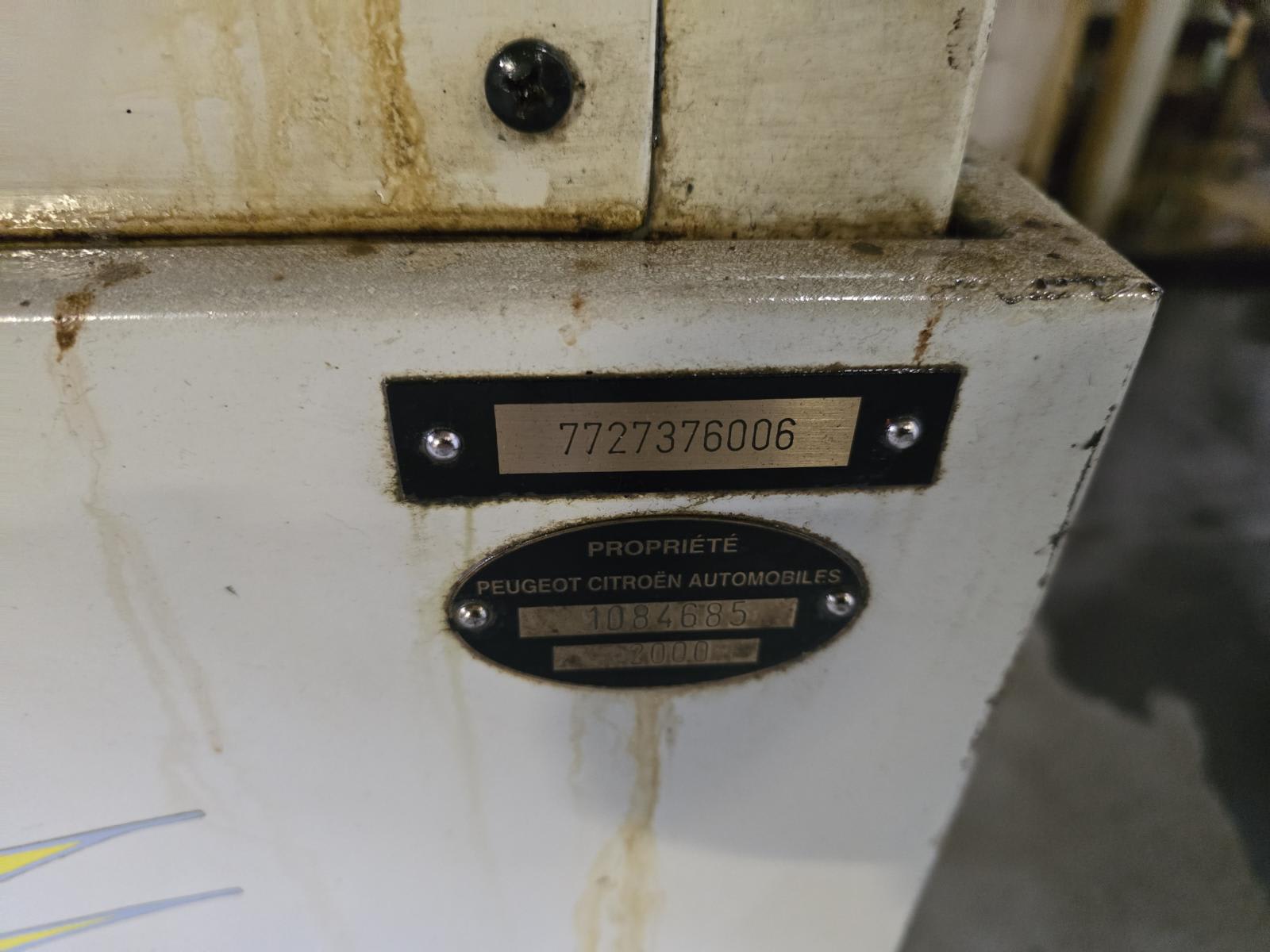

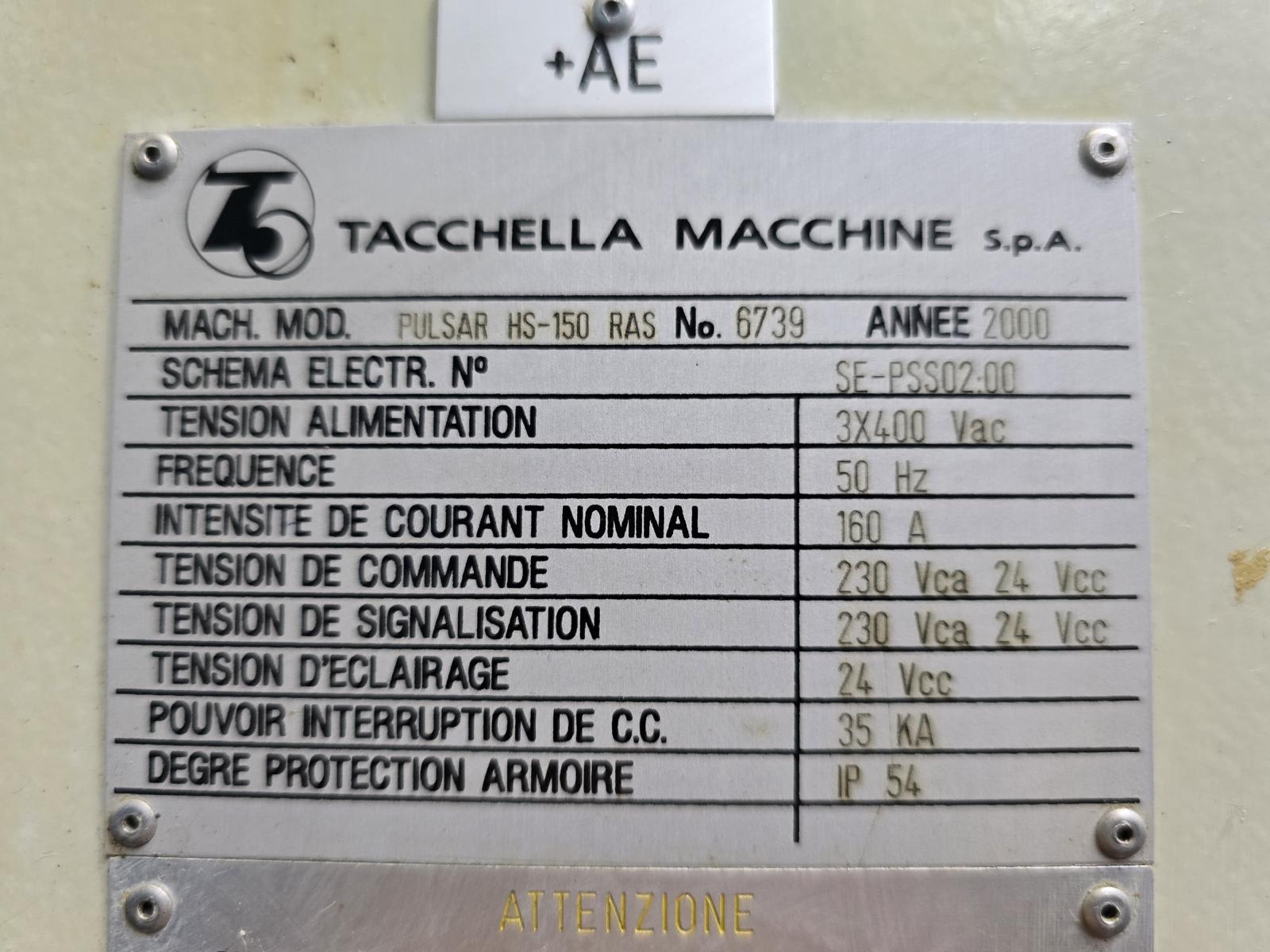

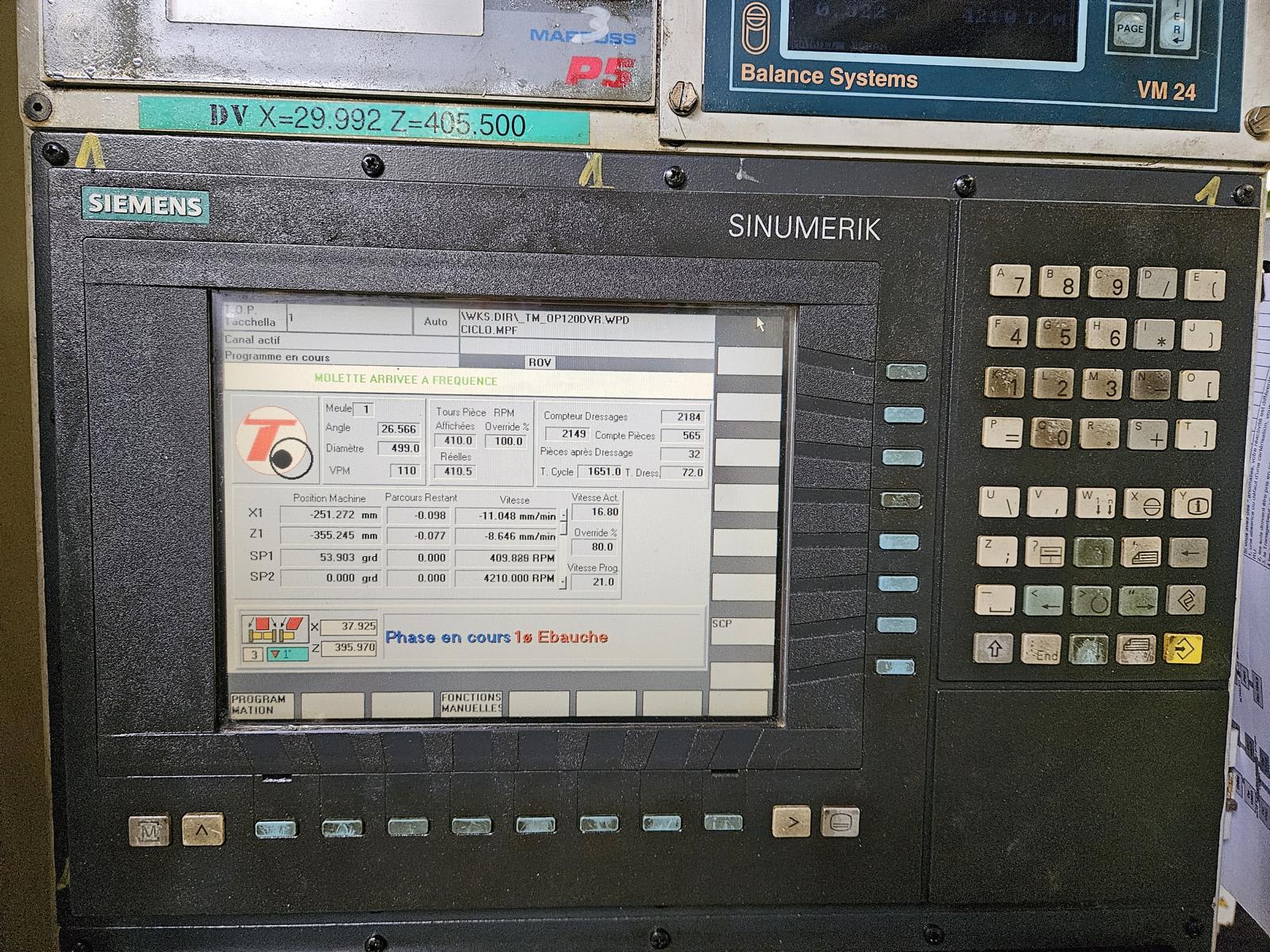

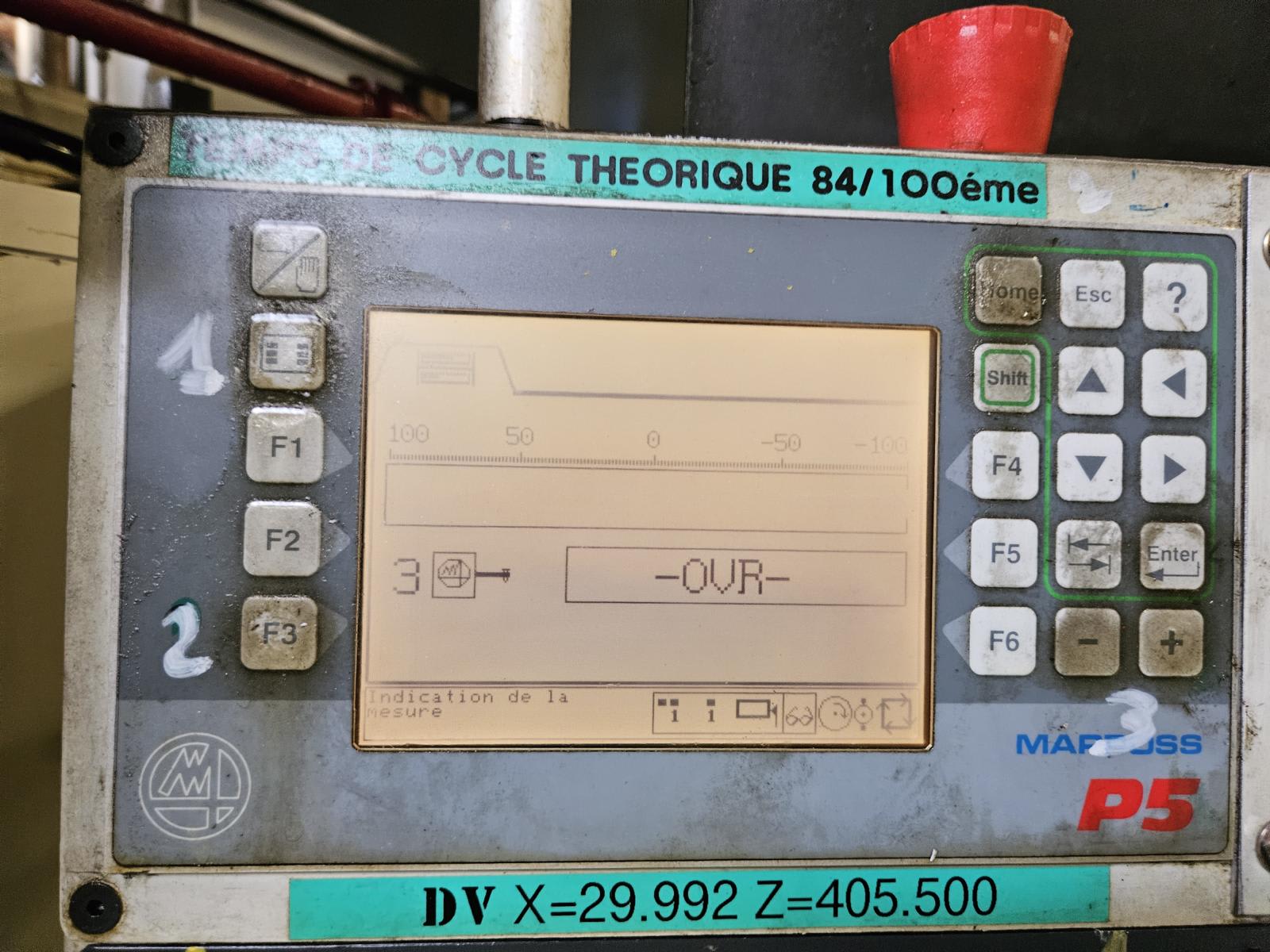

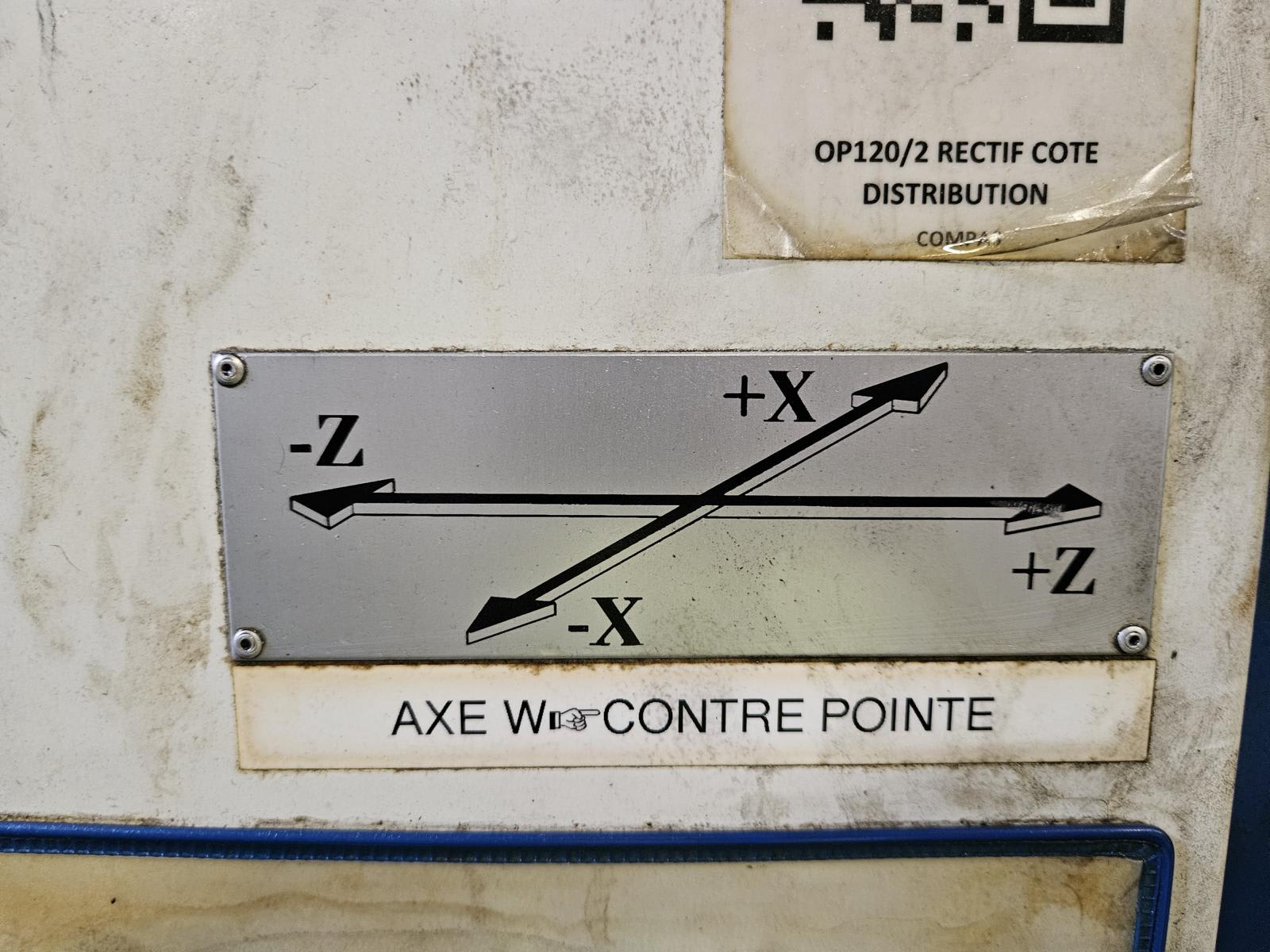

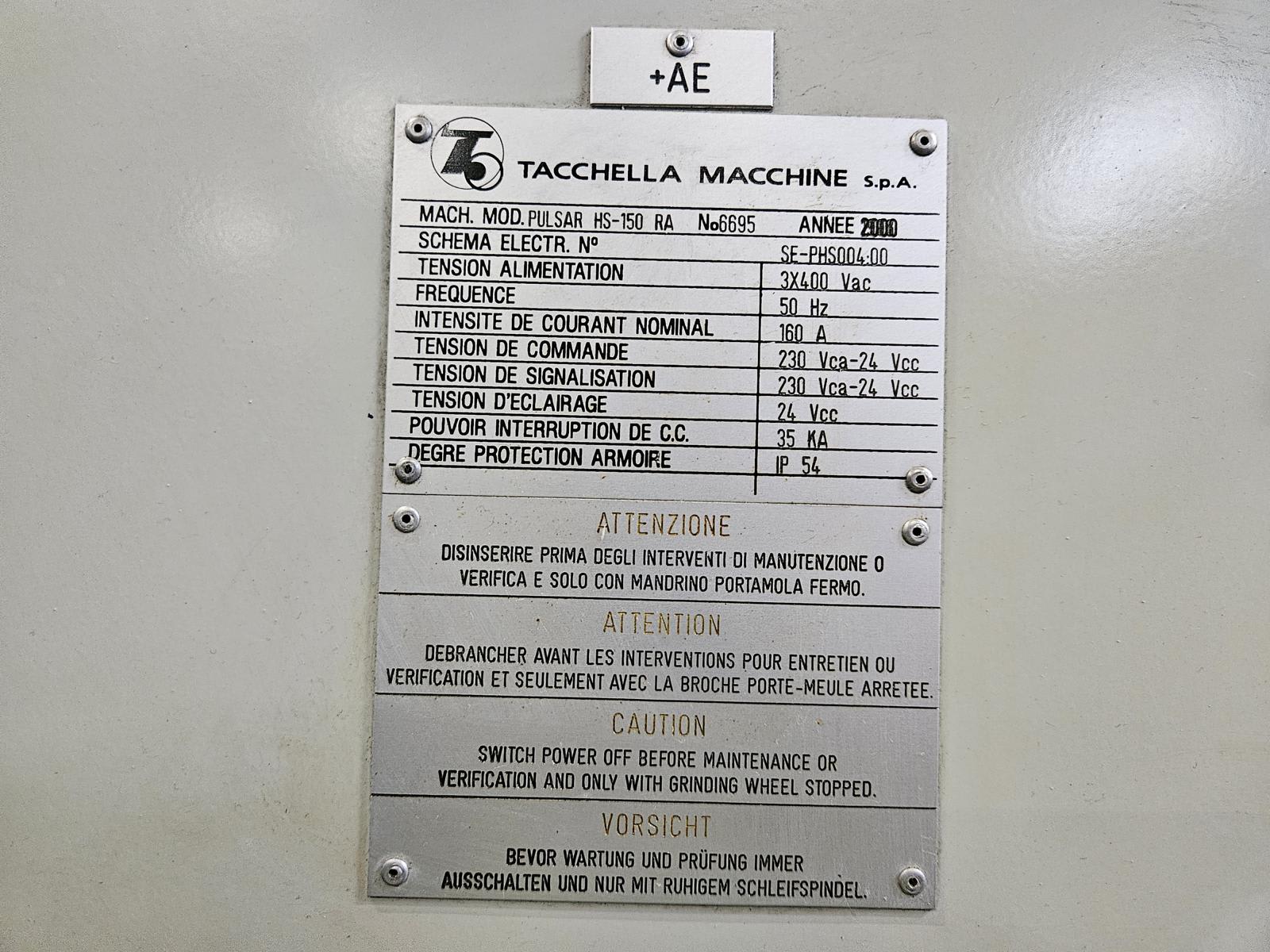

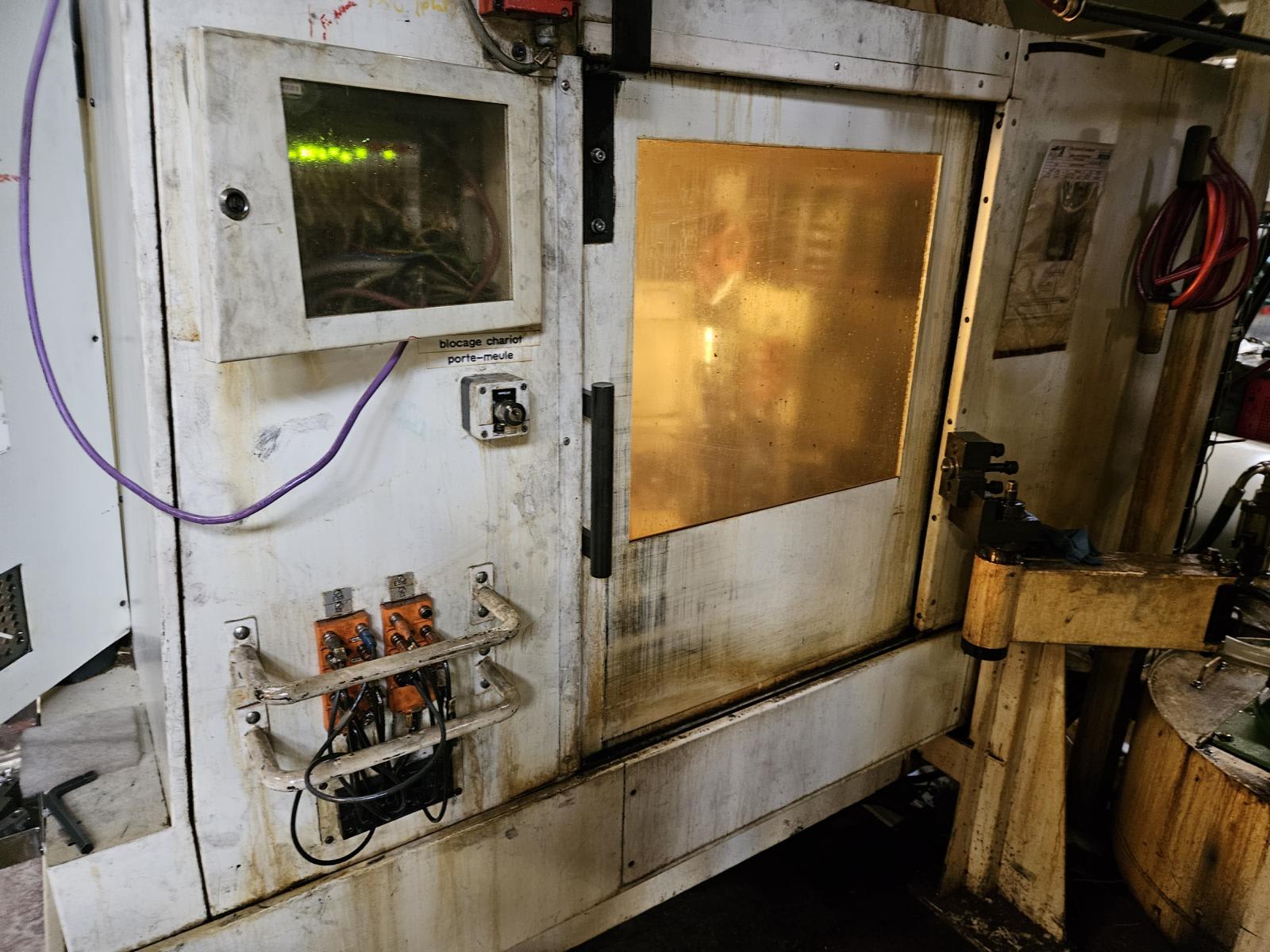

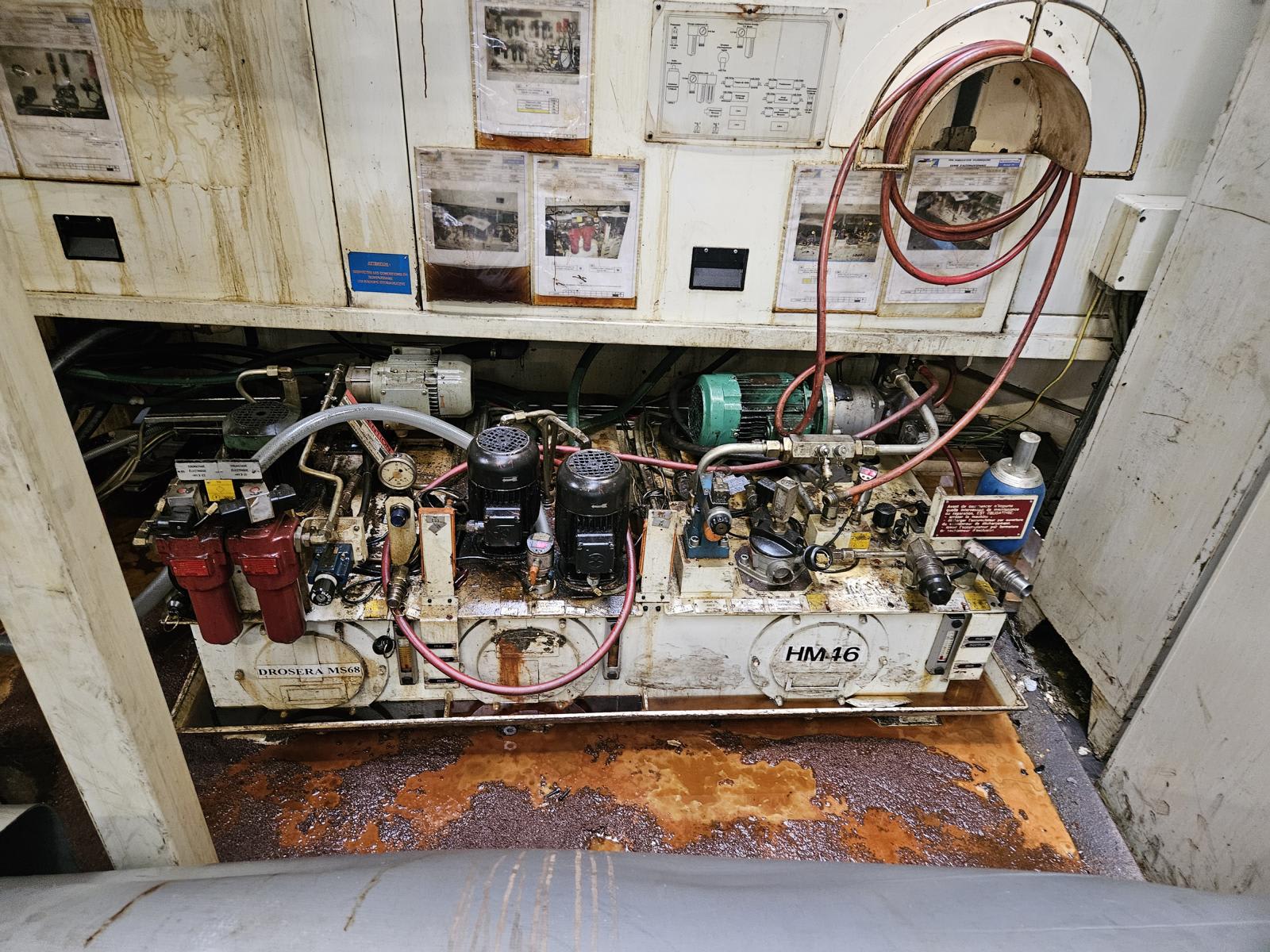

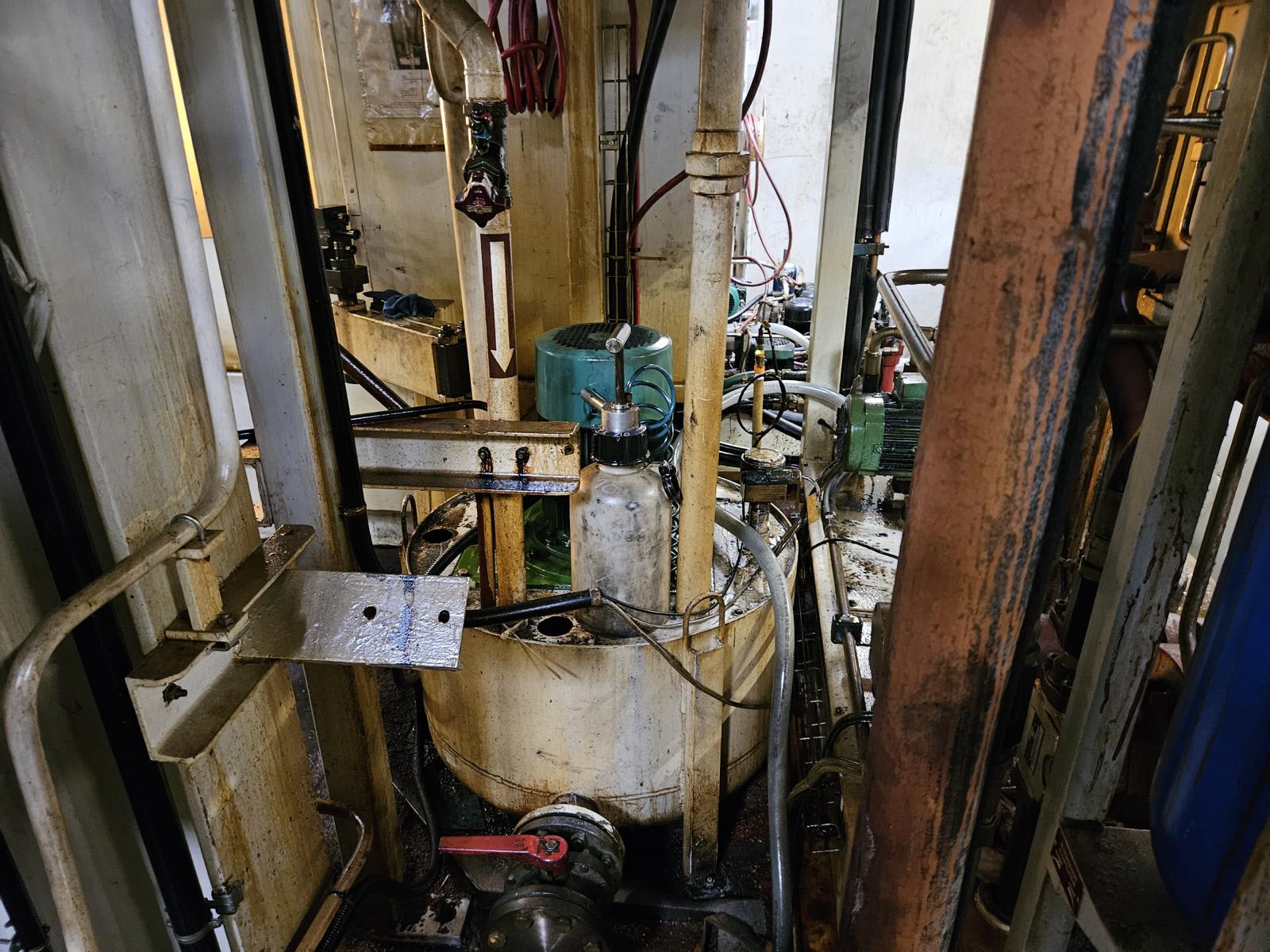

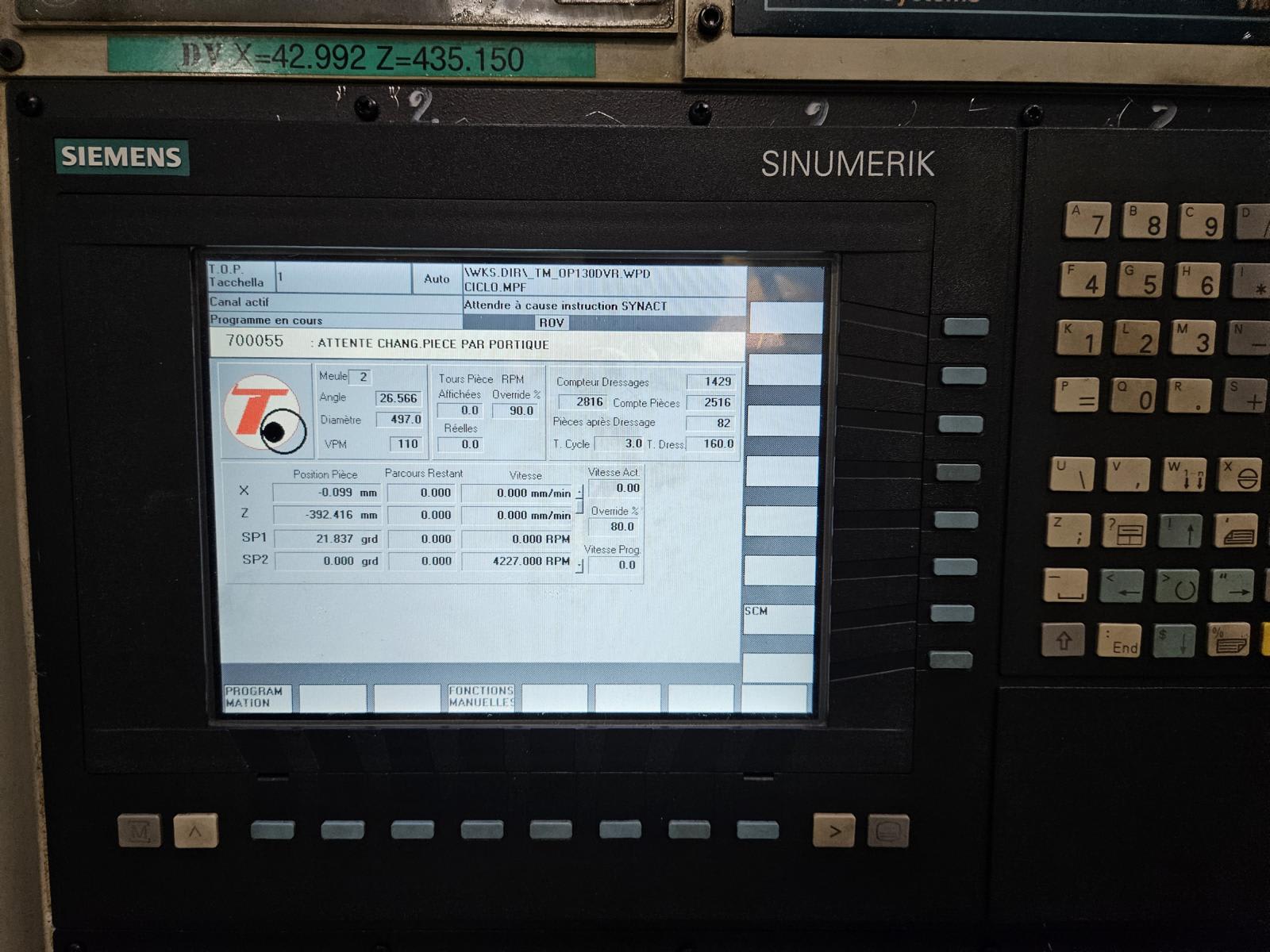

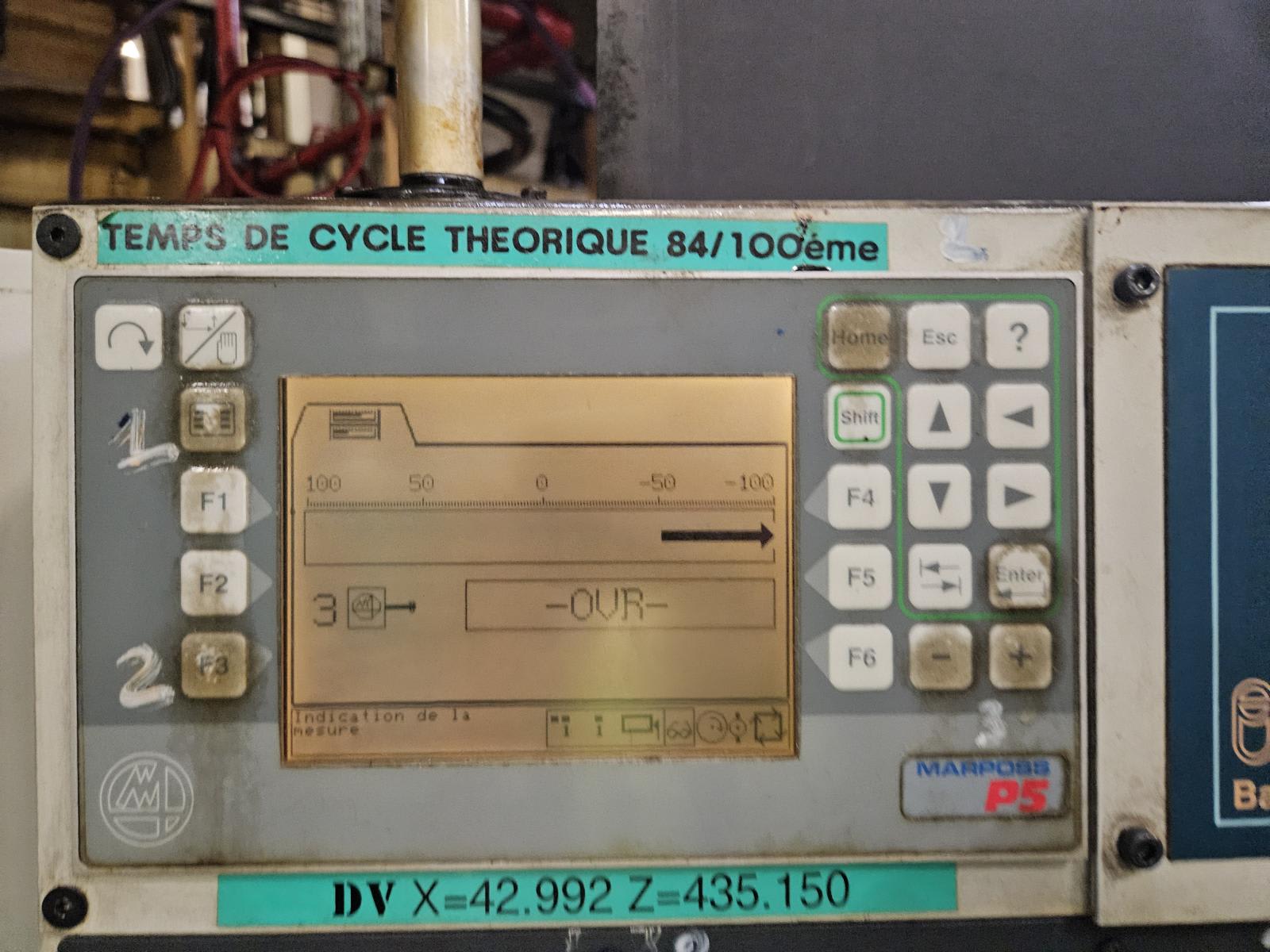

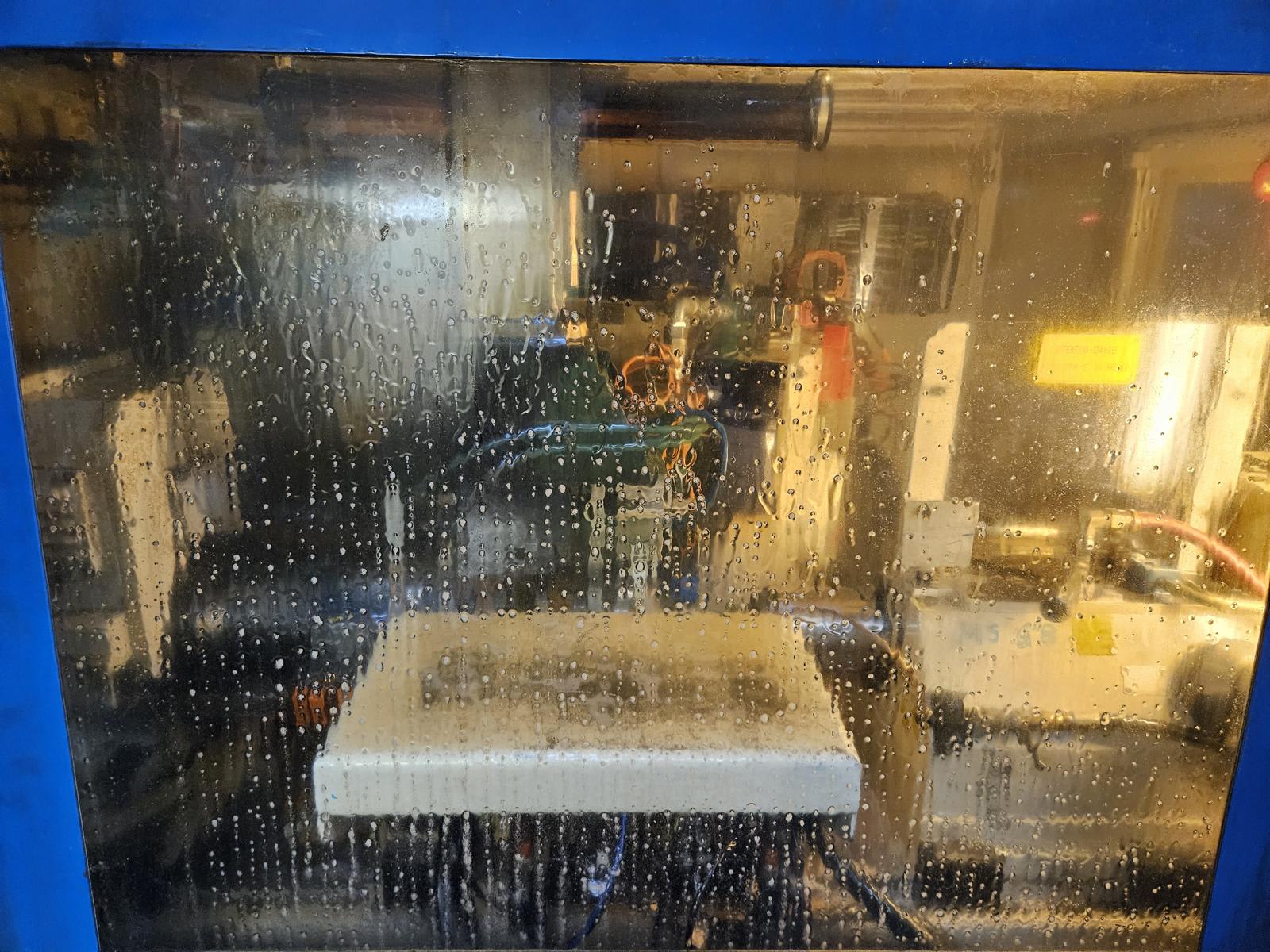

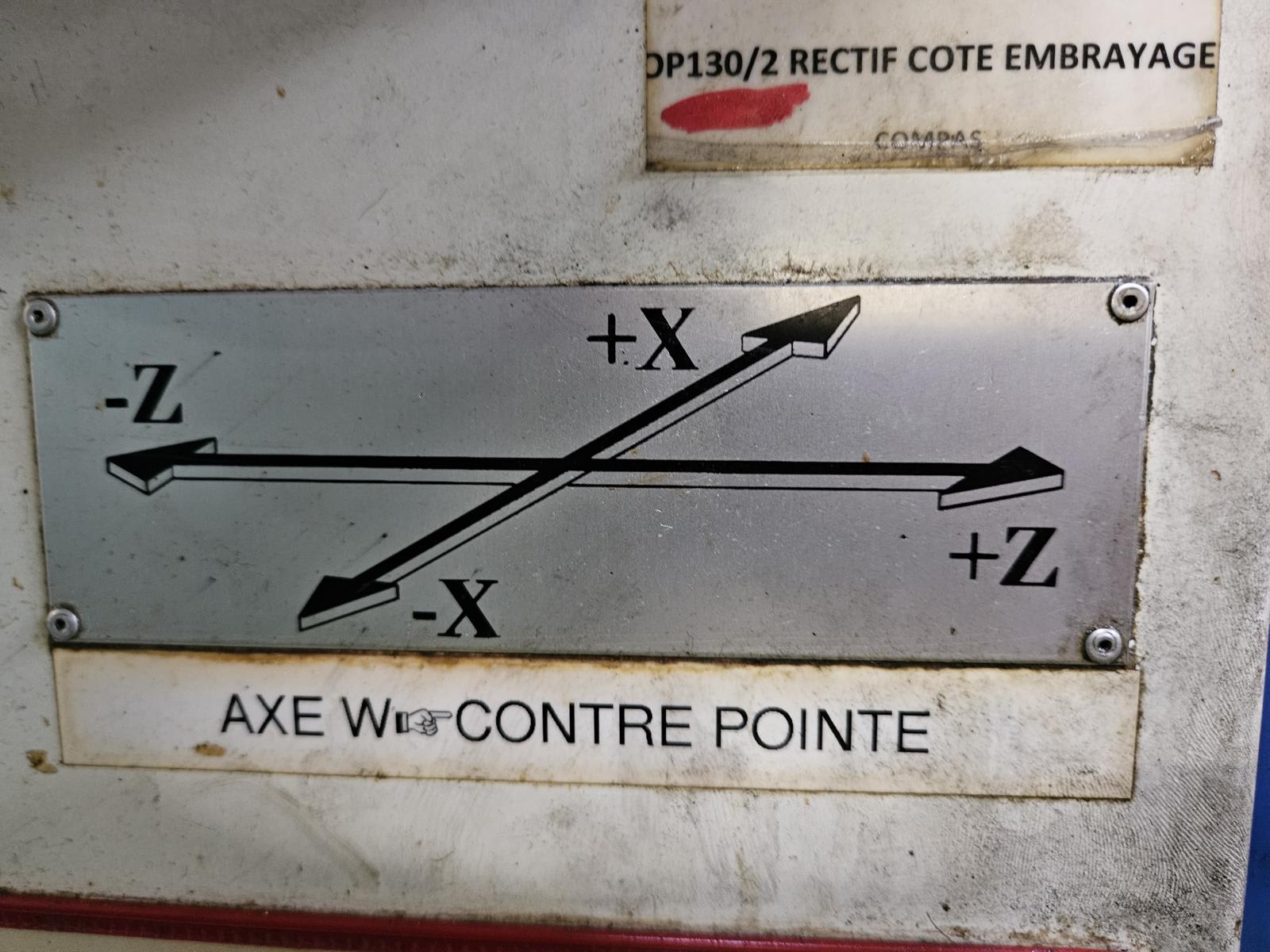

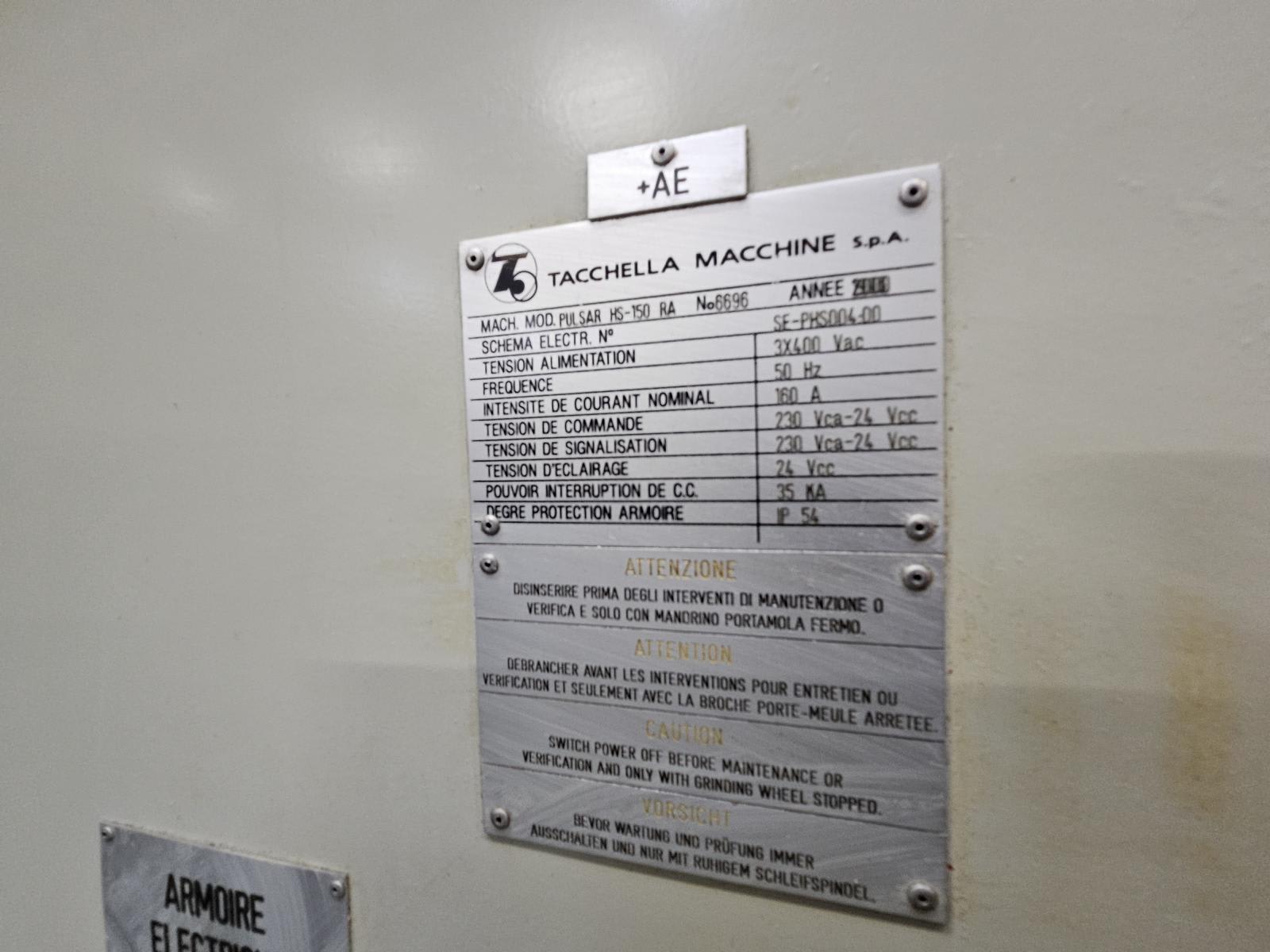

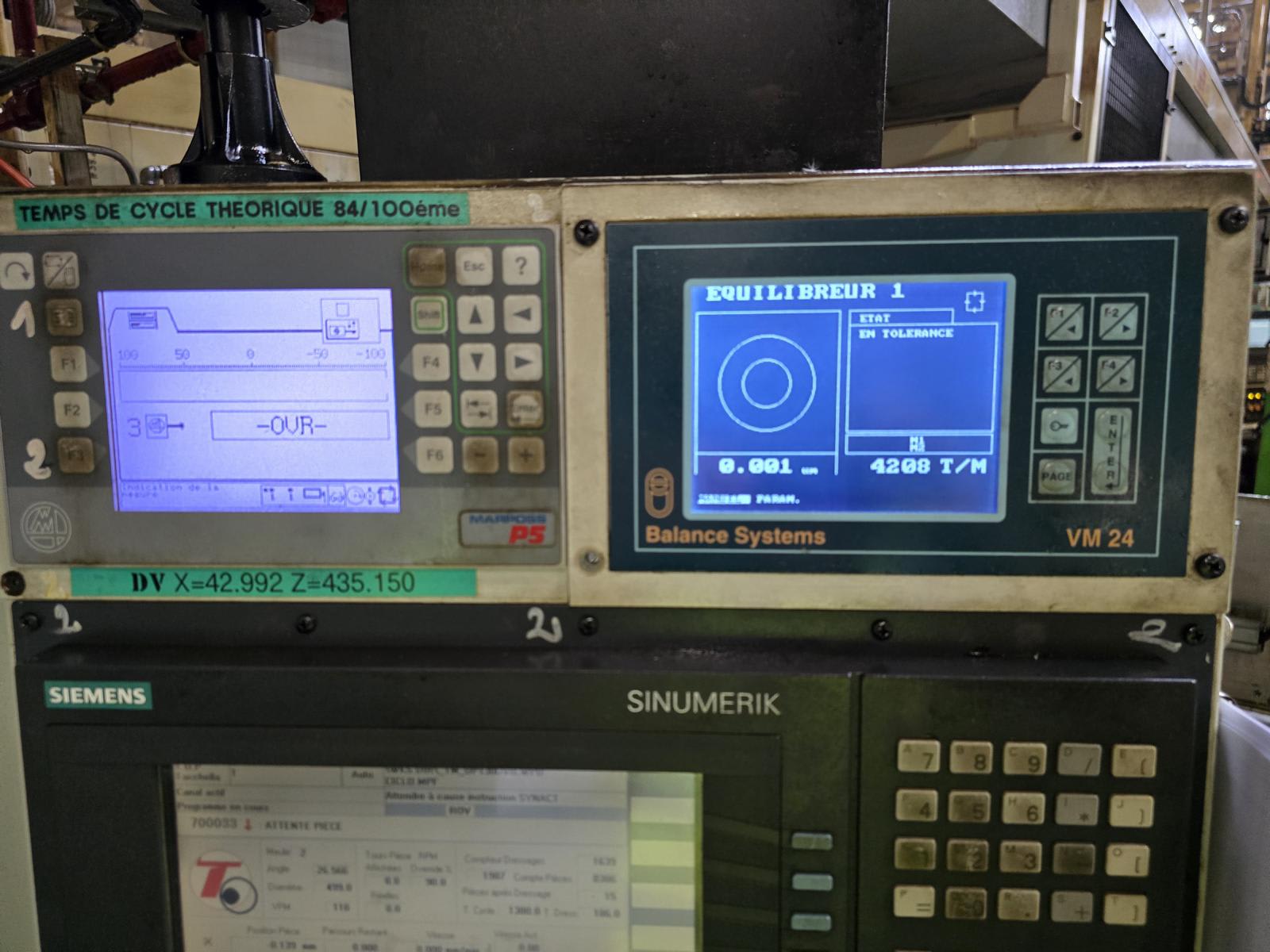

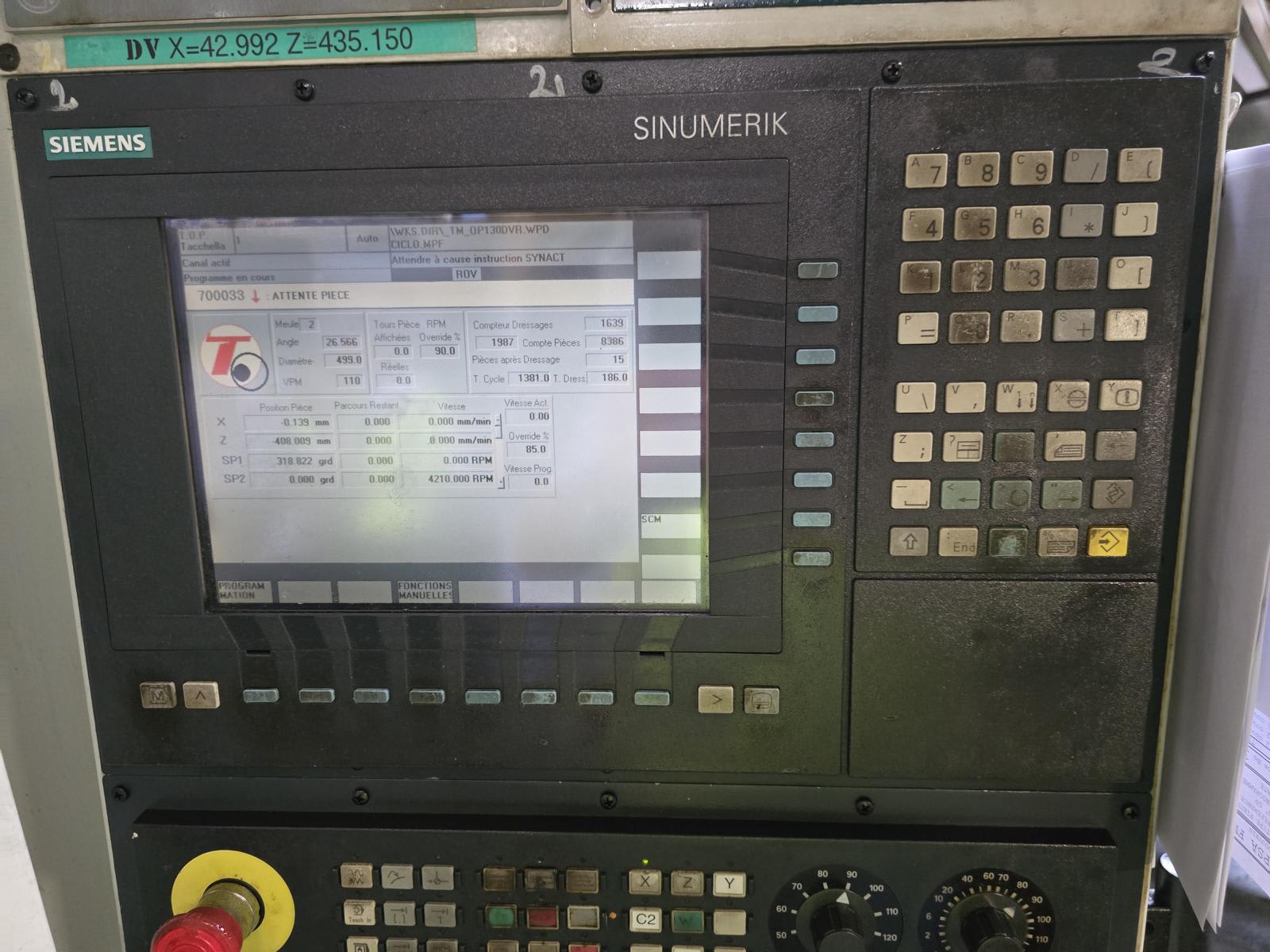

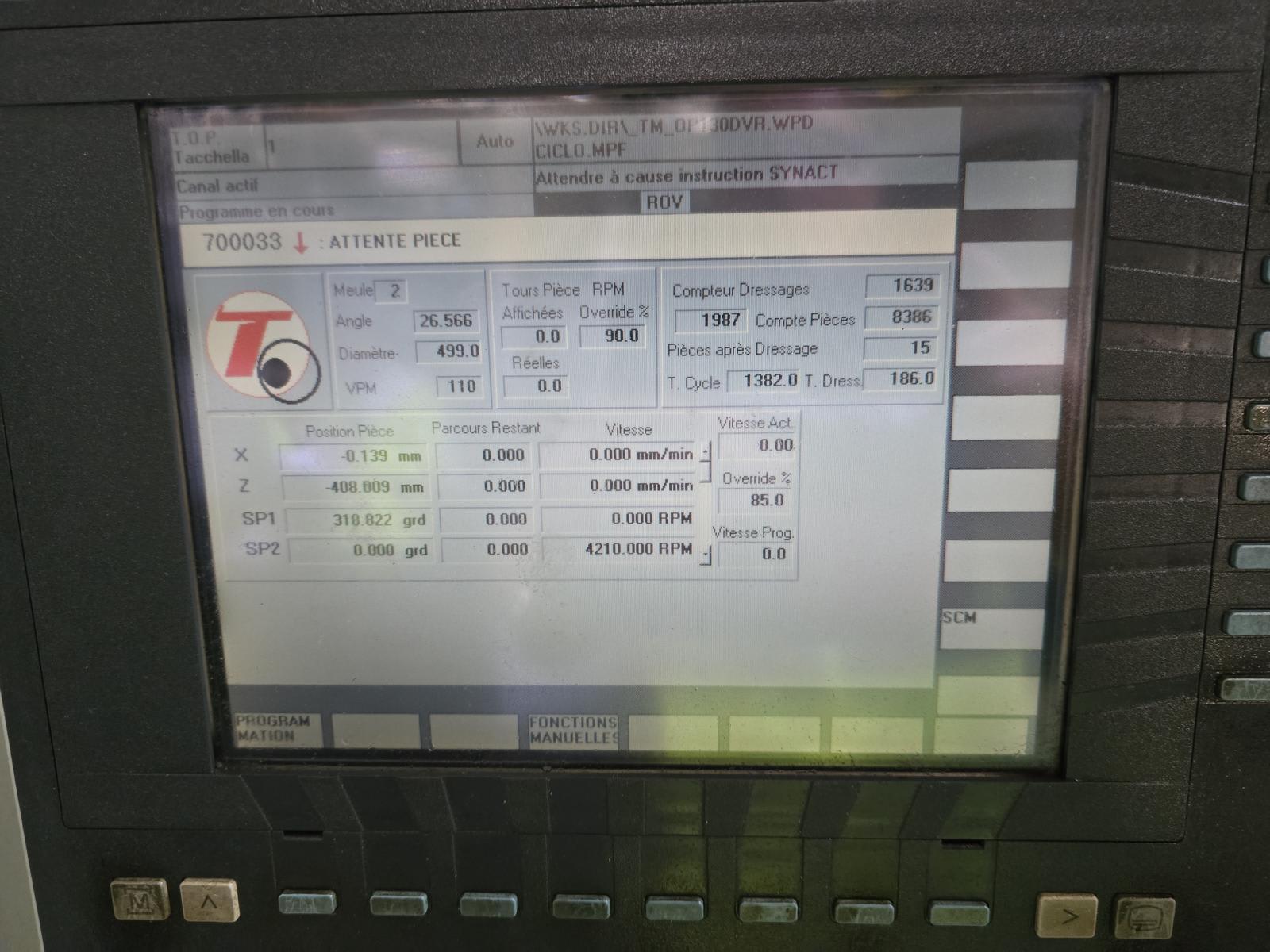

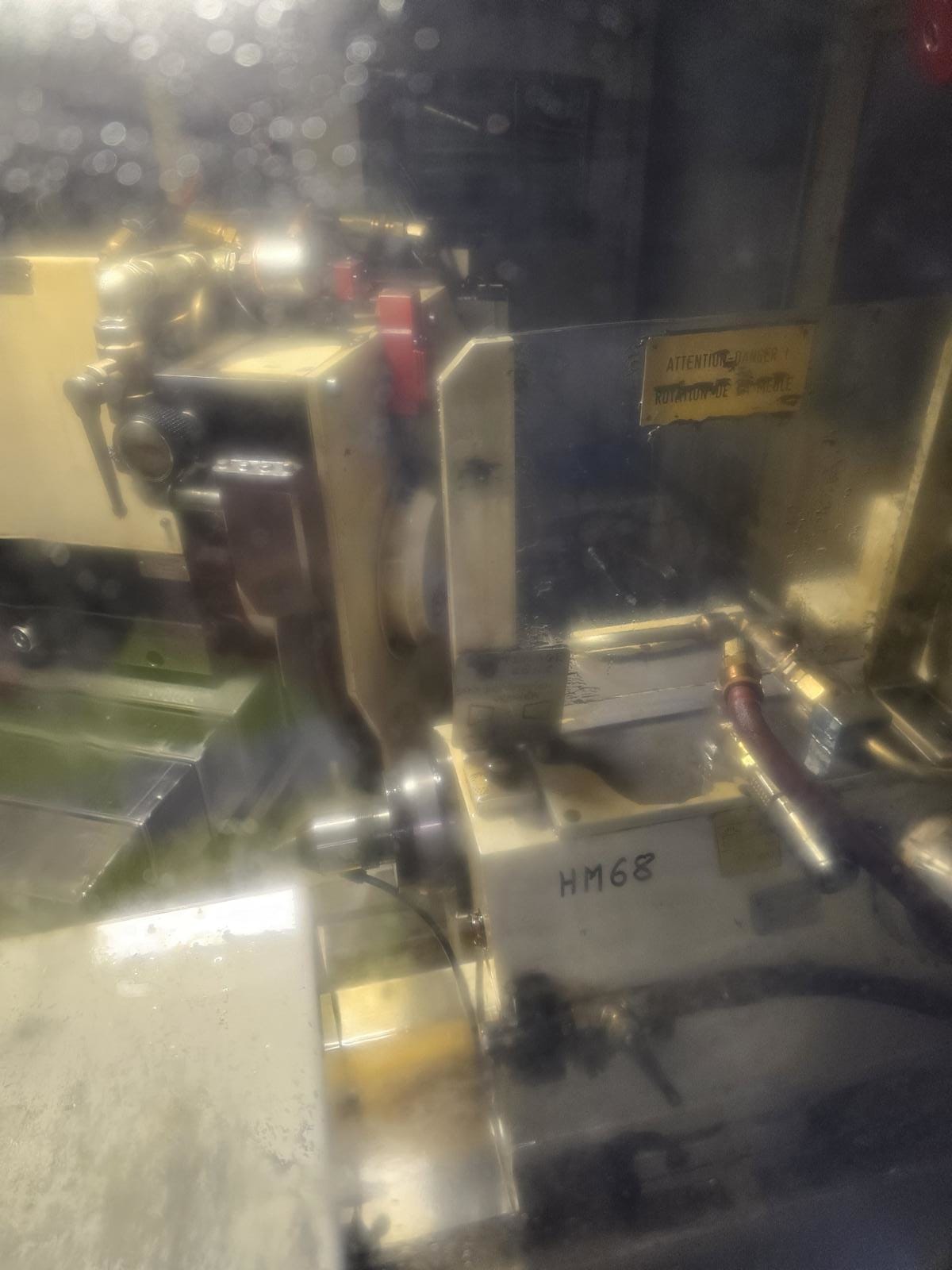

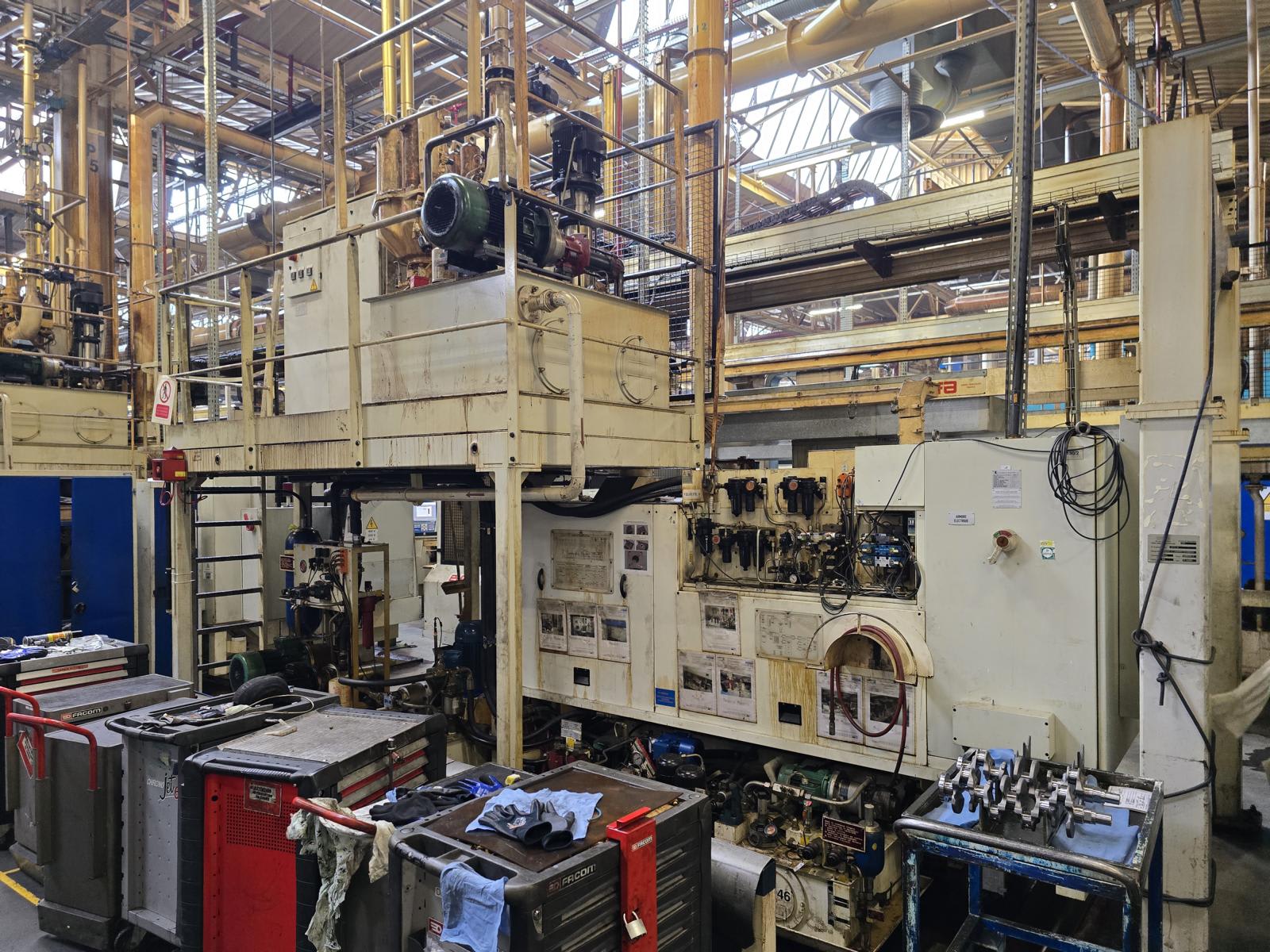

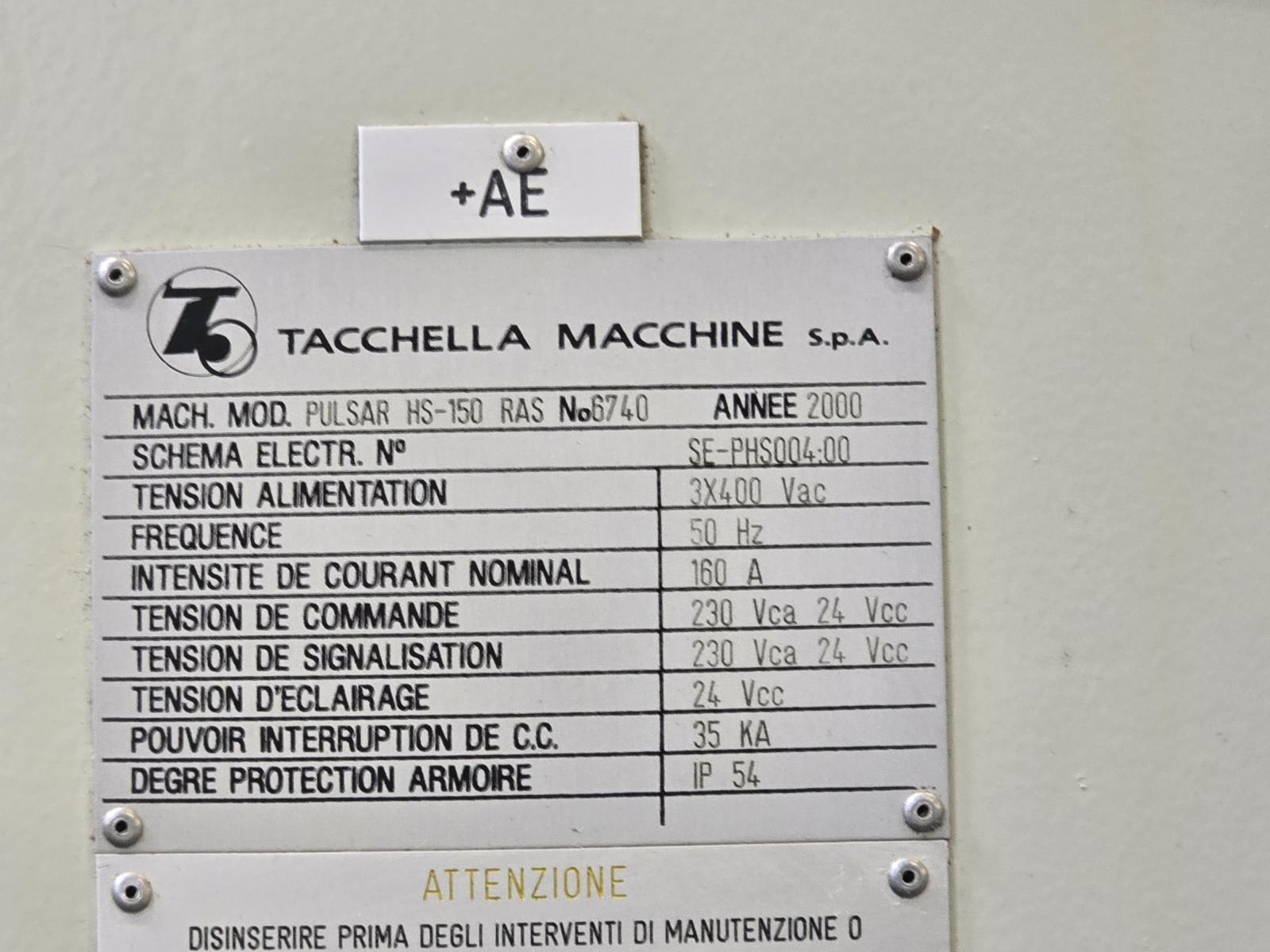

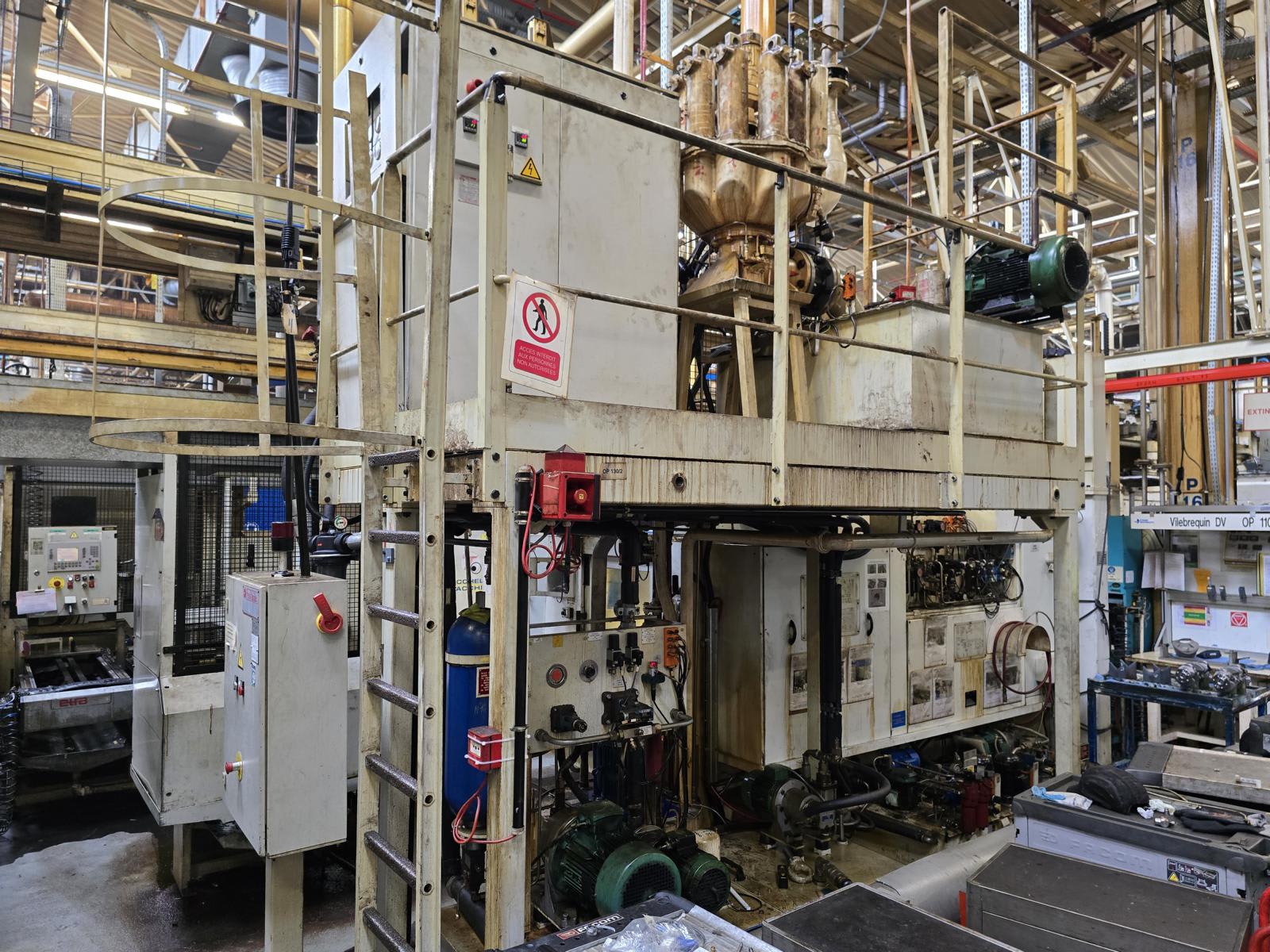

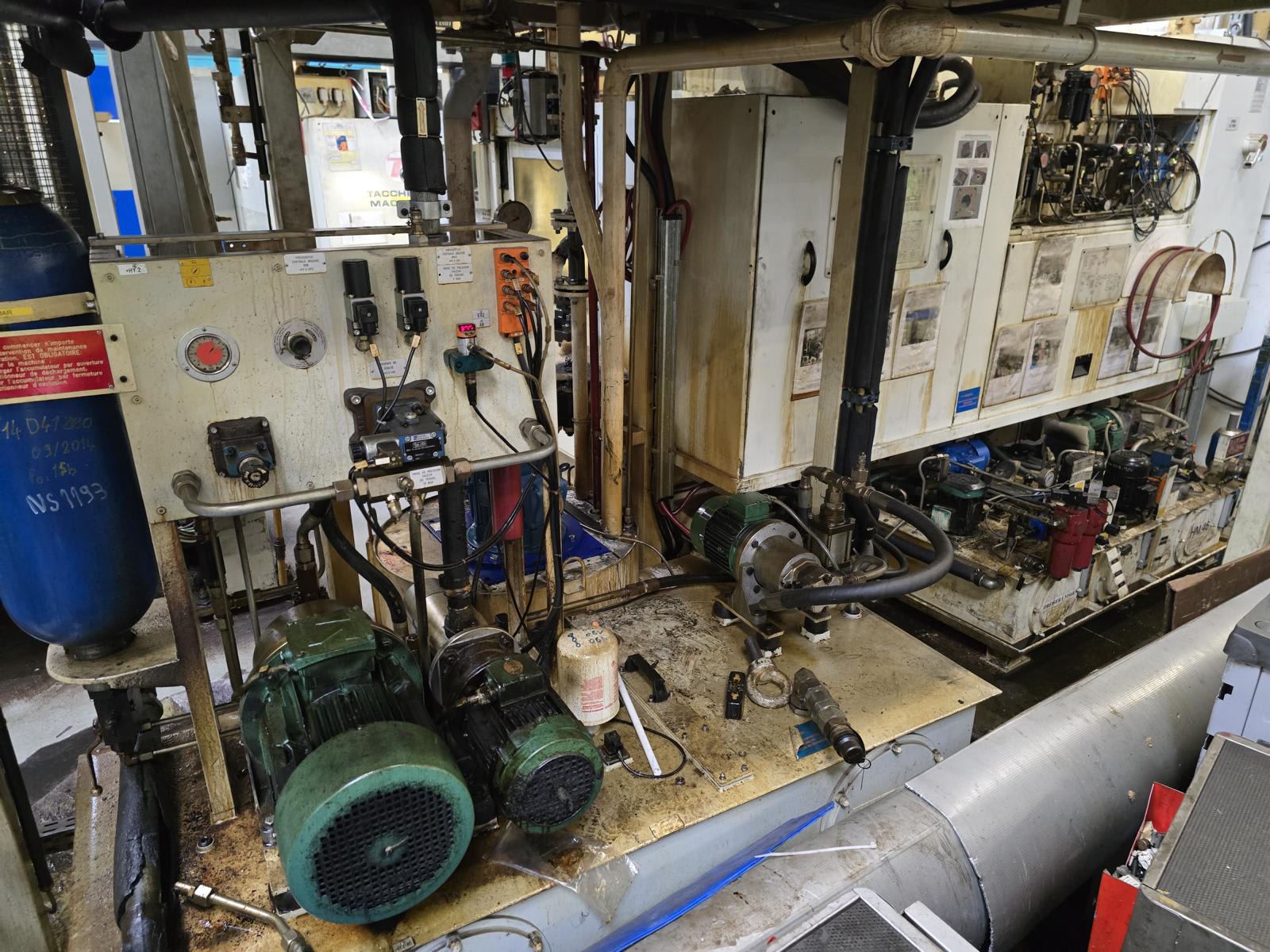

CNC Angle Approach Cylindrical Grinder TACCHELLA Pulsar HS-150RAS | 2000

dia 250 x 800mm, VM24 grinding wheel balancing system, MARPOSS InProcess measuring unit, CNC SIEMENS SINUMERIK 840D - LISTING 2830031

![Français]()

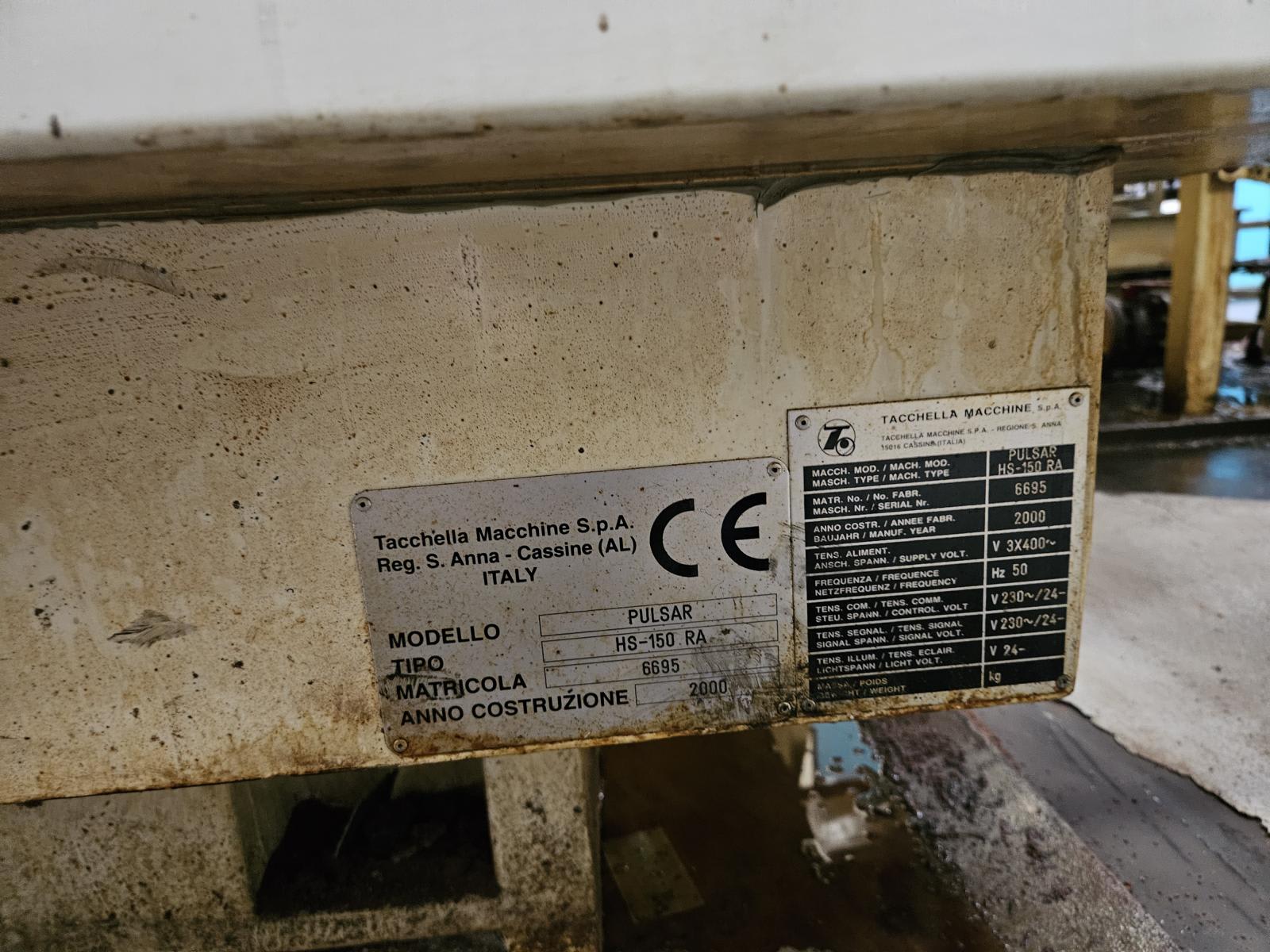

CNC Grinder TACCHELLA Pulsar HS-150RA | 2000

dia 250 x 800mm, VM24 grinding wheel balancing system, MARPOSS InProcess measuring unit, CNC SIEMENS SINUMERIK 840D - LISTING 2830032

![Français]()

CNC Angle Approach Cylindrical Grinder TACCHELLA Pulsar HS-150RAS | 2000

dia 250 x 800mm, VM24 grinding wheel balancing system, MARPOSS InProcess measuring unit, CNC SIEMENS SINUMERIK 840D - LISTING 2830033

![Français]()

CNC Angle Approach Cylindrical Grinder TACCHELLA Pulsar HS-150RAS | 2000

dia 250 x 800mm, VM24 grinding wheel balancing system, MARPOSS InProcess measuring unit, CNC SIEMENS SINUMERIK 840D - LISTING 2830034

![Français]()

