Online Auction | GoodYear Fulda | Closure of Tire Manufacturing Plant

- LISTING 2760002

![Deutsch]()

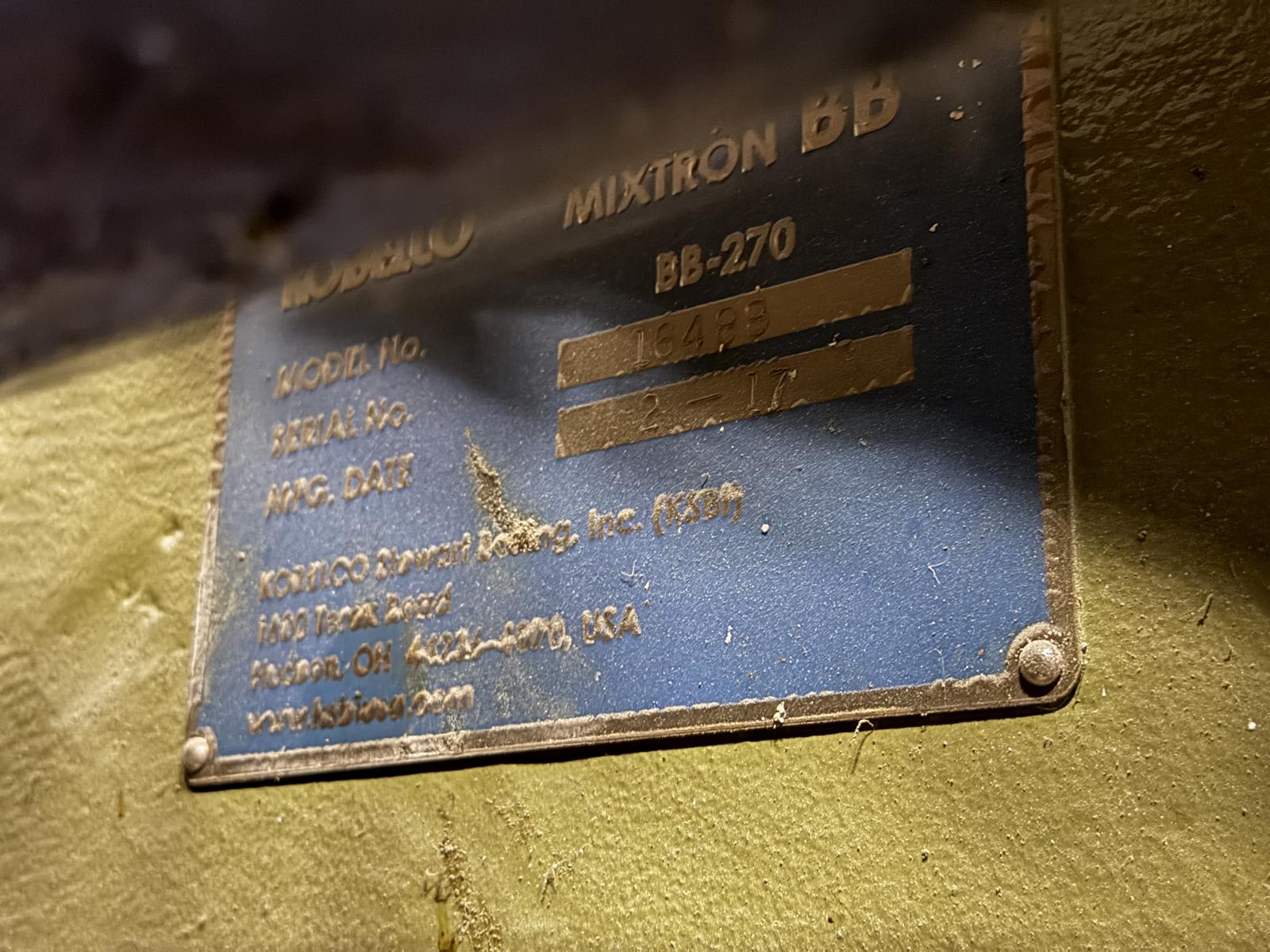

