Private Treaty Sale | HAL Plauen | Closure of Automotive Aluminum Component Plant

Starts: 25 September 2025 at 08:00 BST

Ends: 16 January 2026 at 17:00 GMT

Maynards, in conjunction with AllSurplus are offering Machines and Equipment from the Production formerly used by HAL Automotive in Plauen, Germany. All Assets are in a extraordinary condition. Offers are invited immediately for the PT Sale. Highlights are: SW BAW06-22 & BAW08-22, 4 and 4/5 and 5-Axis (2014 to 2020), Wenzler VKM 1-1 Vertical 5-Axis (2016), Mitutoyo CMM and more.

Share:

Showing 22 of 22 lots

- LISTING 2770001

![Deutsch]()

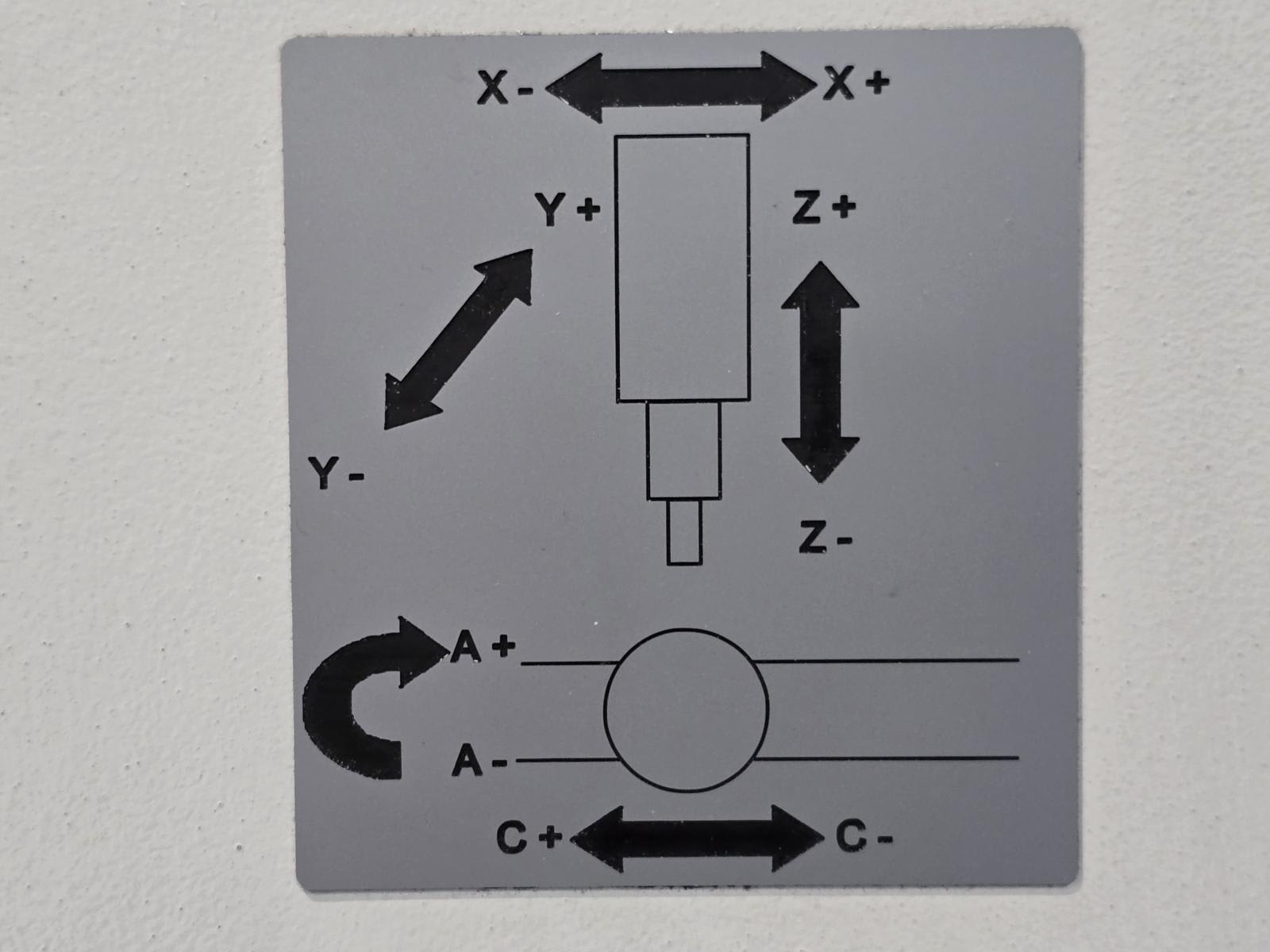

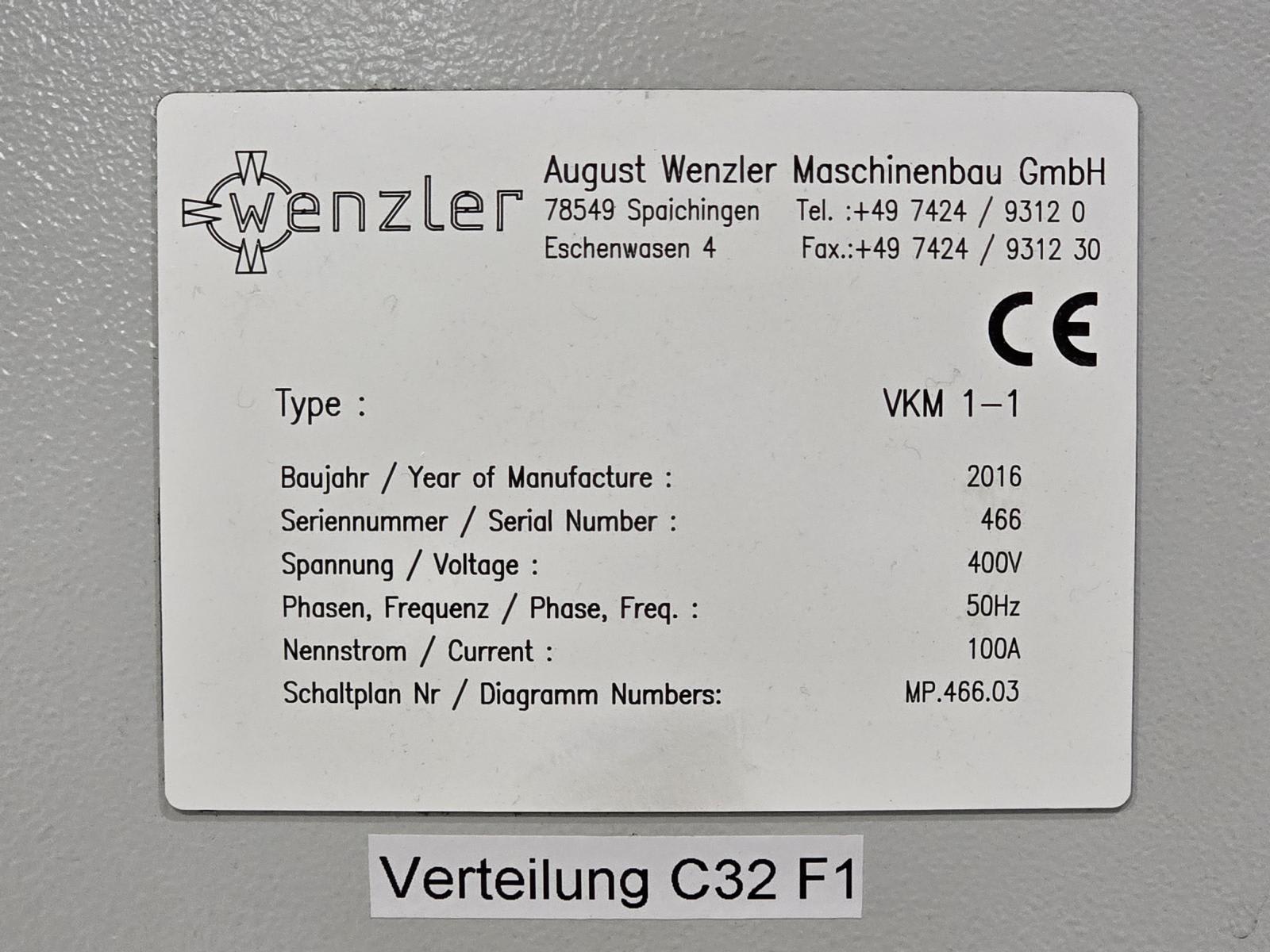

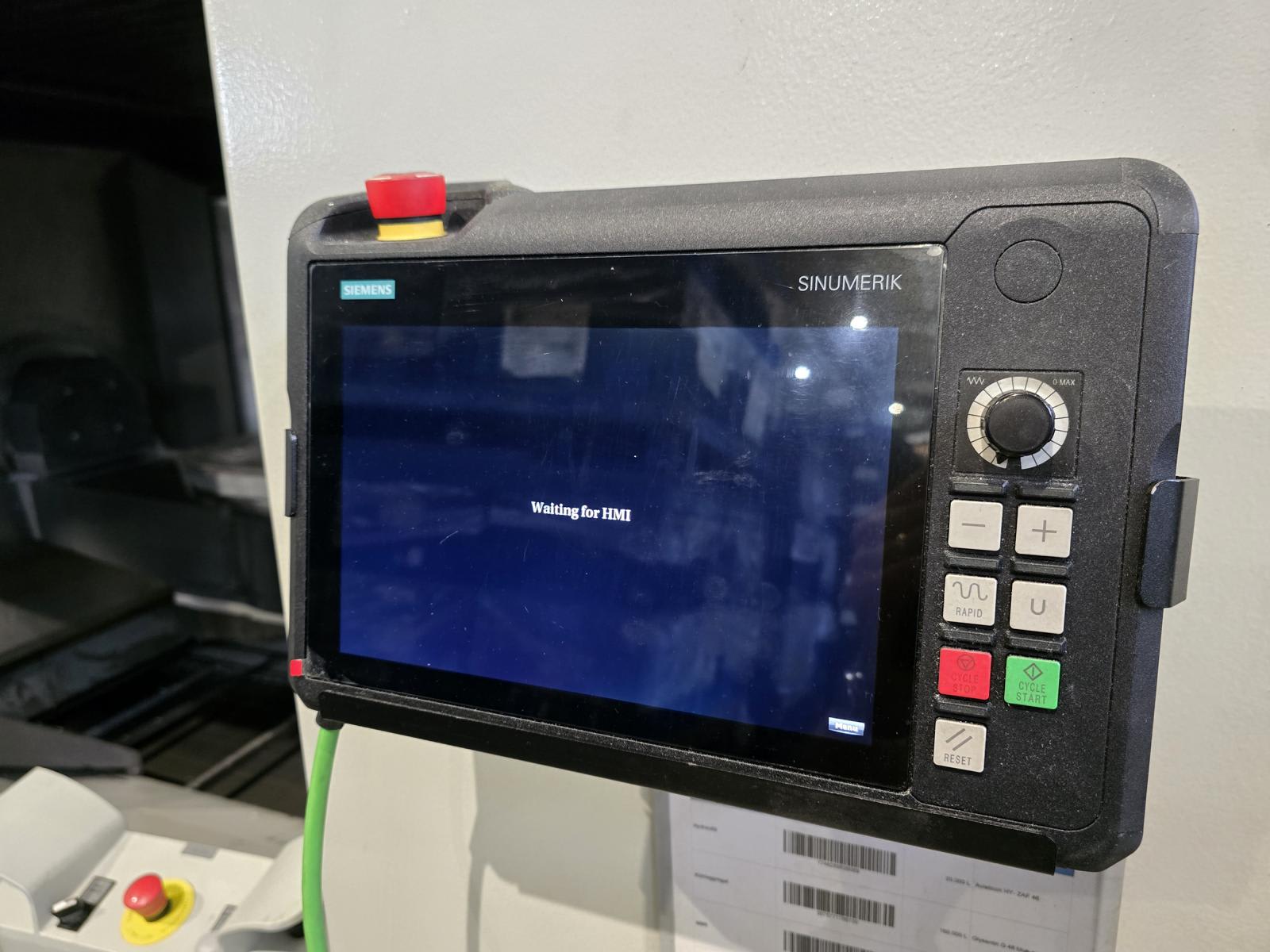

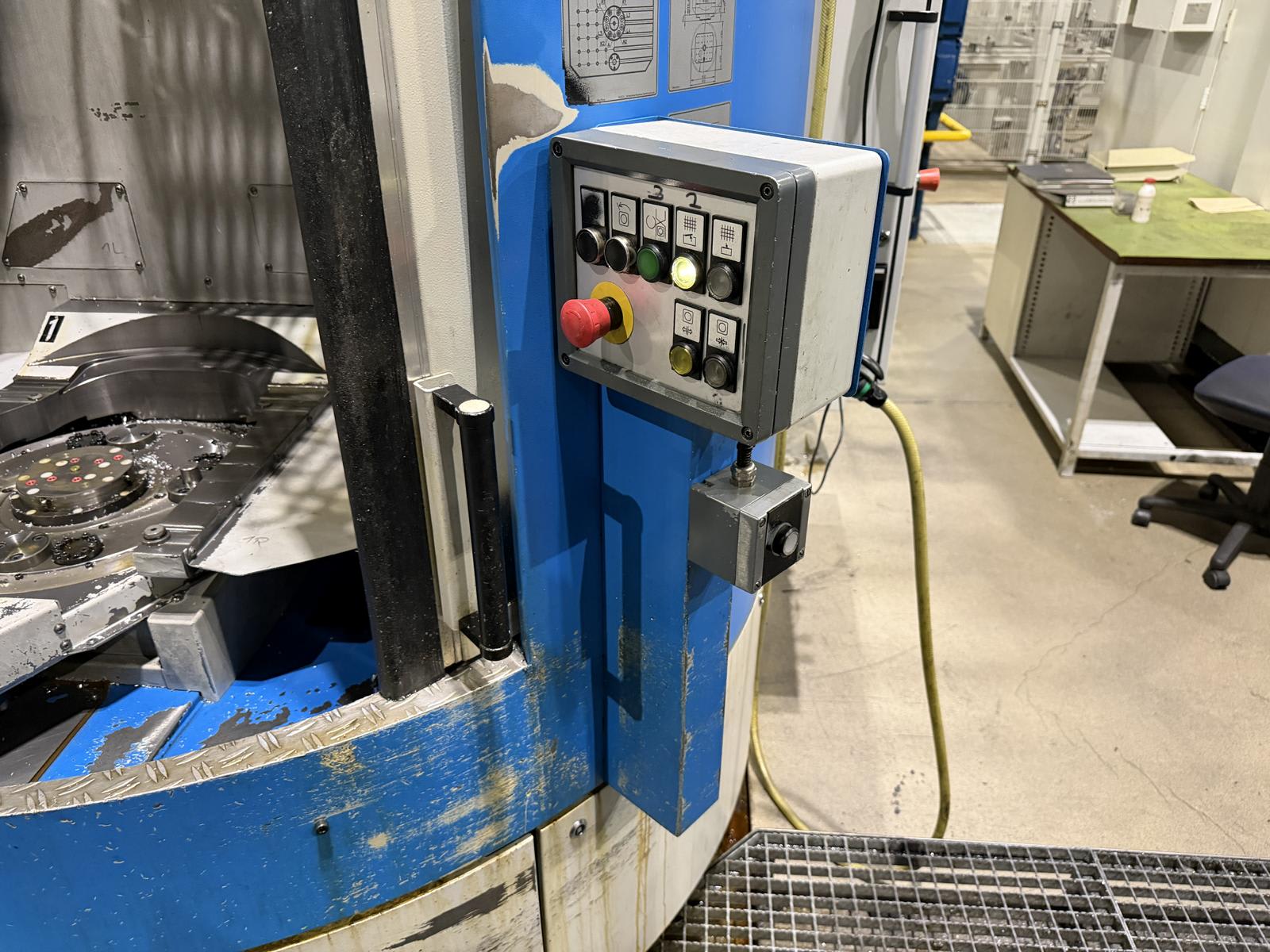

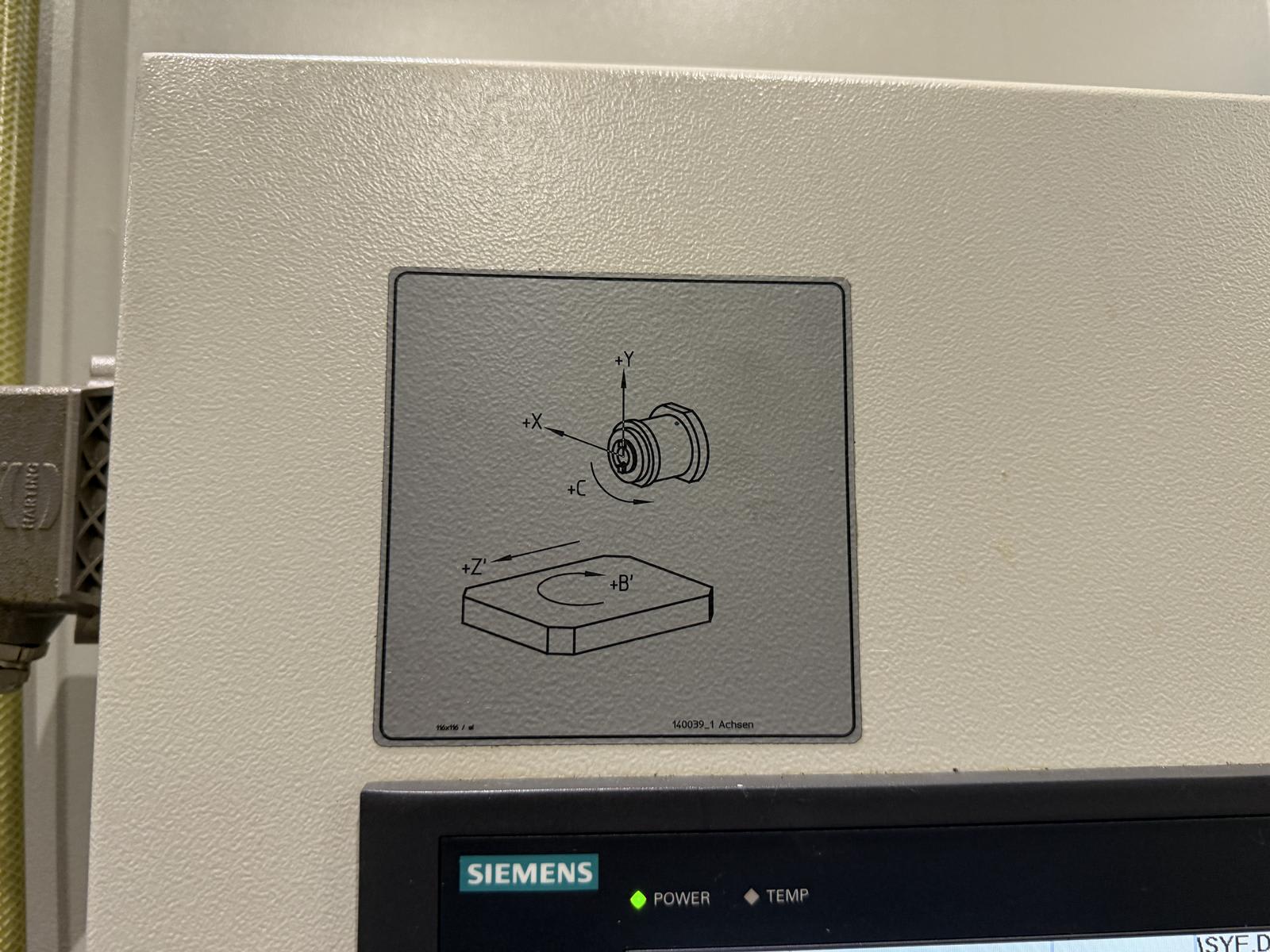

CNC Vertical 5-Axis Machining Center Wenzler VKM 1-1 | 2016

Binding Handling & Service Fee:

8190 € (EURO)

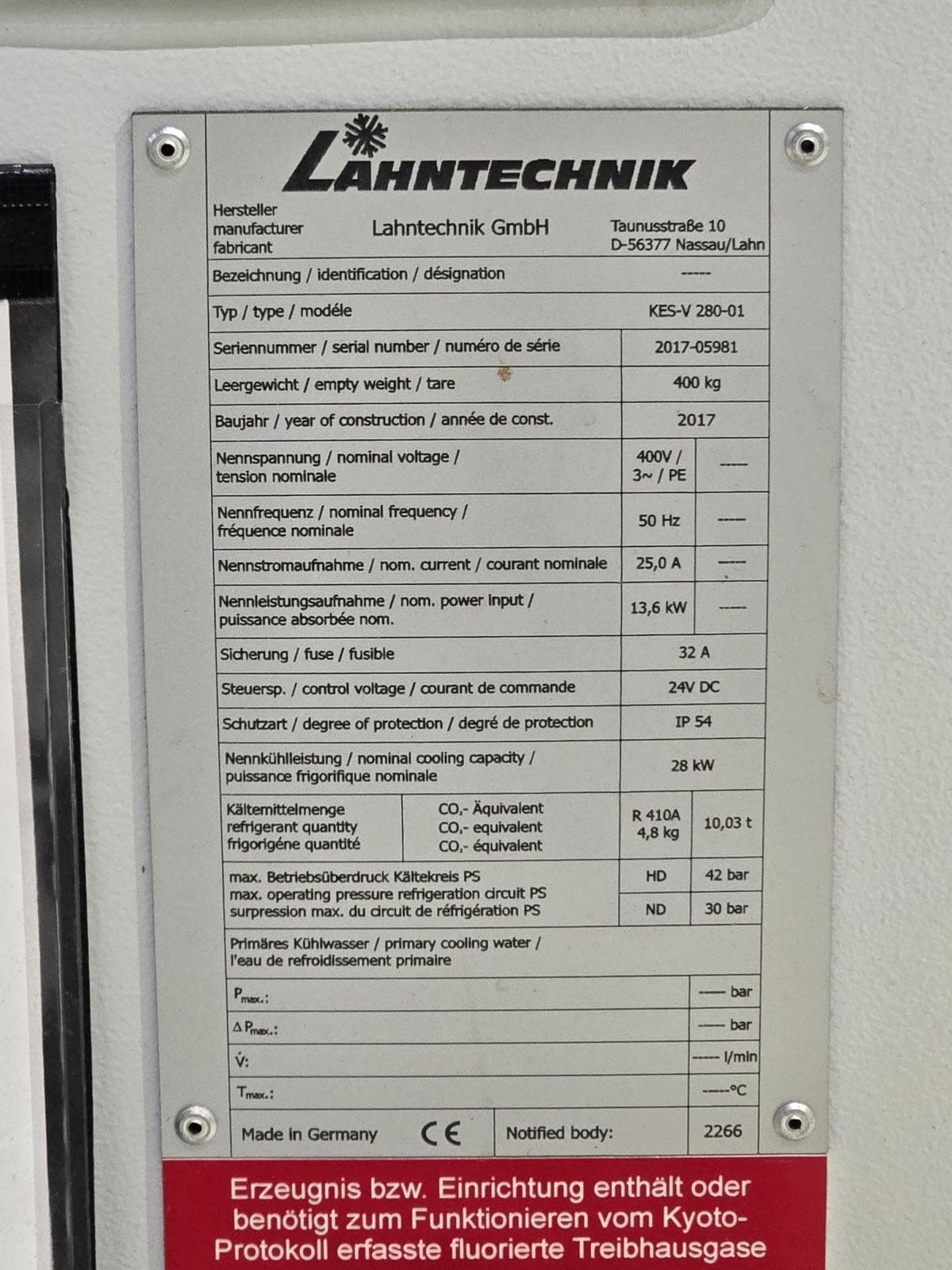

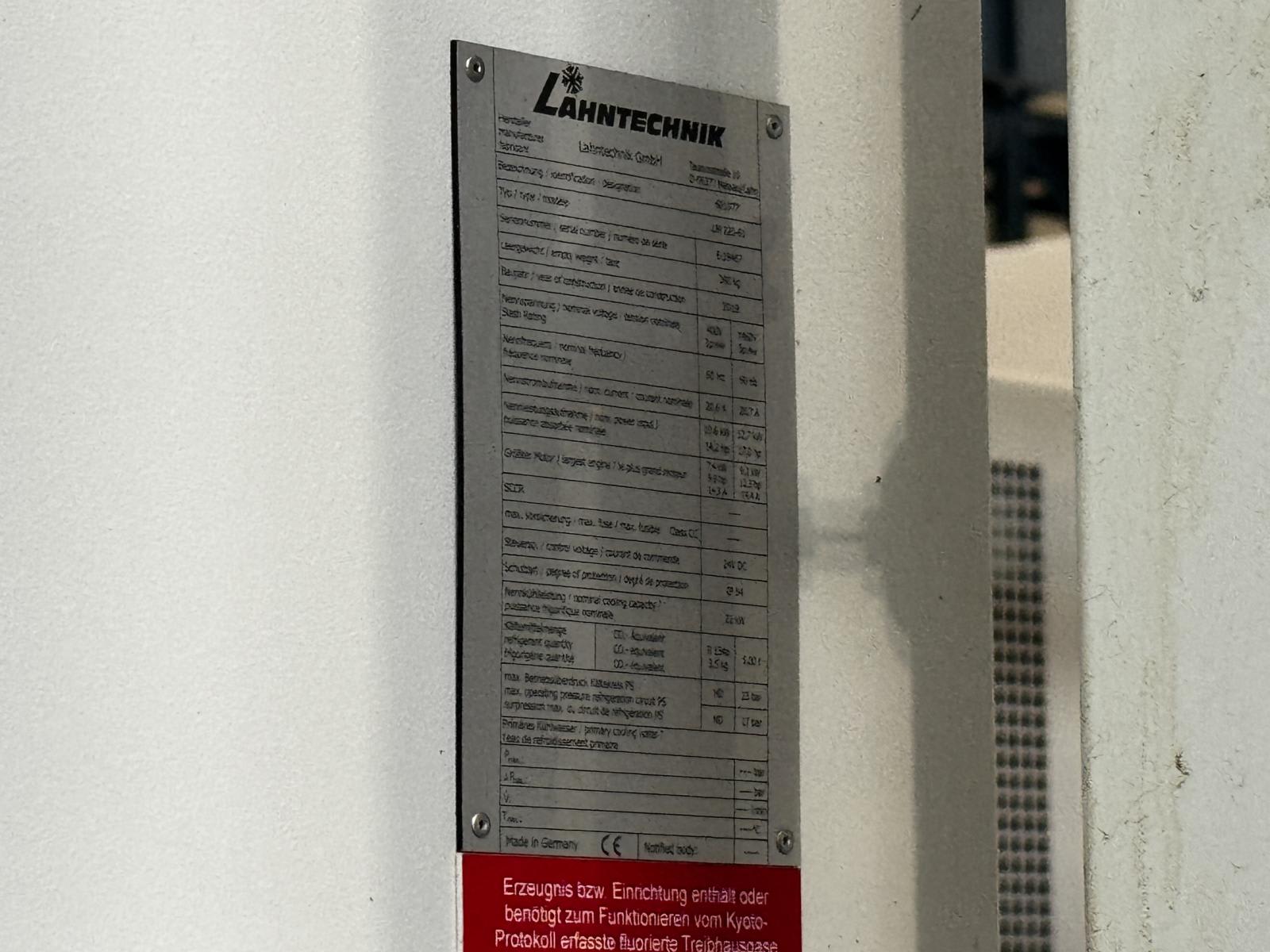

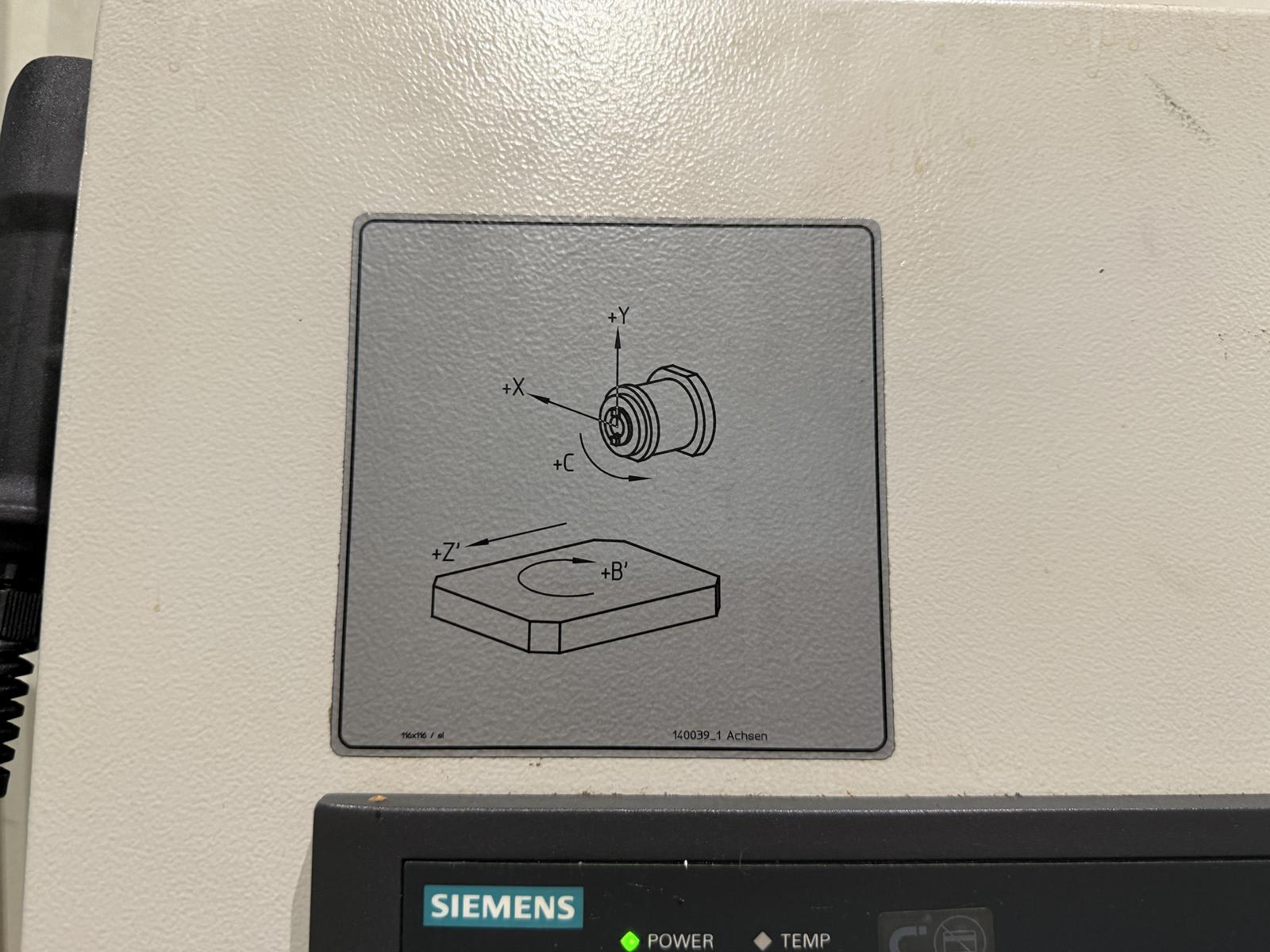

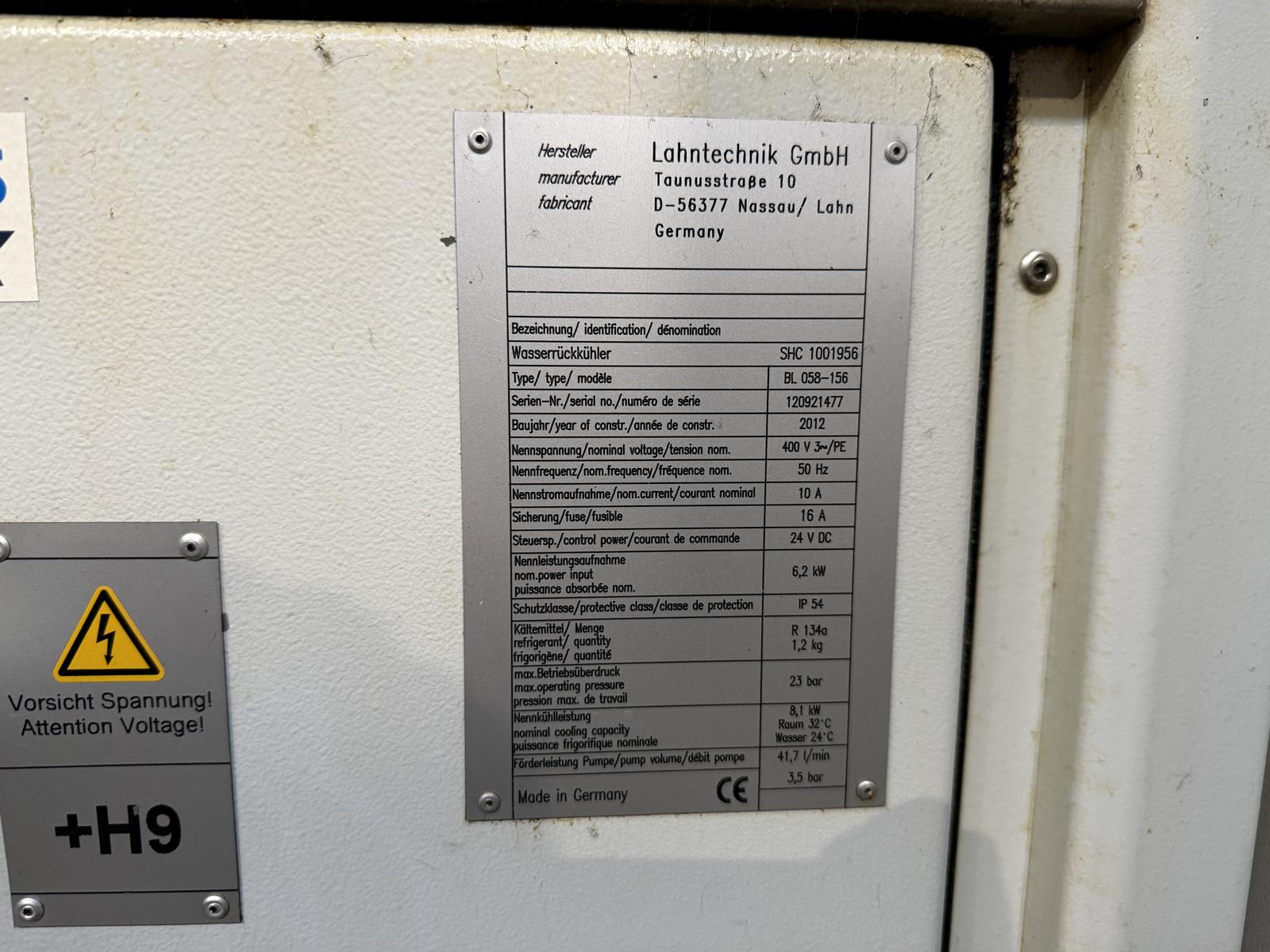

5-Axis Machining Center This Machine was used as Showroom Machine from 2016 until 2022. From 2022 the Machine was used for Production at HAL Plauen for the processing of Axle Carriers. Before it was used for Production, the Machine was fully overhauled/retrofitted. In December 2024 a new Milling Spindle was purchased (Spindle has approx. 500 Working Hours) Machine Working Hours: 24.000 Working Area: -> X-axis 1500 mm -> Y-axis 1250 mm -> Z-axis 880 mm Feed / Rapid Traverse: -> X-axis 100 m/min -> Y-, Z-axis 100 m/min Axis Acceleration: -> X-, Y-axis 7 m/s² -> Z-axis 10 m/s² -> Jerk 150 m/s³ Table Load Capacity: -> Max. weight 400 kg Spindle: -> Tool holder HSK 100 -> Speed range 10,000 rpm -> Power (S6/40% duty) 40 kW -> Max. torque 175 Nm Tool Magazine: -> Positions 36 -> Max. tool length 520 mm -> Max. tool diameter (with free adjacent slot) 205 mm -> Max. tool weight 20 kg -> Total load 200 kg -> Tool change time 3 s with Chip Conveyor and Chiller / Cooling unit • Manufacturer: Lahntechnik GmbH • Model: KESY 280-01 • Serial number: 2017-05981 • Year of manufacture: 2017 • Power rating: 13.6 kW • Nominal voltage: 400 V / 3~ / PE / 50 Hz • Control voltage: 24 V DC • Protection class: IP 54 • Refrigerant: R410A – 10.03 t CO₂ equivalent • Max. operating pressure: 30 bar (HD) / 19 bar (ND) • Empty weight: 400 kg • Country of origin: Germany Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770002

![Deutsch]()