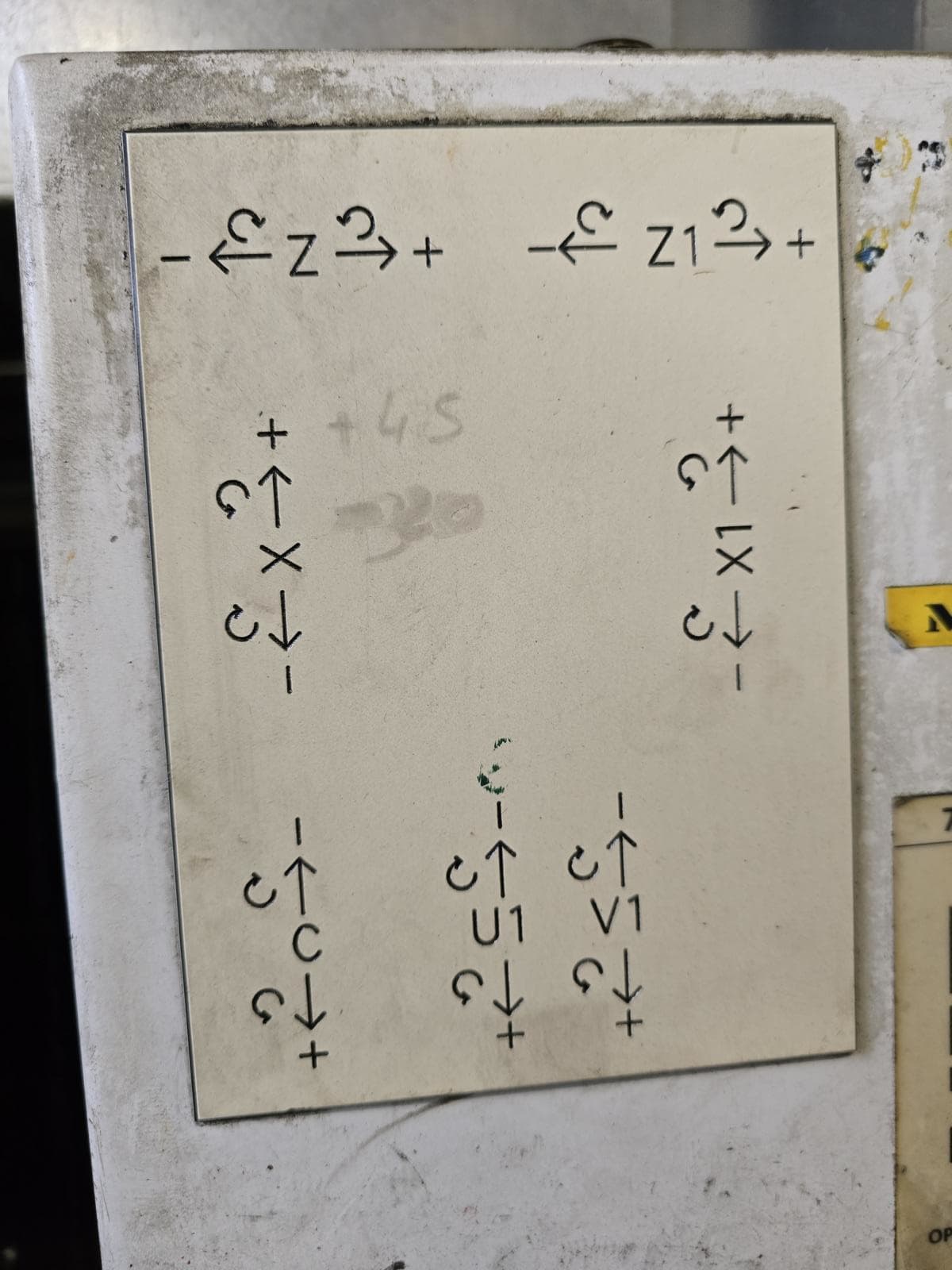

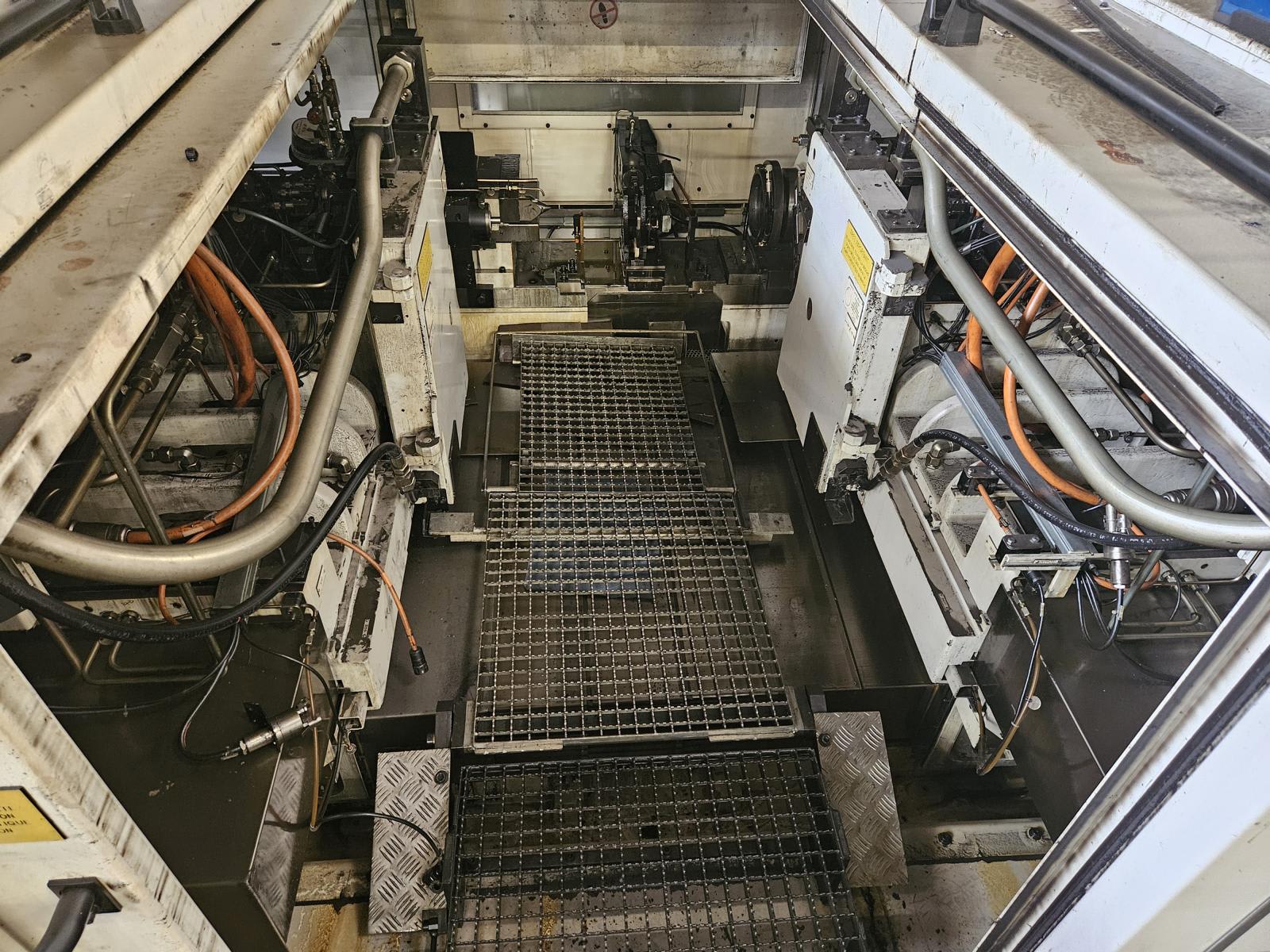

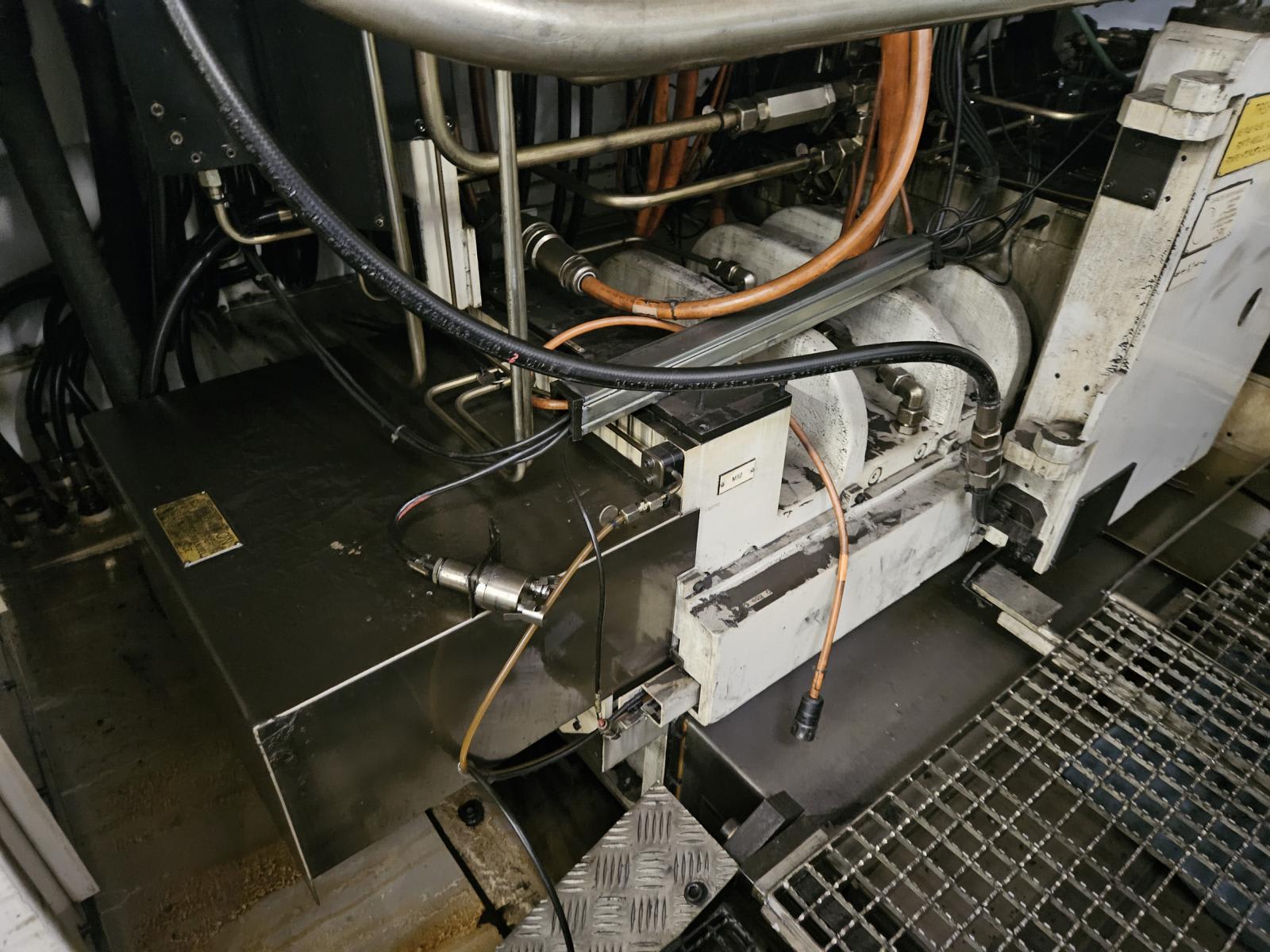

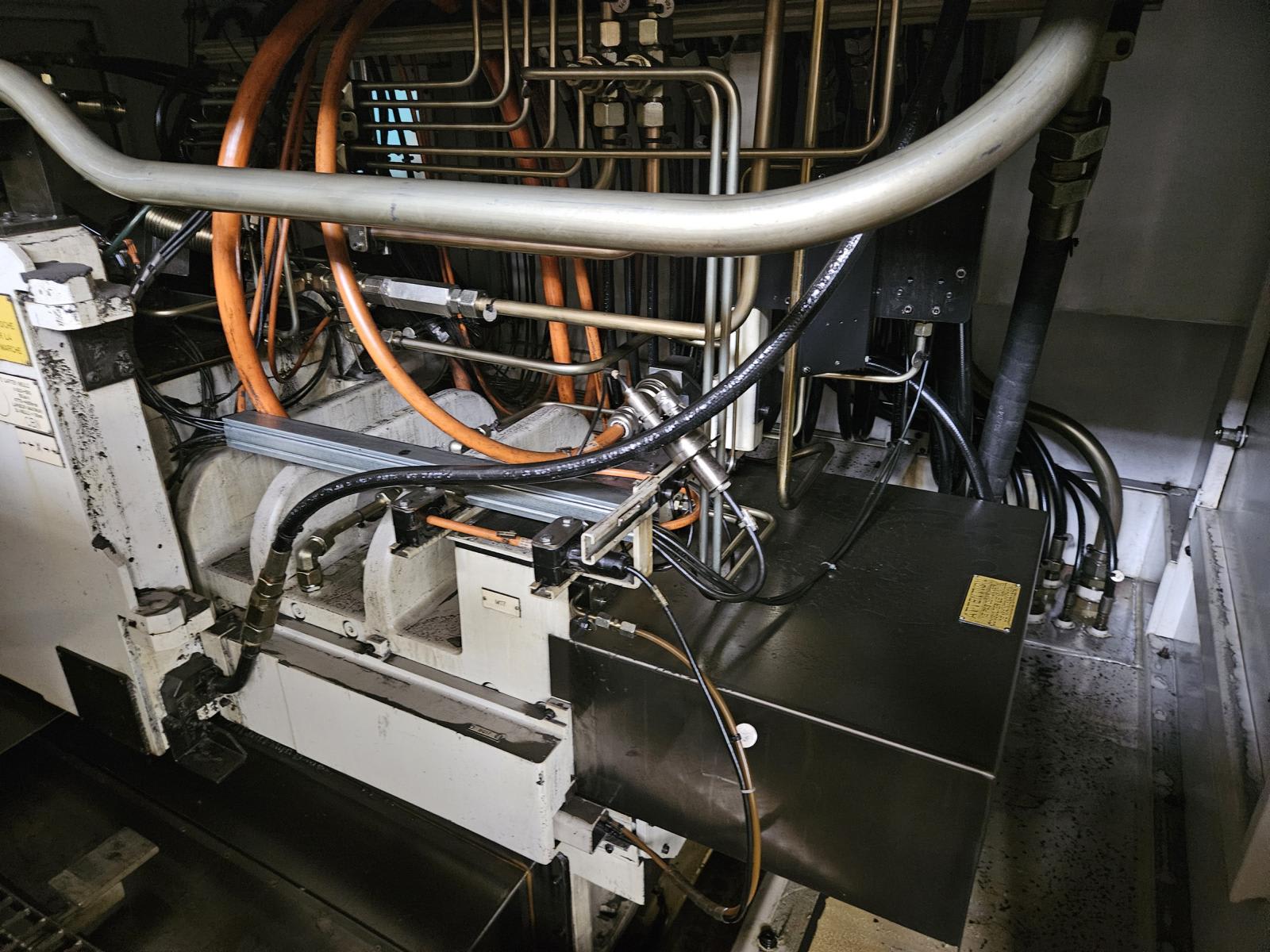

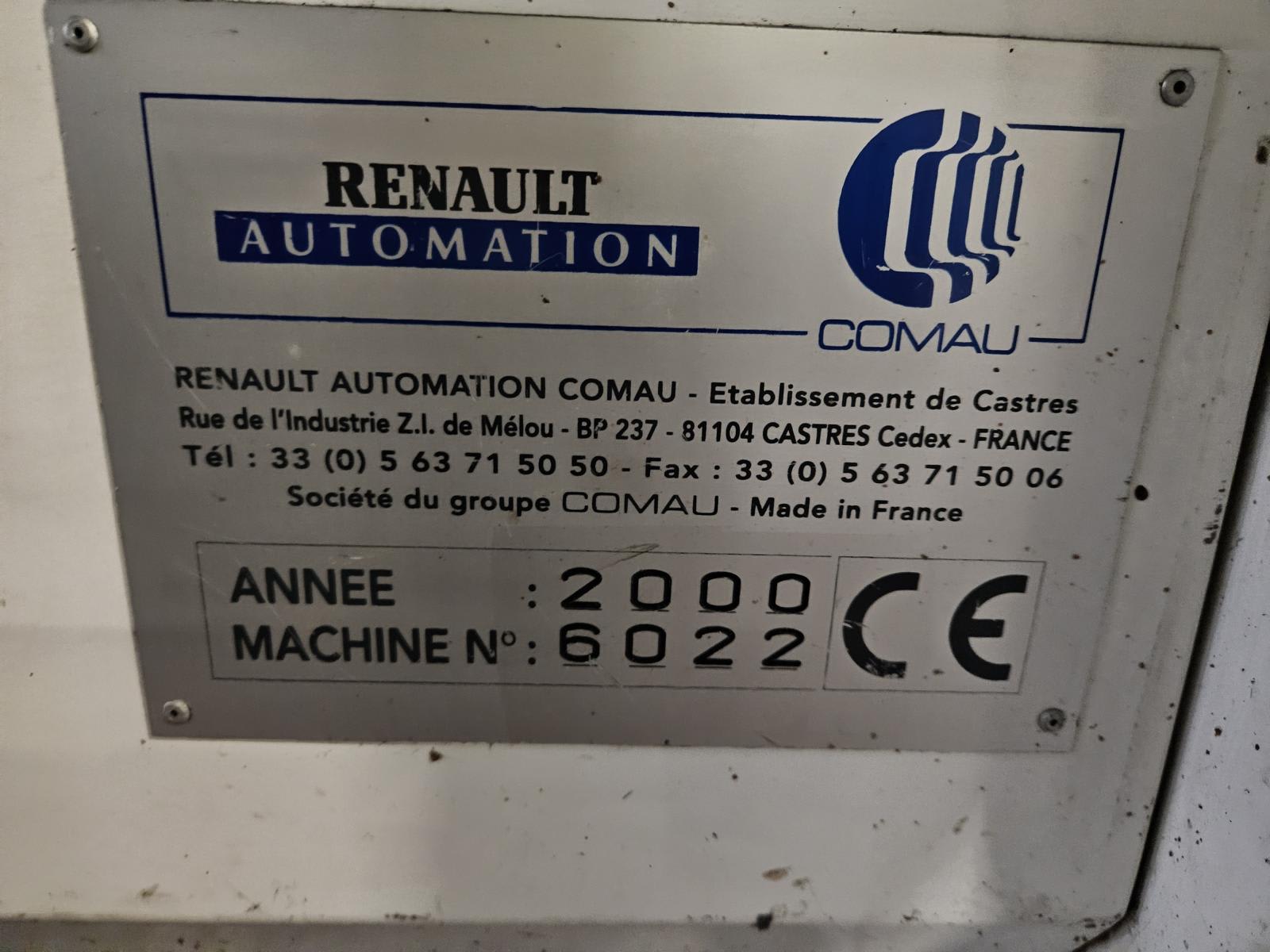

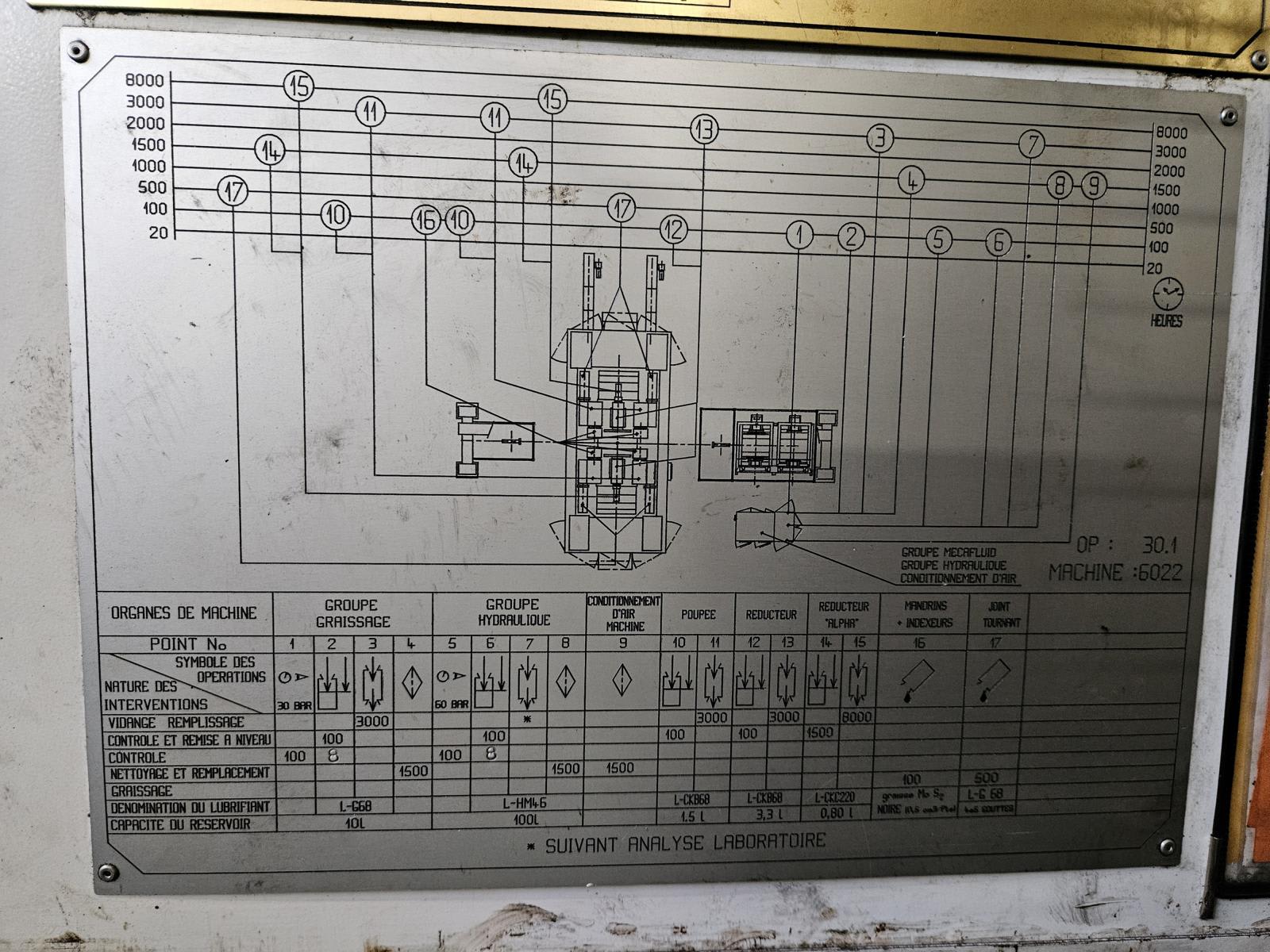

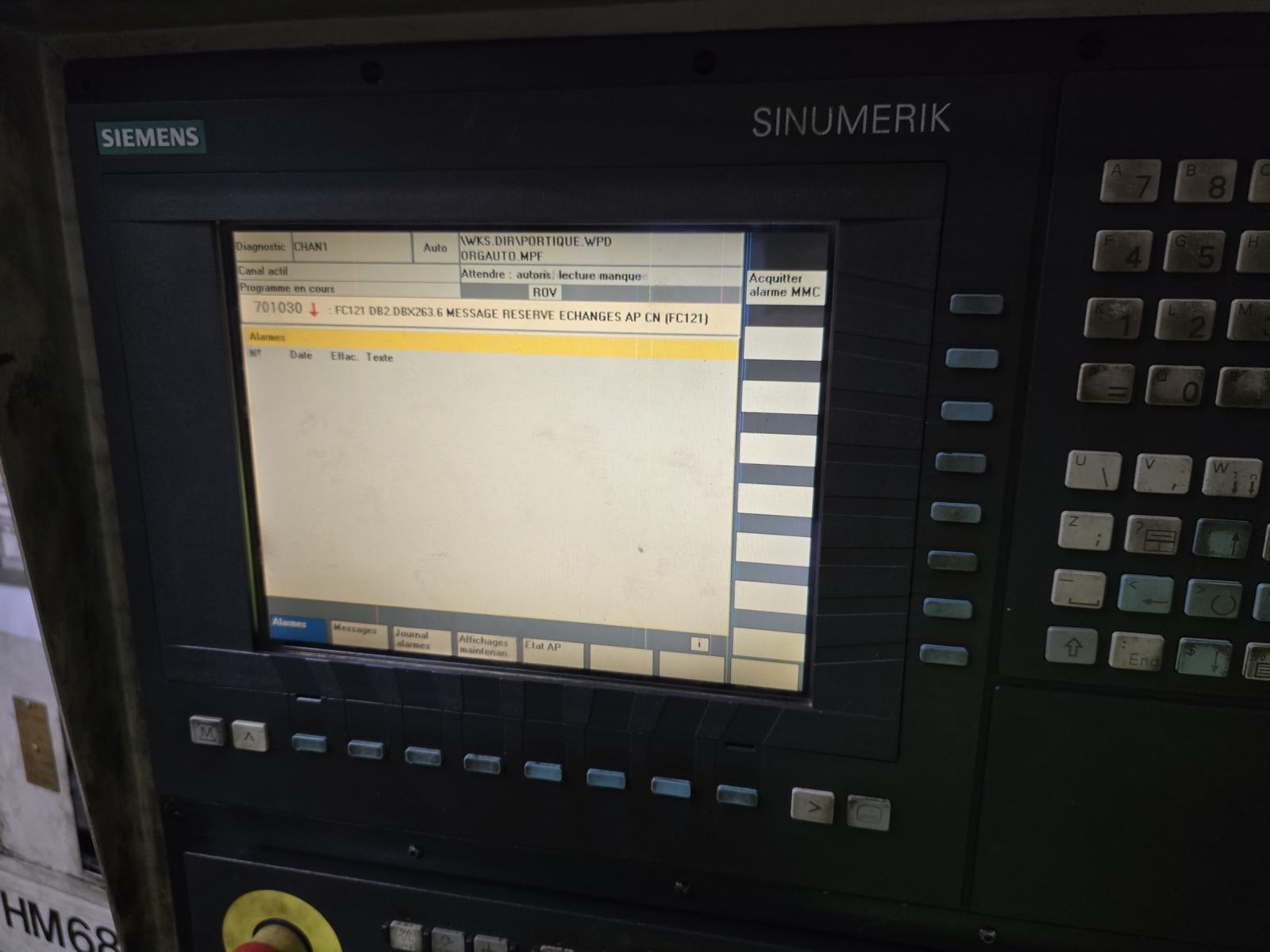

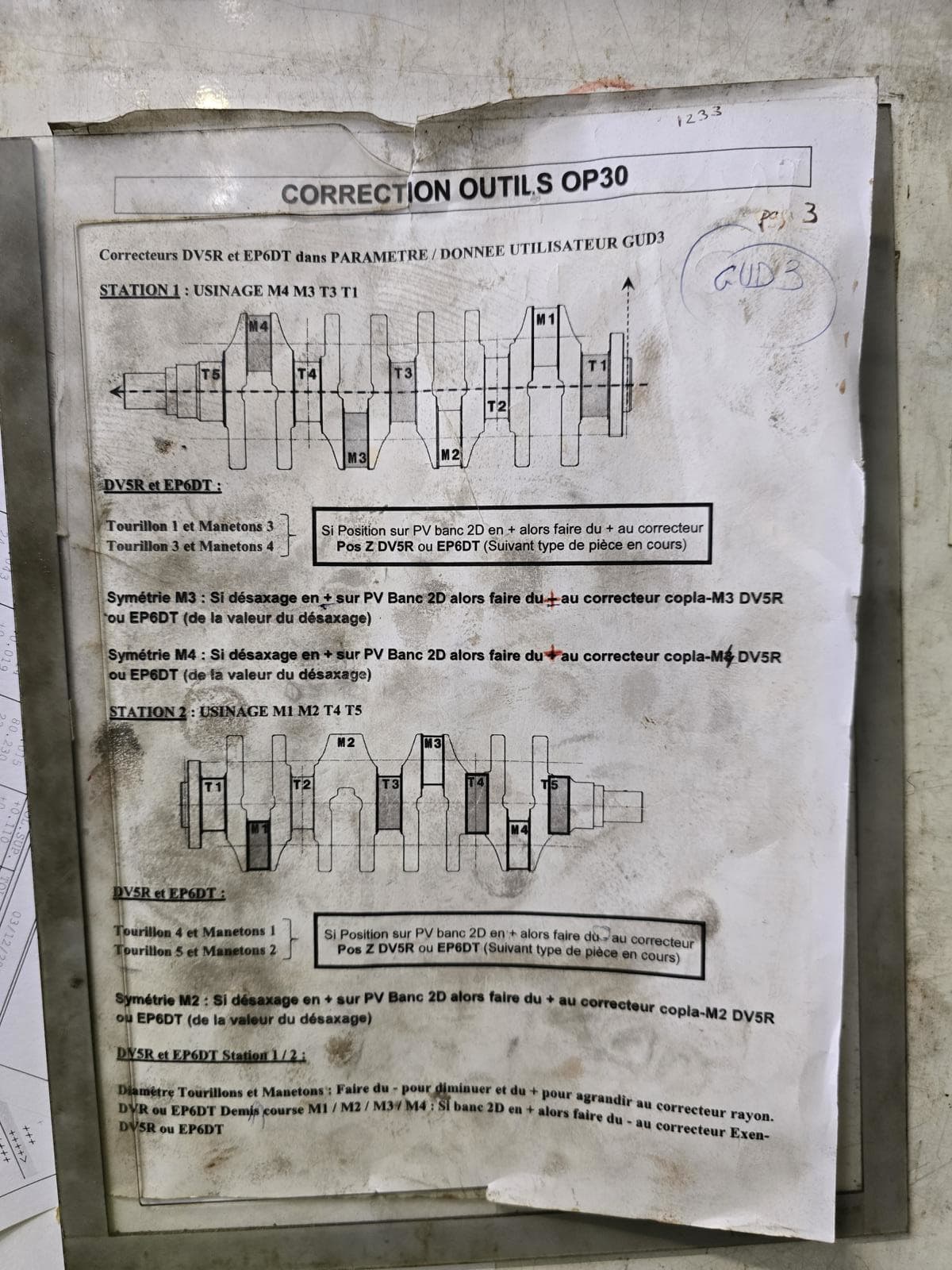

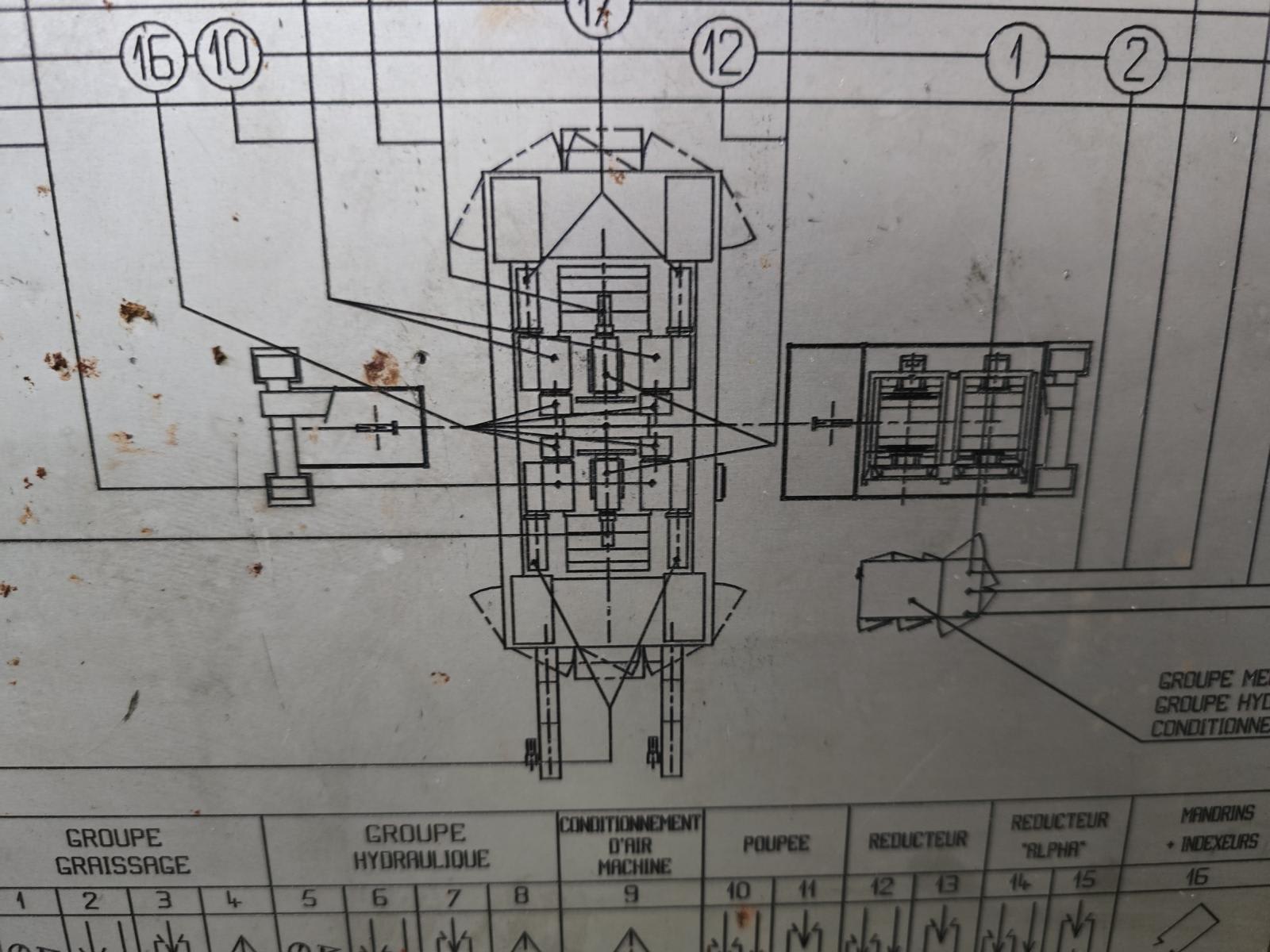

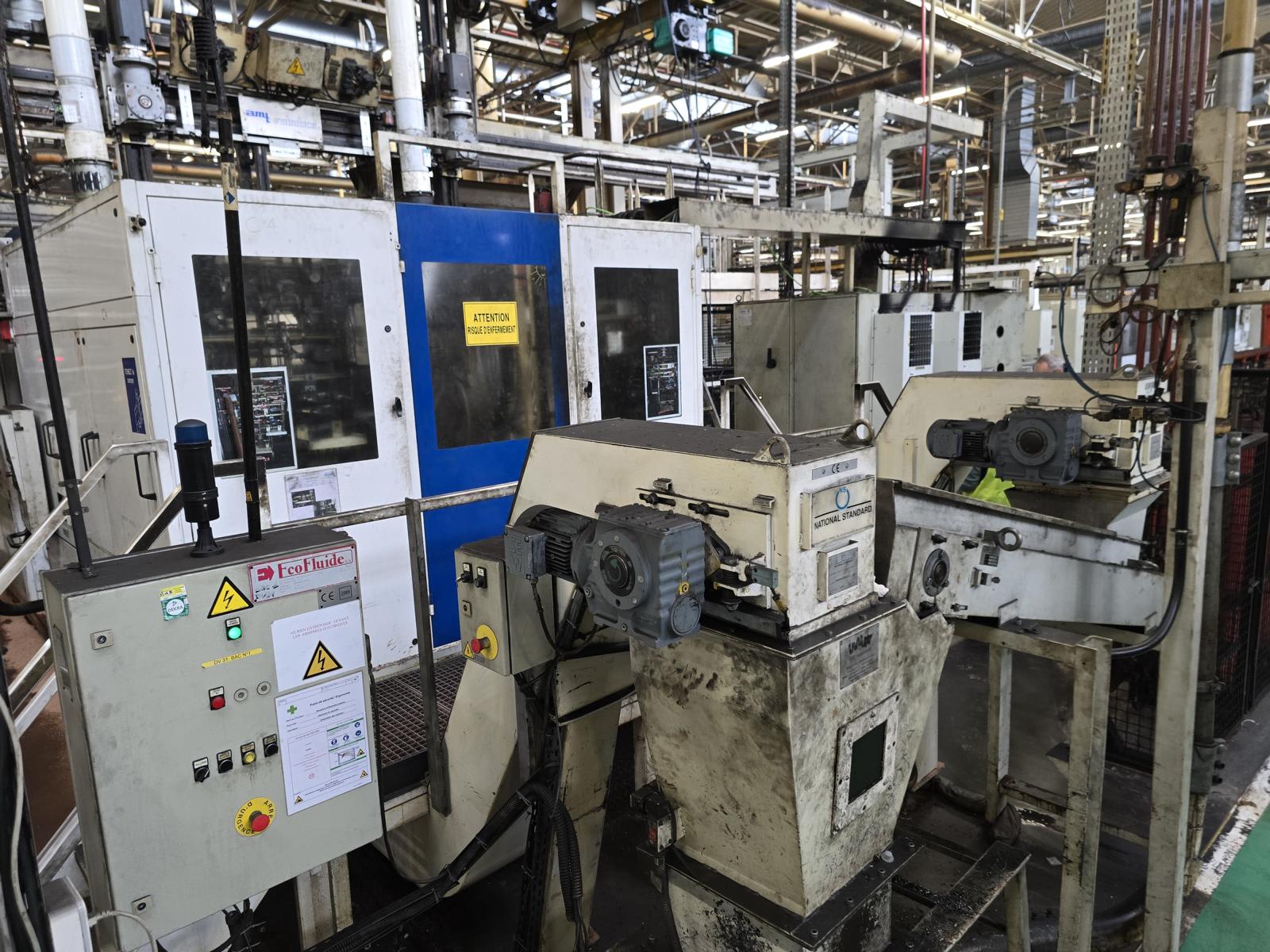

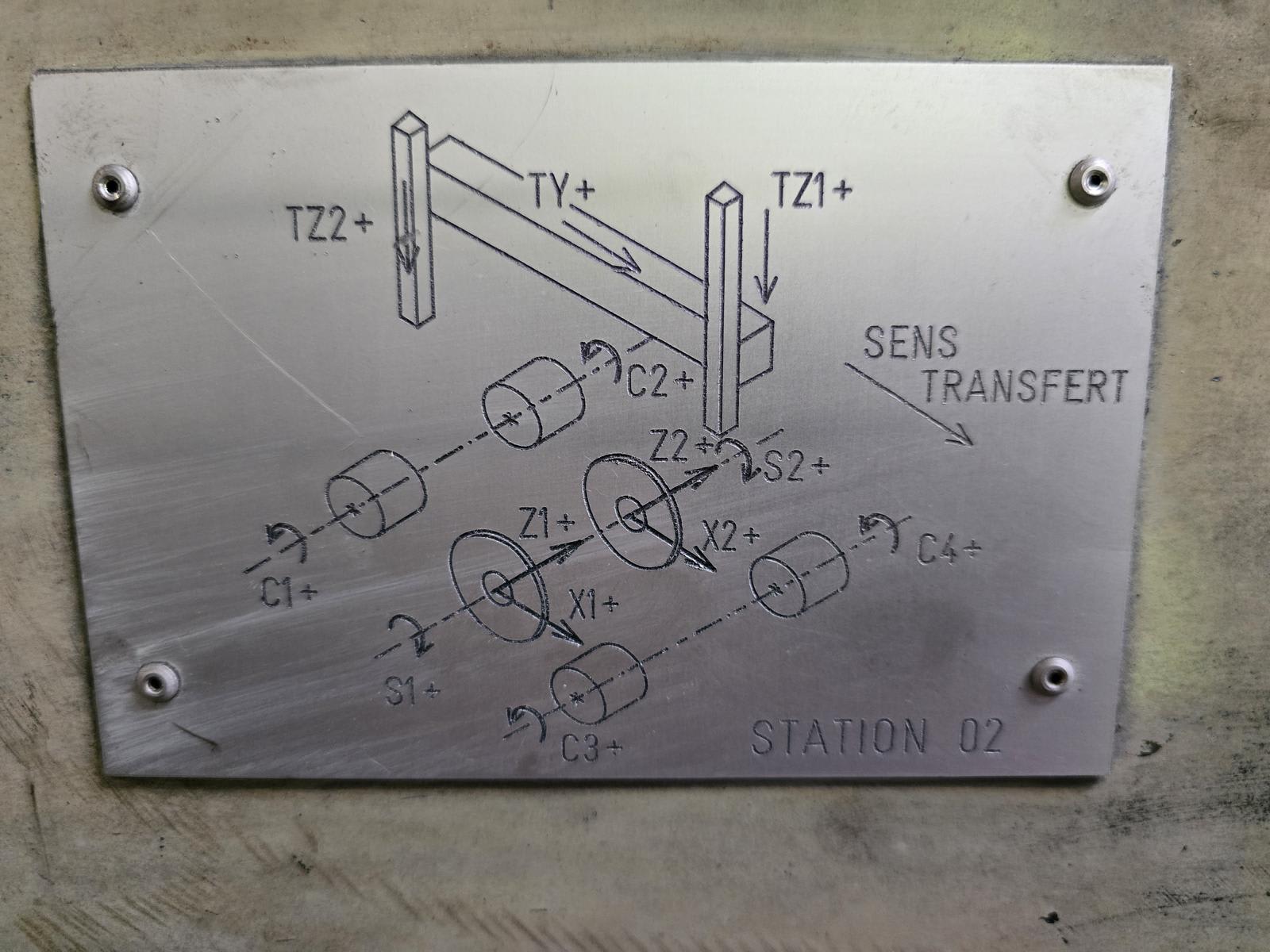

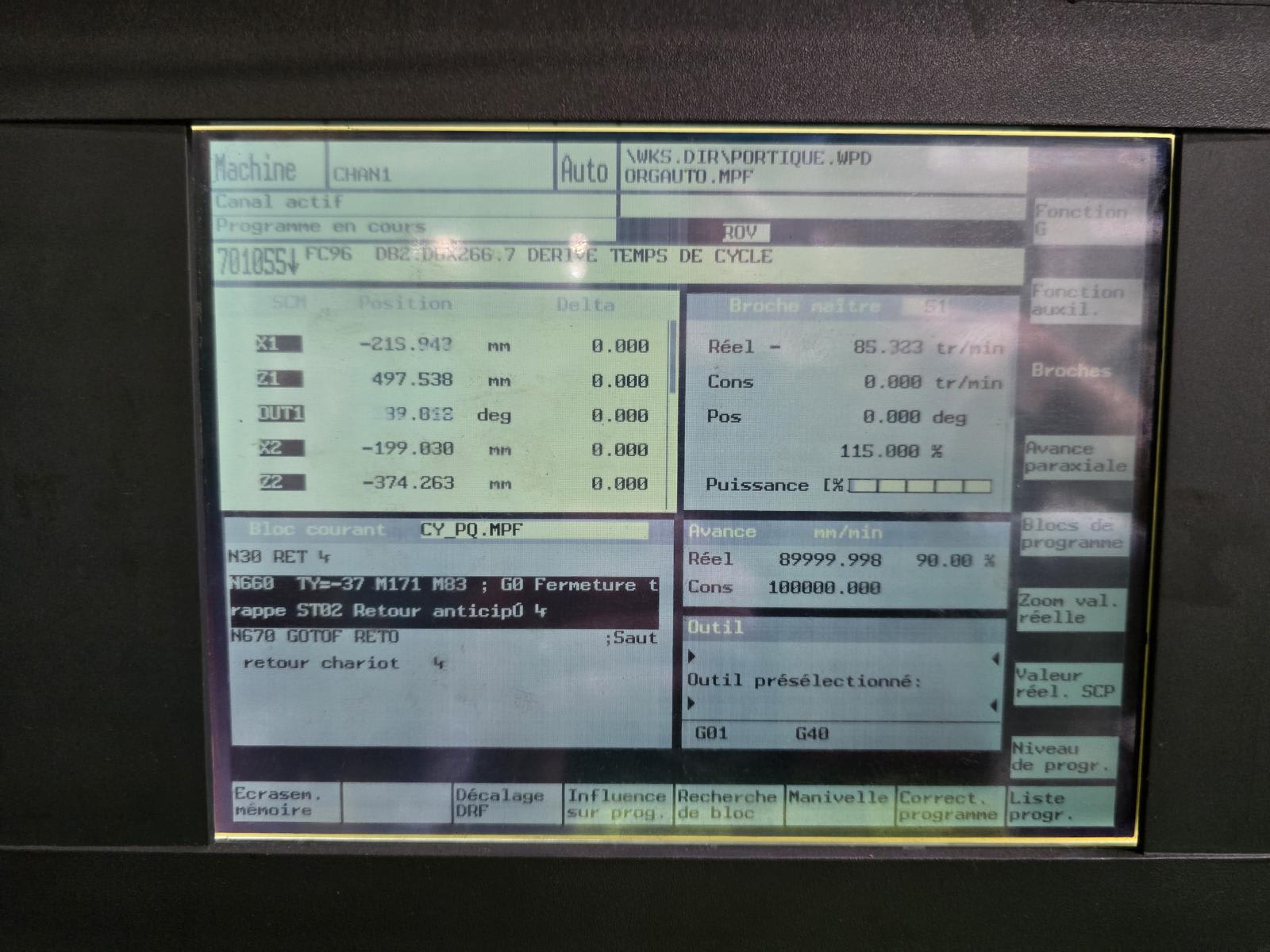

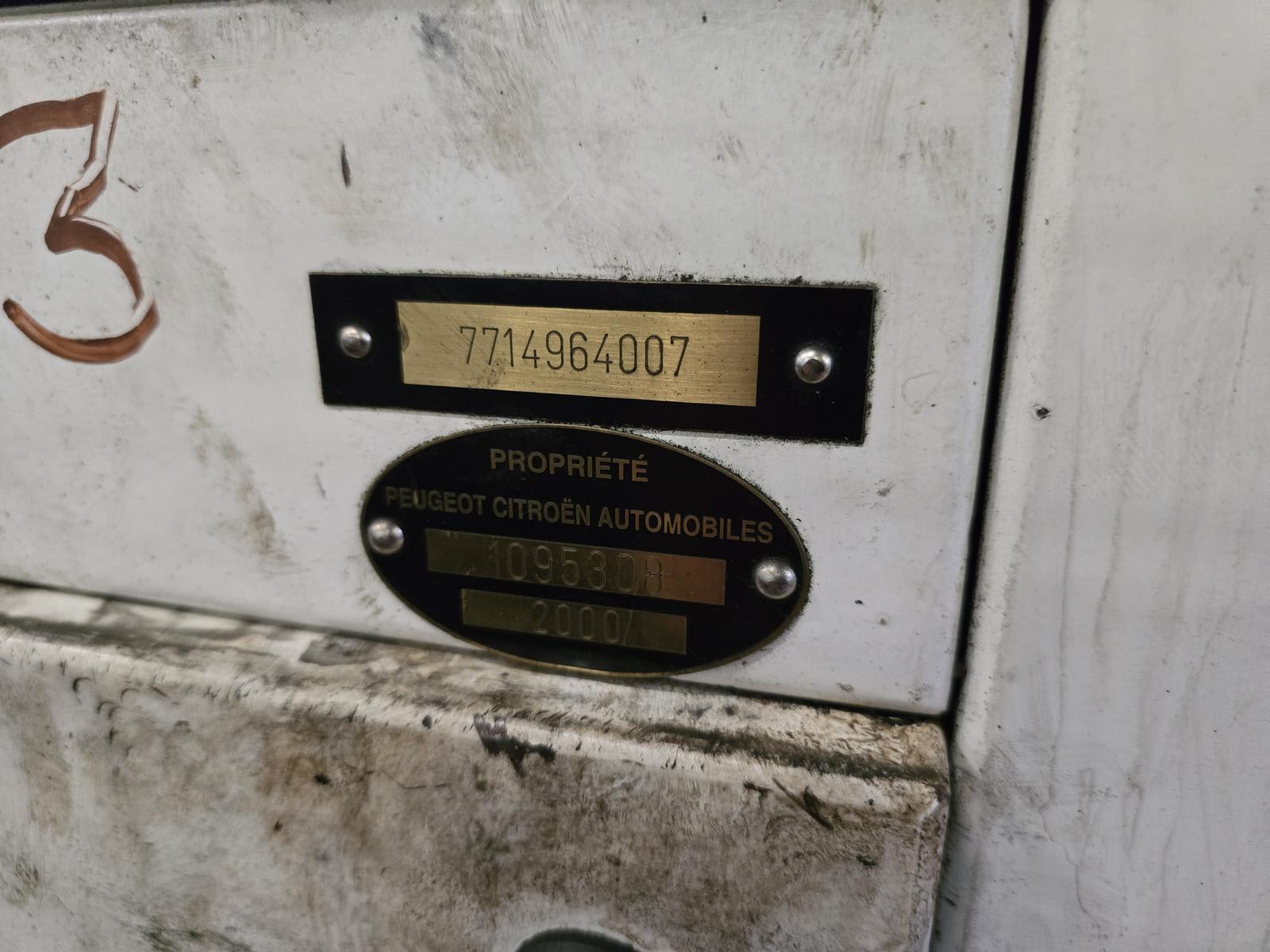

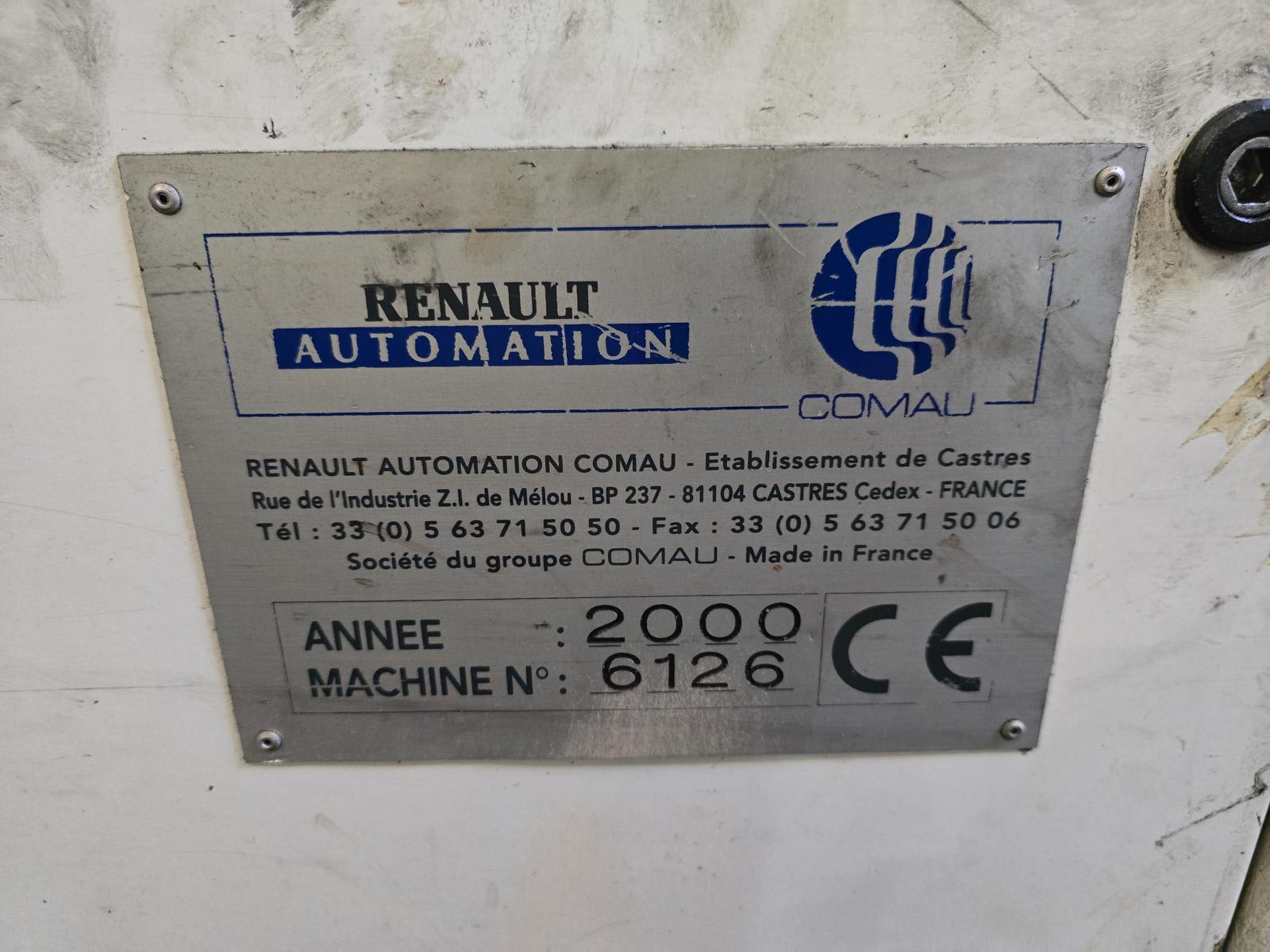

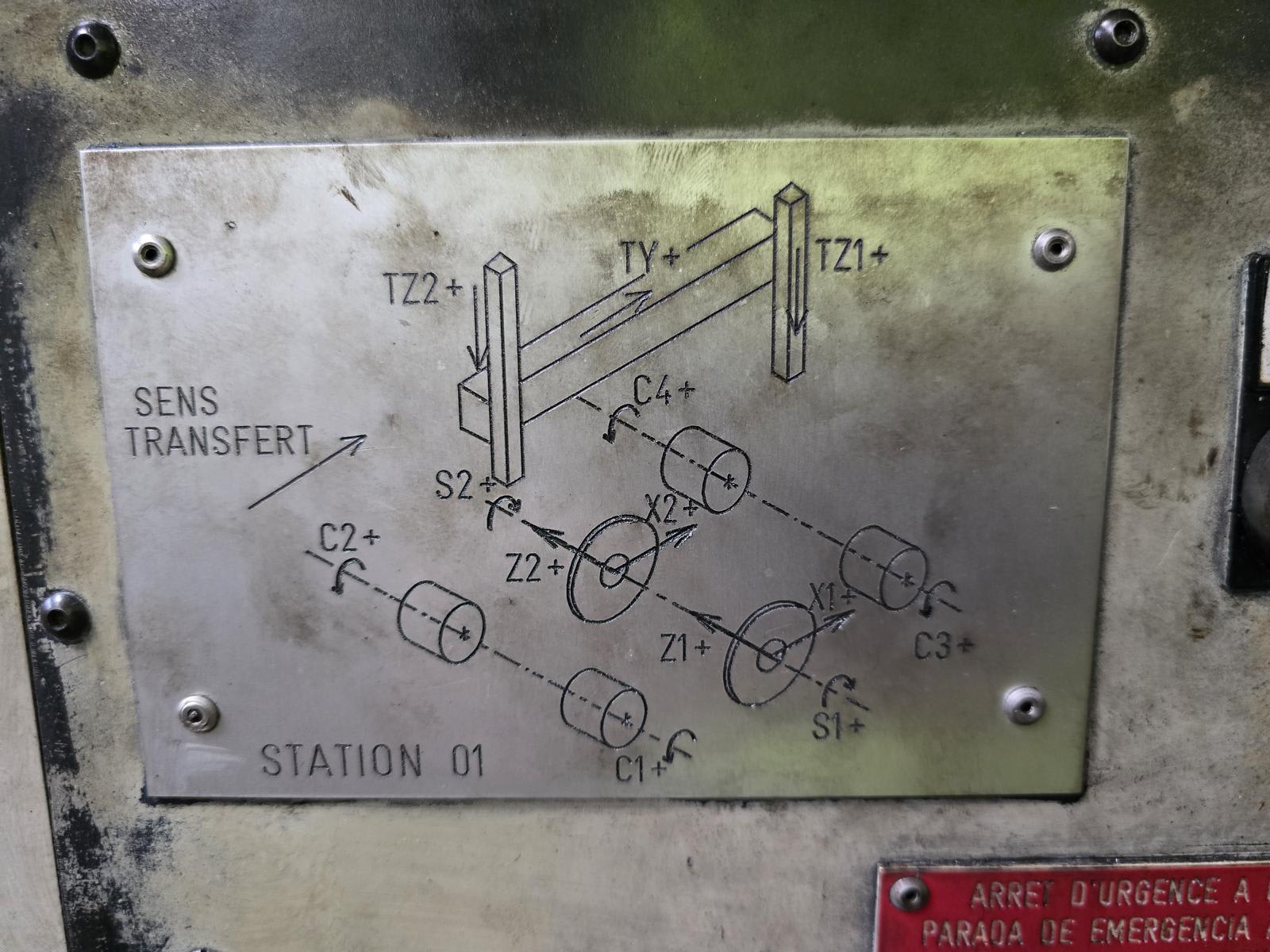

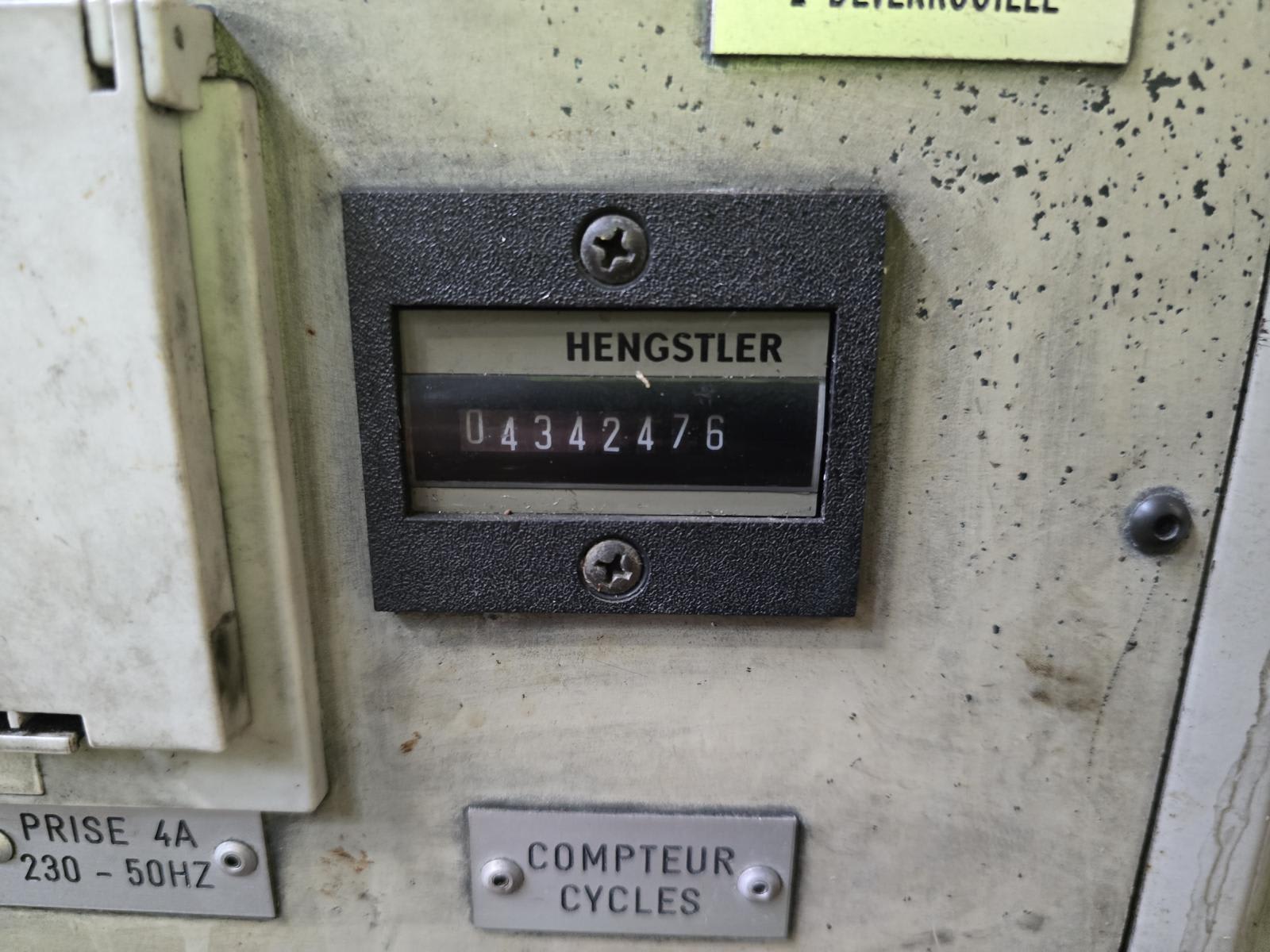

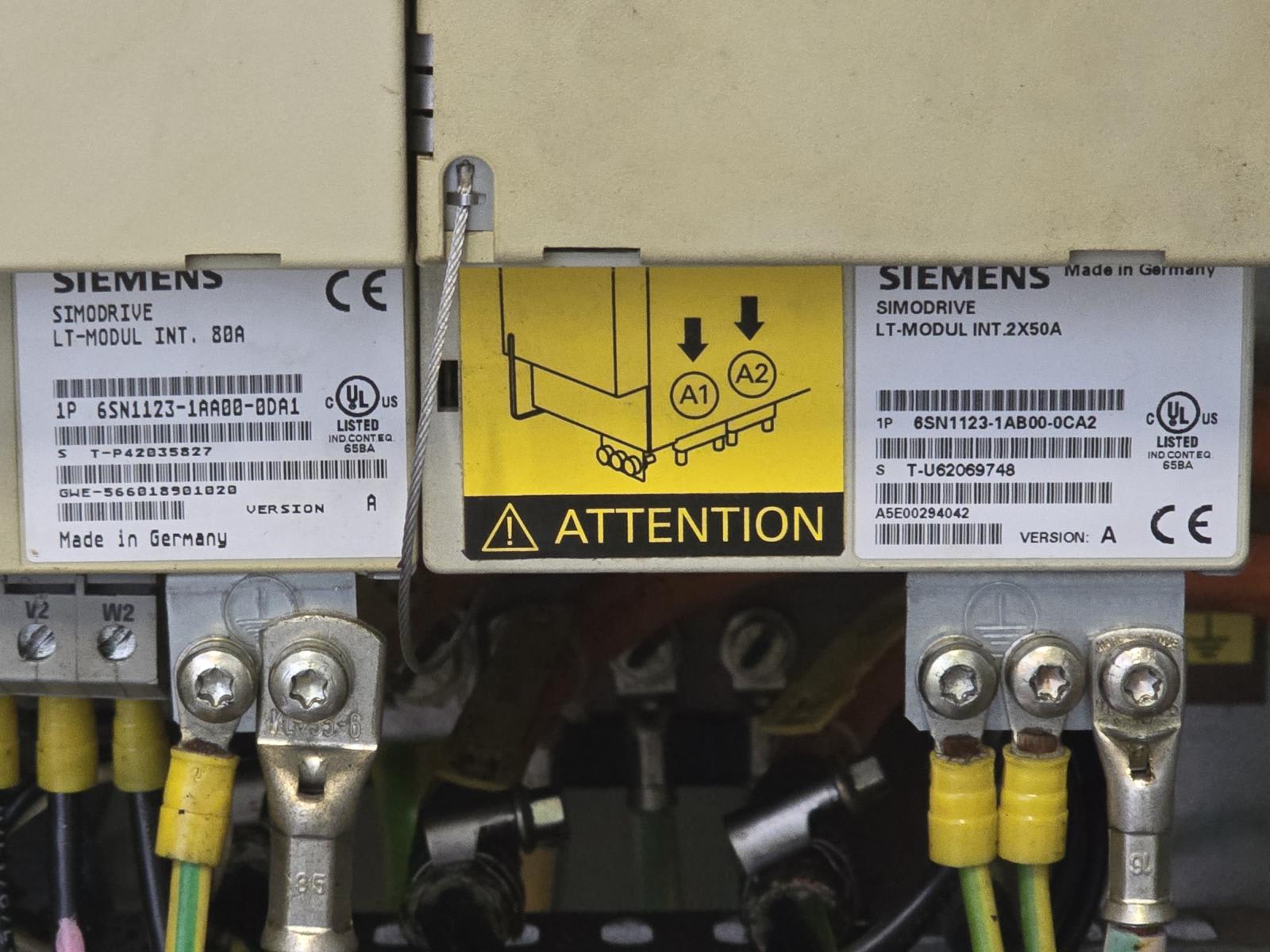

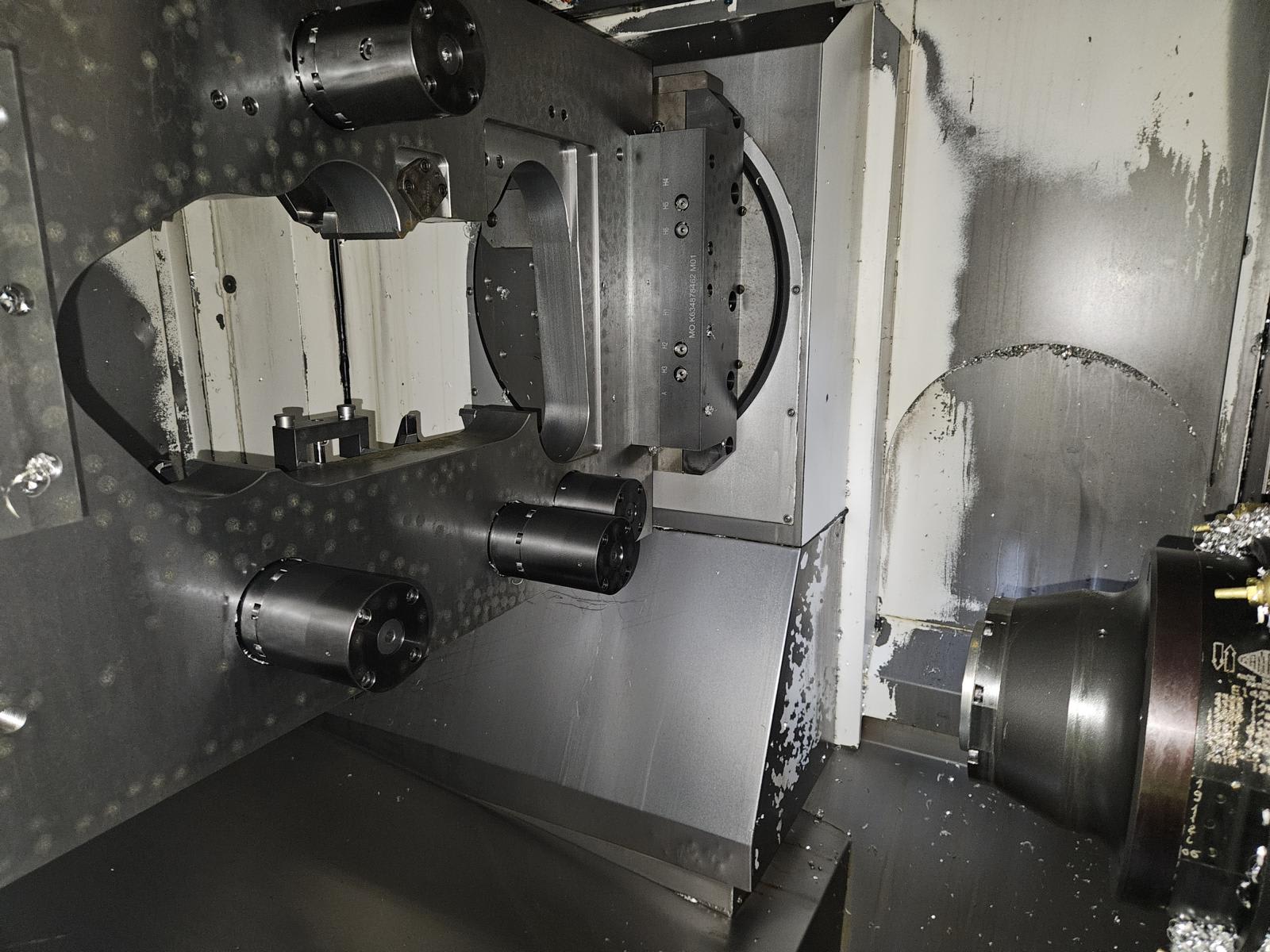

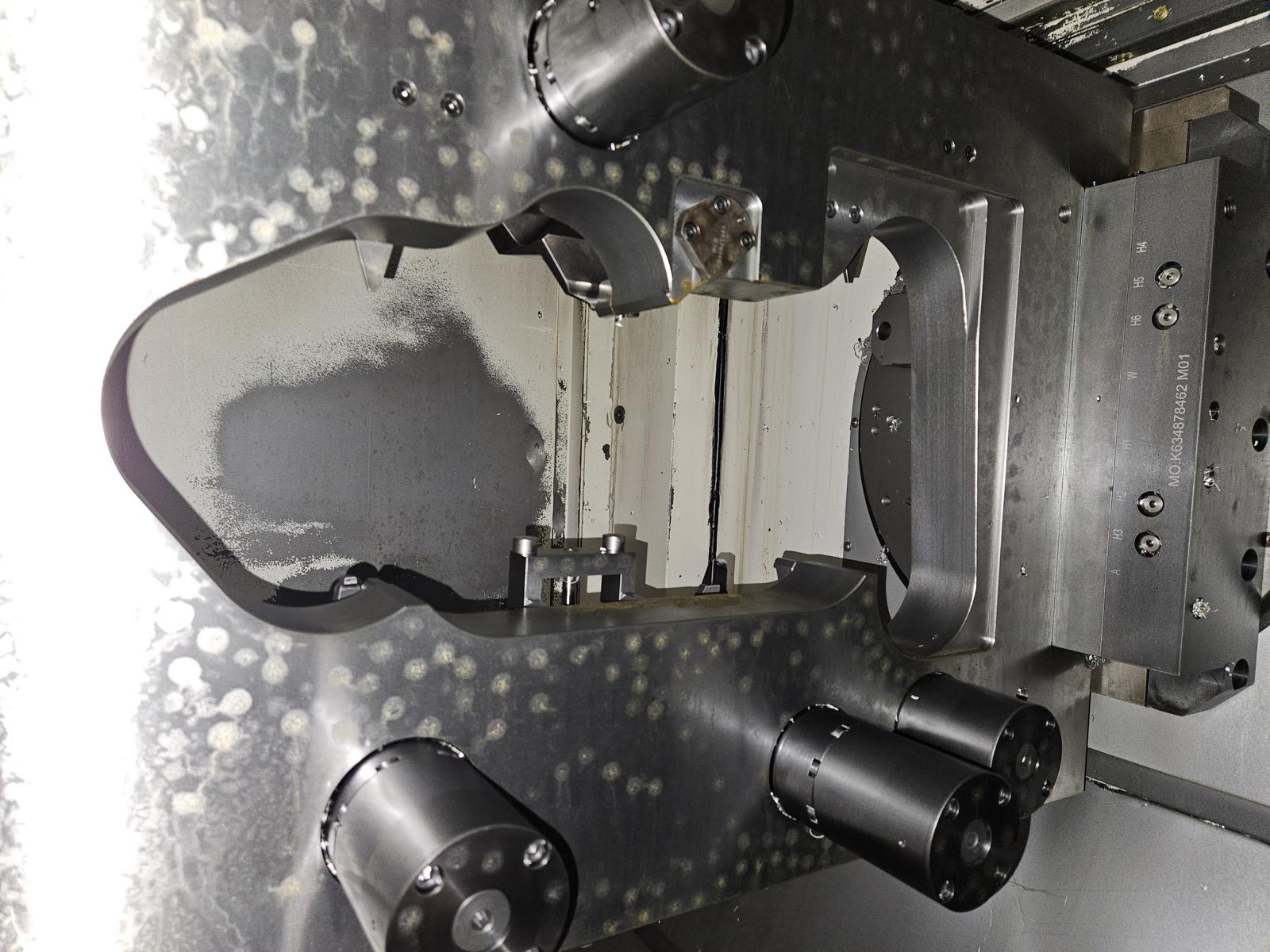

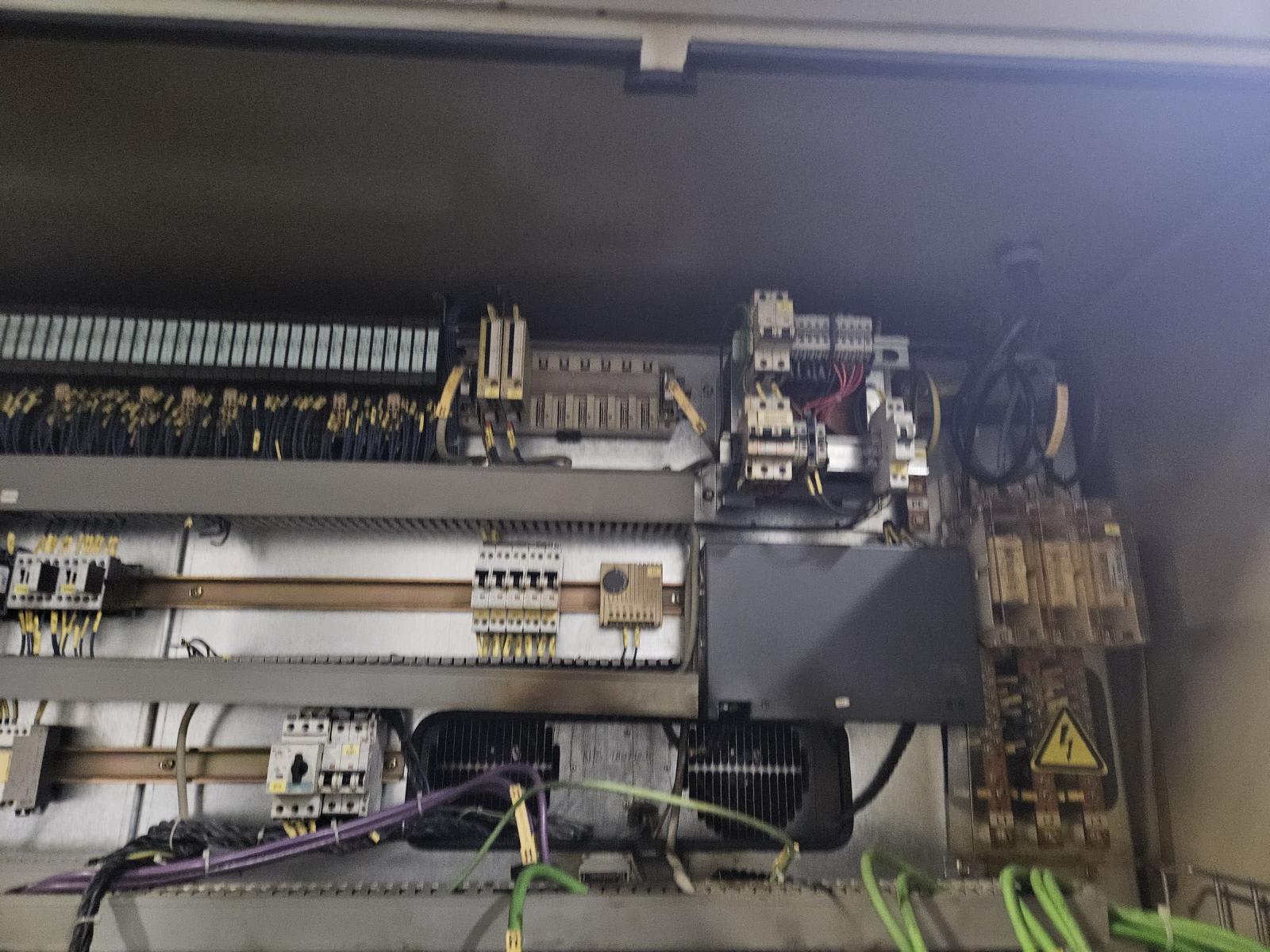

CNC Crankshaft Turn Broaching Machine RENAULT Automation COMAU | 2000

max crankshaft dimensions, ca.: dia 250 x 800 mm, Twin-Station Crankshaft Turn Broaching Machine for Main and Pin Bearings, internal part transfer, two twin-cutting-head stations, one CNC SIEMENS SINUMERIK 840D per station with X1/X2 and Z1/Z2 Axes and C1/C2/C3/C4 rotating spindle Axes for each station, LxWxH, ca. 8x3x3m, weight, ca. 30to - LISTING 2830035

![Français]()

CNC Crankshaft Turn Broaching Machine RENAULT Automation COMAU | 2000

max crankshaft dimensions, ca.: dia 250 x 800 mm, Twin-Station Crankshaft Turn Broaching Machine for Main and Pin Bearings, internal part transfer, two twin-cutting-head stations, one CNC SIEMENS SINUMERIK 840D per station with X1/X2 and Z1/Z2 Axes and C1/C2/C3/C4 rotating spindle Axes for each station, LxWxH, ca. 8x3x3m, weight, ca. 30to - LISTING 2830036

![Français]()