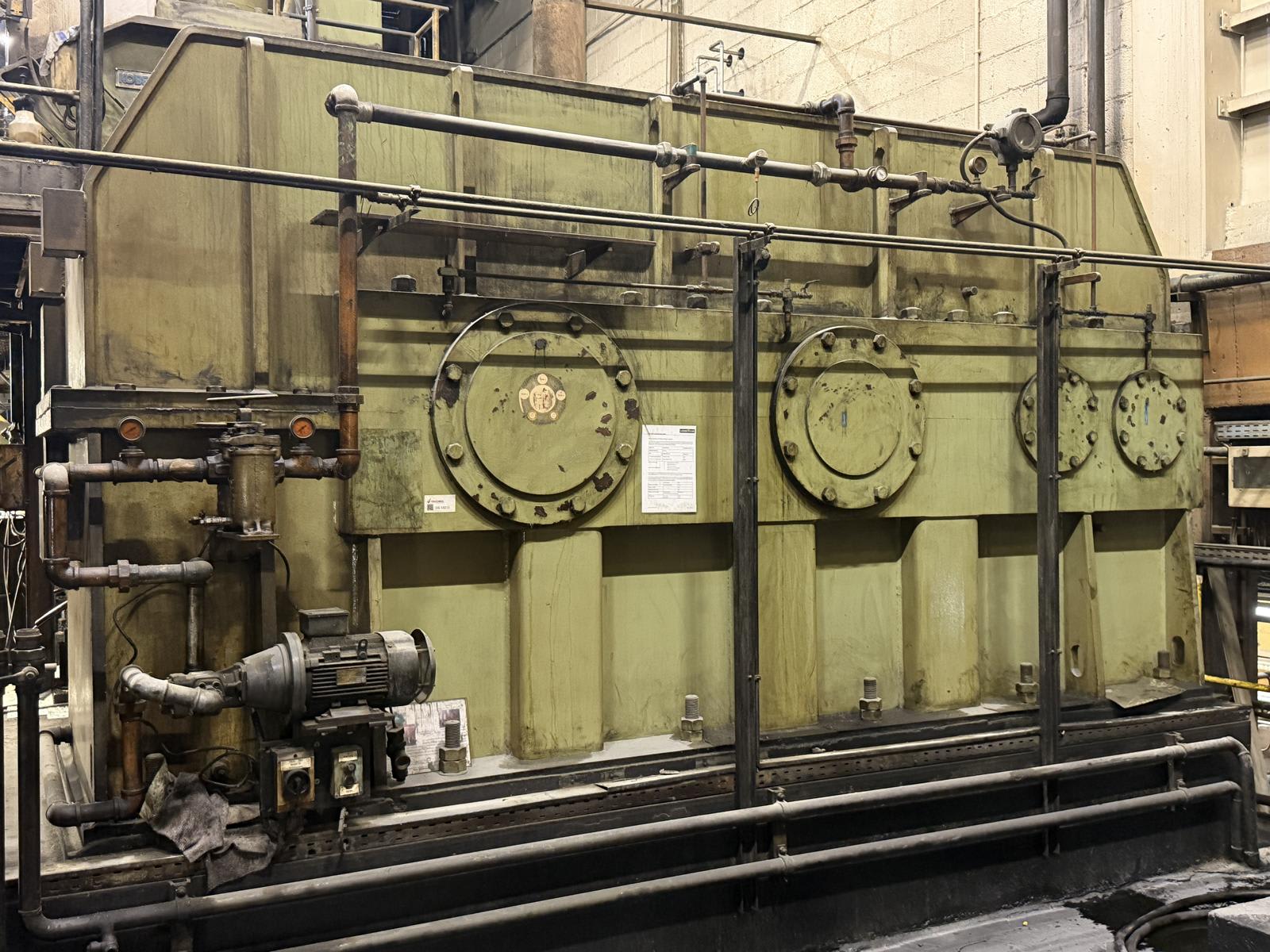

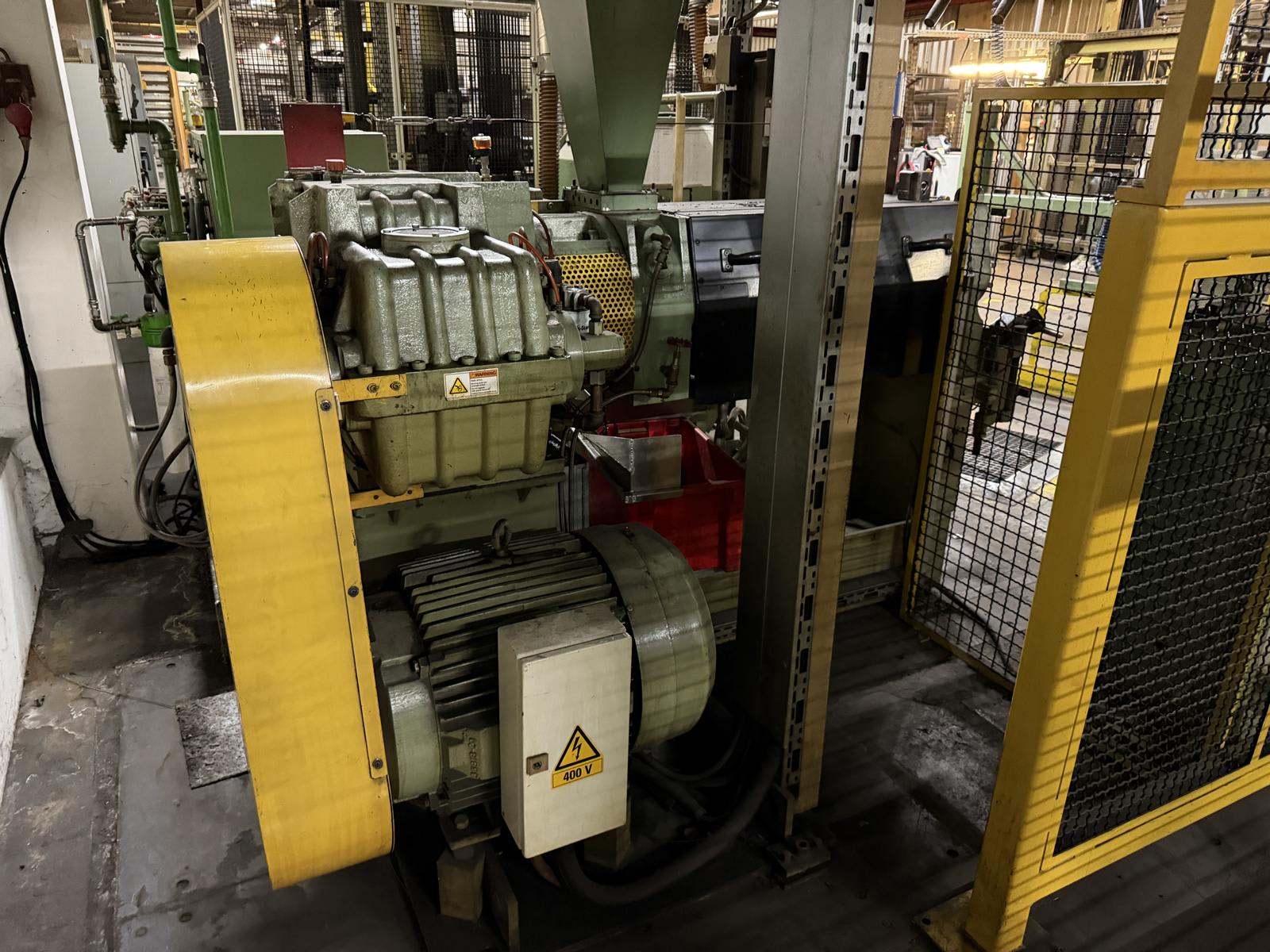

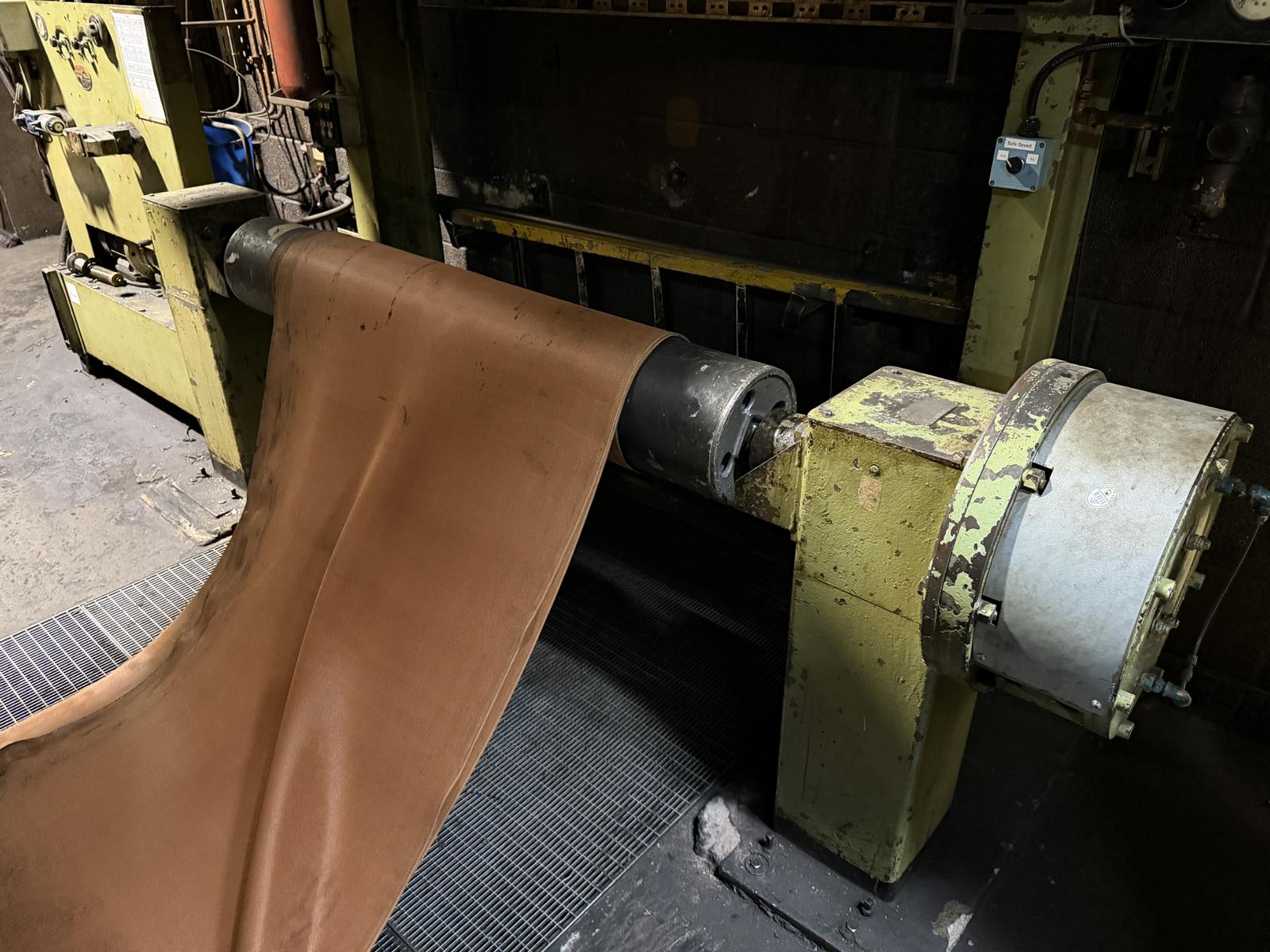

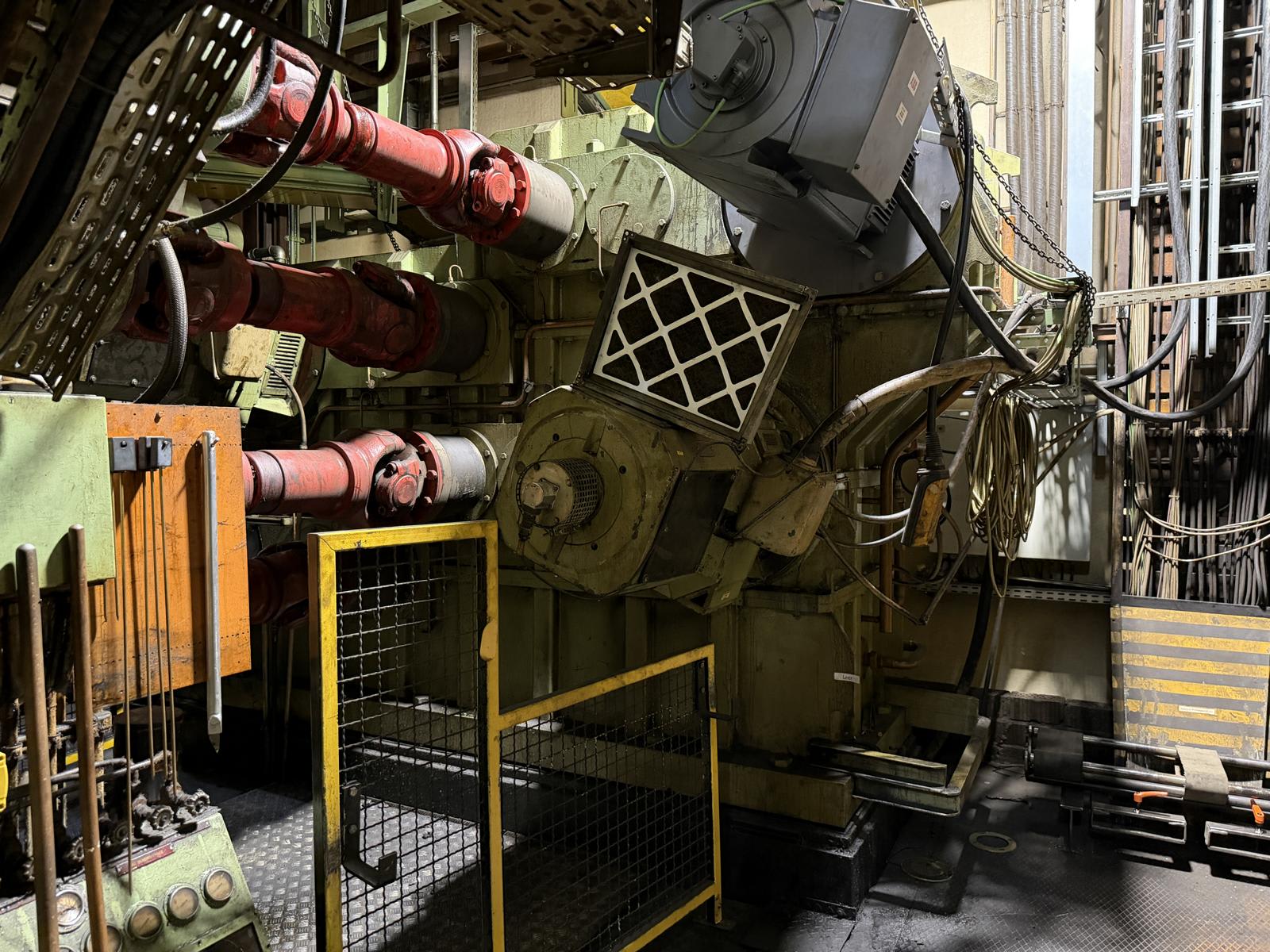