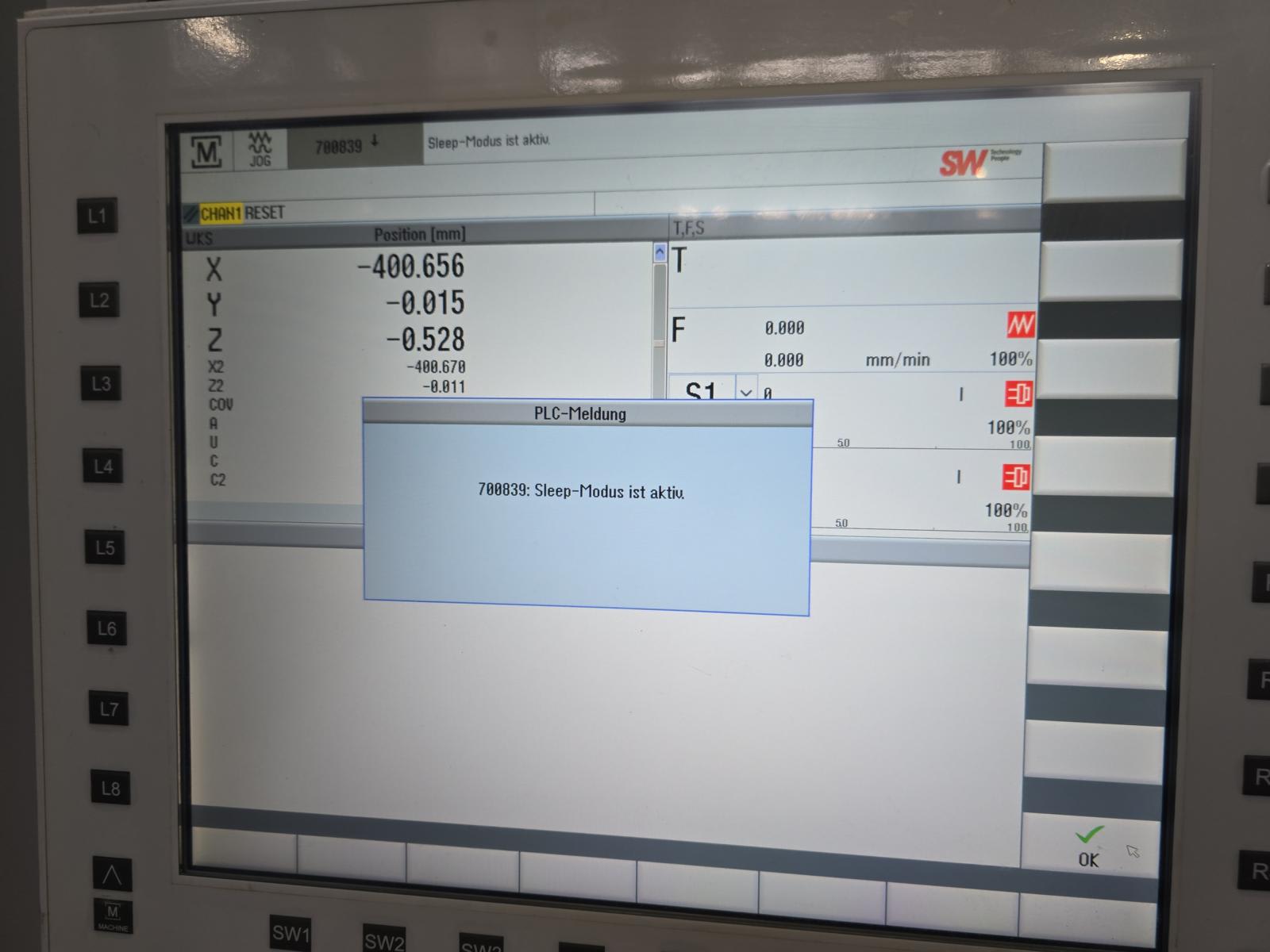

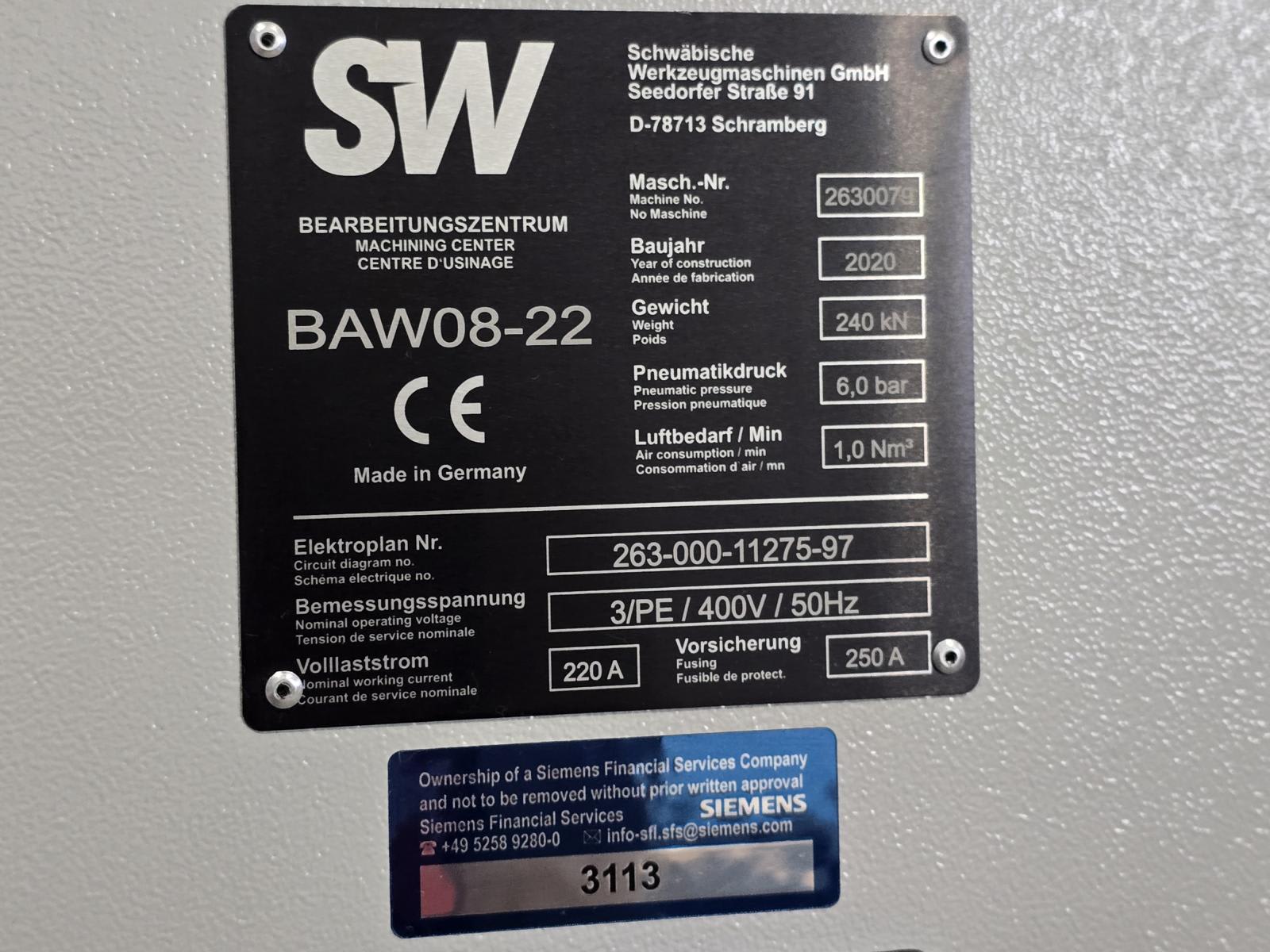

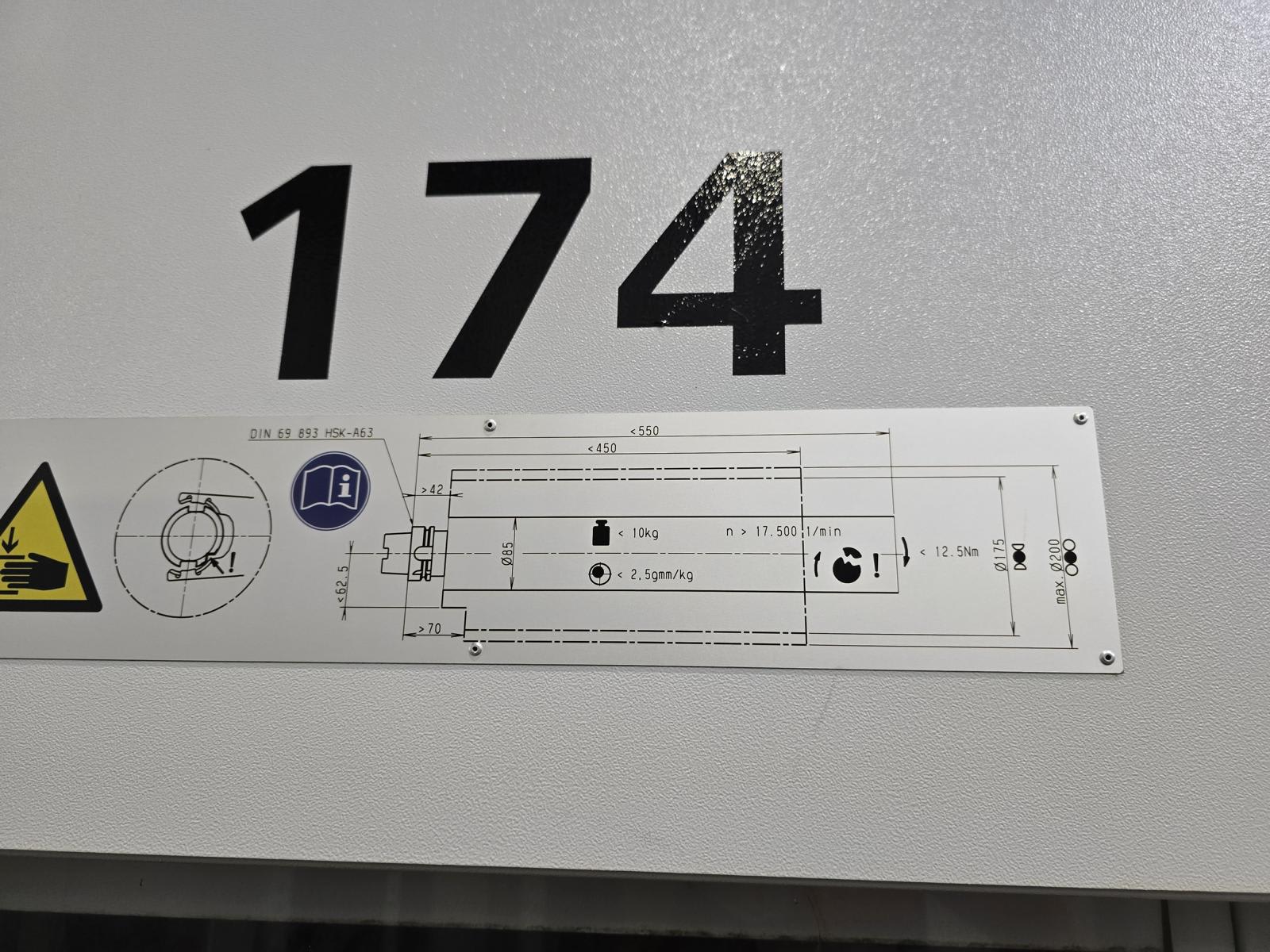

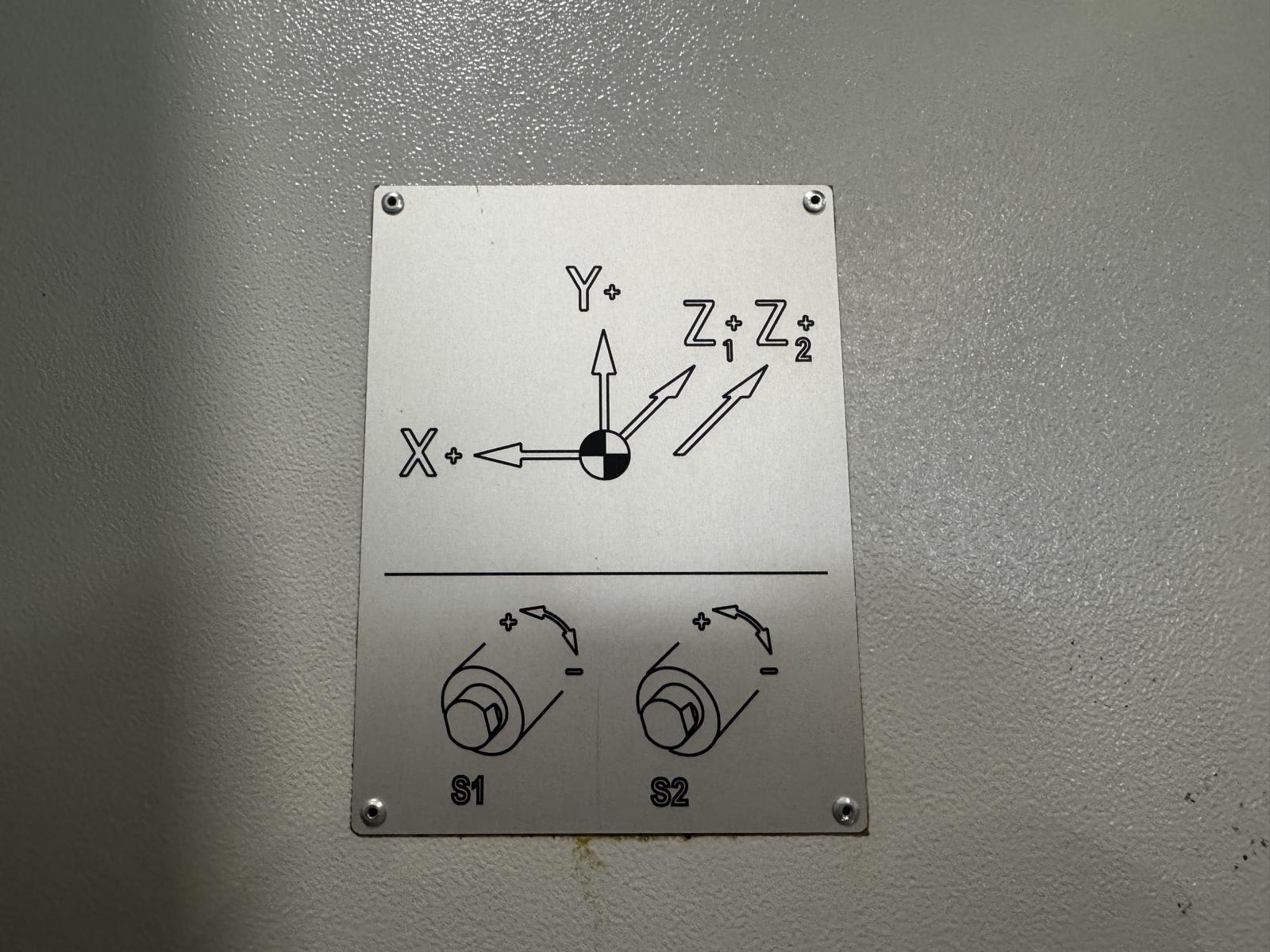

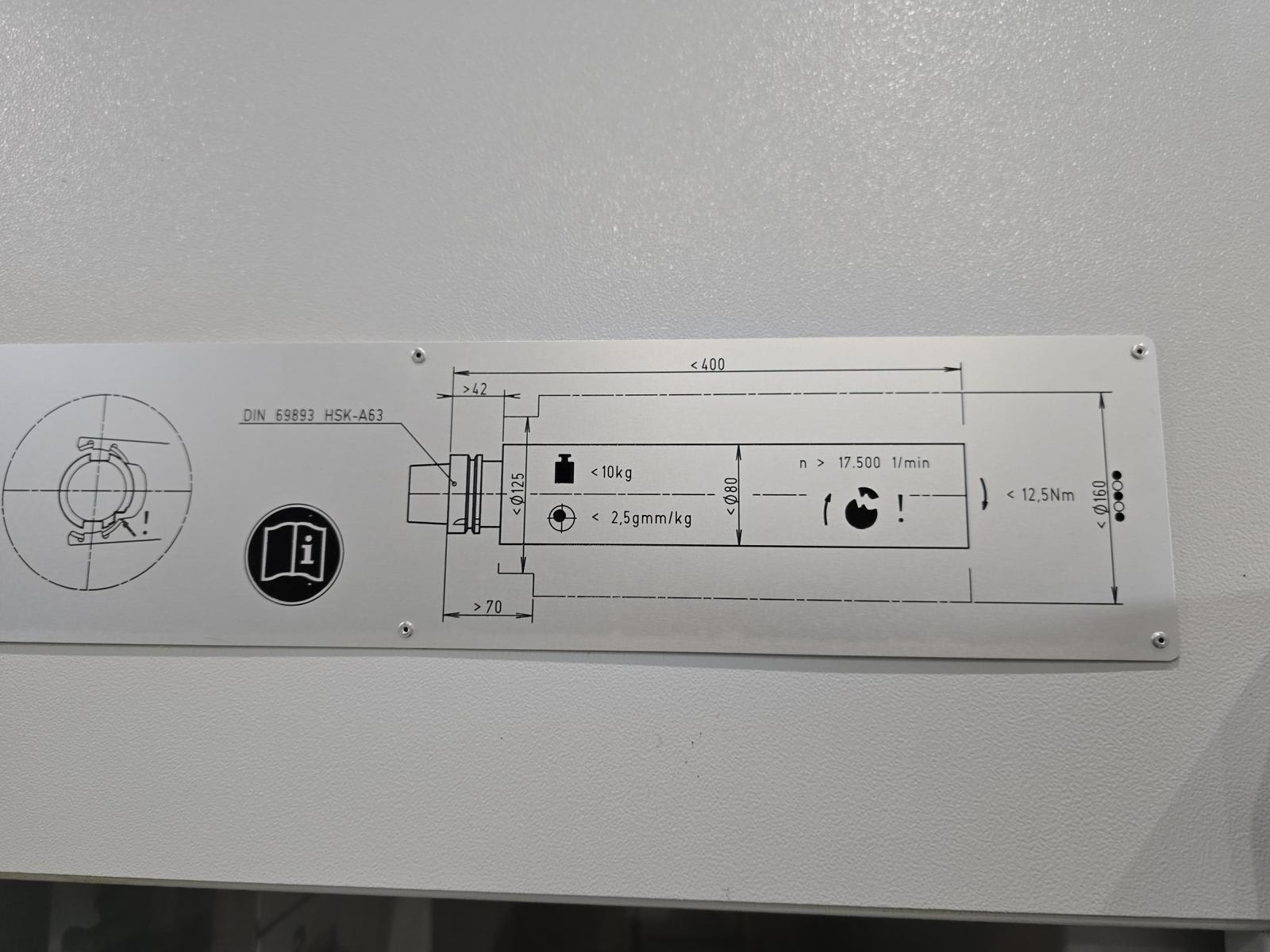

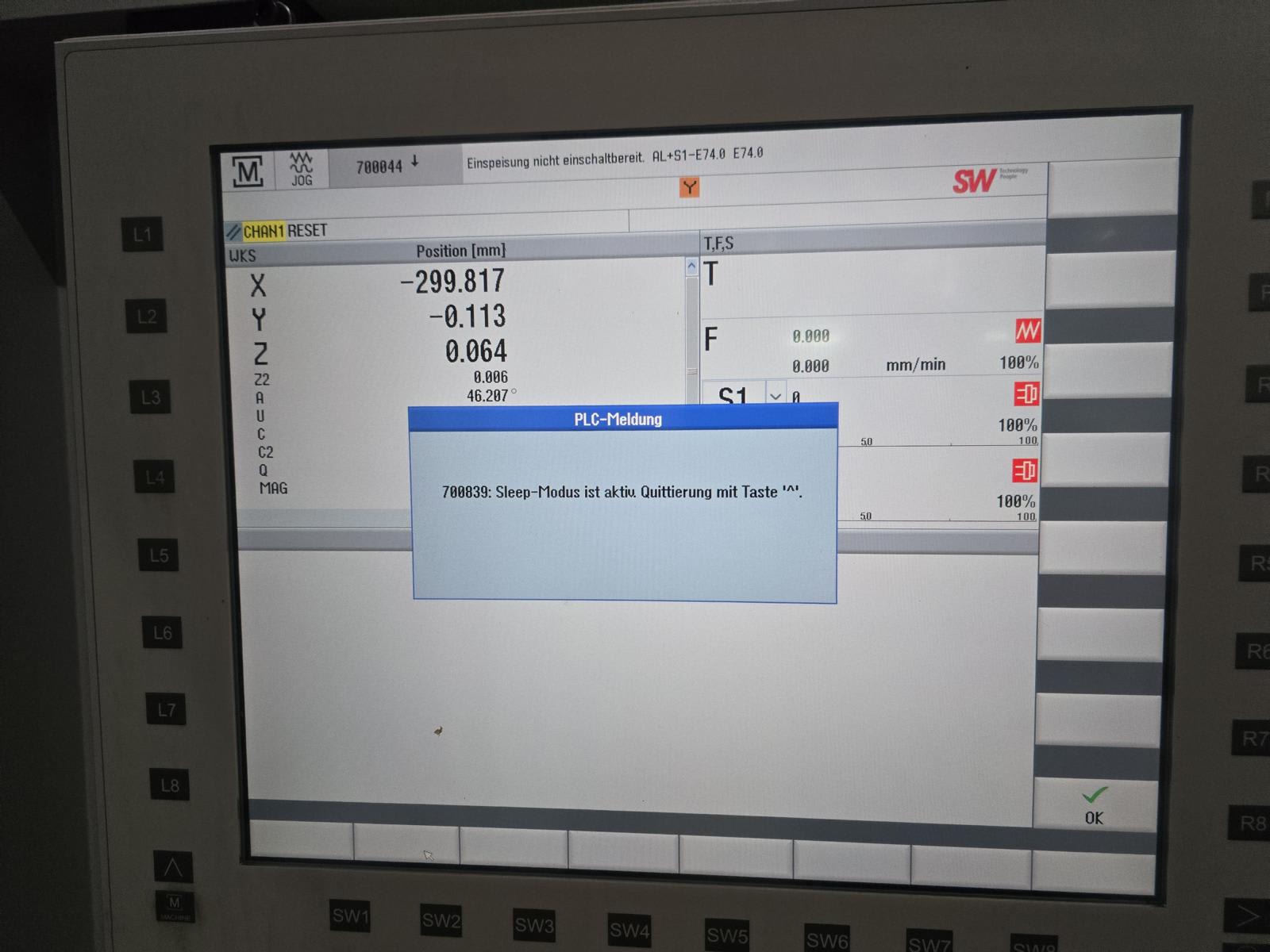

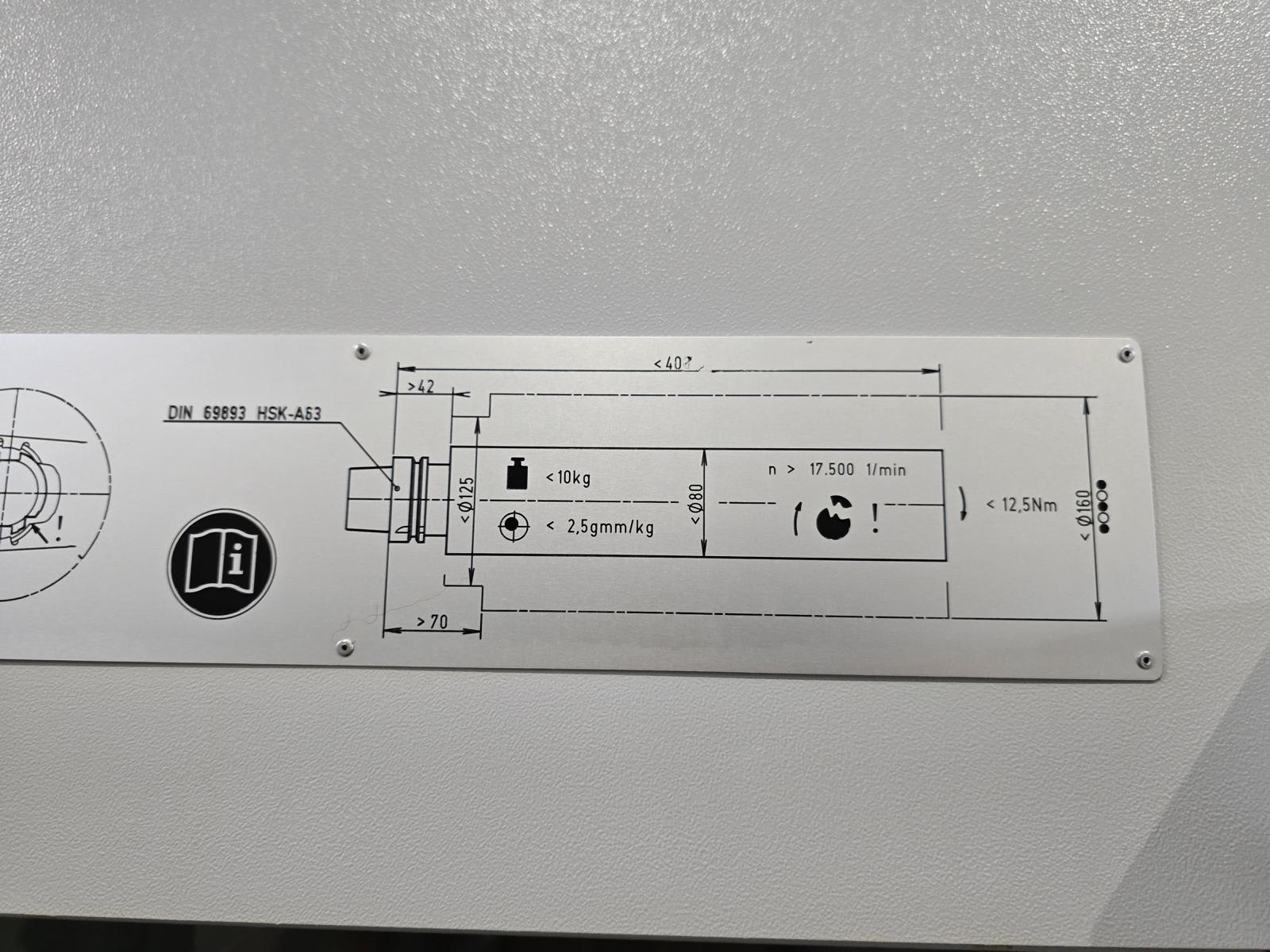

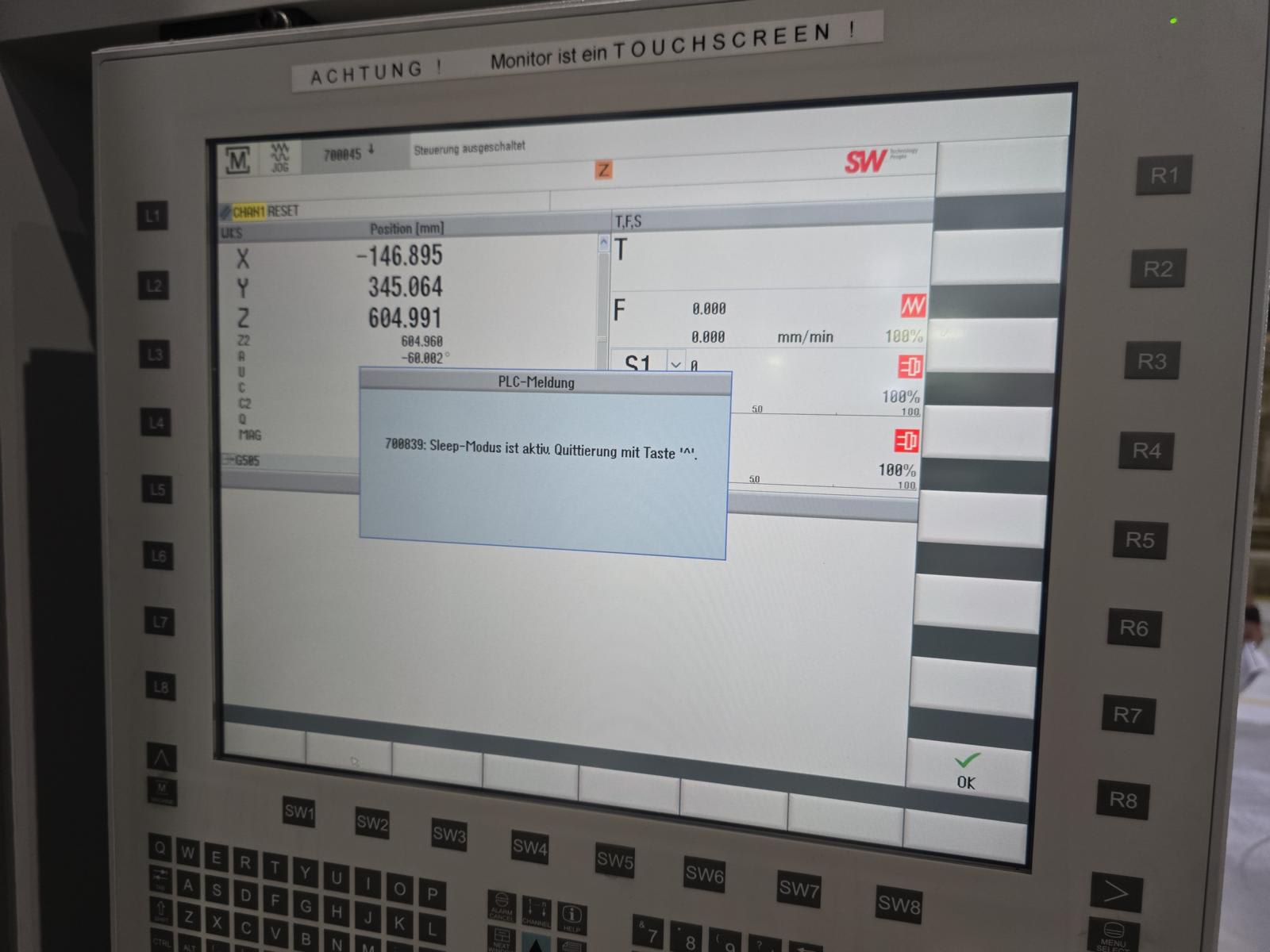

CNC Dual-Spindle Horizontal 5-Axis Machining Center SW BAW08-22 | 2020

Binding Handling & Service Fee:

6590 € (EURO)