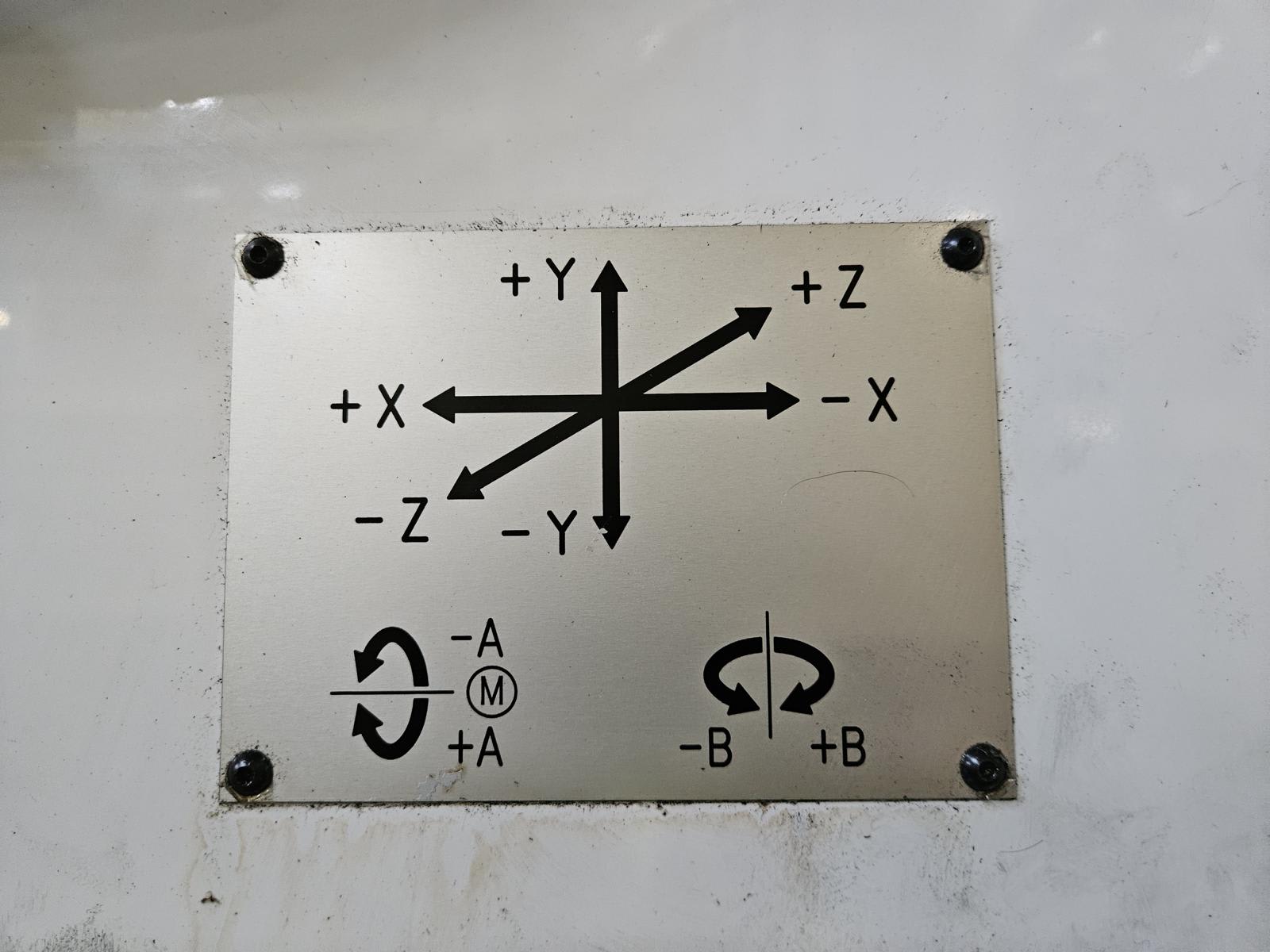

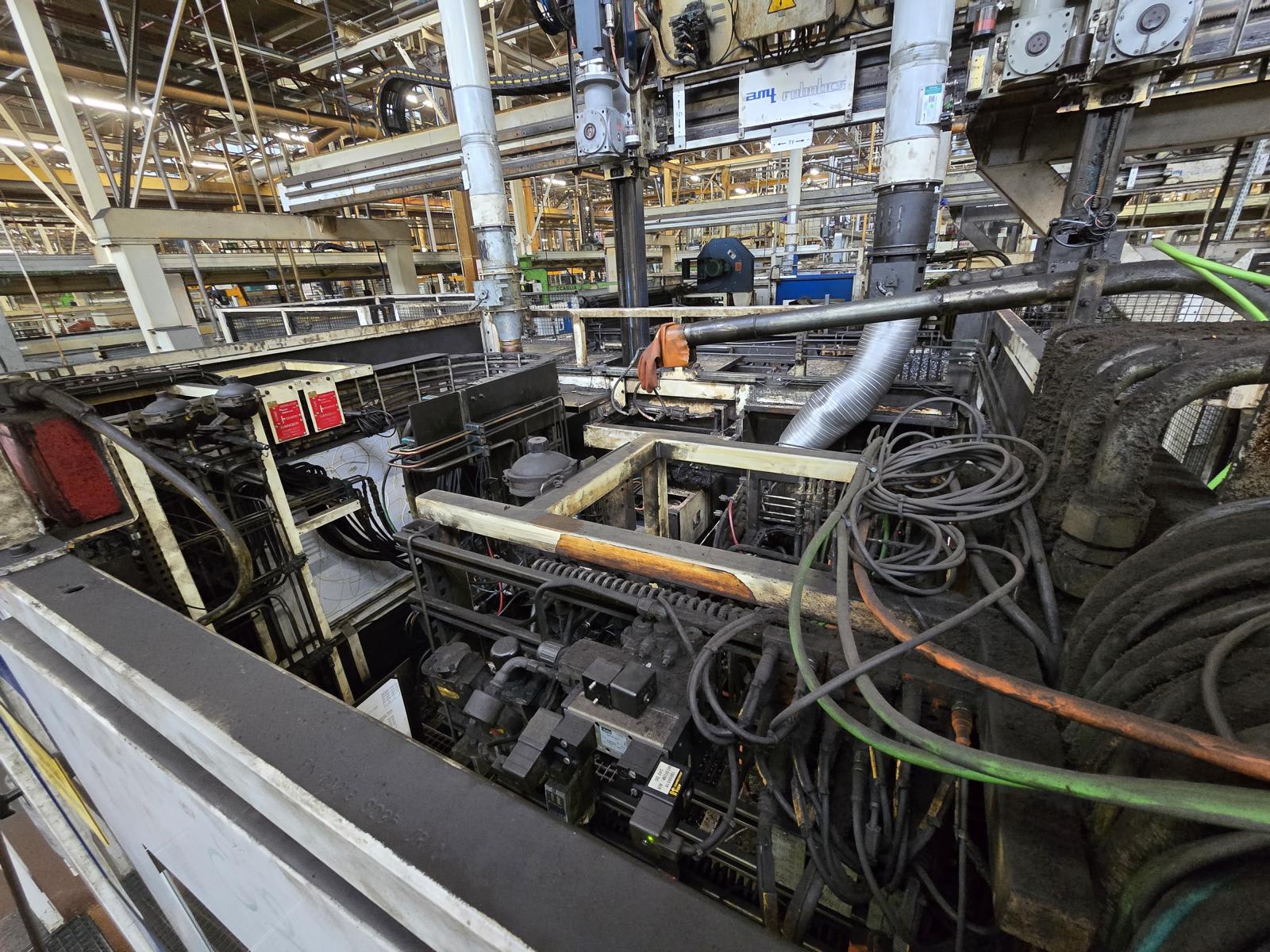

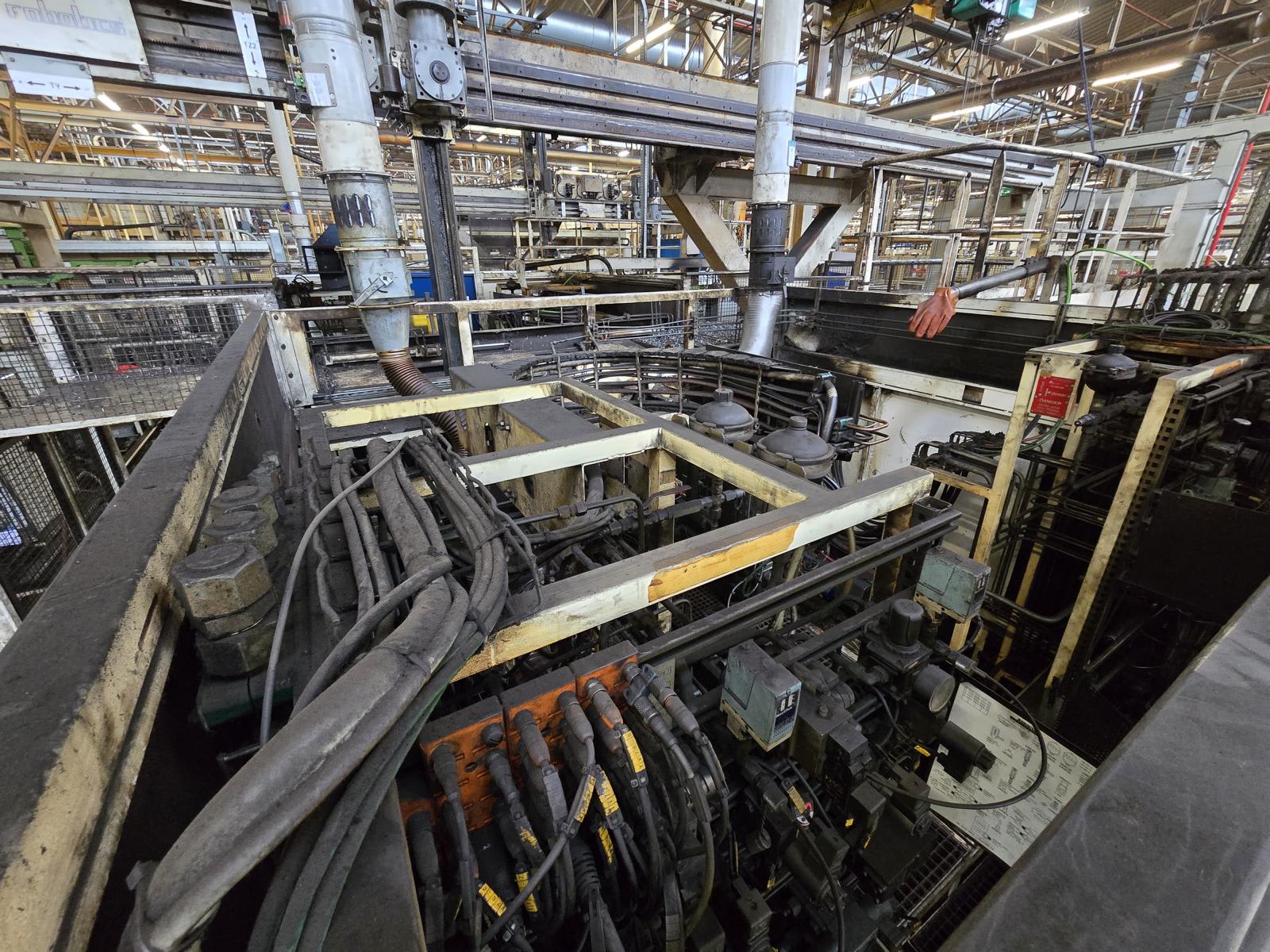

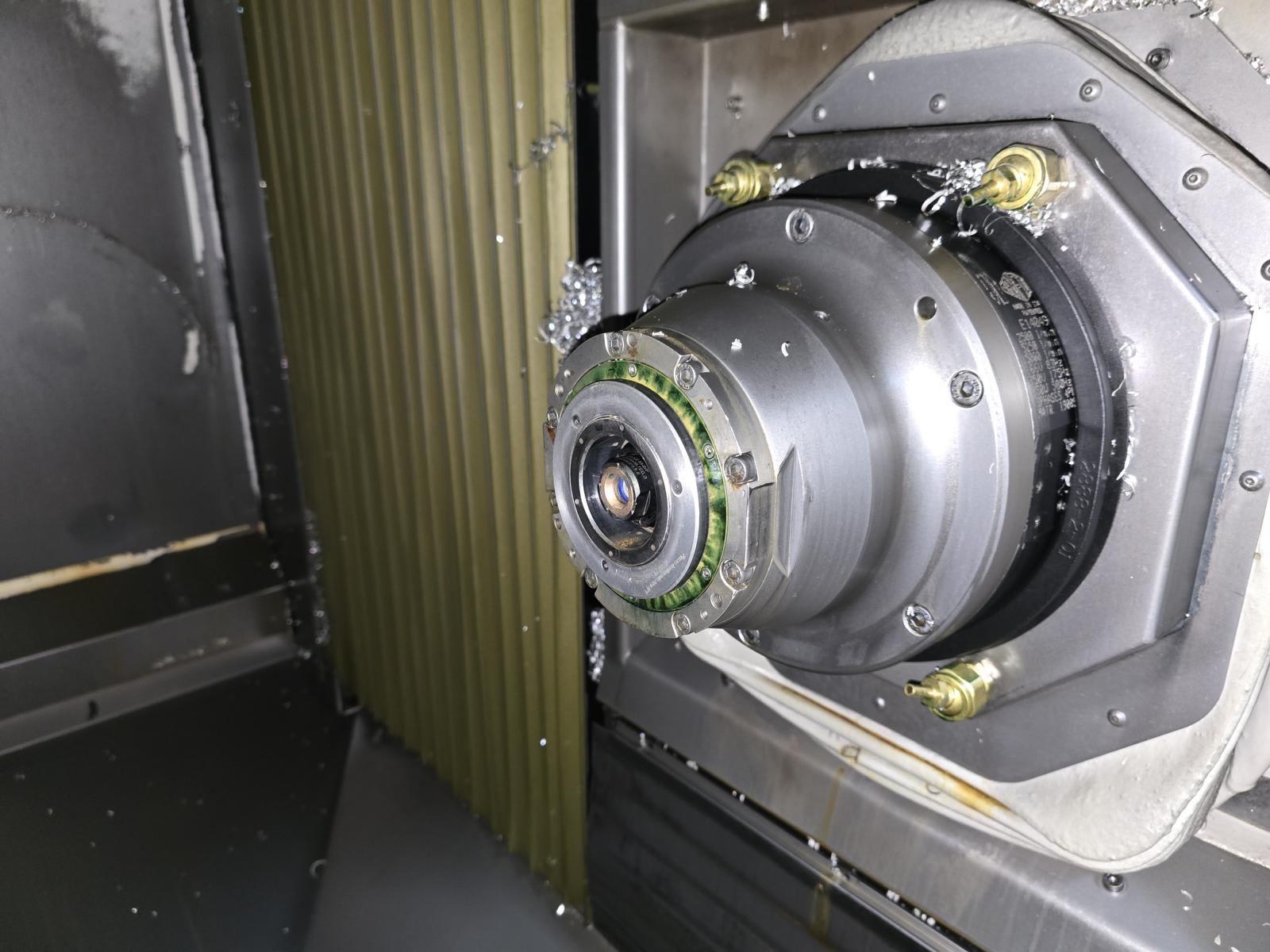

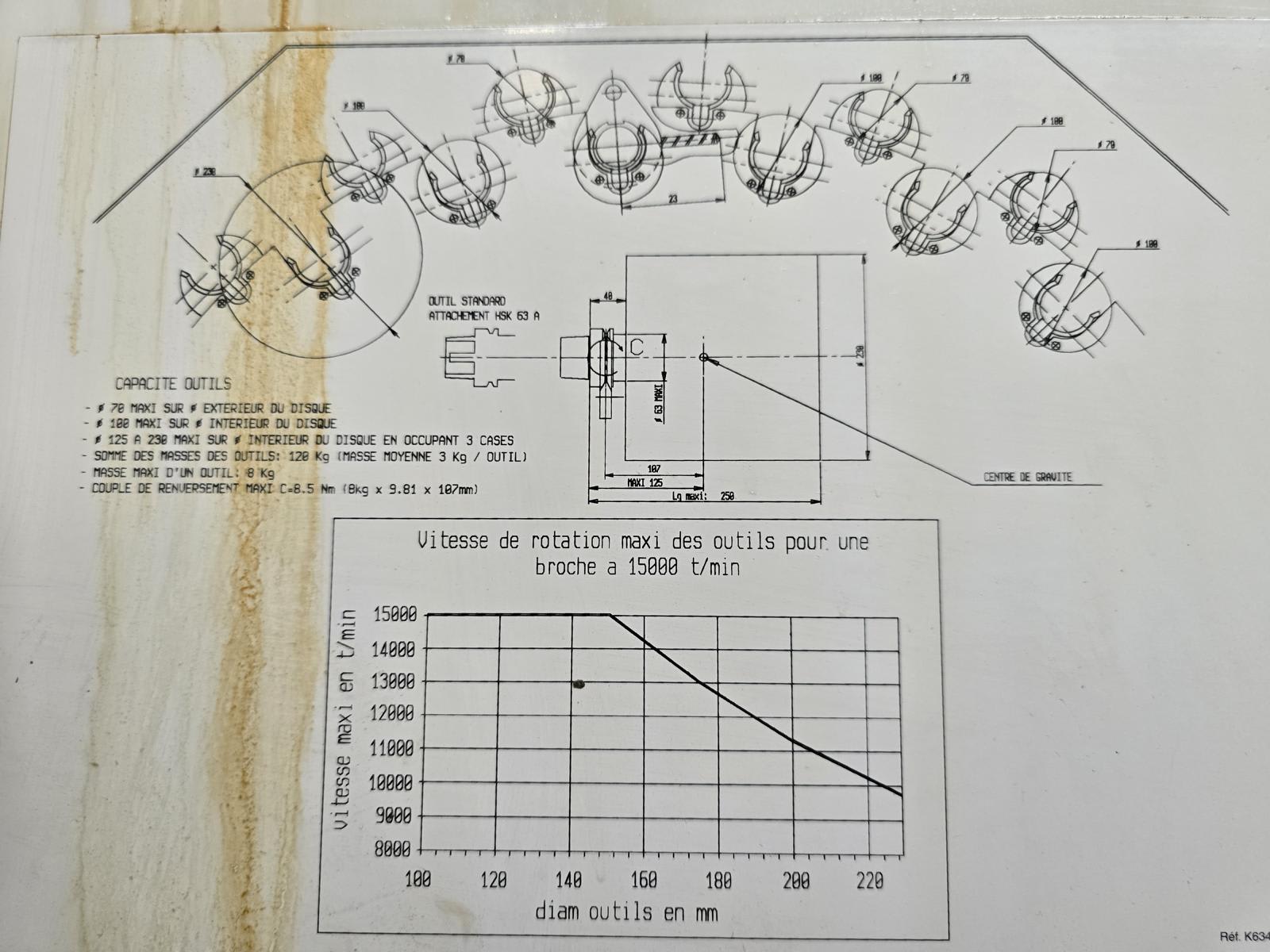

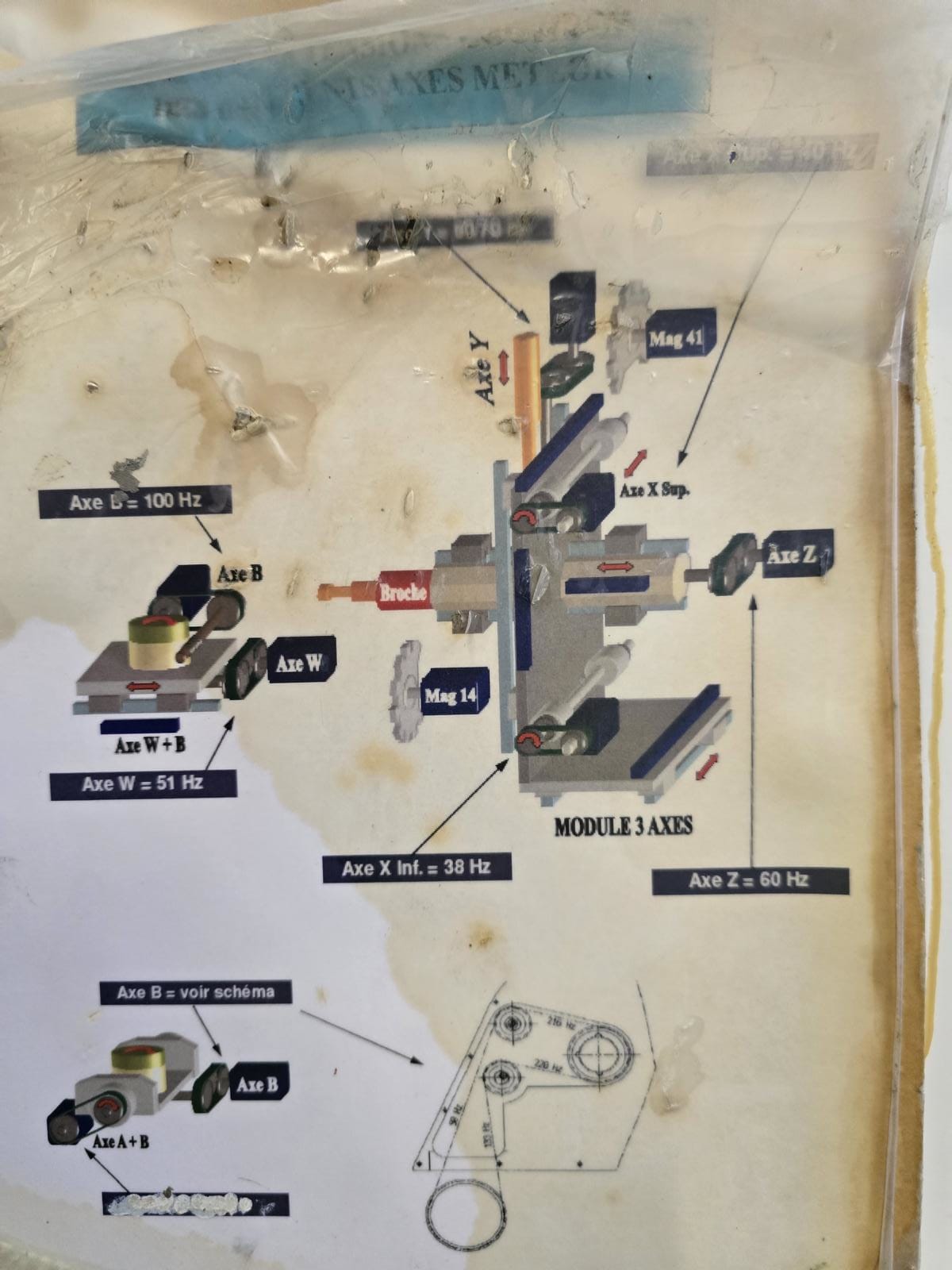

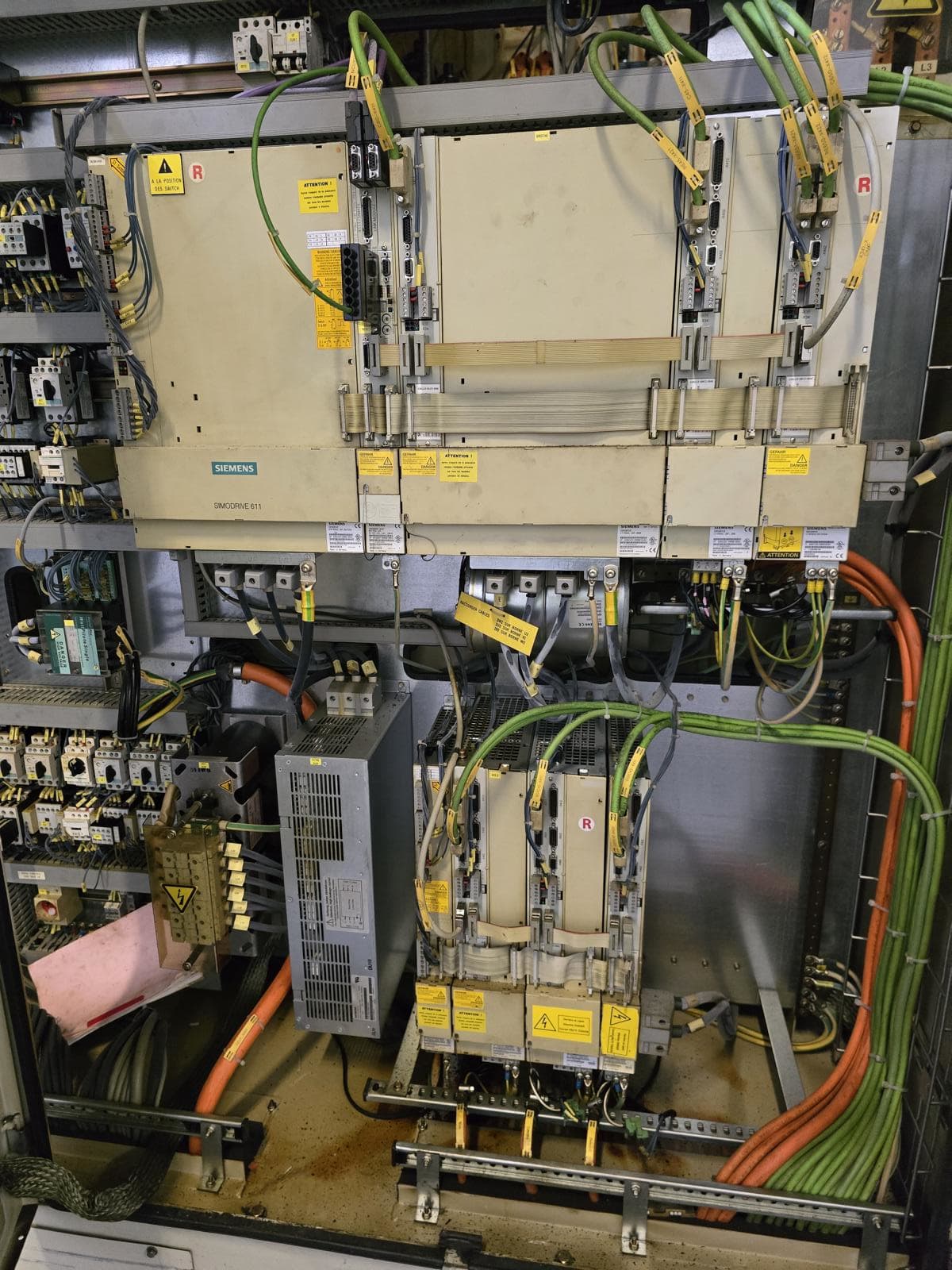

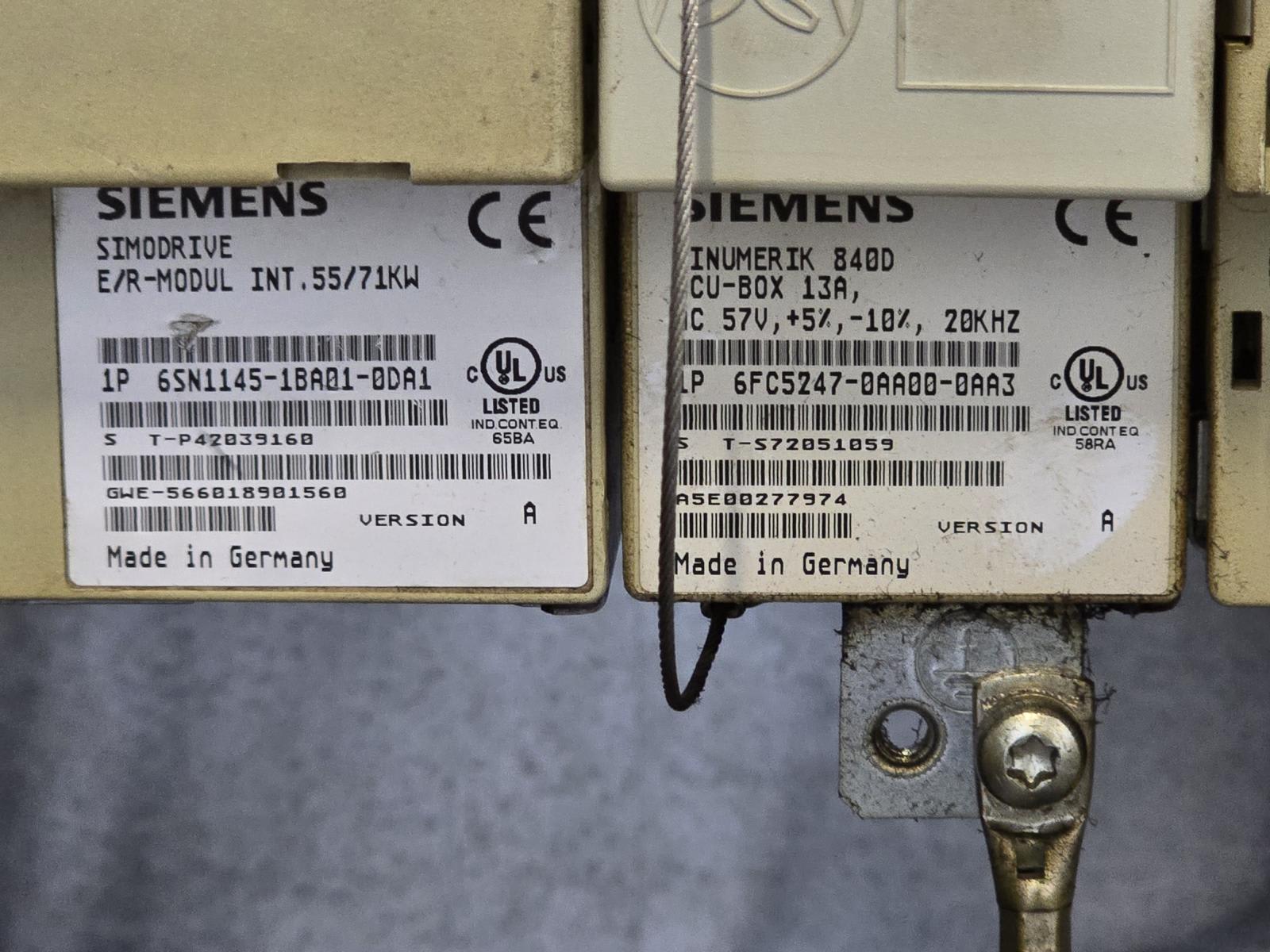

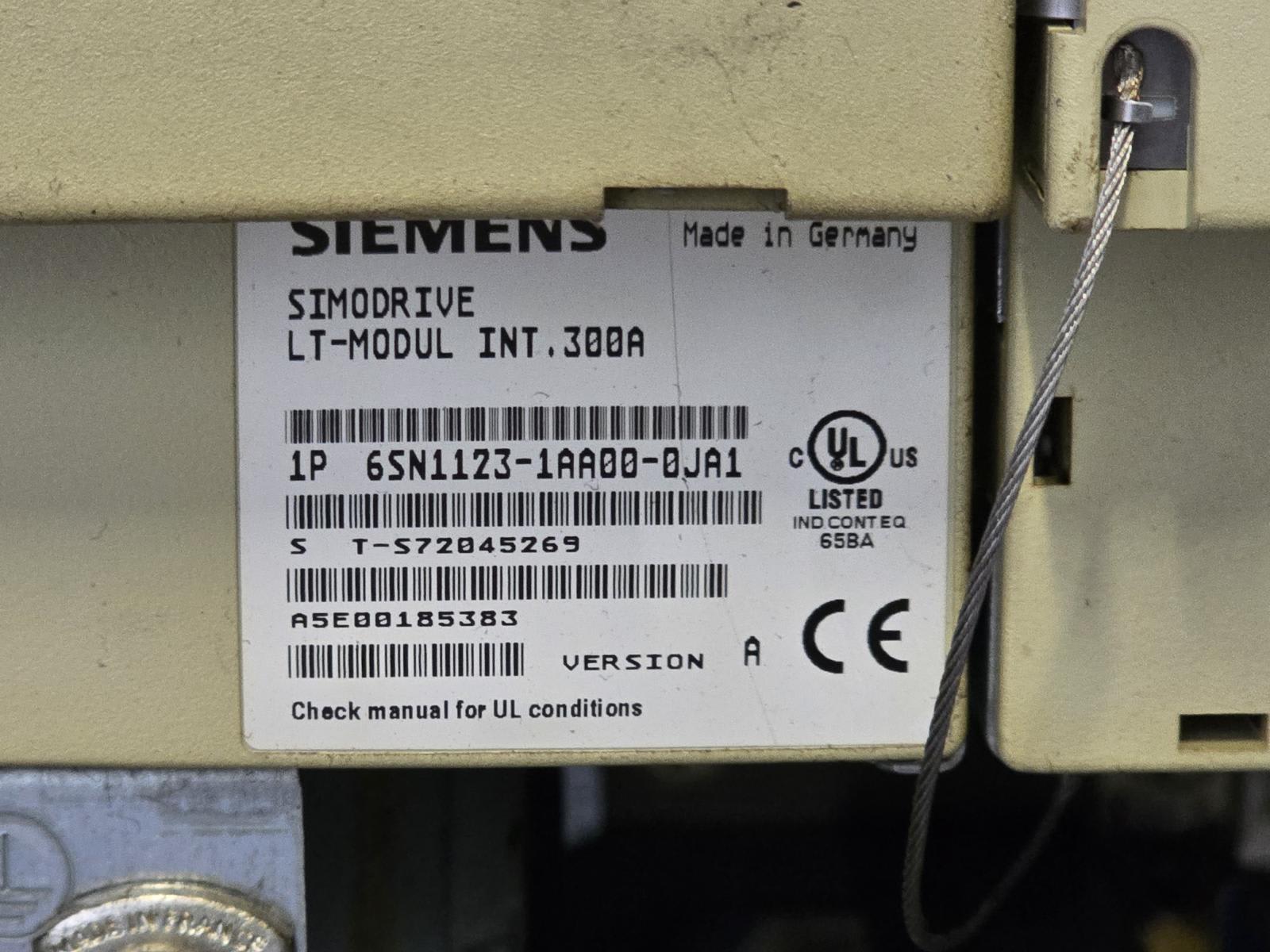

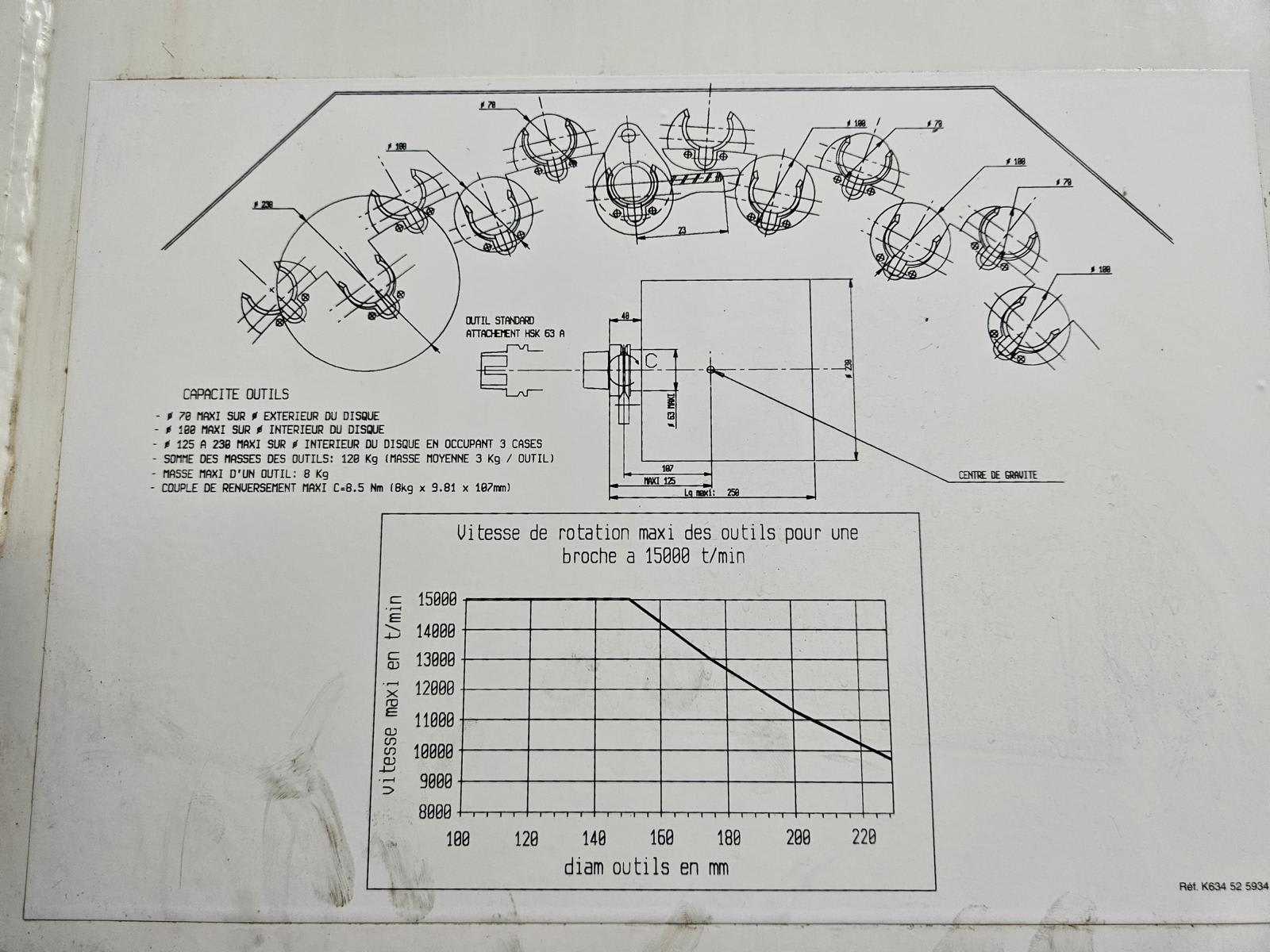

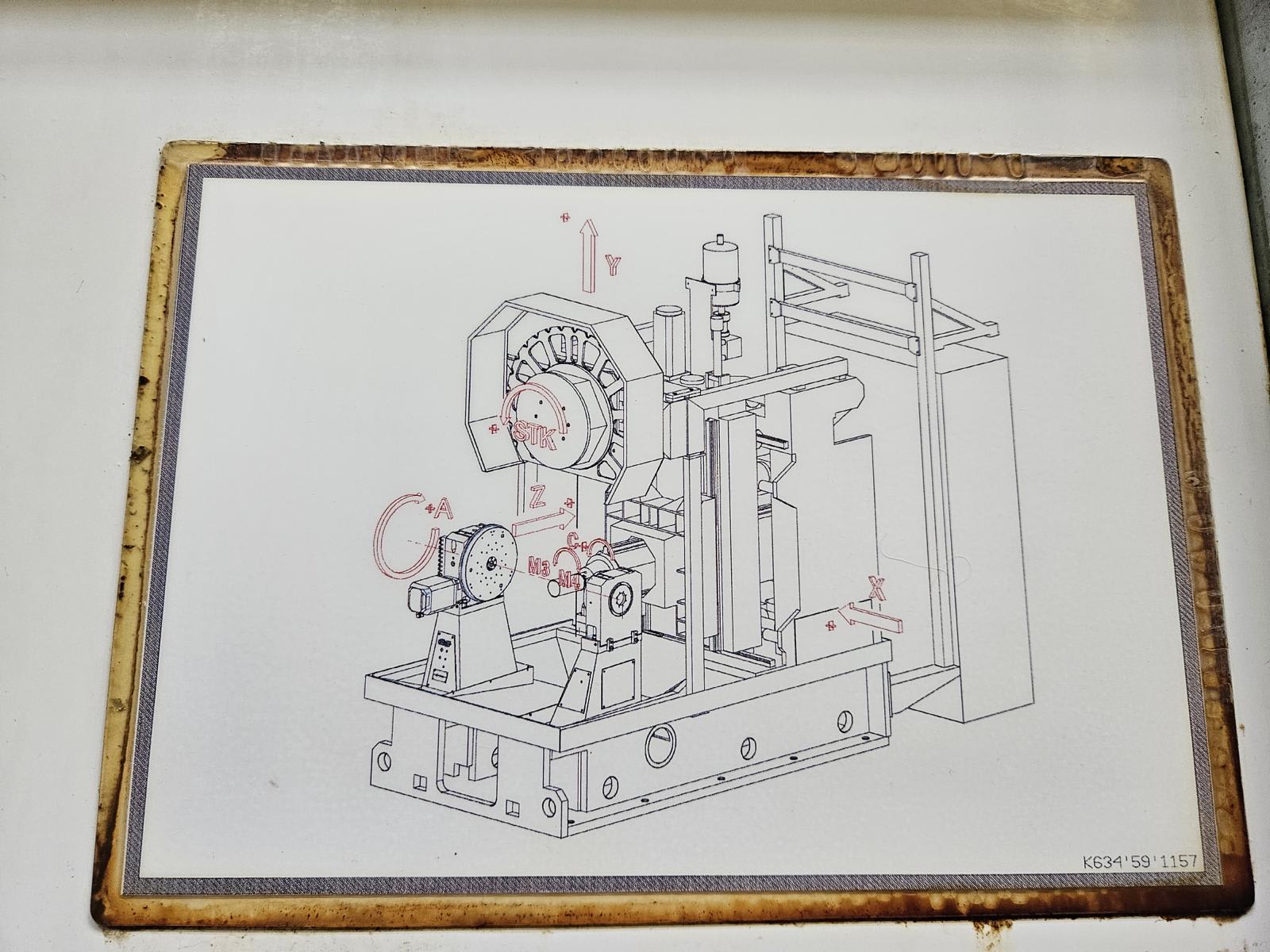

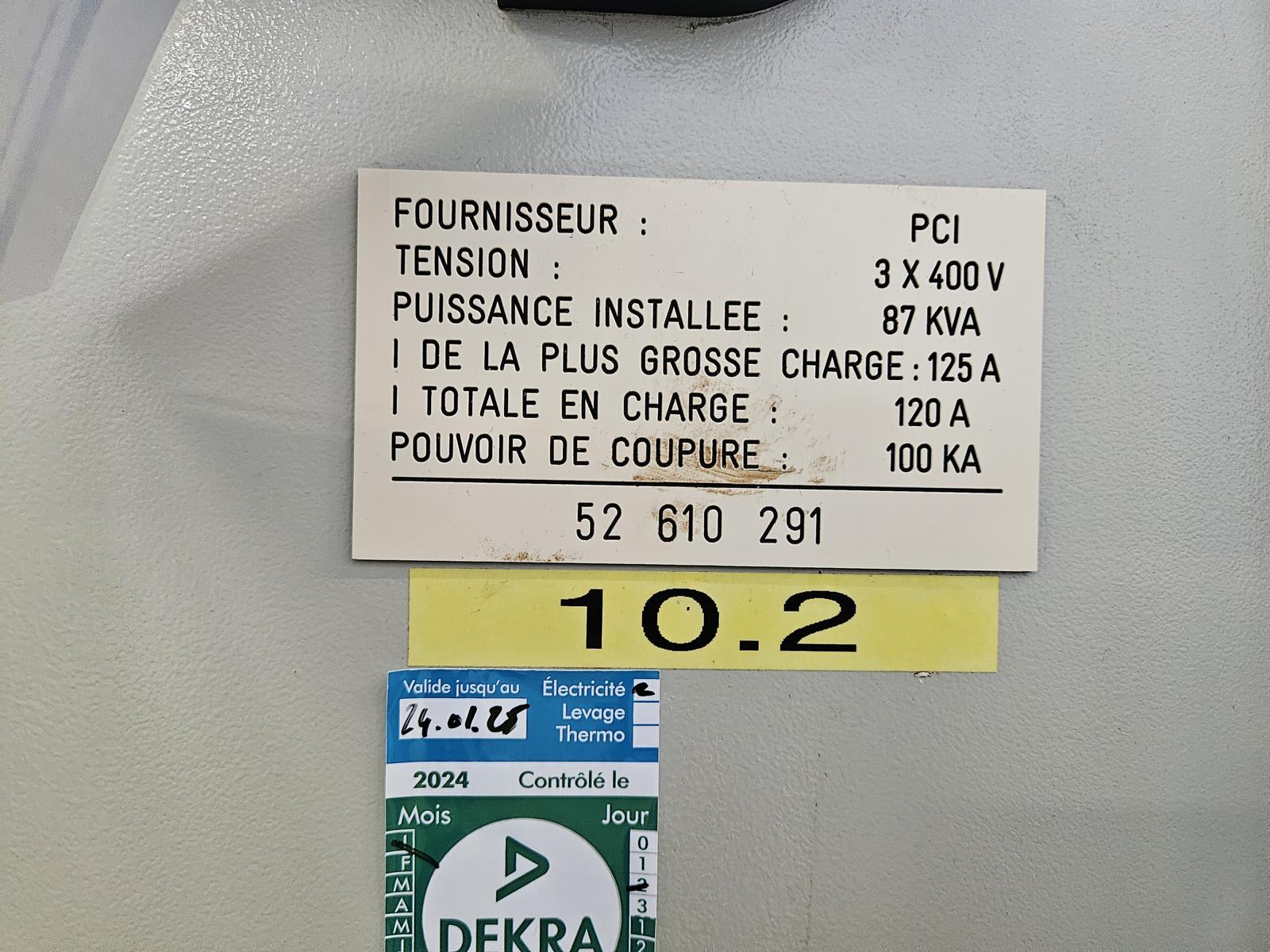

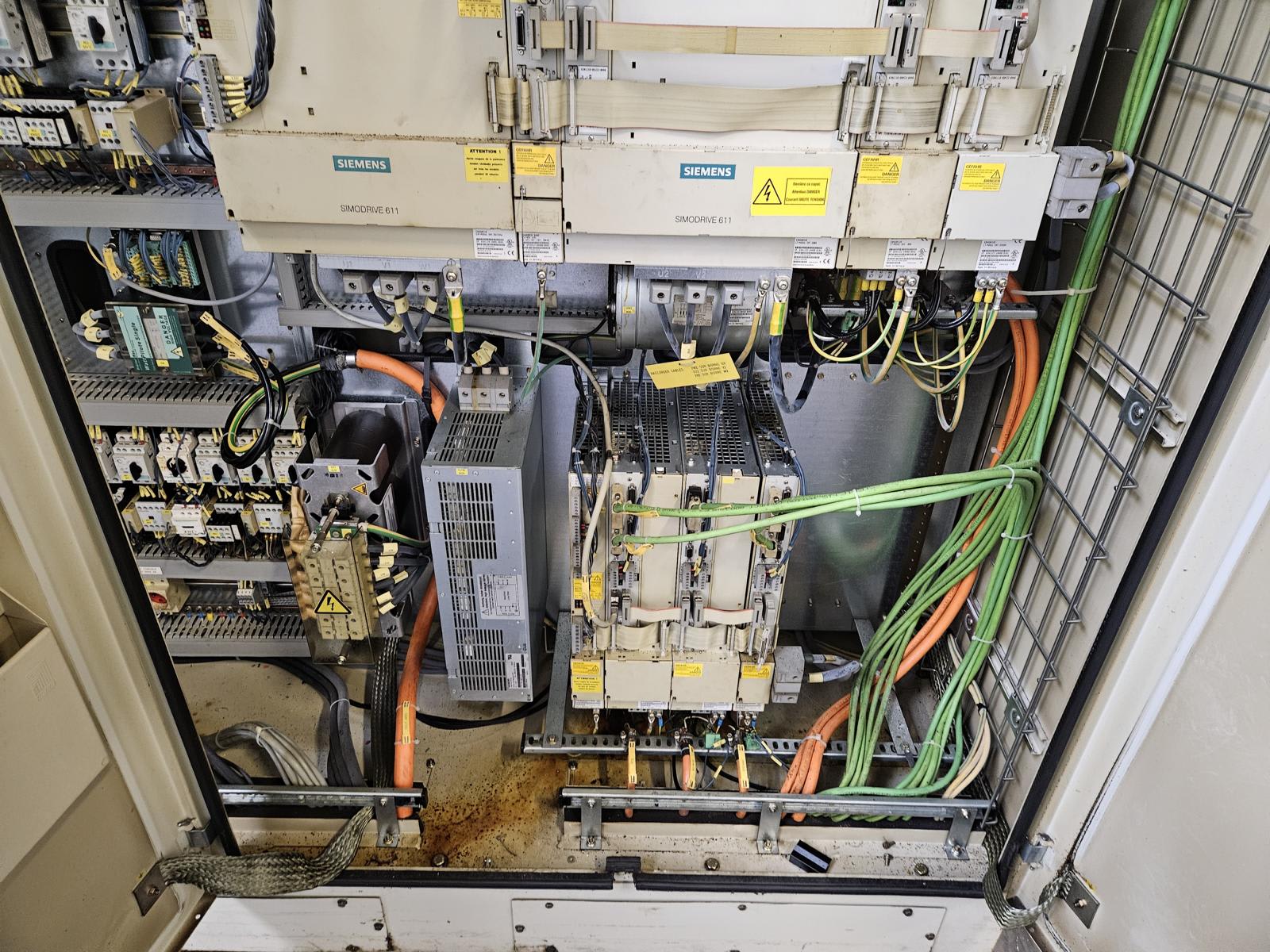

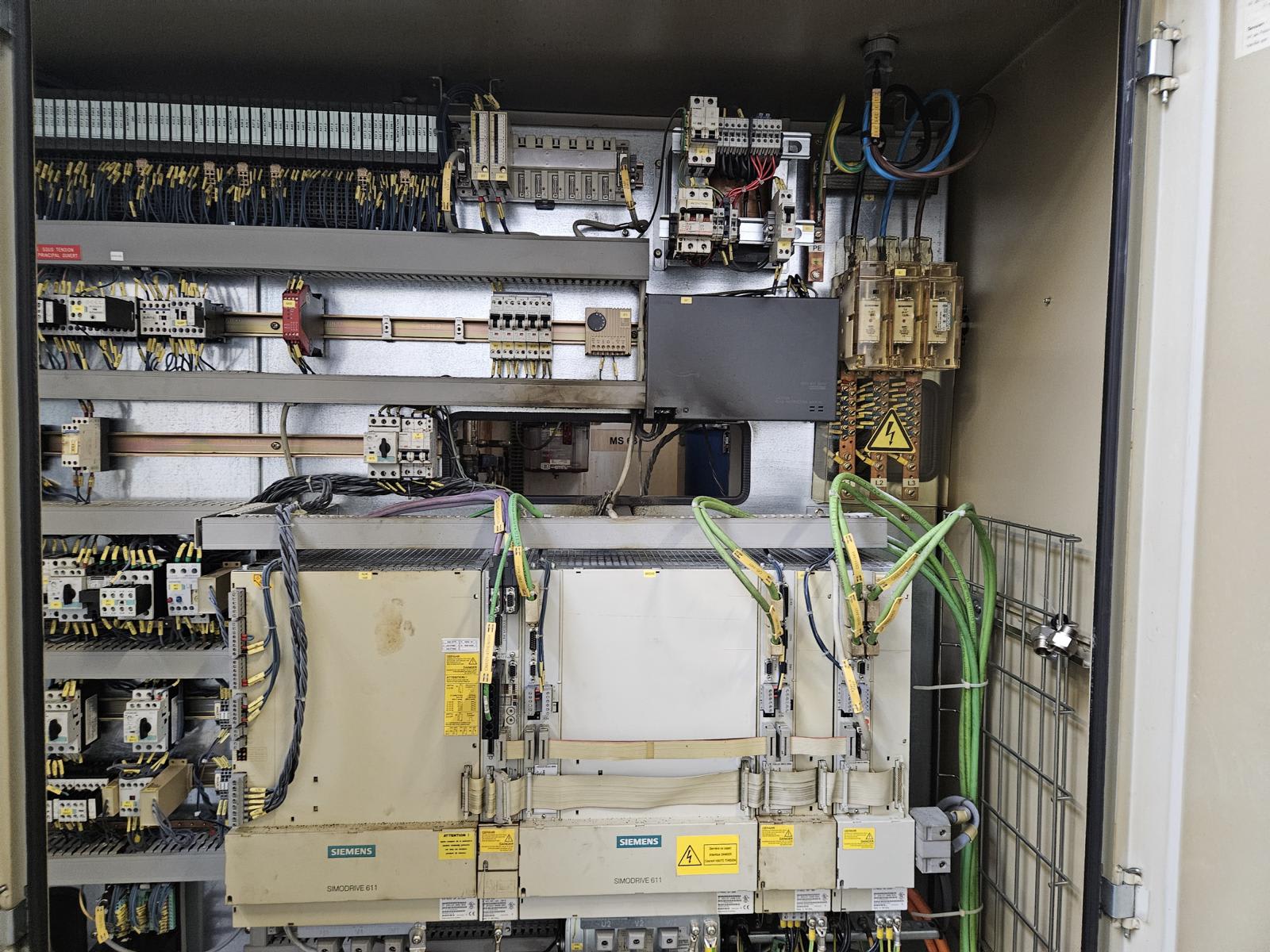

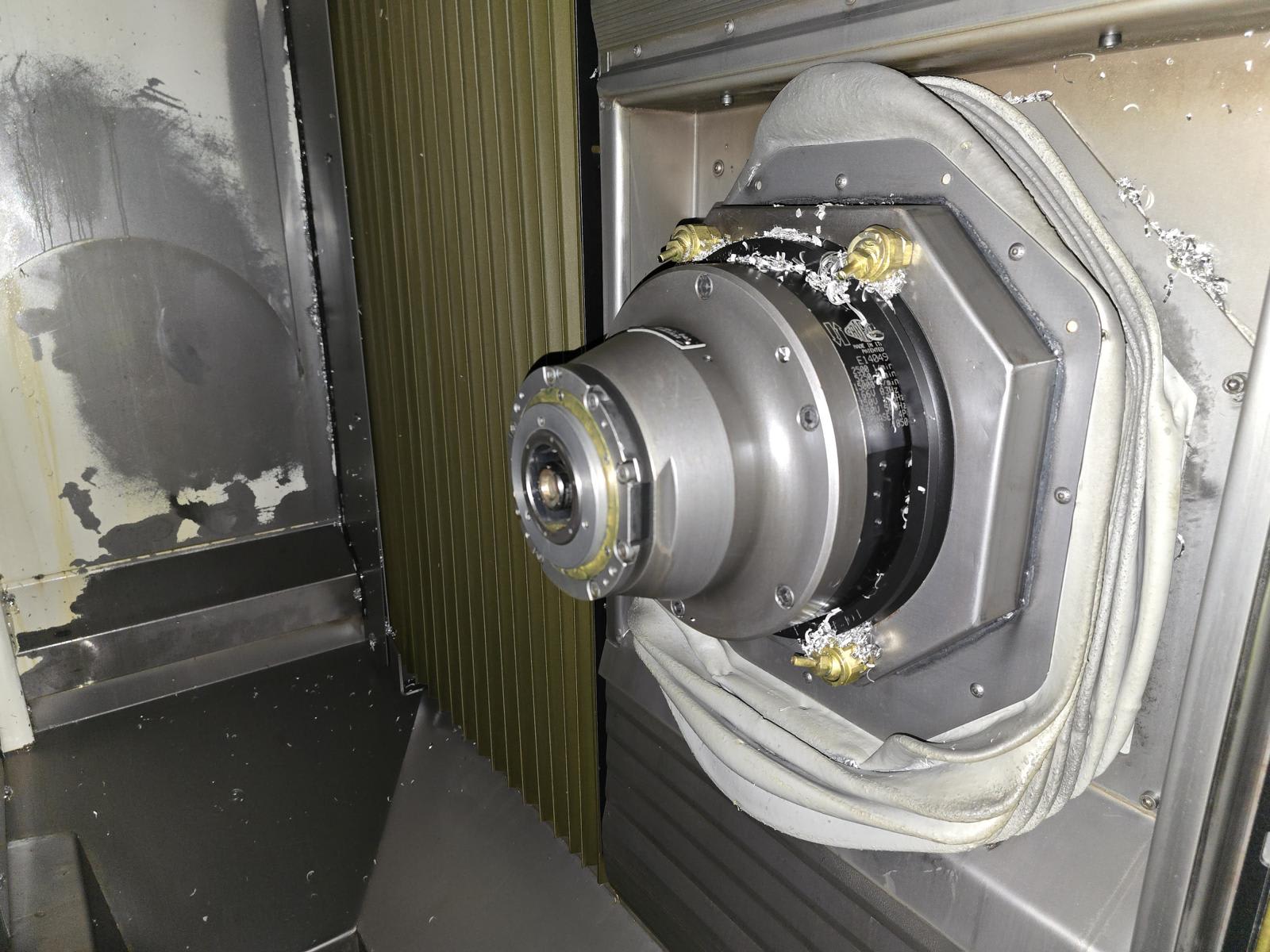

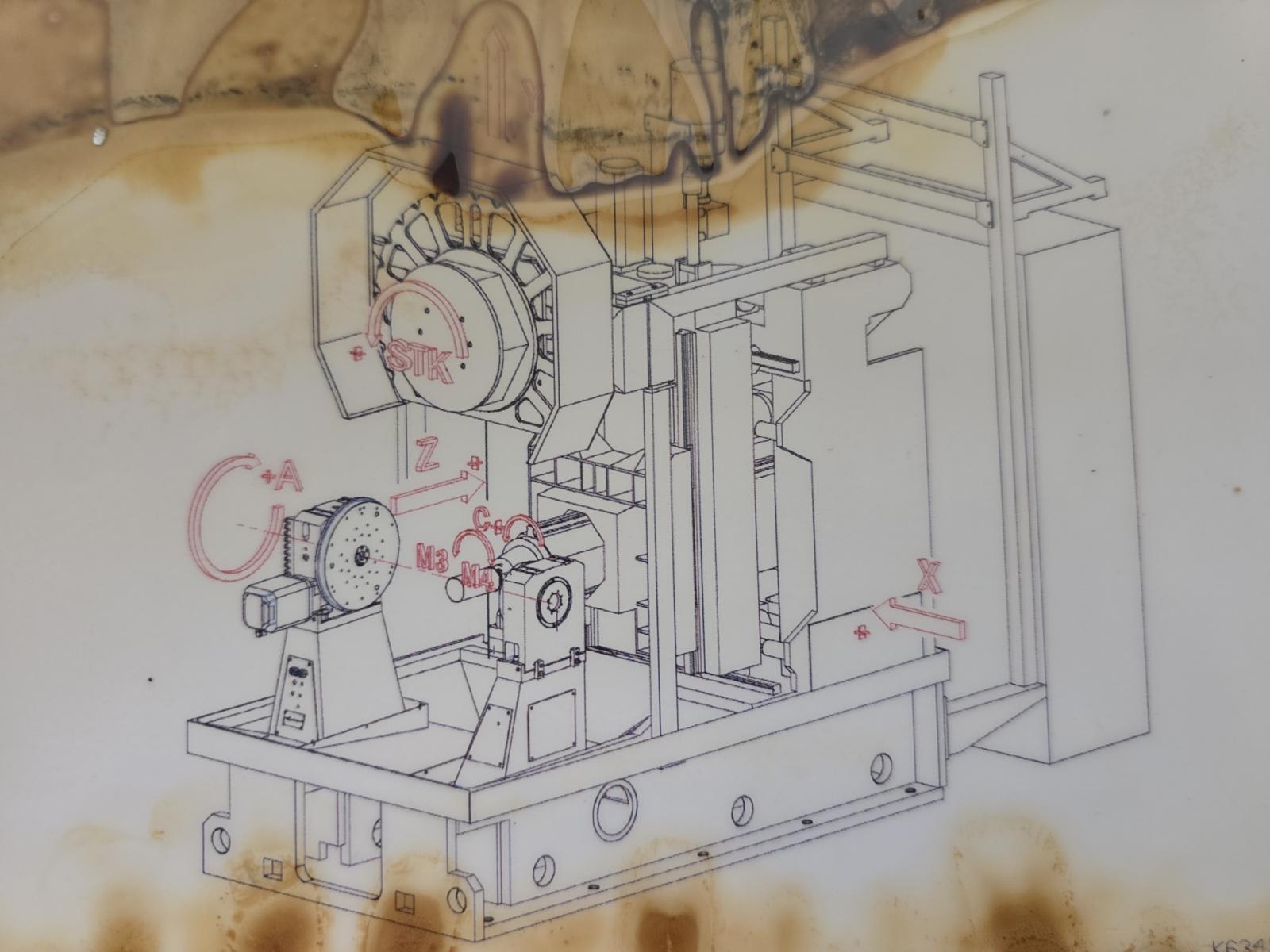

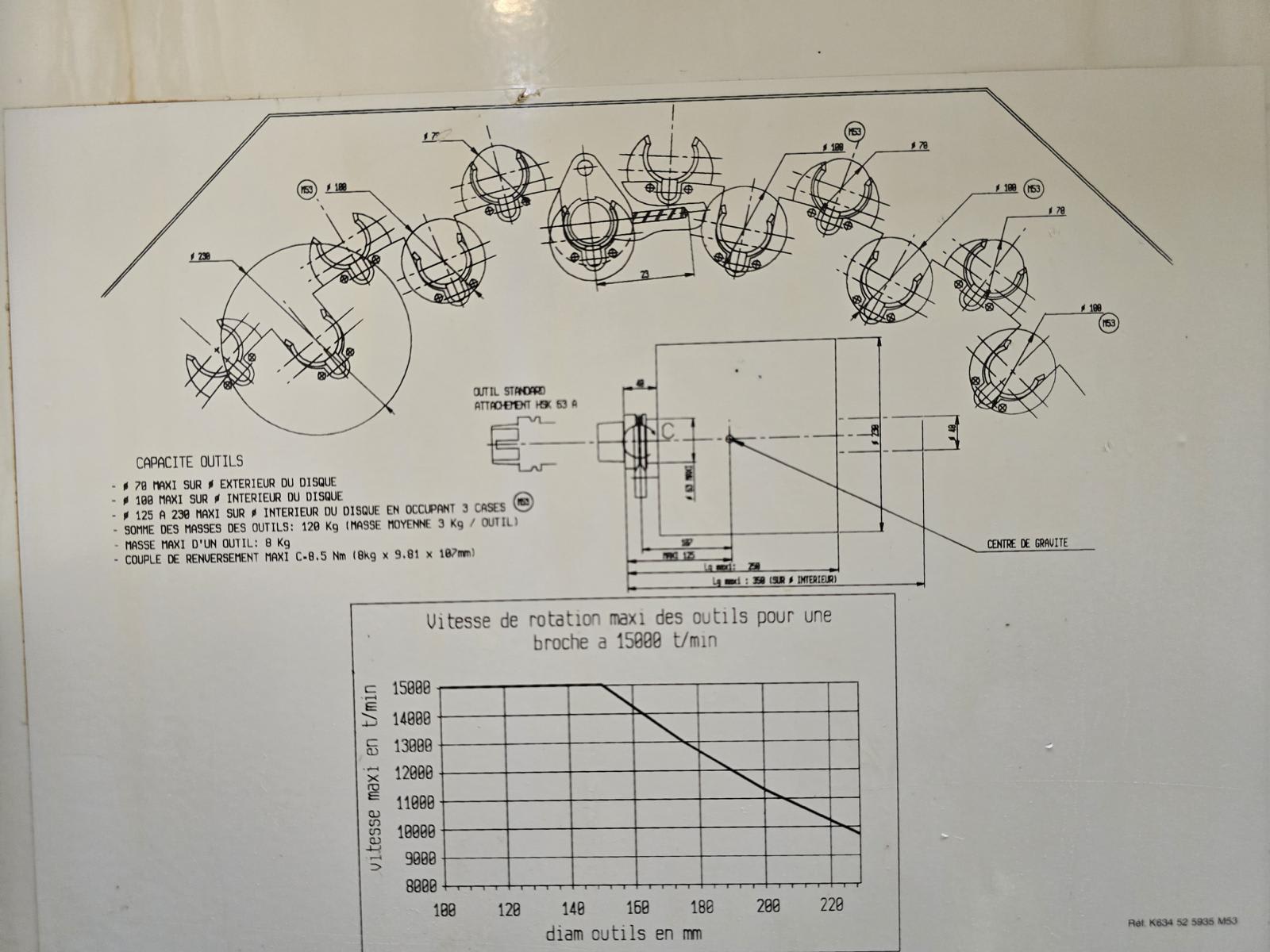

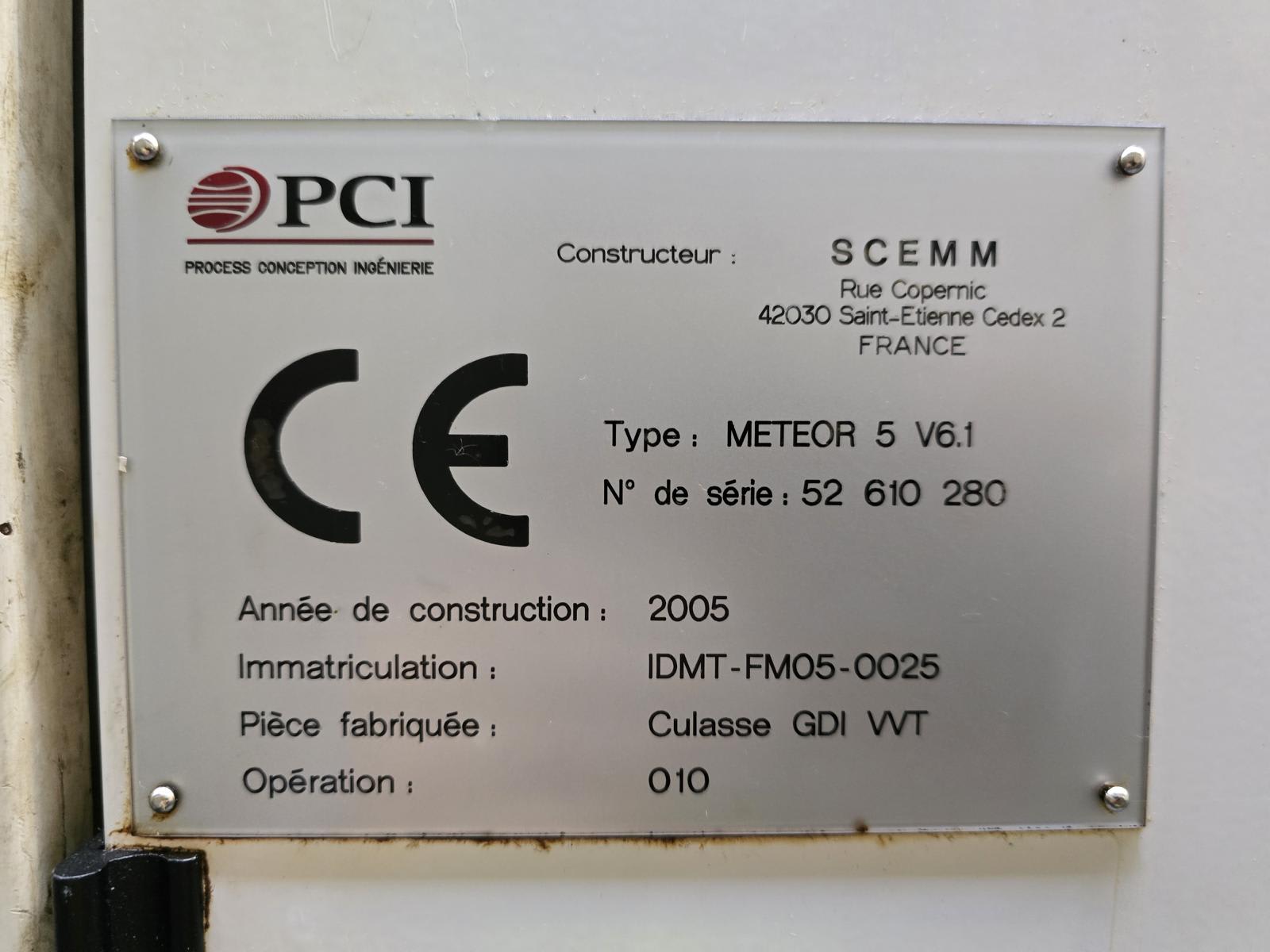

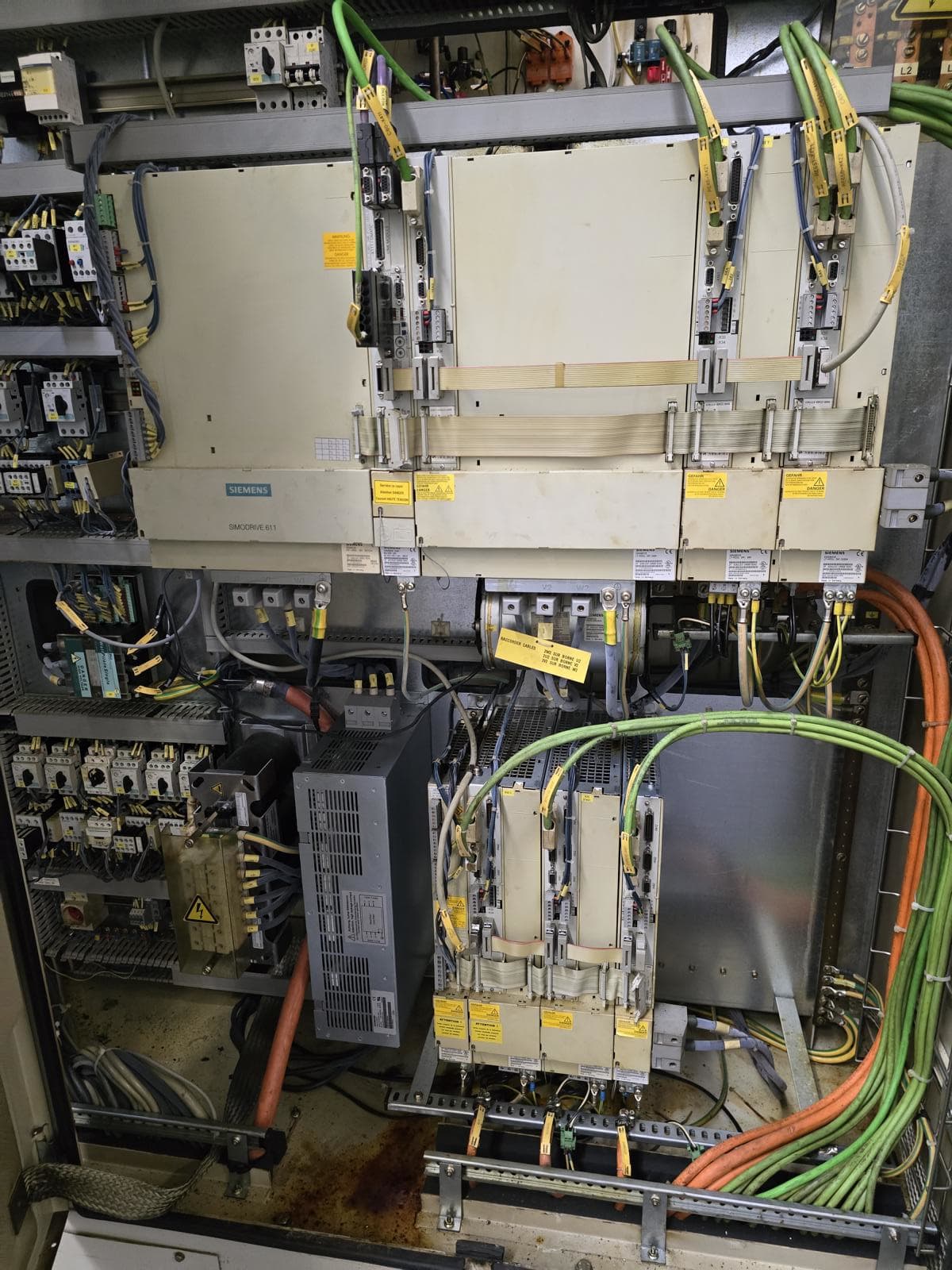

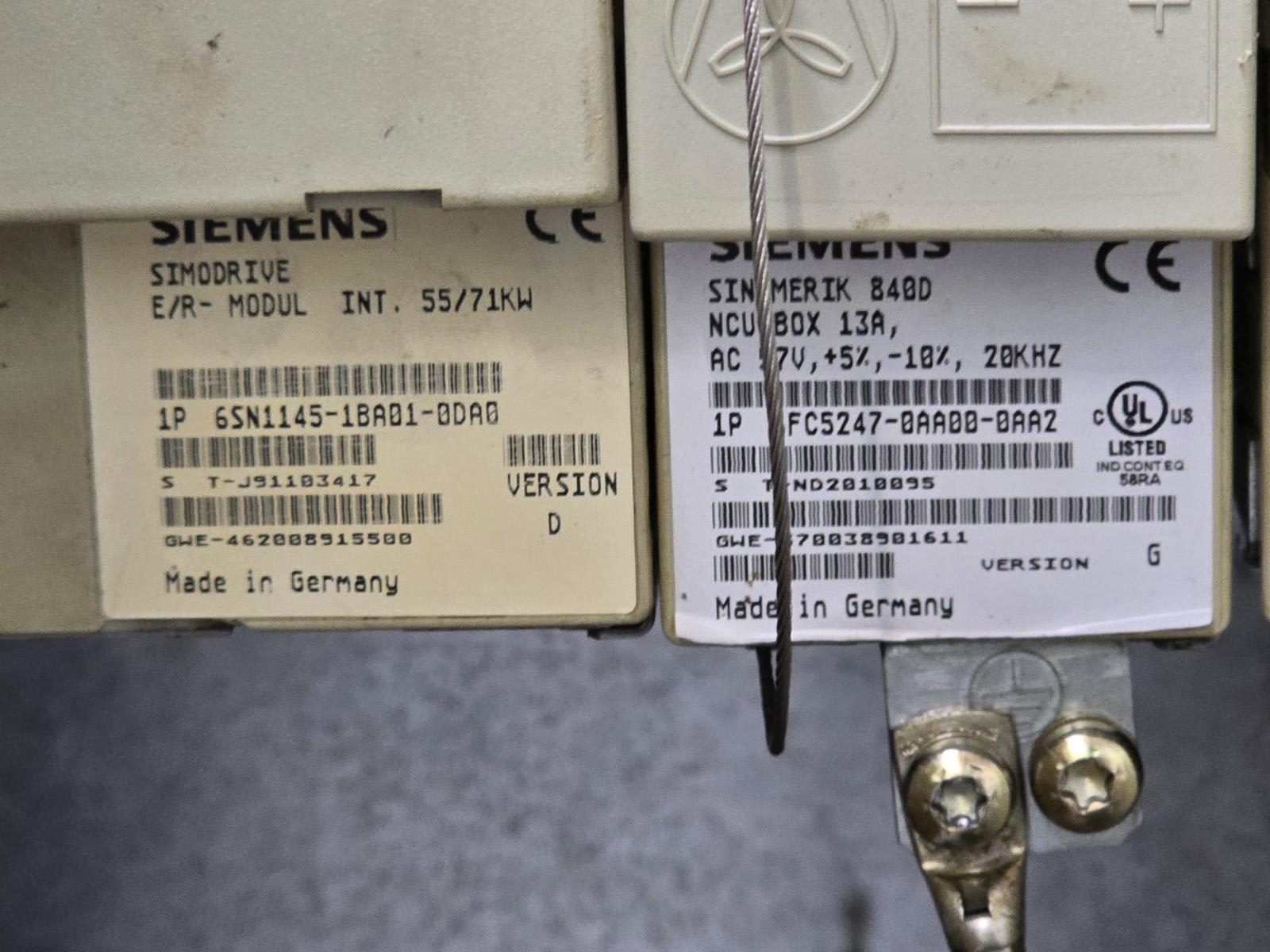

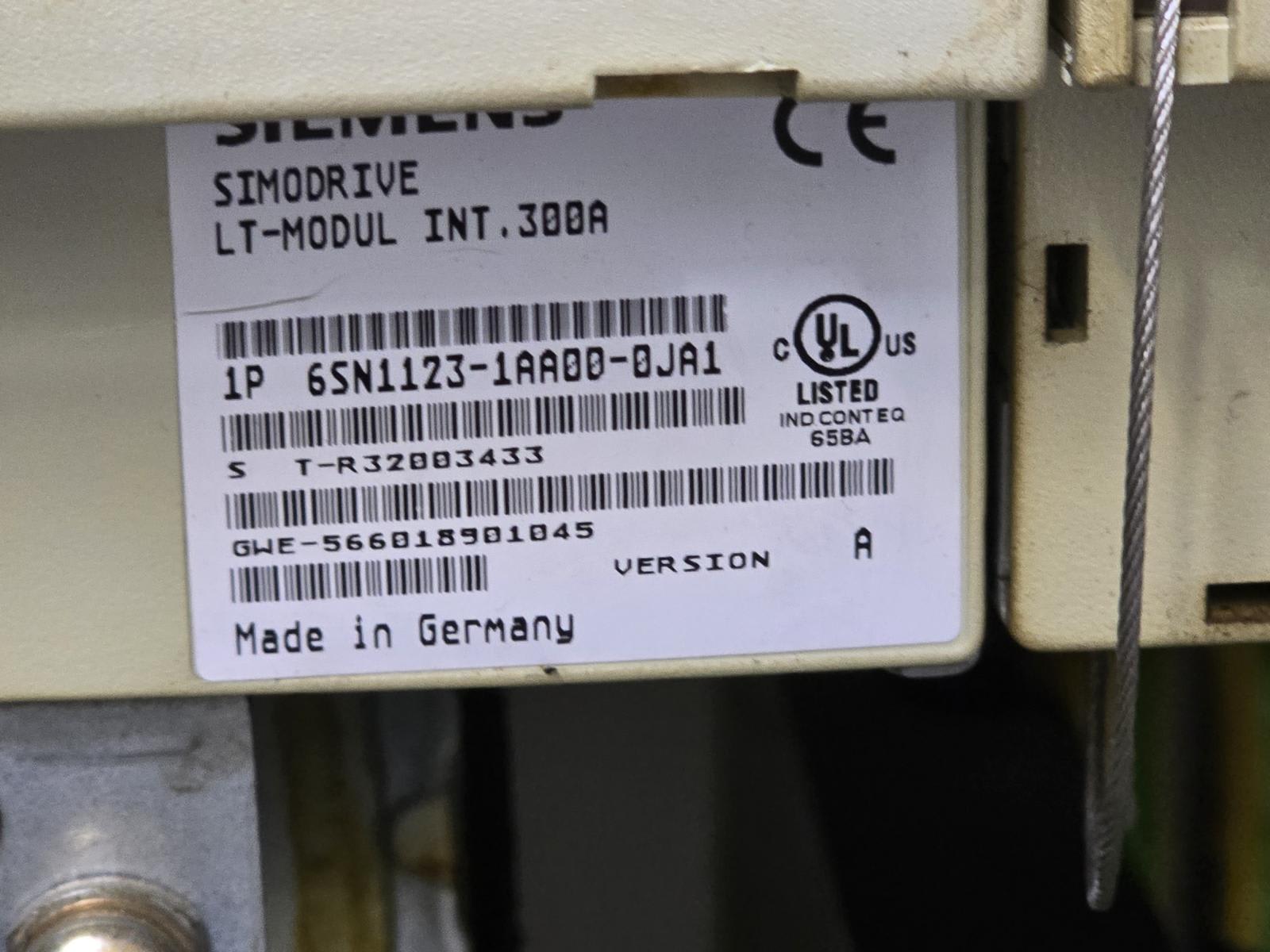

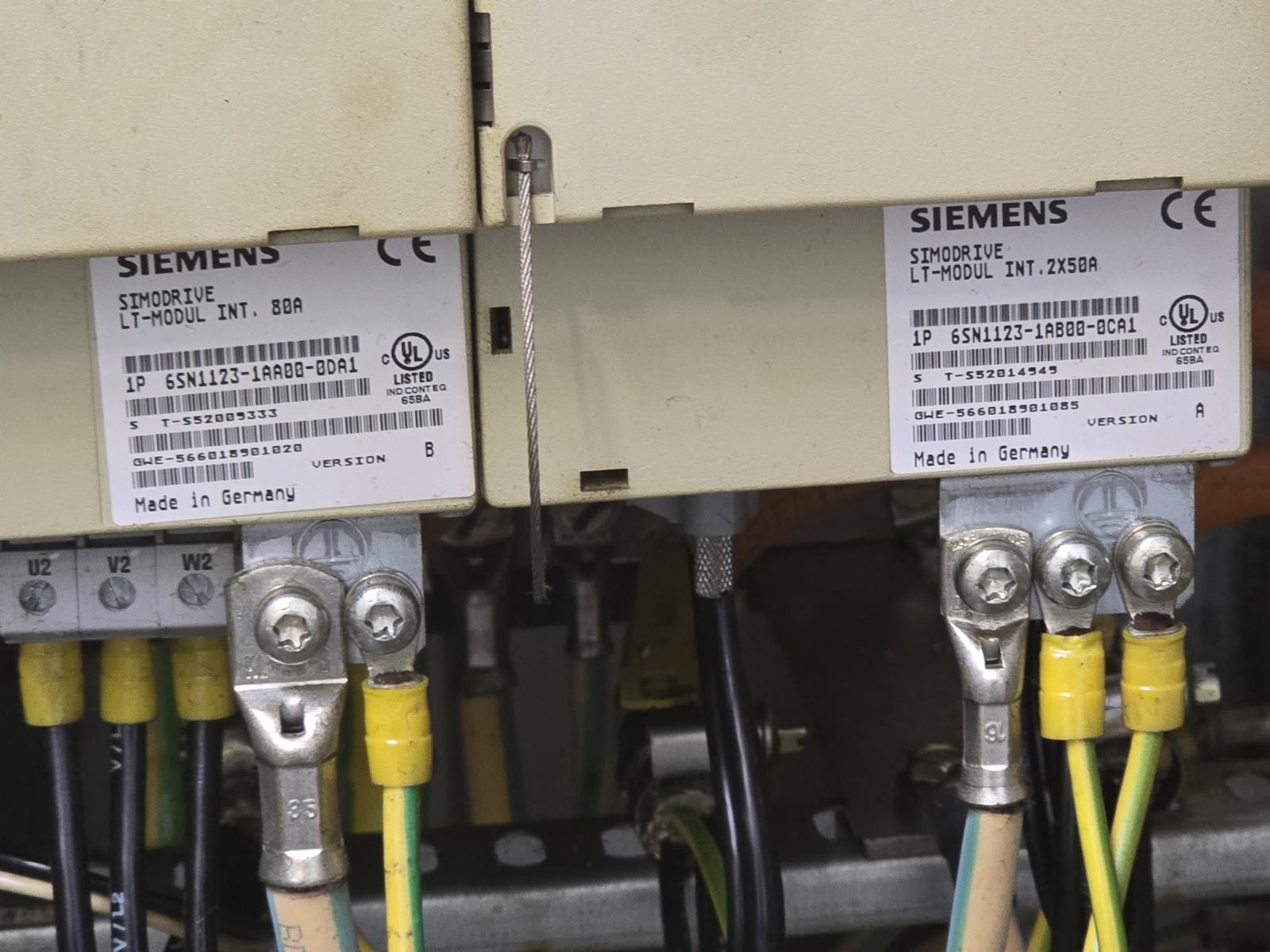

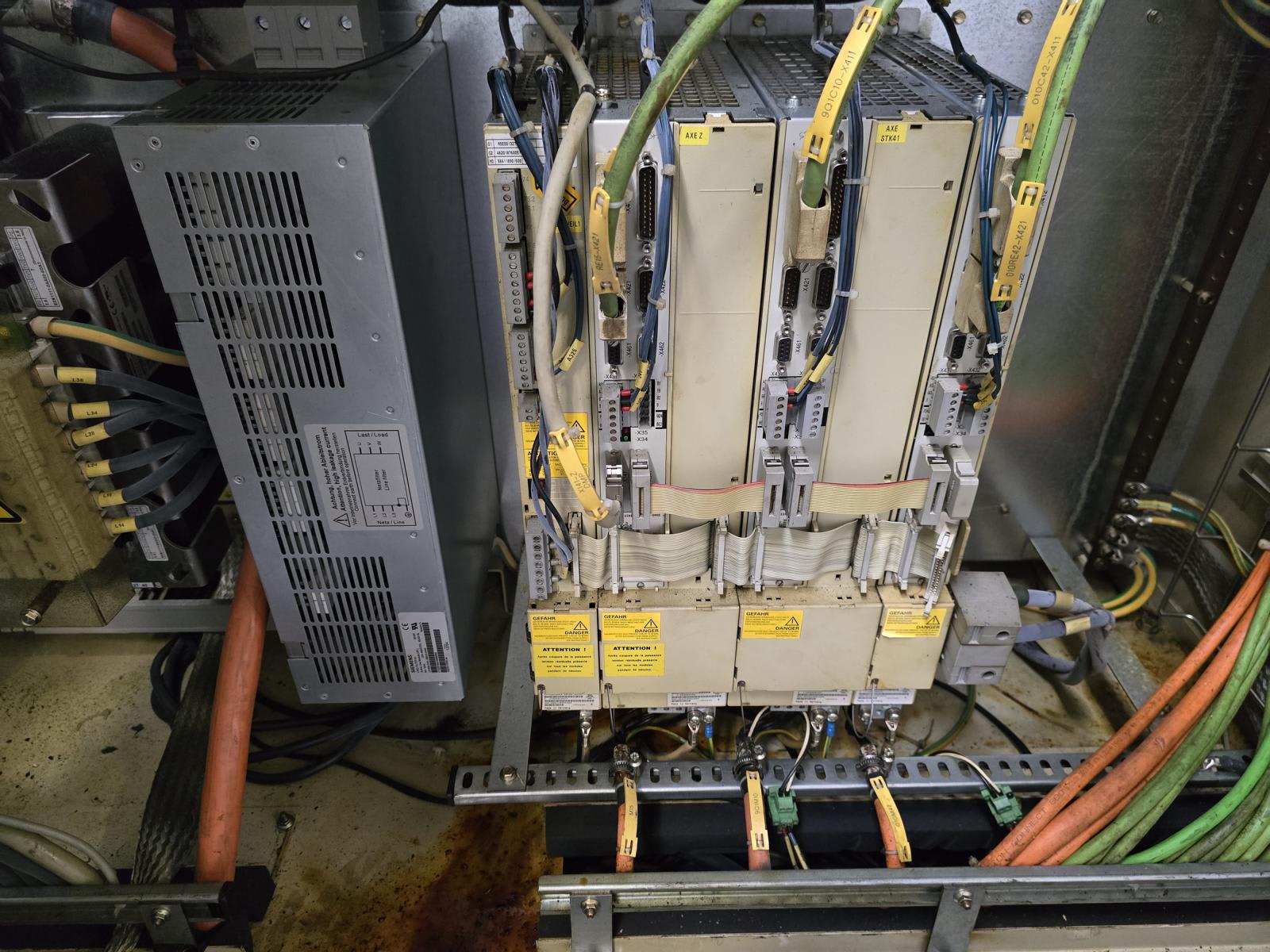

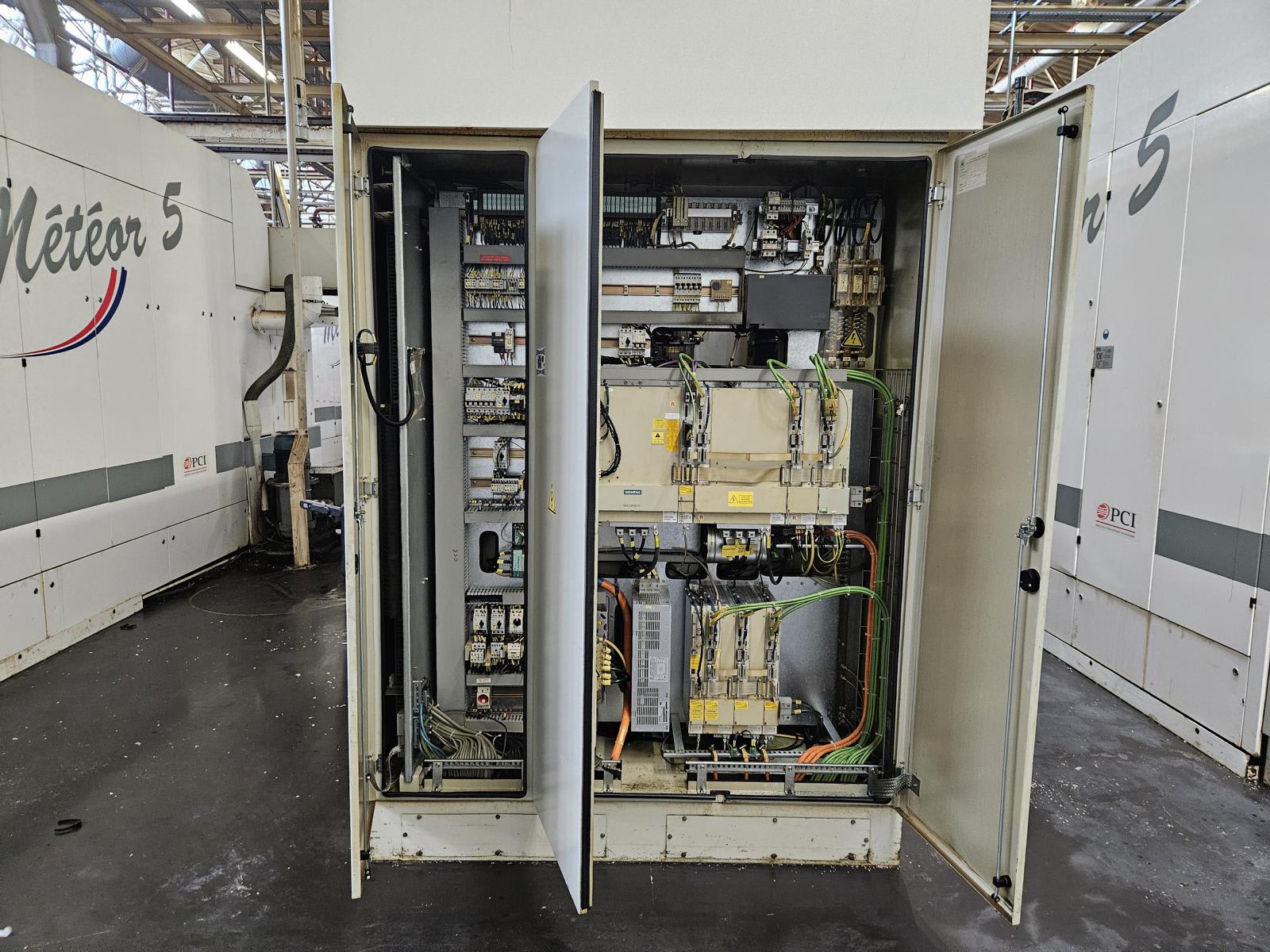

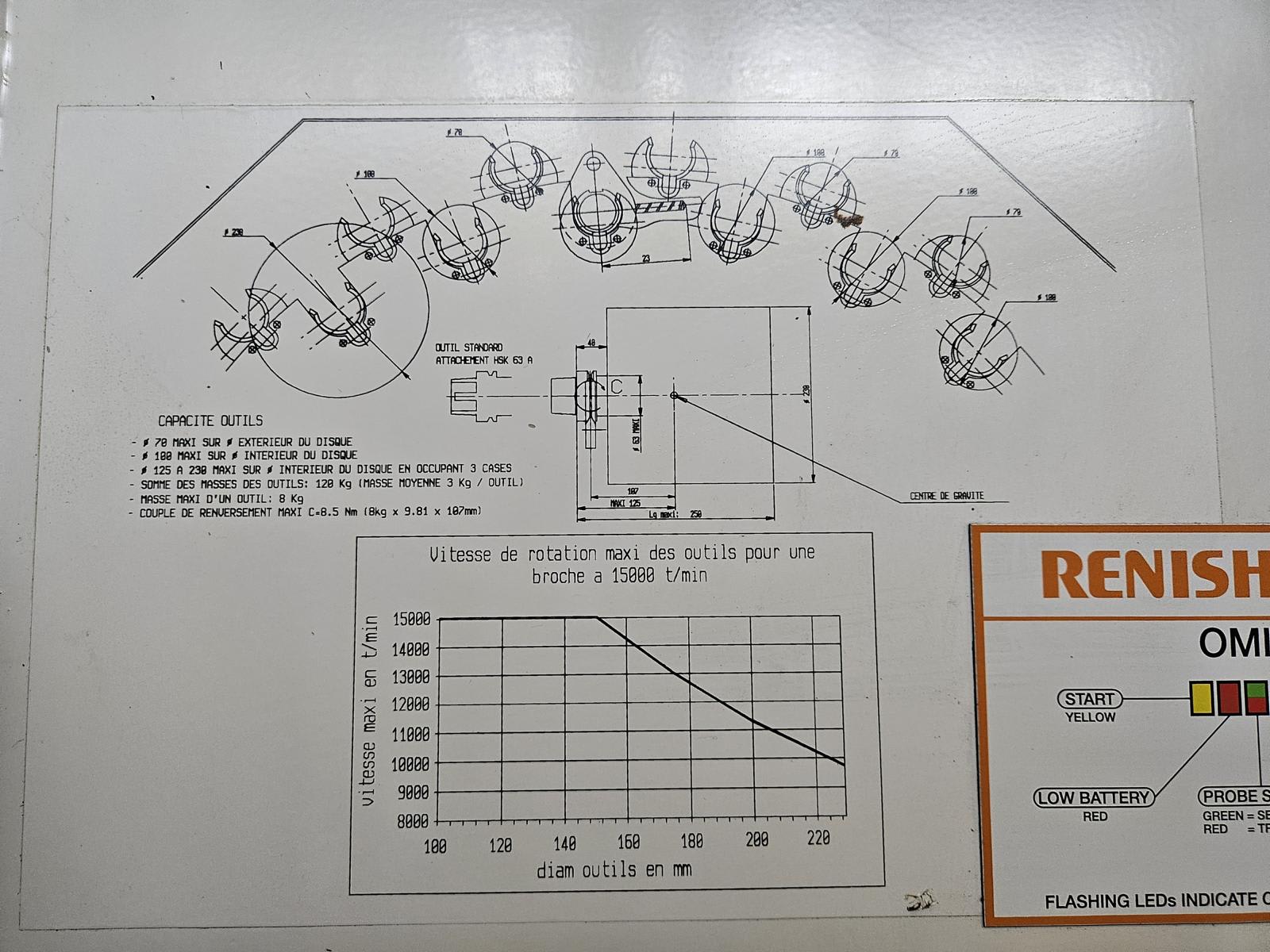

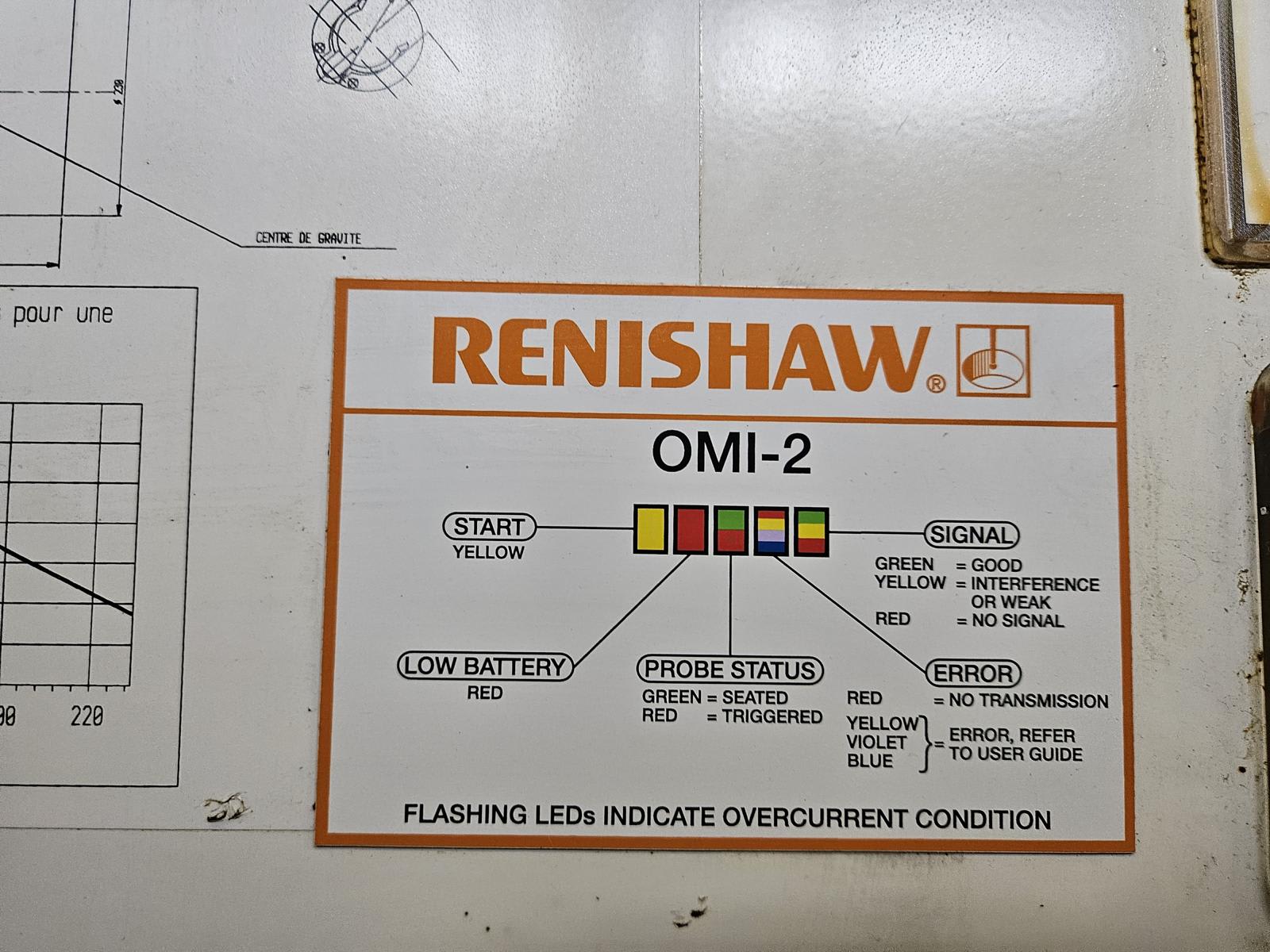

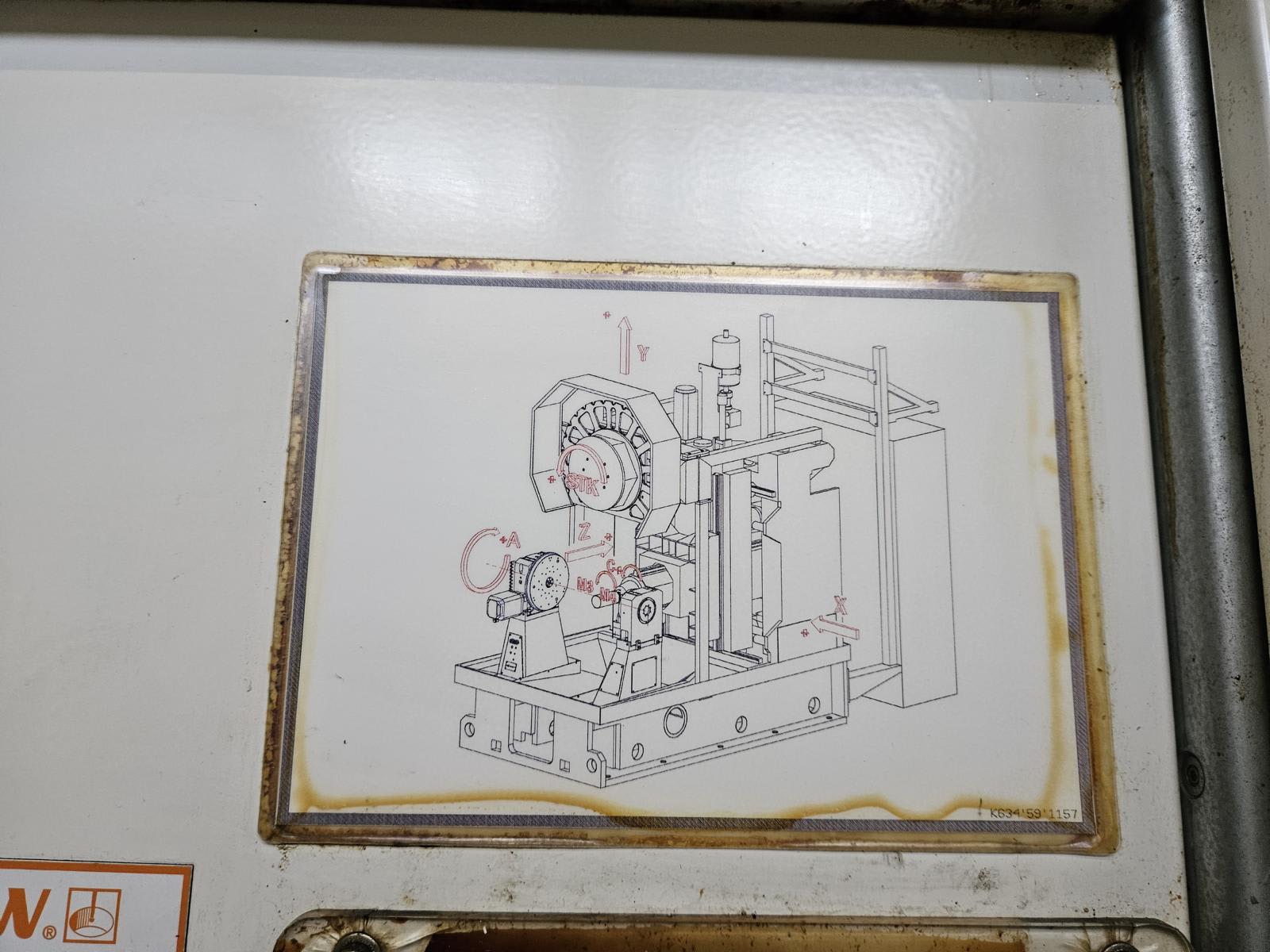

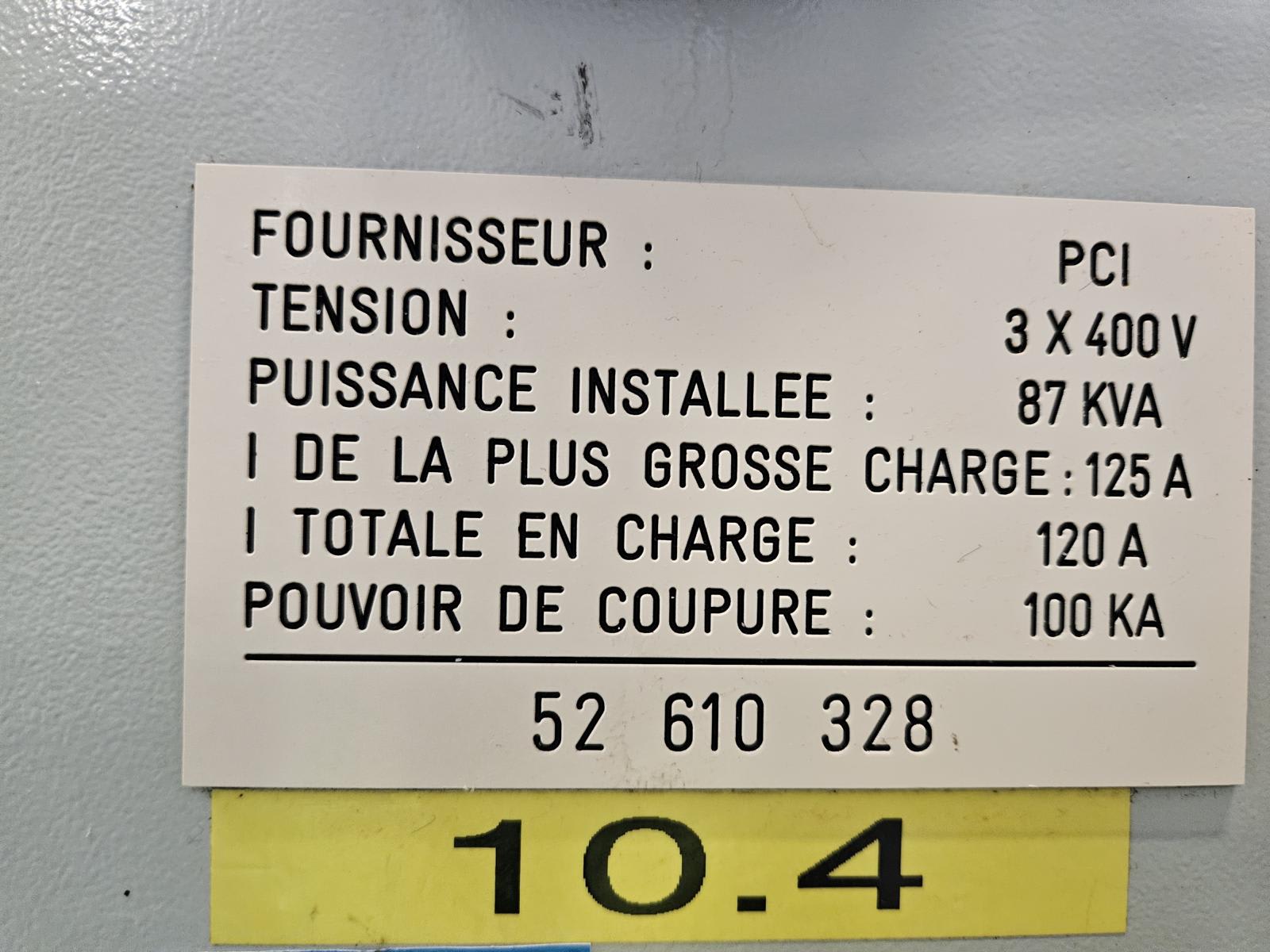

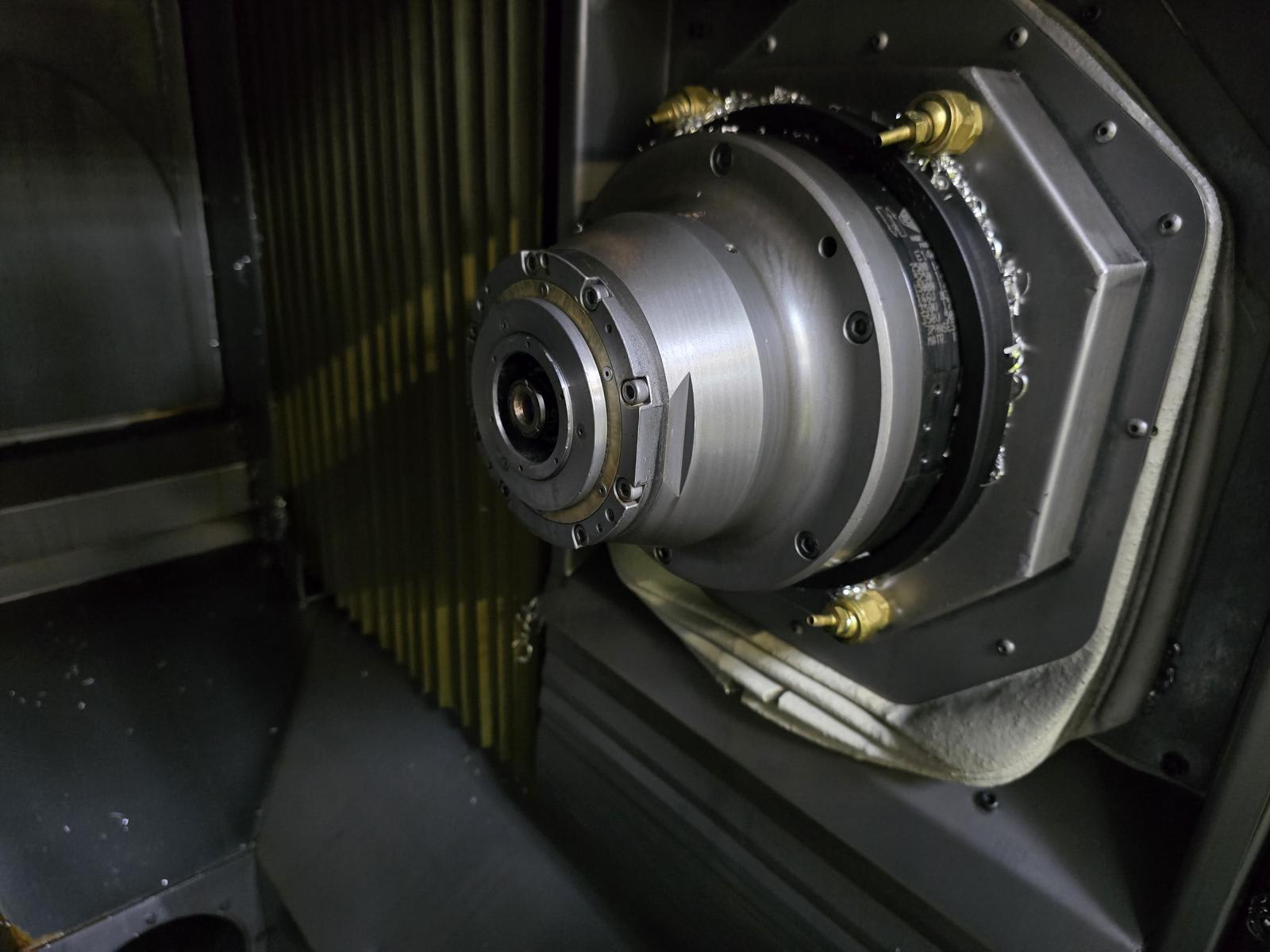

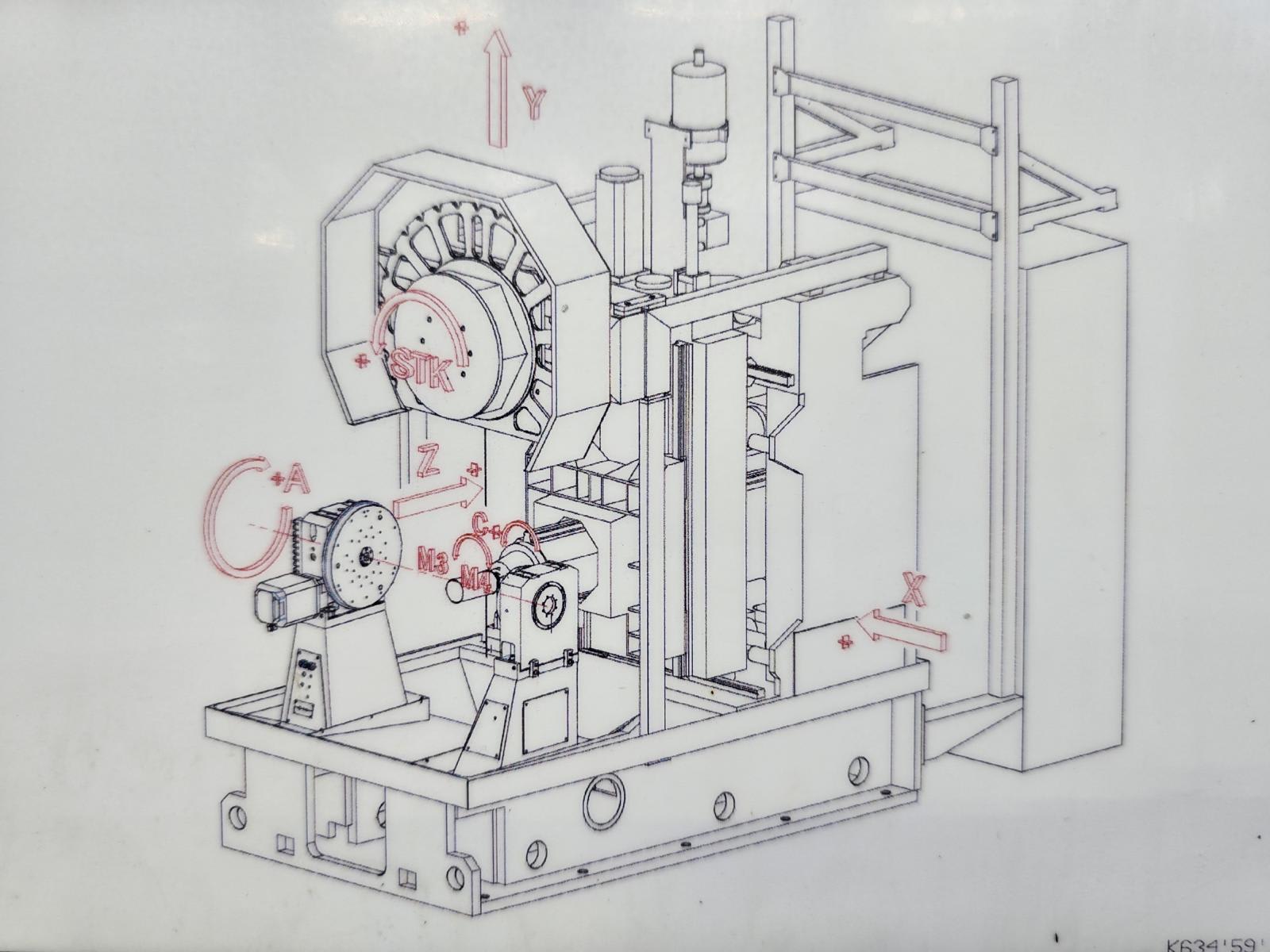

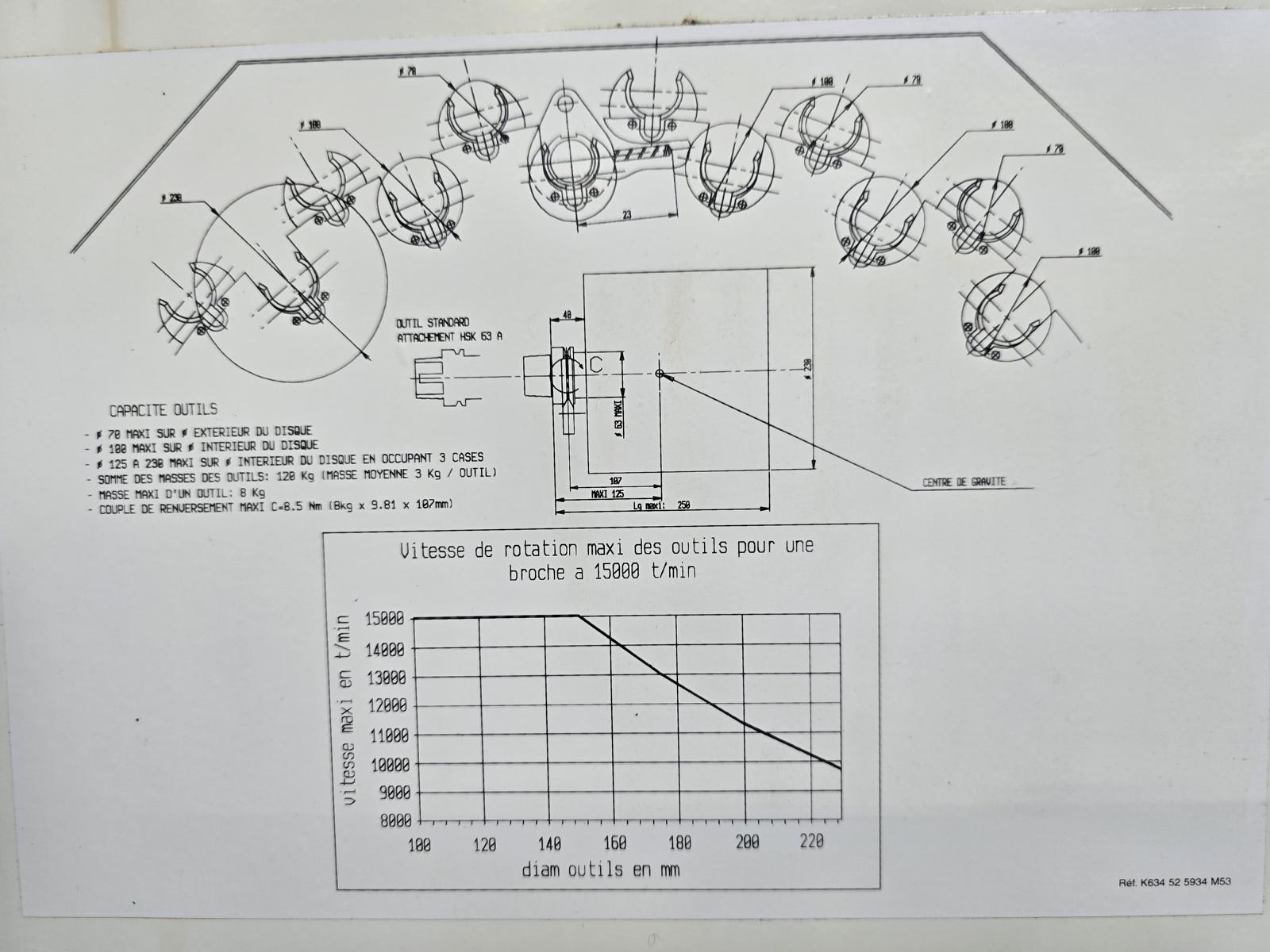

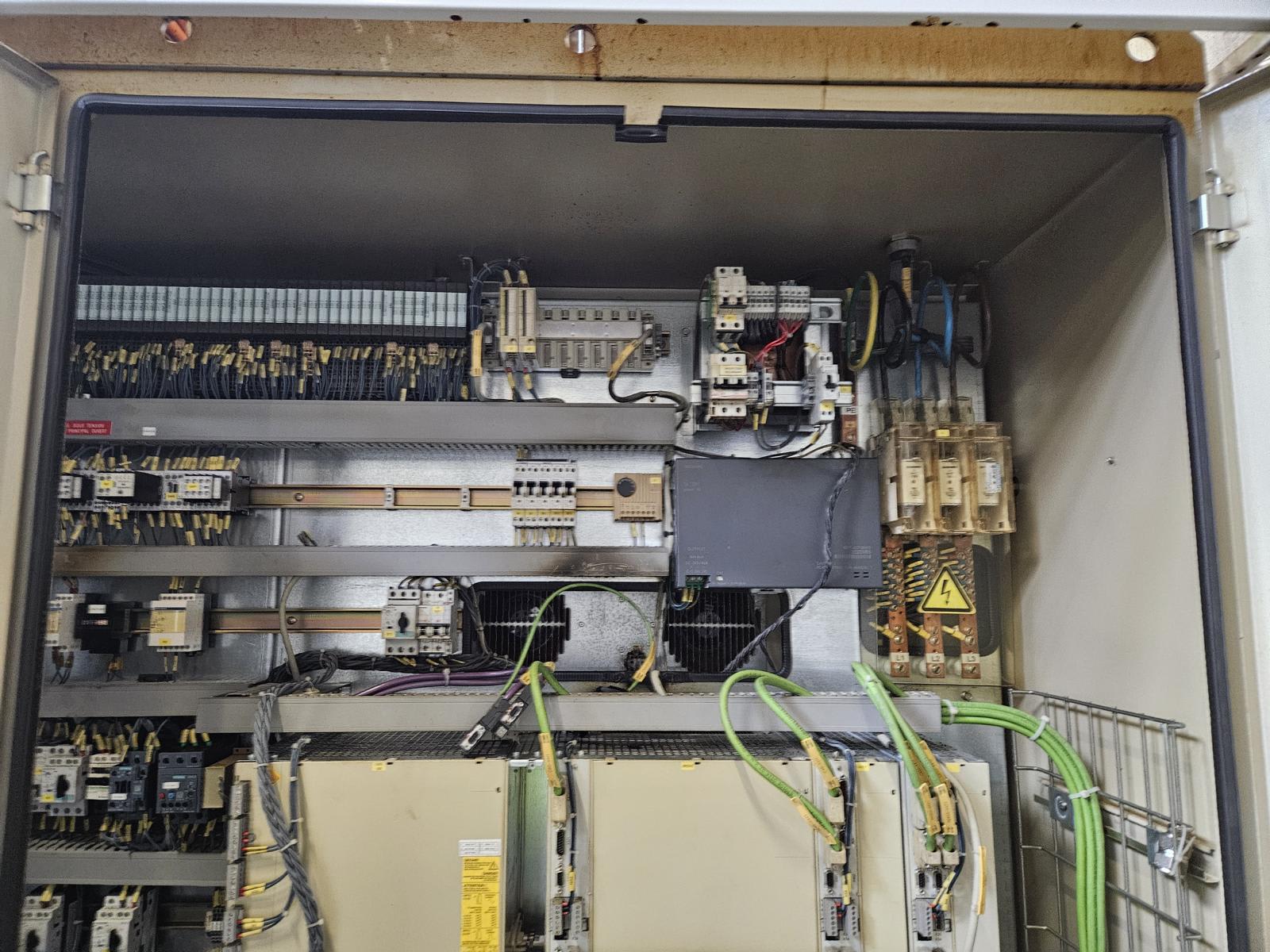

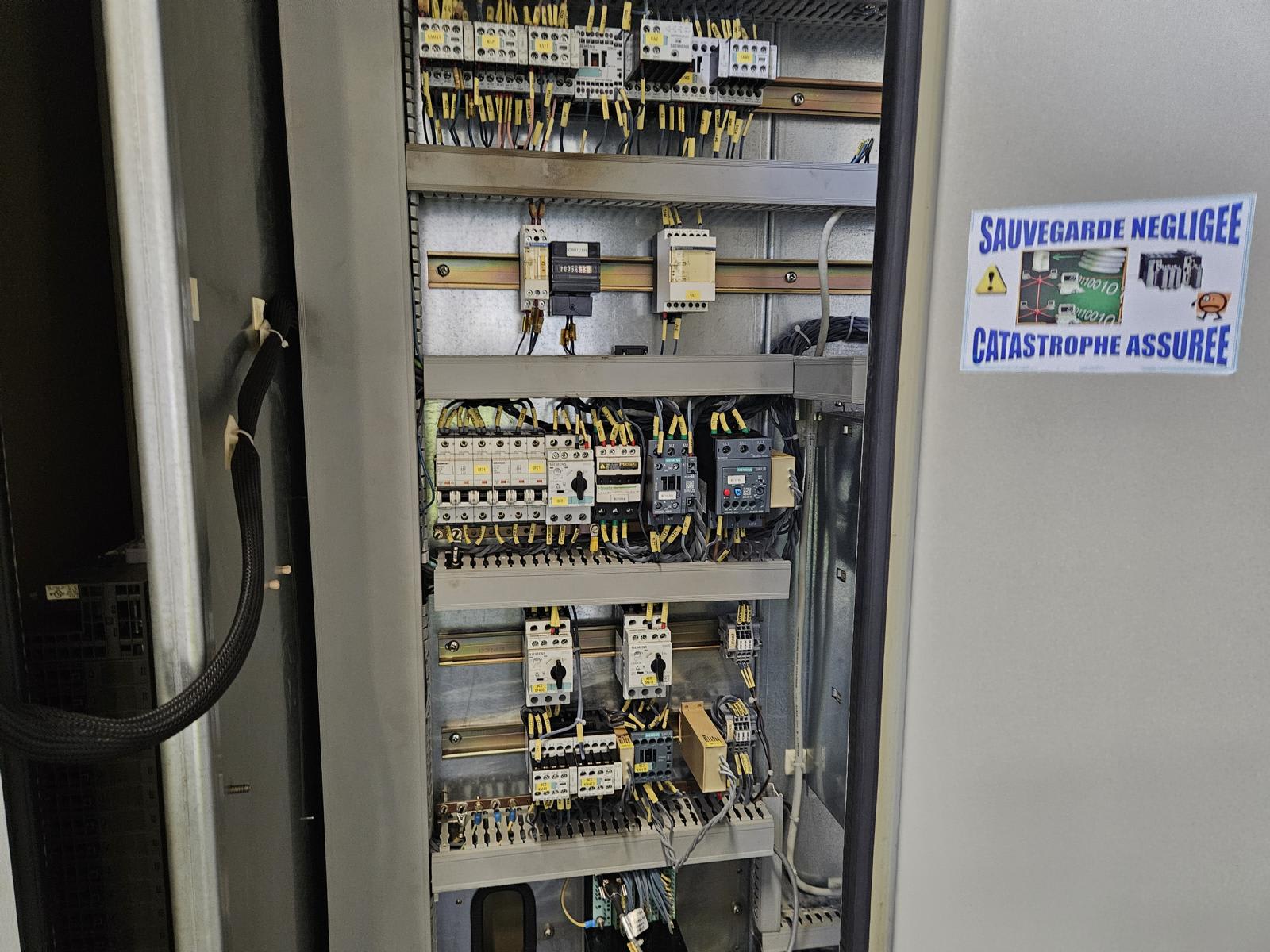

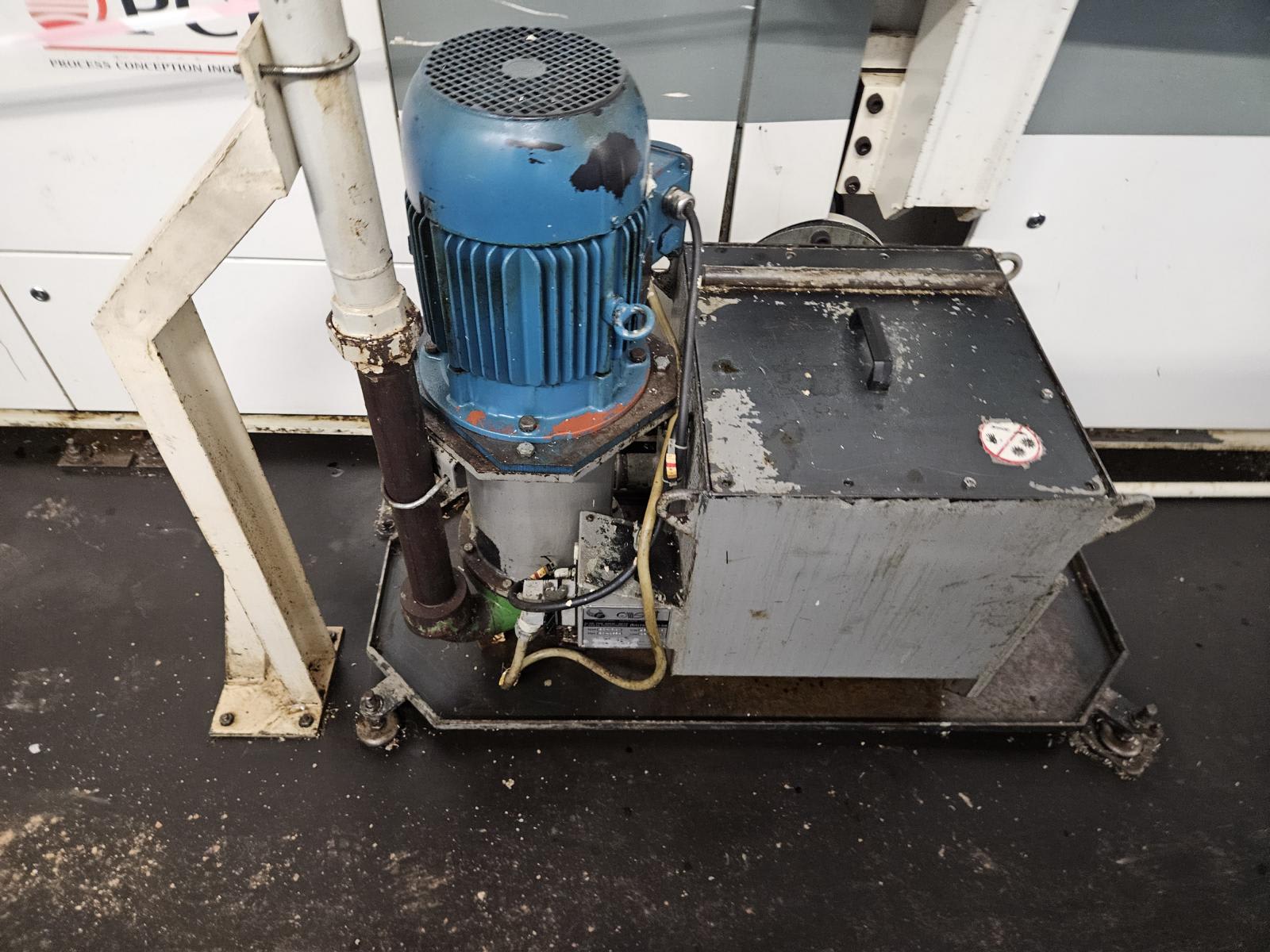

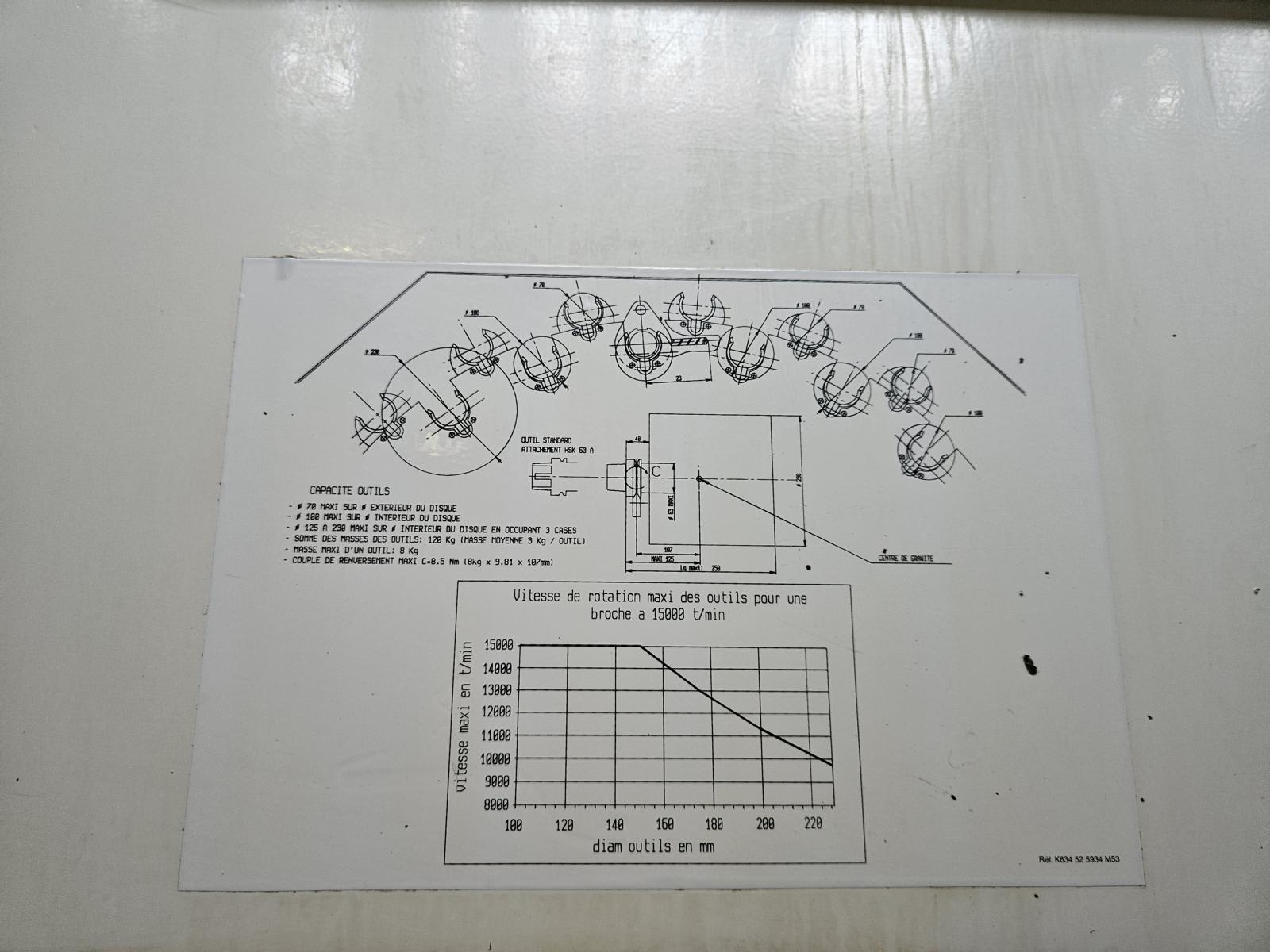

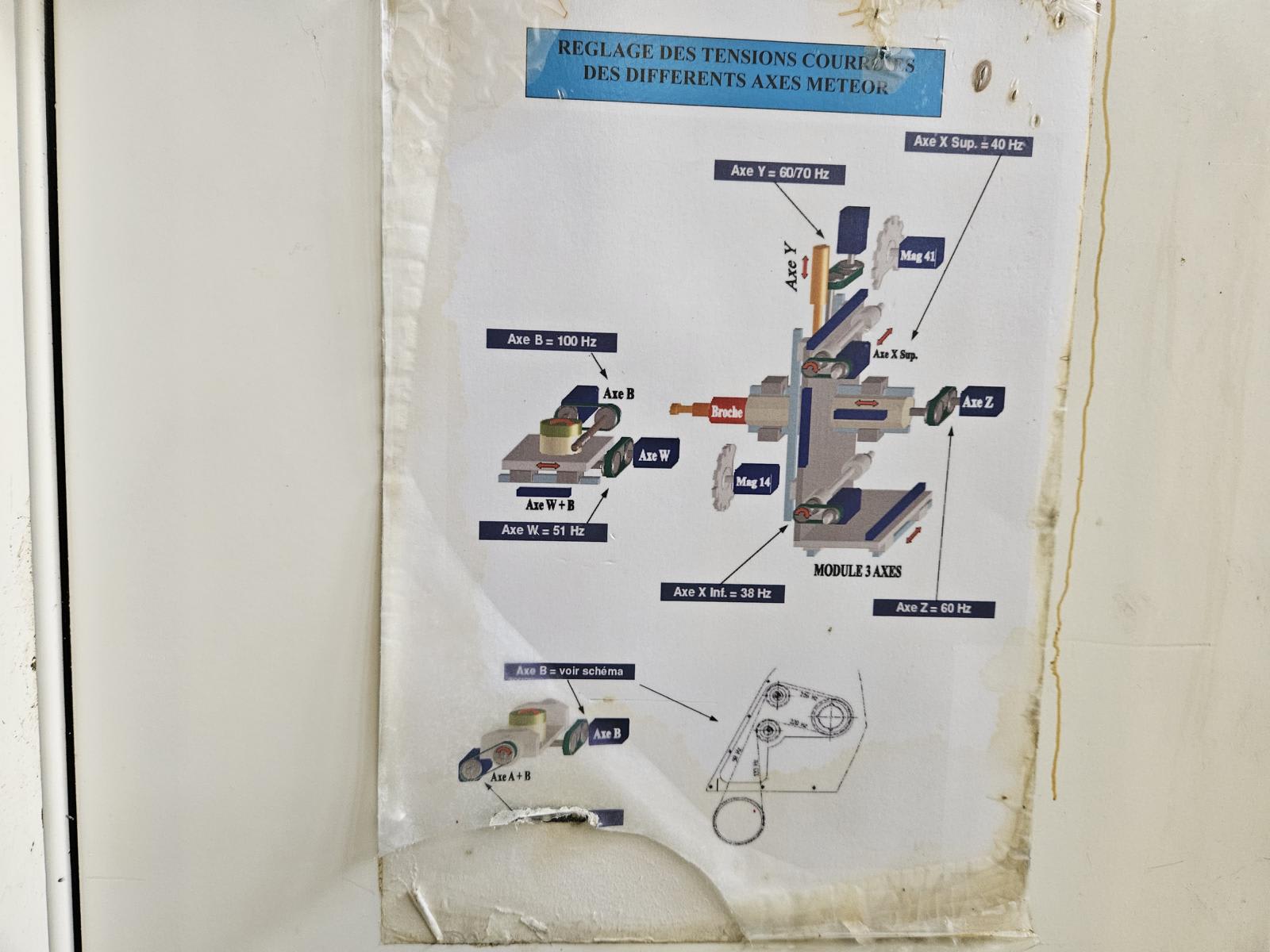

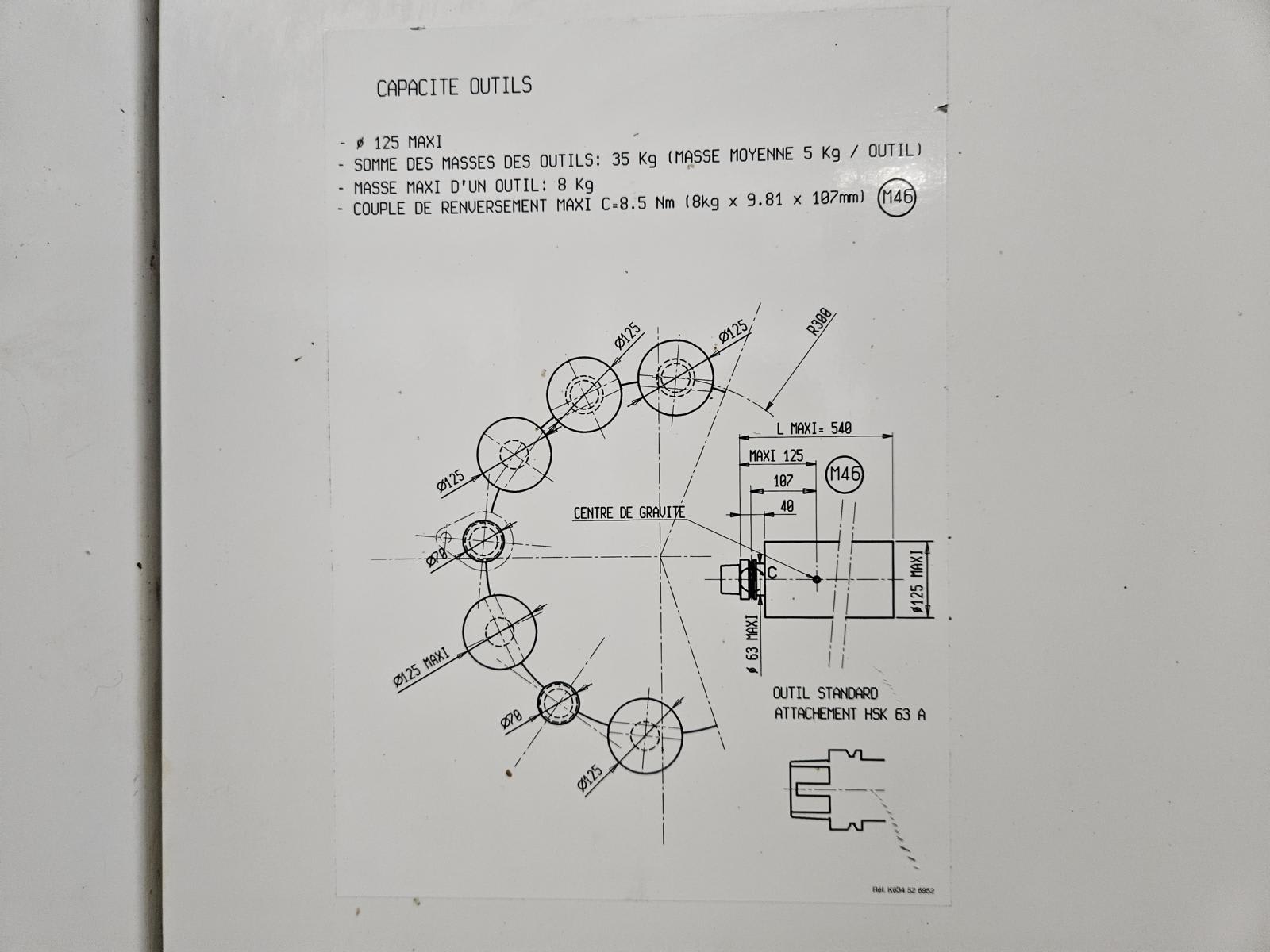

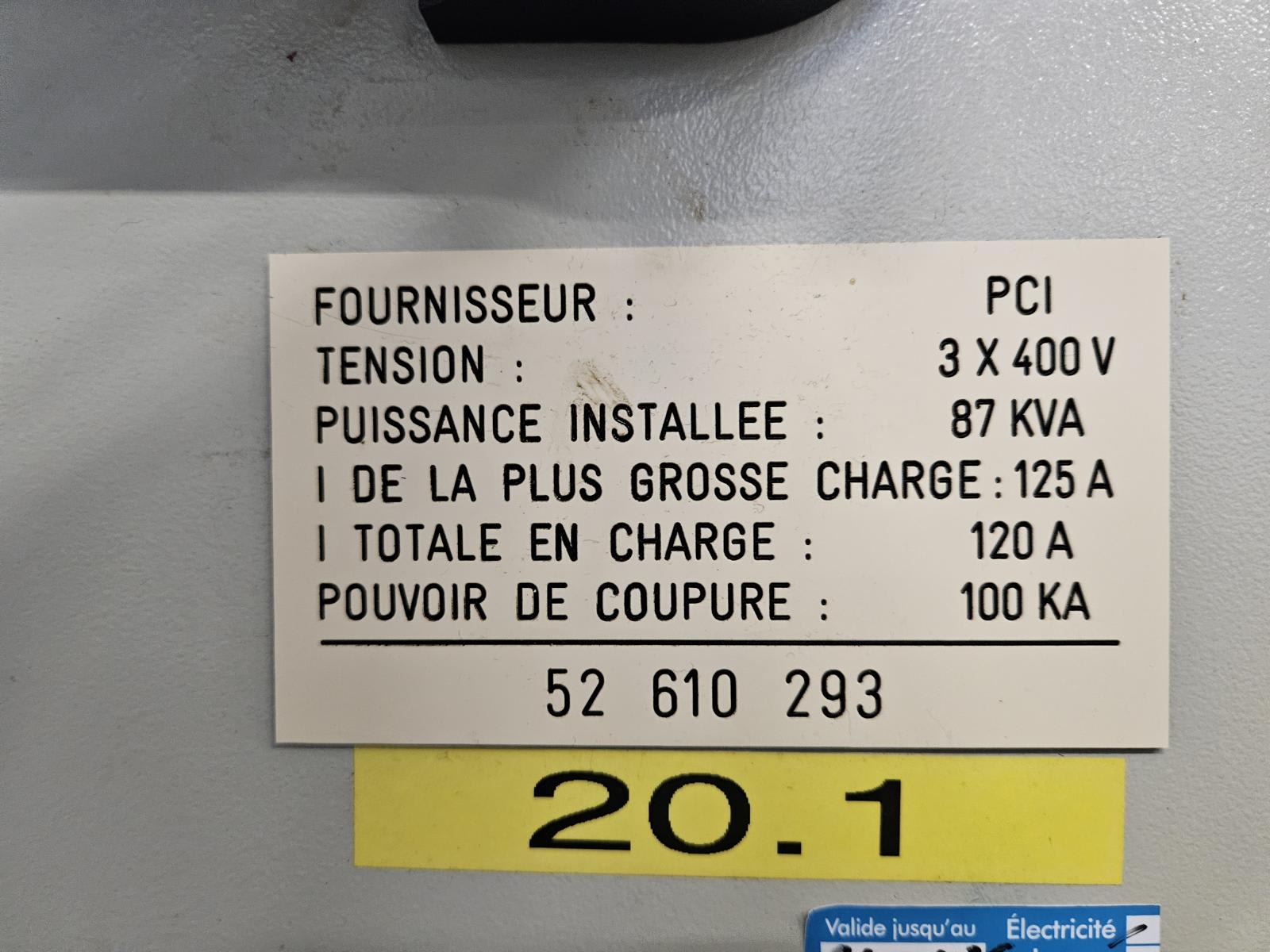

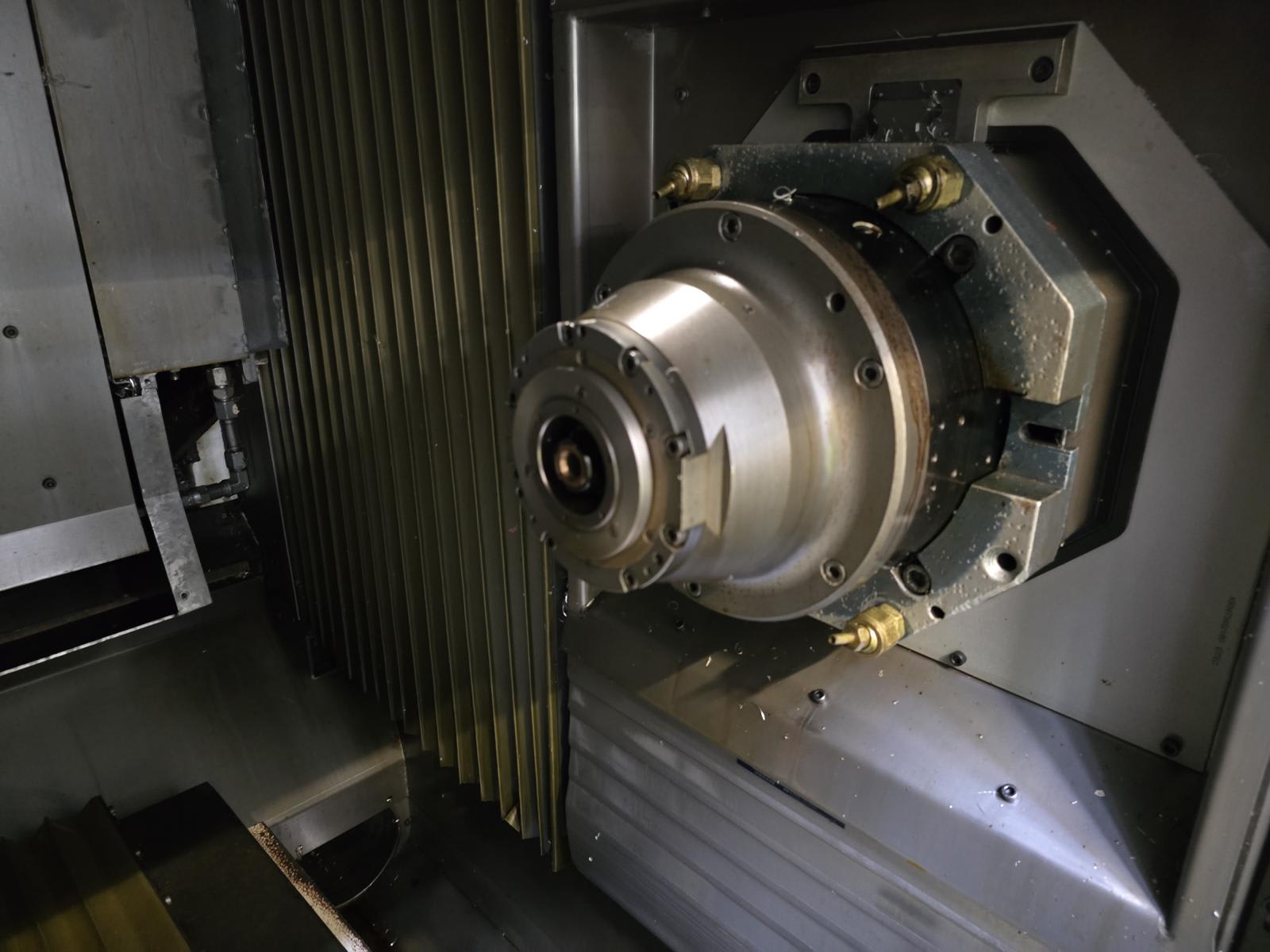

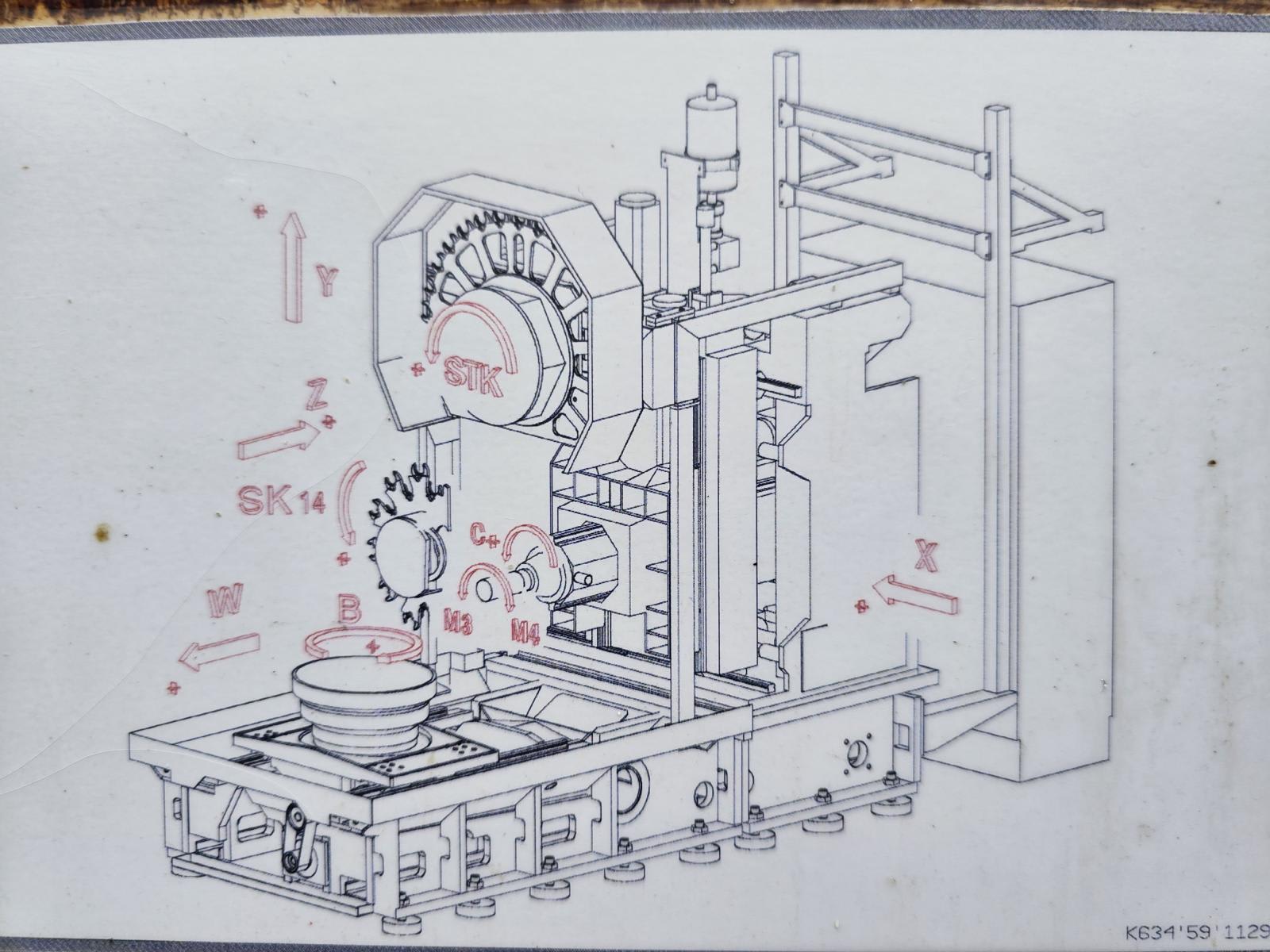

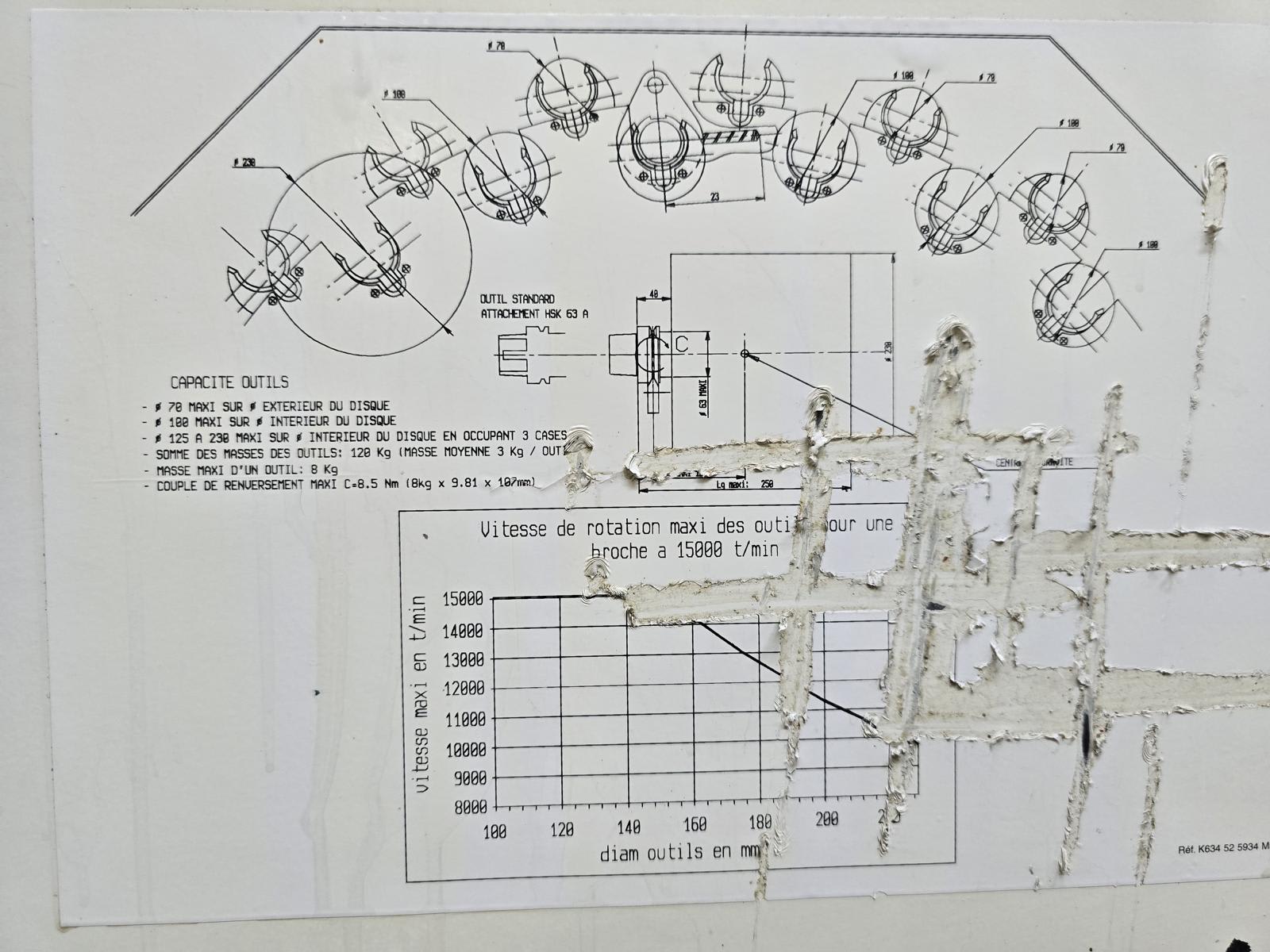

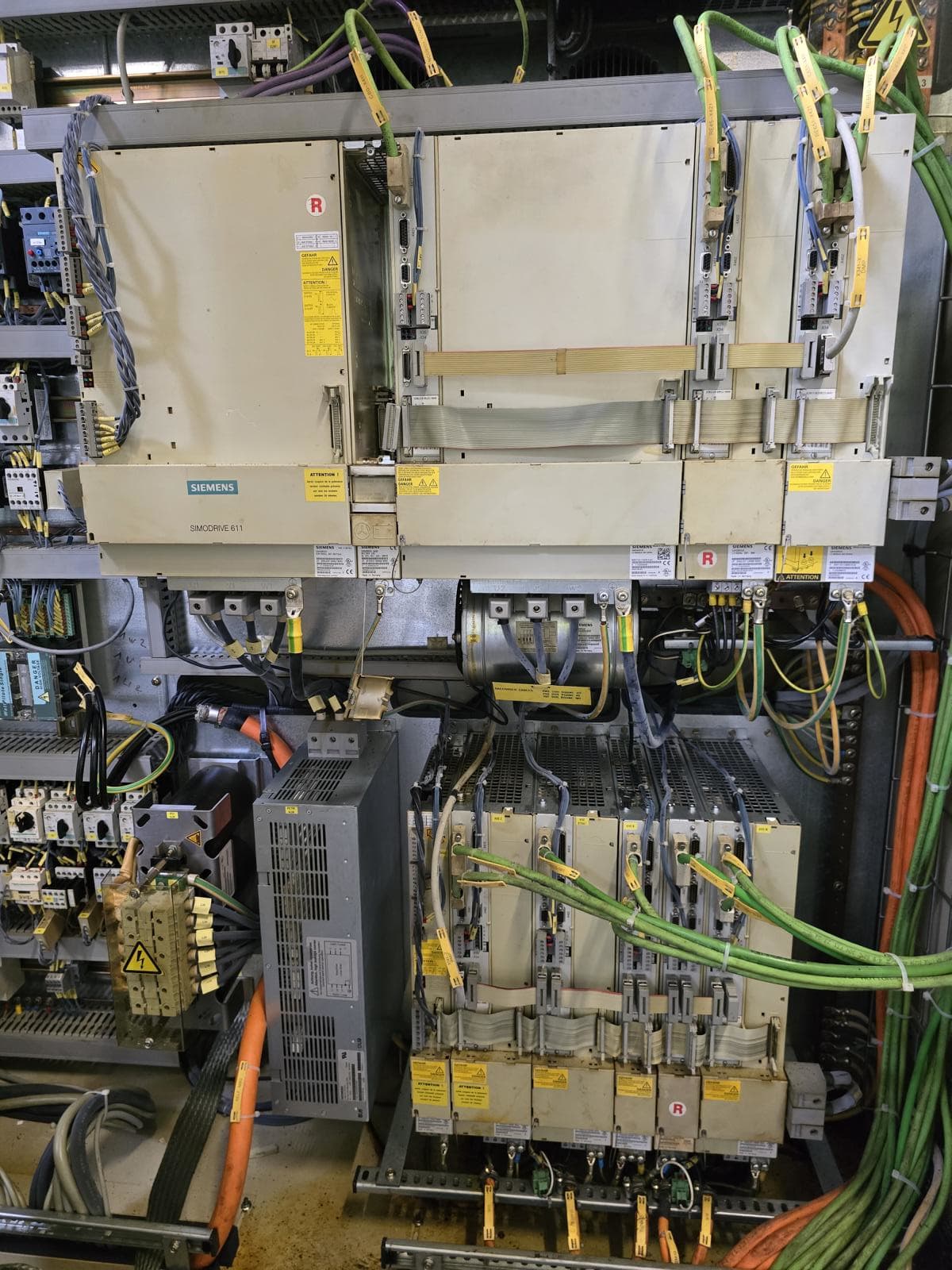

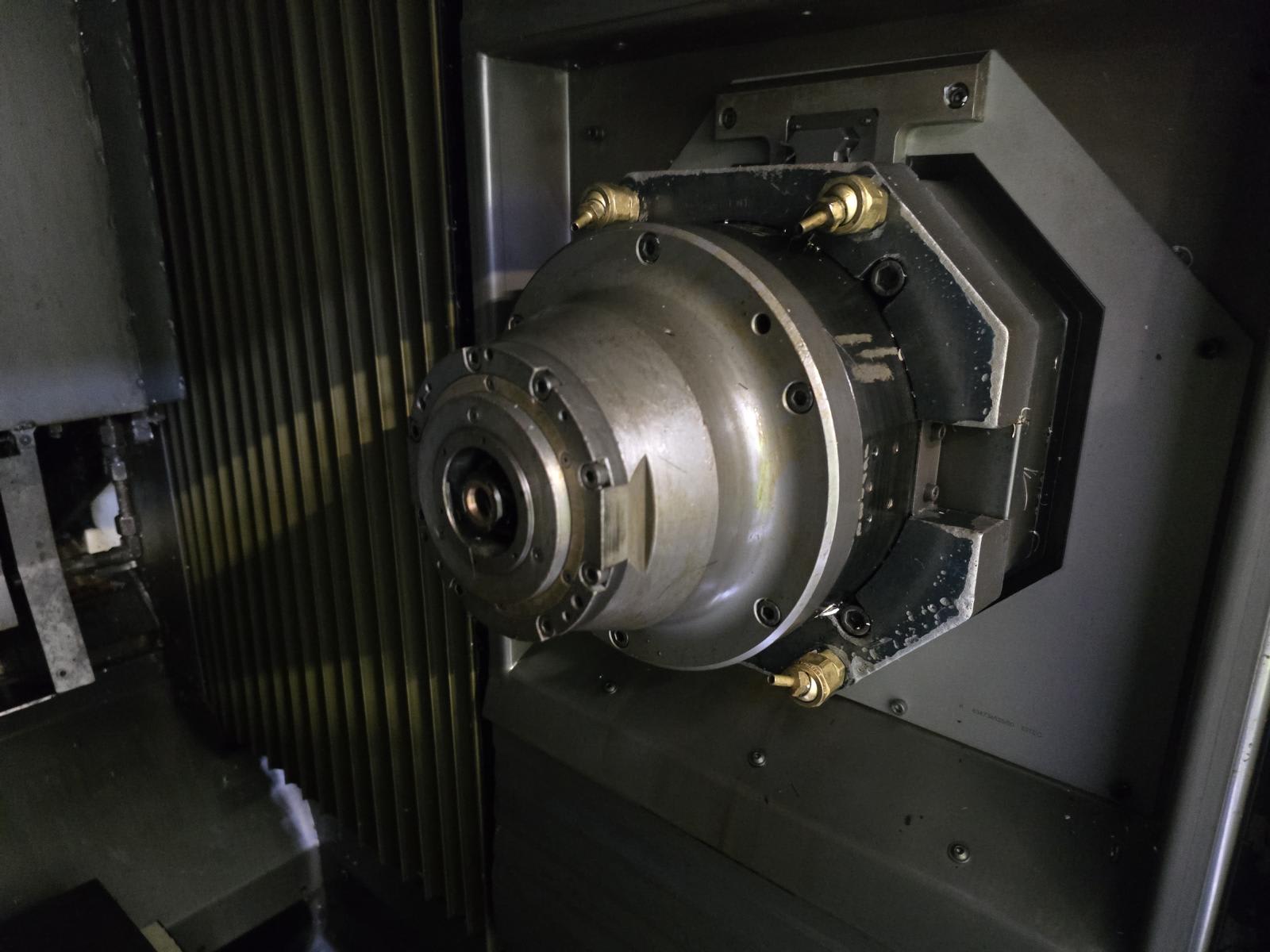

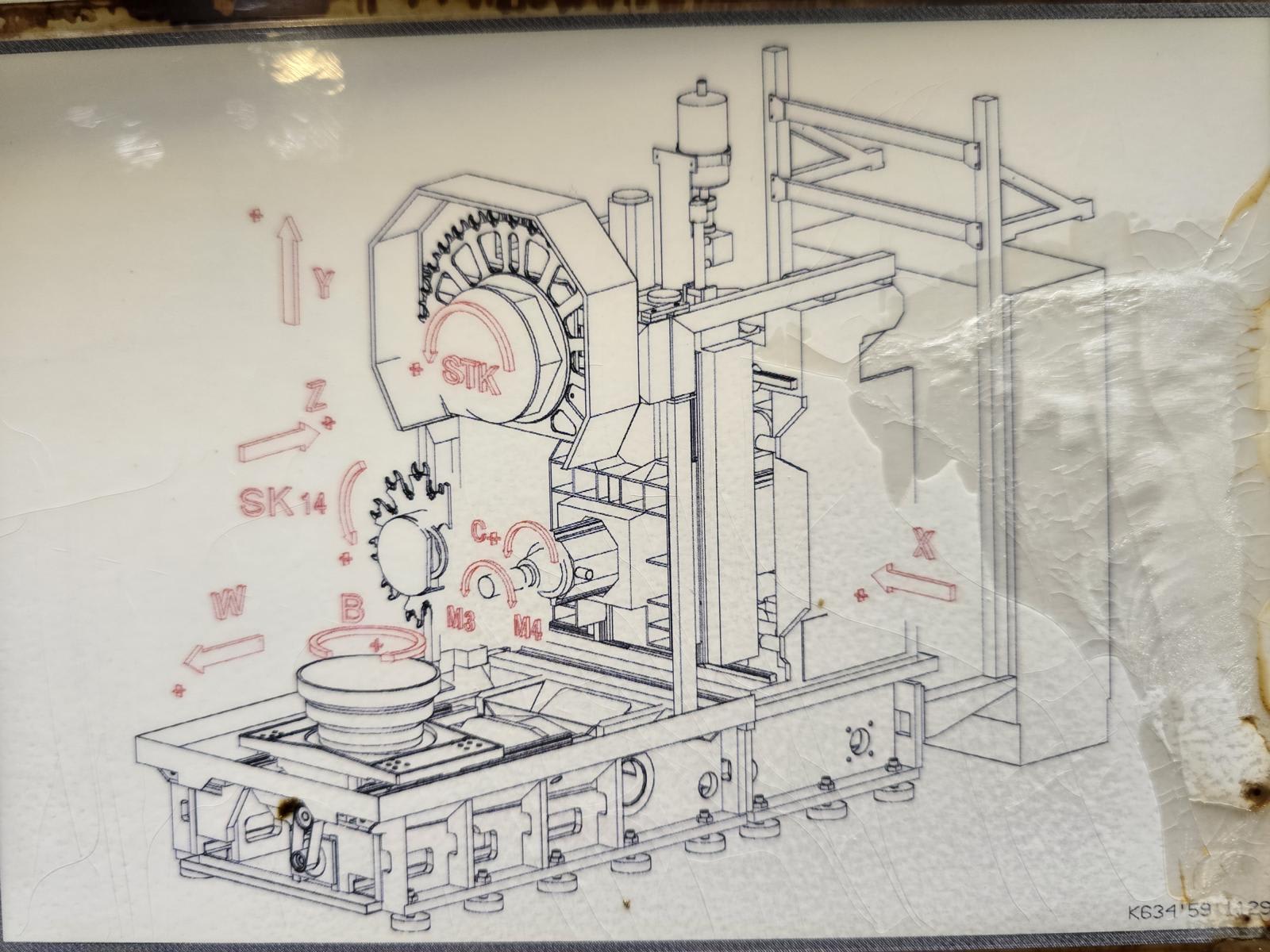

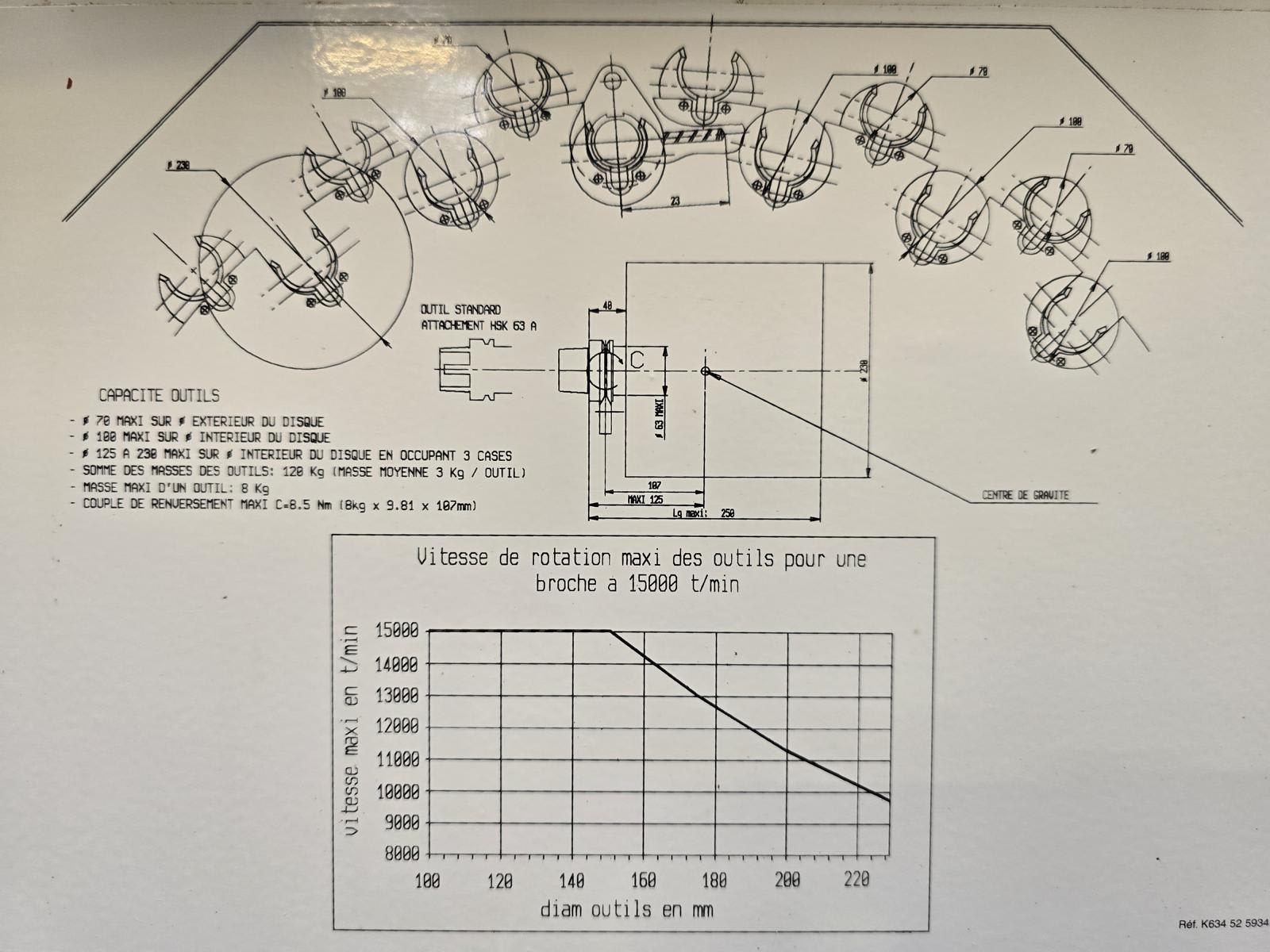

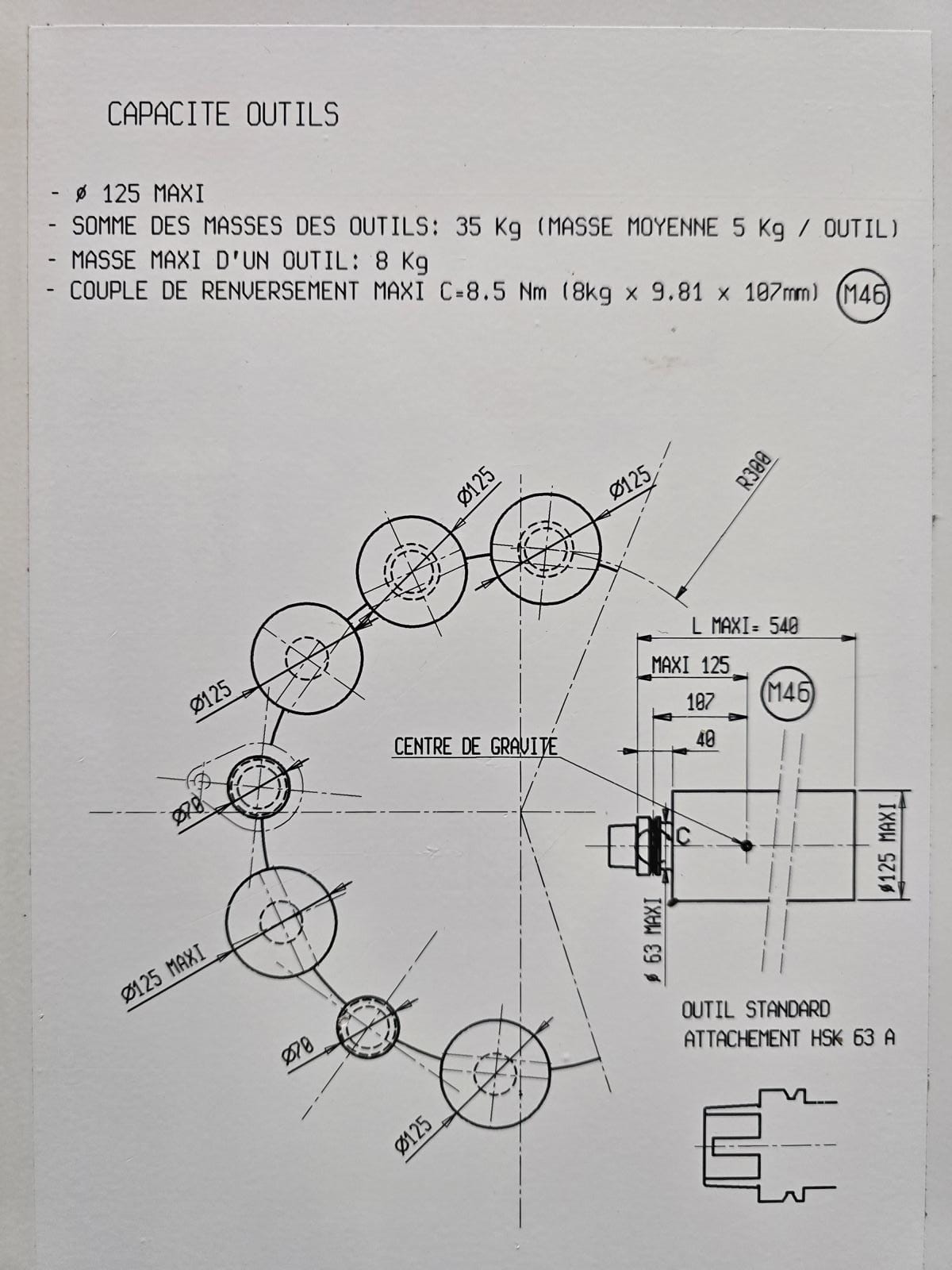

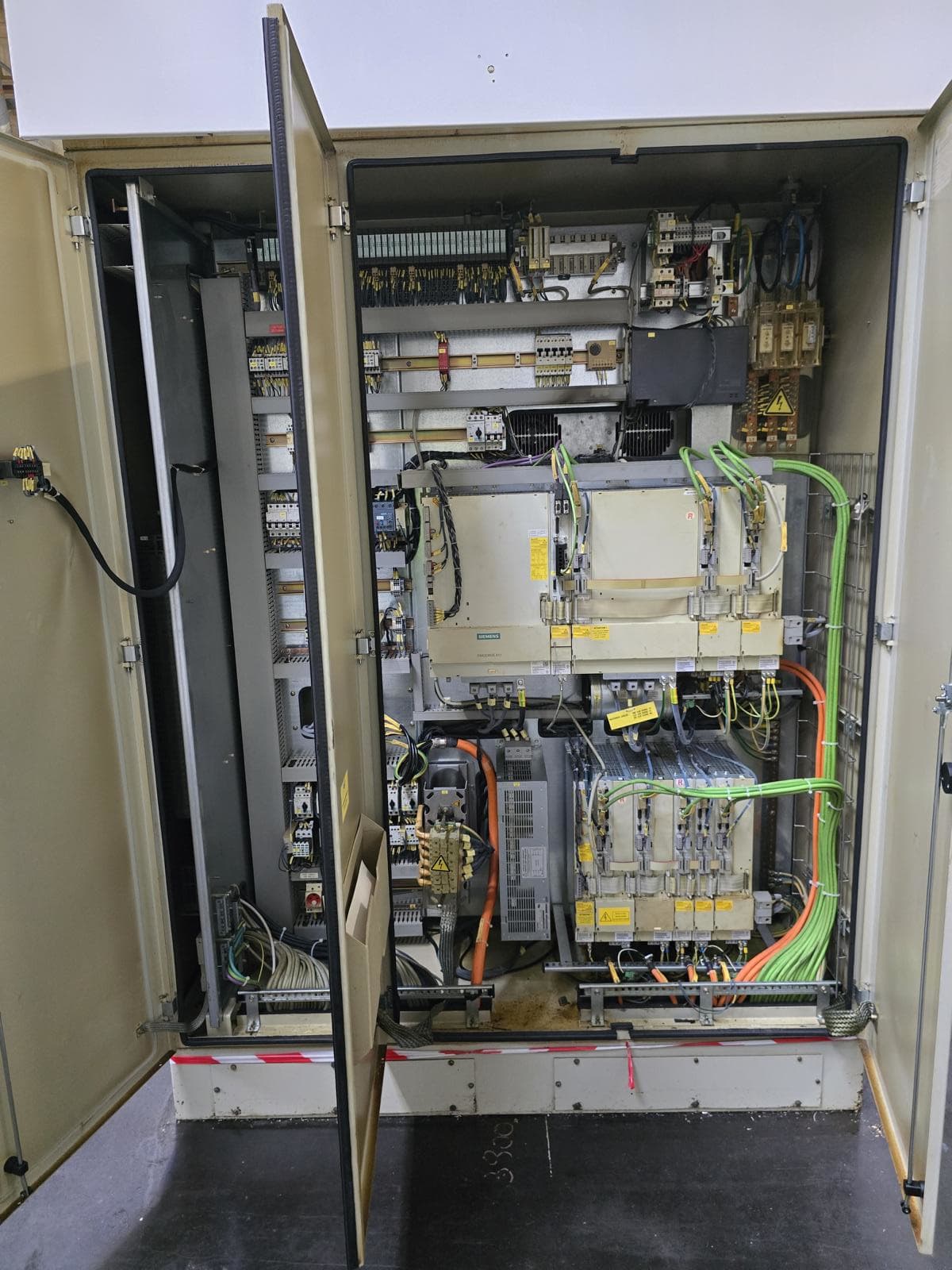

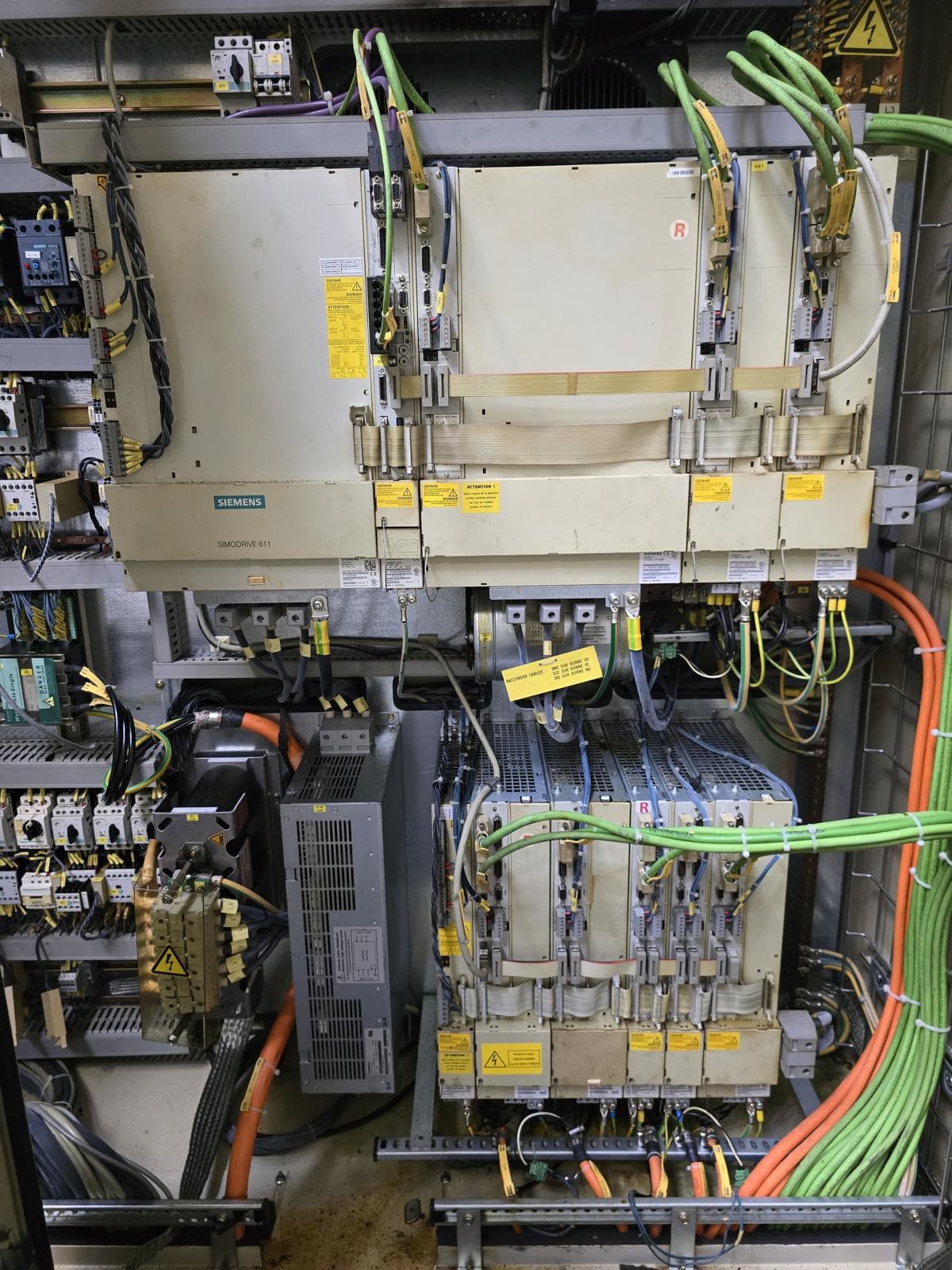

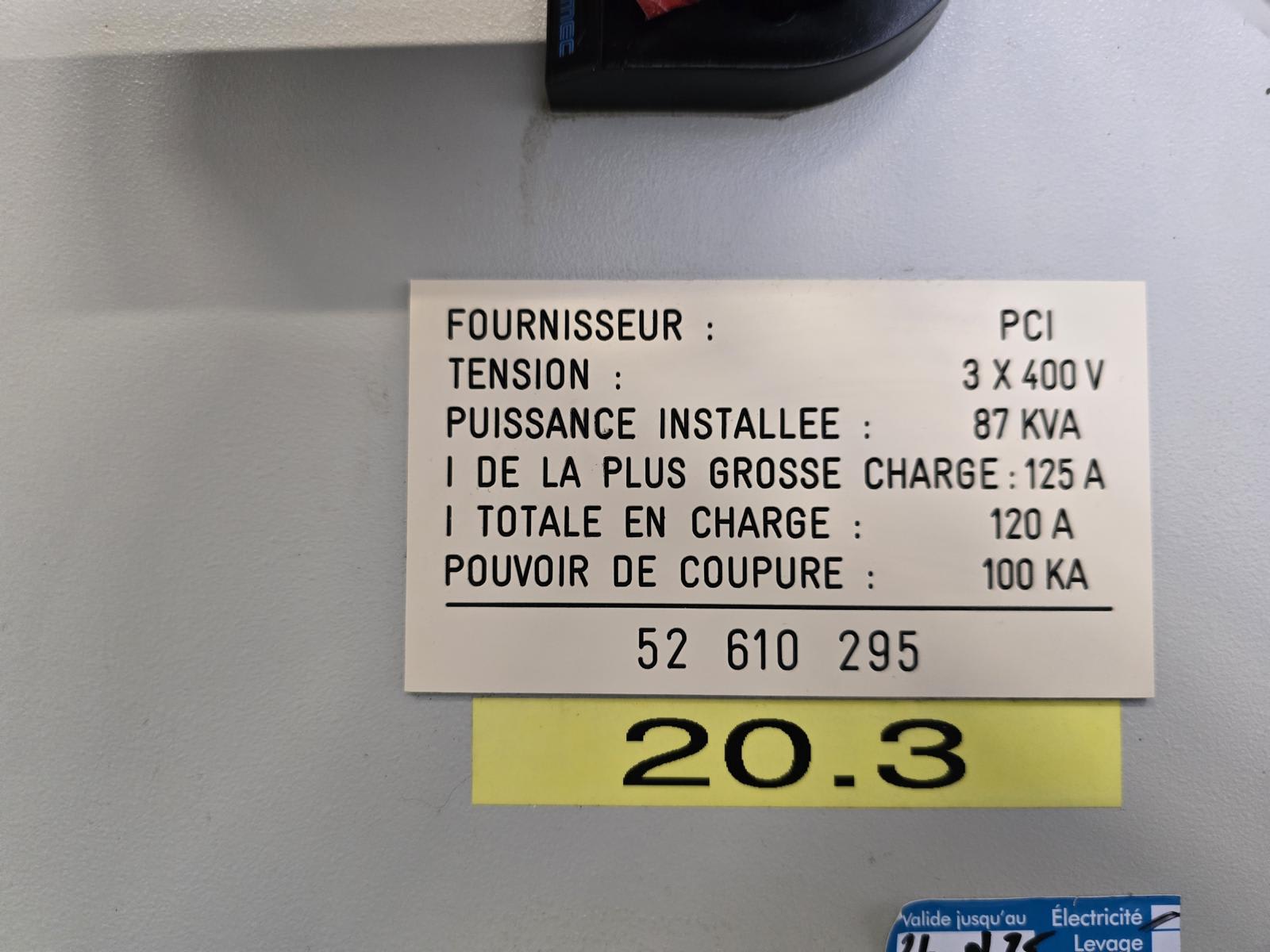

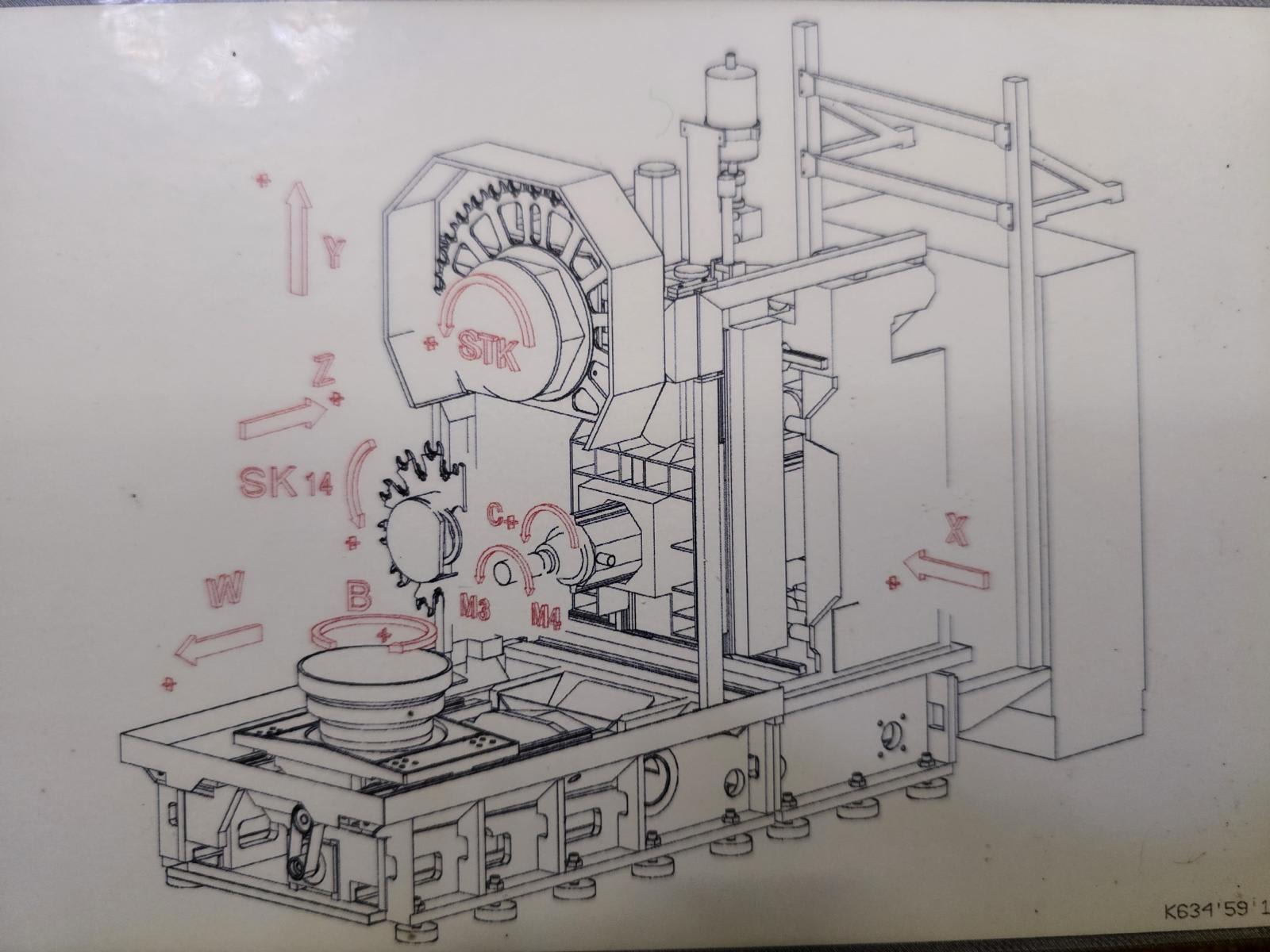