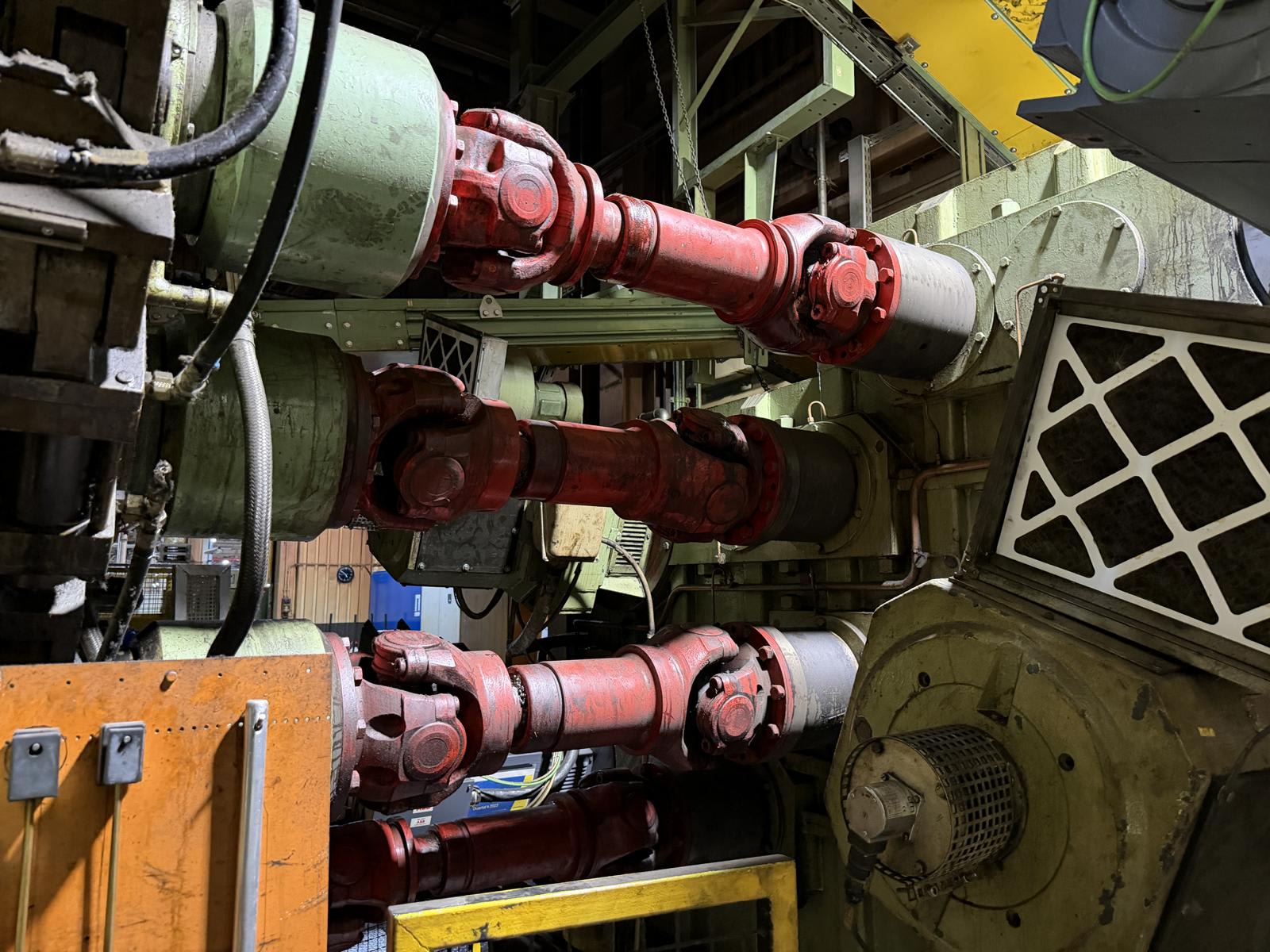

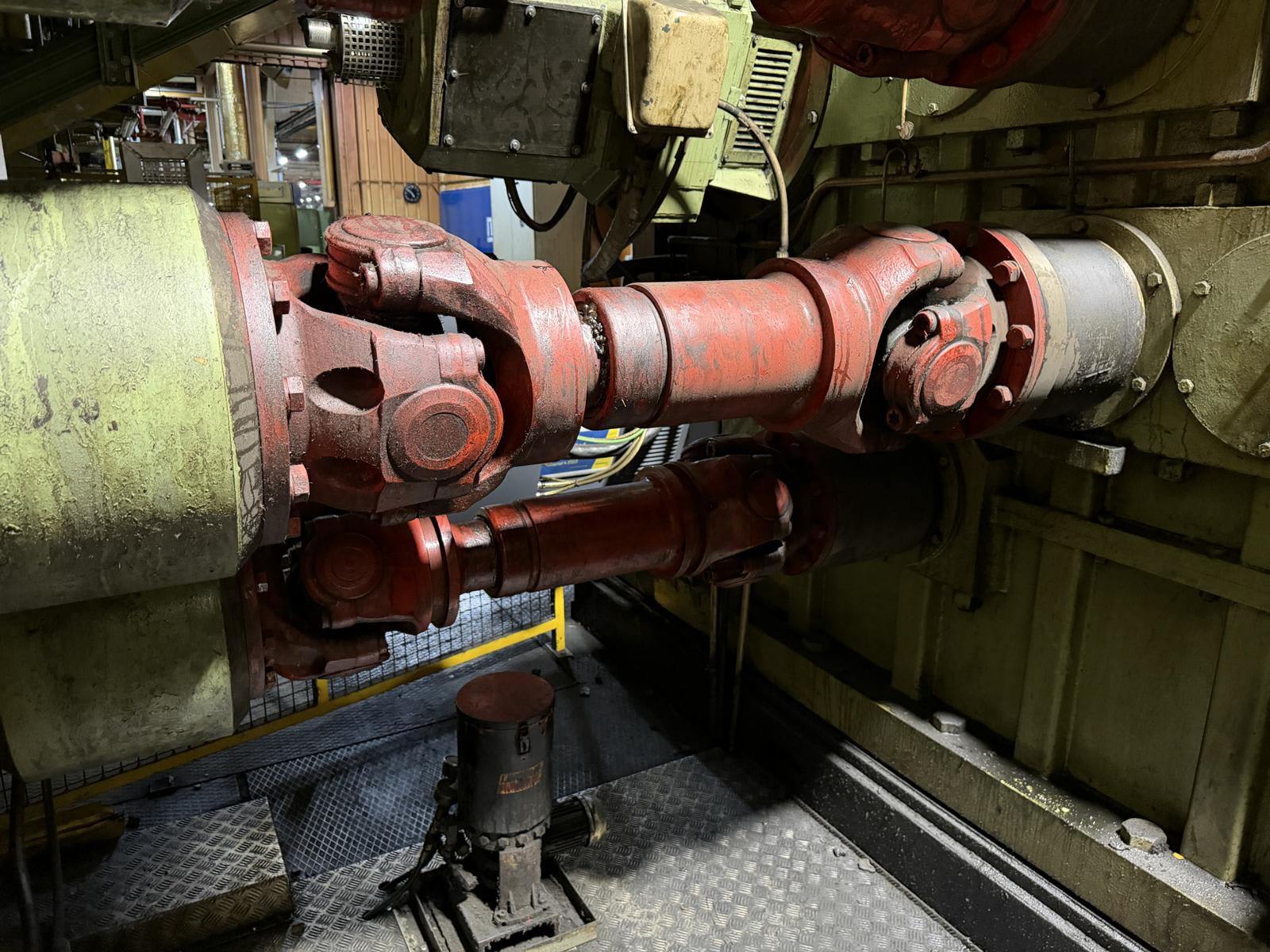

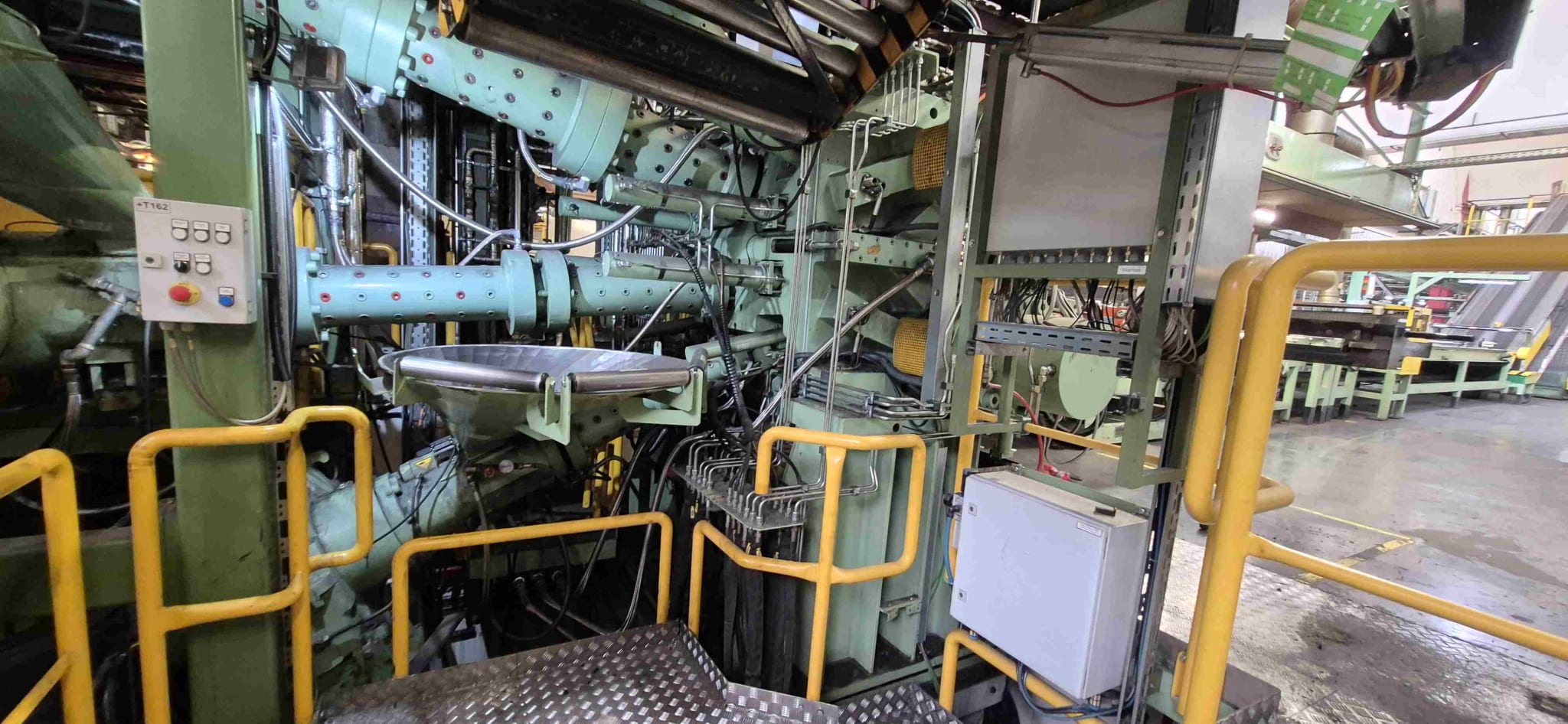

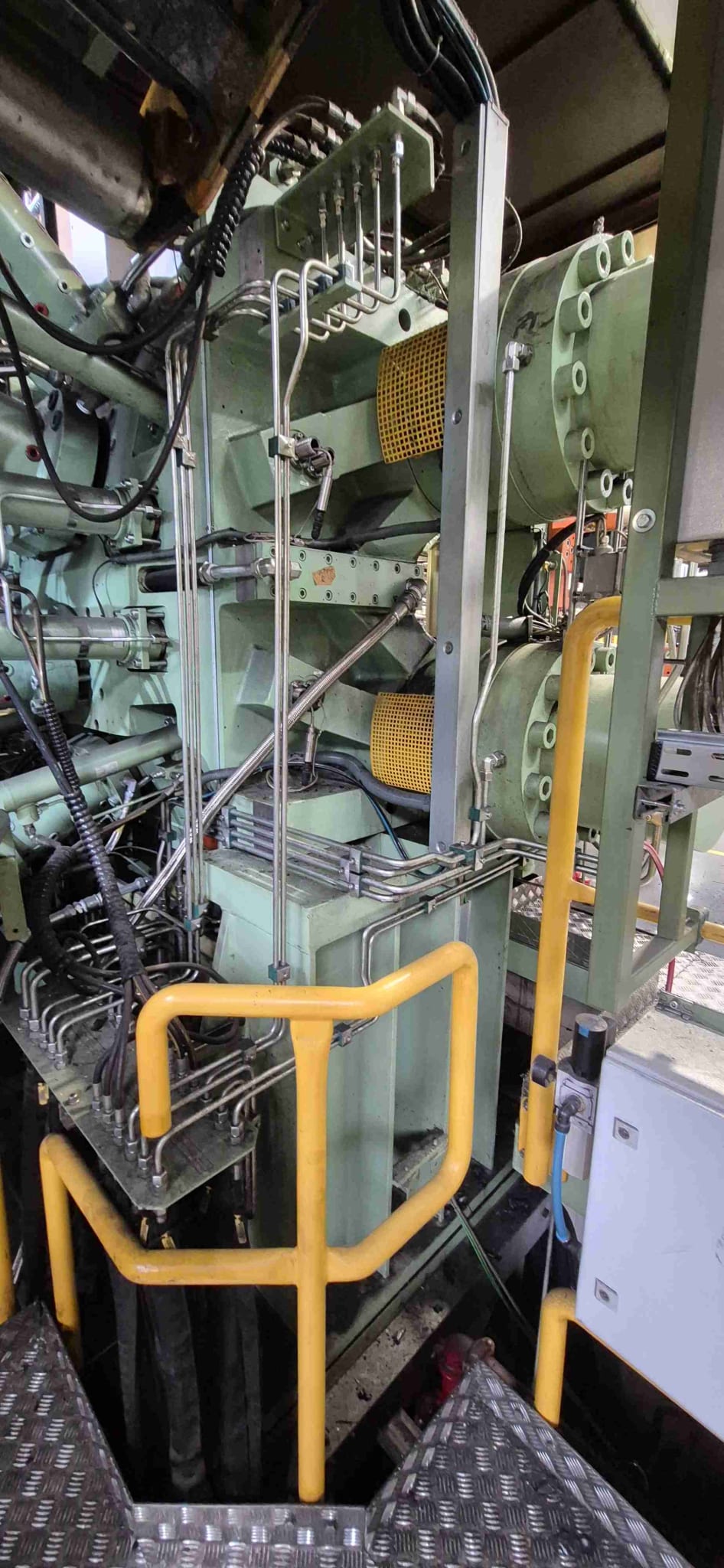

