Private Treaty Sale | KLUDI Hungary | Closure of Premium Bathroom & Kitchen Fittings Plant

Starts: 05 January 2026 at 09:00 GMT

Ends: 26 February 2026 at 10:00 GMT

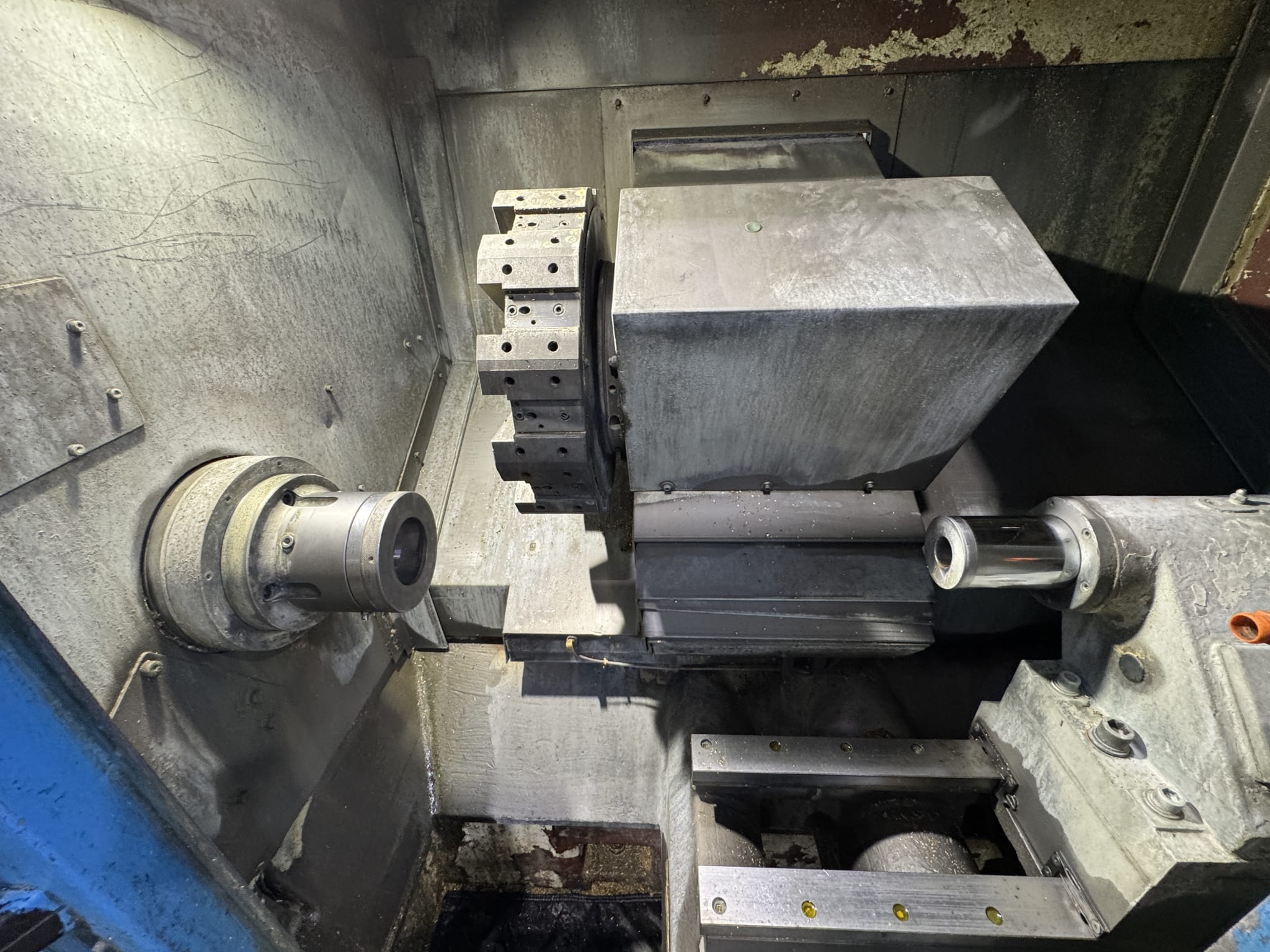

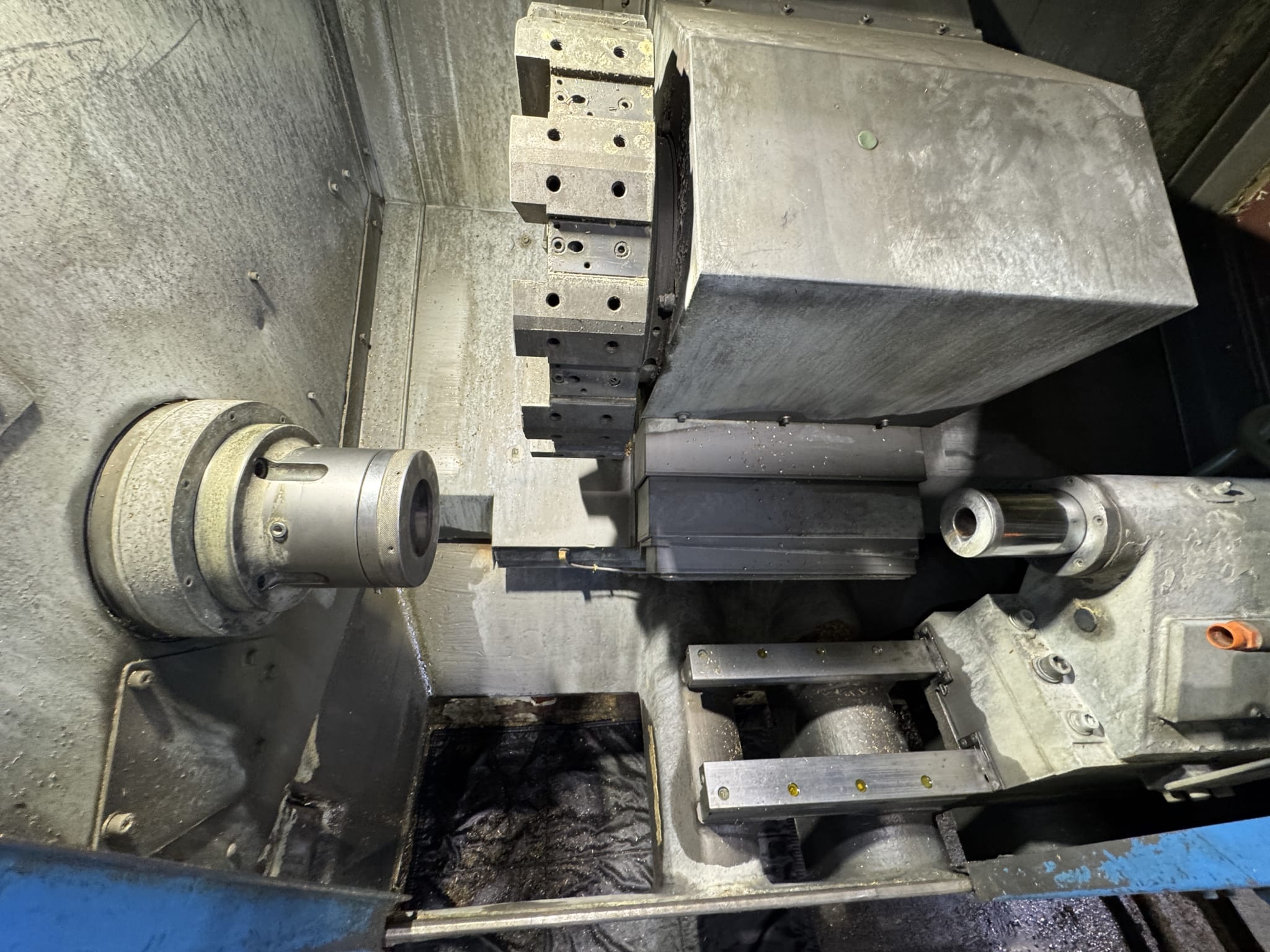

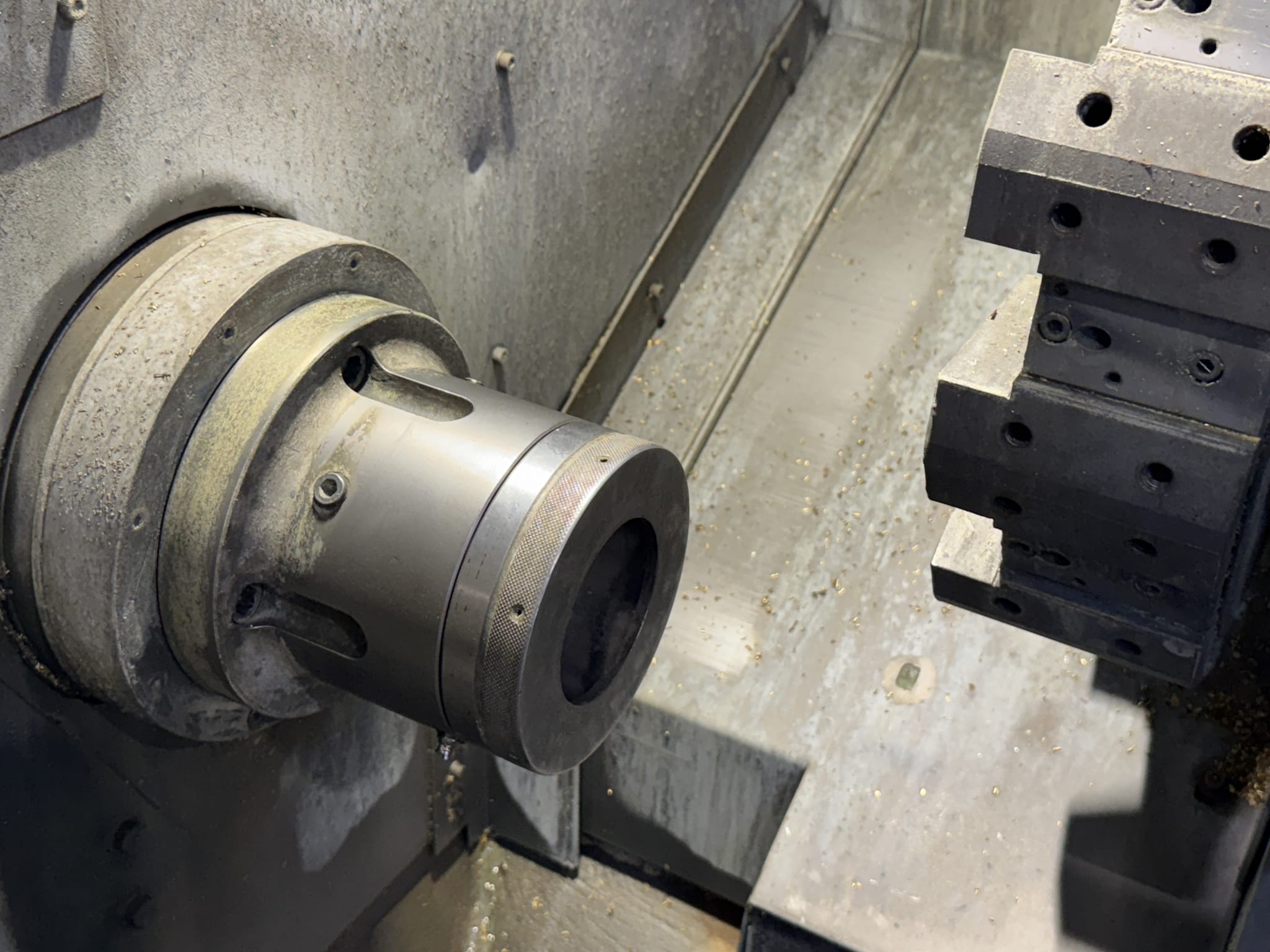

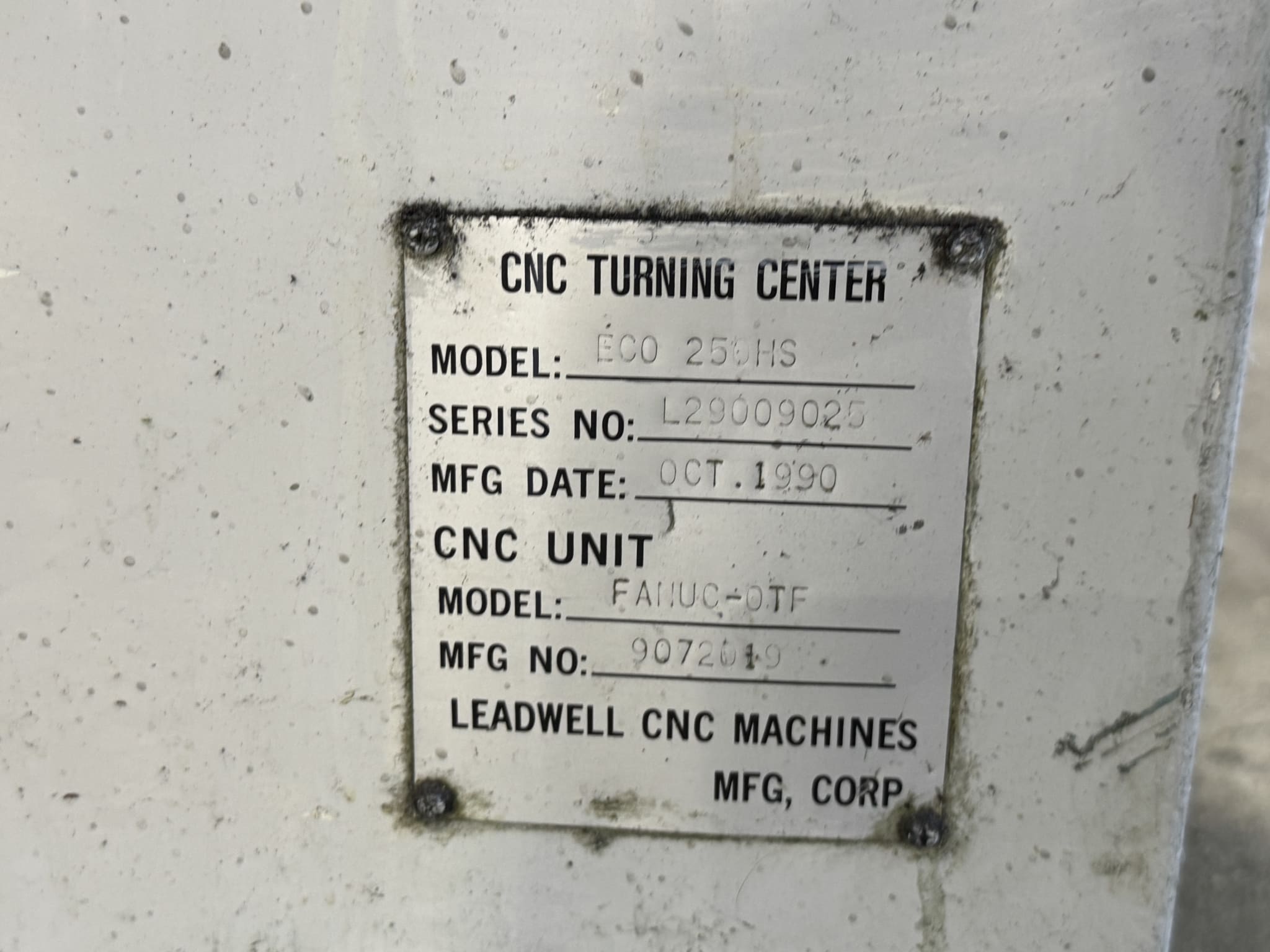

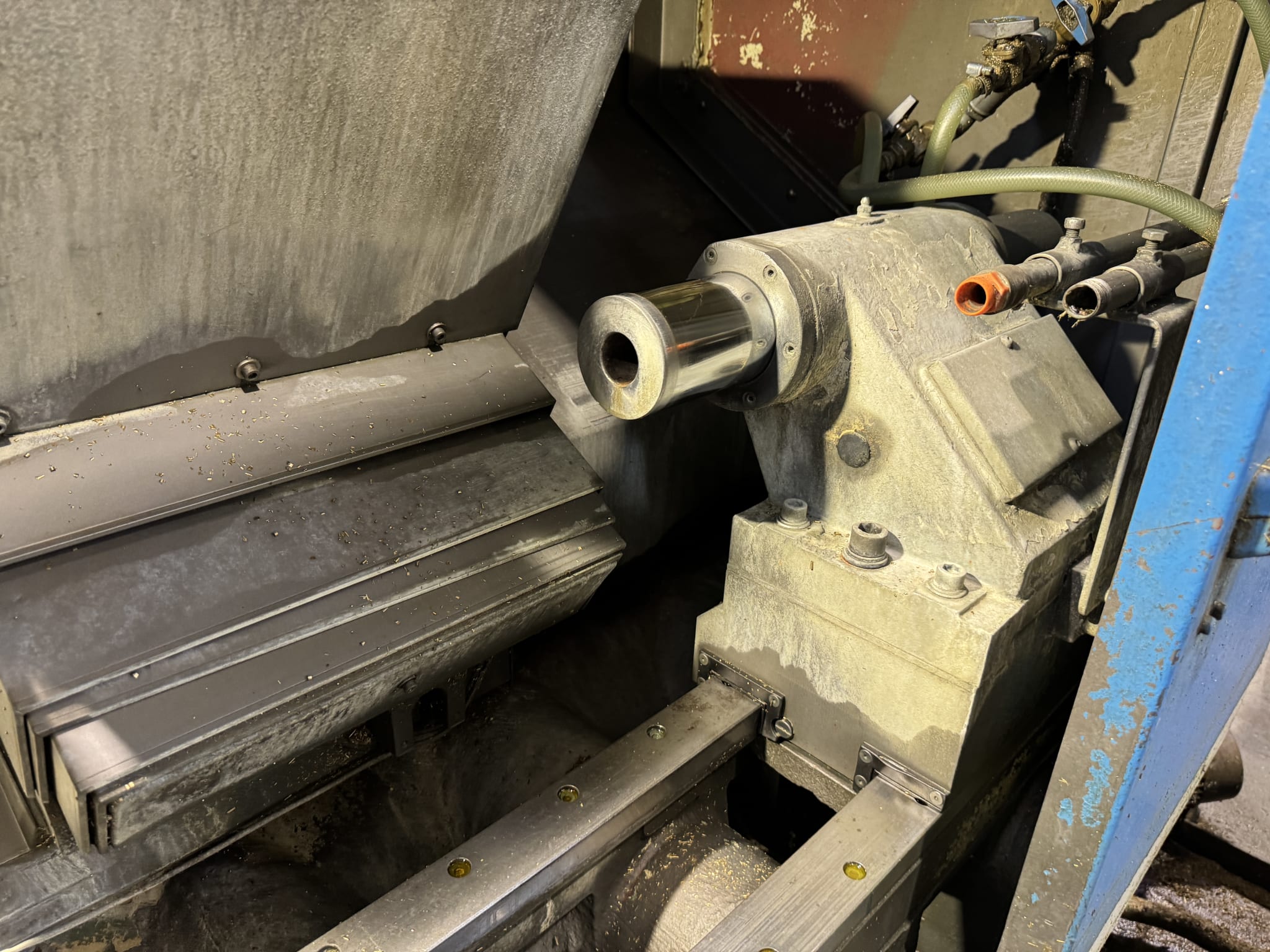

Maynards in conjunction with PRODEQ offers for Sale by Private Treaty Sale, Machinery and Equipment from Kludi Szerelvények Kft. used for the Production of Premium Bathroom and Kitchen Fittings. The Highlights are 4* DMG Mori NHX 5000 Horizontal CNC Machining Centres from 2017 to 2021 as well as 4* Leadwell LCV-760 Vertical 2-Pallet CNC Machining Centres from 2009-2012, 2* Leadwell Ecoturn 250HS CNC Lathes, INDEX G200 CNC Double Spindle Lathes and more

Share:

Showing 77 of 77 lots

- LISTING 2800001

![Hungary]()