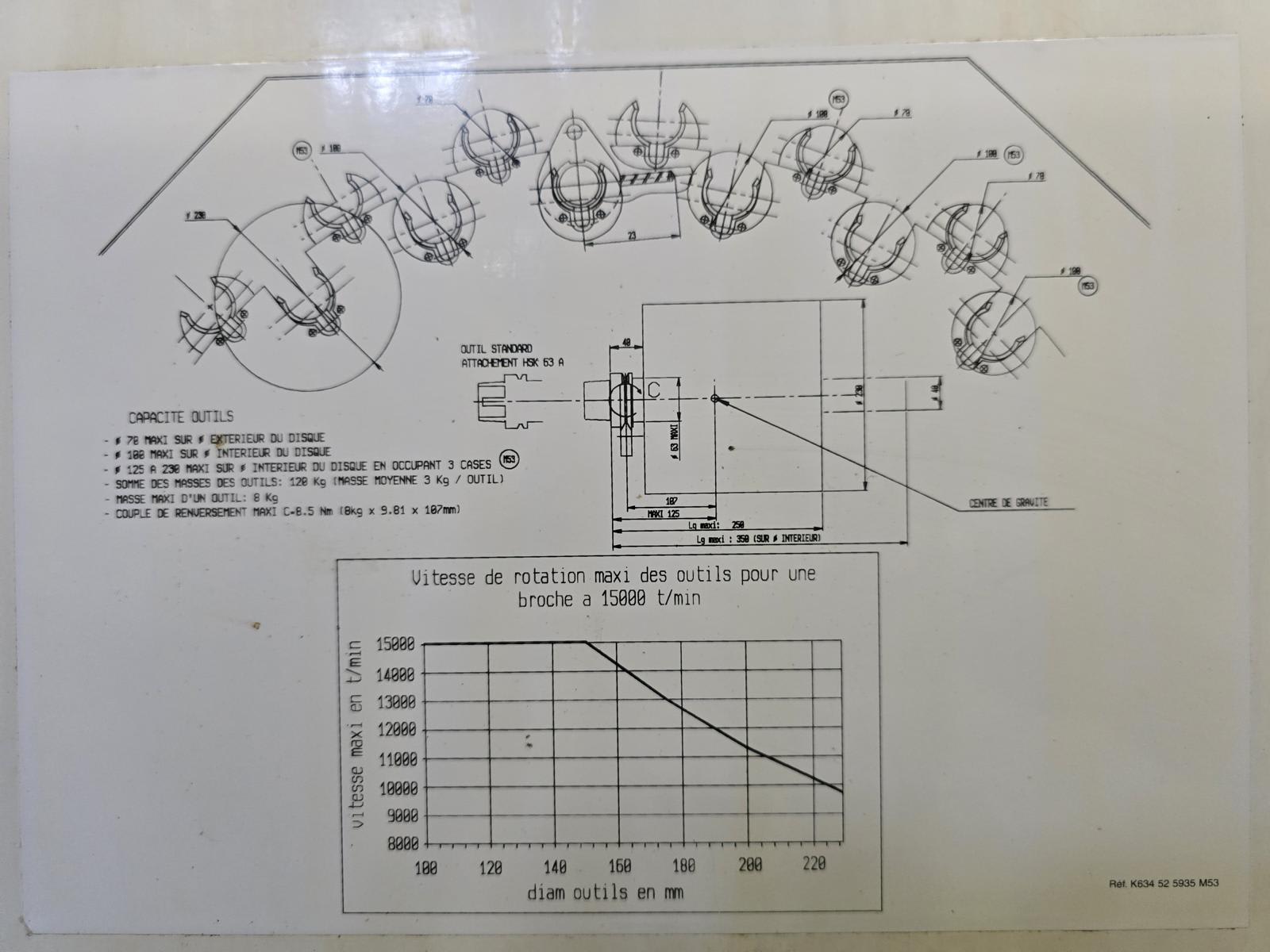

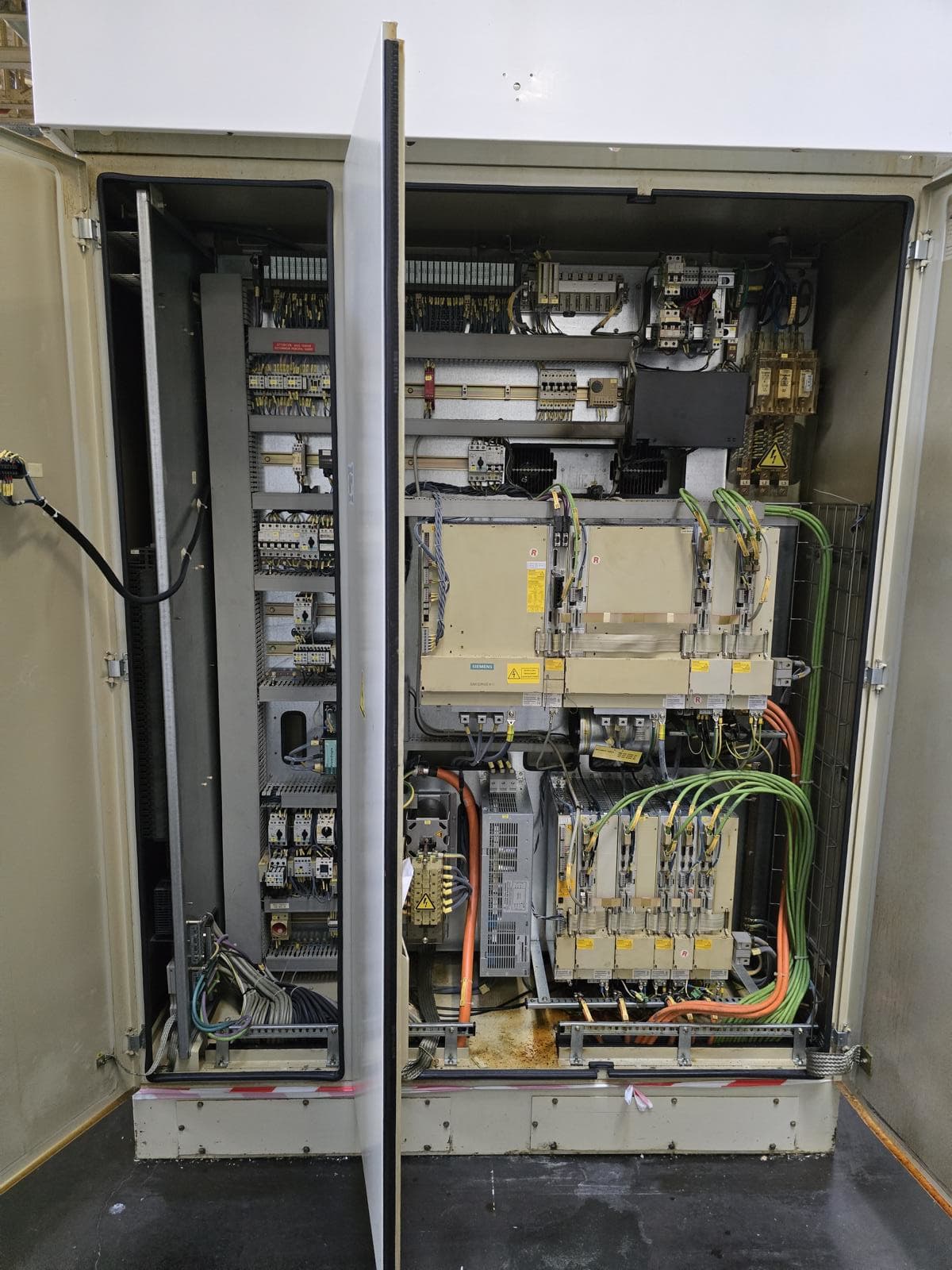

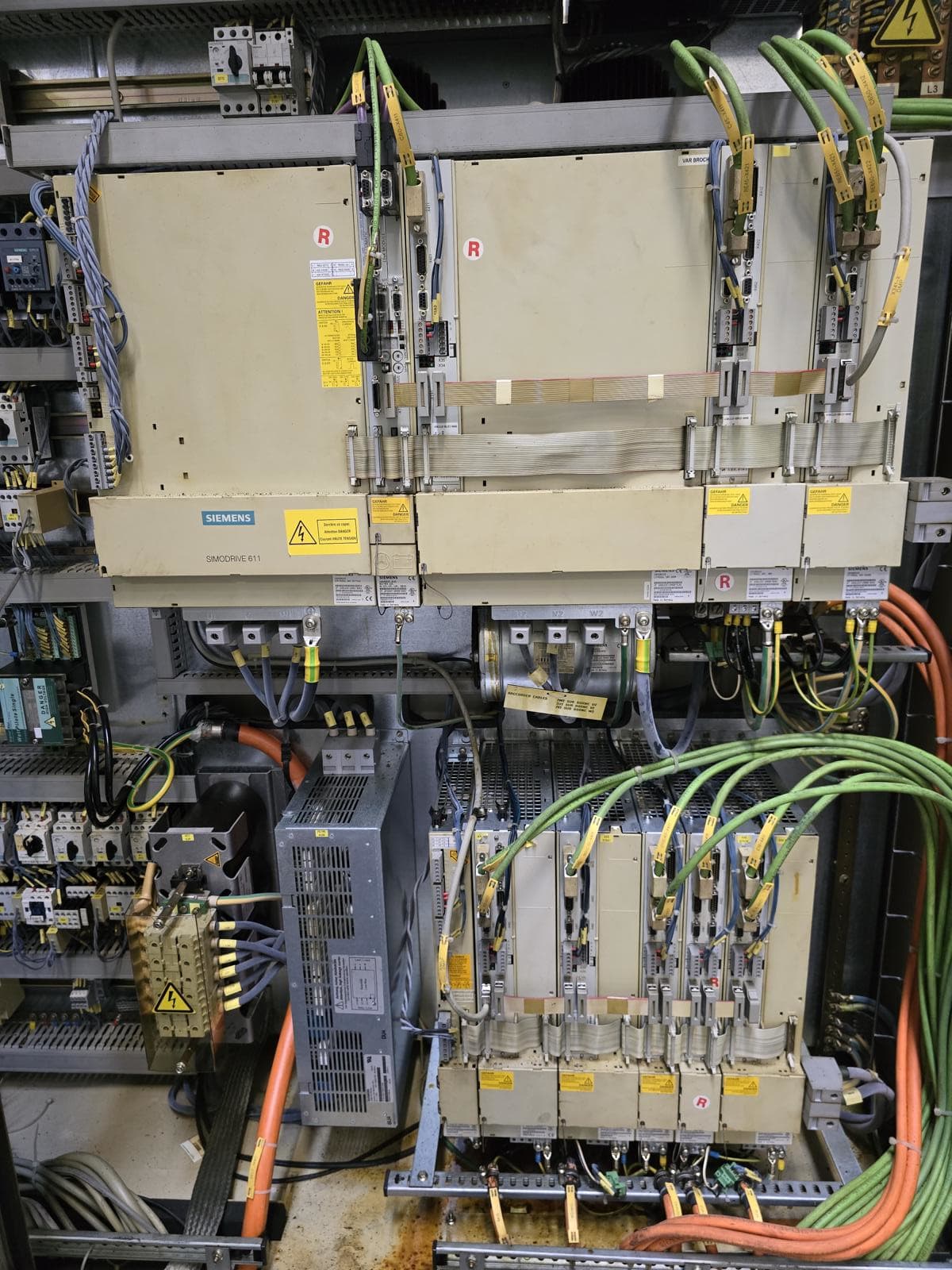

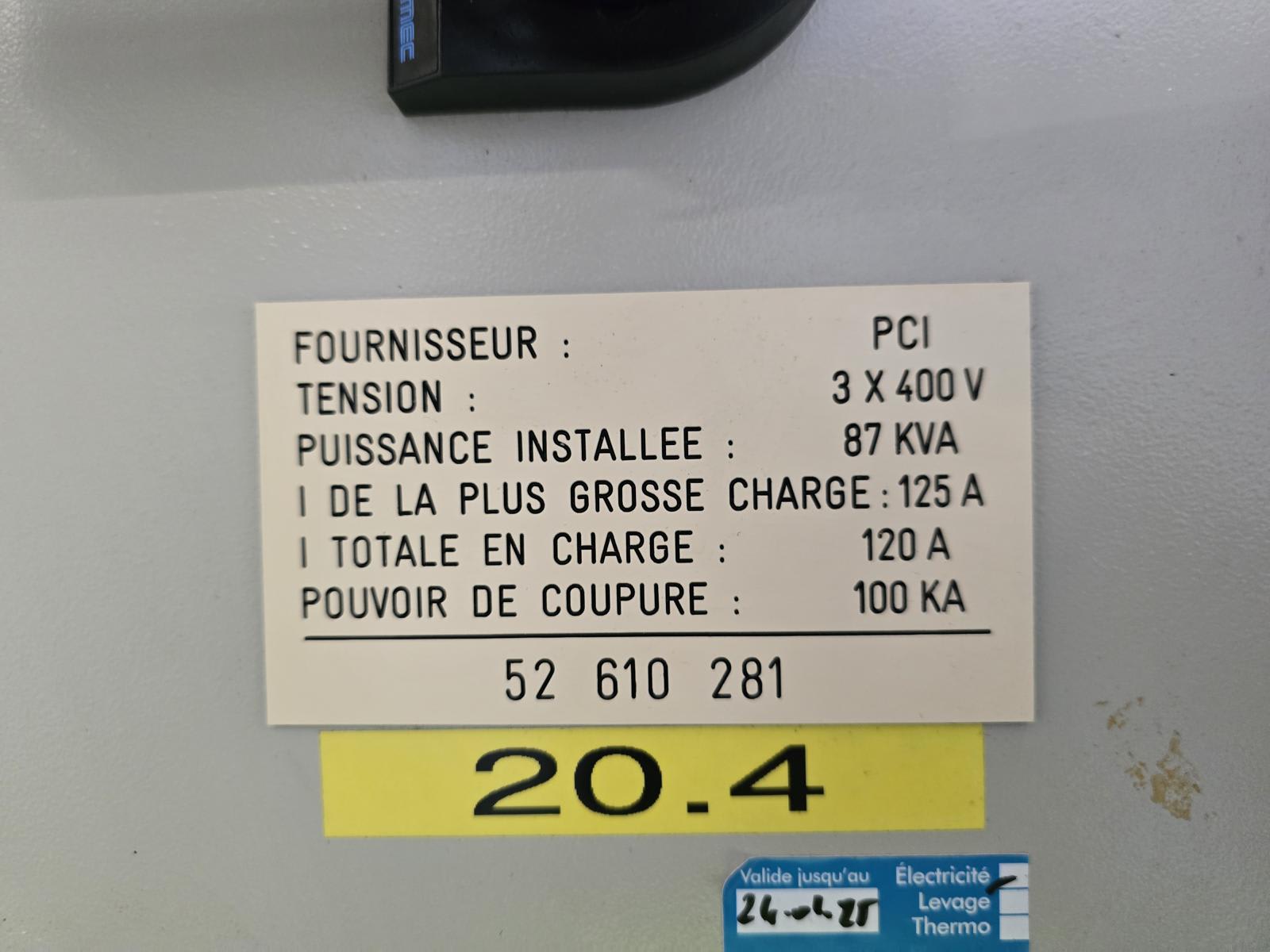

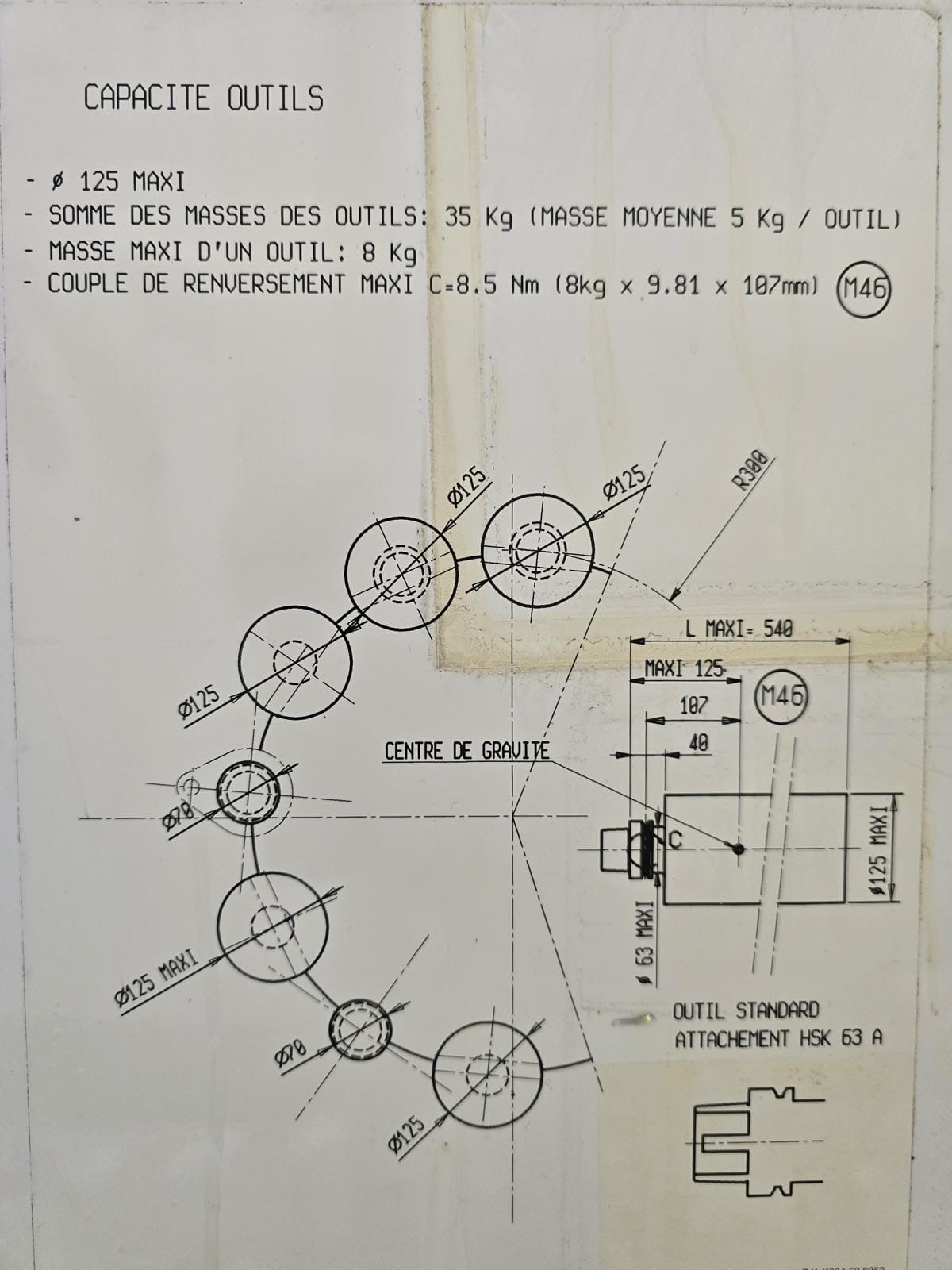

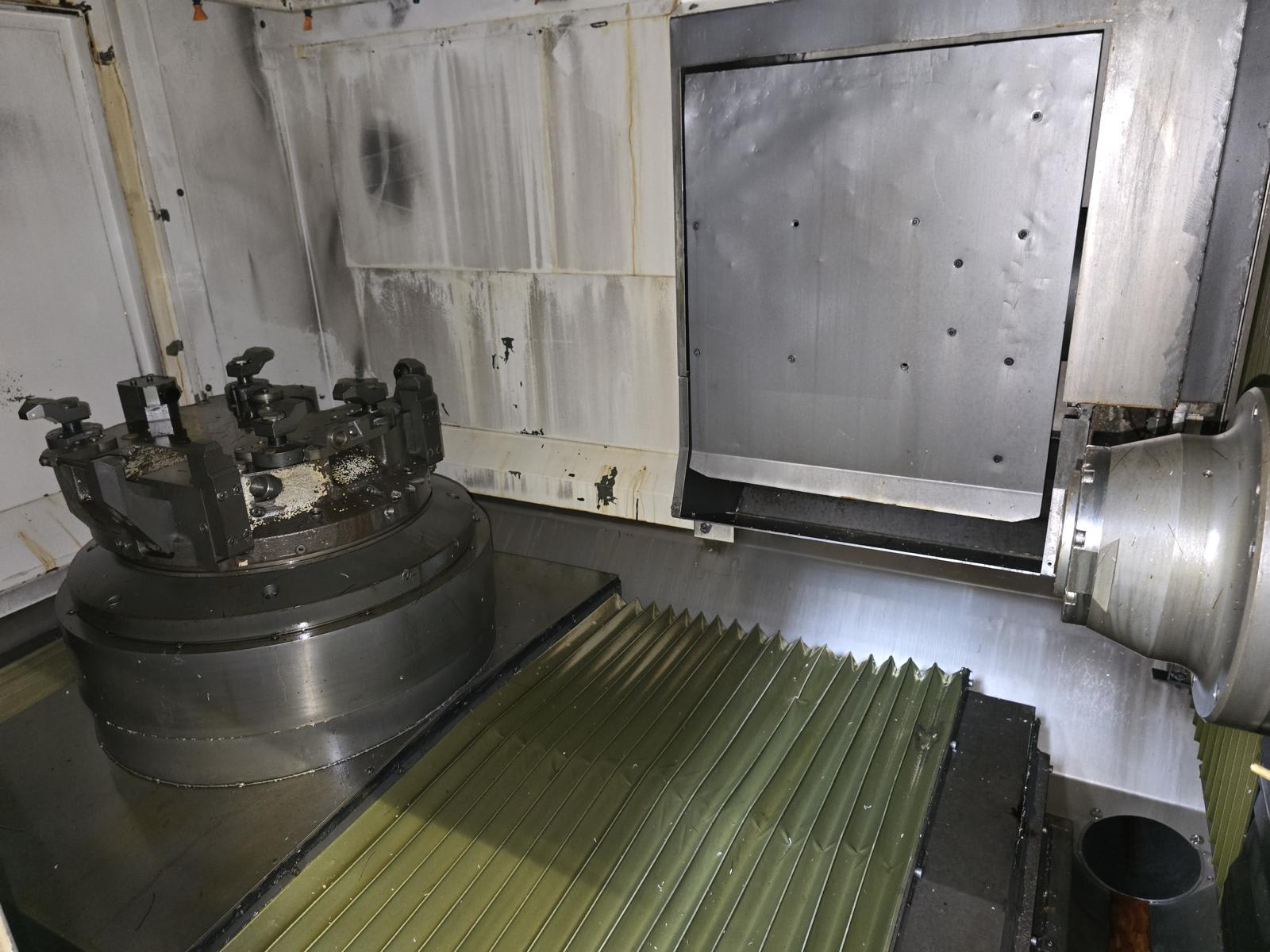

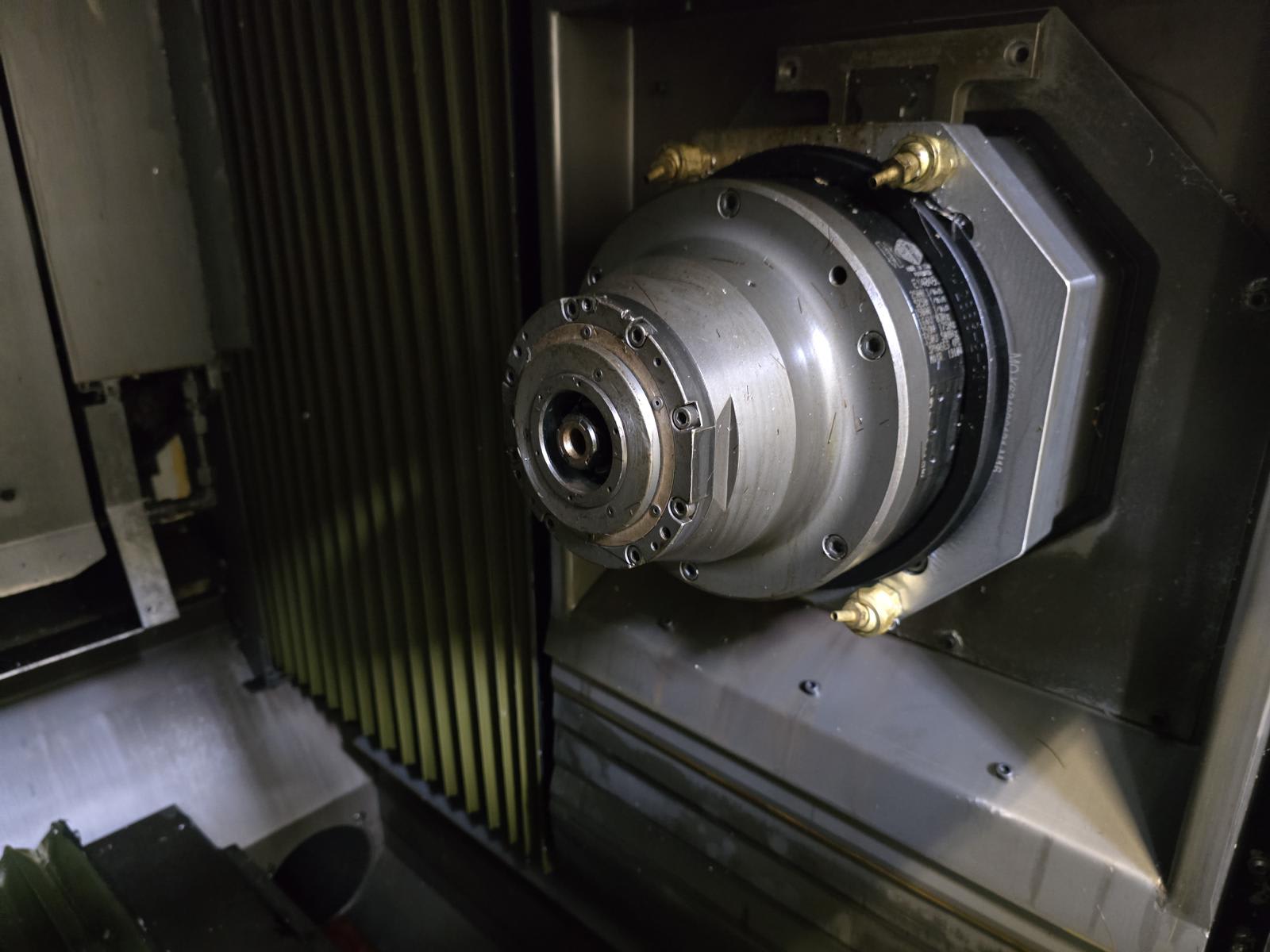

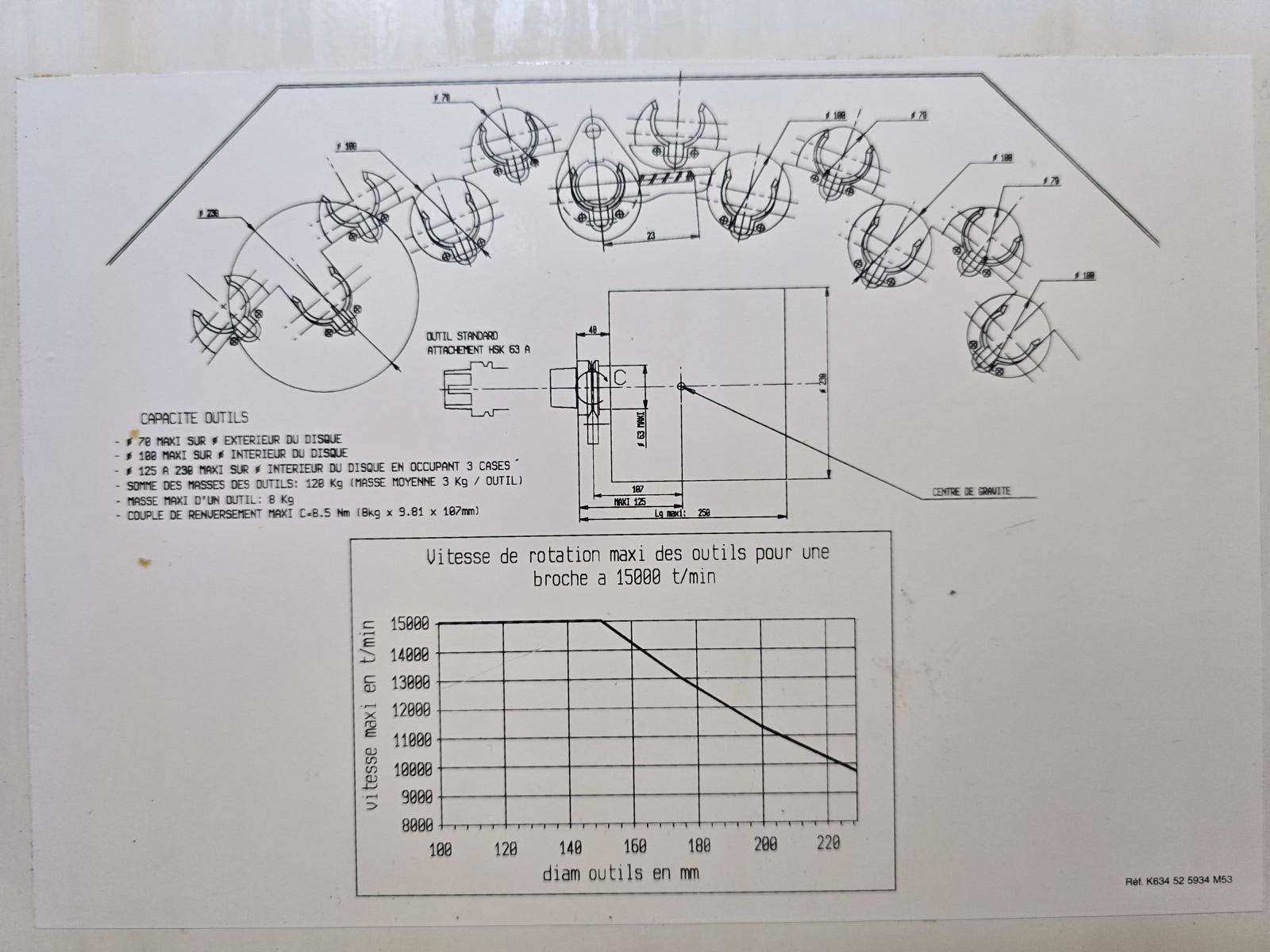

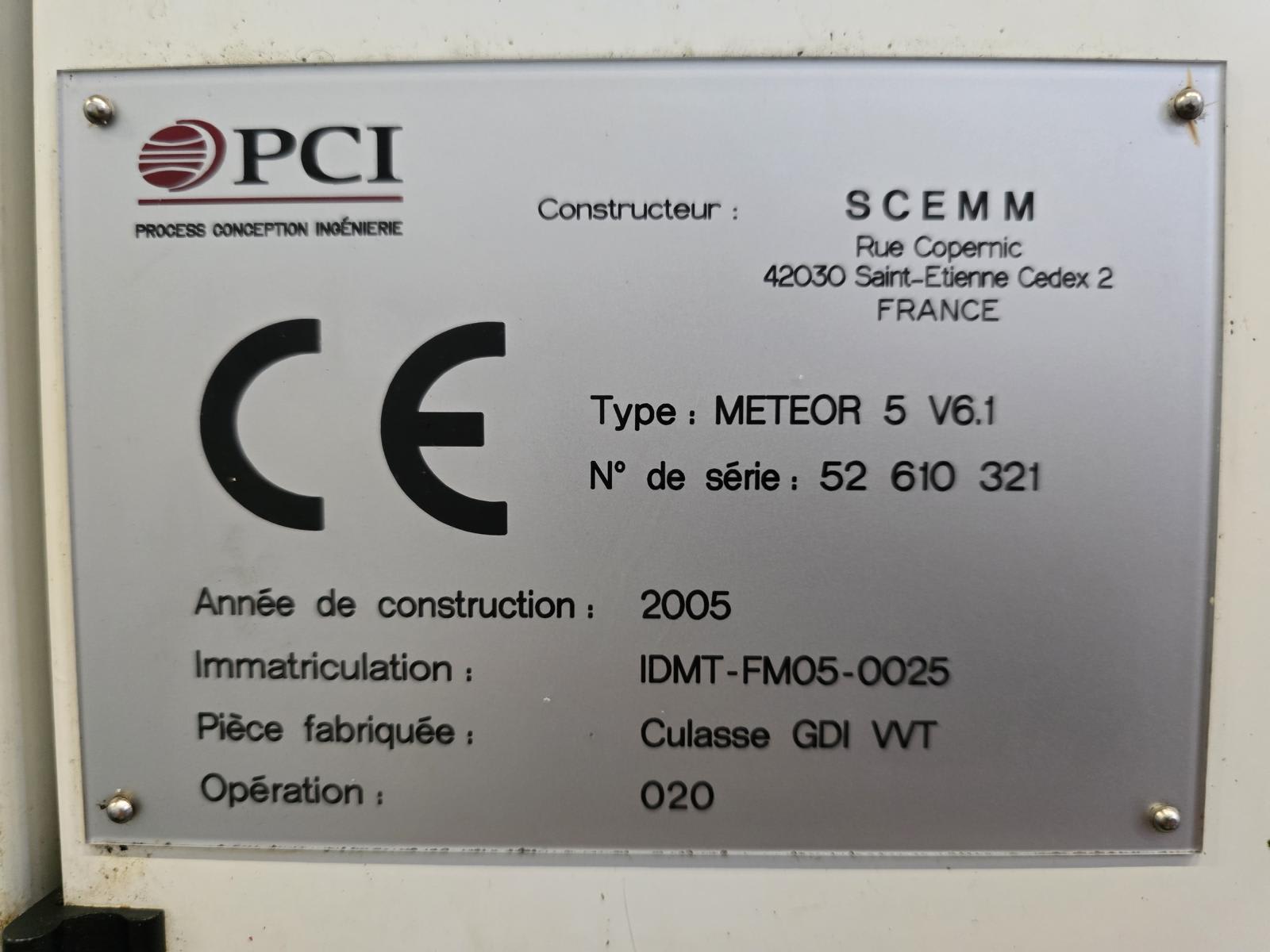

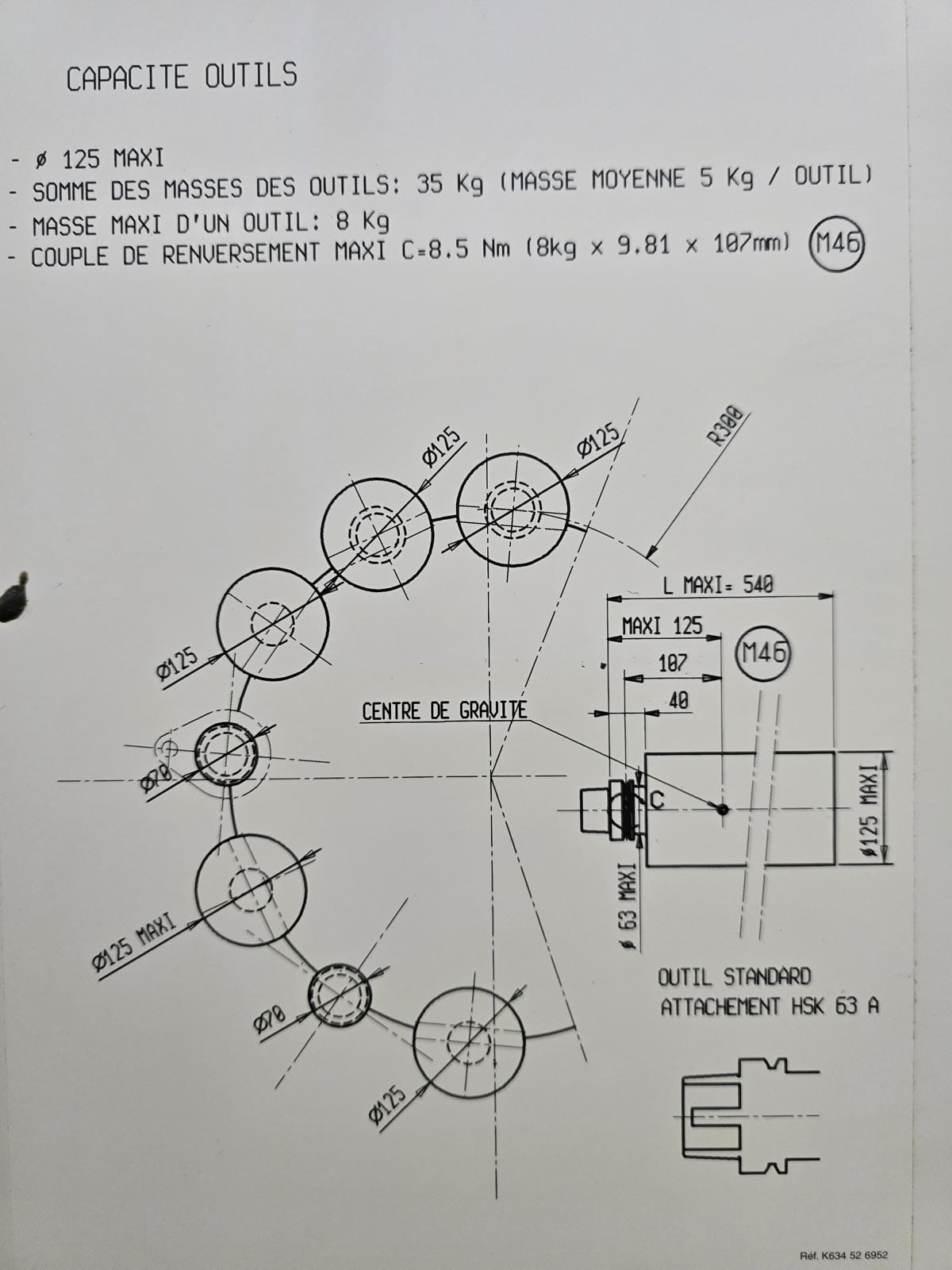

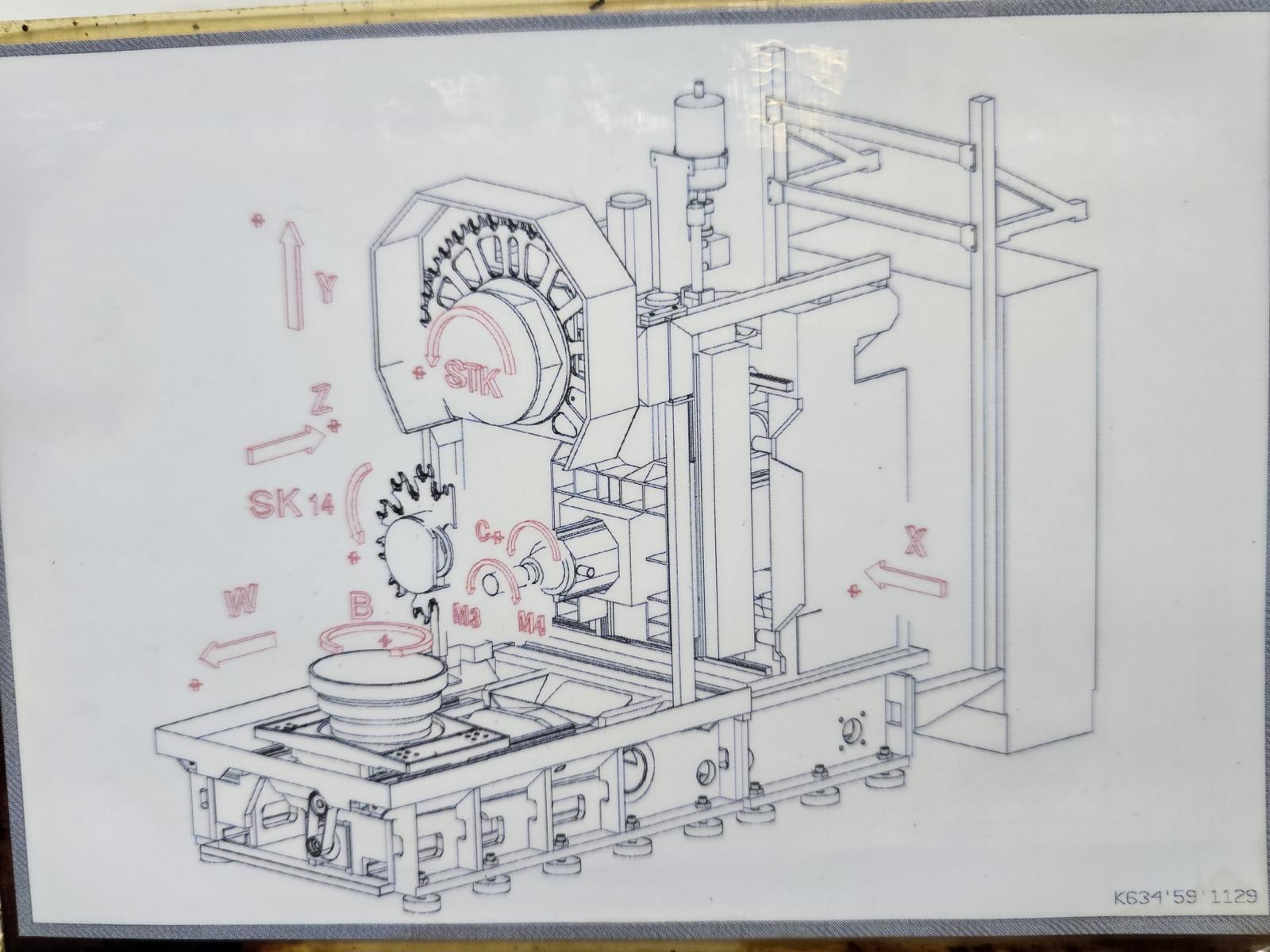

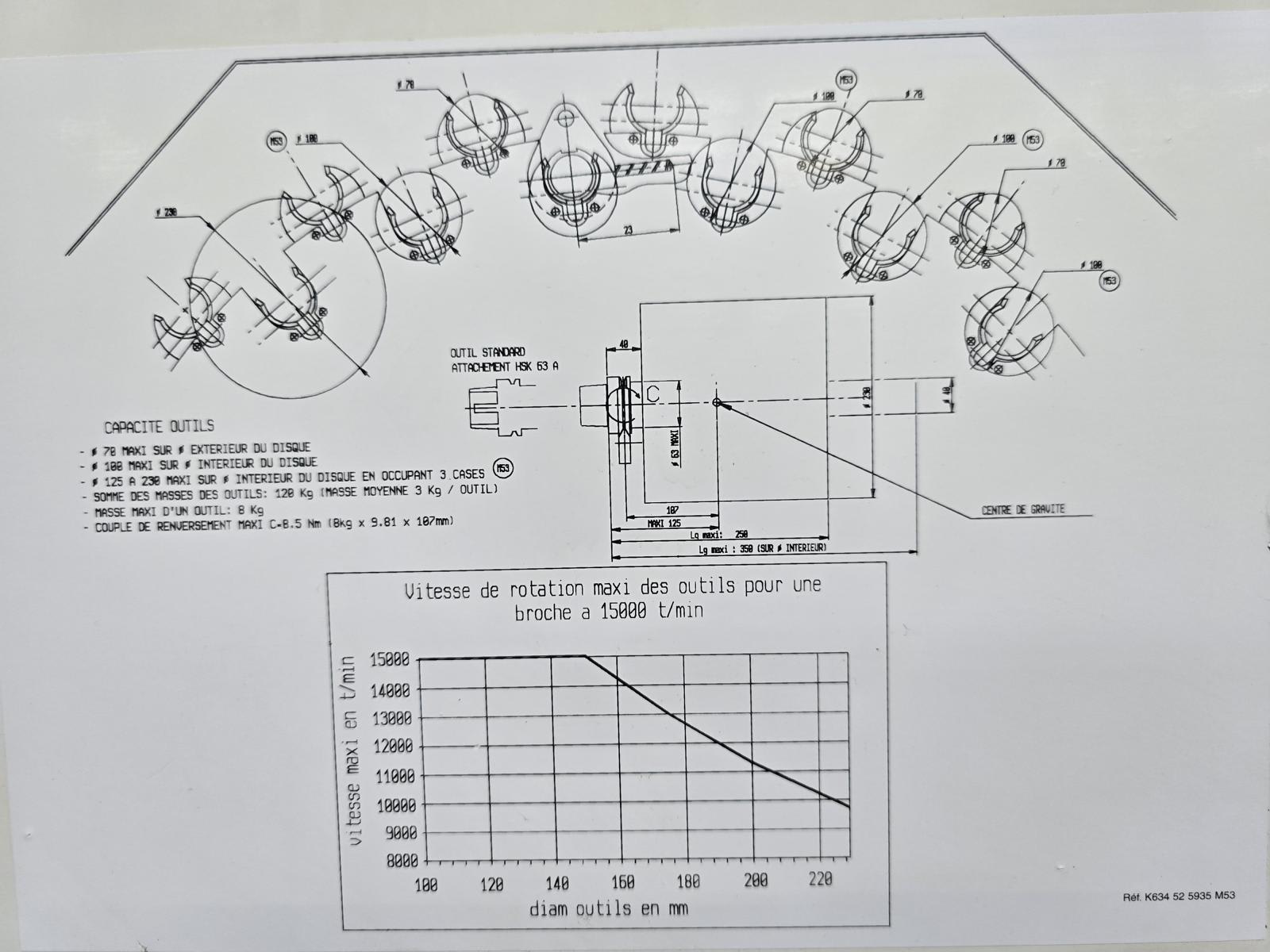

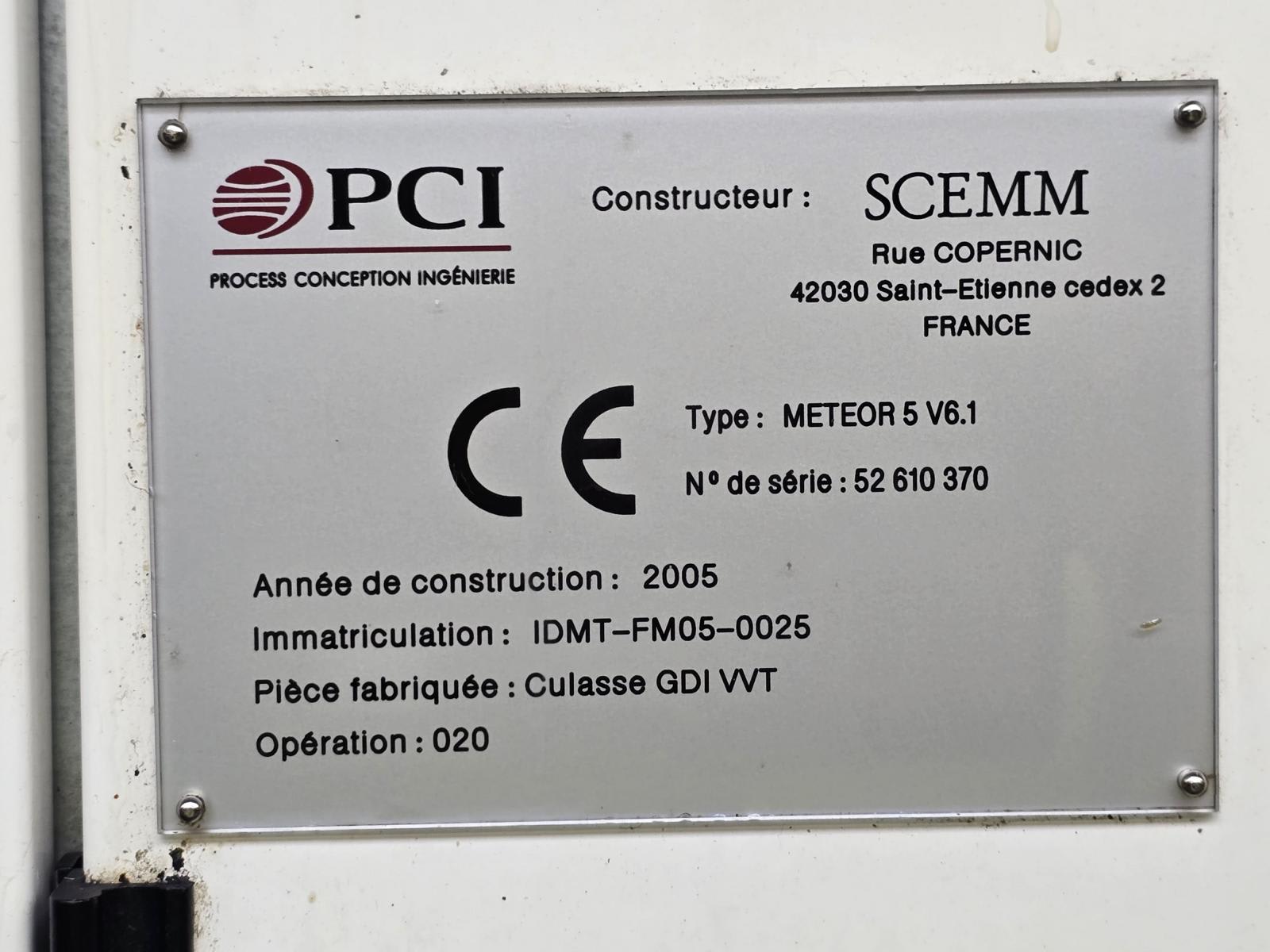

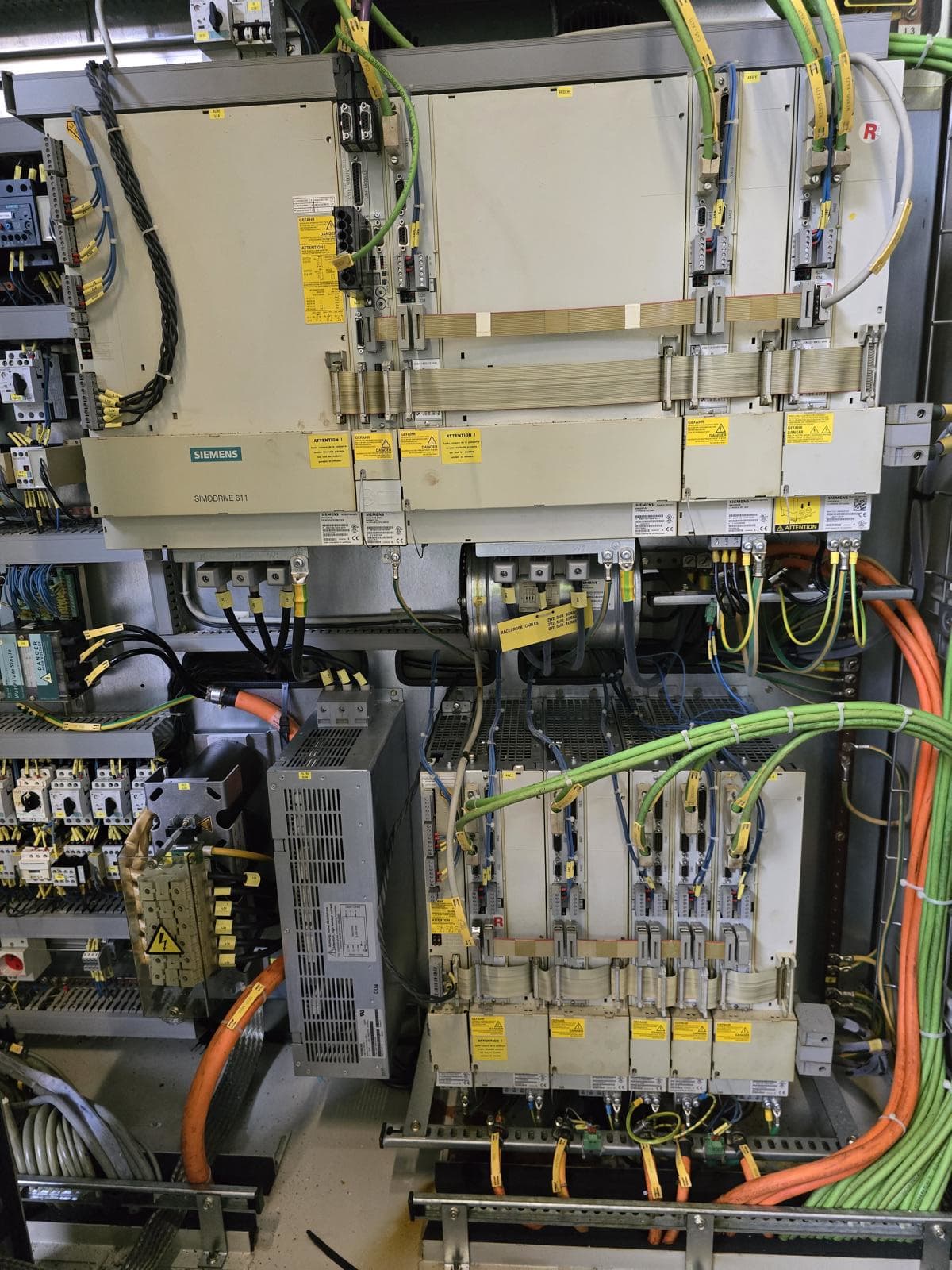

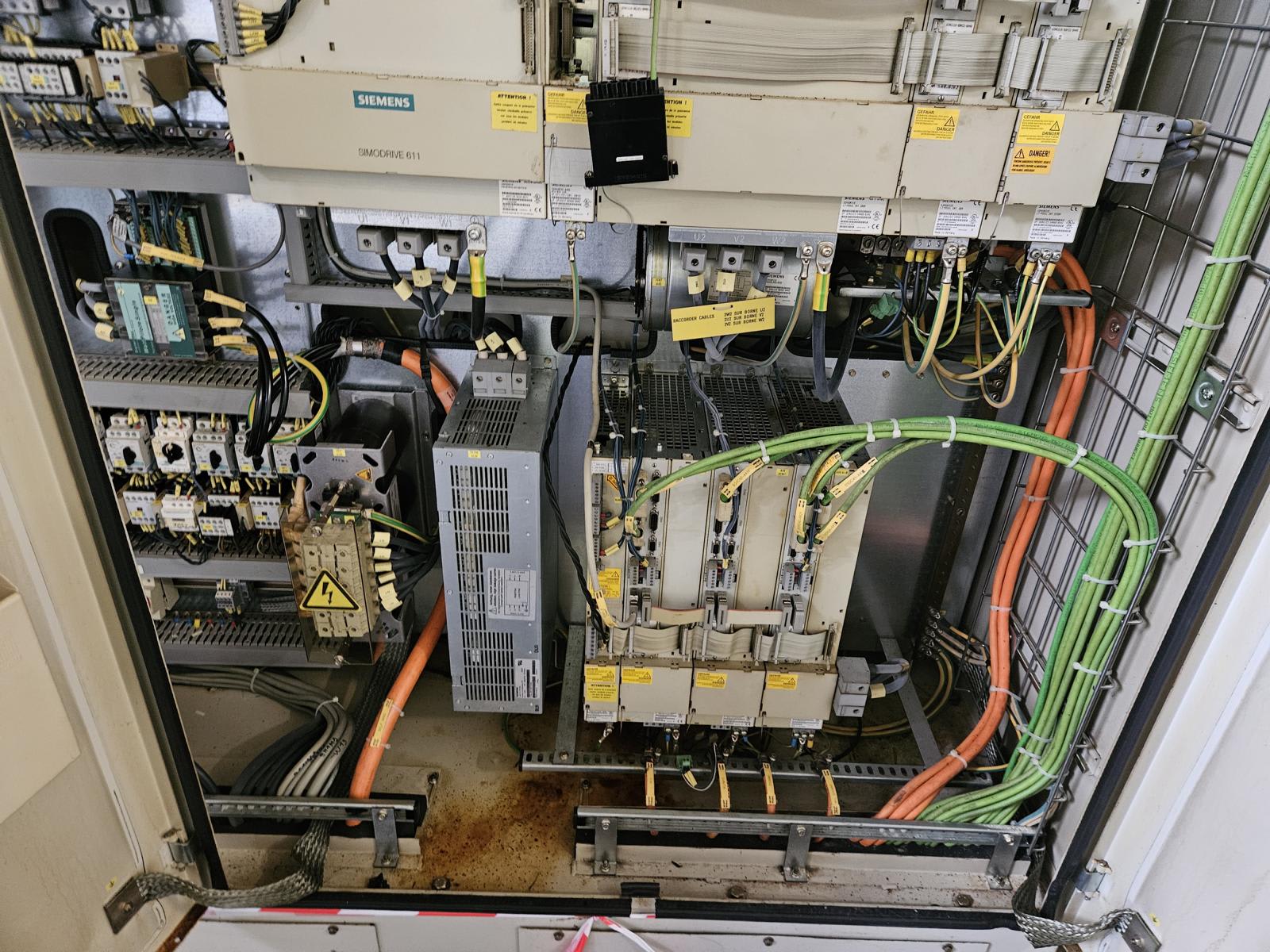

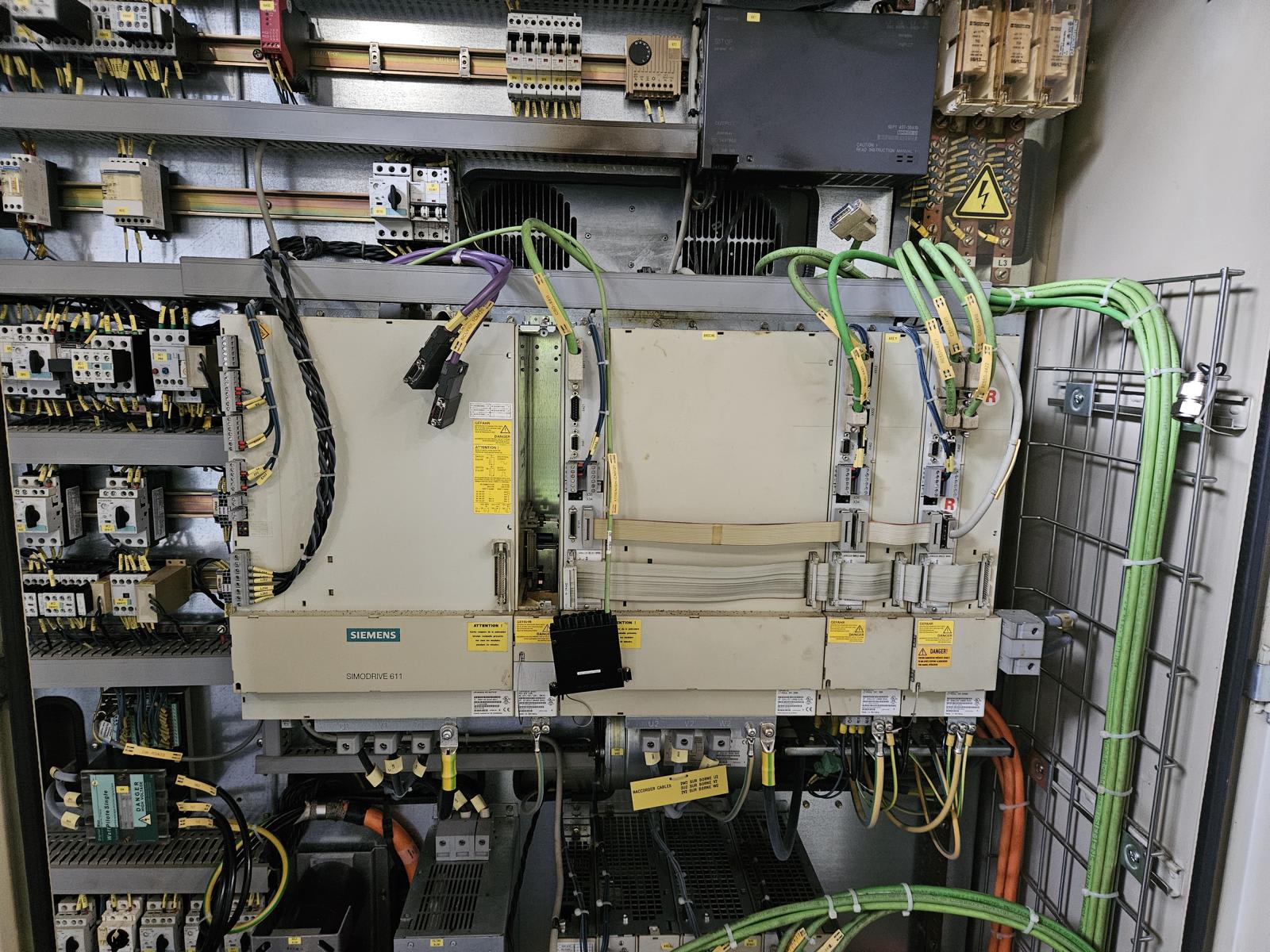

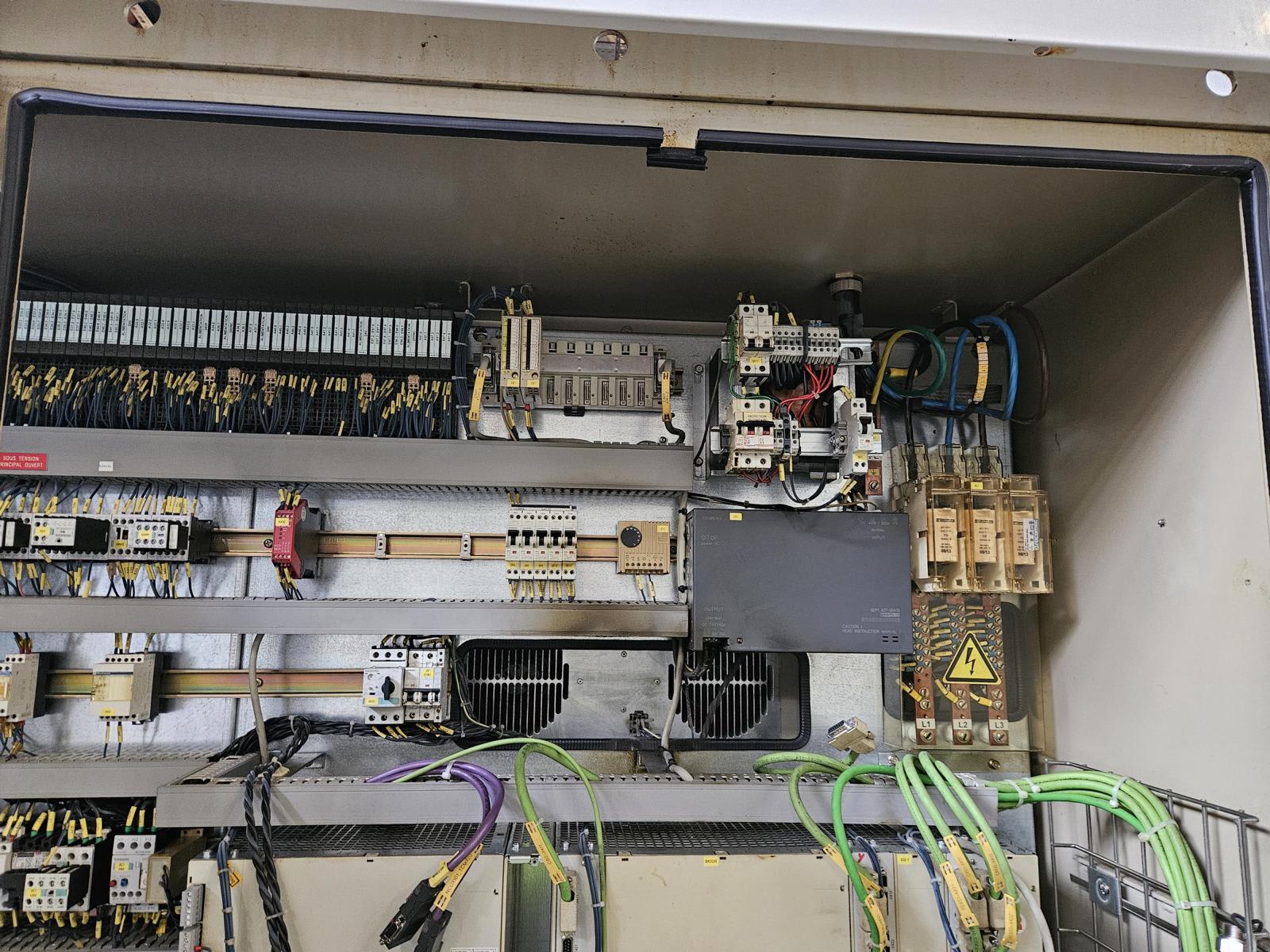

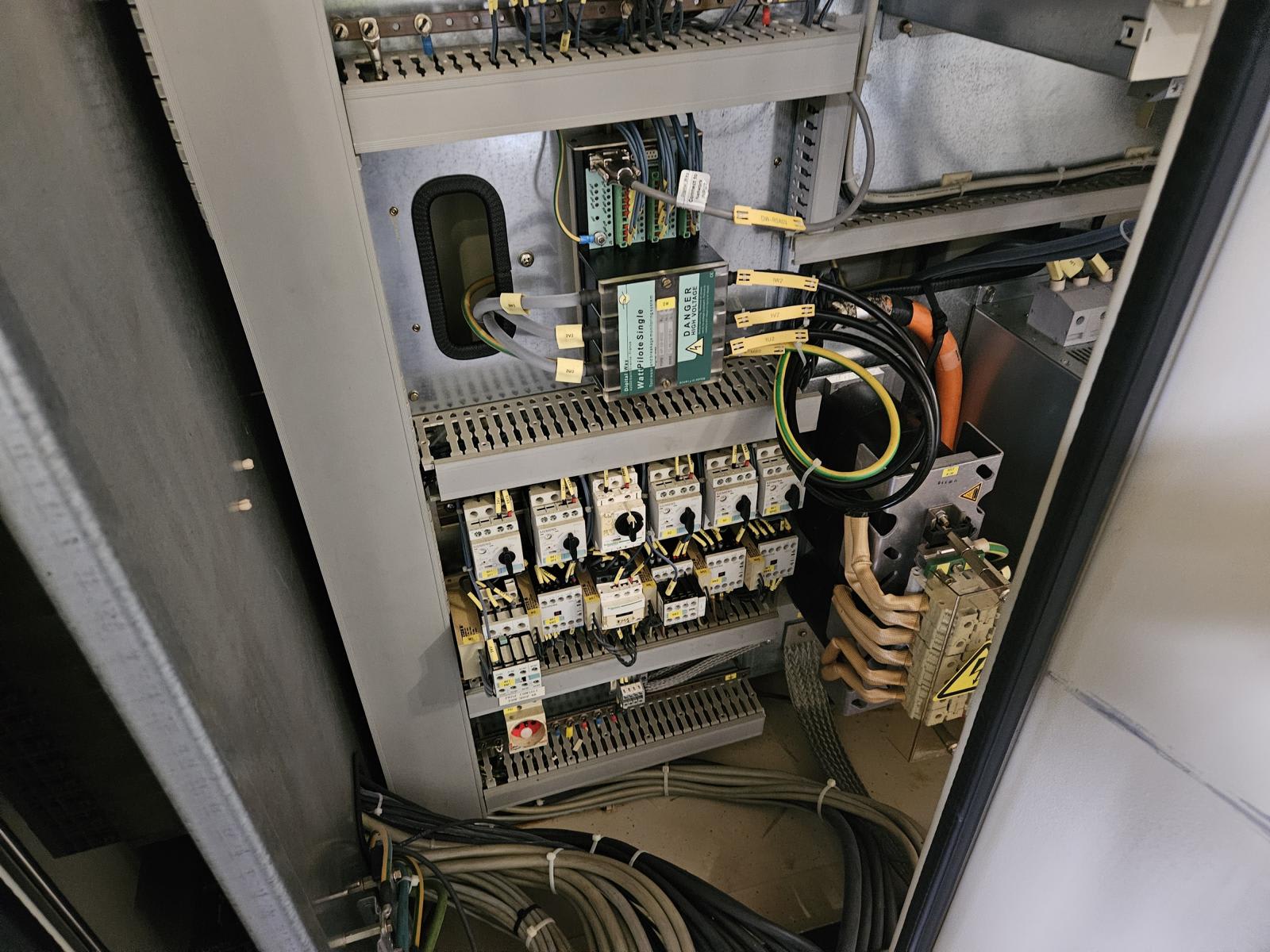

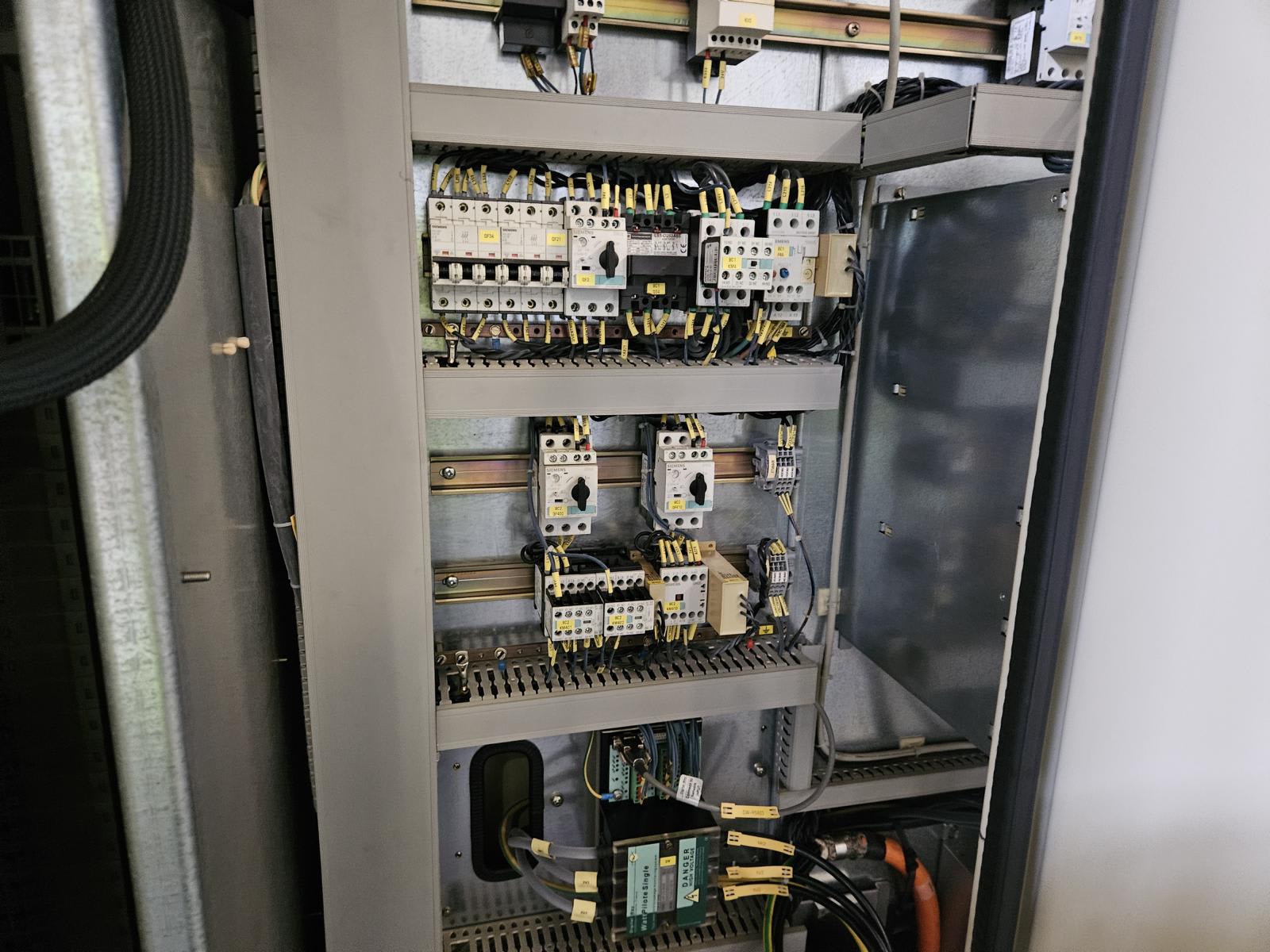

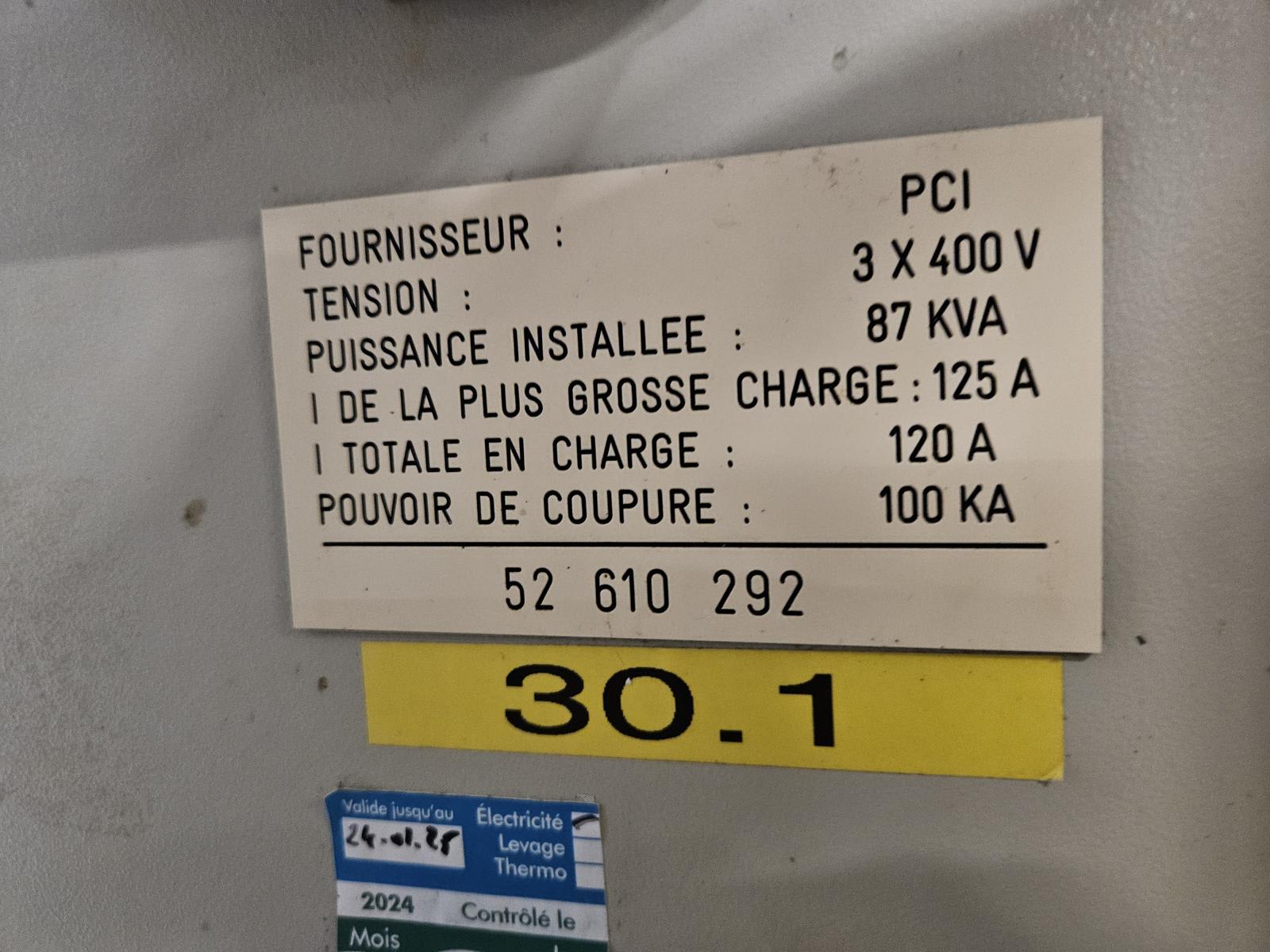

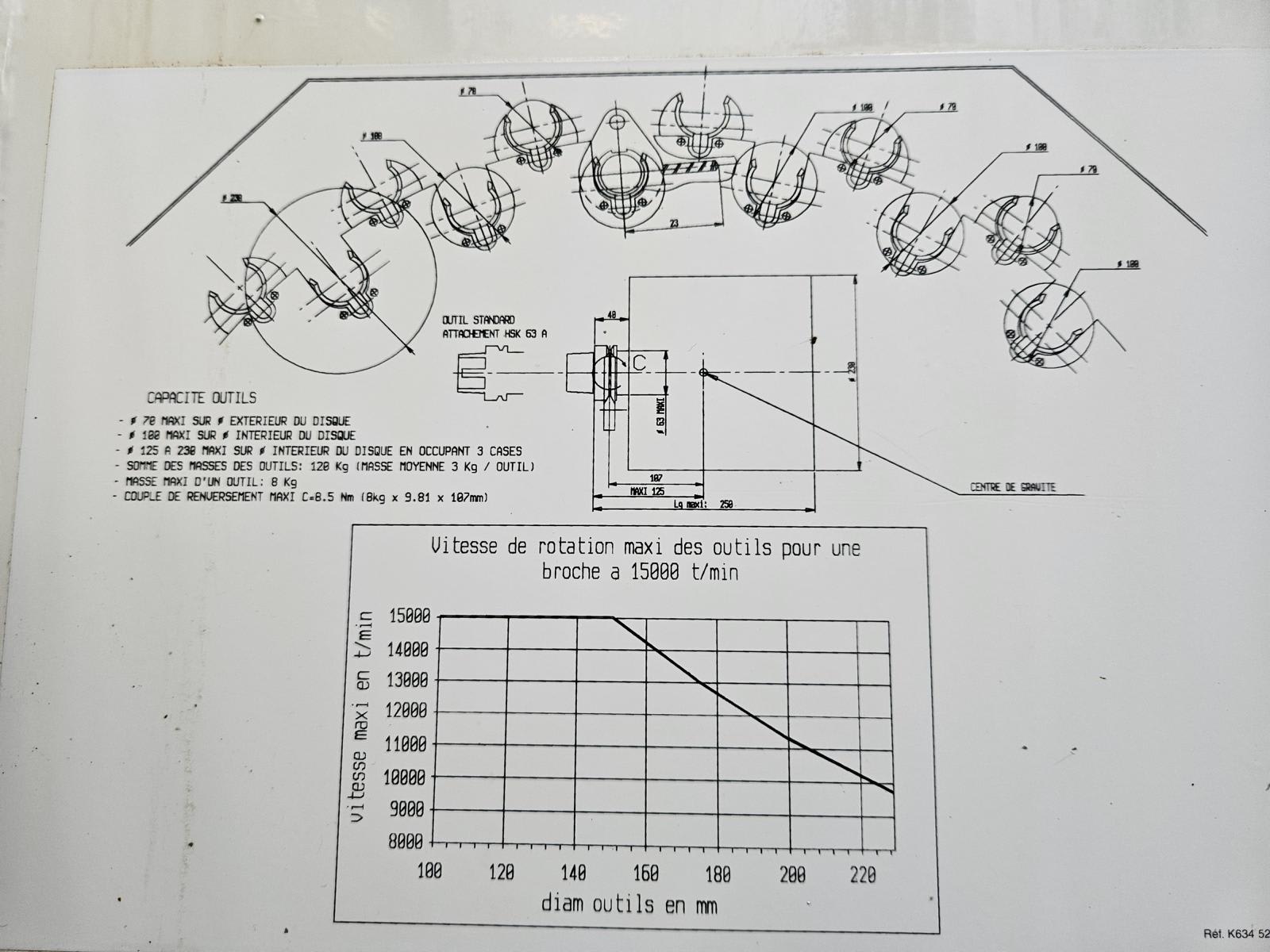

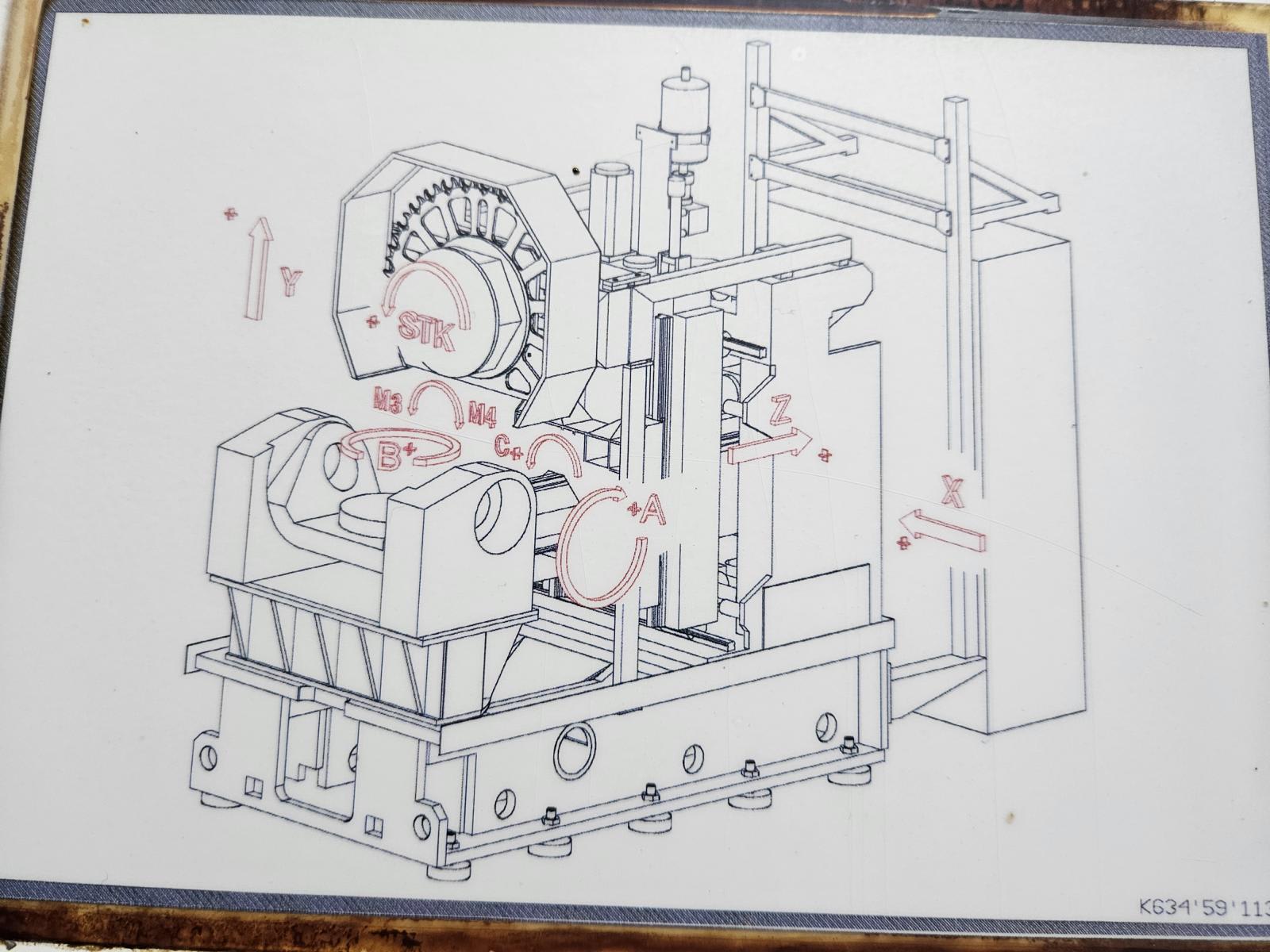

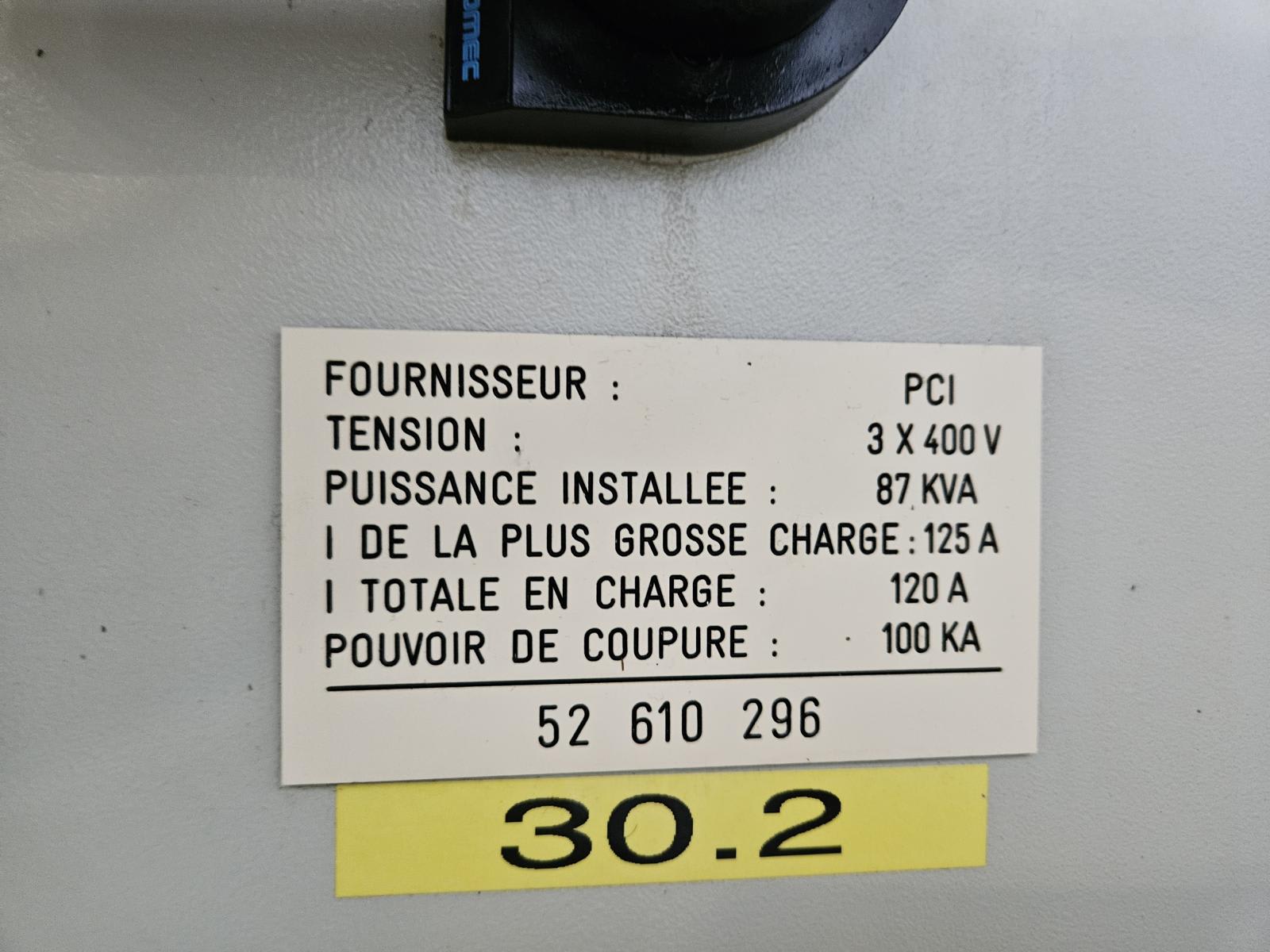

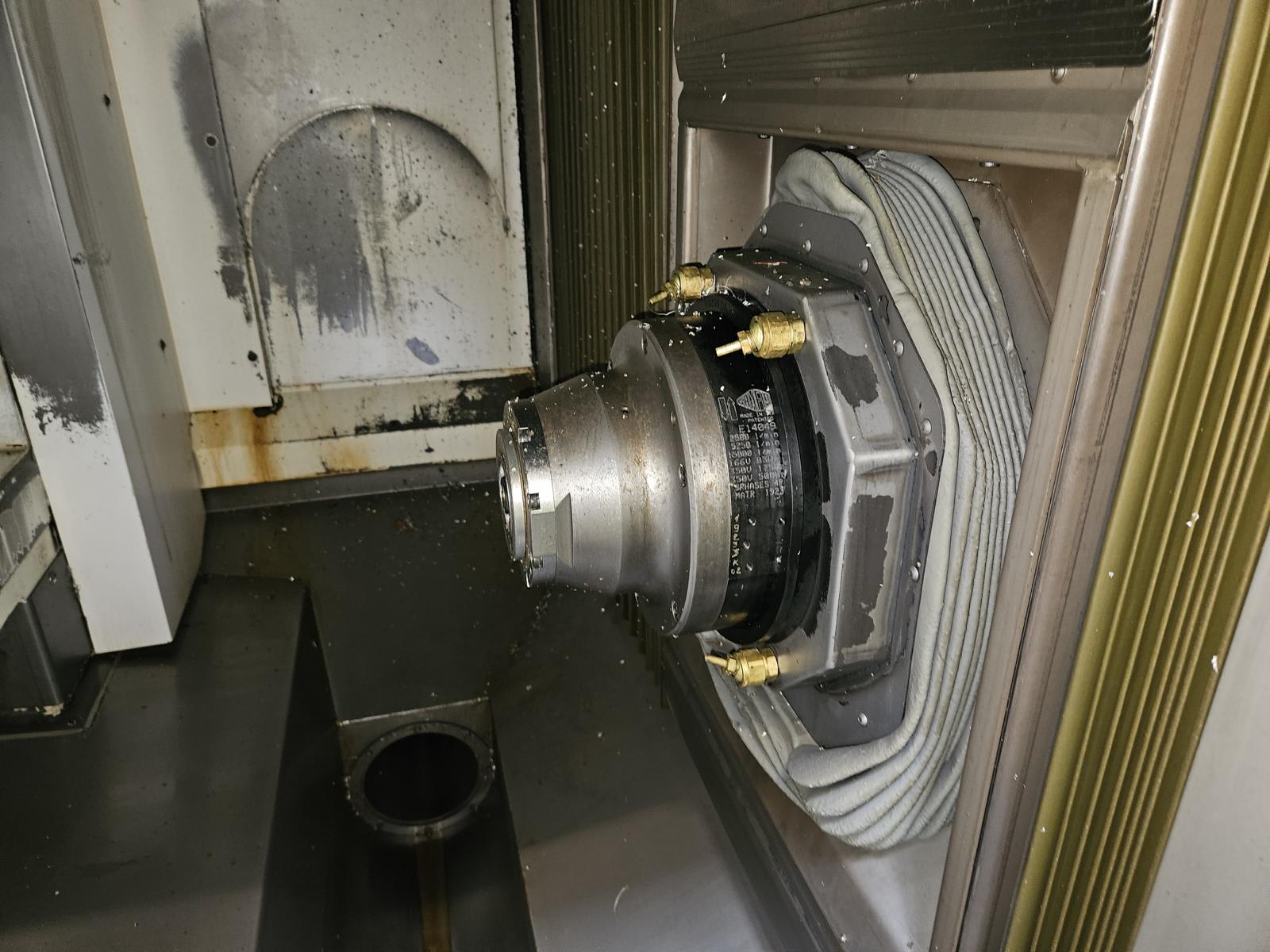

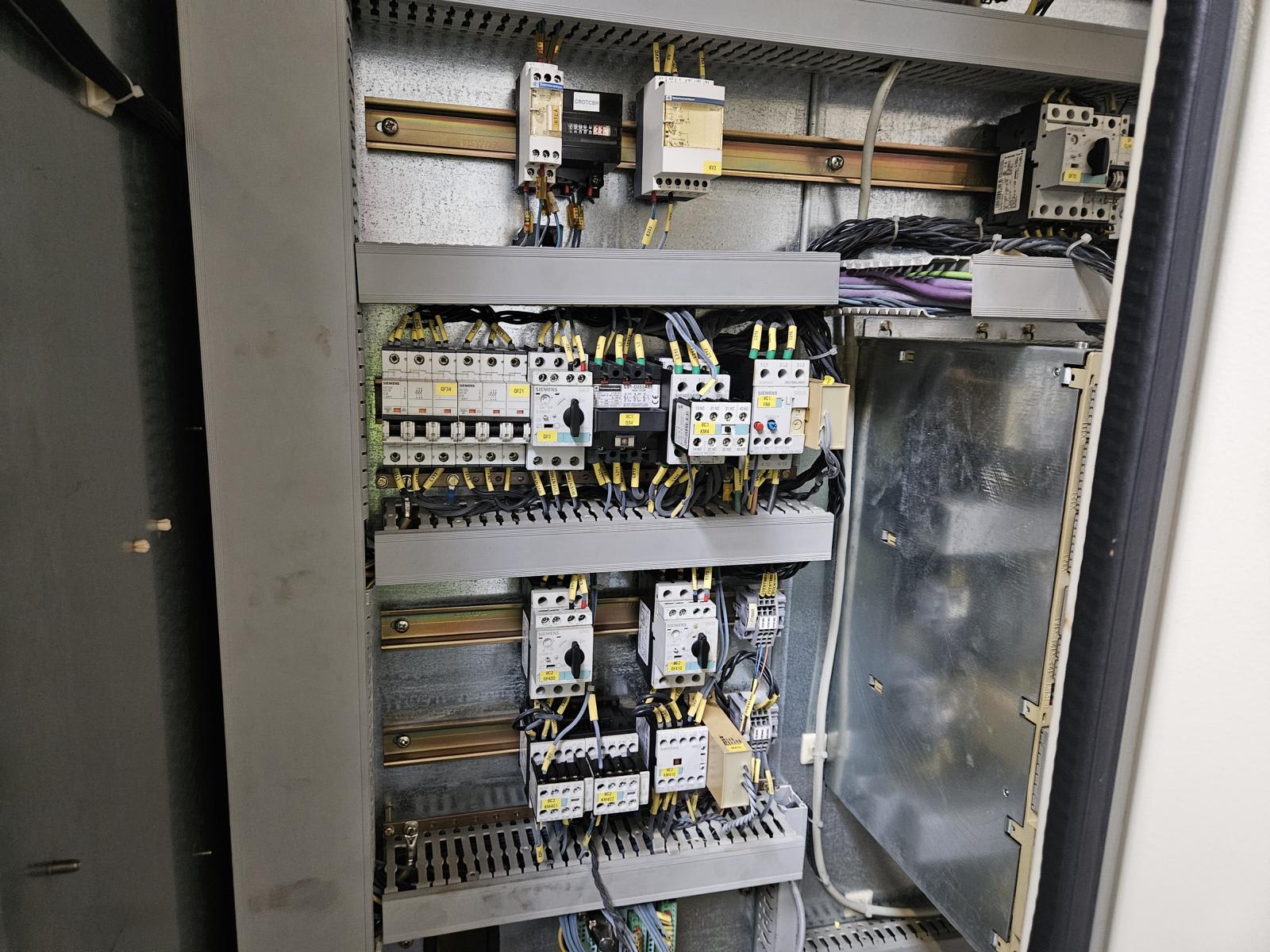

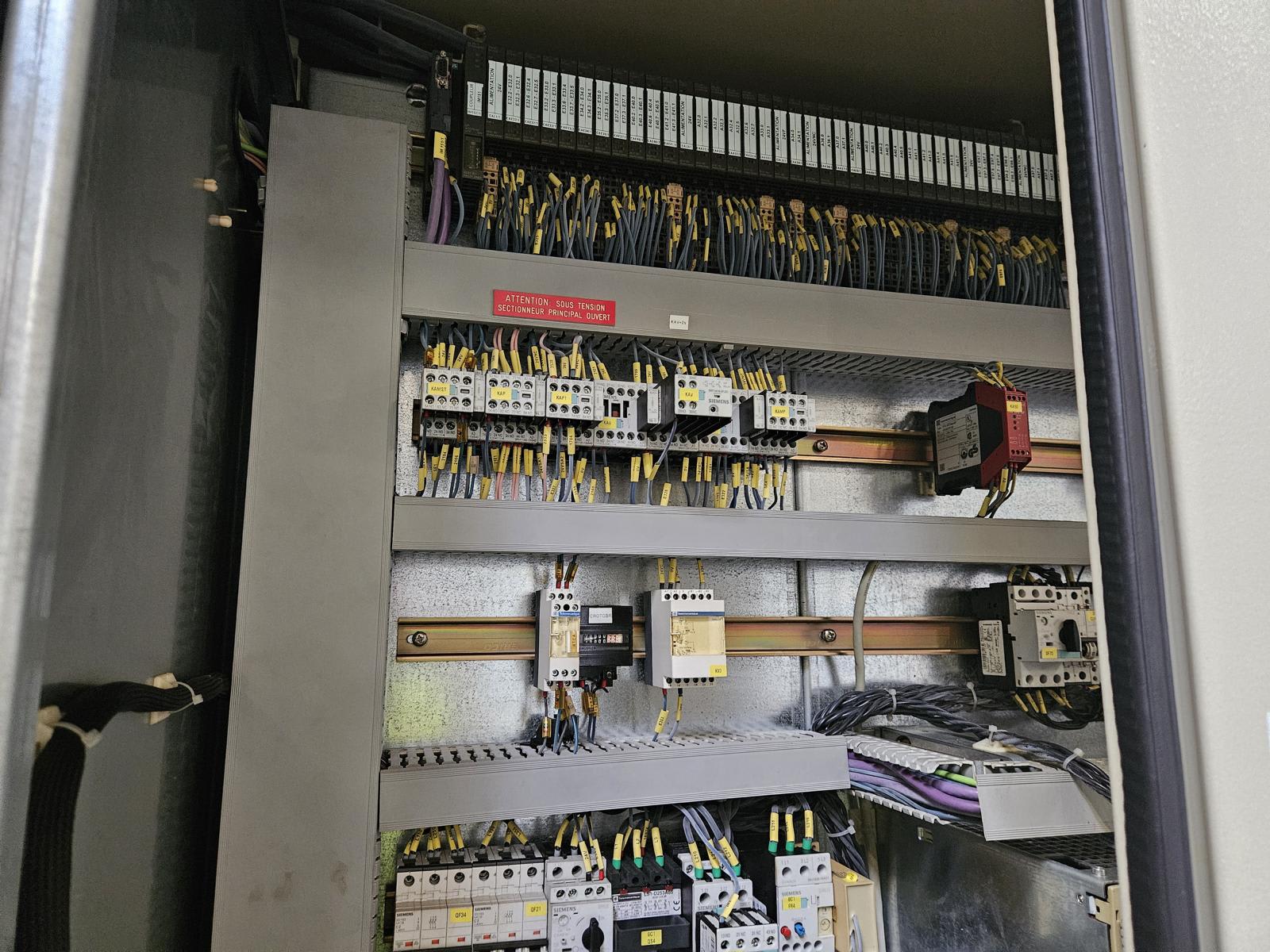

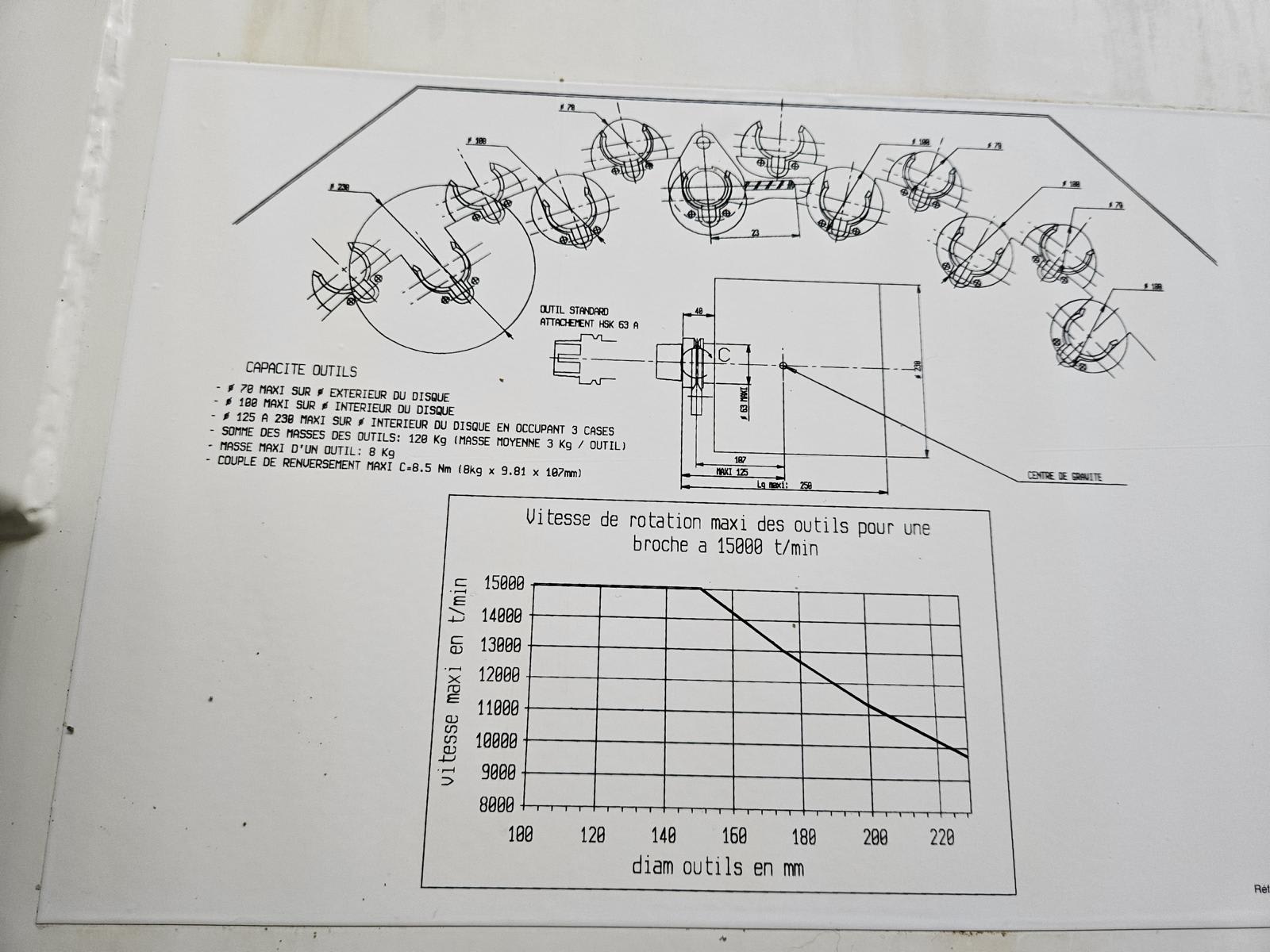

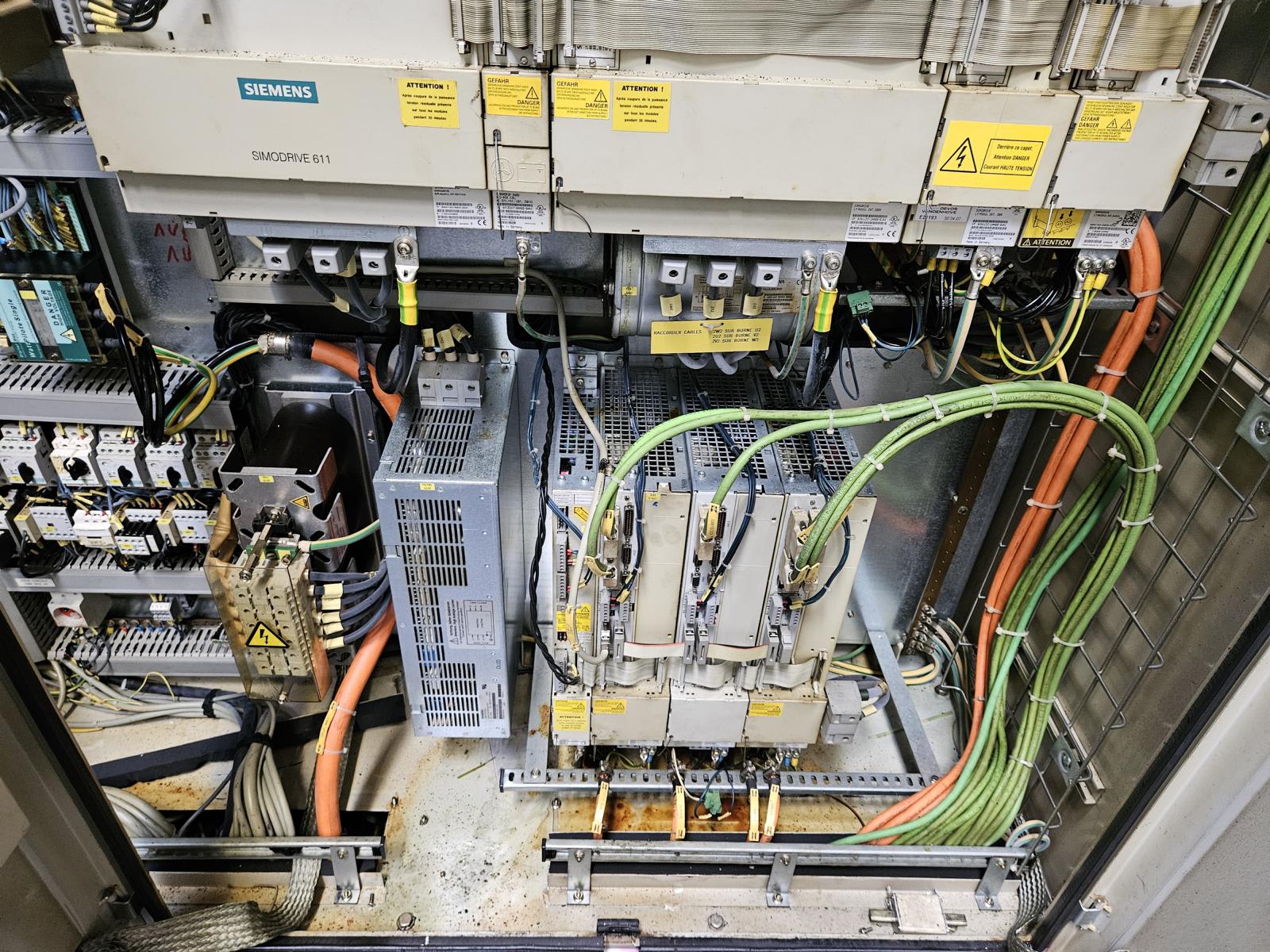

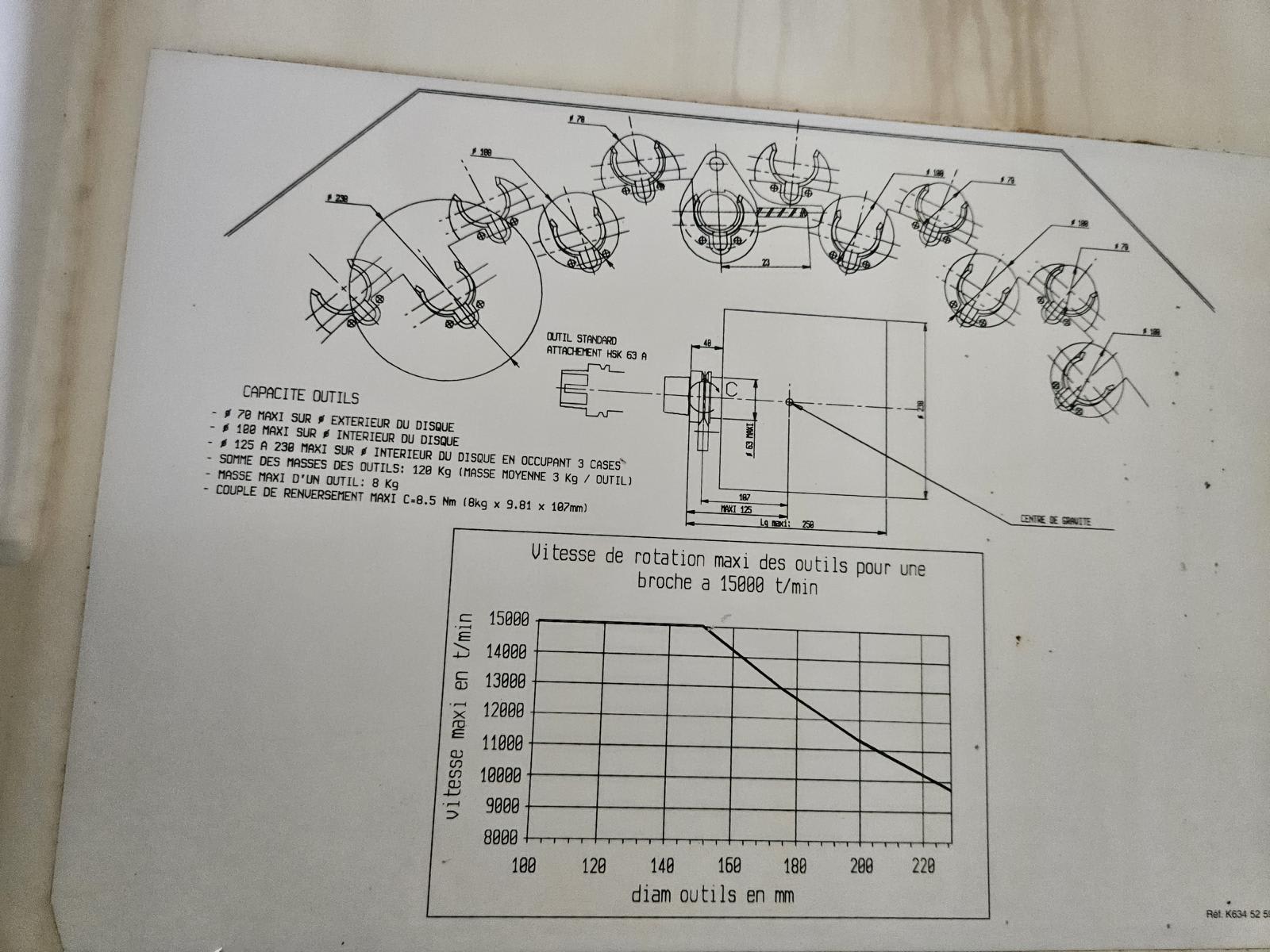

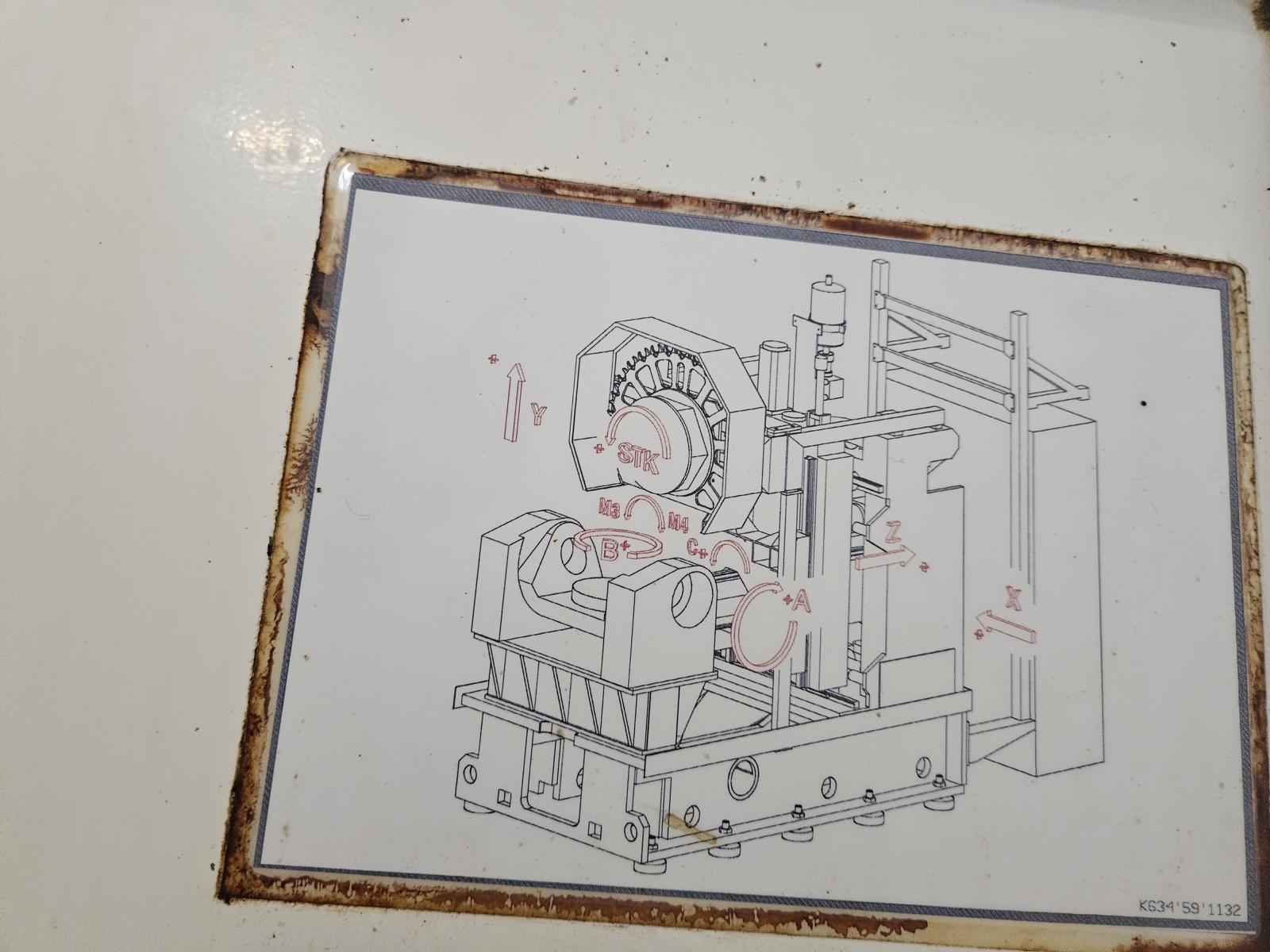

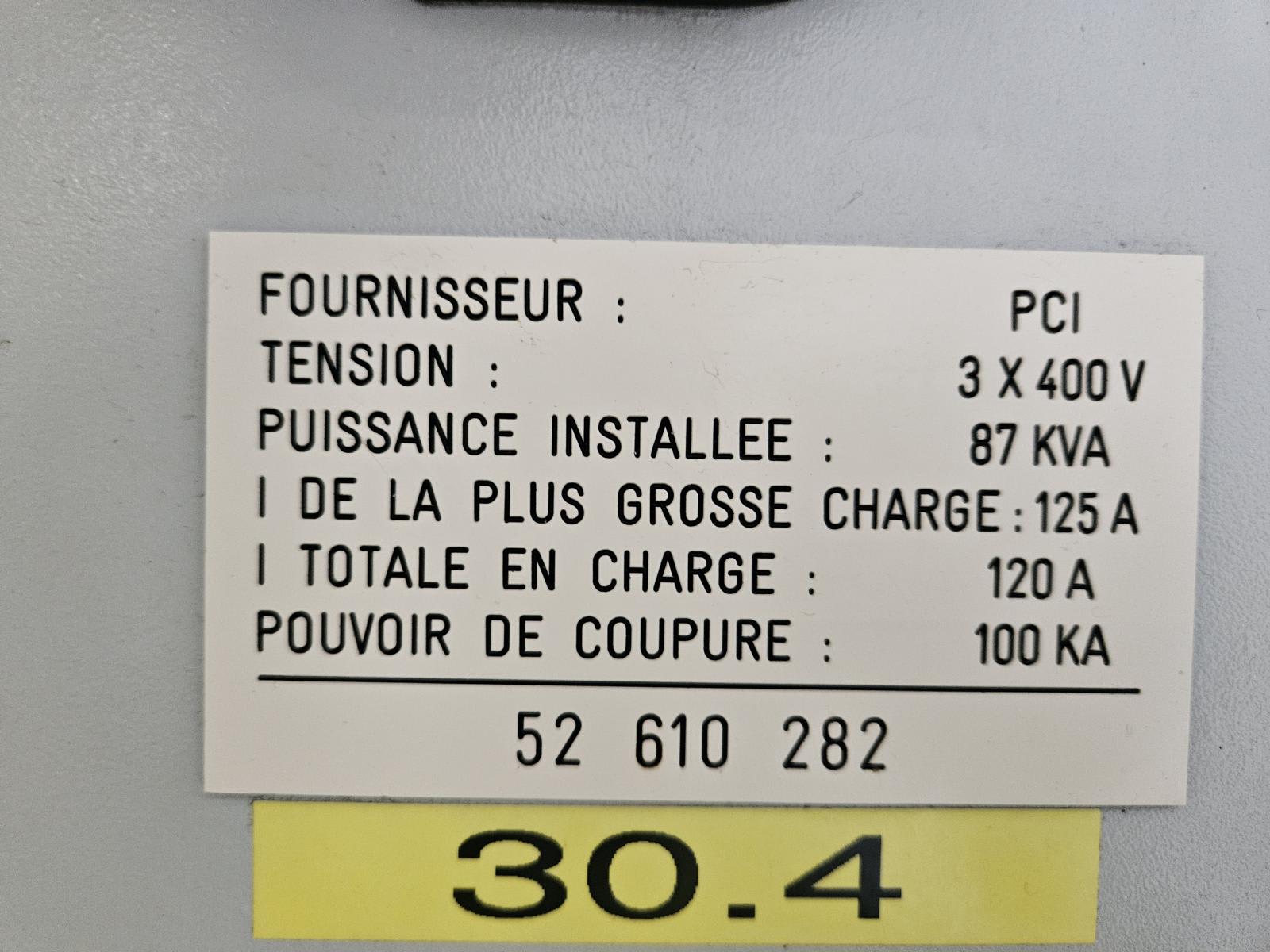

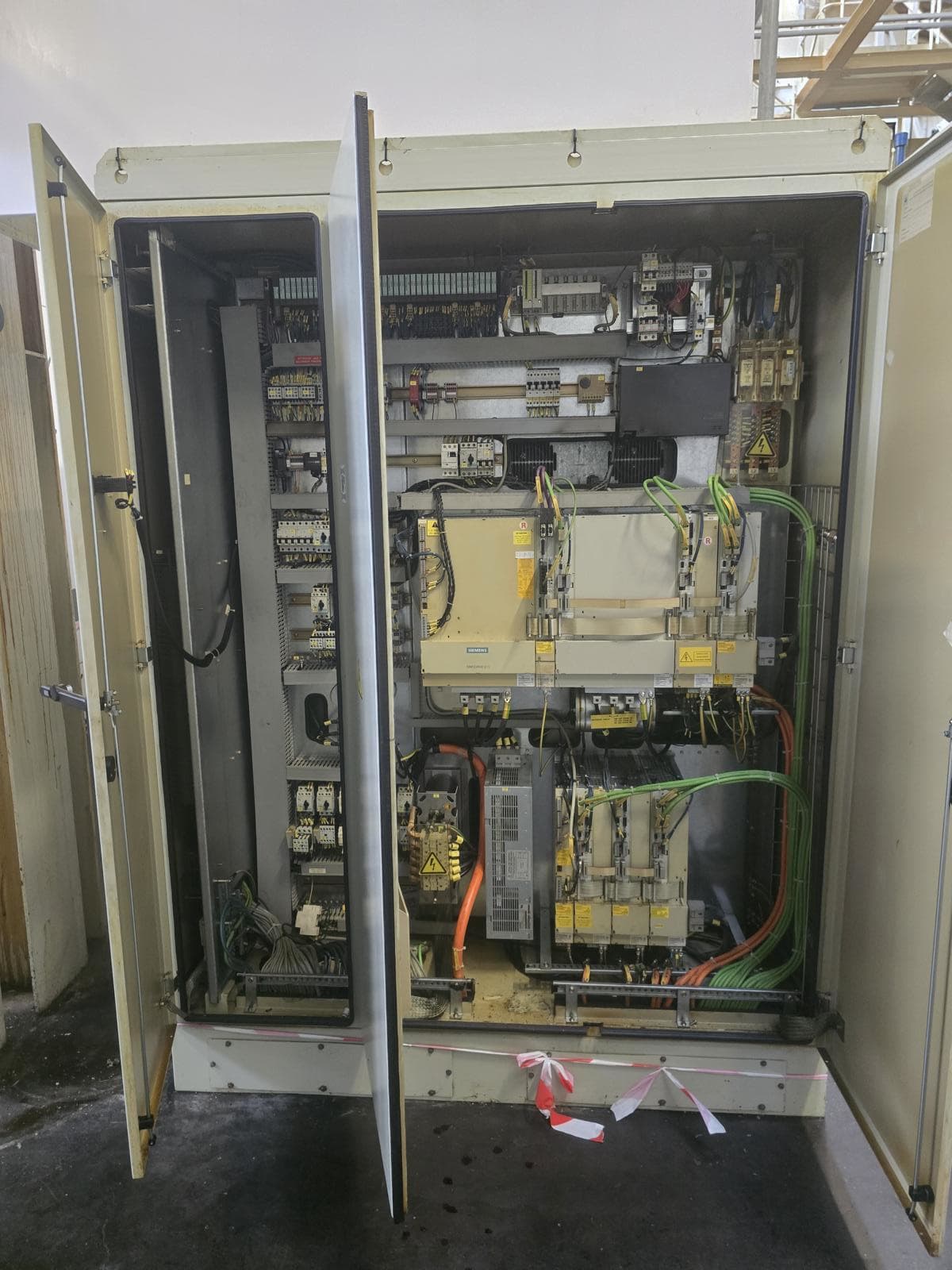

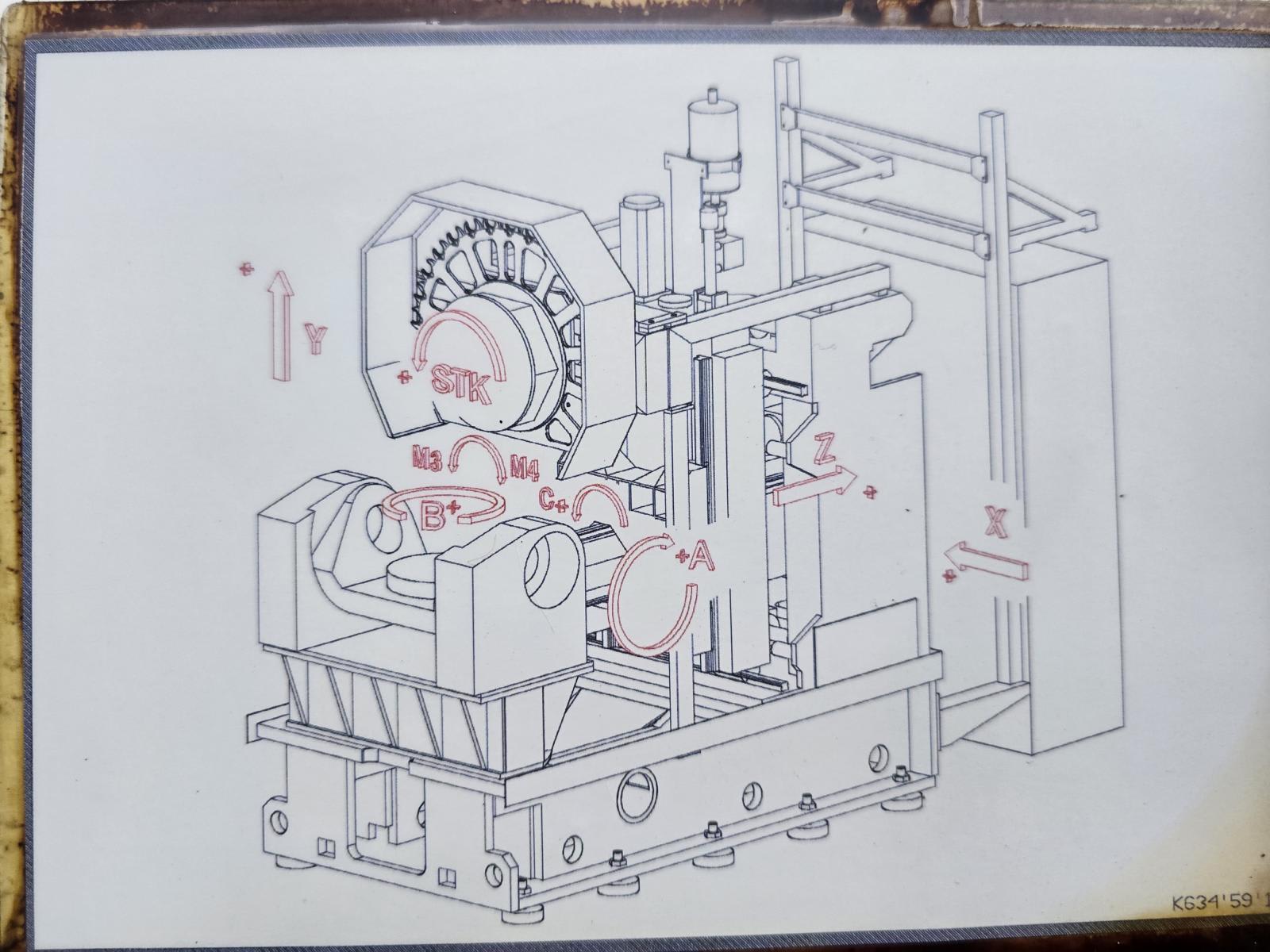

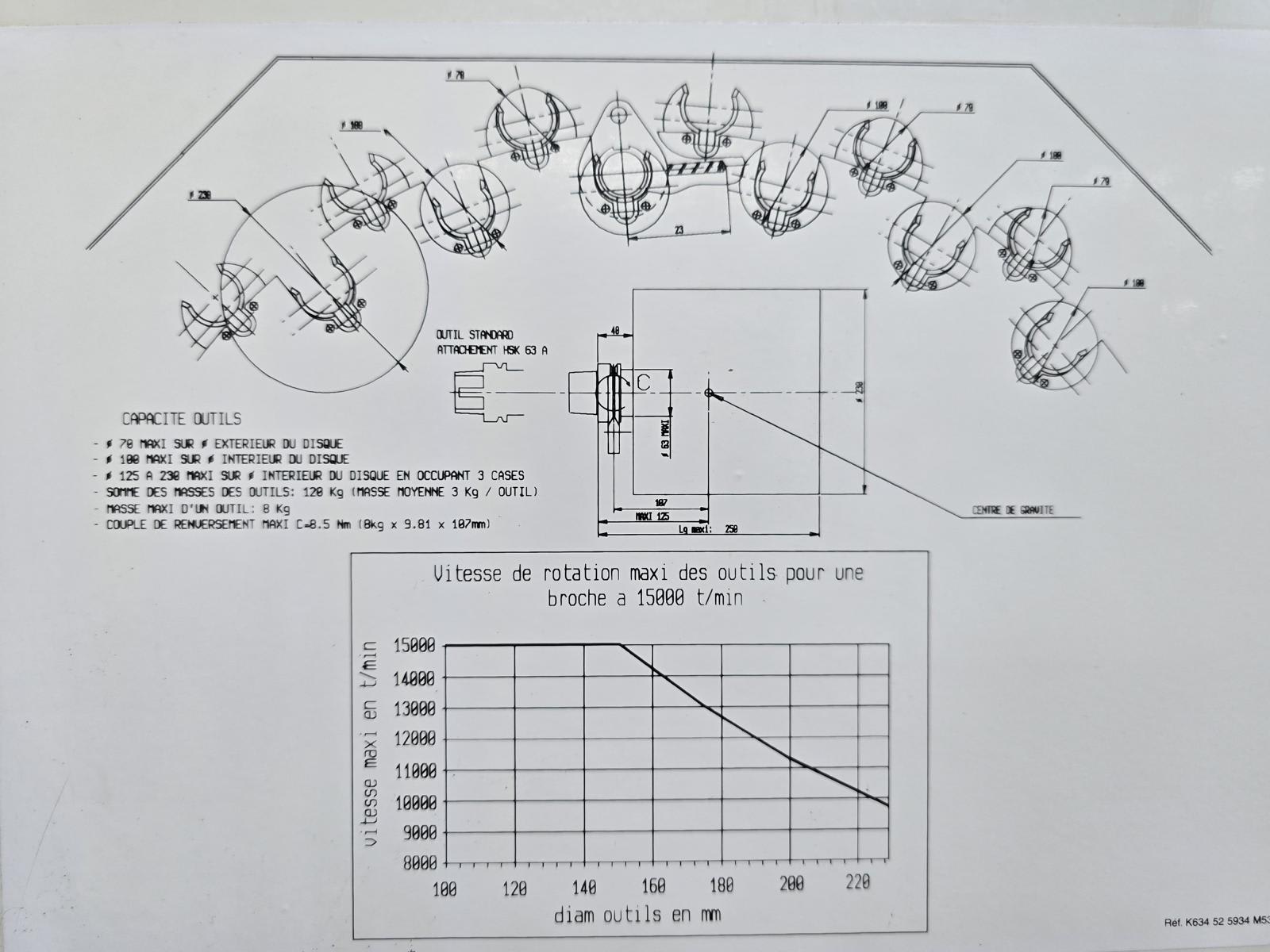

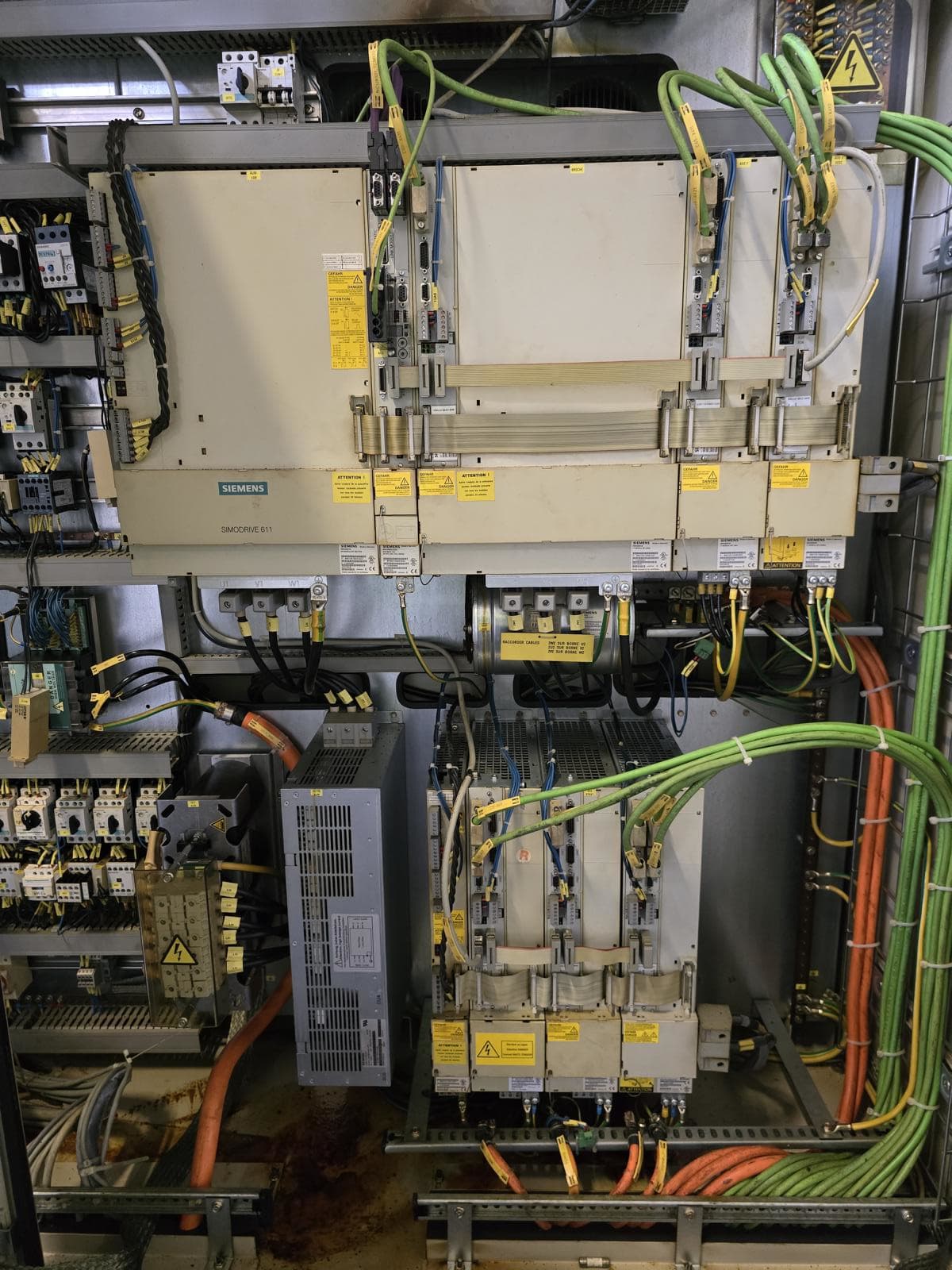

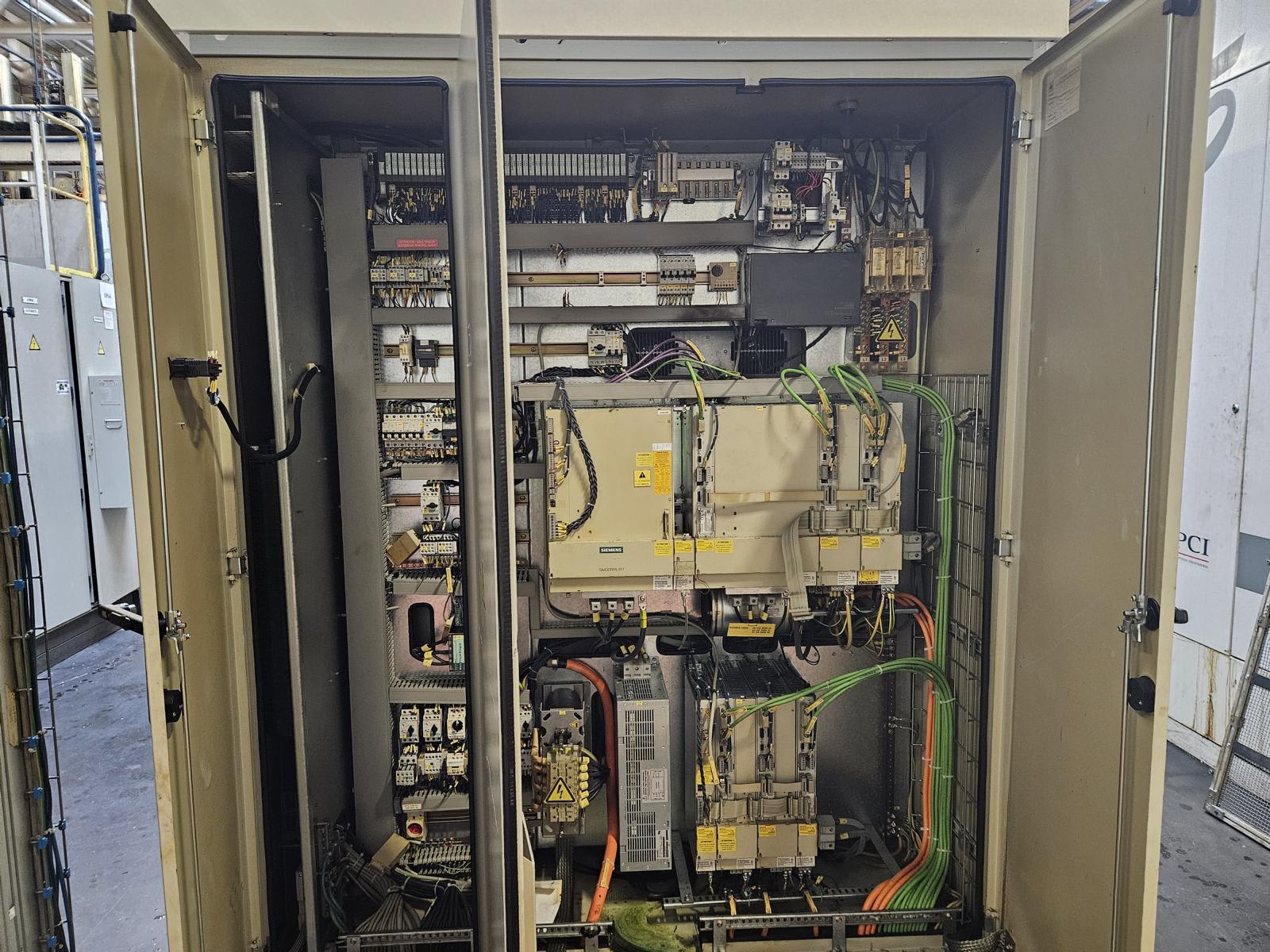

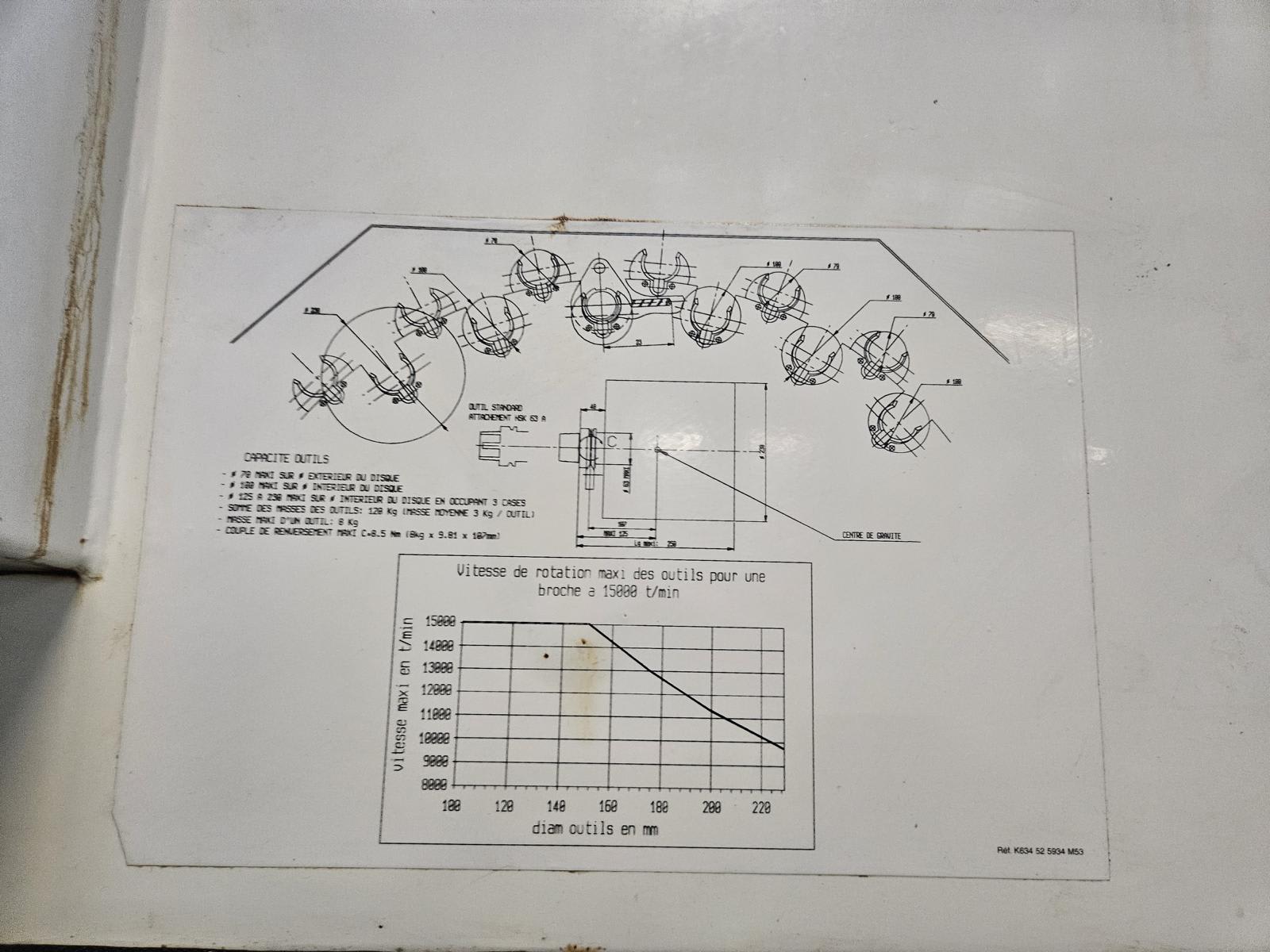

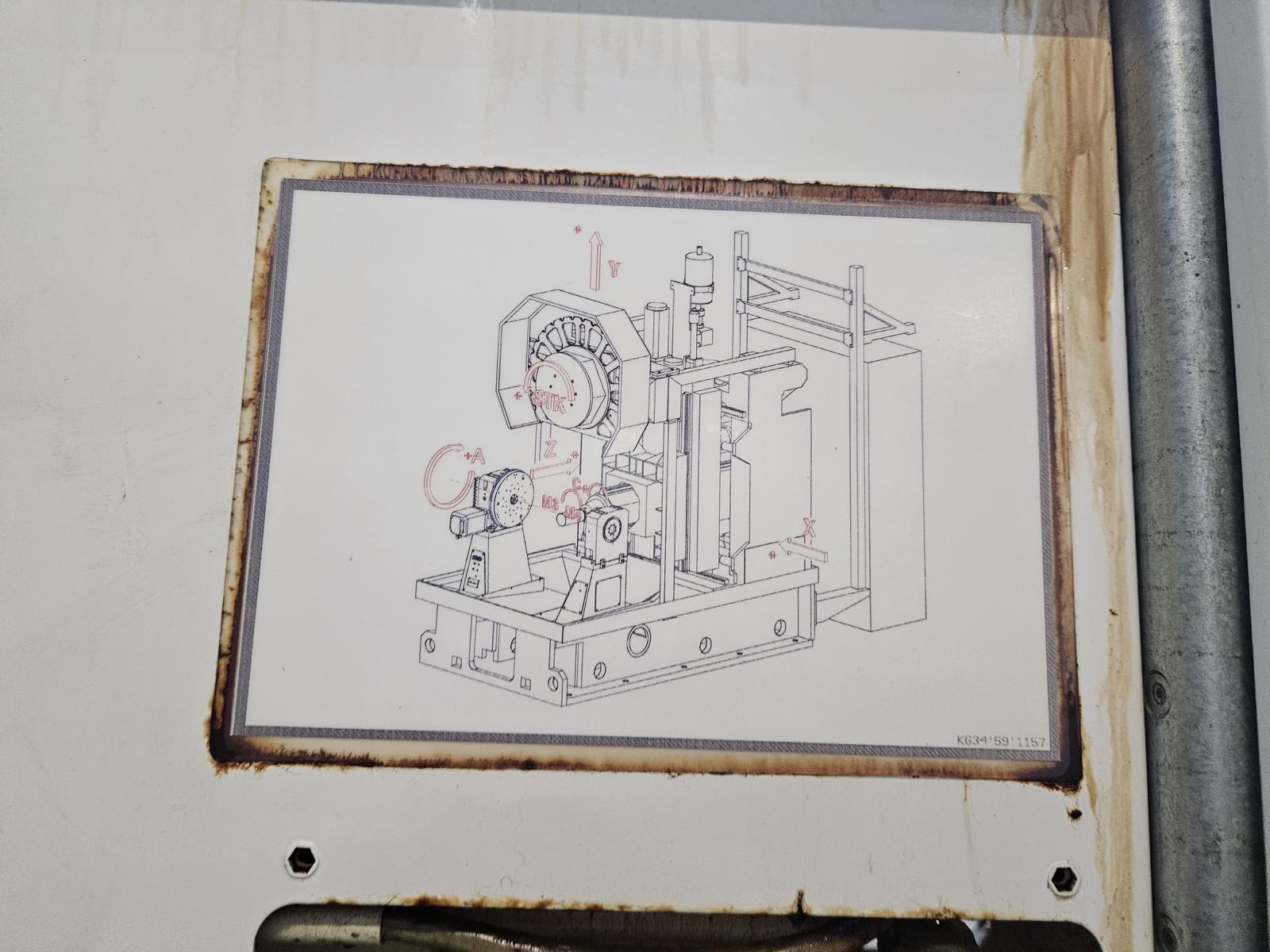

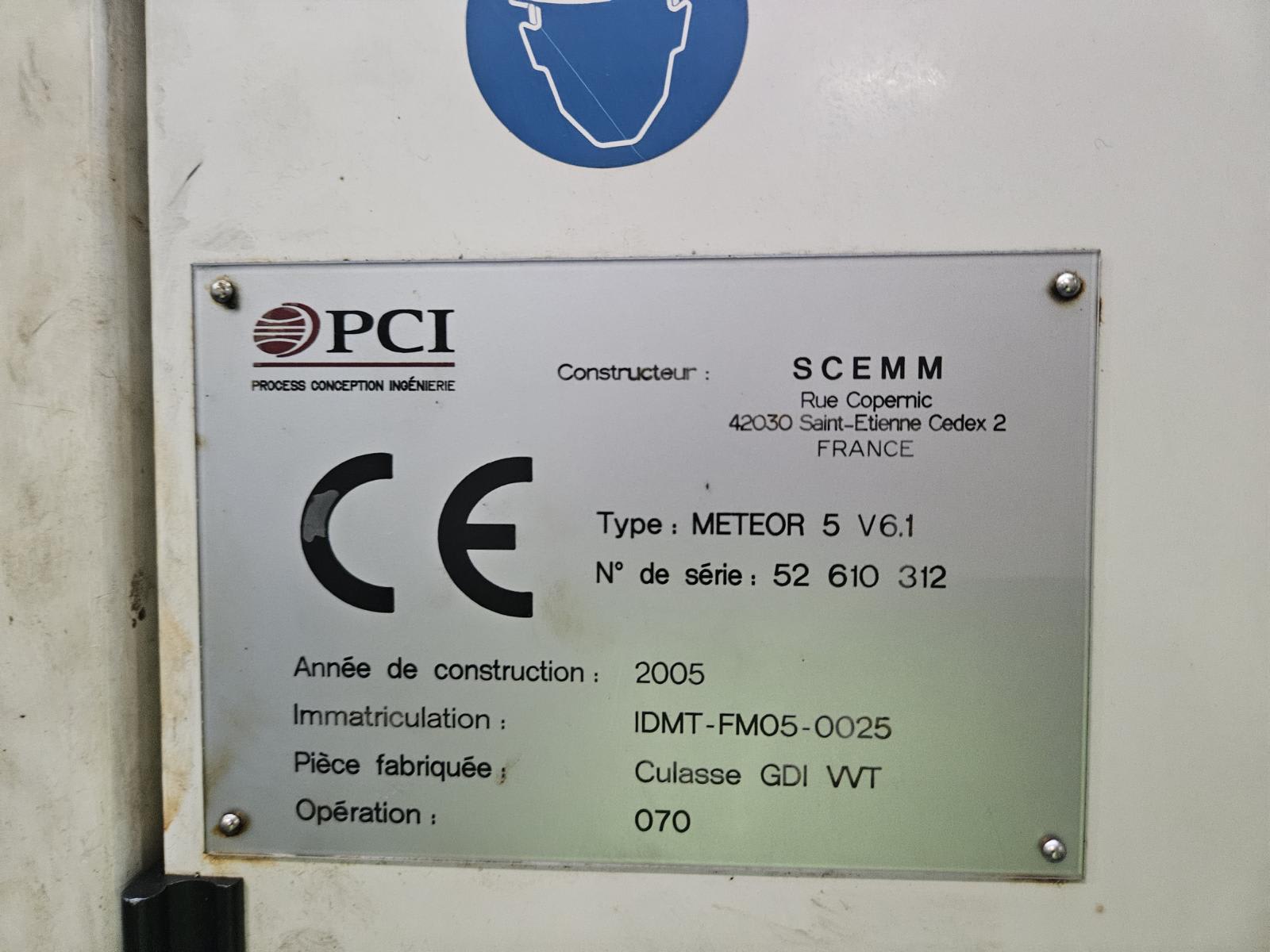

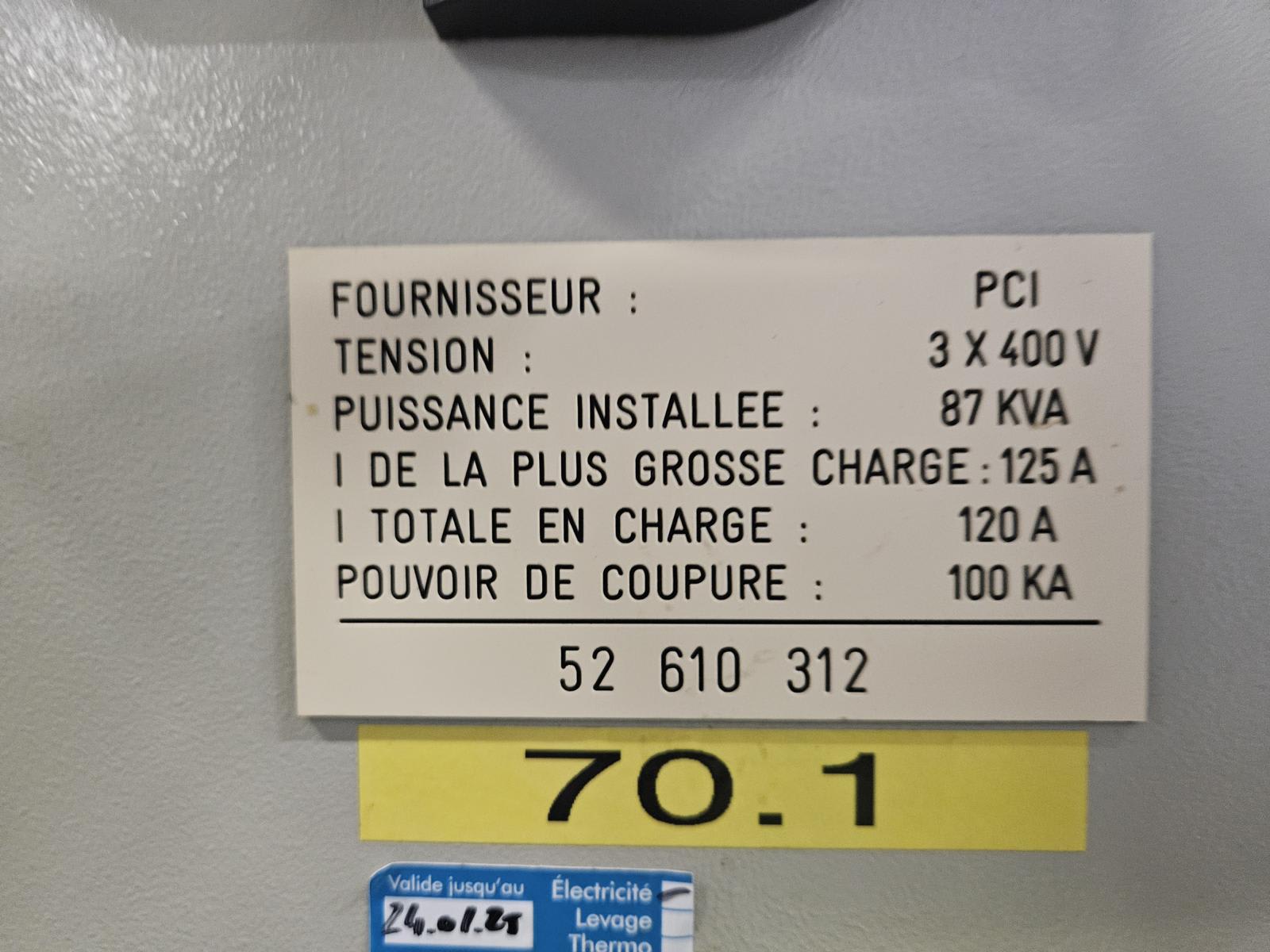

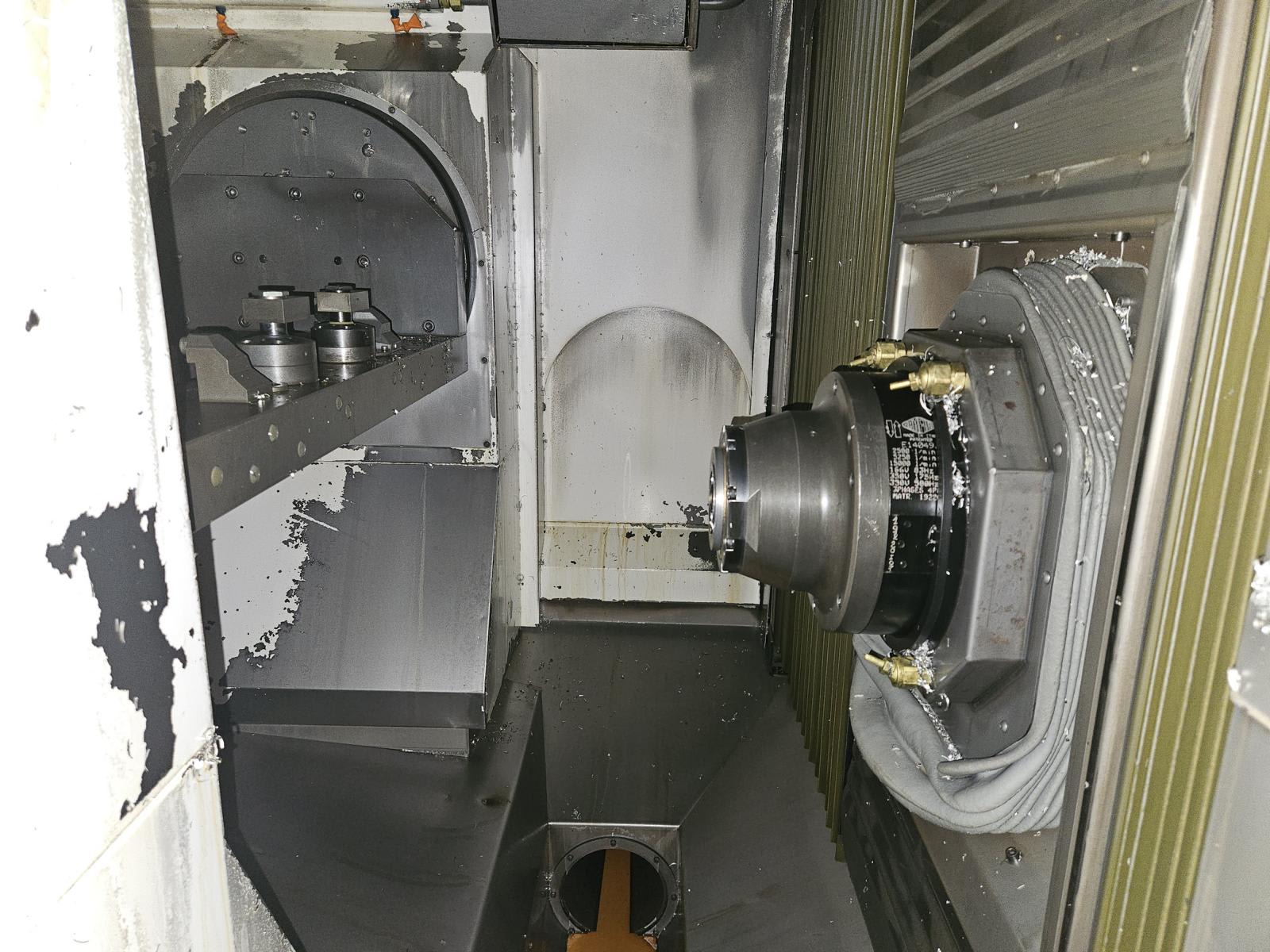

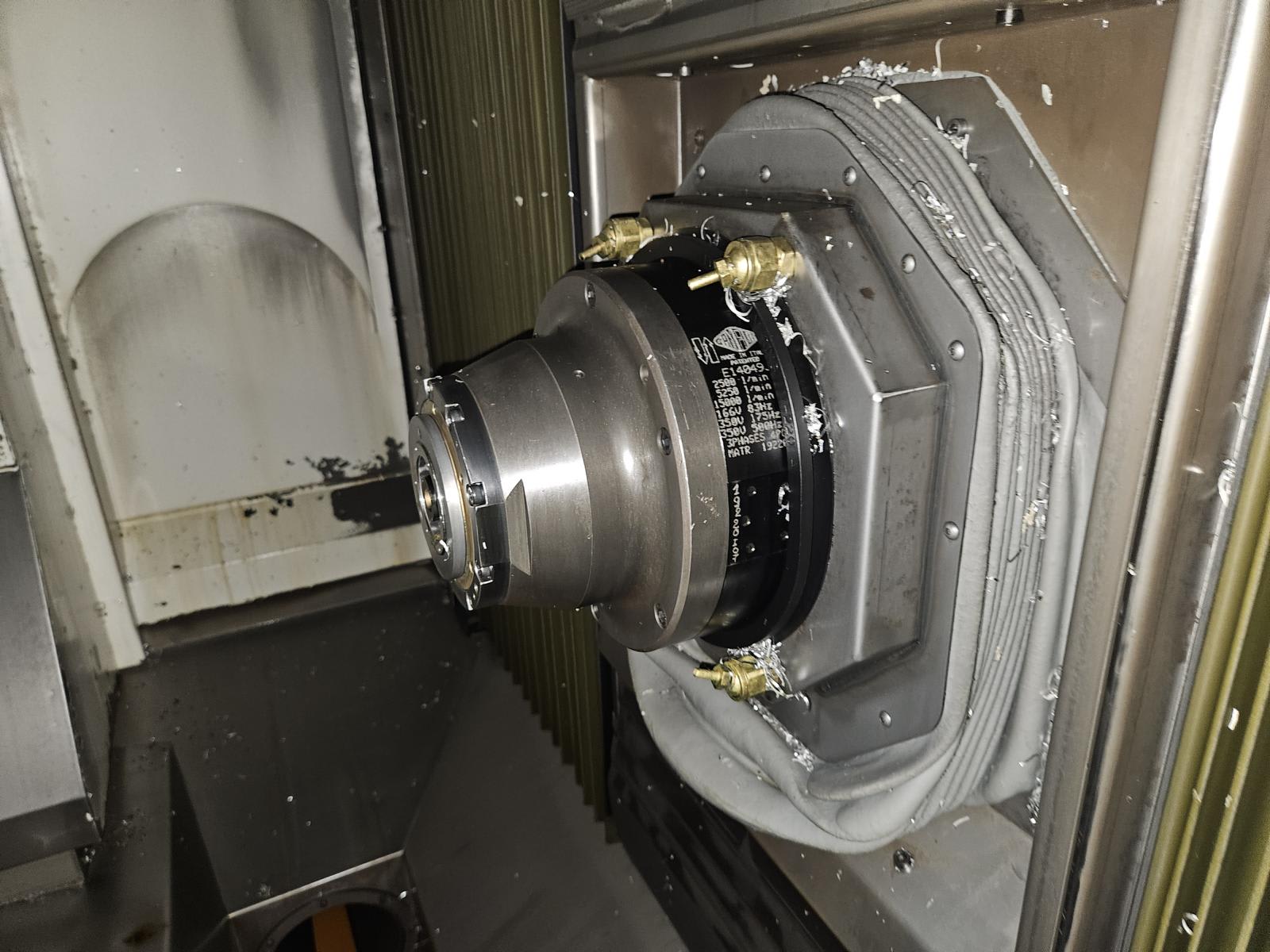

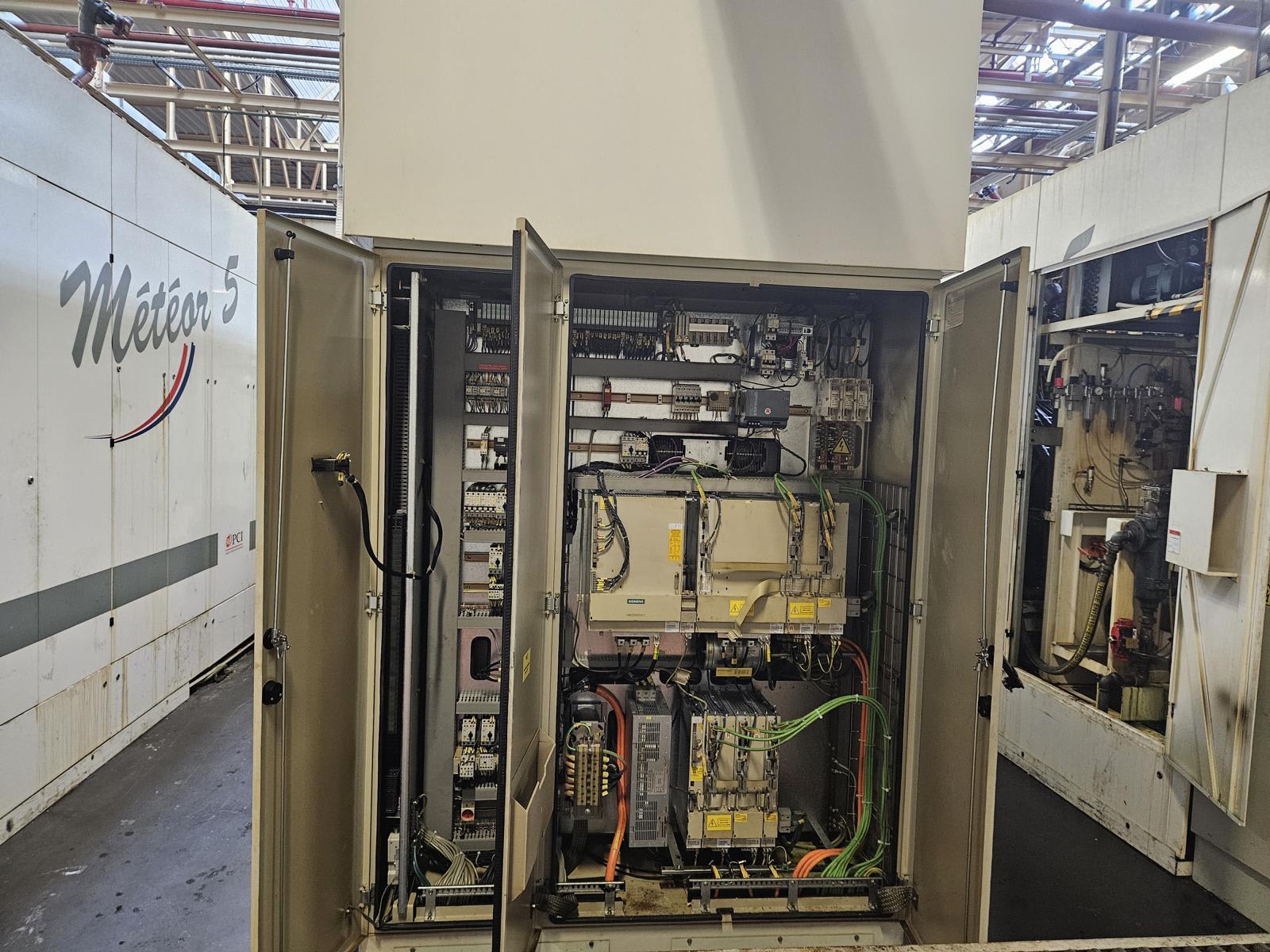

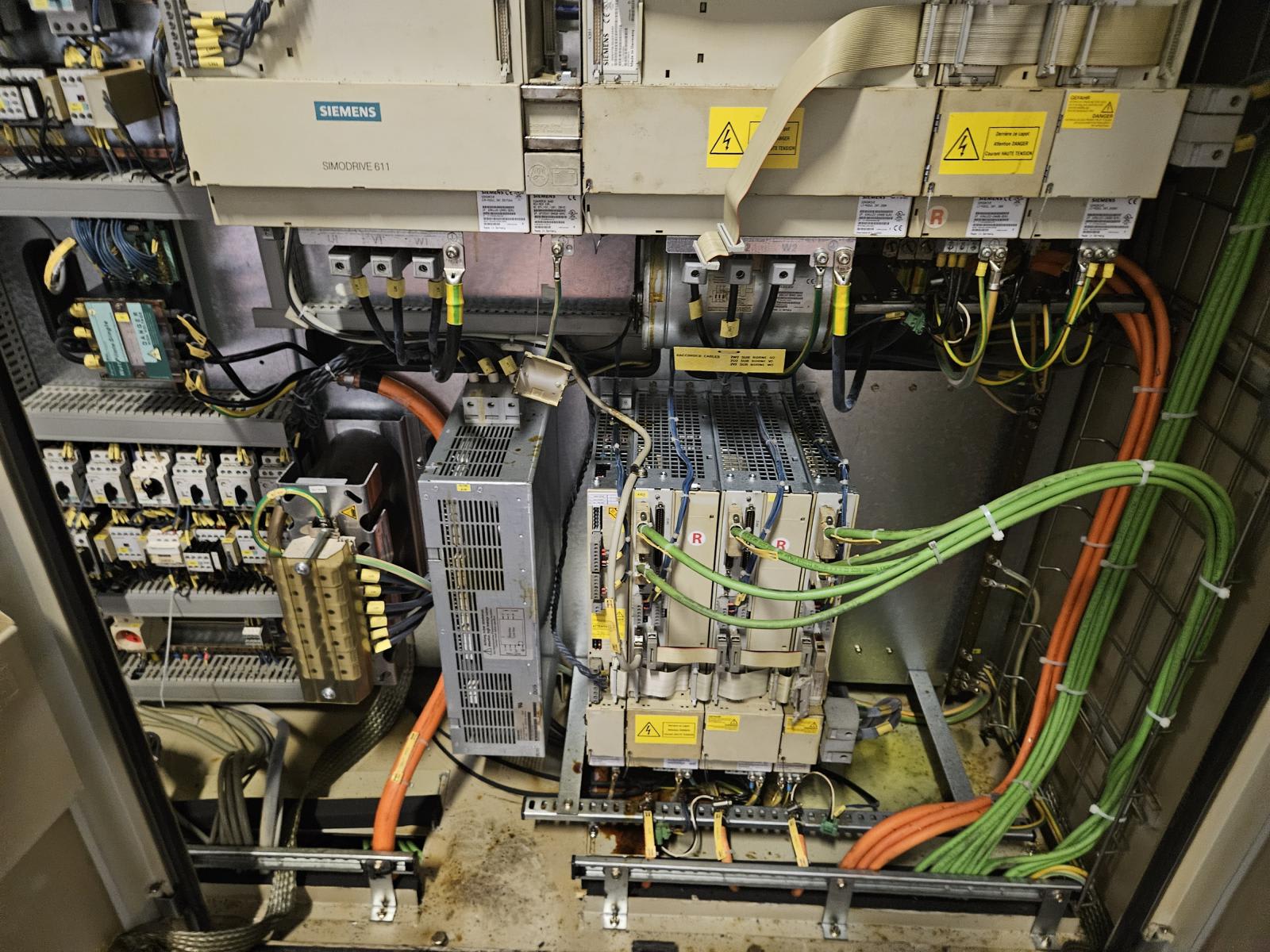

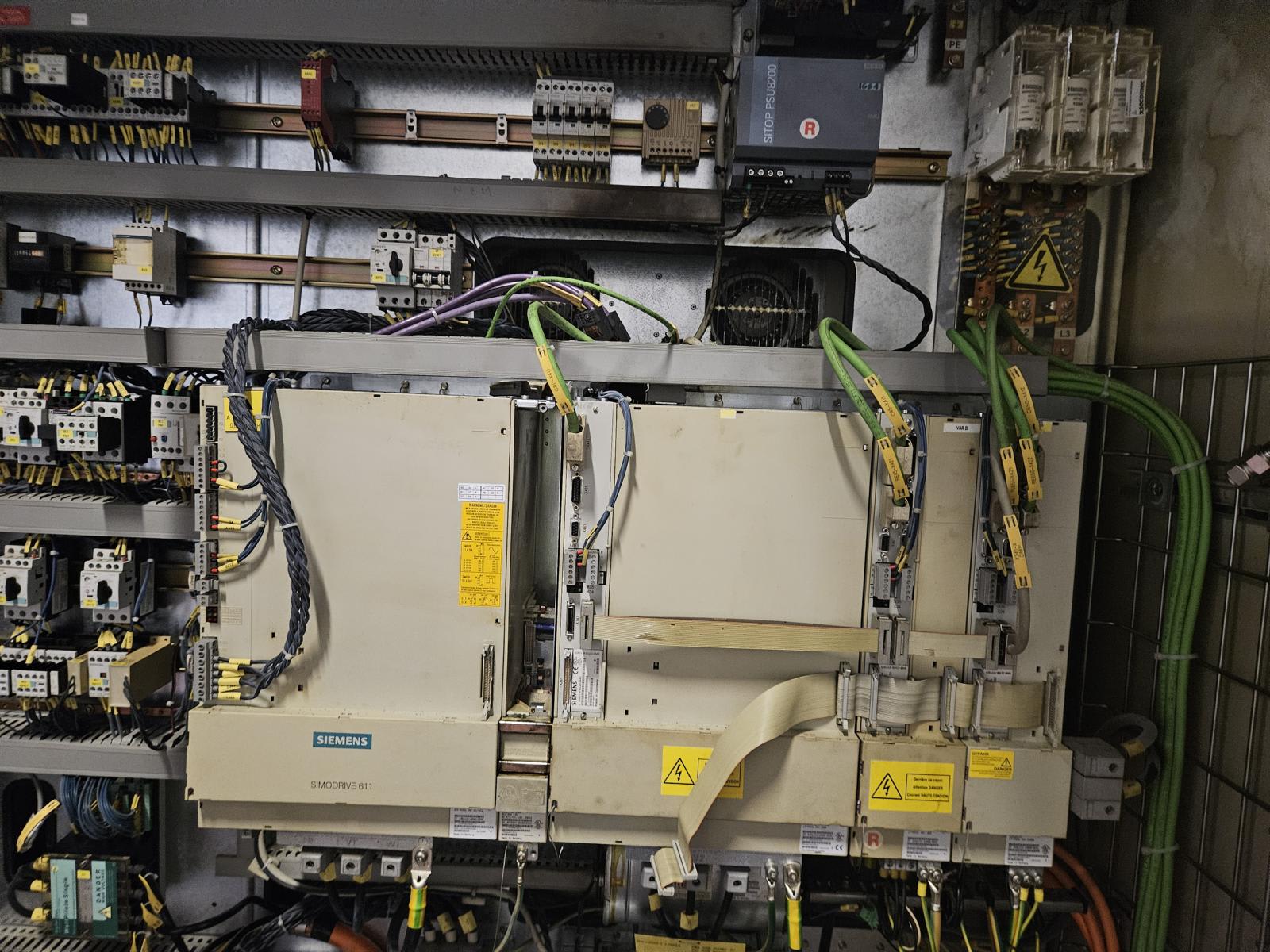

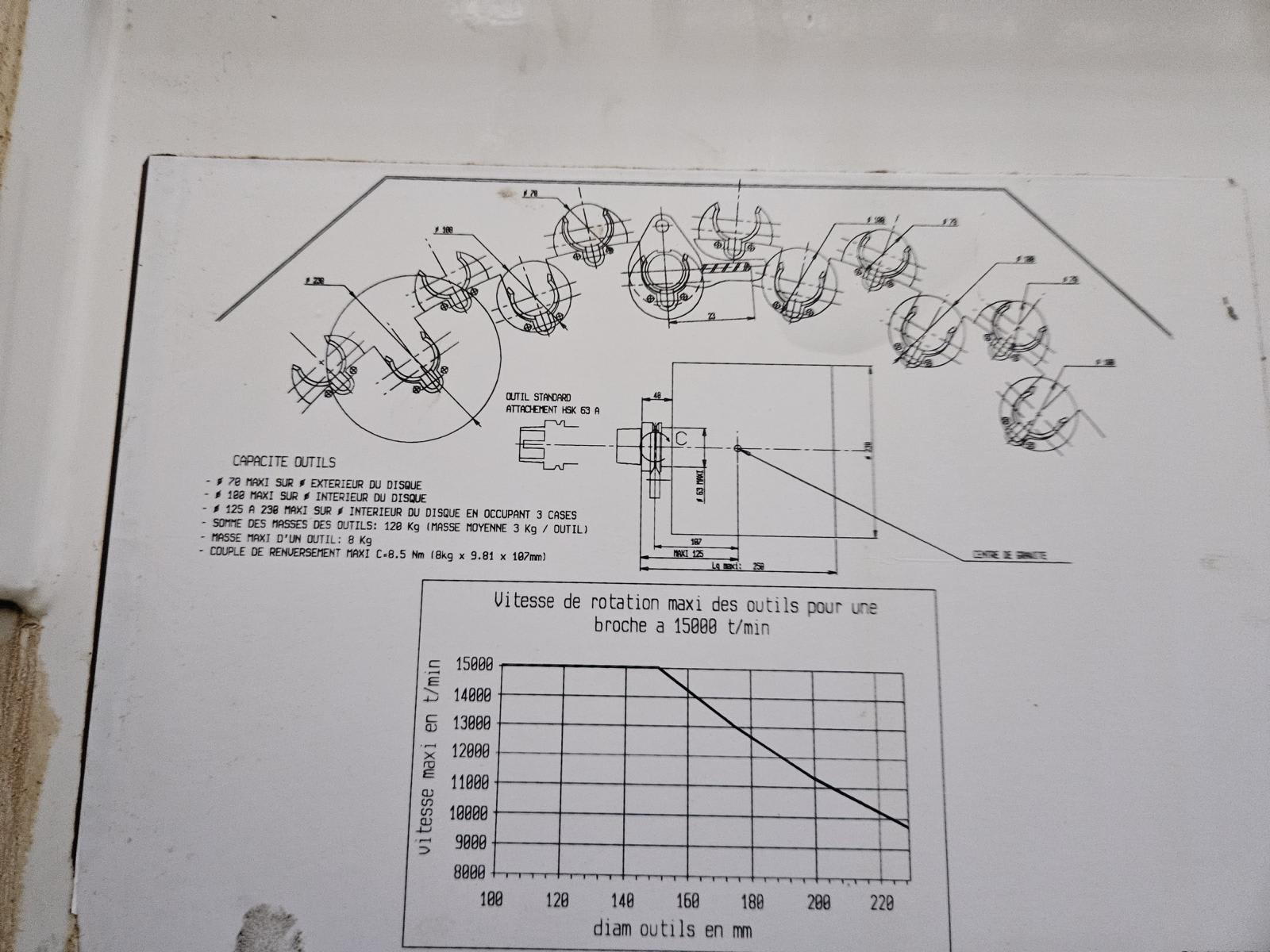

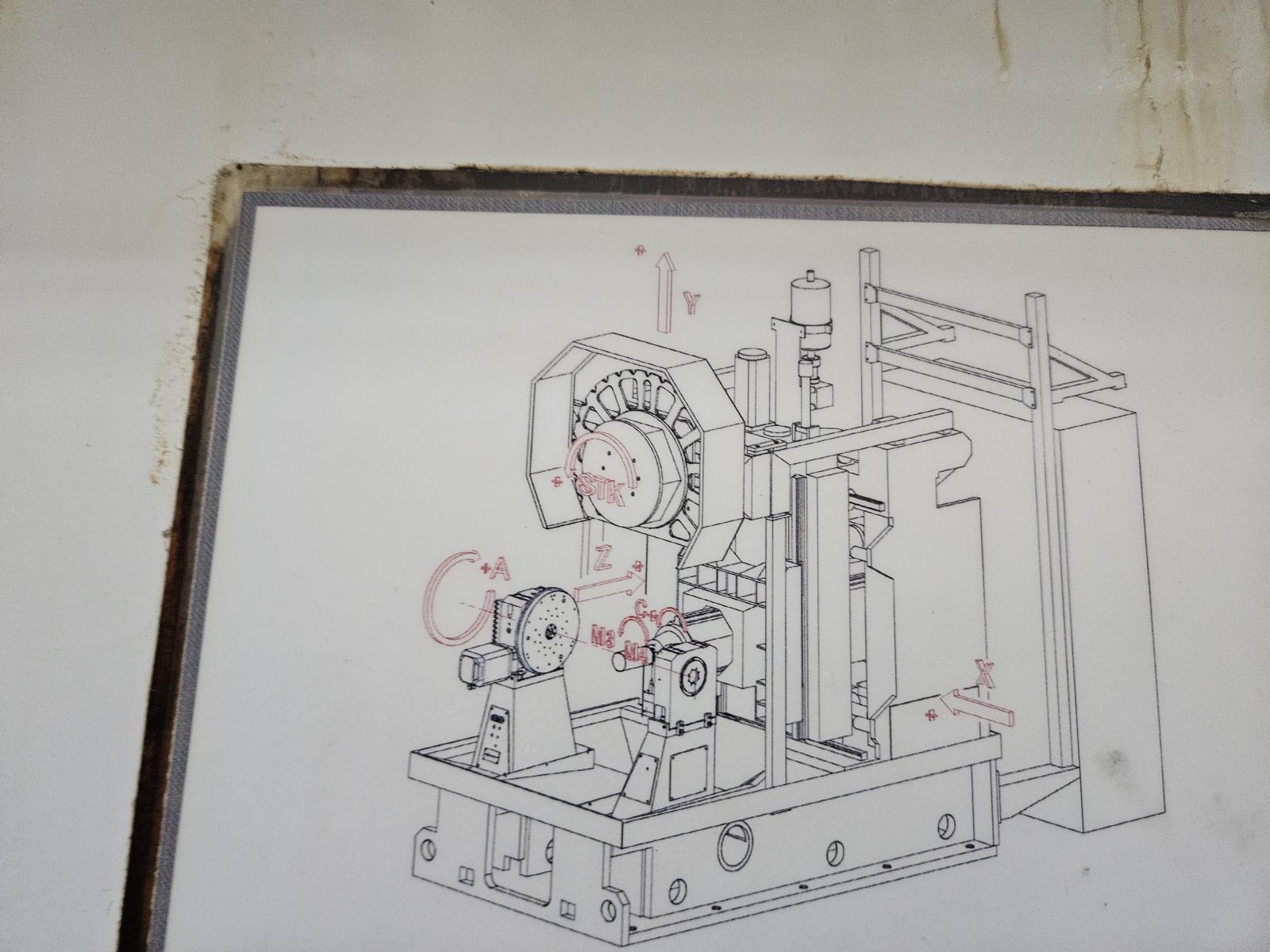

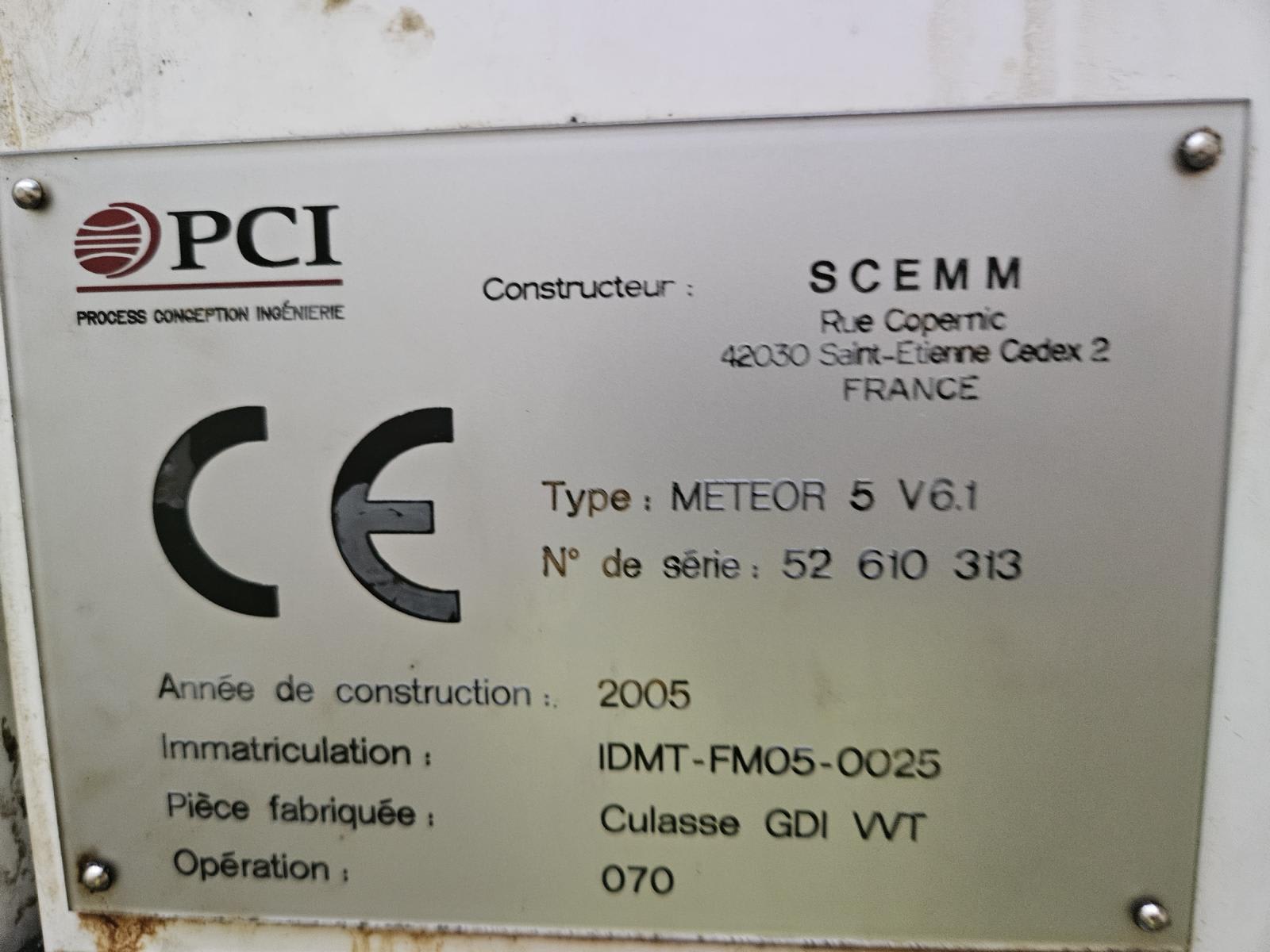

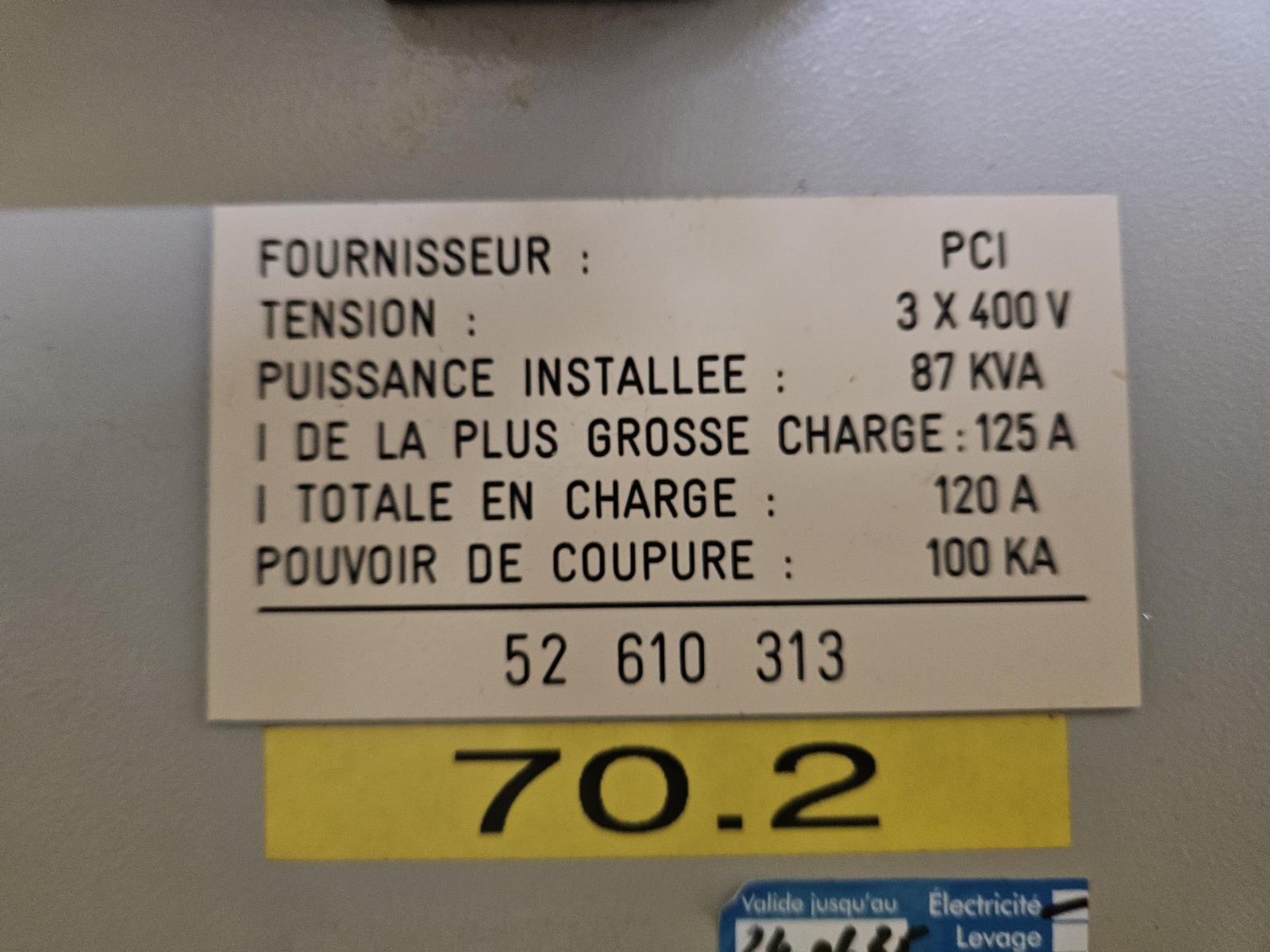