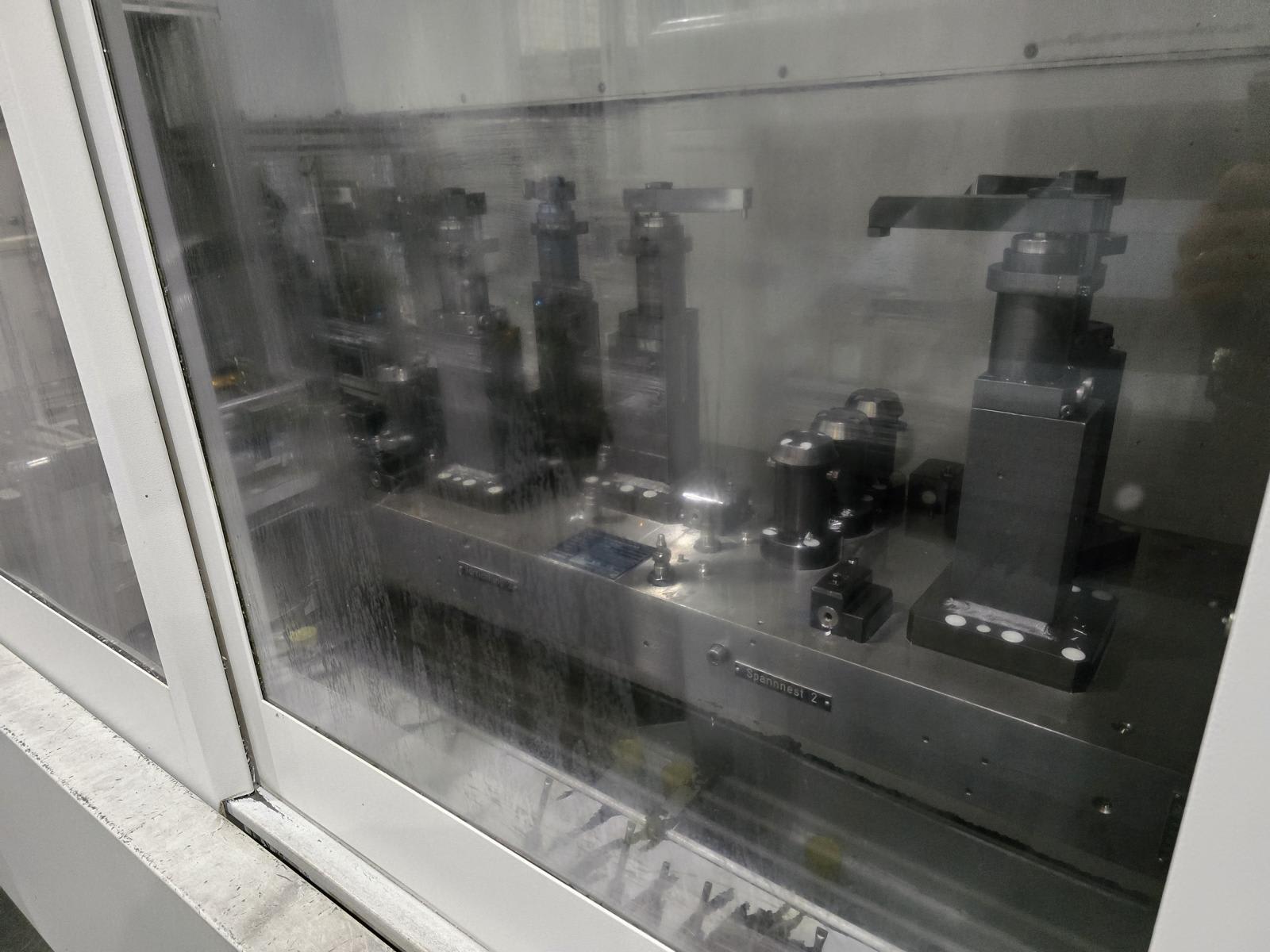

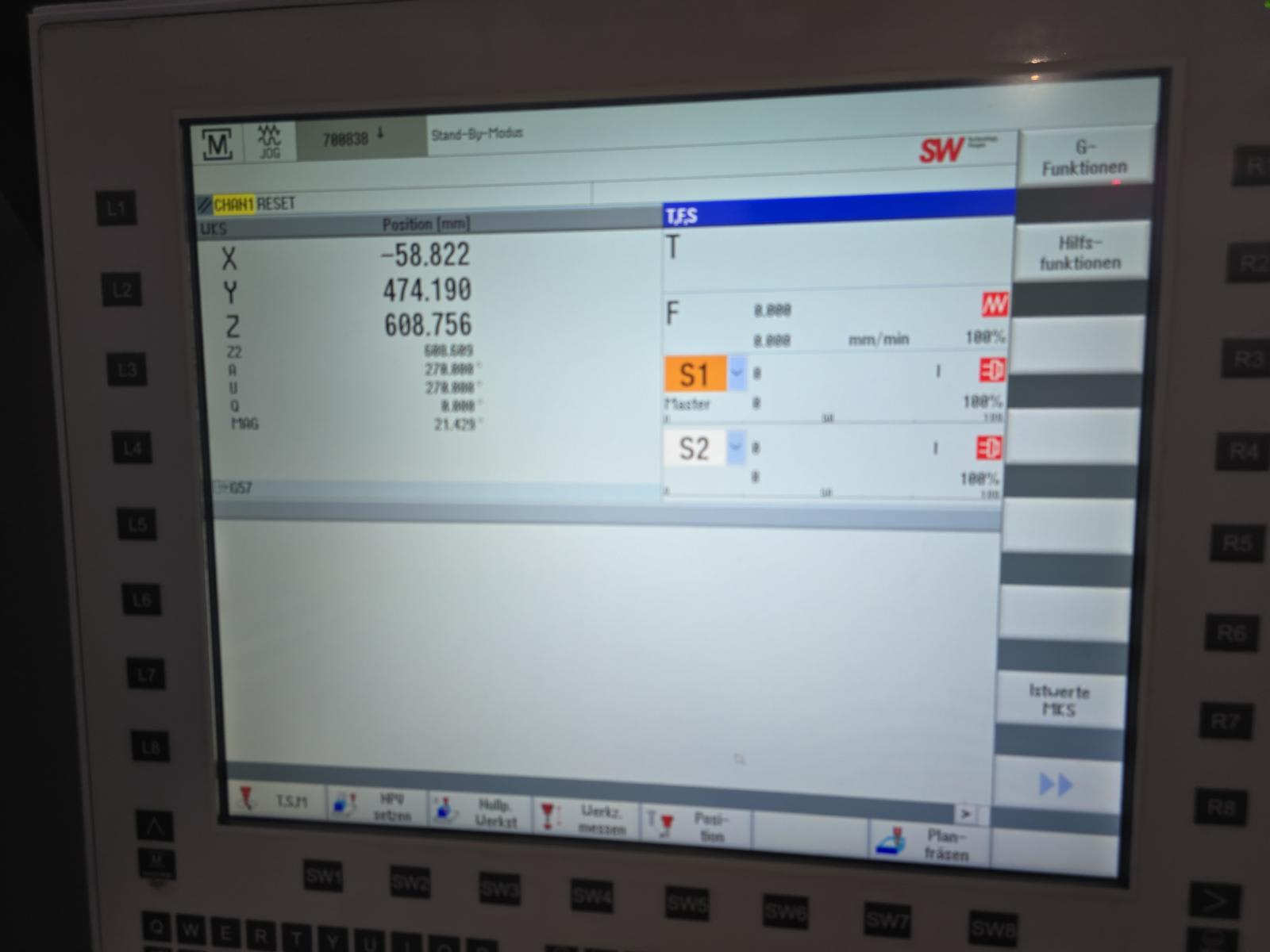

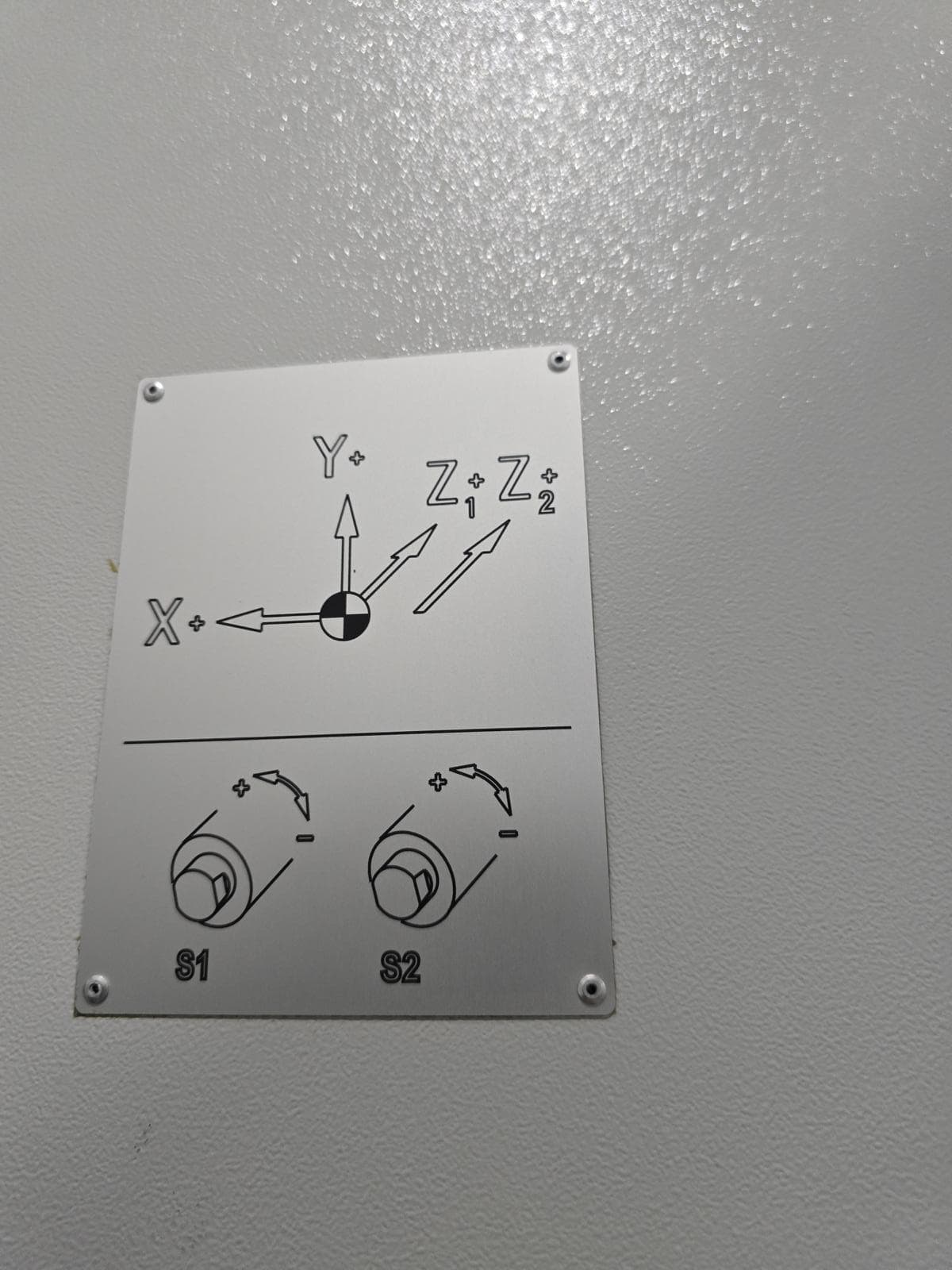

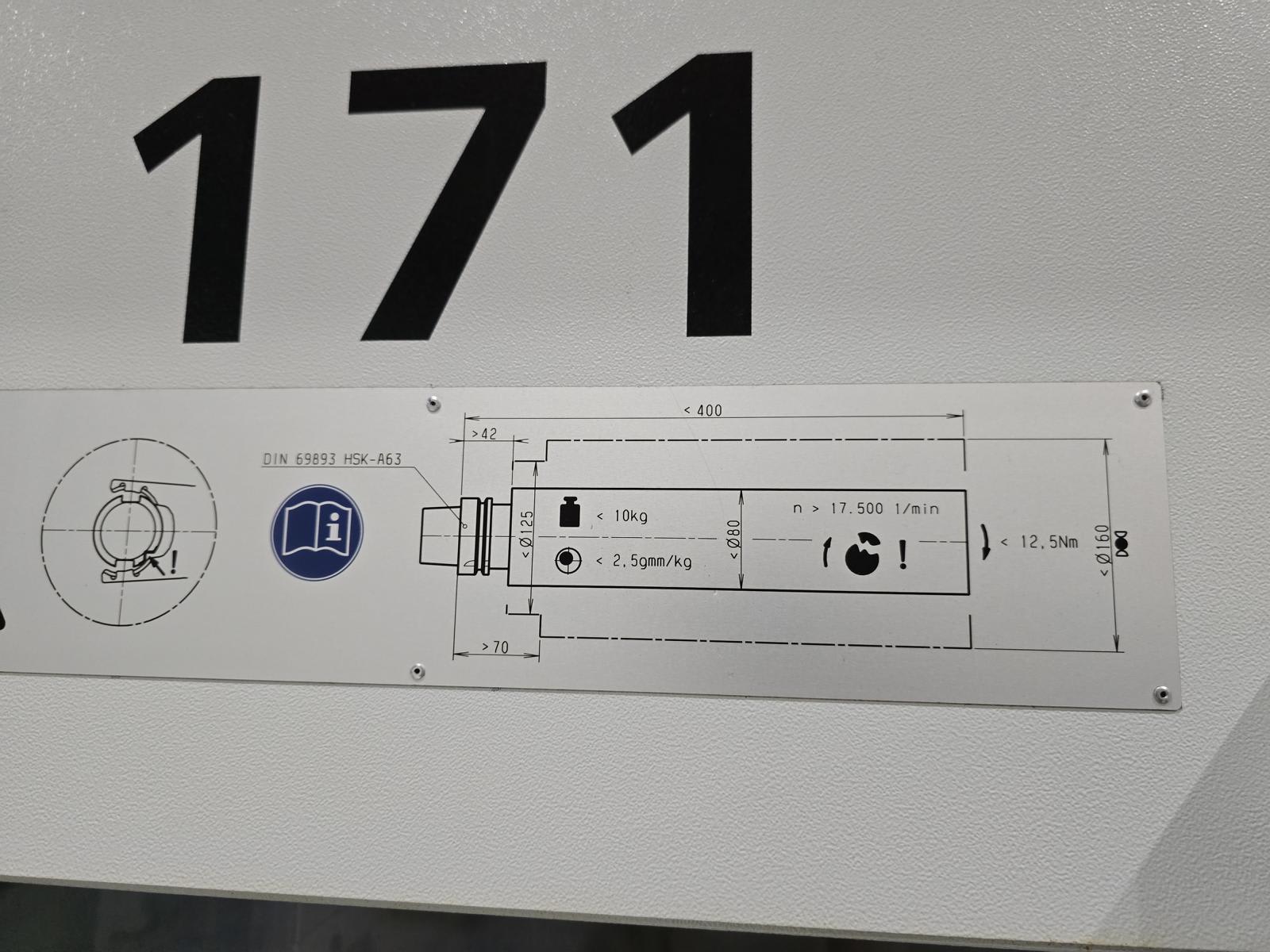

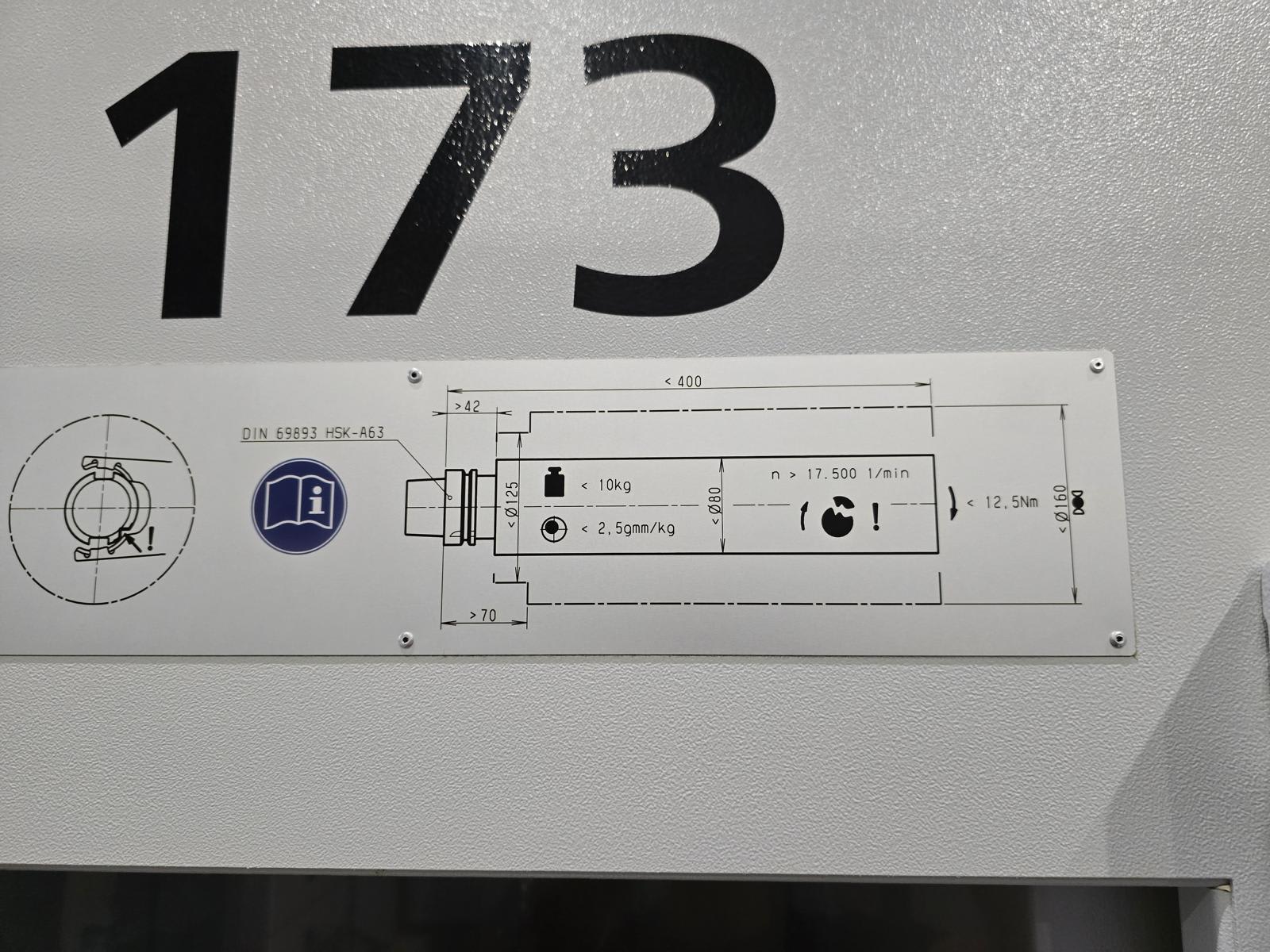

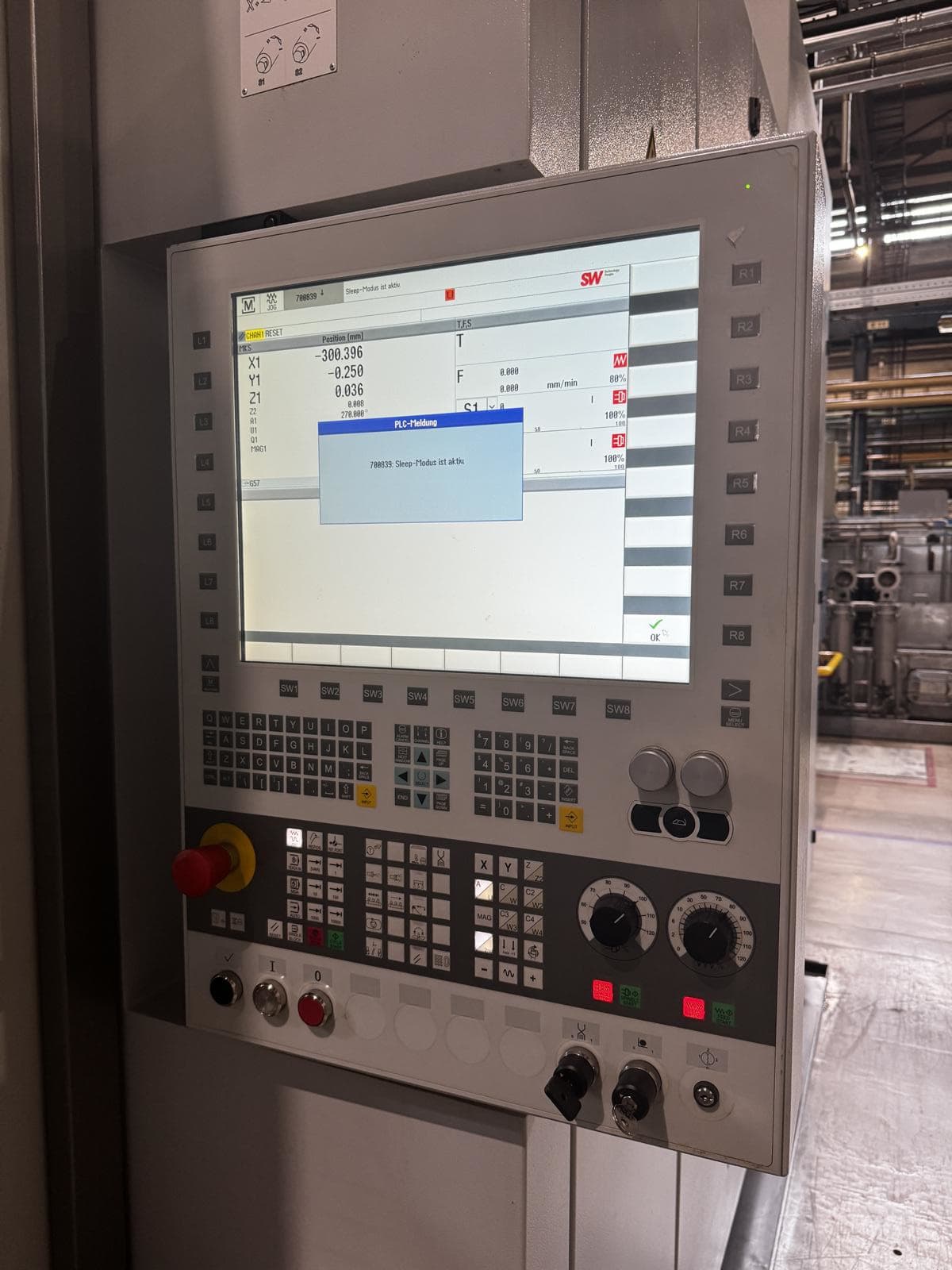

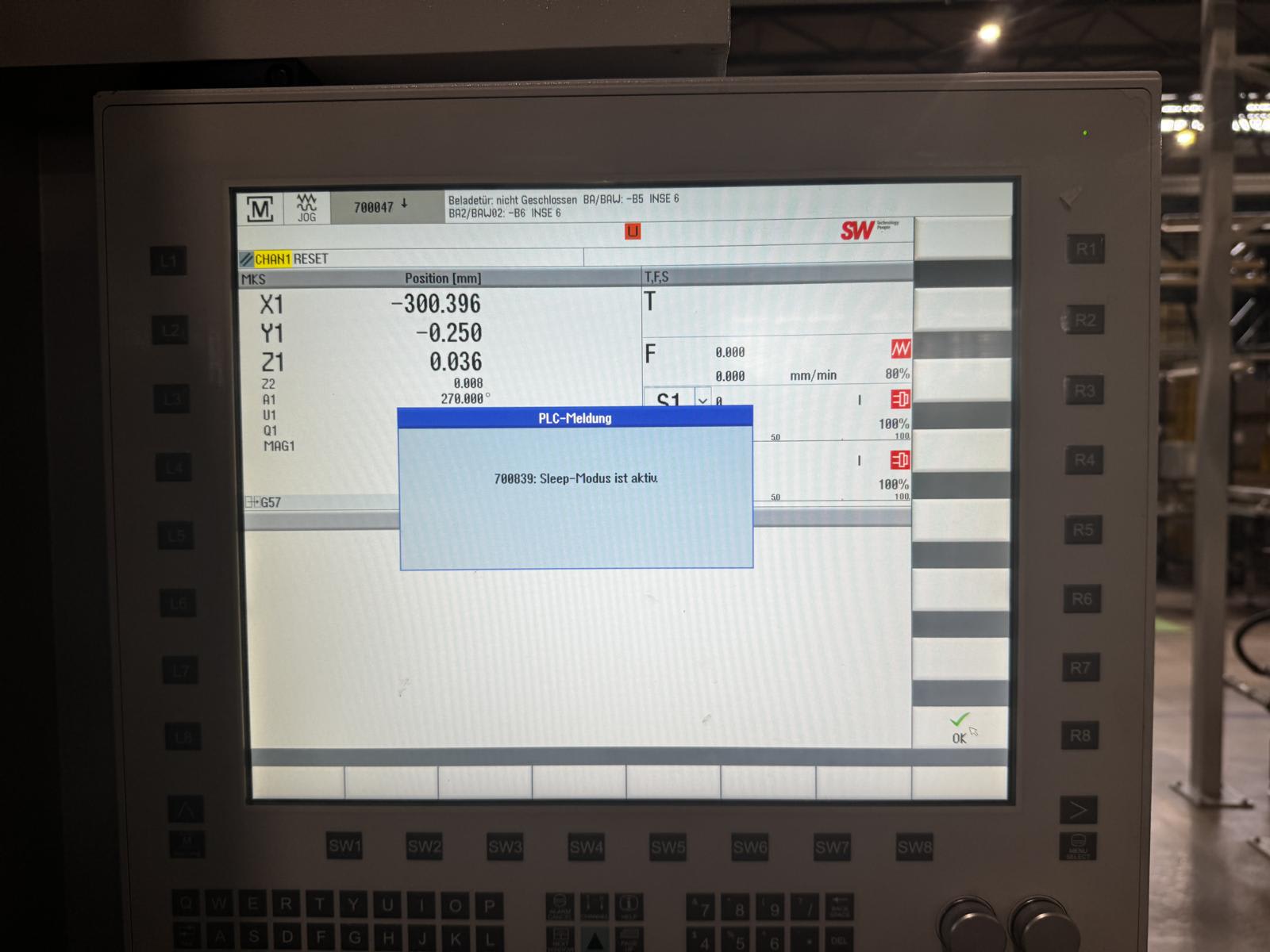

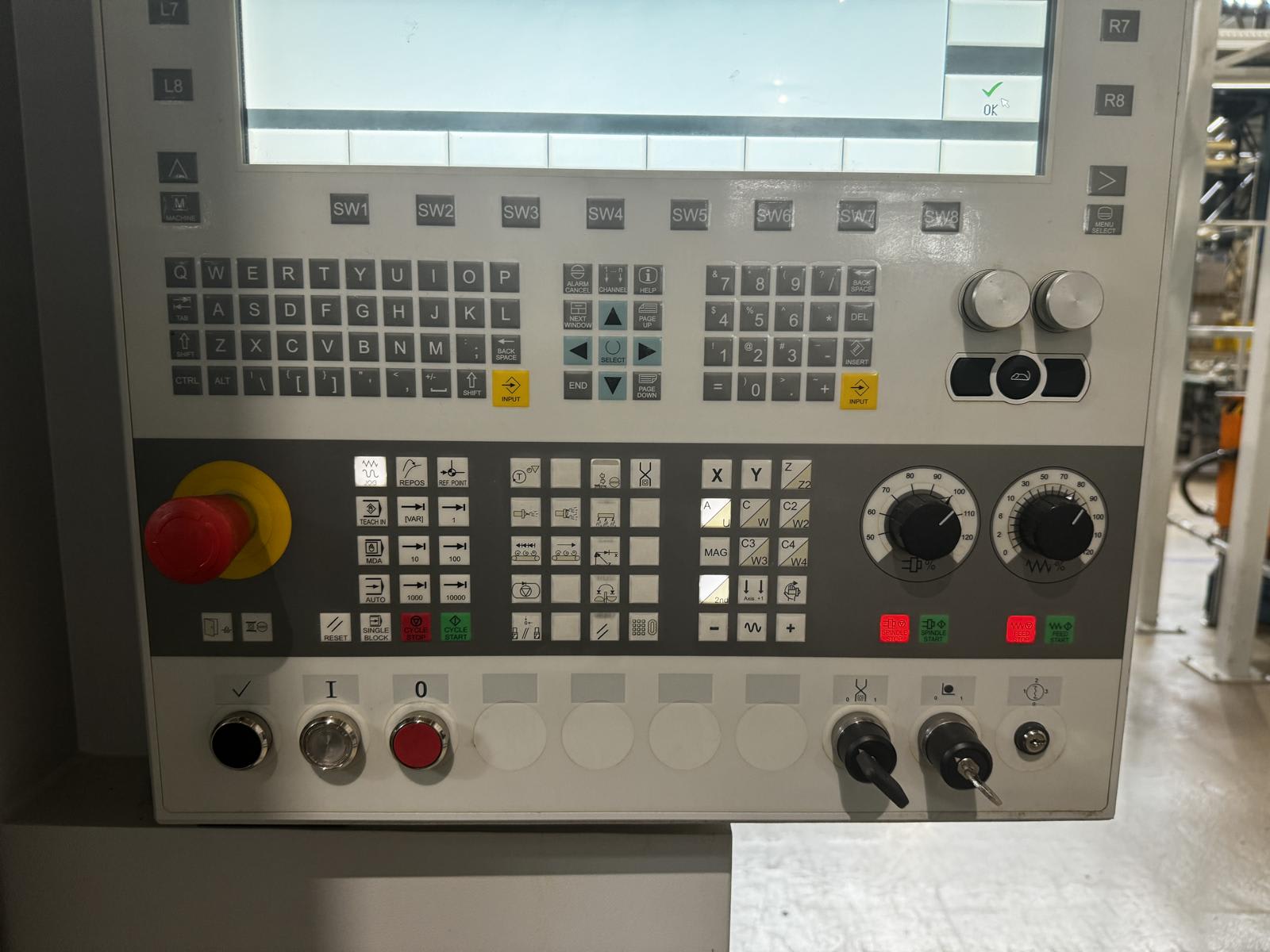

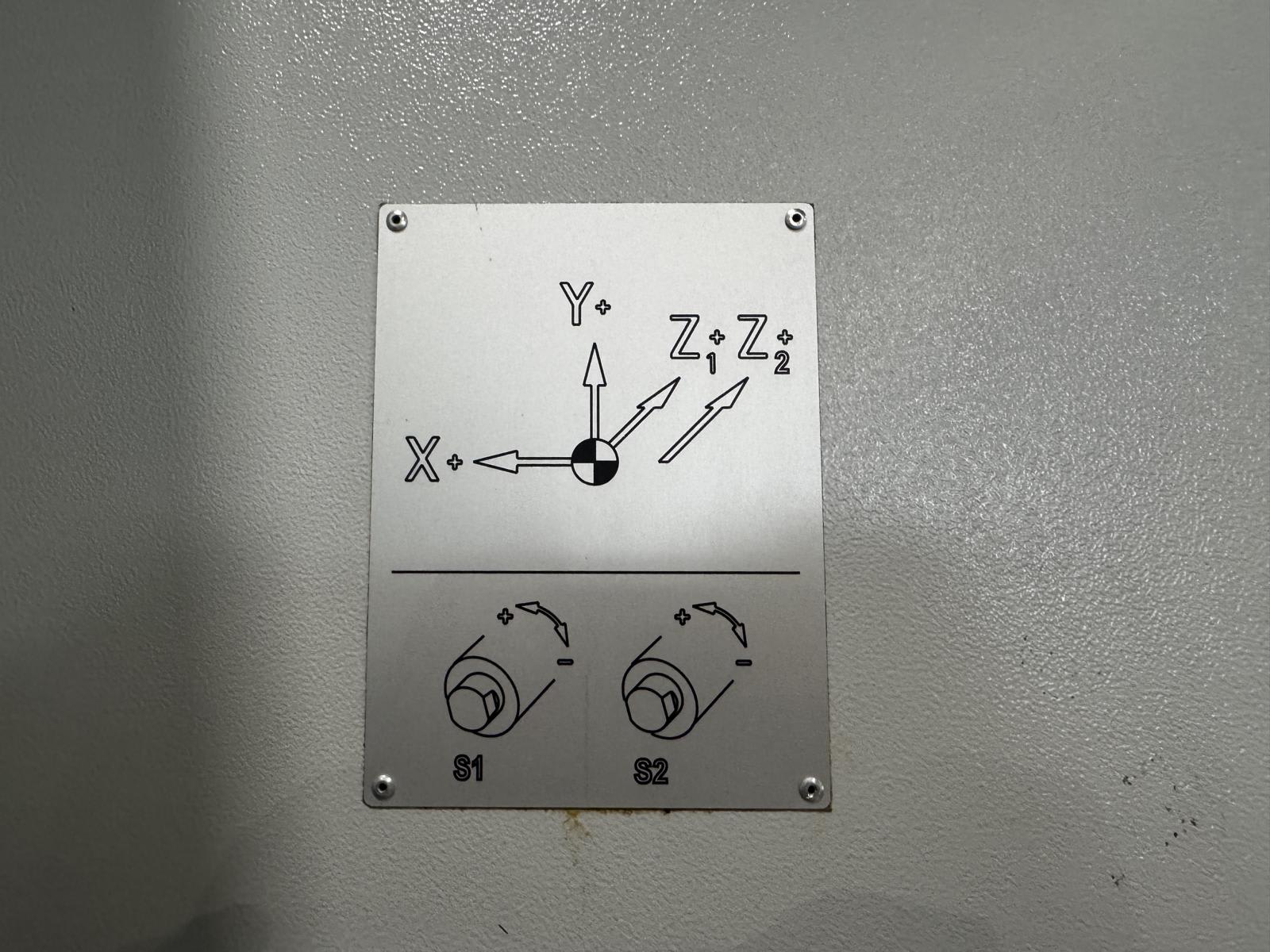

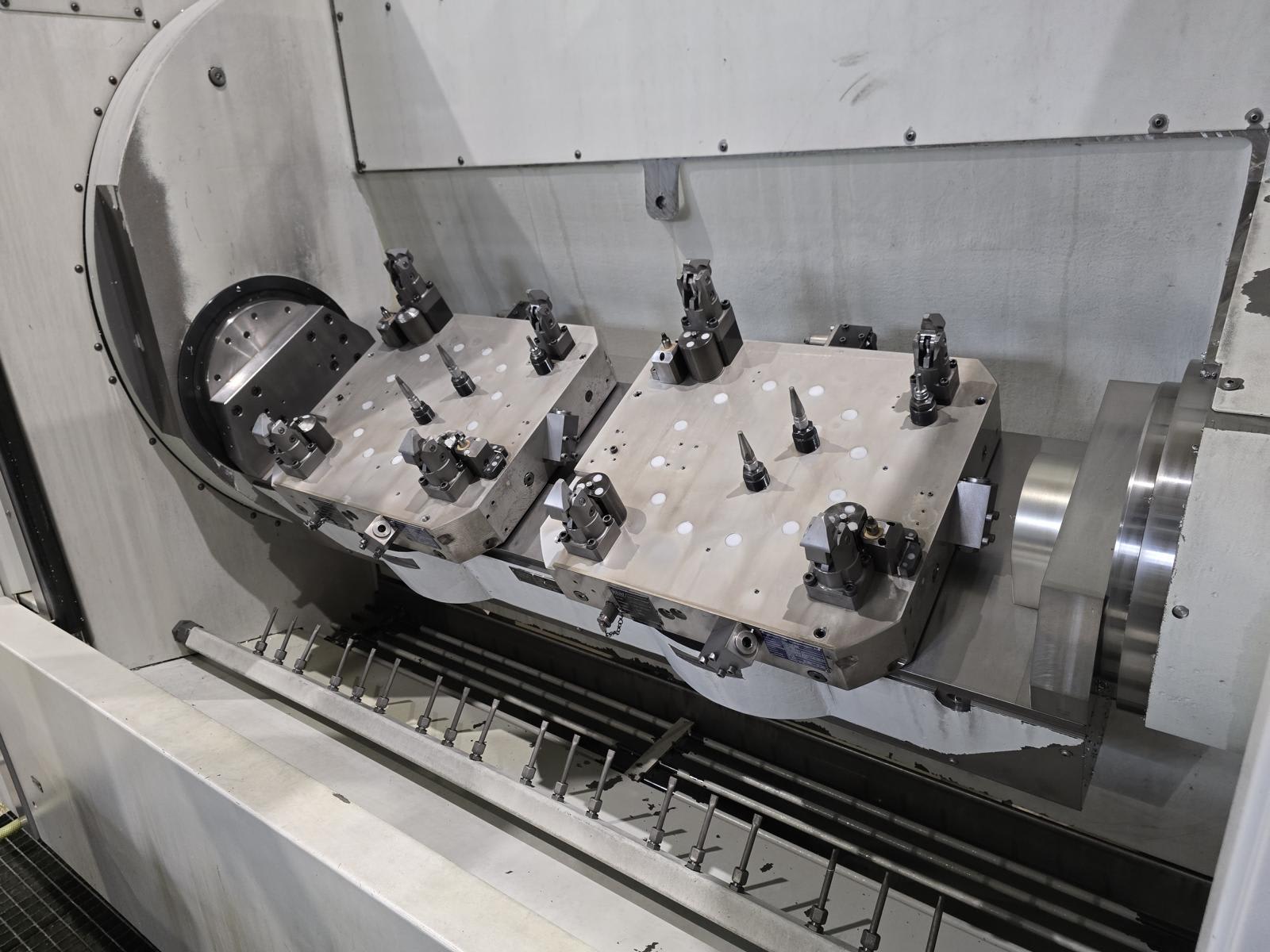

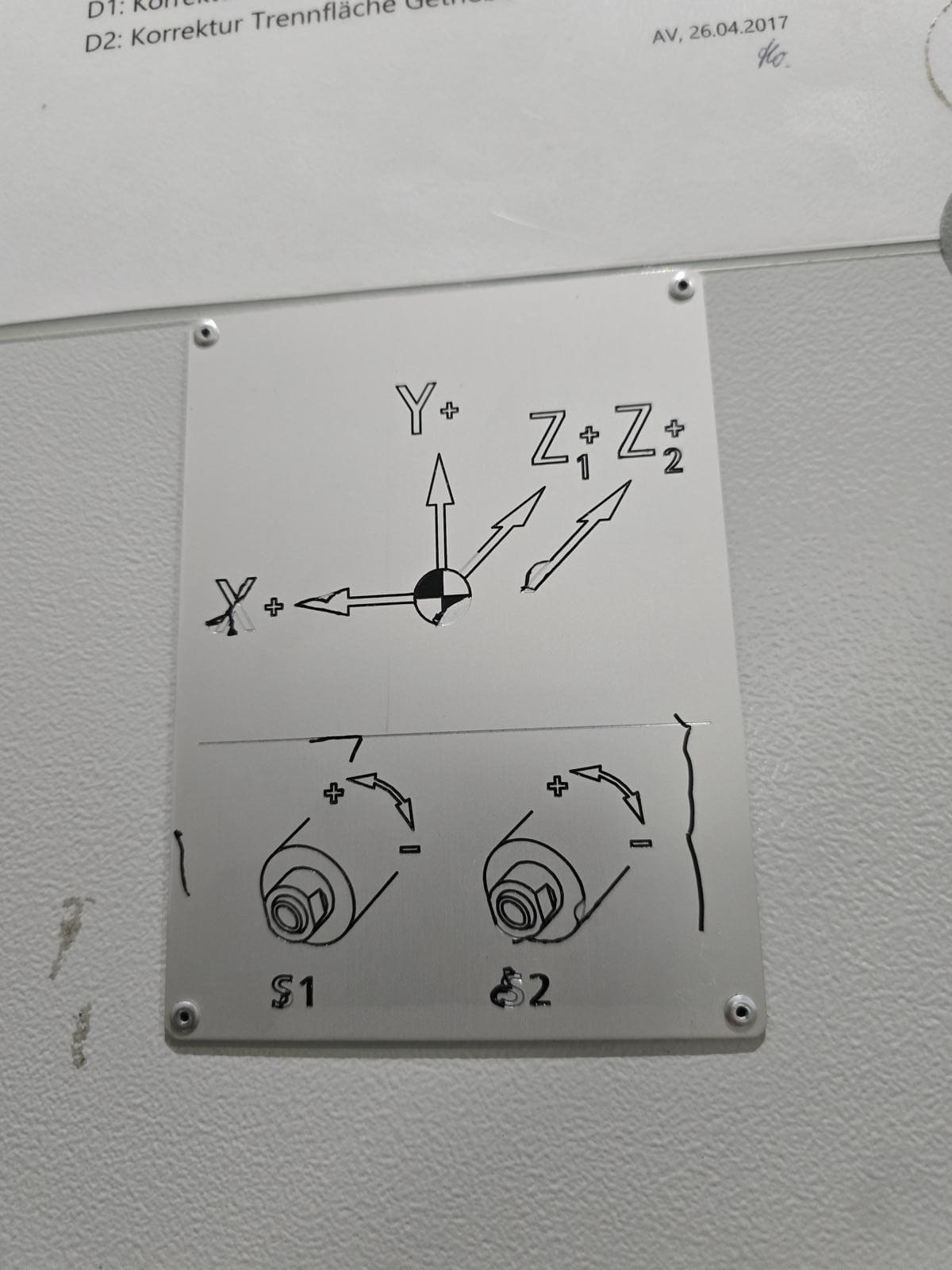

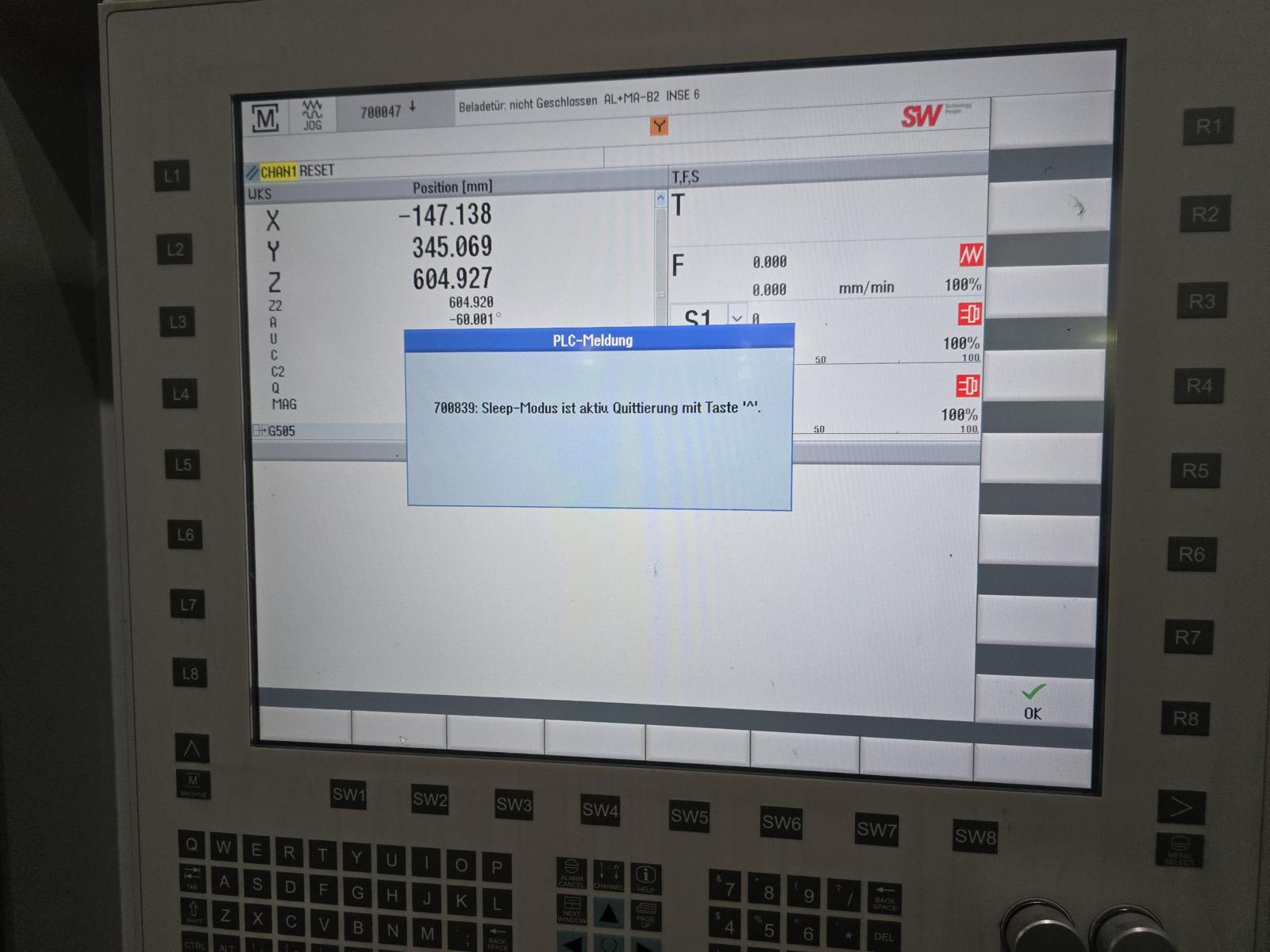

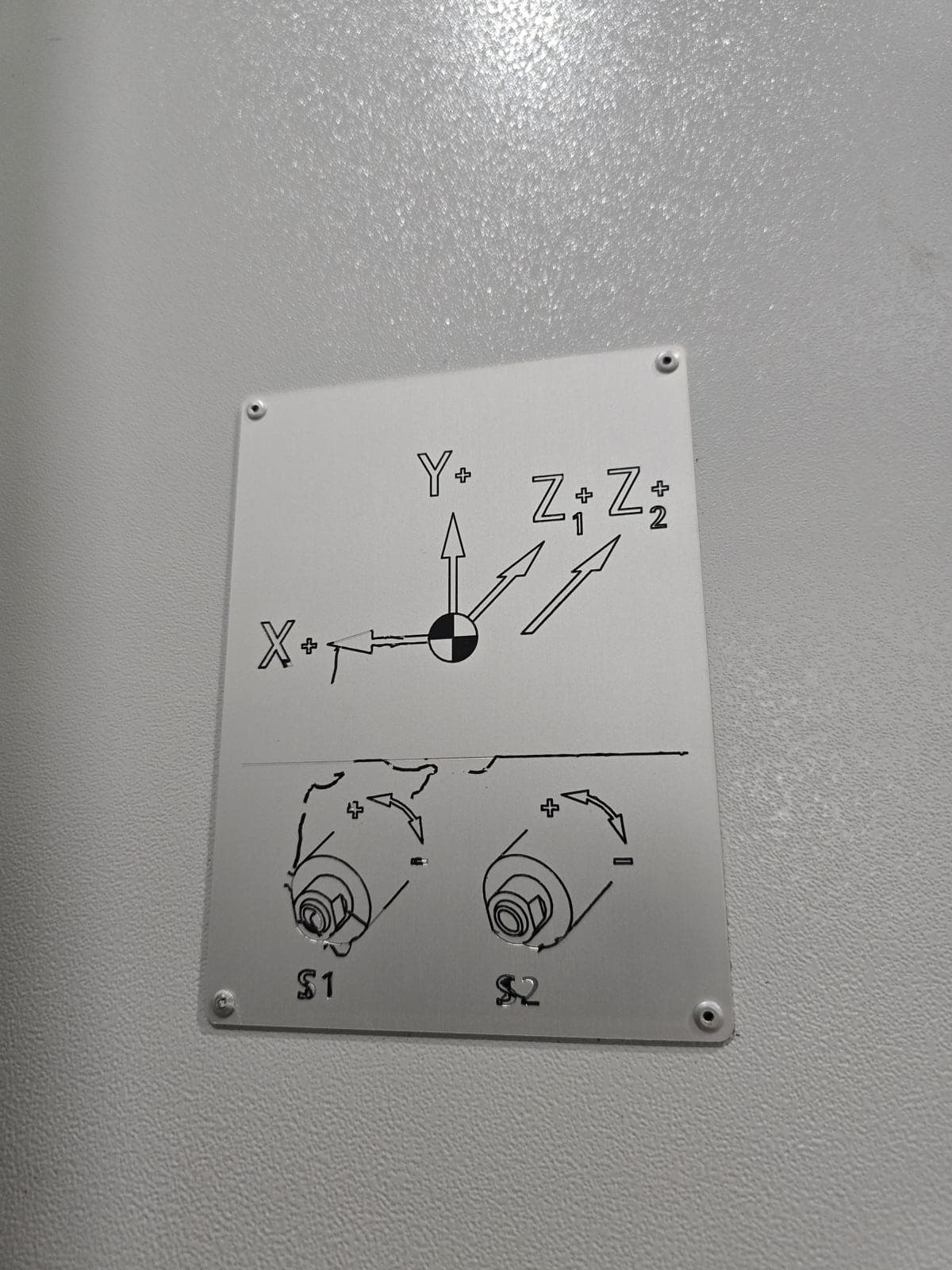

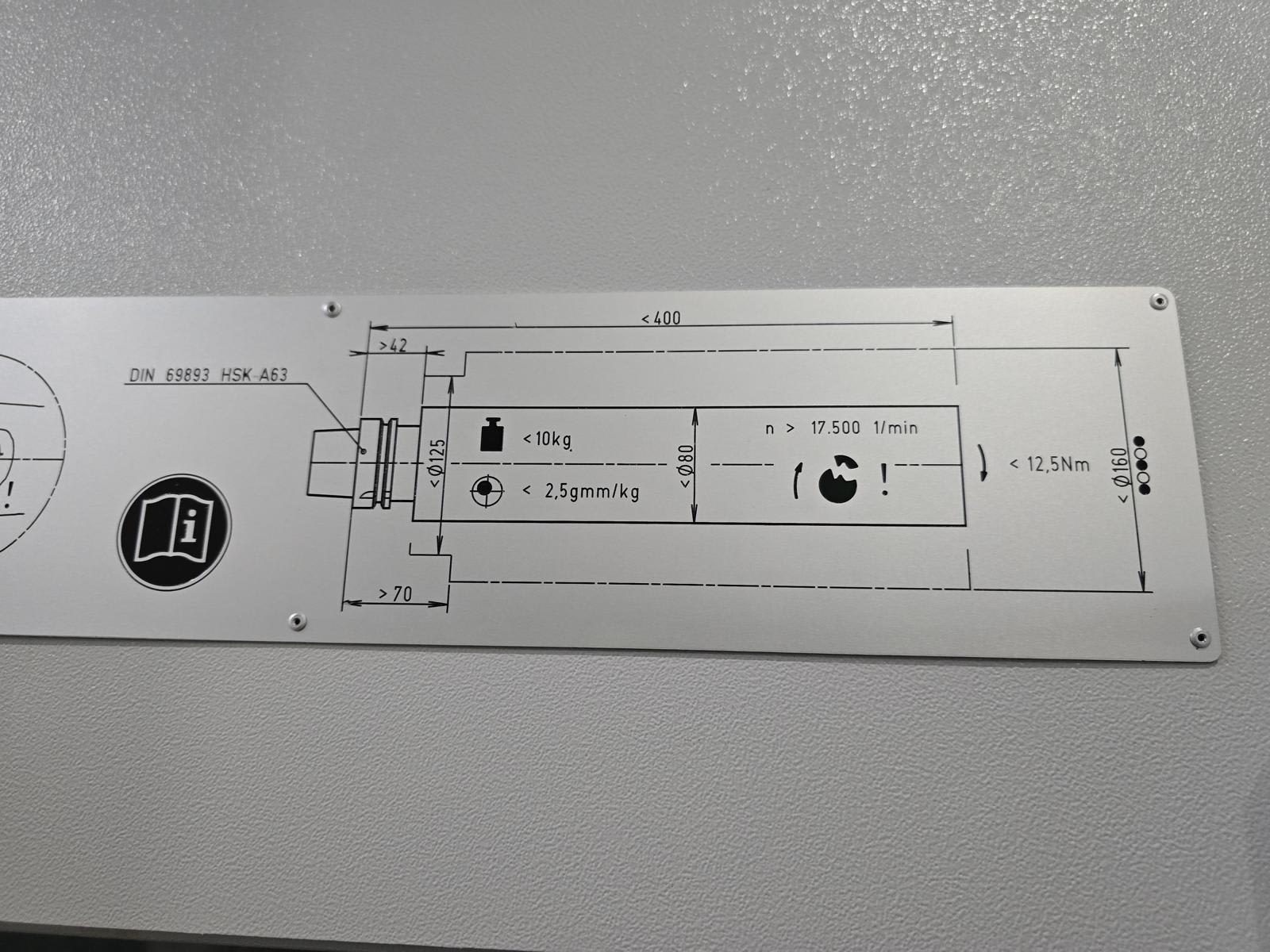

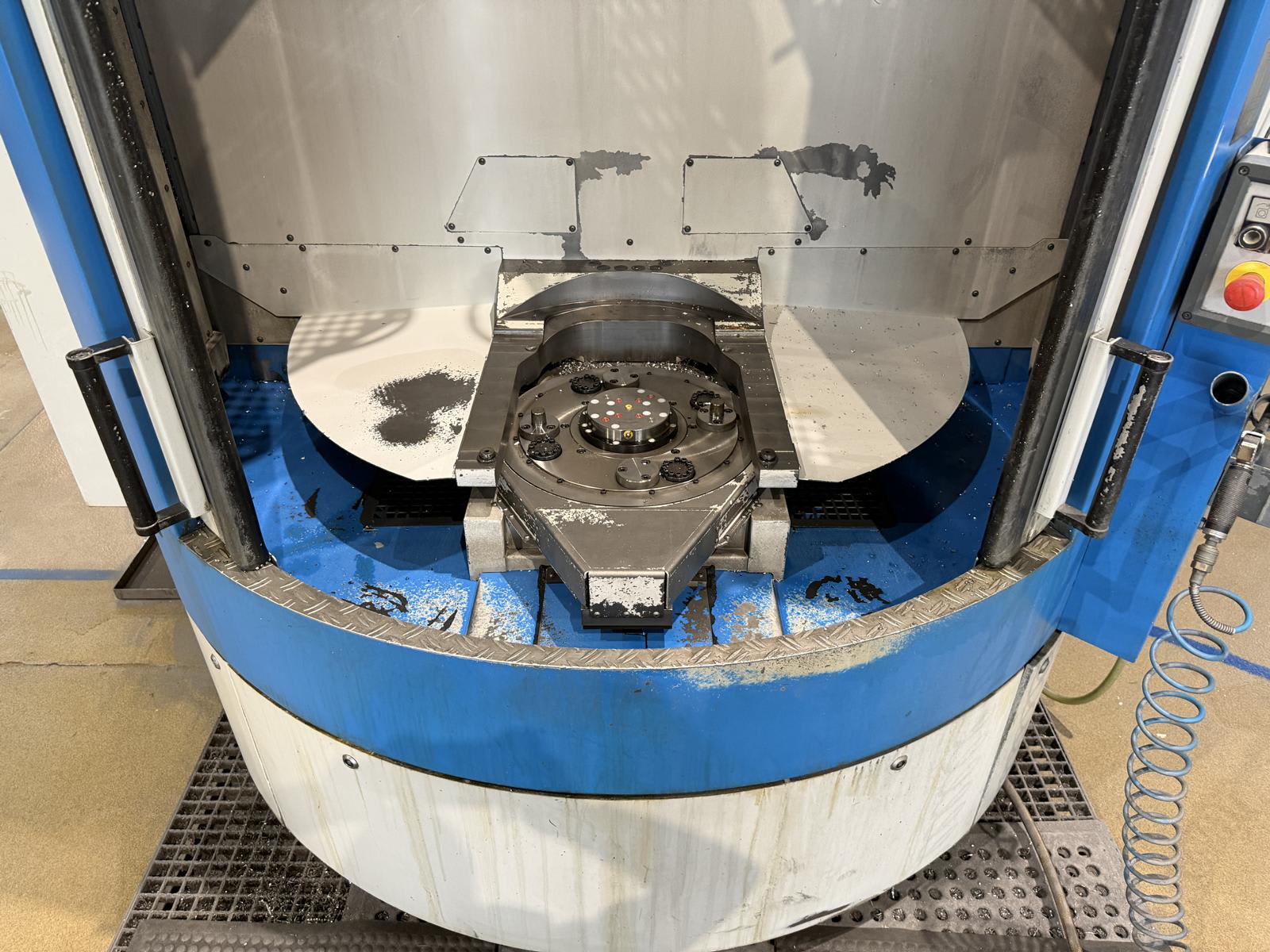

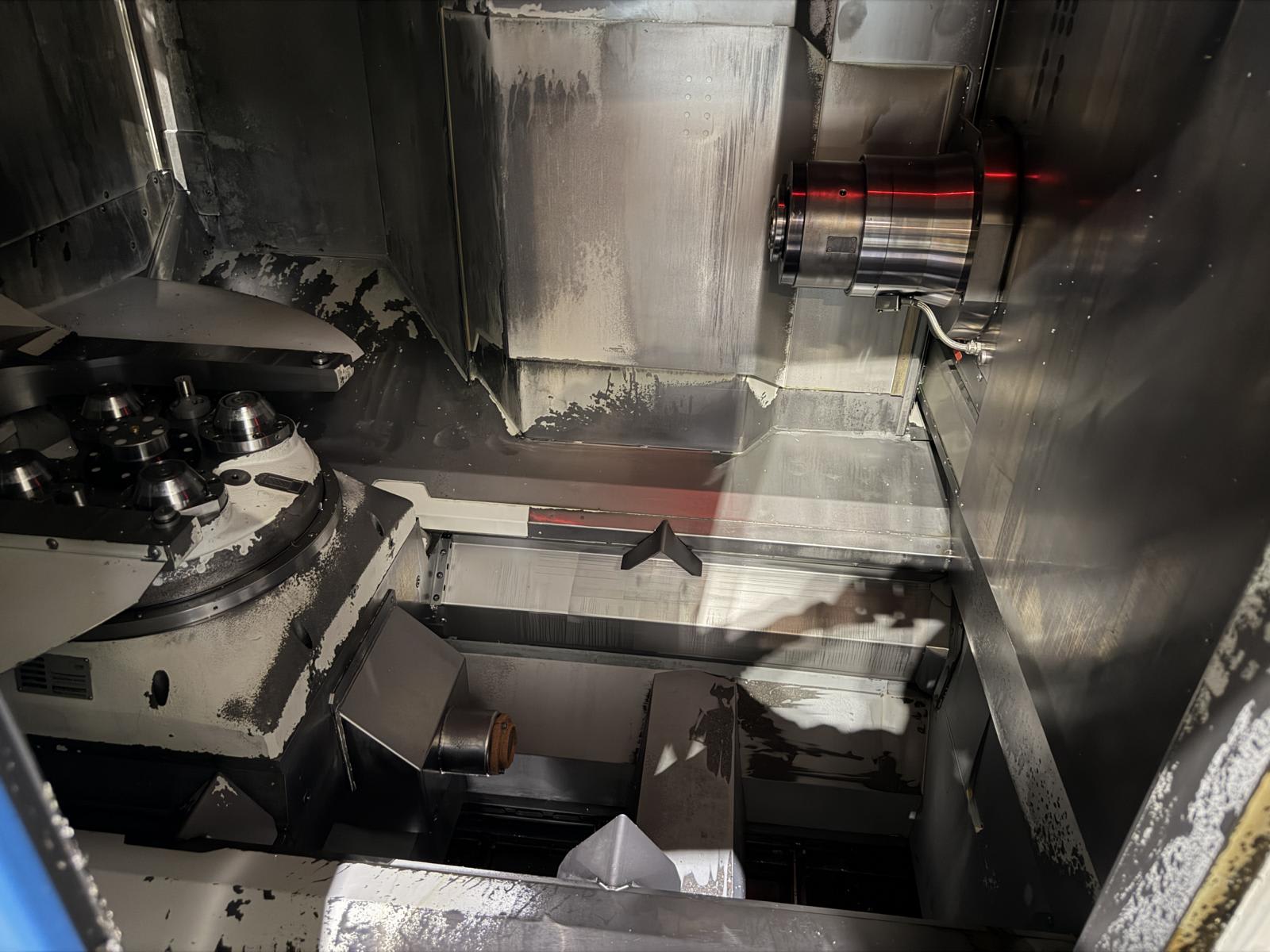

CNC Control SIEMENS 840D SL Electrical Connection Connection voltage: 3 × 400 V / 50 Hz (grounded) Network type: TN-S or TN-C network Total connected load: 152 kVA Power factor: 0.6 Fuse protection: 250 A gG (5 s) Weight Machine operating weight: 28,000 kg Transport weight: 24,500 kg Tool Magazine Tool change: Pick-up system Tool management: Fixed-coded tool positions Capacity: 84 tools (2 × 42) Max. total tool weight: 400 kg Feed drives Drive type: Three-phase synchronous motors Line measuring system X/Y/Z: Direct, absolute X1 and X2 axes Rcs A Hexgpa Rjqn Snsh Rapid traverse: 120 m/min Max. acceleration: 10 m/s² Kv factor: 6 Peak force: 2 × 6,000 N Continuous force: 2 × 3,000 N Positioning accuracy: Tp = 0.008 mm Y-axis Rapid traverse: 120 m/min Max. acceleration: 11 m/s² Kv factor: 6 Peak force: 20,000 N Continuous force: 10,000 N Positioning accuracy: Tp = 0.008 mm Z1 and Z2 axes Rapid traverse: 120 m/min Max. acceleration: 20 m/s² Kv factor: 6 Peak force: 2 × 6,000 N Continuous force: 2 × 3,000 N Positioning accuracy: Tp = 0.008 mm Main spindles Spindle arrangement: Horizontal, twin spindles side by side Spindle diameter: 40 mm Tool holder: HSK-A63 Cooling: Liquid-cooled motor spindles Lubrication: Minimum quantity lubrication (oil) Mechanical clamping force: > 18 kN Wear limit: 16 kN Speed range: 1 – 17,500 rpm Acceleration time: 0.7 s Power: 2 × 35 kW at 4,200 rpm (40% duty cycle) Rated power: 2 × 26 kW at 4,200 rpm Torque: 2 × 80 Nm (40% duty cycle) / 2 × 60 Nm (Rated torque) Machining range Spindle distance: 800 mm Travels: - X-axis: 800 mm - Y-axis: 900 mm (optional 1,200 mm) - Z-axis: 650 mm Difference between coupled Z-axes: < 1.0 mm Difference between coupled X-axes: < 1.0 mm Workpiece clamping / Table system Dual swiveling carriage (Q-axis) with two direct-drive NC rotary tables (A/U-axes) Swivel time 0–180°: 5.0 s Max. asymmetric load: 1,600 Nm Rotary table Ø 800 mm, repeatability: < 0.008 mm Max. workpiece weight: 800 kg Peak torque: 1,900 Nm Rated torque: 1,300 Nm Nm Max. table speed: 40 min⁻¹ Tool change times: Chip-to-chip at n < 10,000 min⁻¹: > 3.0 s Chip-to-chip at n < 17,500 min⁻¹: > 3.15 s Operating Data: -> Spindle hours approx. 10,993 -> Operating hours approx. 22,851 Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770003

![Deutsch]()

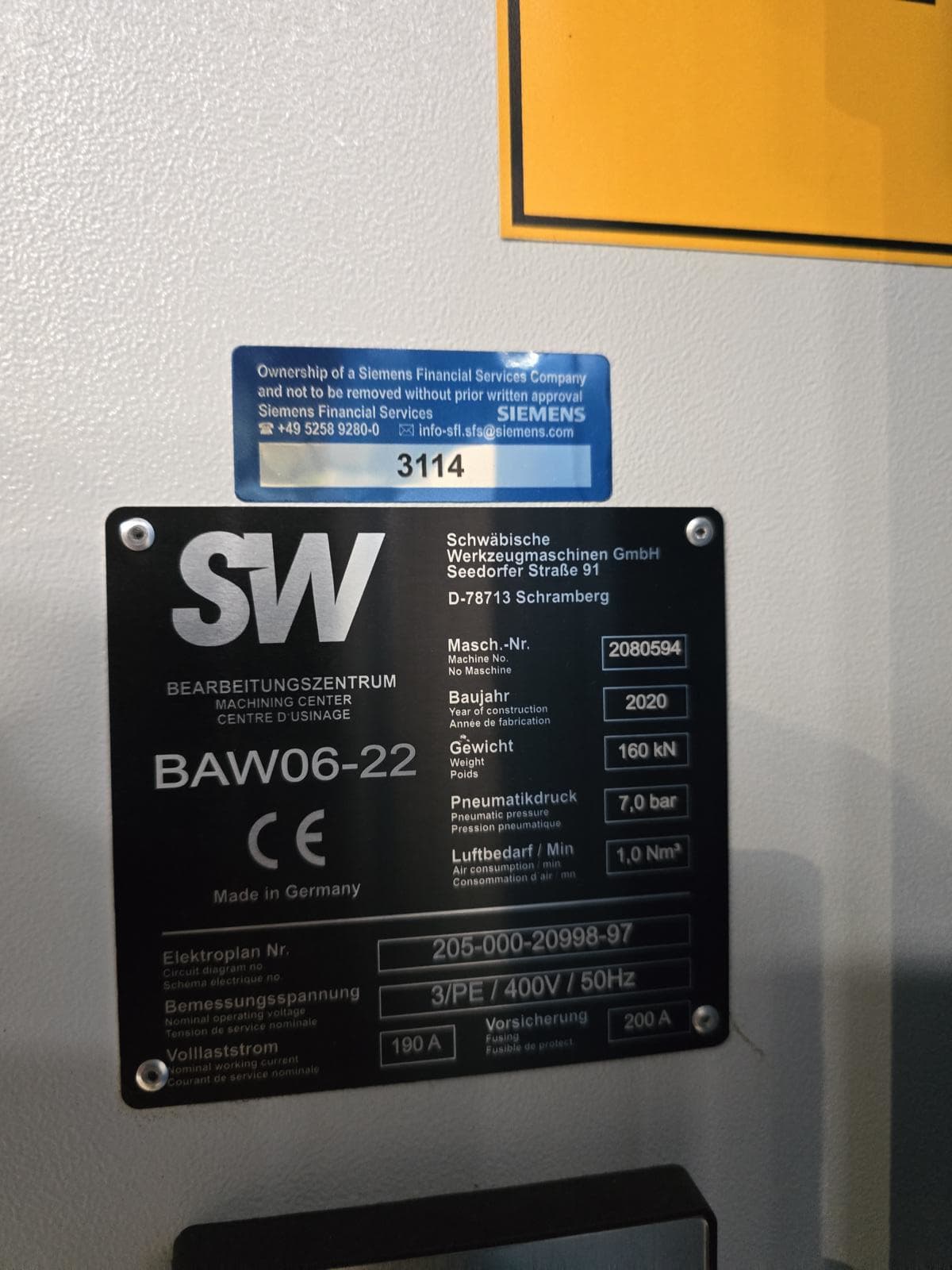

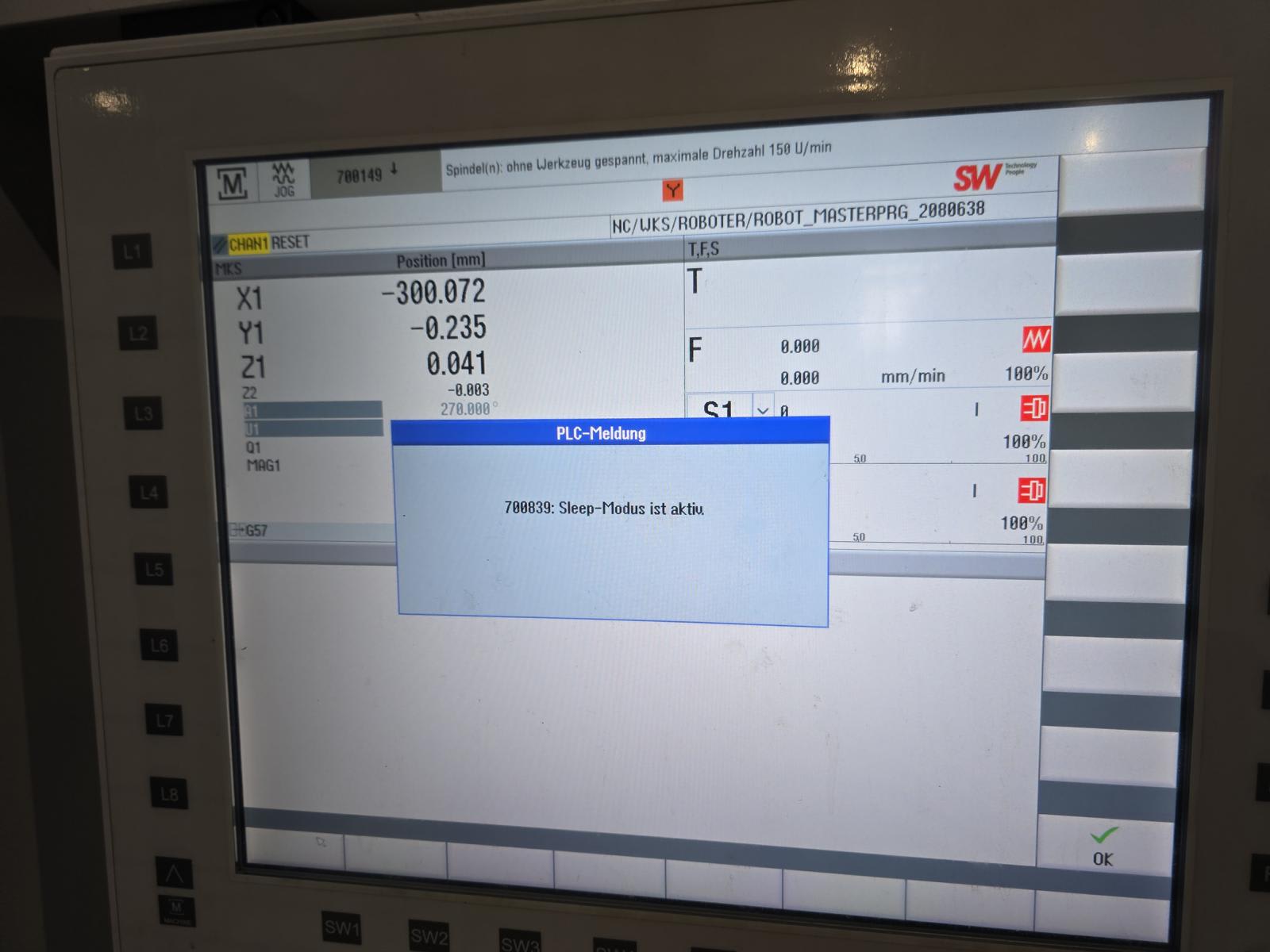

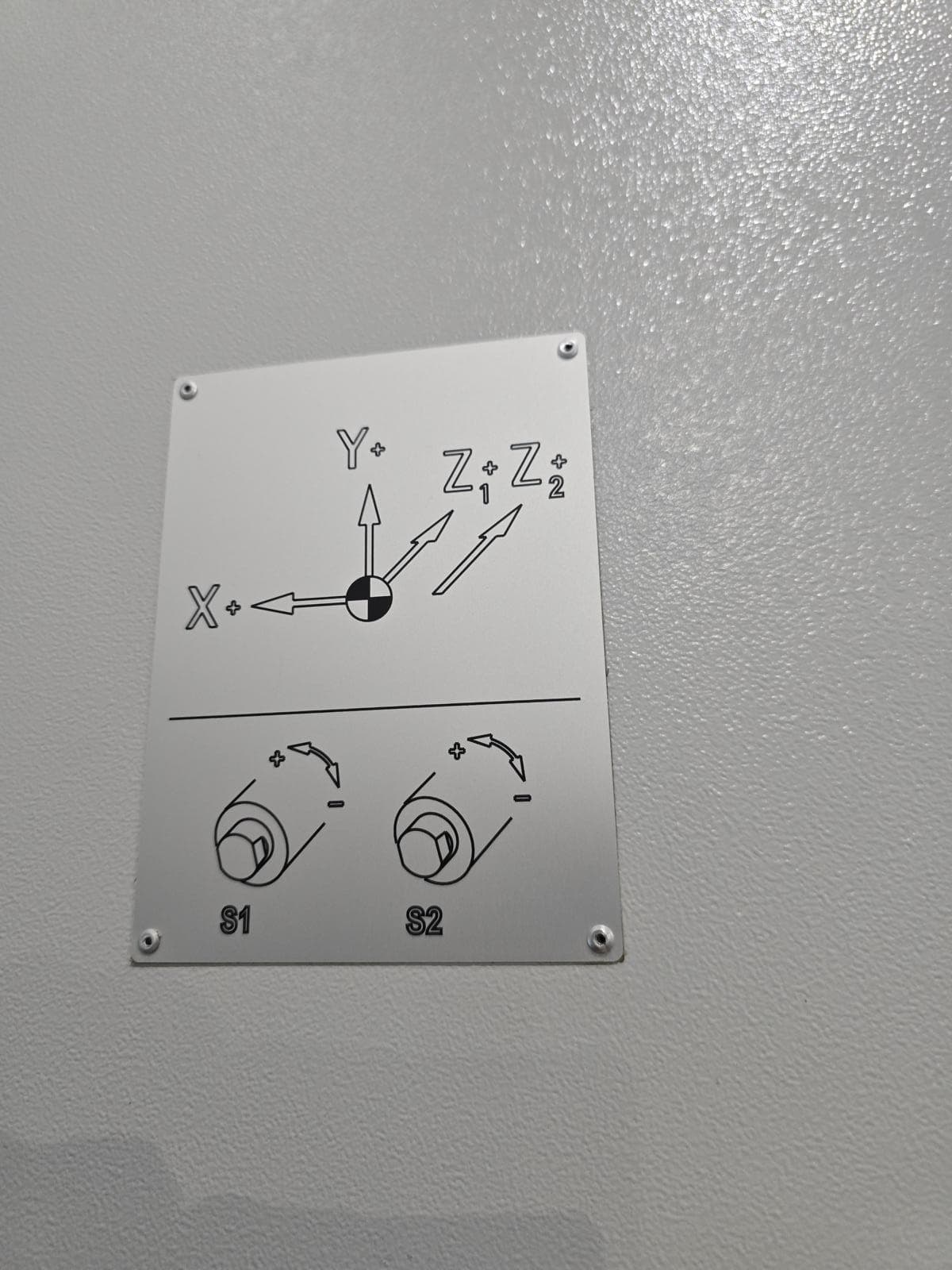

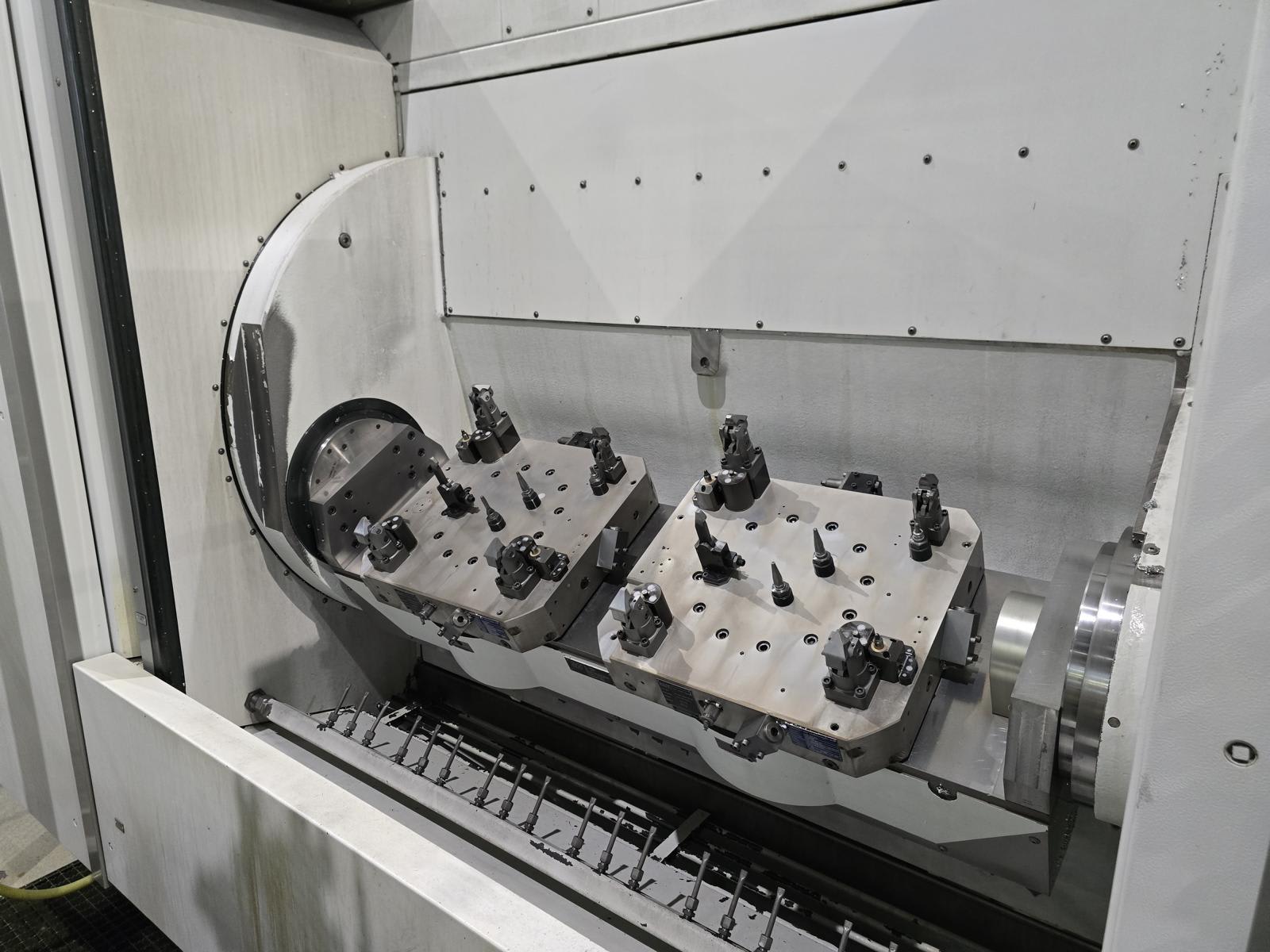

CNC Dual-Spindle Horizontal 4-Axis Machining Center SW BAW06-22 | 2020

Binding Handling & Service Fee:

5950 € (EURO)

CNC Control SIEMENS 840D SL Electrical Connection Connection voltage: 3 × 400 V / 50 Hz (grounded) Network type: TN-S or TN-C network Total connected load: 133 kVA Power factor: 0.6 Fuse protection: 200 A gG (5 s) Weight Machine operating weight: 20,000 kg Transport weight: 16,000 kg Tool magazine Tool change: Pick-up system Tool management: Fixed-coded tool positions Capacity: 84 tools (2 × 42) Maximum total tool weight: 350 kg Feed drives Drive type: Three-phase synchronous motors Line measuring system X/Y/Z: Direct, absolute X-axes (X1 and X2) Rapid traverse: 100 m/min Max. Acceleration: 12 m/s² Kv Factor: 7 Peak Force: 2 × 10,000 N Continuous Force: 2 × 5,000 N Positioning Accuracy: Tp = 0.008 mm Y-Axis Fast Traverse: 100 m/min Max. Acceleration: 10 m/s² Kv Factor: 7 Peak Force: 10,000 N Continuous Force: 5,000 N Positioning Accuracy: Tp = 0.008 mm Z-Axis (Z1 and Z2) Fast Traverse: 100 m/min Max. Acceleration: 20 m/s² Kv Factor: 7 Peak Force: 2 × 5,000 N Continuous Force: 2 × 2,500 N Positioning Accuracy: Tp = 0.008 mm Main Spindles Spindle Arrangement: Horizontal, Twin Spindles side by side Motor Spindles, Liquid-cooled, Synchronous Drive Spindle Diameter: 40 mm Tool Holder: HSK-A63 Lubrication: Minimum Quantity Lubrication (Oil) Mechanical Clamping Force: > 18 kN Wear Limit: 16 kN Speed Range: 1 – 17,500 rpm Acceleration Time: 0.7 s Power: 2 × 35 kW at 4,200 rpm (40% duty cycle) Rated Power: 2 × 26 kW at 4,200 rpm Torque: 2 × 80 Nm (40% duty cycle) / 2 × 60 Nm (Rated Torque) Machining Range Spindle Spacing: 600 mm Travel paths: - X-axis: 600 mm - Y-axis: 600 mm (optional 875 mm) - Z-axis: 500 mm Workpiece clamping / Table system Swivelable fixture with two separate swivel tables for mounting clamping bridges (4-Axis) Swivel time 0–180°: 3.5 s Max. asymmetric load: 800 Nm Rotary table Ø 800 mm, repeatability: < 0.008 mm Max. workpiece weight: 600 kg Peak torque: 981 Nm Rated torque: 698 Nm Max. table speed: 50 min⁻¹ Angular acceleration: 2.5 – 10 rpm Positioning accuracy: ±5″ Tangential torque: 4,500 Nm Max. load torque: 500 Nm Tool change times Chip-to-chip at n < 10,000 min⁻¹: > 2.75 s Chip-to-chip at n < 17,500 min⁻¹: > 3.15 s Operating Data: -> Spindle hours approx. 9,354 -> Operating hours approx. 21,130 Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770004

![Deutsch]()

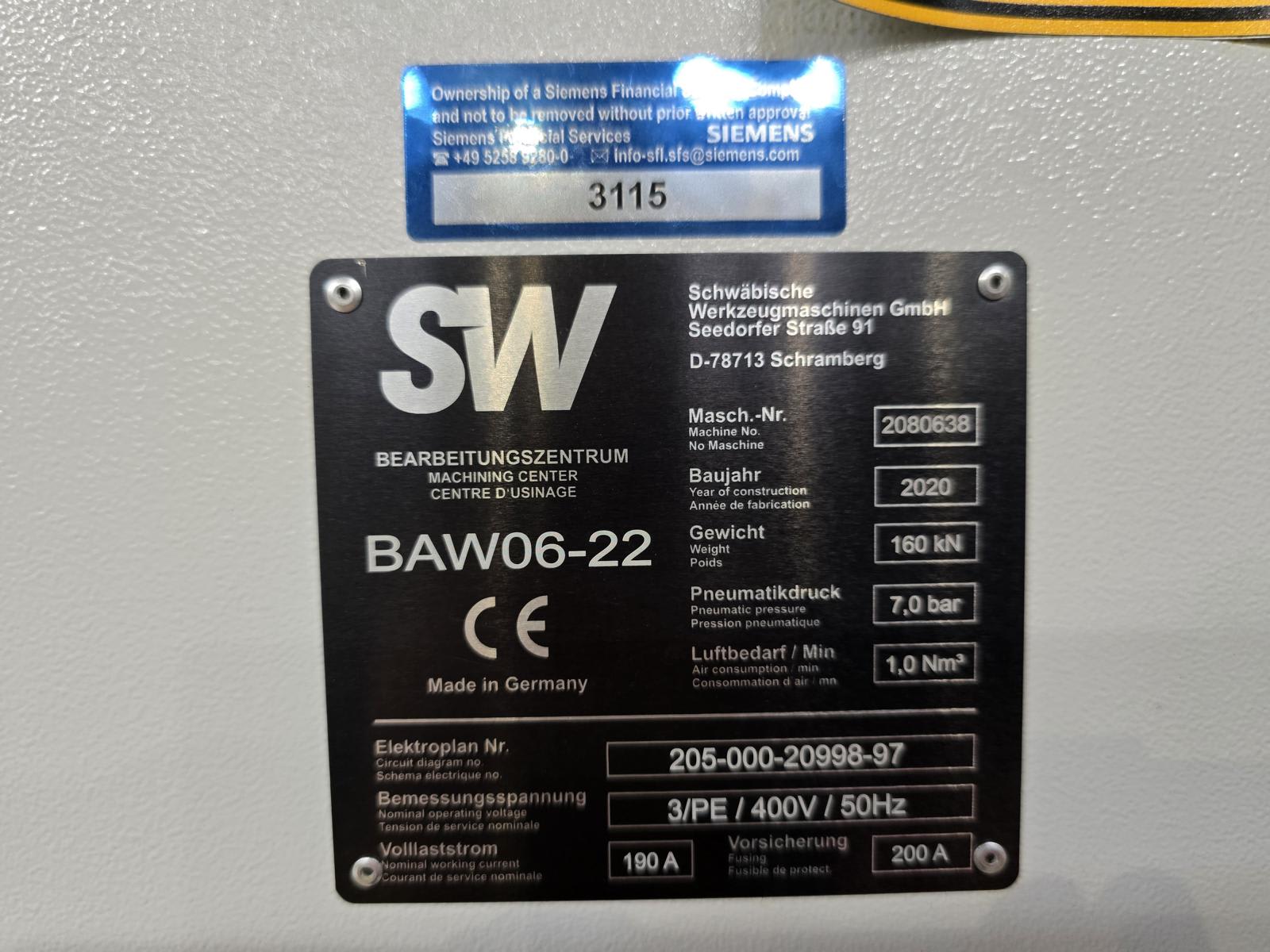

CNC Dual-Spindle Horizontal 4-Axis Machining Center SW BAW06-22 | 2020

Binding Handling & Service Fee:

5950 € (EURO)

CNC Control SIEMENS 840D SL Electrical Connection Connection voltage: 3 × 400 V / 50 Hz (grounded) Network type: TN-S or TN-C network Total connected load: 133 kVA Power factor: 0.6 Fuse protection: 200 A gG (5 s) Weight Machine operating weight: 20,000 kg Transport weight: 16,000 kg Tool magazine Tool change: Pick-up system Tool management: Fixed-coded tool positions Capacity: 84 tools (2 × 42) Maximum total tool weight: 350 kg Feed drives Drive type: Three-phase synchronous motors Line measuring system X/Y/Z: Direct, absolute X-axes (X1 and X2) Rapid traverse: 100 m/min Max. Acceleration: 12 m/s² Kv Factor: 7 Peak Force: 2 × 10,000 N Continuous Force: 2 × 5,000 N Positioning Accuracy: Tp = 0.008 mm Y-Axis Fast Traverse: 100 m/min Max. Acceleration: 10 m/s² Kv Factor: 7 Peak Force: 10,000 N Continuous Force: 5,000 N Positioning Accuracy: Tp = 0.008 mm Z-Axis (Z1 and Z2) Fast Traverse: 100 m/min Max. Acceleration: 20 m/s² Kv Factor: 7 Peak Force: 2 × 5,000 N Continuous Force: 2 × 2,500 N Positioning Accuracy: Tp = 0.008 mm Main Spindles Spindle Arrangement: Horizontal, Twin Spindles side by side Motor Spindles, Liquid-cooled, Synchronous Drive Spindle Diameter: 40 mm Tool Holder: HSK-A63 Lubrication: Minimum Quantity Lubrication (Oil) Mechanical Clamping Force: > 18 kN Wear Limit: 16 kN Speed Range: 1 – 17,500 rpm Acceleration Time: 0.7 s Power: 2 × 35 kW at 4,200 rpm (40% duty cycle) Rated Power: 2 × 26 kW at 4,200 rpm Torque: 2 × 80 Nm (40% duty cycle) / 2 × 60 Nm (Rated Torque) Machining Range Spindle Spacing: 600 mm Travel paths: - X-axis: 600 mm - Y-axis: 600 mm (optional 875 mm) - Z-axis: 500 mm Workpiece clamping / Table system Swivelable fixture with two separate swivel tables for mounting clamping bridges (4-Axis) Swivel time 0–180°: 3.5 s Max. asymmetric load: 800 Nm Rotary table Ø 800 mm, repeatability: < 0.008 mm Max. workpiece weight: 600 kg Peak torque: 981 Nm Rated torque: 698 Nm Max. table speed: 50 min⁻¹ Angular acceleration: 2.5 – 10 rpm Positioning accuracy: ±5″ Tangential torque: 4,500 Nm Max. load torque: 500 Nm Tool change times Chip-to-chip at n < 10,000 min⁻¹: > 2.75 s Chip-to-chip at n < 17,500 min⁻¹: > 3.15 s Operating Data: -> Spindle hours approx. 11,750 -> Operating hours approx. 23,400 Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770005

![Deutsch]()

CNC Dual-Spindle Horizontal 4-Axis Machining Center SW BAW06-22 | 2020

Binding Handling & Service Fee:

5950 € (EURO)

CNC Control SIEMENS 840D SL Electrical Connection Connection voltage: 3 × 400 V / 50 Hz (grounded) Network type: TN-S or TN-C network Total connected load: 133 kVA Power factor: 0.6 Fuse protection: 200 A gG (5 s) Weight Machine operating weight: 20,000 kg Transport weight: 16,000 kg Tool magazine Tool change: Pick-up system Tool management: Fixed-coded tool positions Capacity: 84 tools (2 × 42) Maximum total tool weight: 350 kg Feed drives Drive type: Three-phase synchronous motors Line measuring system X/Y/Z: Direct, absolute X-axes (X1 and X2) Rapid traverse: 100 m/min Max. Acceleration: 12 m/s² Kv Factor: 7 Peak Force: 2 × 10,000 N Continuous Force: 2 × 5,000 N Positioning Accuracy: Tp = 0.008 mm Y-Axis Fast Traverse: 100 m/min Max. Acceleration: 10 m/s² Kv Factor: 7 Peak Force: 10,000 N Continuous Force: 5,000 N Positioning Accuracy: Tp = 0.008 mm Z-Axis (Z1 and Z2) Fast Traverse: 100 m/min Max. Acceleration: 20 m/s² Kv Factor: 7 Peak Force: 2 × 5,000 N Continuous Force: 2 × 2,500 N Positioning Accuracy: Tp = 0.008 mm Main Spindles Spindle Arrangement: Horizontal, Twin Spindles side by side Motor Spindles, Liquid-cooled, Synchronous Drive Spindle Diameter: 40 mm Tool Holder: HSK-A63 Lubrication: Minimum Quantity Lubrication (Oil) Mechanical Clamping Force: > 18 kN Wear Limit: 16 kN Speed Range: 1 – 17,500 rpm Acceleration Time: 0.7 s Power: 2 × 35 kW at 4,200 rpm (40% duty cycle) Rated Power: 2 × 26 kW at 4,200 rpm Torque: 2 × 80 Nm (40% duty cycle) / 2 × 60 Nm (Rated Torque) Machining Range Spindle Spacing: 600 mm Travel paths: - X-axis: 600 mm - Y-axis: 600 mm (optional 875 mm) - Z-axis: 500 mm Workpiece clamping / Table system Swivelable fixture with two separate swivel tables for mounting clamping bridges (4-Axis) Swivel time 0–180°: 3.5 s Max. asymmetric load: 800 Nm Rotary table Ø 800 mm, repeatability: < 0.008 mm Max. workpiece weight: 600 kg Peak torque: 981 Nm Rated torque: 698 Nm Max. table speed: 50 min⁻¹ Angular acceleration: 2.5 – 10 rpm Positioning accuracy: ±5″ Tangential torque: 4,500 Nm Max. load torque: 500 Nm Tool change times Chip-to-chip at n < 10,000 min⁻¹: > 2.75 s Chip-to-chip at n < 17,500 min⁻¹: > 3.15 s Operating Data: -> Spindle hours approx. 11,388 -> Operating hours approx. 21,402 Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770007

![Deutsch]()

CNC Dual-Spindle Horizontal 4/5-Axis Machining Center SW BAW06-22 | 2015

Binding Handling & Service Fee:

5950 € (EURO)

CNC Control SIEMENS 840D Electrical Connection Connection voltage: 3 × 400 V / 50 Hz (grounded) Network type: TN-S or TN-C network Total connected load: 133 kVA Power factor: 0.6 Fuse protection: 190 A gG (5 s) Weight Machine operating weight: 20,000 kg Transport weight: 16,000 kg Tool magazine Tool change: Pick-up system Tool management: Fixed-coded tool positions Capacity: 84 tools (2 × 42) Maximum total tool weight: 350 kg Feed drives Drive type: Three-phase synchronous motors Line measuring system X/Y/Z: Direct, absolute X-axis Rapid traverse: 100 m/min Max. acceleration: 12 m/s² Kv factor: 7 Peak force: 10,000 N Continuous force: 5,000 N Positioning accuracy: Tp = 0.008 mm Y-axis Rapid traverse: 100 m/min Max. acceleration: 10 m/s² Kv factor: 7 Peak force: 10,000 N Continuous force: 5,000 N Positioning accuracy: Tp = 0.008 mm Z-axes (Z1, Z2) Rapid traverse: 100 m/min Max. acceleration: 20 m/s² Kv factor: 7 Peak force: 2 × 5,000 N Continuous force: 2 × 2,500 N Positioning accuracy: Tp = 0.008 mm Main Spindles Spindle Arrangement: Horizontal, Twin Spindles side by side Motor Spindles, Liquid-cooled, Synchronous Technology Spindle Diameter: 40 mm Tool Holder: HSK-A63 Lubrication: Minimum Quantity Lubrication (Oil) Mechanical Clamping Force: > 18 kN Wear Limit: 16 kN Speed Range: 1 – 17,500 rpm Acceleration Time: 0.7 s Power: 2 × 35 kW at 4,200 rpm (40% duty cycle) Rated Power: 2 × 26 kW at 4,200 rpm Torque: 2 × 80 Nm (40% duty cycle) / 2 × 60 Nm (Rated Torque) Machining Range Spindle Spacing: 600 mm Travels: X-axis: 600 mm Y-axis: 600 mm (optional 875 mm) Z-axis: 500 mm Workpiece clamping / Table system OP1: Swivel support with two separate swivel tables for clamping bridges OP2: Double swivel carriage (Q-axis) with two direct-drive NC rotary tables (A-/U-axes) Double-sided gearing on the swivel carriage Swivel time 0–180°: 3.5 s Max. asymmetric load: 800 Nm Repeatability Ø 800 mm: < 0.008 mm Max. clamping device and workpiece diameter: Ø 675 mm × 1,430 mm Max. workpiece weight: 600 kg Peak torque: 981 Nm Rated torque: 698 Nm Max. table speed: 50 min⁻¹ Angular acceleration: 2.5 – 10 rpm/s² Partial accuracy: ±5″ Tangential torque: 4,500 Nm Max. load torque: 500 Nm Tool change times Chip-to-chip at n < 10,000 min⁻¹: > 2.75 s Chip-to-chip at n < 17,500 min⁻¹: > 3.15 s Operating Data: -> Spindle hours approx. 18,267 -> Operating hours approx. 44,240 Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770008

![Deutsch]()

CNC Dual-Spindle Horizontal 4/5-Axis Machining Center SW BAW06-22 | 2014

Binding Handling & Service Fee:

5950 € (EURO)