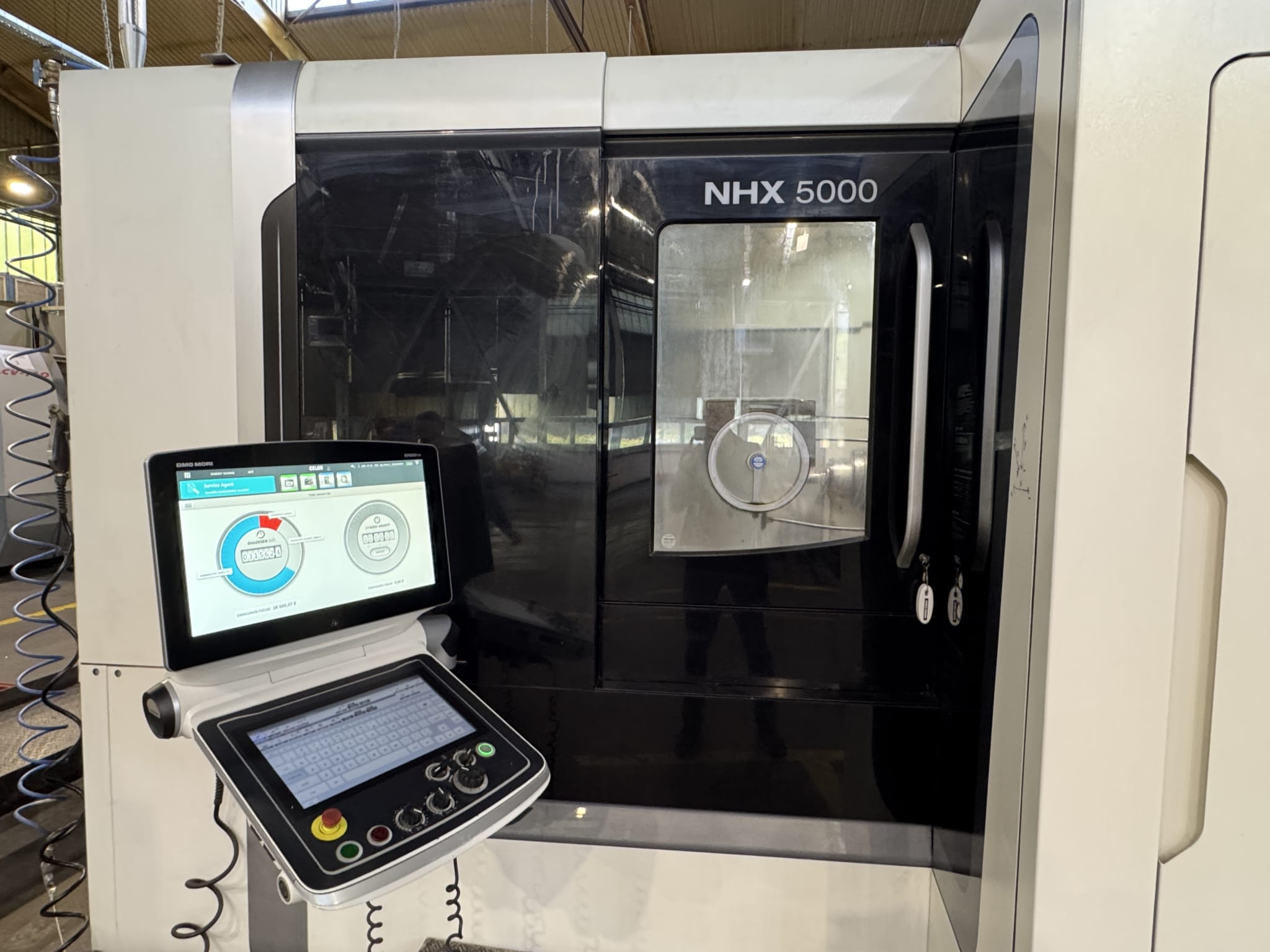

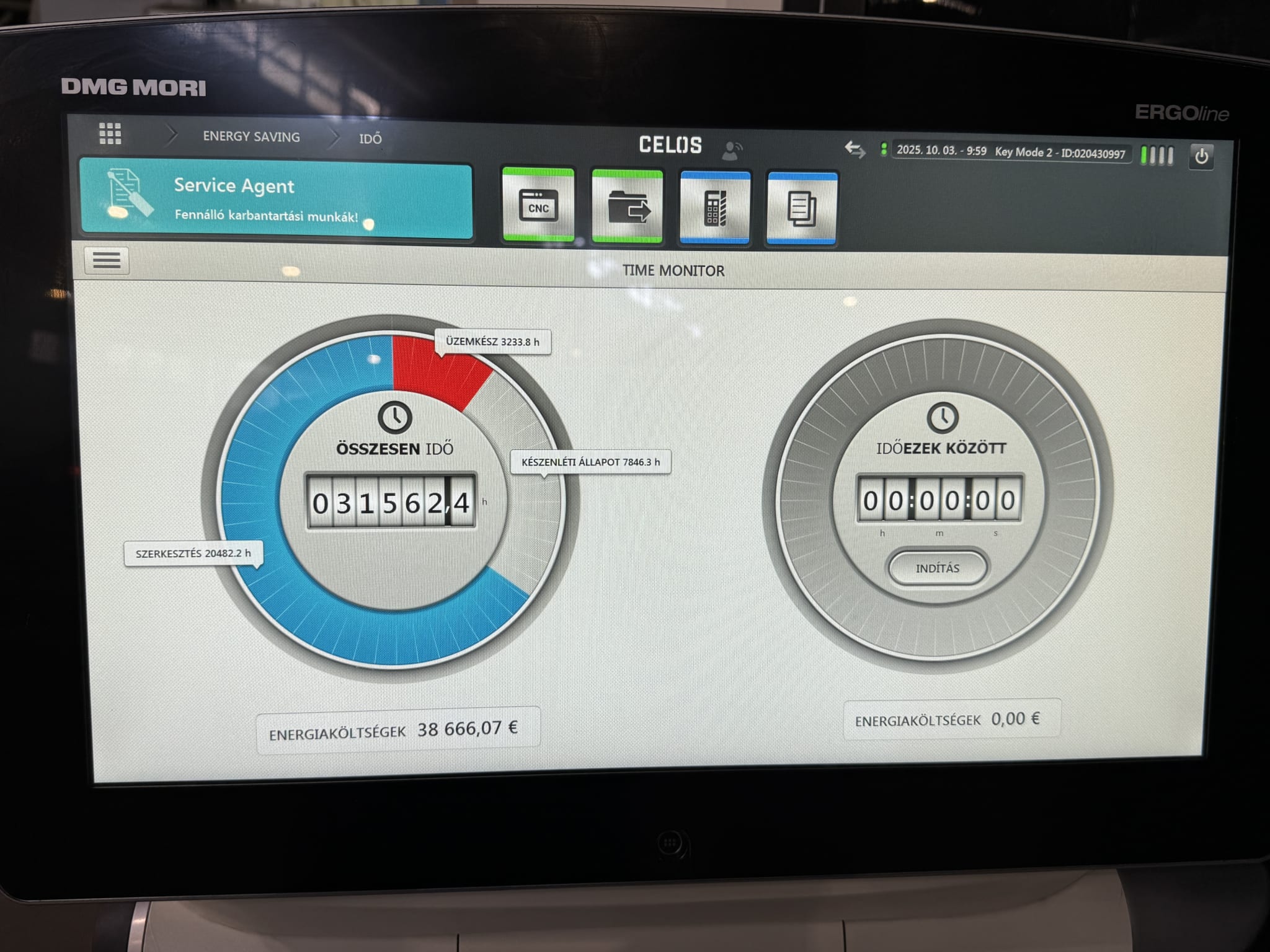

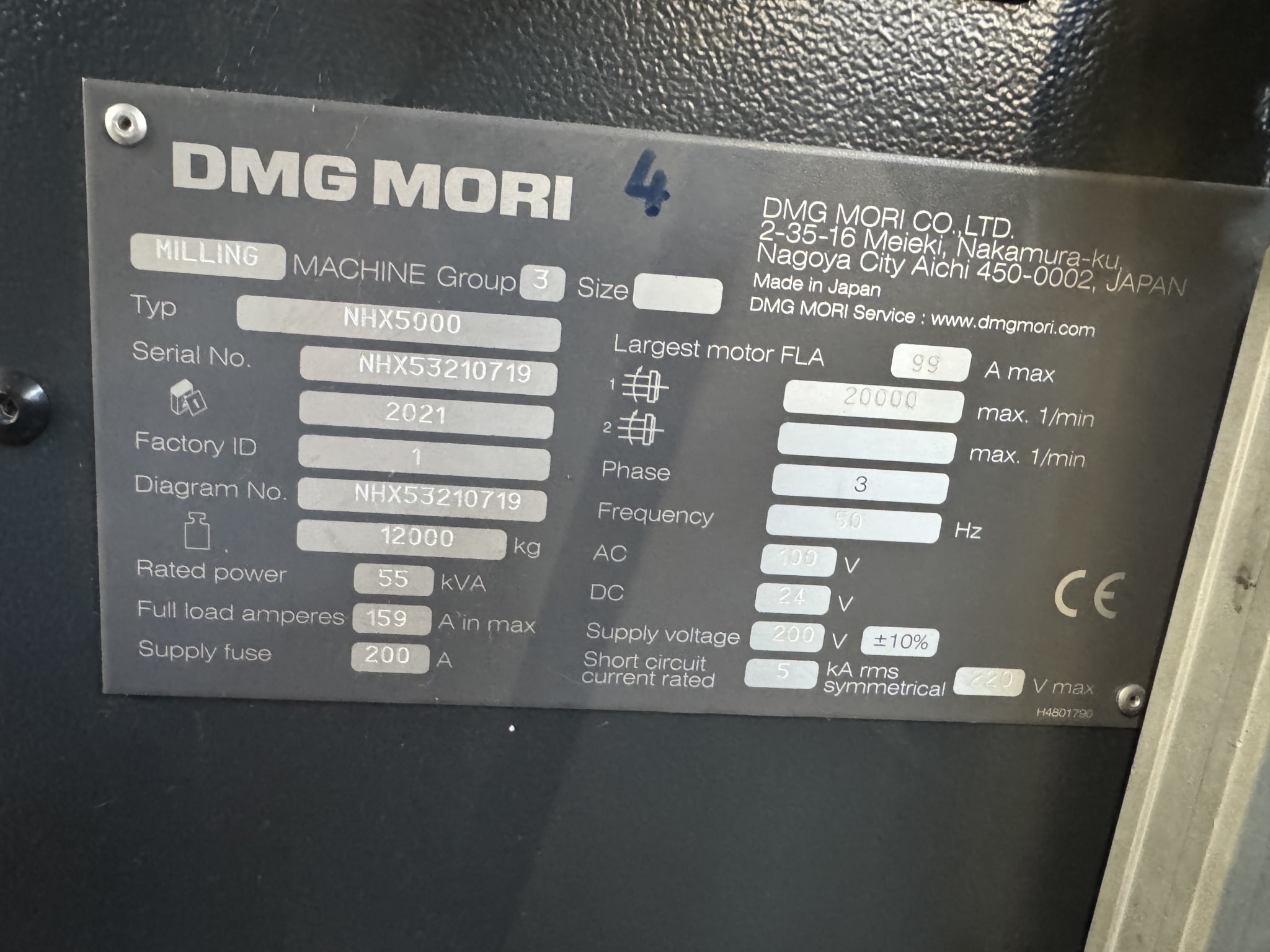

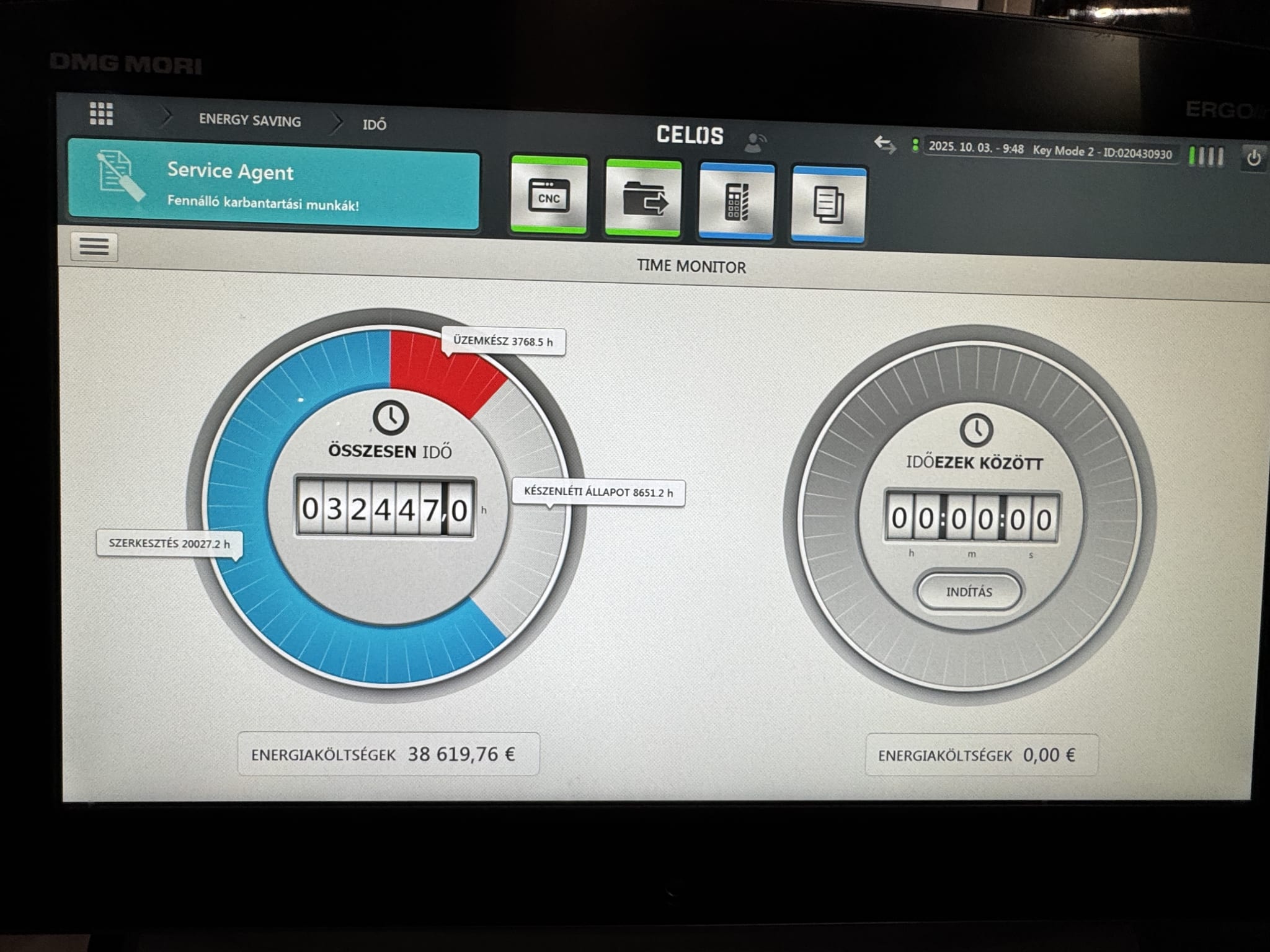

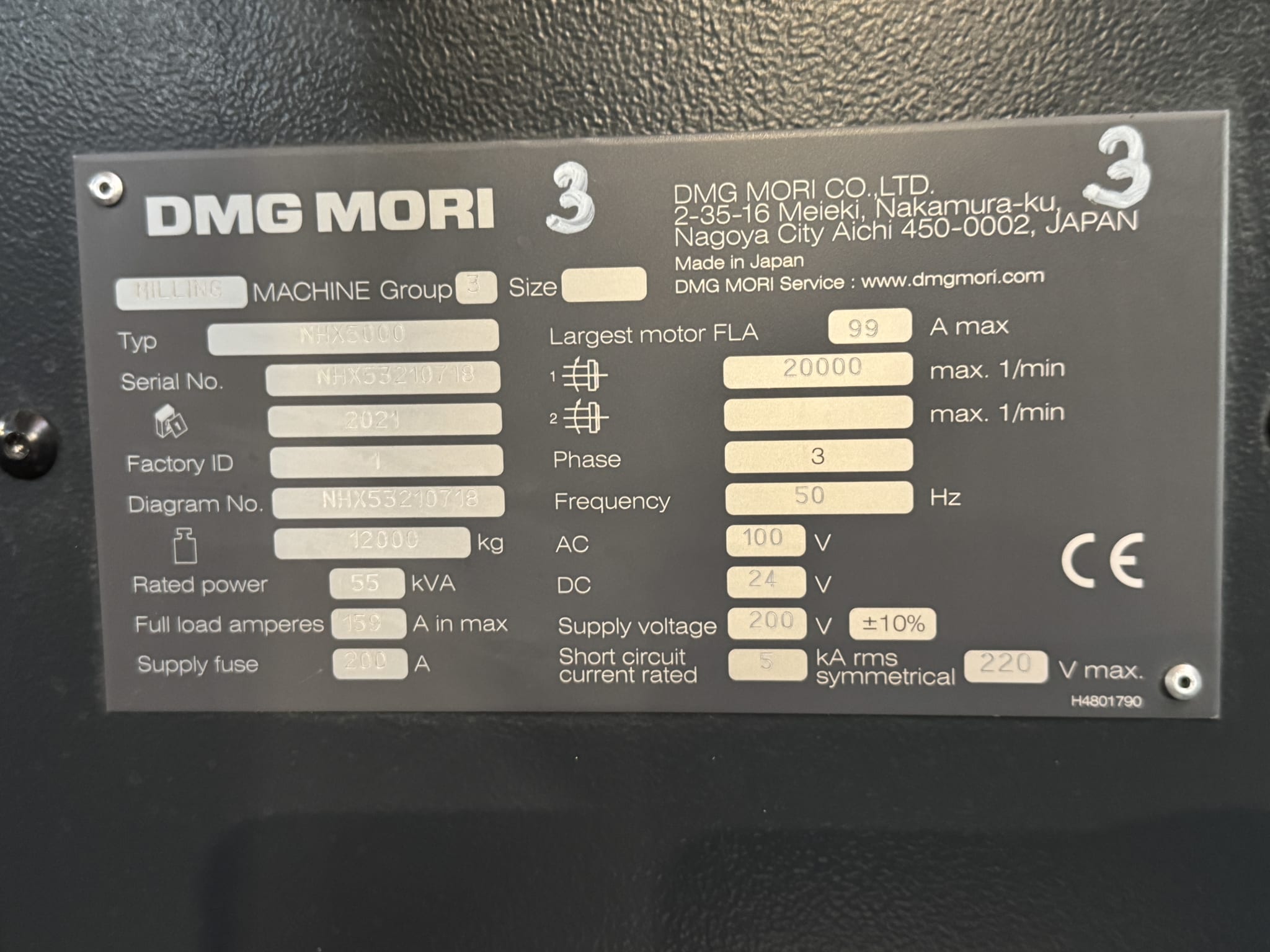

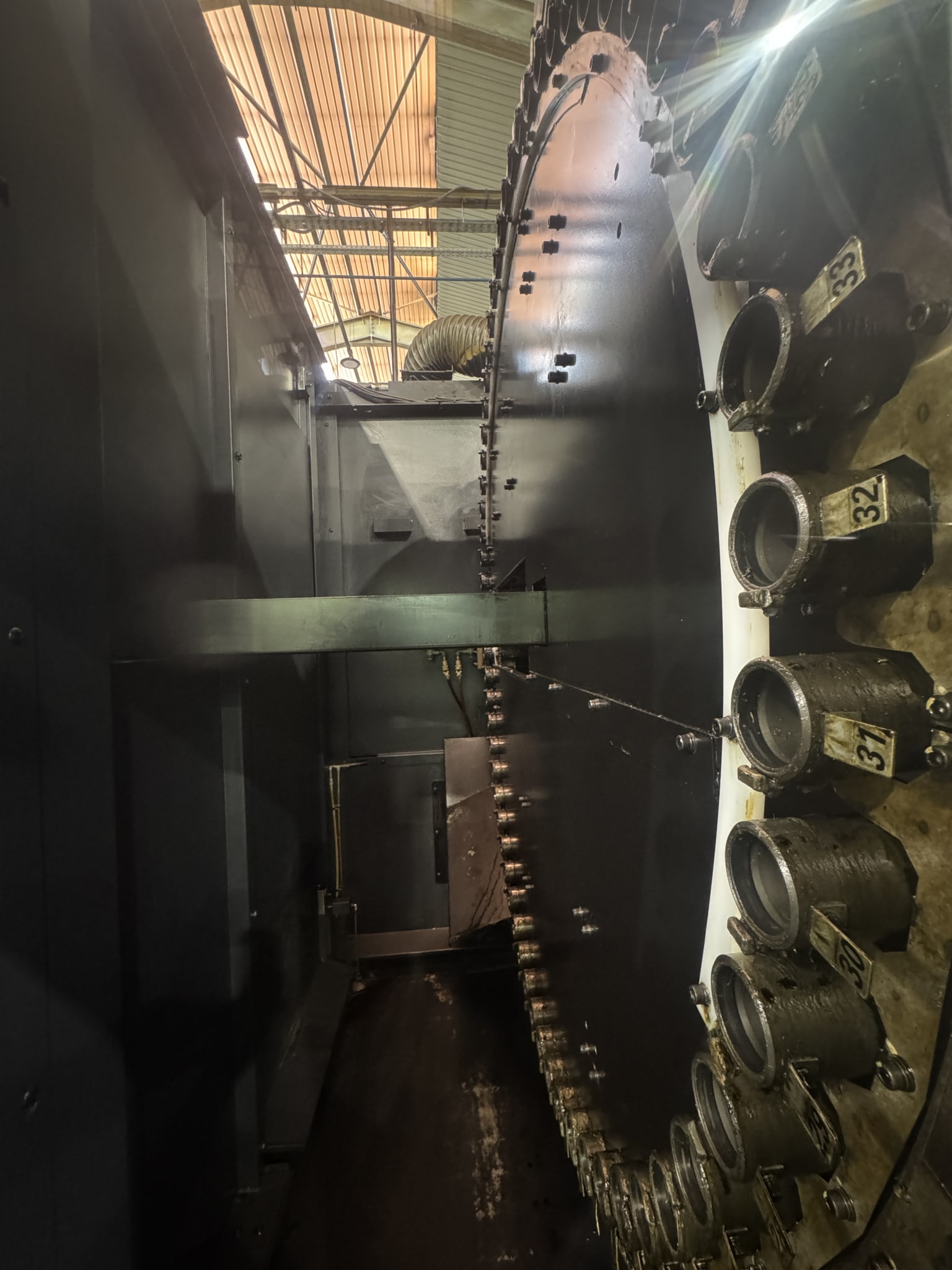

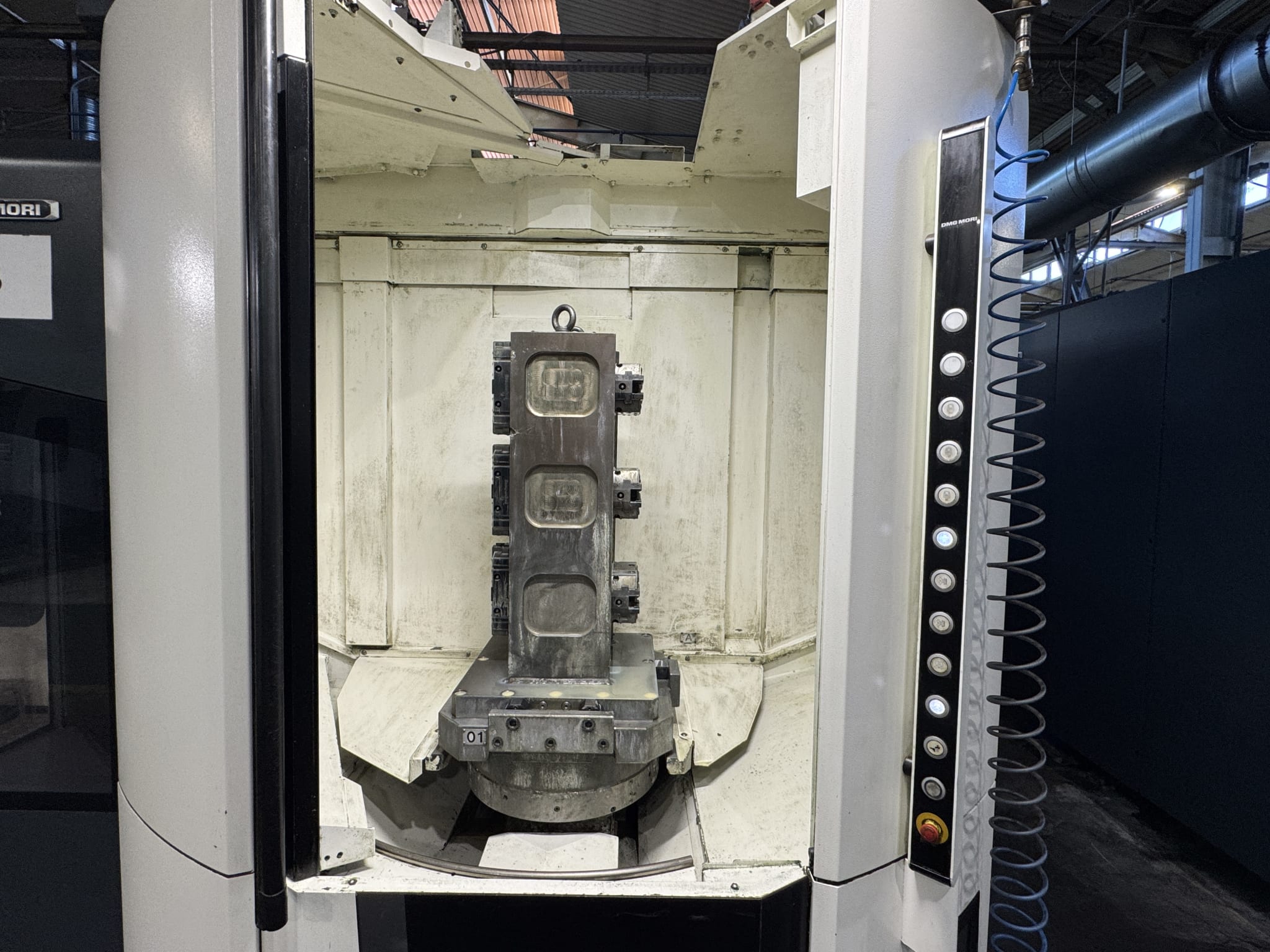

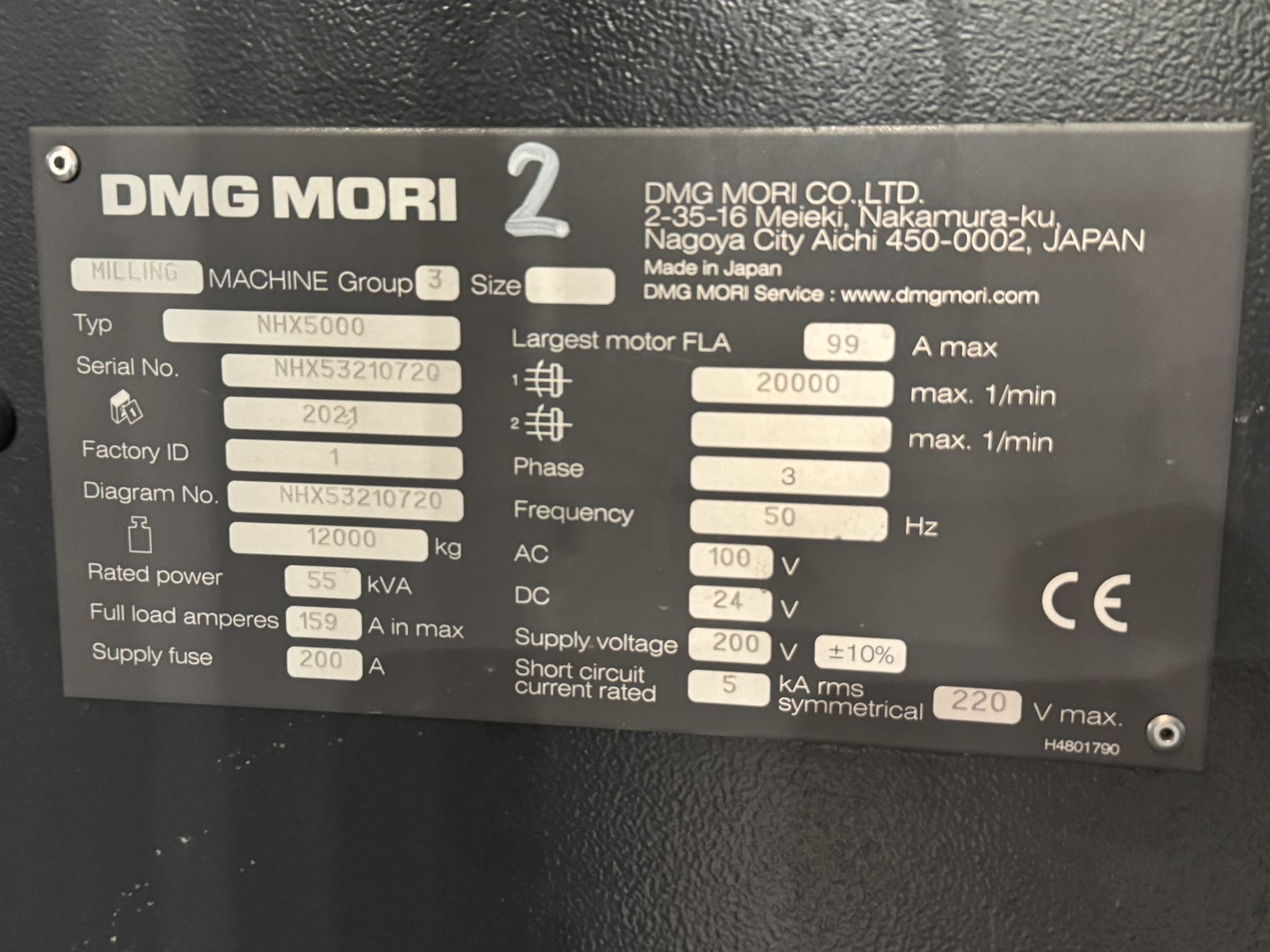

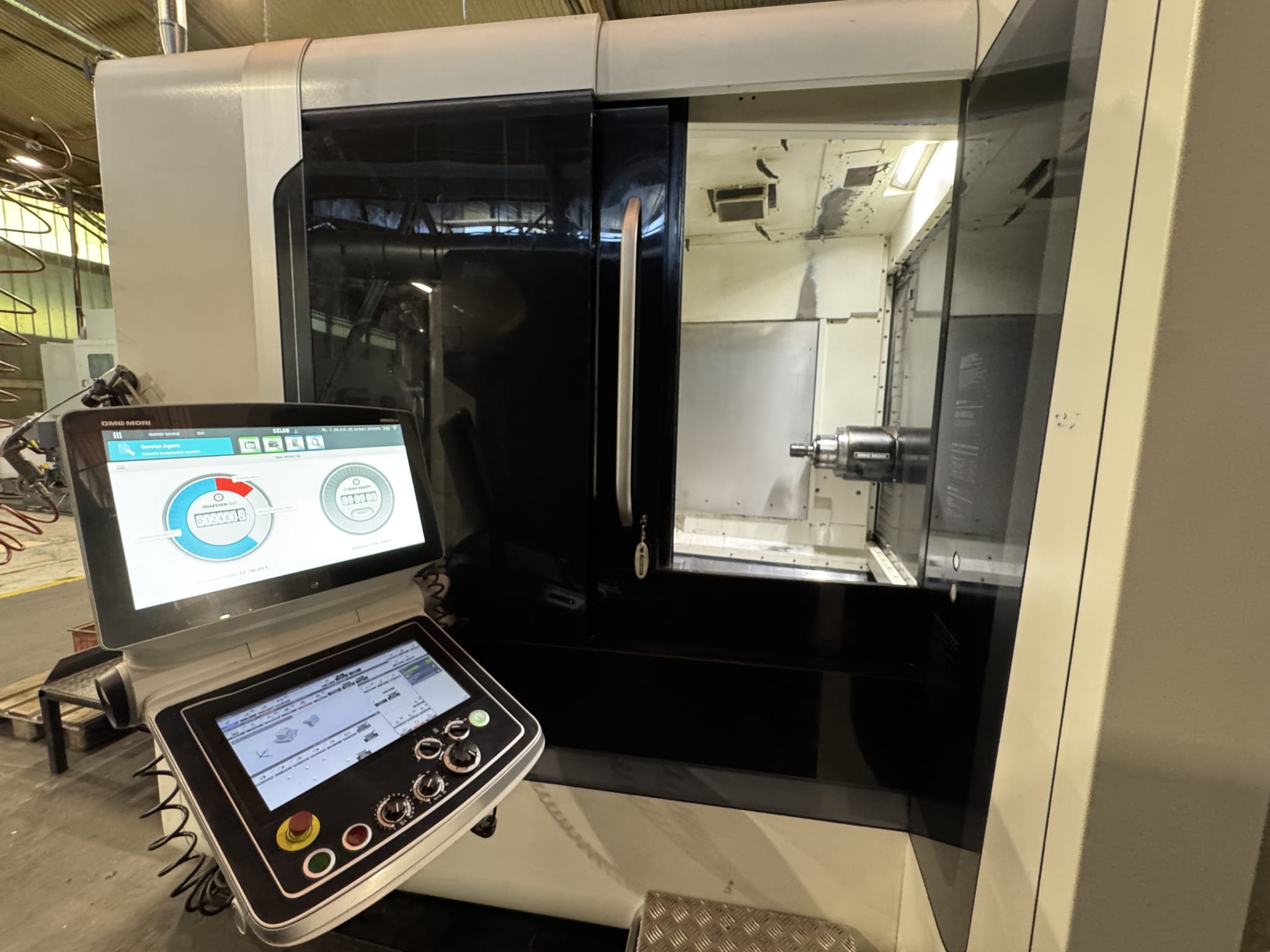

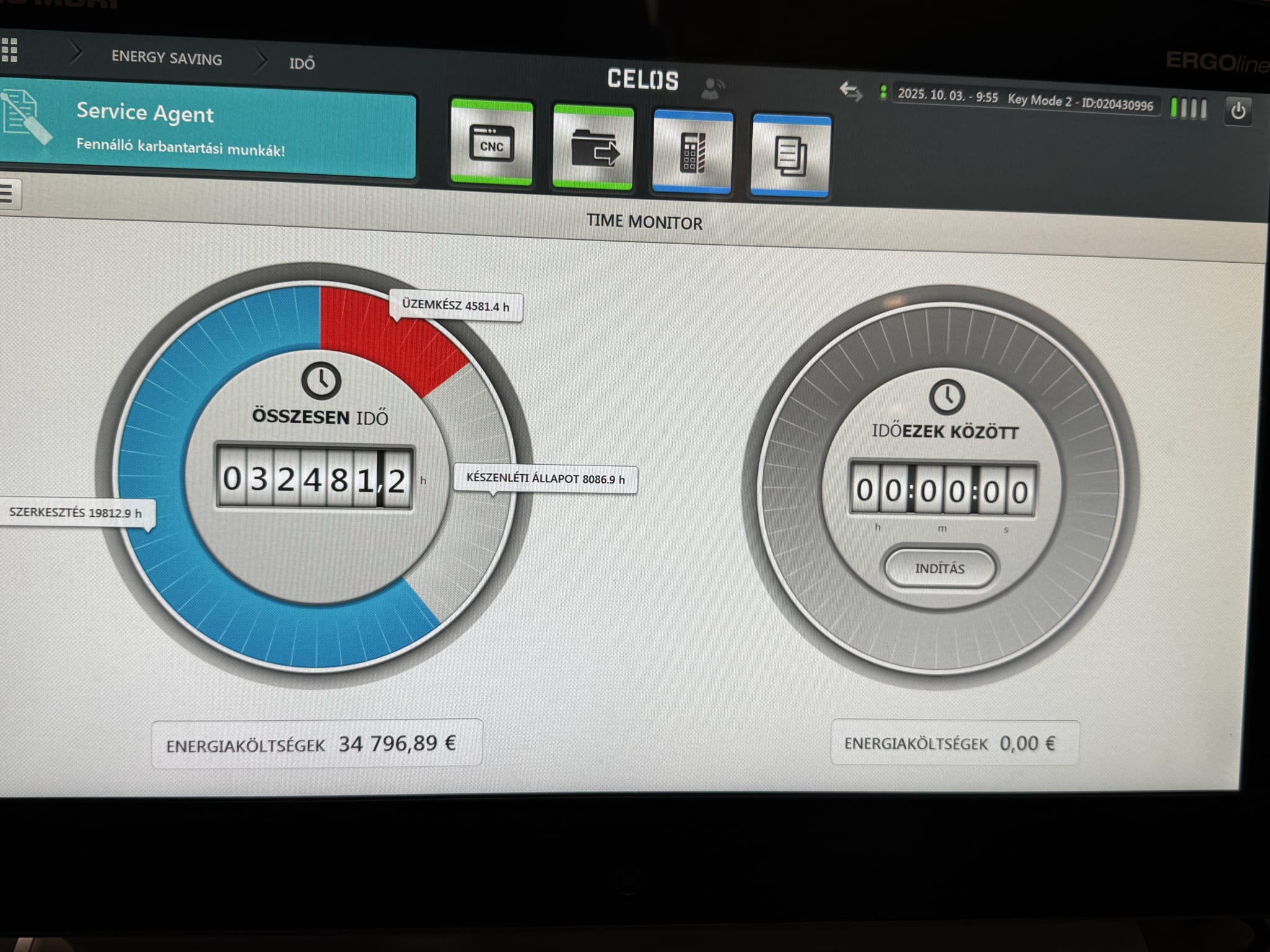

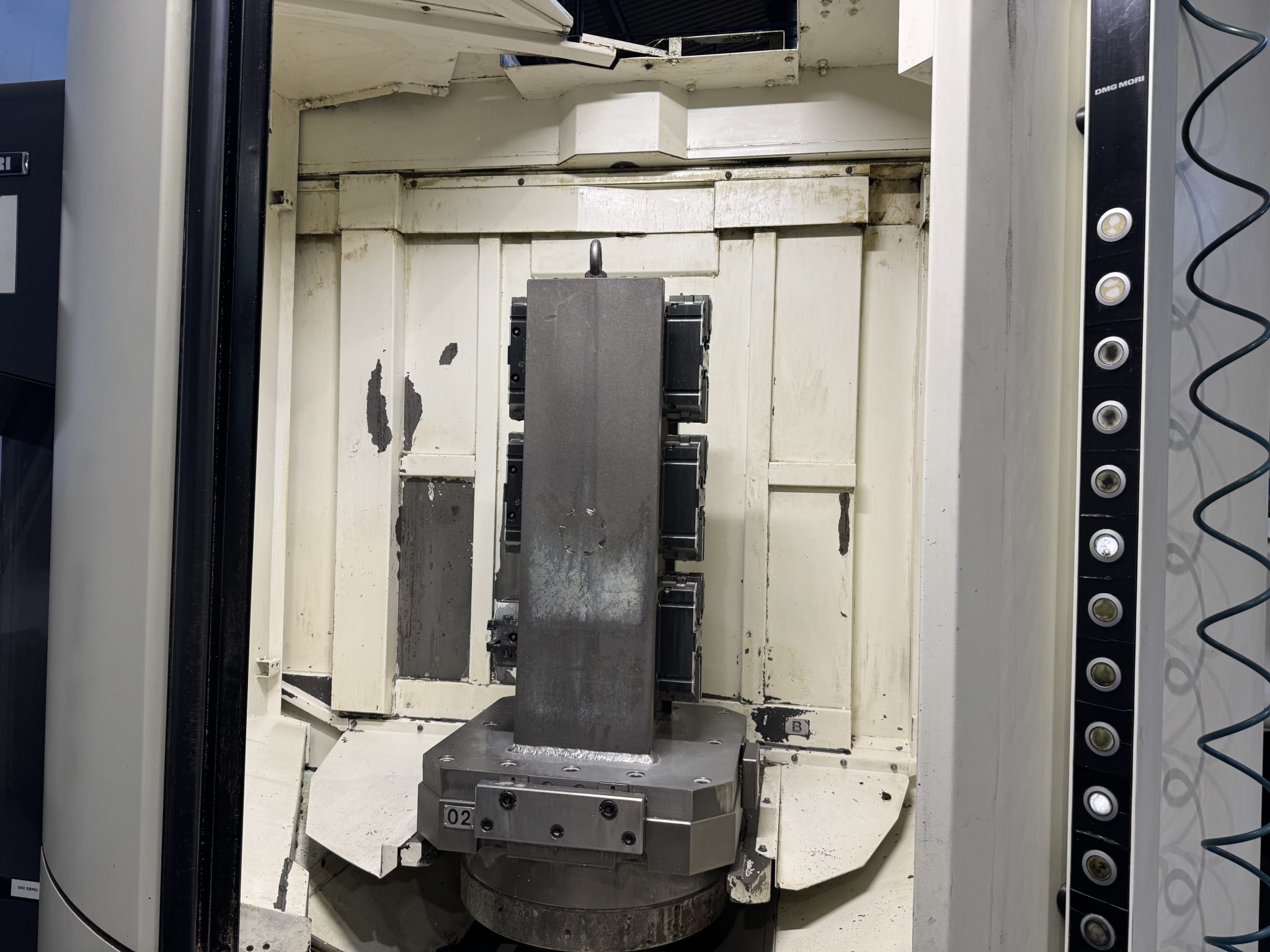

CNC Horizontal Machining Center DMG MORI NHX5000 | 2021

Binding Handling & Service Fee:

4785 € (EURO)

Machine Description for 2021 Model: Horizontal Machining Center NHX 5000 Manufacturer: DMG MORI Bielefeld Hilden GmbH Type / Model: NHX 5000, Fanuc 31iB with CELOS ERGOline Touch Year of Manufacture: 2021 Control System: FANUC 31iB with CELOS / 21.5" Multi-Touchscreen / MAPPS system Technical Data: • Working Area / Travels: Travel X / Y / Z: 730 / 730 / 880 mm Pallet size: 500 × 500 mm Pallet quantity: 2 (with threaded holes) Minimum B-axis indexing angle: 0.001° (DD direct drive) Max. rotary table speed: 100 rpm Pallet load: 500 kg Hydraulic coupling with 2 hydraulic and 2 air circuits (max. 7 MPa) Automatic indexing setup station • Performance / Spindle Speed / Drive Power: Spindle: speedMASTER® motor spindle Speed range: 35 – 20,000 rpm Power: 37 / 26 / 18.5 kW (15% / 30 min / continuous duty) Torque: 221 / 107 / 86.8 Nm Tool taper: SK40 (7/24 taper, face contact) Tool magazine capacity: 60 tools (ring-type, random selection) Max. tool diameter: 70 mm (adjacent) / 170 mm (free) Max. tool length: 550 mm Max. tool weight: 12 kg Chip conveyor: rear discharge with drum filter Through-spindle coolant interface (8-step pressure control, up to 7 MPa) Coolant / air switching via spindle External coolant system: INTERLIT TMF300/600 compact filter unit (70 bar / 32 L/min) • Weight / Dimensions / Electrical Connection: Machine weight: approx. 12,000 kg Coolant tank capacity: 800 L Transformer: 54 kVA Power supply: 400 V, 50 Hz Equipment / Accessories: Renishaw OMP60 spindle probe system (optical transmission) Tool breakage detection system in the magazine Hydraulic coupling on both pallets with integrated pressure regulation (7 MPa) Automatic door for setup station Rotating inspection window (air-driven) Oil mist extraction system: LTA AC3002 (1,050 m³/h, dual electrostatic stages) INTERLIT TMF300/600 high-pressure coolant filter system (70 bar, 32 L/min) EtherNet/IP robot interface IoTconnector, NETservice, Machine Data Connector (MDC), DMG MORI Messenger CELOS with touchscreen and MAPPS functionality Four-color signal light tower Handheld control device (mobile handwheel) Central coolant preparation for through-spindle supply Drain circuit for auto-coupler (to prevent pressure drop) 10 programmable external M-codes 2 hydraulic clamping towers (each with 6 hydraulic 2-jaw chucks, GHHY-2B-200.00/K) Voltage: 400 V, 50 Hz configuration Air filter unit (T105A-1000MSP) - LISTING 2800002

![Hungary]()

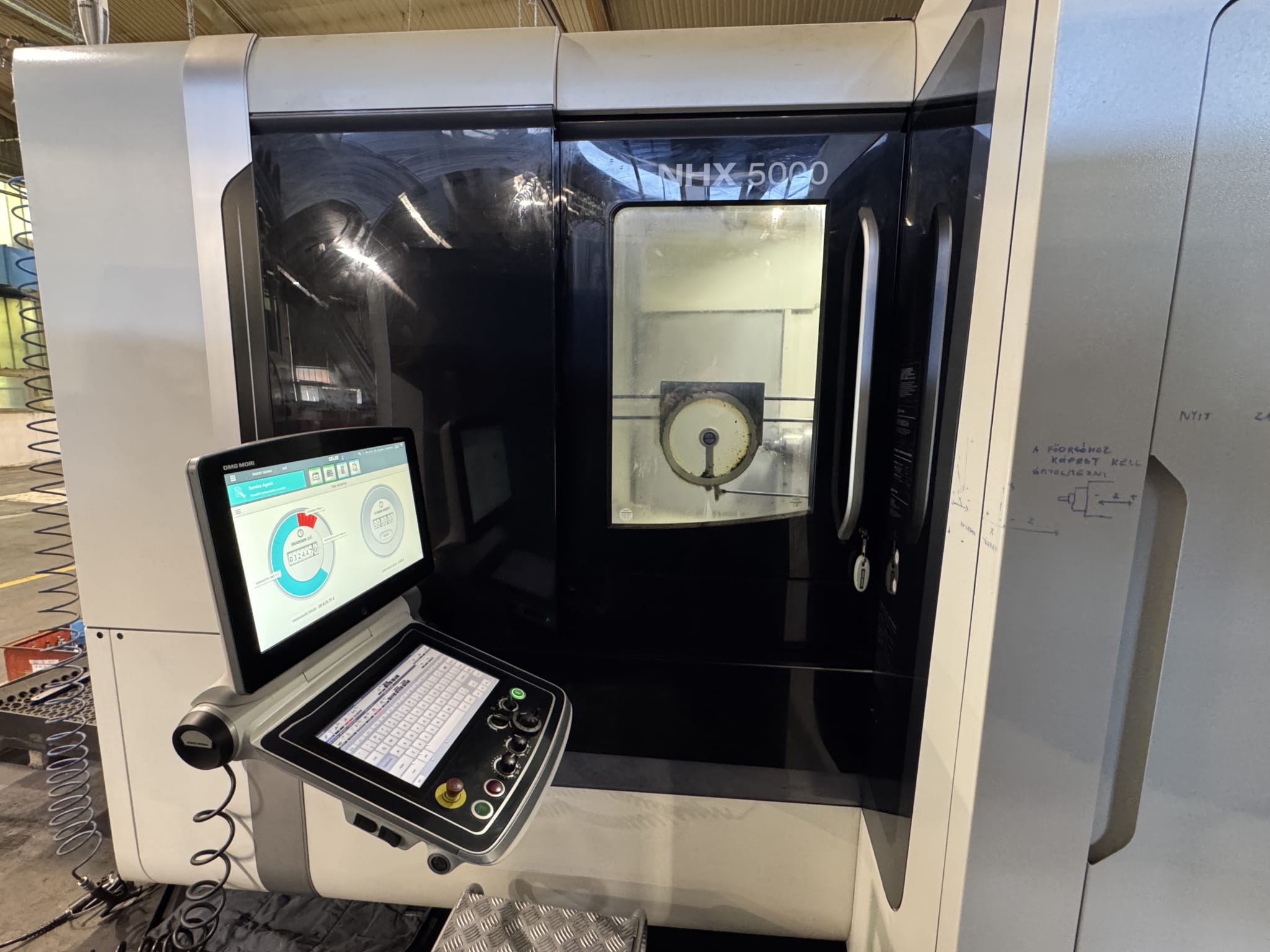

CNC Horizontal Machining Center DMG MORI NHX5000 | 2021

Binding Handling & Service Fee:

4785 € (EURO)

Machine Description for 2021 Model: Horizontal Machining Center NHX 5000 Manufacturer: DMG MORI Bielefeld Hilden GmbH Type / Model: NHX 5000, Fanuc 31iB with CELOS ERGOline Touch Year of Manufacture: 2021 Control System: FANUC 31iB with CELOS / 21.5" Multi-Touchscreen / MAPPS system Technical Data: • Working Area / Travels: Travel X / Y / Z: 730 / 730 / 880 mm Pallet size: 500 × 500 mm Pallet quantity: 2 (with threaded holes) Minimum B-axis indexing angle: 0.001° (DD direct drive) Max. rotary table speed: 100 rpm Pallet load: 500 kg Hydraulic coupling with 2 hydraulic and 2 air circuits (max. 7 MPa) Automatic indexing setup station • Performance / Spindle Speed / Drive Power: Spindle: speedMASTER® motor spindle Speed range: 35 – 20,000 rpm Power: 37 / 26 / 18.5 kW (15% / 30 min / continuous duty) Torque: 221 / 107 / 86.8 Nm Tool taper: SK40 (7/24 taper, face contact) Tool magazine capacity: 60 tools (ring-type, random selection) Max. tool diameter: 70 mm (adjacent) / 170 mm (free) Max. tool length: 550 mm Max. tool weight: 12 kg Chip conveyor: rear discharge with drum filter Through-spindle coolant interface (8-step pressure control, up to 7 MPa) Coolant / air switching via spindle External coolant system: INTERLIT TMF300/600 compact filter unit (70 bar / 32 L/min) • Weight / Dimensions / Electrical Connection: Machine weight: approx. 12,000 kg Coolant tank capacity: 800 L Transformer: 54 kVA Power supply: 400 V, 50 Hz Equipment / Accessories: Renishaw OMP60 spindle probe system (optical transmission) Tool breakage detection system in the magazine Hydraulic coupling on both pallets with integrated pressure regulation (7 MPa) Automatic door for setup station Rotating inspection window (air-driven) Oil mist extraction system: LTA AC3002 (1,050 m³/h, dual electrostatic stages) INTERLIT TMF300/600 high-pressure coolant filter system (70 bar, 32 L/min) EtherNet/IP robot interface IoTconnector, NETservice, Machine Data Connector (MDC), DMG MORI Messenger CELOS with touchscreen and MAPPS functionality Four-color signal light tower Handheld control device (mobile handwheel) Central coolant preparation for through-spindle supply Drain circuit for auto-coupler (to prevent pressure drop) 10 programmable external M-codes 2 hydraulic clamping towers (each with 6 hydraulic 2-jaw chucks, GHHY-2B-200.00/K) Voltage: 400 V, 50 Hz configuration Air filter unit (T105A-1000MSP) - LISTING 2800003

![Hungary]()

CNC Horizontal Machining Center DMG MORI NHX5000 | 2021

Binding Handling & Service Fee:

4785 € (EURO)

Machine Description for 2021 Model: Horizontal Machining Center NHX 5000 Manufacturer: DMG MORI Bielefeld Hilden GmbH Type / Model: NHX 5000, Fanuc 31iB with CELOS ERGOline Touch Year of Manufacture: 2021 Control System: FANUC 31iB with CELOS / 21.5" Multi-Touchscreen / MAPPS system Technical Data: • Working Area / Travels: Travel X / Y / Z: 730 / 730 / 880 mm Pallet size: 500 × 500 mm Pallet quantity: 2 (with threaded holes) Minimum B-axis indexing angle: 0.001° (DD direct drive) Max. rotary table speed: 100 rpm Pallet load: 500 kg Hydraulic coupling with 2 hydraulic and 2 air circuits (max. 7 MPa) Automatic indexing setup station • Performance / Spindle Speed / Drive Power: Spindle: speedMASTER® motor spindle Speed range: 35 – 20,000 rpm Power: 37 / 26 / 18.5 kW (15% / 30 min / continuous duty) Torque: 221 / 107 / 86.8 Nm Tool taper: SK40 (7/24 taper, face contact) Tool magazine capacity: 60 tools (ring-type, random selection) Max. tool diameter: 70 mm (adjacent) / 170 mm (free) Max. tool length: 550 mm Max. tool weight: 12 kg Chip conveyor: rear discharge with drum filter Through-spindle coolant interface (8-step pressure control, up to 7 MPa) Coolant / air switching via spindle External coolant system: INTERLIT TMF300/600 compact filter unit (70 bar / 32 L/min) • Weight / Dimensions / Electrical Connection: Machine weight: approx. 12,000 kg Coolant tank capacity: 800 L Transformer: 54 kVA Power supply: 400 V, 50 Hz Equipment / Accessories: Renishaw OMP60 spindle probe system (optical transmission) Tool breakage detection system in the magazine Hydraulic coupling on both pallets with integrated pressure regulation (7 MPa) Automatic door for setup station Rotating inspection window (air-driven) Oil mist extraction system: LTA AC3002 (1,050 m³/h, dual electrostatic stages) INTERLIT TMF300/600 high-pressure coolant filter system (70 bar, 32 L/min) EtherNet/IP robot interface IoTconnector, NETservice, Machine Data Connector (MDC), DMG MORI Messenger CELOS with touchscreen and MAPPS functionality Four-color signal light tower Handheld control device (mobile handwheel) Central coolant preparation for through-spindle supply Drain circuit for auto-coupler (to prevent pressure drop) 10 programmable external M-codes 2 hydraulic clamping towers (each with 6 hydraulic 2-jaw chucks, GHHY-2B-200.00/K) Voltage: 400 V, 50 Hz configuration Air filter unit (T105A-1000MSP) - LISTING 2800004

![Hungary]()

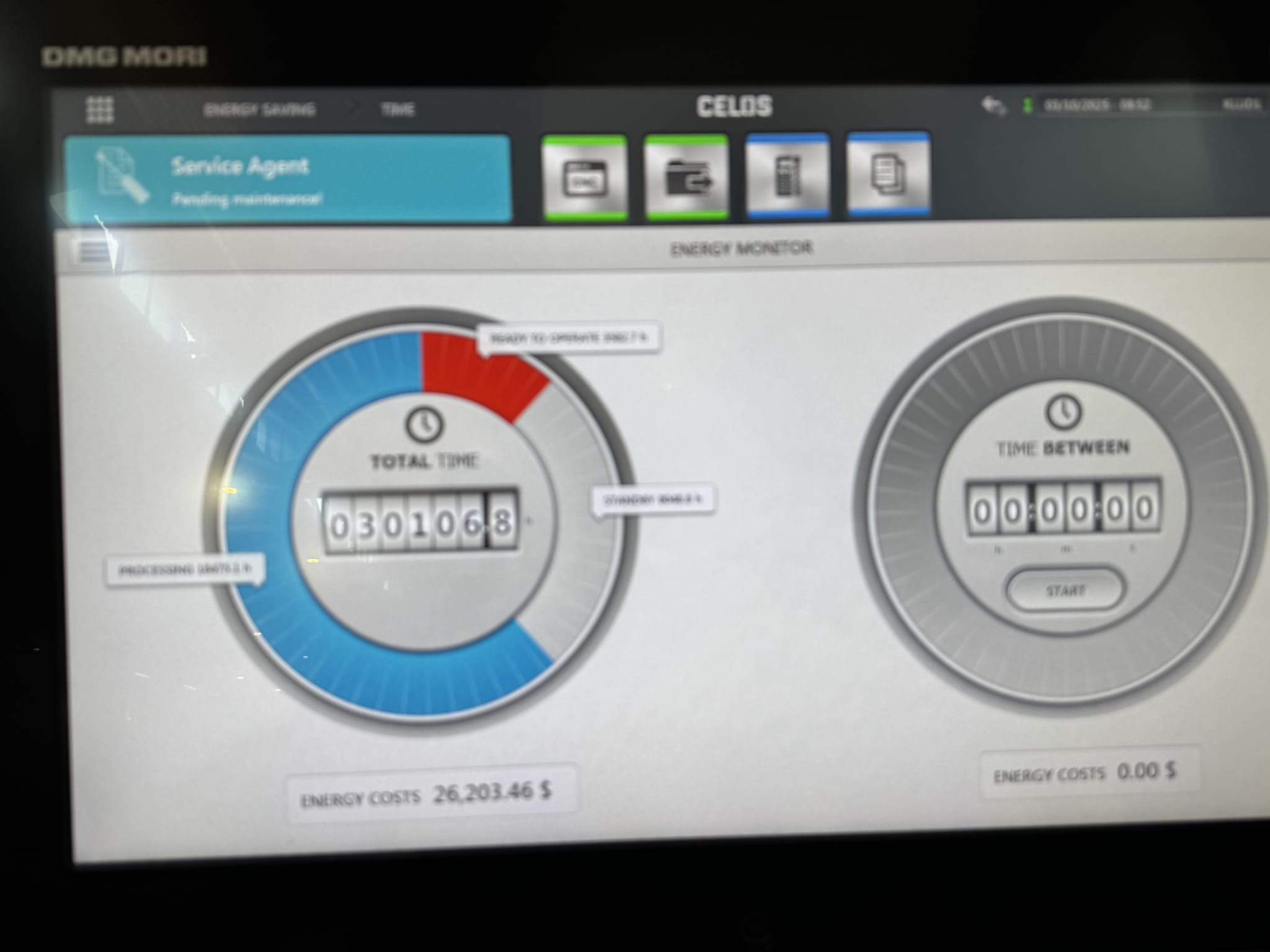

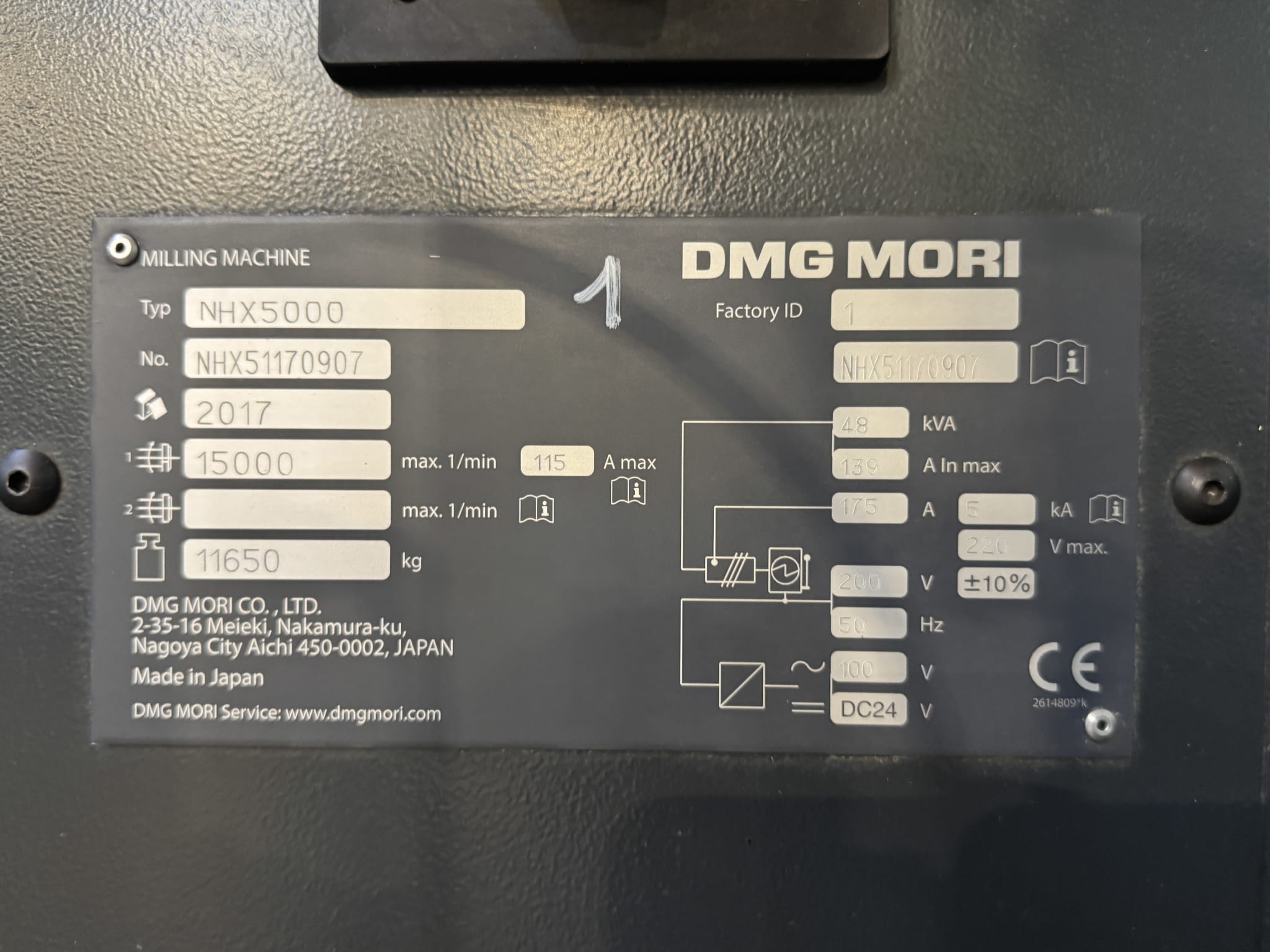

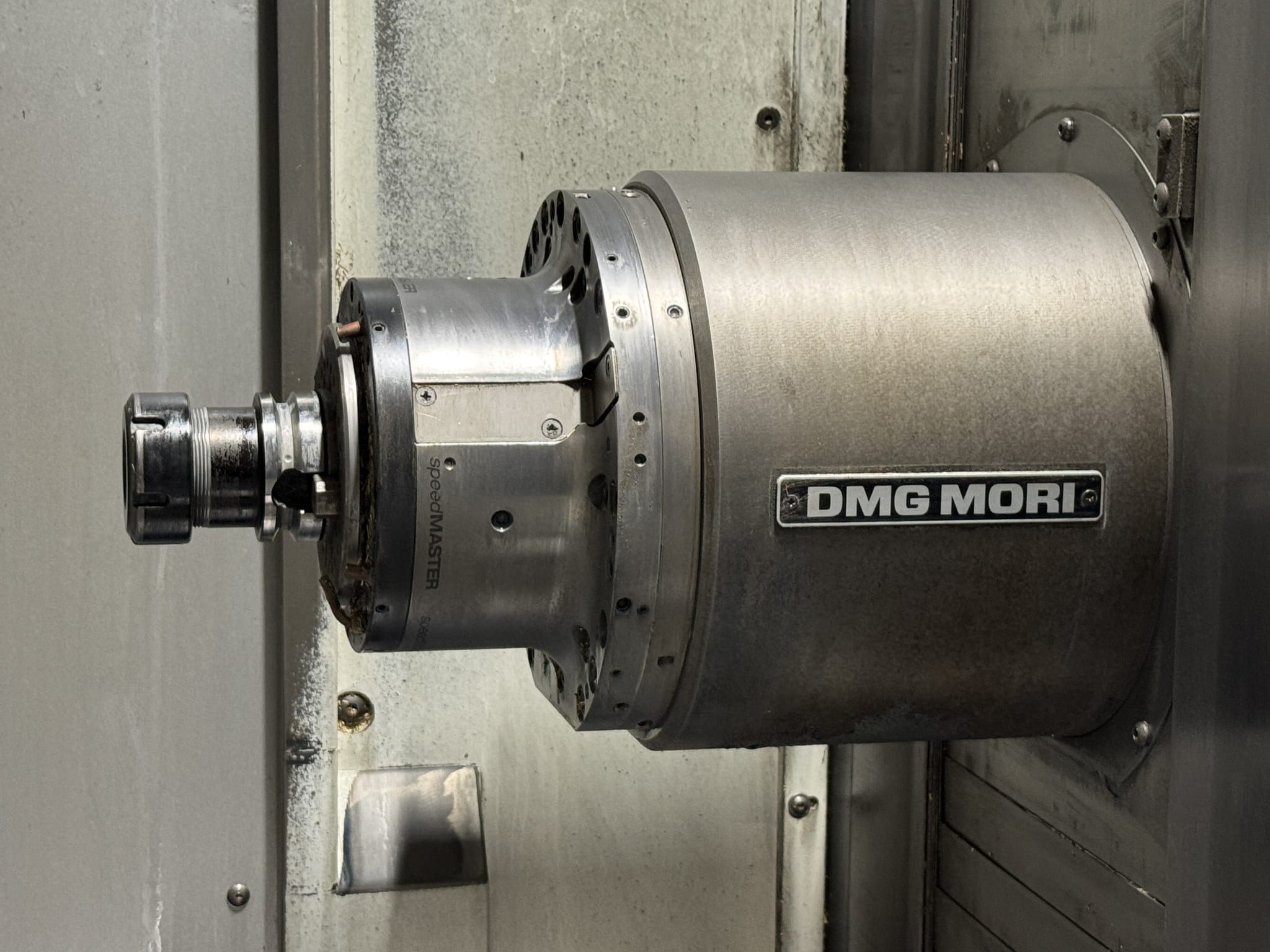

CNC Horizontal Machining Center DMG MORI NHX5000 | 2017

Binding Handling & Service Fee:

4785 € (EURO)

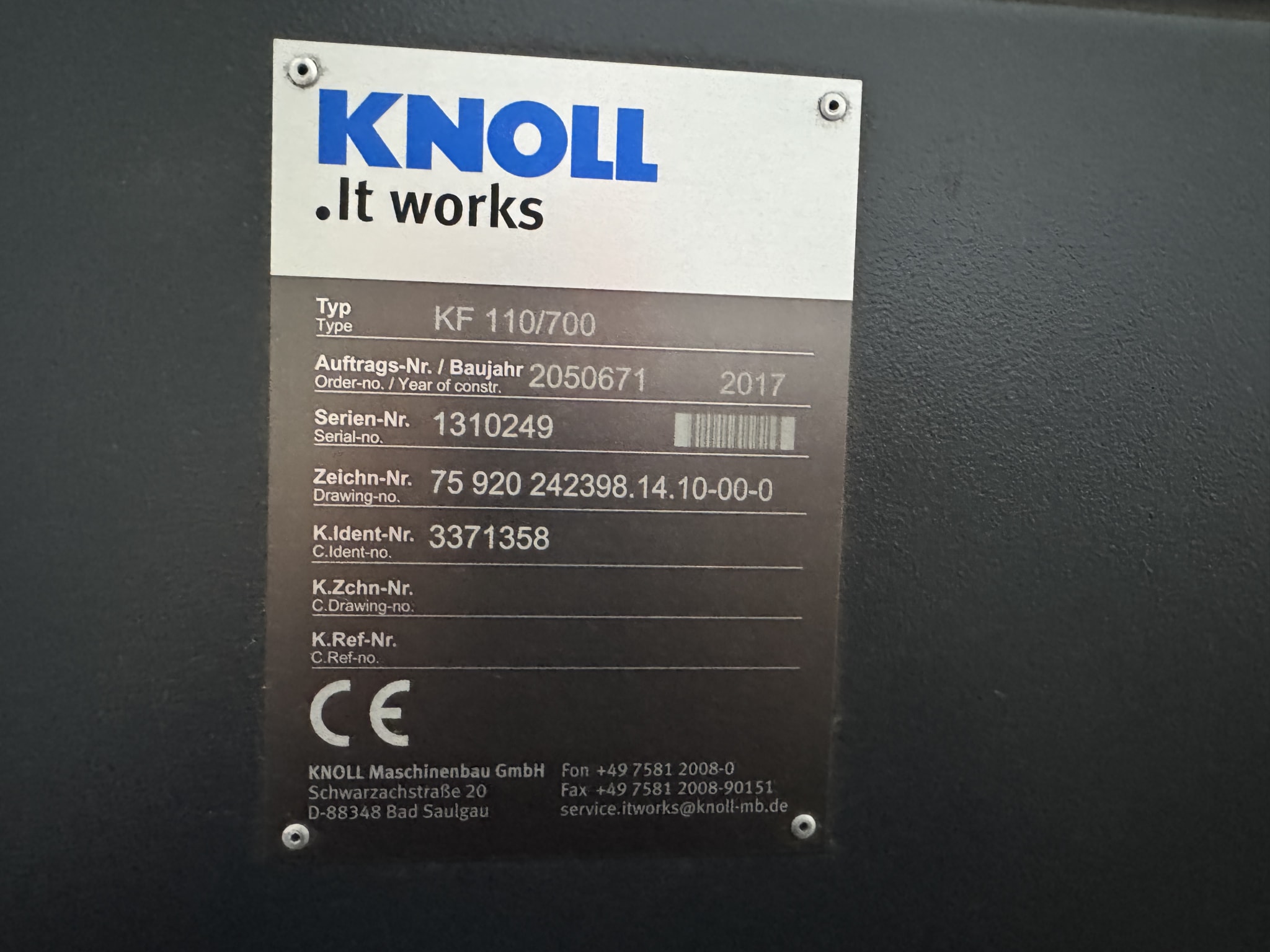

Machine Description for 2017 Model: Horizontal Machining Center NHX 5000 Manufacturer: DMG MORI Co. Ltd. Type / Model: NHX 5000_M730UM, Series J-NHX5000-C_C01 Year of Manufacture: 2016 Control System: MAPPS M730UM with CELOS / 21.5" ERGOline Touch Technical Data: • Working Area / Travels: Travel X / Y / Z: 730 / 730 / 880 mm Pallet size: 500 × 500 mm Max. workpiece diameter: 800 mm Max. workpiece height: 1,000 mm Distance spindle center to pallet surface: 80 – 810 mm Distance pallet center to spindle reference plane: 70 – 950 mm Pallet load: 500 kg [optional 700 kg] Number of pallets: 2 Minimum table indexing angle: 1° [optional 0.001° rotary table] • Performance / Spindle Speed / Drive Power: Spindle type: speedMASTER® motor spindle Spindle speed range: 35 – 15,000 rpm Power: 30.7 / 26 / 18.5 kW (15% ED / 30 min / continuous) Torque: 207 / 95.5 Nm (10% / 100% duty) Tool taper: BT40 / #40 Tool magazine capacity: 40 tools [optional 60 / 120 / 180 / 240] Max. tool diameter: 70 mm (adjacent) / 170 mm (free) Max. tool length: 550 mm Max. tool weight: 12 kg Tool change time (chip-to-chip): 2.5 s Rapid traverse X/Y/Z: 60 m/min Feedrate range: 0 – 60,000 mm/min Acceleration: 1 G • Weight / Dimensions / Electrical Connection: Machine weight (incl. coolant tank): approx. 12,000 kg Floor space (W × L): 3,078 × 4,784 mm Total height: 2,852 mm Coolant tank capacity: 800 L Power supply: 37.3 kVA Compressed air: 0.5 MPa / 420 L/min Equipment / Accessories: NC rotary table with 0.001° indexing (DDM optional) Automatic 2-pallet changer (rotary APC) Two pallets with threaded bores and interface for hydraulic fixtures Chip conveyor (rear discharge) Direct measuring systems on X/Y/Z axes Renishaw OMP60 spindle probe system Tool breakage control system in the magazine High-pressure coolant interface (70 bar, Knoll) Coolant / air switching device for through-spindle supply Rotating inspection window Coolant gun Oil mist separator interface Ø200 mm (LTA AC3002 optional) Automatic loading station door Signal tower (red/yellow/green/blue) Portable manual pulse generator (handwheel) Air filter unit for clean compressed air supply 45 kVA transformer Knoll KF110/700 high-pressure coolant unit (7.0 MPa, 31 L/min) Three hydraulic clamping towers with double-jaw chucks CELOS system with apps (Production, Accessories, Support, Monitoring, Configuration) MAPPS M730UM control with 21.5" touchscreen and 15.6" sub-display SmartKey® operator access management - LISTING 2800005

![Hungary]()