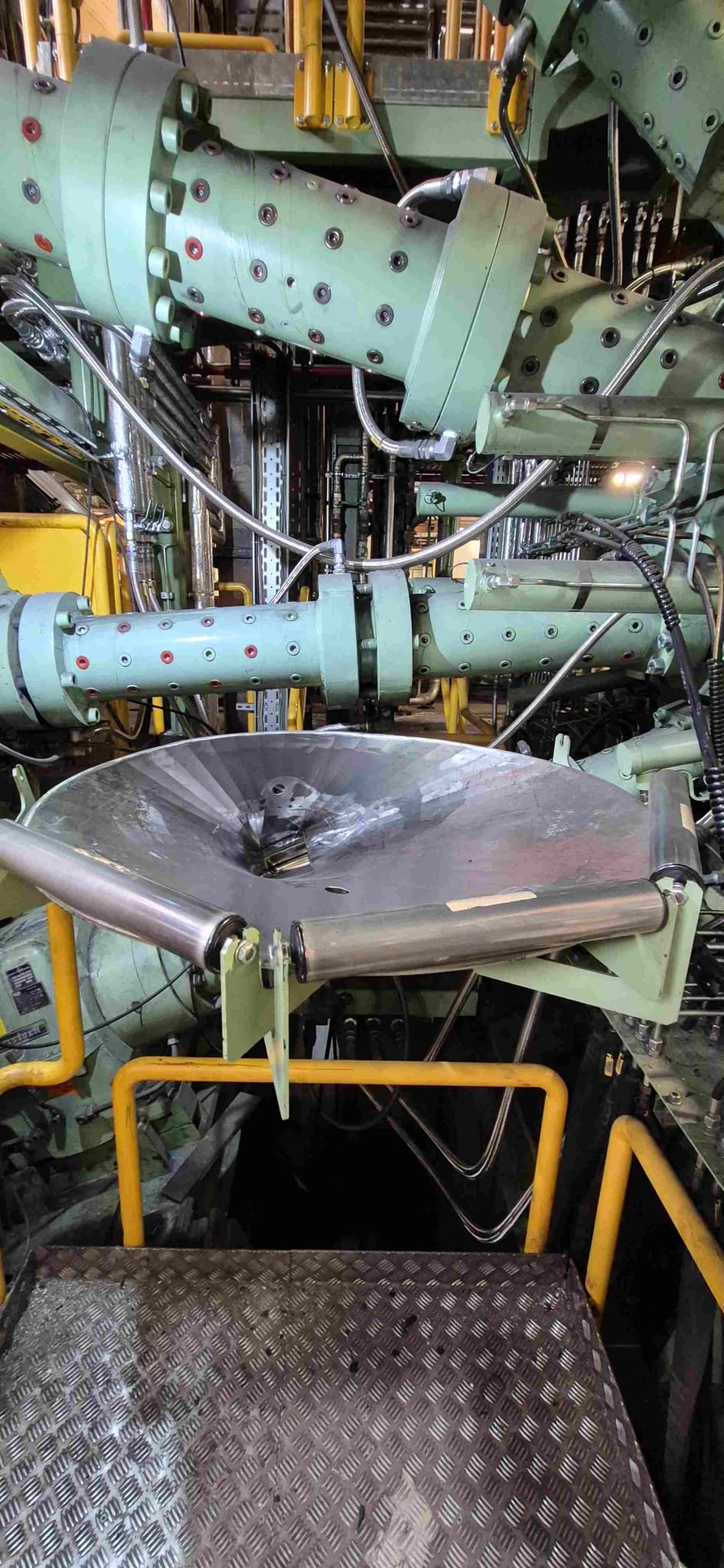

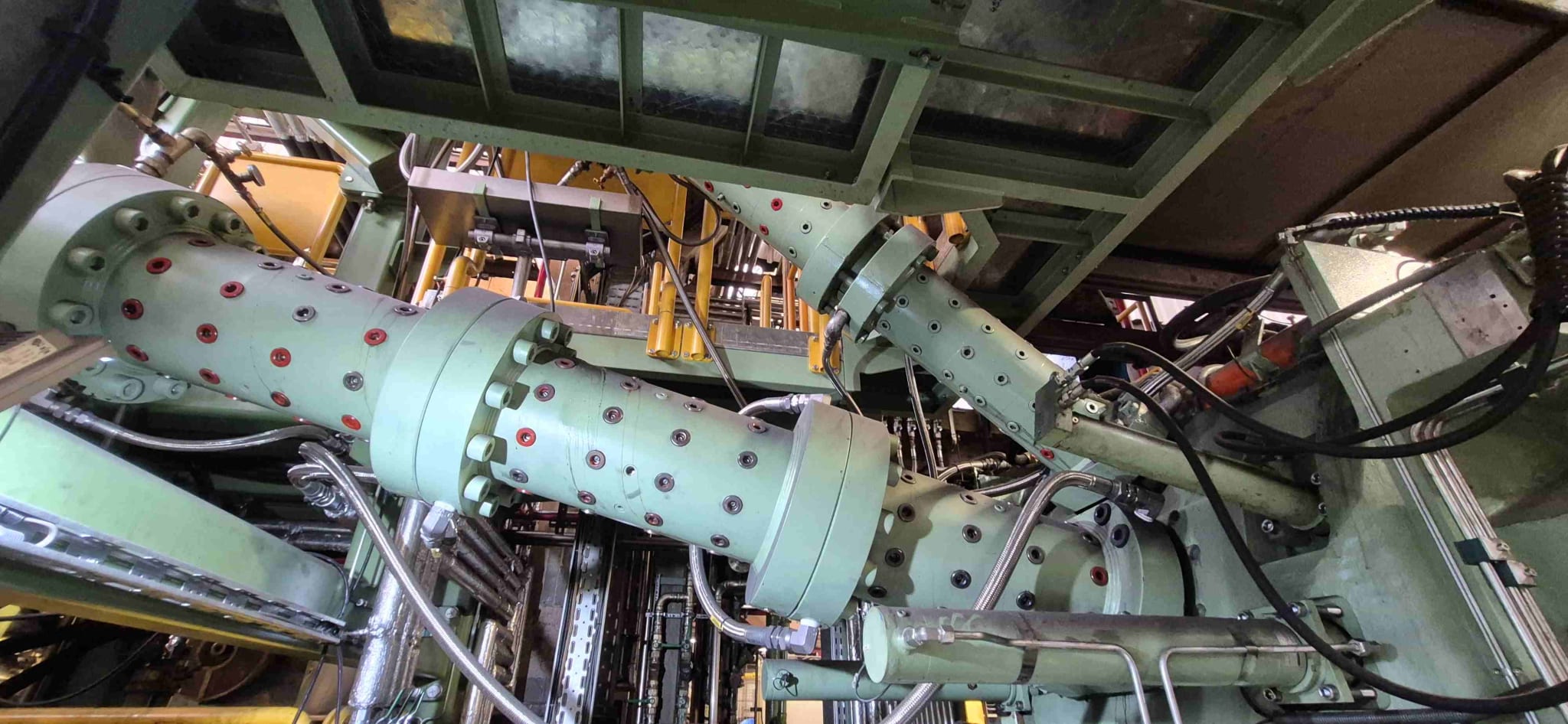

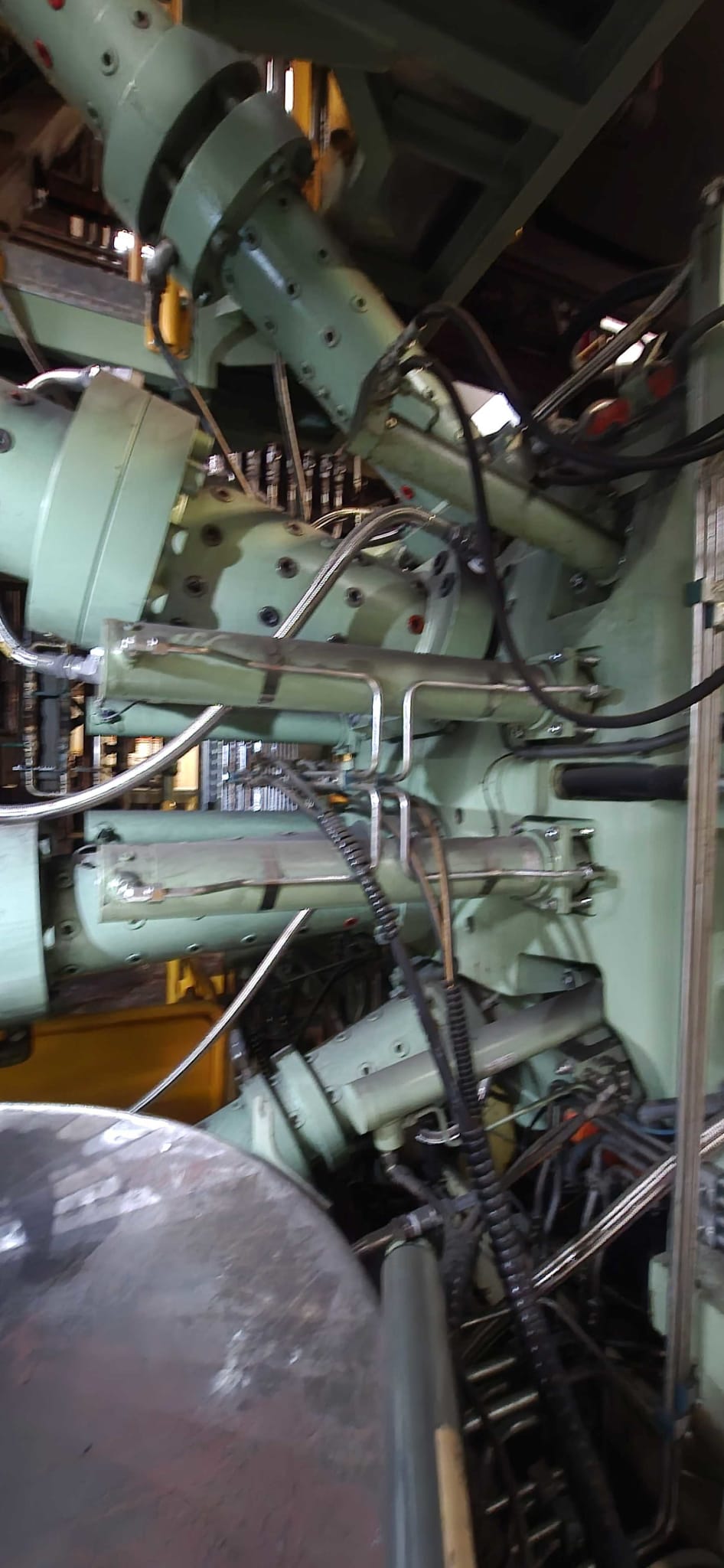

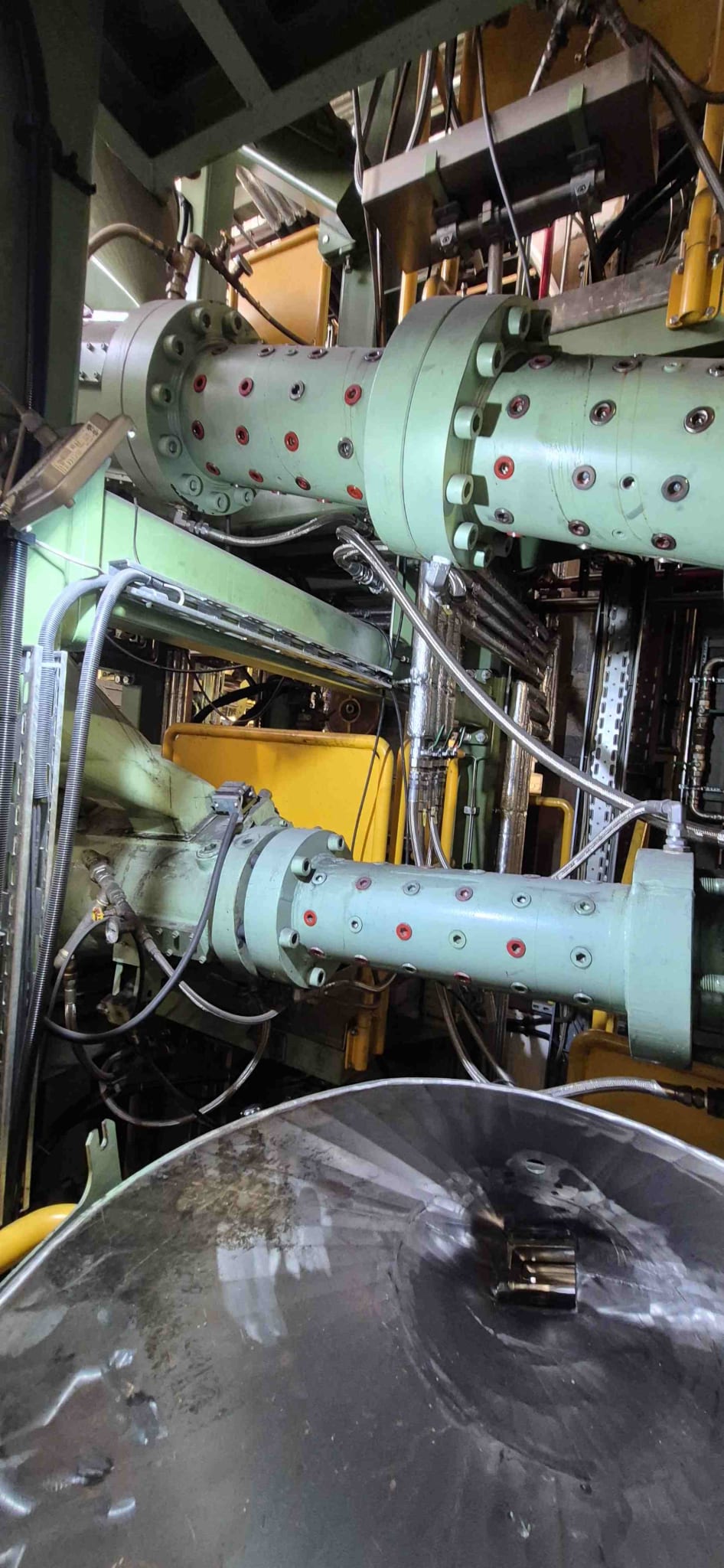