CNC Control SIEMENS 840D Electrical Connection Connection voltage: 3 × 400 V / 50 Hz (grounded) Network type: TN-S or TN-C network Total connected load: 133 kVA Power factor: 0.6 Fuse protection: 190 A gG (5 s) Weight Machine operating weight: 20,000 kg Transport weight: 16,000 kg Tool magazine Tool change: Pick-up system Tool management: Fixed-coded tool positions Capacity: 84 tools (2 × 42) Maximum total tool weight: 350 kg Feed drives Drive type: Three-phase synchronous motors Line measuring system X/Y/Z: Direct, absolute X-axis Rapid traverse: 100 m/min Max. acceleration: 12 m/s² Kv factor: 7 Peak force: 10,000 N Continuous force: 5,000 N Positioning accuracy: Tp = 0.008 mm Y-axis Rapid traverse: 100 m/min Max. acceleration: 10 m/s² Kv factor: 7 Peak force: 10,000 N Continuous force: 5,000 N Positioning accuracy: Tp = 0.008 mm Z-axes (Z1, Z2) Rapid traverse: 100 m/min Max. acceleration: 20 m/s² Kv factor: 7 Peak force: 2 × 5,000 N Continuous force: 2 × 2,500 N Positioning accuracy: Tp = 0.008 mm Main Spindles Spindle Arrangement: Horizontal, Twin Spindles side by side Motor Spindles, Liquid-cooled, Synchronous Technology Spindle Diameter: 40 mm Tool Holder: HSK-A63 Lubrication: Minimum Quantity Lubrication (Oil) Mechanical Clamping Force: > 18 kN Wear Limit: 16 kN Speed Range: 1 – 17,500 rpm Acceleration Time: 0.7 s Power: 2 × 35 kW at 4,200 rpm (40% duty cycle) Rated Power: 2 × 26 kW at 4,200 rpm Torque: 2 × 80 Nm (40% duty cycle) / 2 × 60 Nm (Rated Torque) Machining Range Spindle Spacing: 600 mm Travels: X-axis: 600 mm Y-axis: 600 mm (optional 875 mm) Z-axis: 500 mm Workpiece clamping / Table system OP1: Swivel support with two separate swivel tables for clamping bridges OP2: Double swivel carriage (Q-axis) with two direct-drive NC rotary tables (A-/U-axes) Double-sided gearing on the swivel carriage Swivel time 0–180°: 3.5 s Max. asymmetric load: 800 Nm Repeatability Ø 800 mm: < 0.008 mm Max. clamping device and workpiece diameter: Ø 675 mm × 1,430 mm Max. workpiece weight: 600 kg Peak torque: 981 Nm Rated torque: 698 Nm Max. table speed: 50 min⁻¹ Angular acceleration: 2.5 – 10 rpm/s² Partial accuracy: ±5″ Tangential torque: 4,500 Nm Max. load torque: 500 Nm Tool change times Chip-to-chip at n < 10,000 min⁻¹: > 2.75 s Chip-to-chip at n < 17,500 min⁻¹: > 3.15 s Operating Data: -> Spindle hours approx. 21.000 -> Operating hours approx. 47.000 Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770009

![Deutsch]()

CNC Dual-Spindle Horizontal 4/5-Axis Machining Center SW BAW06-22 | 2014

Binding Handling & Service Fee:

5950 € (EURO)

CNC Control SIEMENS 840D Electrical Connection Connection voltage: 3 × 400 V / 50 Hz (grounded) Network type: TN-S or TN-C network Total connected load: 133 kVA Power factor: 0.6 Fuse protection: 190 A gG (5 s) Weight Machine operating weight: 20,000 kg Transport weight: 16,000 kg Tool magazine Tool change: Pick-up system Tool management: Fixed-coded tool positions Capacity: 84 tools (2 × 42) Maximum total tool weight: 350 kg Feed drives Drive type: Three-phase synchronous motors Line measuring system X/Y/Z: Direct, absolute X-axis Rapid traverse: 100 m/min Max. acceleration: 12 m/s² Kv factor: 7 Peak force: 10,000 N Continuous force: 5,000 N Positioning accuracy: Tp = 0.008 mm Y-axis Rapid traverse: 100 m/min Max. acceleration: 10 m/s² Kv factor: 7 Peak force: 10,000 N Continuous force: 5,000 N Positioning accuracy: Tp = 0.008 mm Z-axes (Z1, Z2) Rapid traverse: 100 m/min Max. acceleration: 20 m/s² Kv factor: 7 Peak force: 2 × 5,000 N Continuous force: 2 × 2,500 N Positioning accuracy: Tp = 0.008 mm Main Spindles Spindle Arrangement: Horizontal, Twin Spindles side by side Motor Spindles, Liquid-cooled, Synchronous Technology Spindle Diameter: 40 mm Tool Holder: HSK-A63 Lubrication: Minimum Quantity Lubrication (Oil) Mechanical Clamping Force: > 18 kN Wear Limit: 16 kN Speed Range: 1 – 17,500 rpm Acceleration Time: 0.7 s Power: 2 × 35 kW at 4,200 rpm (40% duty cycle) Rated Power: 2 × 26 kW at 4,200 rpm Torque: 2 × 80 Nm (40% duty cycle) / 2 × 60 Nm (Rated Torque) Machining Range Spindle Spacing: 600 mm Travels: X-axis: 600 mm Y-axis: 600 mm (optional 875 mm) Z-axis: 500 mm Workpiece clamping / Table system OP1: Swivel support with two separate swivel tables for clamping bridges OP2: Double swivel carriage (Q-axis) with two direct-drive NC rotary tables (A-/U-axes) Double-sided gearing on the swivel carriage Swivel time 0–180°: 3.5 s Max. asymmetric load: 800 Nm Repeatability Ø 800 mm: < 0.008 mm Max. clamping device and workpiece diameter: Ø 675 mm × 1,430 mm Max. workpiece weight: 600 kg Peak torque: 981 Nm Rated torque: 698 Nm Max. table speed: 50 min⁻¹ Angular acceleration: 2.5 – 10 rpm/s² Partial accuracy: ±5″ Tangential torque: 4,500 Nm Max. load torque: 500 Nm Tool change times Chip-to-chip at n < 10,000 min⁻¹: > 2.75 s Chip-to-chip at n < 17,500 min⁻¹: > 3.15 s Operating Data: -> Spindle hours approx. 22.000 -> Operating hours approx. 48.000 Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770010

![Deutsch]()

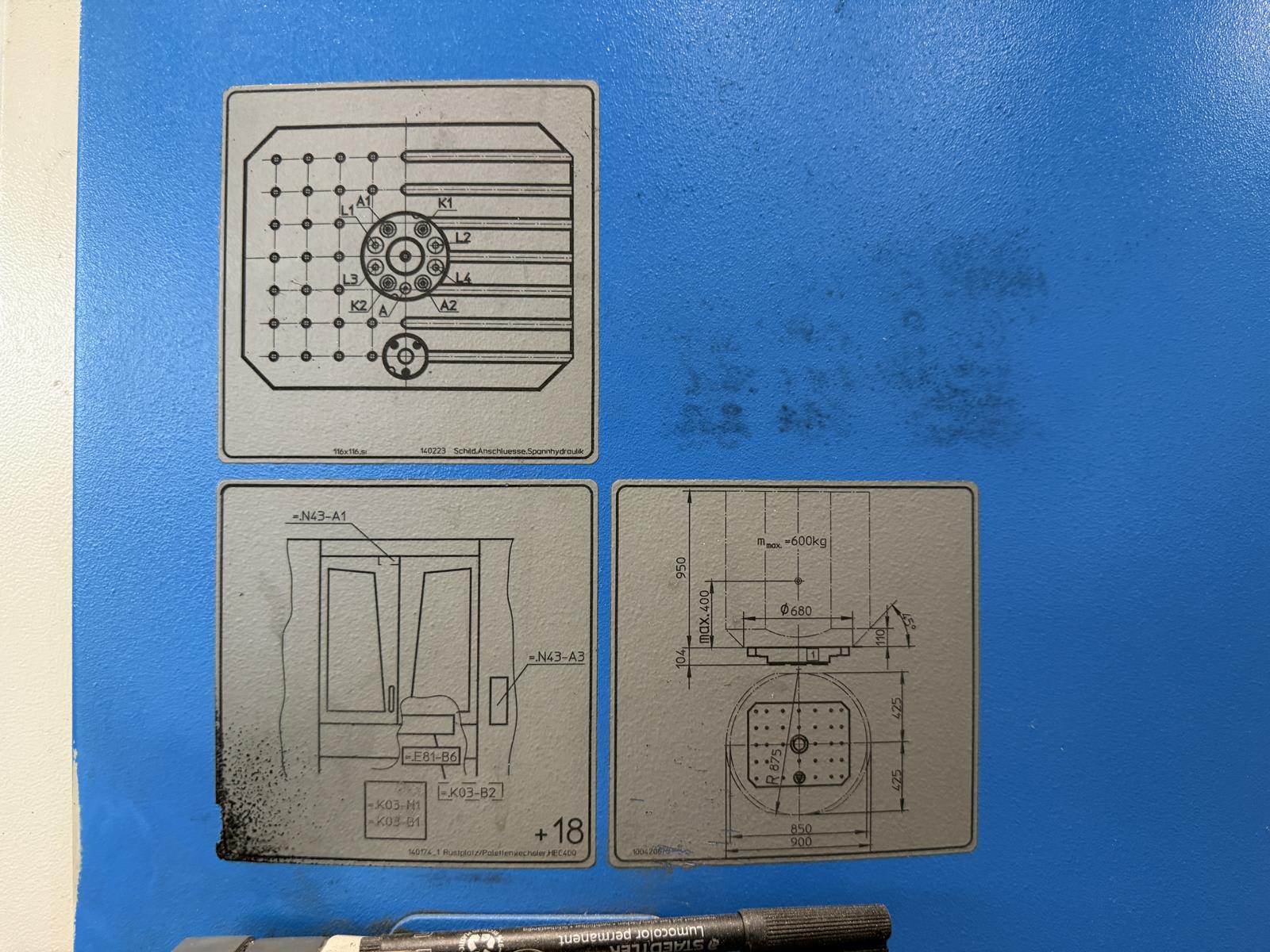

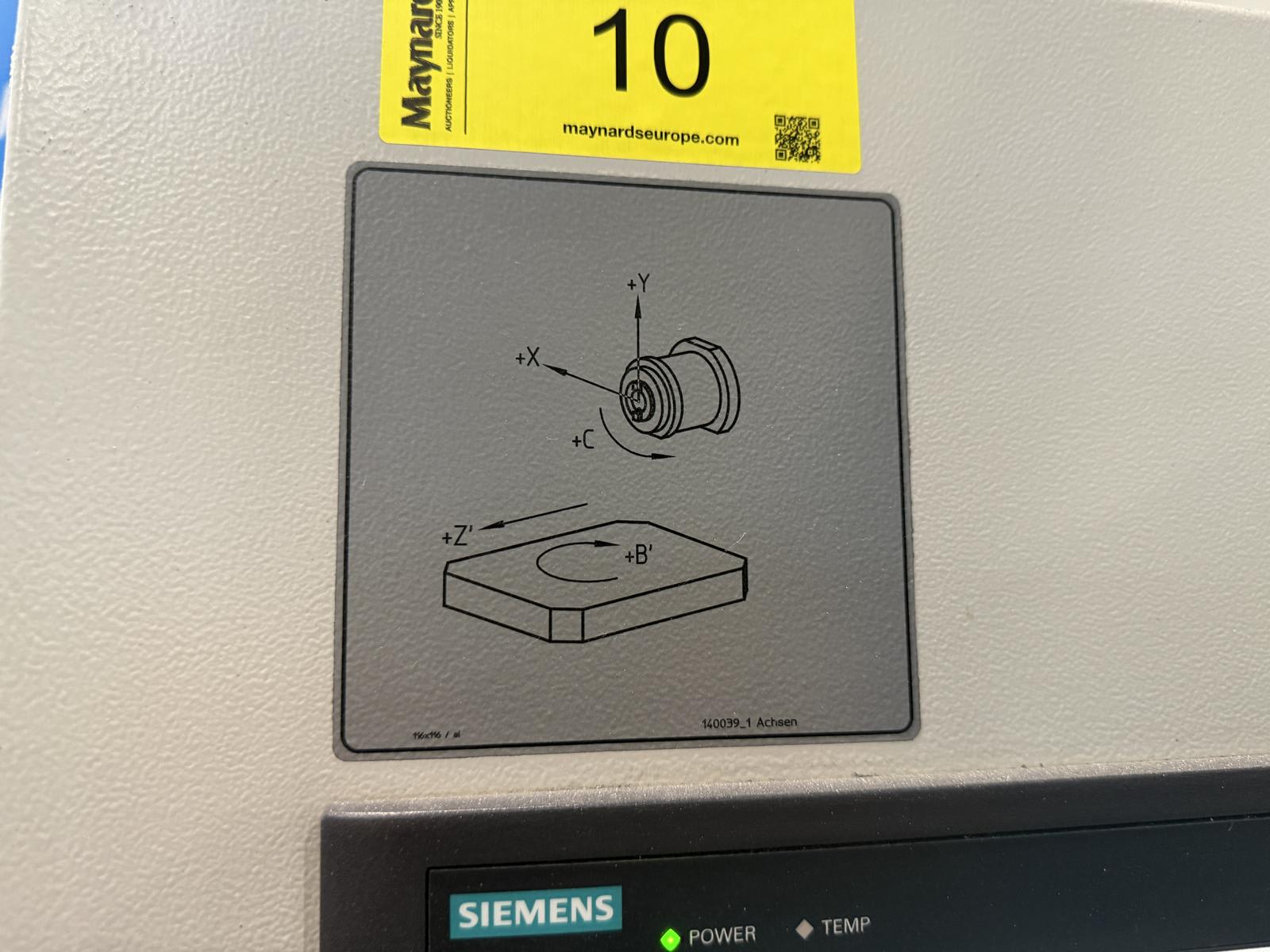

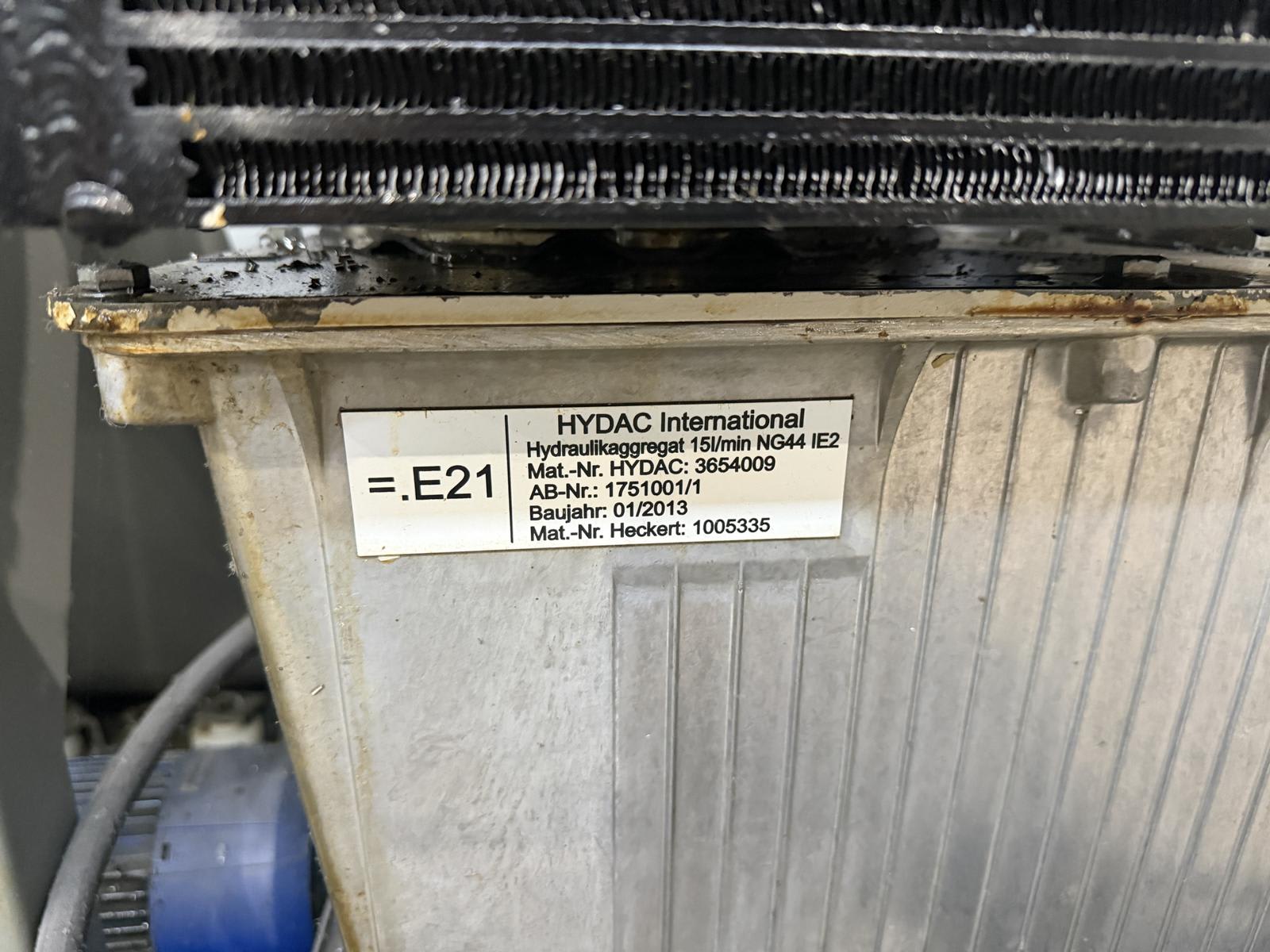

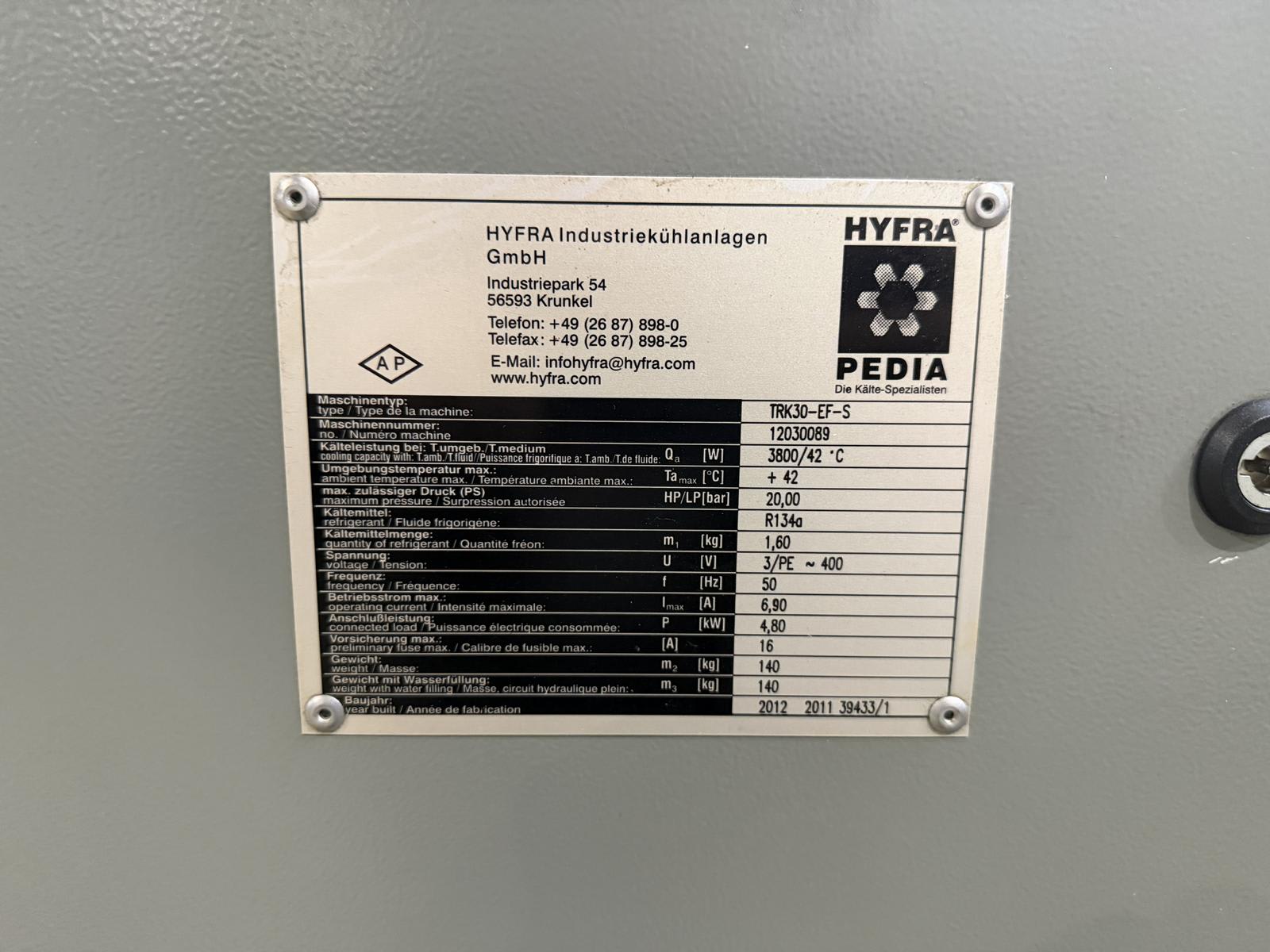

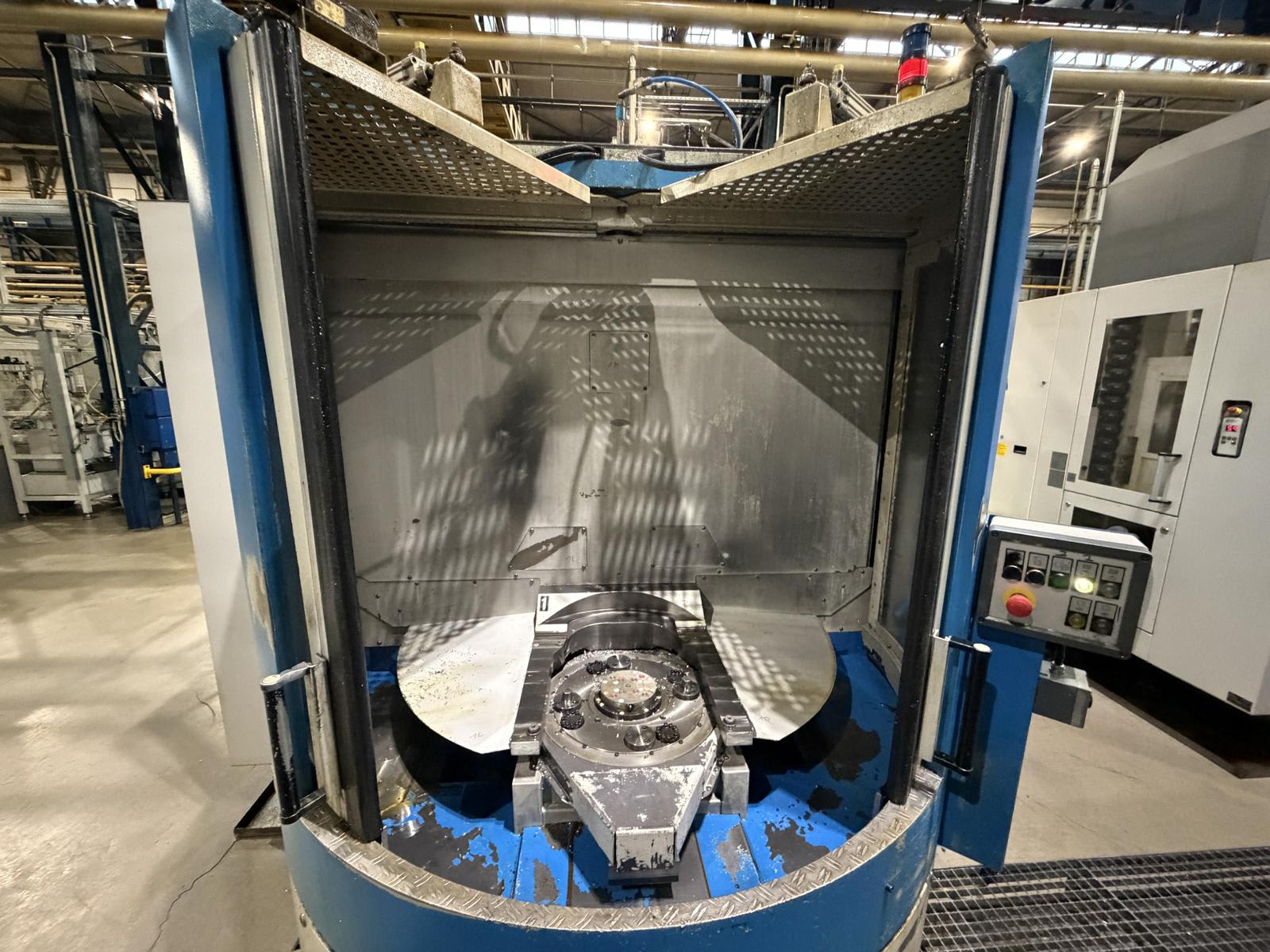

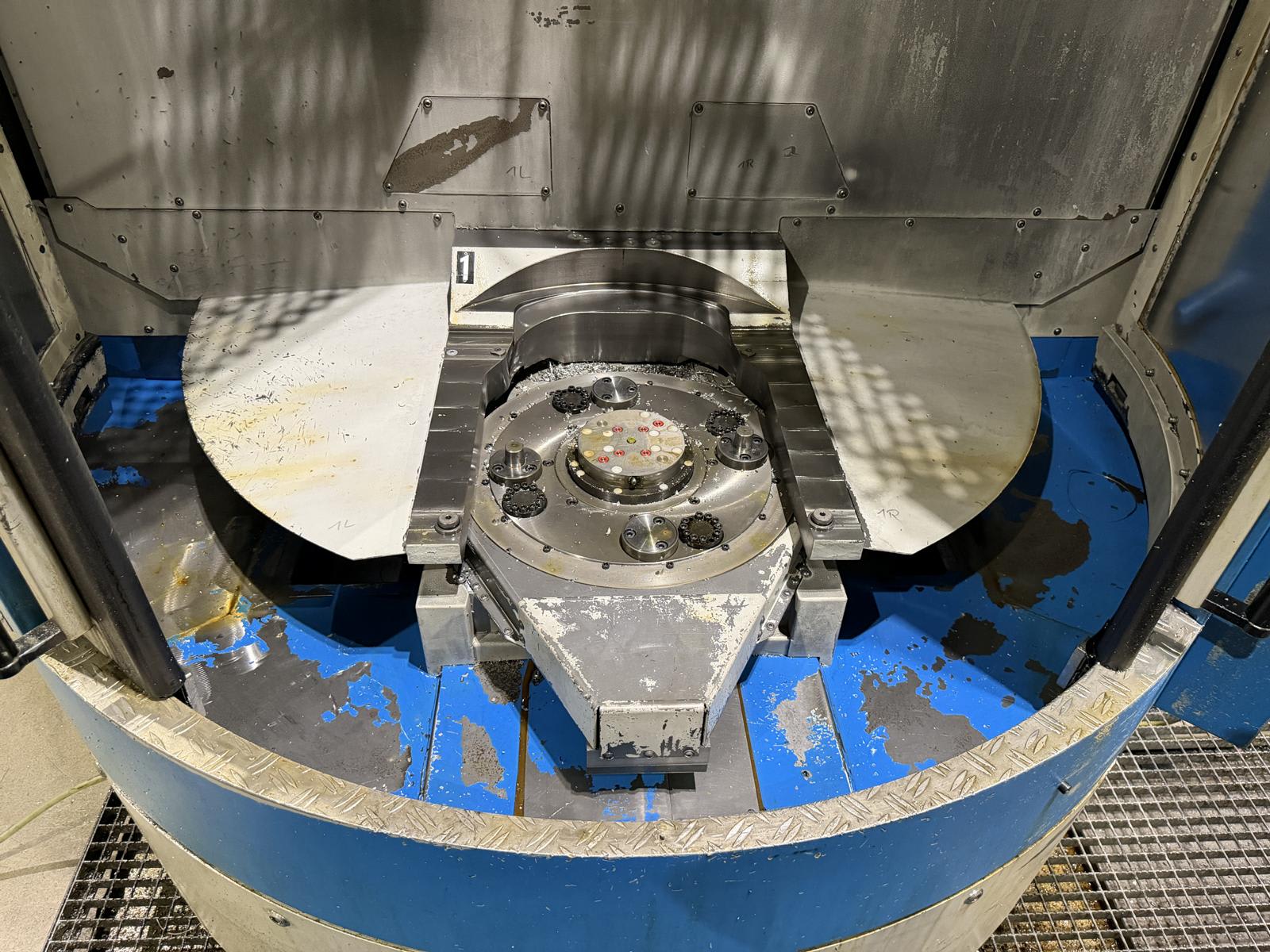

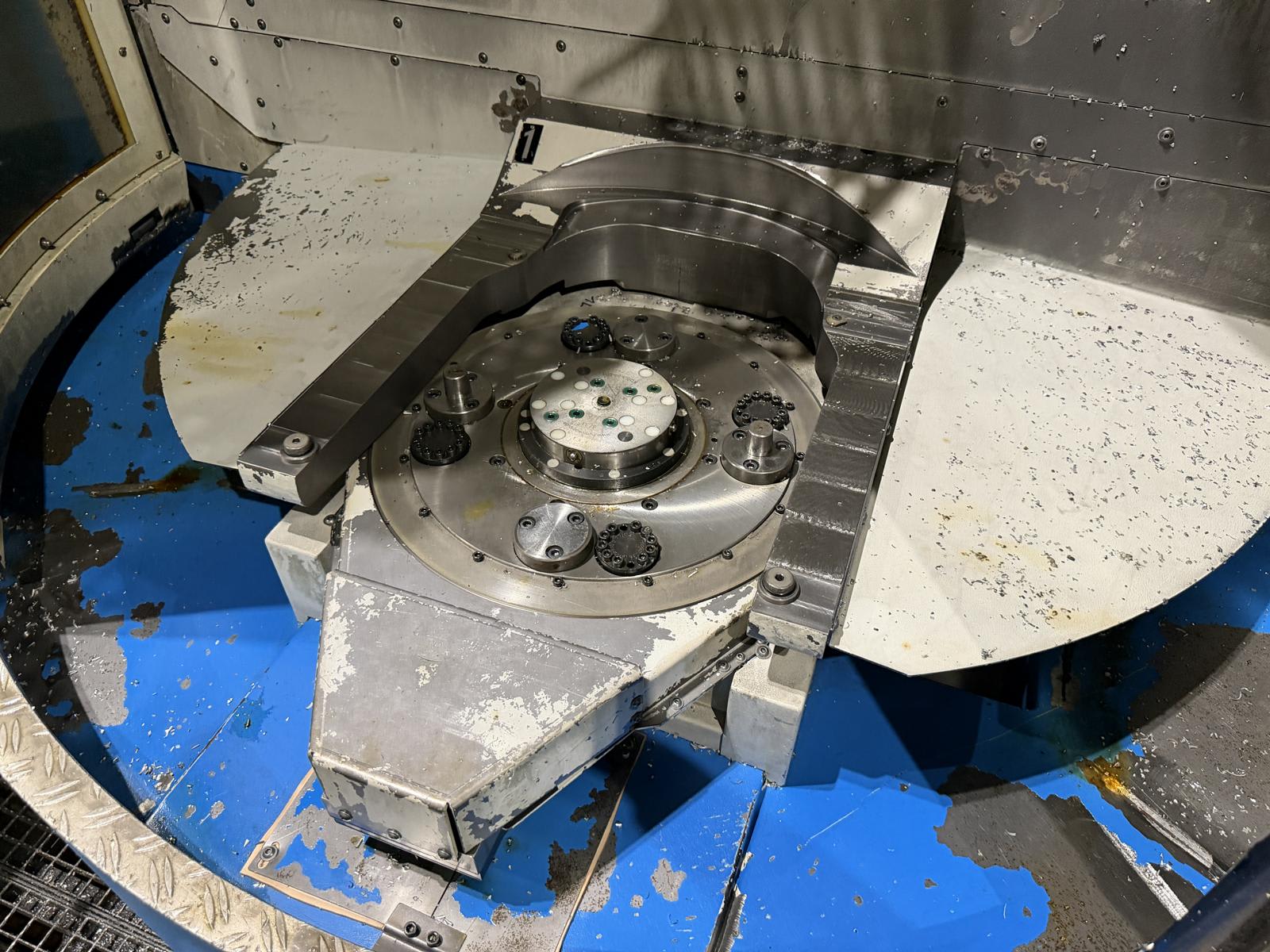

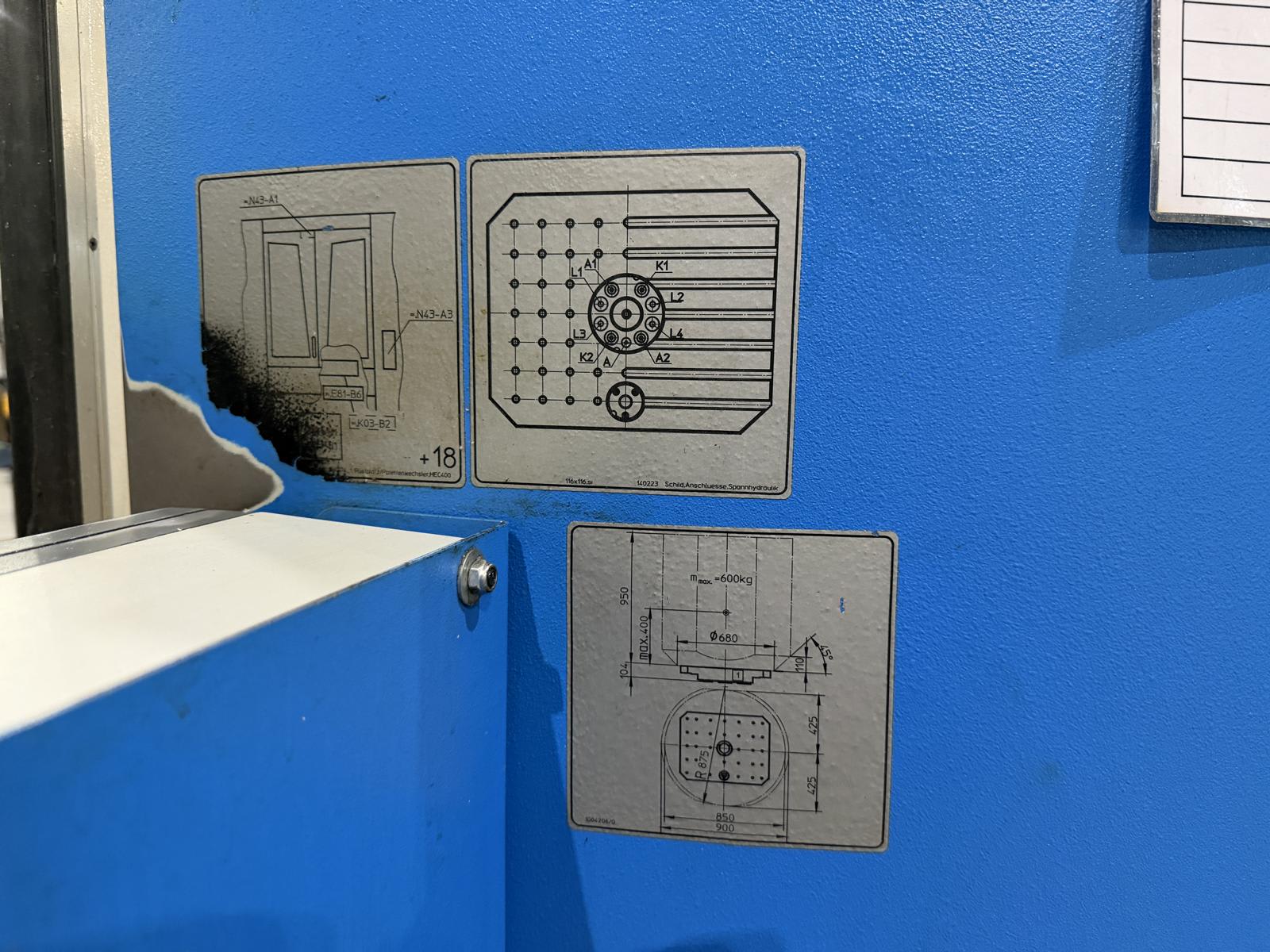

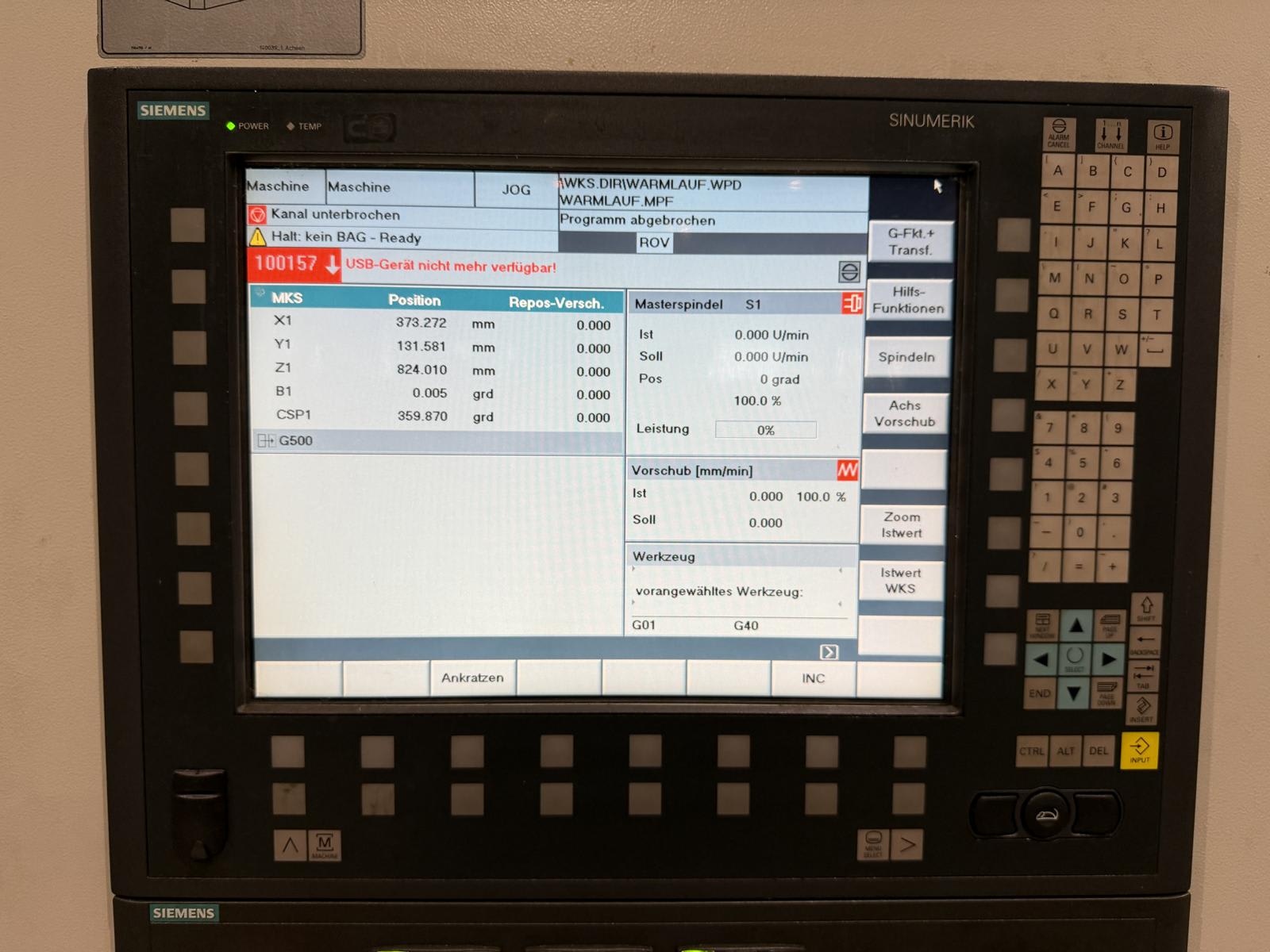

CNC 4-Axis Horizontal Machining Center Starrag Heckert HEC 500D | 2013

Binding Handling & Service Fee:

5390 € (EURO)

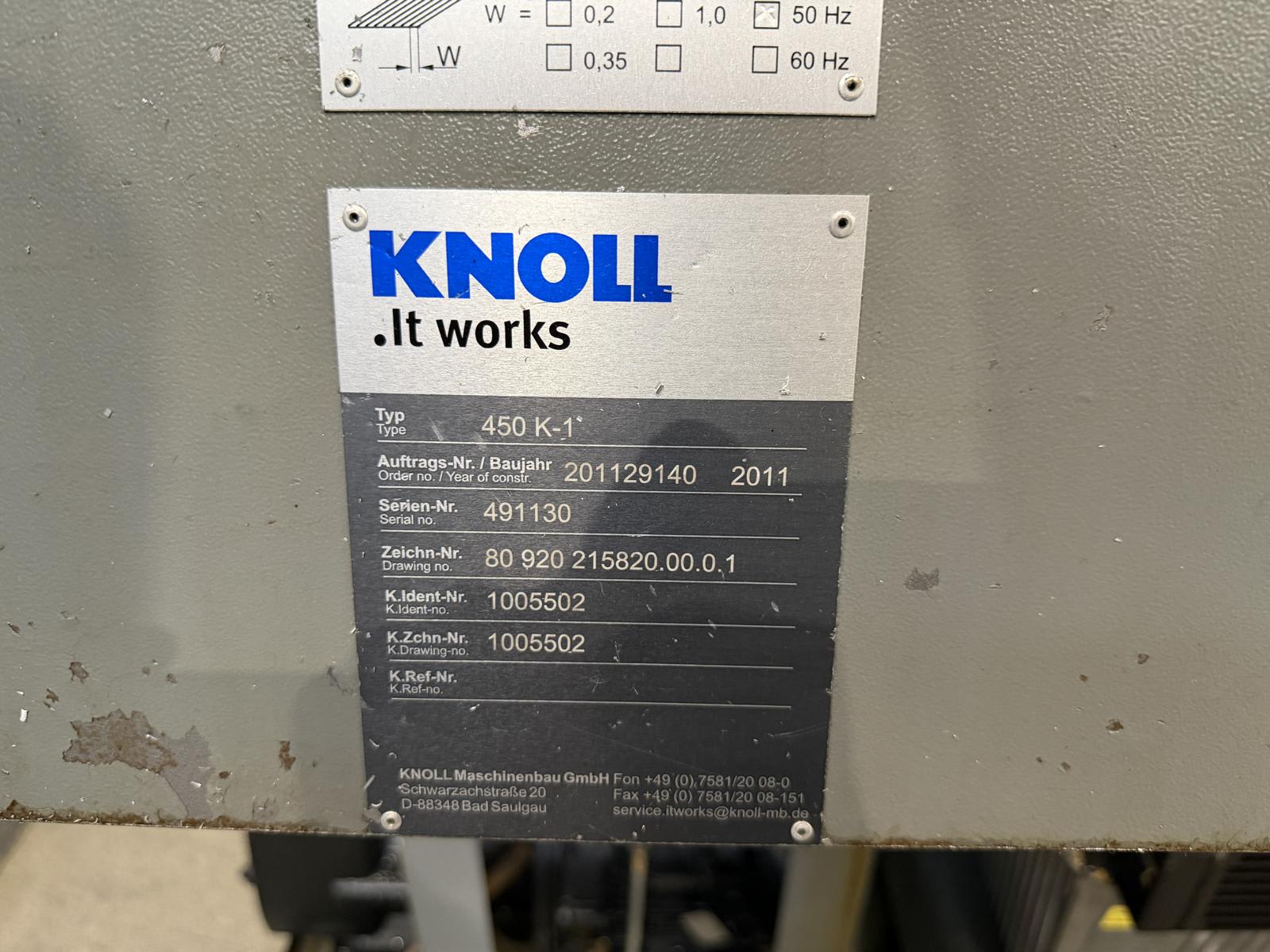

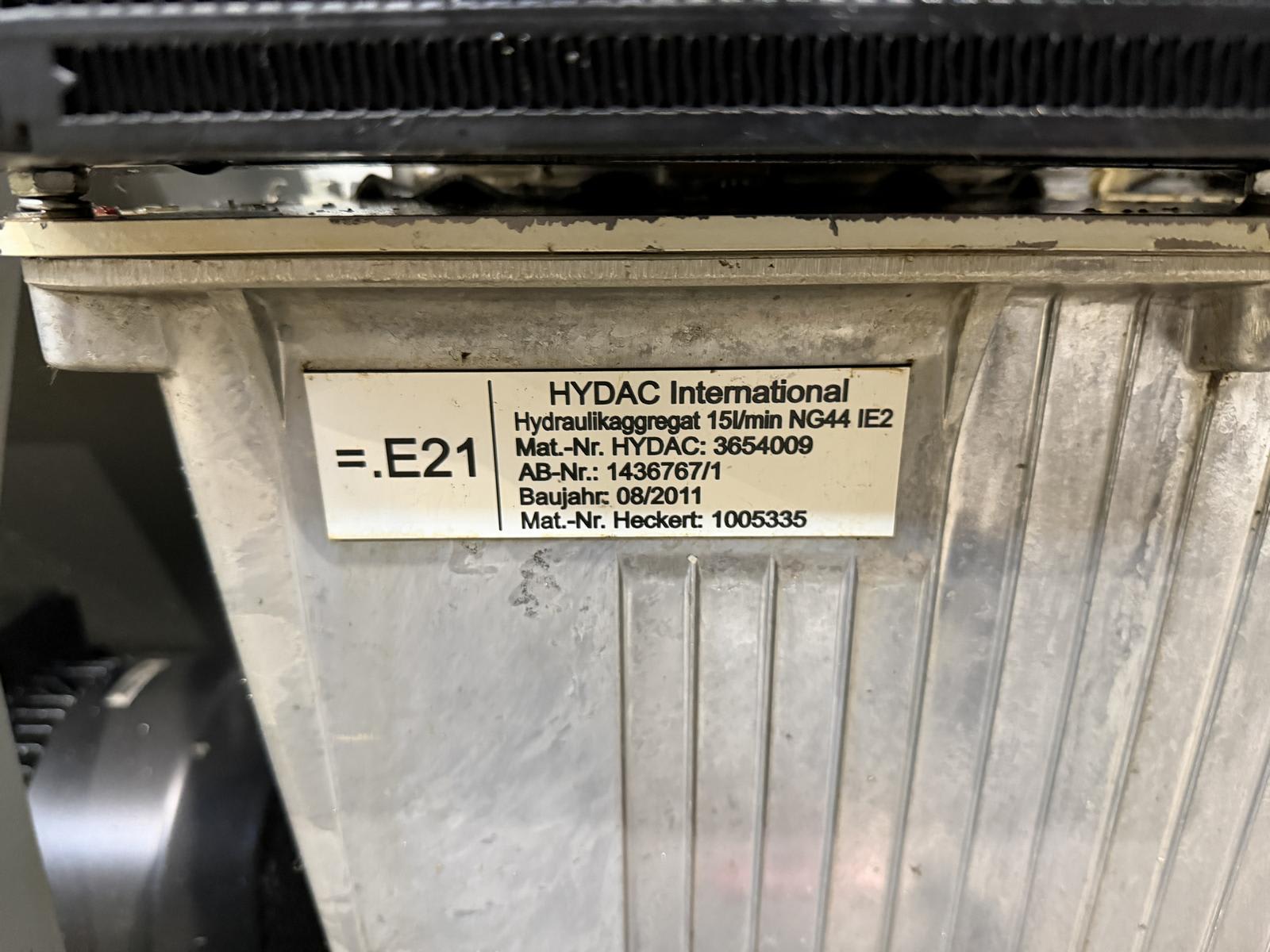

Pallet Changer: -> included Spindle: -> Tool holder HSK63 -> Speed 20,000 rpm Linear Axes: -> X-axis 750 mm -> Y-axis 750 mm -> Z-axis 725 mm Tool Changer: -> 60 stations This Machine comes with a Coolant Filtration System with Chiller • Manufacturer: KNOLL Maschinenbau GmbH / HYFRA Industriekühlanlagen GmbH • Type: PF 210 (Knoll) + TRK30-EF-S (Hyfra Pedia) • Year of Manufacture: 2012 • Serial Numbers: - KNOLL: 501973 / 201139433 - HYFRA: 12030089 • Electrical Connection: 3×400 V / 50 Hz • Control Voltage: 24 V DC • Power Consumption: 11.1 kW (Knoll) + 4.8 kW (Hyfra) • Fuse Protection: 16 / 25 A (Knoll), 16 A (Hyfra) • Cooling Capacity (Chiller): 3.8 kW at 42 °C • Refrigerant: R134a, 1.6 kg • Max. Pressure: 20 bar • Weight (with coolant): 140 kg Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) Spindle Hours approx. 9.300 Working Hours approx. 45.500 - LISTING 2770011

![Deutsch]()

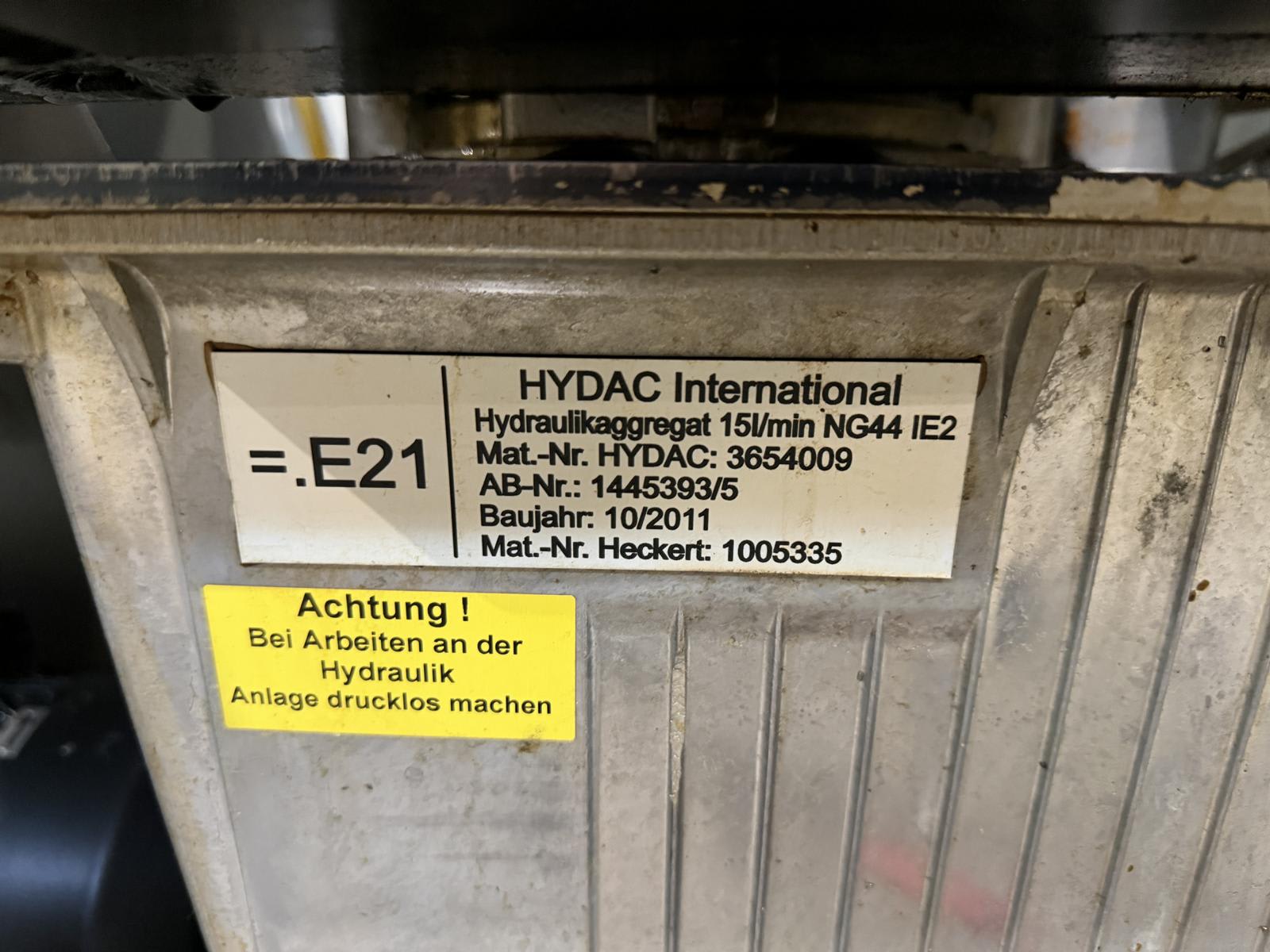

CNC 4-Axis Horizontal Machining Center Starrag Heckert HEC 500D | 2011

Binding Handling & Service Fee:

5090 € (EURO)

Pallet Changer: -> included Spindle: -> Tool holder HSK63 -> Speed 20,000 rpm Linear Axes: -> X-axis 750 mm -> Y-axis 750 mm -> Z-axis 725 mm Tool Changer: -> 60 stations This Machine used one single Cooling Unit with another Machine (Lot 2770012). This Machine does NOT include a Cooling Unit. Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) Spindle Hours approx. 26.000 Working Hours approx. 50.500 - LISTING 2770012

![Deutsch]()

CNC 4-Axis Horizontal Machining Center Starrag Heckert HEC 500D | 2012

Binding Handling & Service Fee:

5090 € (EURO)

Pallet Changer: -> included Spindle: -> Tool holder HSK63 -> Speed 20,000 rpm Linear Axes: -> X-axis 750 mm -> Y-axis 750 mm -> Z-axis 725 mm Tool Changer: -> 60 stations This Machine used one single Cooling Unit with another Machine (Lot 2770012). The Cooling Unit (Lot 2770249) is offered separately.This Machine does NOT include a Cooling Unit. Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) Spindle Hours approx. 25.600 Working Hours approx. 44.900 - LISTING 2770014

![Deutsch]()