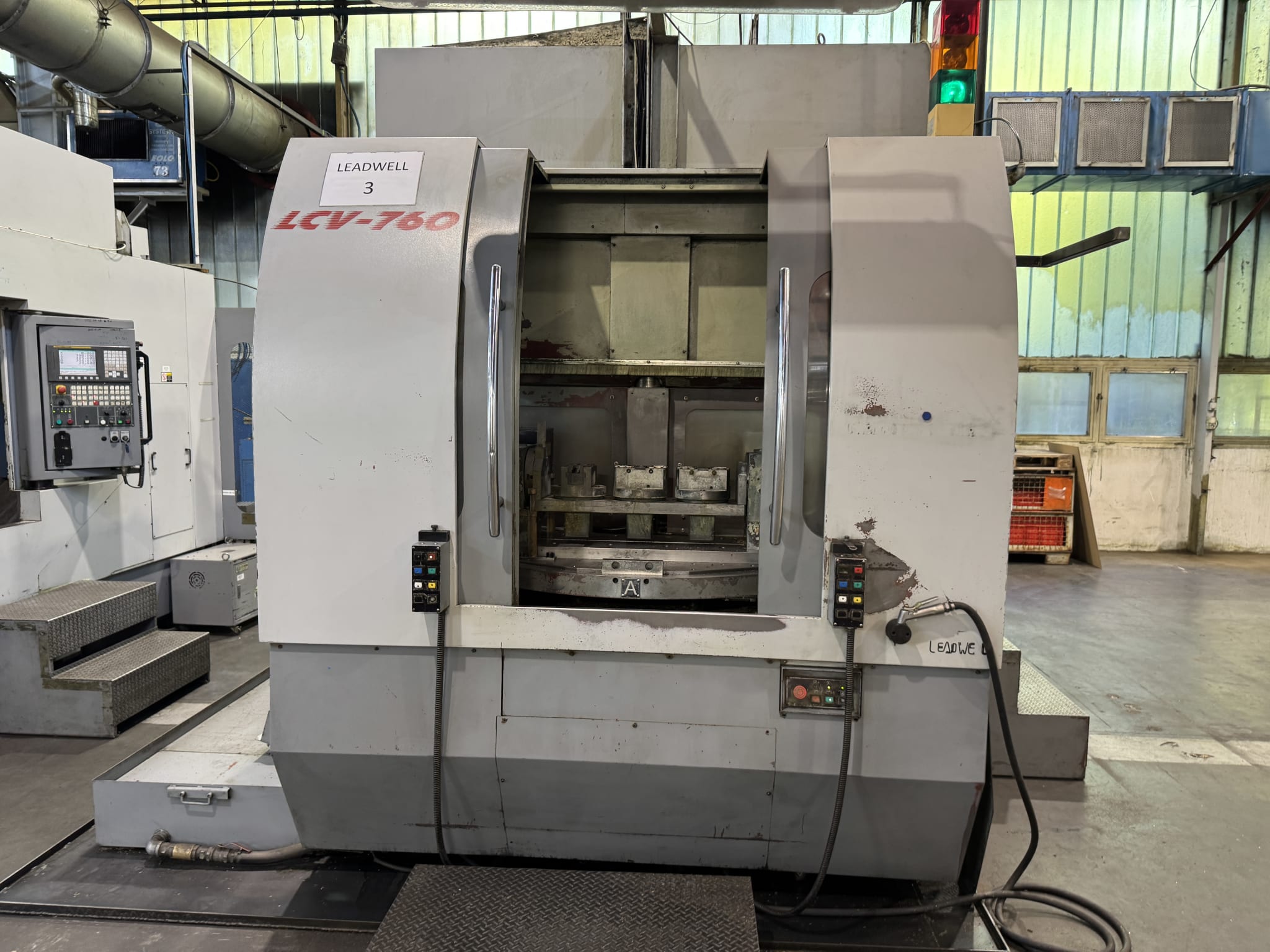

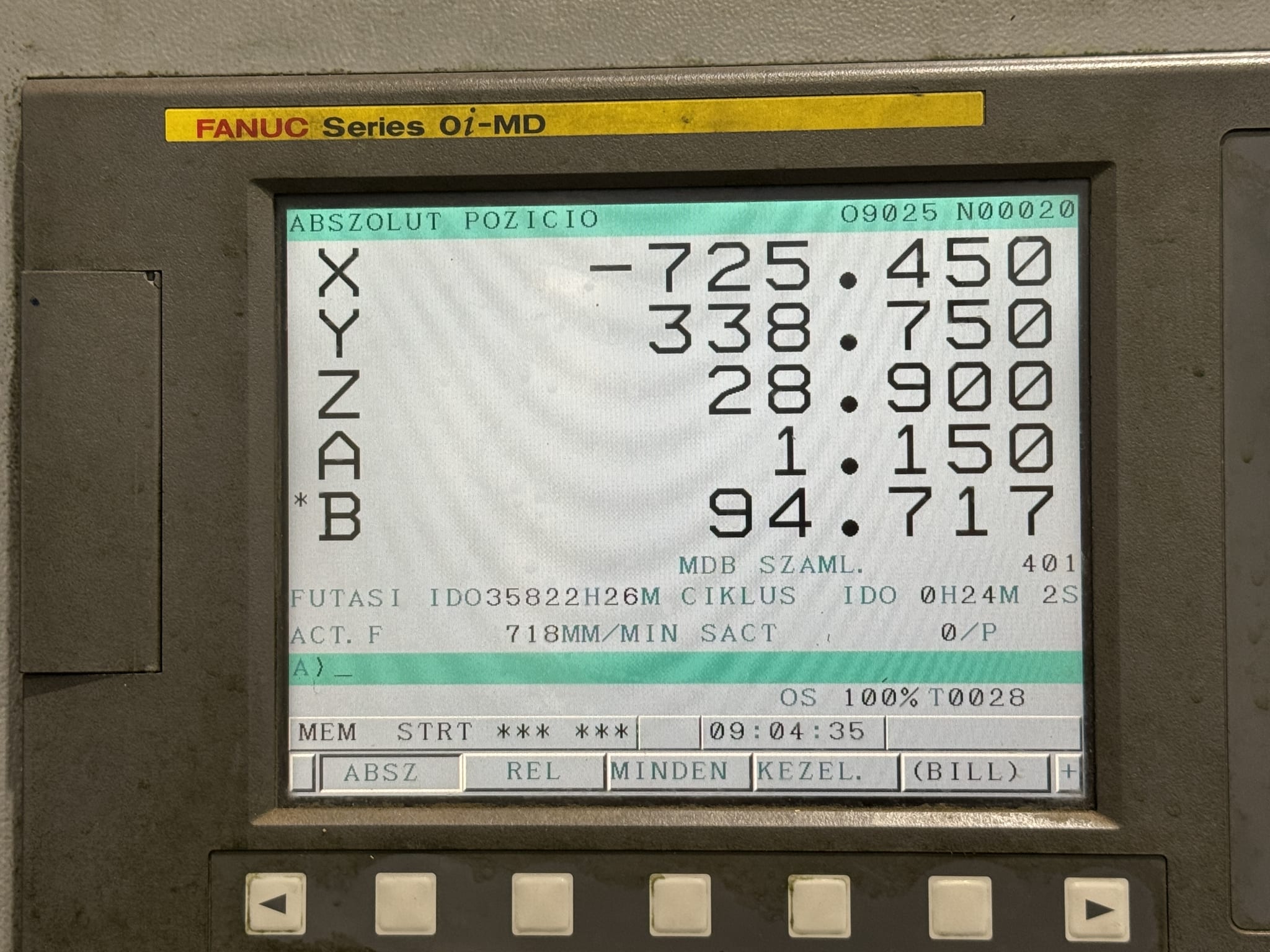

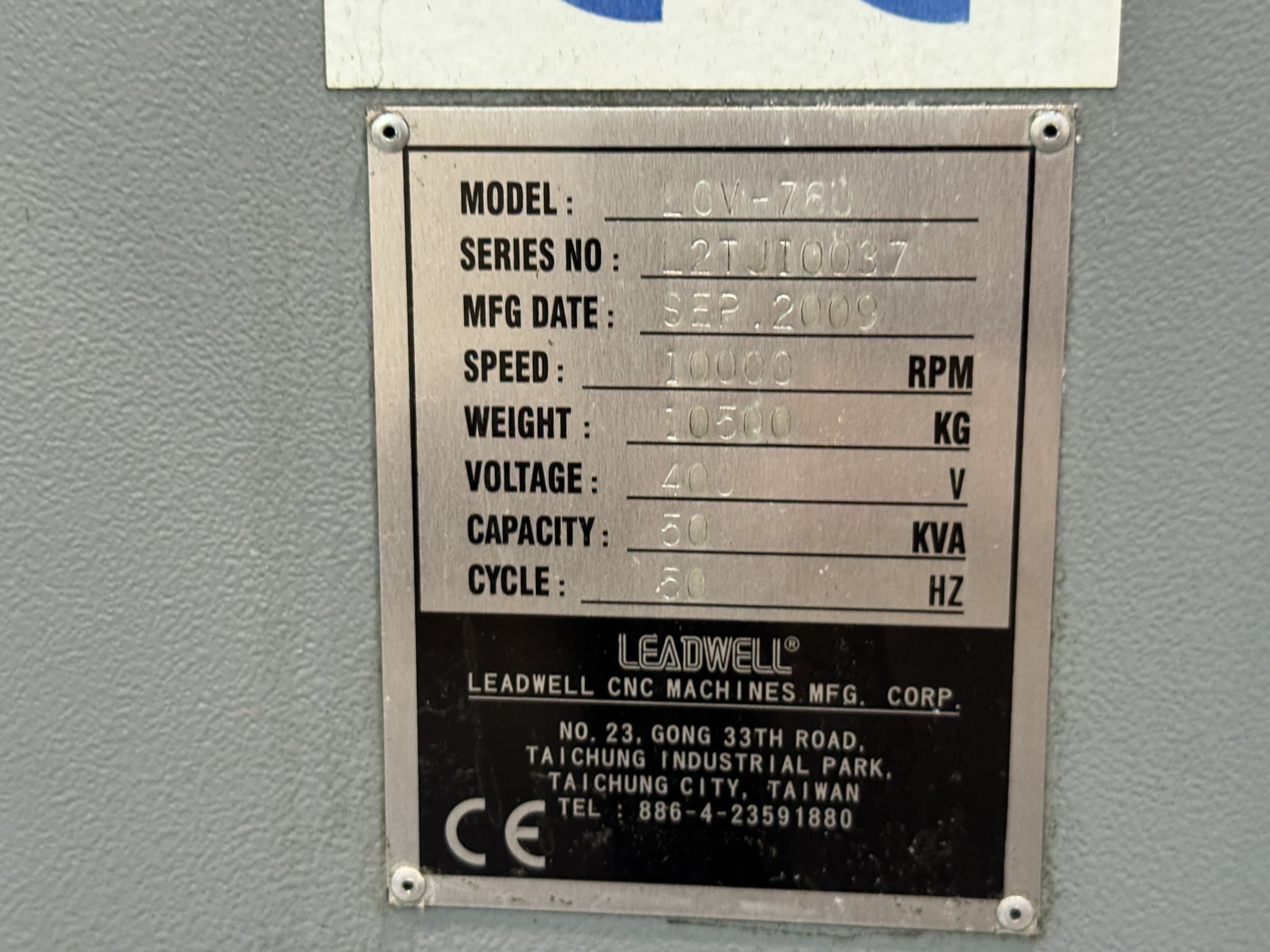

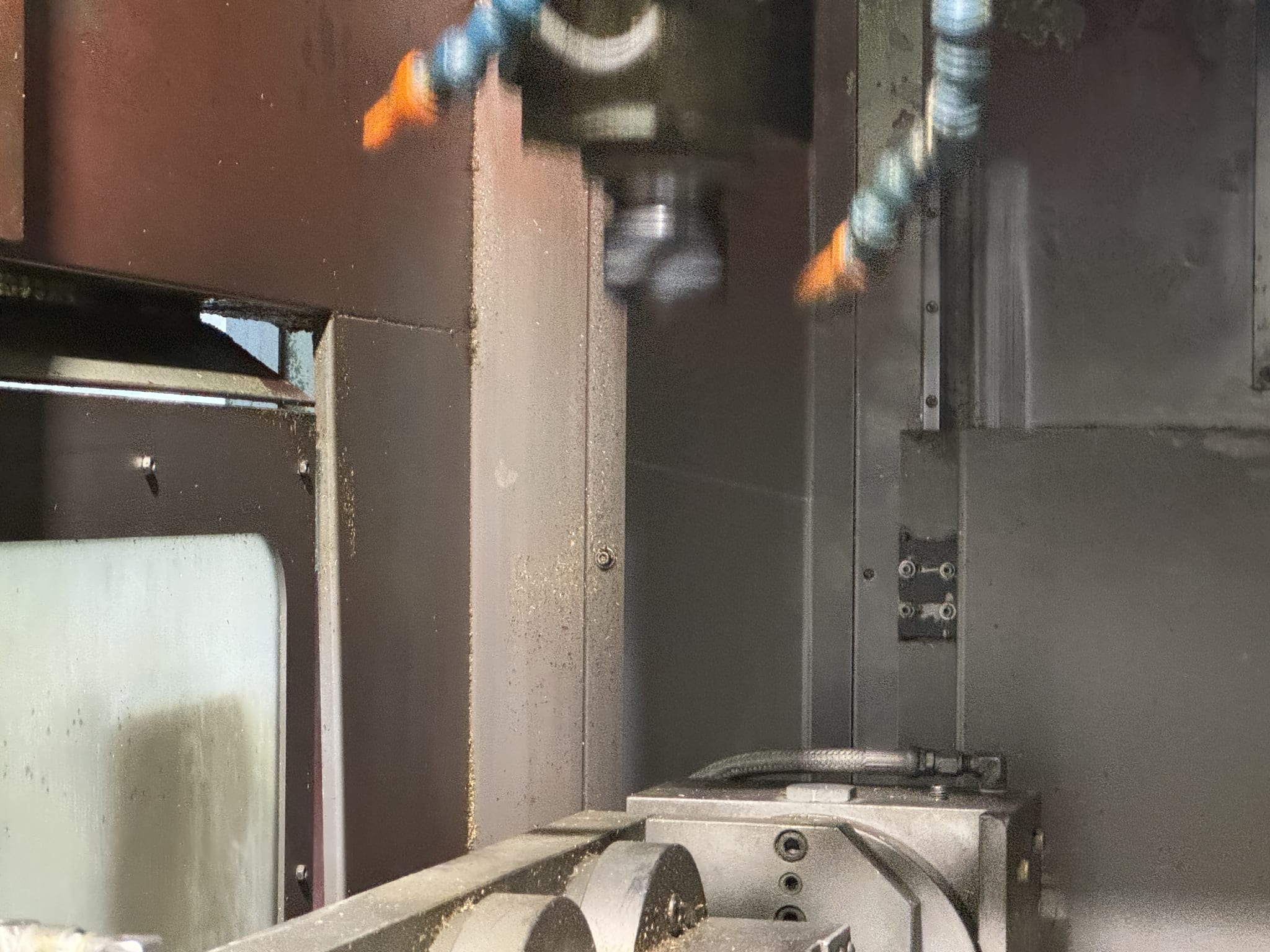

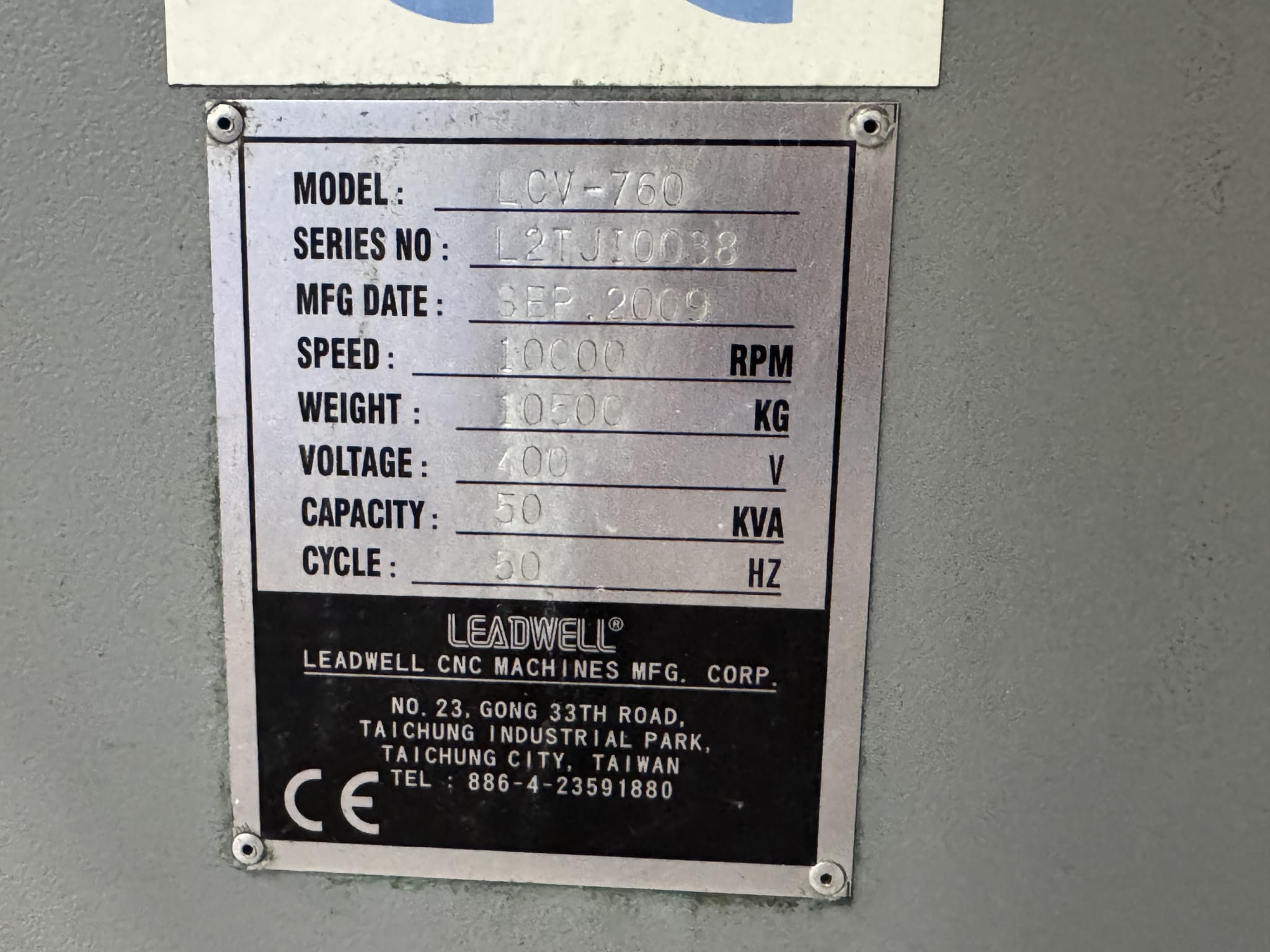

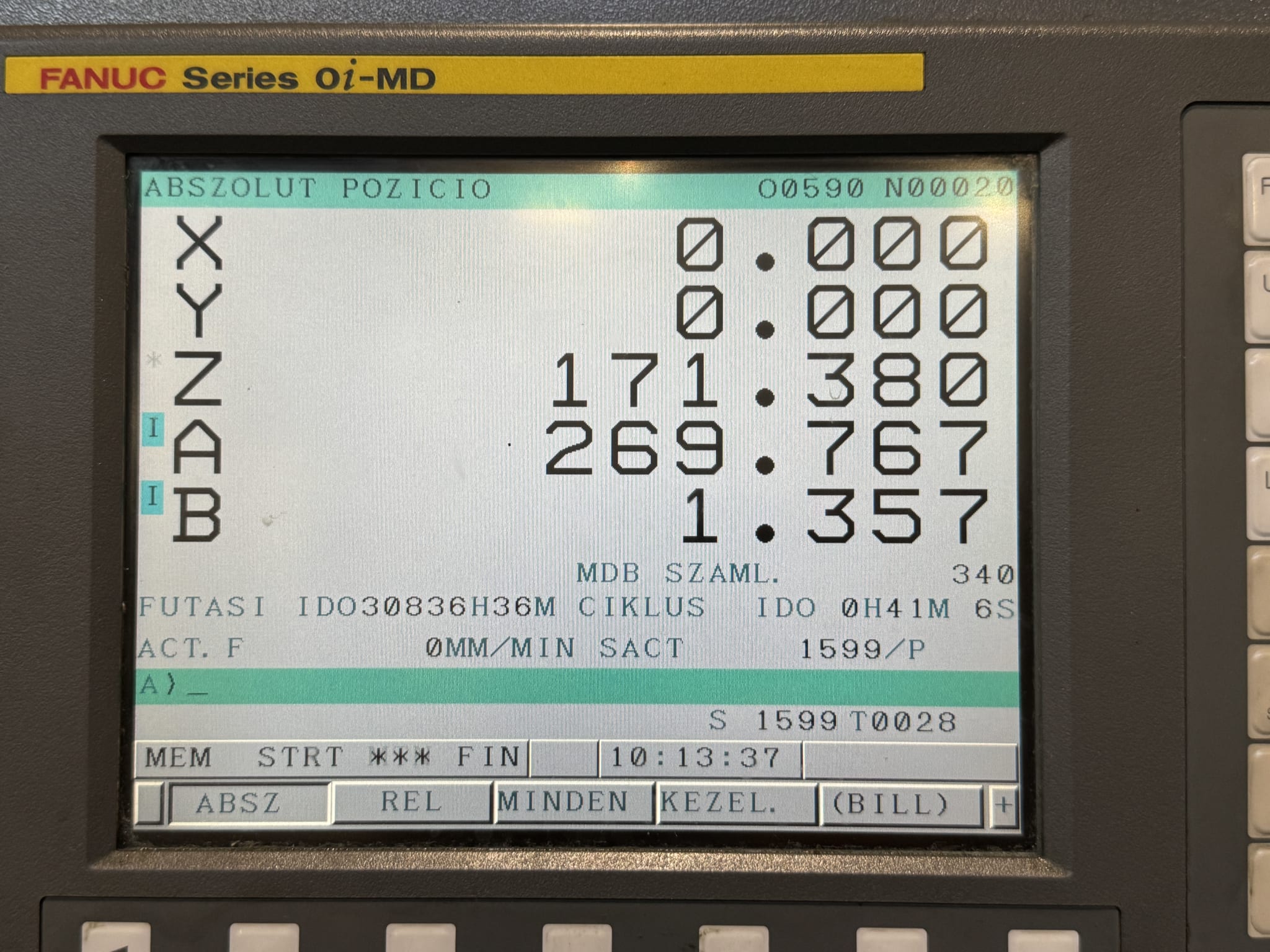

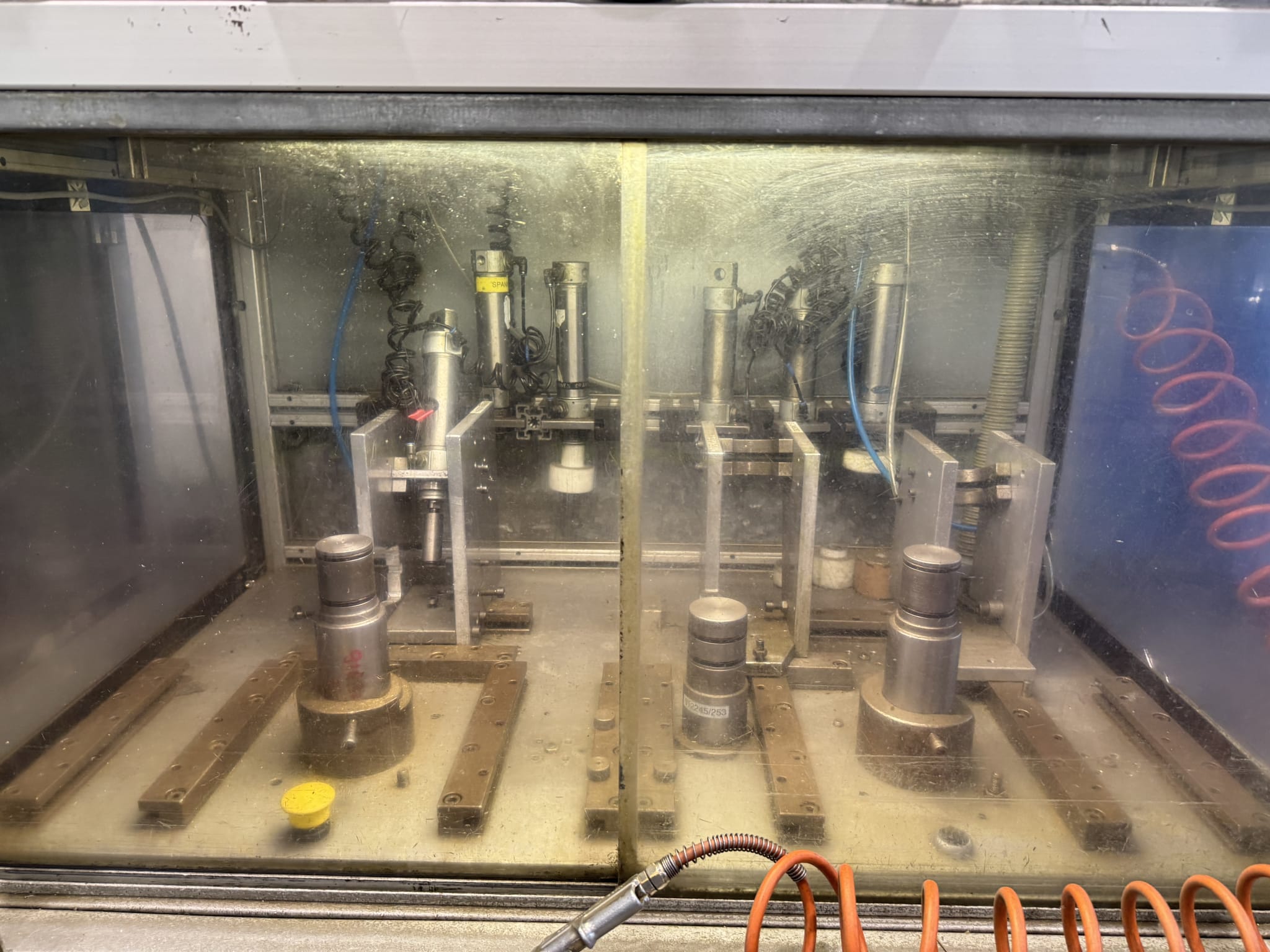

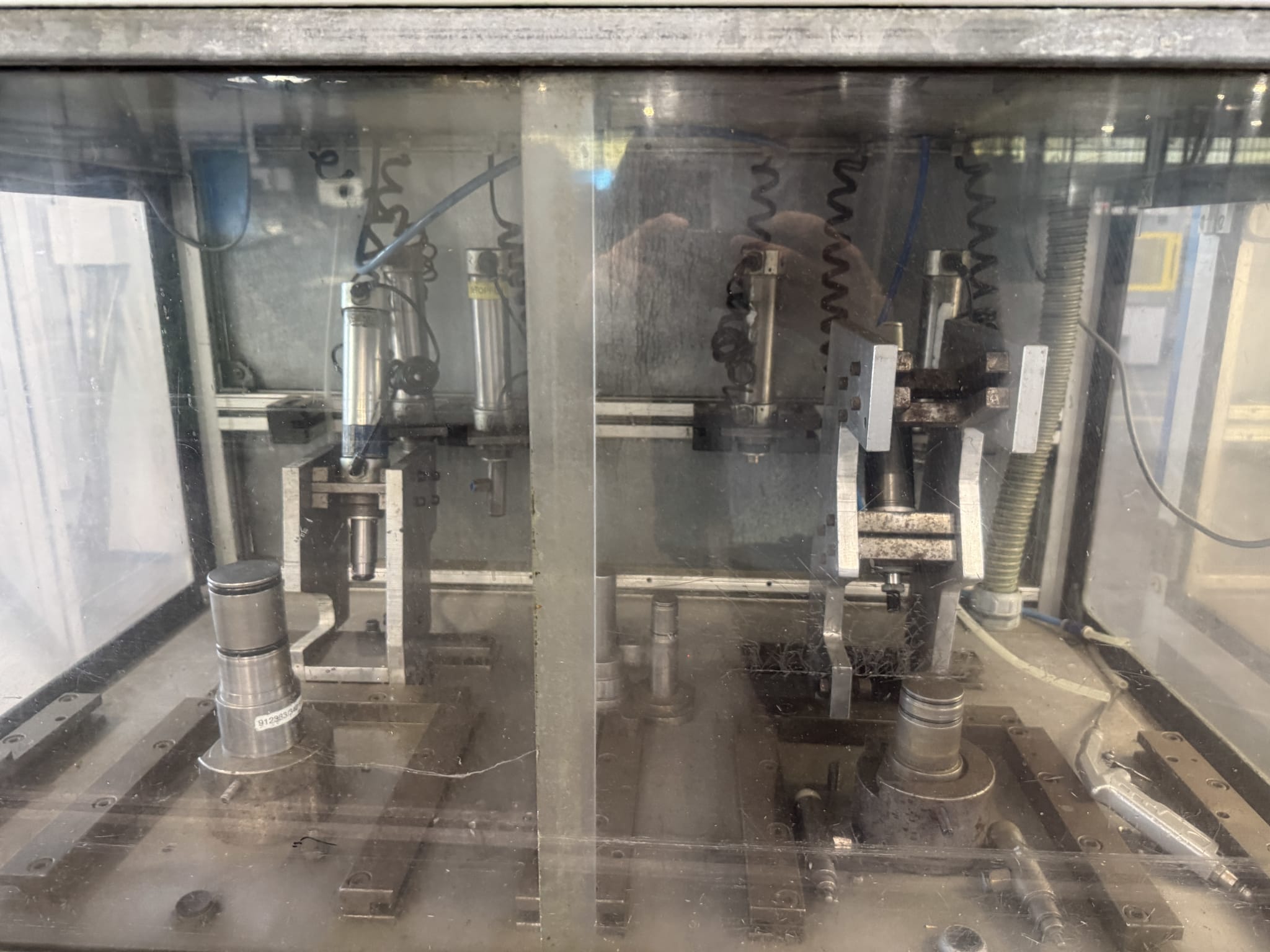

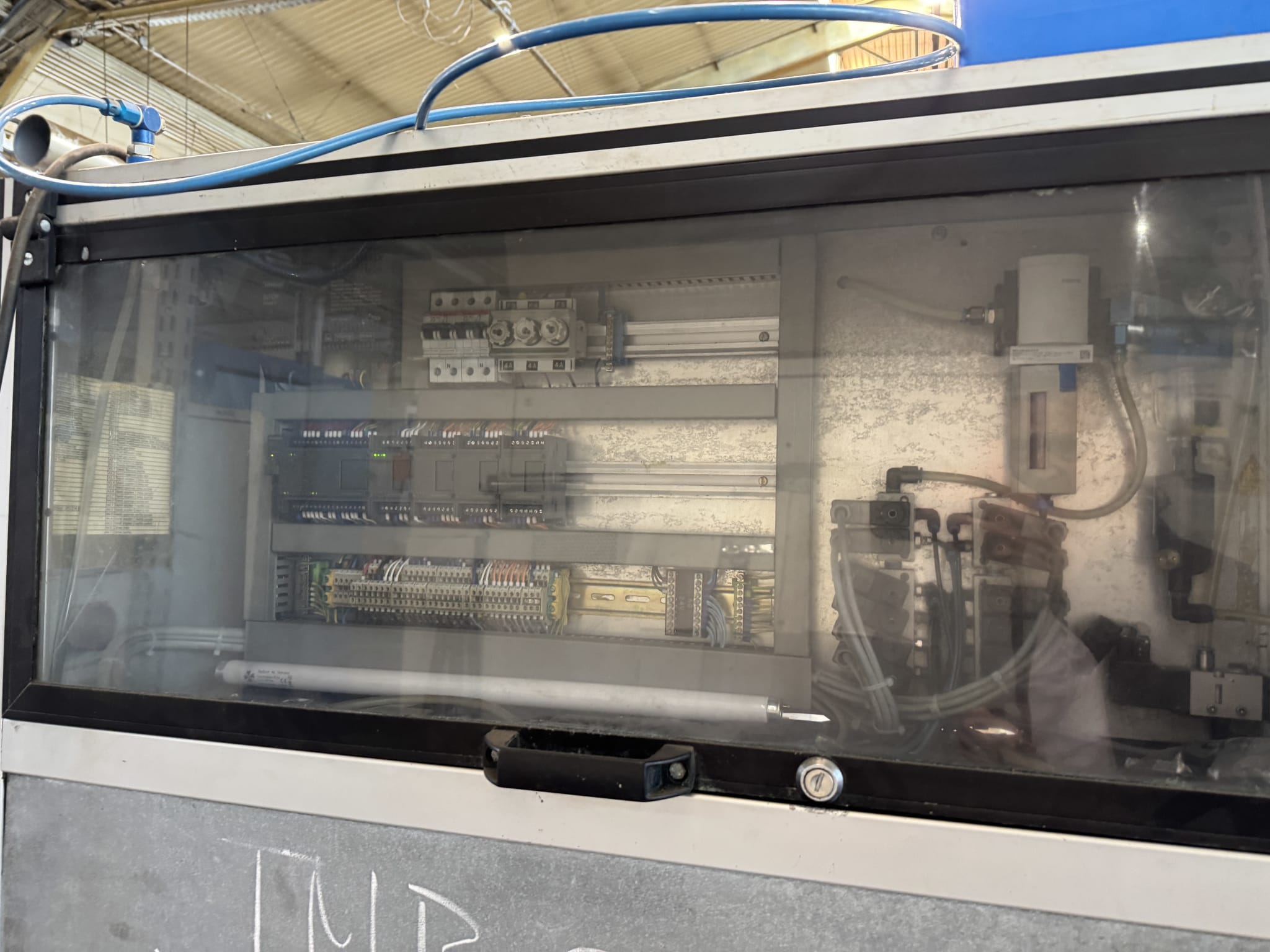

CNC 2-Pallet Vertical Machining Center Leadwell LCV-760 | 2009

Binding Handling & Service Fee:

3850 € (EURO)

Machine Designation: Vertical Machining Center LCV-760 (Column Moving Type) Manufacturer: LEADWELL CNC Machines Mfg. Corp., Taichung, Taiwan Type / Model: LCV-760 Control System: FANUC Oi-MD Technical Data • Working Area / Travels: X-axis travel: 760 mm Y-axis travel: 610 mm Z-axis travel: 610 mm Distance from table (pallet) top to spindle end: 150 – 760 mm Distance from column front to spindle center: 718 mm Table size: 850 × 600 mm Permissible workpiece weight: 400 kg Table configuration: M16 × P2.0 mm T-slots Table height (floor to top): 1033 mm • Spindle / Drive: Spindle speed: 10 000 rpm (optional 12 000 rpm) Spindle motor: 18.5 / 24 kW (30 min / continuous) Max. spindle torque: 95 Nm (67.5 ft-lb) Spindle taper: 7/24 TAPER No. 40 (BT-40) Spindle bearing inner diameter: Ø 70 mm Tool clamping force: 1200 kgf Transmission: HT.D belt drive Spindle oil chiller: included Rigid tapping: standard • Feedrates: Rapid traverse (X / Y / Z): 32 / 32 / 32 m/min Cutting feedrate: 10 m/min Jog feedrate: 2500 mm/min • Automatic Tool Changer (ATC): Type: arm-type changer Tool capacity: 30 tools Tool taper: BT-40 Retention knob: MAS P40T-1 (JIS B-6339) Max. tool diameter (adjacent): Ø 80 mm Max. tool diameter (free): Ø 100 mm Max. tool length: 250 mm Max. tool weight: 7 kg Tool change time (tool-to-tool): 2 s Chip-to-chip: 6 s • Automatic Pallet Changer (APC): Number of pallets: 2 Change method: hydraulic “swapper” type Pallet change time: 12 s • Motors: Spindle motor: 18.5 kW (24 HP) X-axis feed motor: 4.5 kW (6.4 HP), 30 Nm torque Y-axis feed motor: 4.5 kW (6.4 HP), 30 Nm torque Z-axis feed motor: 3.88 kW (5.4 HP), 22 Nm torque Hydraulic pump motor: 3 kW Lubrication pump motor: 0.01 kW Coolant pump motor: 0.76 kW • Guideways: X-axis: SNS45C2SSCOEx3 (600 mm width, 1000 mm distance) Y-axis: SNS45LC2X151SLHx2 (600 mm width, 600 mm distance) Z-axis: SHS45R2SSCOEx1305×2 (500 mm distance) • Utilities / Connections: Electrical power supply: 45 kVA Compressed air: 0.6 MPa (87 psi) @ 400 L/min Hydraulic oil tank: 400 L Lubrication tank: 2 L Coolant tank: 300 L • Dimensions / Weight: Machine height: 2885 mm Floor space: 3510 × 2410 mm Machine weight: 9200 – 9500 kg (≈ 10 t lifting requirement) • Cutting Capacity: Milling: 230 cm³/min Drilling: Ø 40 mm Tapping: M30 - LISTING 2800006

![Hungary]()

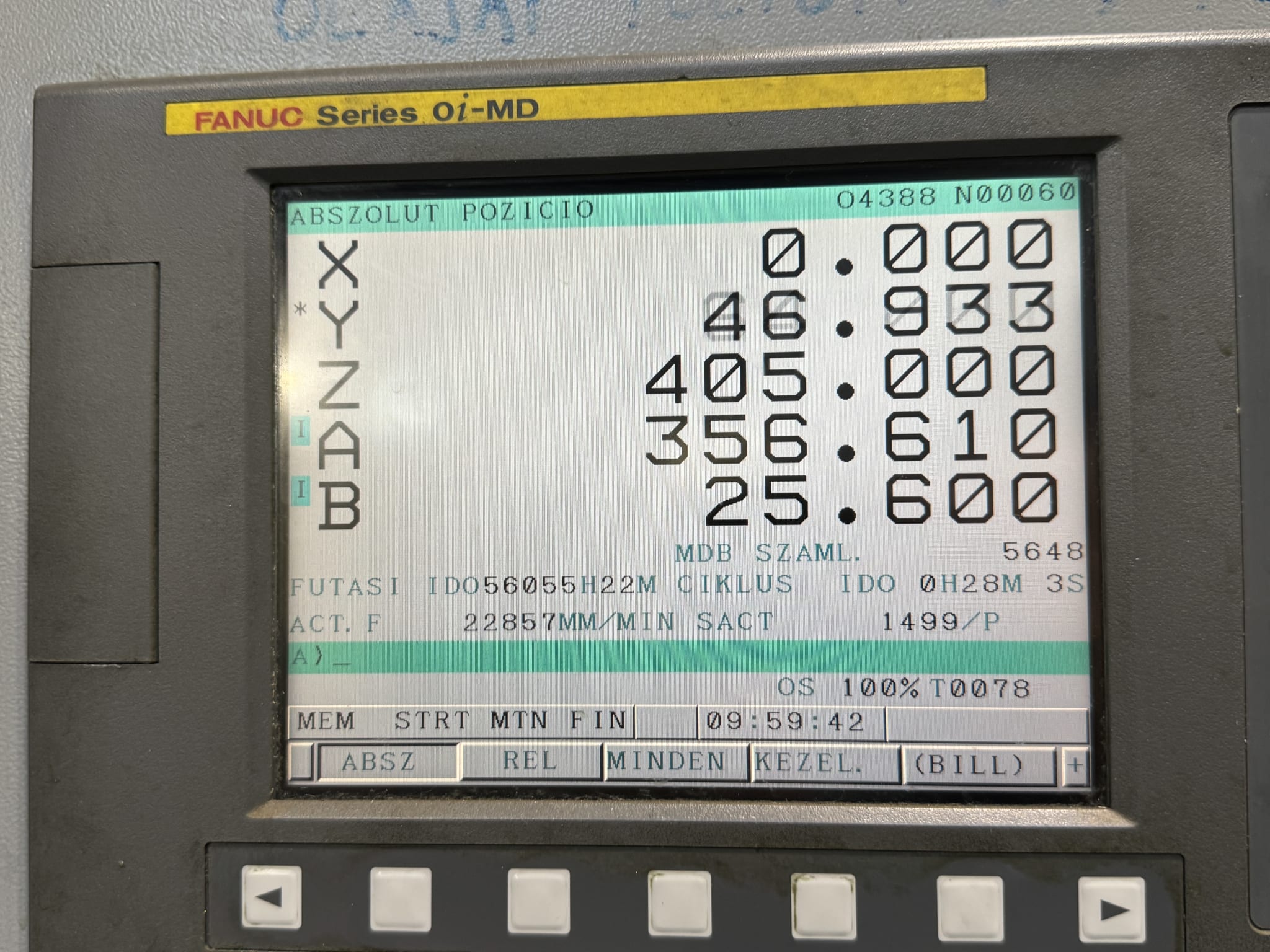

CNC 2-Pallet Vertical Machining Center Leadwell LCV-760 | 2009

Binding Handling & Service Fee:

3850 € (EURO)

Machine Designation: Vertical Machining Center LCV-760 (Column Moving Type) Manufacturer: LEADWELL CNC Machines Mfg. Corp., Taichung, Taiwan Type / Model: LCV-760 Control System: FANUC Oi-MD Technical Data • Working Area / Travels: X-axis travel: 760 mm Y-axis travel: 610 mm Z-axis travel: 610 mm Distance from table (pallet) top to spindle end: 150 – 760 mm Distance from column front to spindle center: 718 mm Table size: 850 × 600 mm Permissible workpiece weight: 400 kg Table configuration: M16 × P2.0 mm T-slots Table height (floor to top): 1033 mm • Spindle / Drive: Spindle speed: 10 000 rpm (optional 12 000 rpm) Spindle motor: 18.5 / 24 kW (30 min / continuous) Max. spindle torque: 95 Nm (67.5 ft-lb) Spindle taper: 7/24 TAPER No. 40 (BT-40) Spindle bearing inner diameter: Ø 70 mm Tool clamping force: 1200 kgf Transmission: HT.D belt drive Spindle oil chiller: included Rigid tapping: standard • Feedrates: Rapid traverse (X / Y / Z): 32 / 32 / 32 m/min Cutting feedrate: 10 m/min Jog feedrate: 2500 mm/min • Automatic Tool Changer (ATC): Type: arm-type changer Tool capacity: 30 tools Tool taper: BT-40 Retention knob: MAS P40T-1 (JIS B-6339) Max. tool diameter (adjacent): Ø 80 mm Max. tool diameter (free): Ø 100 mm Max. tool length: 250 mm Max. tool weight: 7 kg Tool change time (tool-to-tool): 2 s Chip-to-chip: 6 s • Automatic Pallet Changer (APC): Number of pallets: 2 Change method: hydraulic “swapper” type Pallet change time: 12 s • Motors: Spindle motor: 18.5 kW (24 HP) X-axis feed motor: 4.5 kW (6.4 HP), 30 Nm torque Y-axis feed motor: 4.5 kW (6.4 HP), 30 Nm torque Z-axis feed motor: 3.88 kW (5.4 HP), 22 Nm torque Hydraulic pump motor: 3 kW Lubrication pump motor: 0.01 kW Coolant pump motor: 0.76 kW • Guideways: X-axis: SNS45C2SSCOEx3 (600 mm width, 1000 mm distance) Y-axis: SNS45LC2X151SLHx2 (600 mm width, 600 mm distance) Z-axis: SHS45R2SSCOEx1305×2 (500 mm distance) • Utilities / Connections: Electrical power supply: 45 kVA Compressed air: 0.6 MPa (87 psi) @ 400 L/min Hydraulic oil tank: 400 L Lubrication tank: 2 L Coolant tank: 300 L • Dimensions / Weight: Machine height: 2885 mm Floor space: 3510 × 2410 mm Machine weight: 9200 – 9500 kg (≈ 10 t lifting requirement) • Cutting Capacity: Milling: 230 cm³/min Drilling: Ø 40 mm Tapping: M30 - LISTING 2800007

![Hungary]()

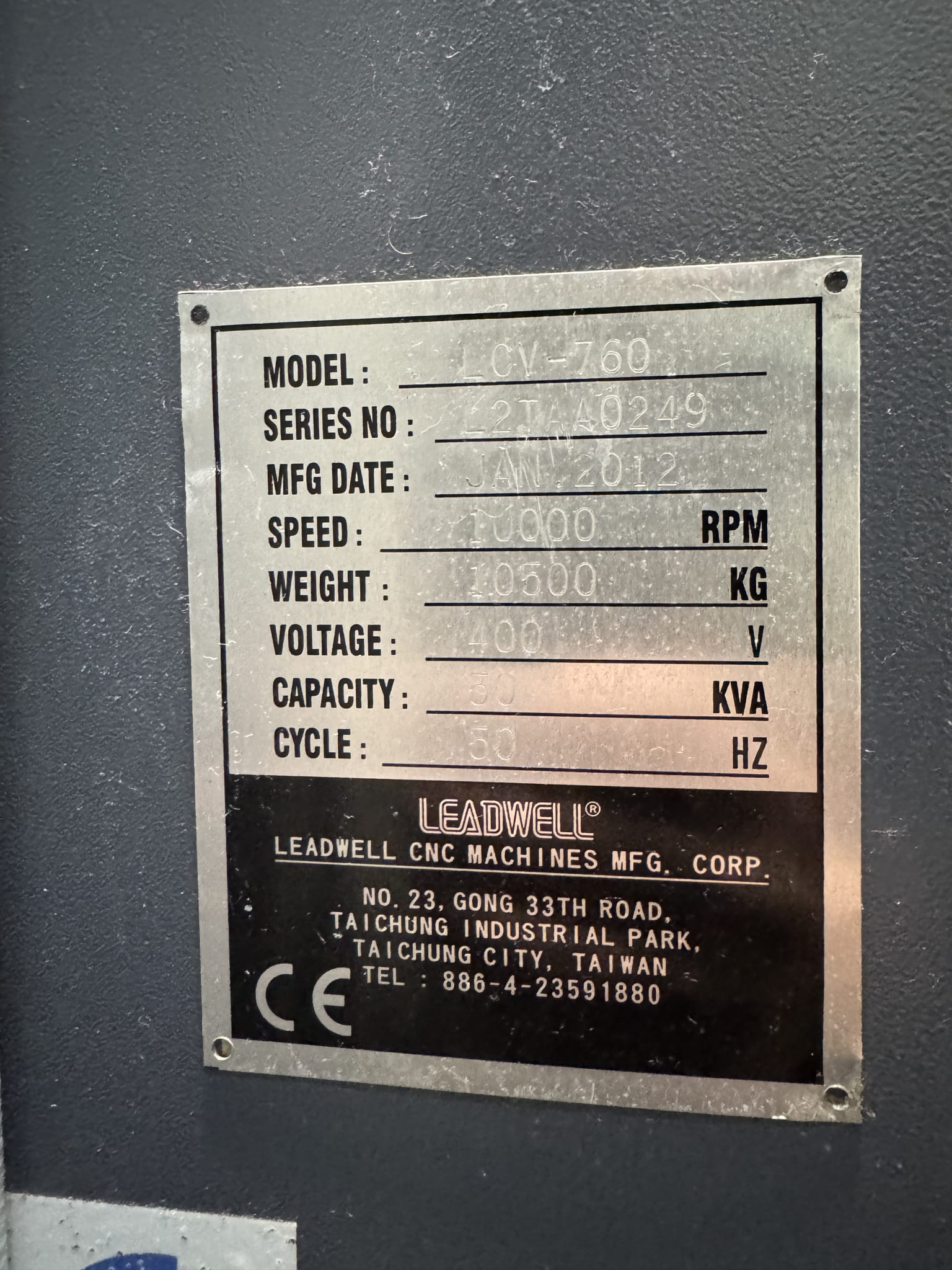

CNC 2-Pallet Vertical Machining Center Leadwell LCV-760 | 2012

Binding Handling & Service Fee:

3850 € (EURO)

Machine Designation: Vertical Machining Center LCV-760 (Column Moving Type) Manufacturer: LEADWELL CNC Machines Mfg. Corp., Taichung, Taiwan Type / Model: LCV-760 Control System: FANUC Oi-MD Technical Data • Working Area / Travels: X-axis travel: 760 mm Y-axis travel: 610 mm Z-axis travel: 610 mm Distance from table (pallet) top to spindle end: 150 – 760 mm Distance from column front to spindle center: 718 mm Table size: 850 × 600 mm Permissible workpiece weight: 400 kg Table configuration: M16 × P2.0 mm T-slots Table height (floor to top): 1033 mm • Spindle / Drive: Spindle speed: 10 000 rpm (optional 12 000 rpm) Spindle motor: 18.5 / 24 kW (30 min / continuous) Max. spindle torque: 95 Nm (67.5 ft-lb) Spindle taper: 7/24 TAPER No. 40 (BT-40) Spindle bearing inner diameter: Ø 70 mm Tool clamping force: 1200 kgf Transmission: HT.D belt drive Spindle oil chiller: included Rigid tapping: standard • Feedrates: Rapid traverse (X / Y / Z): 32 / 32 / 32 m/min Cutting feedrate: 10 m/min Jog feedrate: 2500 mm/min • Automatic Tool Changer (ATC): Type: arm-type changer Tool capacity: 30 tools Tool taper: BT-40 Retention knob: MAS P40T-1 (JIS B-6339) Max. tool diameter (adjacent): Ø 80 mm Max. tool diameter (free): Ø 100 mm Max. tool length: 250 mm Max. tool weight: 7 kg Tool change time (tool-to-tool): 2 s Chip-to-chip: 6 s • Automatic Pallet Changer (APC): Number of pallets: 2 Change method: hydraulic “swapper” type Pallet change time: 12 s • Motors: Spindle motor: 18.5 kW (24 HP) X-axis feed motor: 4.5 kW (6.4 HP), 30 Nm torque Y-axis feed motor: 4.5 kW (6.4 HP), 30 Nm torque Z-axis feed motor: 3.88 kW (5.4 HP), 22 Nm torque Hydraulic pump motor: 3 kW Lubrication pump motor: 0.01 kW Coolant pump motor: 0.76 kW • Guideways: X-axis: SNS45C2SSCOEx3 (600 mm width, 1000 mm distance) Y-axis: SNS45LC2X151SLHx2 (600 mm width, 600 mm distance) Z-axis: SHS45R2SSCOEx1305×2 (500 mm distance) • Utilities / Connections: Electrical power supply: 45 kVA Compressed air: 0.6 MPa (87 psi) @ 400 L/min Hydraulic oil tank: 400 L Lubrication tank: 2 L Coolant tank: 300 L • Dimensions / Weight: Machine height: 2885 mm Floor space: 3510 × 2410 mm Machine weight: 9200 – 9500 kg (≈ 10 t lifting requirement) • Cutting Capacity: Milling: 230 cm³/min Drilling: Ø 40 mm Tapping: M30 - LISTING 2800011

![Hungary]()

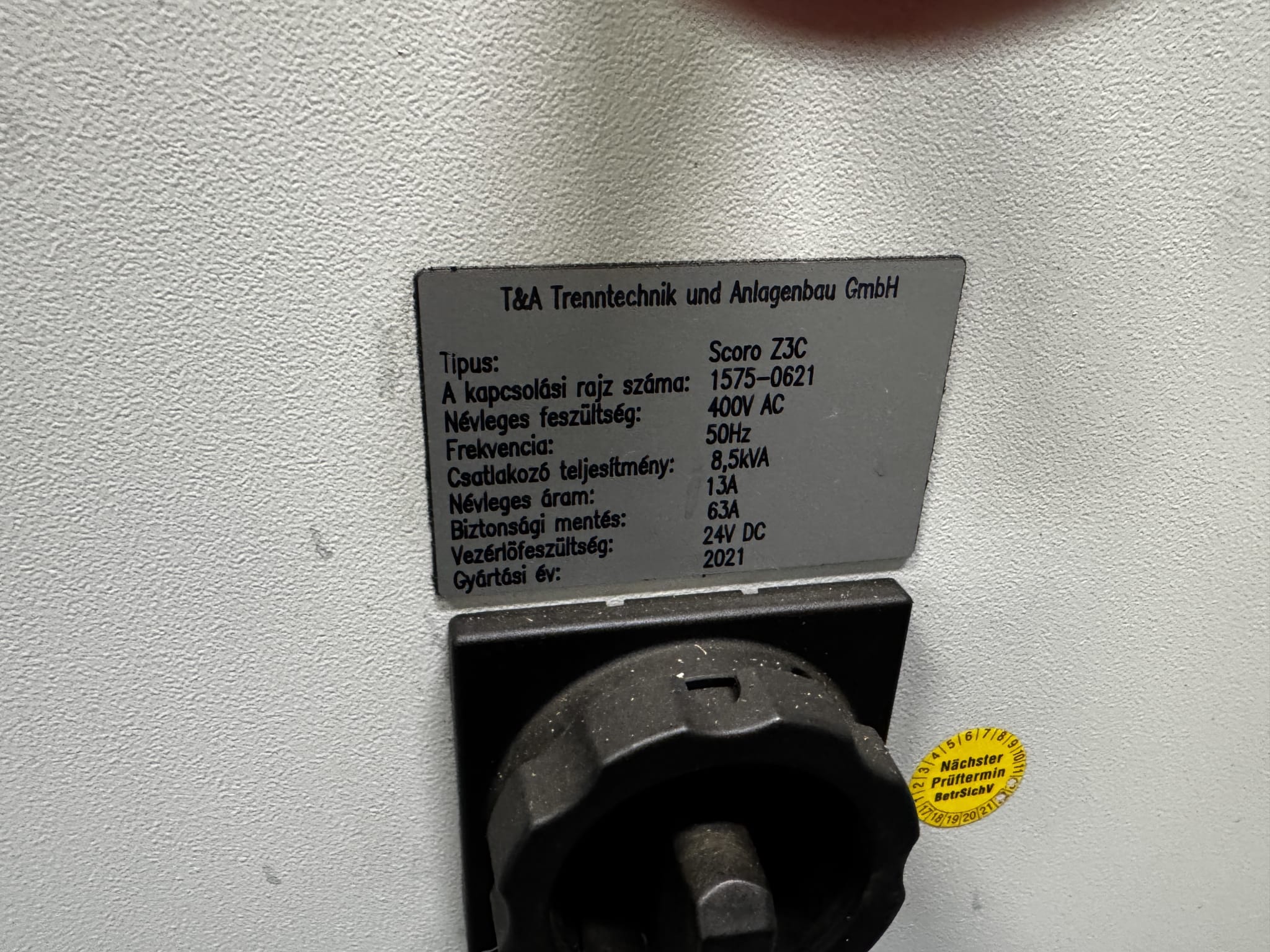

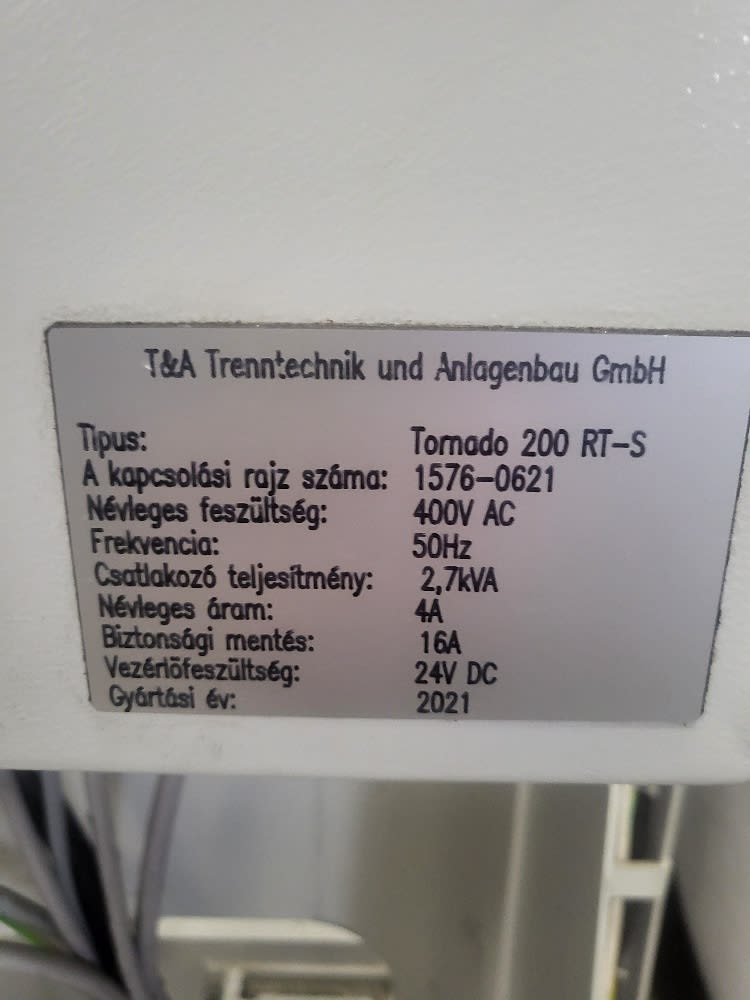

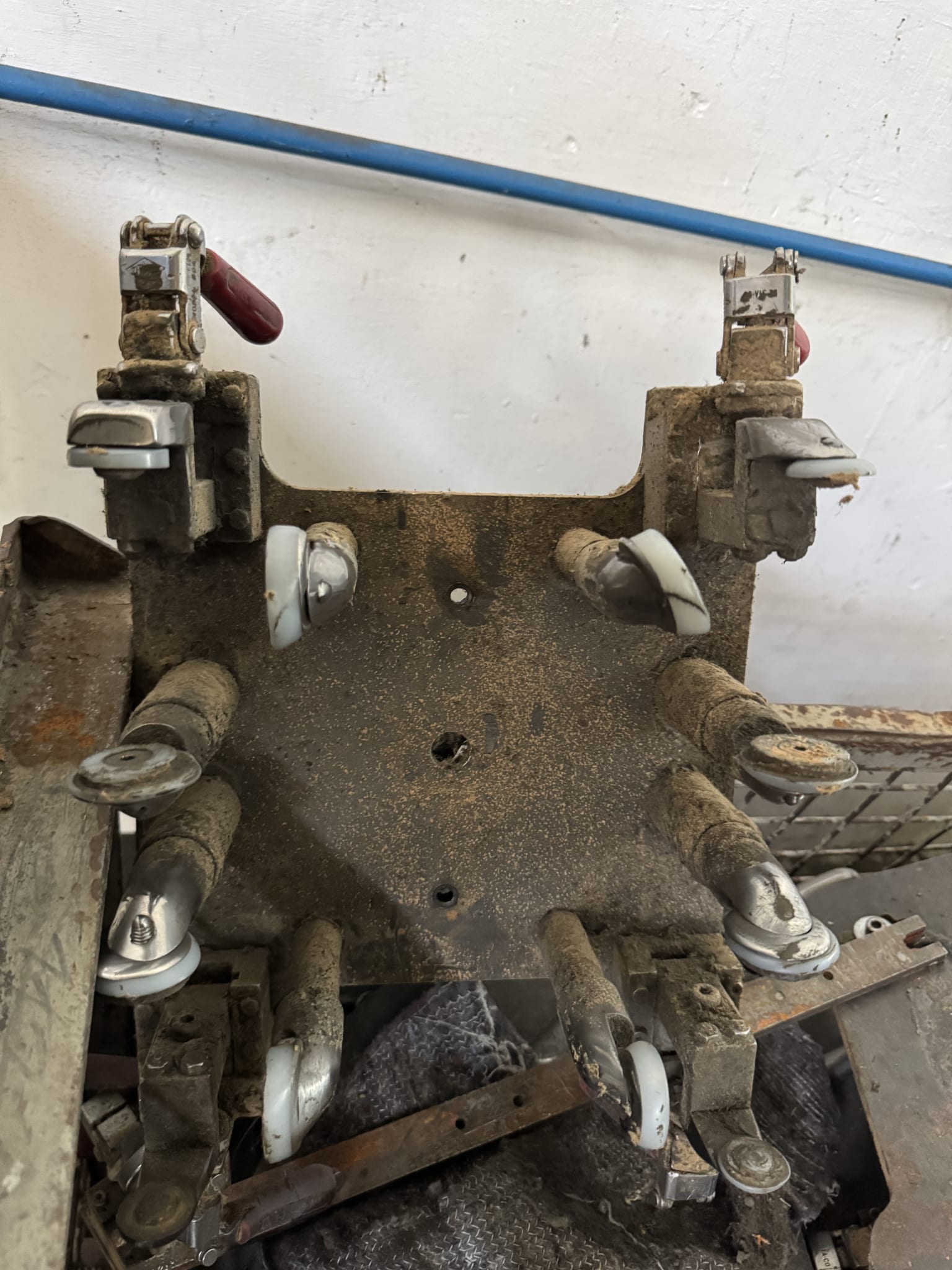

Automatic Chips Wringer with Loading System Scoro Z3C T&A | 2021

Binding Handling & Service Fee:

1210 € (EURO)

Machine Designation: Chip Drying and Cleaning System with Centrifugal Dryer and Coolant Cleaning Unit Manufacturer: T & A Trenntechnik & Anlagenbau GmbH, Ettenheim, Germany Type / Model: SCORO Z3C chip wringer system with TORNADO 200 RT-S 2-phase coolant centrifuge Year of Manufacture: 2021 Control System: Siemens S7 PLC control according to EN 60204 Technical Data: • Application / Capacity: Material: short, free-flowing brass chips (various alloys) Throughput: up to 6 t / week (3-shift operation) Max. residual moisture: 3 % Coolant type: water-miscible Chip feeding: via lifting-tilting device Discharge: into Big-Bag (91 × 91 × 110 cm, max. 1000 kg) • Main Components: Lifting-tilting unit EHKG 250: • Load capacity 250 kg • Tilting angle 150° • Tilting height 2200 mm • Manual bin feeding • Lifting speed 7 m/min Protective fence: • Electrically interlocked door • Height 2500 mm • Built to UVV safety standards Scraper-belt chip conveyor KF 300/380/2: • Total length ≈ 4000 mm • Discharge height 1800 mm • Conveyor width 380 mm, height 300 mm • Pitch angle 60° • Chain type DIN 8165, pitch 63 mm, breaking load 60 000 N • Gear motor drive with safety clutch and standstill monitoring • Wear-resistant manganese steel bottom lining and full covering Feed hopper: • Volume 1 m³ • Ultrasonic level sensor for automatic stop when empty Chip wringer / centrifuge SCORO Z3C: • Fully automatic de-oiling centrifuge for short free-flowing chips • Inlet 350 × 350 mm • Chip discharge Ø 400 mm • Motor 2.2 kW, IP54, 400 V / 50 Hz, with brake 24 V and thermal protection • Drum Ø 300 mm, speed 1900 rpm, slot width 0.2 mm, stainless steel screen • Throughput ≈ 400 kg brass chips (depending on shape and material) Base frame for centrifuge: steel welded construction adapted to Big-Bag height Coolant tank (3-chamber type): 600 × 600 × 350 mm with rinse pump, discharge pump and level control Drip tray: covers entire system footprint Electrical control cabinet: • Siemens S7 PLC • 400 V / 50 Hz supply • 24 V DC control • Operator elements mounted in door • Prepared for future integration of chip crusher V200 Paint finish: system RAL (specified by customer), control cabinet RAL 7035 Documentation: Operating manual, parts list, drawings, circuit diagrams, CE declaration, test book (in German and Hungarian) Installation & Commissioning: Includes transport, assembly, start-up and training of operating staff Chip collection trolleys: 16 pcs (600 × 600 × 600 mm, ≈ 180 L each) 2-phase coolant centrifuge TORNADO 200 RT-S: • Stationary design for cleaning recovered coolant and drying solids • Drive motor 2.2 kW, 400 V / 50 Hz with electric and mechanical brake • Drum speed 3900 rpm • Sludge capacity 15 kg • Drum insert NBR • Noise level < 70 dB(A) • Safety interlocks IFM & Euchner • Pump A40-110B/A (0.55 kW, ≈ 60 L/min) with suction hose DN 25 • Independent electrical control cabinet (400 V / 50 Hz, 24 V DC) - LISTING 2800012

![Hungary]()