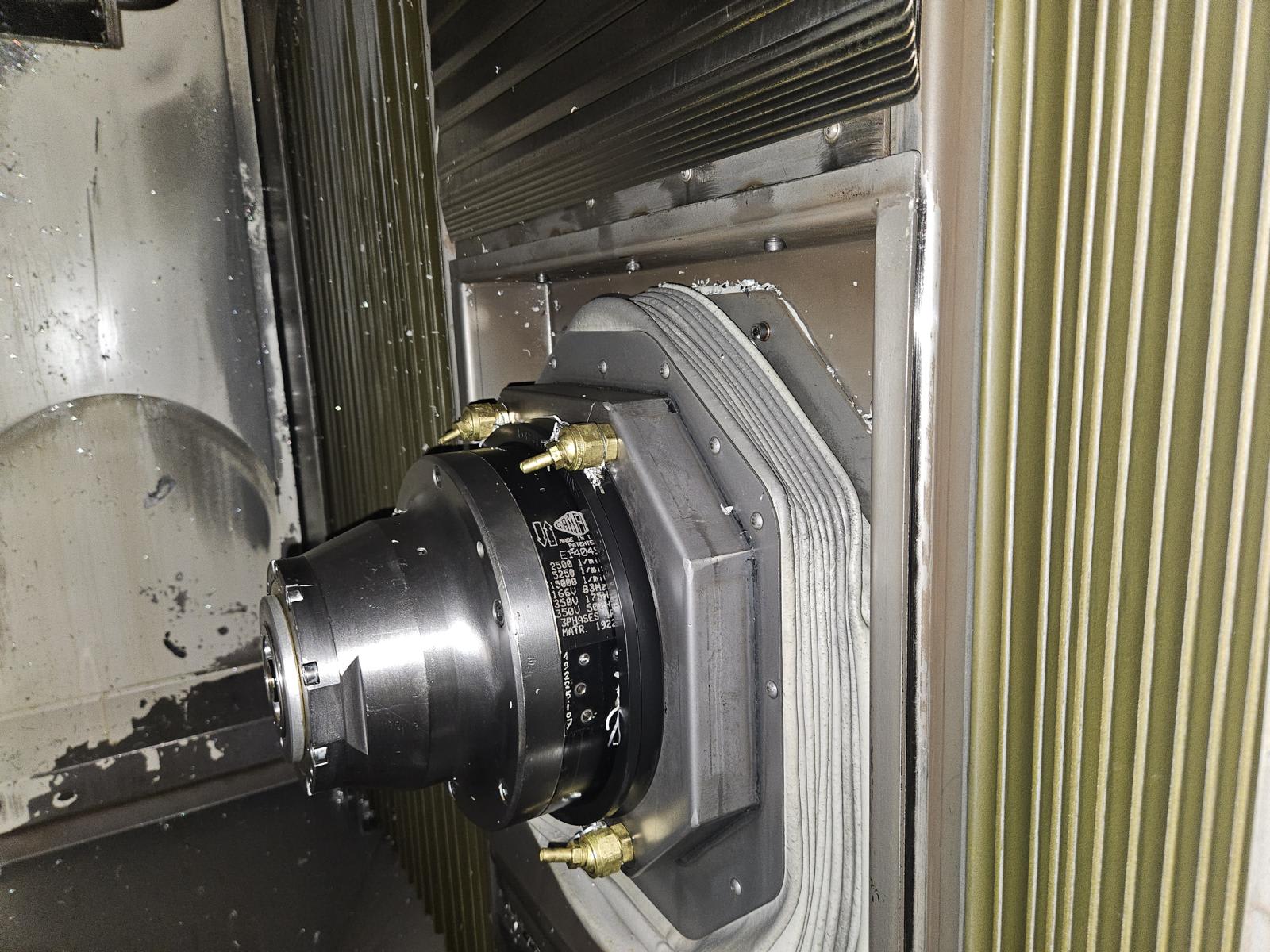

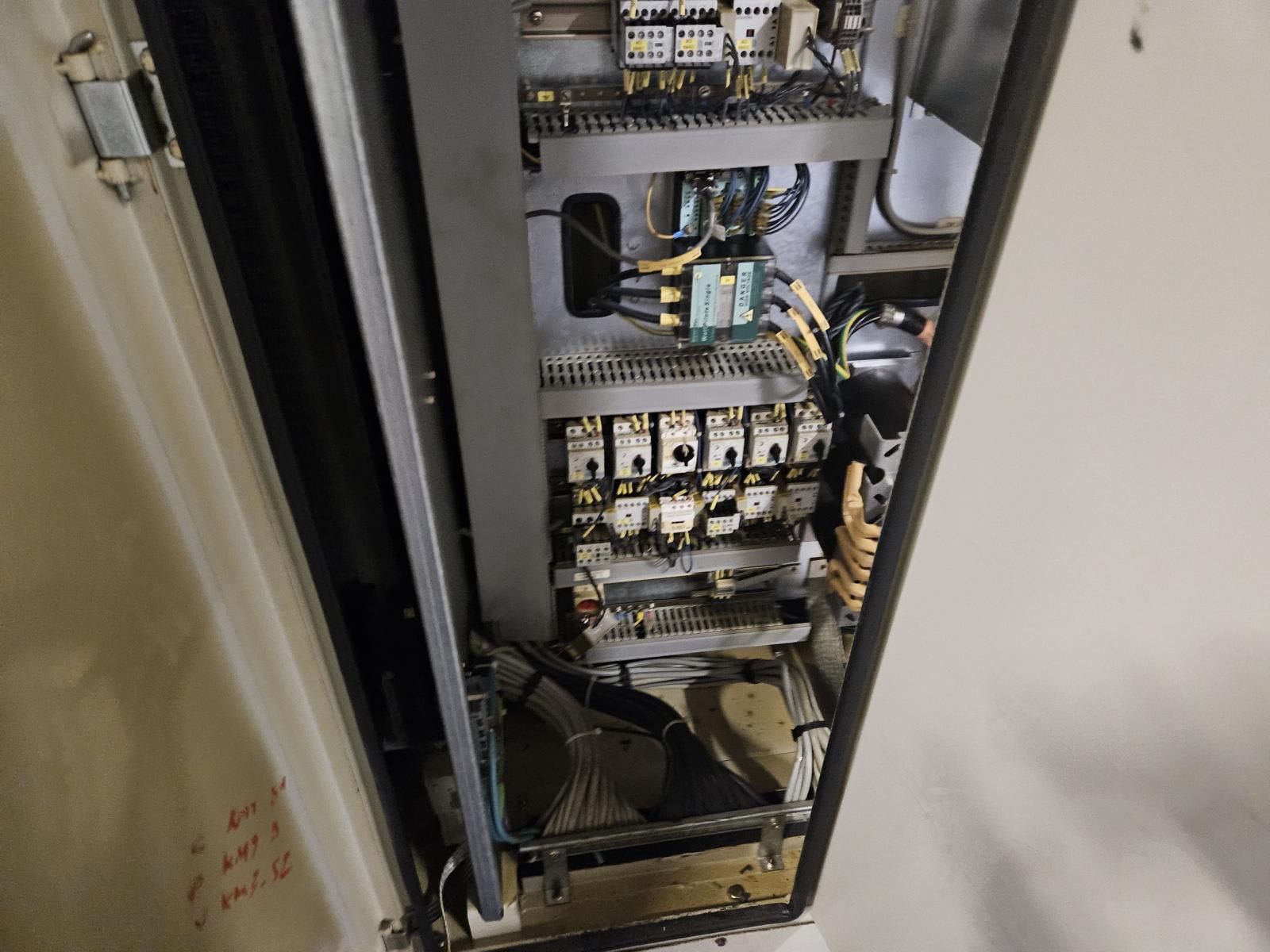

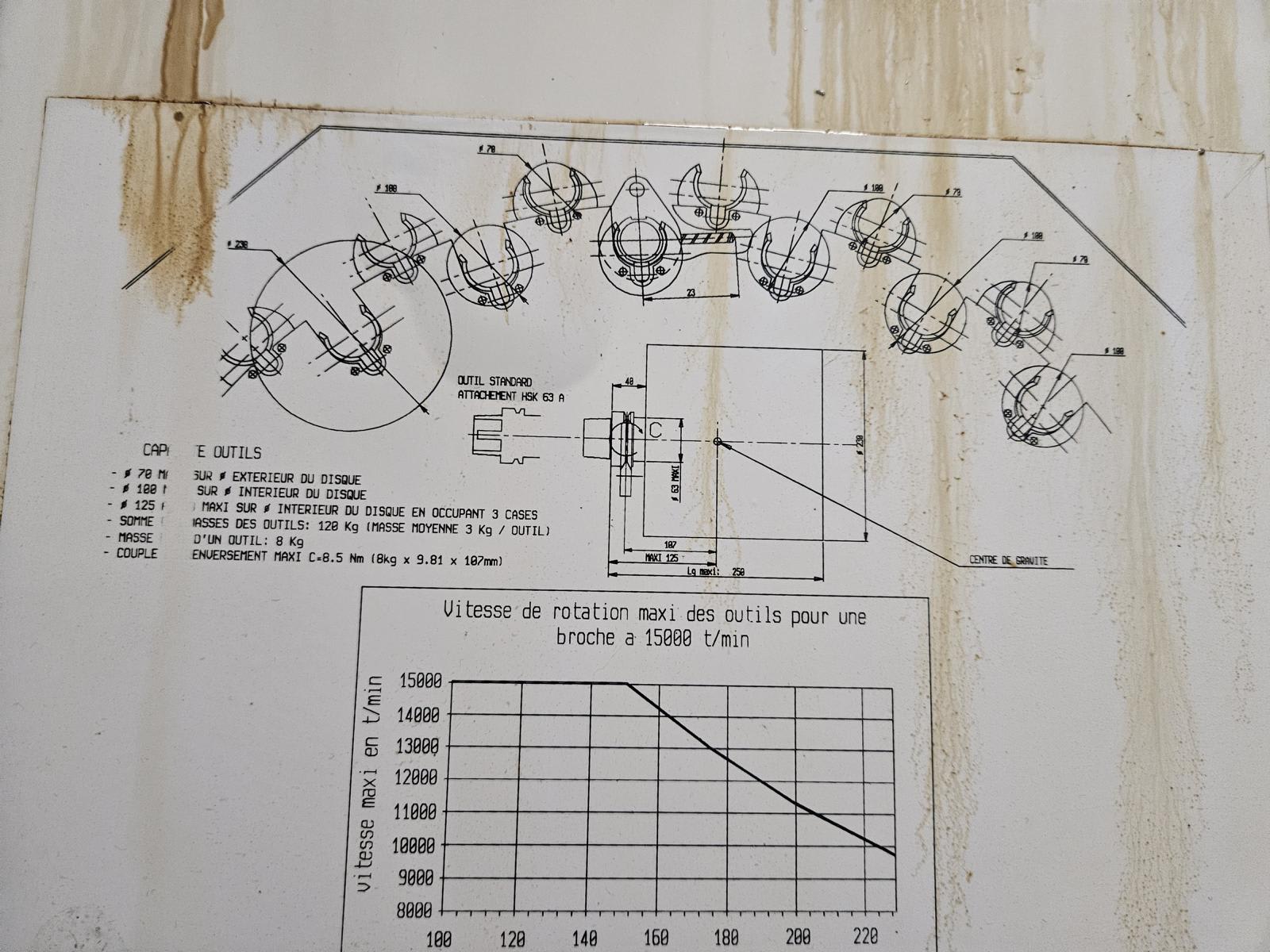

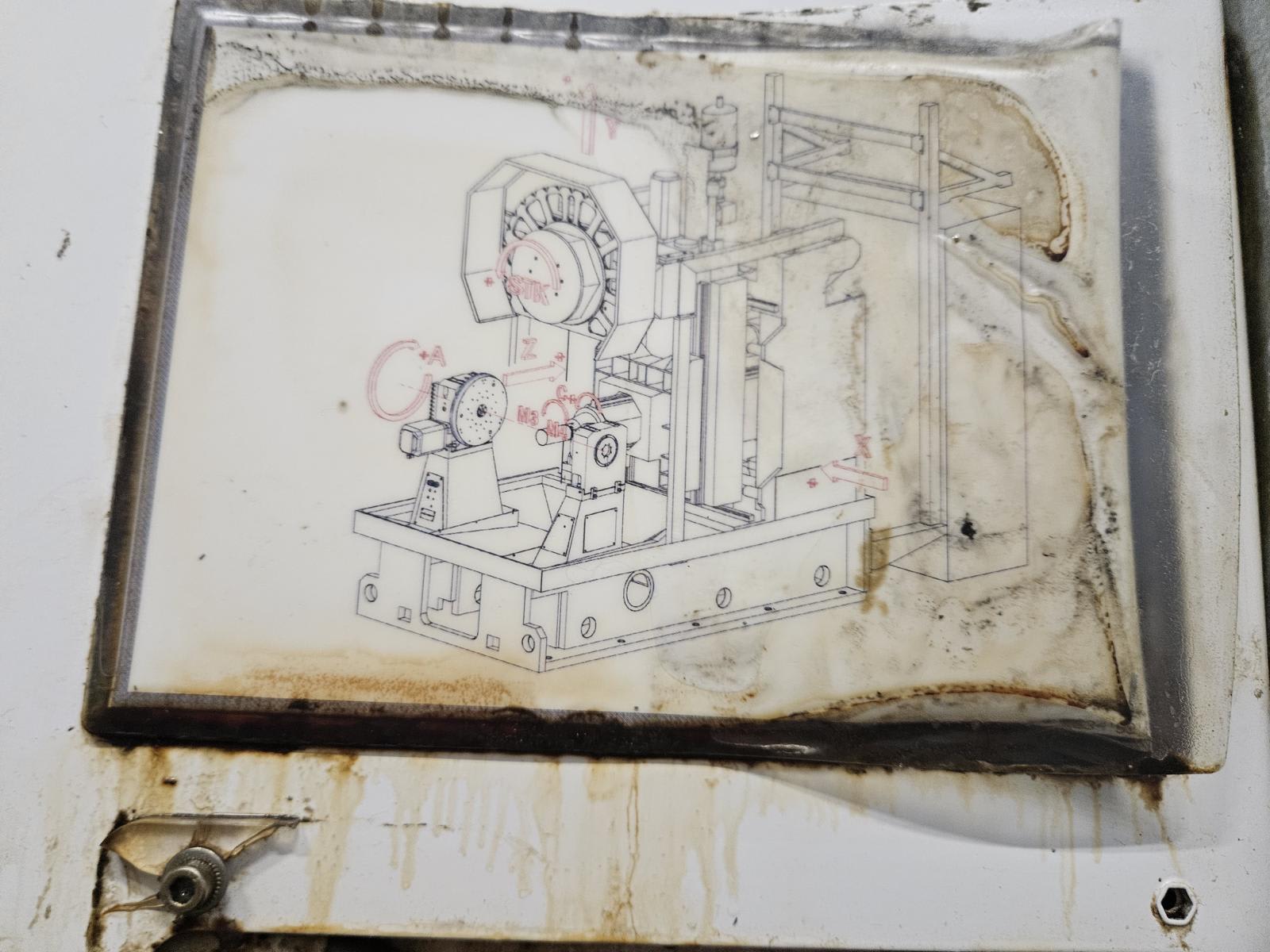

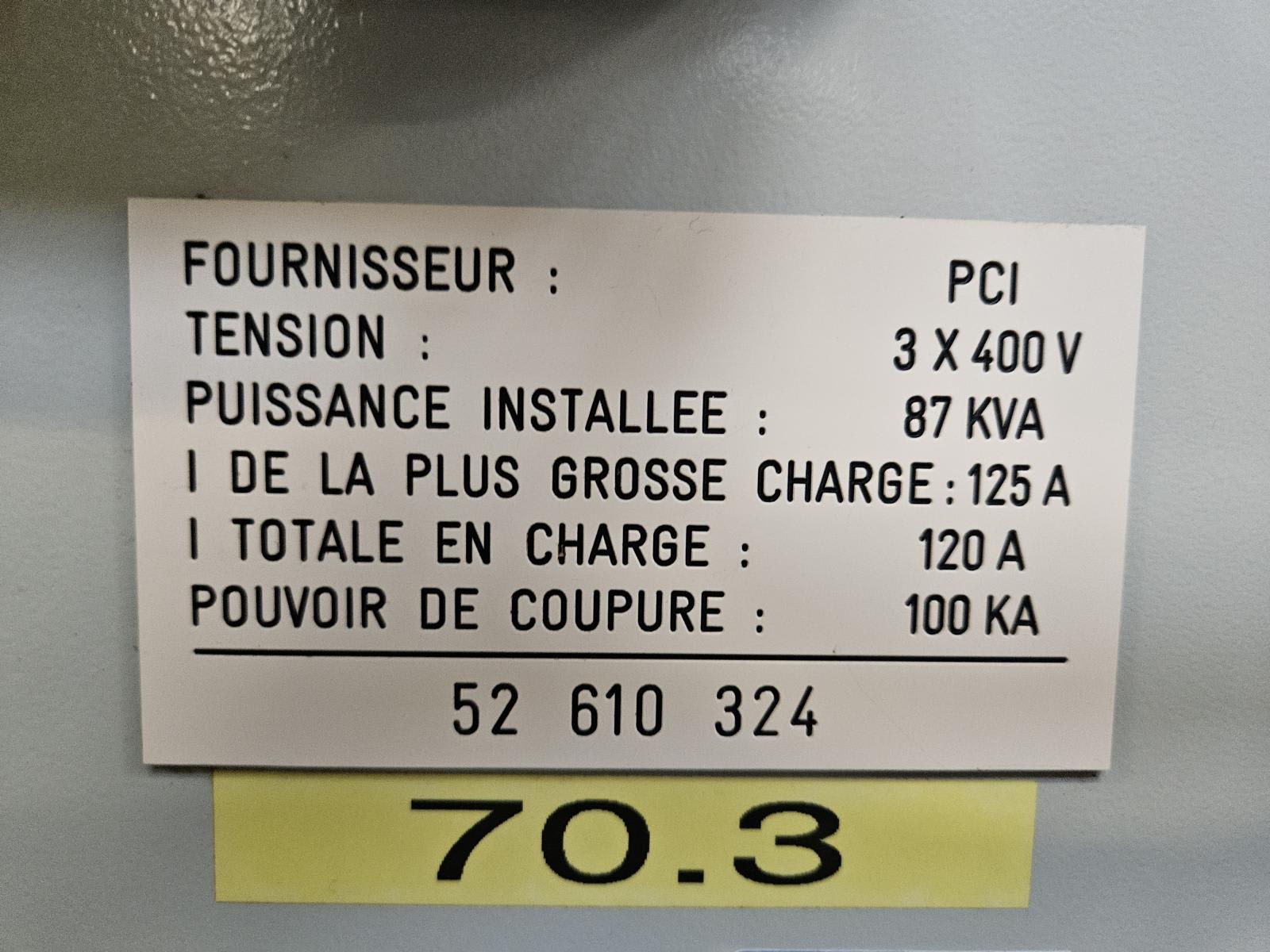

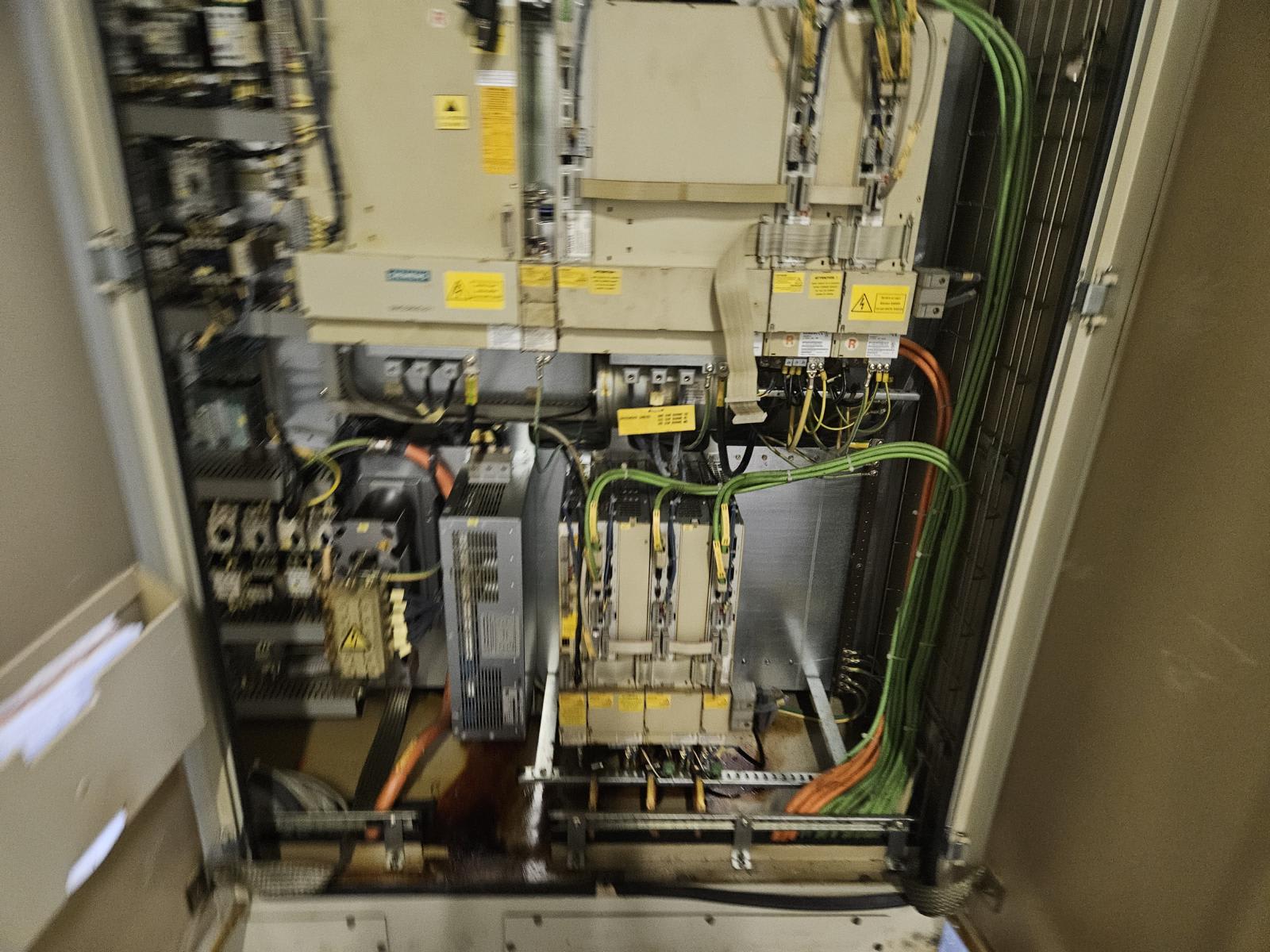

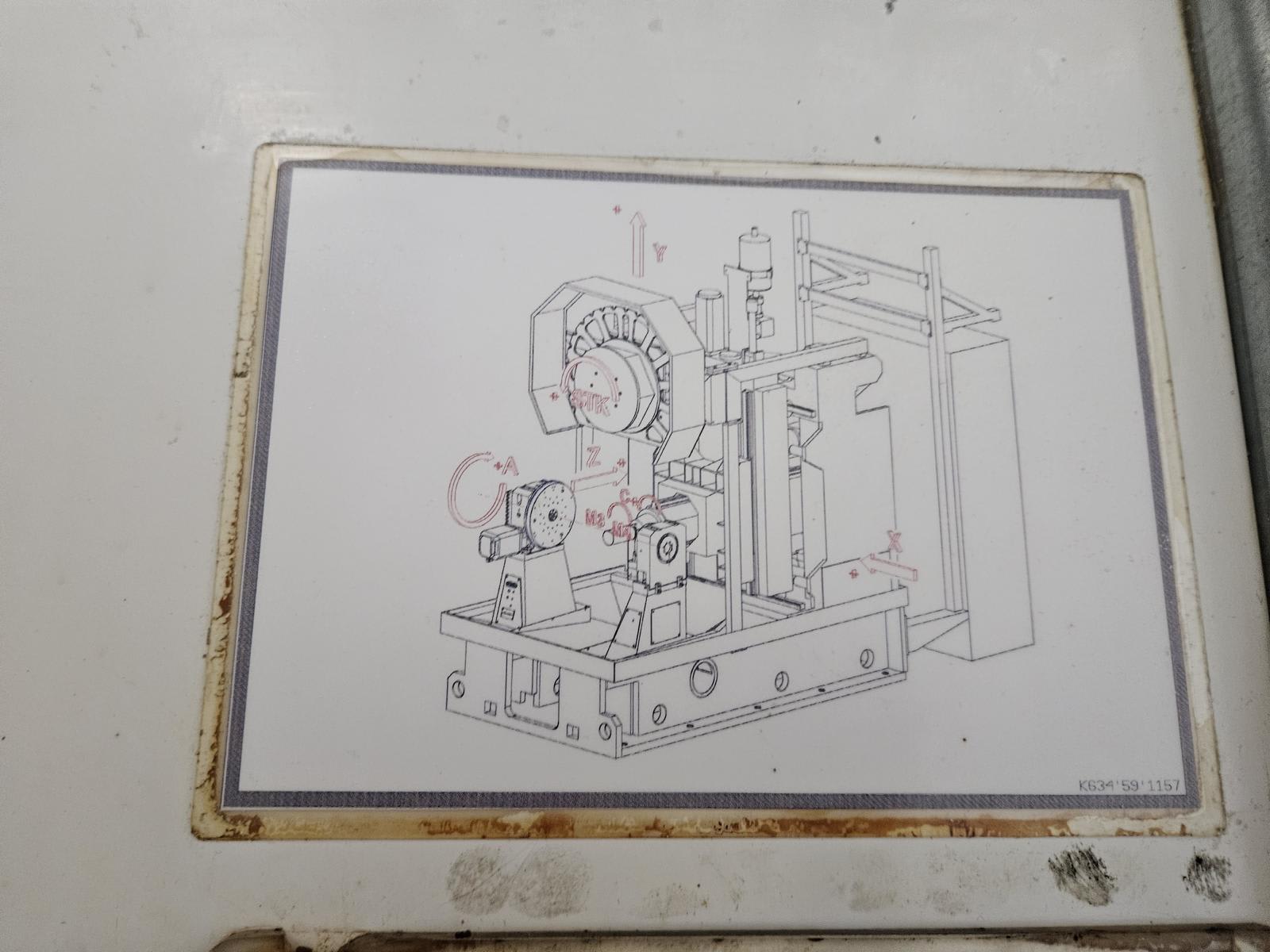

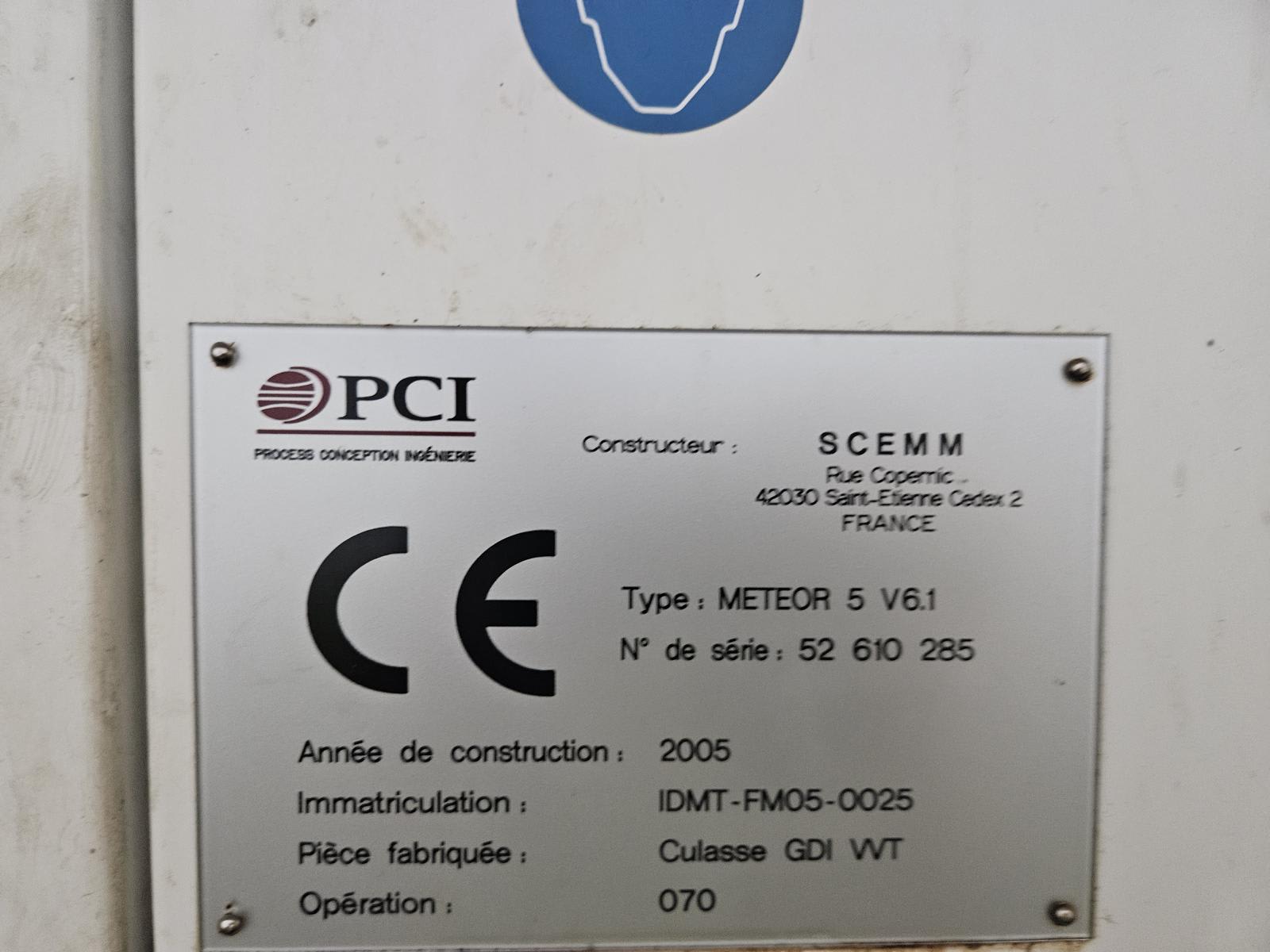

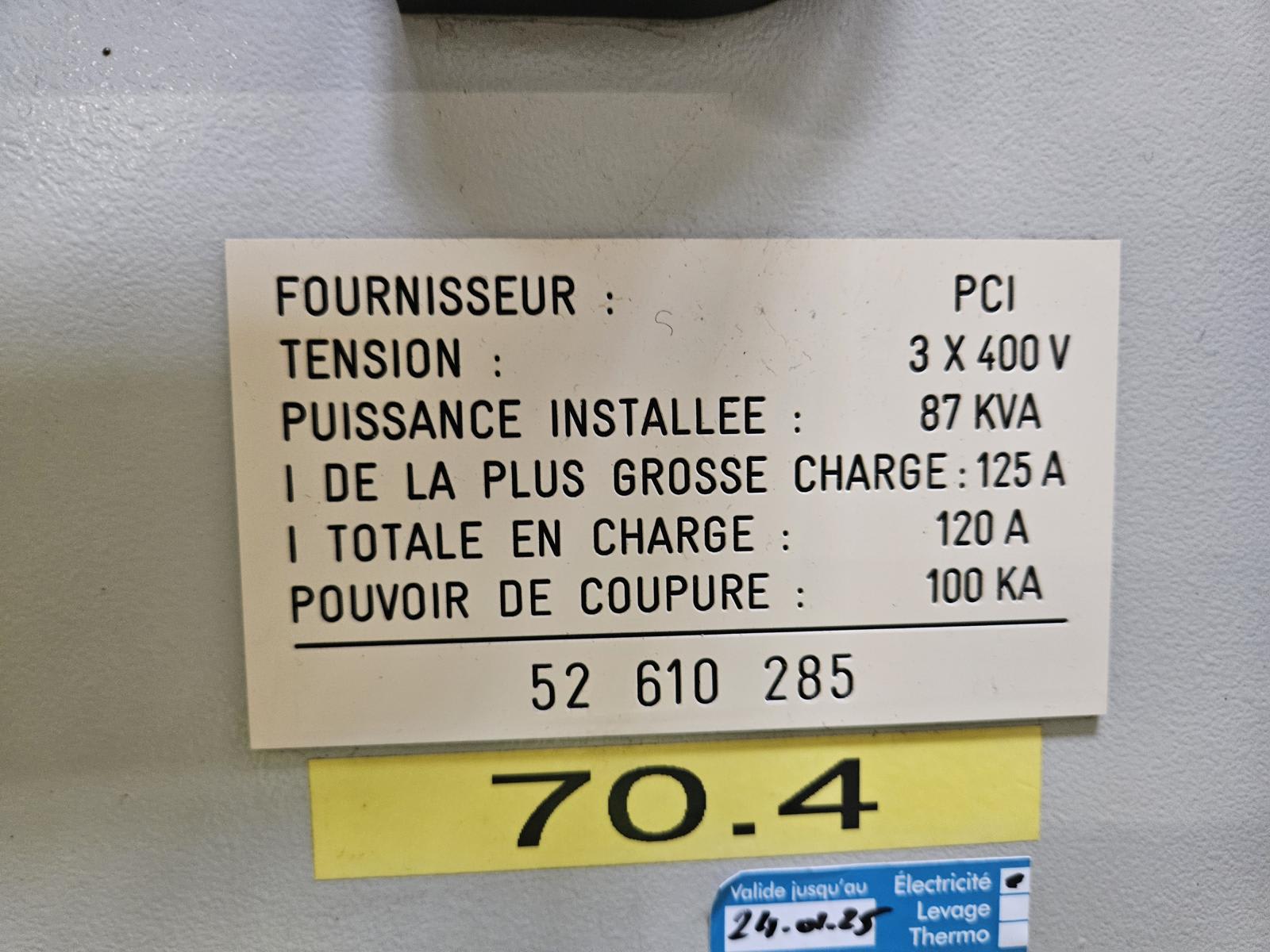

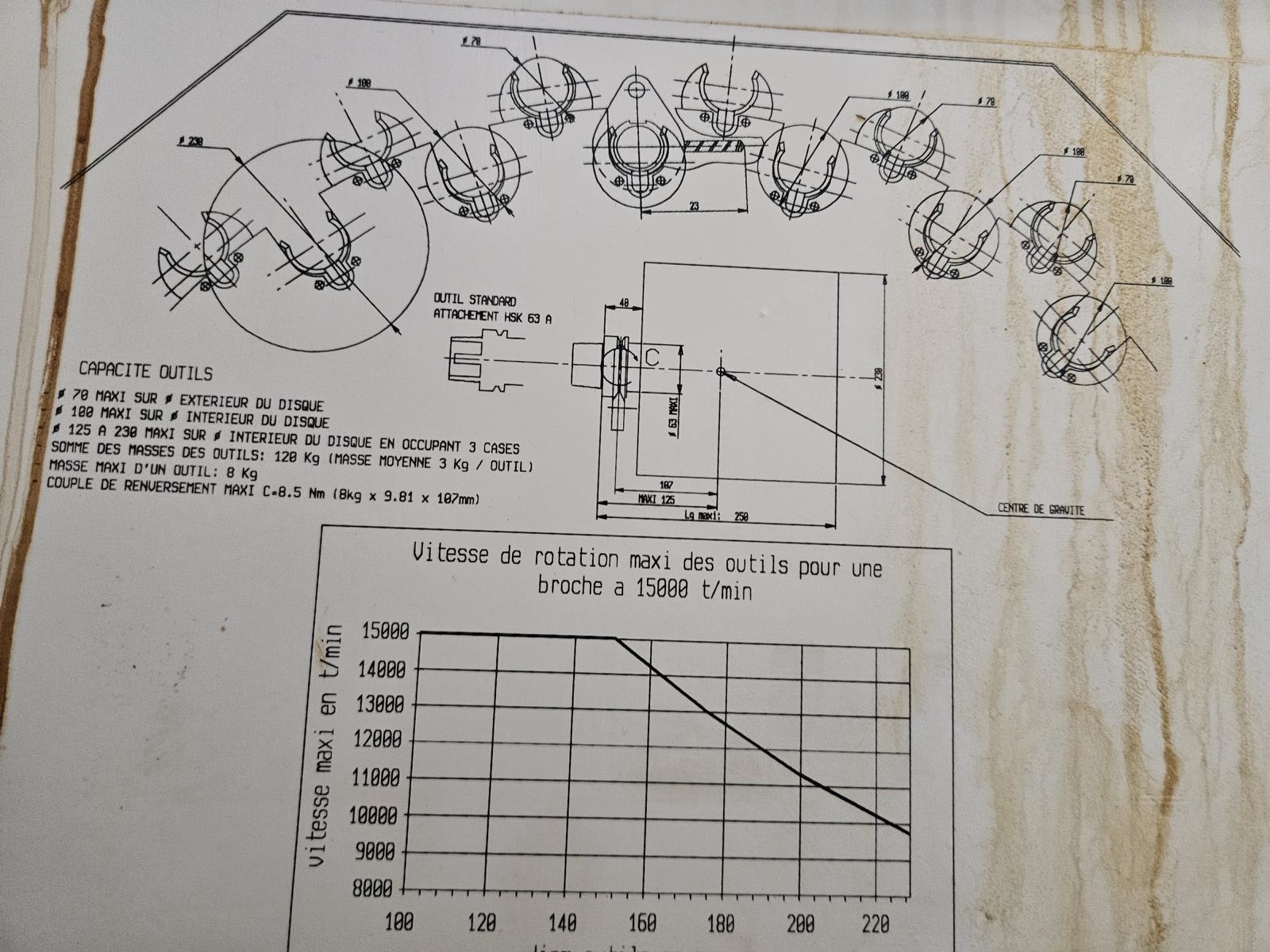

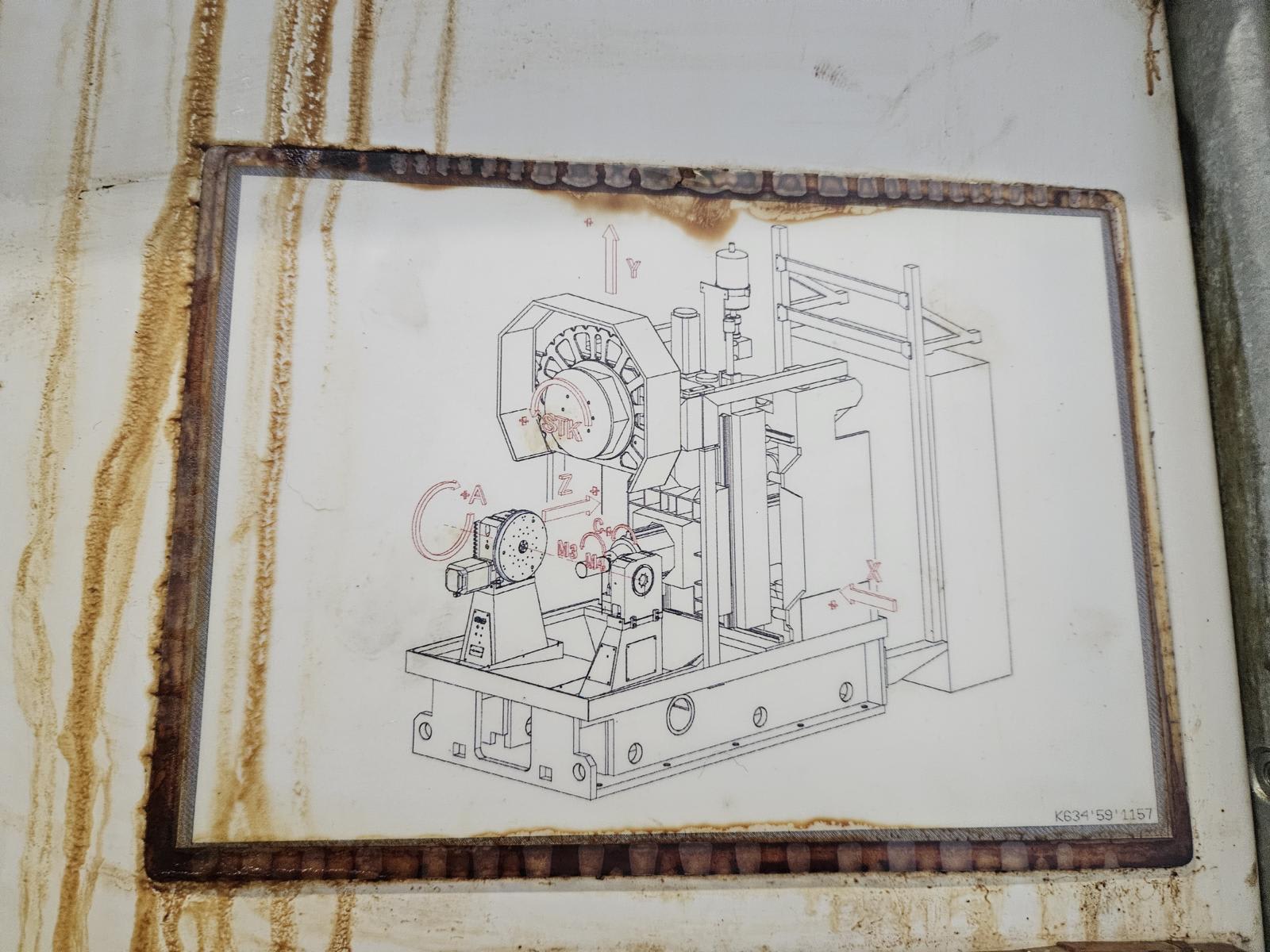

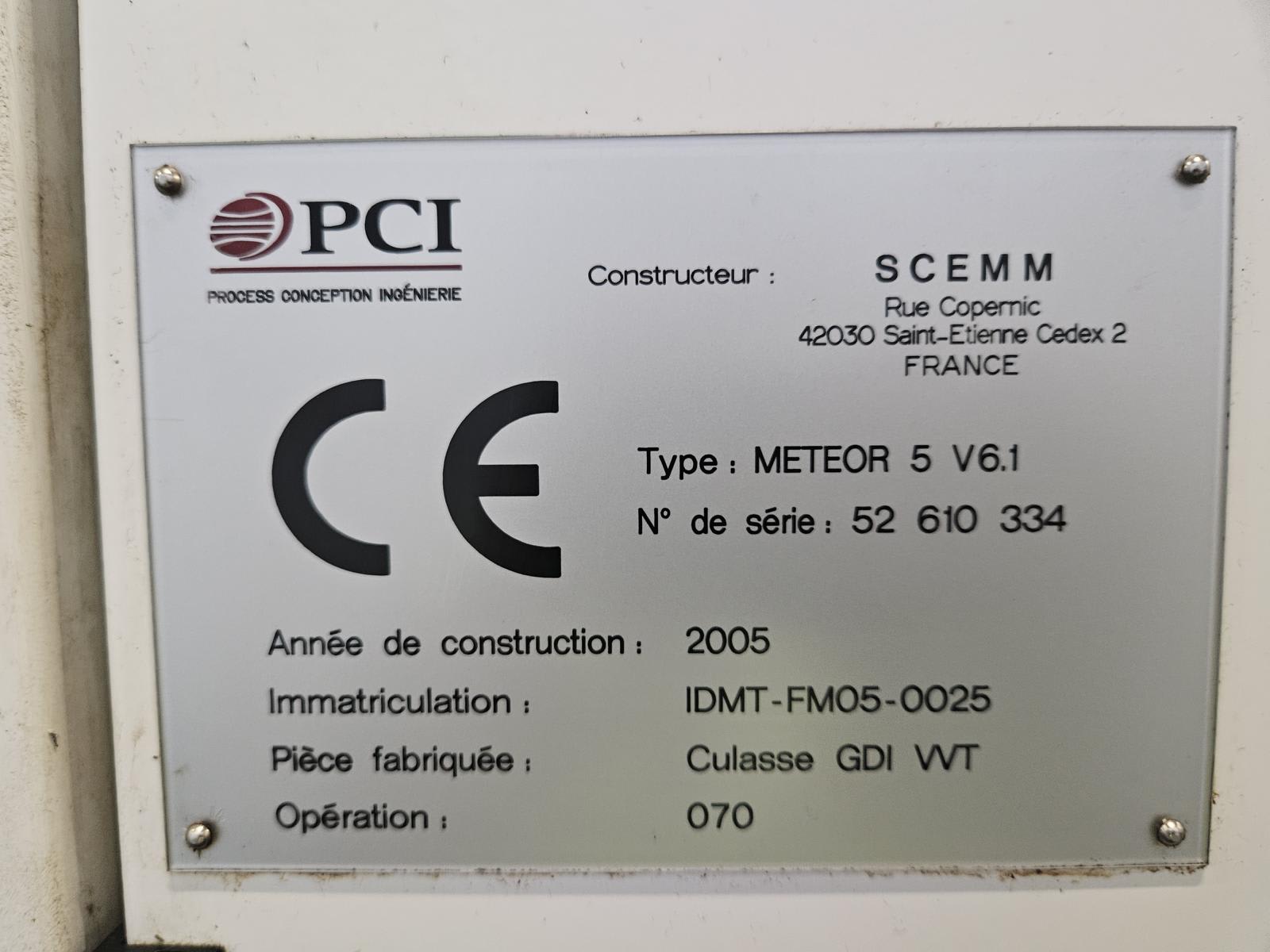

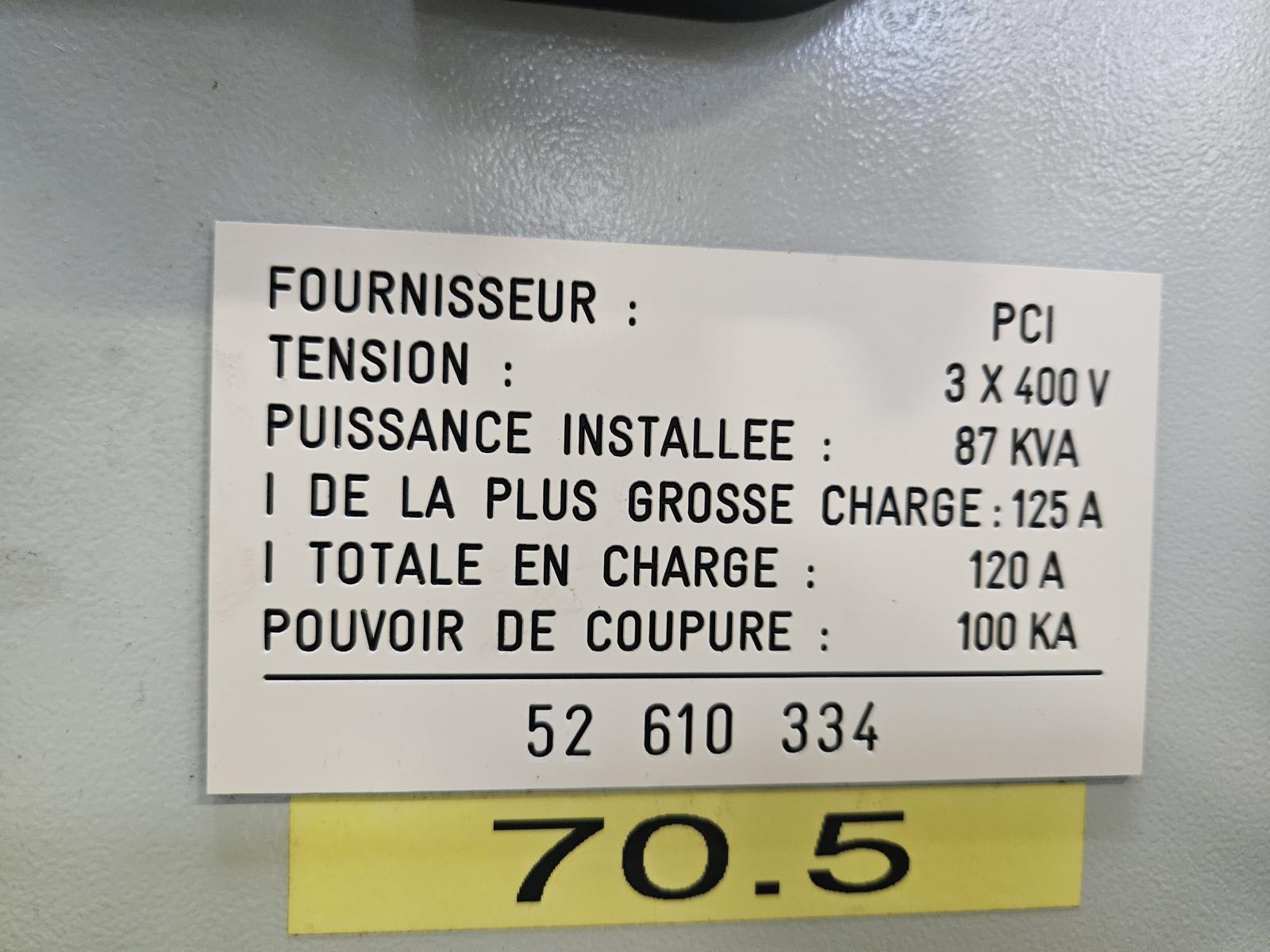

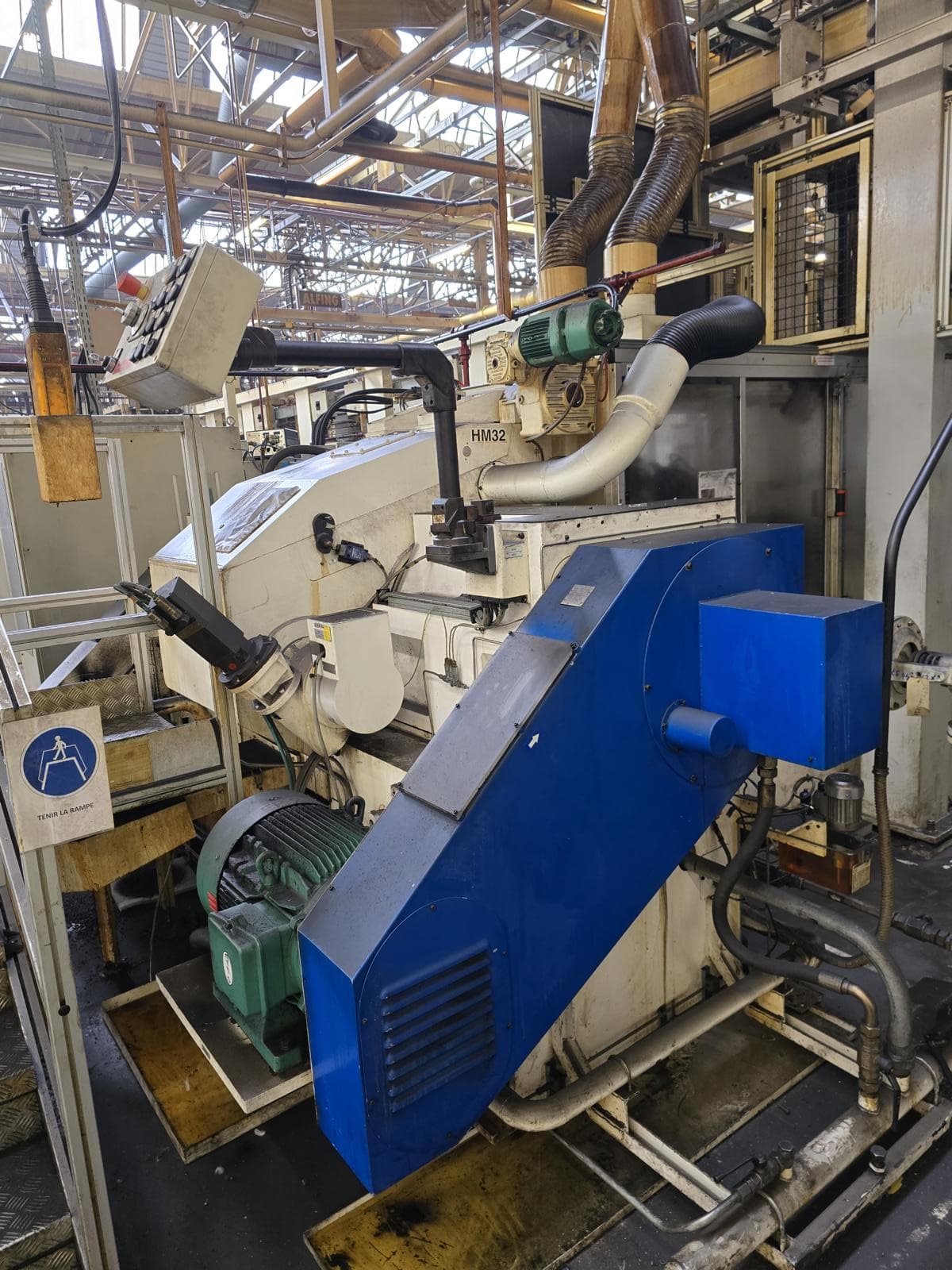

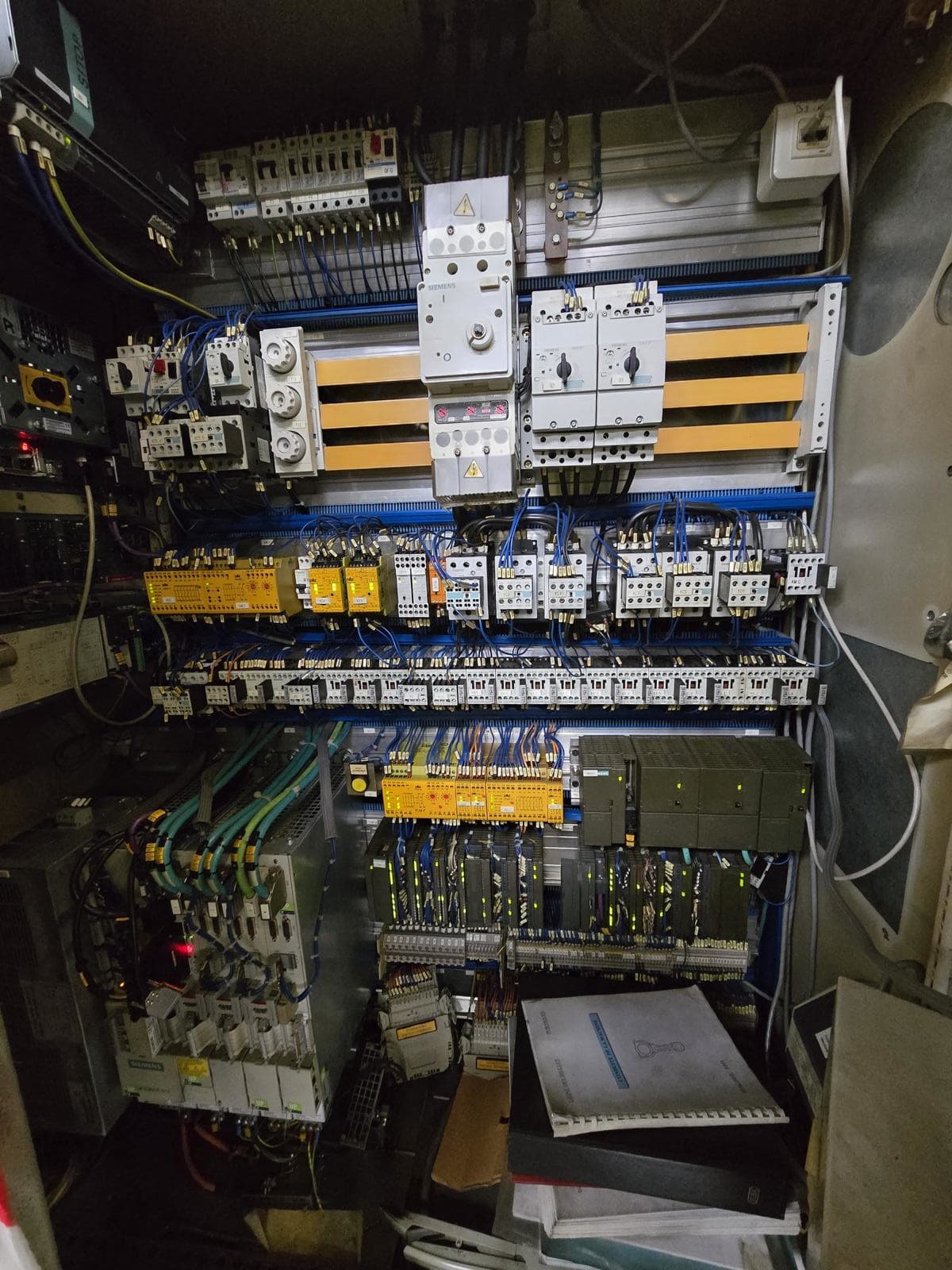

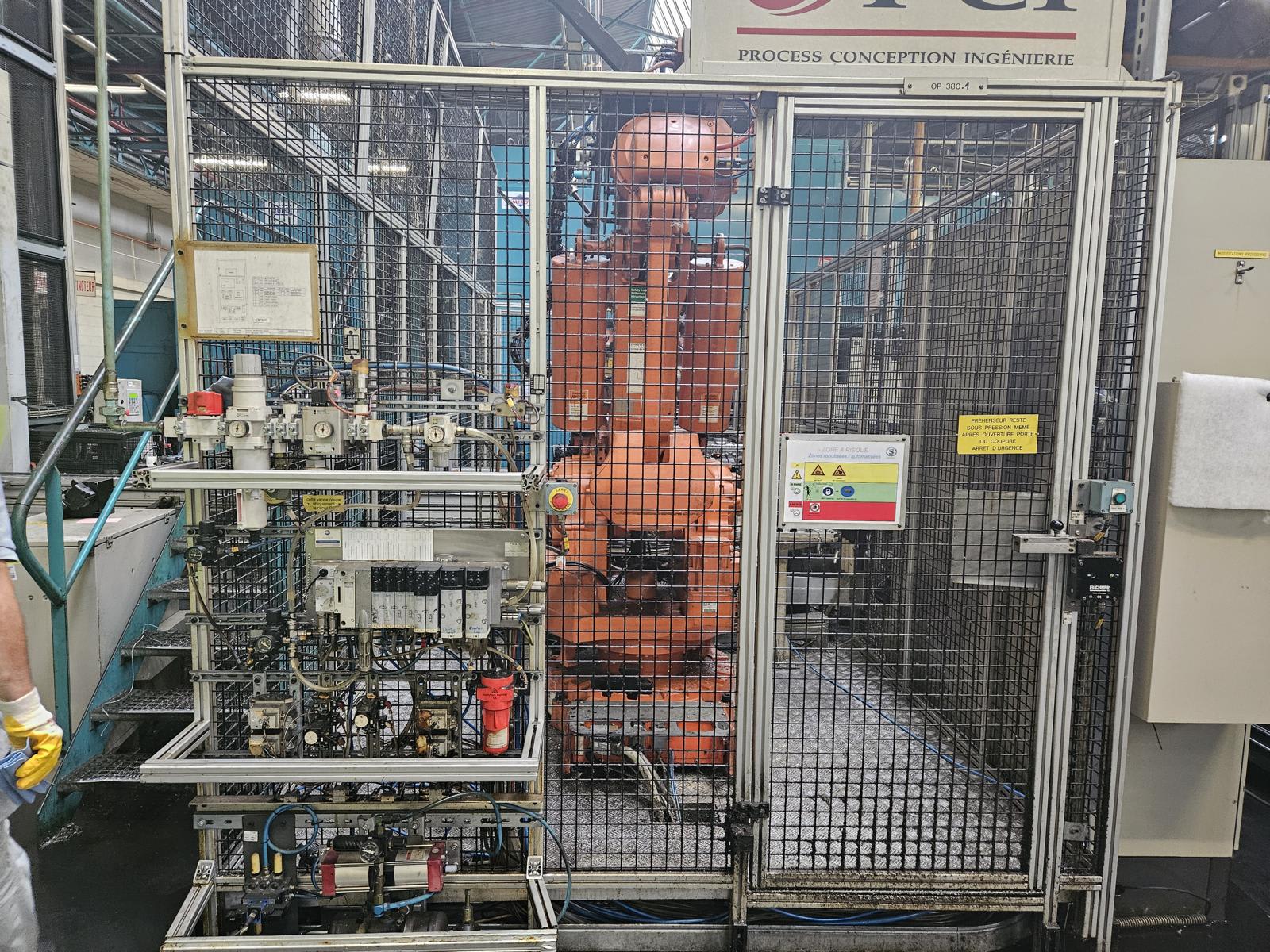

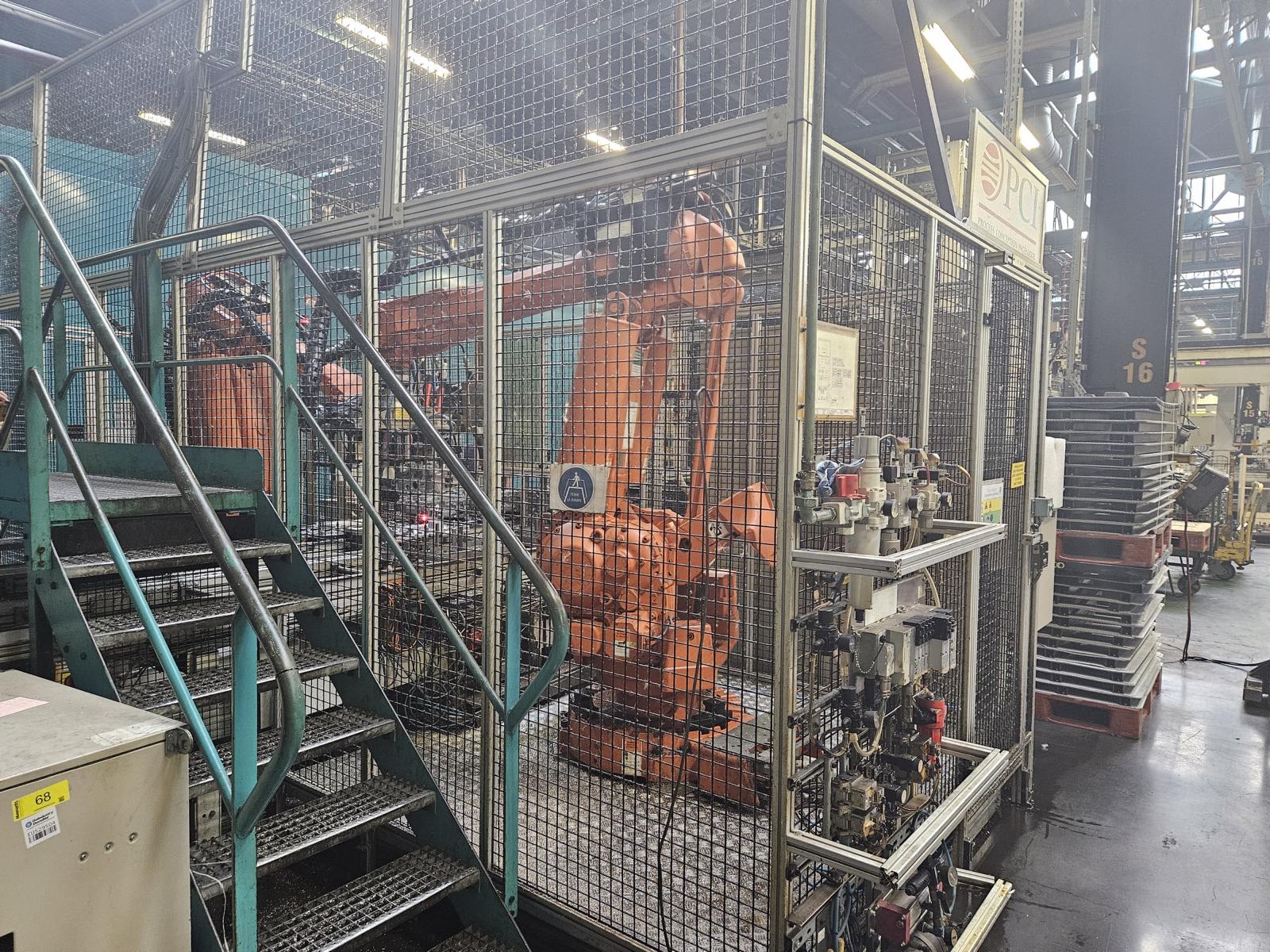

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830037

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830038

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

-OPERATION PANEL MISSING- X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830039

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830040

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830041

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830042

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830043

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830044

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830045

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830046

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830047

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830048

![Français]()

5-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveking table, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830049

![Français]()

5-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveking table, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830050

![Français]()

5-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveking table, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830051

![Français]()

5-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveking table, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830052