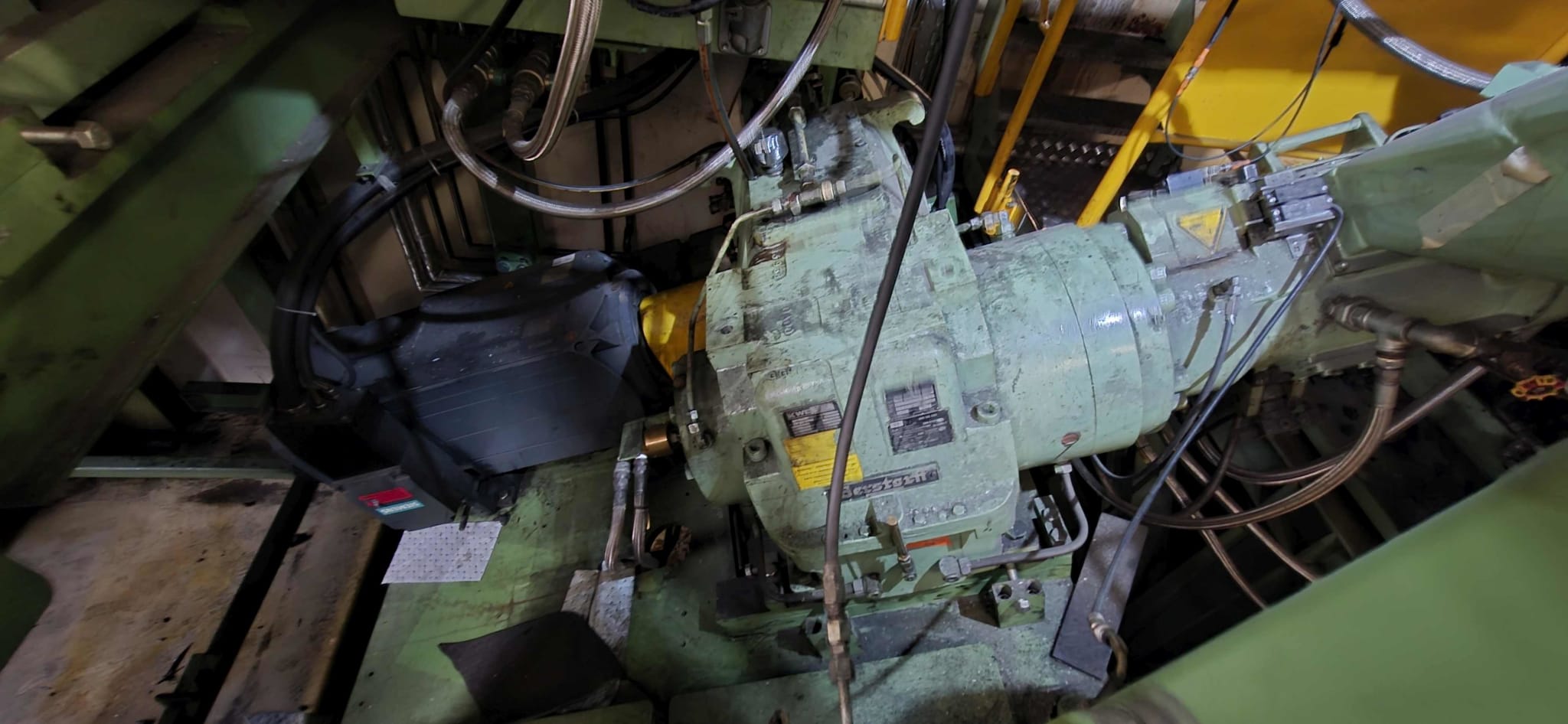

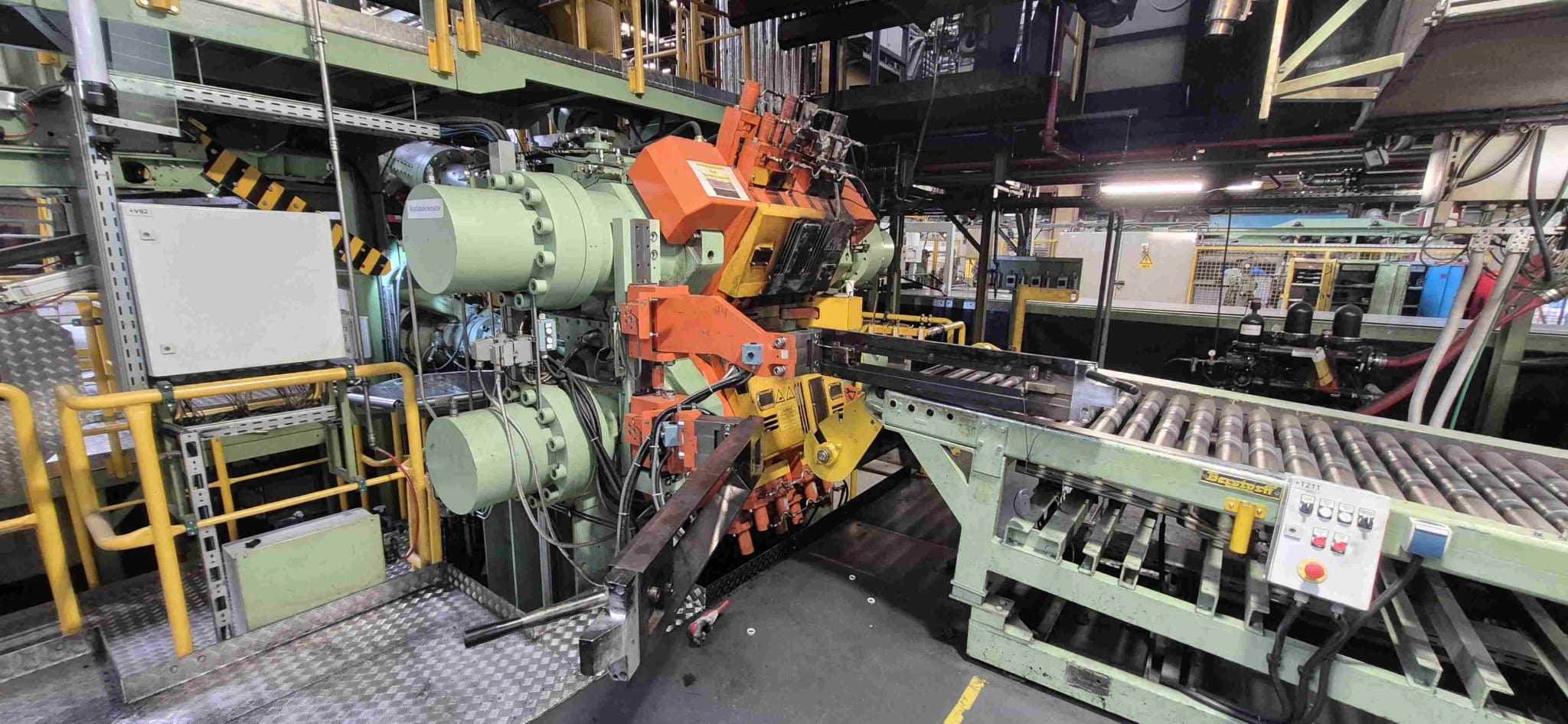

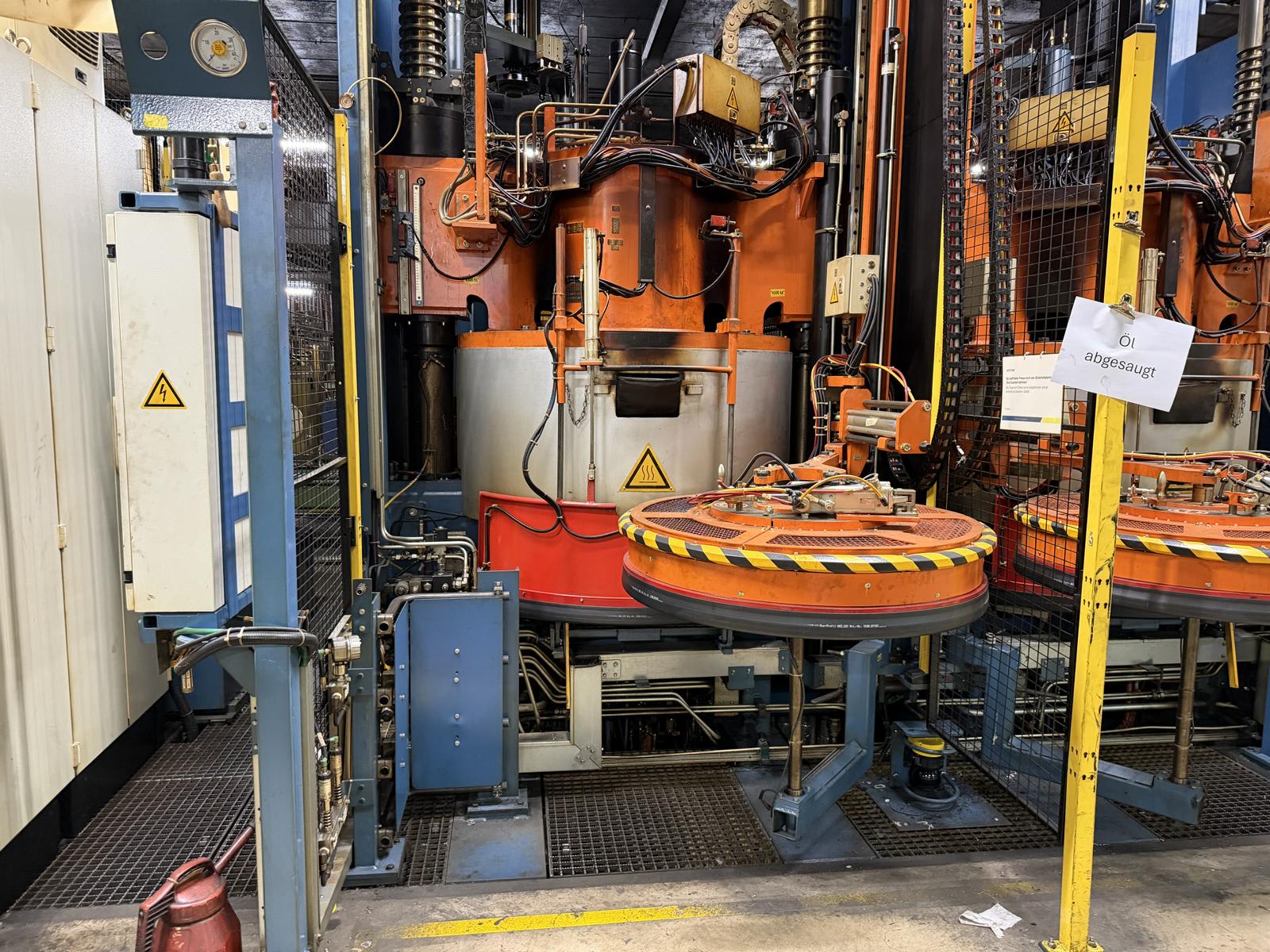

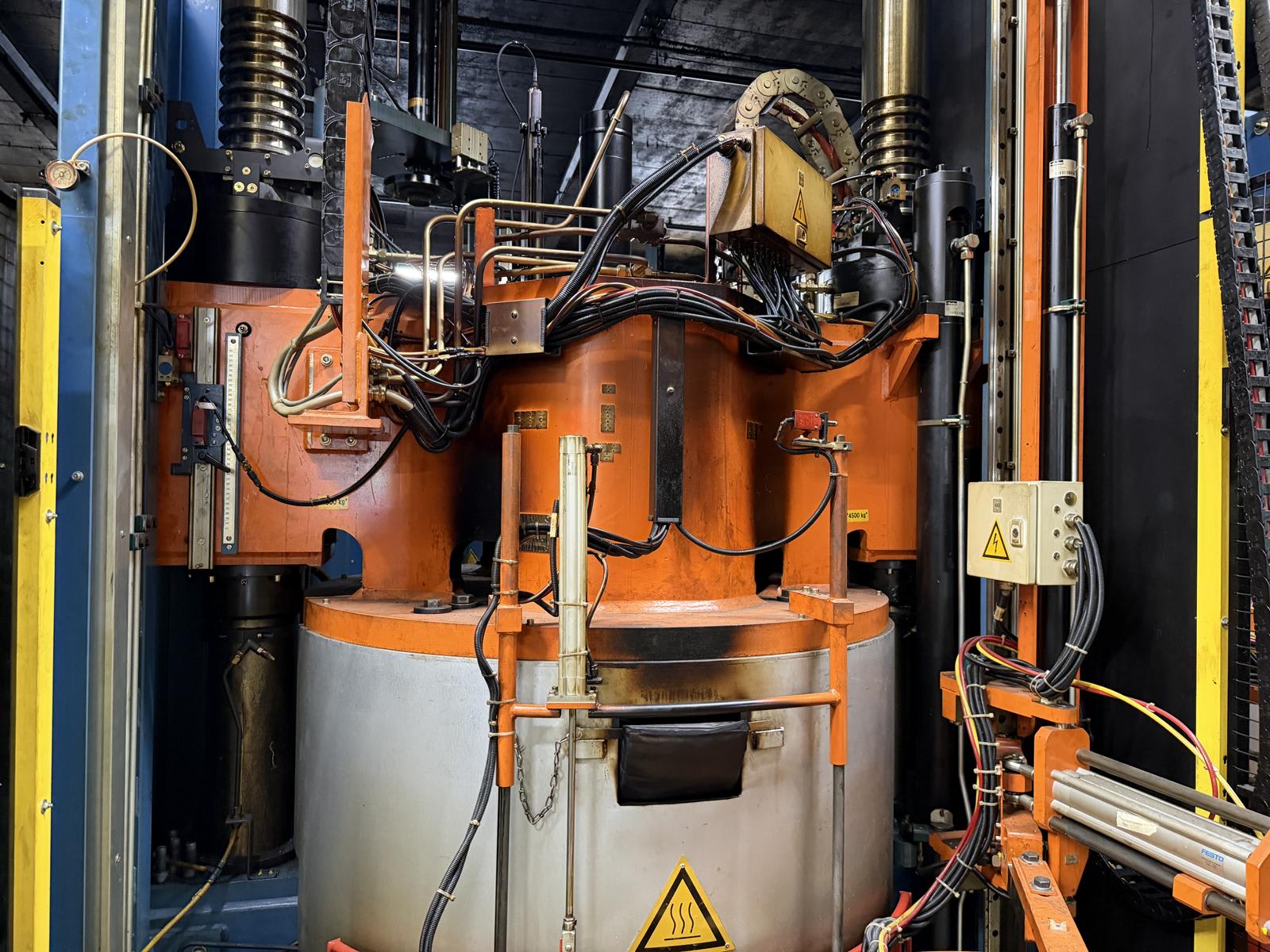