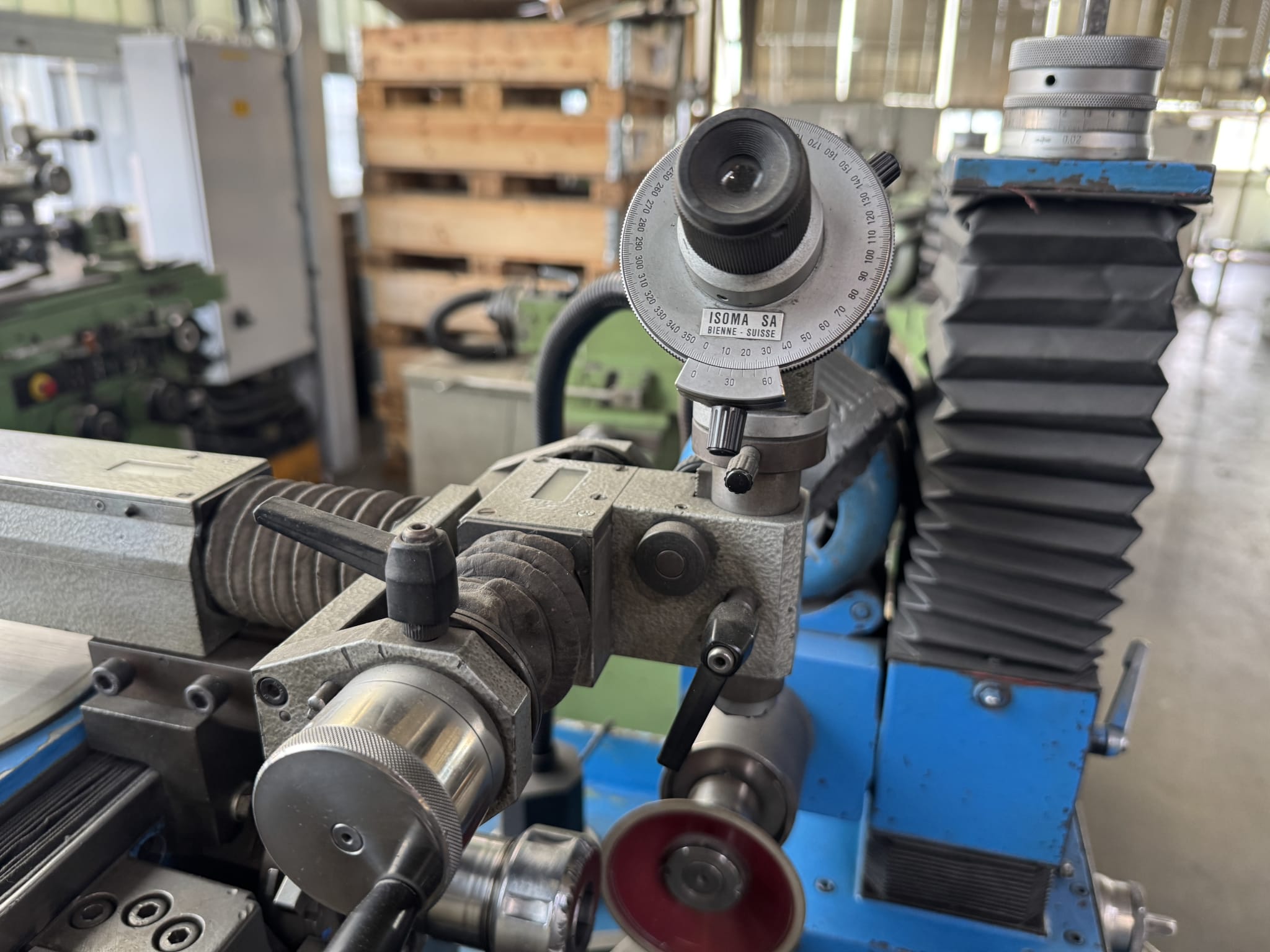

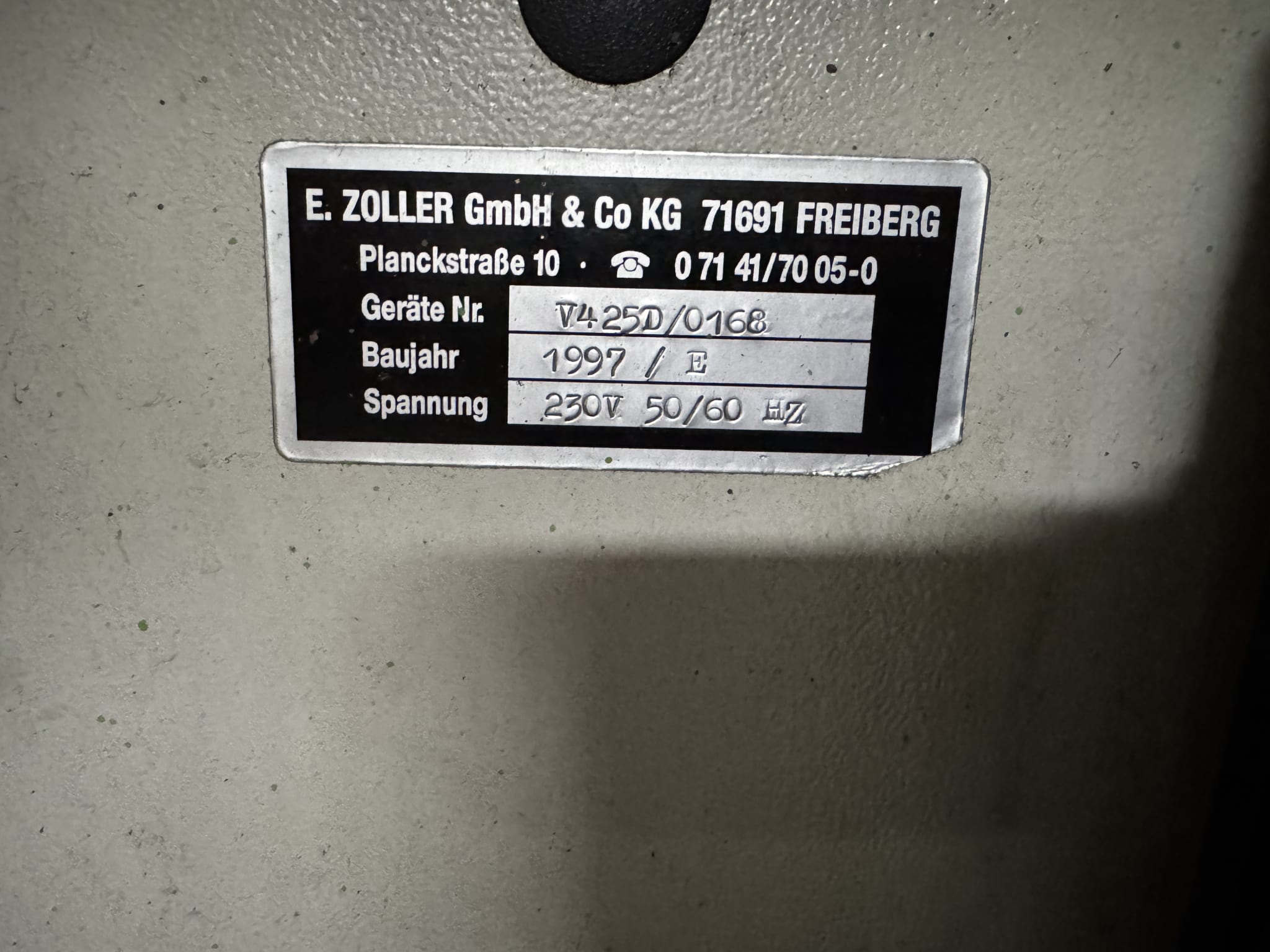

Tool Setter Zoller Hyperion 500 H500UF3-00089 | 2015

Binding Handling & Service Fee:

198 € (EURO) - LISTING 2800013

![Hungary]()

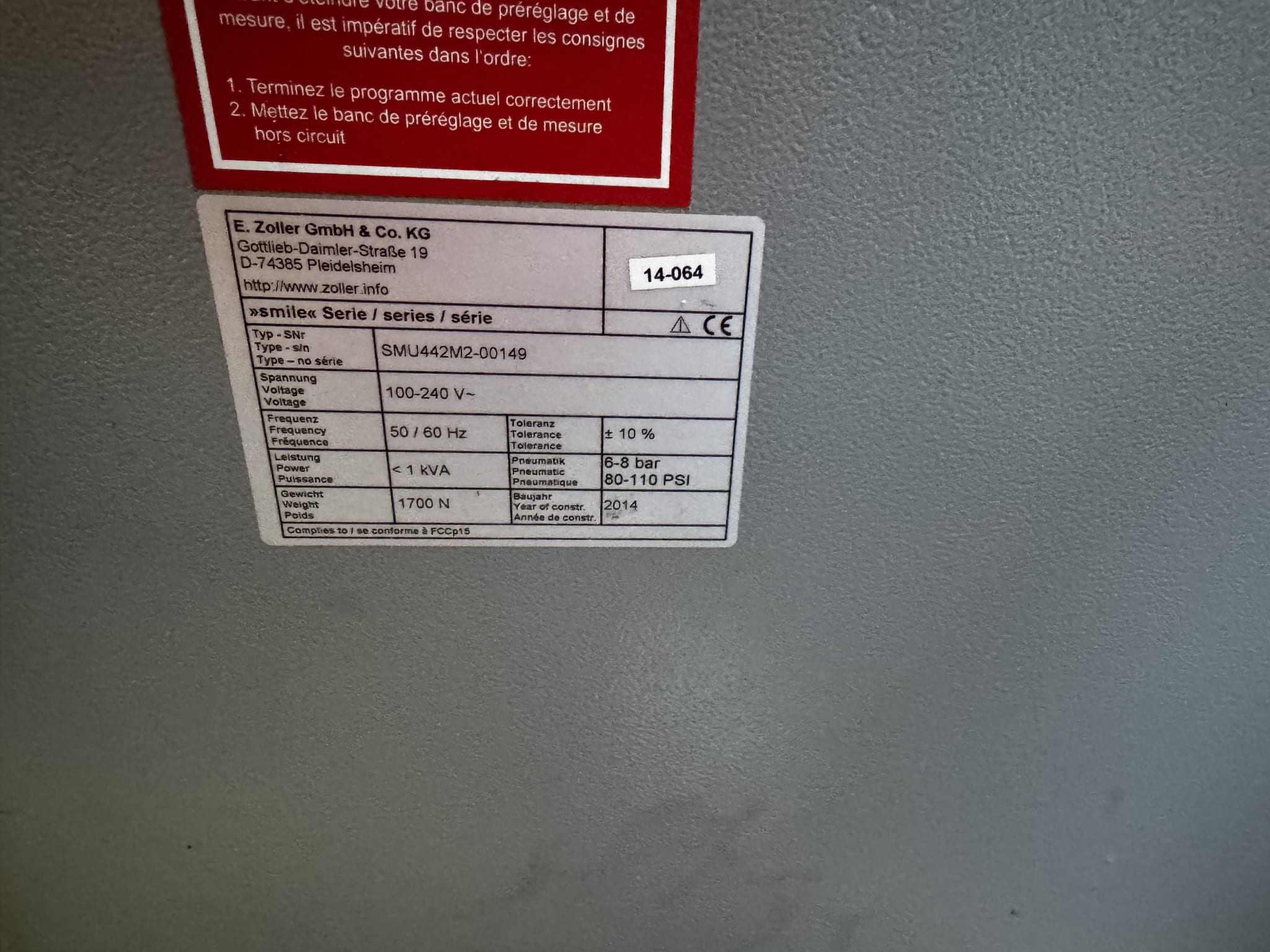

Tool Setter Zoller Smile 400 / SMU442M2-00149 | 2014

Binding Handling & Service Fee:

198 € (EURO) - LISTING 2800014

![Hungary]()

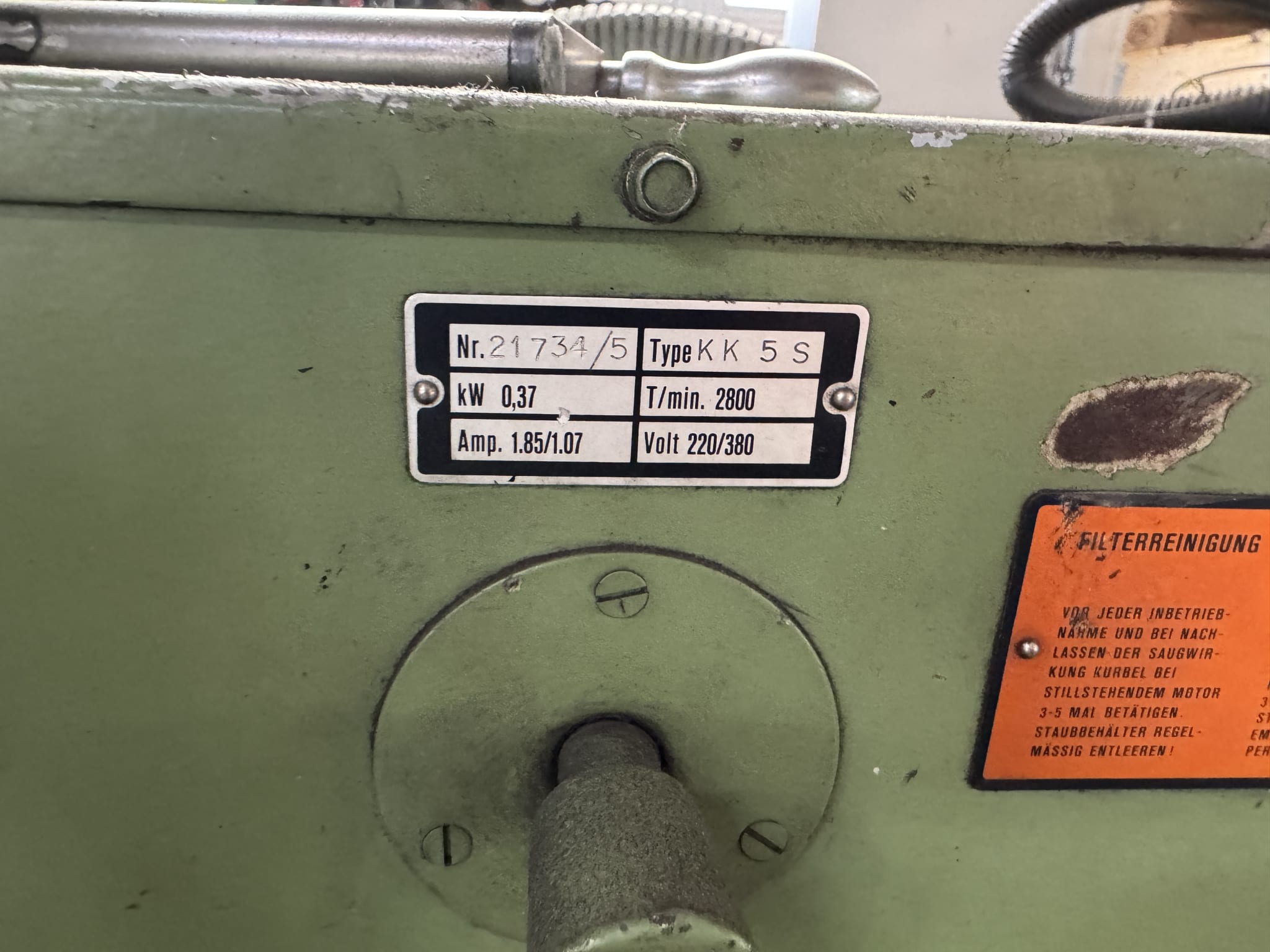

- LISTING 2800015

![Hungary]()

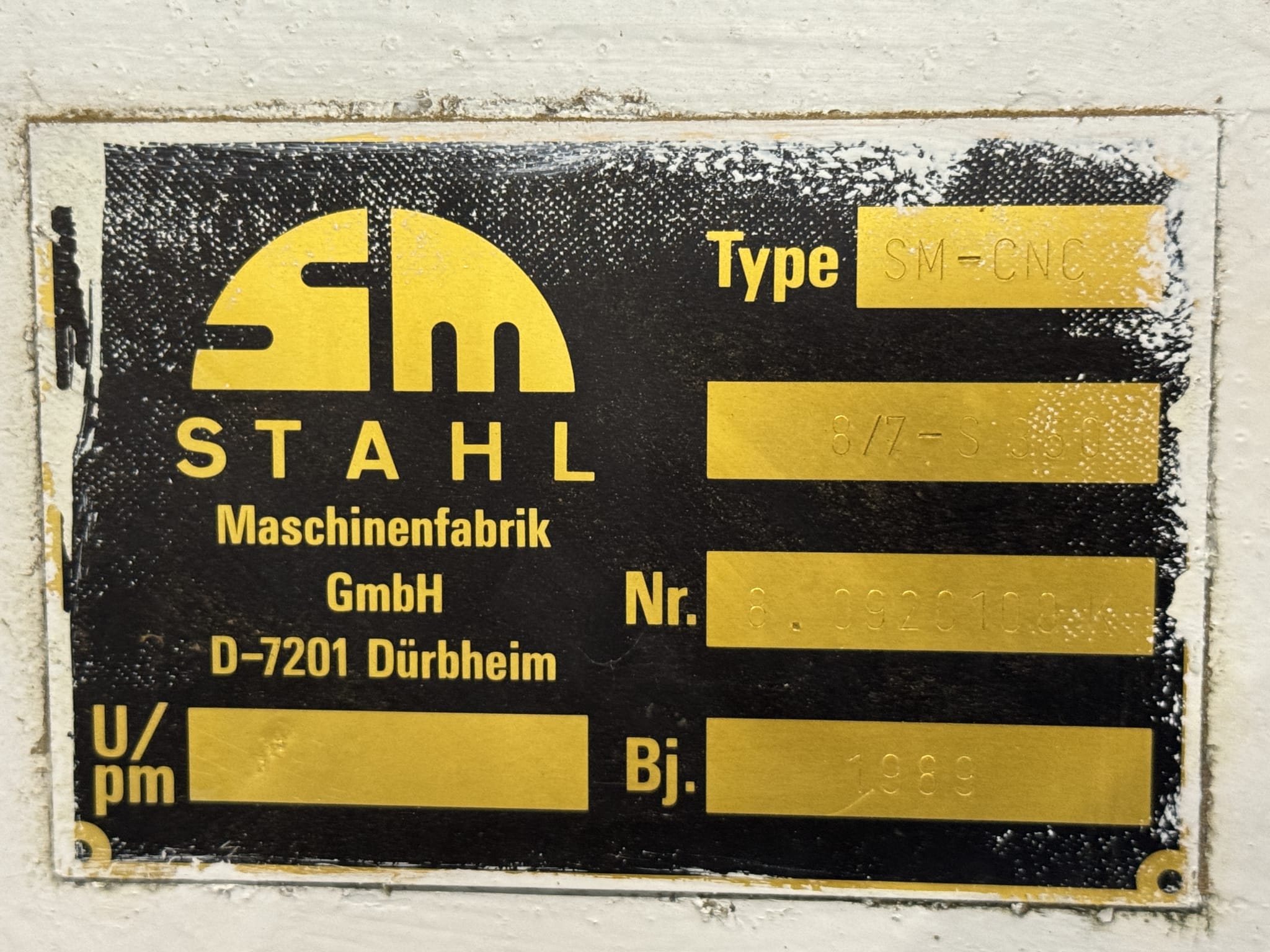

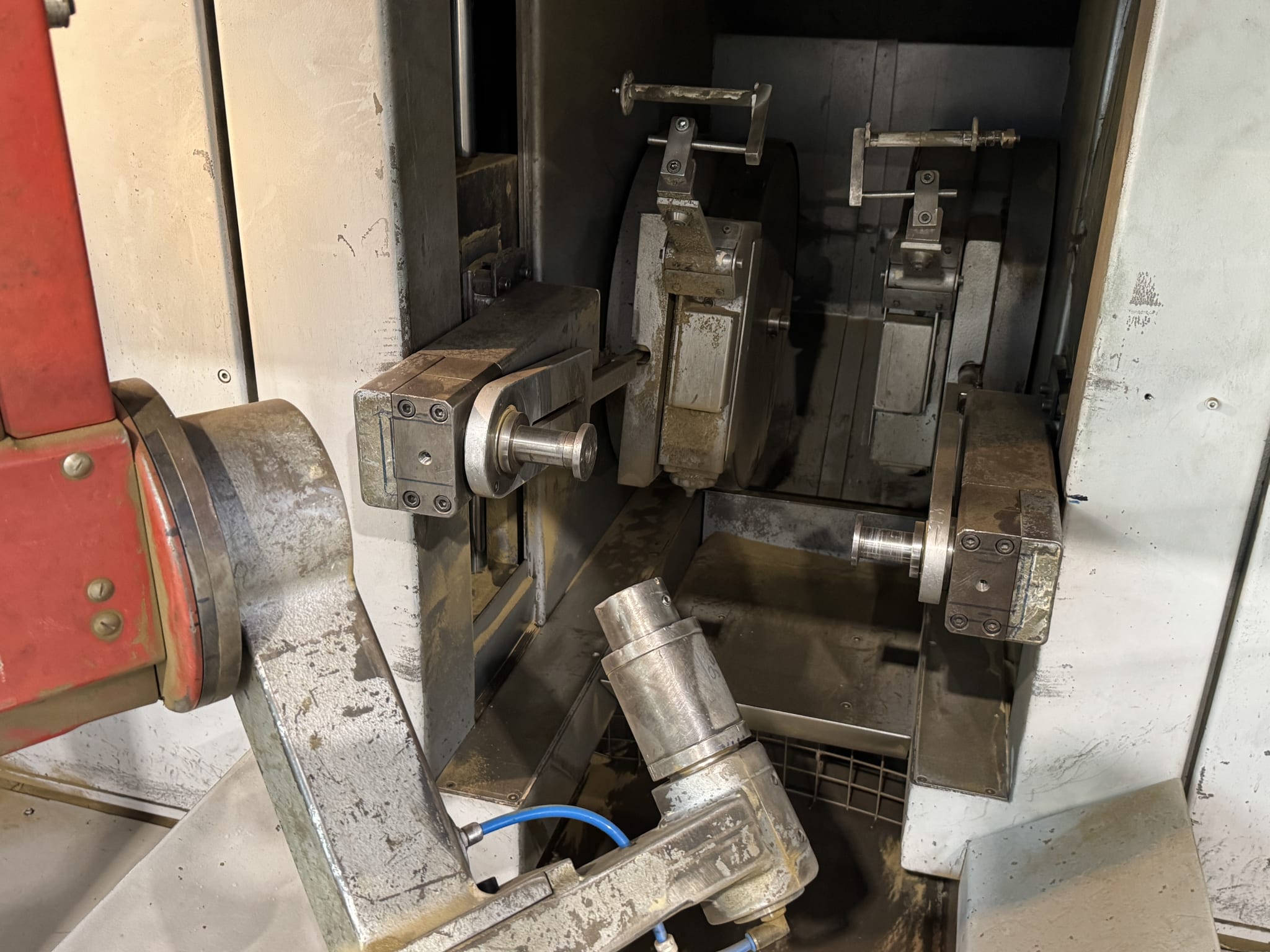

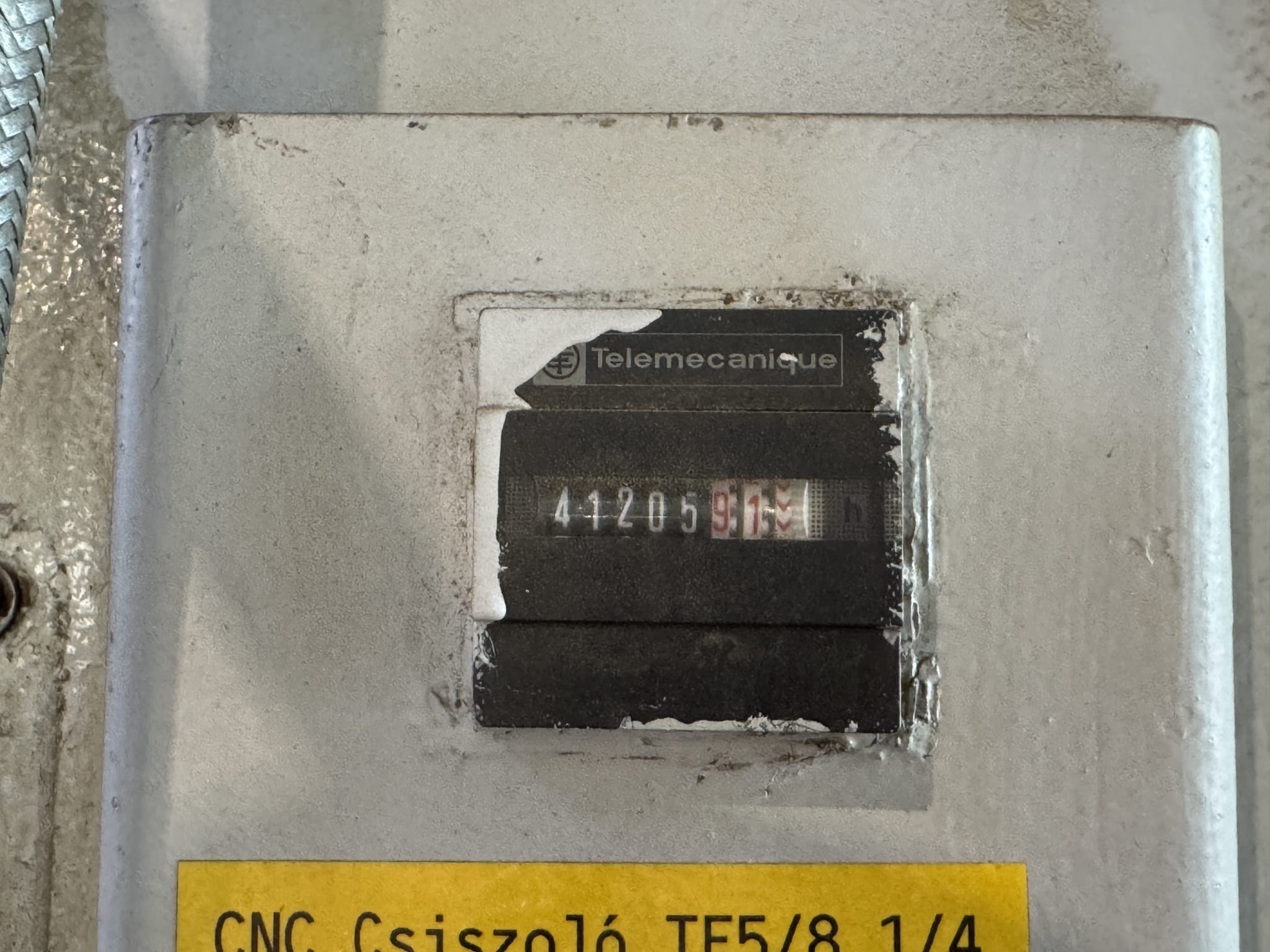

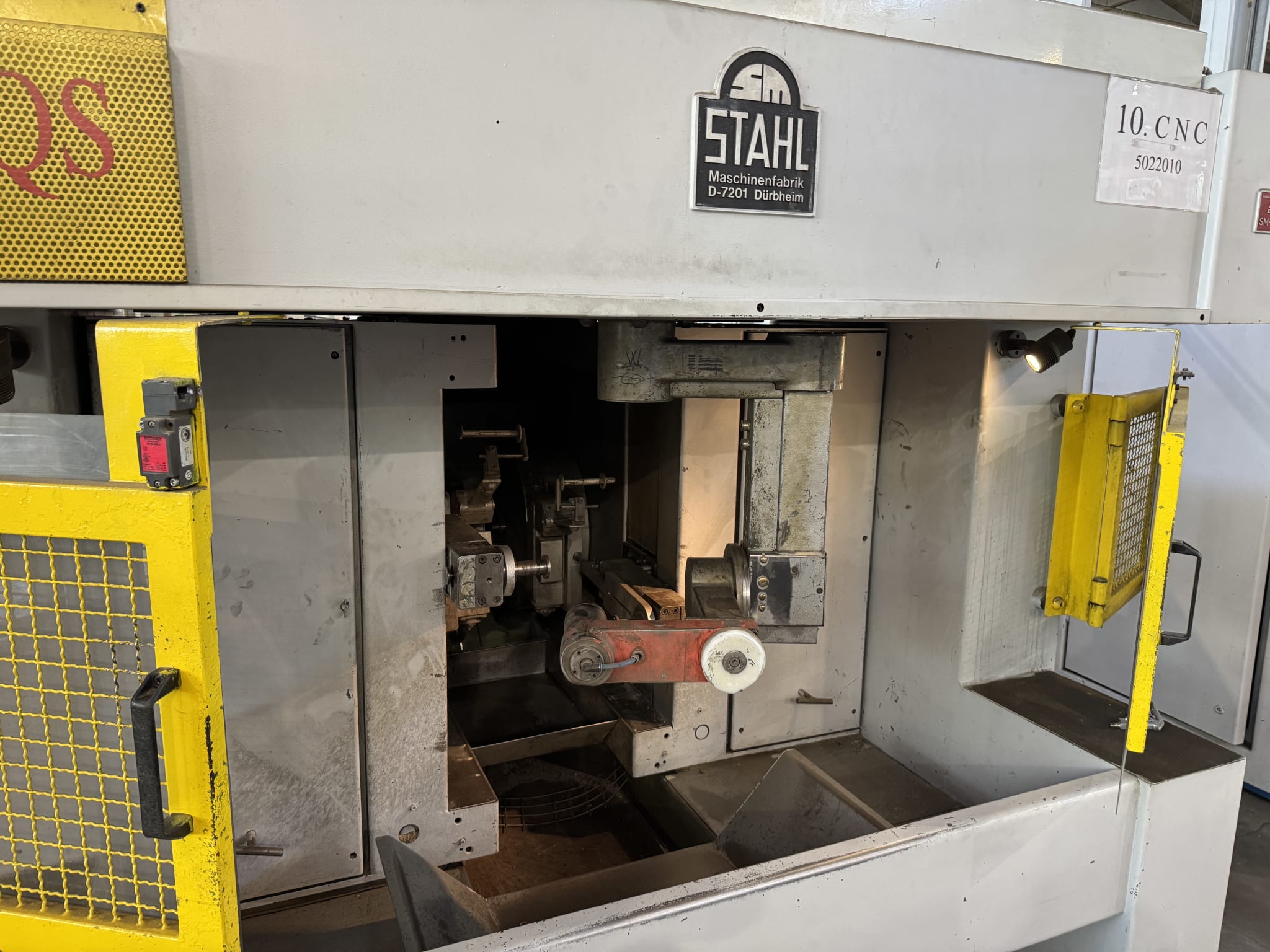

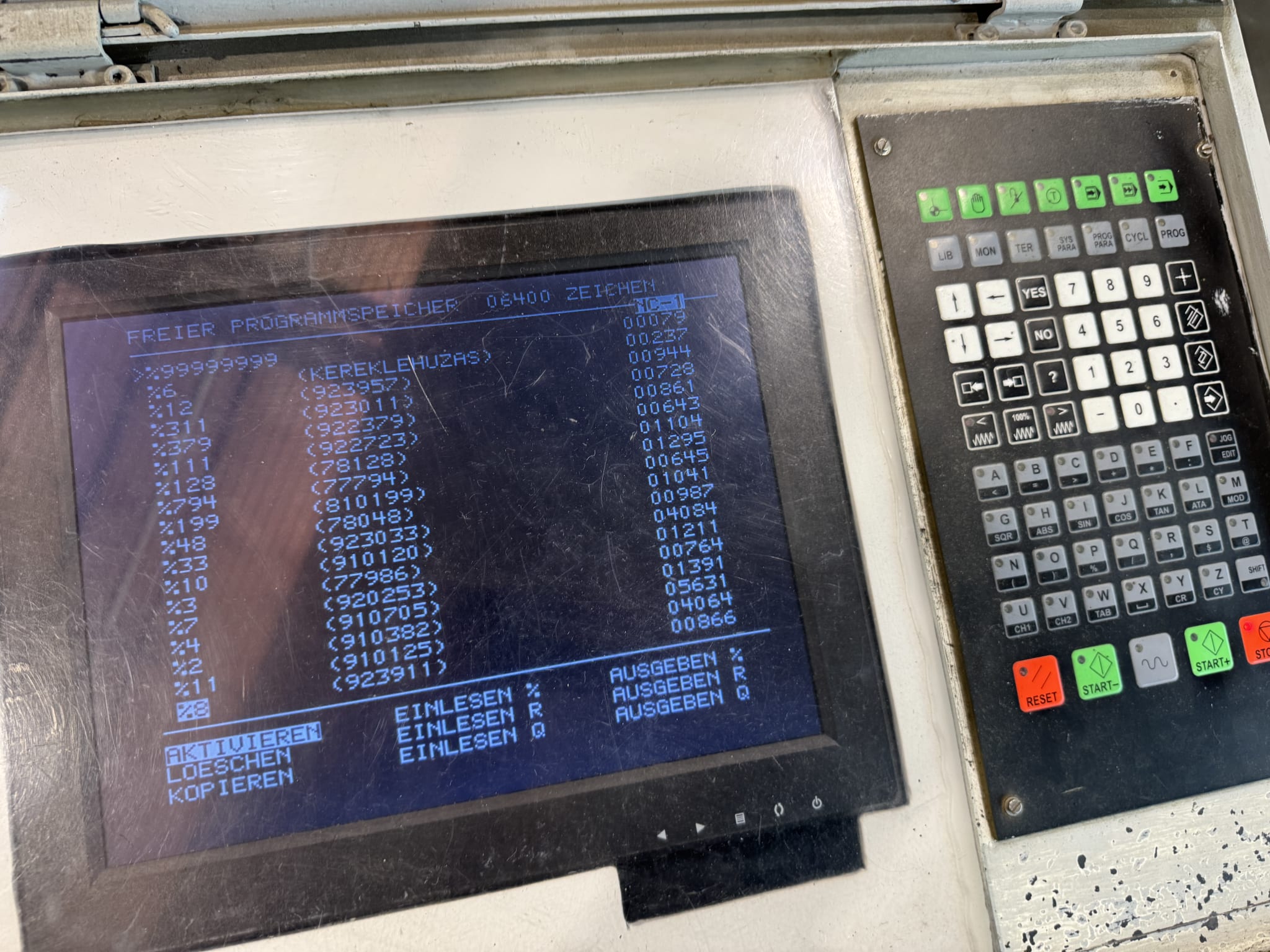

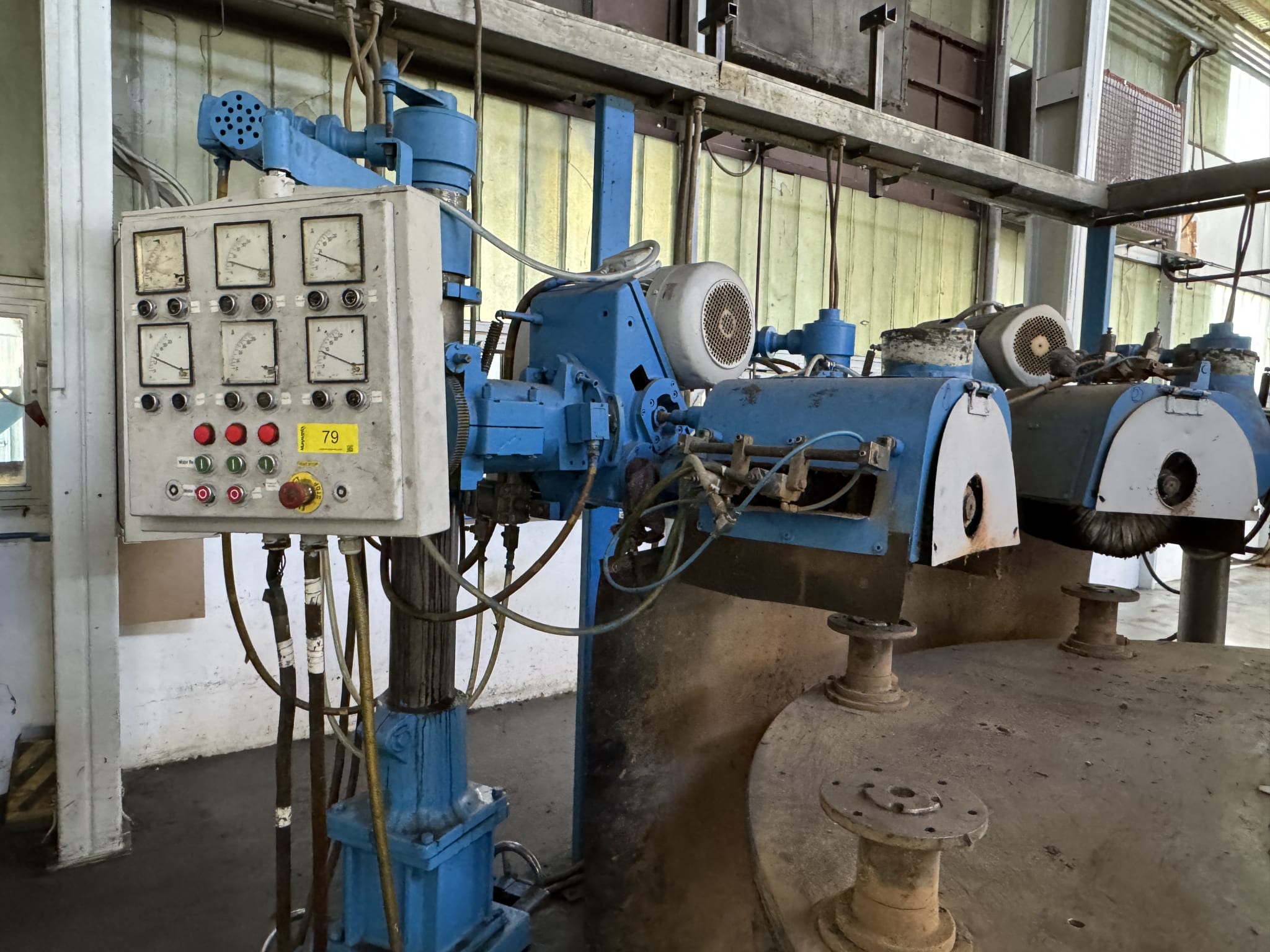

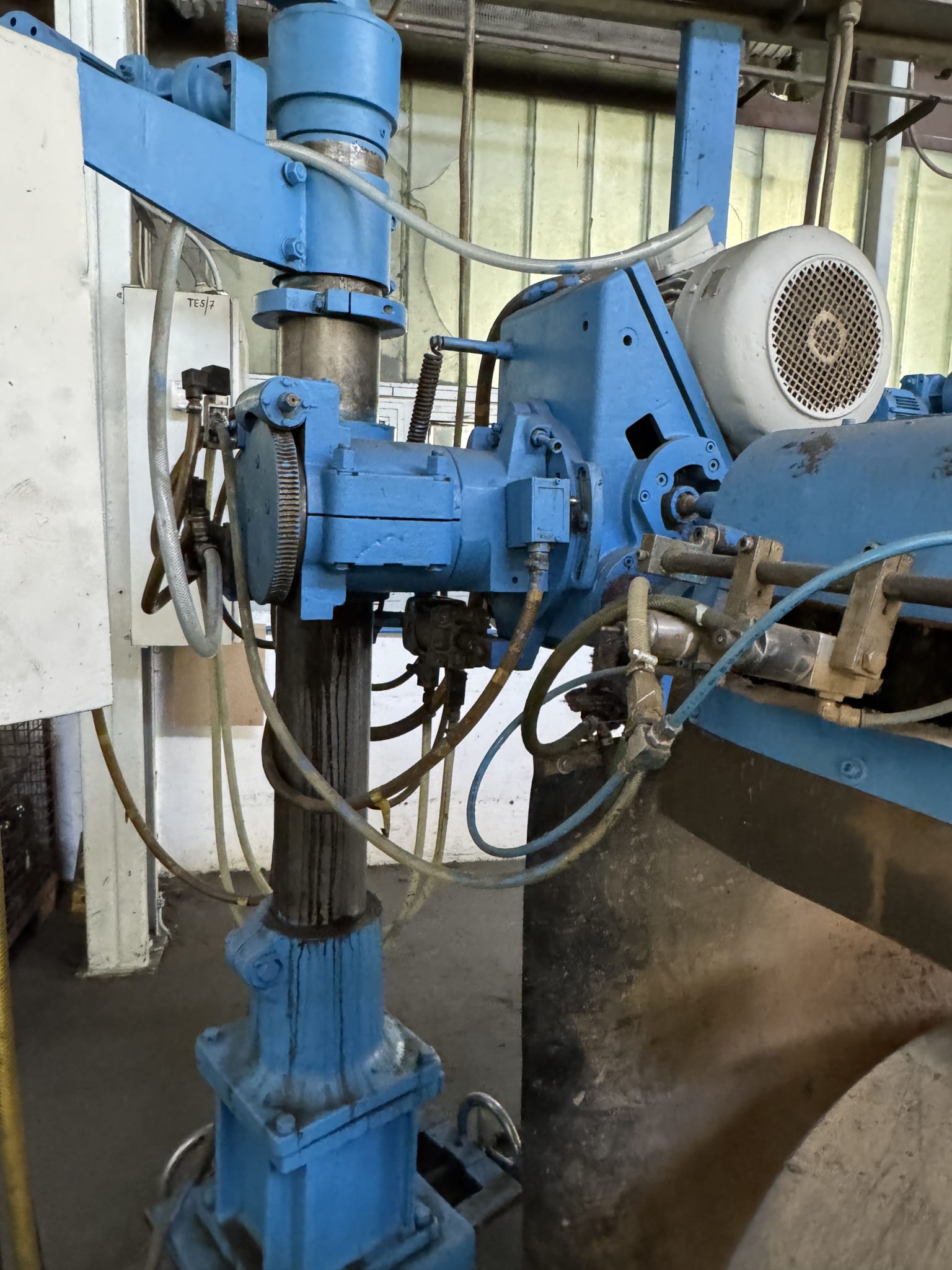

CNC Belt Grinding and Polishing System STAHL SM-CNC 8/7 - S350 | 1989

Binding Handling & Service Fee:

605 € (EURO)

The digital stand control-unit visible on the pictures and video is not included (visible because exchangeable between machines). The machine works with its own controller. - LISTING 2800016

![Hungary]()

CNC Belt Grinding and Polishing System STAHL CNC 8/5 P 1000 | 1989

Binding Handling & Service Fee:

605 € (EURO) - LISTING 2800017

![Hungary]()

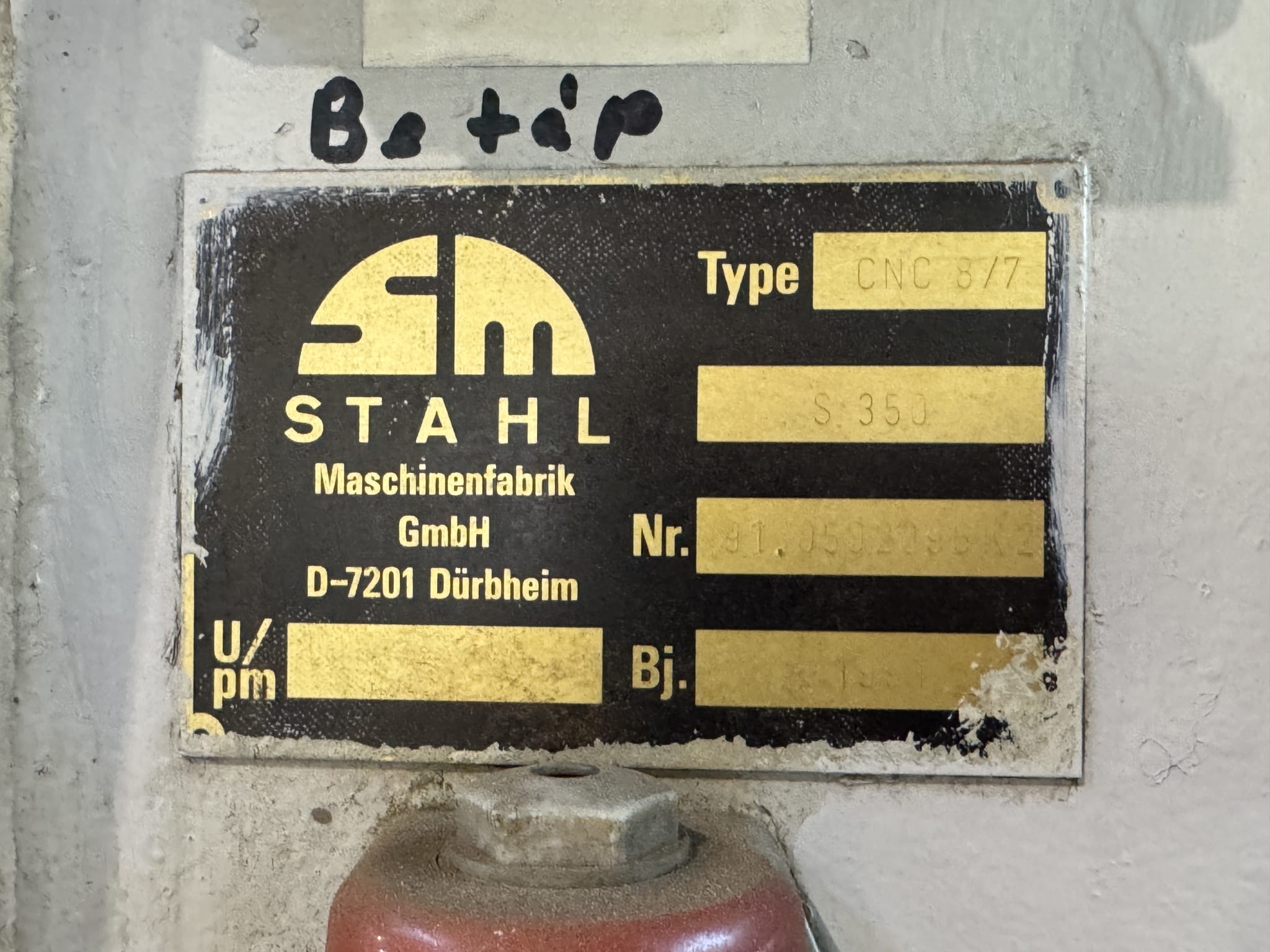

CNC Belt Grinding and Polishing System STAHL CNC 8/7 S 350 | 1991

Binding Handling & Service Fee:

605 € (EURO)

The digital stand control-unit visible on the pictures and video is not included (visible because exchangeable between machines). The machine works with its own controller. - LISTING 2800018

![Hungary]()

CNC Belt Grinding and Polishing System STAHL CNC 8/7 S 350 | 1991

Binding Handling & Service Fee:

605 € (EURO)

The digital stand control-unit visible on the pictures and video is not included (visible because exchangeable between machines). The machine works with its own controller. - LISTING 2800020

![Hungary]()

CNC Belt Grinding and Polishing System STAHL CNC 8/7 S 350

Binding Handling & Service Fee:

605 € (EURO)

The digital stand control-unit visible on the pictures and video is not included (visible because exchangeable between machines). The machine works with its own controller. - LISTING 2800021

![Hungary]()

CNC Belt Grinding and Polishing System STAHL CNC 8/5 P 1000 | 1989

Binding Handling & Service Fee:

605 € (EURO) - LISTING 2800024

![Hungary]()

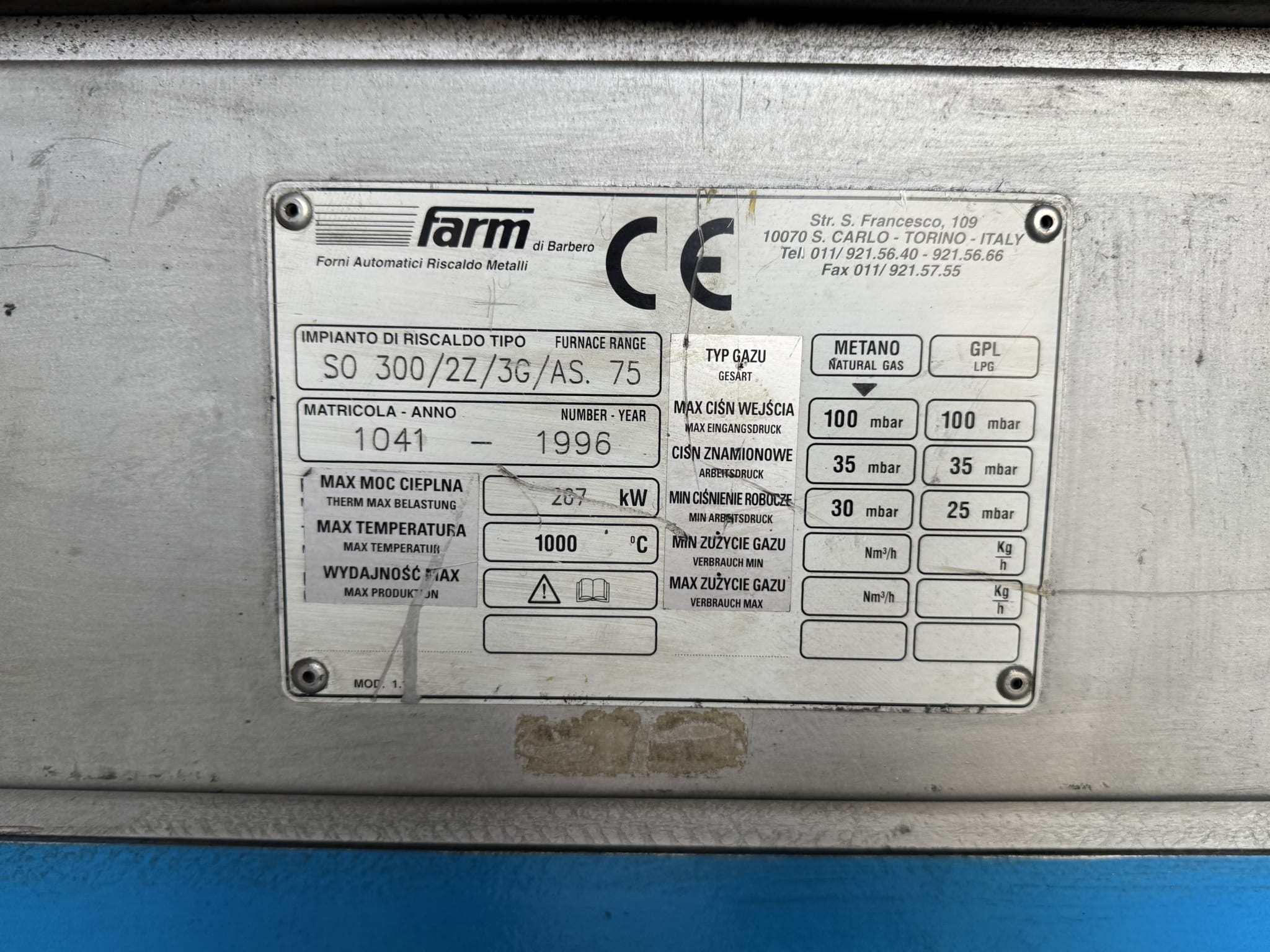

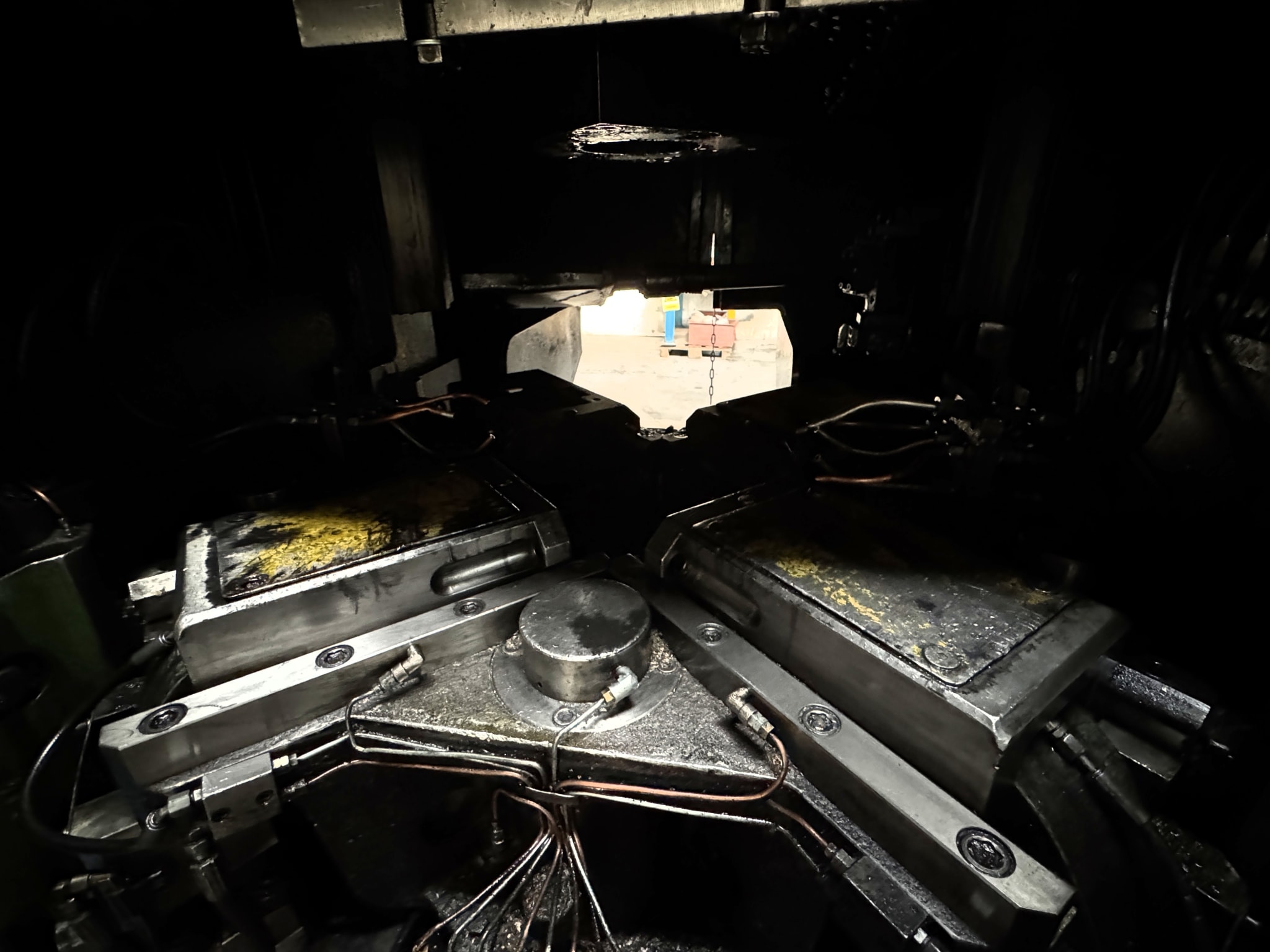

Hot forging press 150t with brass furnace MECOL PRESS SOV150 | 1982

Binding Handling & Service Fee:

3850 € (EURO)

Excenter; 15 kW; Capacity 150 t.; strokes per minute 120; push stroke 175 mm - LISTING 2800025

![Hungary]()

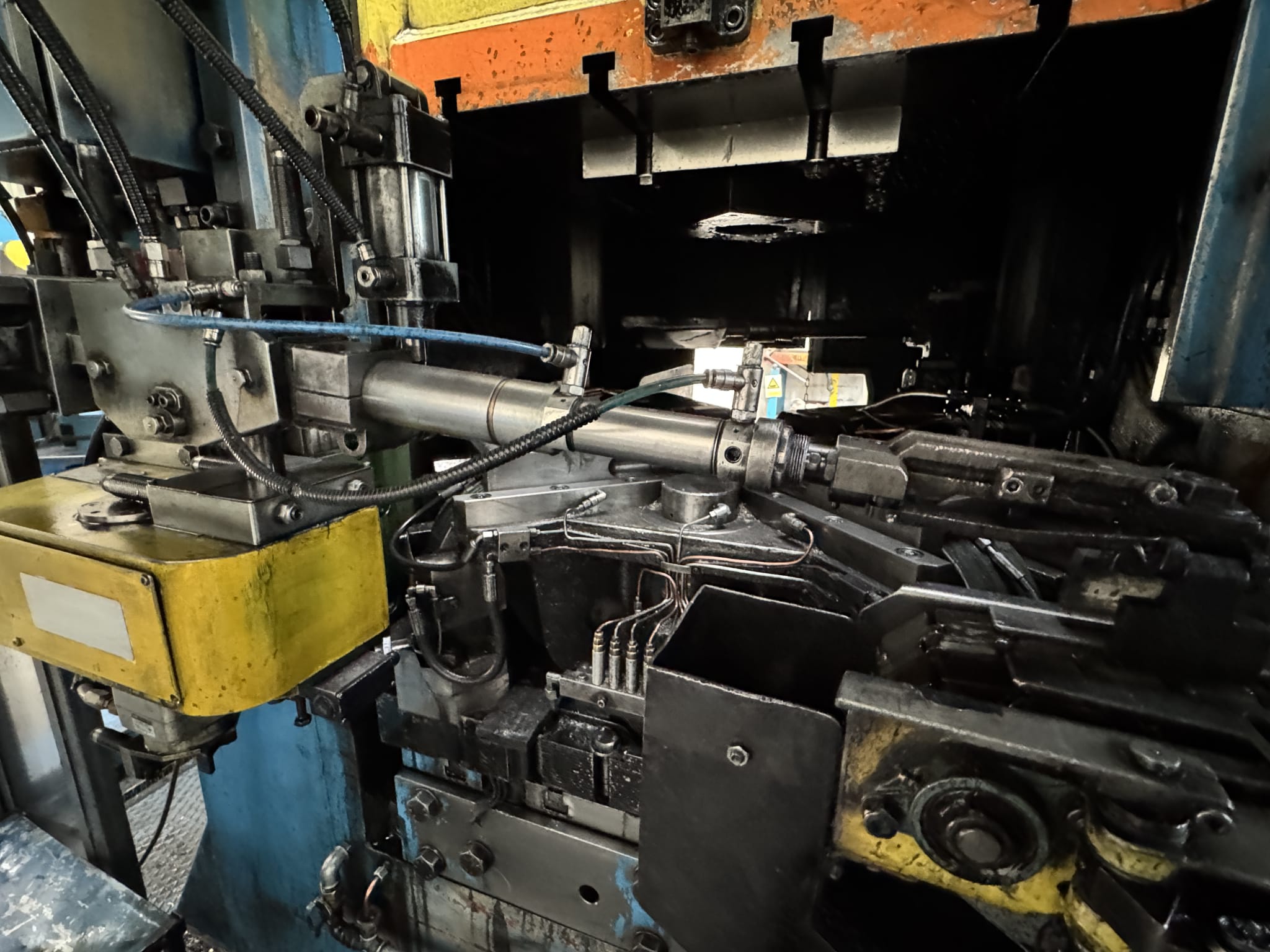

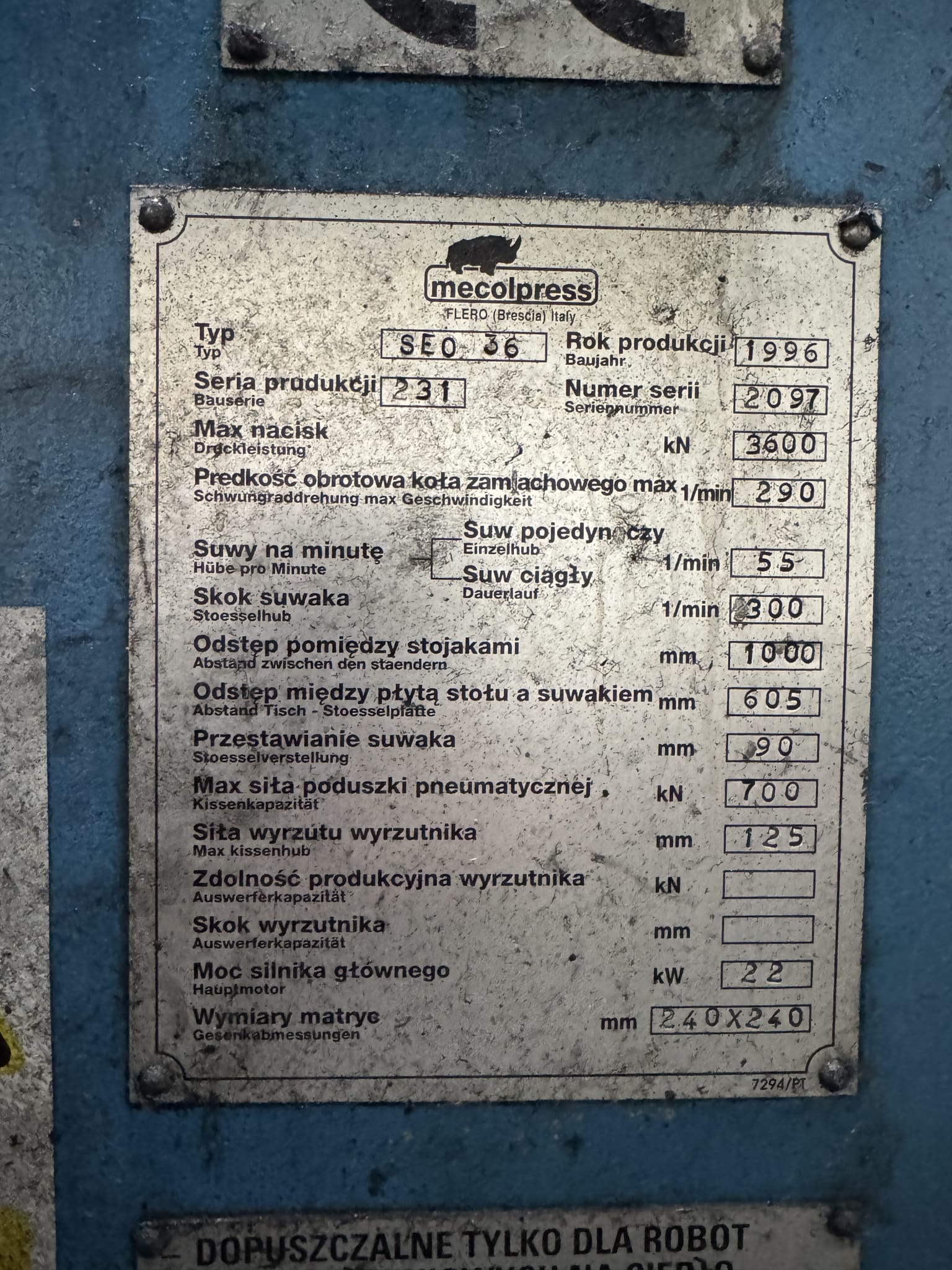

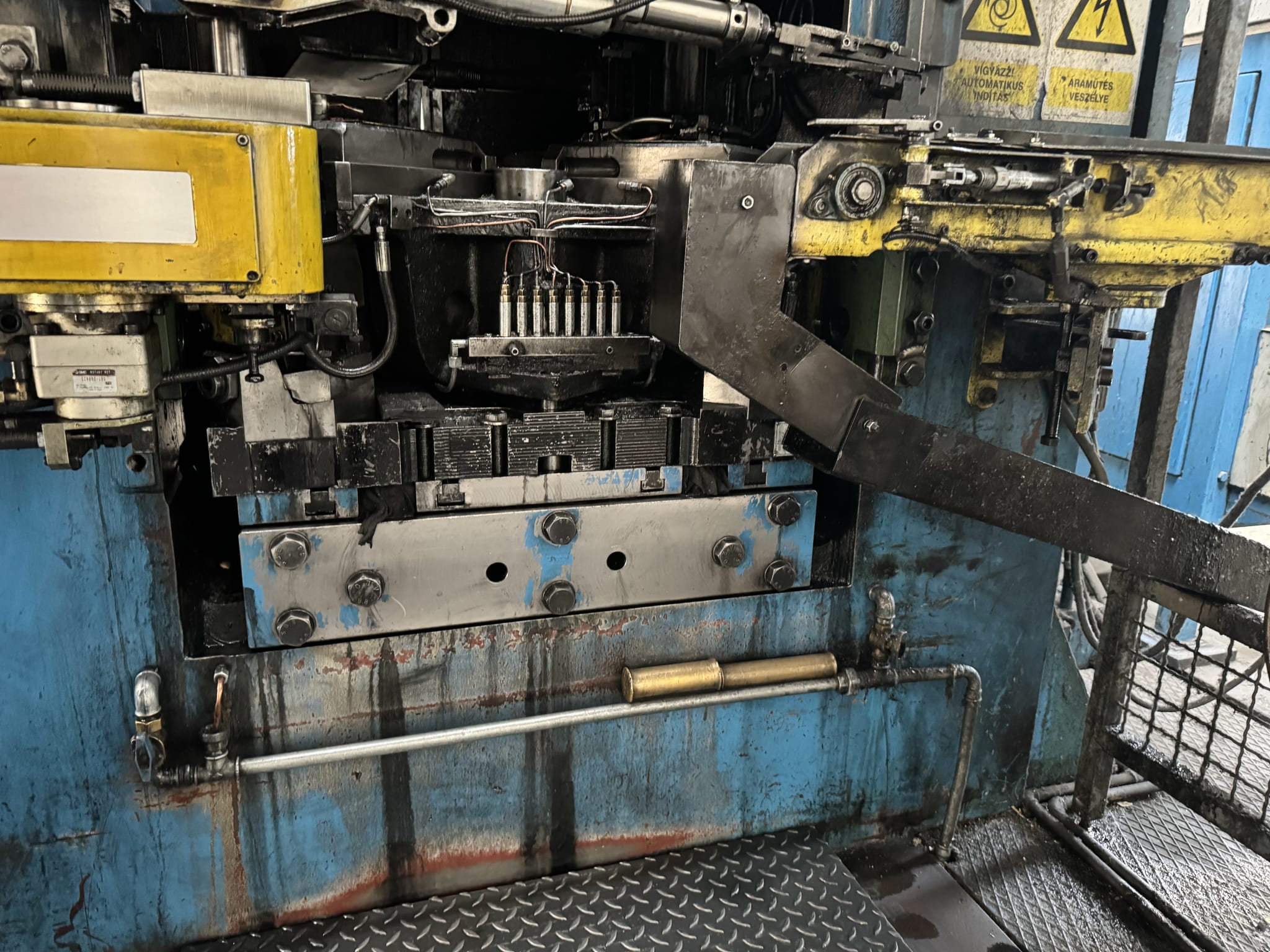

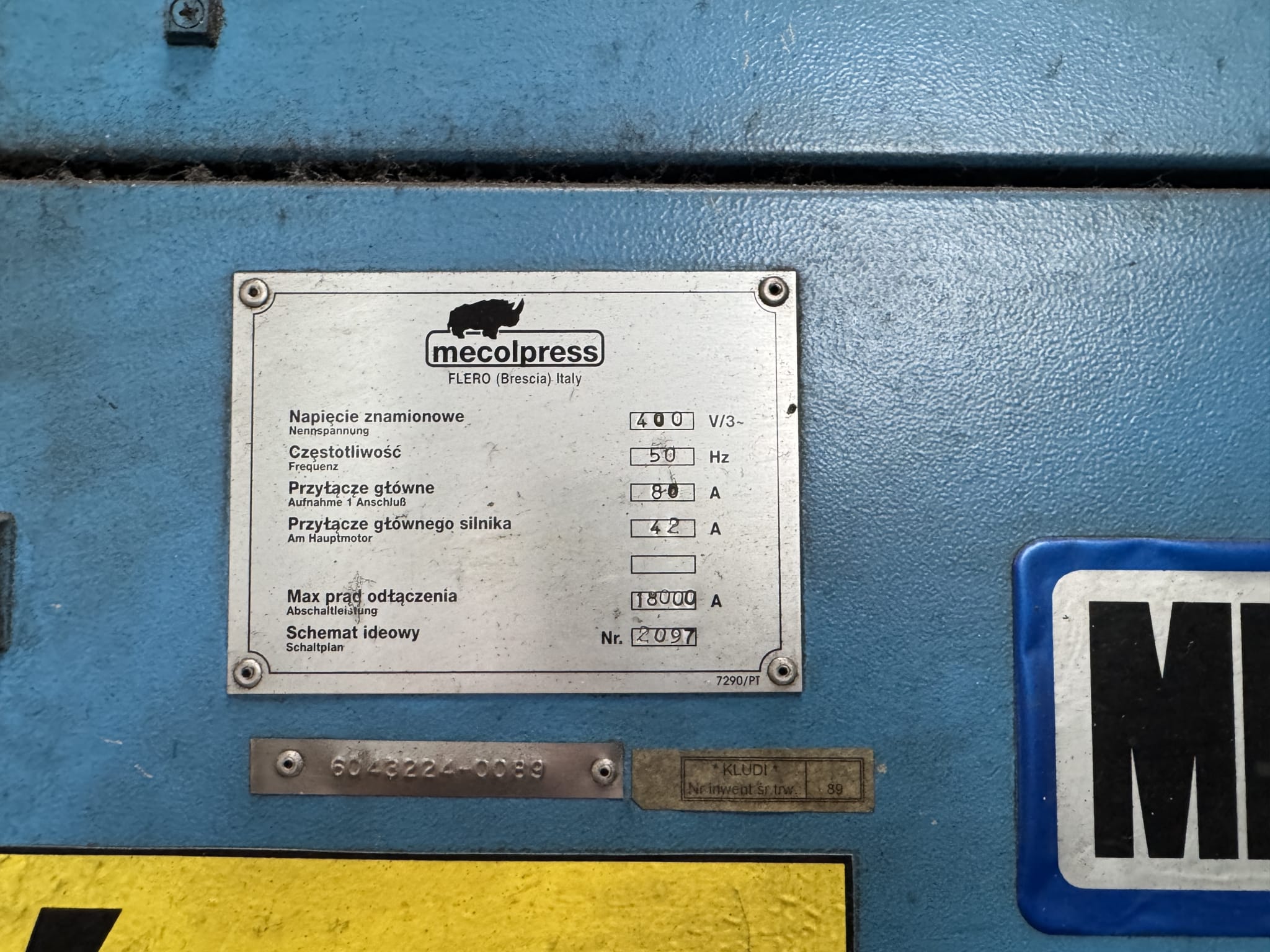

Hot forging press 360t with brass furnace MECOL PRESS SEO 36 | 1996

Binding Handling & Service Fee:

6380 € (EURO)

Excenter; 22 kW; Capacity 360 t; control Siemens; tool dimensions 240x240mm; strokes per minute 1/min 55 - LISTING 2800027

![Hungary]()

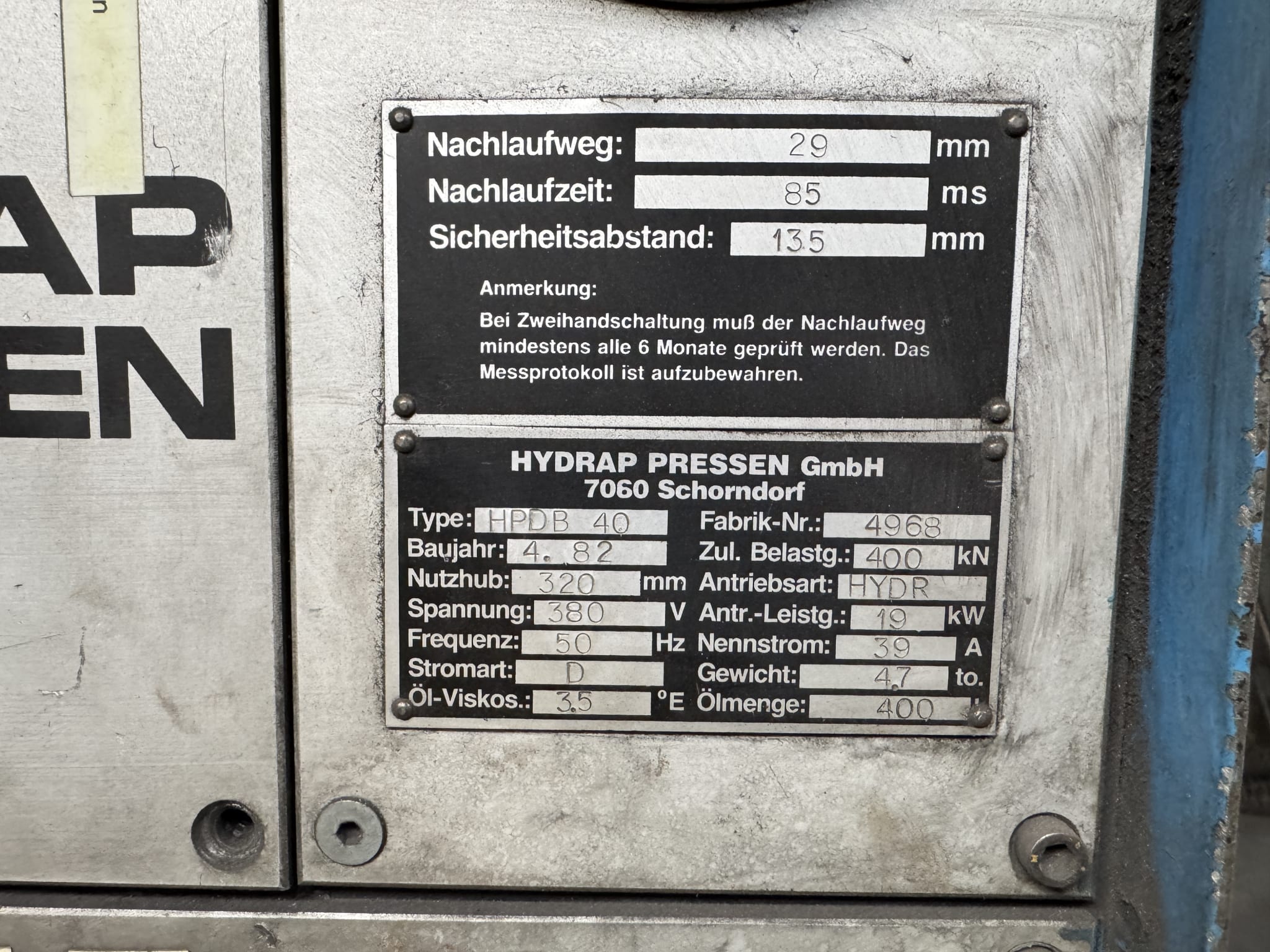

Hydraulic trimming press HYDRAP PRESSEN HPDB 40 | 1982

Binding Handling & Service Fee:

1210 € (EURO)

Overtravel distance 9 mm; overtravel time 85 ms - LISTING 2800028

![Hungary]()

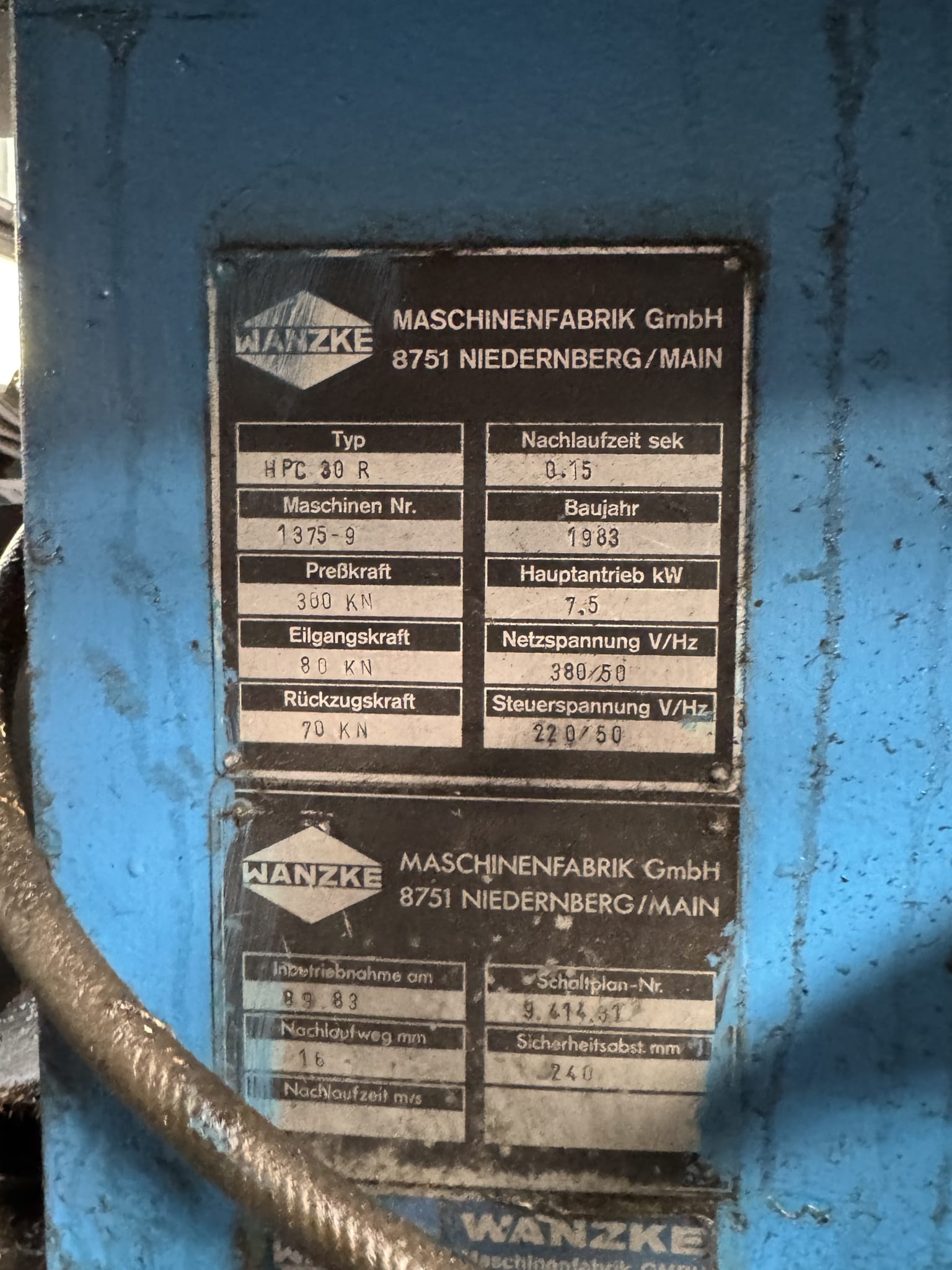

Hydraulic gap frame press WANZKE HPC 30R | 1983

Binding Handling & Service Fee:

990 € (EURO)

Pressing force 300 kN; rapid traverse force 80 kN, lag time 0.15 - LISTING 2800030

![Hungary]()

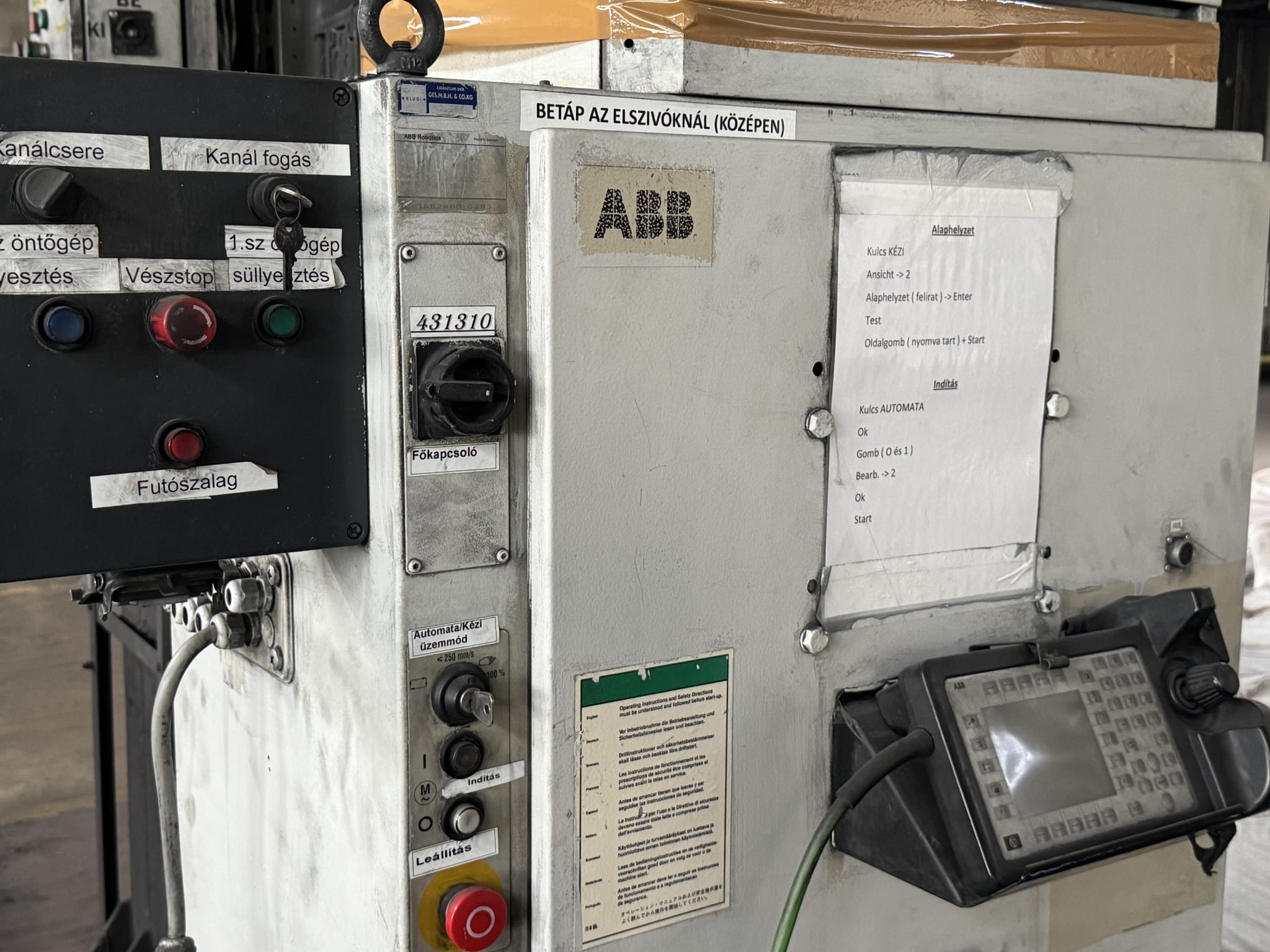

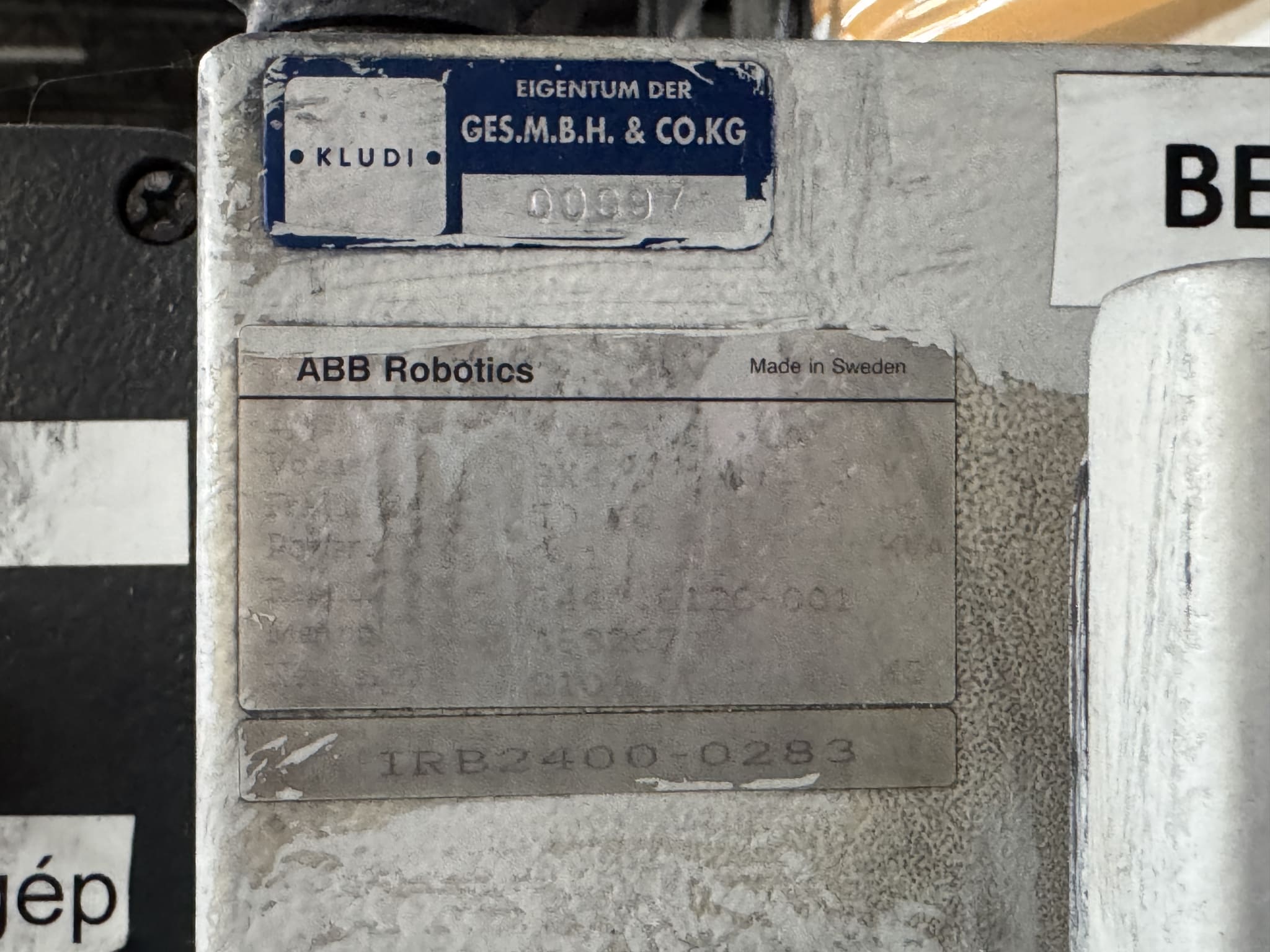

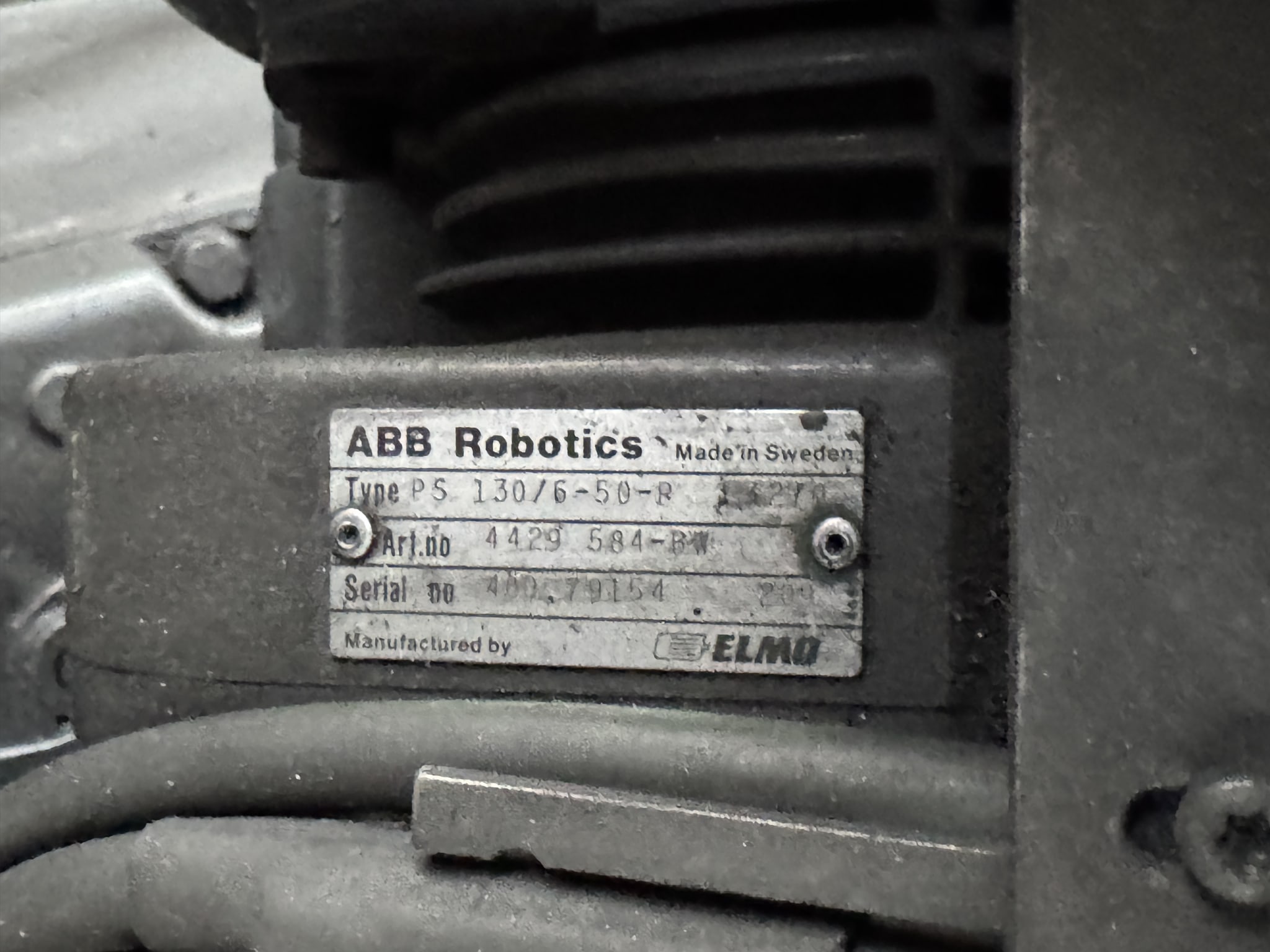

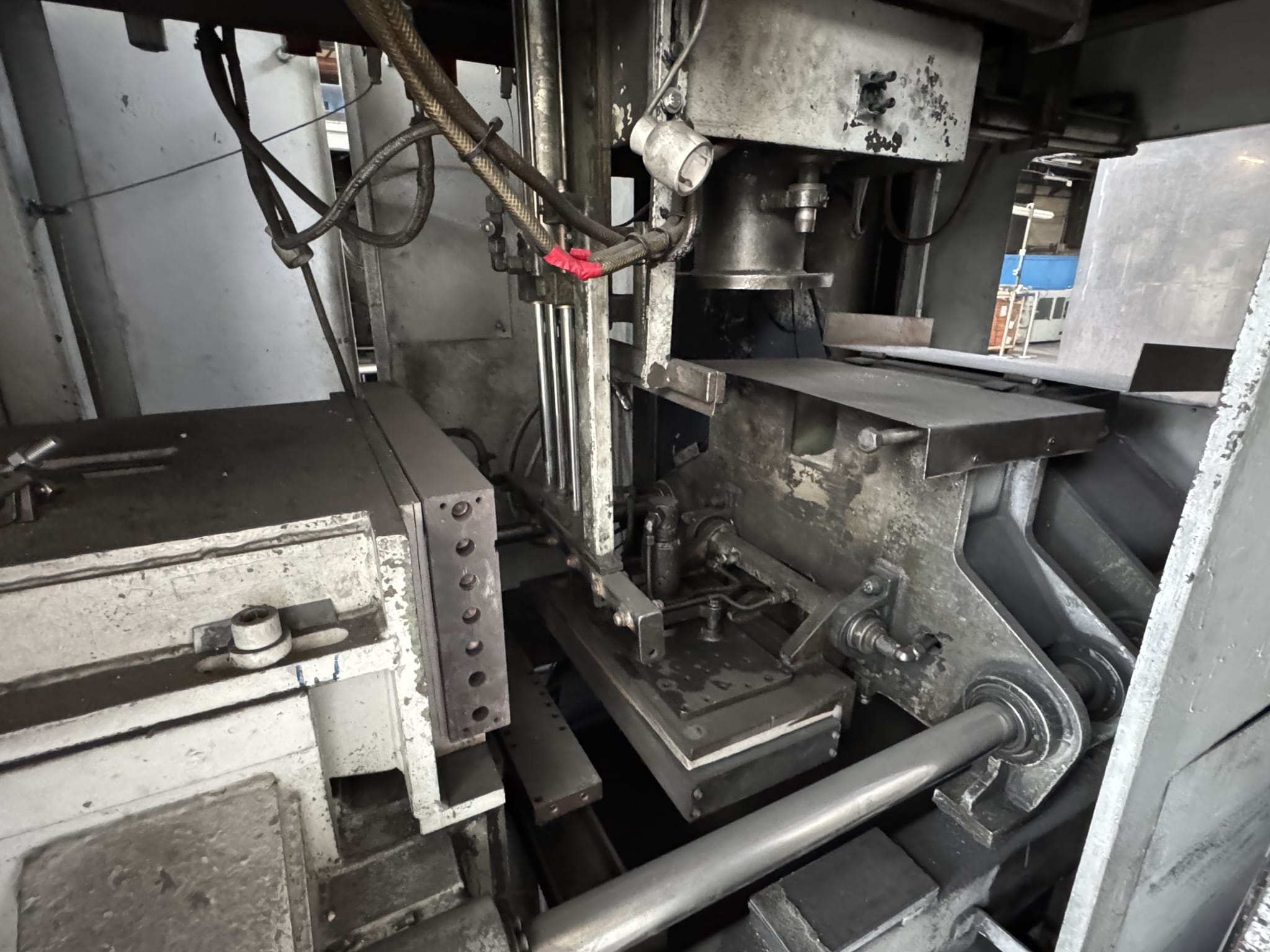

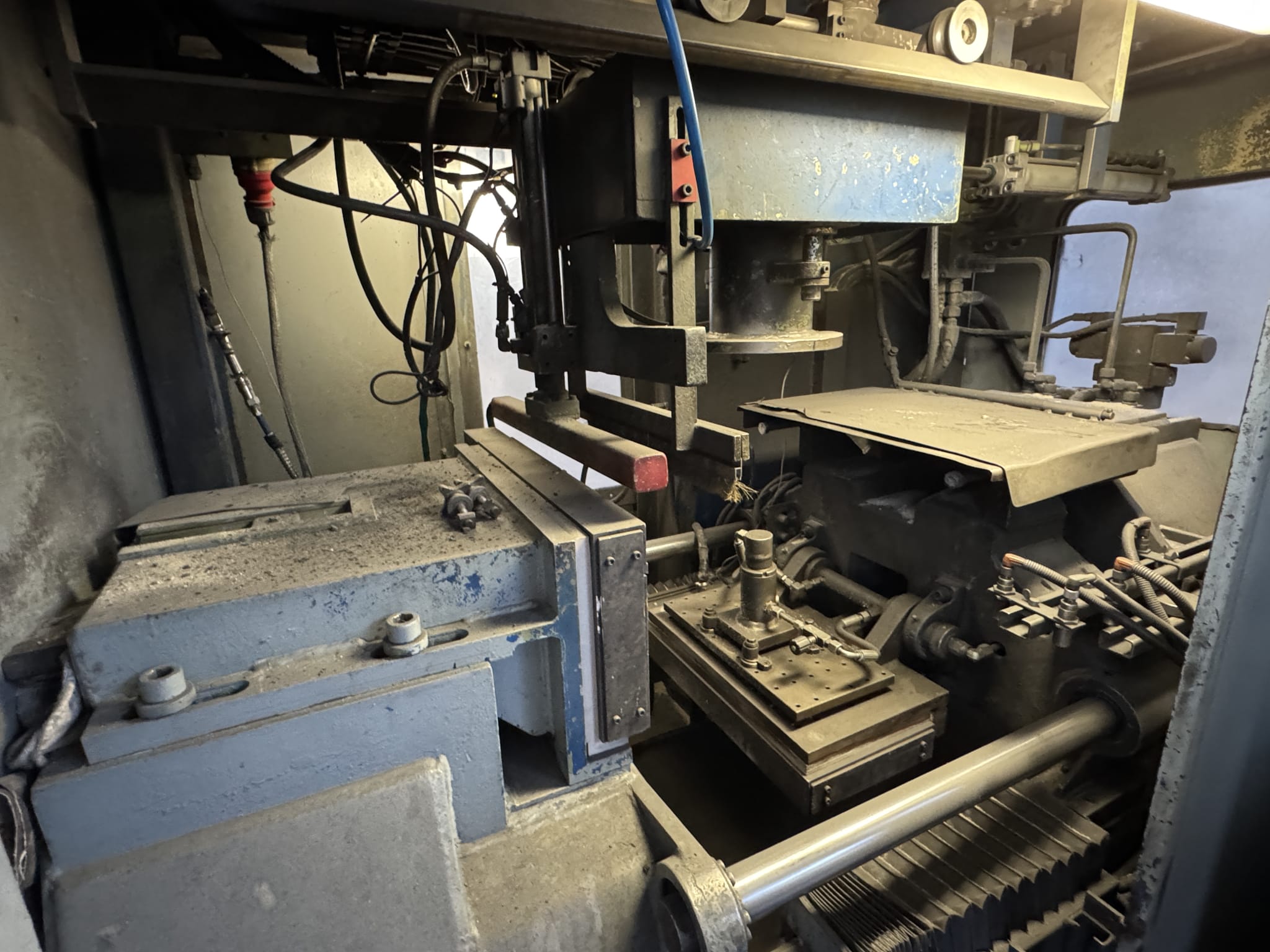

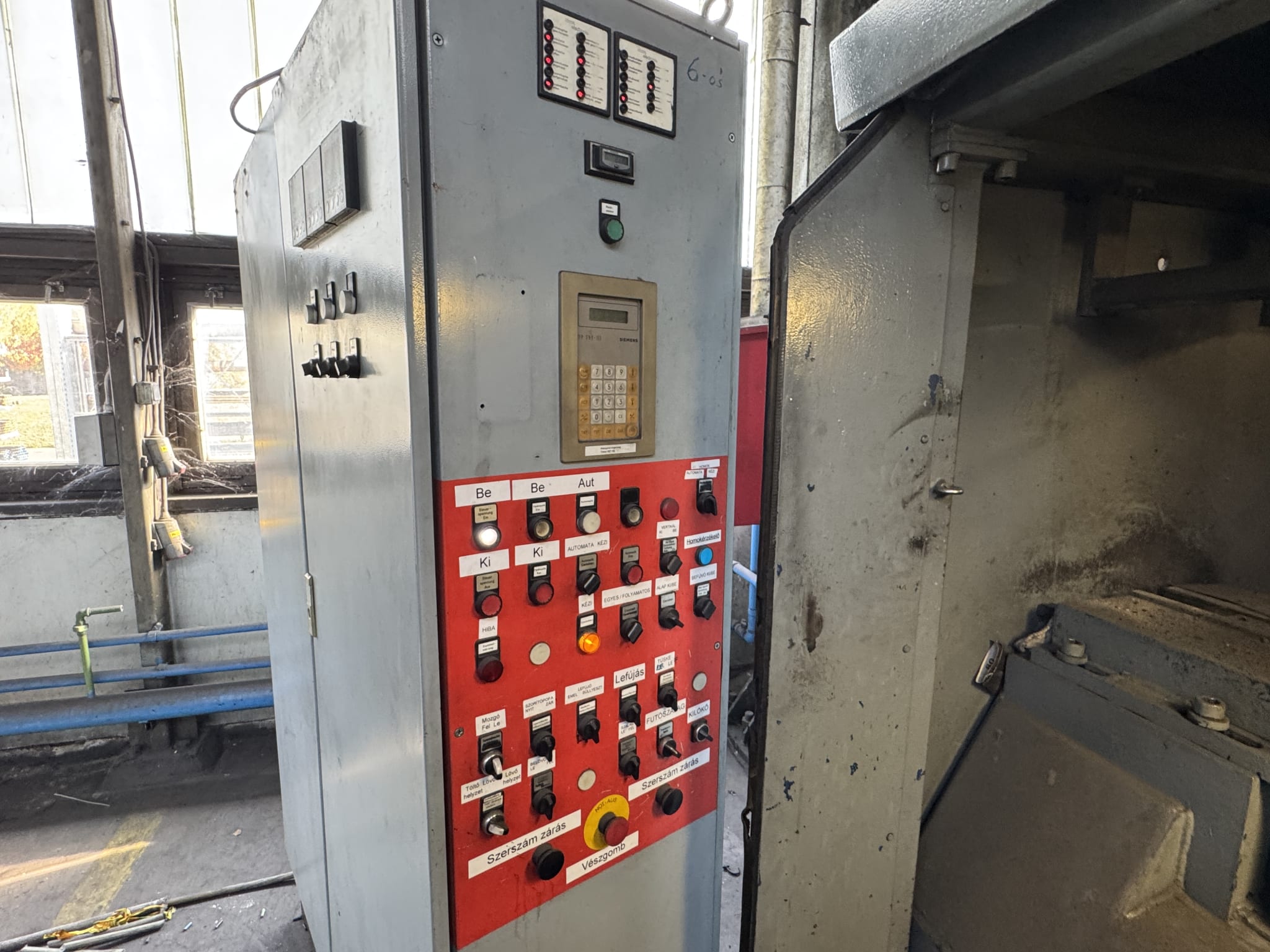

Robot casting with controller ABB IRB 2400 | 1994

Binding Handling & Service Fee:

198 € (EURO) - LISTING 2800031

![Hungary]()

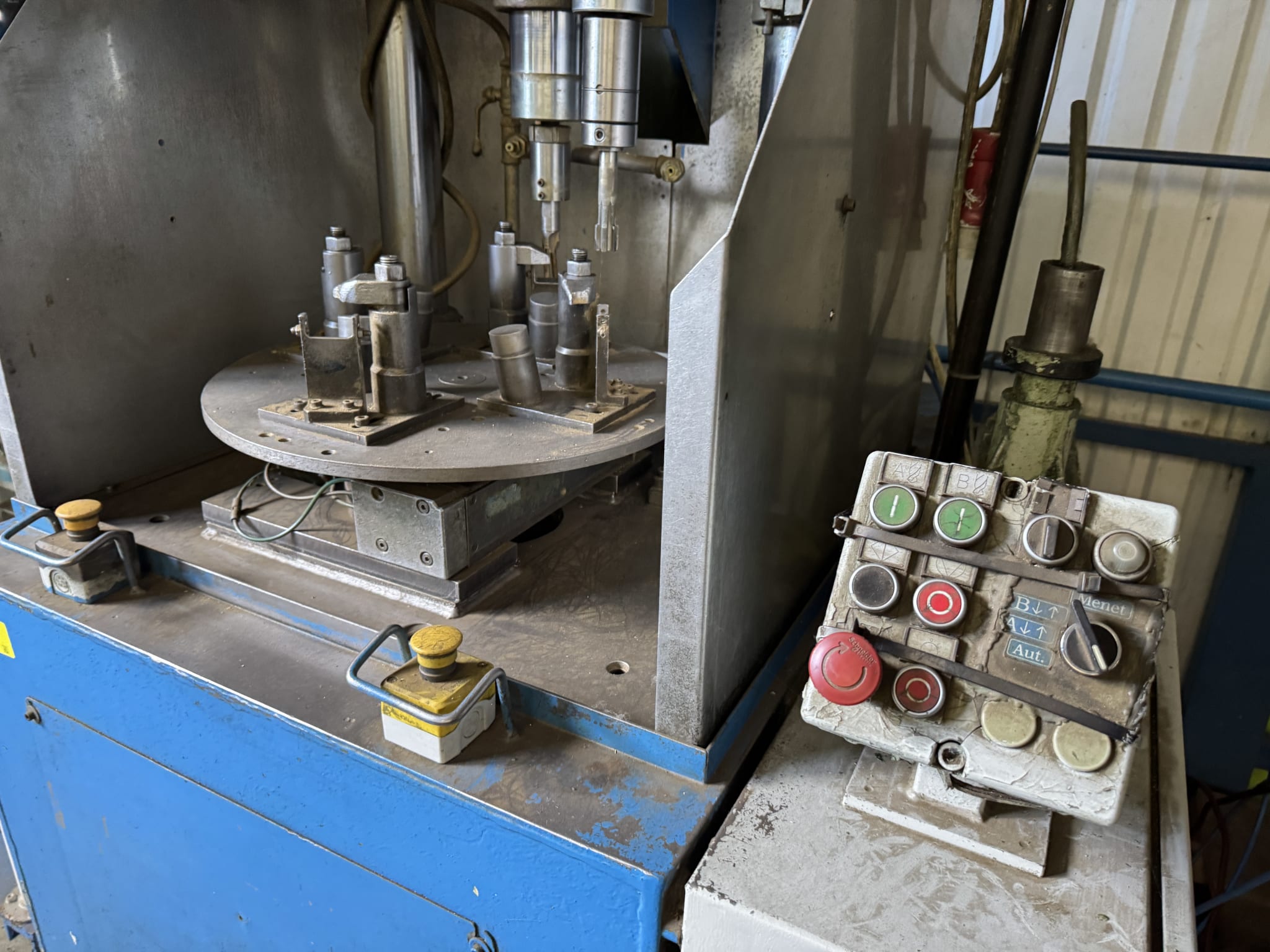

Sandcore shooter with sliding table VOGEL & SCHEMMANN KSM 6.05 HB/E | 1984

Binding Handling & Service Fee:

495 € (EURO)

Hotbox process; 40 kW, tool dimension 500x150x60mm; control Siemens - LISTING 2800032

![Hungary]()

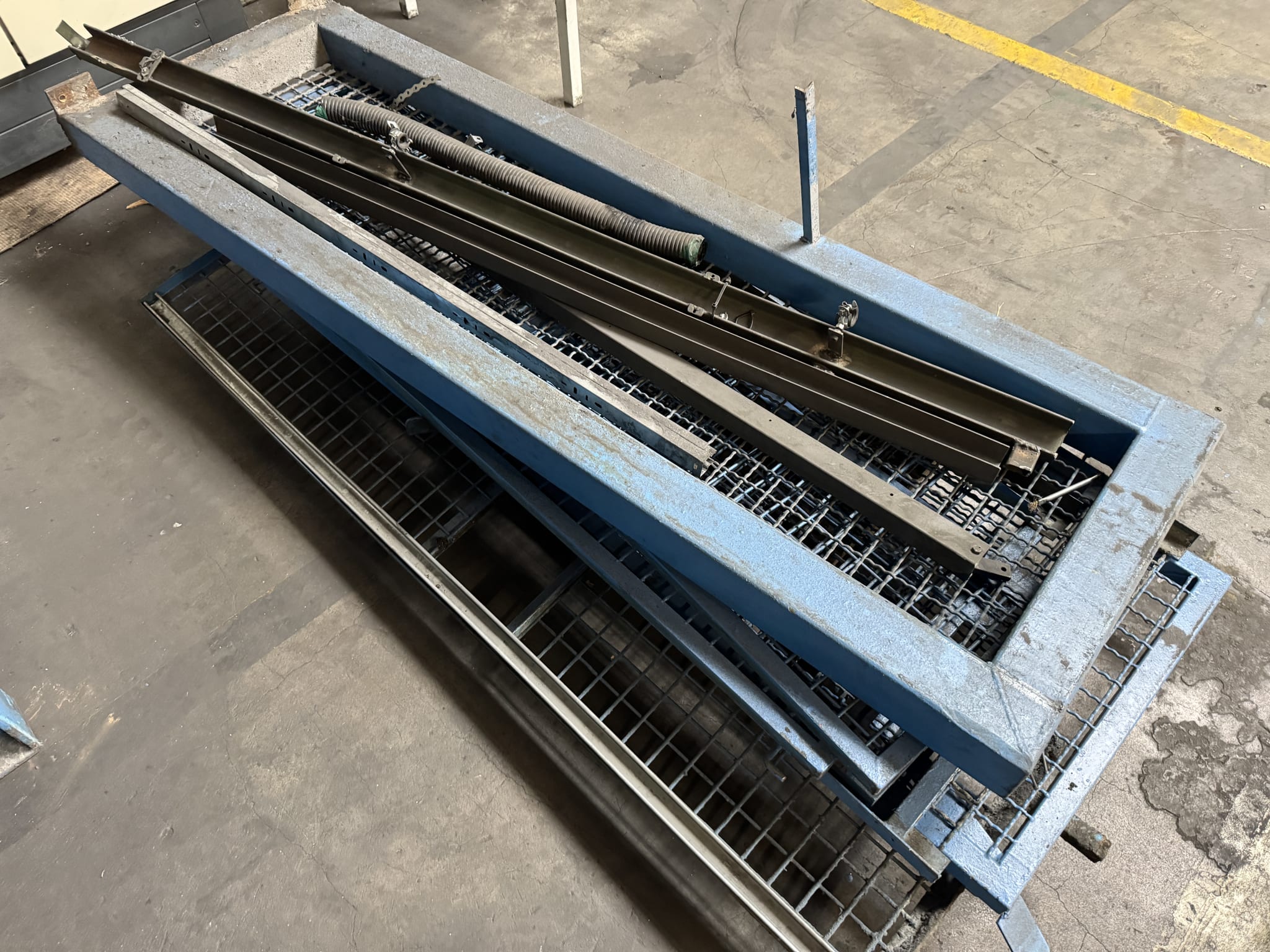

Automatic hydraulic sandcore shooter with belt conveyor VOGEL & SCHEMMANN BA-05.00-HB/E/SPS | 1990

Binding Handling & Service Fee:

495 € (EURO)

Hotbox process; 34 kW, tool dimension 500x250x60mm; control Siemens - LISTING 2800033

![Hungary]()

Automatic hydraulic sandcore shooter with belt conveyor VOGEL & SCHEMMANN BA-05.00-HB/E/SPS | 1990

Binding Handling & Service Fee:

495 € (EURO)

Hotbox process; 34 kW, tool dimension 500x250x60mm; control Siemens - LISTING 2800034

![Hungary]()

Automatic hydraulic sandcore shooter with belt conveyor VOGEL & SCHEMMANN BA-05.00-HB/E/SPS | 1993

Binding Handling & Service Fee:

495 € (EURO)

Hotbox process; 34 kW, tool dimension 500x250x60mm; control Siemens - LISTING 2800036

![Hungary]()

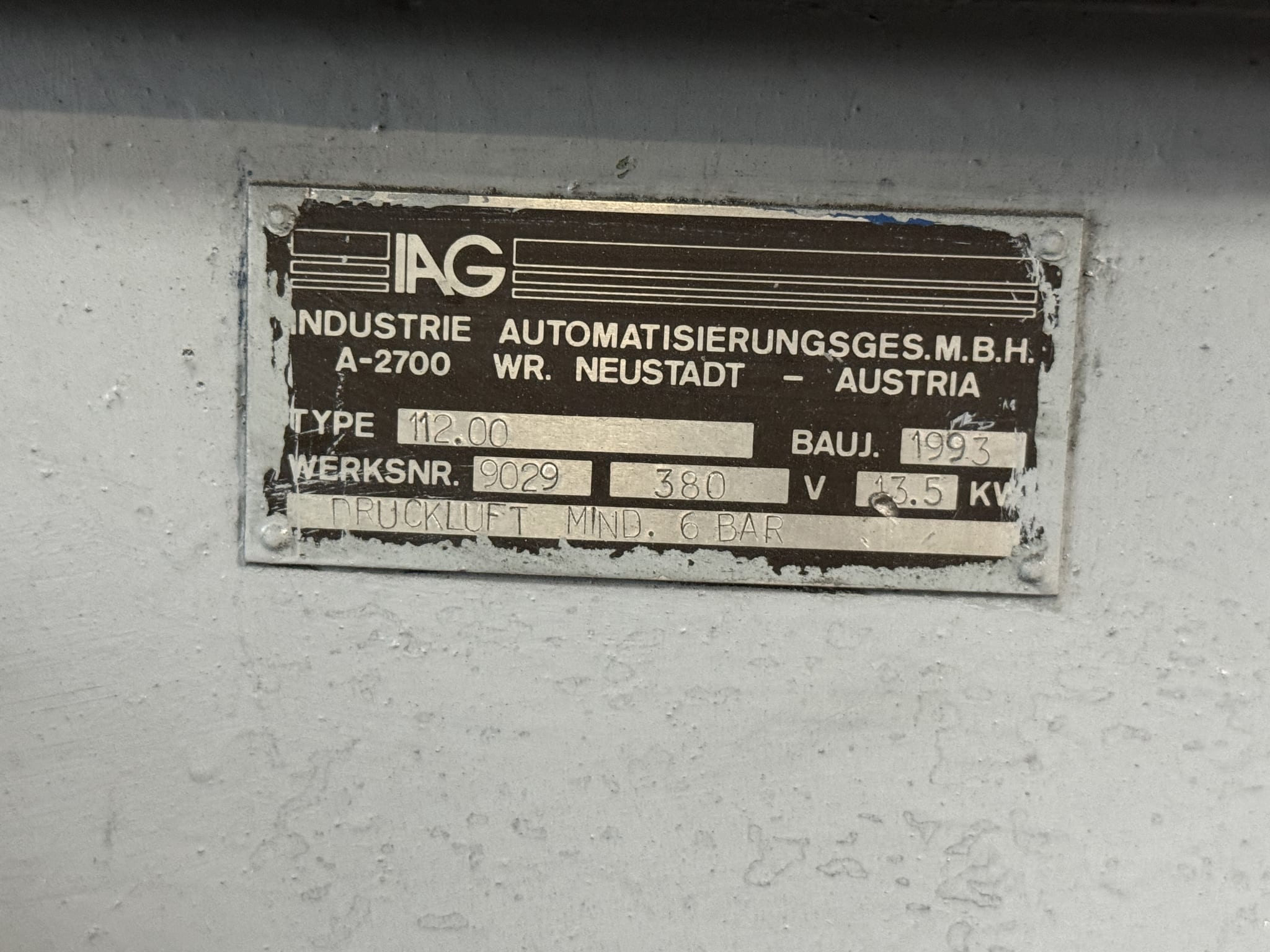

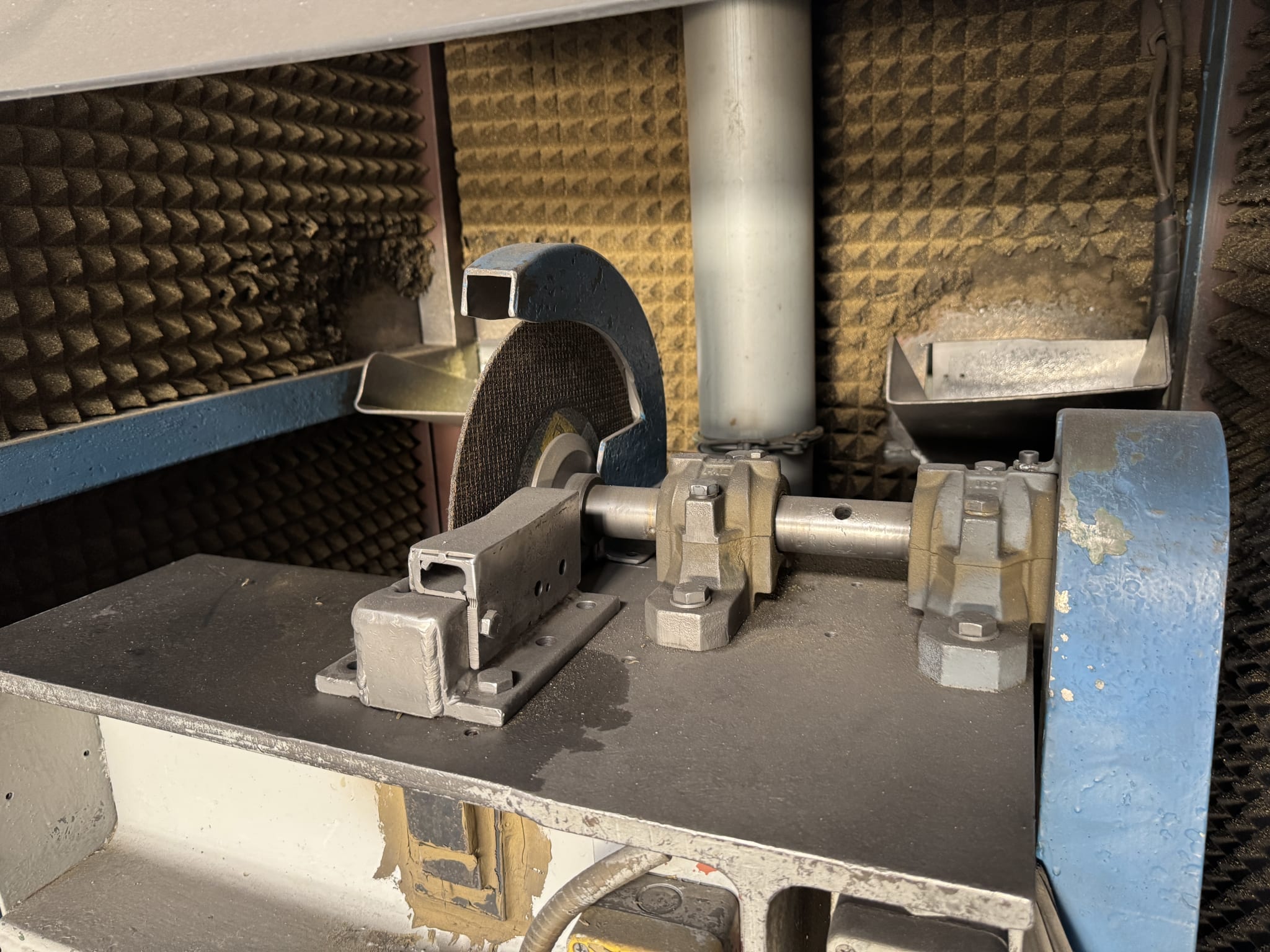

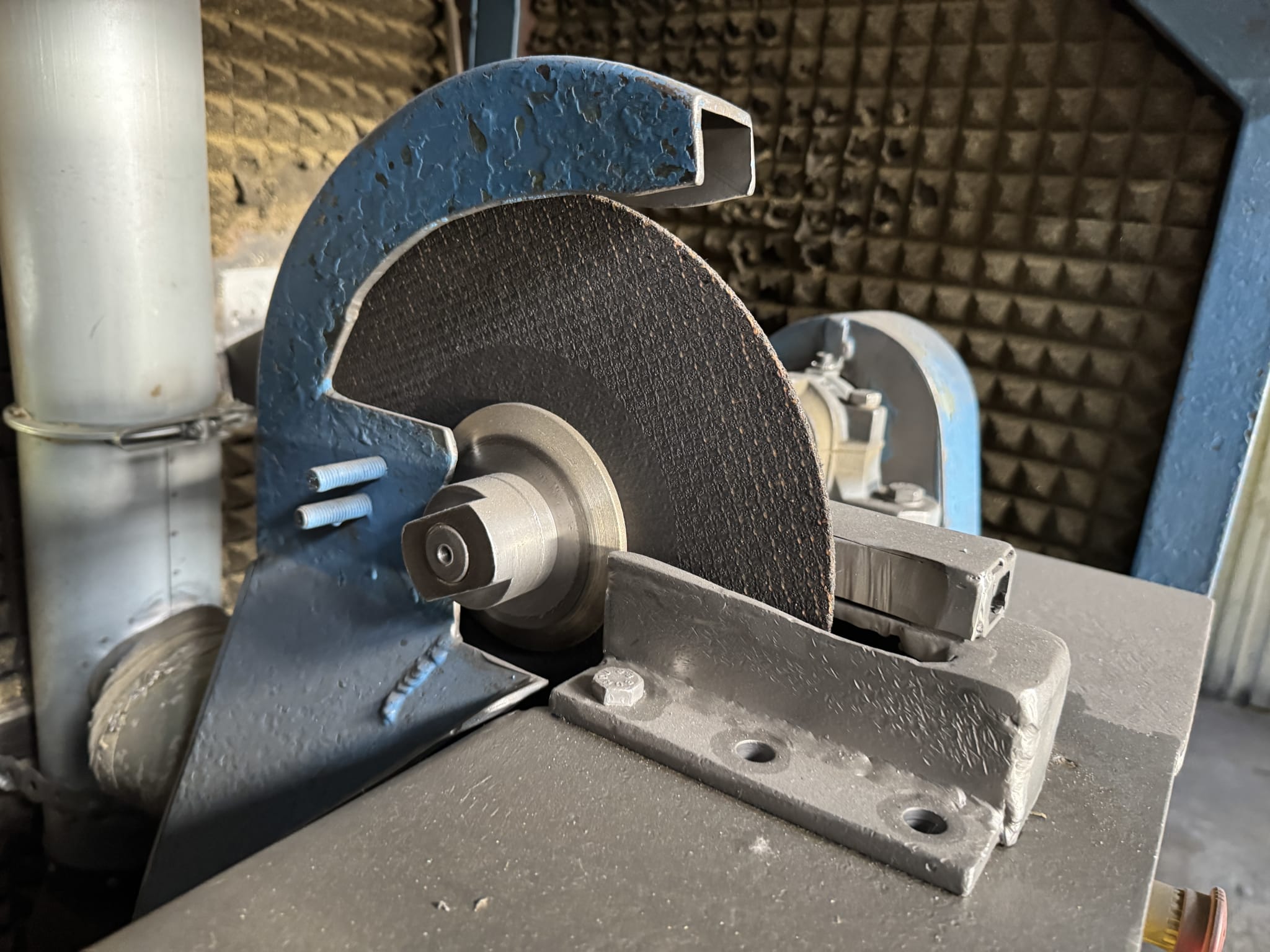

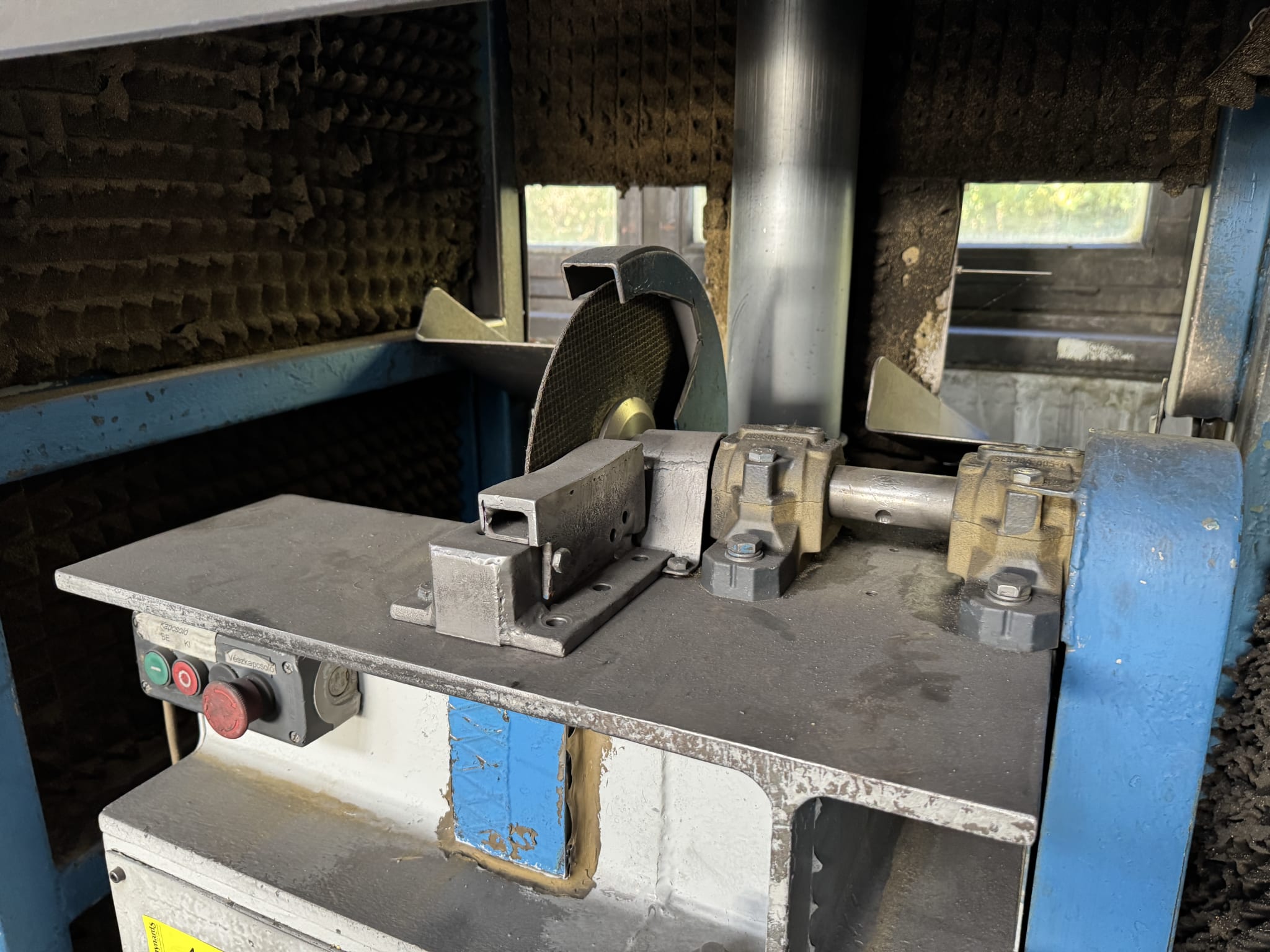

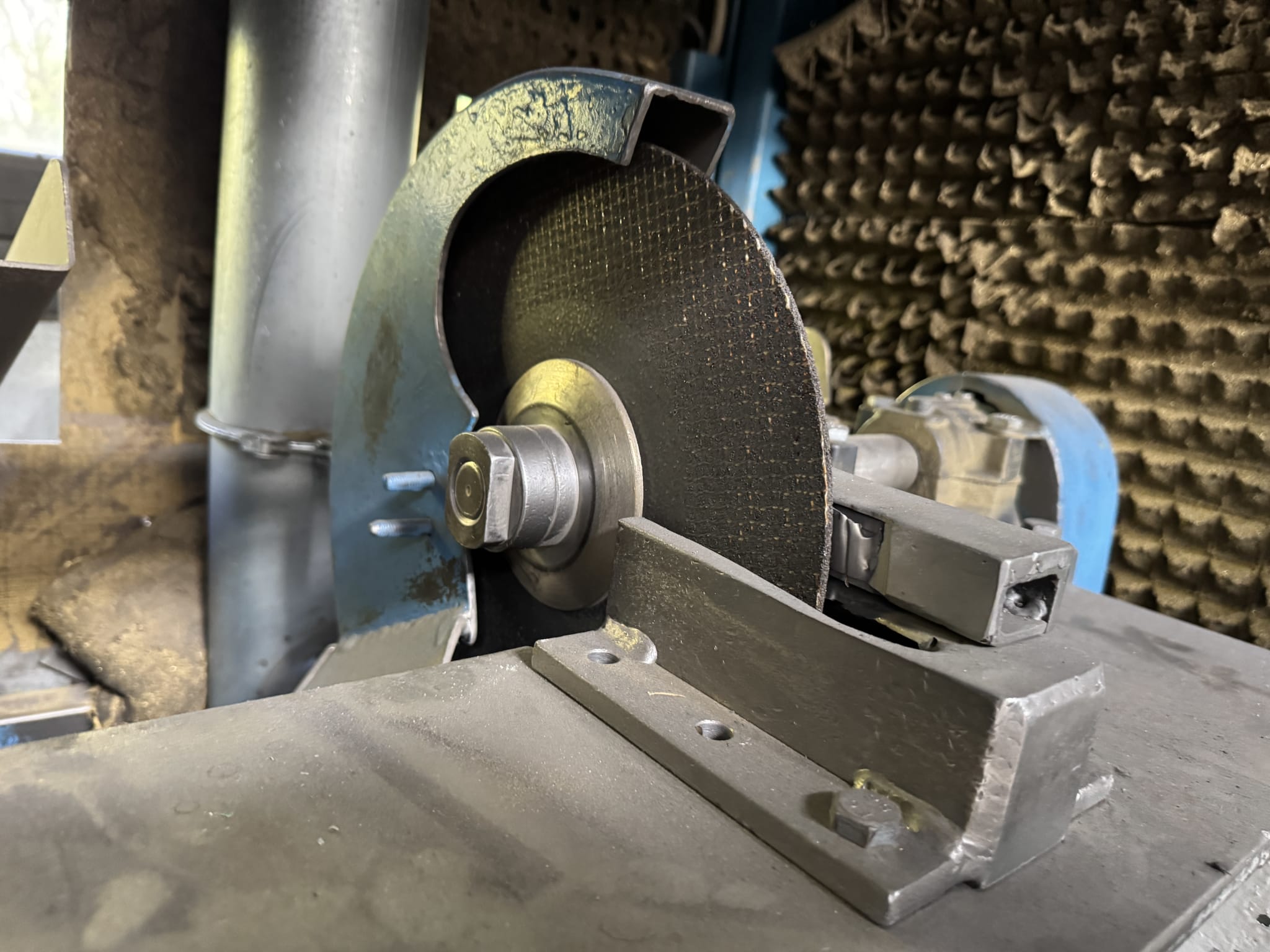

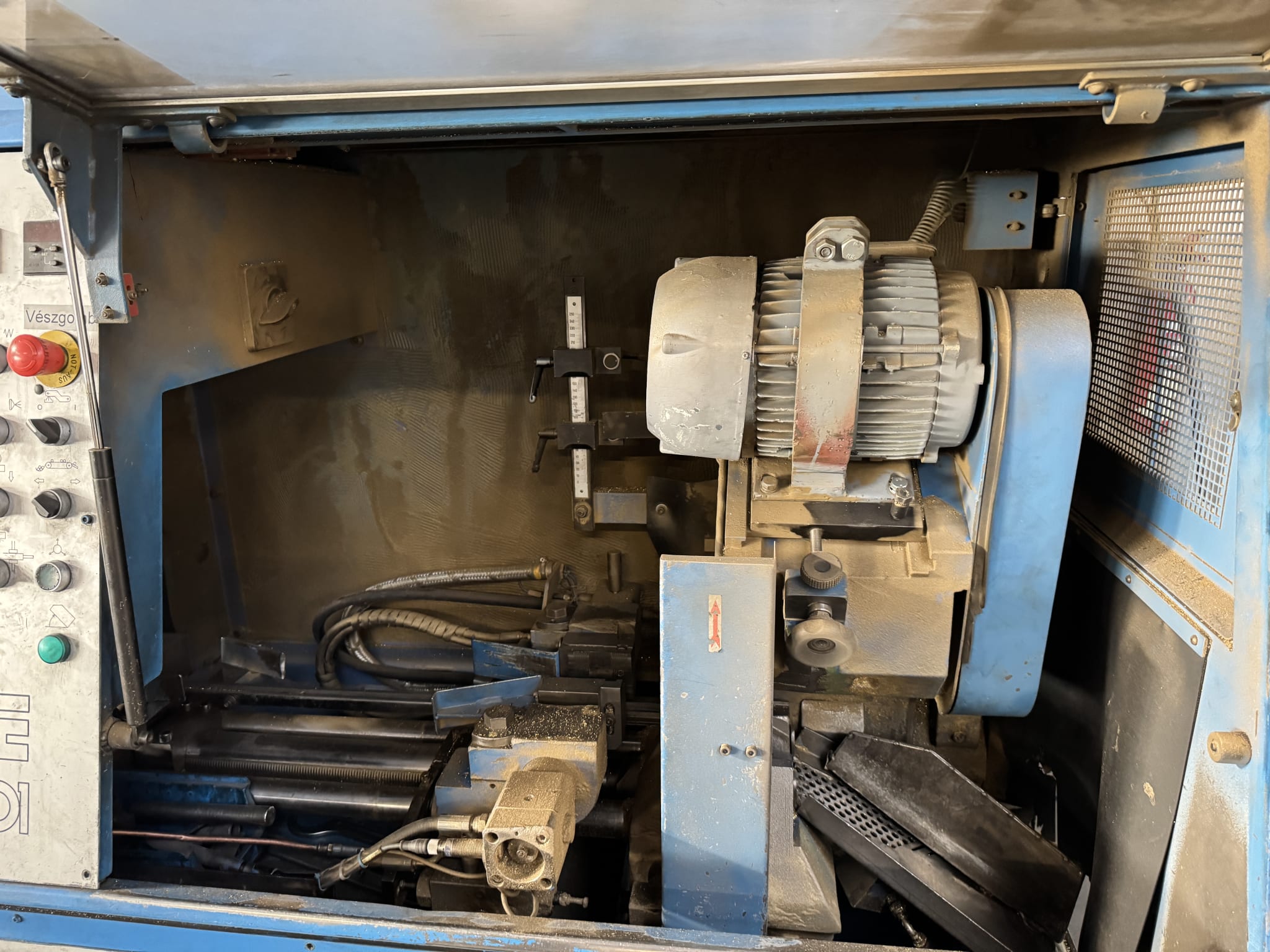

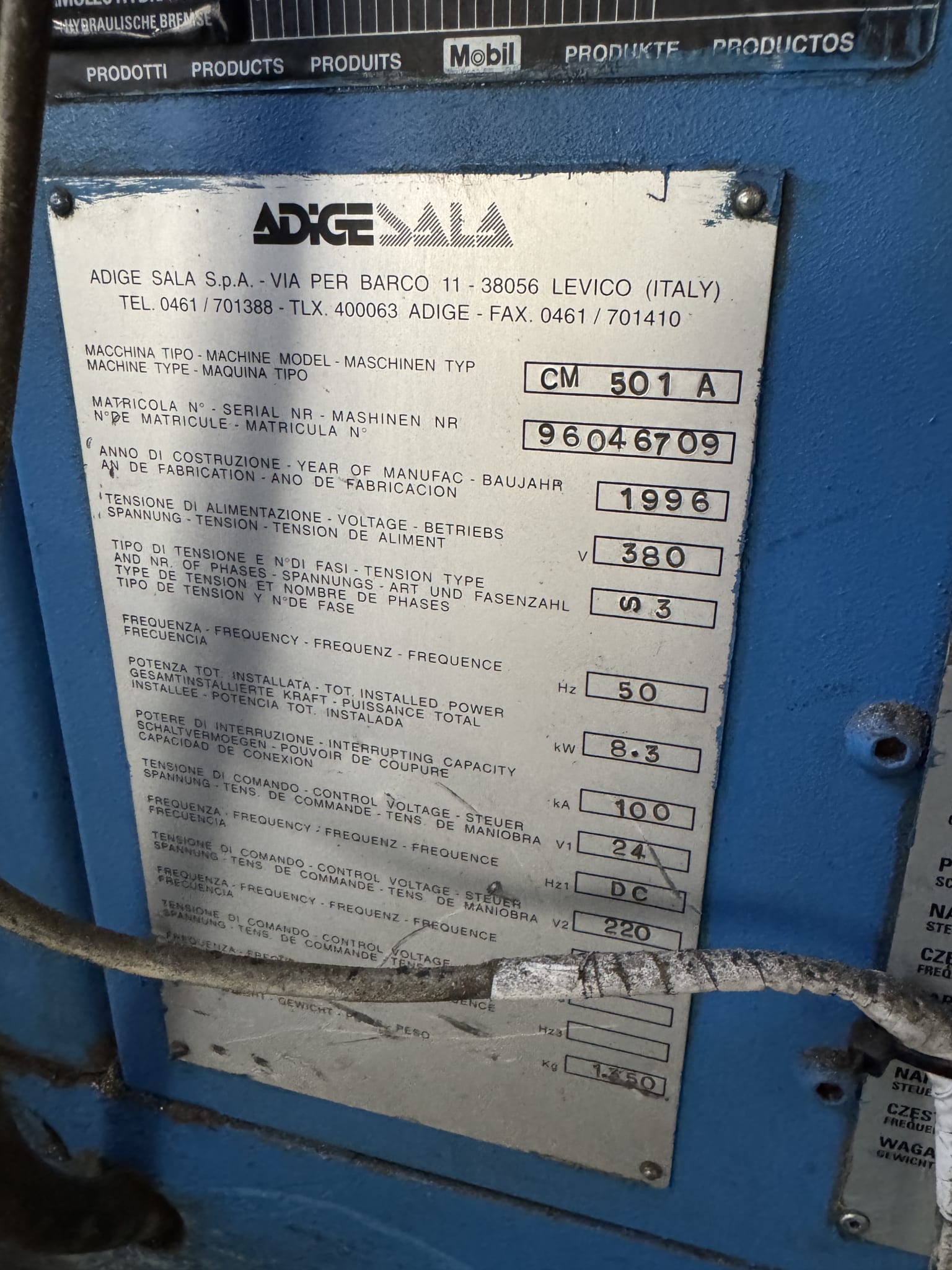

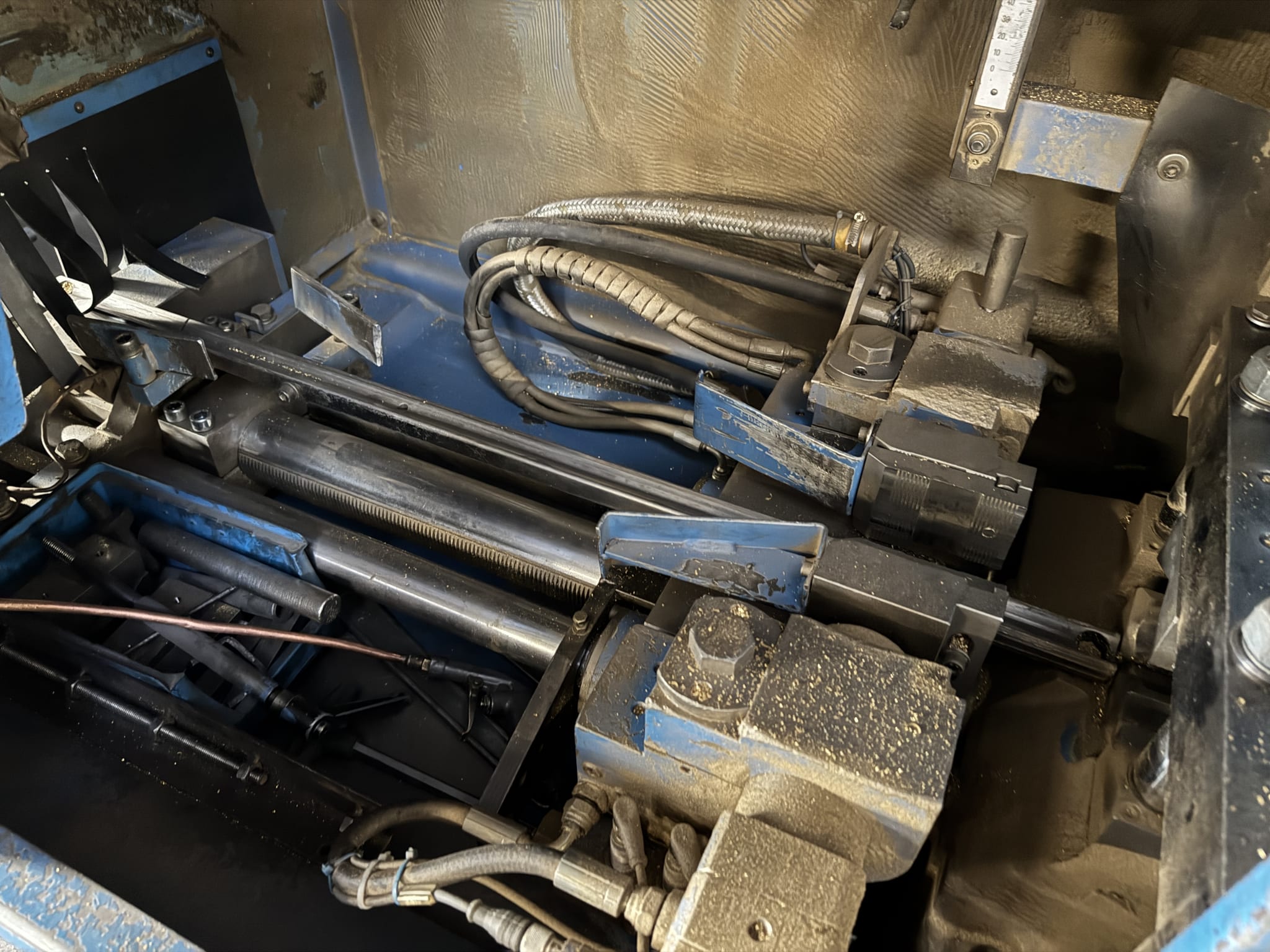

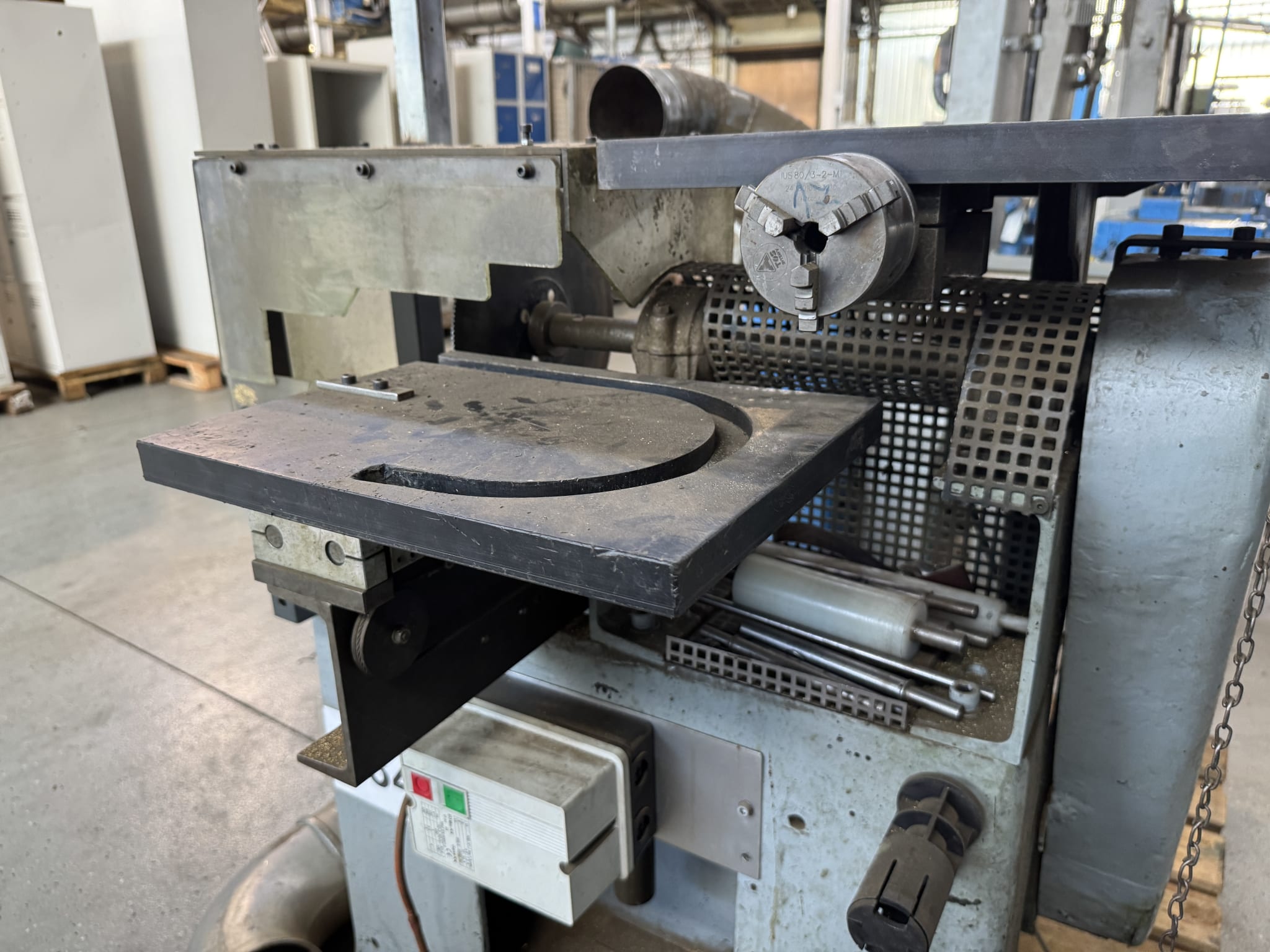

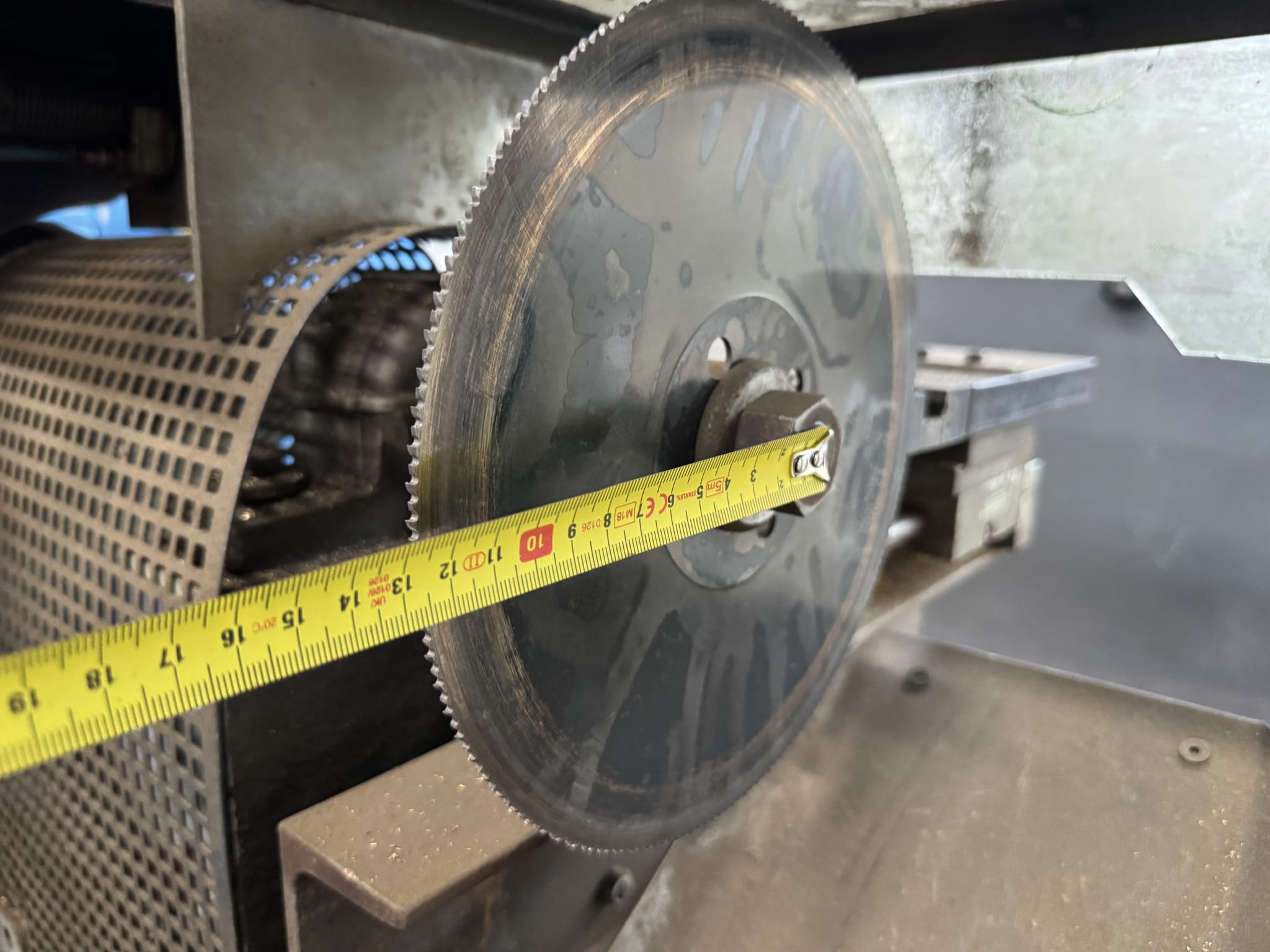

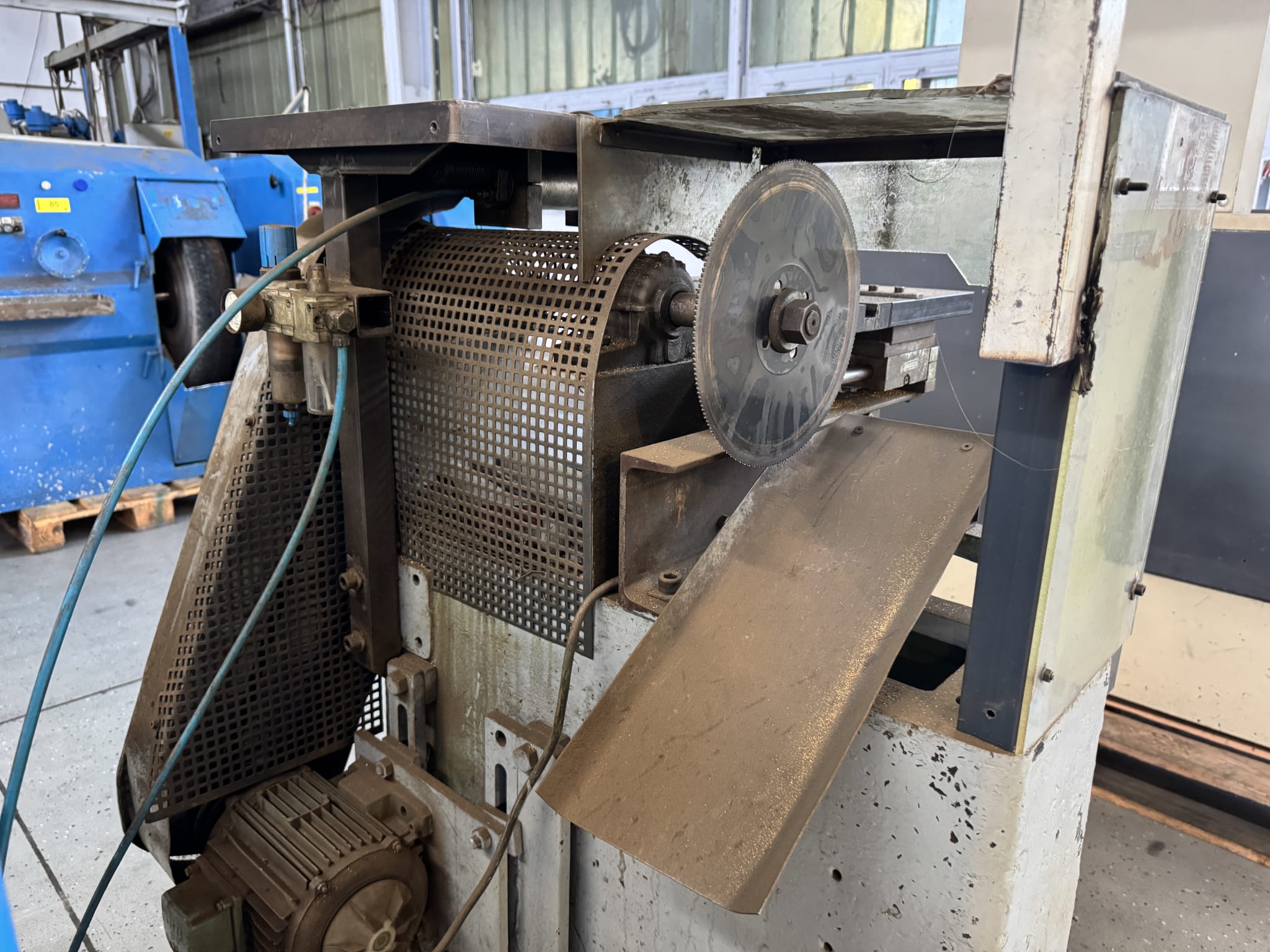

Automatic sprue gate disc saw machine IAG 112.00 | 1993

Binding Handling & Service Fee:

352 € (EURO) - LISTING 2800037

![Hungary]()

Induction furnace 600 kg with controller IMR B2R 85 | 1988

Binding Handling & Service Fee:

352 € (EURO) - LISTING 2800038

![Hungary]()

Induction furnace 600 kg with controller IMR | 1990

Binding Handling & Service Fee:

352 € (EURO) - LISTING 2800039

![Hungary]()

Induction furnace 600 kg with controller IMR | 1990

Binding Handling & Service Fee:

352 € (EURO) - LISTING 2800040

![Hungary]()

Induction furnace 600 kg with controller IMR B2R 85

Binding Handling & Service Fee:

352 € (EURO) - LISTING 2800041

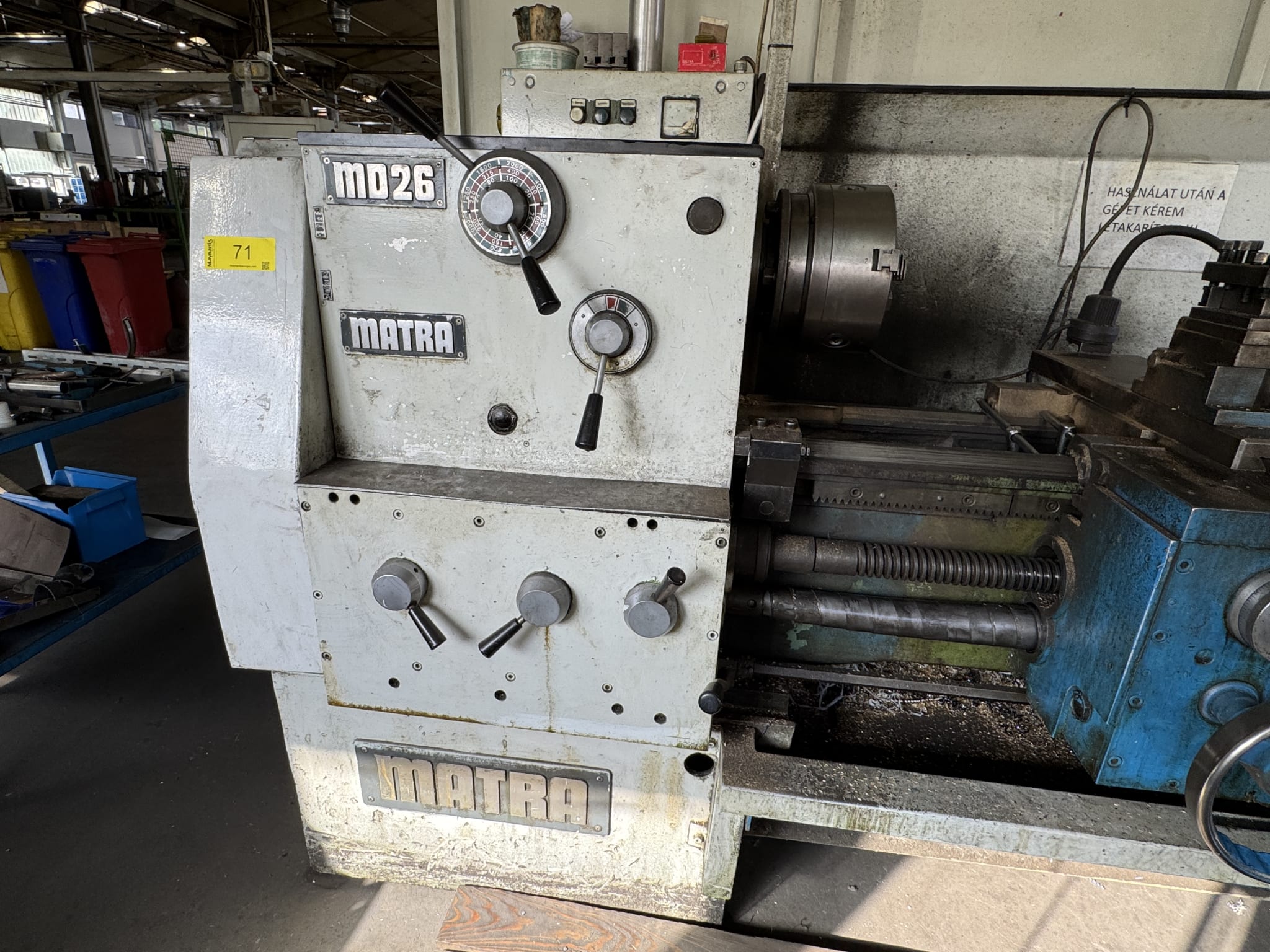

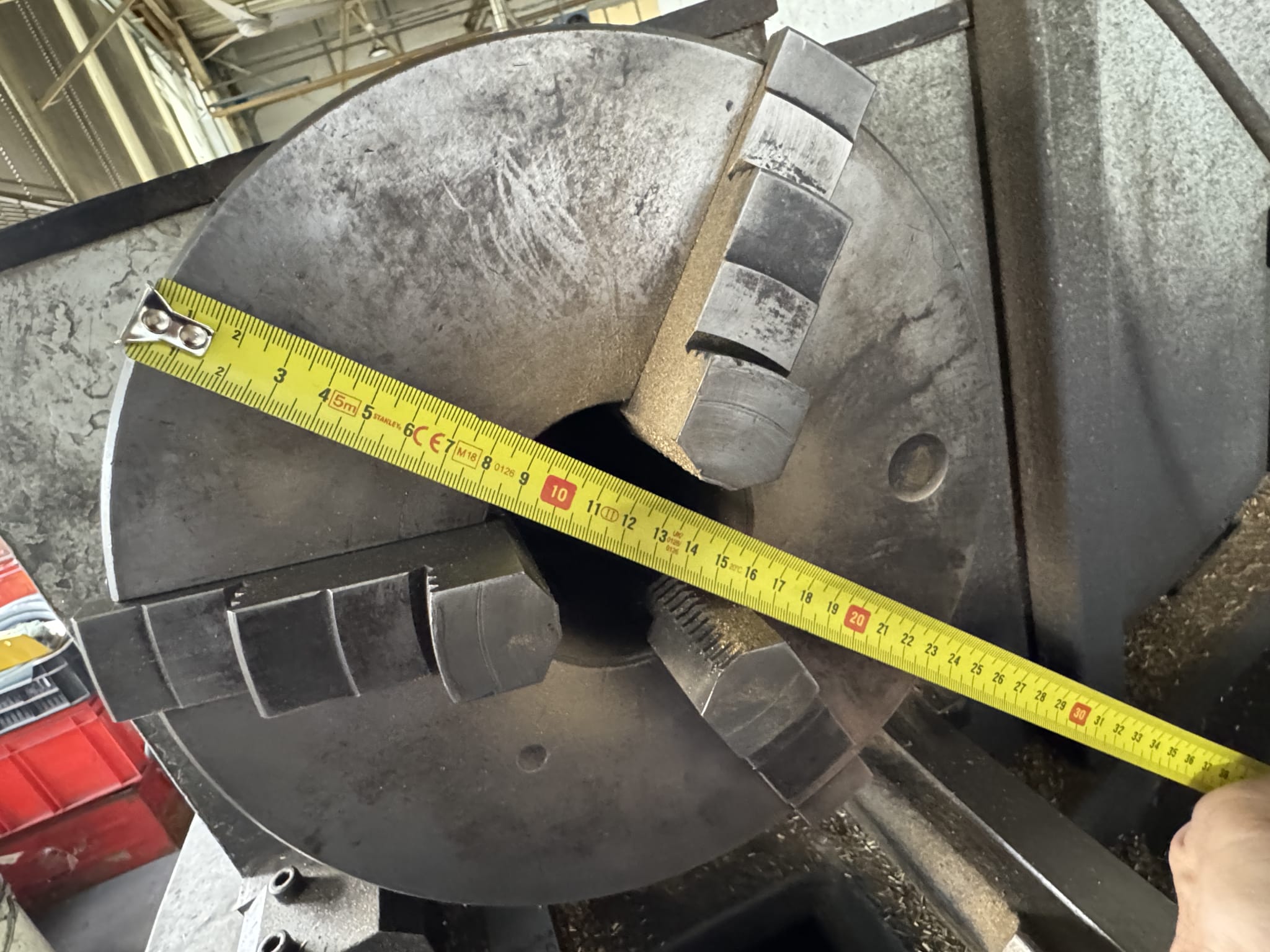

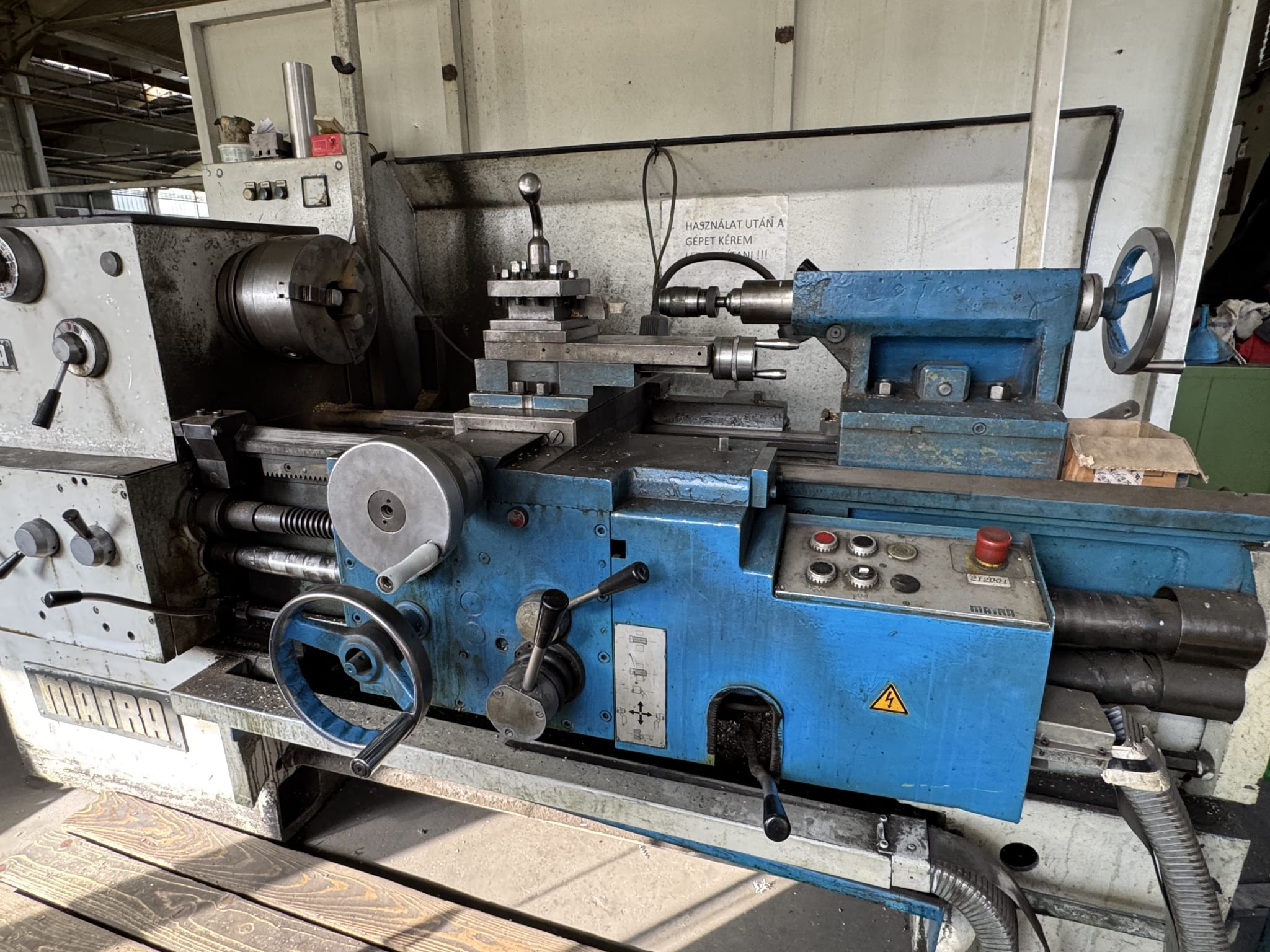

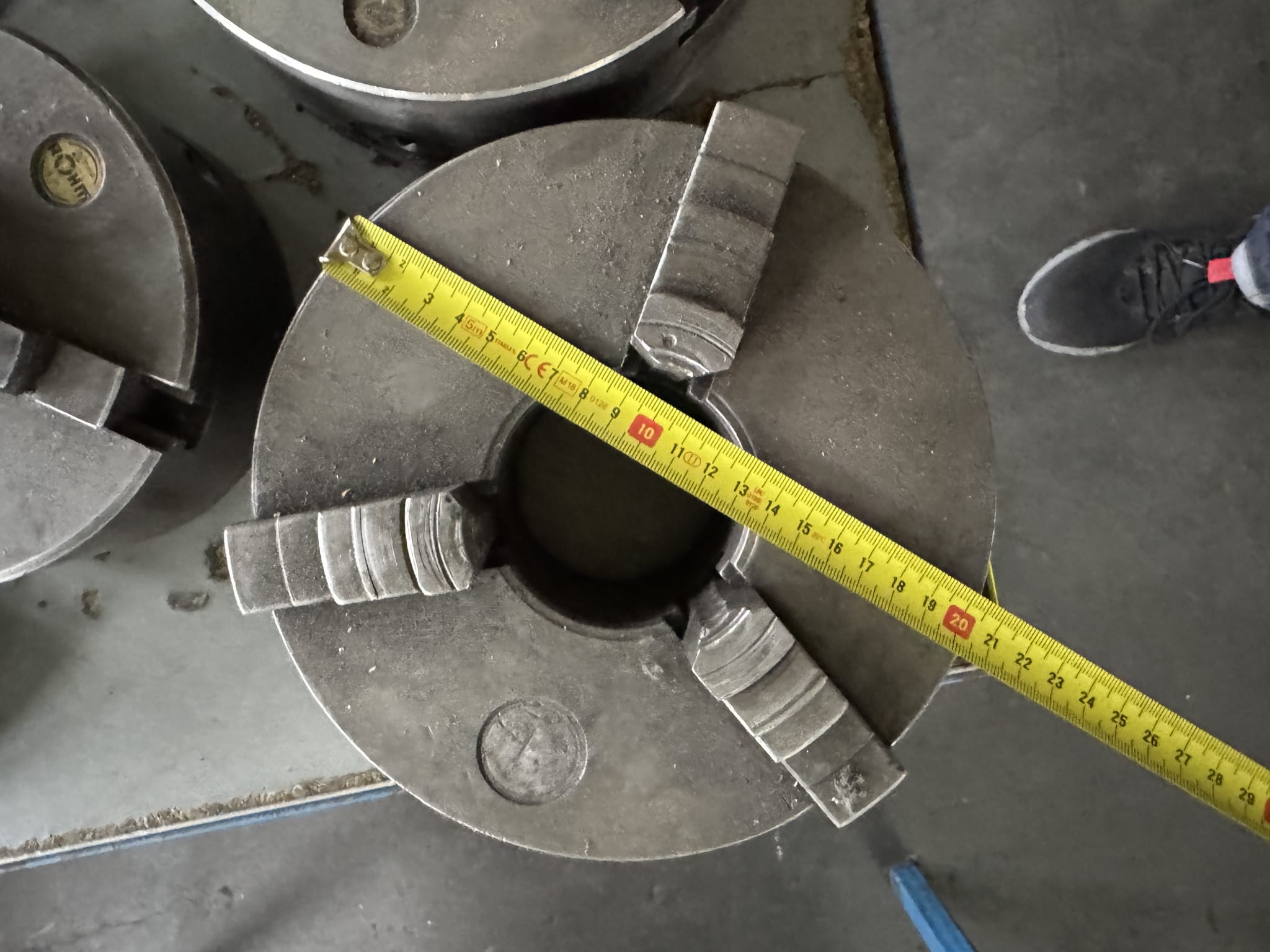

![Hungary]()

- LISTING 2800042

![Hungary]()

- LISTING 2800043

![Hungary]()

- LISTING 2800047

![Hungary]()

- LISTING 2800048

![Hungary]()

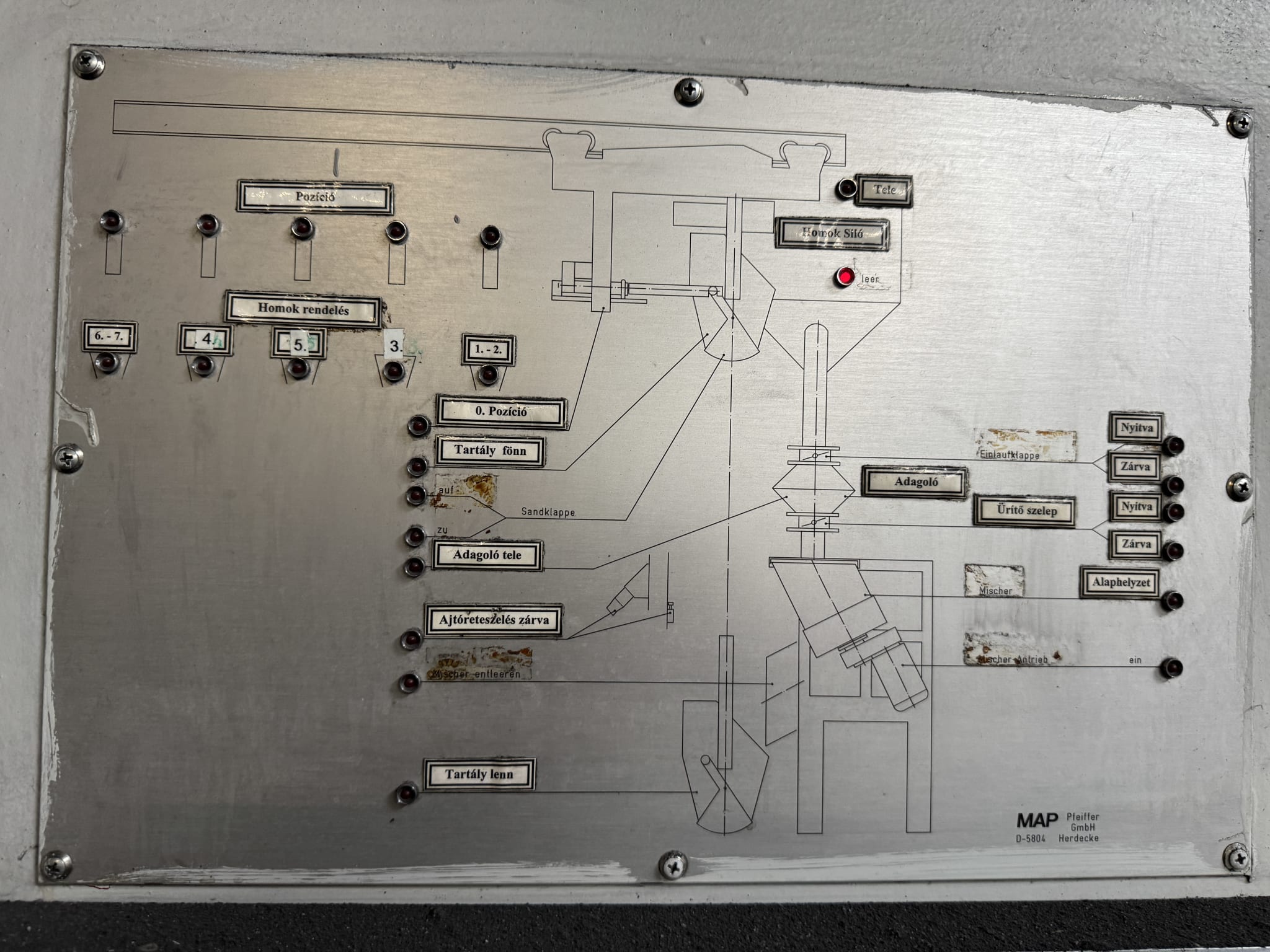

Sand dosing and mixing system KLANN + MAP PFEIFFER | 1991

Binding Handling & Service Fee:

275 € (EURO) - LISTING 2800049

![Hungary]()

(2) 2 induction furnaces 1,100 kg, 1,000 kg RUSS / LEICH | 1990

Binding Handling & Service Fee:

330 € (EURO) - LISTING 2800052

![Hungary]()

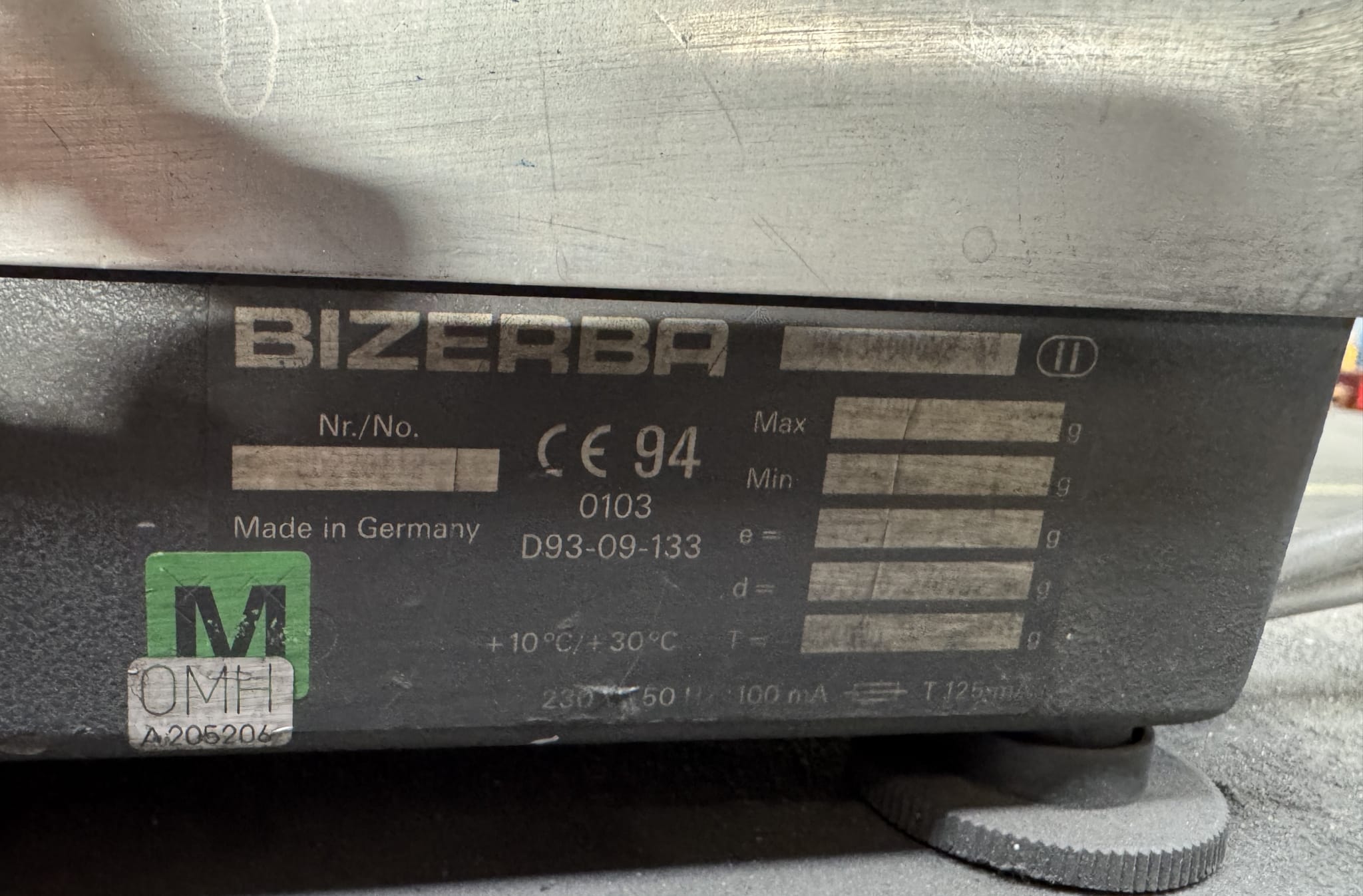

Weighing station for pallets and parcels with printer BIZERBA

Binding Handling & Service Fee:

220 € (EURO) - LISTING 2800057

![Hungary]()

- LISTING 2800060

![Hungary]()

- LISTING 2800064

![Hungary]()

- LISTING 2800065

![Hungary]()

- LISTING 2800068

![Hungary]()

- LISTING 2800069

![Hungary]()

- LISTING 2800071

![Hungary]()

- LISTING 2800074

![Hungary]()

- LISTING 2800077

![Hungary]()

- LISTING 2800079

![Hungary]()

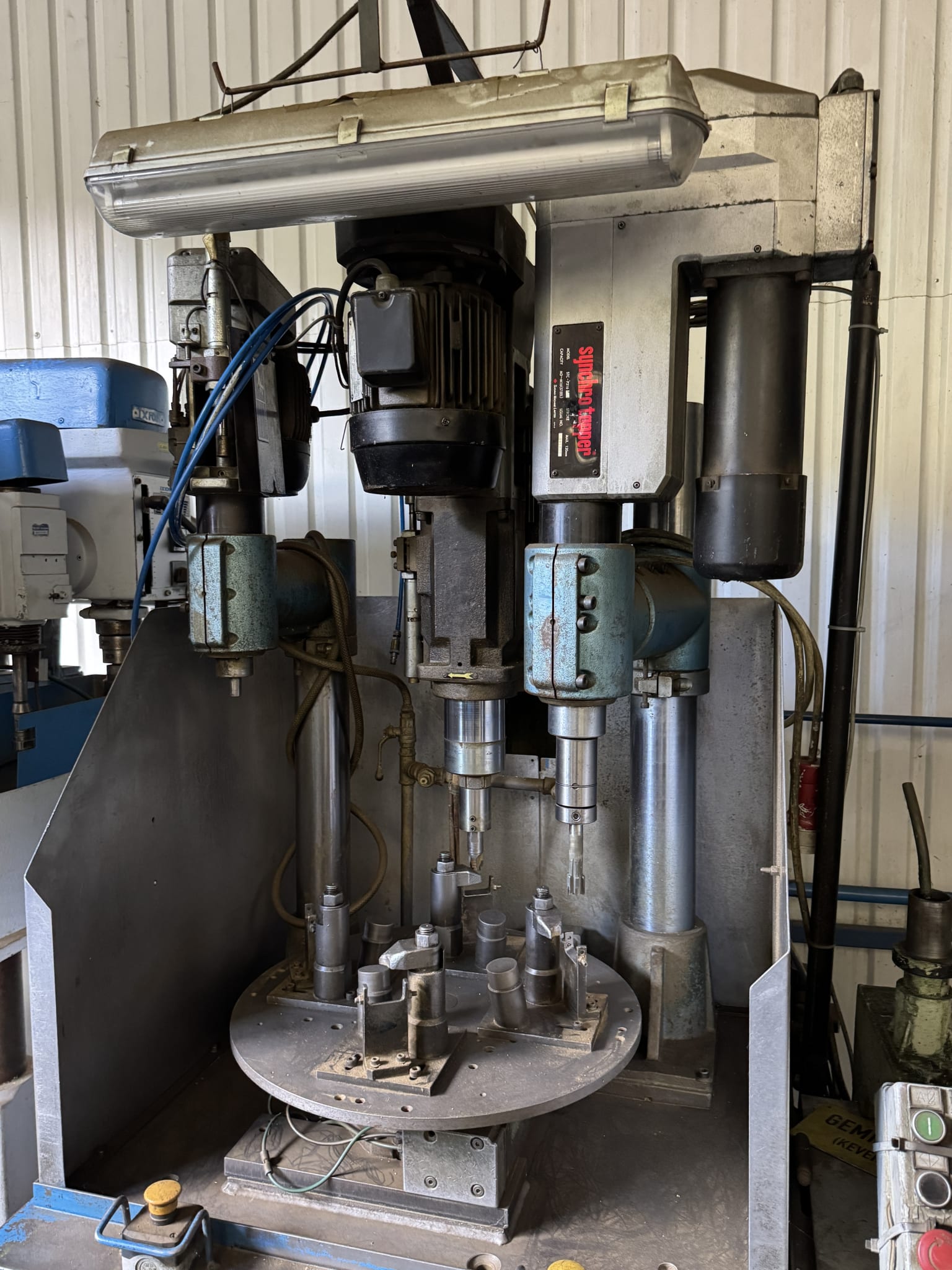

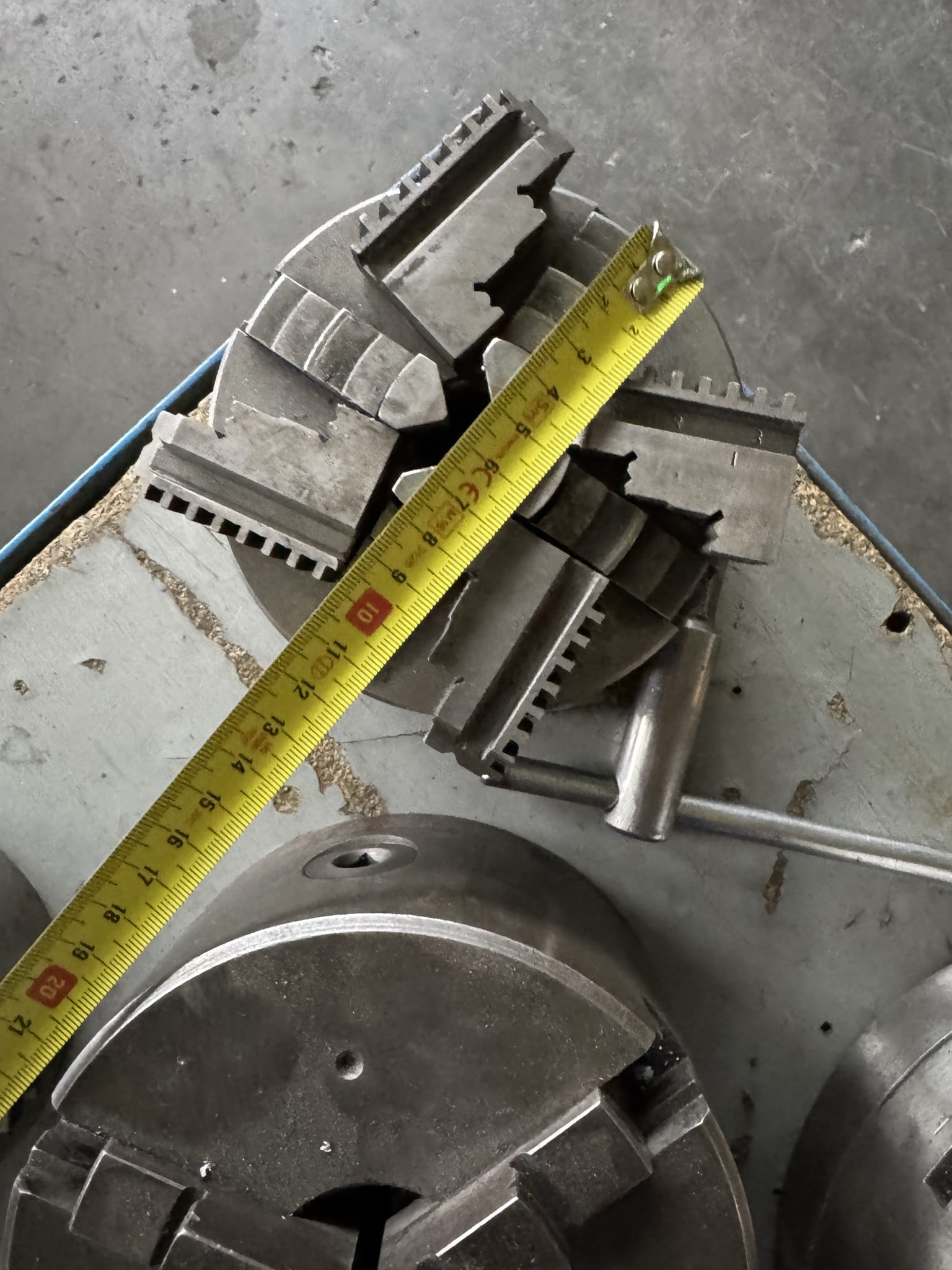

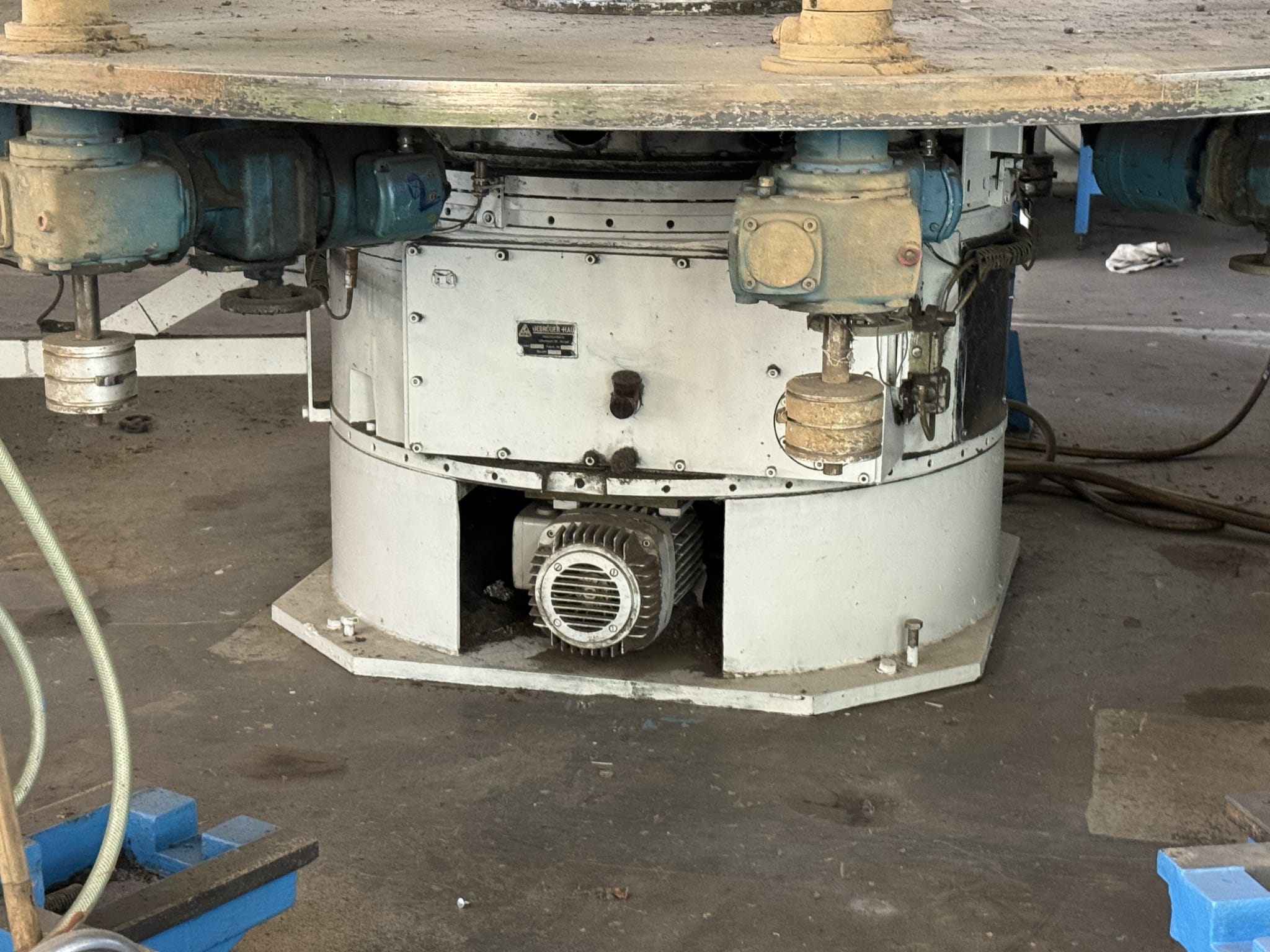

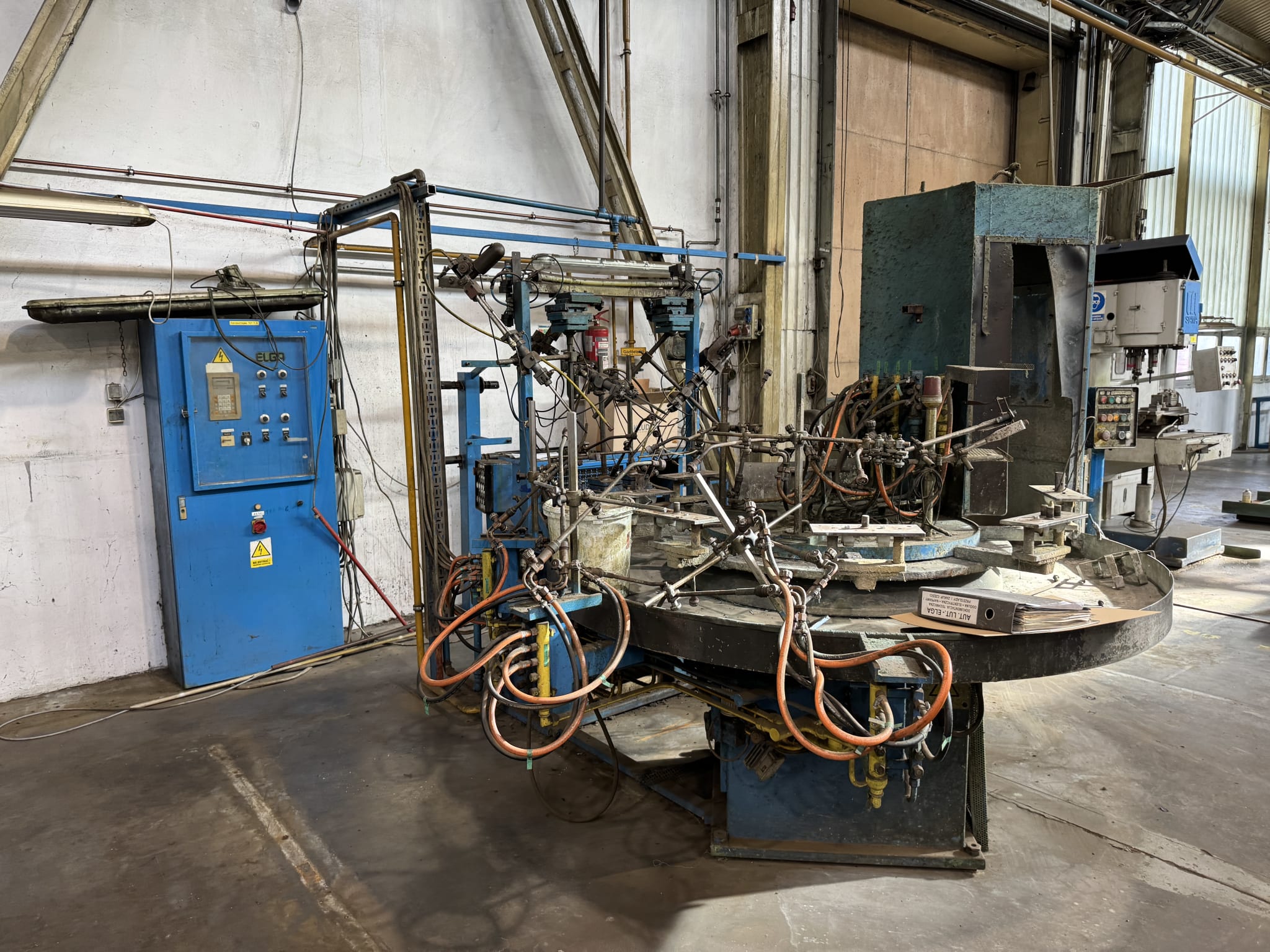

(6) 6 head polishing rotative station HAU RKS88/2400 | 1979

Binding Handling & Service Fee:

495 € (EURO) - LISTING 2800080

![Hungary]()

(4) 4 head polishing rotative station HAU RK0/3 | 1972

Binding Handling & Service Fee:

220 € (EURO) - LISTING 2800081

![Hungary]()