![Français]()

5-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveking table, B-Axes rotary table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830059

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830060

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830061

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830062

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830063

![Français]()

4-Axes HMC PCI SCEMM Meteor 5 V6.1 | 2005

X/Y/Z 630mm, spindle 15.000rpm / HSK-63-A, A-Axes swiveling table, CNC SIEMENS SINUMERIK 840 D - LISTING 2830064

![Français]()

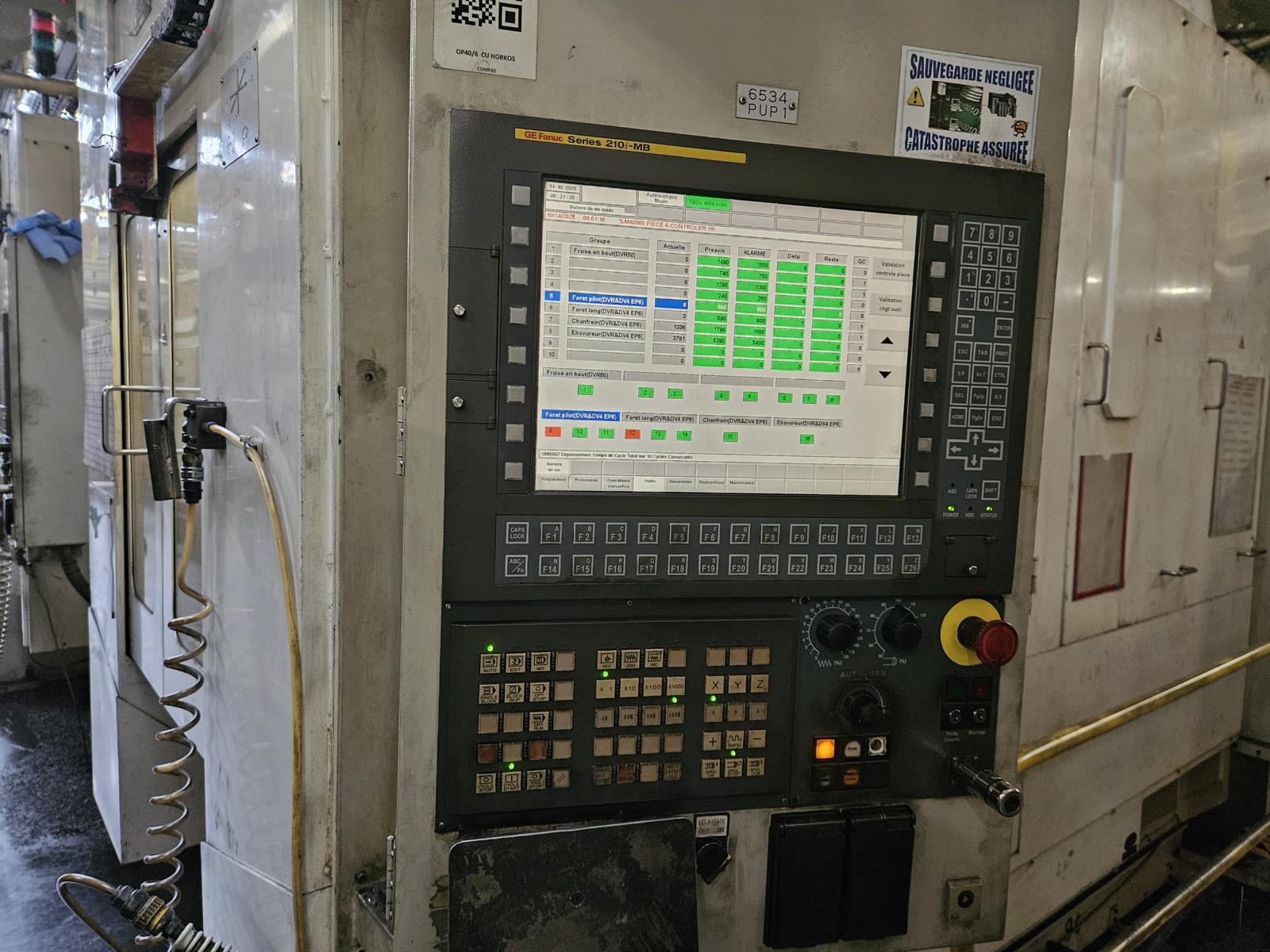

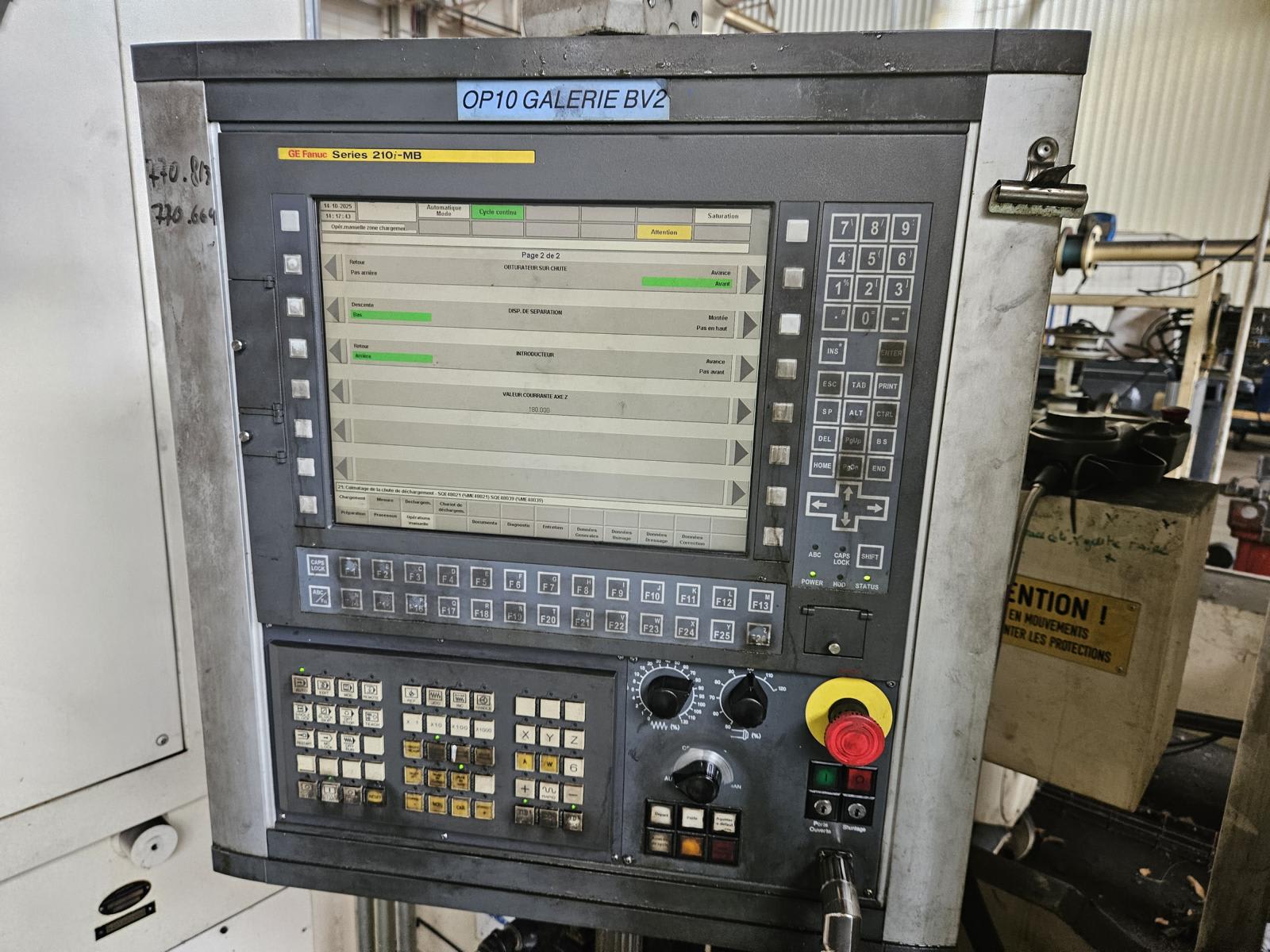

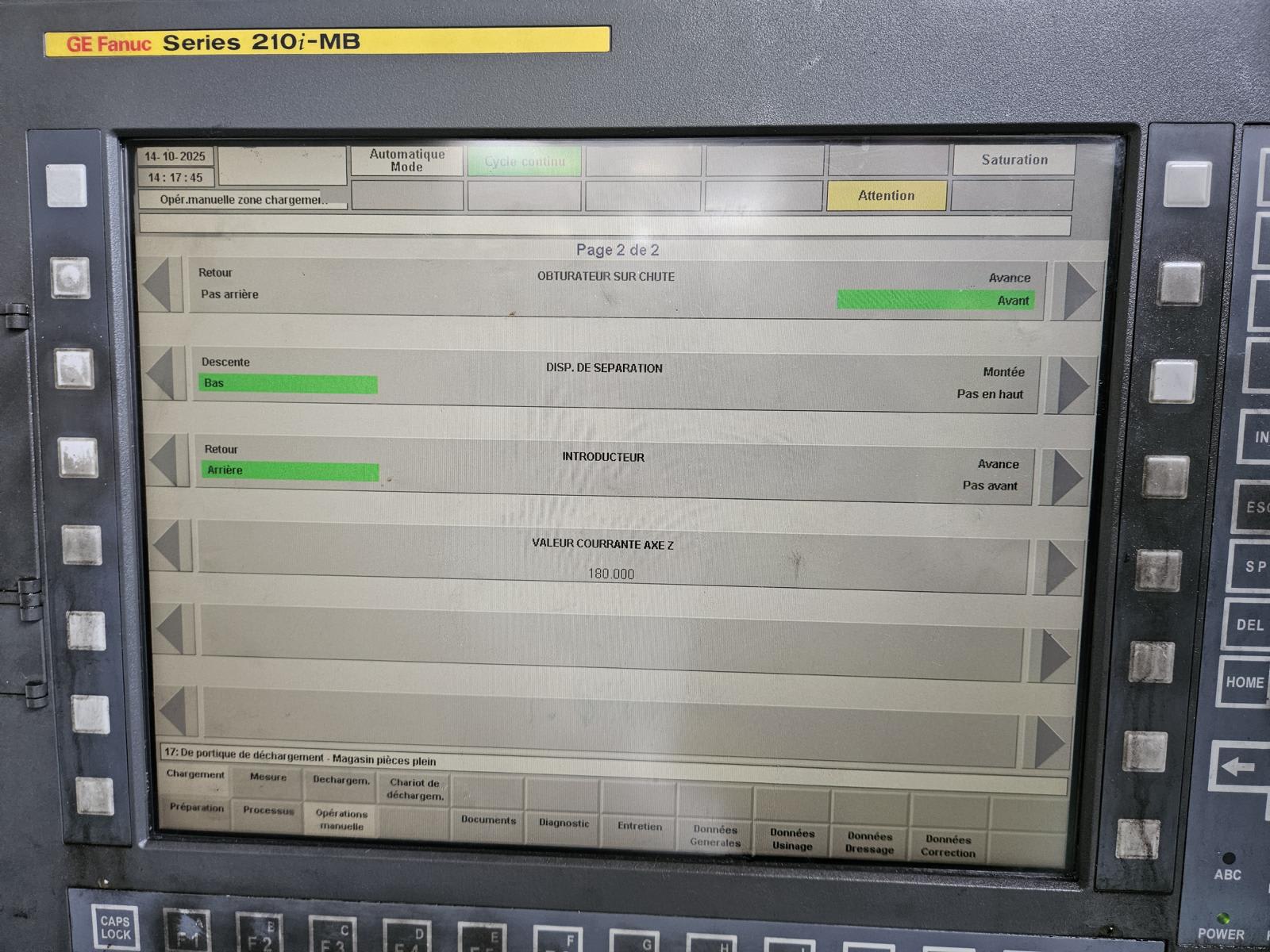

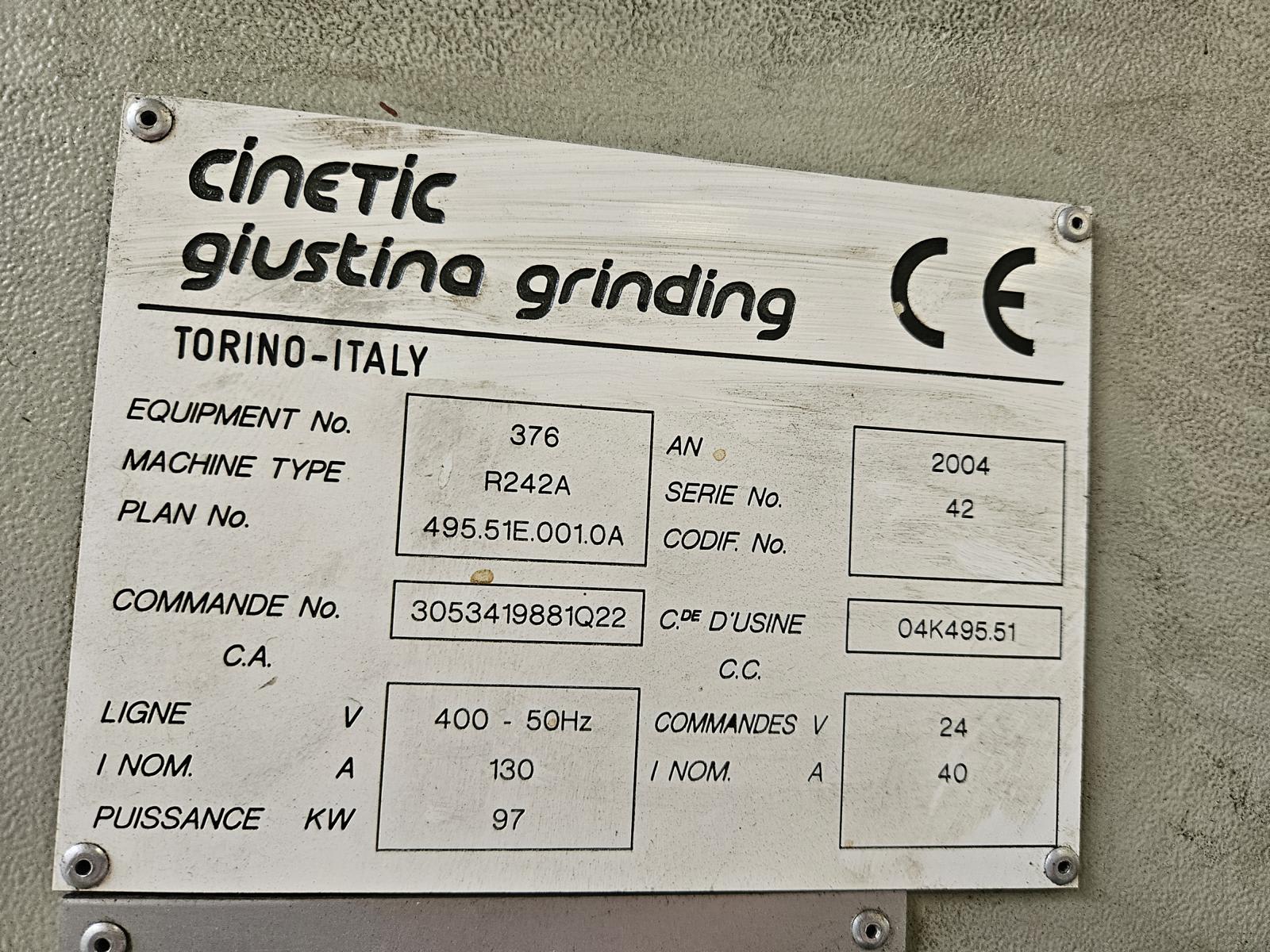

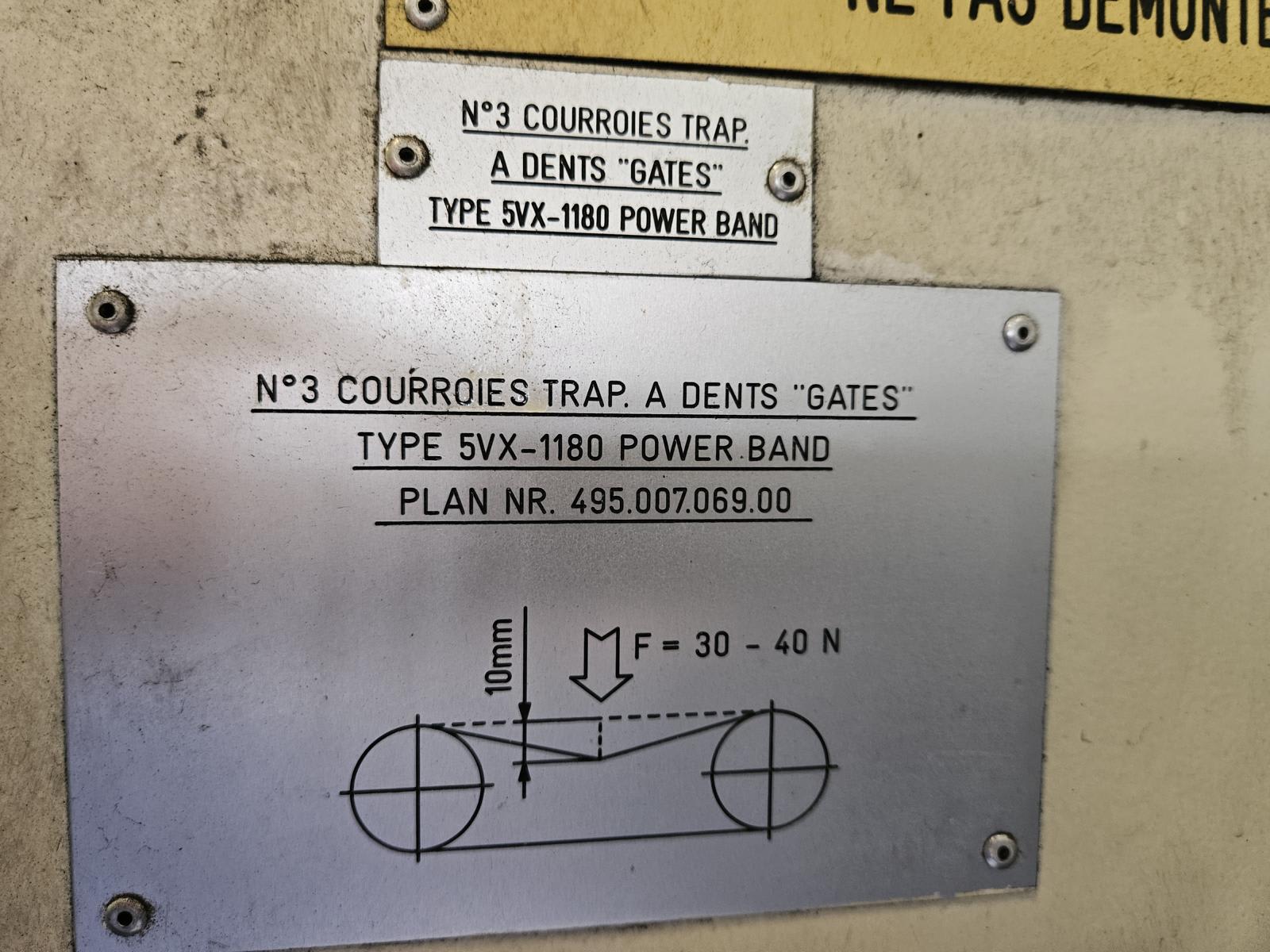

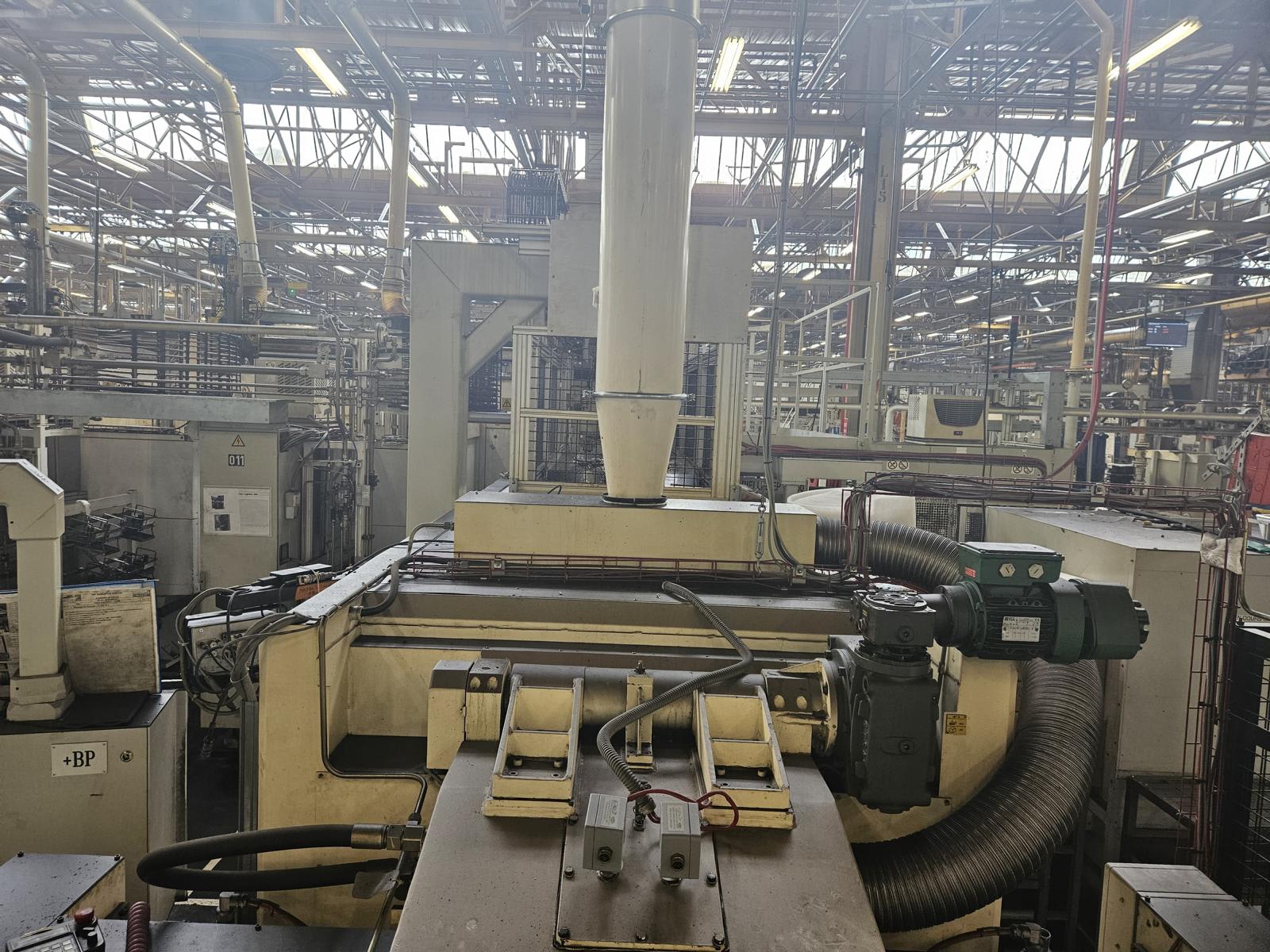

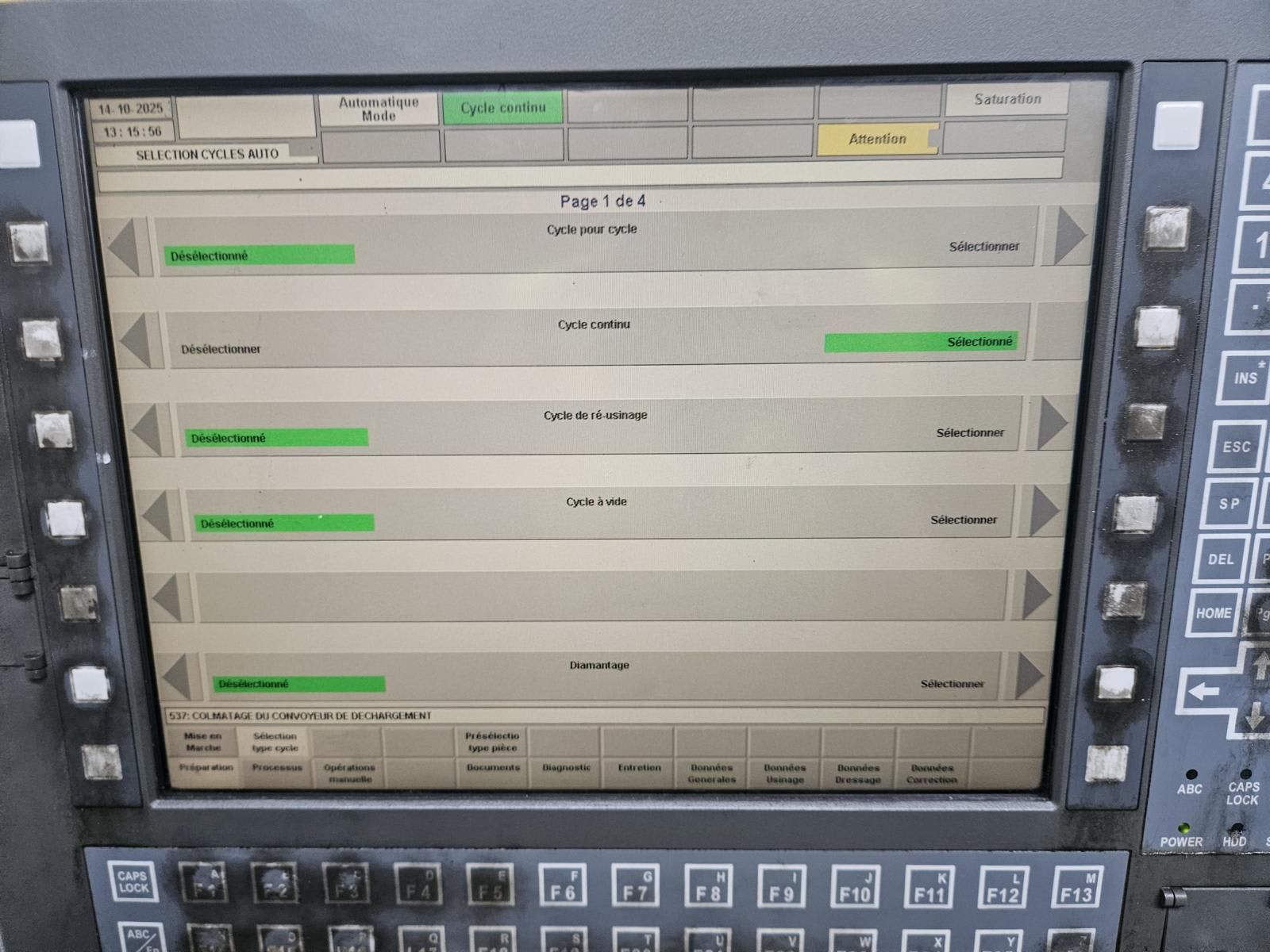

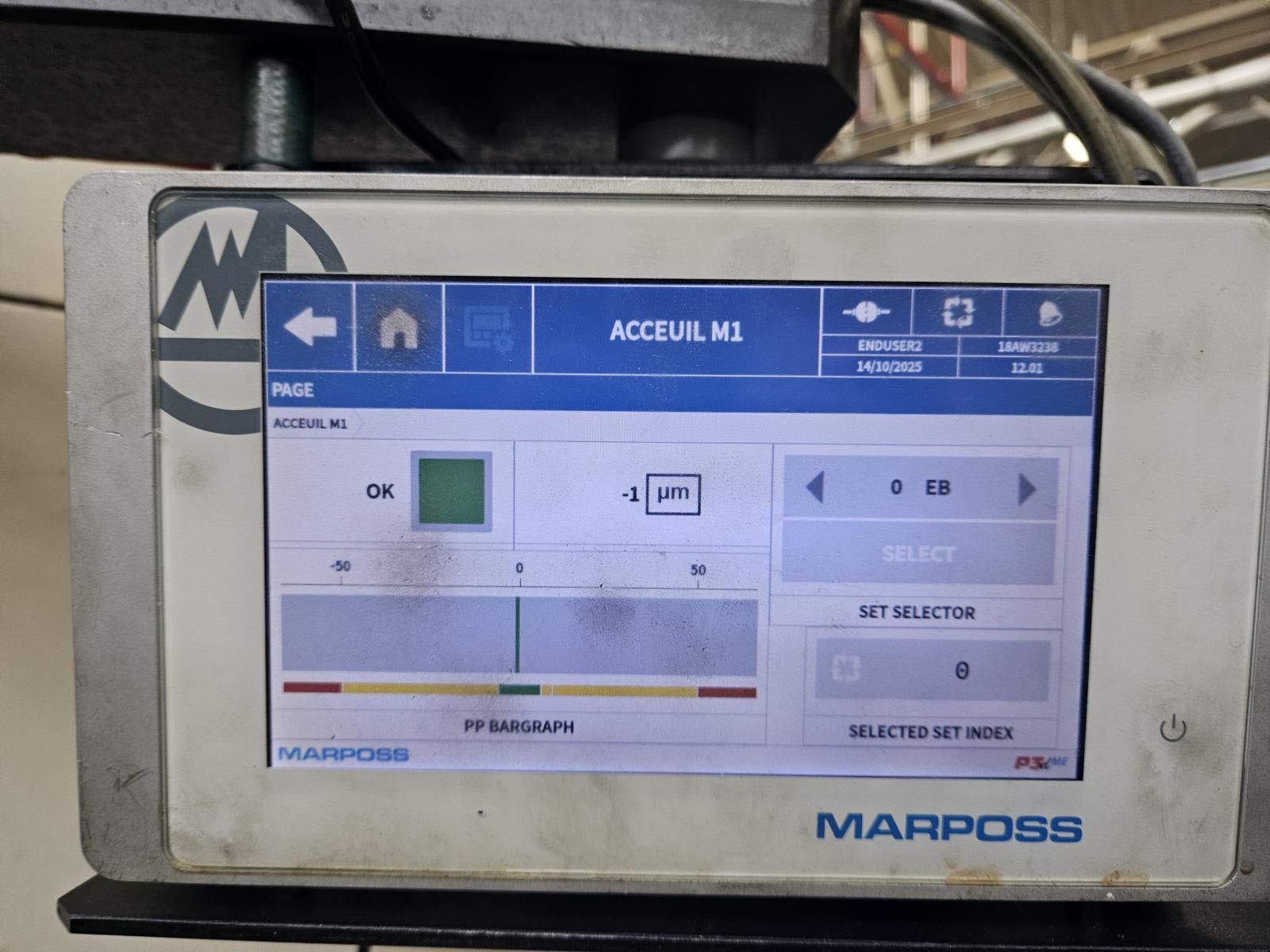

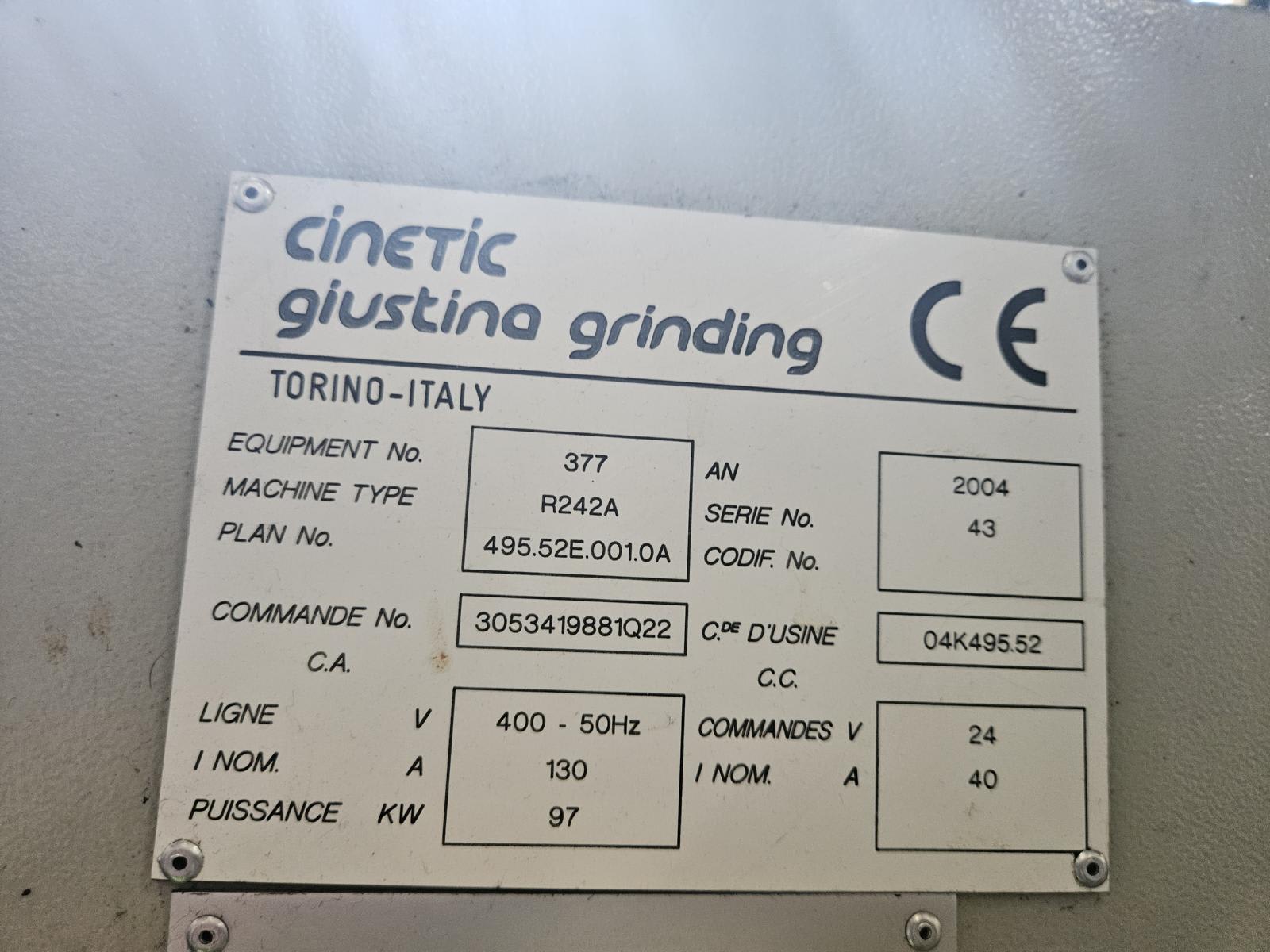

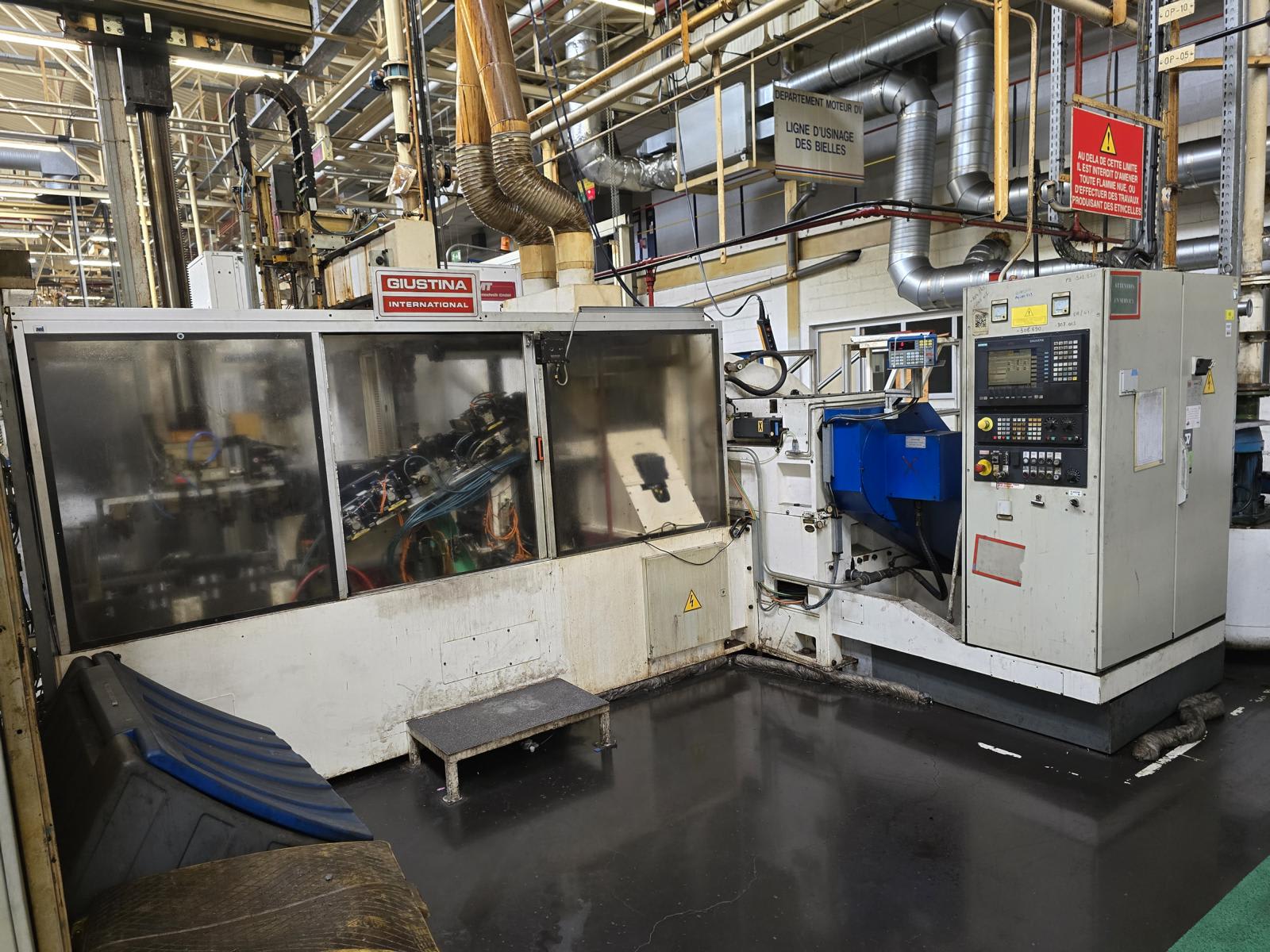

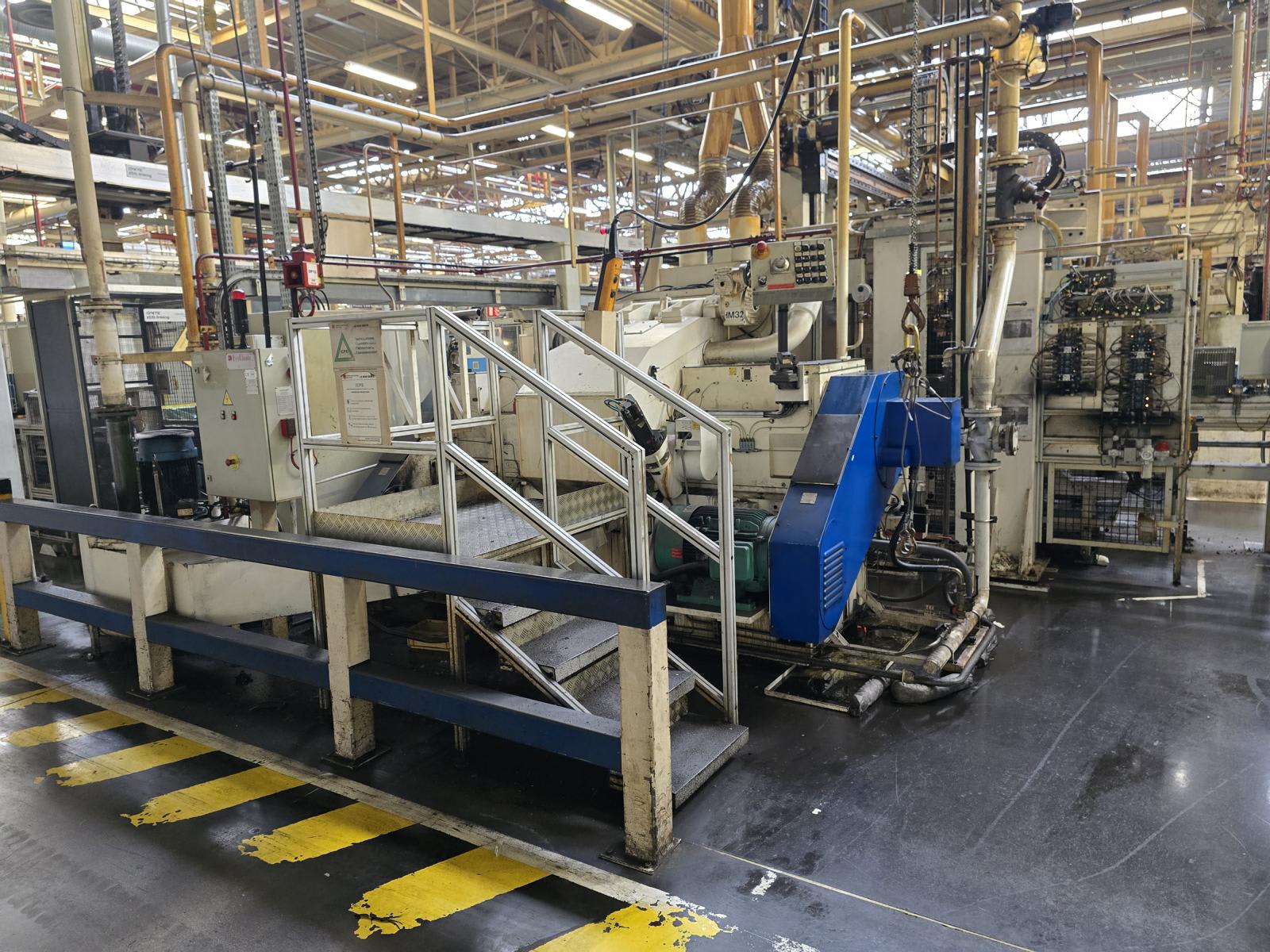

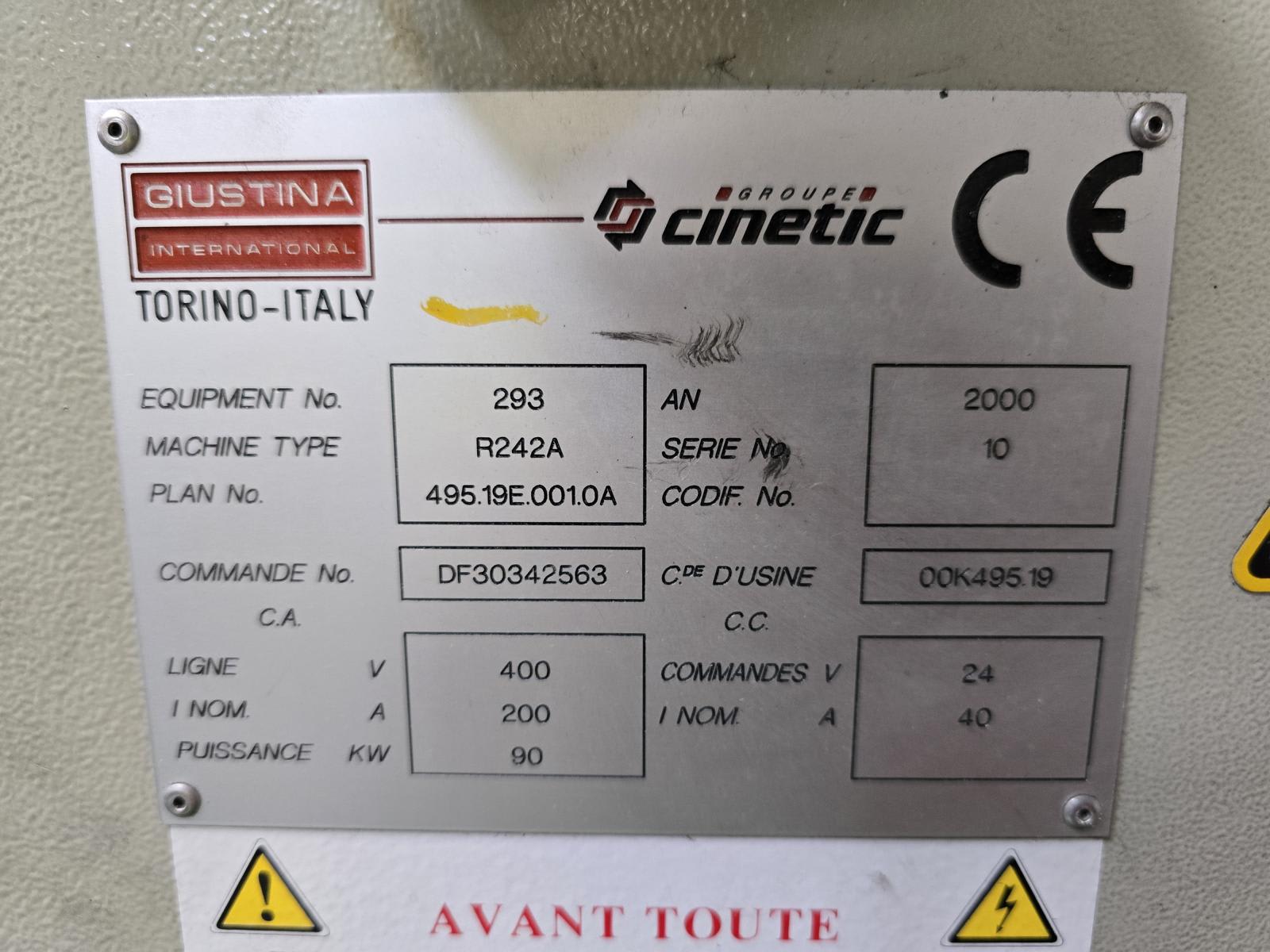

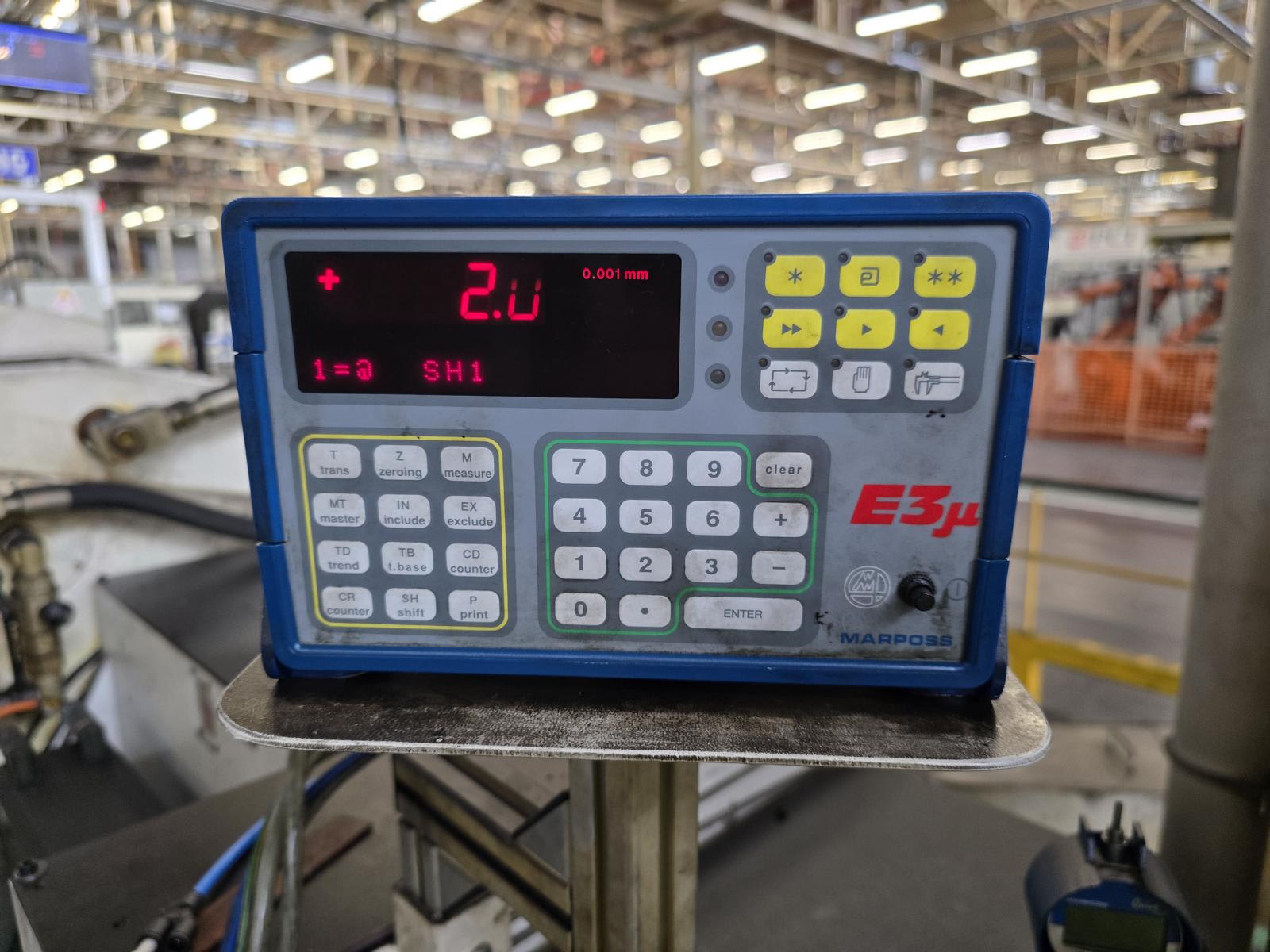

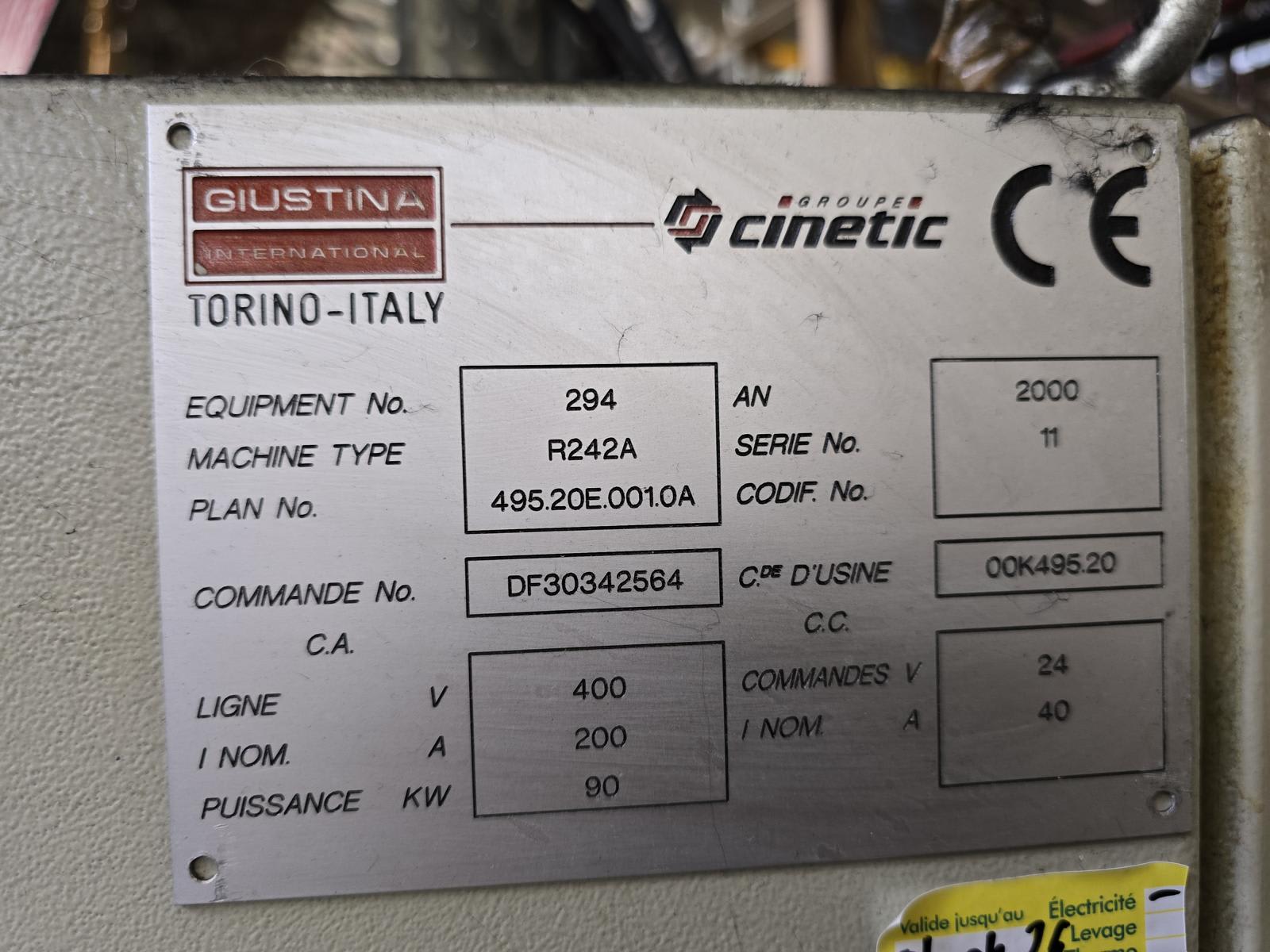

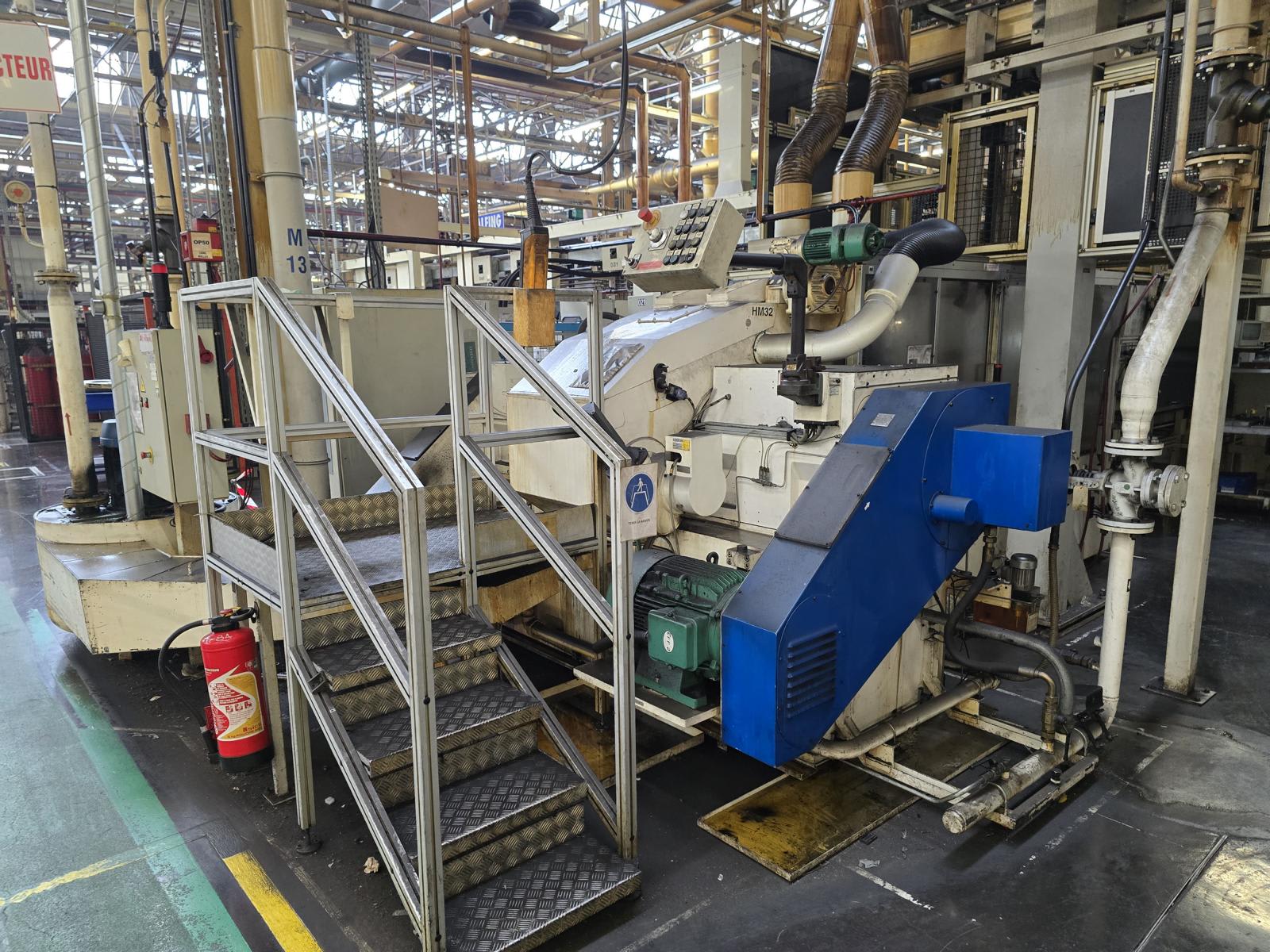

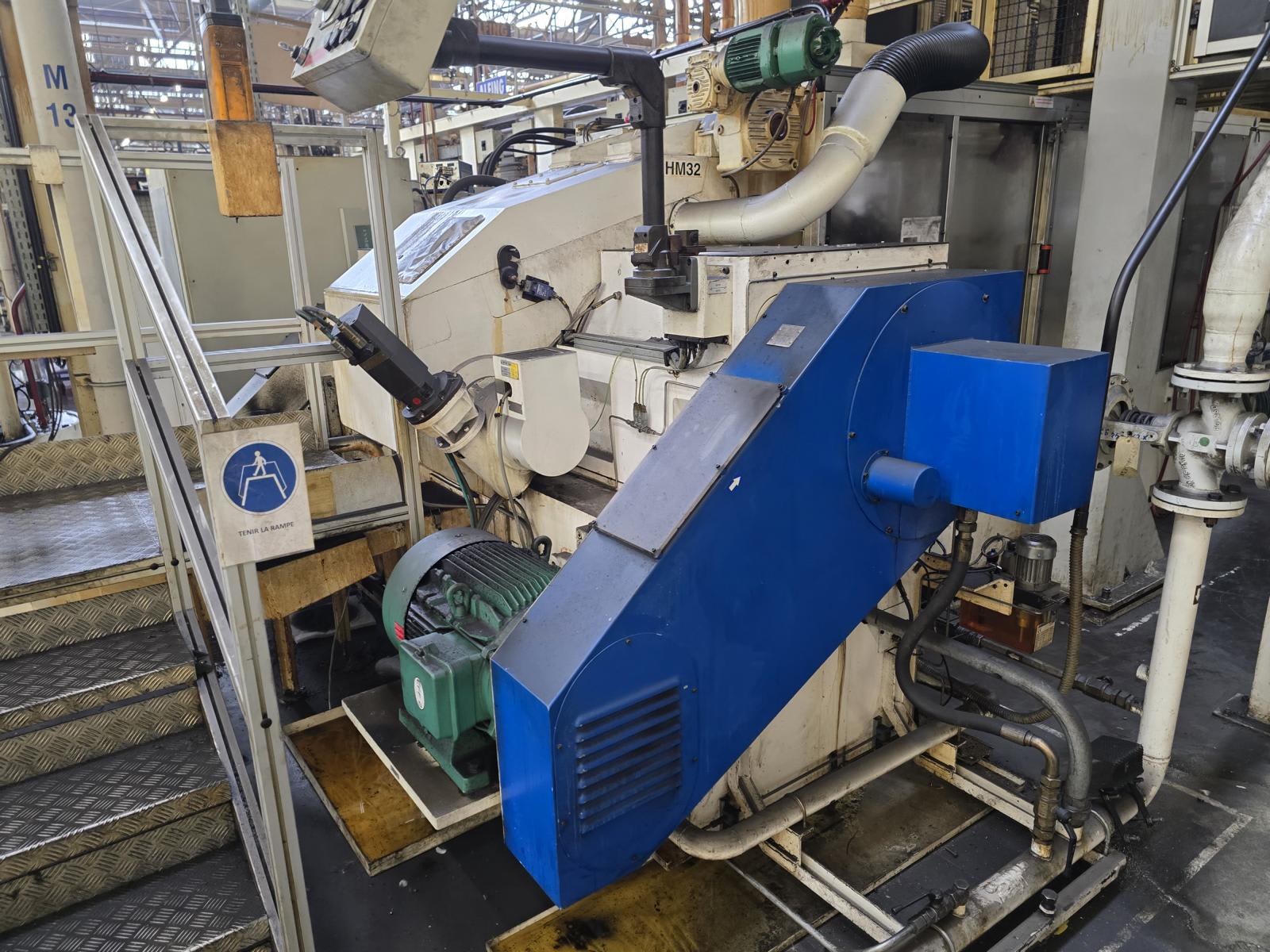

CNC Horizontal Double-Disc-Surface-Grinder CINETIC GIUSTINA R 242 A | 2004

grinding wheel dia x width 762 x 220mm, MARPOSS E3 InProcess Measuring System, CNC FANUC 210i-MB, 400V 50Hz 97kW, weight, ca. 13to - LISTING 2830065

![Français]()

CNC Horizontal Double-Disc-Surface-Grinder CINETIC GIUSTINA R 242 A | 2004

grinding wheel dia x width 762 x 220mm, MARPOSS InProcess Measuring System, CNC FANUC 210i-MB, 400V 50Hz 97kW, weight, ca. 13to - LISTING 2830066

![Français]()

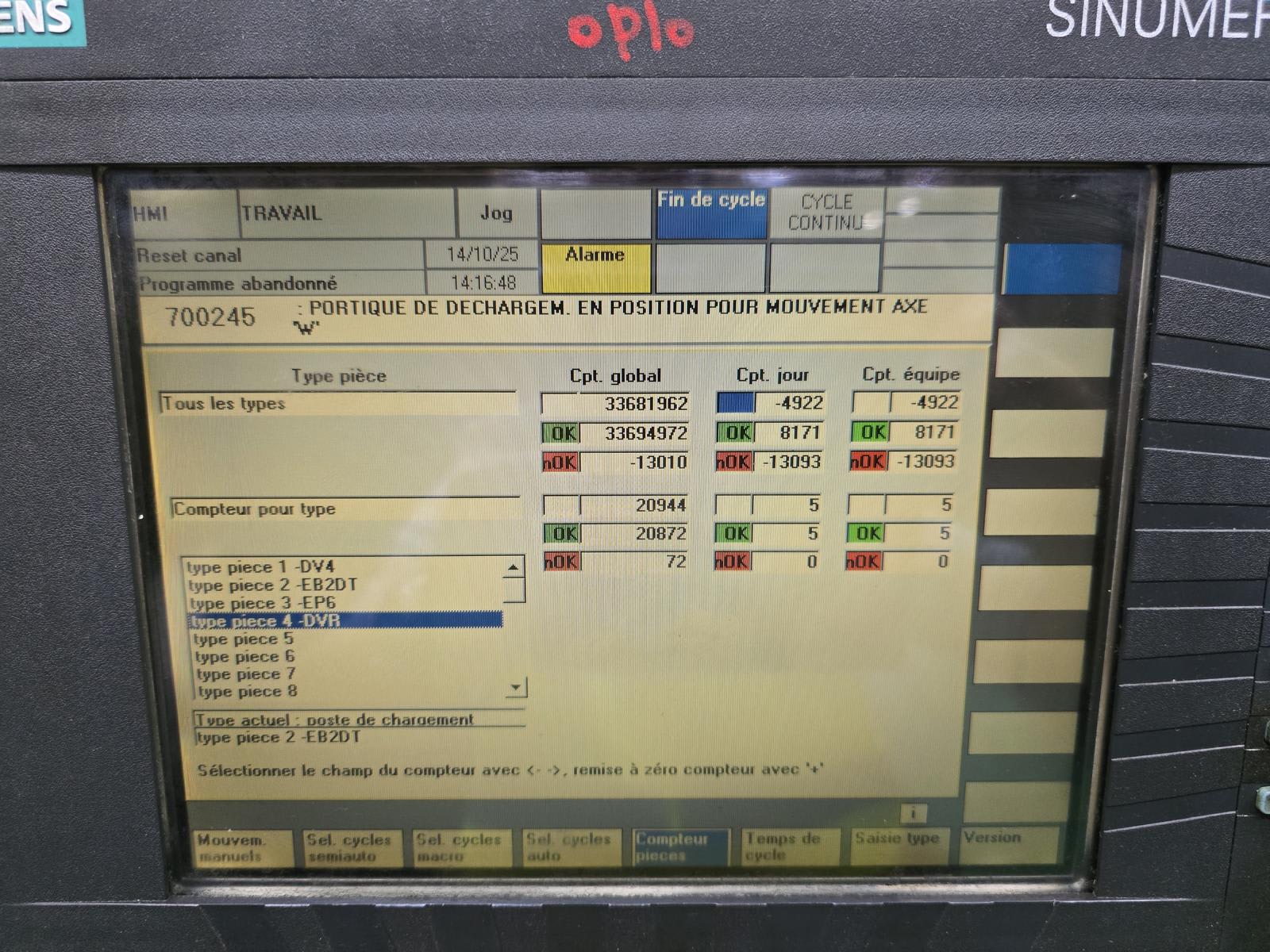

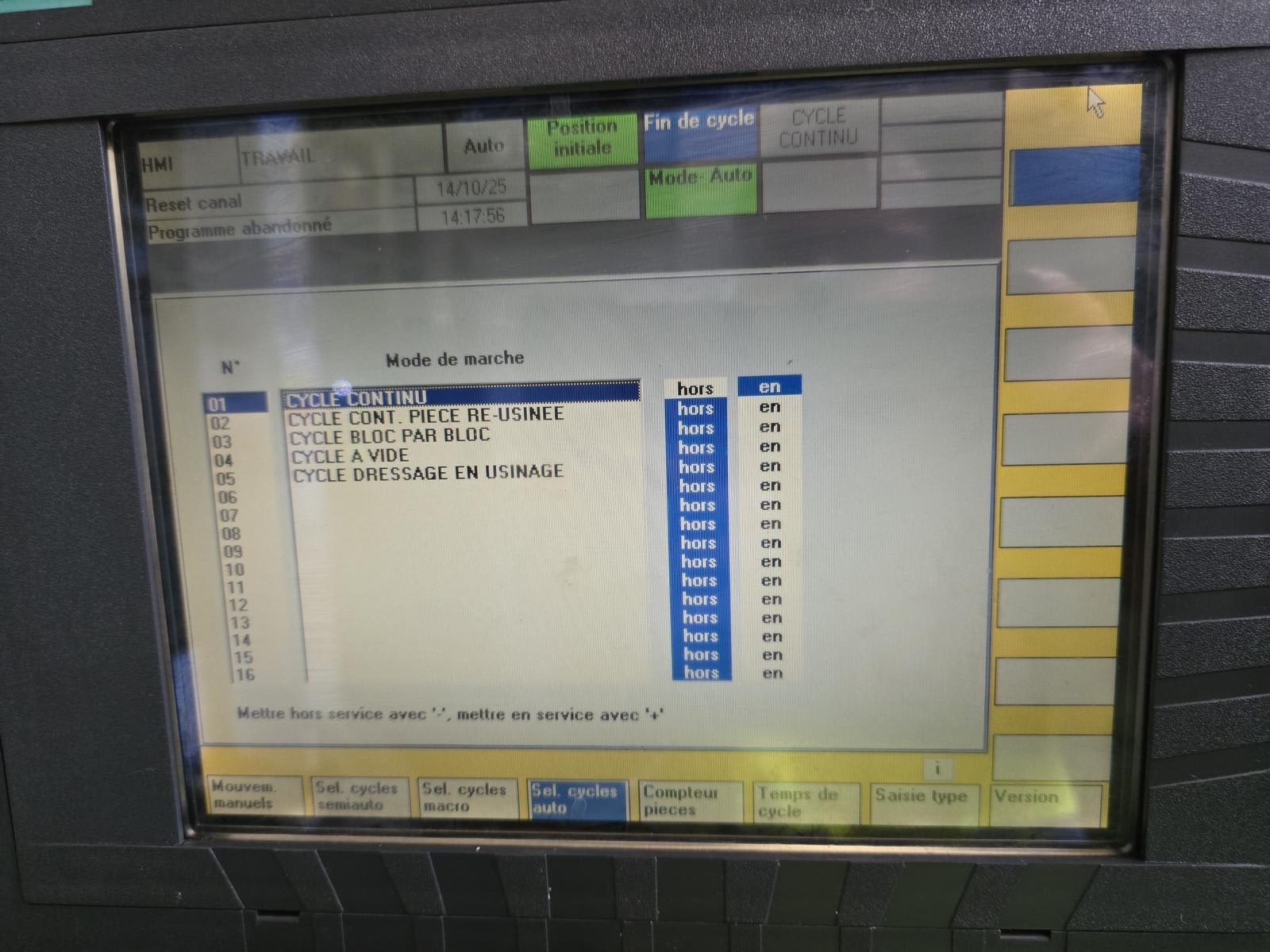

CNC Horizontal Double-Disc-Surface-Grinder CINETIC GIUSTINA R 242 A | 2000

grinding wheel dia x width 762 x 220mm, MARPOSS E3 InProcess Measuring System, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 97kW, weight, ca. 13to - LISTING 2830067