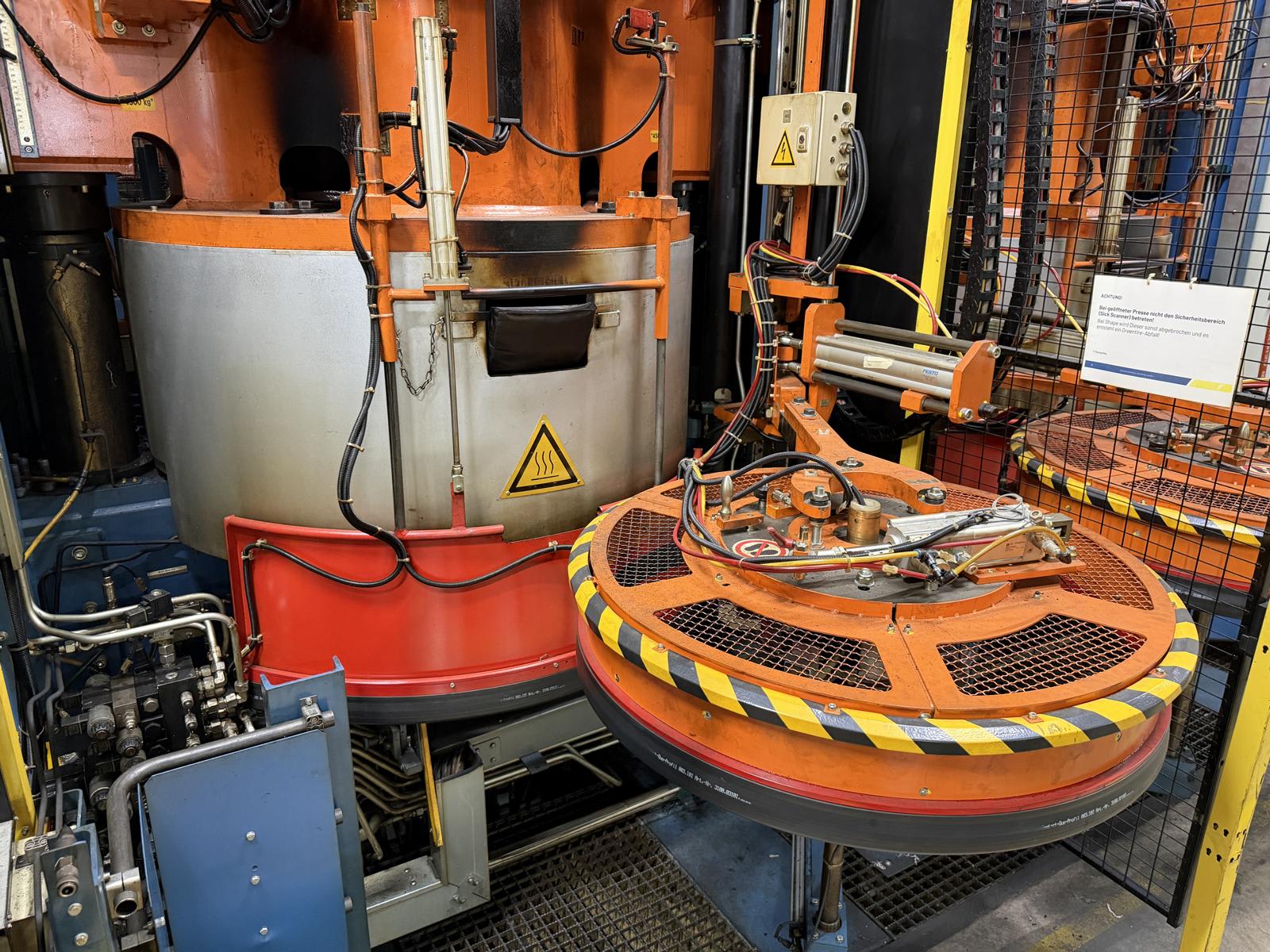

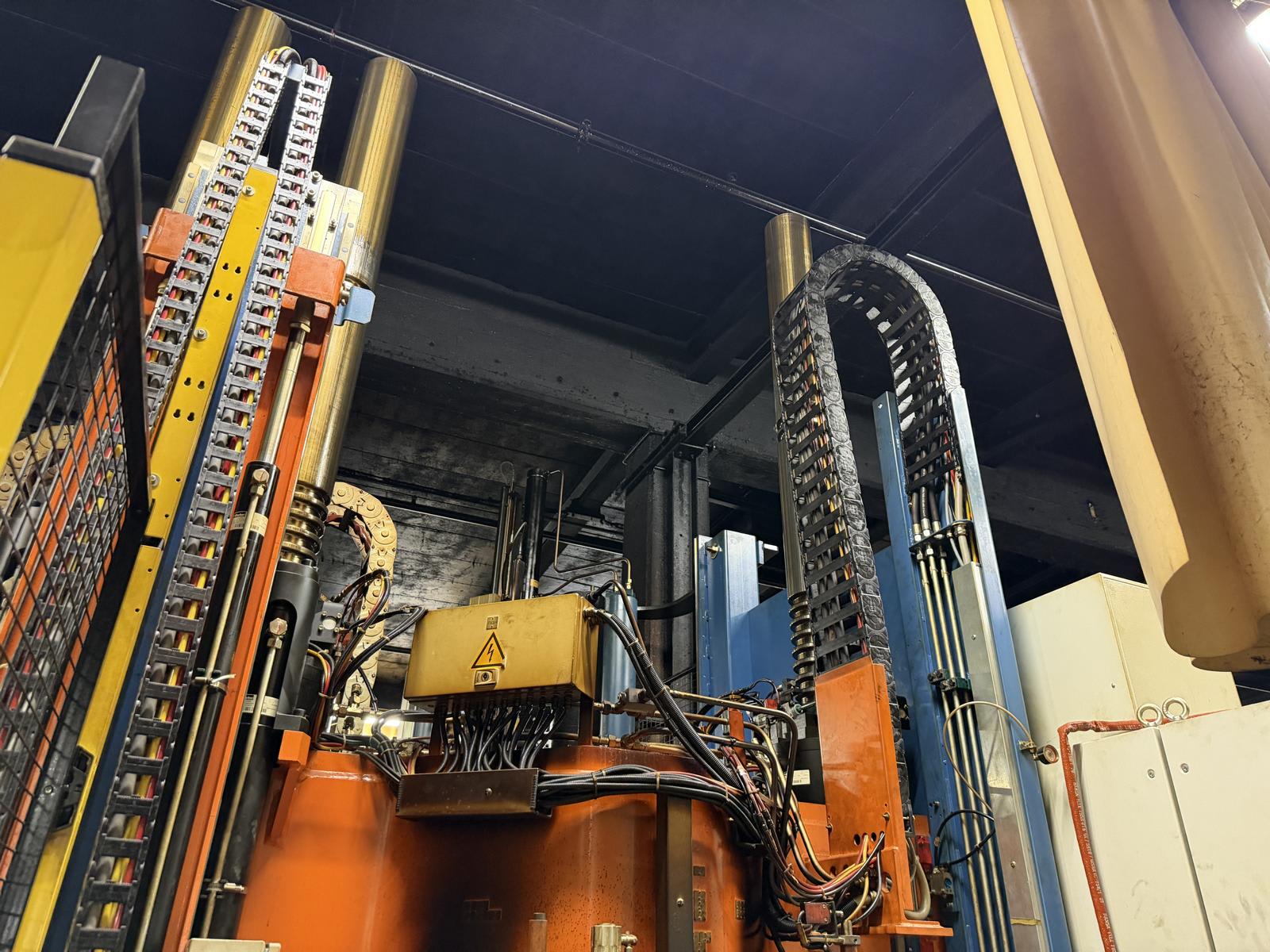

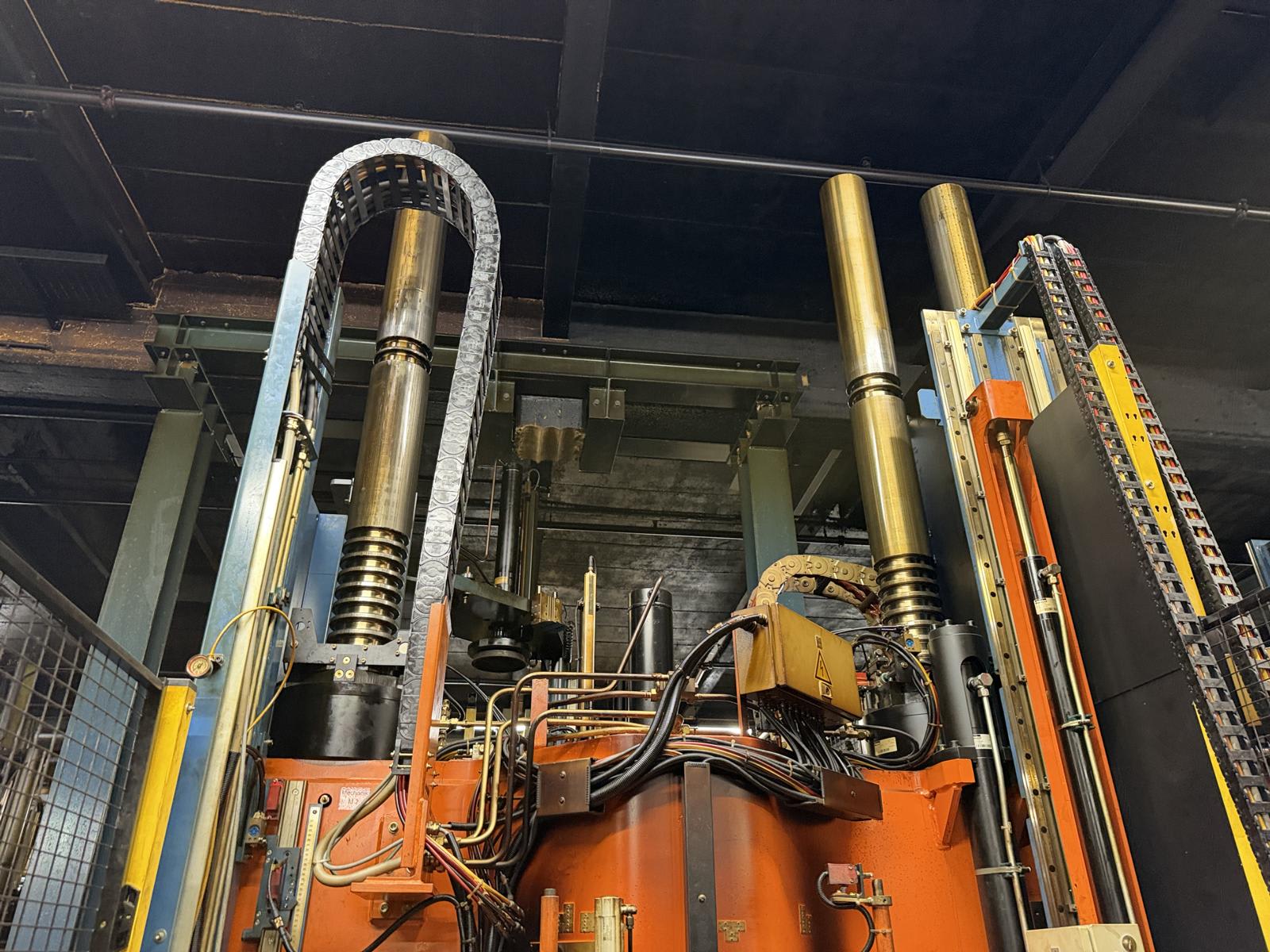