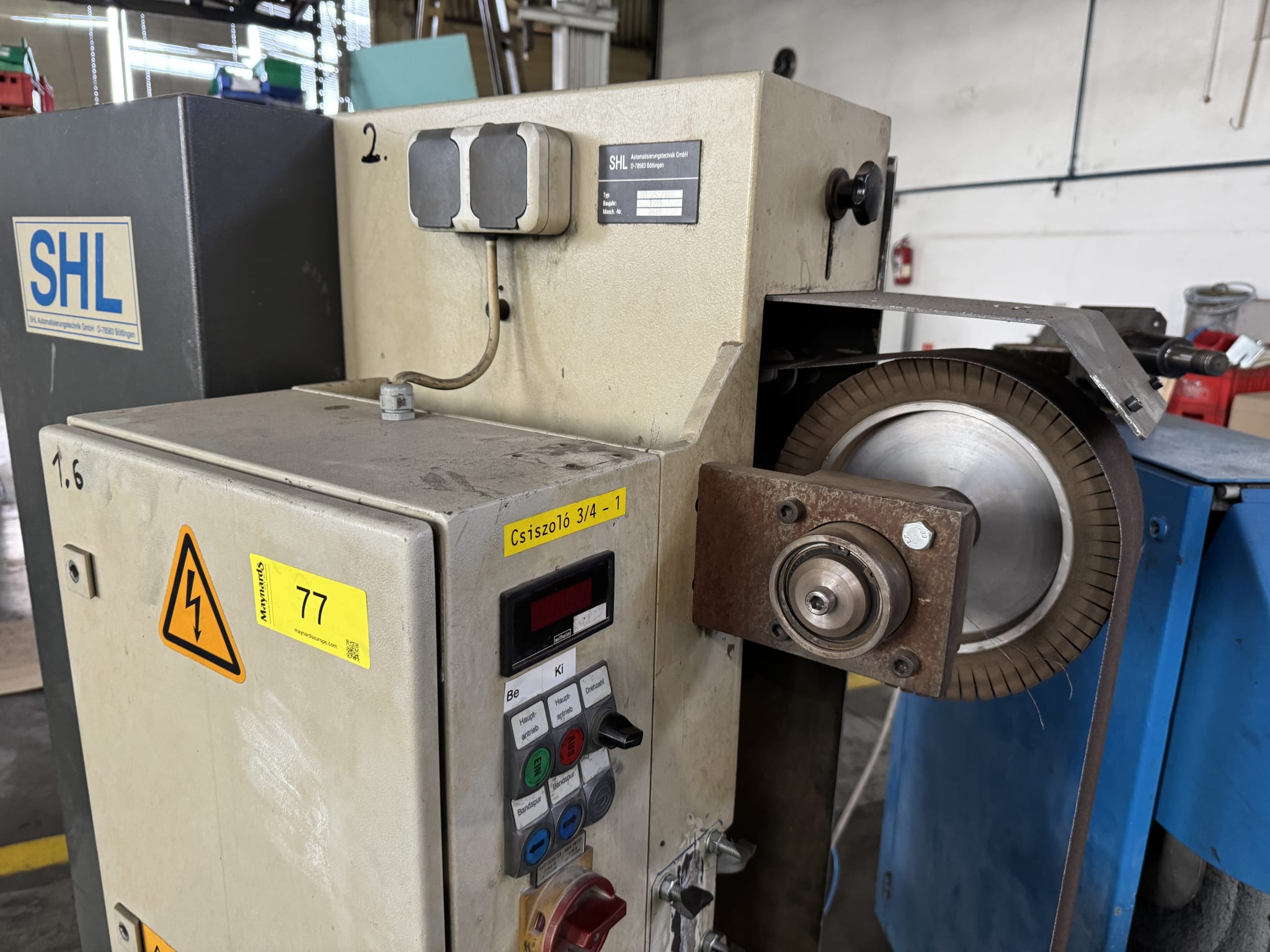

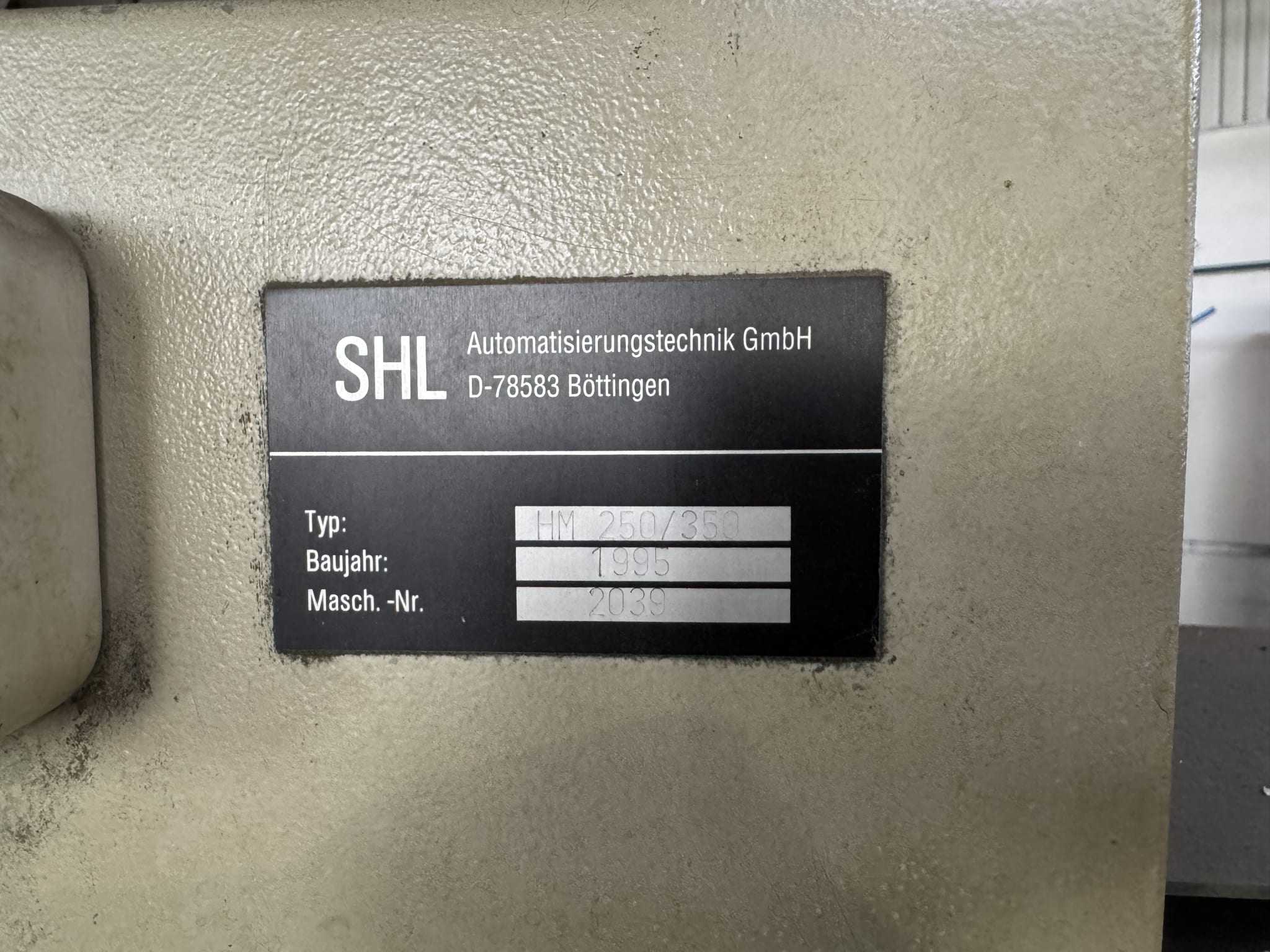

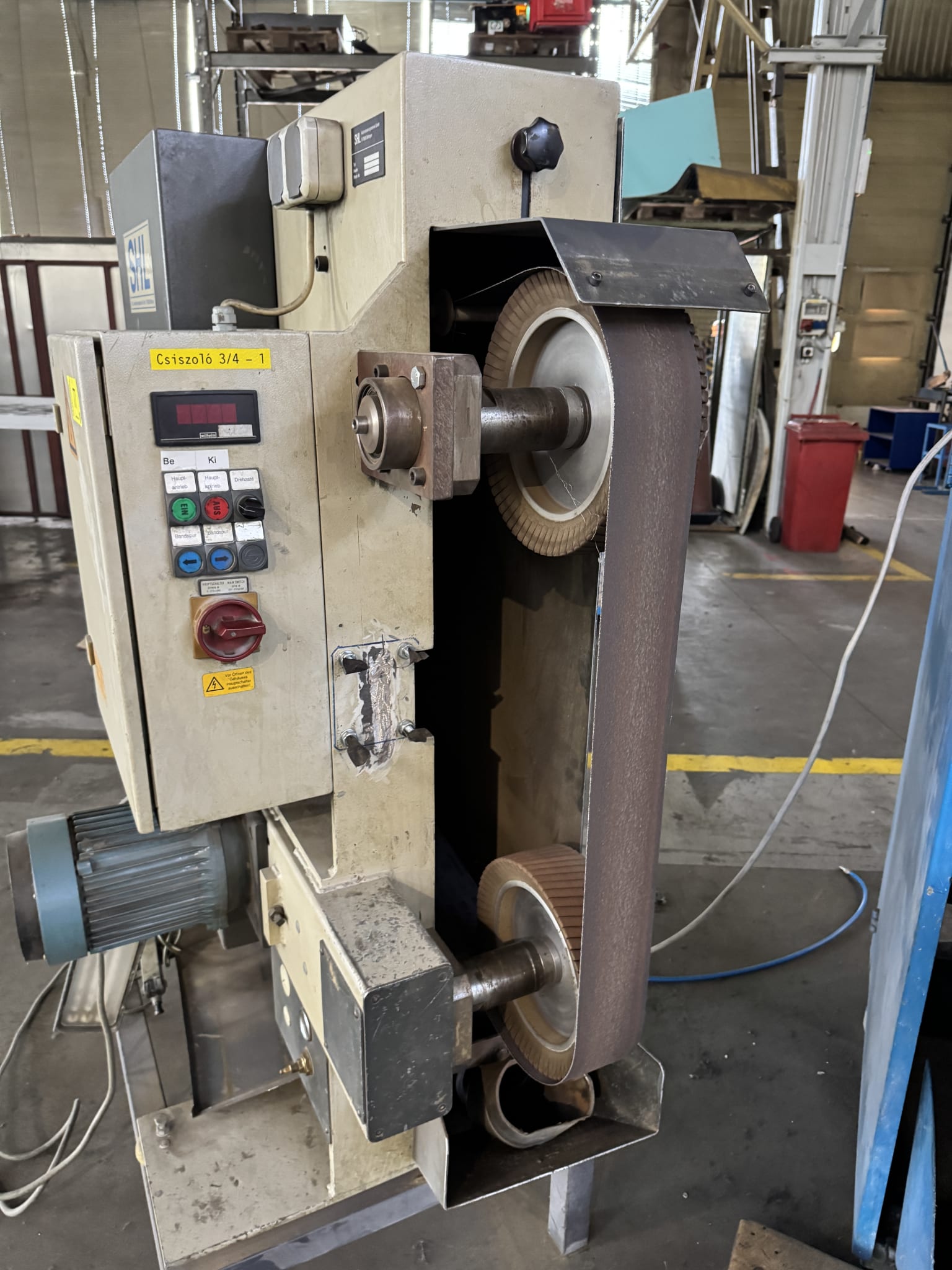

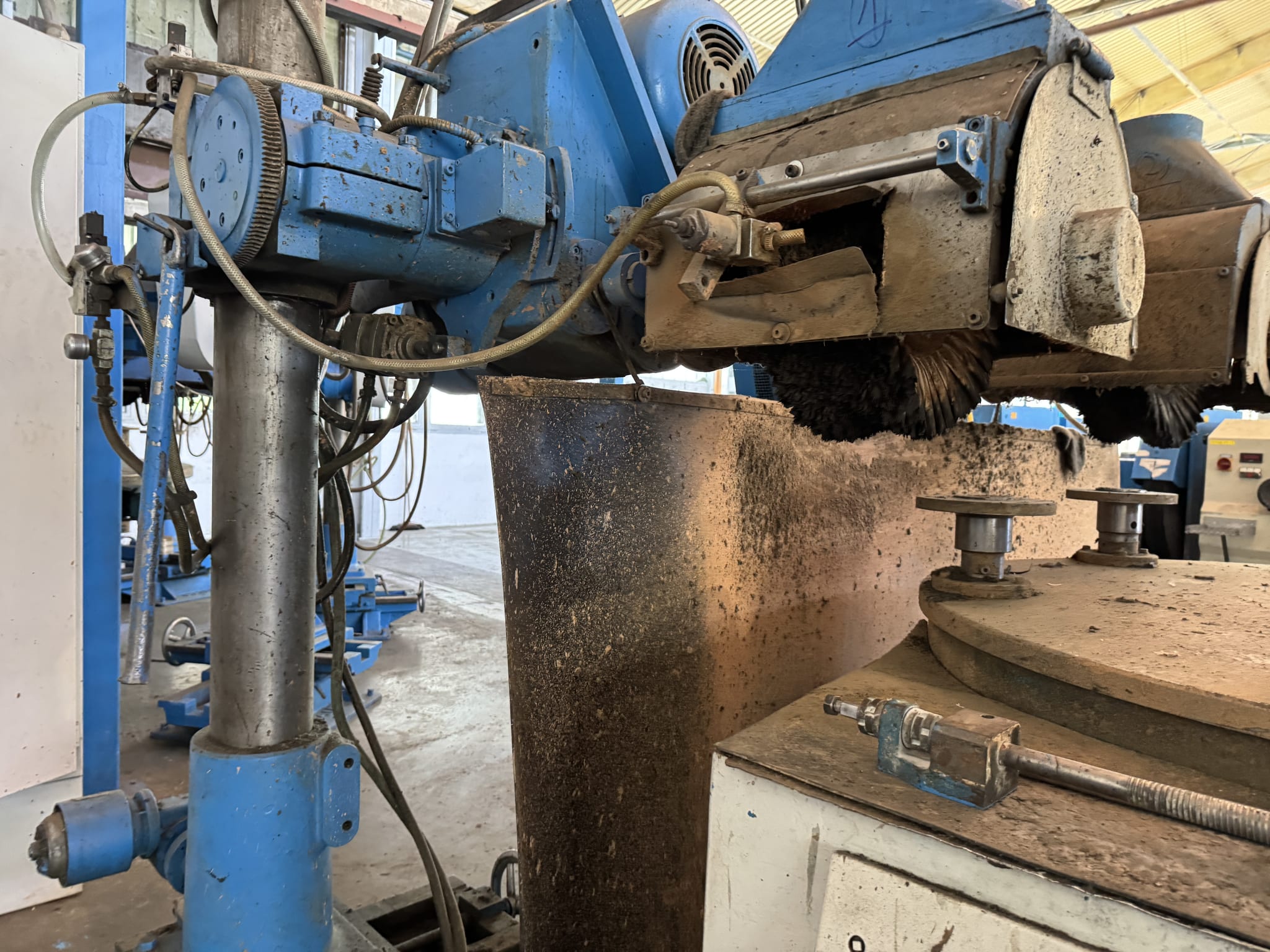

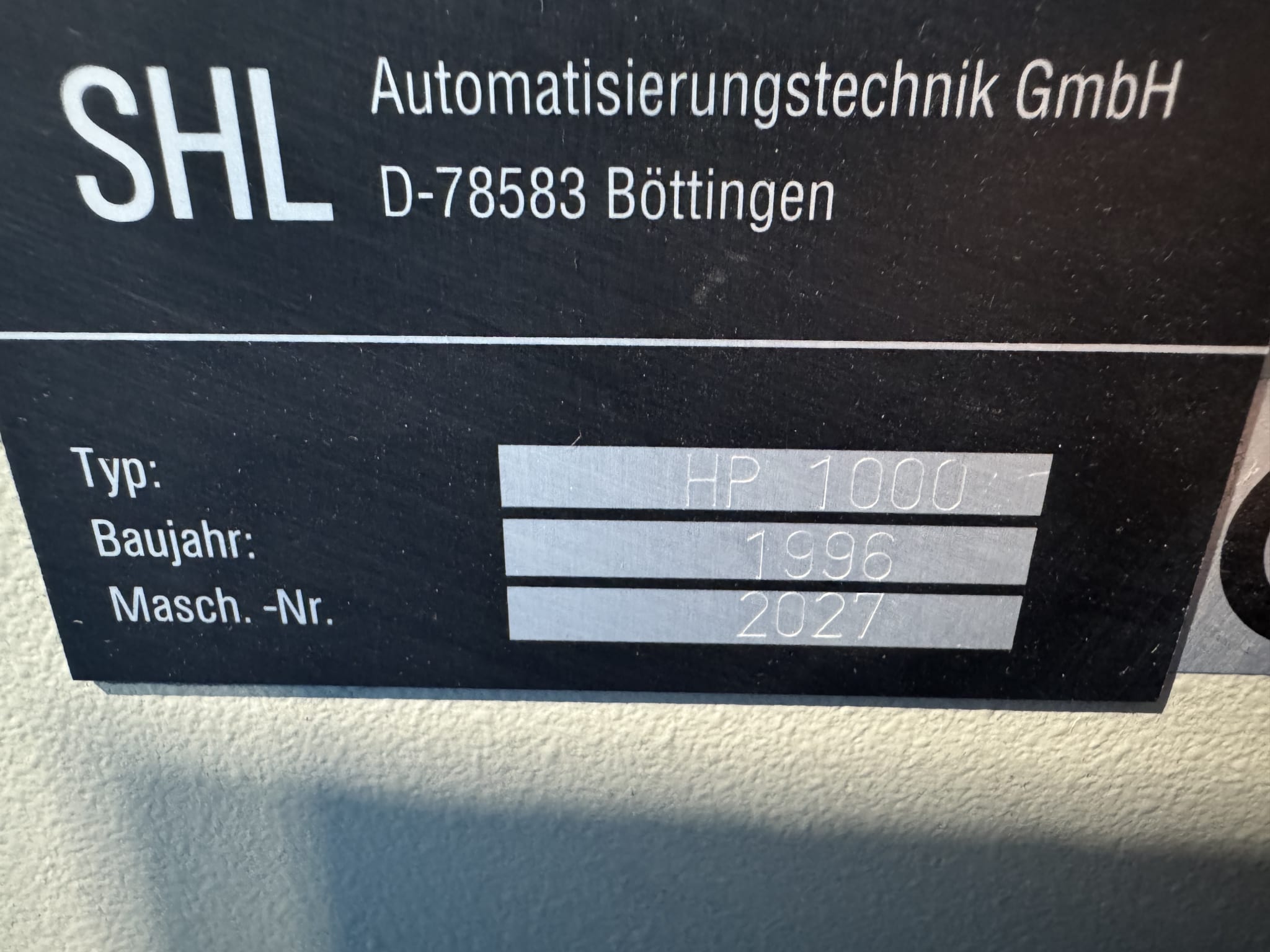

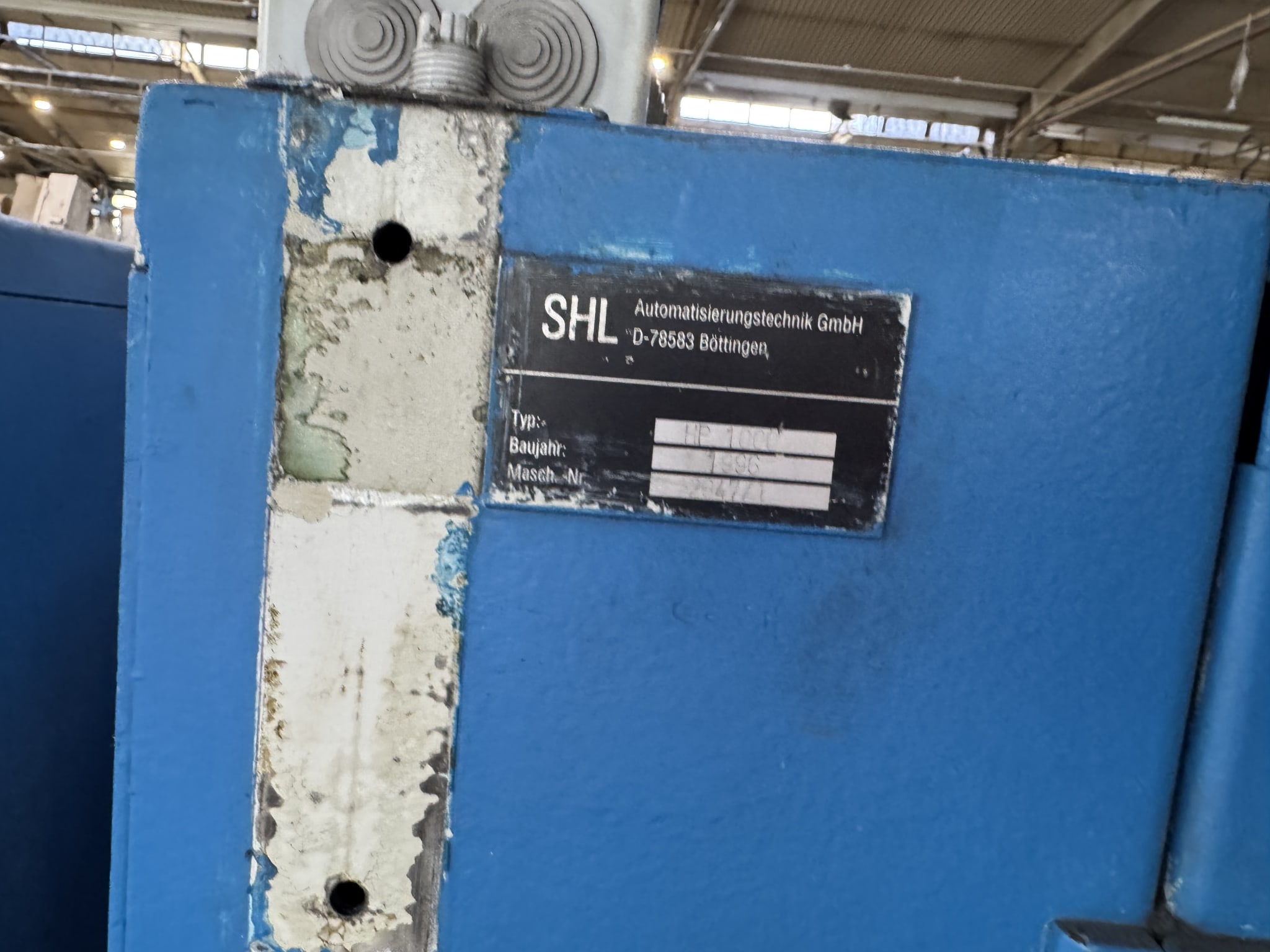

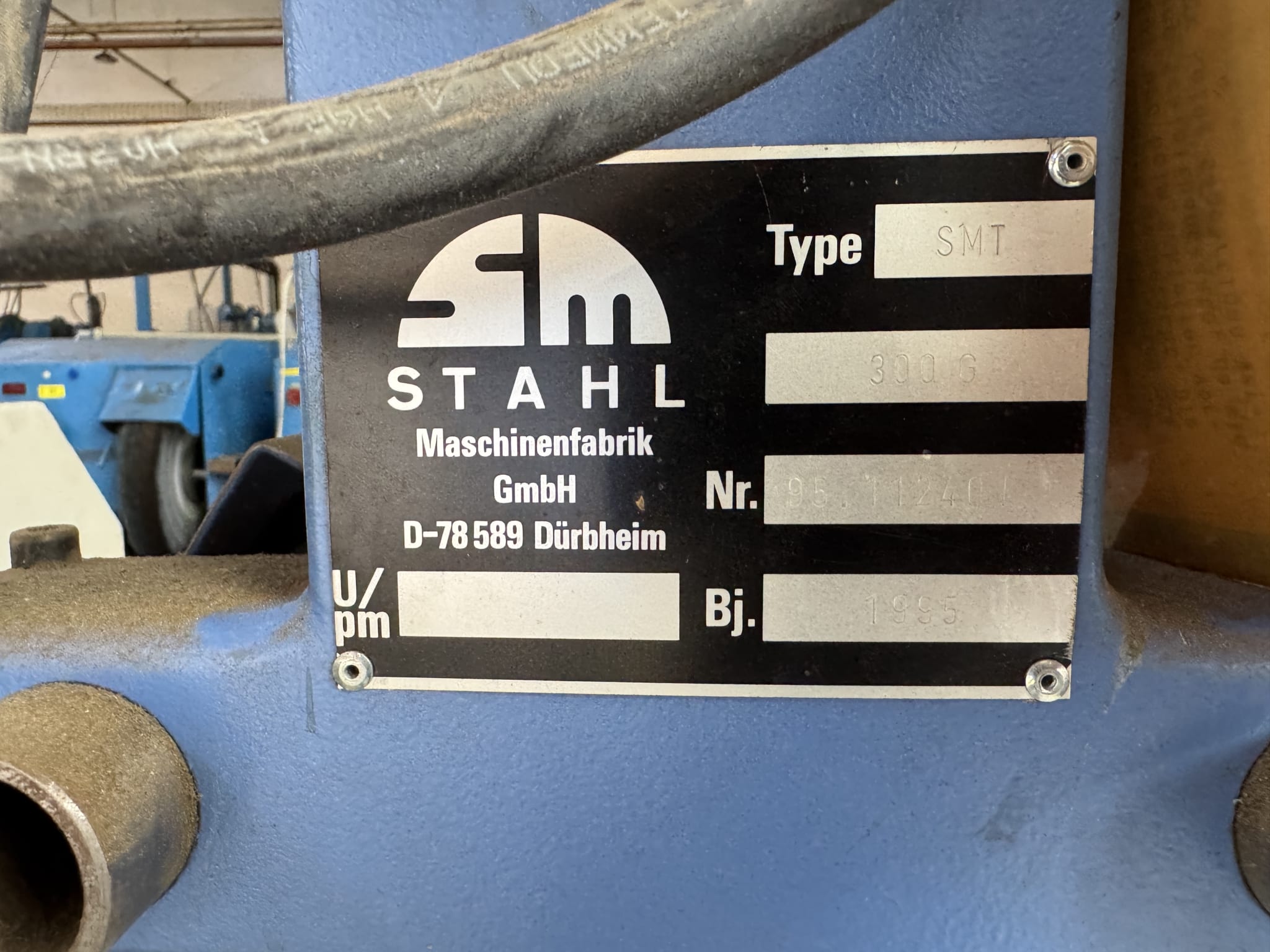

Manual polishing machine, 960 mm wheel SHL HP 1000 | 1996

Binding Handling & Service Fee:

165 € (EURO) - LISTING 2800084

![Hungary]()

(3) Lot of 3 manual polishing machines SHL 1000 | 1996

Binding Handling & Service Fee:

220 € (EURO)

960 mm diam. wheel - LISTING 2800086

![Hungary]()

- LISTING 2800087

![Hungary]()

- LISTING 2800088

![Hungary]()

- LISTING 2800090

![Hungary]()

(2) Lot 2 manual double belt grinders METABO | 1997

Binding Handling & Service Fee:

220 € (EURO) - LISTING 2800091

![Hungary]()

(2) Lot 2 manual double belt grinders METABO | 1997

Binding Handling & Service Fee:

220 € (EURO) - LISTING 2800092

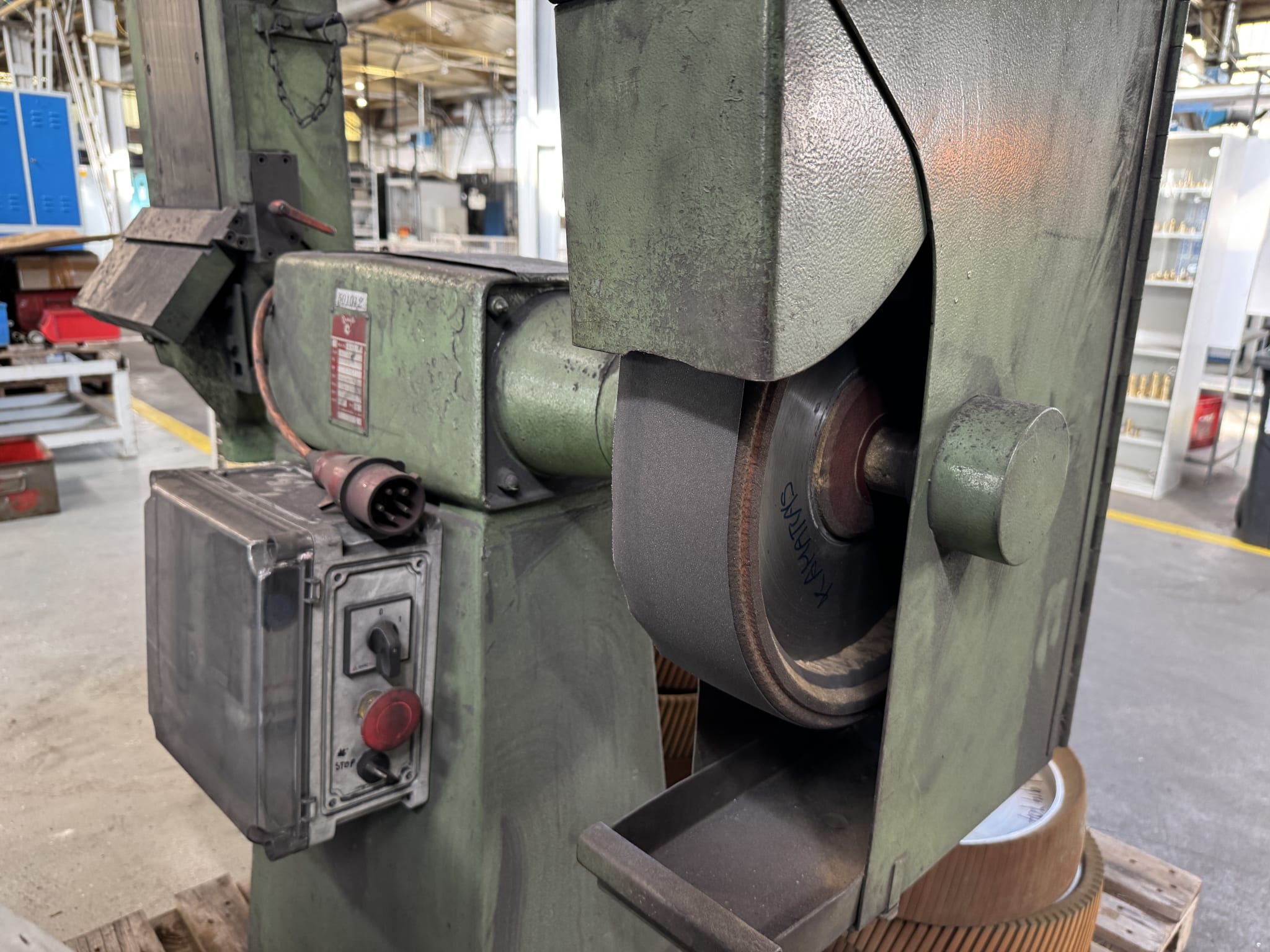

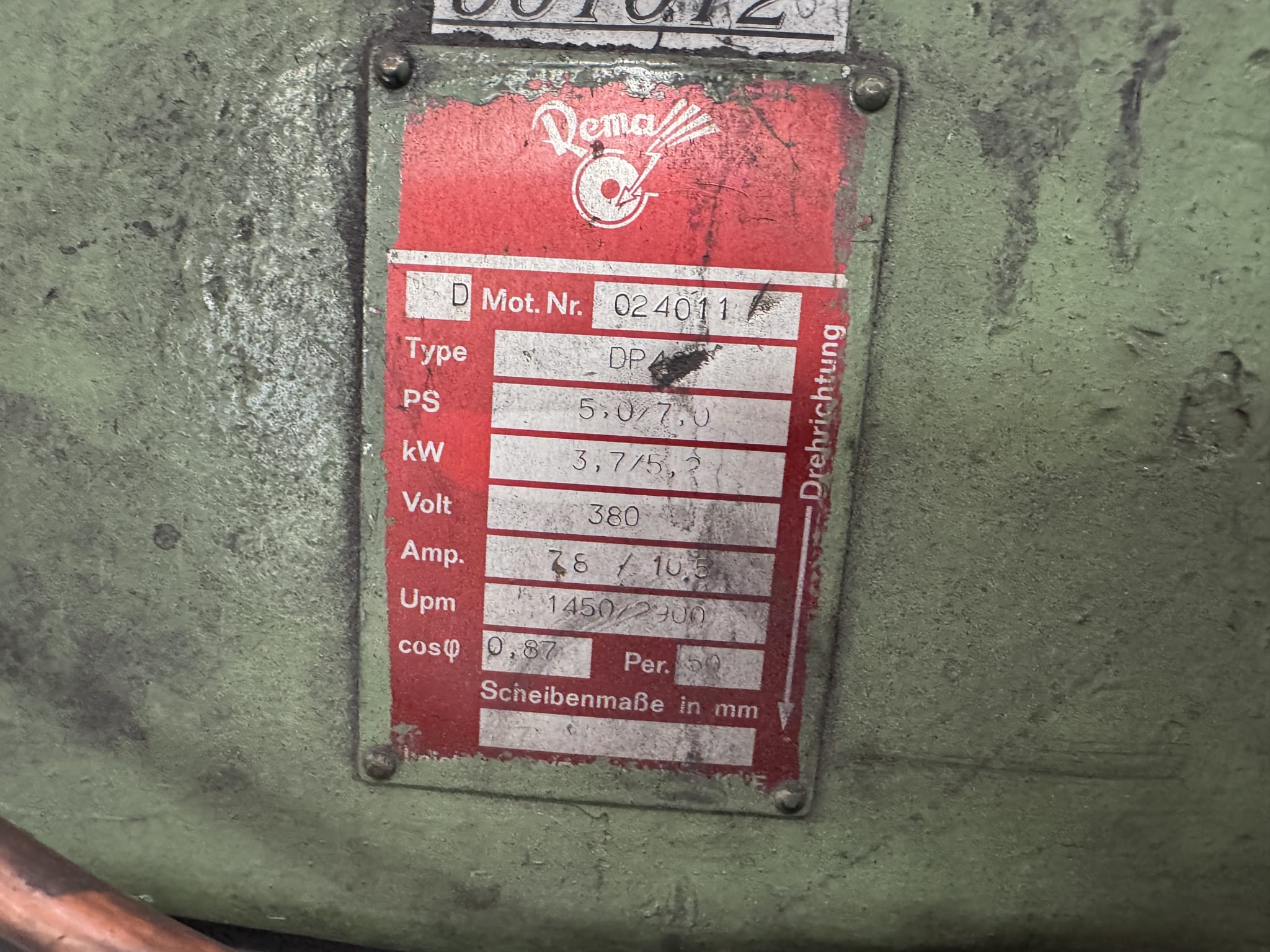

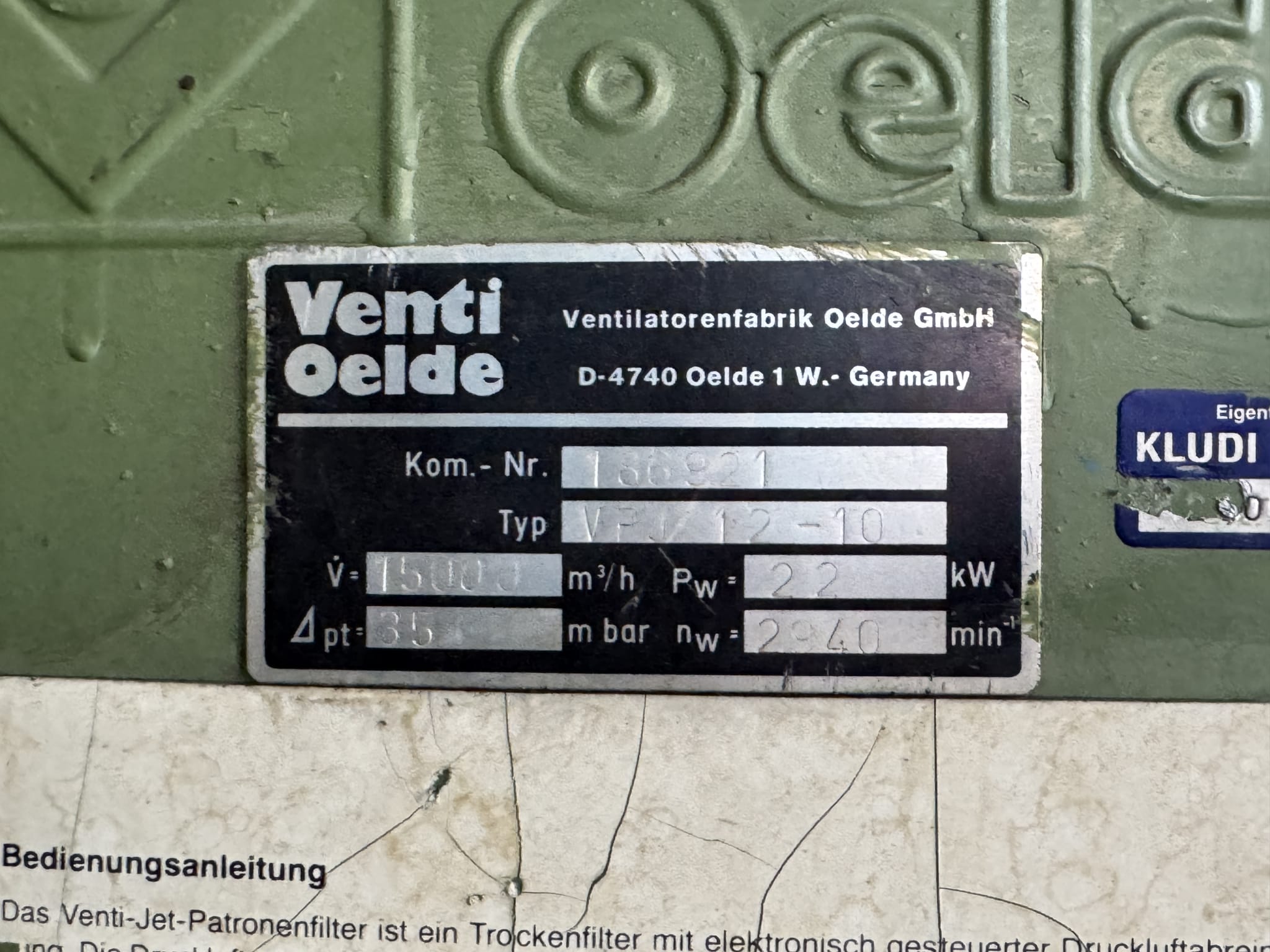

![Hungary]()

(2) Lot 2 manual double belt grinders METABO/REMA

Binding Handling & Service Fee:

220 € (EURO) - LISTING 2800102

![Hungary]()

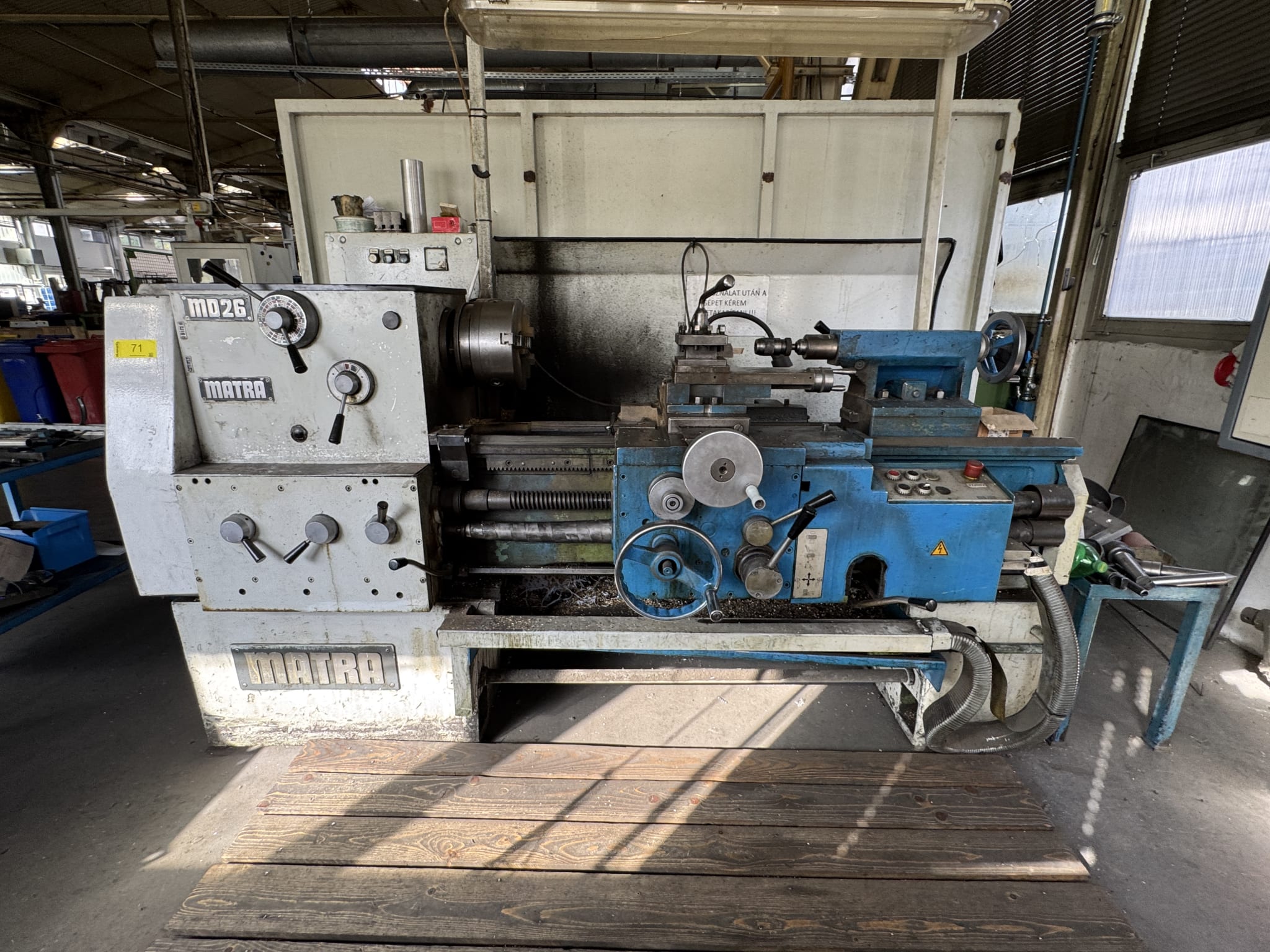

- LISTING 2800103

![Hungary]()

- LISTING 2800104

![Hungary]()

- LISTING 2800106

![Hungary]()

- LISTING 2800107

![Hungary]()

- LISTING 2800108

![Hungary]()

Induction furnace 1,000 kg water cooling RUSS TIV 50H 120 | 2000

Binding Handling & Service Fee:

990 € (EURO)

120 kW; capacity 400 Kg/h - LISTING 2800109

![Hungary]()

- LISTING 2800110

![Hungary]()

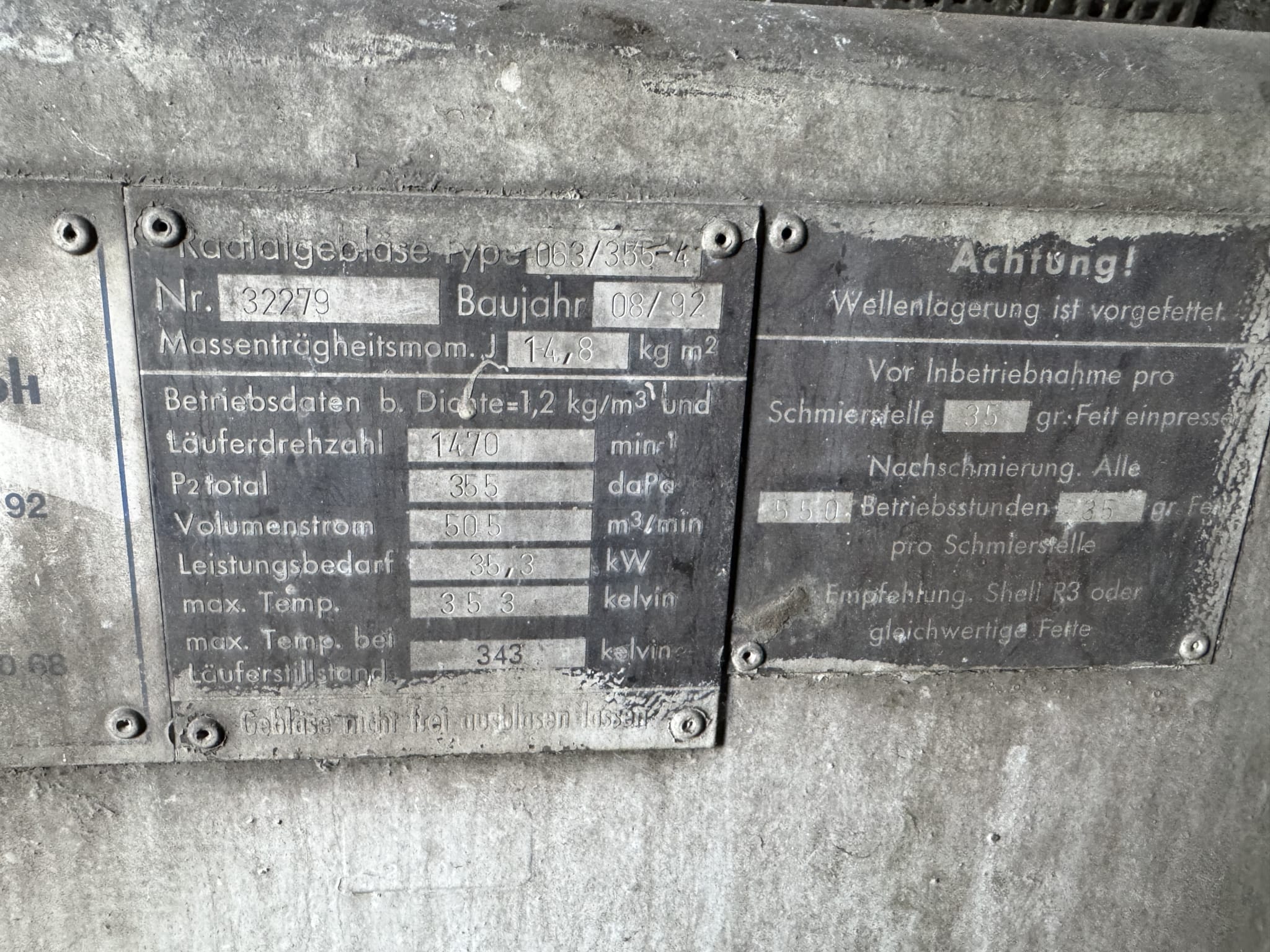

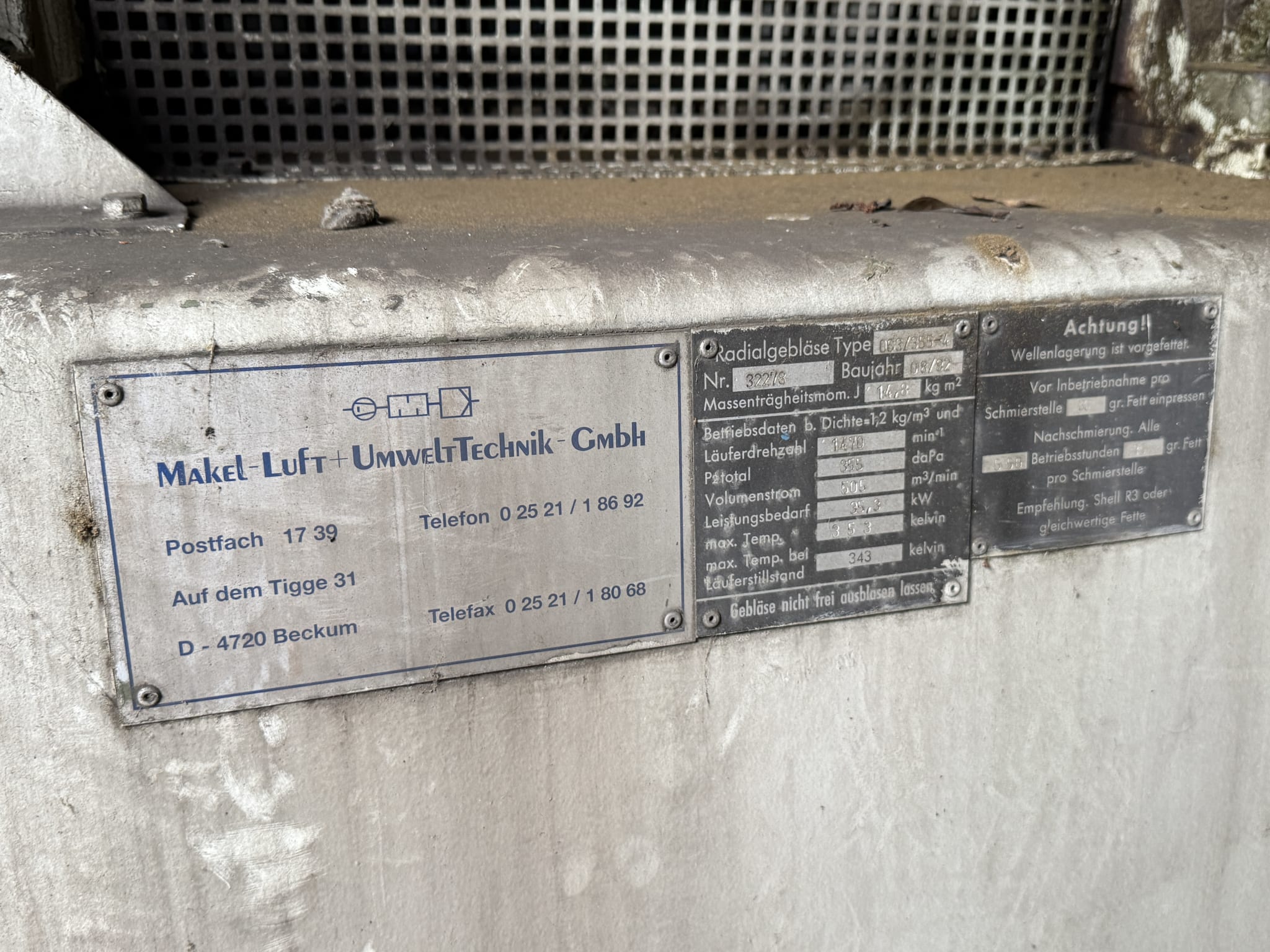

Exhaust system 30,000 m3/h MAKEL-LUFT+UMWELTECHNIK 063/355-4 | 1992

Binding Handling & Service Fee:

1980 € (EURO)

Mass moment of inertia J 14.8 kg/m² Operating data based on density = 1.2 kg/m³ and rotor speed 1470 rpm P2total 355 daPa Flow rate 505 m³/min Power requirement 35.3 kW - LISTING 2800111

![Hungary]()

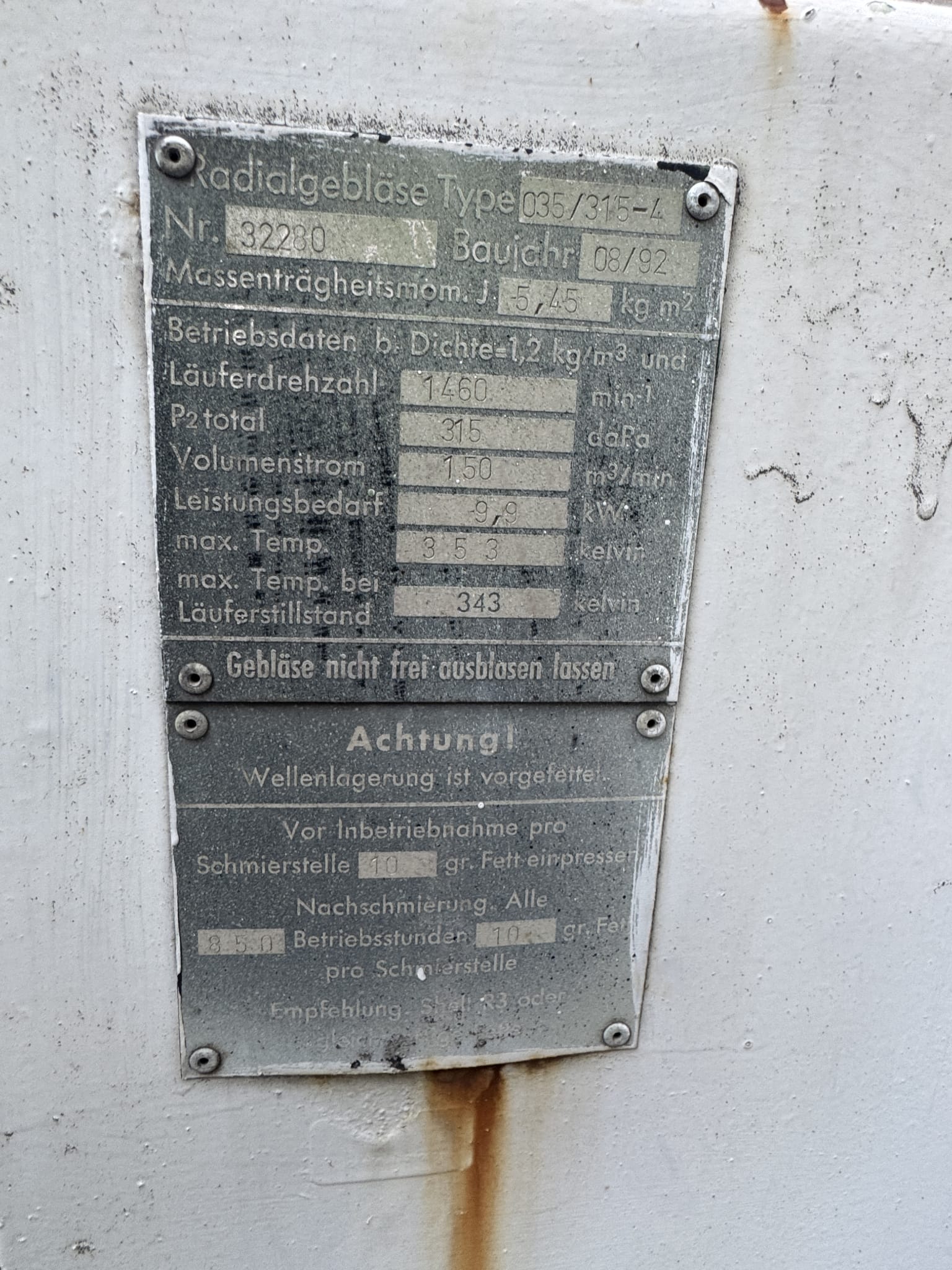

Exhaust system 14,000 m3/h MAKEL-LUFT+UMWELTECHNIK 035/315-4 | 1992

Binding Handling & Service Fee:

2090 € (EURO) - LISTING 2800112

![Hungary]()

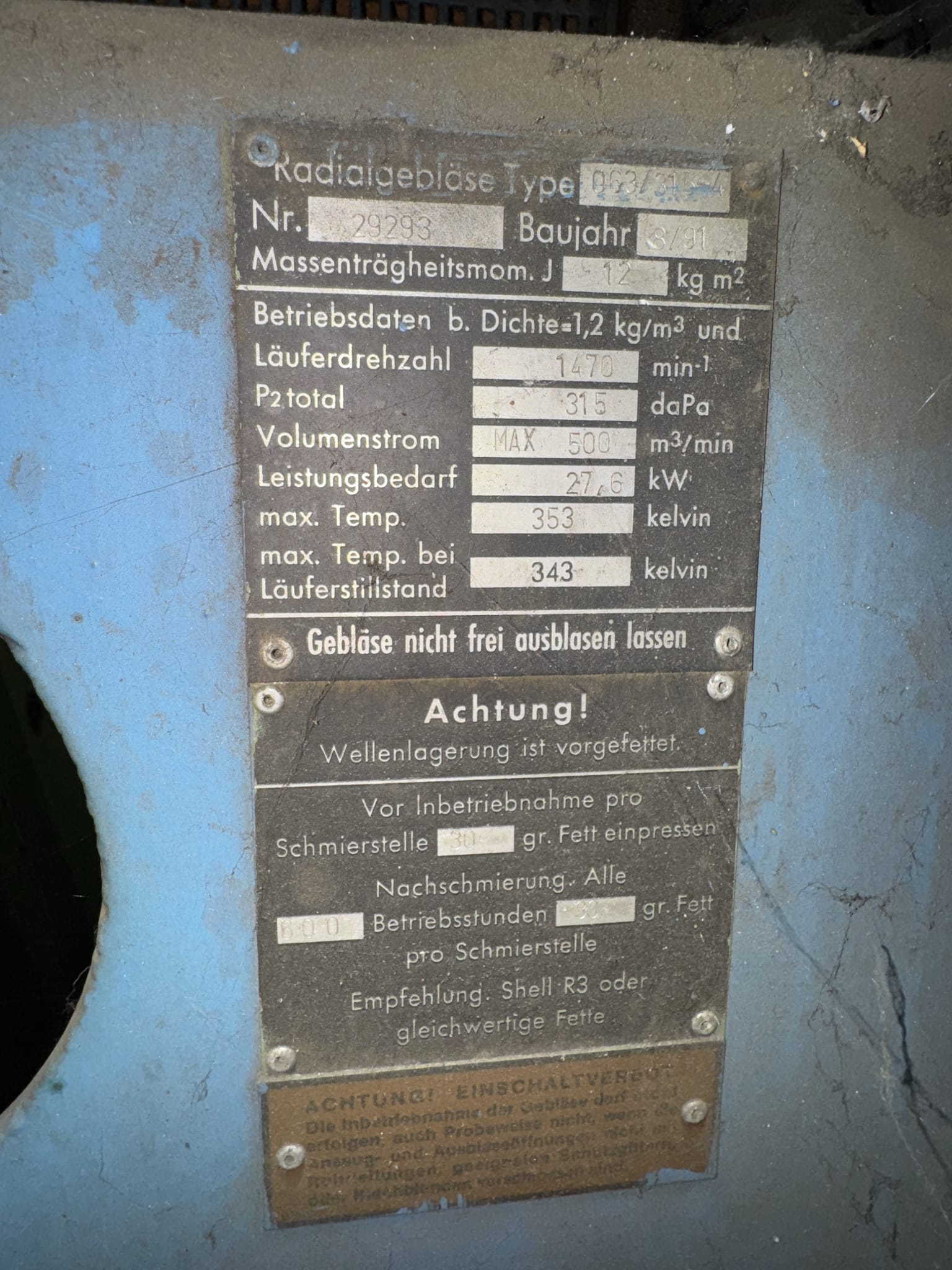

Exhaust system 30,000 m3/h MAKEL-LUFT+UMWELTECHNIK 063/355-4 | 1992

Binding Handling & Service Fee:

2090 € (EURO)

Mass moment of inertia J 14.8 kg/m² Operating data based on density = 1.2 kg/m³ and rotor speed 1470 rpm P2total 355 daPa Flow rate 505 m³/min Power requirement 35.3 kW - LISTING 2800113

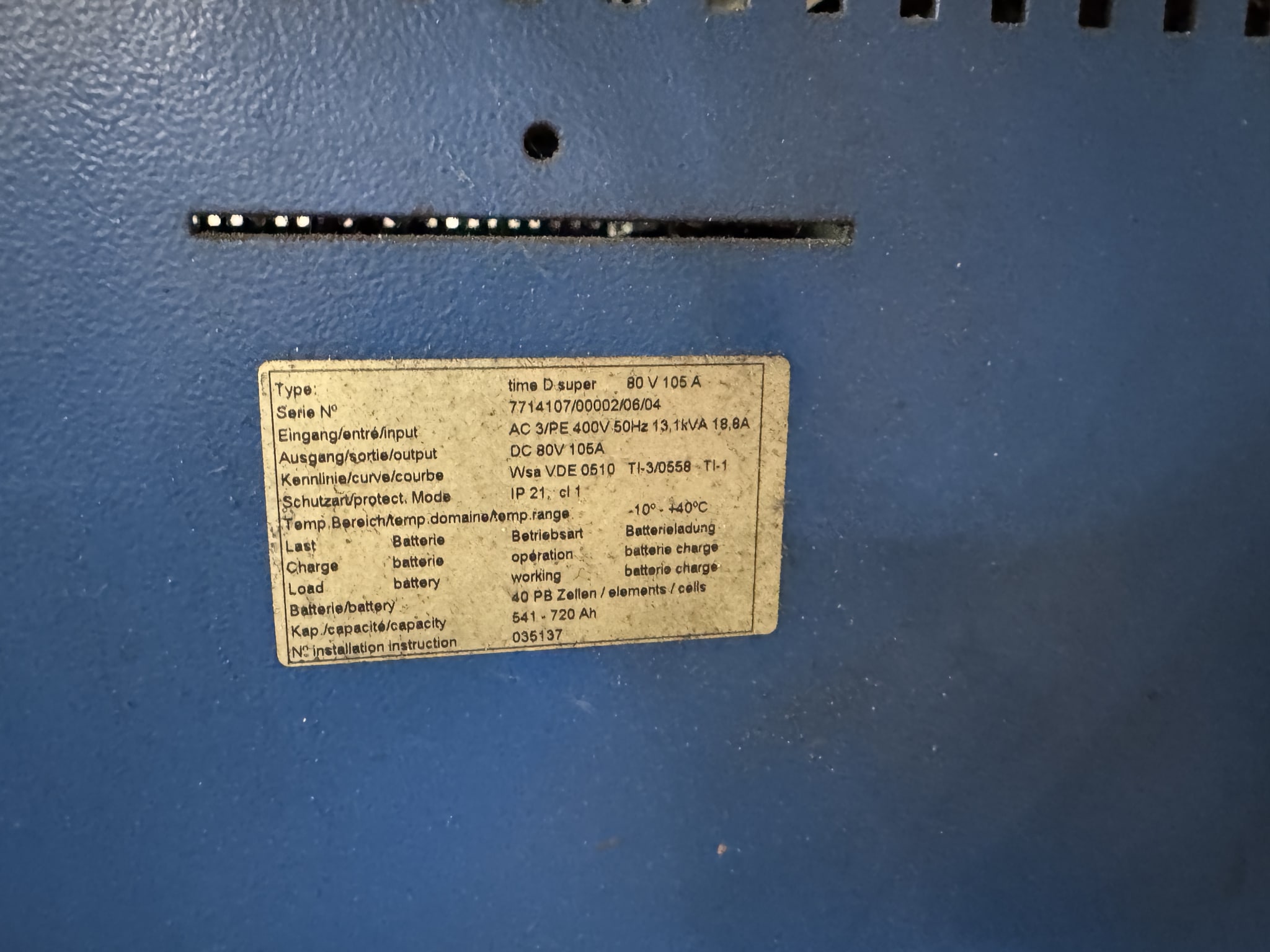

![Hungary]()

Exhaust system 14,000 m3/h MAKEL-LUFT+UMWELTECHNIK 063/315-4 | 1991

Binding Handling & Service Fee:

2090 € (EURO) - LISTING 2800119

![Hungary]()

Electric drawbar forklift 1,2 t JUNGHEINRICH EJC 112 | 2008

Binding Handling & Service Fee:

110 € (EURO)

Working hours 7,530 - LISTING 2800123

![Hungary]()

- LISTING 2800124

![Hungary]()

- LISTING 2800130

![Hungary]()

- LISTING 2800136

![Hungary]()

- LISTING 2800137

![Hungary]()

- LISTING 2800138

![Hungary]()

- LISTING 2800139

![Hungary]()

- LISTING 2800141

![Hungary]()

Essential Information

General Information

- Auction Dates

- Starts: 05 January 2026 at 09:00 GMTEnds: 26 February 2026 at 10:00 GMT

- Site Address

- Kludi Szerelvények Kft. Homokbánya u. 75 Diosd 2049Hungary

- Viewing Days

- 05 January 2026 at 09:00 GMT - 26 February 2026 at 10:00 GMT

Fees & Payment

- Currency

- EUR

- Buyers Premium

- 18% or as specified on individual items

- Payment

General Payment Information

- Per bidder, there will only one invoice be issued for all lots won in one auction/sale.

- The invoice will be in PDF format and will be emailed to successful bidders within 24 hours after the last lot in the auction has closed. Alternatively, a link will be emailed from where the invoice can be downloaded.

- Payment is due immediately on receipt of invoice unless stated differently on the invoice.

- All payments must be made in the currency stated on the issued invoice.

- The only accepted form of payment is bank transfer.

- We DO NOT accept payment by cheque, debit or credit card.

- Please reference the invoice number on the bank transfer.

- For all bidders with residence outside of the country from where the assets are being sold, Maynards Europe will collect 20% of the invoice total as a deposit. This deposit will be refunded in full after Maynards Europe have received proof of export.

- It happens frequently that Maynards Europe at first only issue a so-called “proforma invoice”. After receipt of full payment, collection of the items and receipt of export documentation (if applicable), the final invoice will be issued.

Goods

- Clearance days

- 01 January 1970 at 01:00 GMT+1 - 01 January 1970 at 01:00 GMT+1

- General Collection Information

- Buyers are fully responsible for the removal of the items purchased including all transport and rigging charges.

- Items only become available for collection after Maynards Europe have received payment in full, and a collection appointment has been booked with the project manager / on-site contact.

- Buyers or third-party movers must present the ‘Paid Invoice’ confirmation to the on-site personnel when collecting and removing their items. The ‘Paid Invoice’ confirmation will be issued by Maynards Europe after receipt of the full payment and will be emailed in PDF format to the buyer.

- Buyers must complete the removal of items within the clearance deadline (individually stated for each auction / sale). Removal is by appointment only.

- Removal and on-site contact information will be emailed to buyers at the same time invoices are issued.

- Entrance to the site is subject to the Conditions of Admission for customers, agents and contractors. For your protection you will be required to wear safety equipment including high visibility jackets and safety footwear as a minimum. Everybody entering the site has to undergo a short security briefing.

- Conditions of Site Admission: All Customers, agents & contractors must report to the site manager / foreman on arrival and must not proceed on to site without permission. No persons under 16 years of age will be allowed on site.

- Buyers / Transport Companies must bring their ‘Paid Invoice’ document to site together with proof of appropriate insurance coverage. It is the buyer’s responsibility to ensure their removal contractor has the appropriate insurance coverage. As a standard, an insurance cover of 5 million EUR is required. We reserve the right to deny access to the site if these requirements are not met or the contractor fails to provide proof of this. If you have any questions on this, please do not hesitate to contact us on +49 8151 973420.

- There is NEITHER lifting equipment NOR tools for dismantling available on site. Please make your own arrangements.

- Removal of items is solely the responsibility of the purchaser and/or those collecting on their behalf. This may require you to remove other items to gain access although efforts will be made to keep this to a minimum. Dismantling of machinery may be required.

- The buyer and their removal company are responsible for the condition of the site after removal of their goods. Electrical connections must be left in a safe condition and protrusions (grouting, hold down bolts / studs) must be removed and left flush to ground level. The site must be cleaned after removal and all waste must be disposed of.

- The buyer and their removal company are responsible for conducting the removal and transportation of their goods according to the standard environmental regulations.

- Removal must be carried out without damage to the site itself or any property/ items on or near the site. Liability for any such damage lies with the buyer.

- If items have not been removed by the clearance deadline, our standard Terms & Conditions apply.

- Our staff are on site to supervise and control removals only, they are not permitted to move equipment or assist with the removal in any way. We thank you for your cooperation in helping to keep yourself and others safe while on site and for aiding us in the timely removal of goods from site.

- Sales Contacts

- Auction informationCustomer Service Maynards Europe GmbHGewerbealle 3

Poecking

82343

Germany inquiry@maynards.com+ 49 (0) 8151 1878 400Maxence DutatMaynards Europe

Budapest

-

Hungary maxence@maynards.com+36 704197313