![Français]()

CNC Horizontal Double-Disc-Surface-Grinder CINETIC GIUSTINA R 242 A | 2000

grinding wheel dia x width 762 x 220mm, MARPOSS E3 InProcess Measuring System, CNC SIEMENS SINUMERIK 840D, 400V 50Hz 97kW, weight, ca. 13to - LISTING 2830068

![Français]()

- LISTING 2830069

![Français]()

- LISTING 2830070

![Français]()

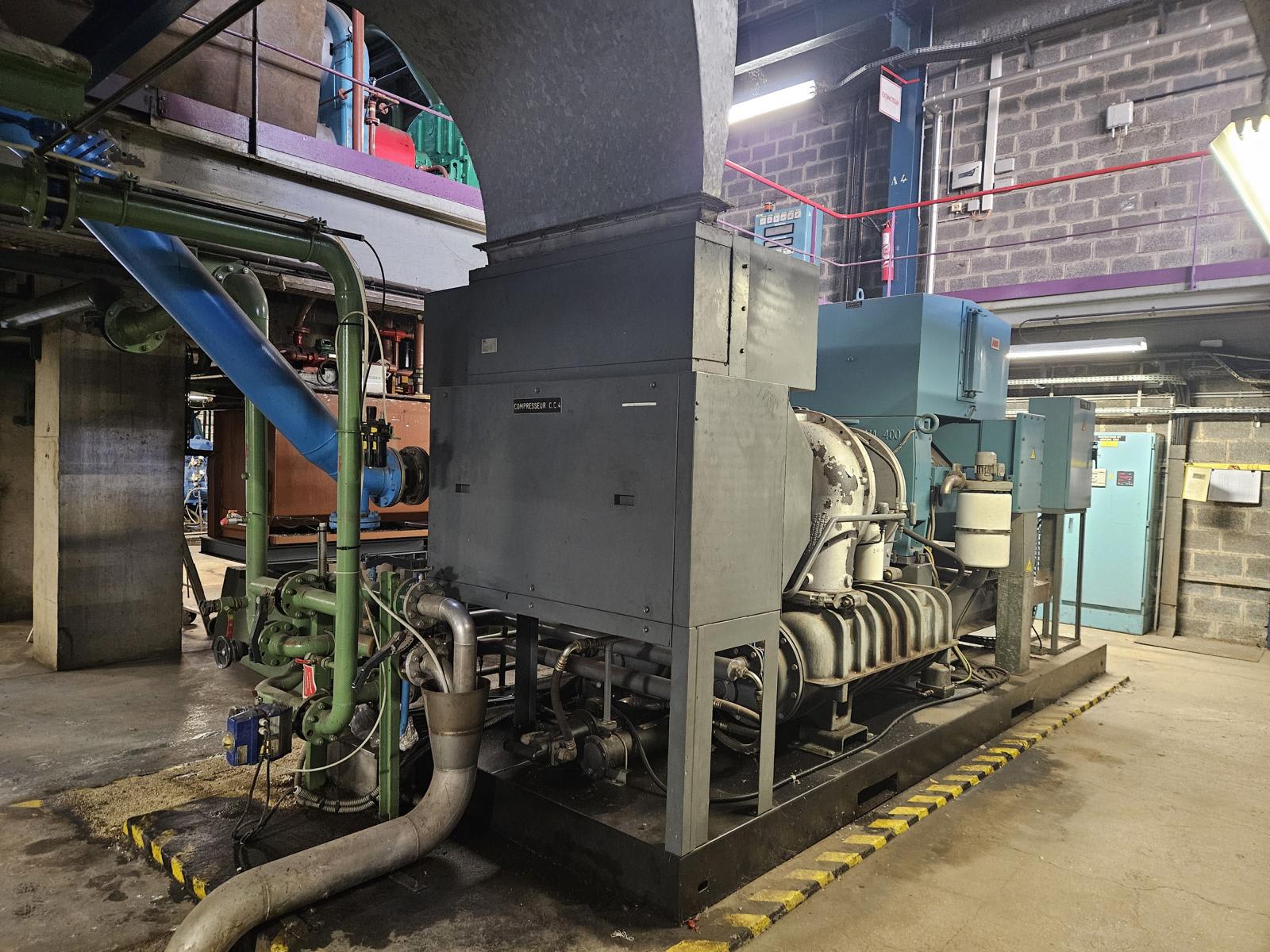

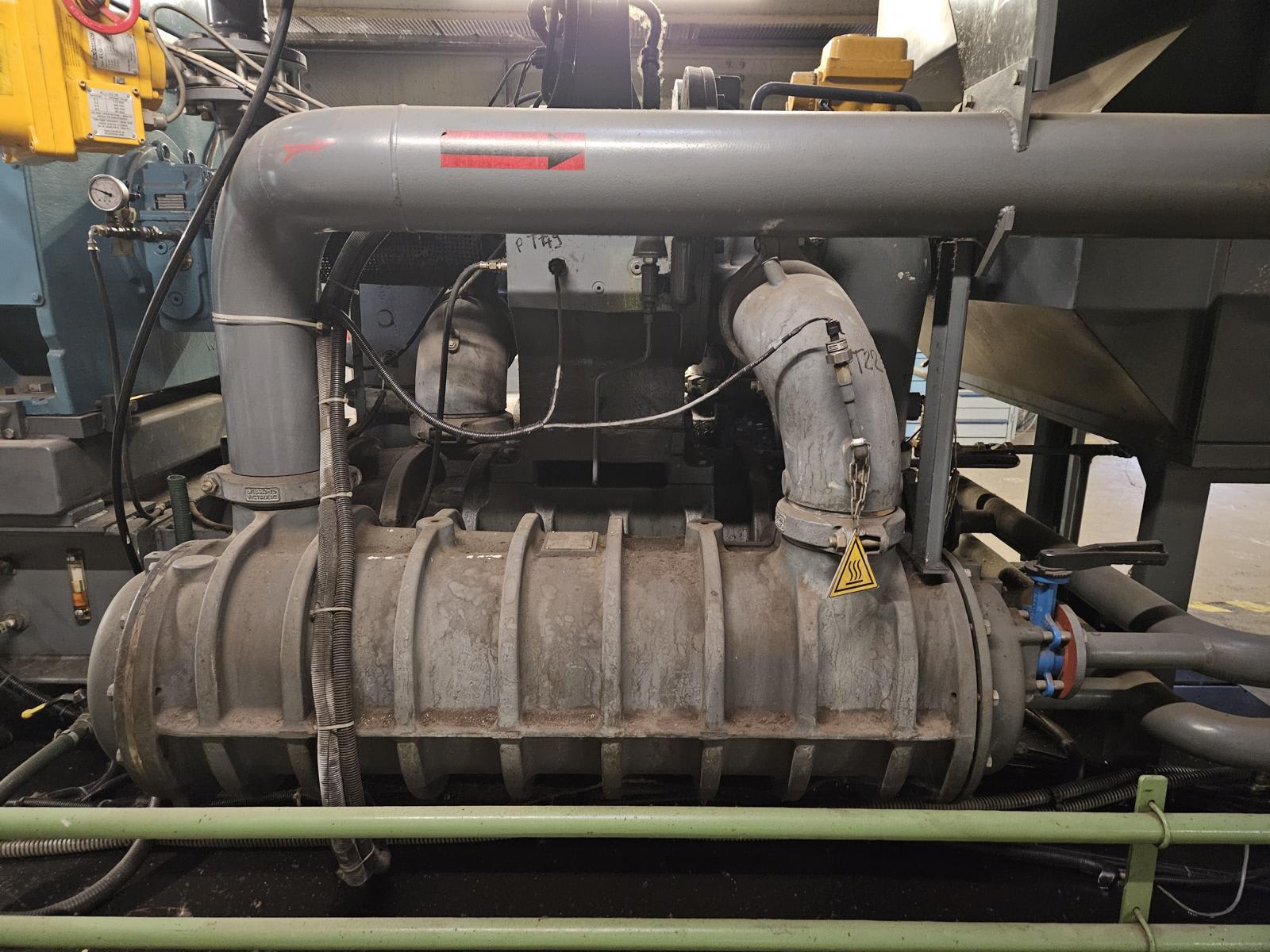

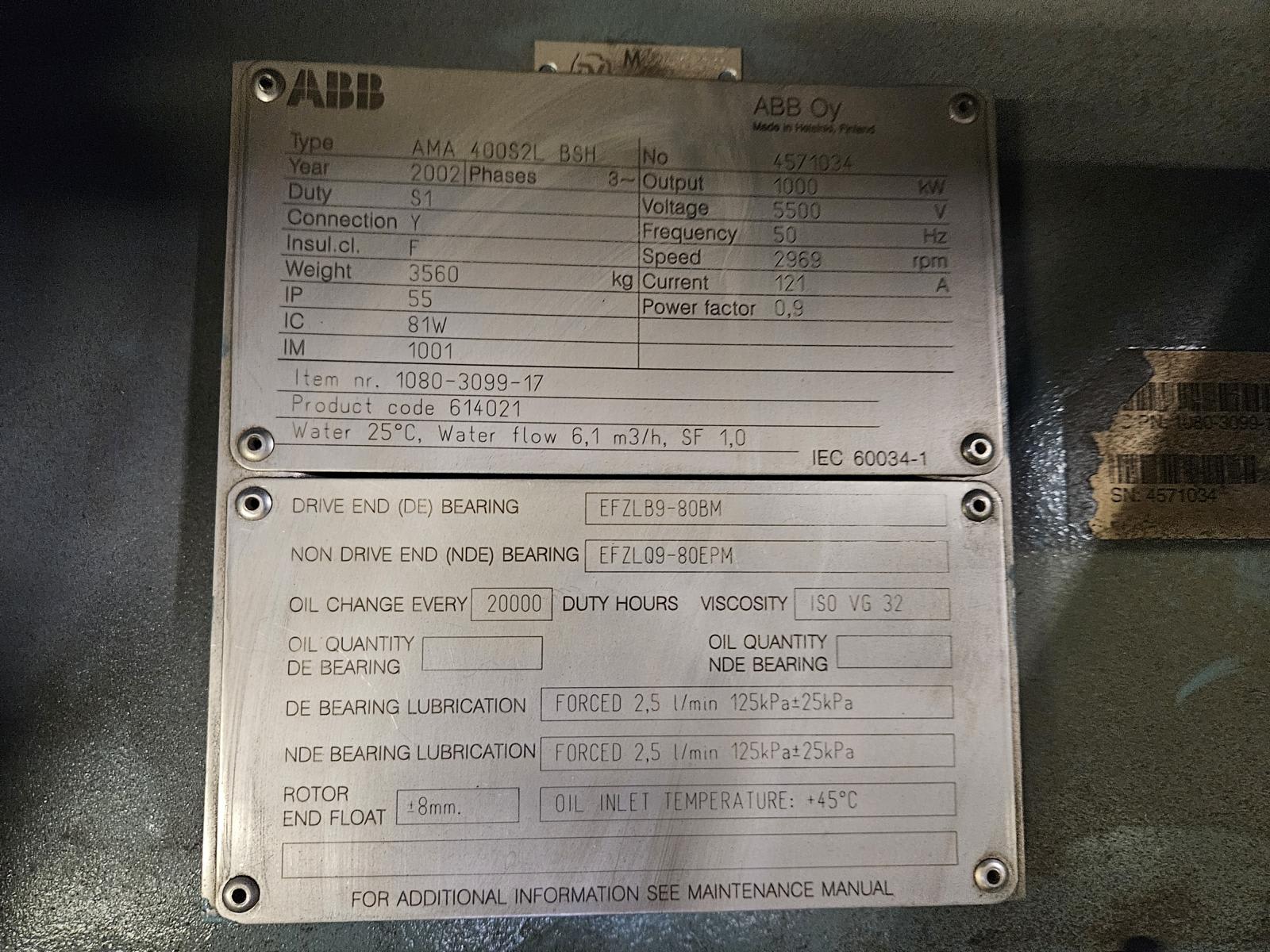

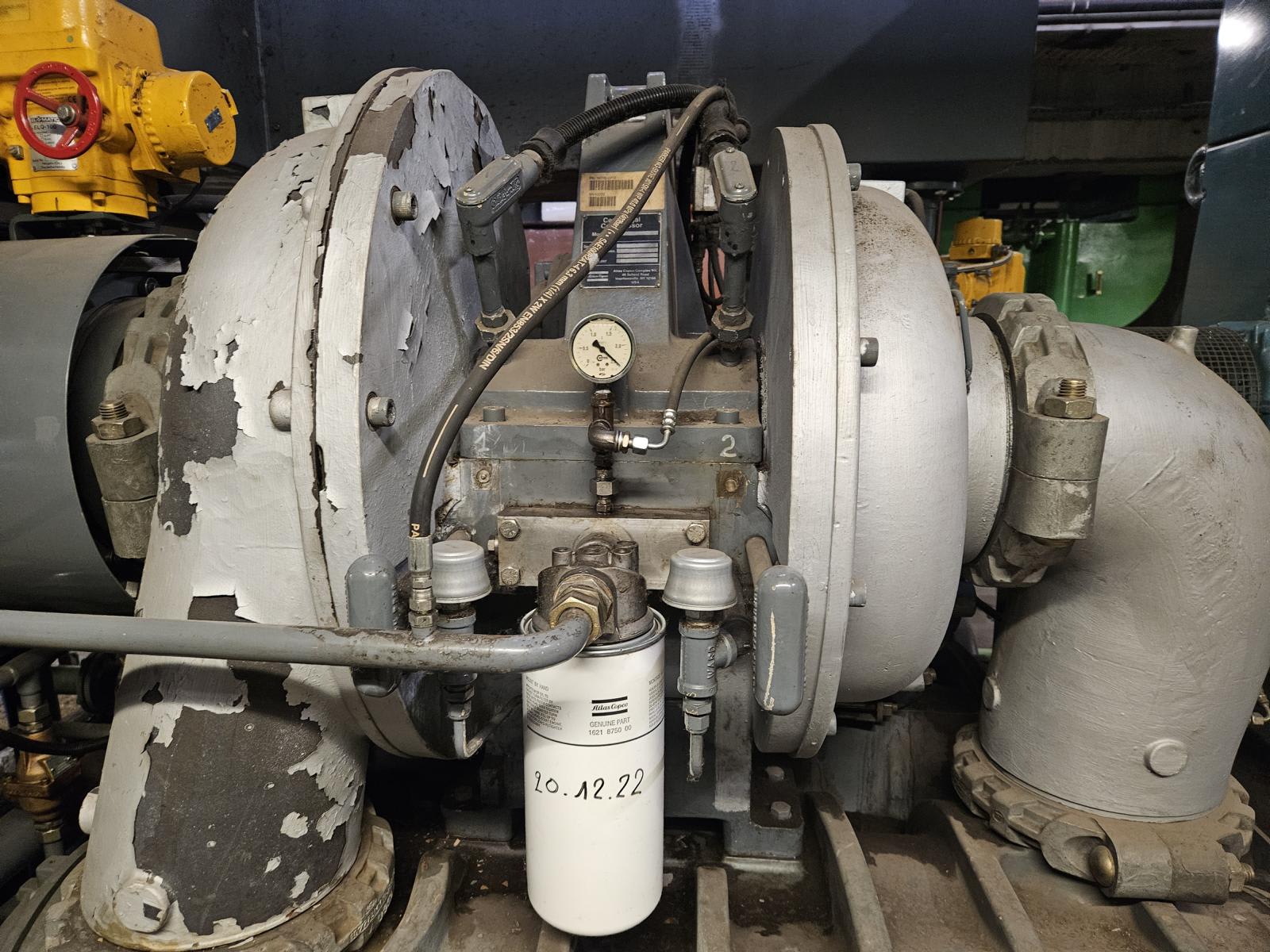

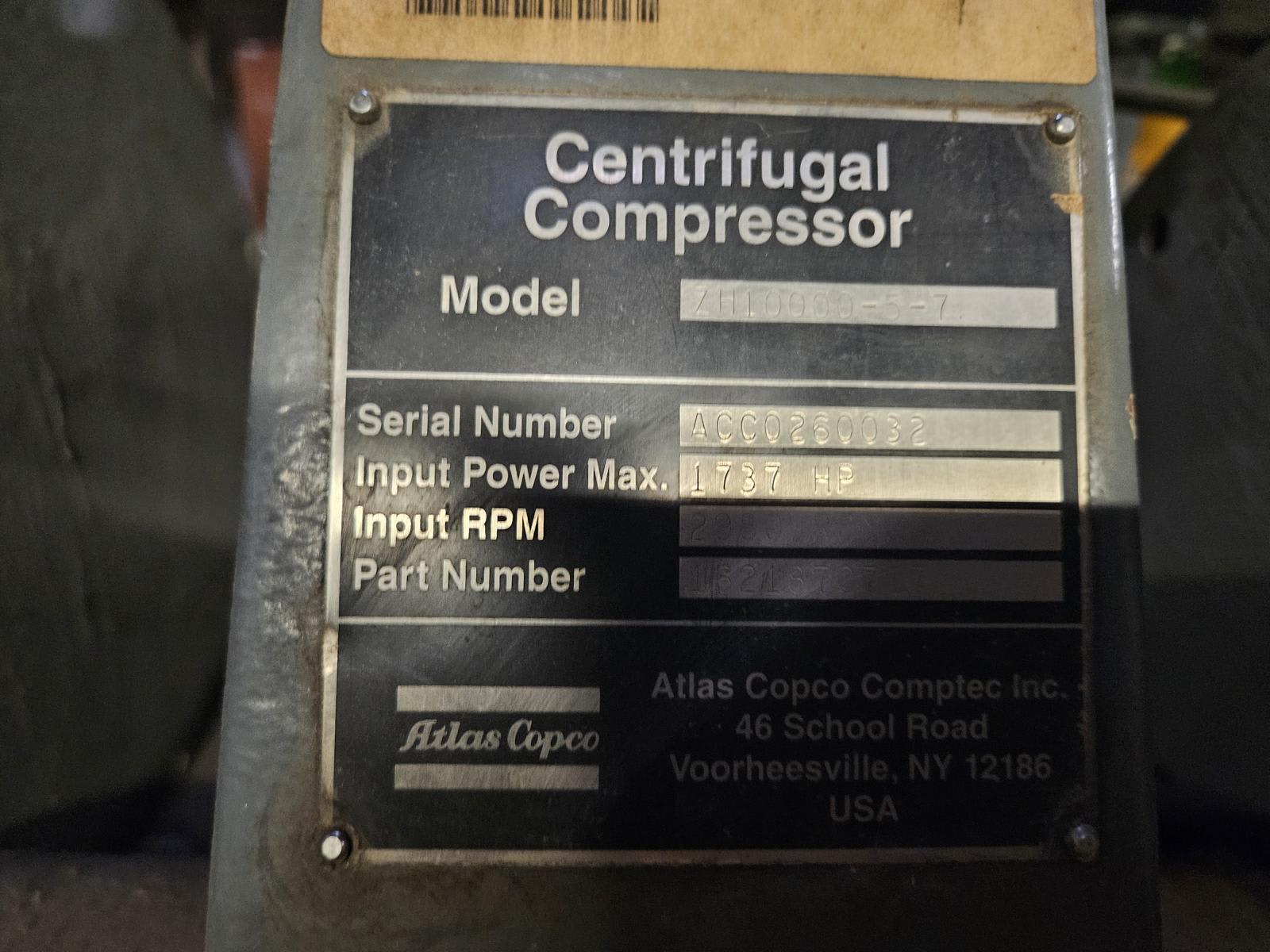

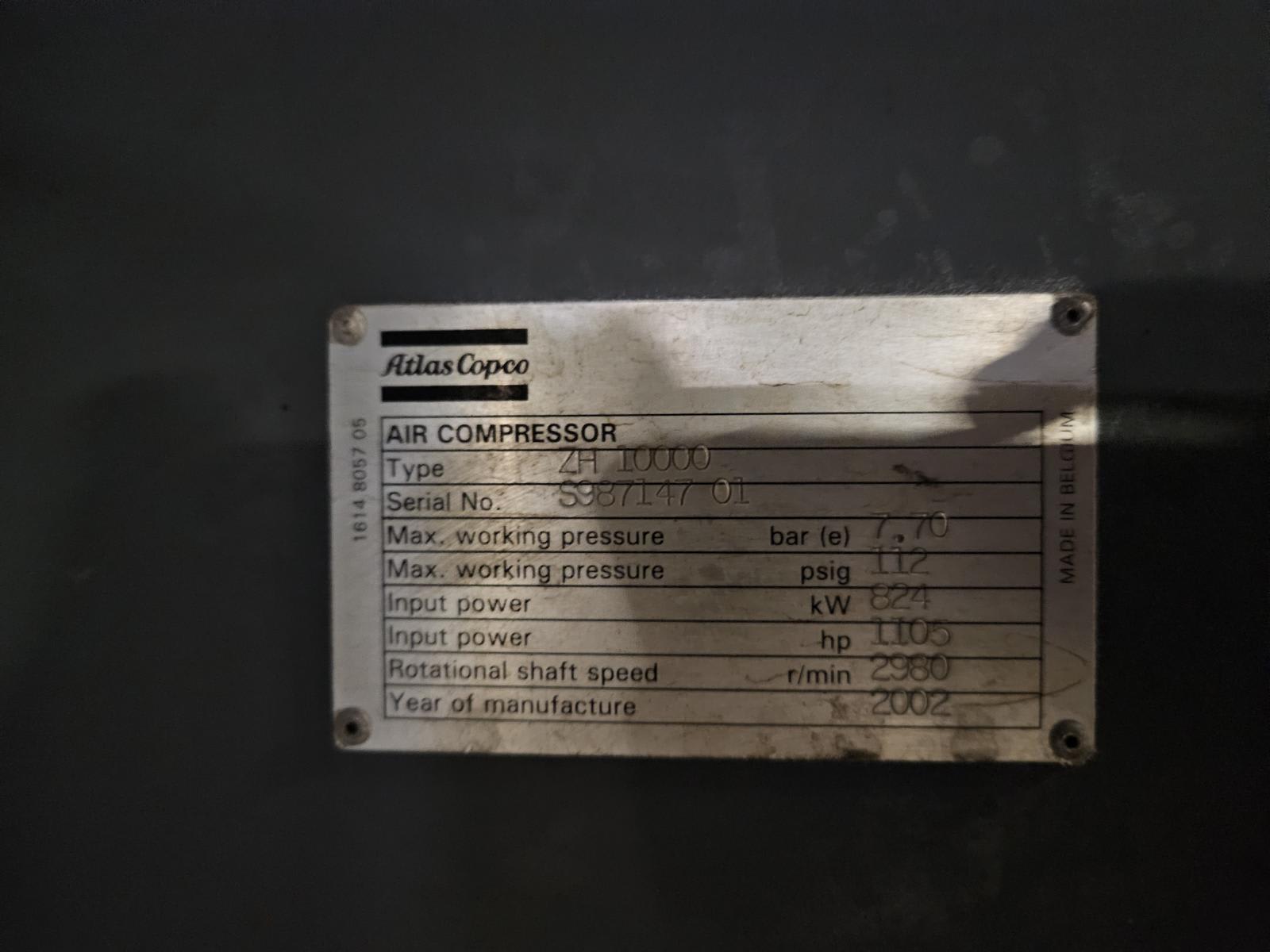

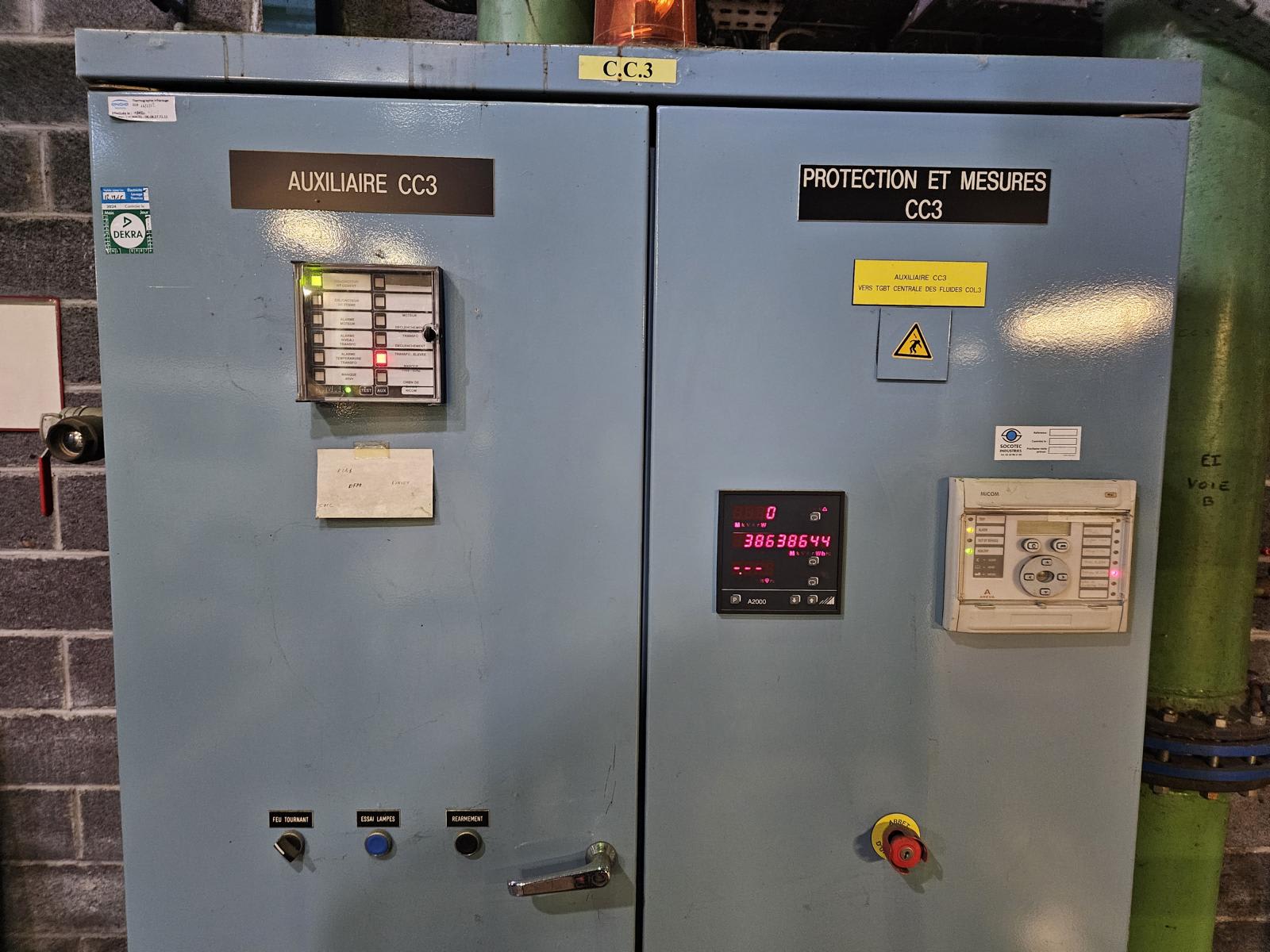

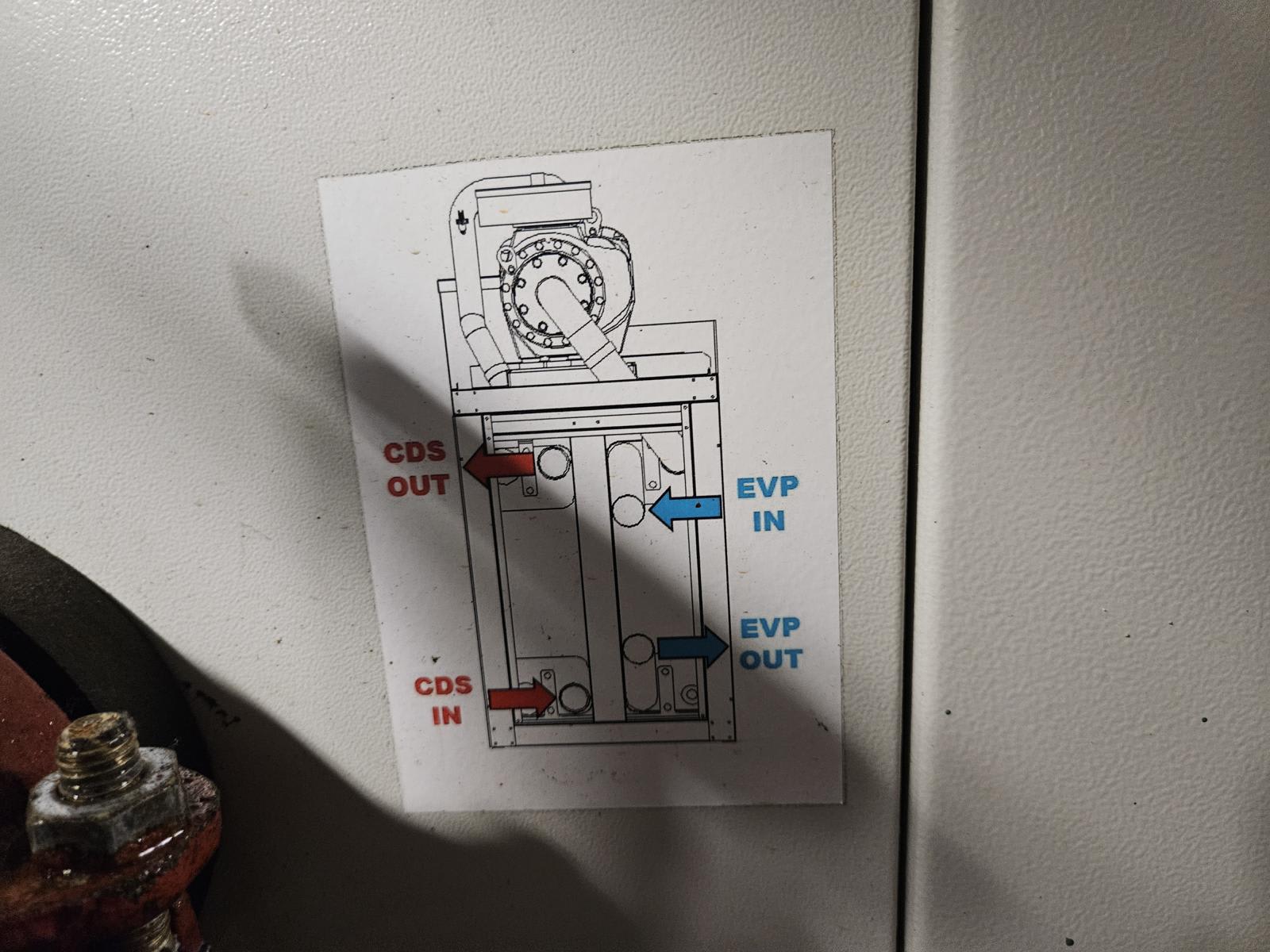

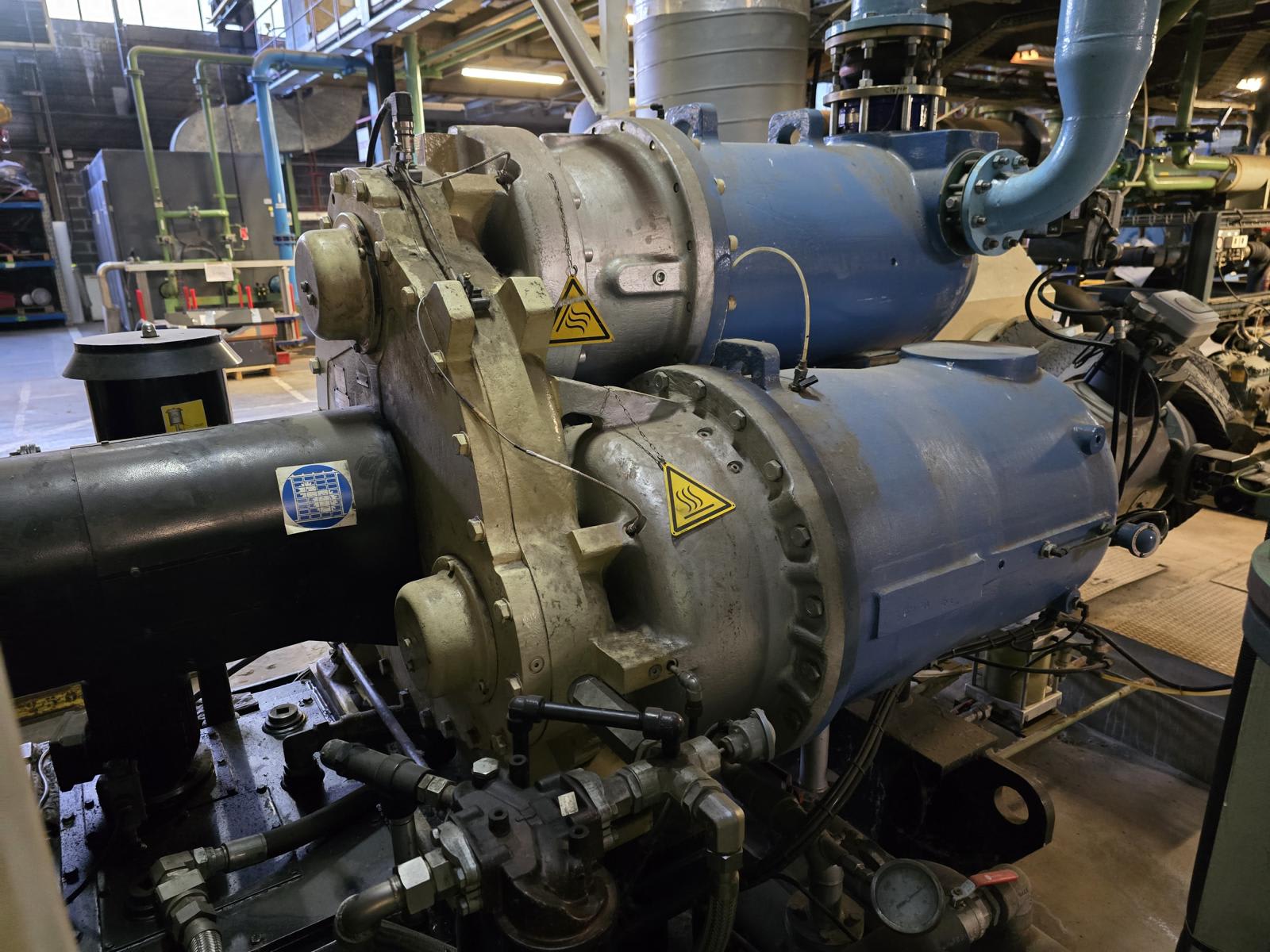

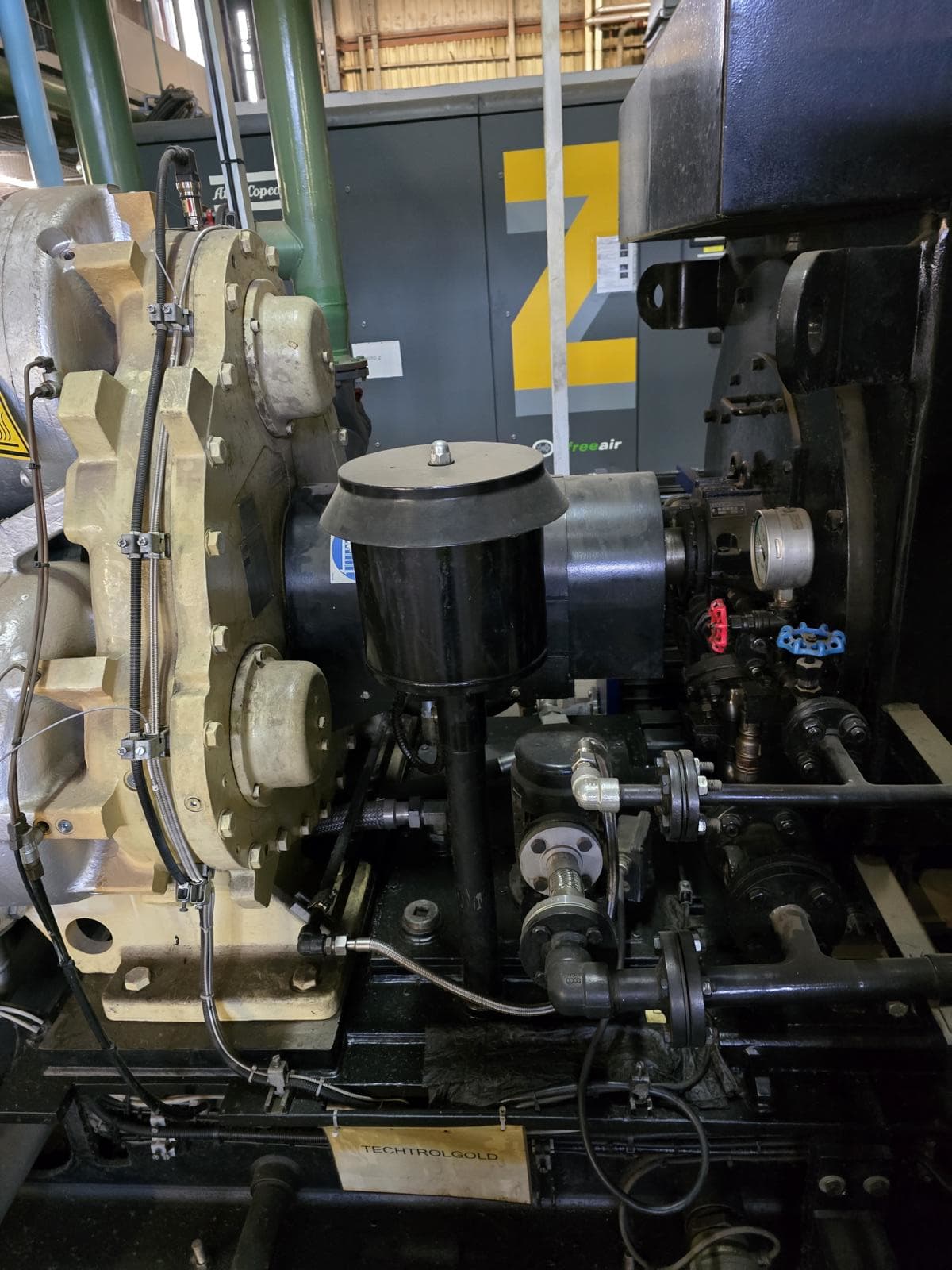

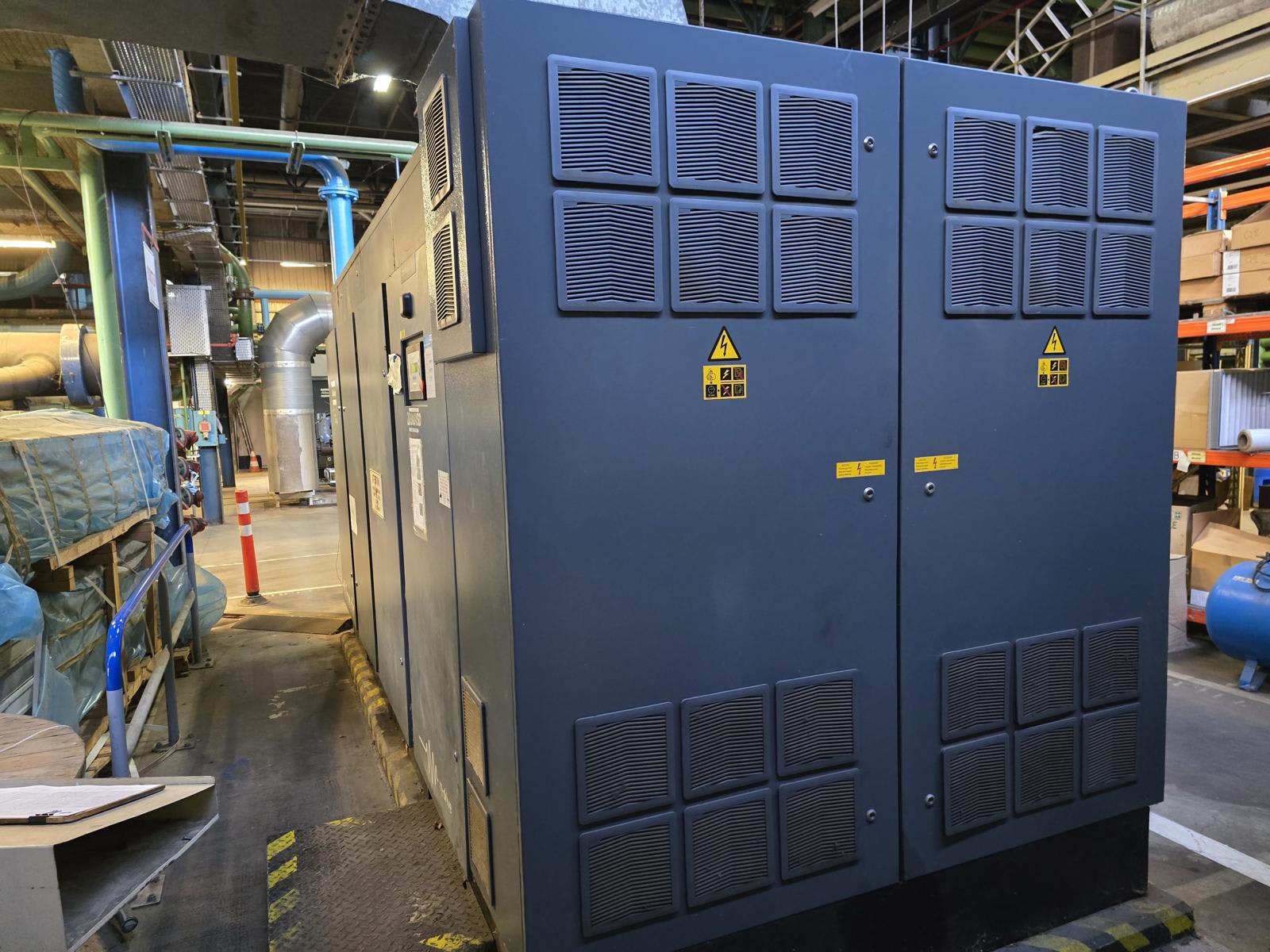

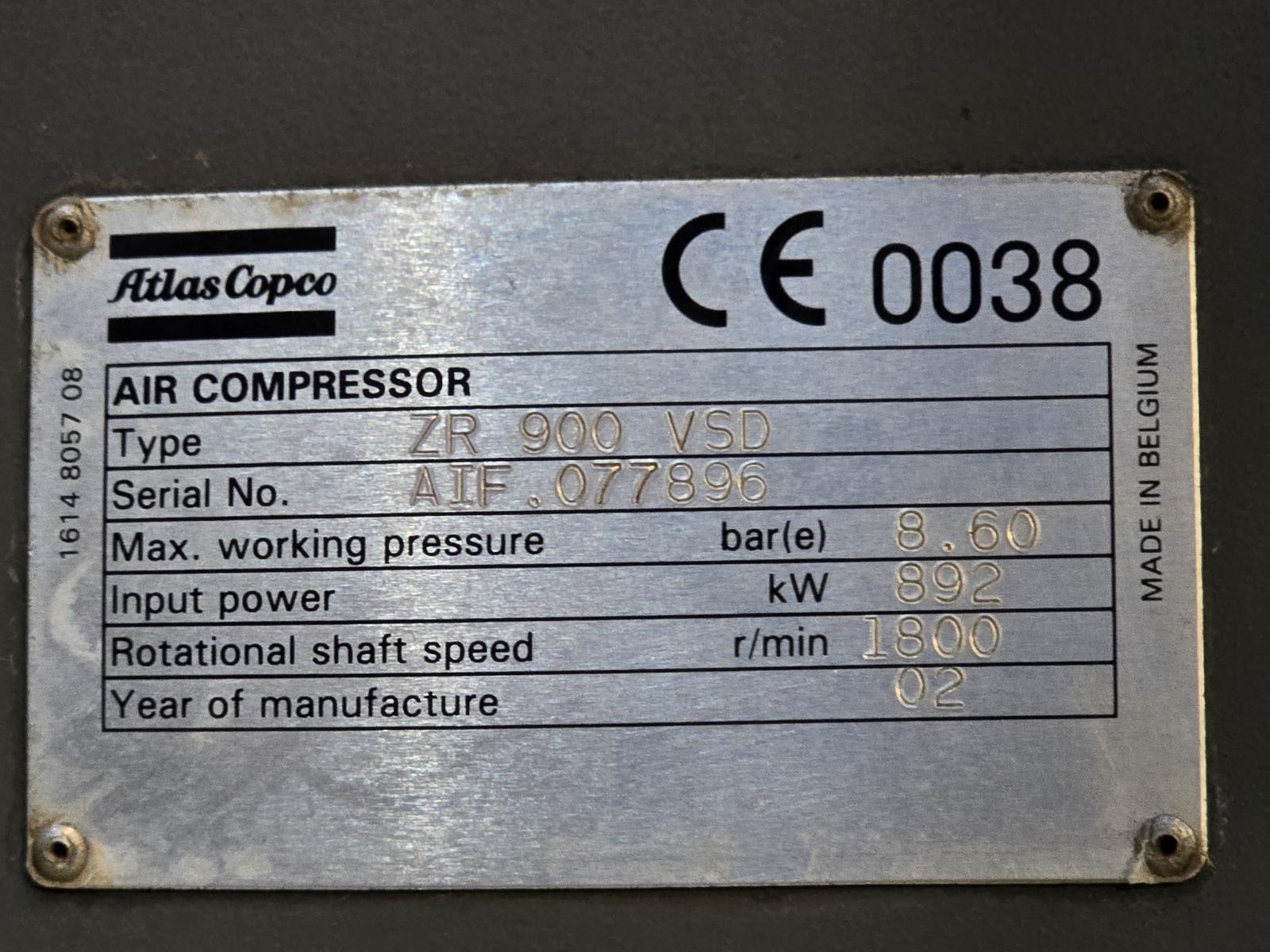

Compressor ATLAS COPCO ZH 10.000-5 | 2002

max working pressure 7,7bar, Volume, ca. 280 qbm/min, Input Power 824kW /// Drive Motor: model AMA 400S2L BSH, 1.000kW / 5.500V / 121A / 50Hz / 2.969rpm, weight, ca. 3,5to /// Centrifugal Compressor: model ZH 10.000-5-7, max Input 1.737HP, Input 2.969rpm, max Output 12 bar - LISTING 2830071

![Français]()

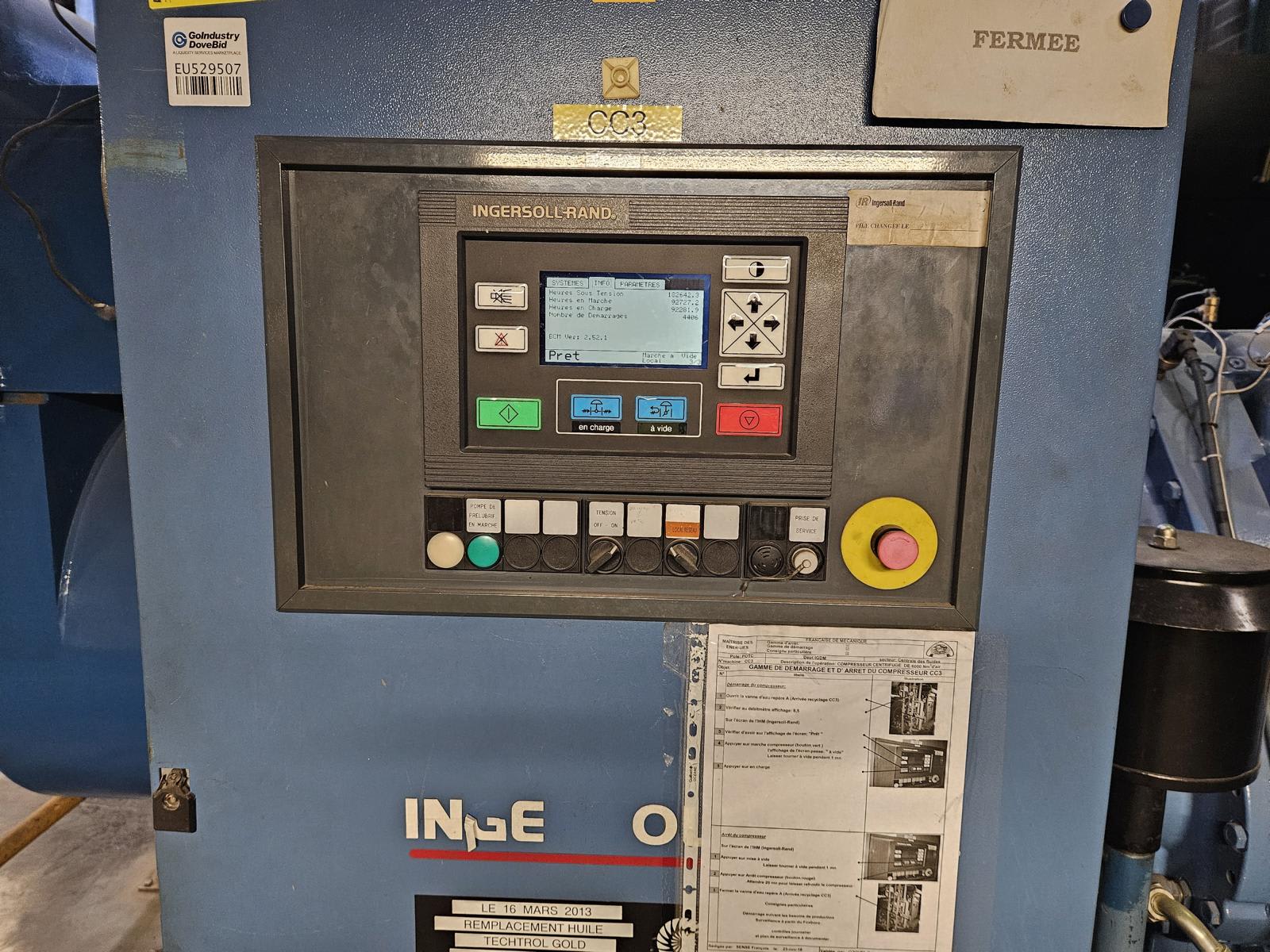

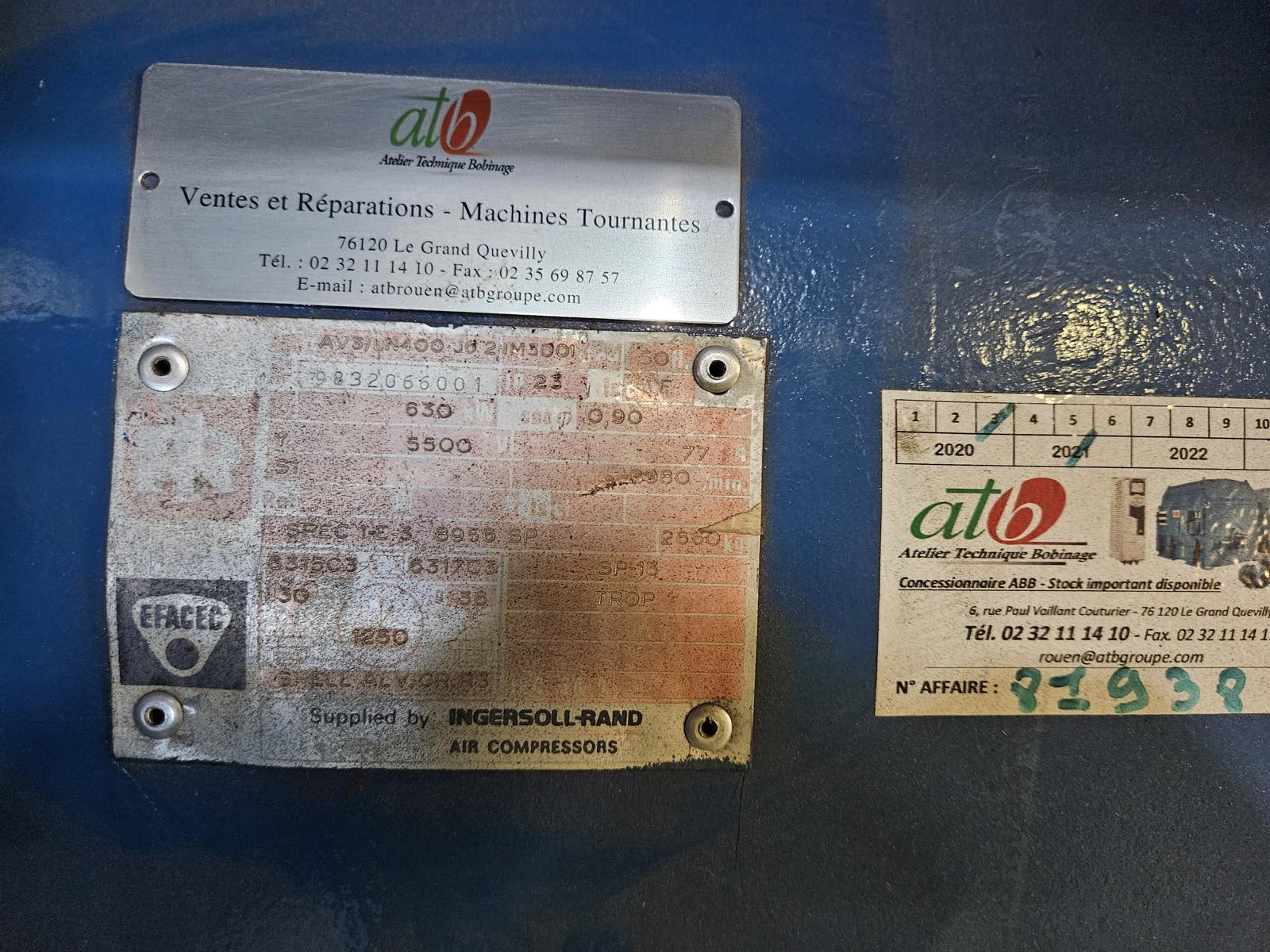

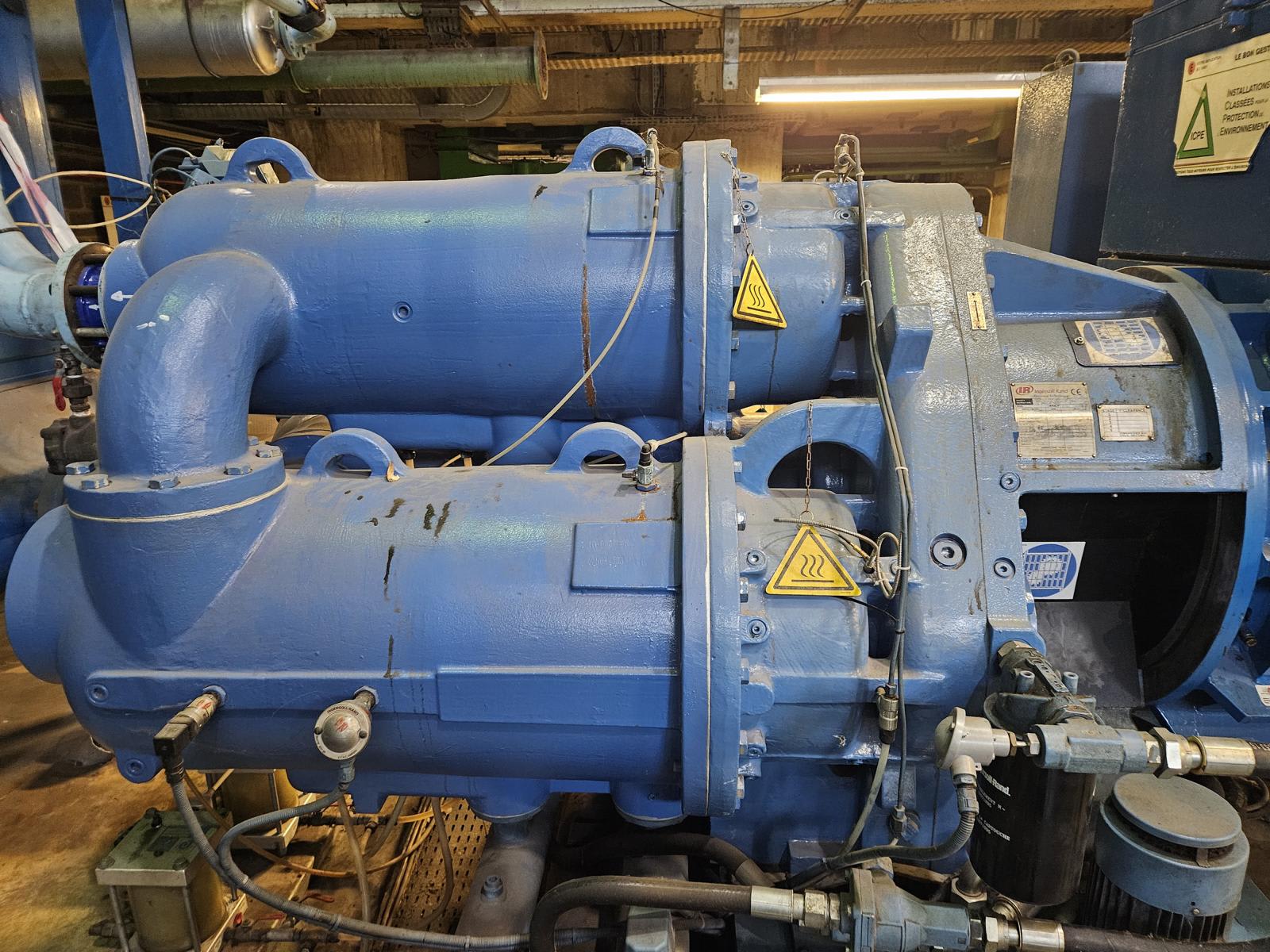

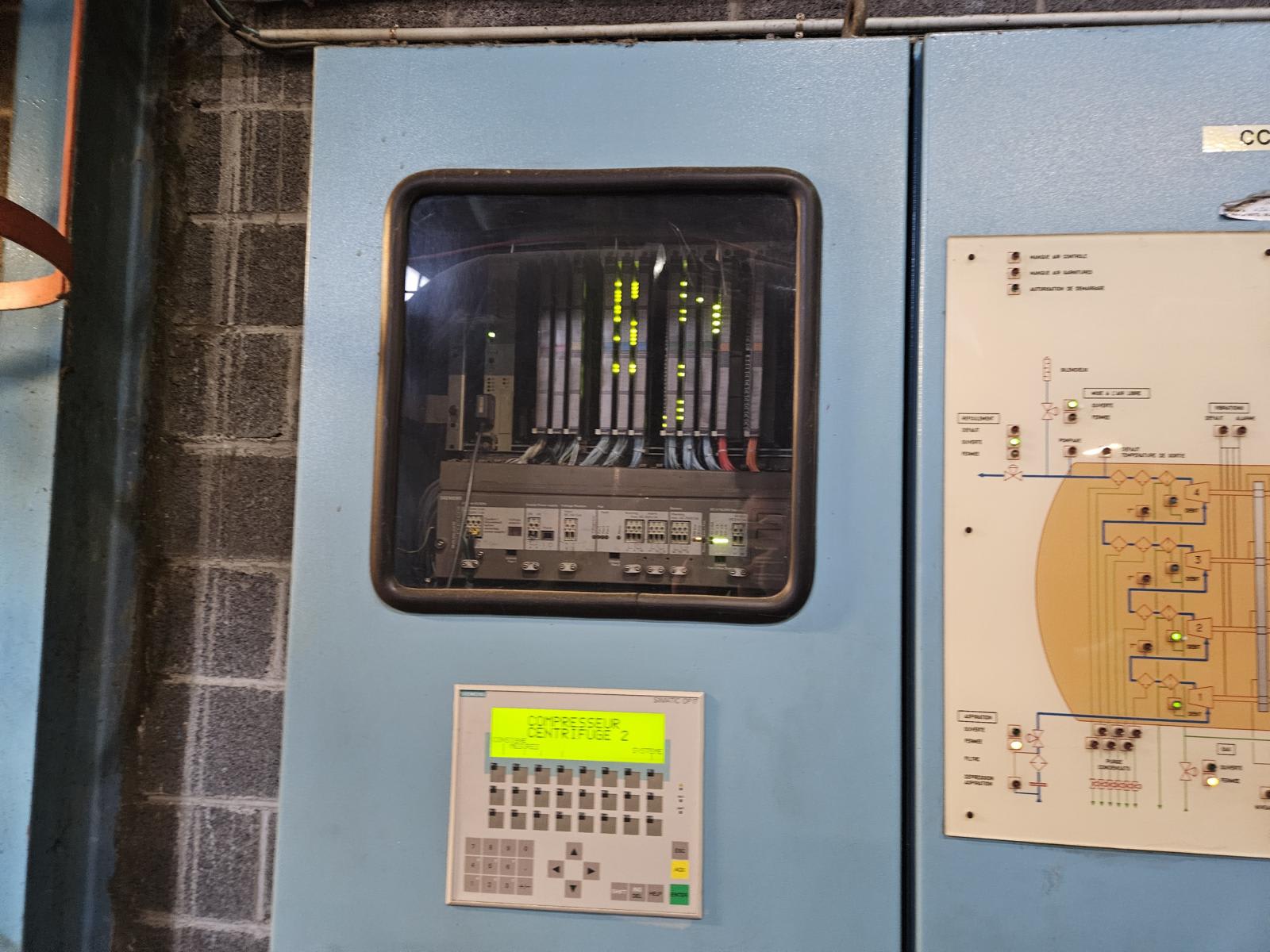

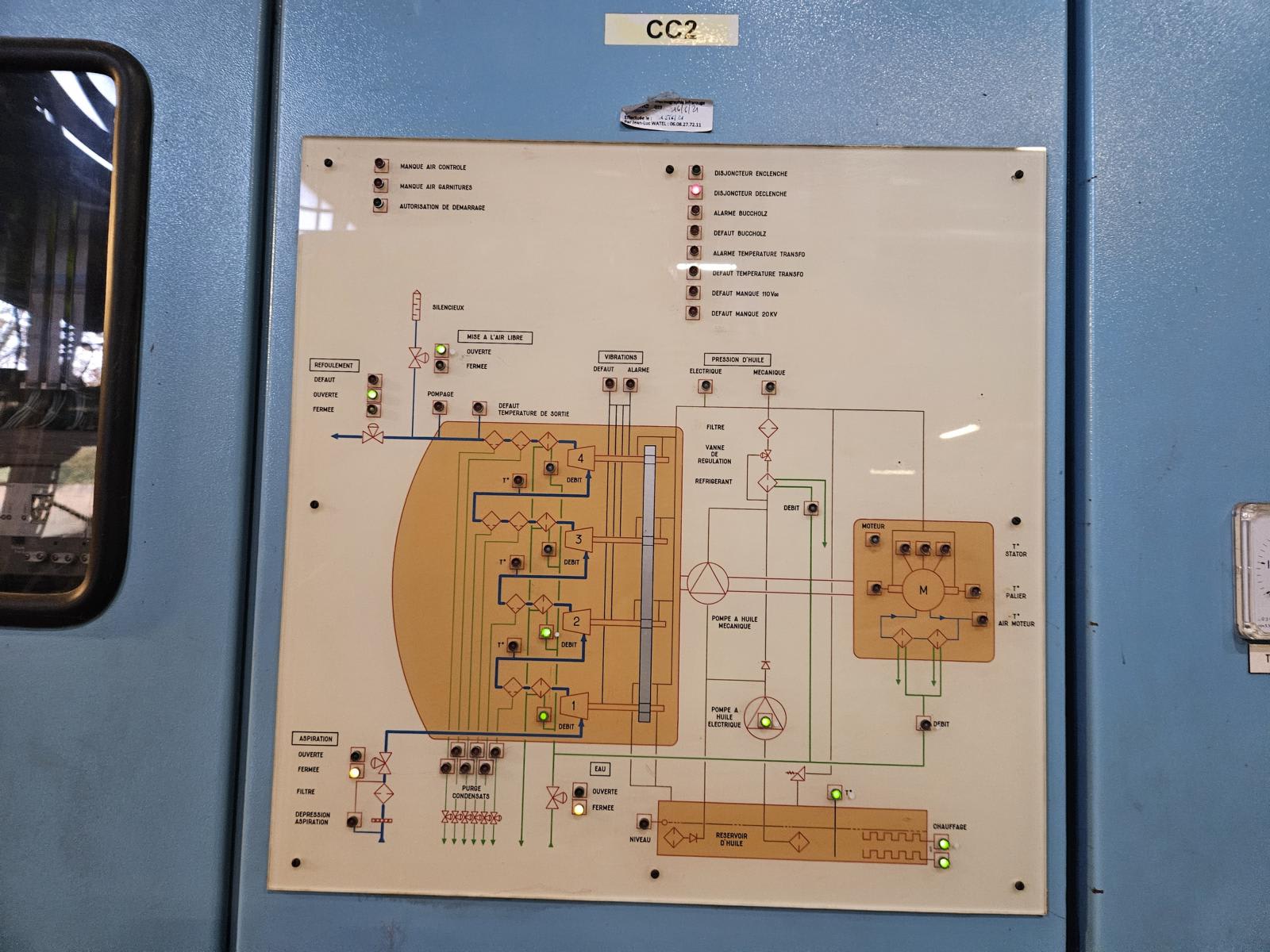

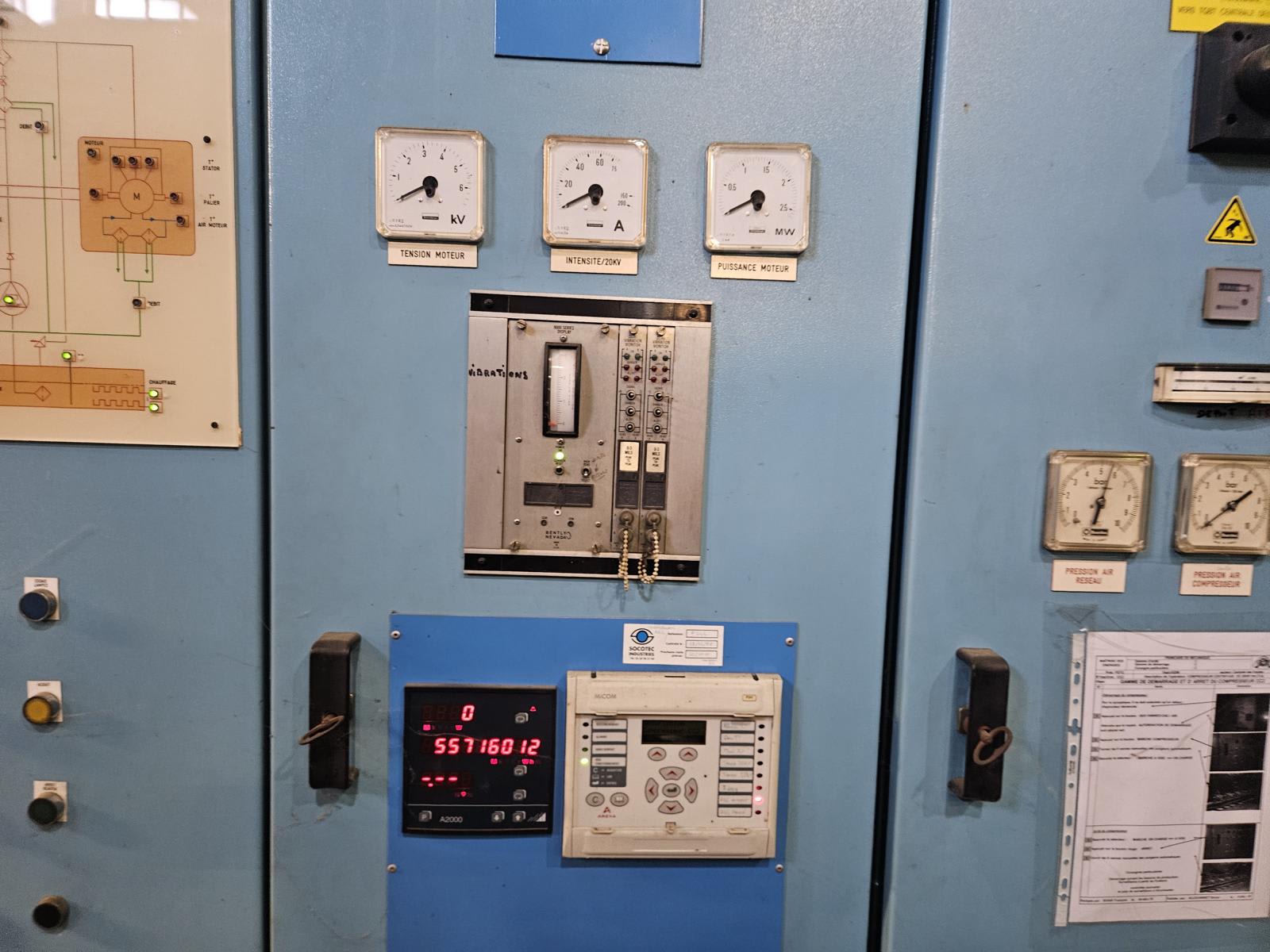

Compressor INGERSOLL RAND

Motor Drive: AV3LN400J02IM3001, 630kW, 3980rpm /// Compressor: CV2-C100, Output Pressure 8bar, - LISTING 2830072

![Français]()

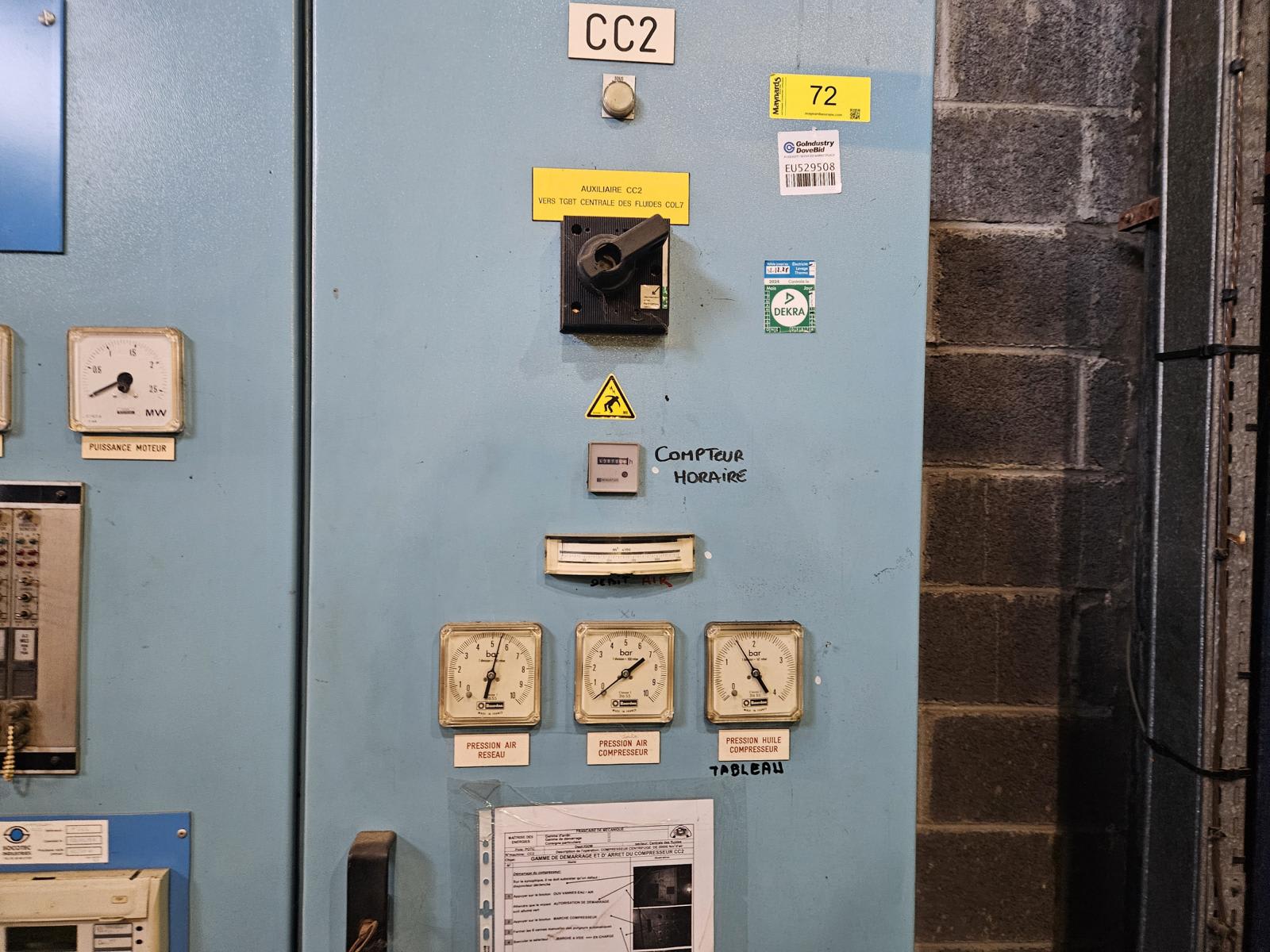

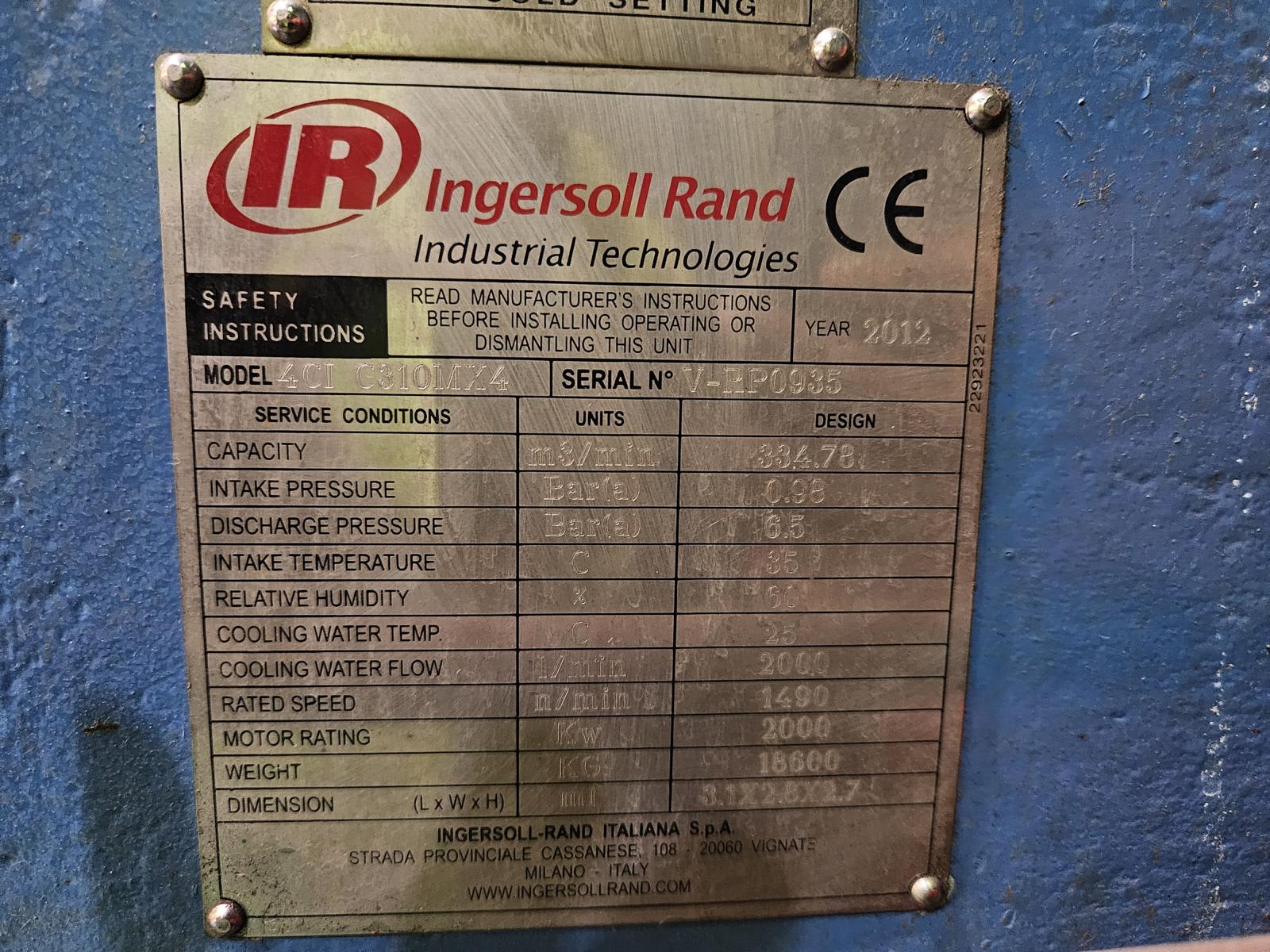

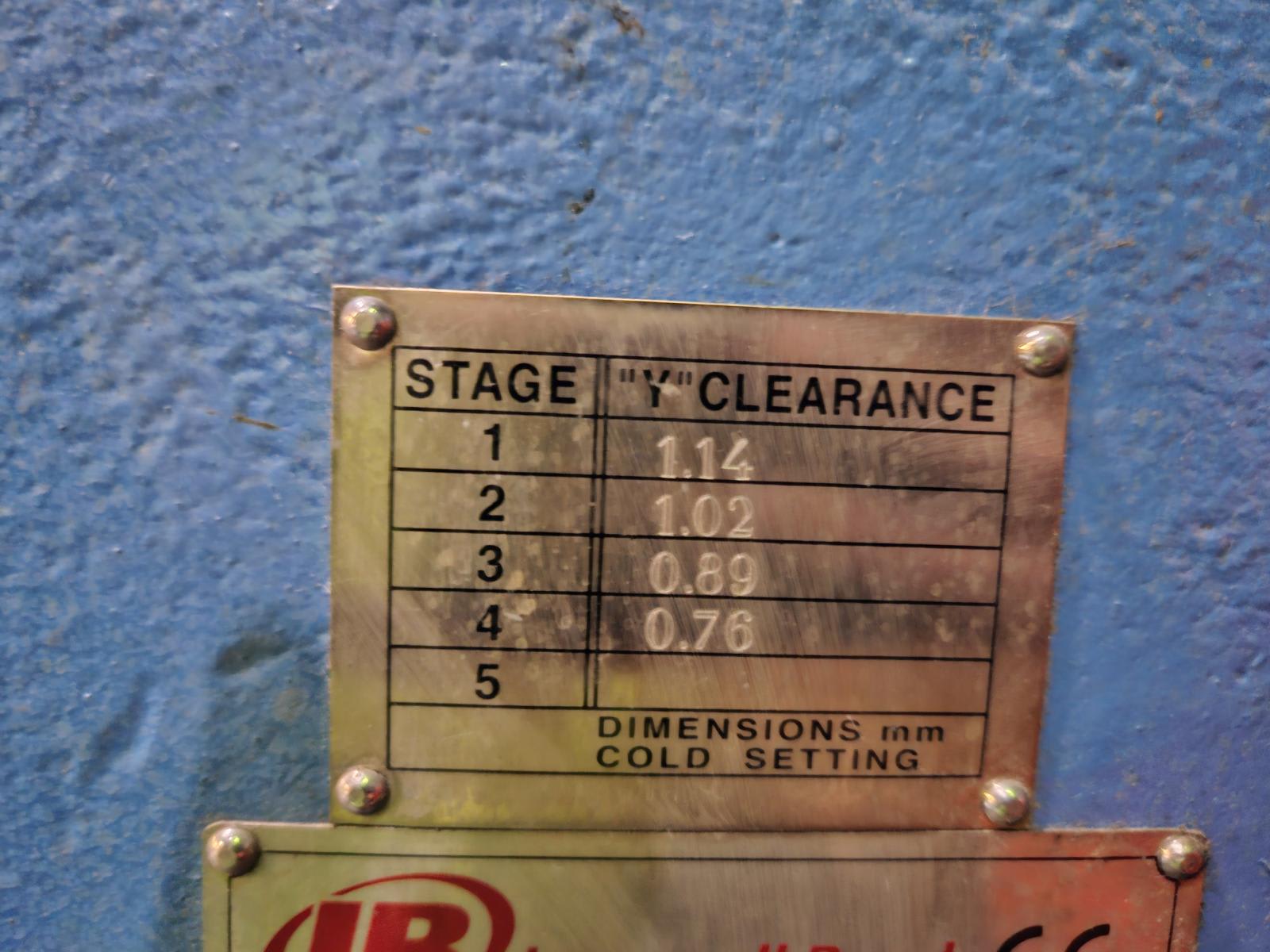

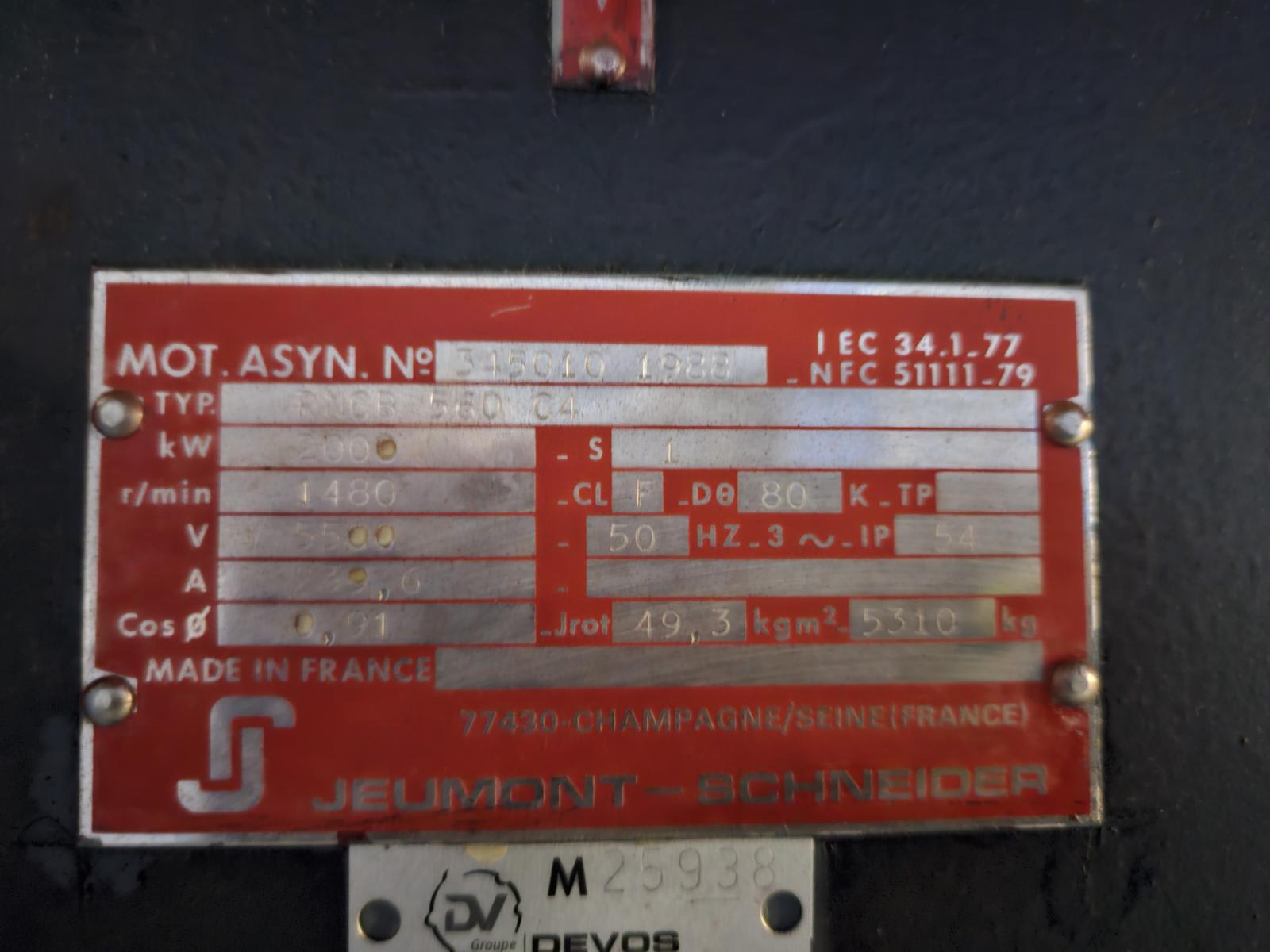

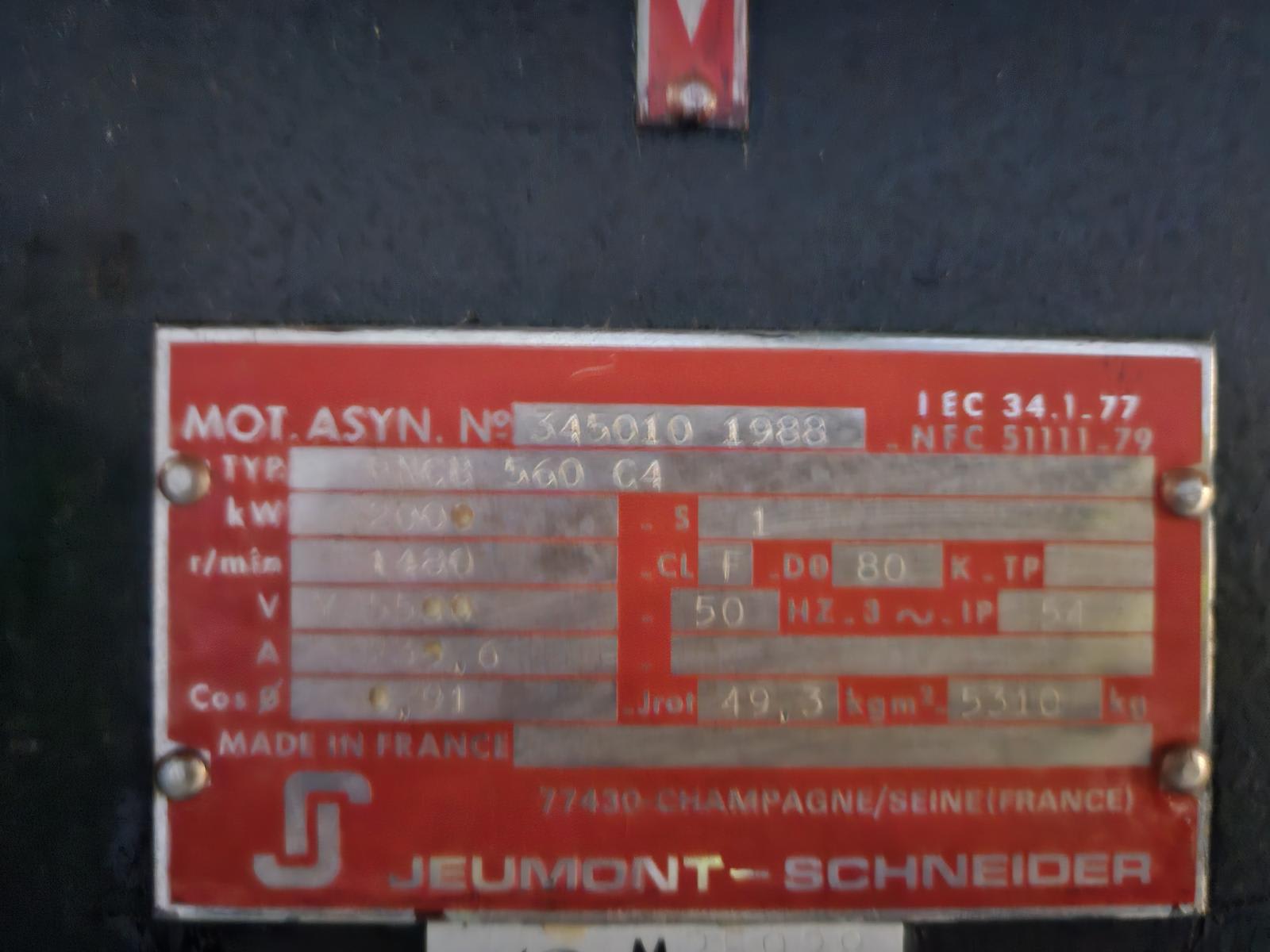

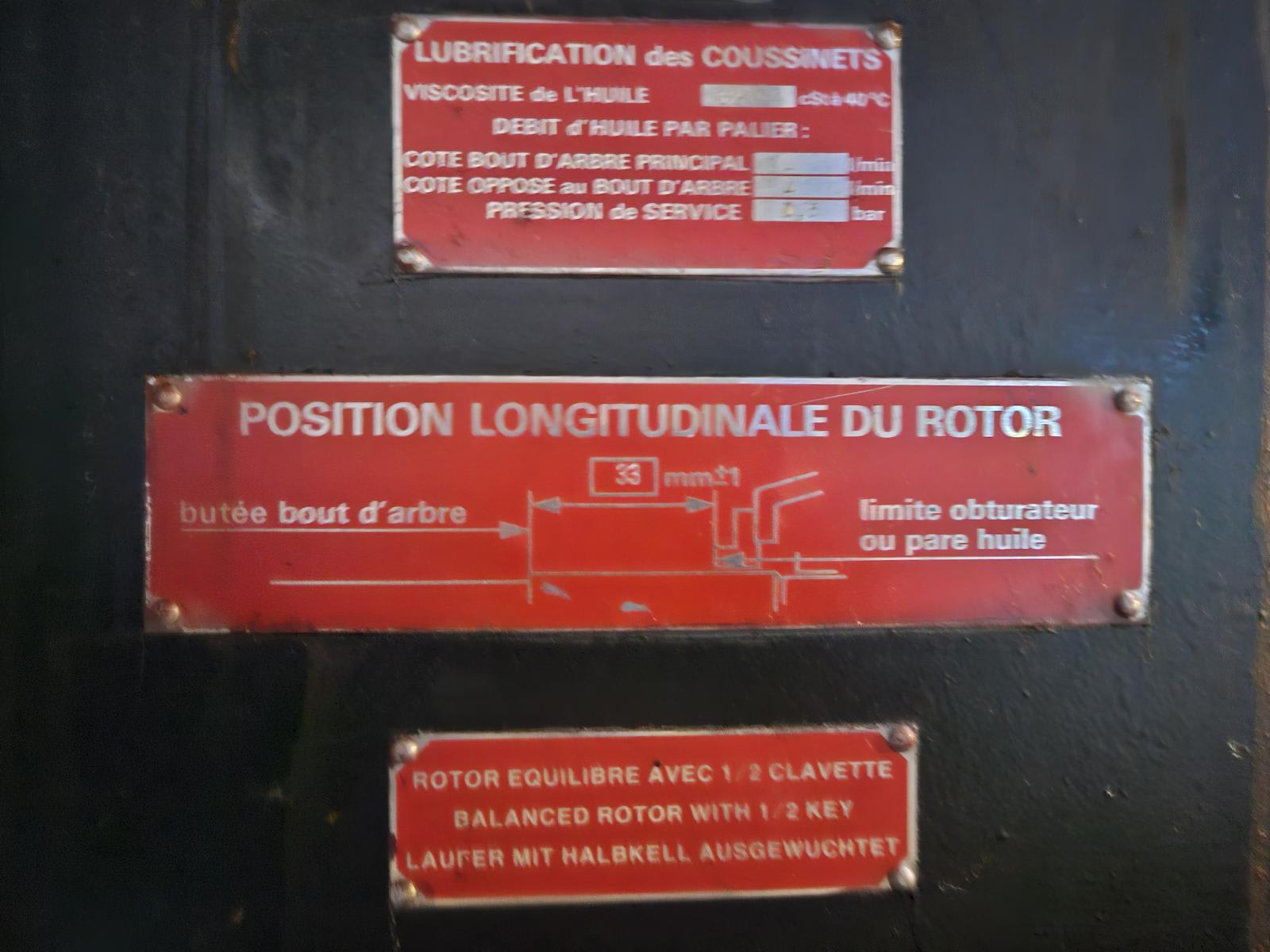

Compressor INGERSOLL RAND JEUMONT-SCHNEIDER | 1988

Motor Drive: RNCR 560-C4, 2.000kW / 1.480rpm, 5.500V / 50Hz, weight 5,3to /// Compressor: 4CI G3101/1X4, capacity 334qbm/min and 6,5bar, LxWxH 3,1x2,8x2,7m, weight 19to - LISTING 2830073

![Français]()