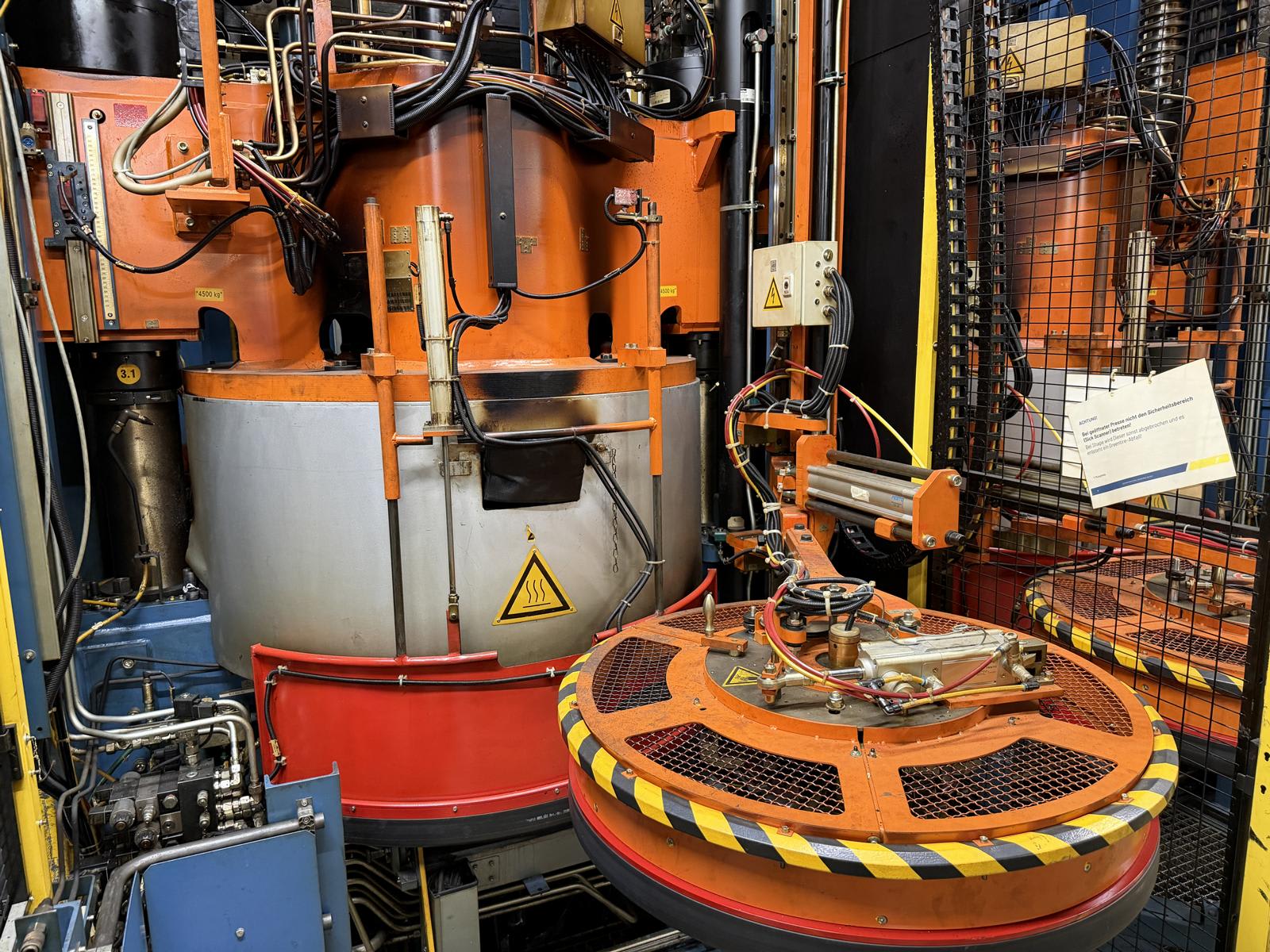

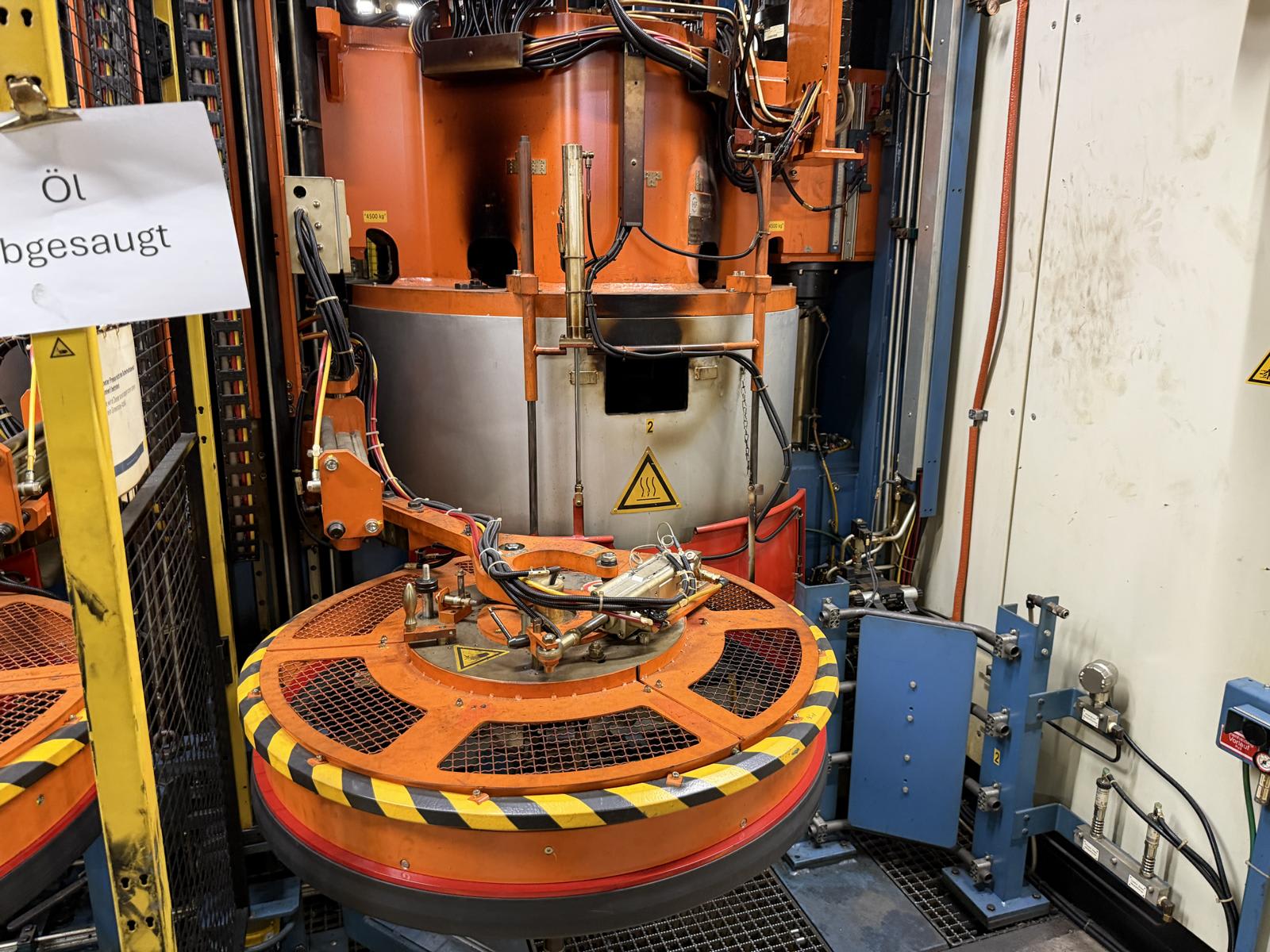

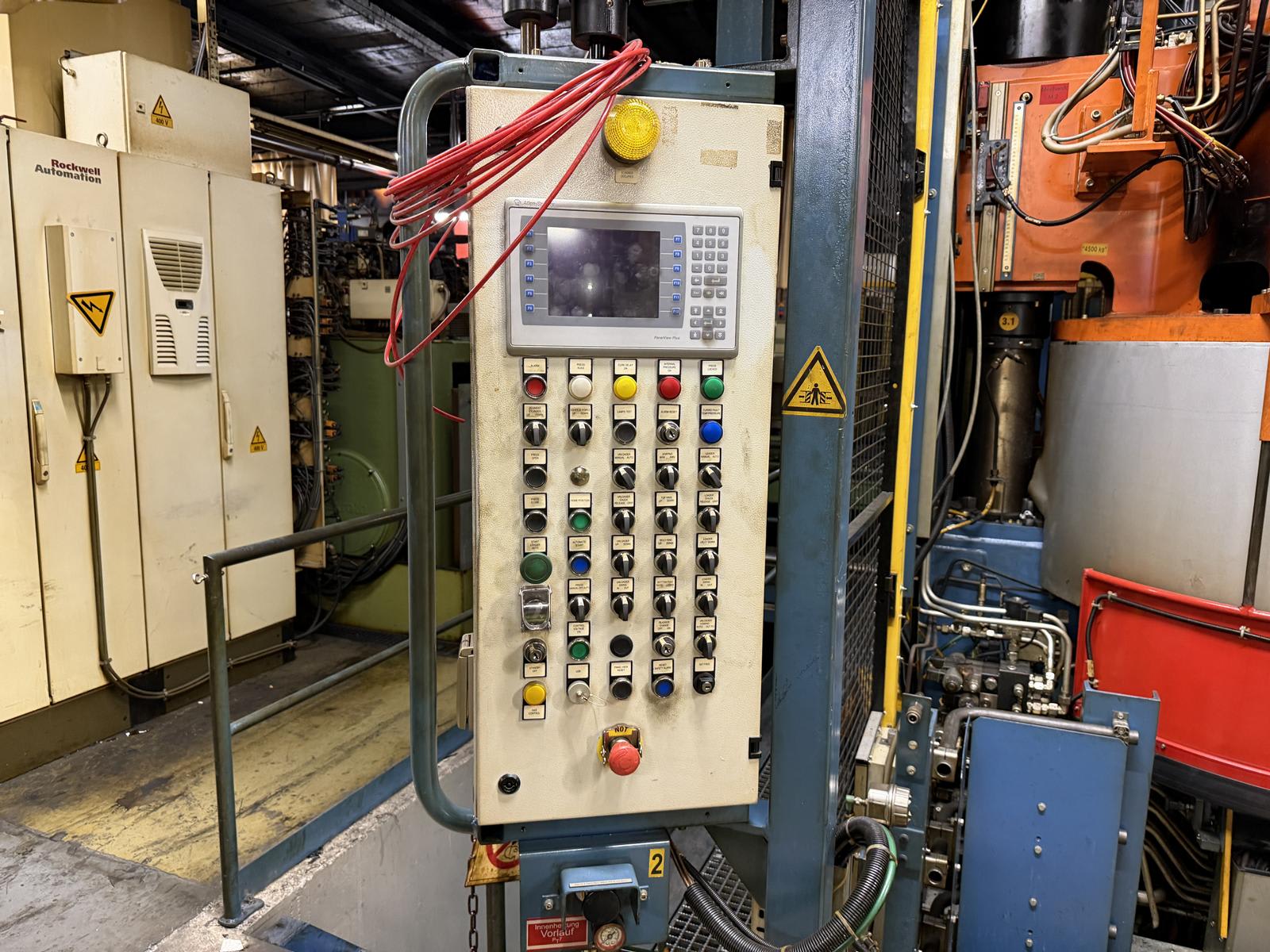

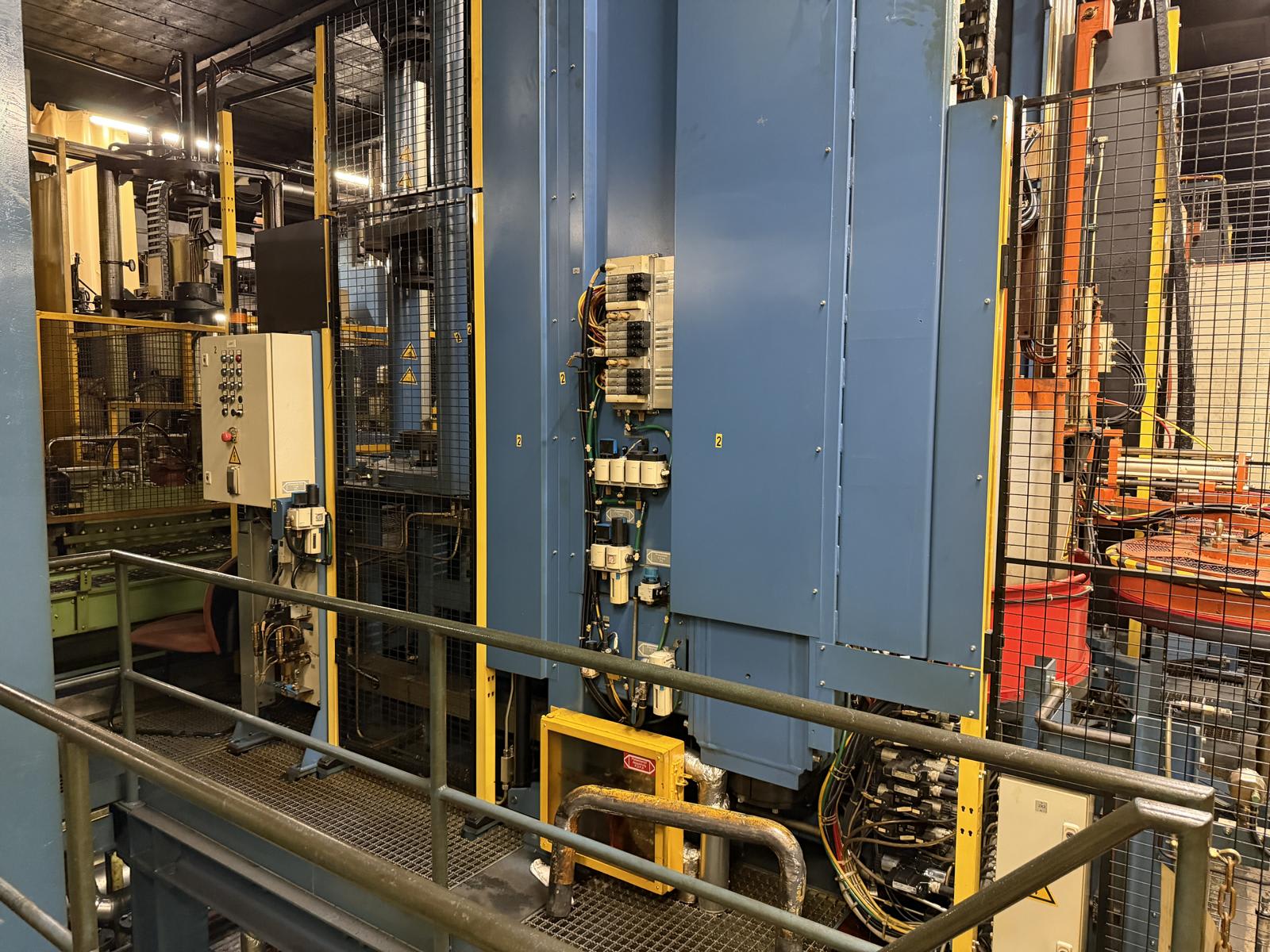