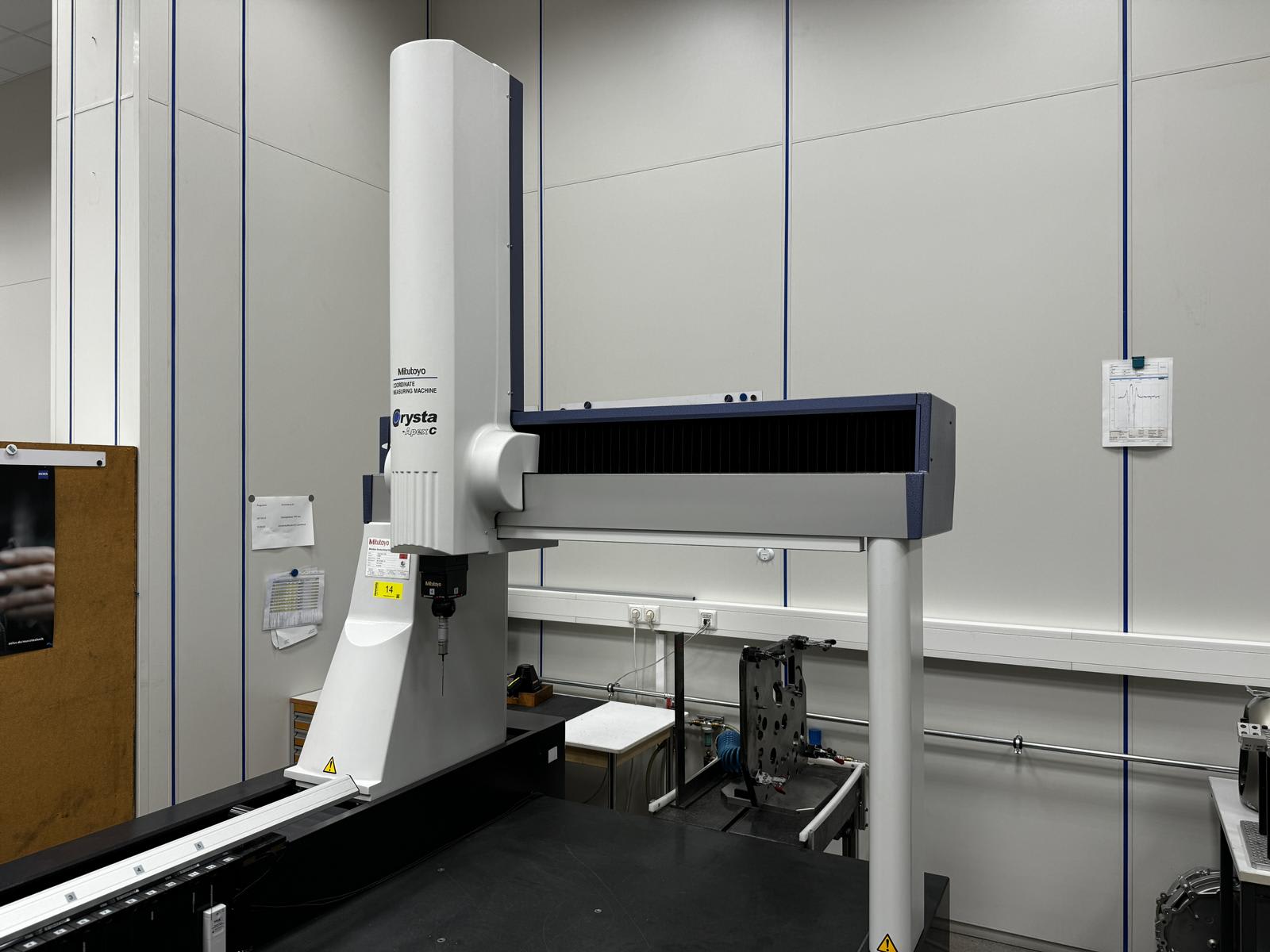

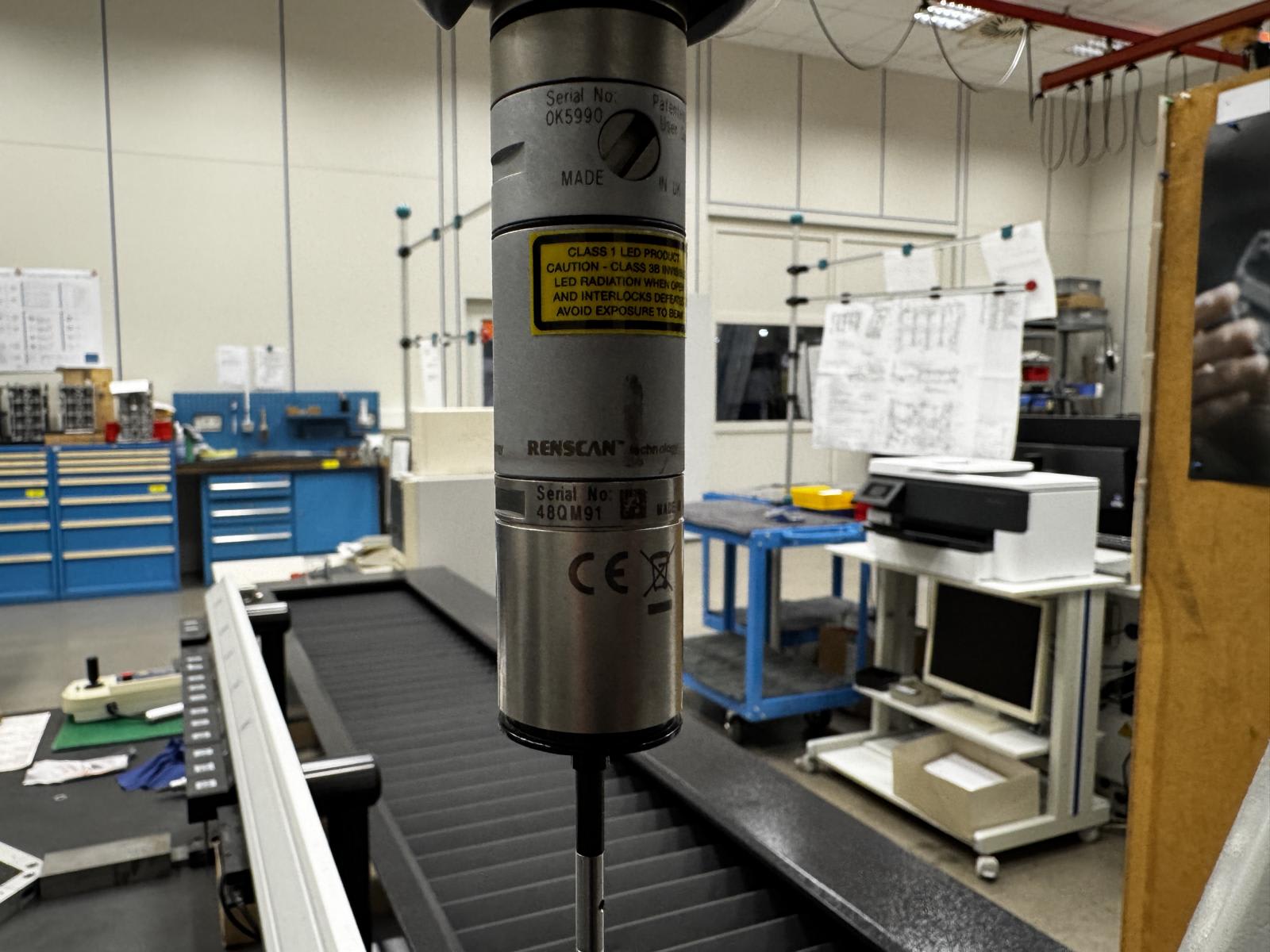

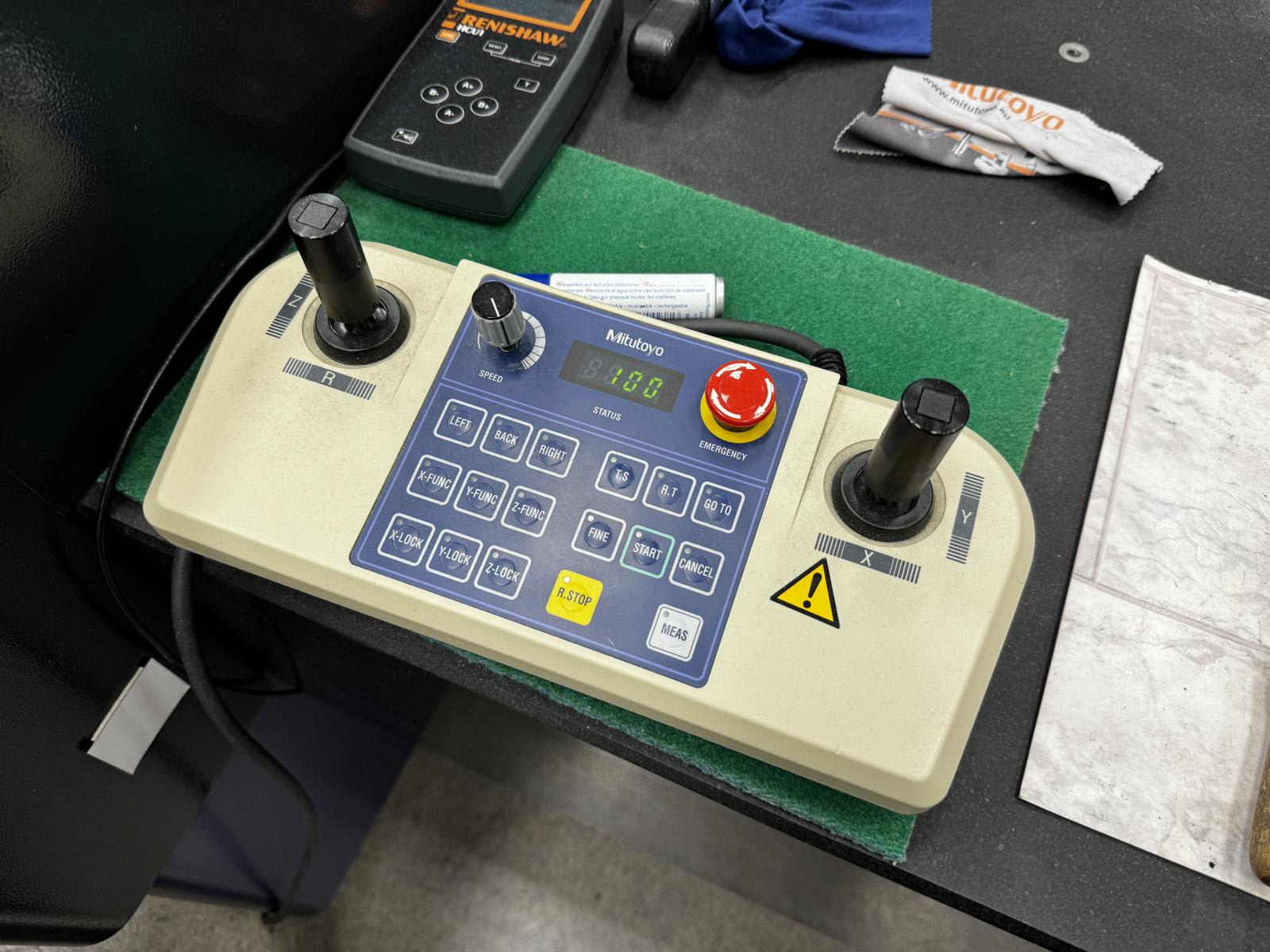

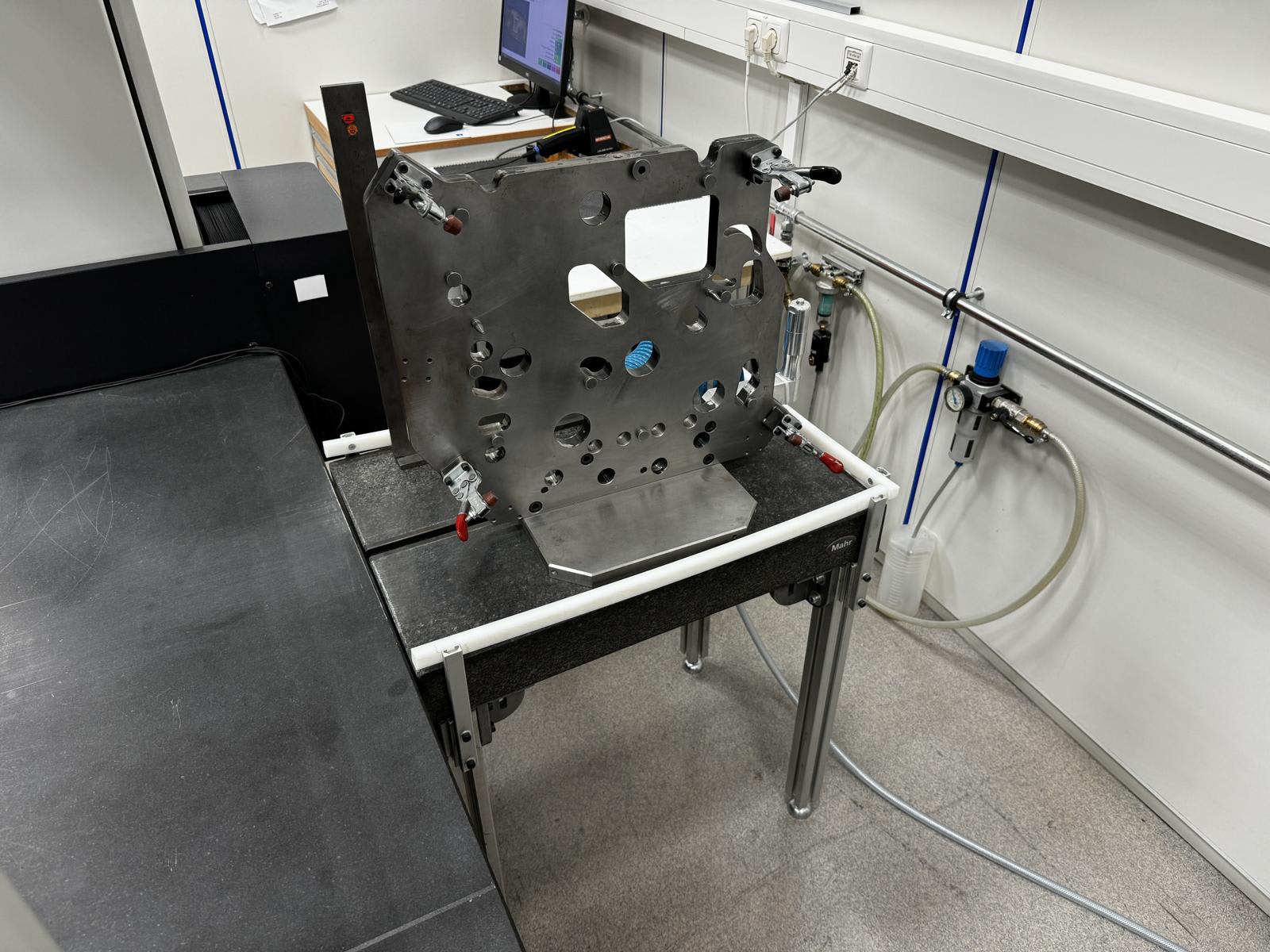

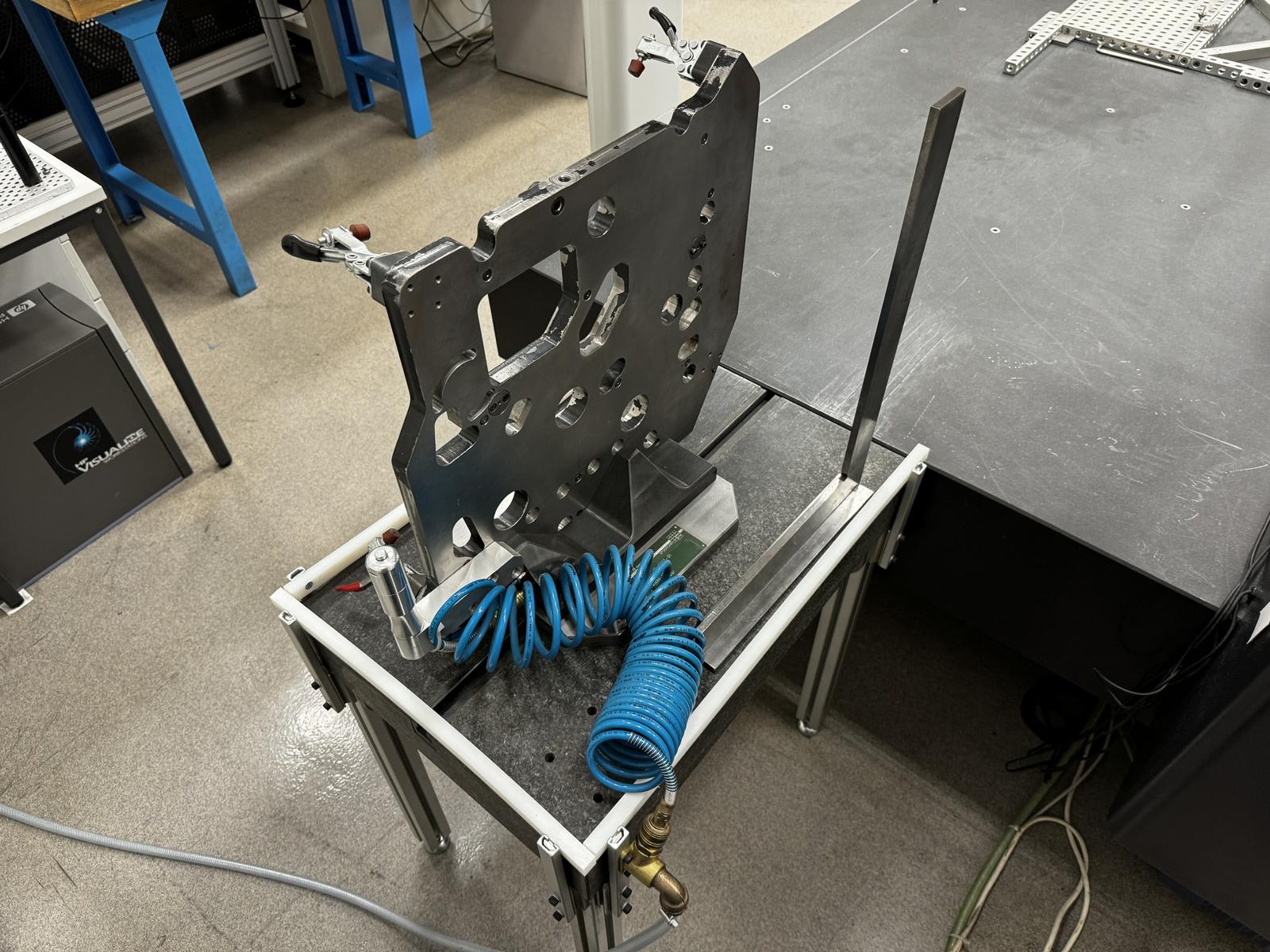

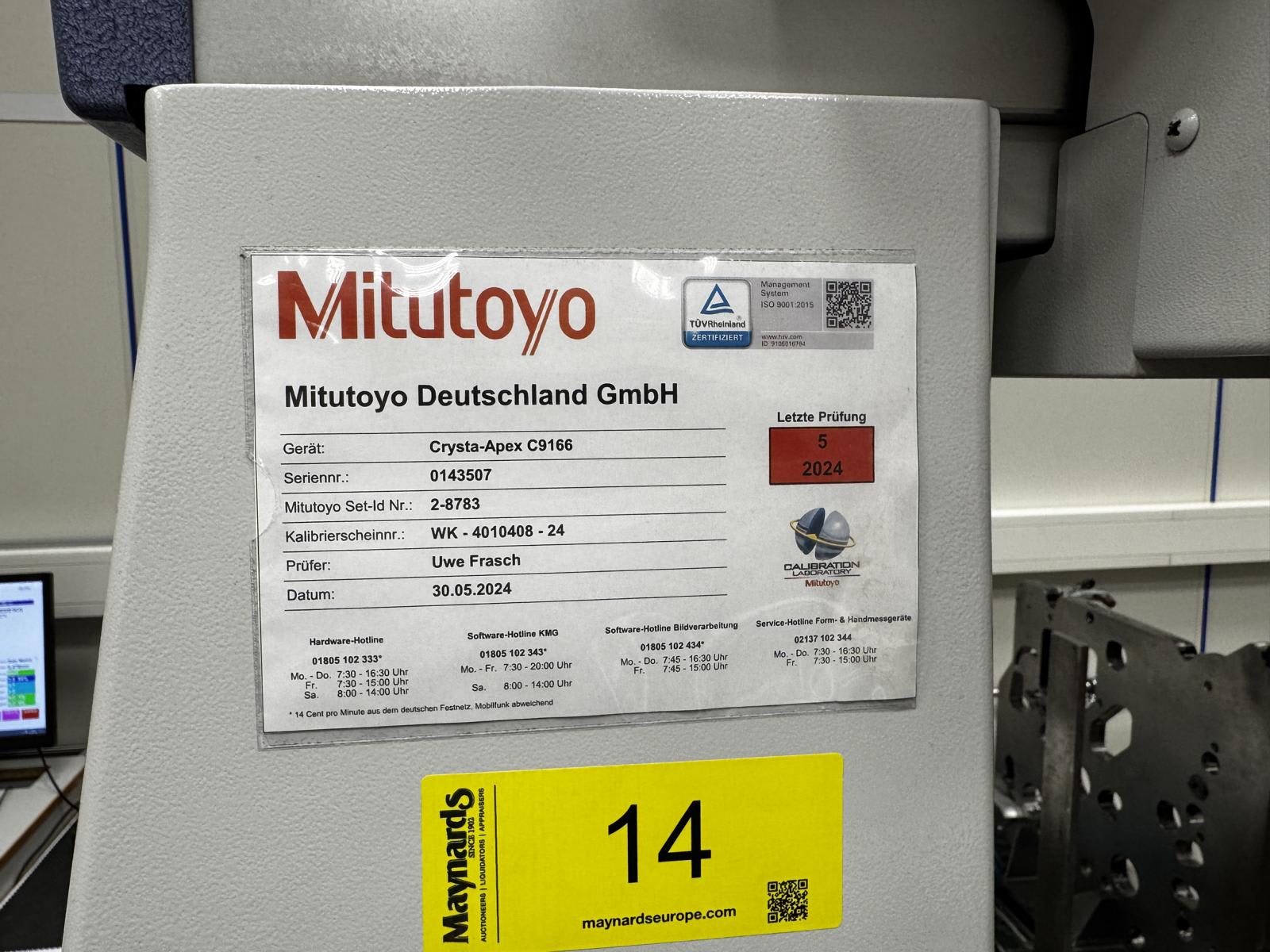

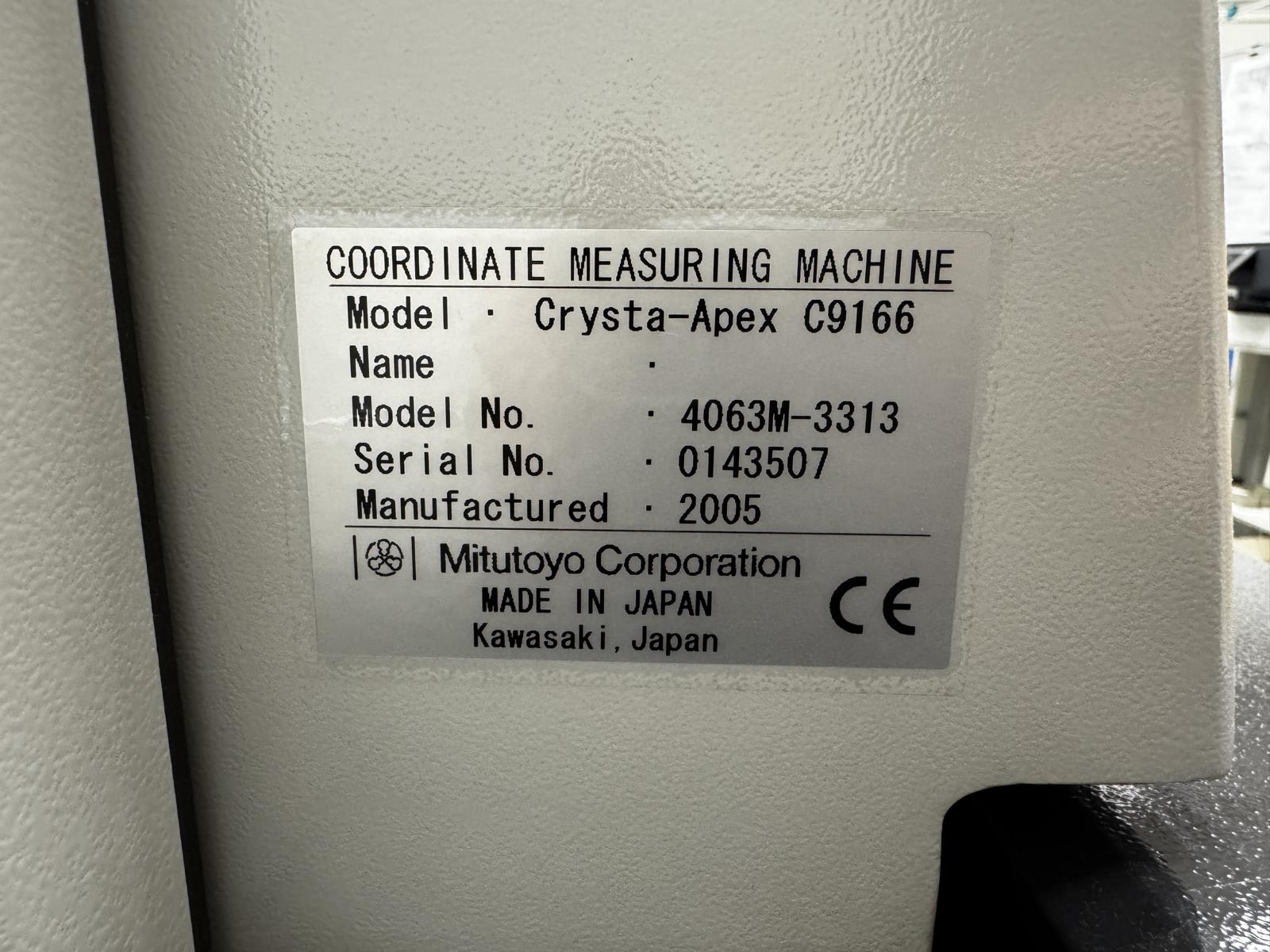

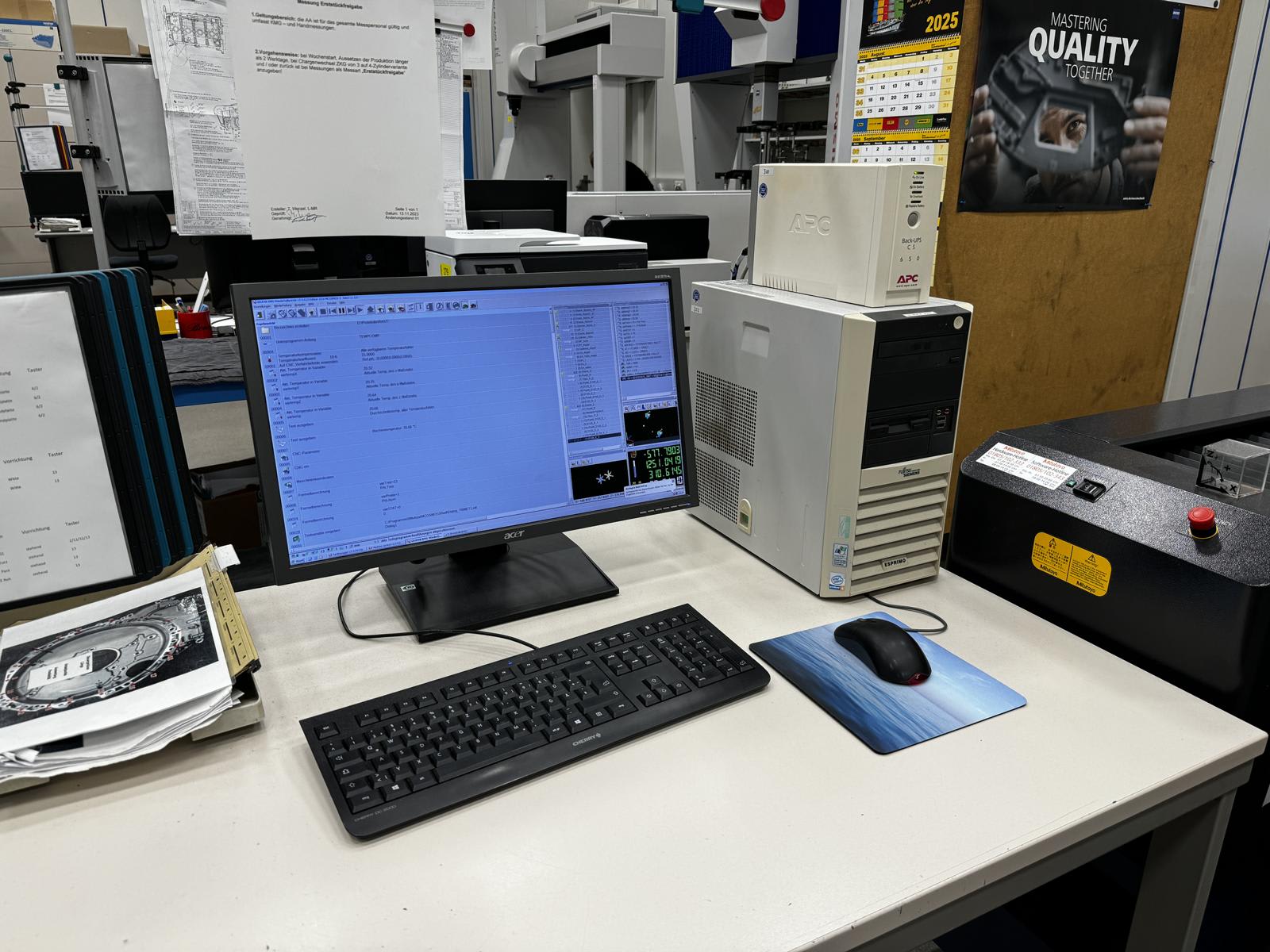

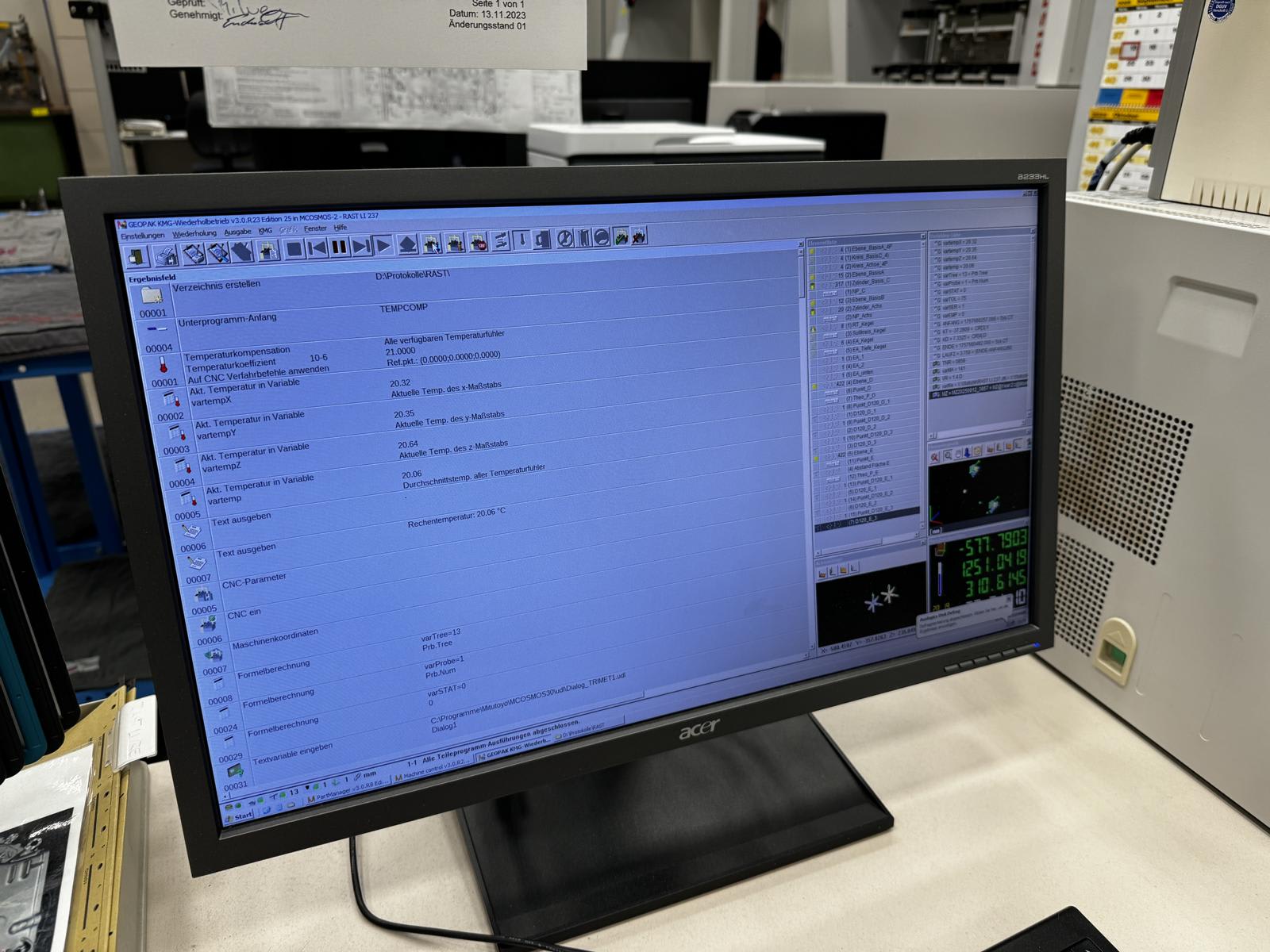

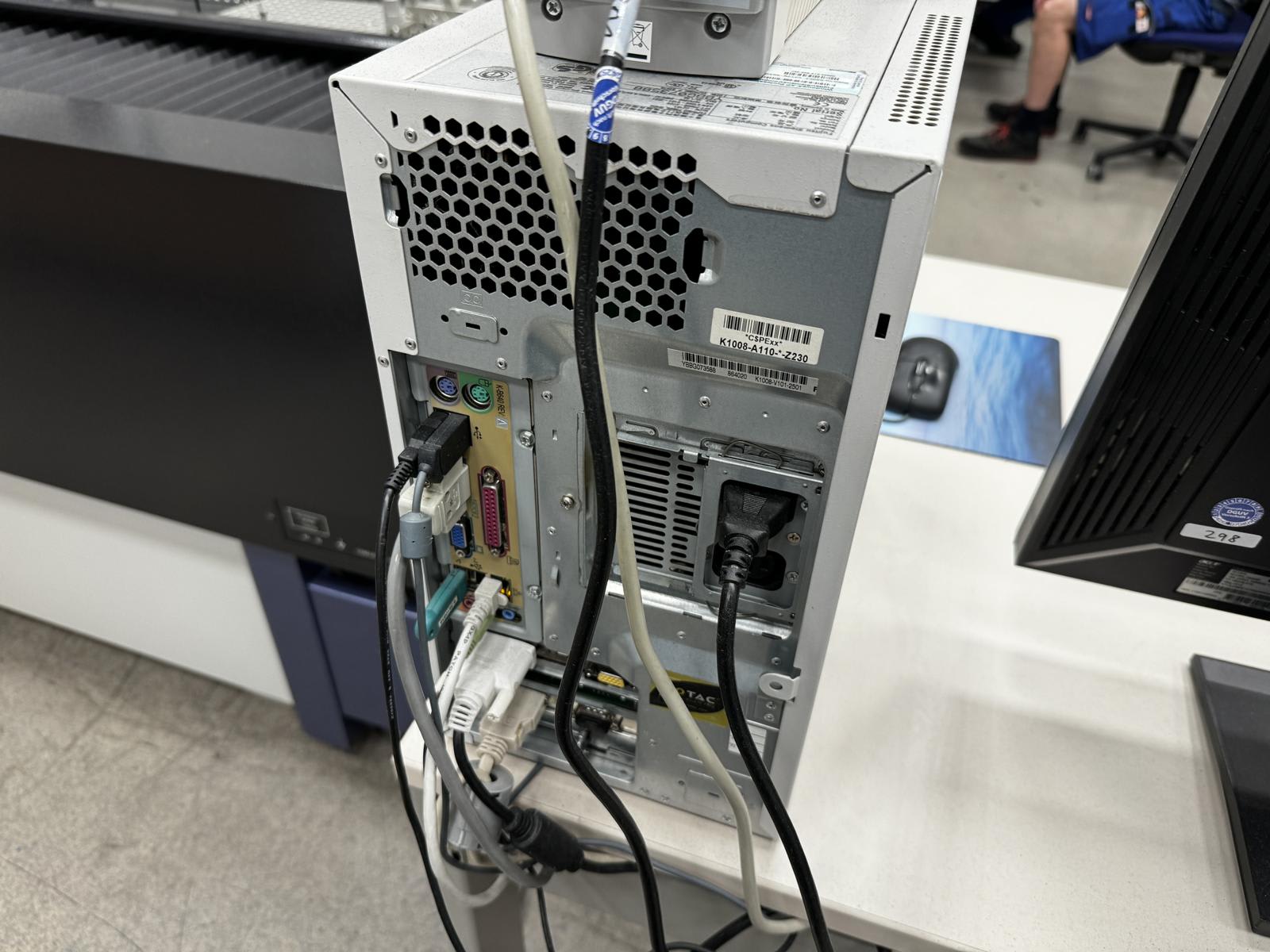

Coordinate Measuring Machine (3-axis) Mitutoyo Crysta-Apex C9166 | 2005

Binding Handling & Service Fee:

4200 € (EURO)

with PC, Software & Dongle to include various Measuring Probes Important: The Handling/Dismantling Service includes the professional Transport Locking with Original parts from Mitutoyo by Mitutoyo Technicans, the securing of sensitive Parts e. g. with Bubble Foil and the Loading onto Truck - LISTING 2770015

![Deutsch]()