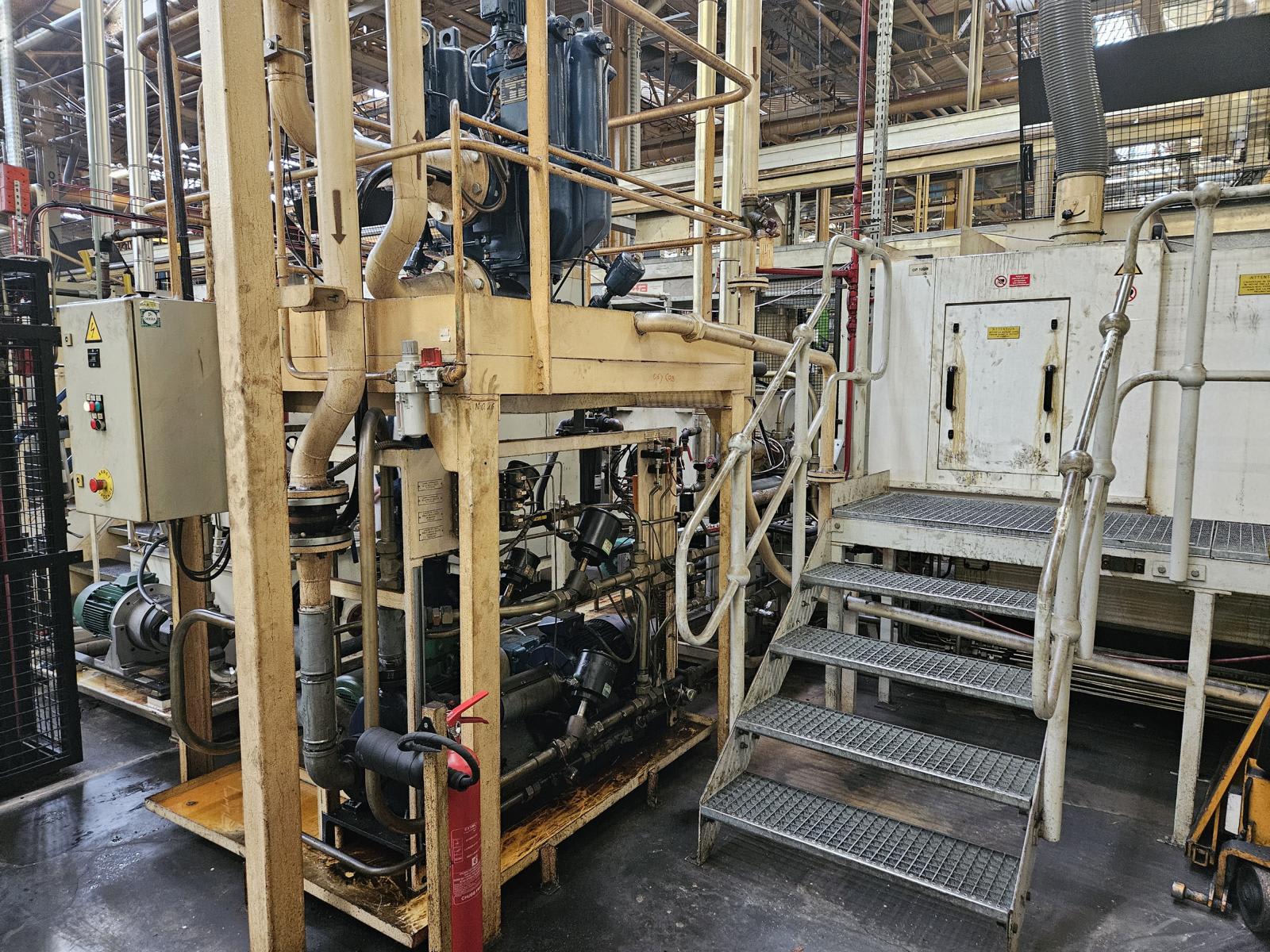

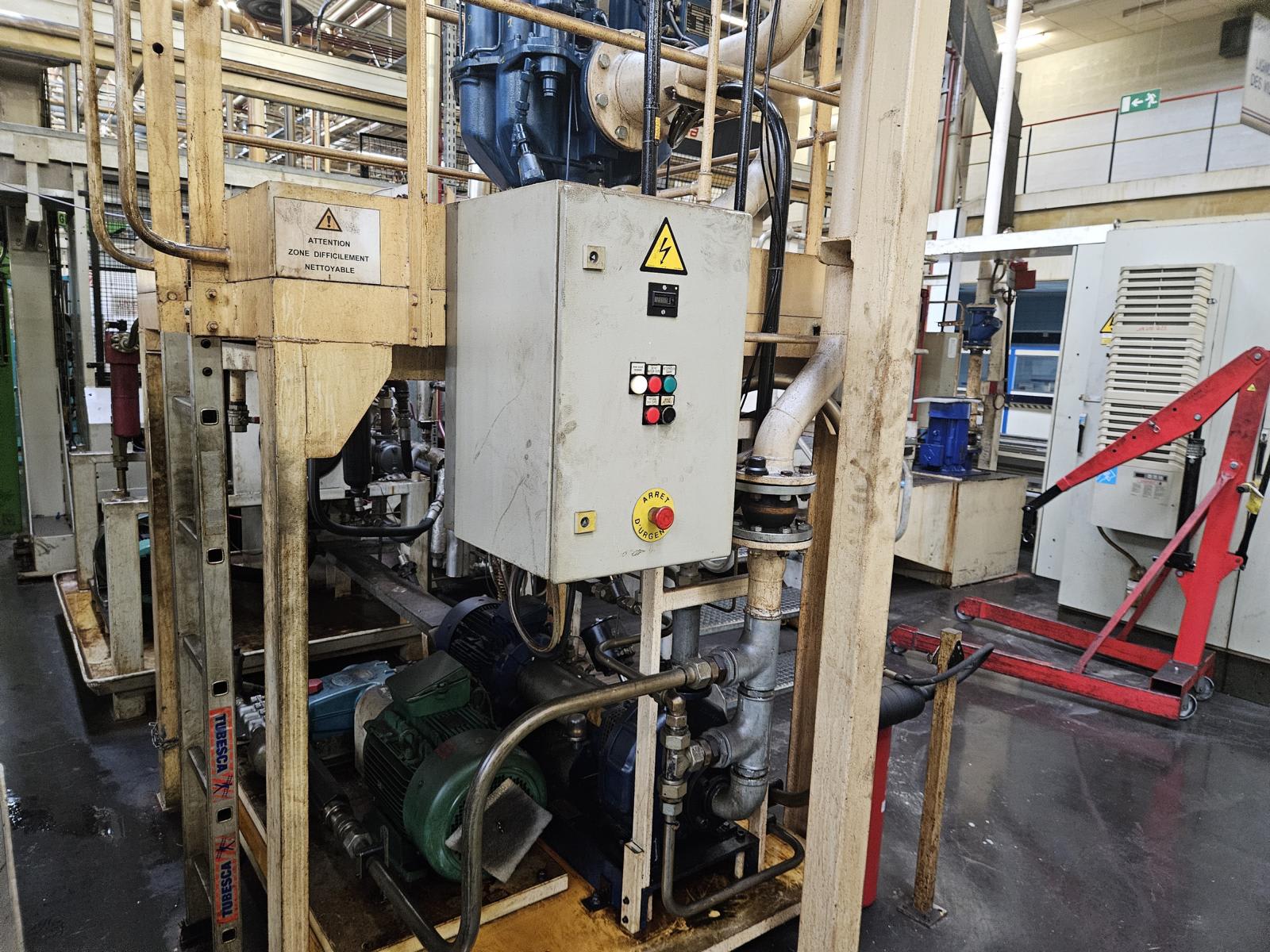

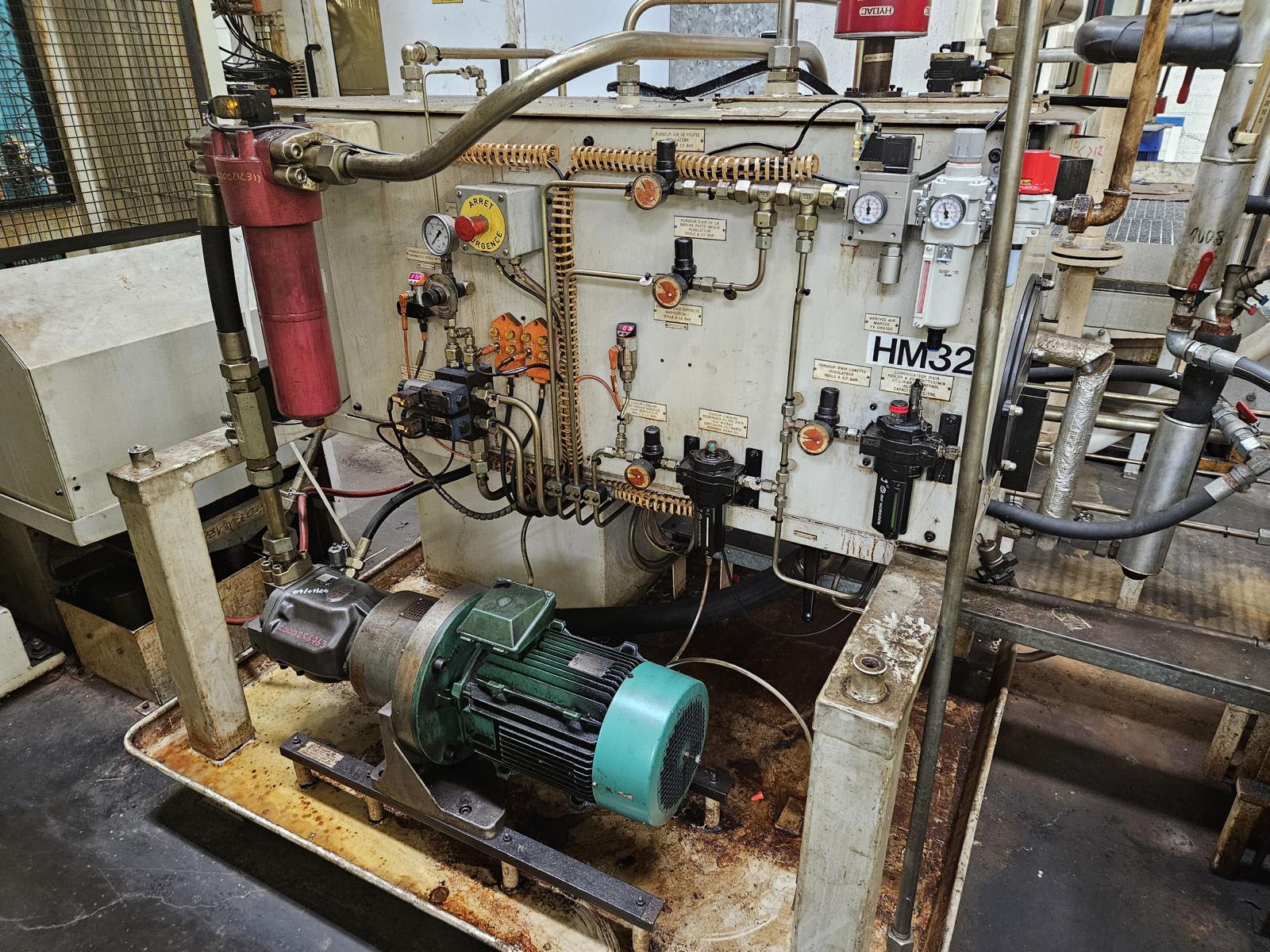

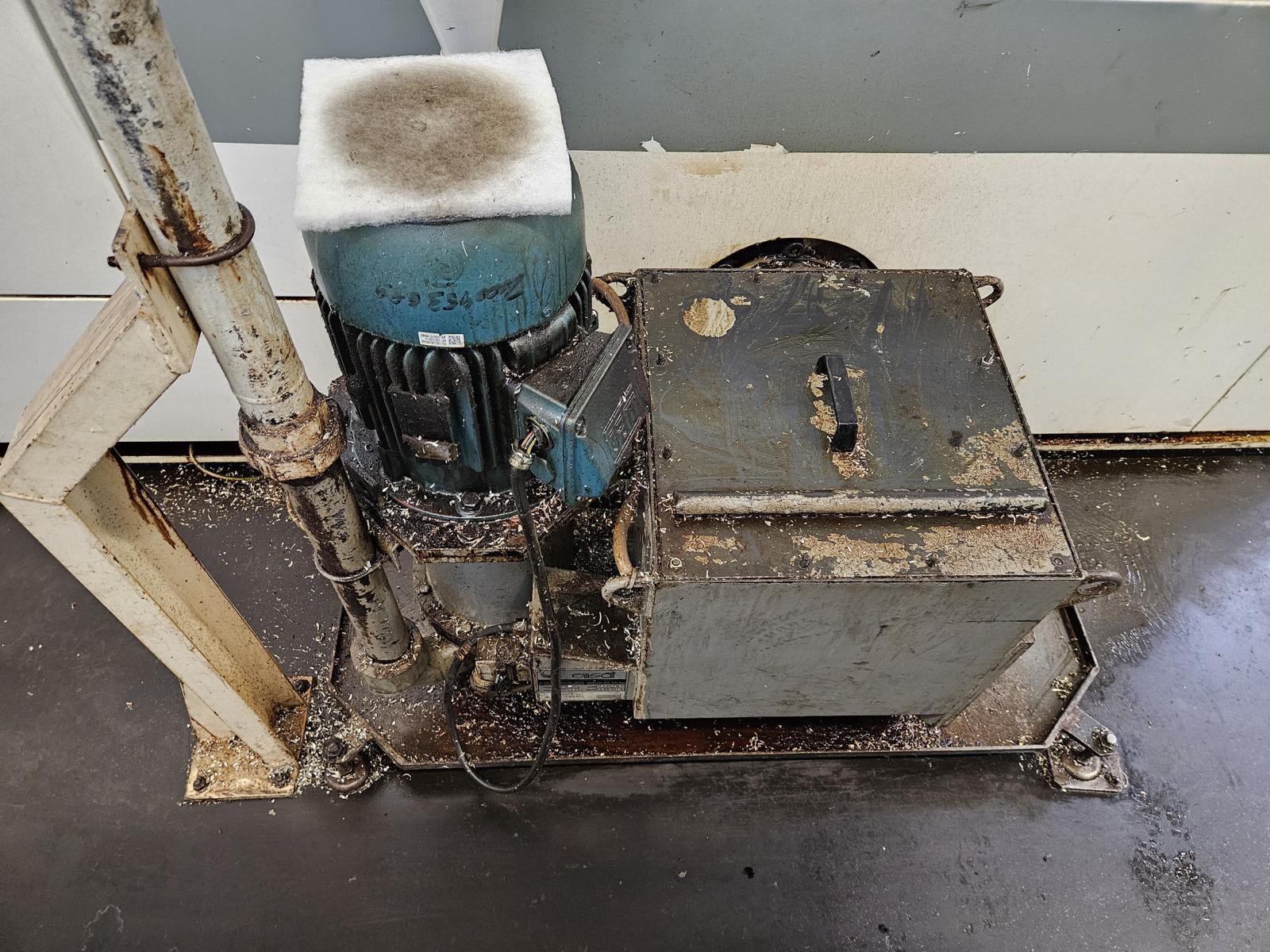

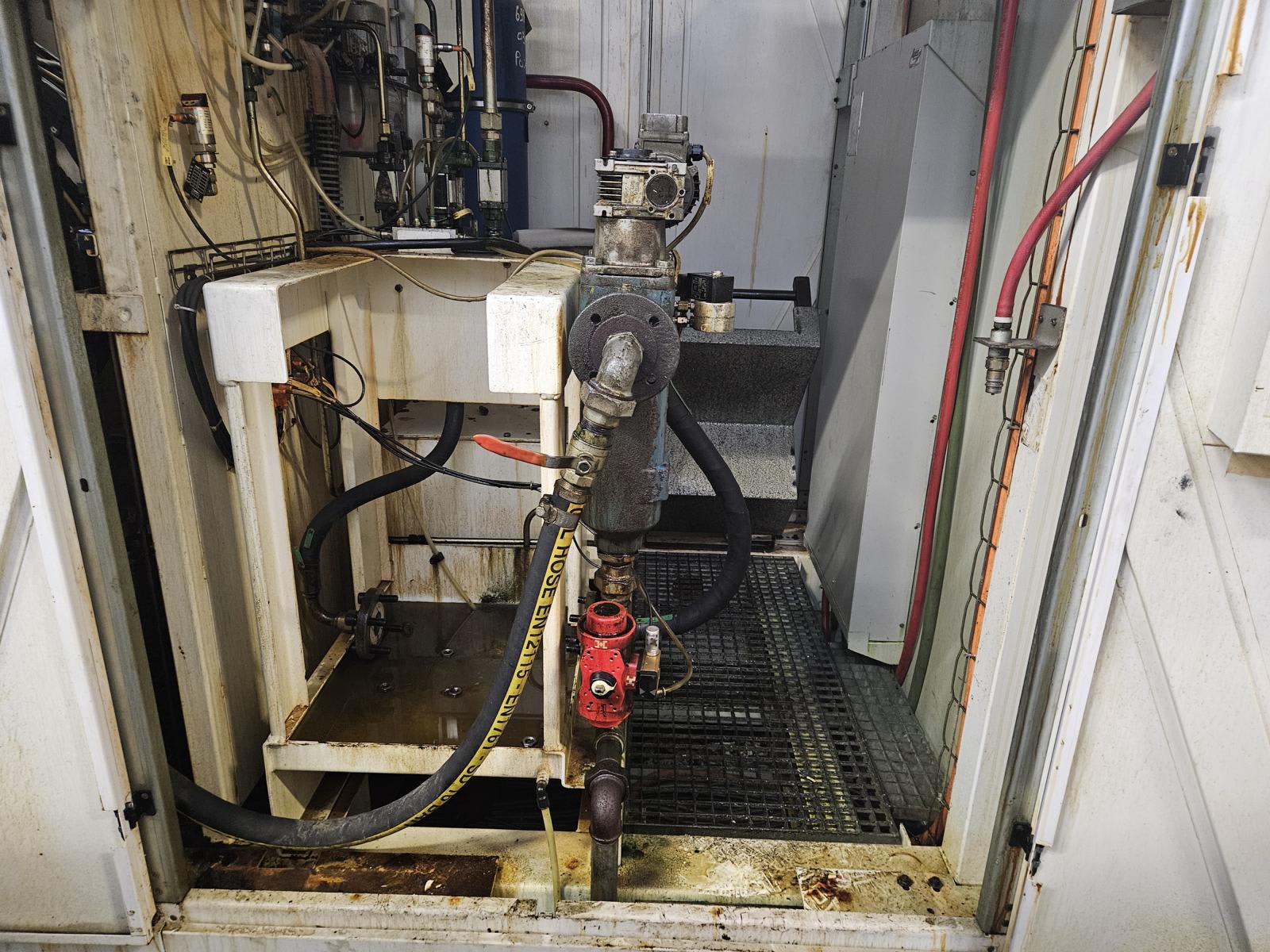

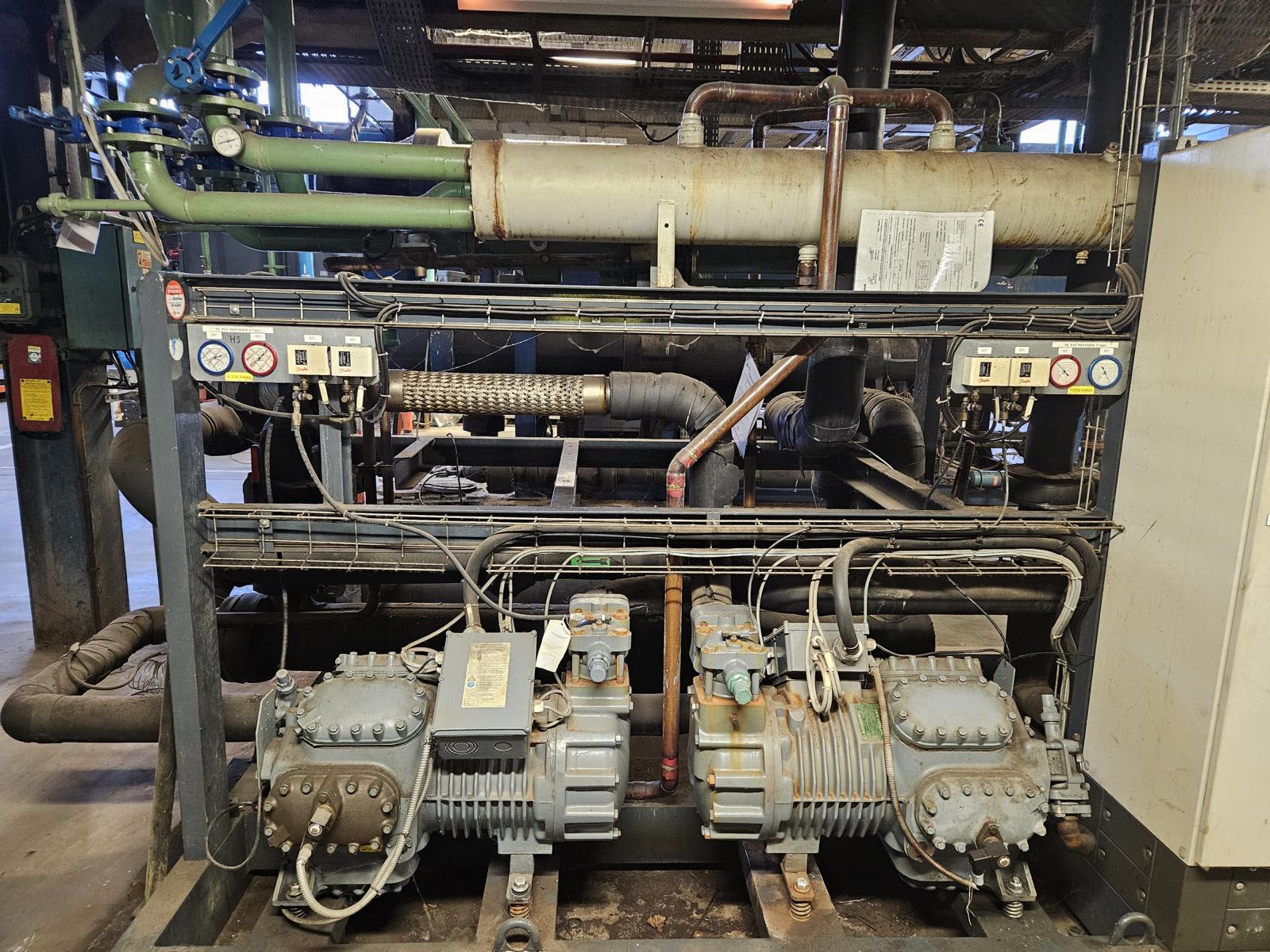

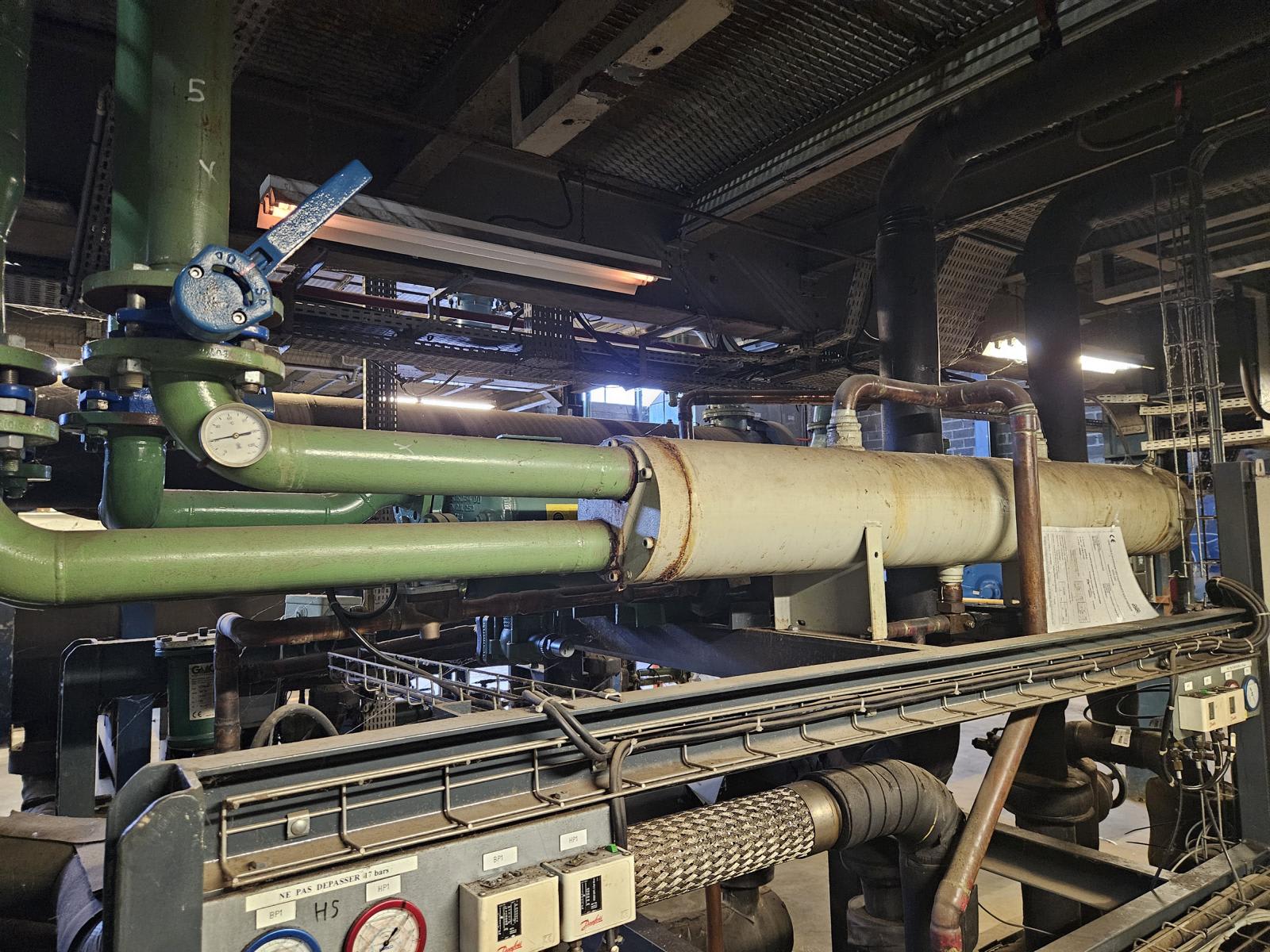

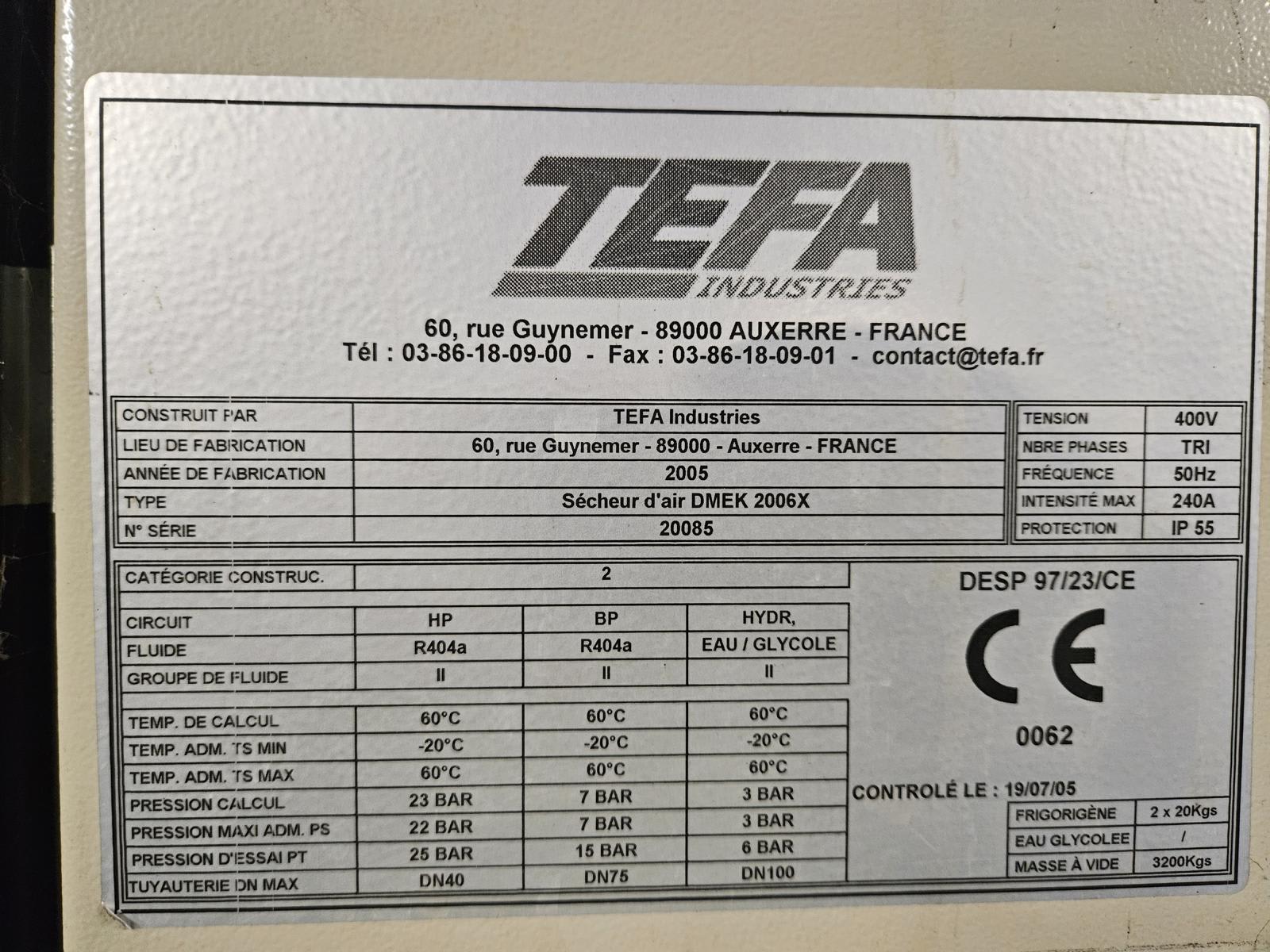

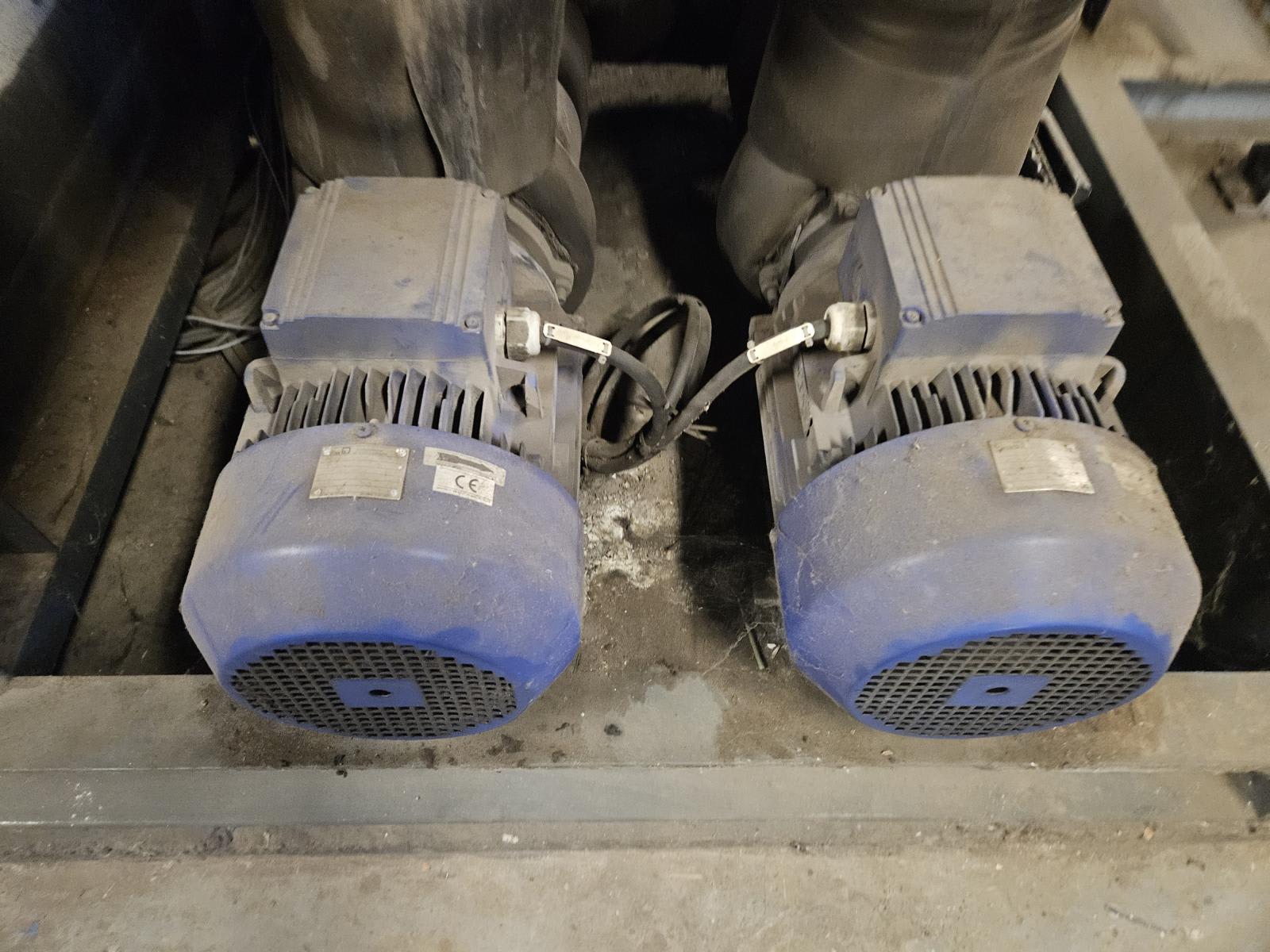

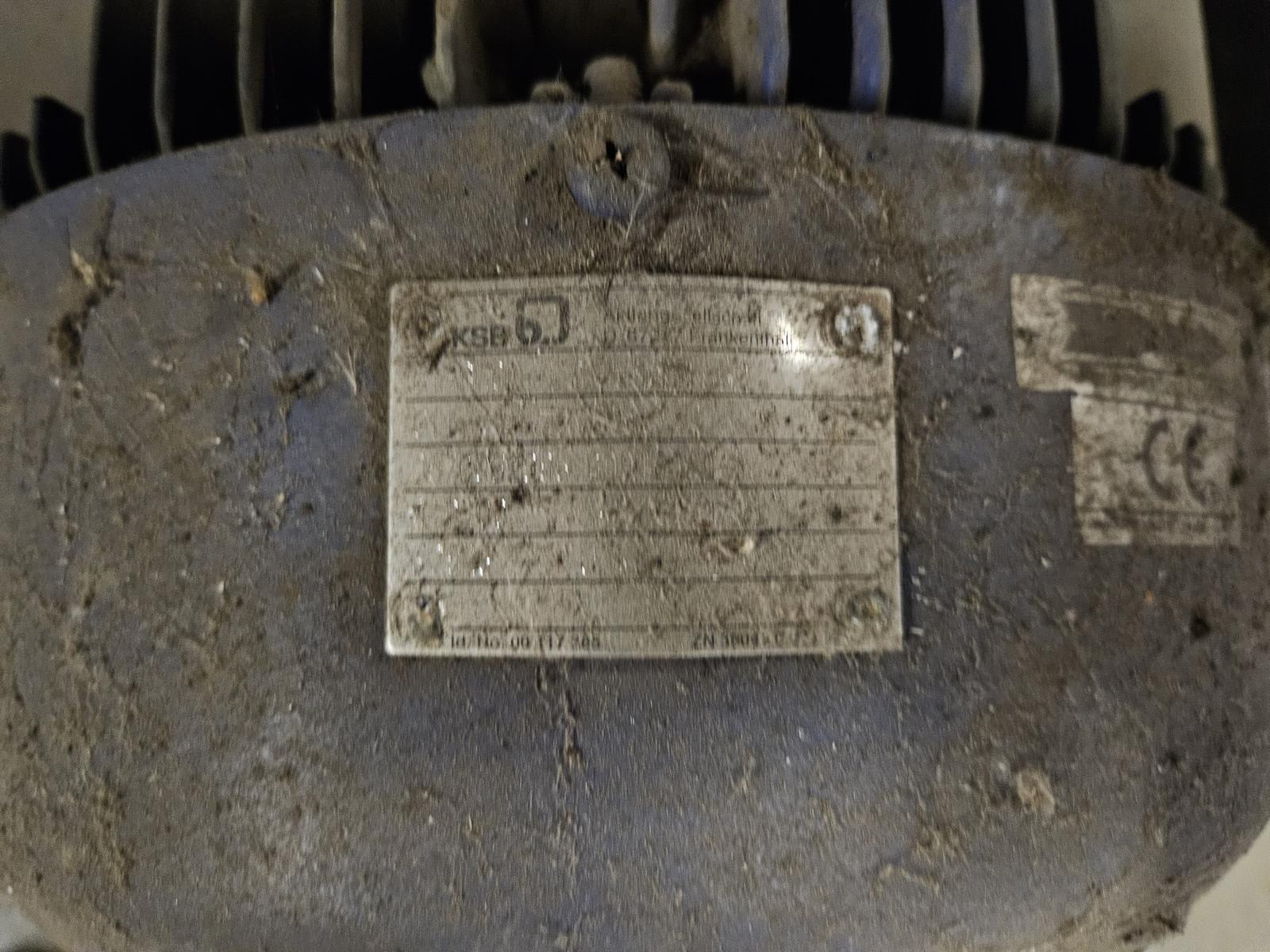

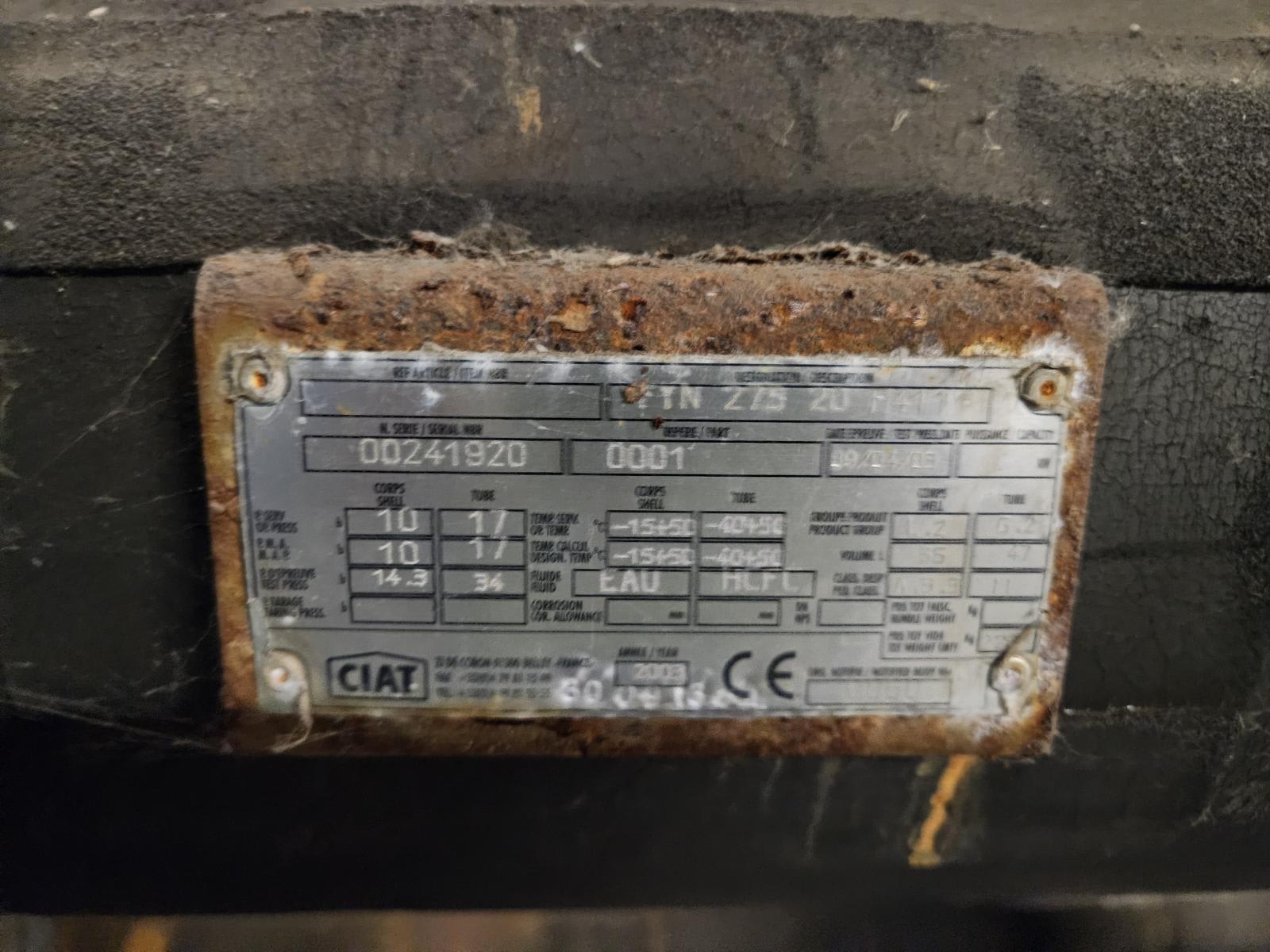

Coolant Unit TEFA Industries | 2005

HP-Loop: R404A, 60Deg C, 23bar, DN40 /// BP_Loop: R400A, 60Deg C, 7bar, DN75 /// HYDR-Loop: 60DegC, 3bar, DN100 /// 400V 50Hz, 240A, IP55 - LISTING 2830074

![Français]()

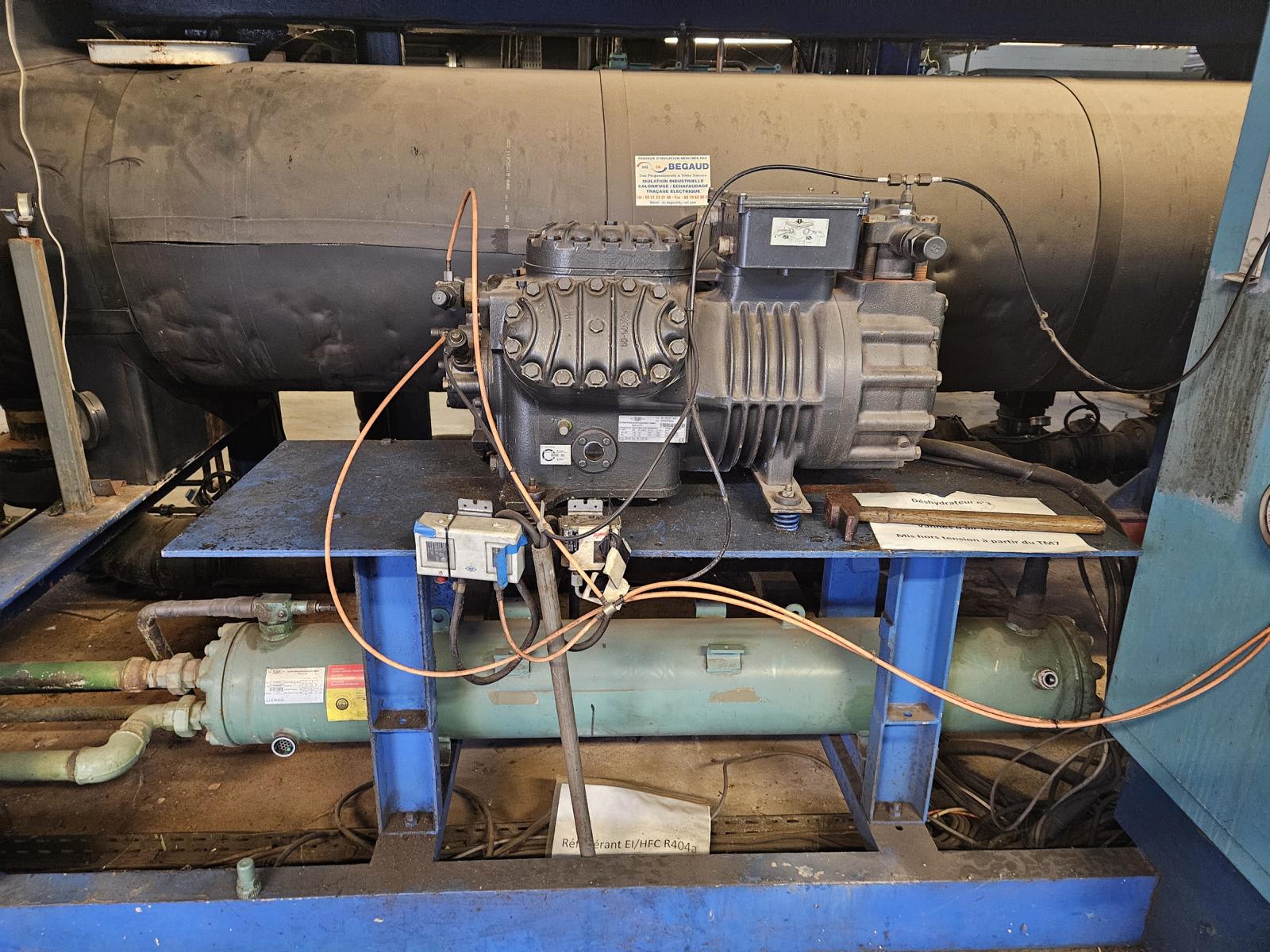

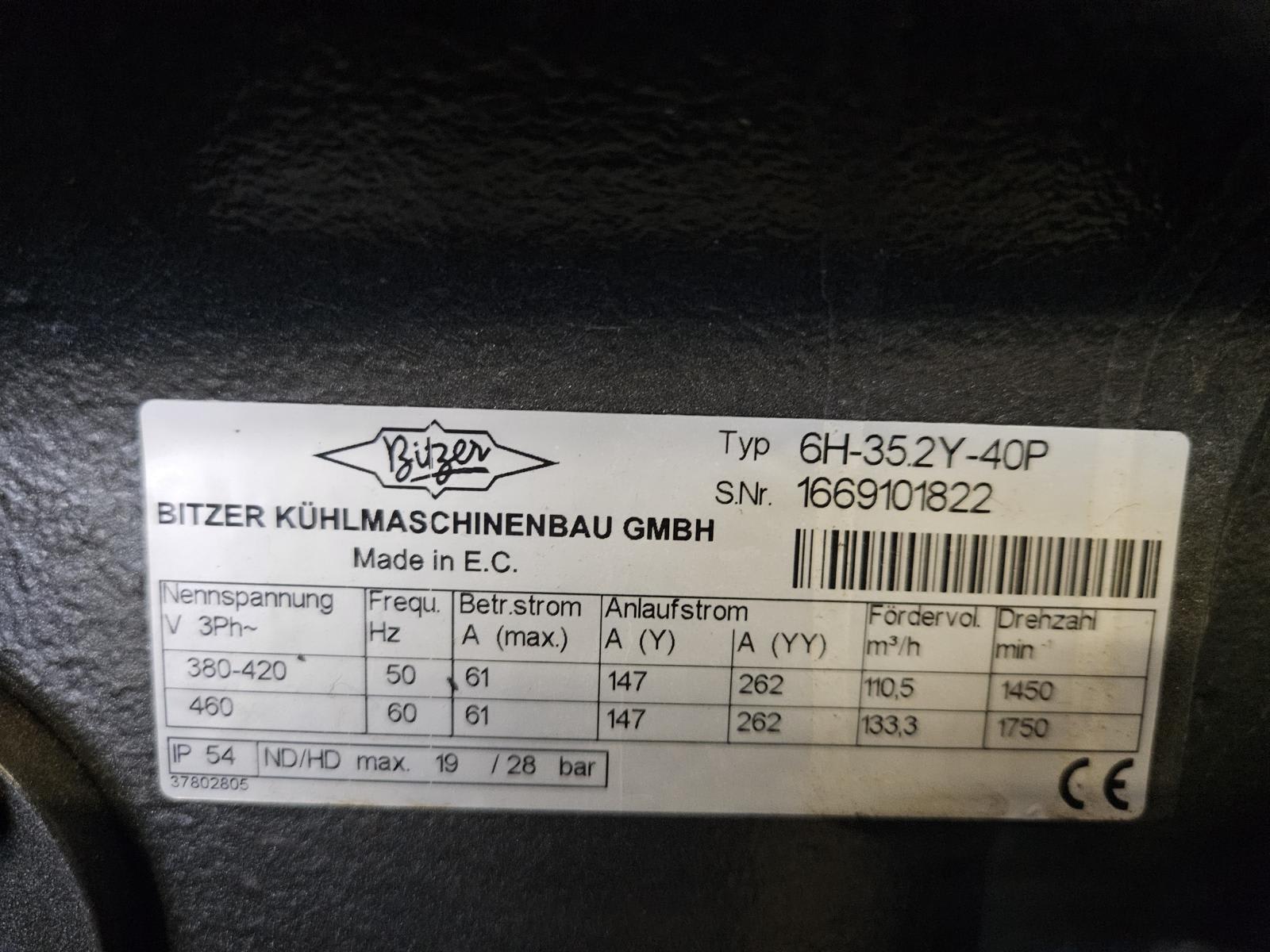

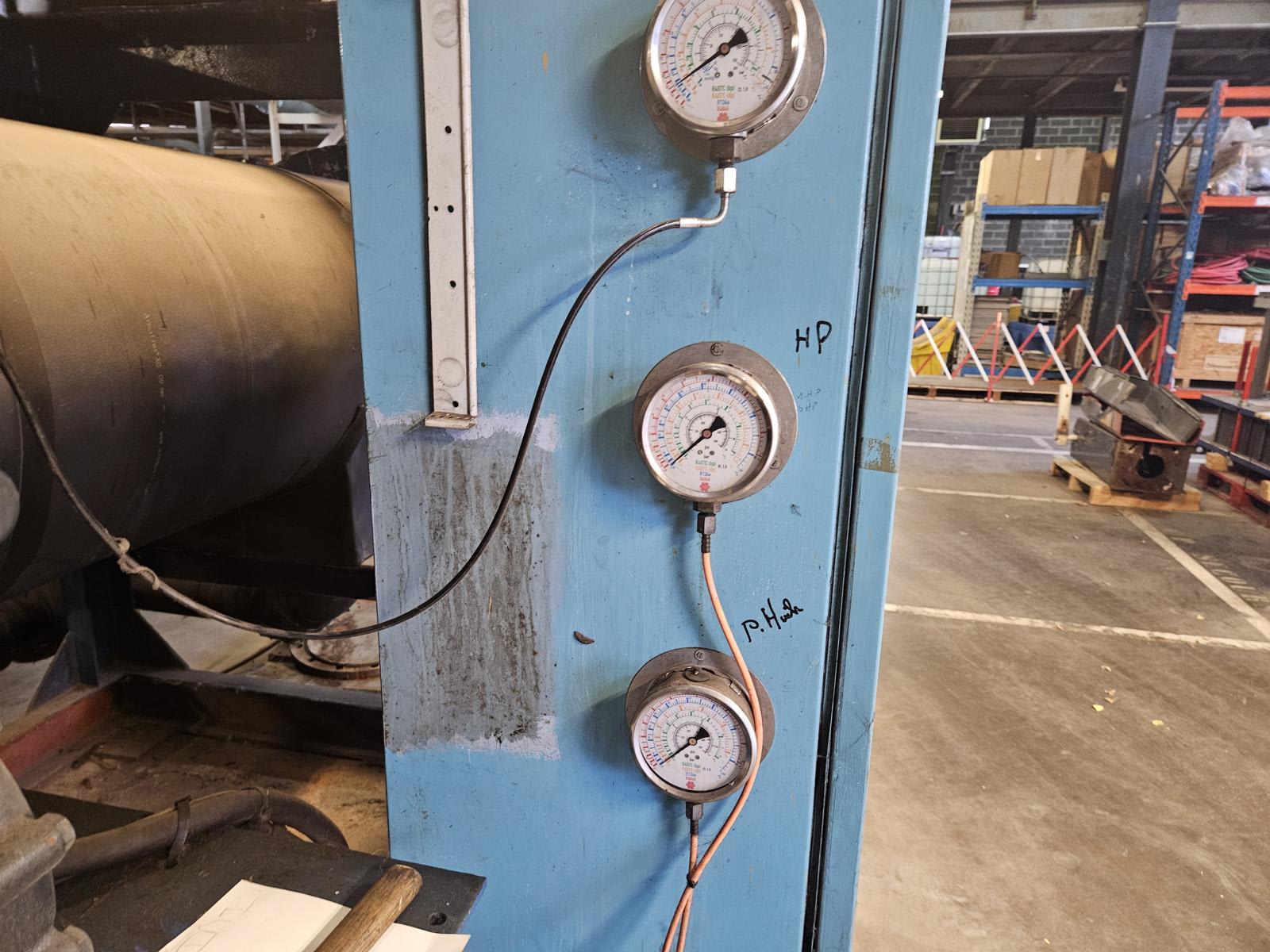

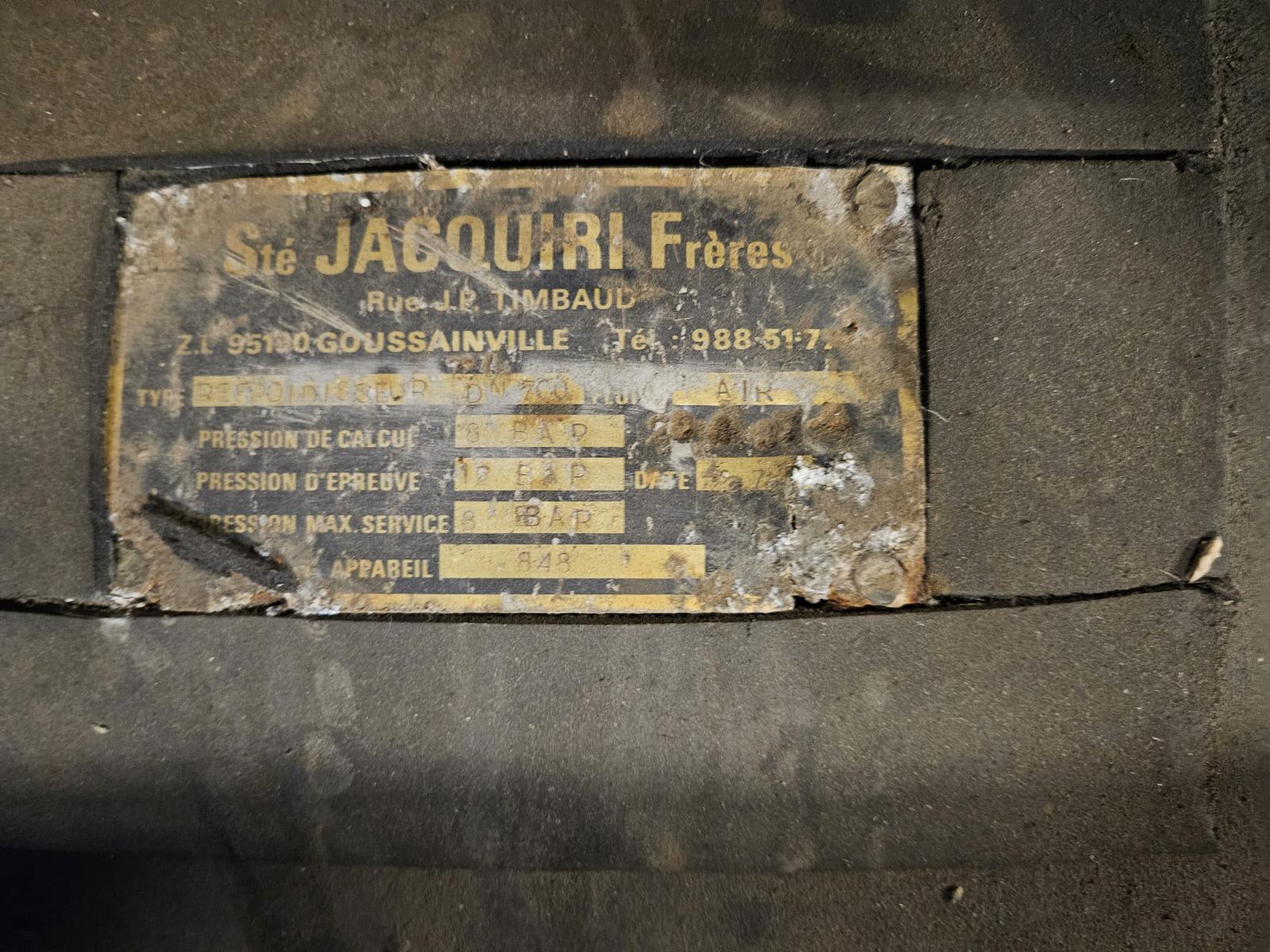

Coolant Unit BITZER K1053H 6H-35.2Y-40P | 2007

Coolant Unit: Fluid-Group: 2, Volume 40 / 9,3 L, min/max Temp -10/120DegC / -10/95DegC, max pressures: 33 / 10 bar /// Motor: 400V 50Hz 61A, 110qbm/h, 1.450rpm, ND/HD max 19/28bar - LISTING 2830075

![Français]()

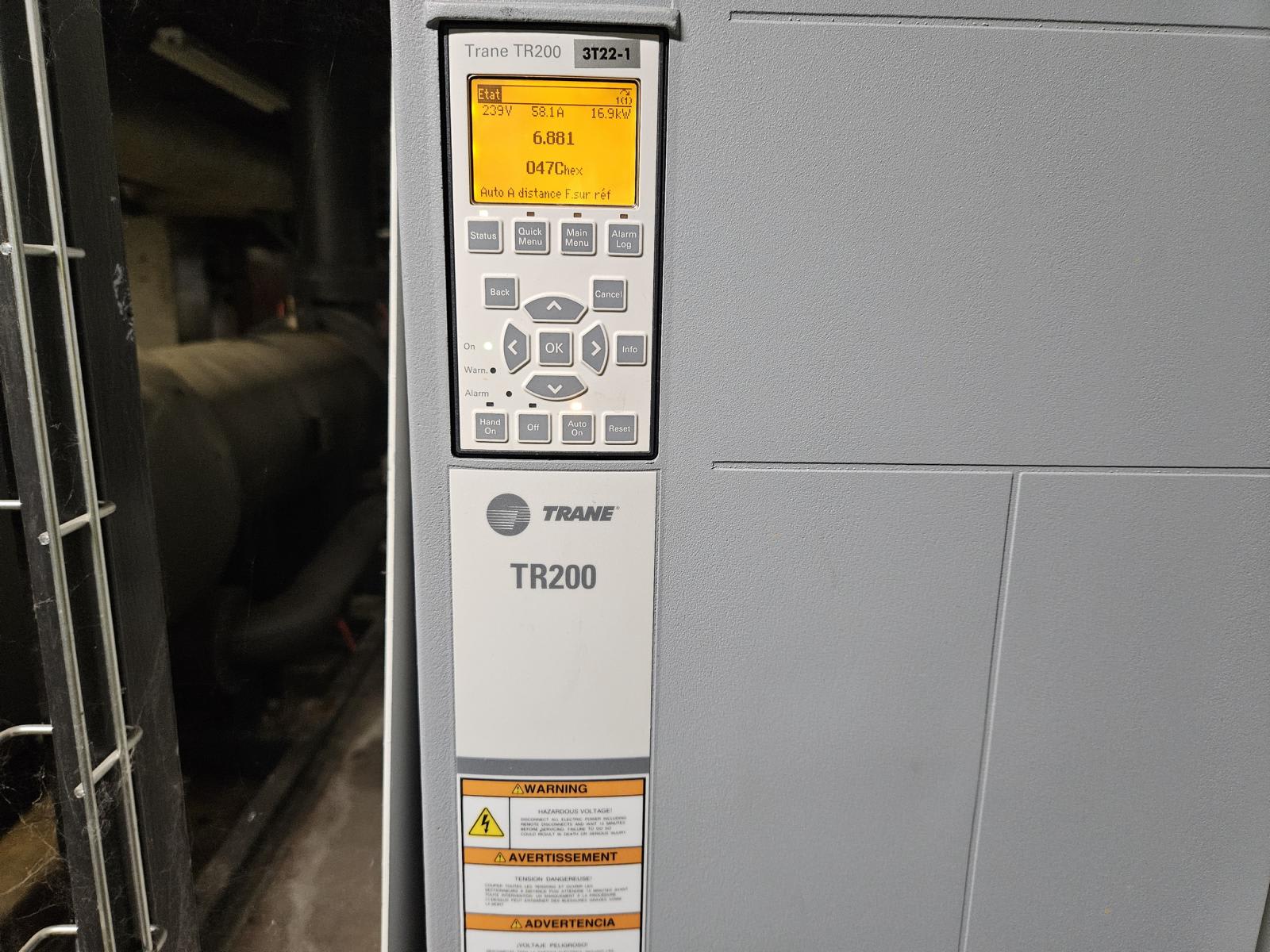

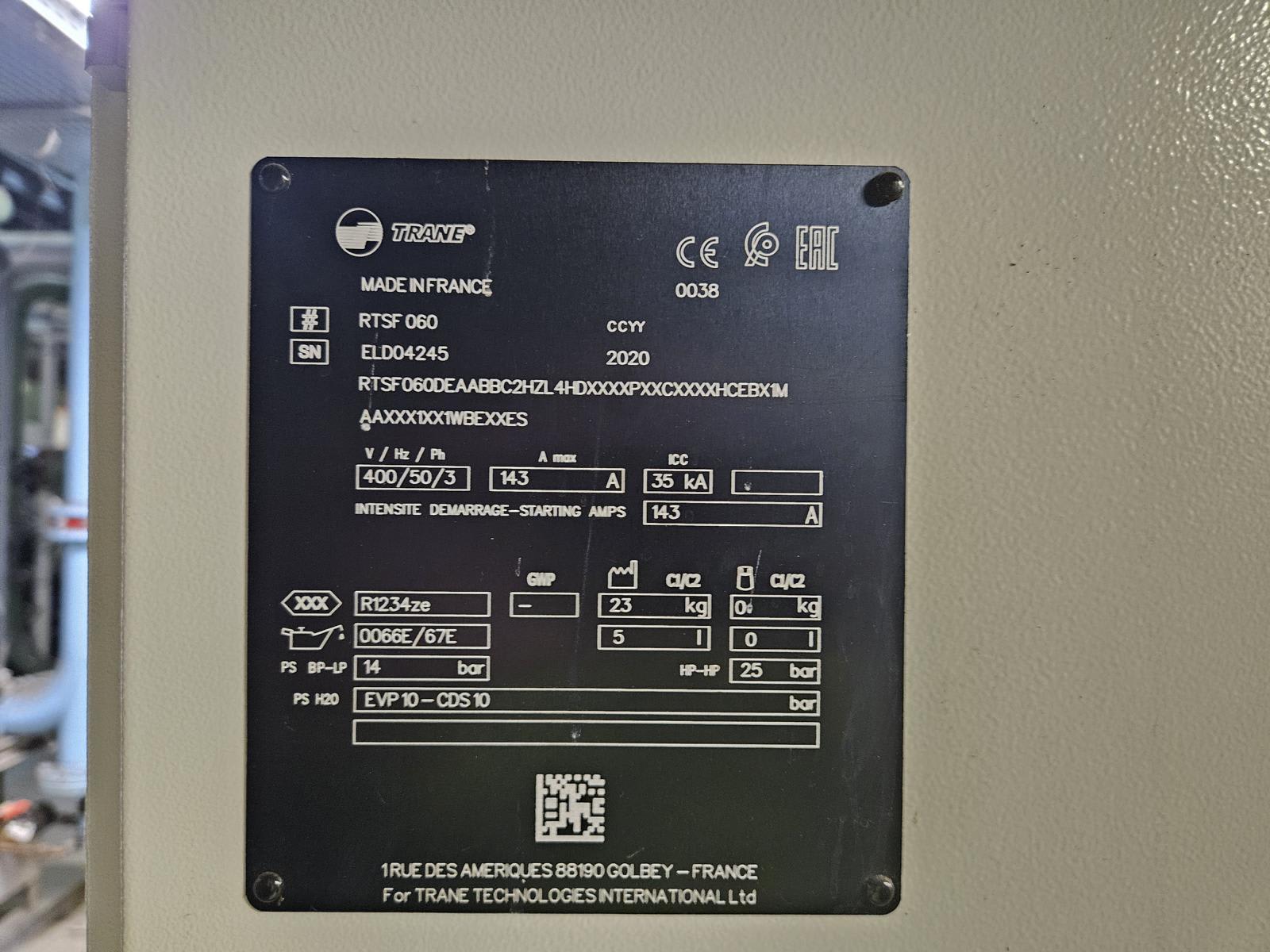

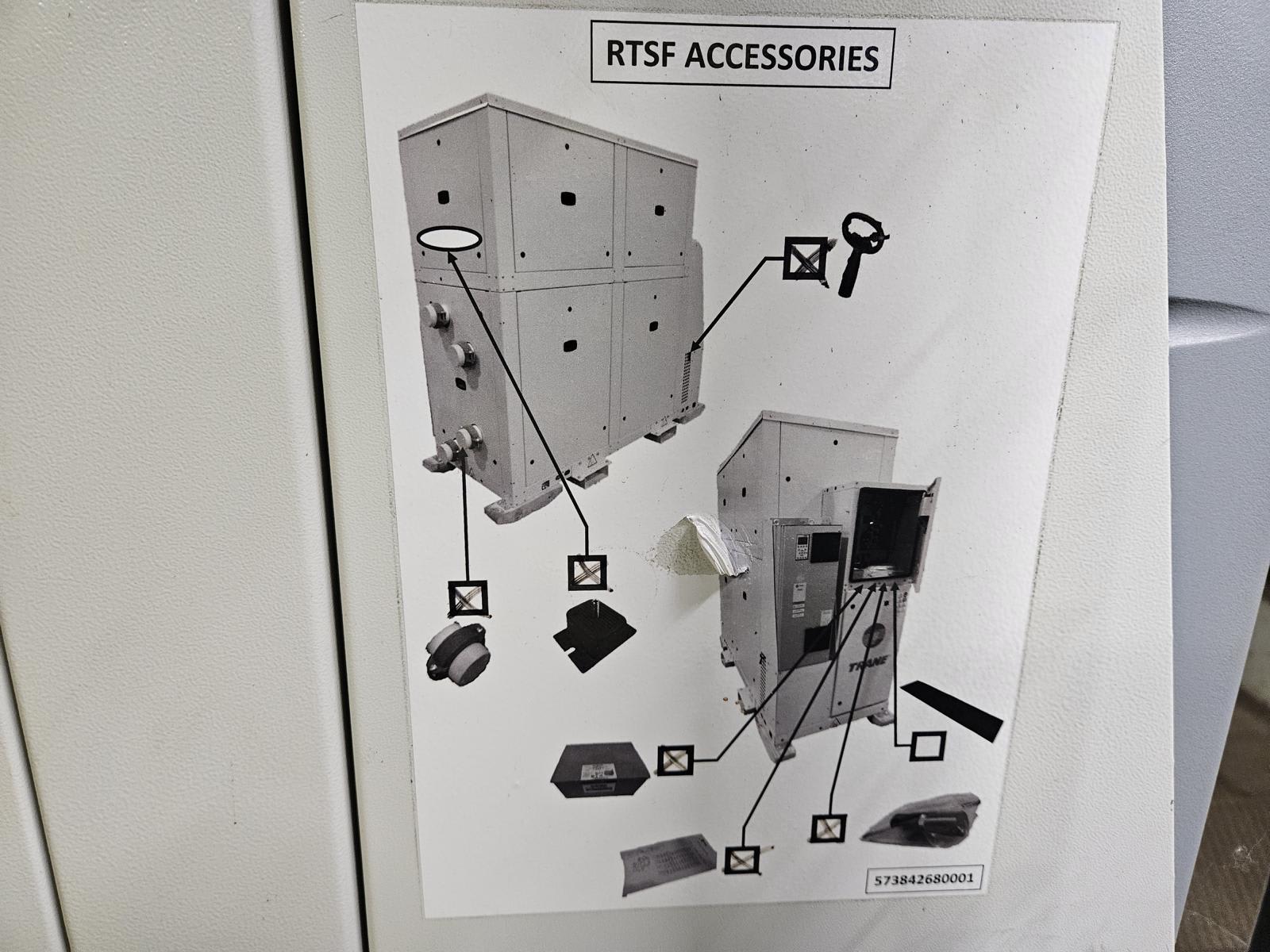

Coolant Unit TRANE RTSF 060 | 2020

coolant liquid: R1234ze, 23kg, BP-LP 14bar / HP-HP 25bar, 400V 50Hz 143A 35kA - LISTING 2830076

![Français]()

- LISTING 2830077

![Français]()

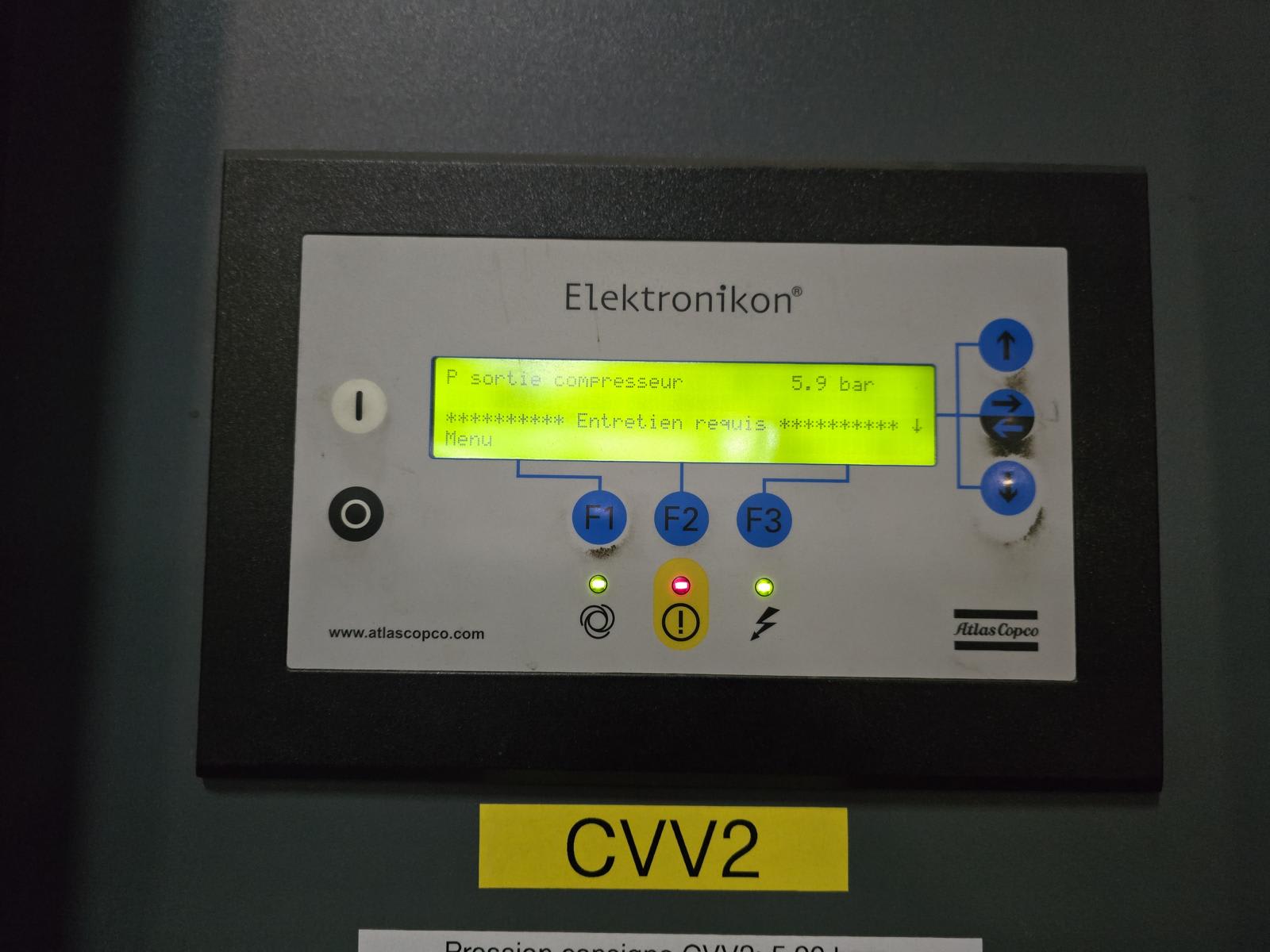

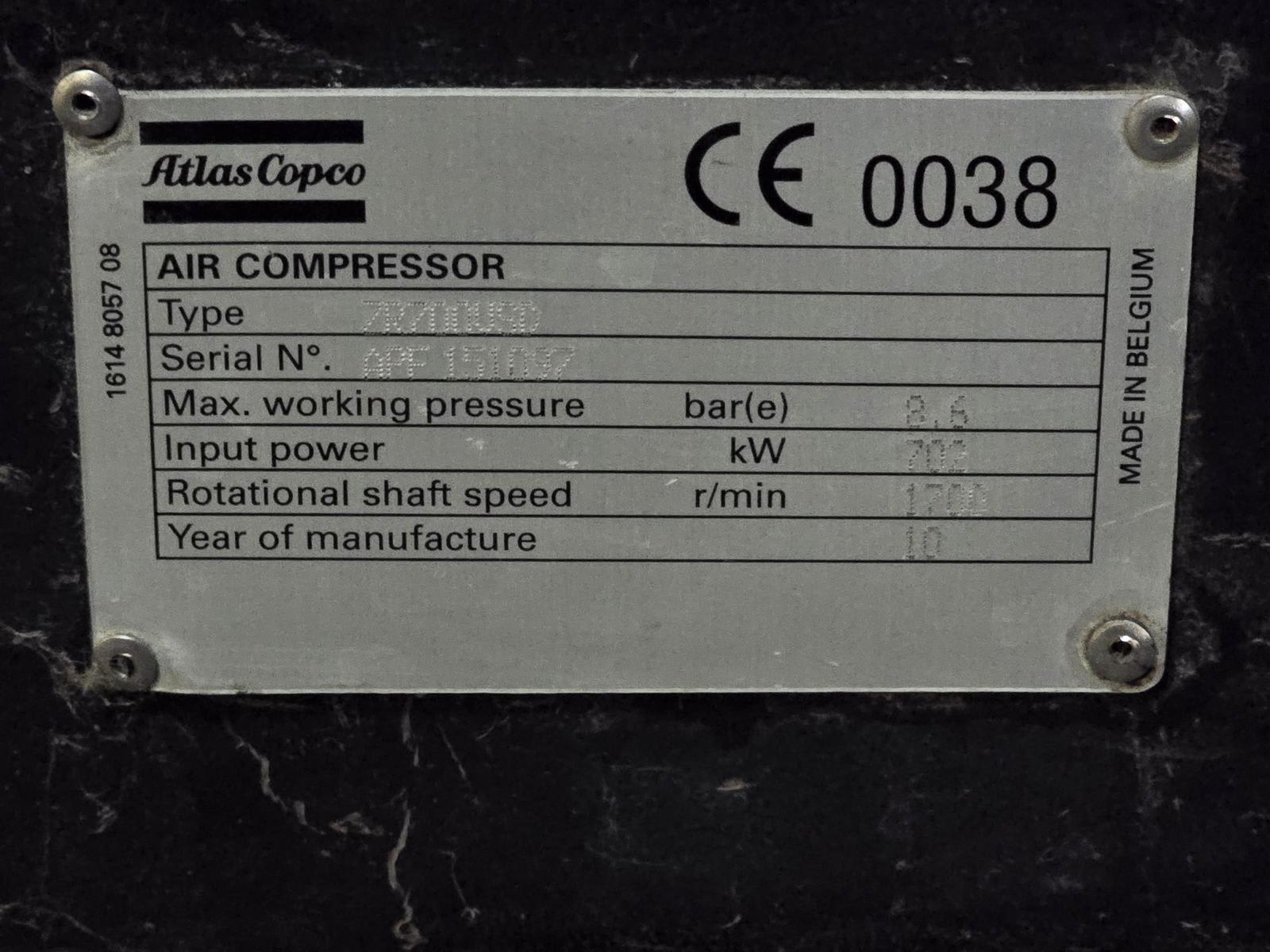

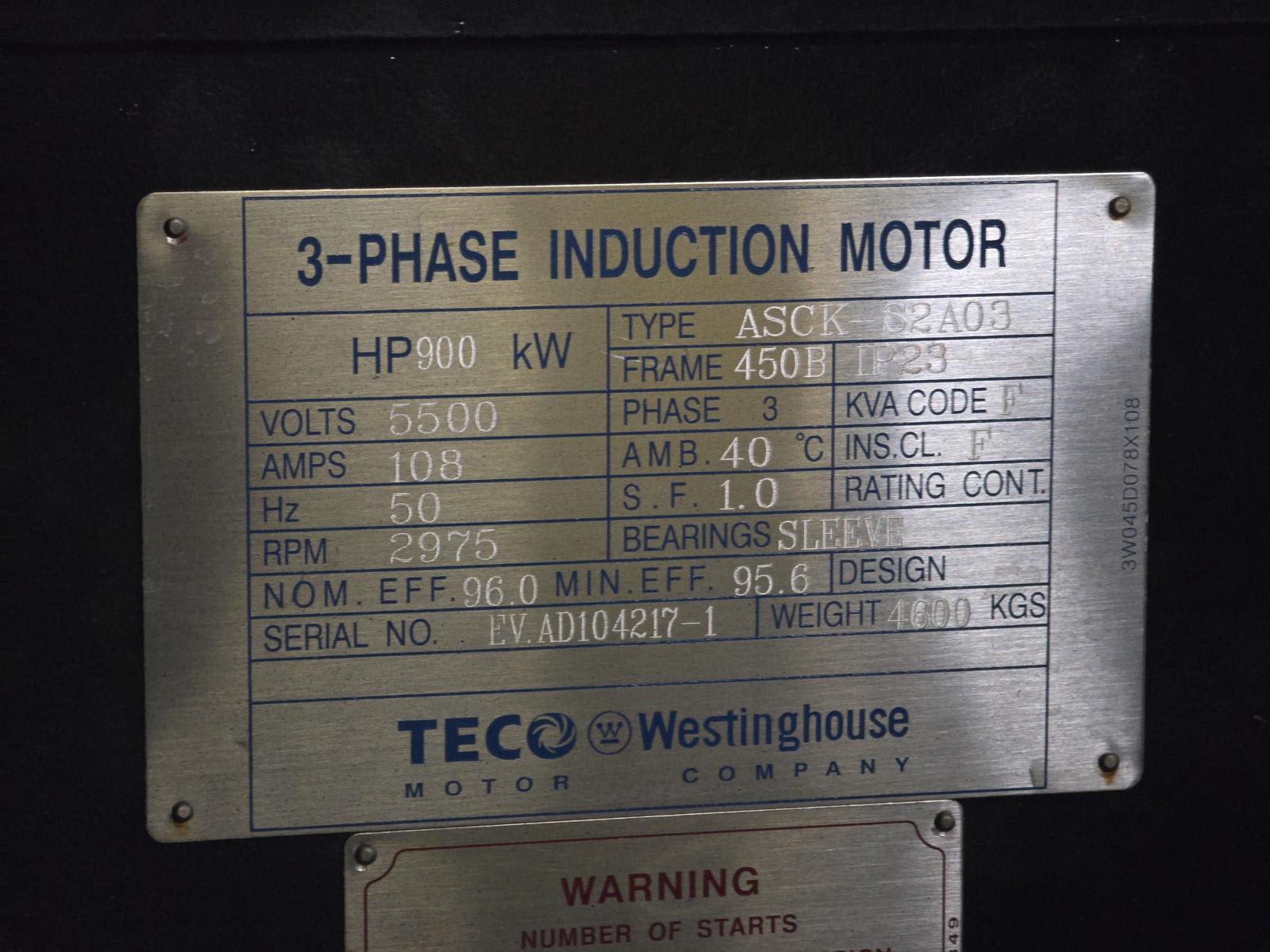

Compressor INGERSOLL RAND TECO Westinghaus C950-C1 40MX3 ASCK-S2A03 | 2010

Motor: 5.500V 108A 900kW, weight 4,6to /// Compressor: 7.500 qbm/h, 6 bar. LxWxH 4,5x3,3x2,2m, weight 12,5to - LISTING 2830078

![Français]()

- LISTING 2830079

![Français]()

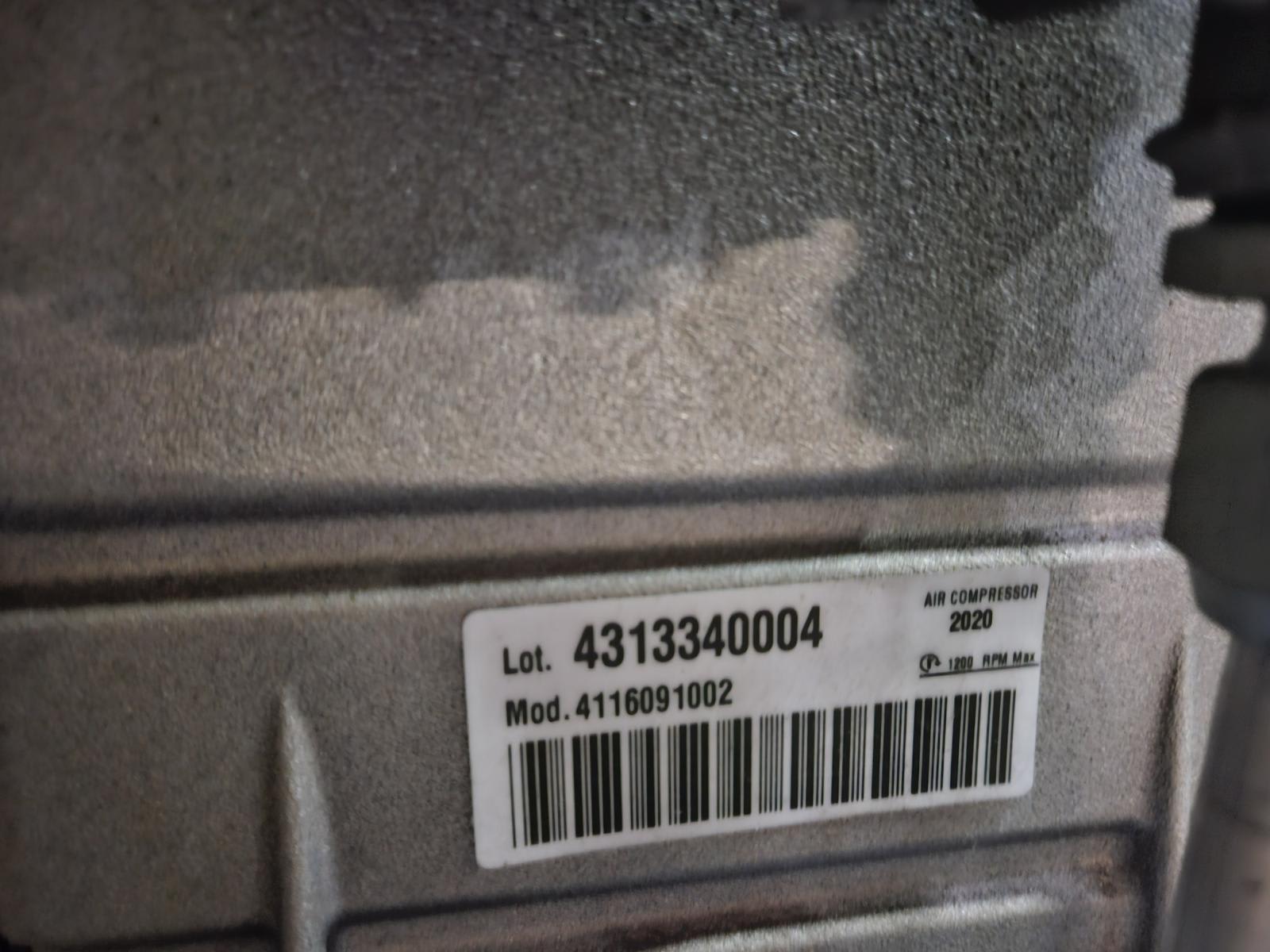

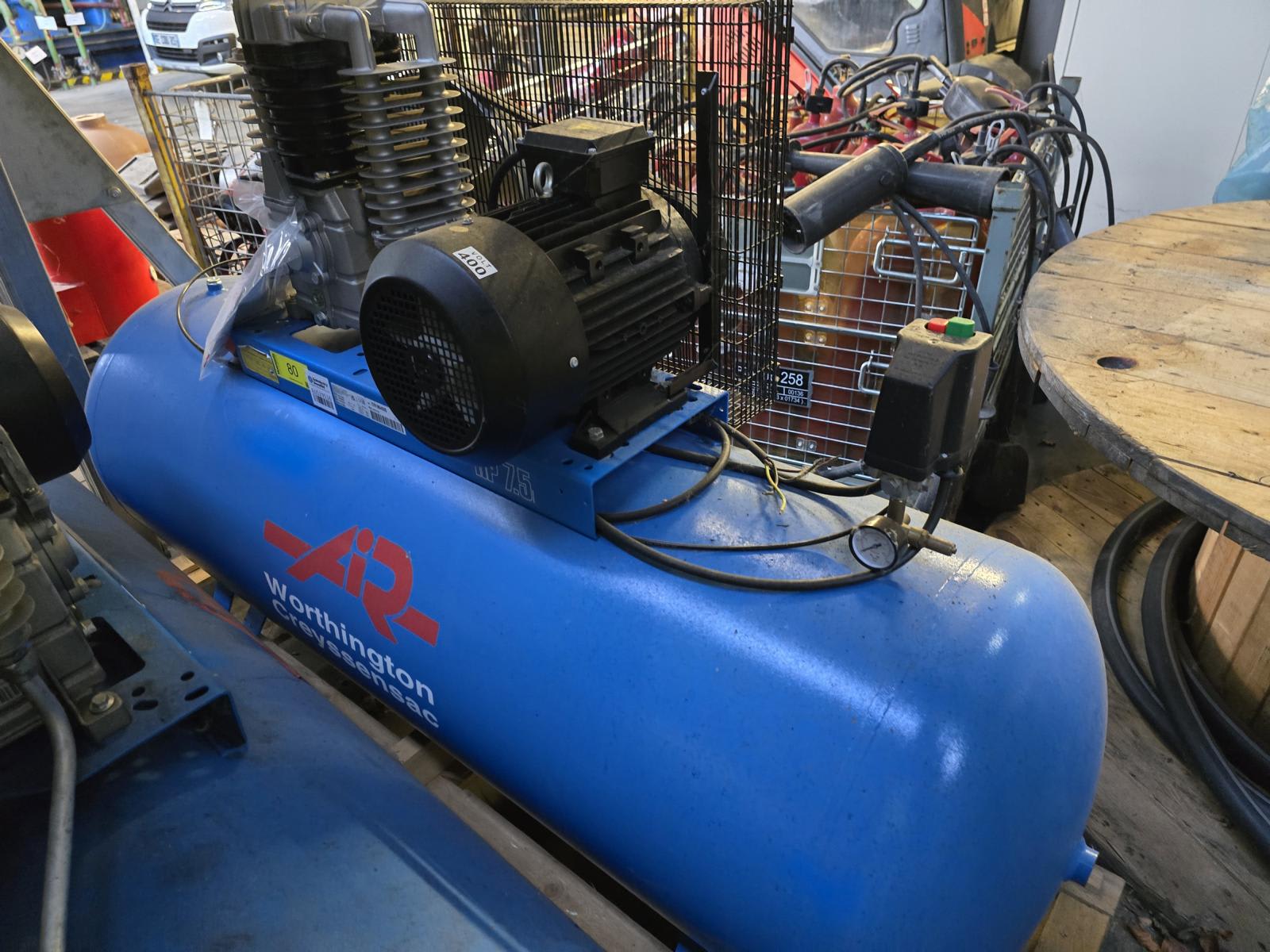

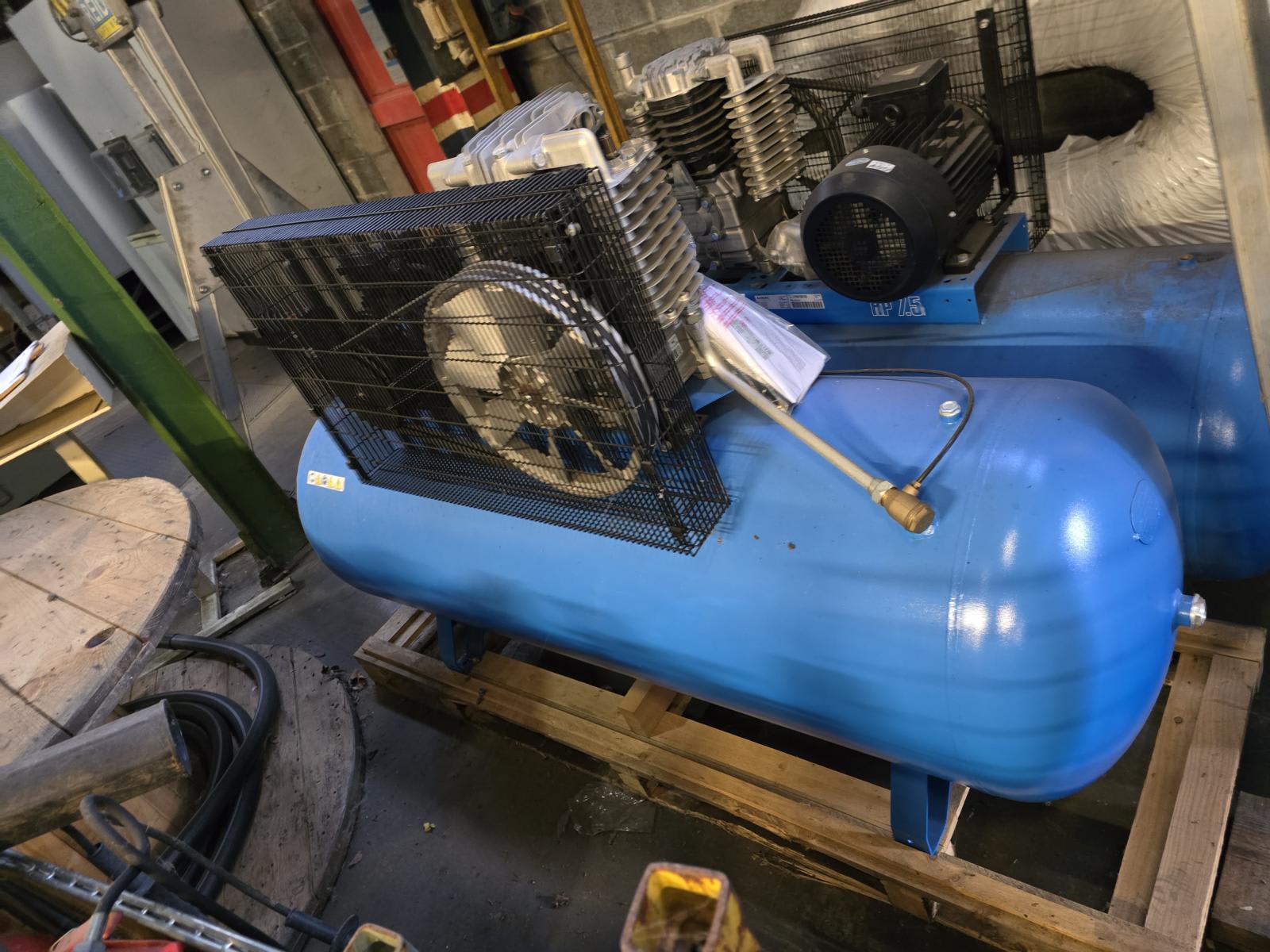

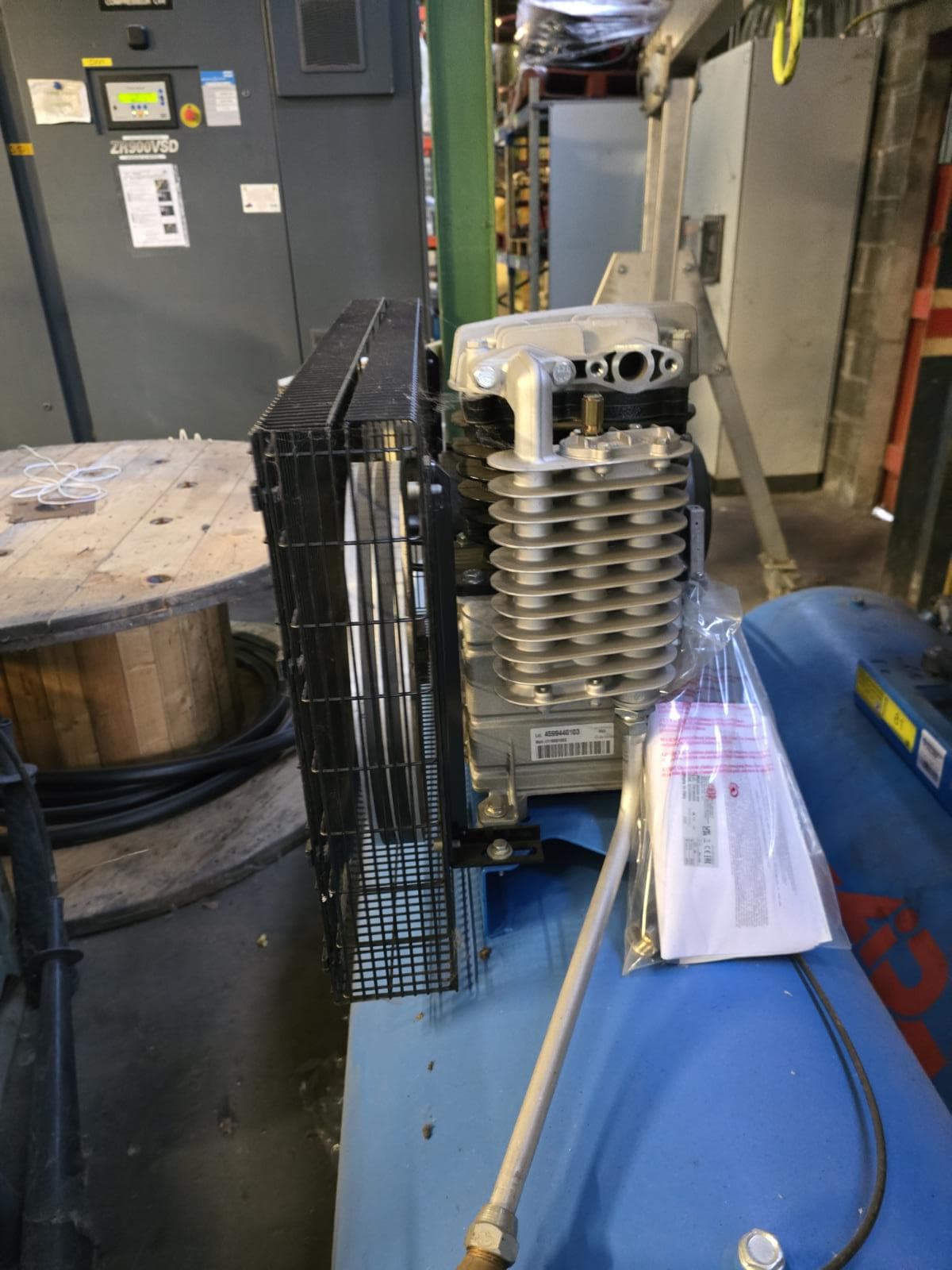

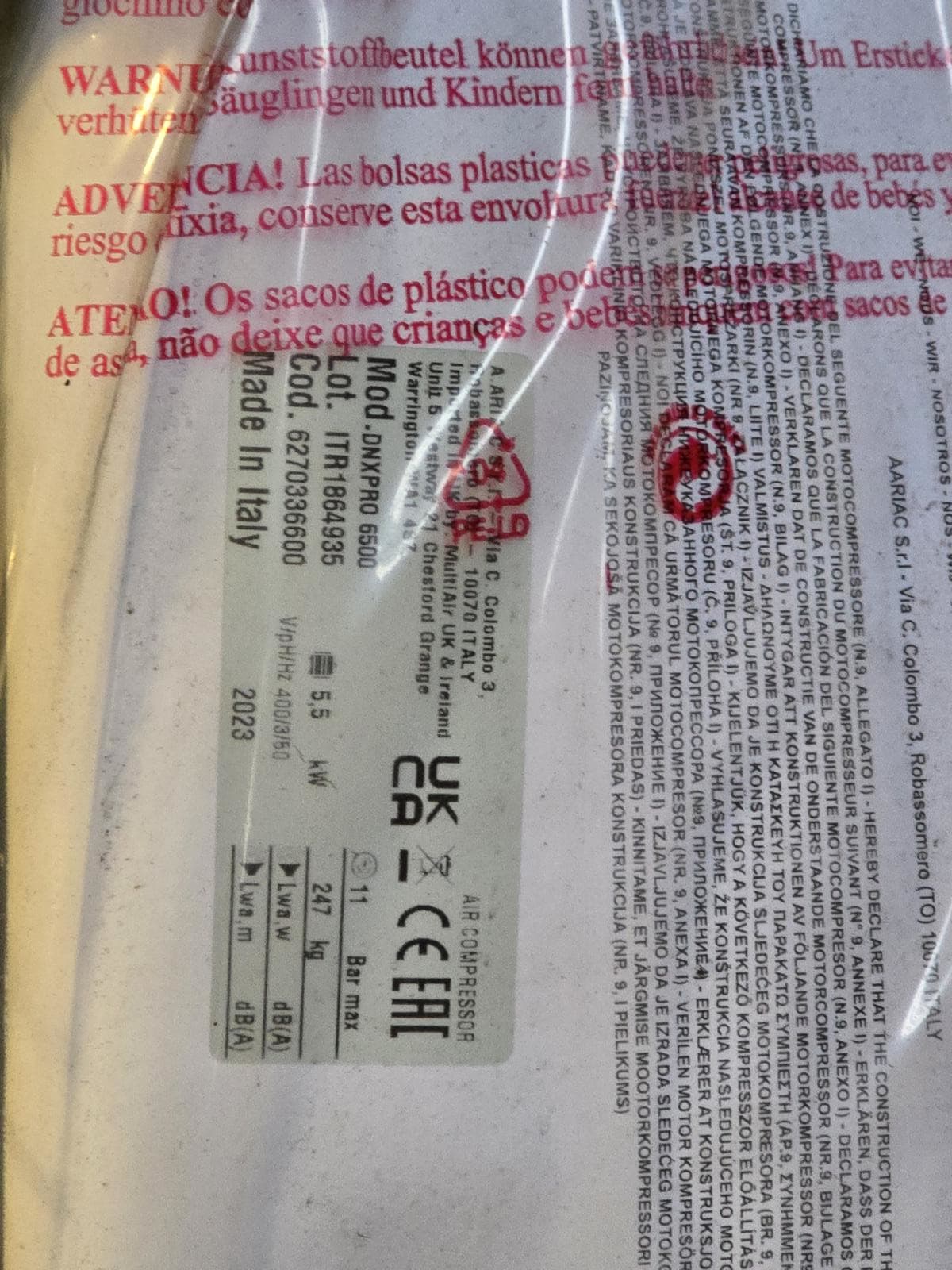

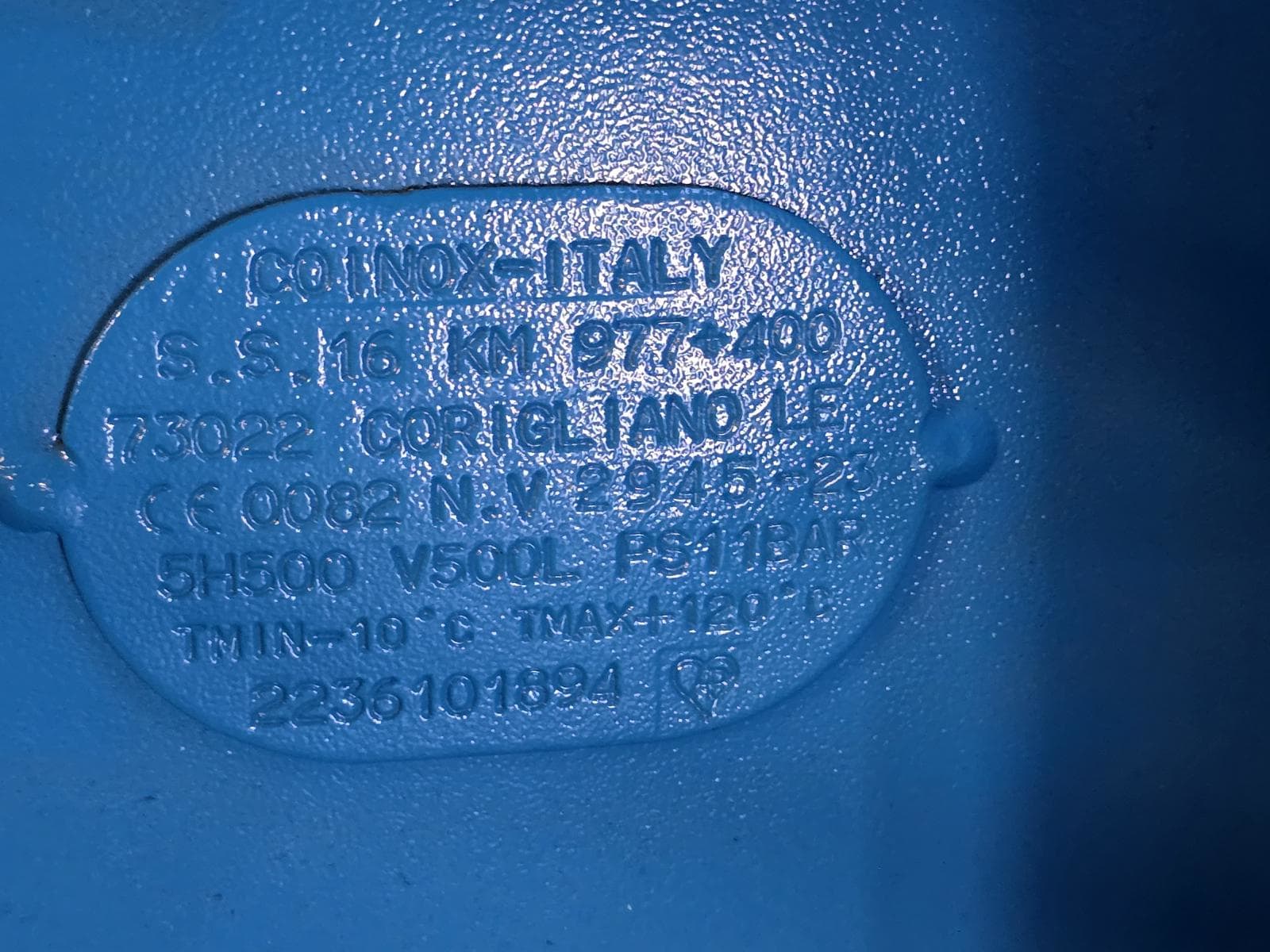

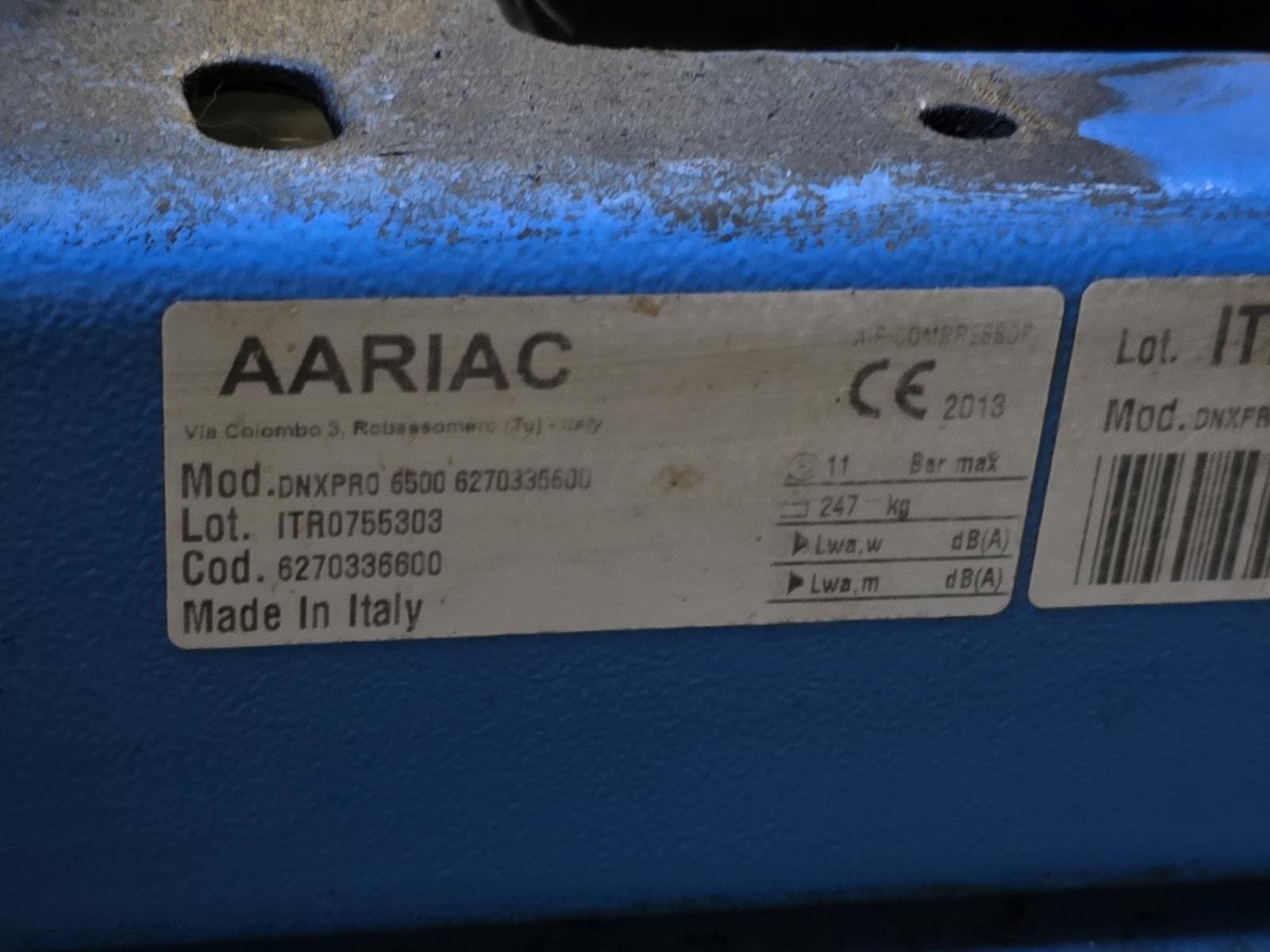

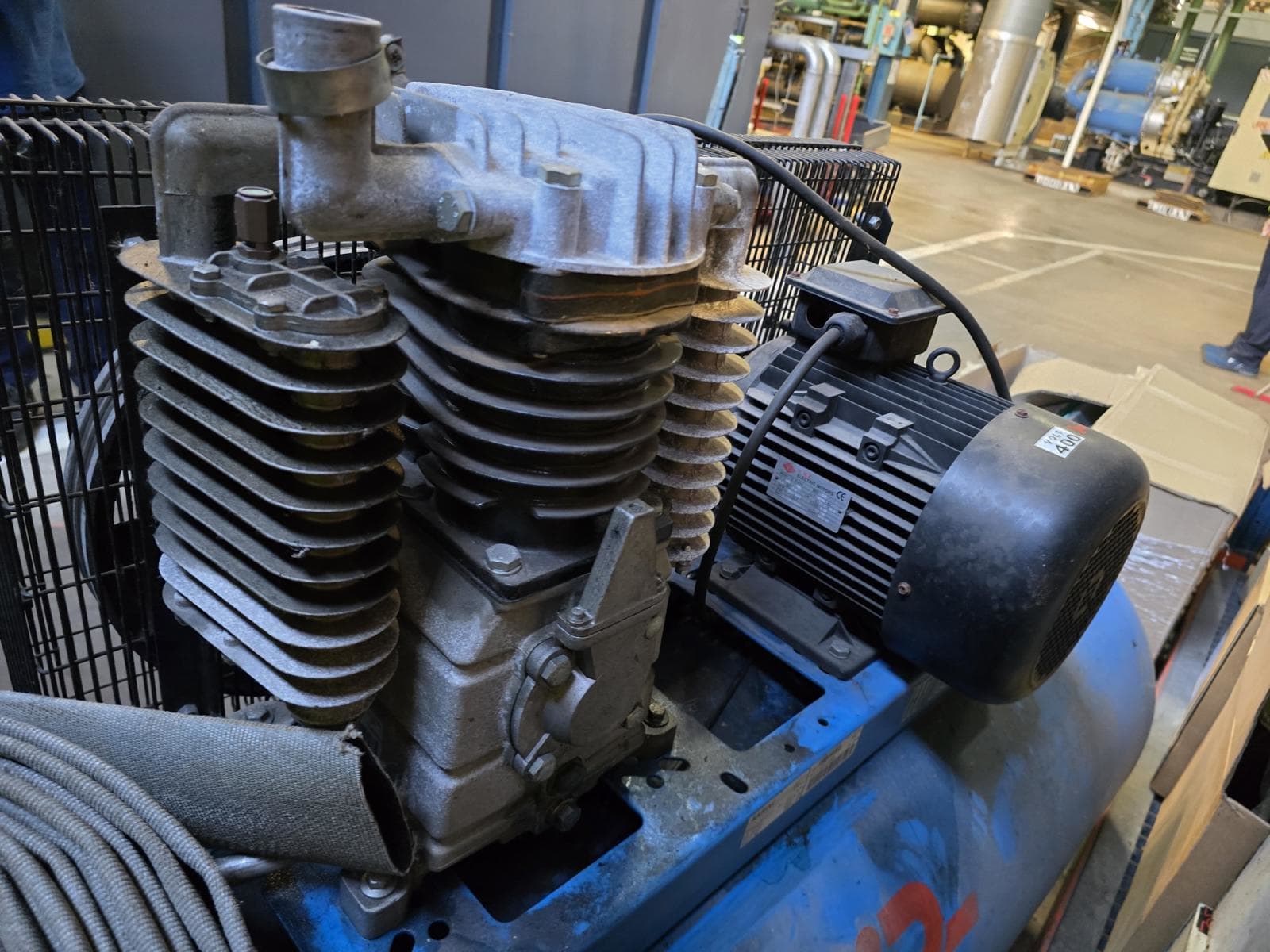

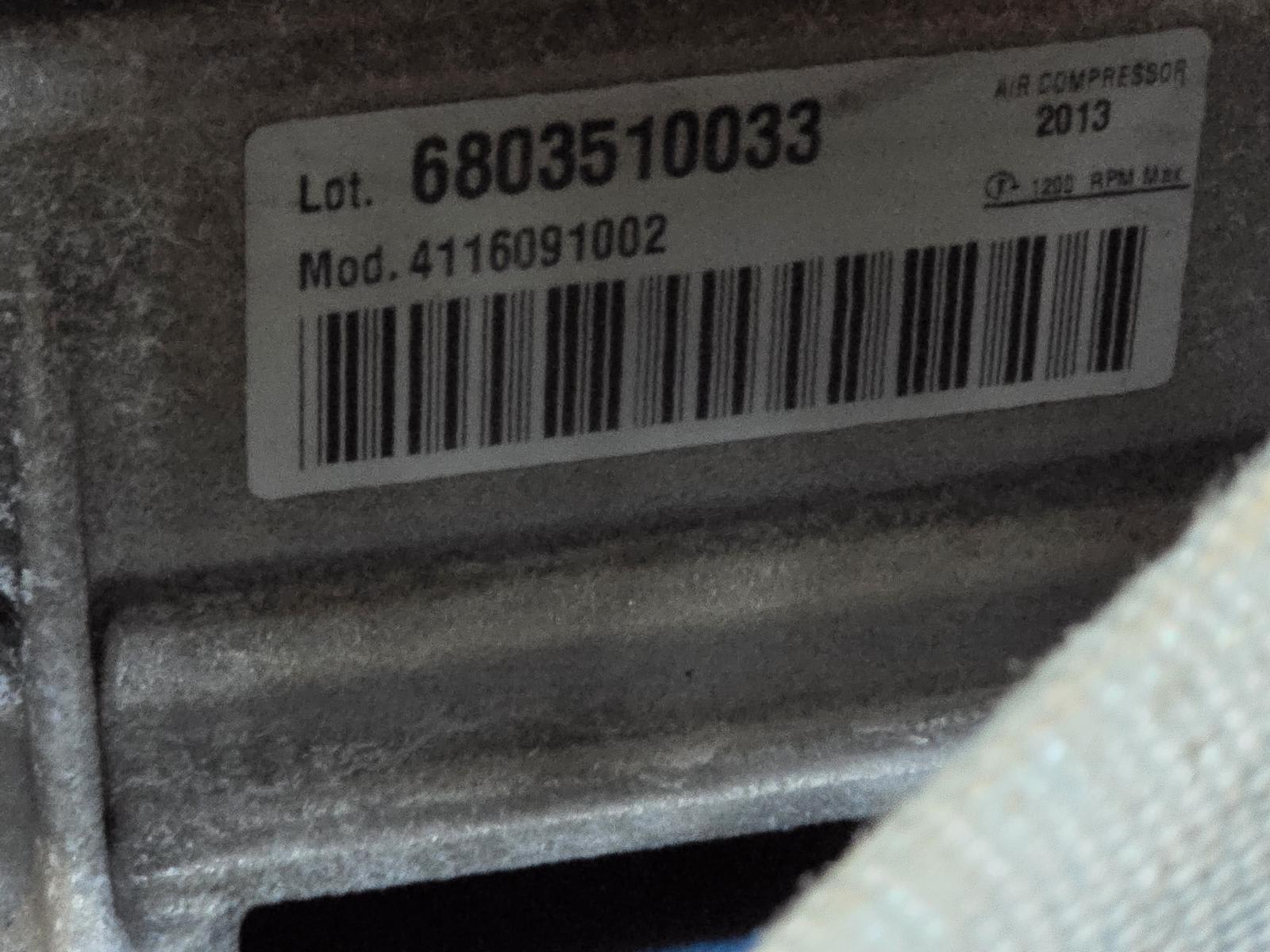

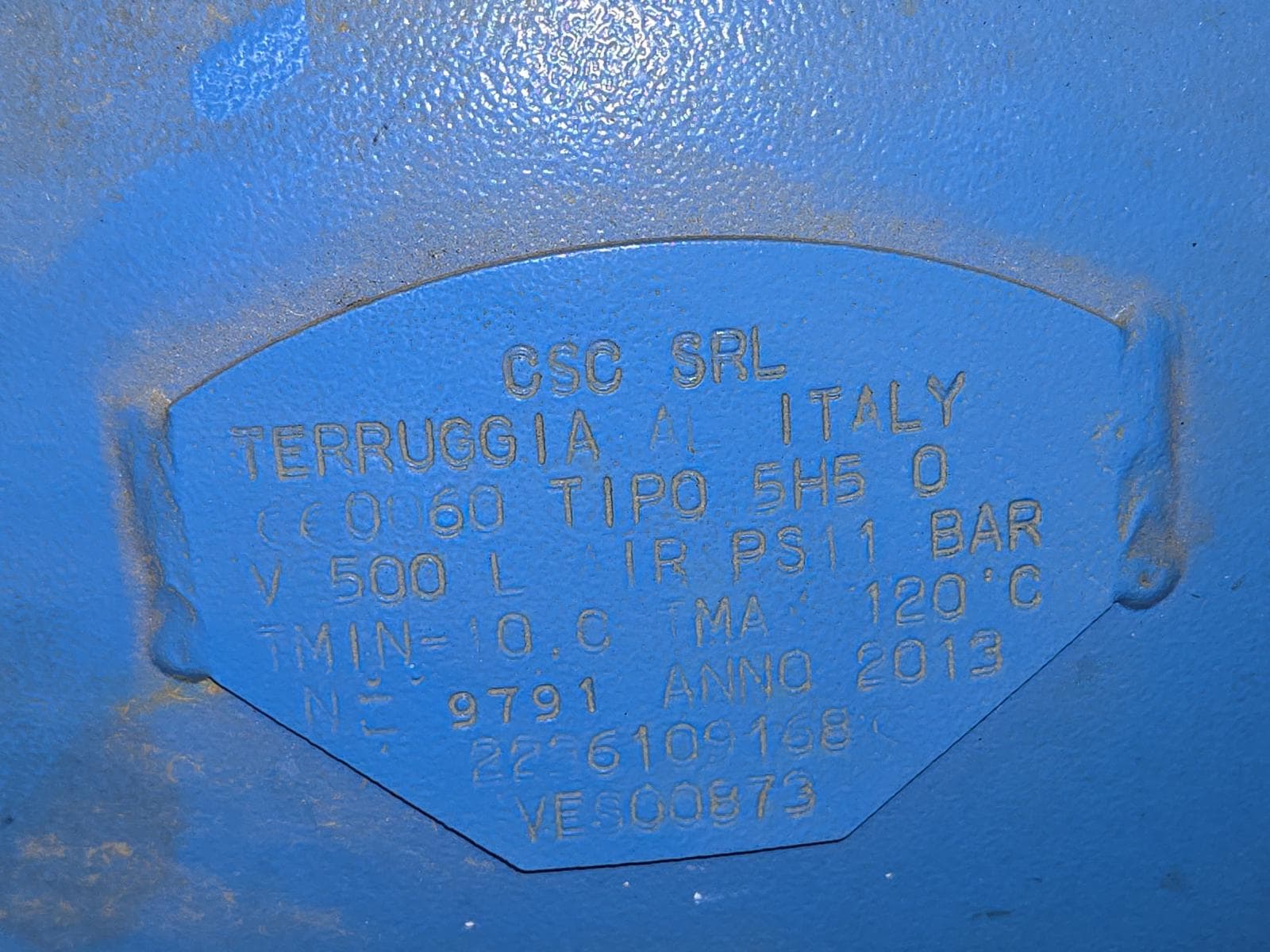

Compressor WORTHINGTON CREYSSENSAC HP 7.5 DNXPRO 6500 | 2020

max 11bar, 400V 50Hz 5,5kW, weight 247kg, air tank 500L - LISTING 2830080

![Français]()

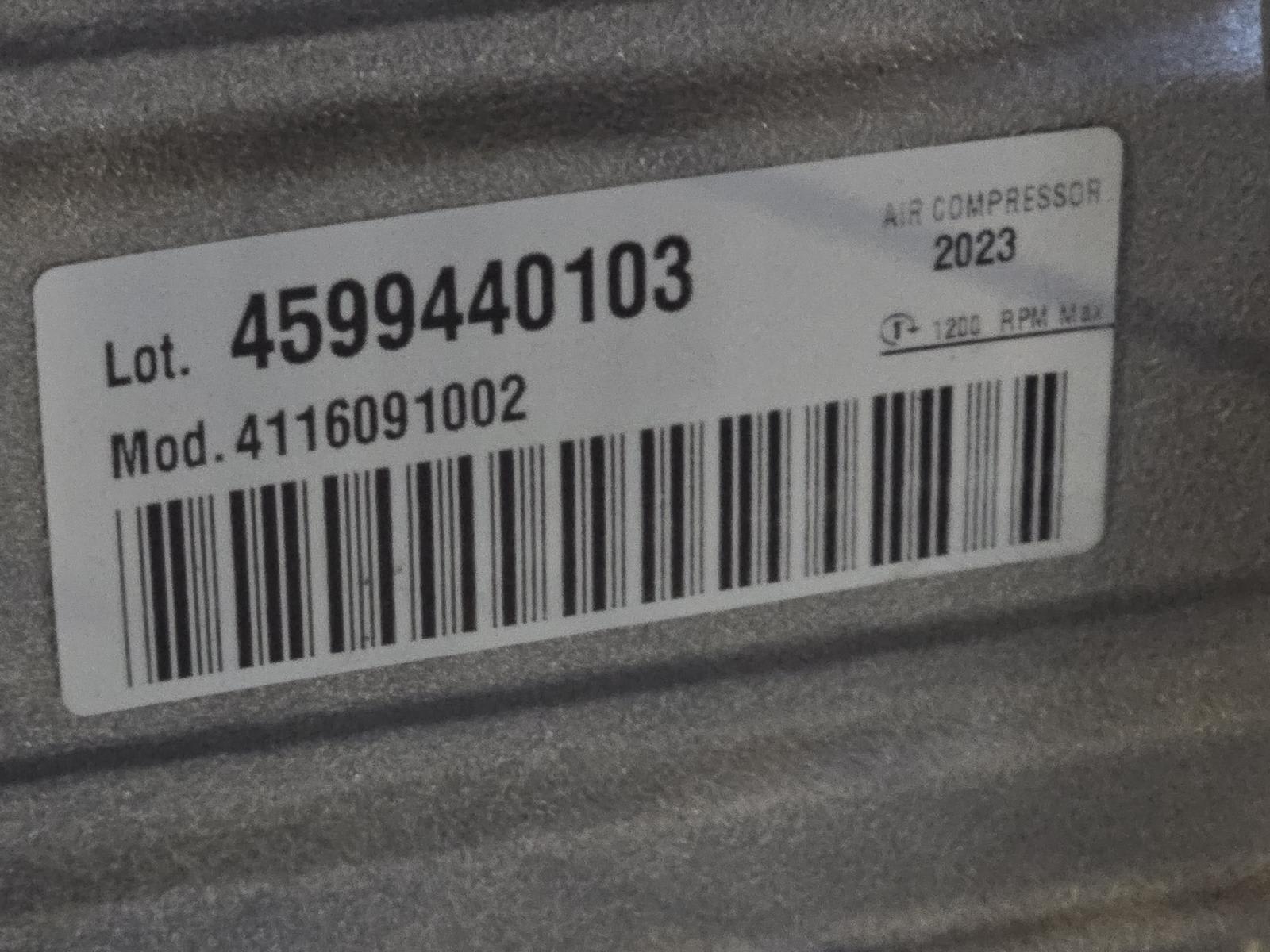

Compressor WORTHINGTON CREYSSENSAC HP 7.5 DNXPRO 6500 | 2023

max 11bar, 400V 50Hz 5,5kW, weight 247kg, air tank 500L - LISTING 2830081

![Français]()

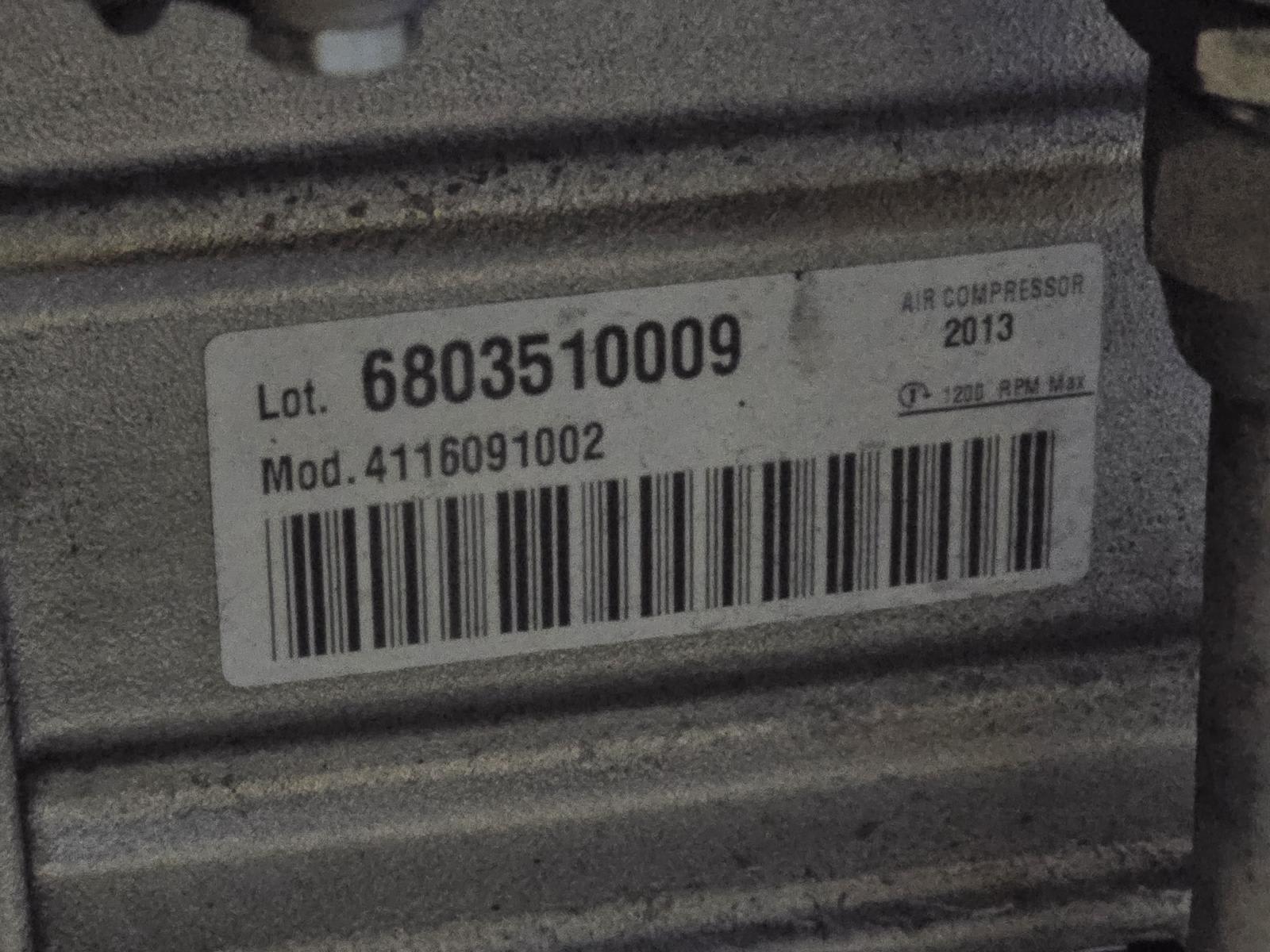

Compressor WORTHINGTON CREYSSENSAC HP 7.5 DNXPRO 6500 | 2013

max 11bar, 400V 50Hz 5,5kW, weight 247kg, air tank 500L - LISTING 2830082

![Français]()

Compressor WORTHINGTON CREYSSENSAC HP 7.5 DNXPRO 6500 | 2013

max 11bar, 400V 50Hz 5,5kW, weight 247kg, air tank 500L

Essential Information

General Information

- Auction Dates

- Starts: 13 November 2025 at 07:00 GMTEnds: 31 March 2026 at 15:00 BST

- Site Address

- DouvrinFrance

- Viewing Days

- By Appointment OnlyInspection by prior Appointment only | Please contact Inquiry@Maynards.com to arrange an Inspection appointment

Fees & Payment

- Currency

- EUR

- Buyers Premium

- 18% or as specified on individual items

- Payment

General Payment Information

- Per bidder, there will only one invoice be issued for all lots won in one auction/sale.

- The invoice will be in PDF format and will be emailed to successful bidders within 24 hours after the last lot in the auction has closed. Alternatively, a link will be emailed from where the invoice can be downloaded.

- Payment is due immediately on receipt of invoice unless stated differently on the invoice.

- All payments must be made in the currency stated on the issued invoice.

- The only accepted form of payment is bank transfer.

- We DO NOT accept payment by cheque, debit or credit card.

- Please reference the invoice number on the bank transfer.

- For all bidders with residence outside of the country from where the assets are being sold, Maynards Europe will collect 20% of the invoice total as a deposit. This deposit will be refunded in full after Maynards Europe have received proof of export.

- It happens frequently that Maynards Europe at first only issue a so-called “proforma invoice”. After receipt of full payment, collection of the items and receipt of export documentation (if applicable), the final invoice will be issued.

Goods

- Clearance days

- 01 January 1970 at 01:00 GMT+1 - 01 January 1970 at 01:00 GMT+1

- General Collection Information

- Buyers are fully responsible for the removal of the items purchased including all transport and rigging charges.

- Items only become available for collection after Maynards Europe have received payment in full, and a collection appointment has been booked with the project manager / on-site contact.

- Buyers or third-party movers must present the ‘Paid Invoice’ confirmation to the on-site personnel when collecting and removing their items. The ‘Paid Invoice’ confirmation will be issued by Maynards Europe after receipt of the full payment and will be emailed in PDF format to the buyer.

- Buyers must complete the removal of items within the clearance deadline (individually stated for each auction / sale). Removal is by appointment only.

- Removal and on-site contact information will be emailed to buyers at the same time invoices are issued.

- Entrance to the site is subject to the Conditions of Admission for customers, agents and contractors. For your protection you will be required to wear safety equipment including high visibility jackets and safety footwear as a minimum. Everybody entering the site has to undergo a short security briefing.

- Conditions of Site Admission: All Customers, agents & contractors must report to the site manager / foreman on arrival and must not proceed on to site without permission. No persons under 16 years of age will be allowed on site.

- Buyers / Transport Companies must bring their ‘Paid Invoice’ document to site together with proof of appropriate insurance coverage. It is the buyer’s responsibility to ensure their removal contractor has the appropriate insurance coverage. As a standard, an insurance cover of 5 million EUR is required. We reserve the right to deny access to the site if these requirements are not met or the contractor fails to provide proof of this. If you have any questions on this, please do not hesitate to contact us on +49 8151 973420.

- There is NEITHER lifting equipment NOR tools for dismantling available on site. Please make your own arrangements.

- Removal of items is solely the responsibility of the purchaser and/or those collecting on their behalf. This may require you to remove other items to gain access although efforts will be made to keep this to a minimum. Dismantling of machinery may be required.

- The buyer and their removal company are responsible for the condition of the site after removal of their goods. Electrical connections must be left in a safe condition and protrusions (grouting, hold down bolts / studs) must be removed and left flush to ground level. The site must be cleaned after removal and all waste must be disposed of.

- The buyer and their removal company are responsible for conducting the removal and transportation of their goods according to the standard environmental regulations.

- Removal must be carried out without damage to the site itself or any property/ items on or near the site. Liability for any such damage lies with the buyer.

- If items have not been removed by the clearance deadline, our standard Terms & Conditions apply.

- Our staff are on site to supervise and control removals only, they are not permitted to move equipment or assist with the removal in any way. We thank you for your cooperation in helping to keep yourself and others safe while on site and for aiding us in the timely removal of goods from site.

- Sales Contacts