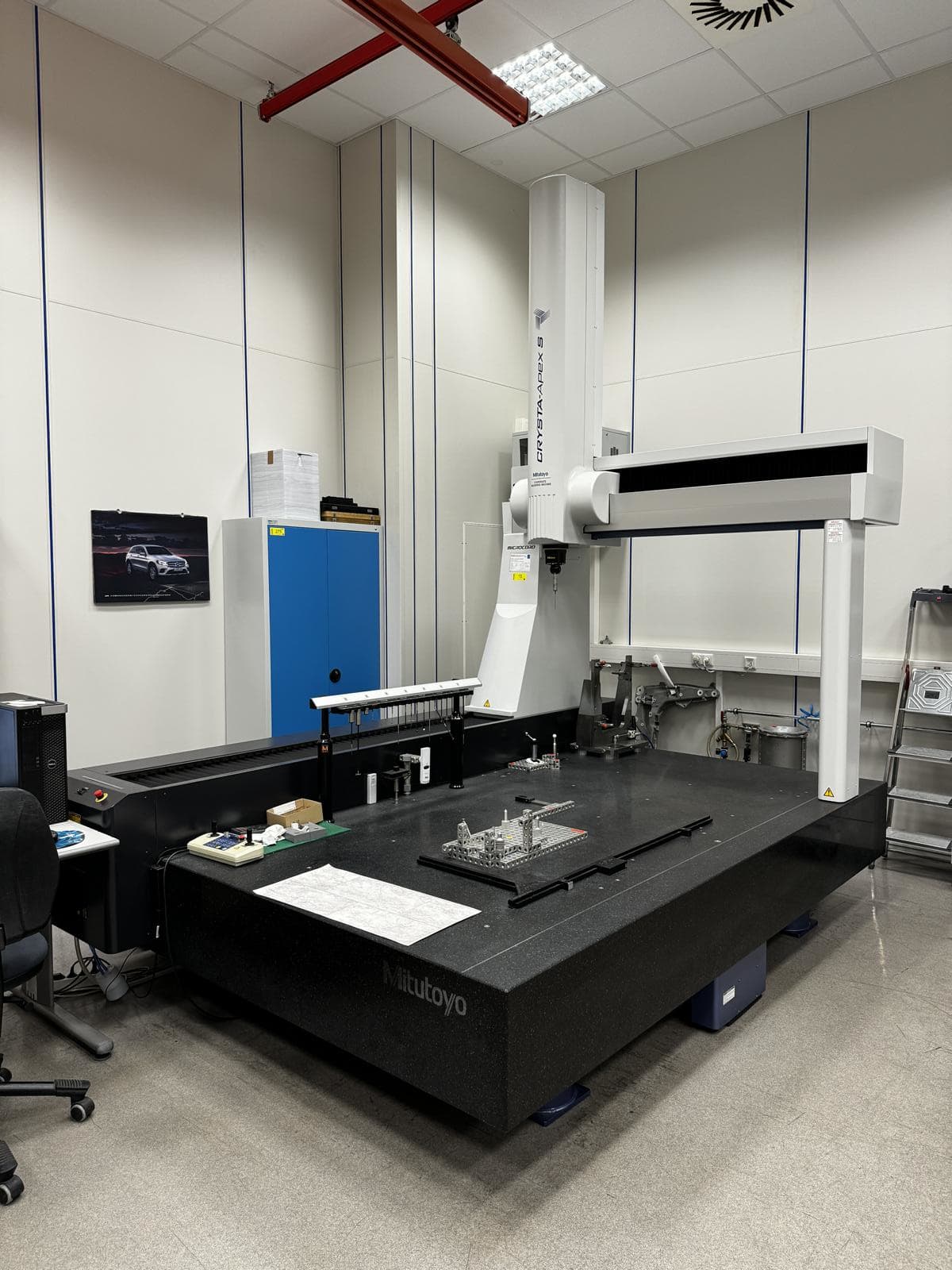

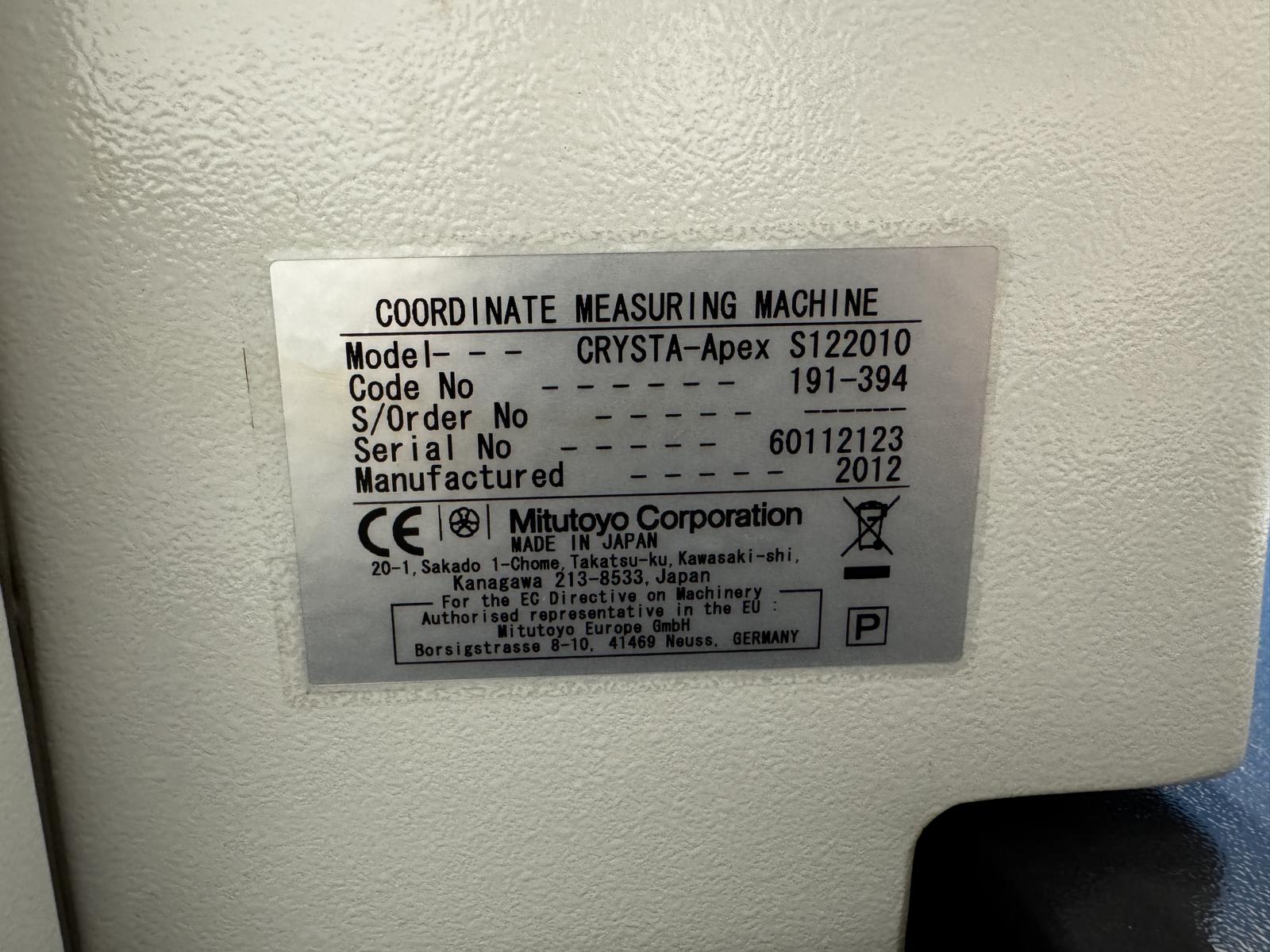

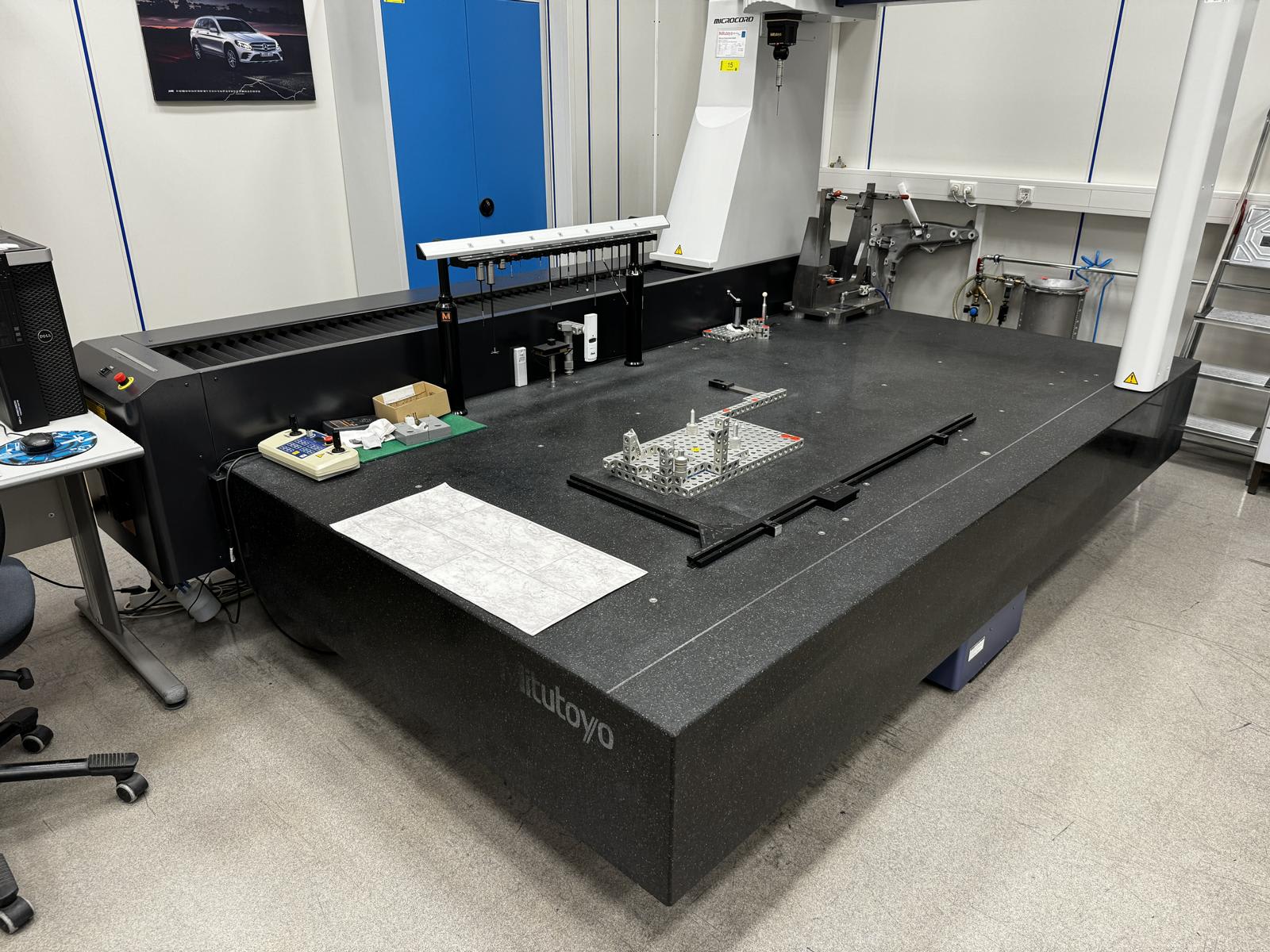

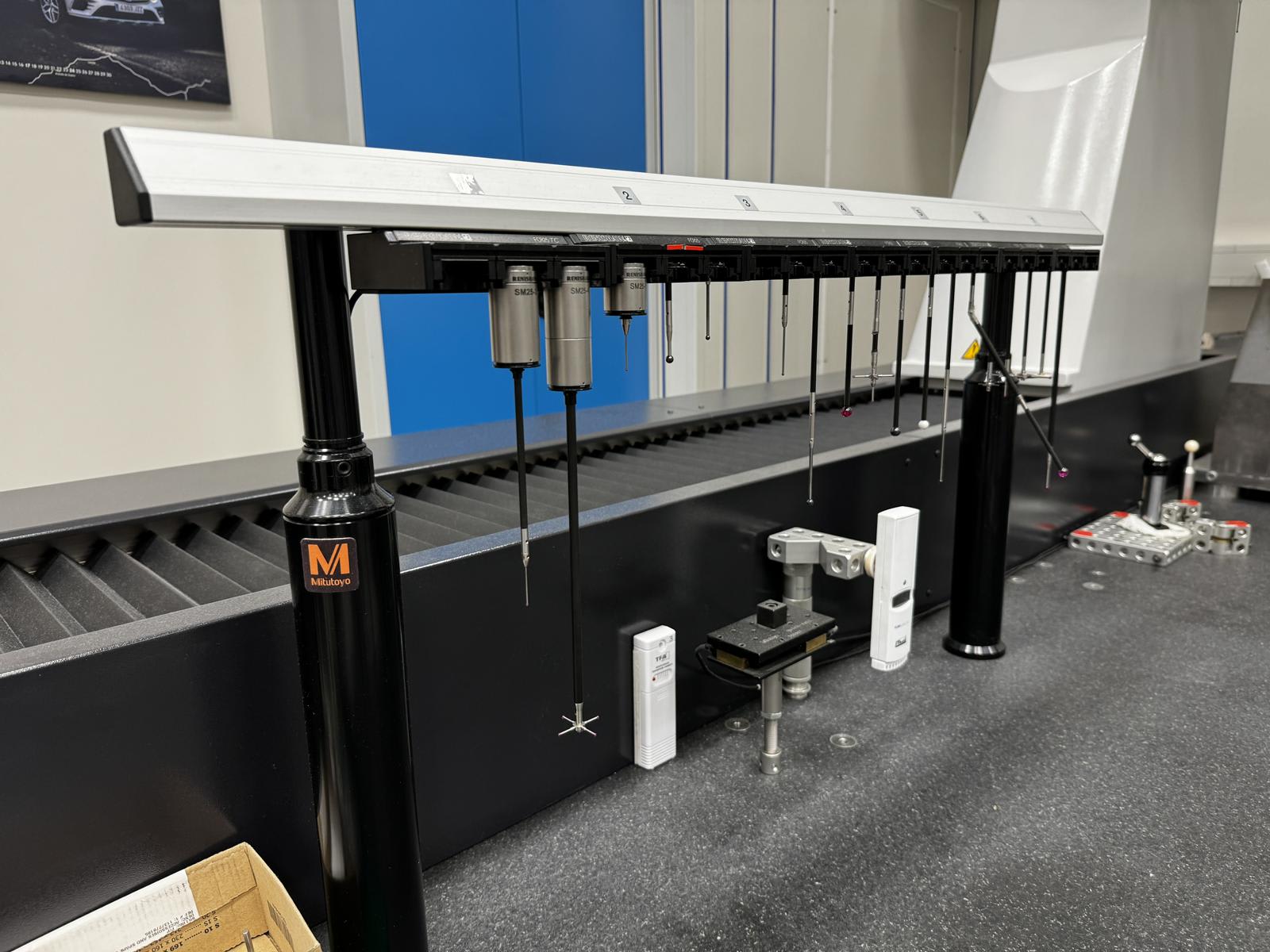

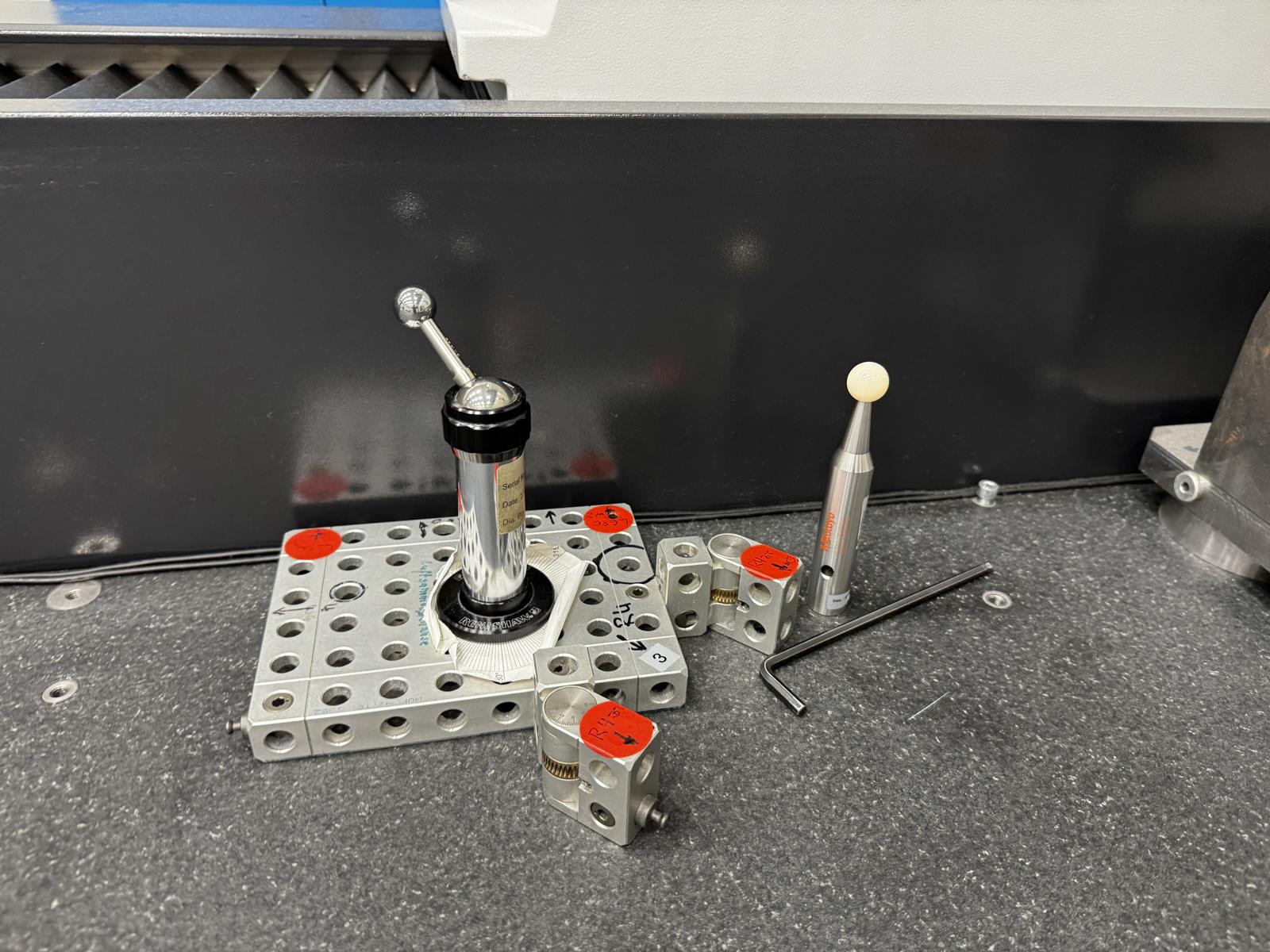

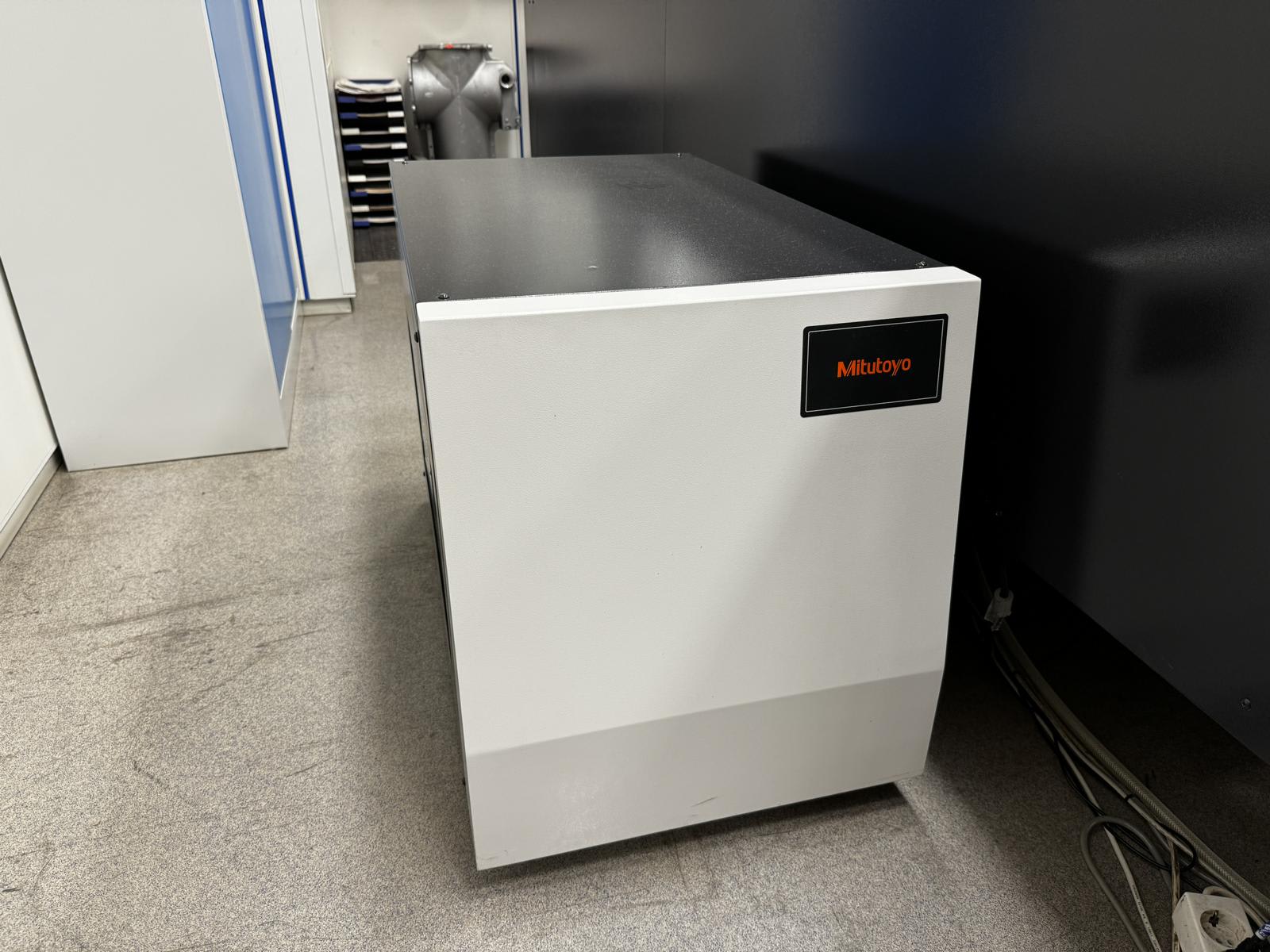

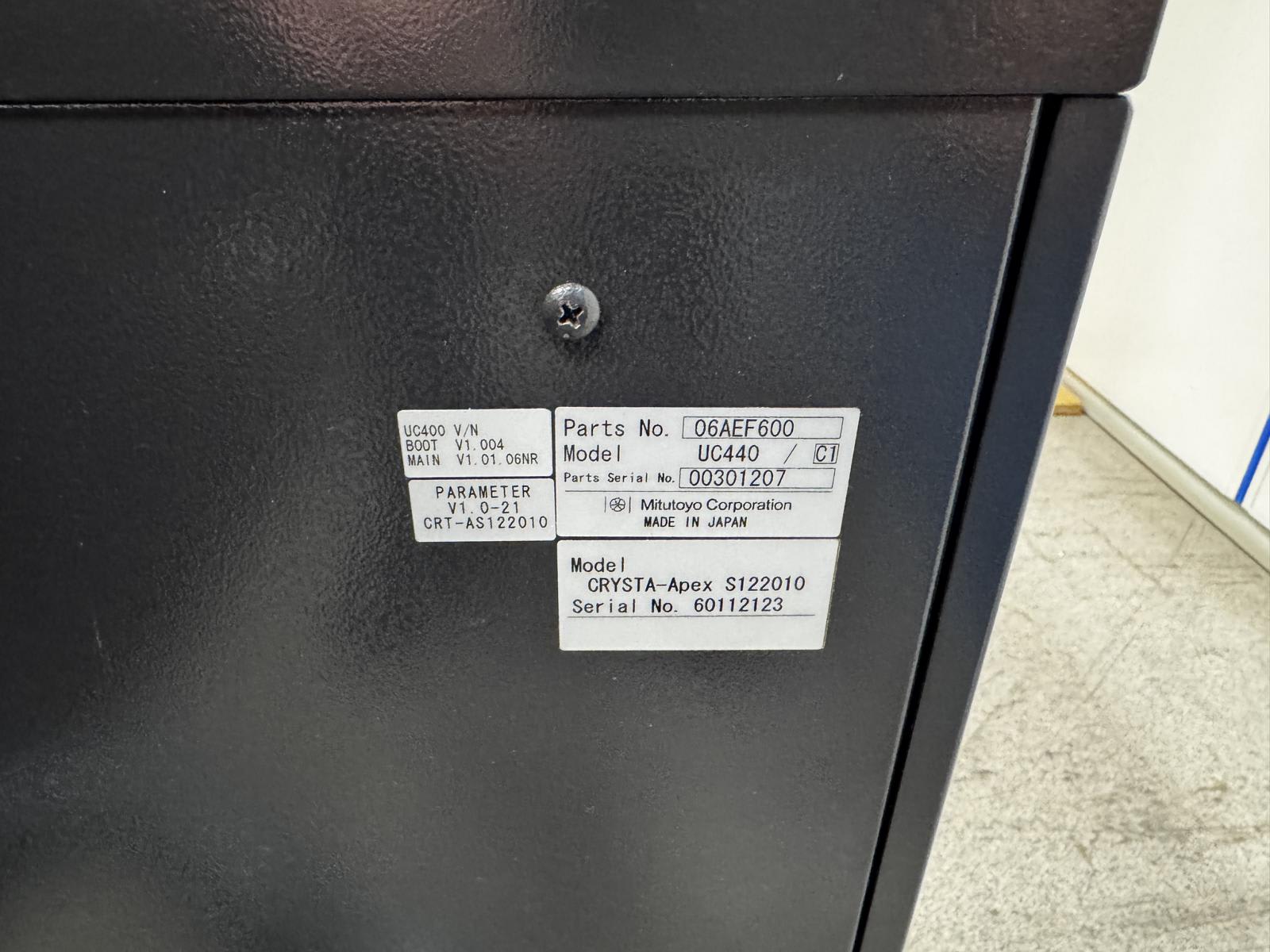

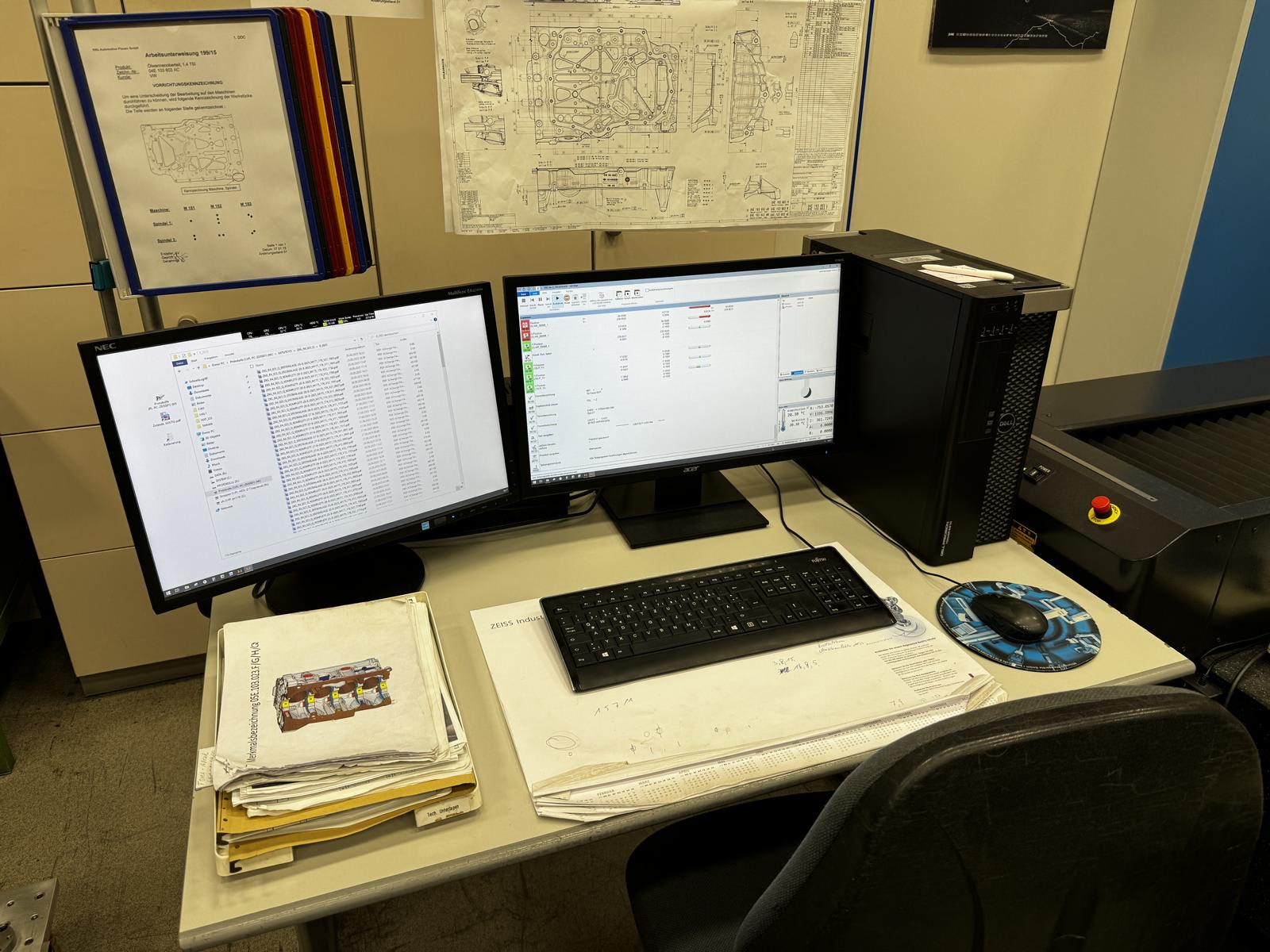

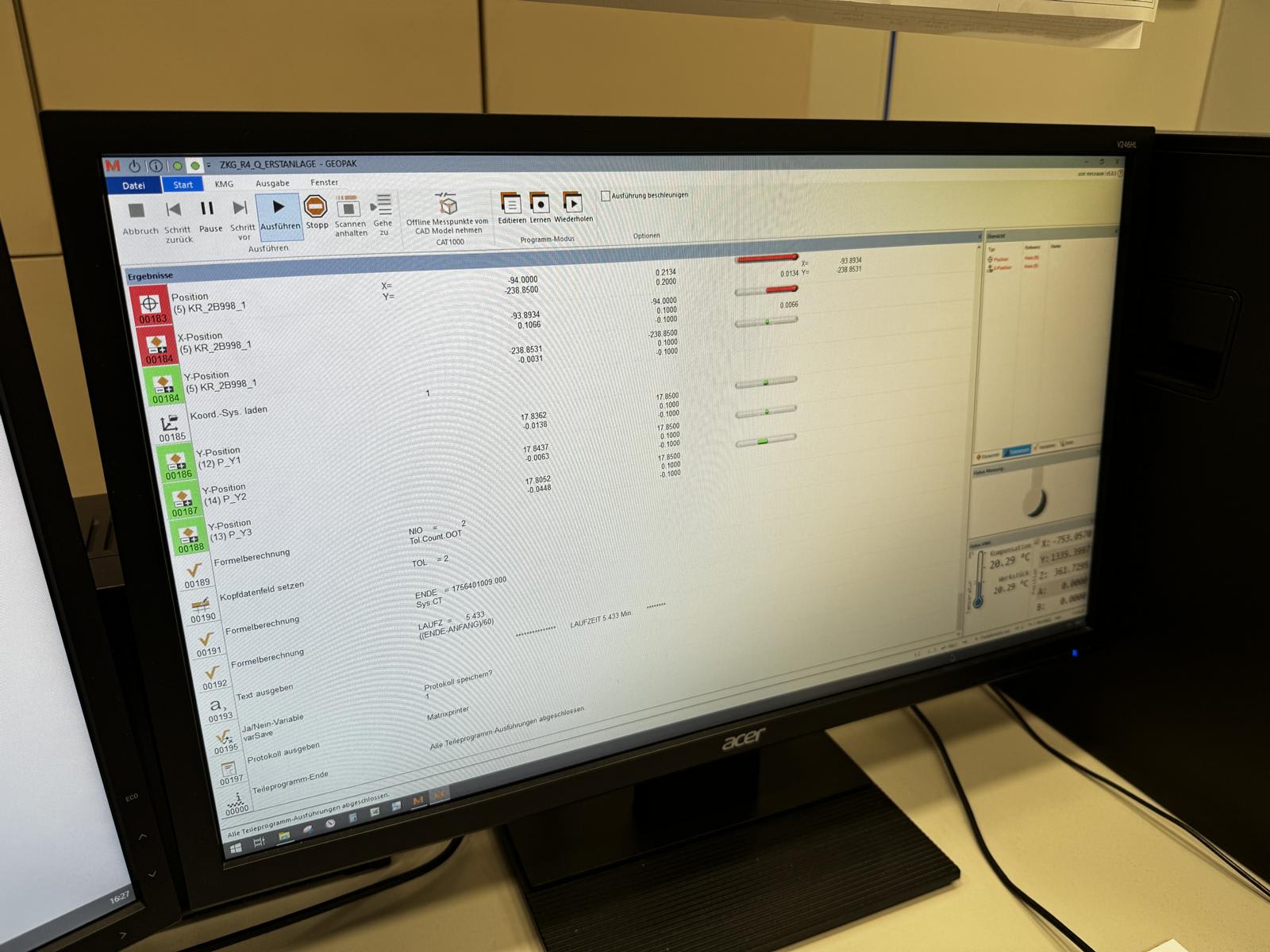

Coordinate Measuring Machine (3-axis) Mitutoyo Crysta-Apex S122010 | 2012

Binding Handling & Service Fee:

4500 € (EURO)

with PC, Software (Software has no extra Dongle, its installed on the PC) to include various Measuring Probes Important: The Handling/Dismantling Service includes the professional Transport Locking with Original parts from Mitutoyo by Mitutoyo Technicans, the securing of sensitive Parts e. g. with Bubble Foil and the Loading onto Truck - LISTING 2770016

![Deutsch]()

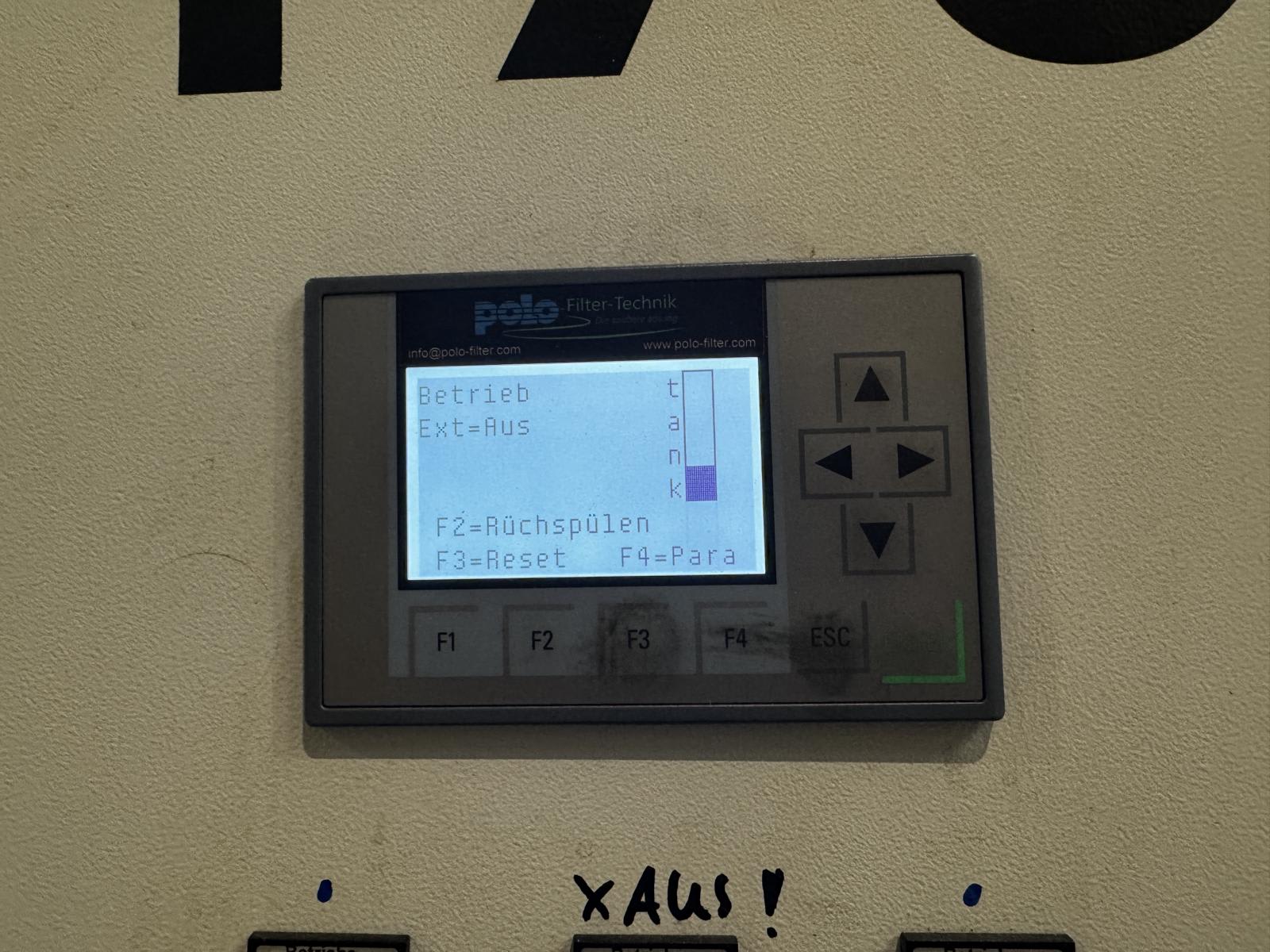

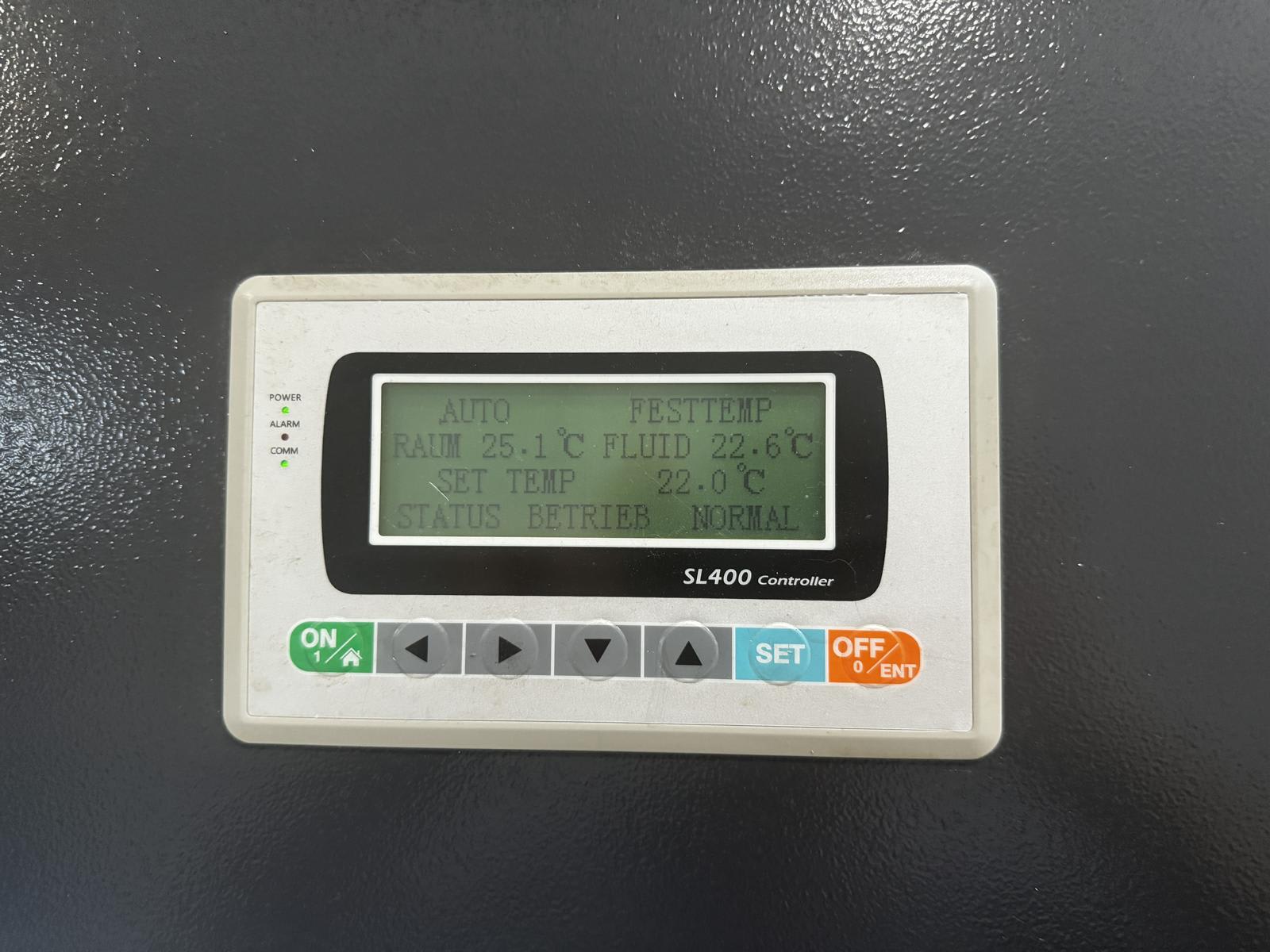

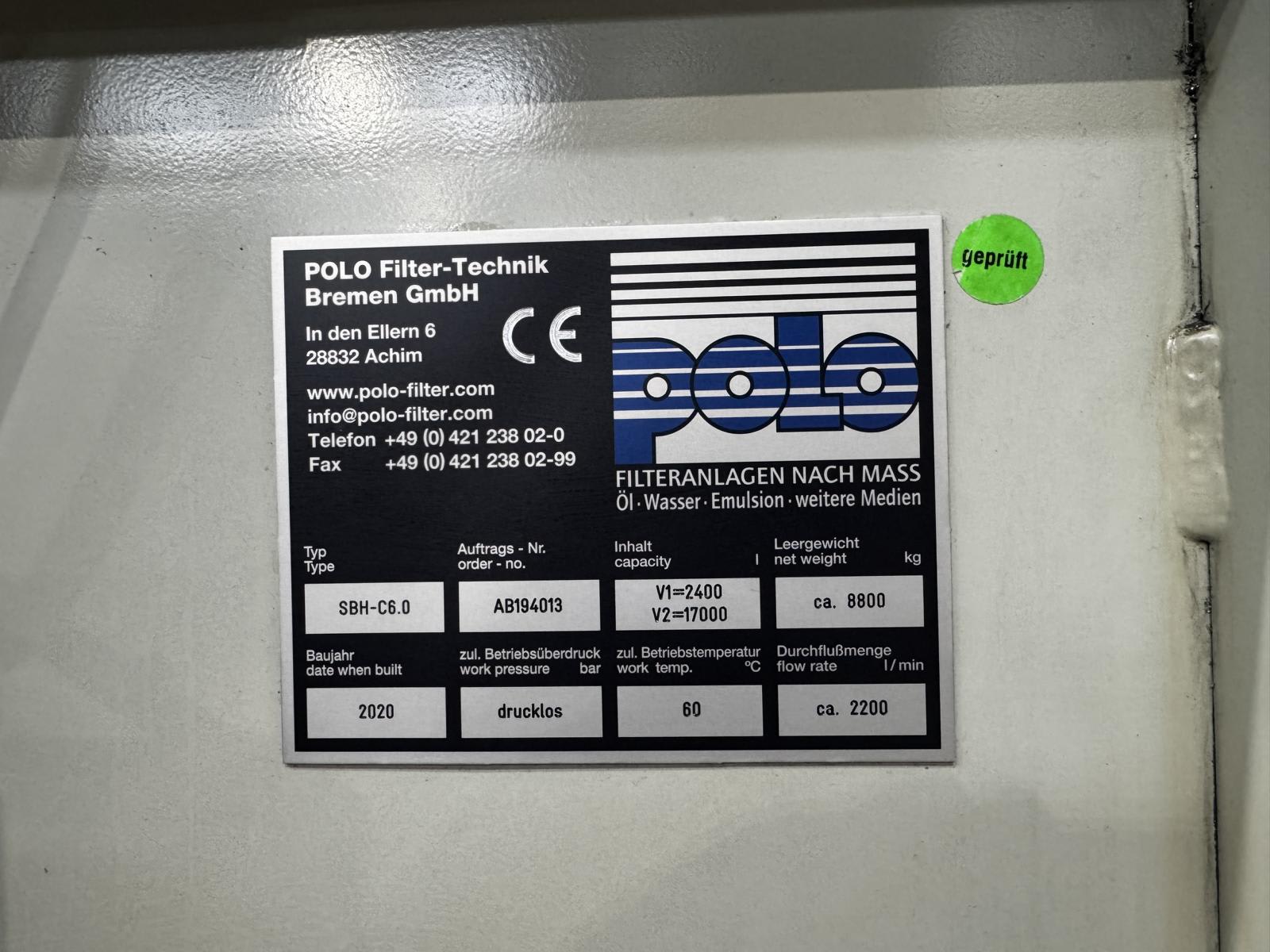

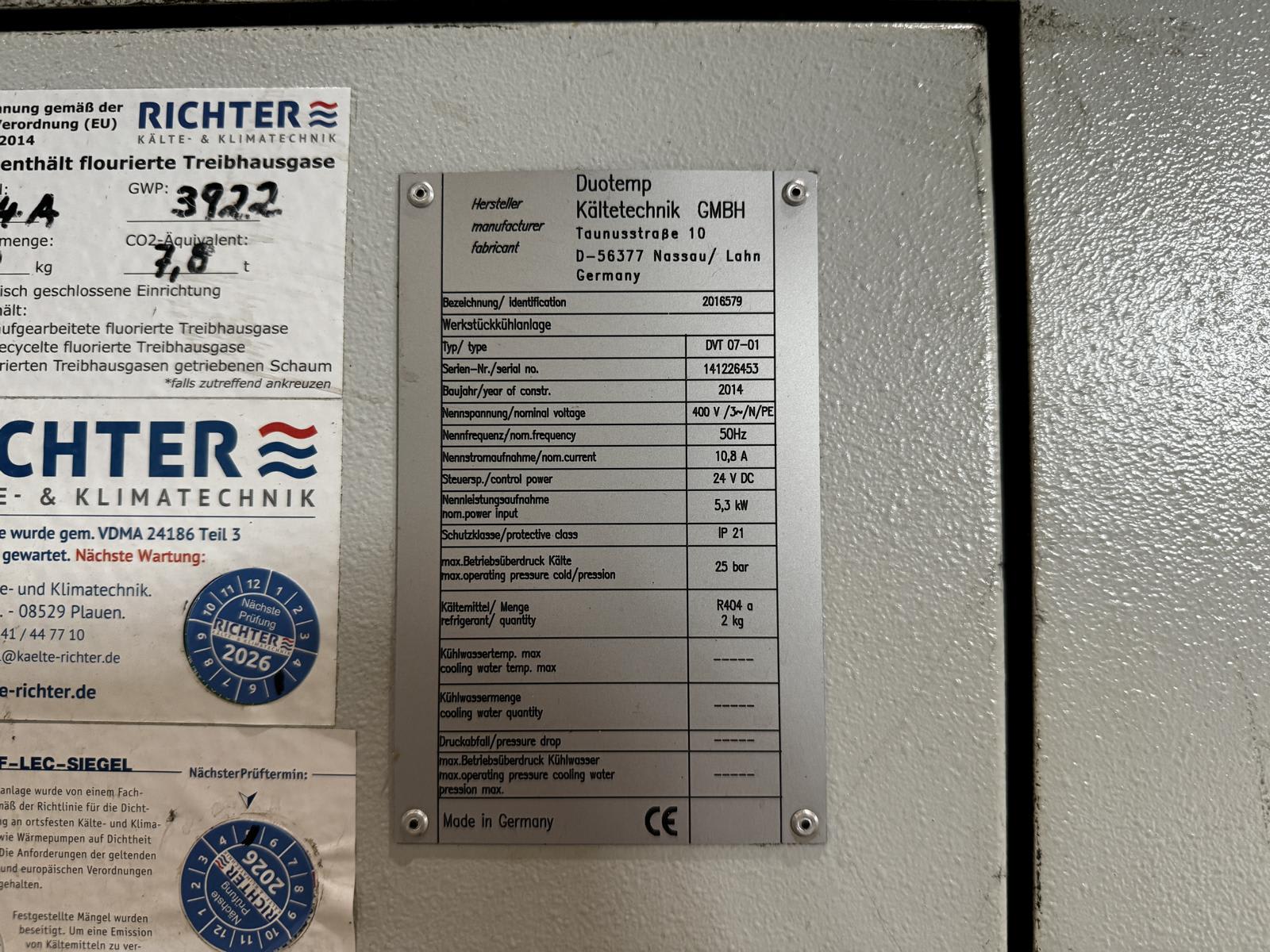

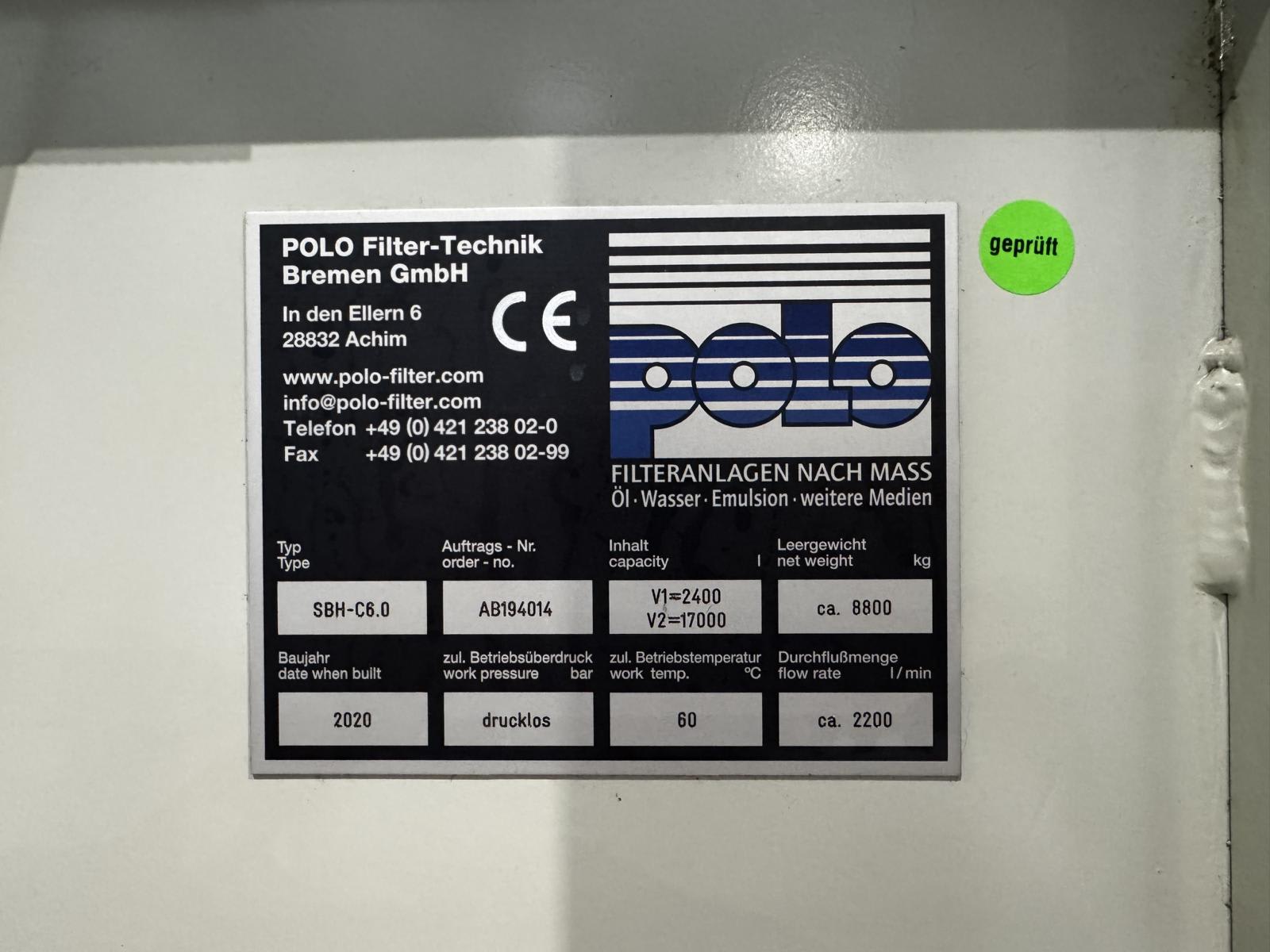

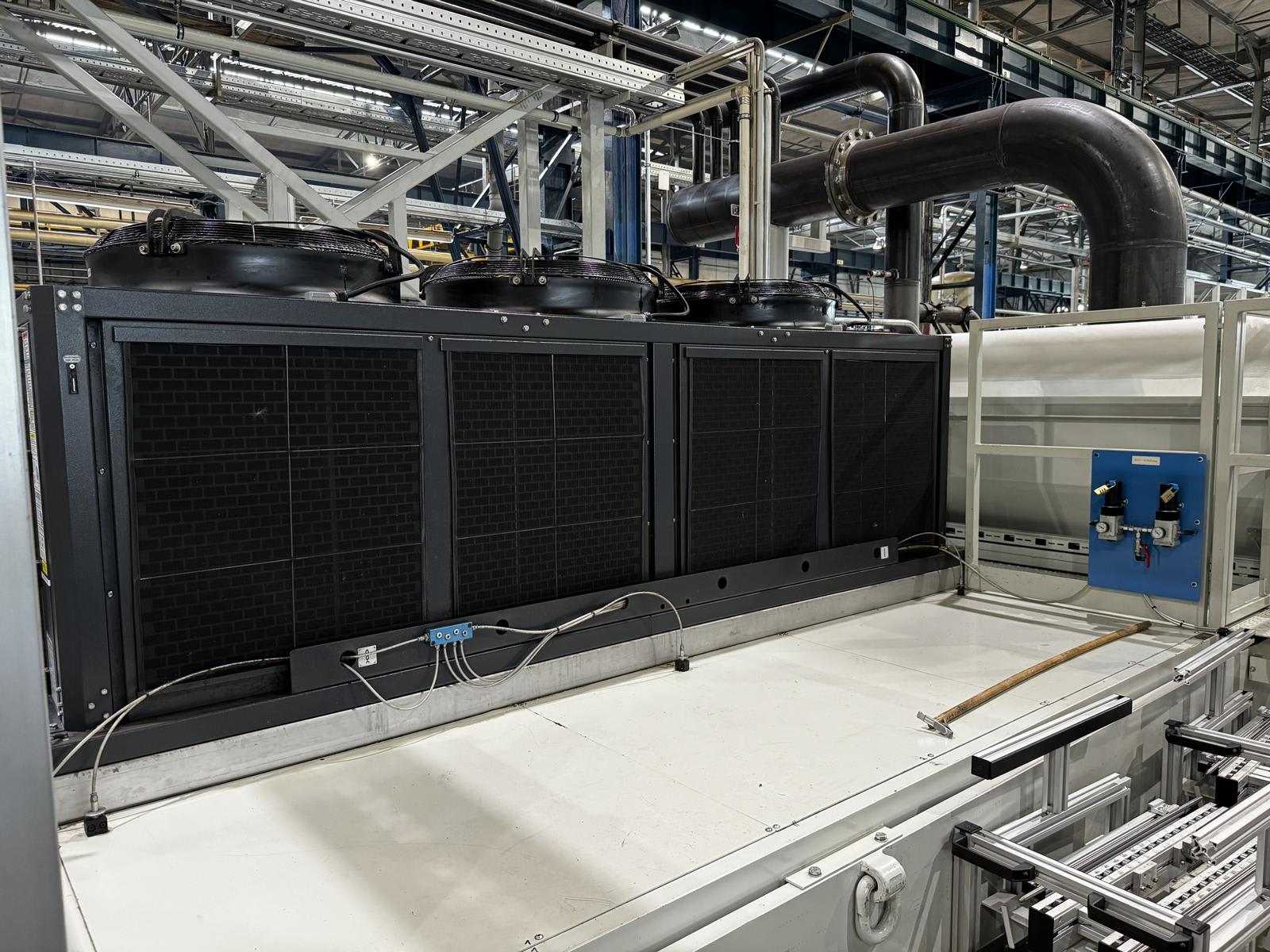

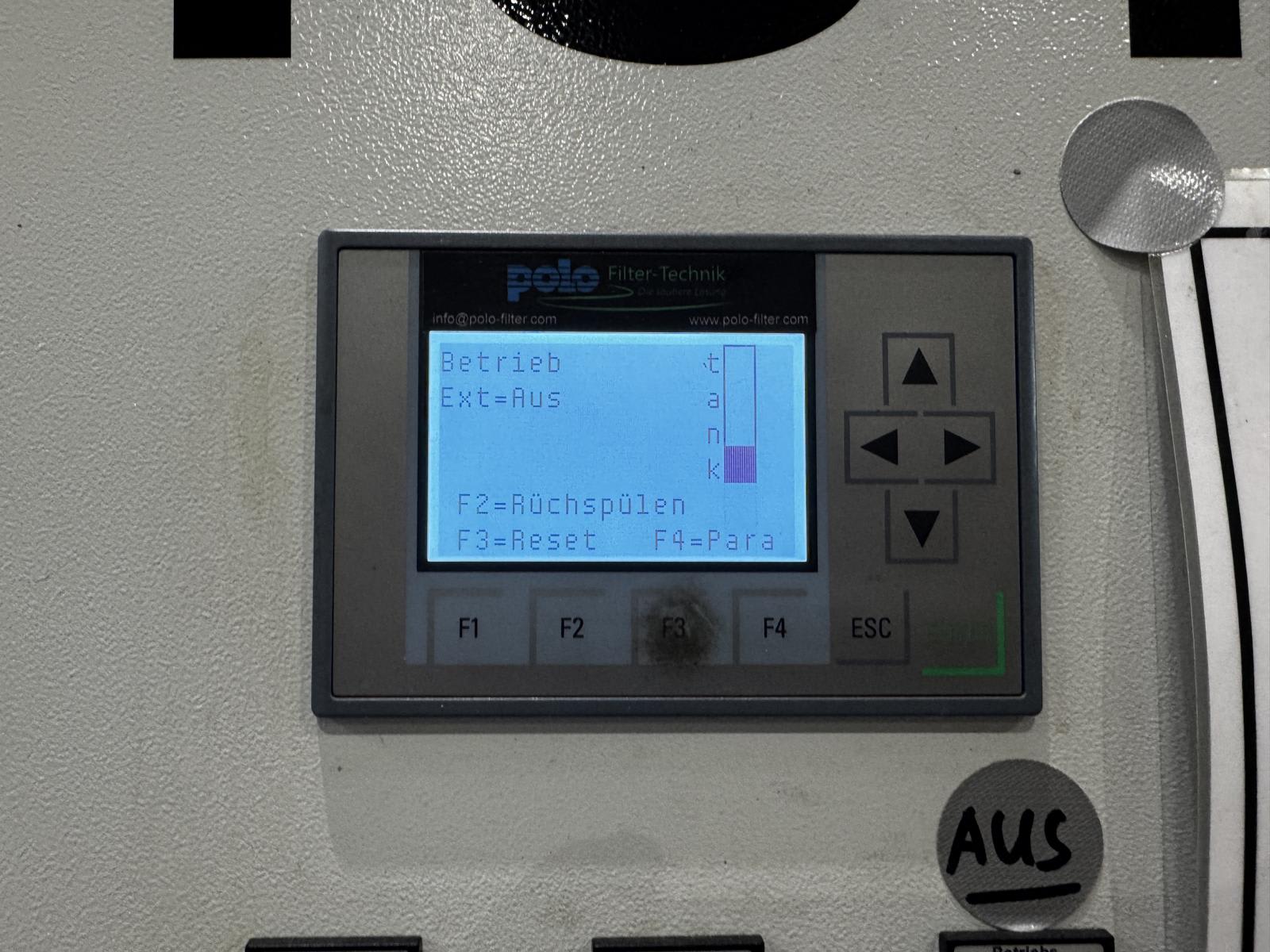

Cooling Lubricant System with Belt Filter POLO SBH-C6.0 | 2020

Binding Handling & Service Fee:

3355 € (EURO)

Description: Filter system for oil, water, and emulsions Manufacturer: Polo Filter-Technik Bremen GmbH Type/Model: SBH-C6.0 Year of manufacture: 2020 Order No.: AB194013 Technical specifications of the filter system: Capacity: V1 = 2,400 l, V2 = 17,000 l Empty weight: approx. 8,800 kg Maximum operating temperature: 60 °C Flow rate: approx. 2,200 l/min Maximum Operating pressure: Pressureless Control: Control cabinet with display and control panel Additional system: Immersion chiller Manufacturer: Haosch / ATF Cooling GmbH Type / Model: MCS-1200S-010PS3UZ1-3405C Cooling capacity: 120.0 kW Connected load: 41.0 kW Rated current: 69.5 A Refrigerant: R407C, 17.0 kg × 2 Design: 3PH+PE / AC 400V / 50Hz Dimensions (W x D x H): 1,400 × 3,300 × 2,180 mm Weight: 1,412.5 kg Machine no.: C2020068 - LISTING 2770017

![Deutsch]()

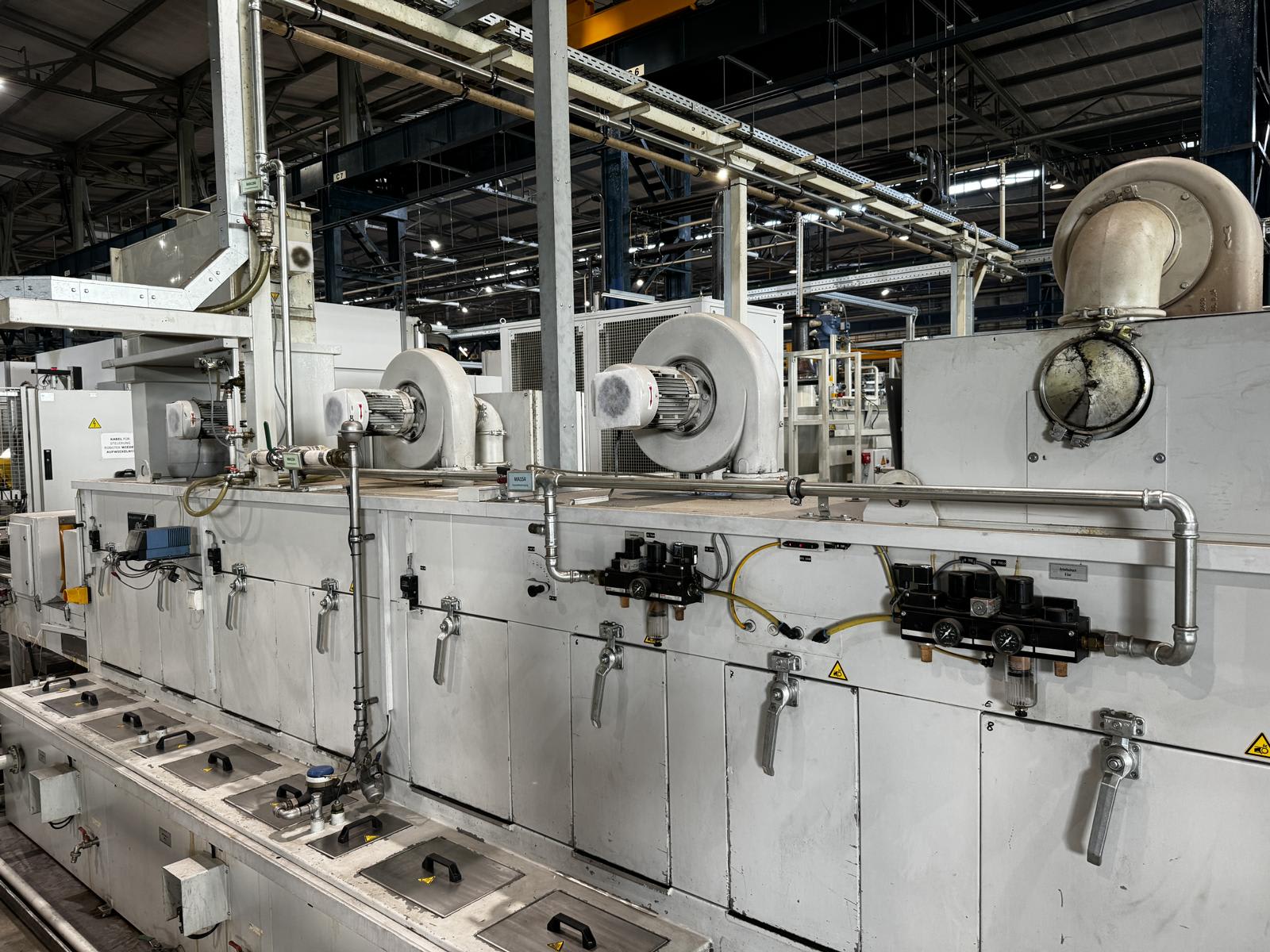

Continuous Washing System PERO KDA50WSSNT | 2014

Binding Handling & Service Fee:

3950 € (EURO)

Designation: Industrial parts cleaning system Manufacturer: Pero AG, Gotha branch Type / Model: KDA50WSSNT Machine No.: 1388 Year of manufacture: 2014 Circuit diagram No.: 4014311 Technical specifications: Operating voltage: 400 V Frequency: 50 Hz Rated current: 258 A Total power: 157 kW Heating power: 117 kW Usable media: According to the operating manual (suitable for aqueous or special cleaning media) Control system: Control cabinet with control panel and visualization Accessories / options: Integrated pump systems, filter units, conveyor belt technology Foundation: Floor-mounted - LISTING 2770018

![Deutsch]()

Cooling Lubricant System with Belt Filter POLO SBH-B2.9 | 2014

Binding Handling & Service Fee:

3355 € (EURO)

Designation: Filter system for oil, water, and emulsions Manufacturer: Polo Filter-Technik Bremen GmbH Type / Model: SBH-B2.9 Year of manufacture: 2014 Order No.: B14.2873 Technical specifications: Capacity: V1 = 11,000 l, V2 = 1,150 l Empty weight: 6,900 kg Maximum operating temperature: 60 °C Flow rate: 1,260 l/min Maximum operating pressure: Pressureless Control system: Control cabinet with control panel, signaling and monitoring devices Accessories / options: Pump systems, chip/sludge separators, integrated filter modules - LISTING 2770020

![Deutsch]()

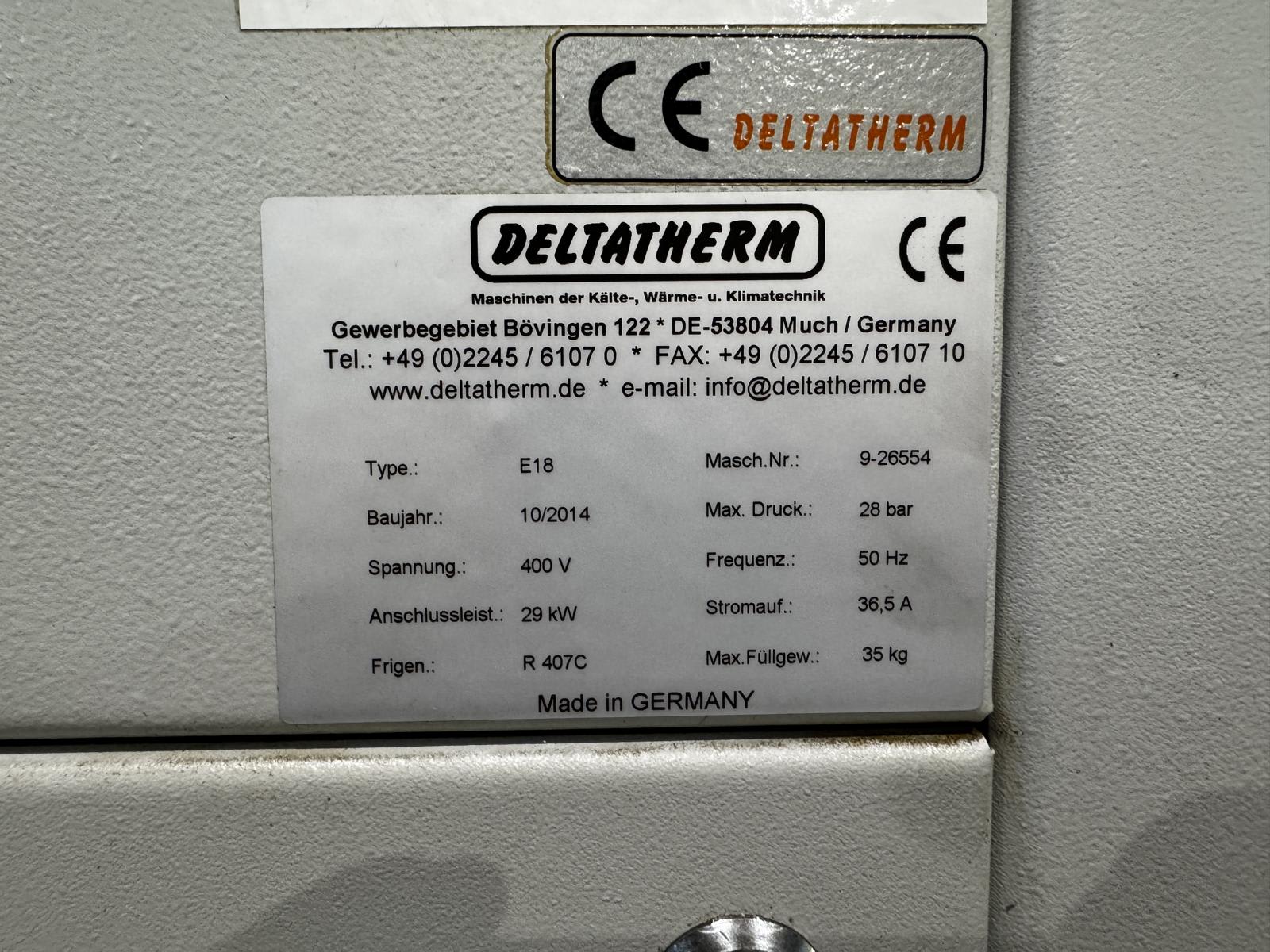

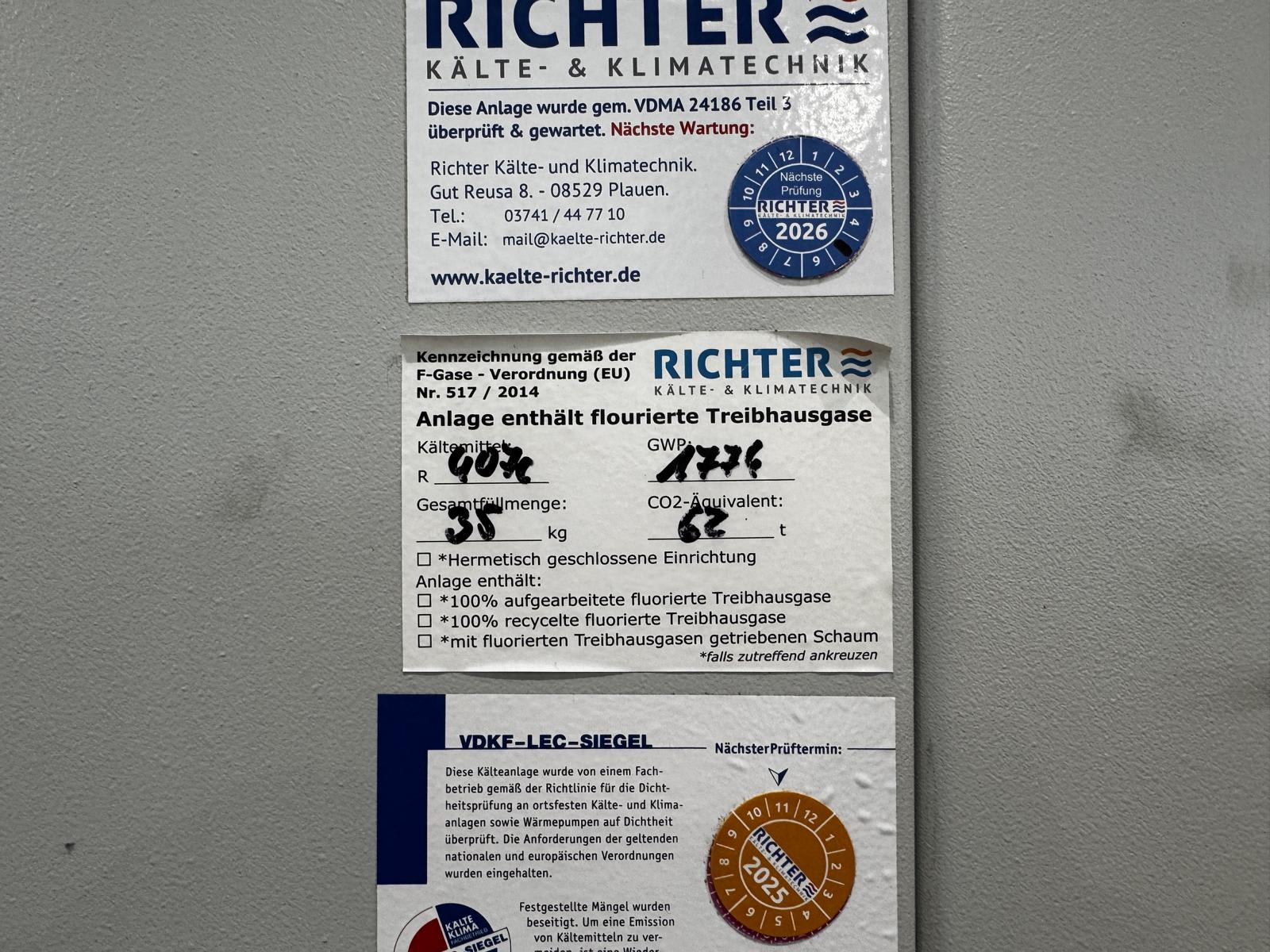

Cooling Lubricant System with Belt Filter POLO SBH-C6.0 | 2020

Binding Handling & Service Fee:

3355 € (EURO)

Description: Filter system with cooling technology (industrial fluids, oil/water/emulsions) Manufacturer: Polo Filter-Technik Bremen GmbH Type/Model: SBH-C6.0 Order No.: AB194014 Year of manufacture: 2020 Technical specifications of the filter system: Capacity: V1 = 2,400 l, V2 = 17,000 l Empty weight: approx. 8,800 kg Maximum operating temperature: 60 °C Flow rate: approx. 2,200 l/min Maximum Operating pressure: pressureless Additional component: Haosch Immersion Chiller Type: MCS-1200S-010PS3UZ1-3405C Cooling capacity: 120.0 kW Operating voltage: 3PH + PE / AC 400 V / 50 Hz Connected load: 41.0 kW Rated current: 69.5 A Refrigerant: R407C / 17.0 kg × 2 Dimensions (W x L x H): 1,400 × 3,300 × 2,180 mm Weight: 1,412.5 kg Machine no.: C20020067 - LISTING 2770025

![Deutsch]()

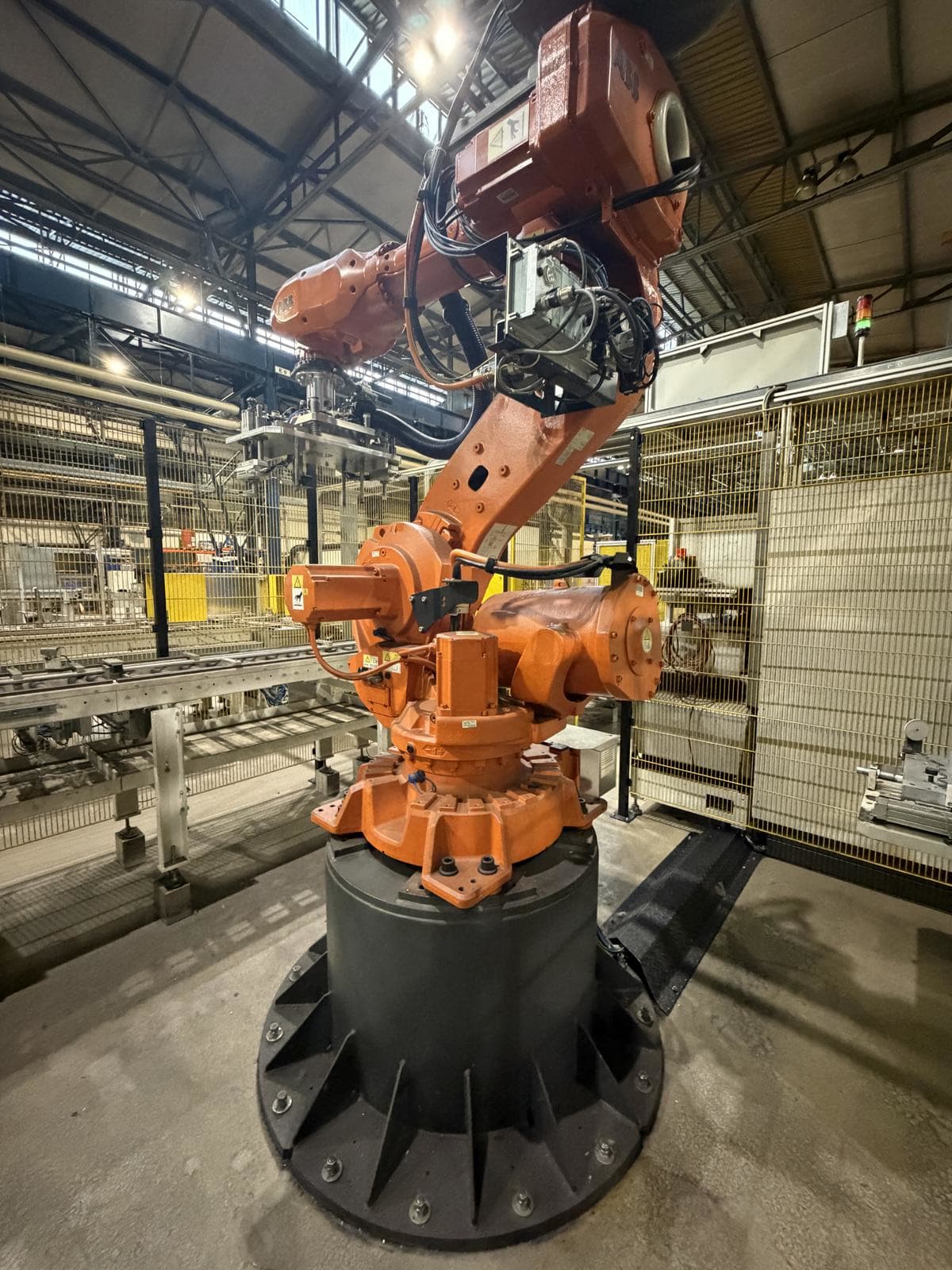

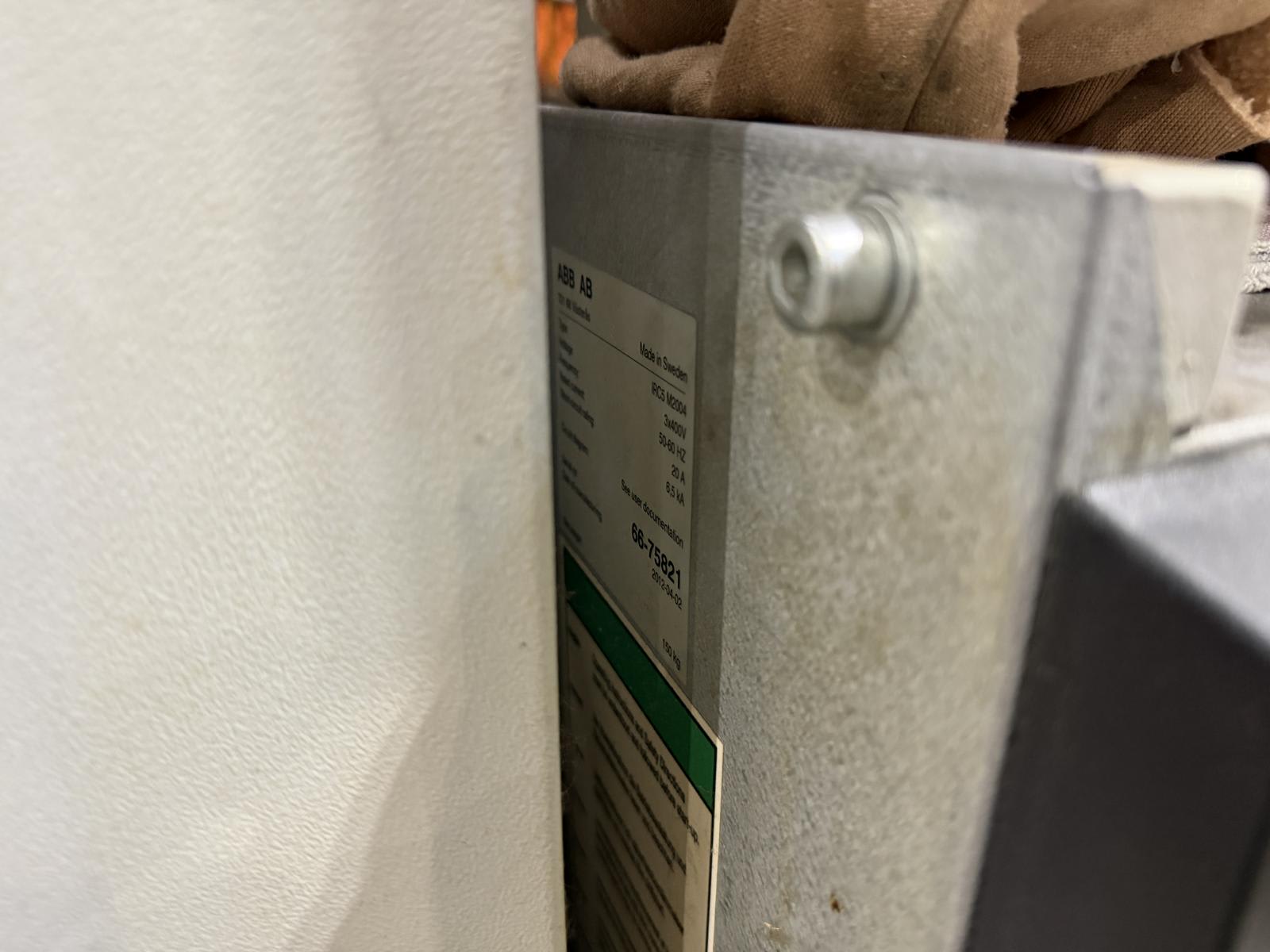

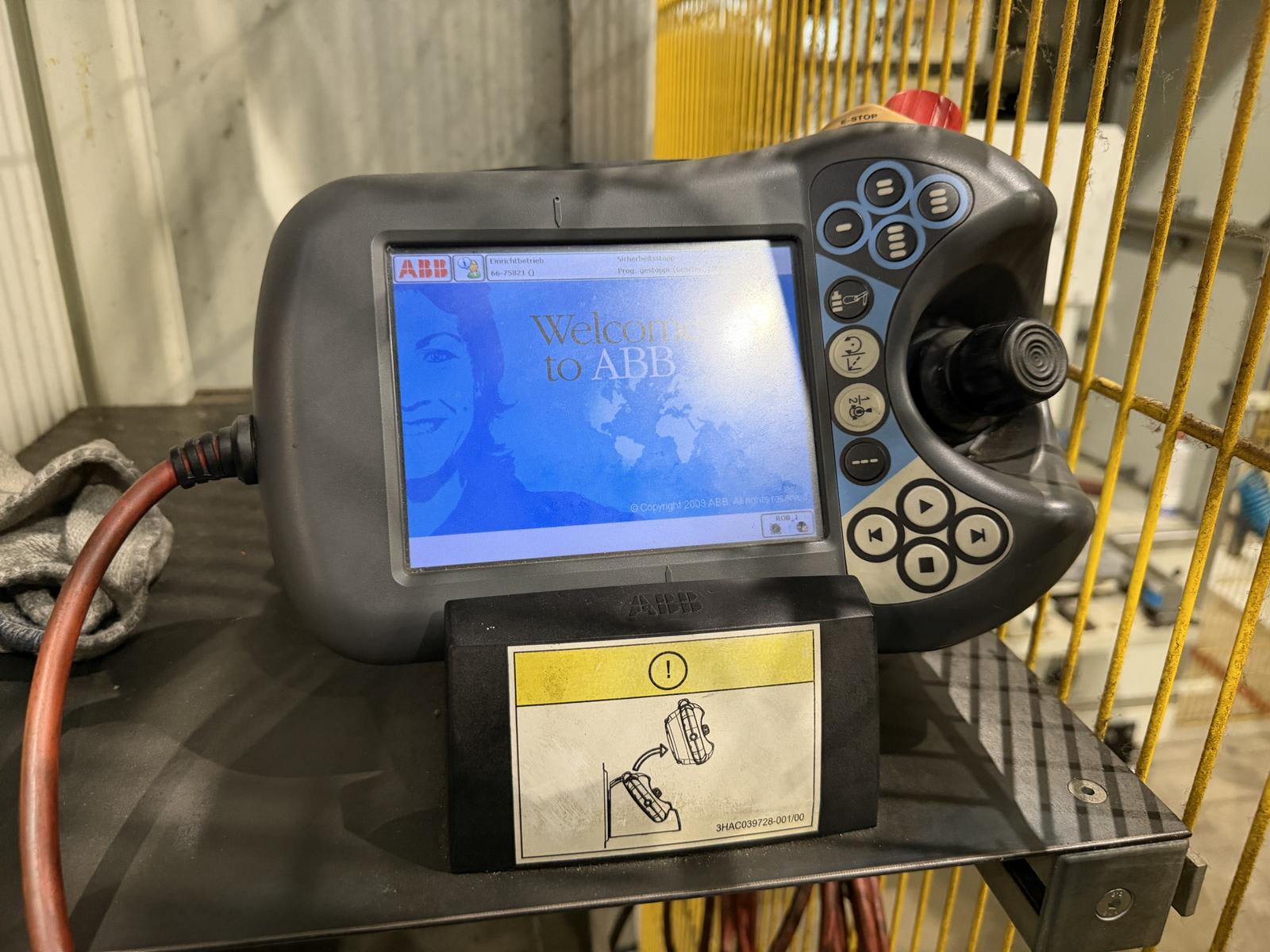

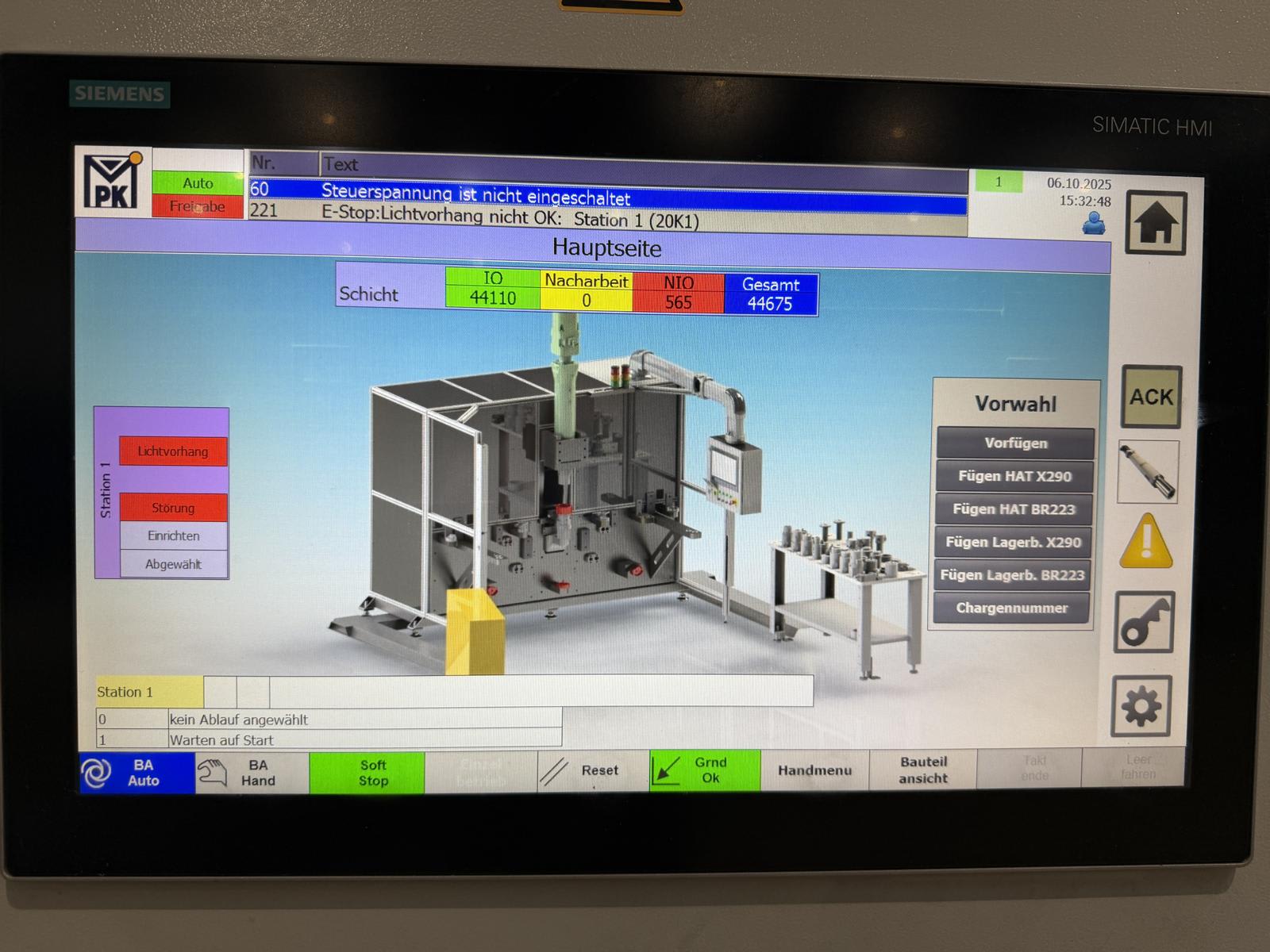

Industrial Robot ABB IRB 6640-180/2.55 | 2012

Binding Handling & Service Fee:

750 € (EURO)

• Axes: 6 • Maximum payload: 180 kg • Reach: 2550 mm • Repeatability: ± 0.07 mm • Mechanical weight: approx. 1310 kg • Maximum wrist torque: approx. 961 Nm • Protection rating: IP67 (entire robot) • Mounting: floor-mounted • Controller: IRC5 (single or dual cabinet) • Power supply: 200–600 V, 50/60 Hz • Power consumption (ISO-Cube): approx. 2.7 kW Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770133

![Deutsch]()

- LISTING 2770341

![Deutsch]()

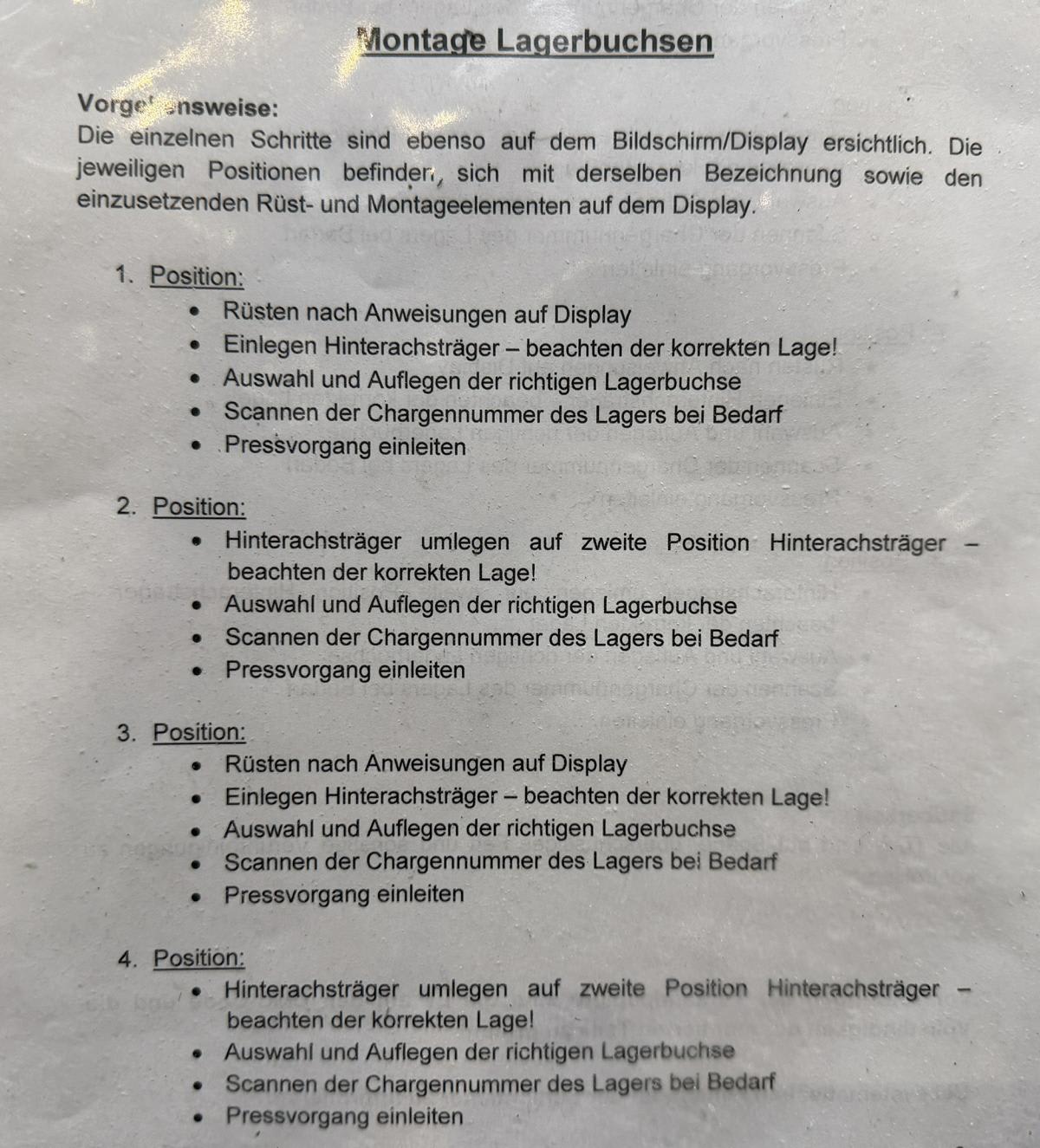

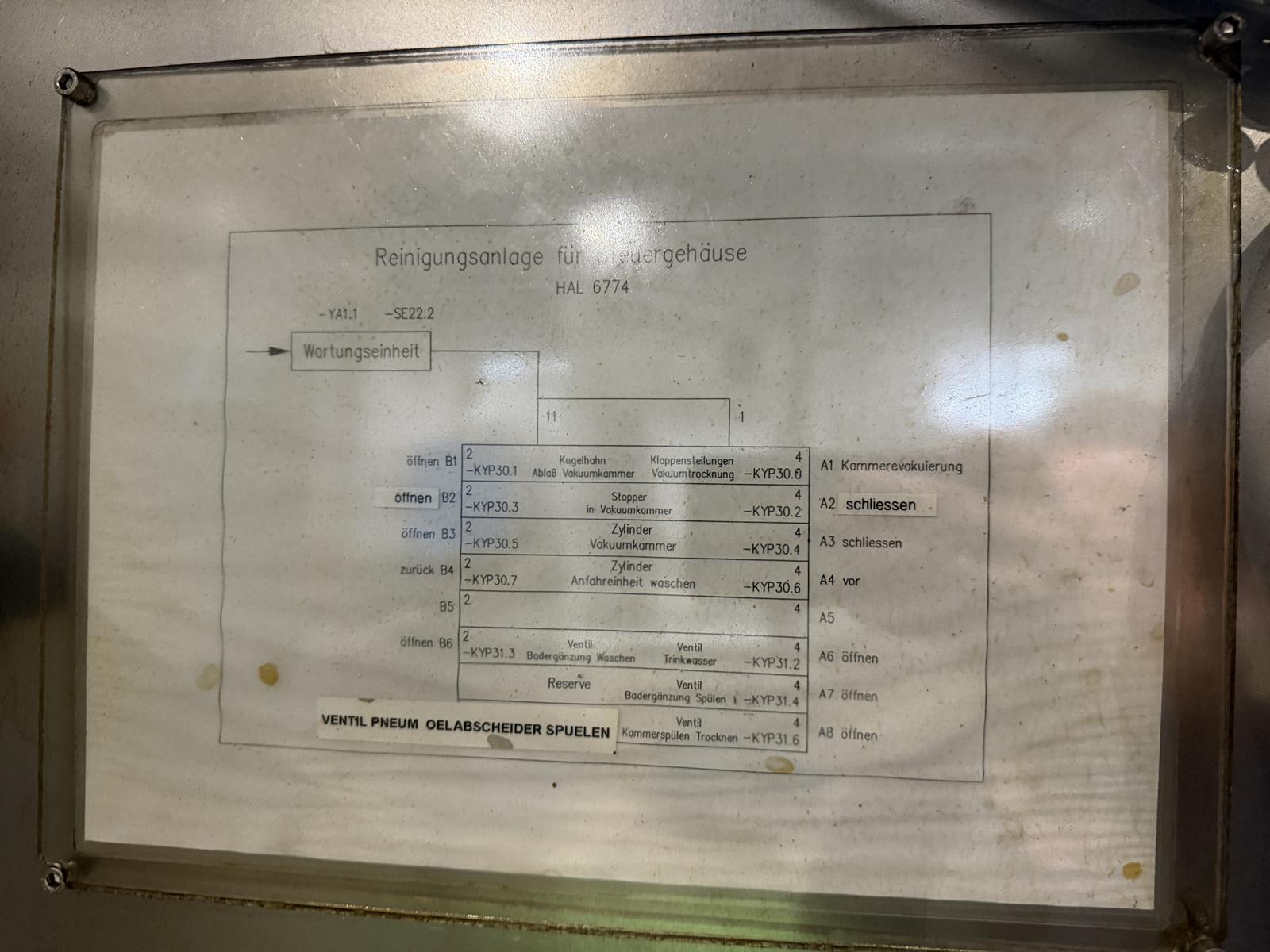

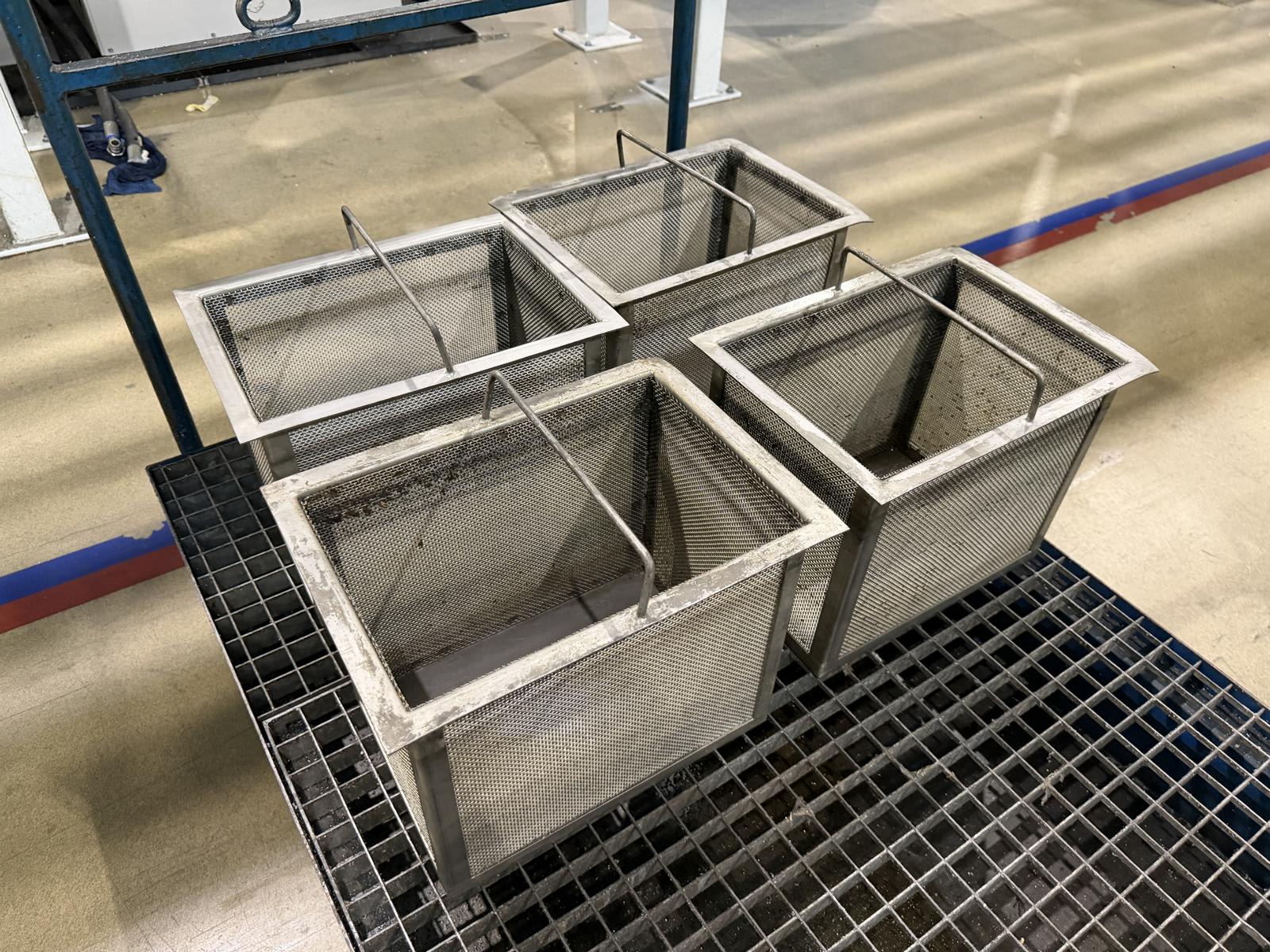

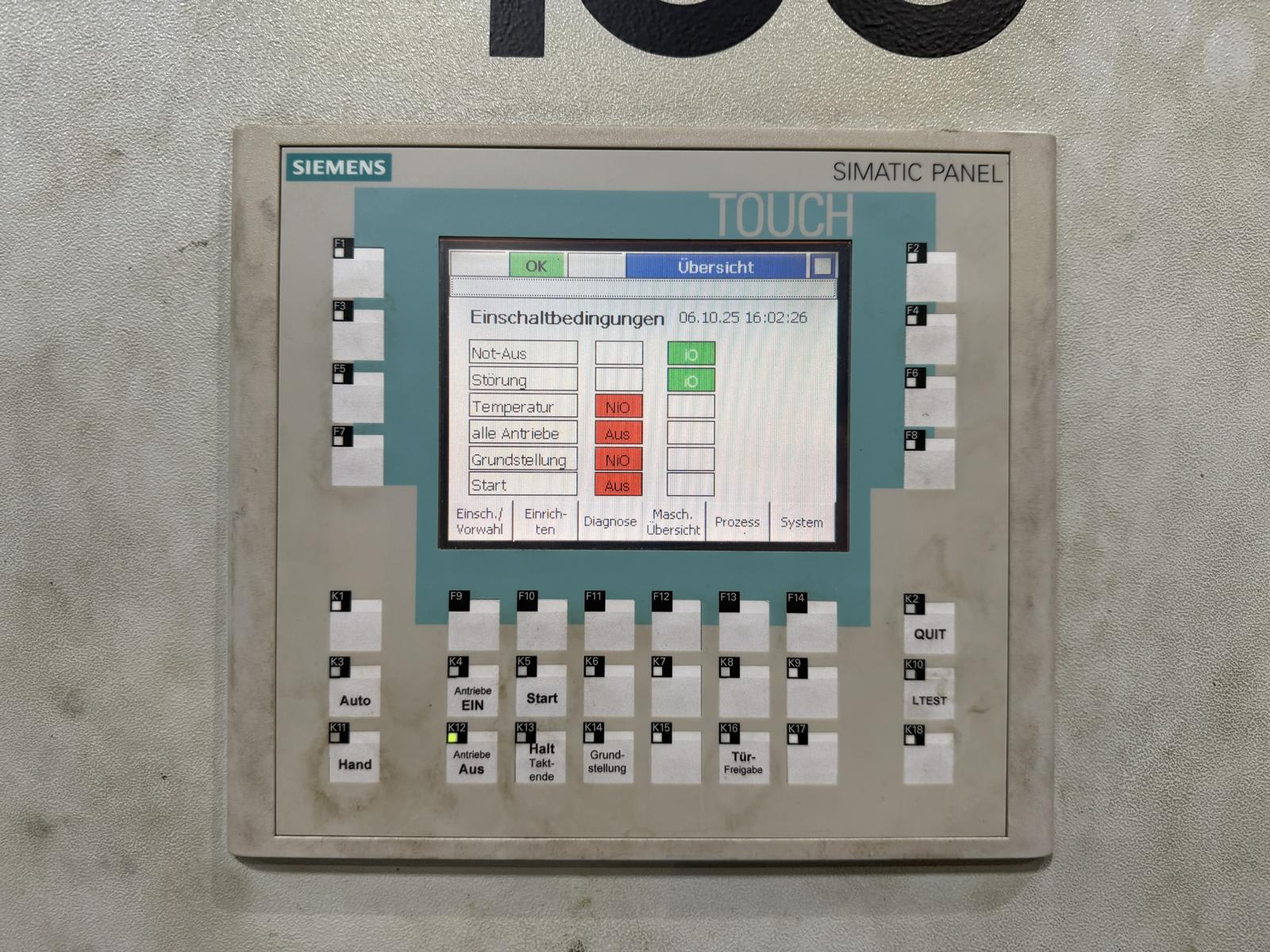

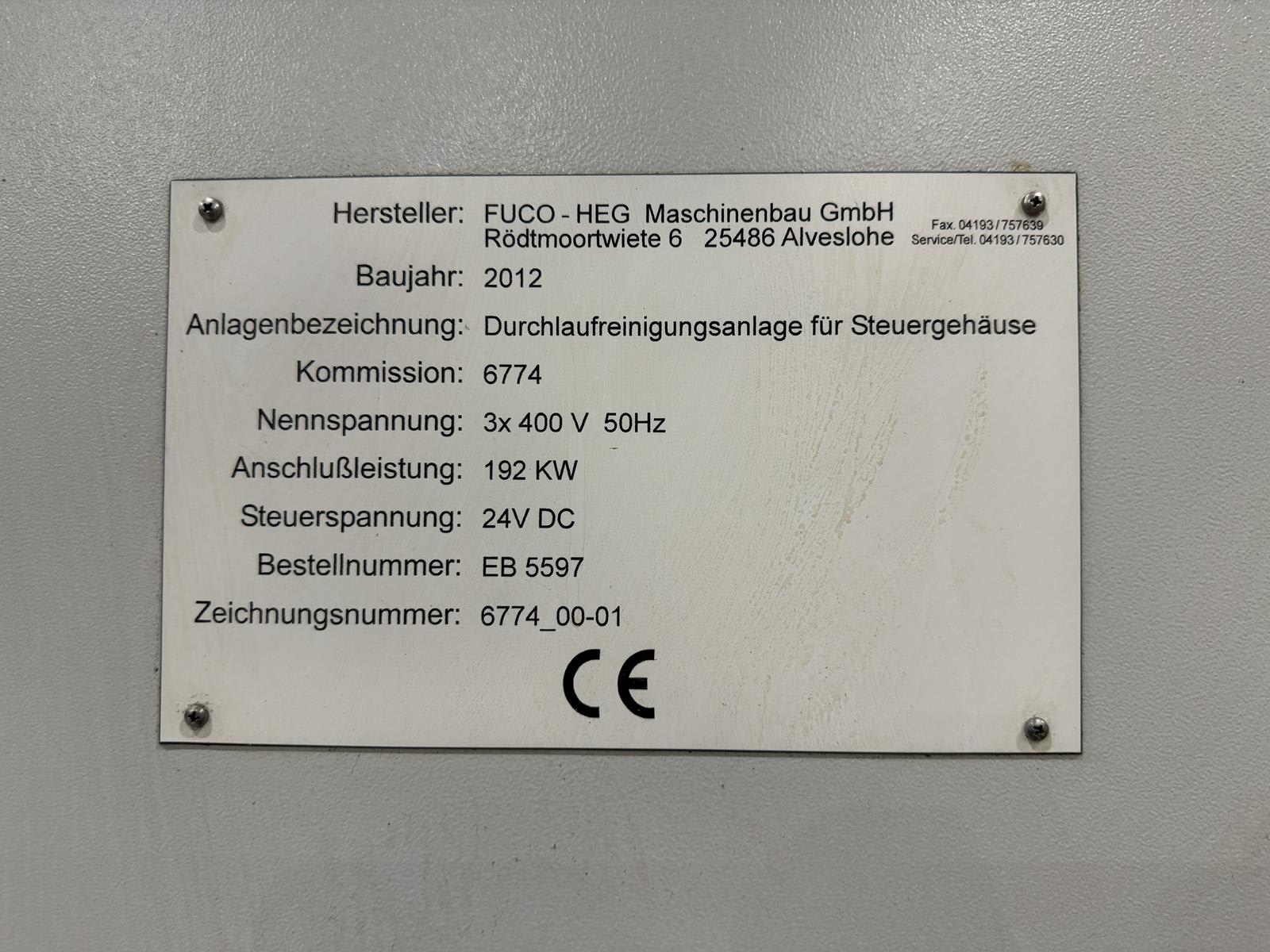

Parts Washing Machine Fuco-Heg | 2012

10 basket capacity Qty 8 Eaton washing tubes model TBF-0102-AD10 - LISTING 2770344

![Deutsch]()

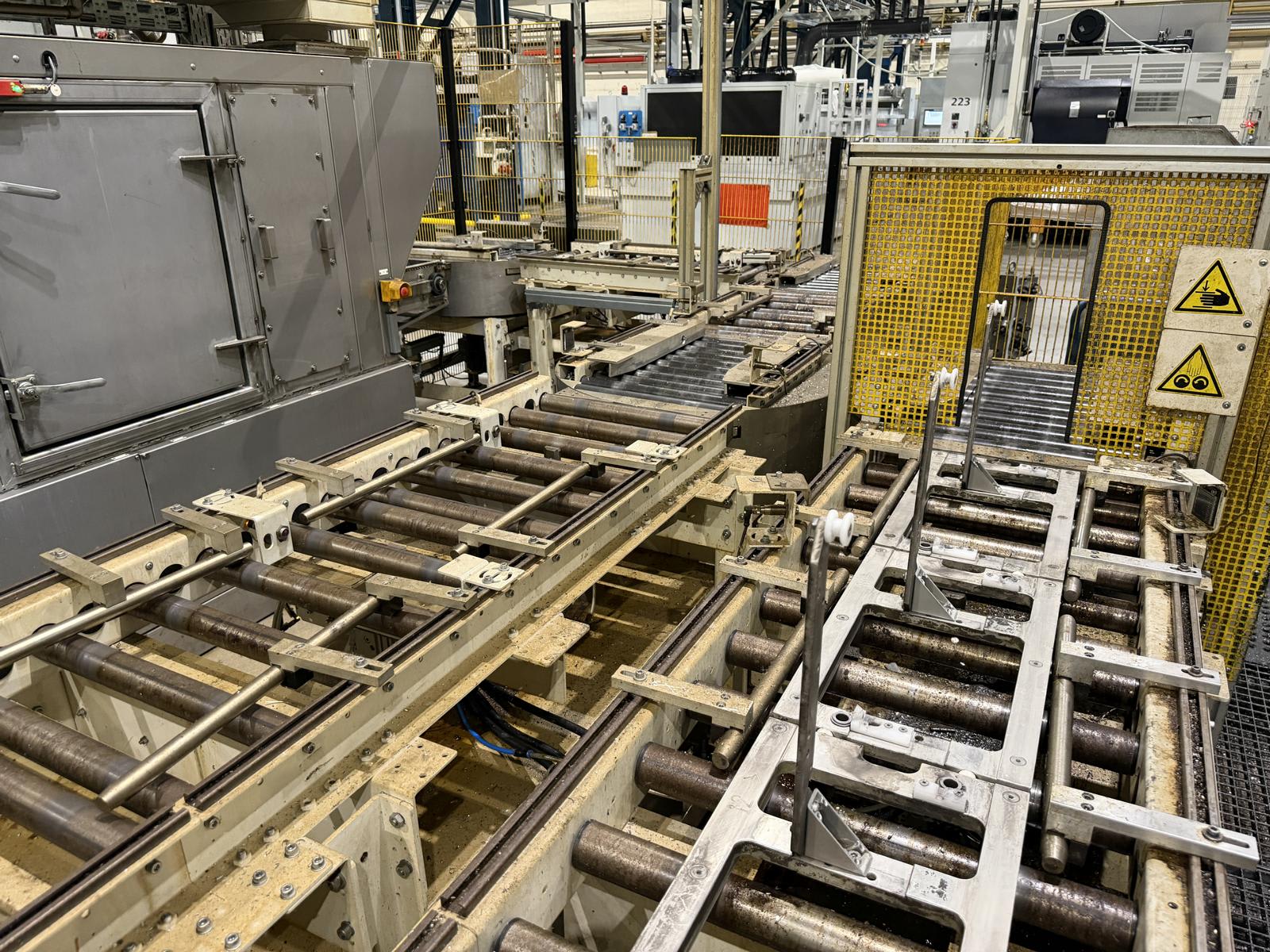

Conveyor System

Approx 35 mtr in length Fitted with 2 rotation tables Machine/Asset does not include any Product related Tool/Fixture or Gripper (Robot) - LISTING 2770352

![Deutsch]()

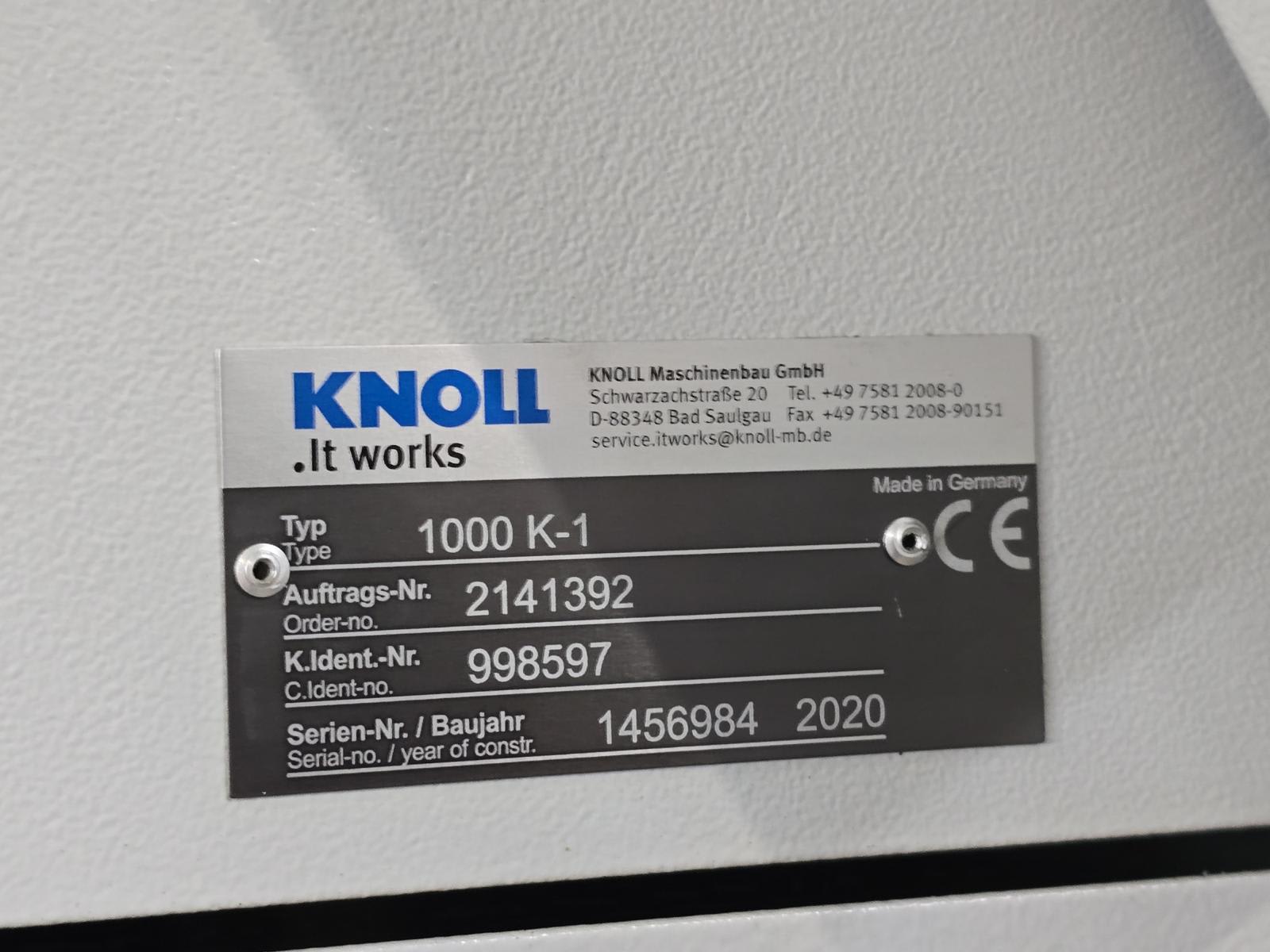

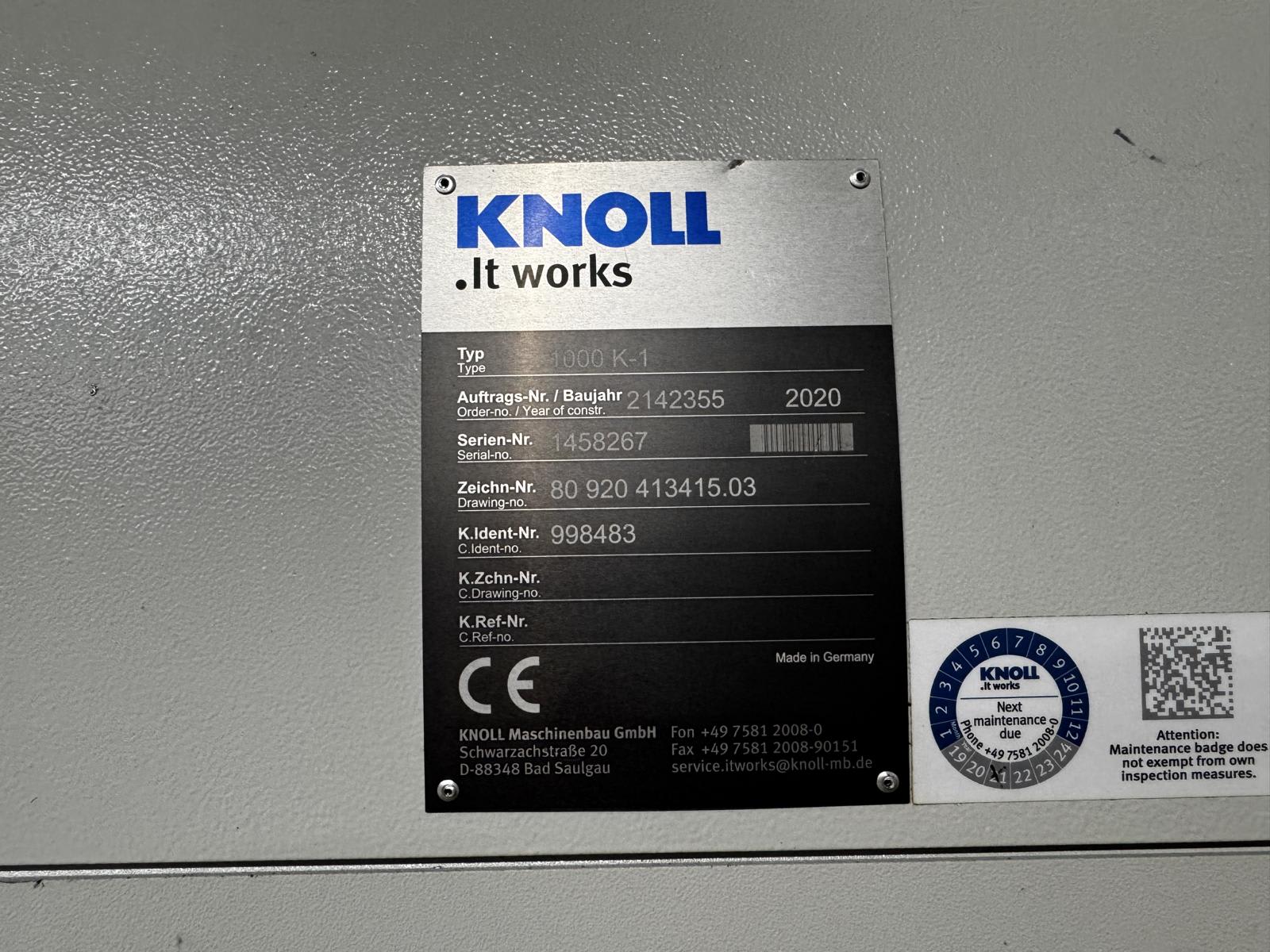

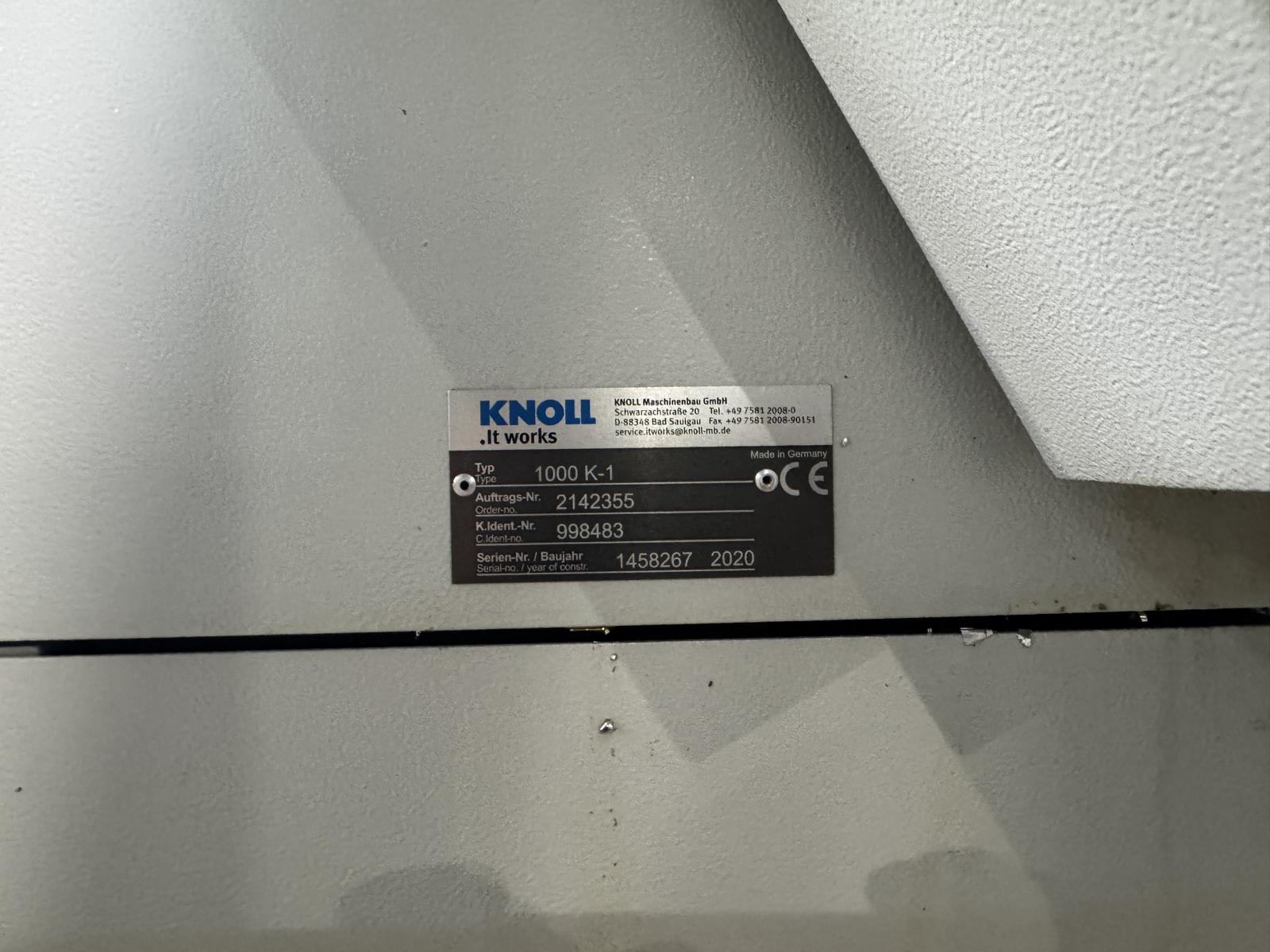

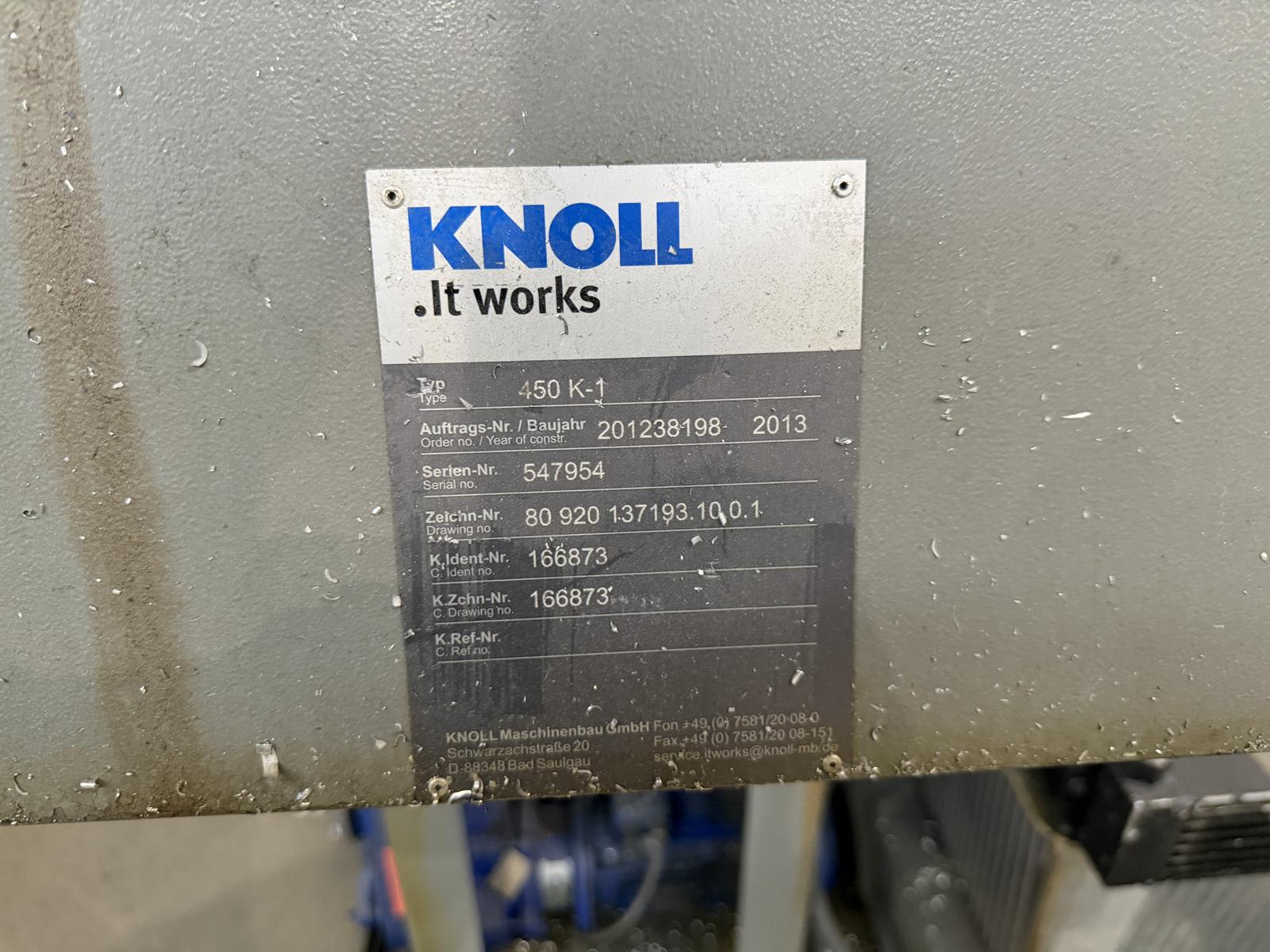

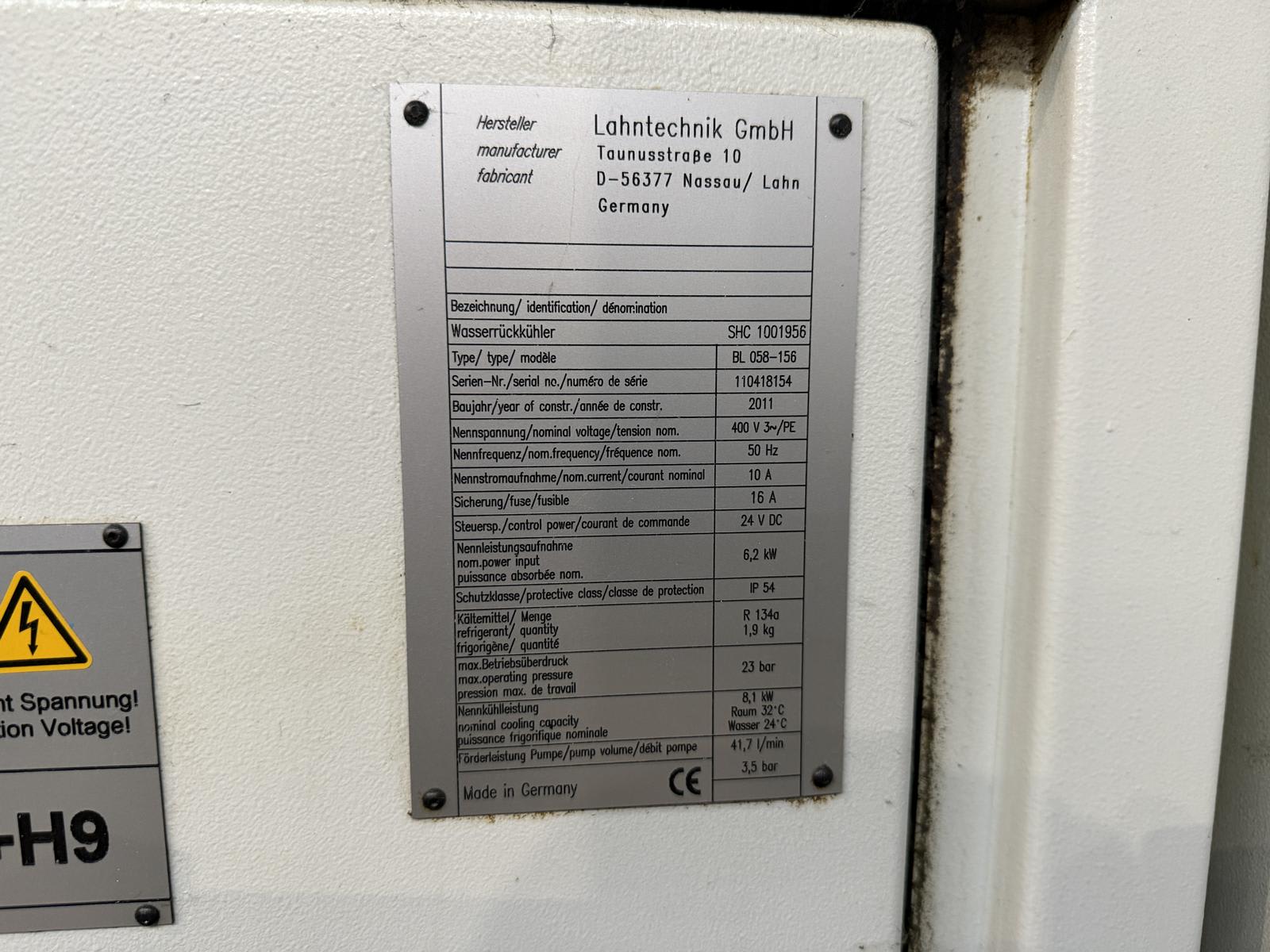

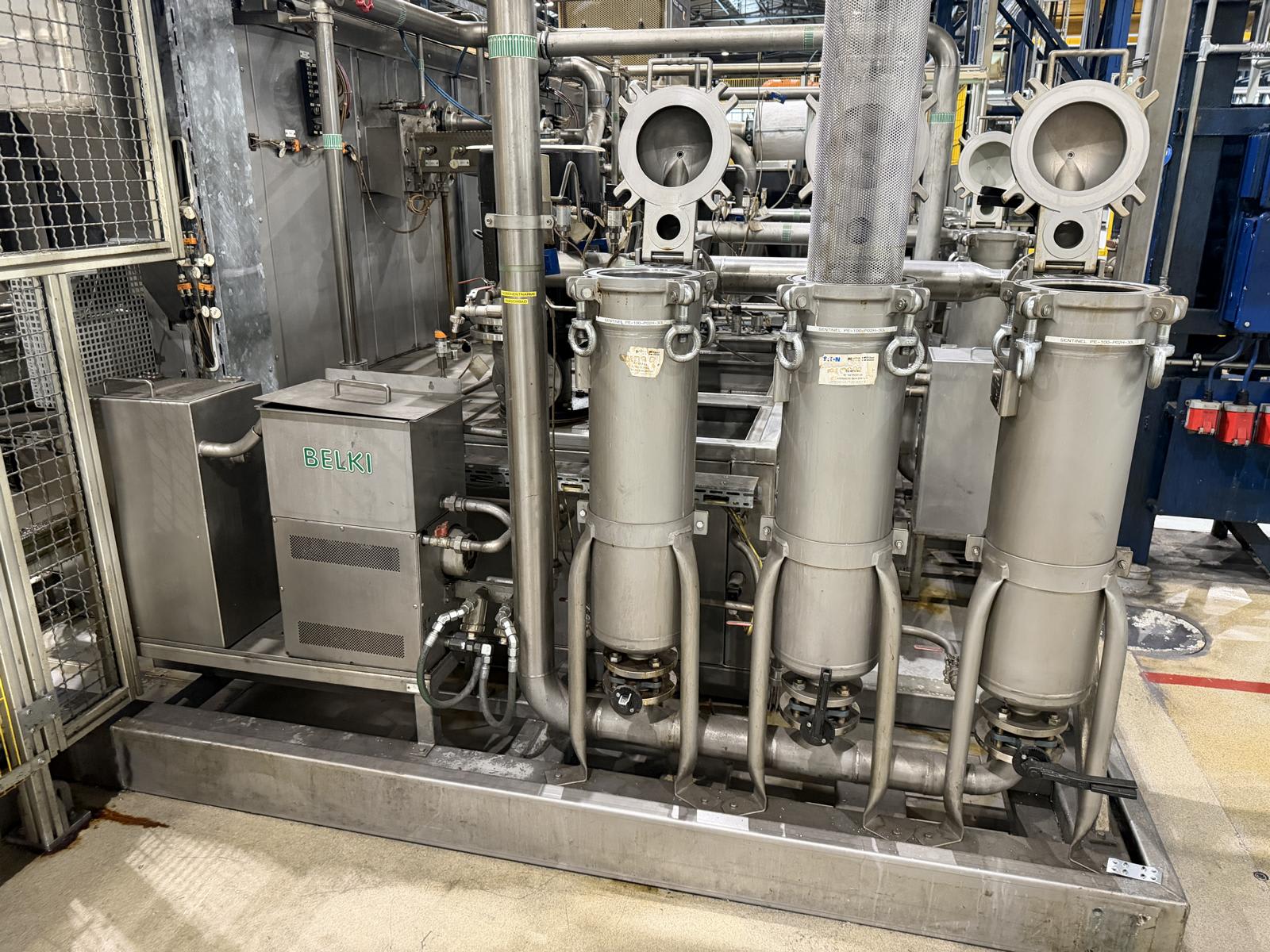

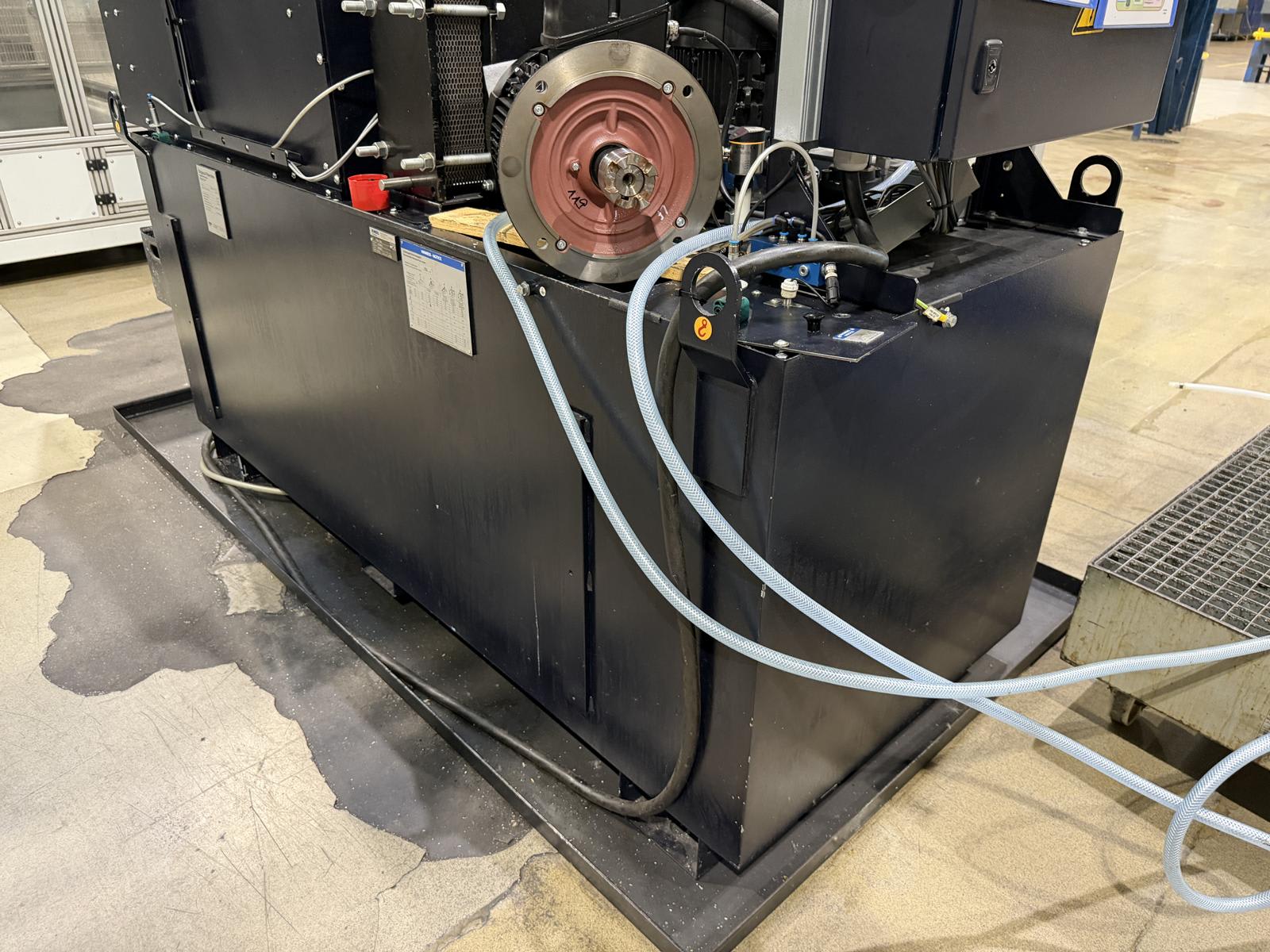

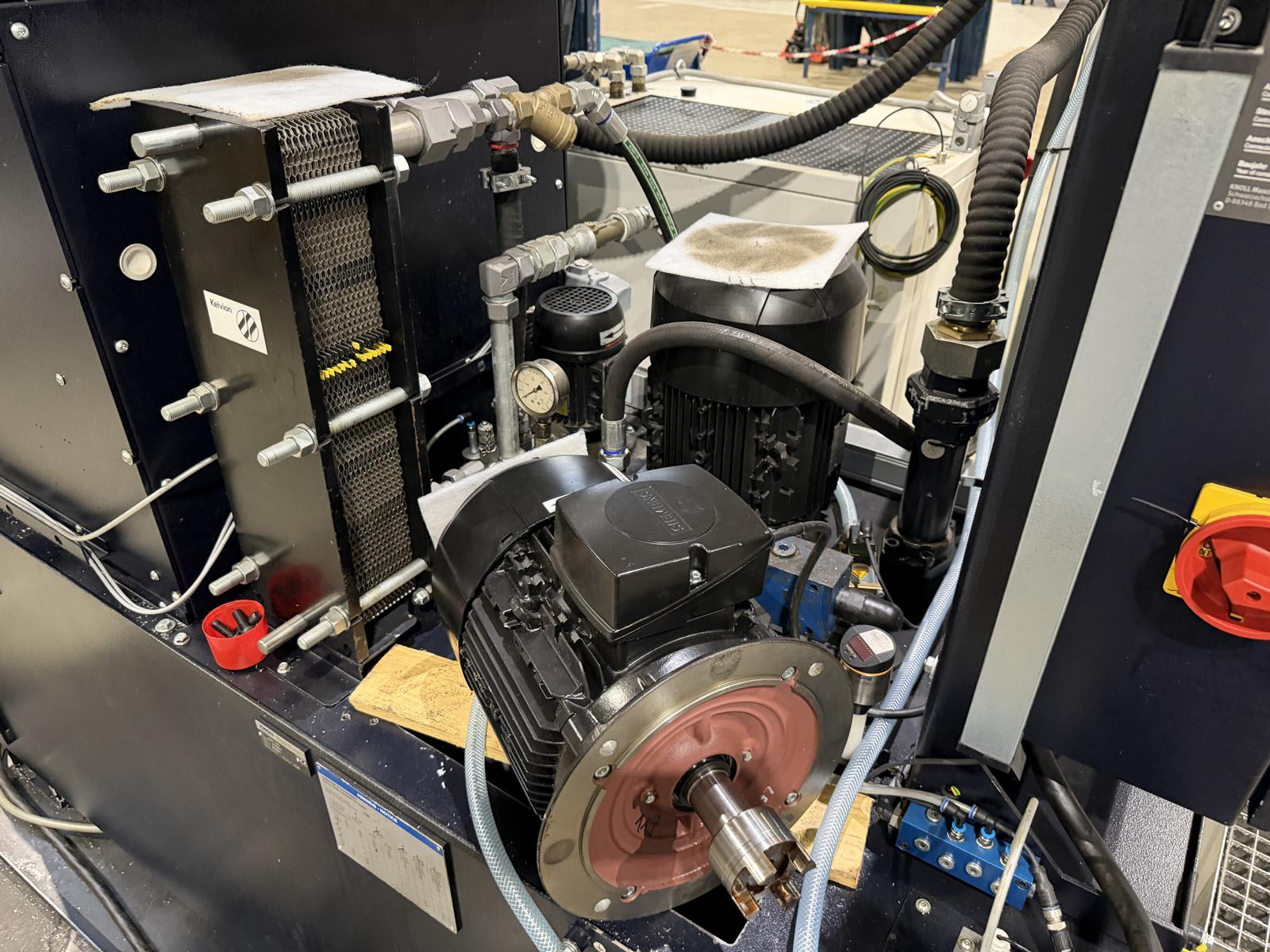

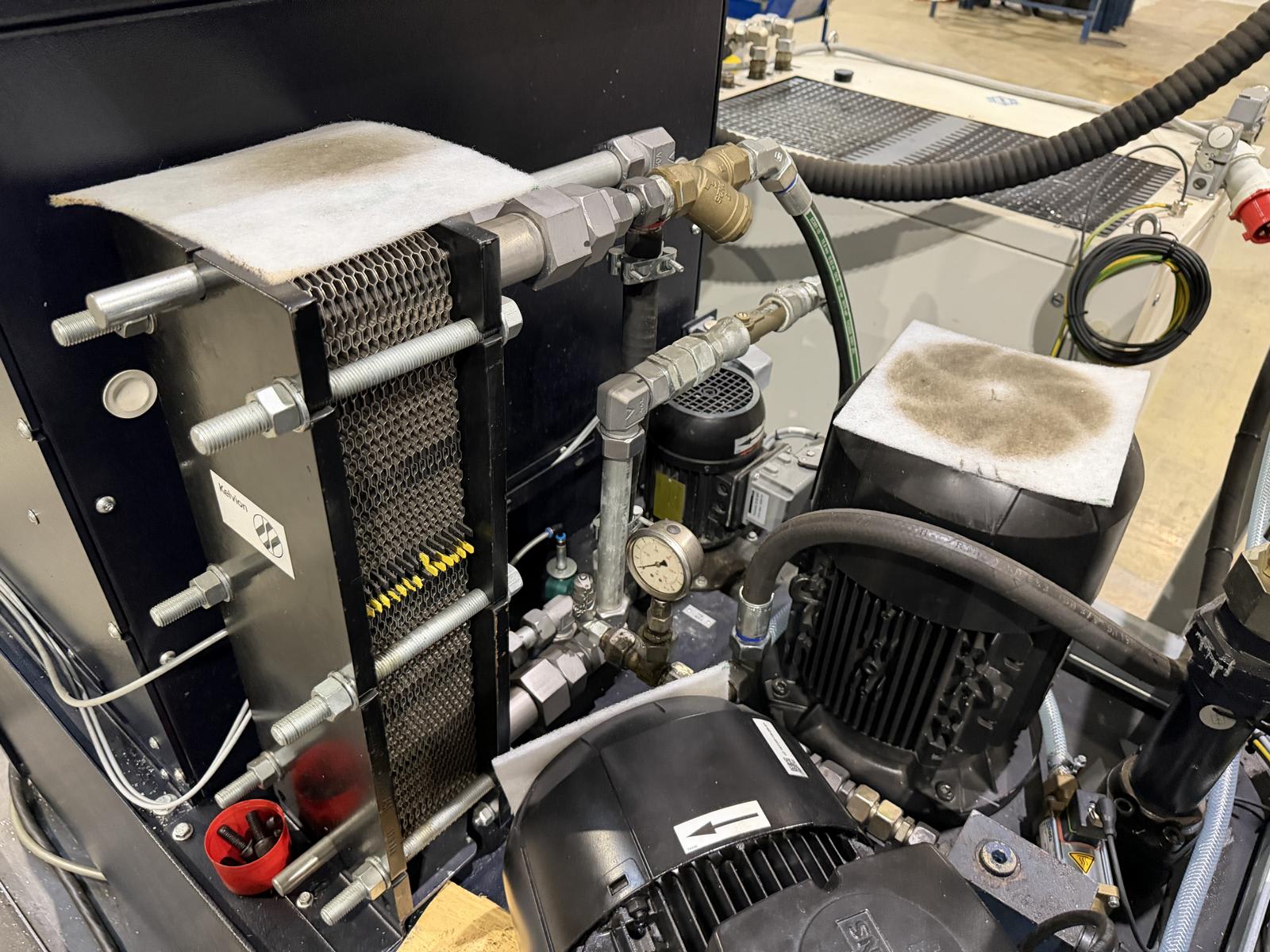

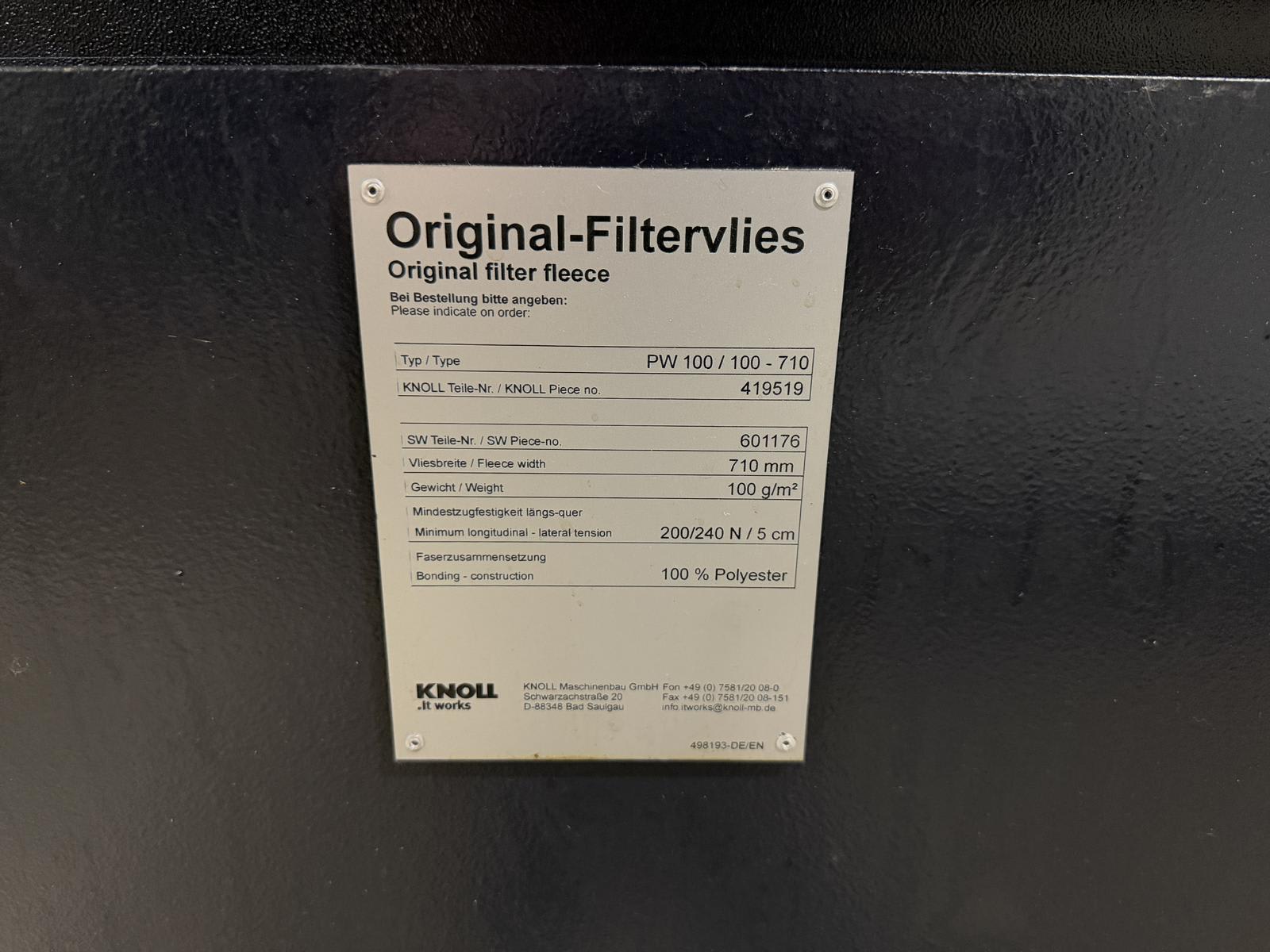

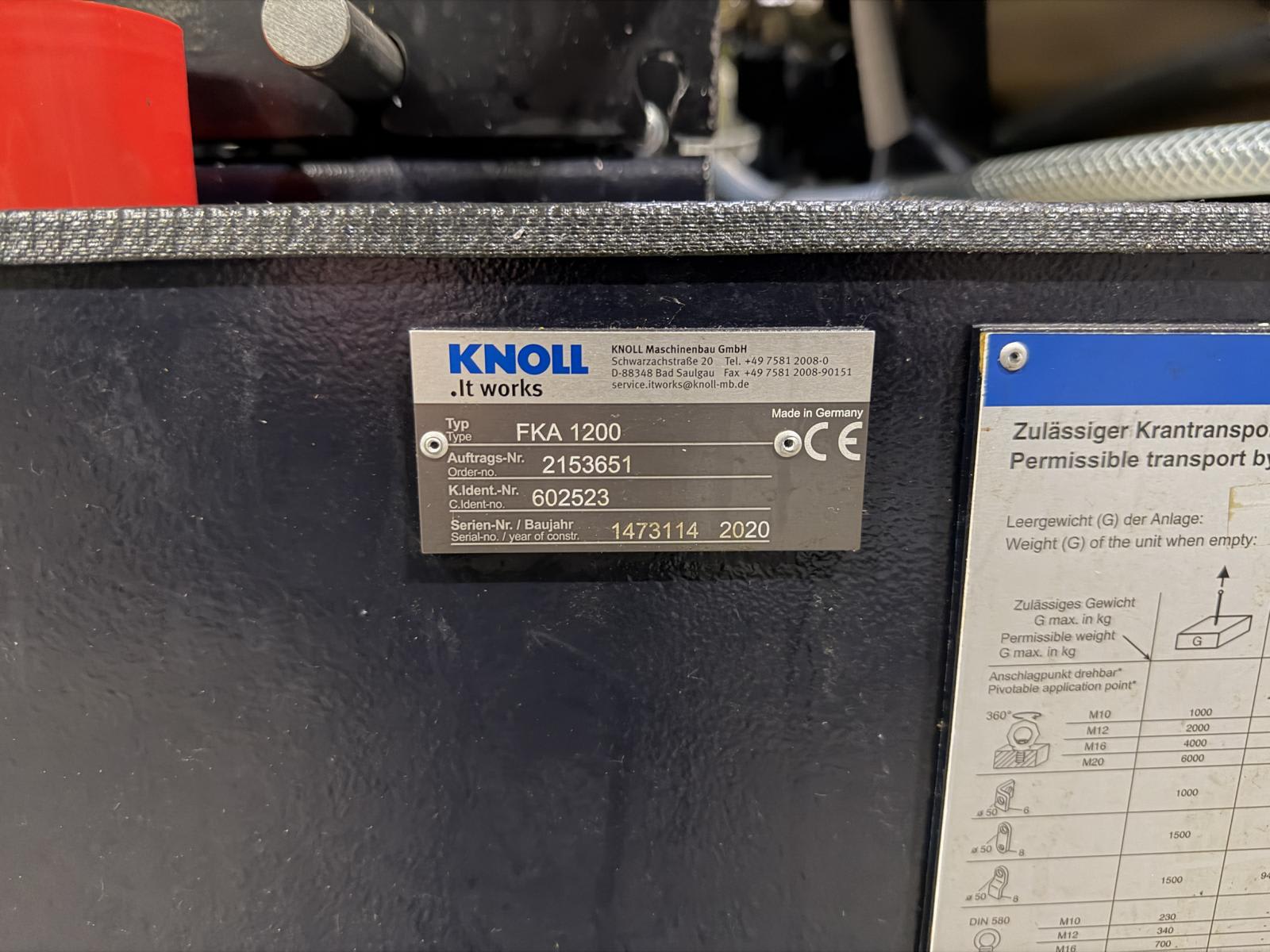

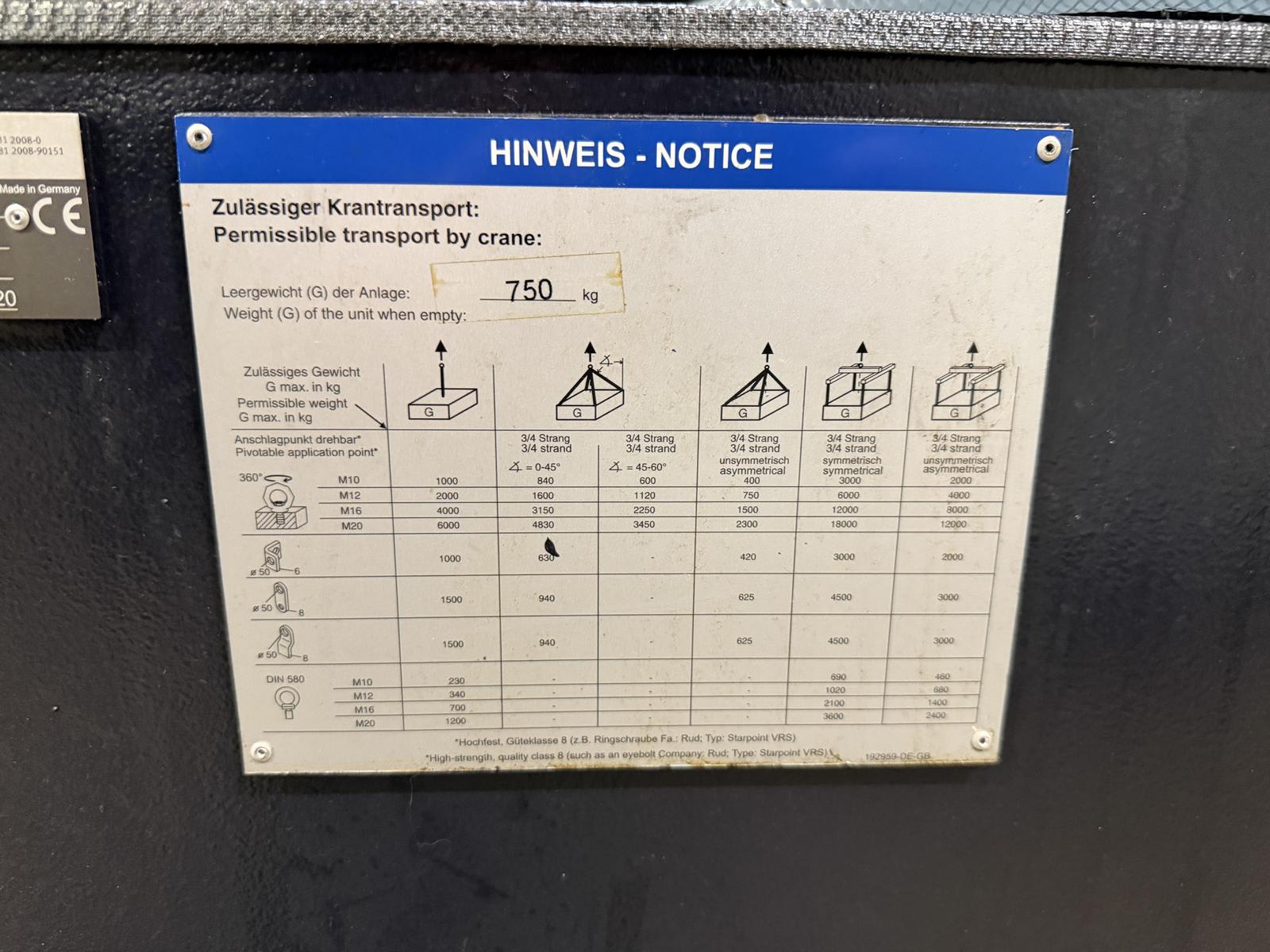

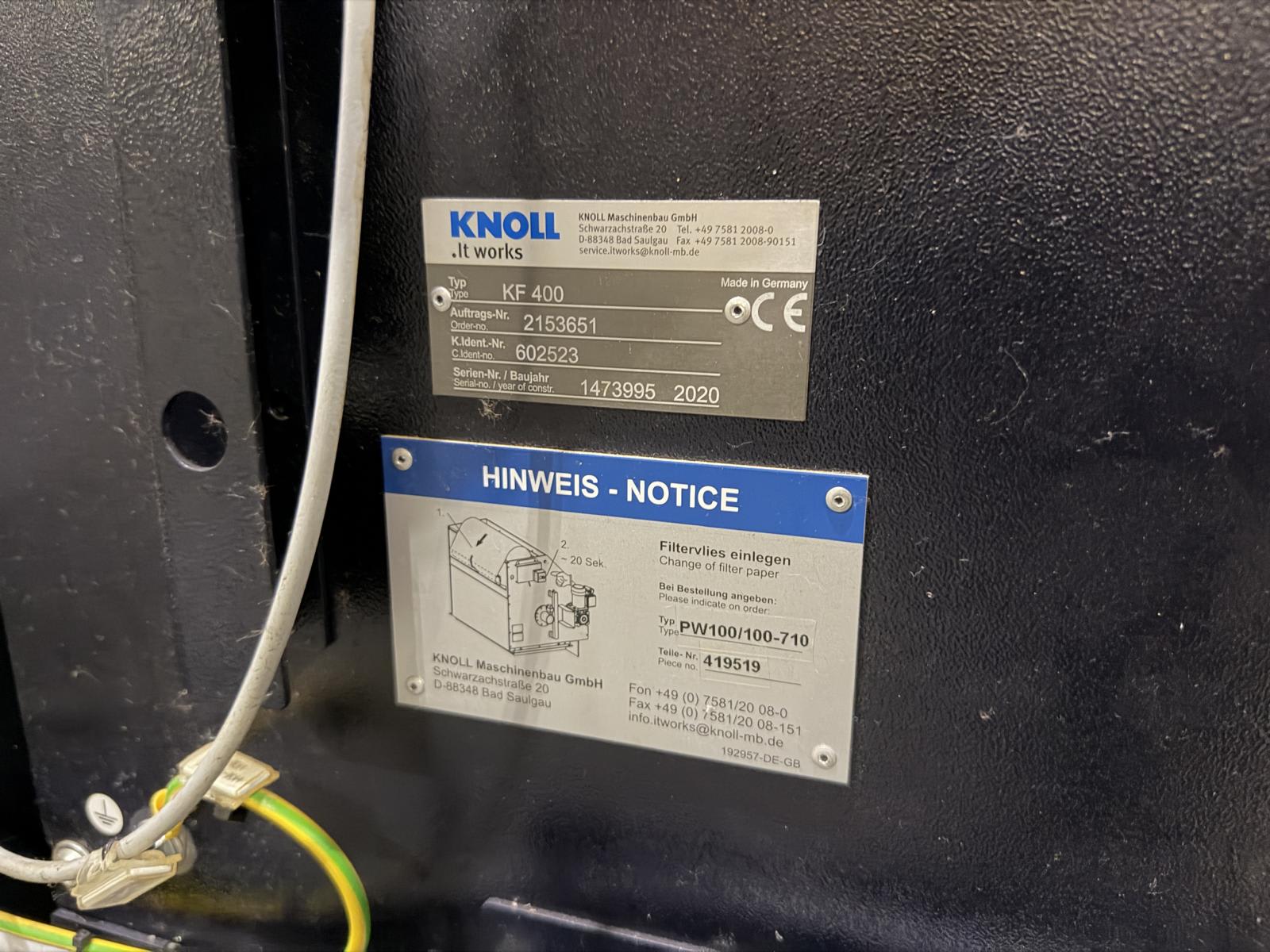

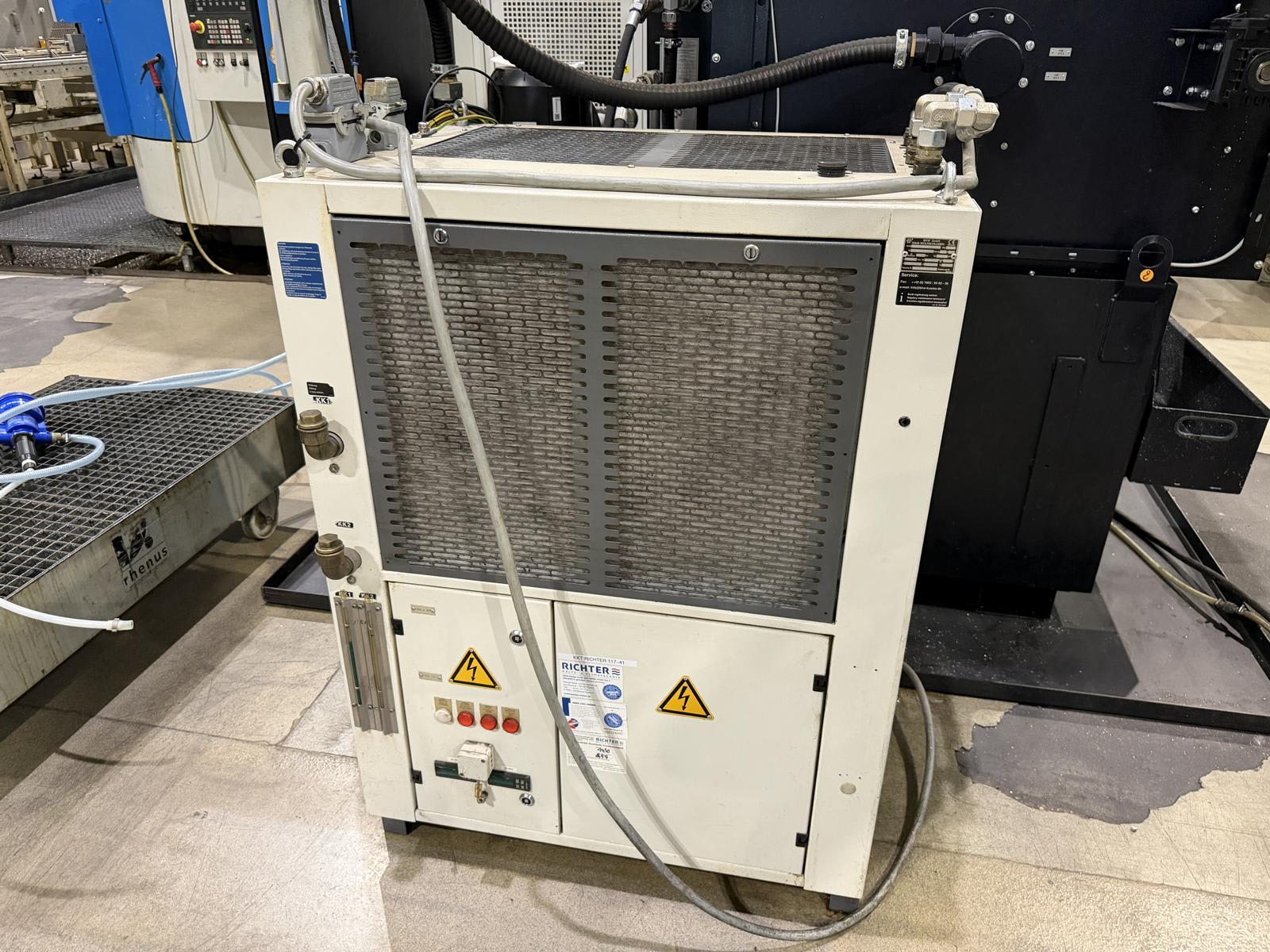

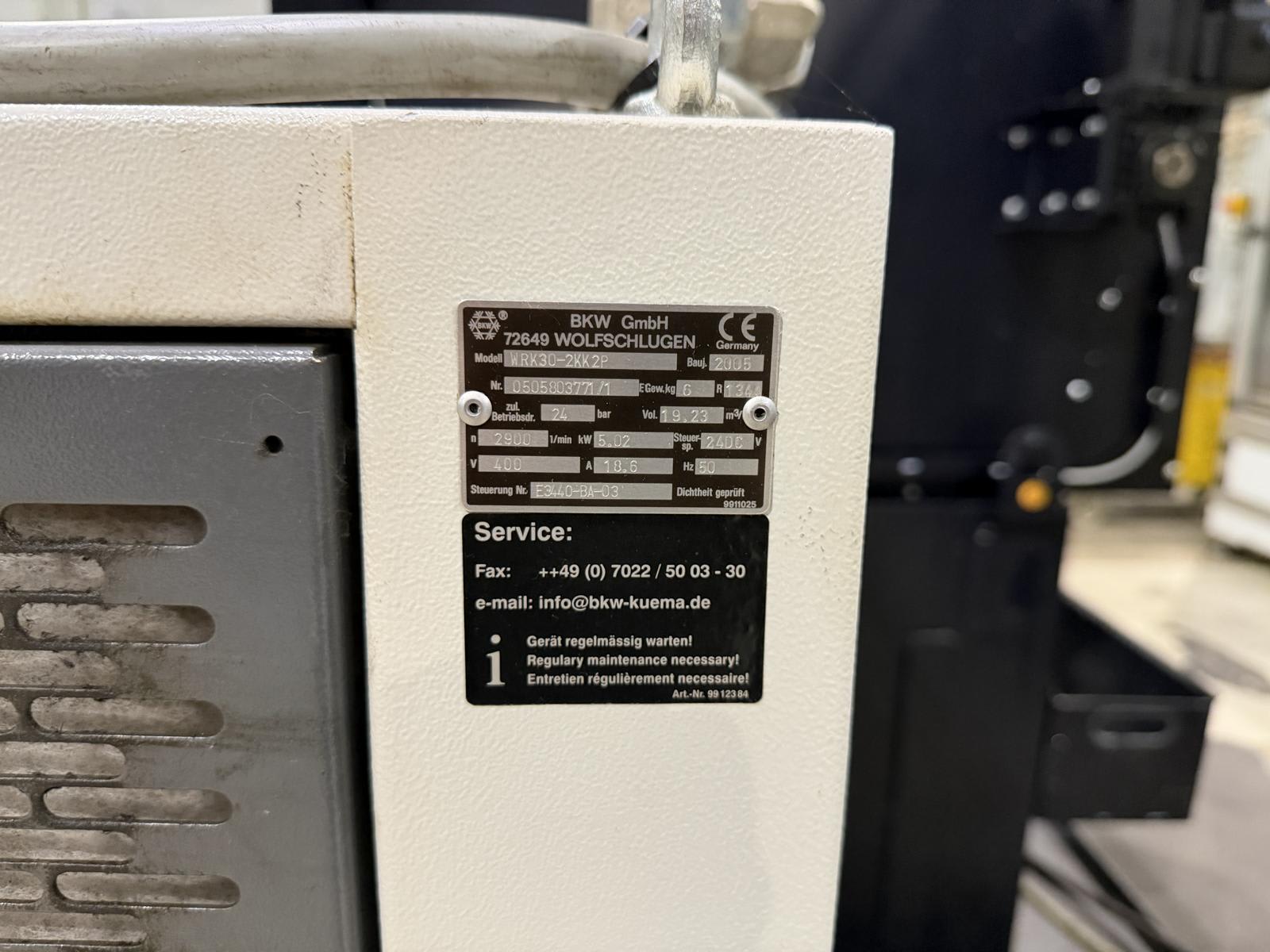

Coolant Filtration and Recirculation System Knoll / BKW FKA 1200 | 2020

Binding Handling & Service Fee:

490 € (EURO)

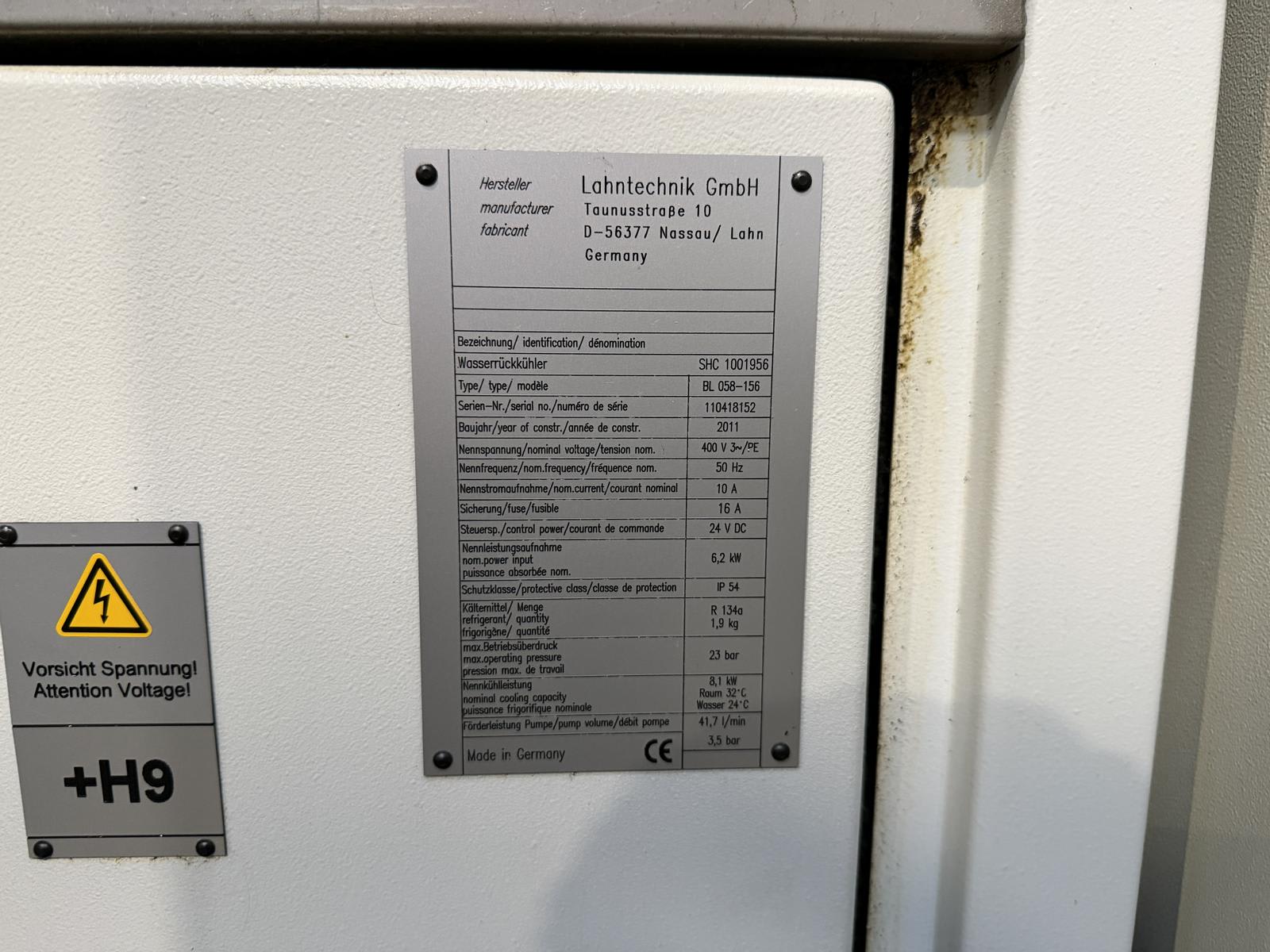

This Filter and Cooling Unit was previously used for two Starrag Heckert Machining Centers (Lot 2770011 and 12) Order number: 2153651 Control voltage: 24 V DC Connection voltage: 3×400 V + PE / 50 Hz Connection load: 6.30 kW Fuse: 50 A Country of manufacture: Germany Additional unit: Manufacturer: BKW GmbH, Wolfschlugen Model: WRK3C-2KK2P Year of manufacture: 2005 Refrigerant: R134a Permissible operating pressure: 24 bar Voltage: 400 V / 50 Hz Power: 5.02 kW Control voltage: 24 V DC Country of manufacture: Germany

Essential Information

General Information

- Auction Dates

- Starts: 25 September 2025 at 08:00 BSTEnds: 16 January 2026 at 17:00 GMT

- Site Address

- PlauenGermany

- Viewing Days

- By Appointment OnlyInspection by prior Appointment only | Please contact Inquiry@Maynards.com to arrange an Inspection appointment

Fees & Payment

- Currency

- EUR

- Buyers Premium

- 18% or as specified on individual items

- Payment

General Payment Information

- Per bidder, there will only one invoice be issued for all lots won in one auction/sale.

- The invoice will be in PDF format and will be emailed to successful bidders within 24 hours after the last lot in the auction has closed. Alternatively, a link will be emailed from where the invoice can be downloaded.

- Payment is due immediately on receipt of invoice unless stated differently on the invoice.

- All payments must be made in the currency stated on the issued invoice.

- The only accepted form of payment is bank transfer.

- We DO NOT accept payment by cheque, debit or credit card.

- Please reference the invoice number on the bank transfer.

- For all bidders with residence outside of the country from where the assets are being sold, Maynards Europe will collect 20% of the invoice total as a deposit. This deposit will be refunded in full after Maynards Europe have received proof of export.

- It happens frequently that Maynards Europe at first only issue a so-called “proforma invoice”. After receipt of full payment, collection of the items and receipt of export documentation (if applicable), the final invoice will be issued.

Goods

- Clearance days

- 18 January 2026 at 07:00 GMT - 13 February 2026 at 17:00 GMTMore Information in the Sales Information

- General Collection Information

- Buyers are fully responsible for the removal of the items purchased including all transport and rigging charges.

- Items only become available for collection after Maynards Europe have received payment in full, and a collection appointment has been booked with the project manager / on-site contact.

- Buyers or third-party movers must present the ‘Paid Invoice’ confirmation to the on-site personnel when collecting and removing their items. The ‘Paid Invoice’ confirmation will be issued by Maynards Europe after receipt of the full payment and will be emailed in PDF format to the buyer.

- Buyers must complete the removal of items within the clearance deadline (individually stated for each auction / sale). Removal is by appointment only.

- Removal and on-site contact information will be emailed to buyers at the same time invoices are issued.

- Entrance to the site is subject to the Conditions of Admission for customers, agents and contractors. For your protection you will be required to wear safety equipment including high visibility jackets and safety footwear as a minimum. Everybody entering the site has to undergo a short security briefing.

- Conditions of Site Admission: All Customers, agents & contractors must report to the site manager / foreman on arrival and must not proceed on to site without permission. No persons under 16 years of age will be allowed on site.

- Buyers / Transport Companies must bring their ‘Paid Invoice’ document to site together with proof of appropriate insurance coverage. It is the buyer’s responsibility to ensure their removal contractor has the appropriate insurance coverage. As a standard, an insurance cover of 5 million EUR is required. We reserve the right to deny access to the site if these requirements are not met or the contractor fails to provide proof of this. If you have any questions on this, please do not hesitate to contact us on +49 8151 973420.

- There is NEITHER lifting equipment NOR tools for dismantling available on site. Please make your own arrangements.

- Removal of items is solely the responsibility of the purchaser and/or those collecting on their behalf. This may require you to remove other items to gain access although efforts will be made to keep this to a minimum. Dismantling of machinery may be required.

- The buyer and their removal company are responsible for the condition of the site after removal of their goods. Electrical connections must be left in a safe condition and protrusions (grouting, hold down bolts / studs) must be removed and left flush to ground level. The site must be cleaned after removal and all waste must be disposed of.

- The buyer and their removal company are responsible for conducting the removal and transportation of their goods according to the standard environmental regulations.

- Removal must be carried out without damage to the site itself or any property/ items on or near the site. Liability for any such damage lies with the buyer.

- If items have not been removed by the clearance deadline, our standard Terms & Conditions apply.

- Our staff are on site to supervise and control removals only, they are not permitted to move equipment or assist with the removal in any way. We thank you for your cooperation in helping to keep yourself and others safe while on site and for aiding us in the timely removal of goods from site.

- Sales Contacts

- Auction informationAdrian MatuszczakMaximilianstr. 4B

Starnberg

82319

Germany adrian@maynards.com+49 (0) 8151 1878 430Customer Service Maynards Europe GmbHGewerbealle 3

Poecking

82343

Germany inquiry@maynards.com+ 49 (0) 8151 1878 400