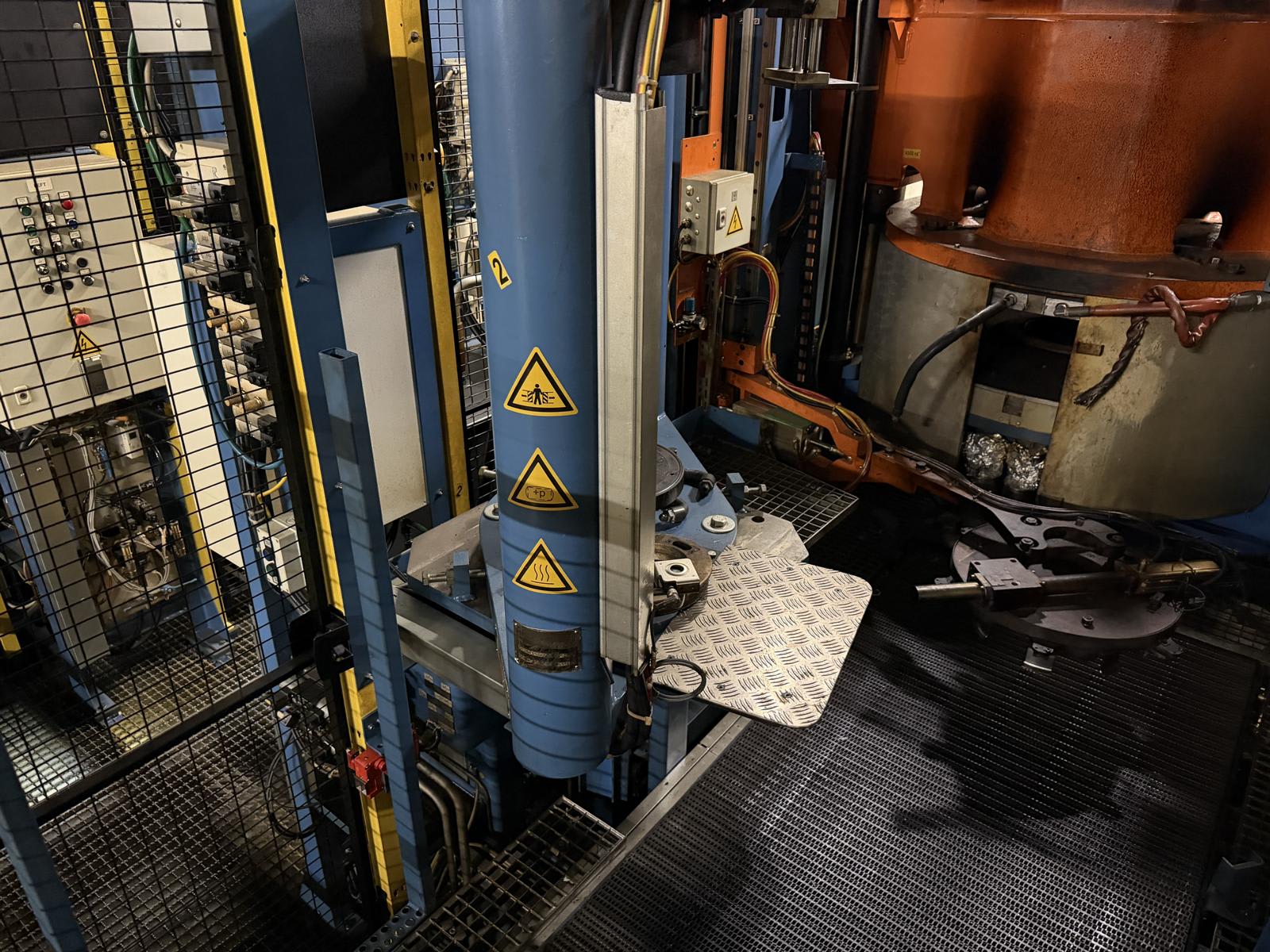

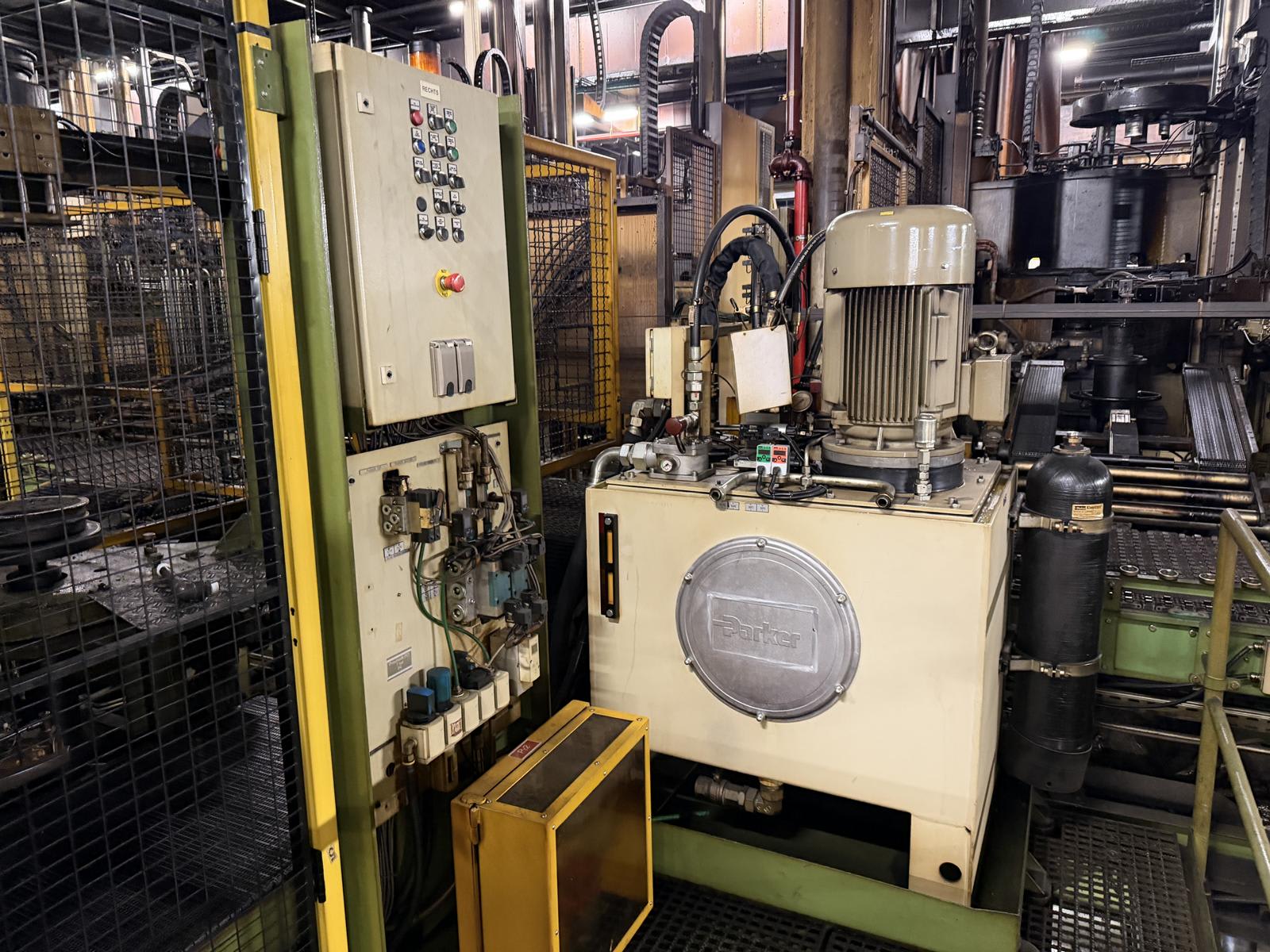

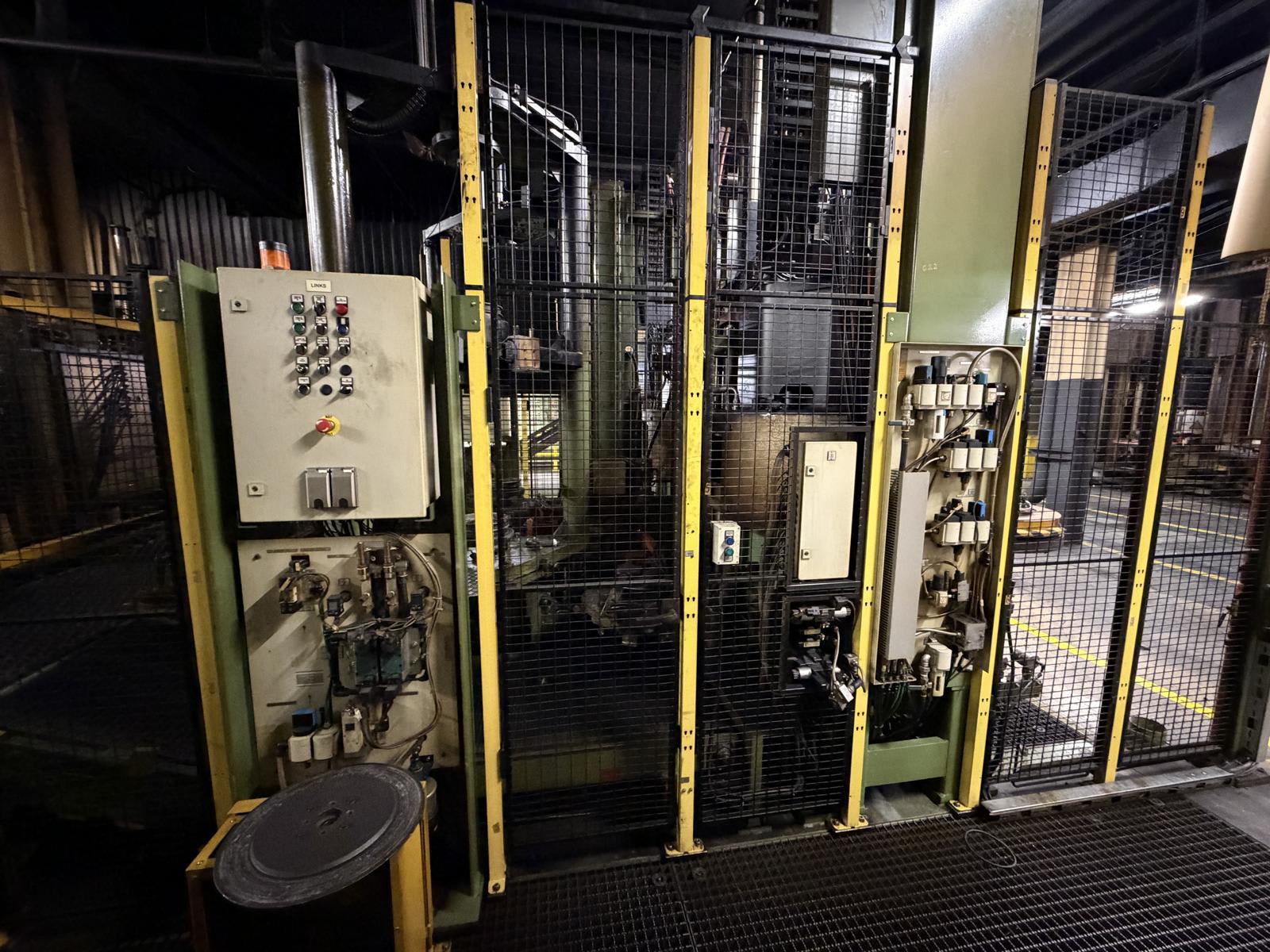

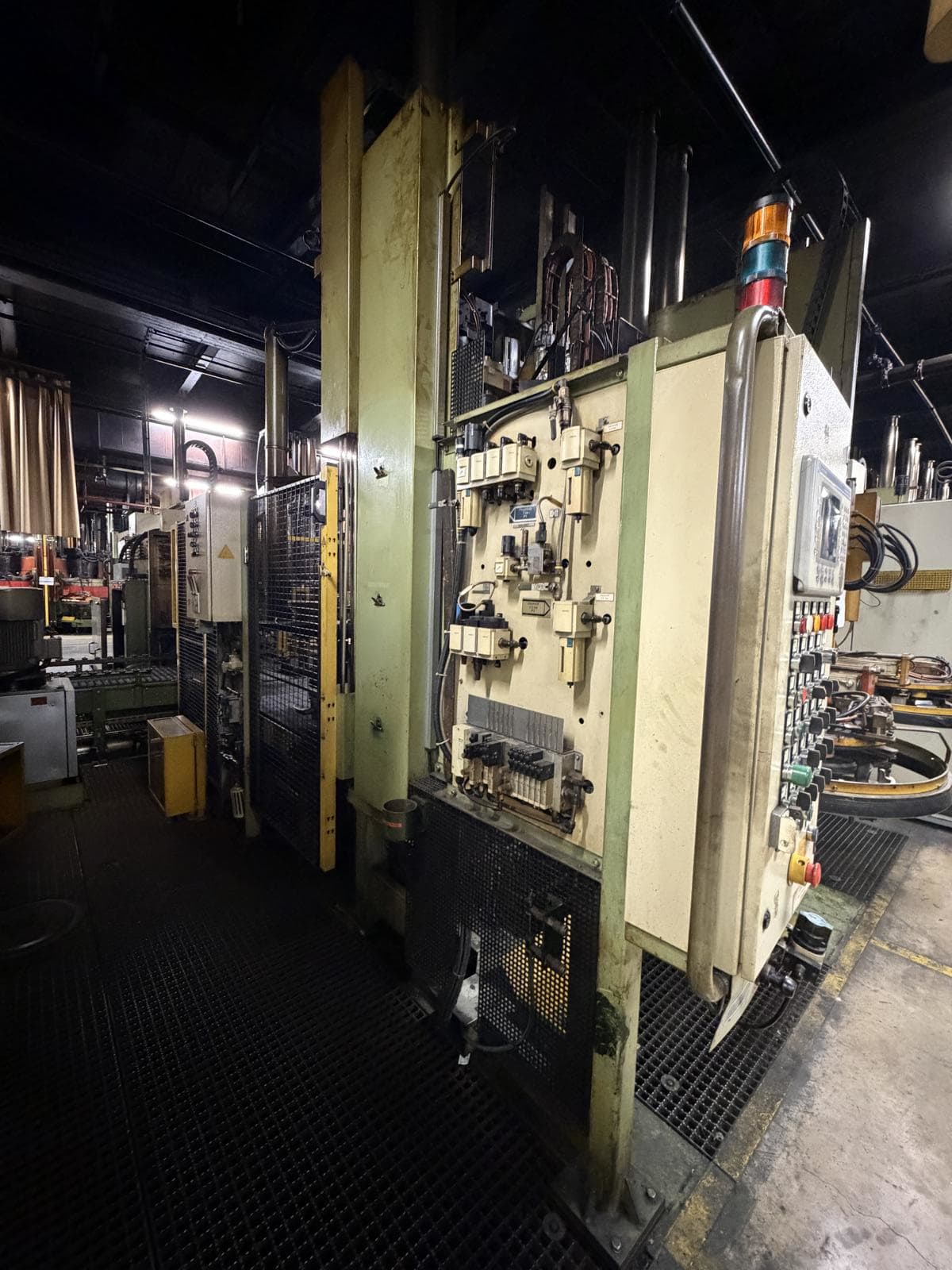

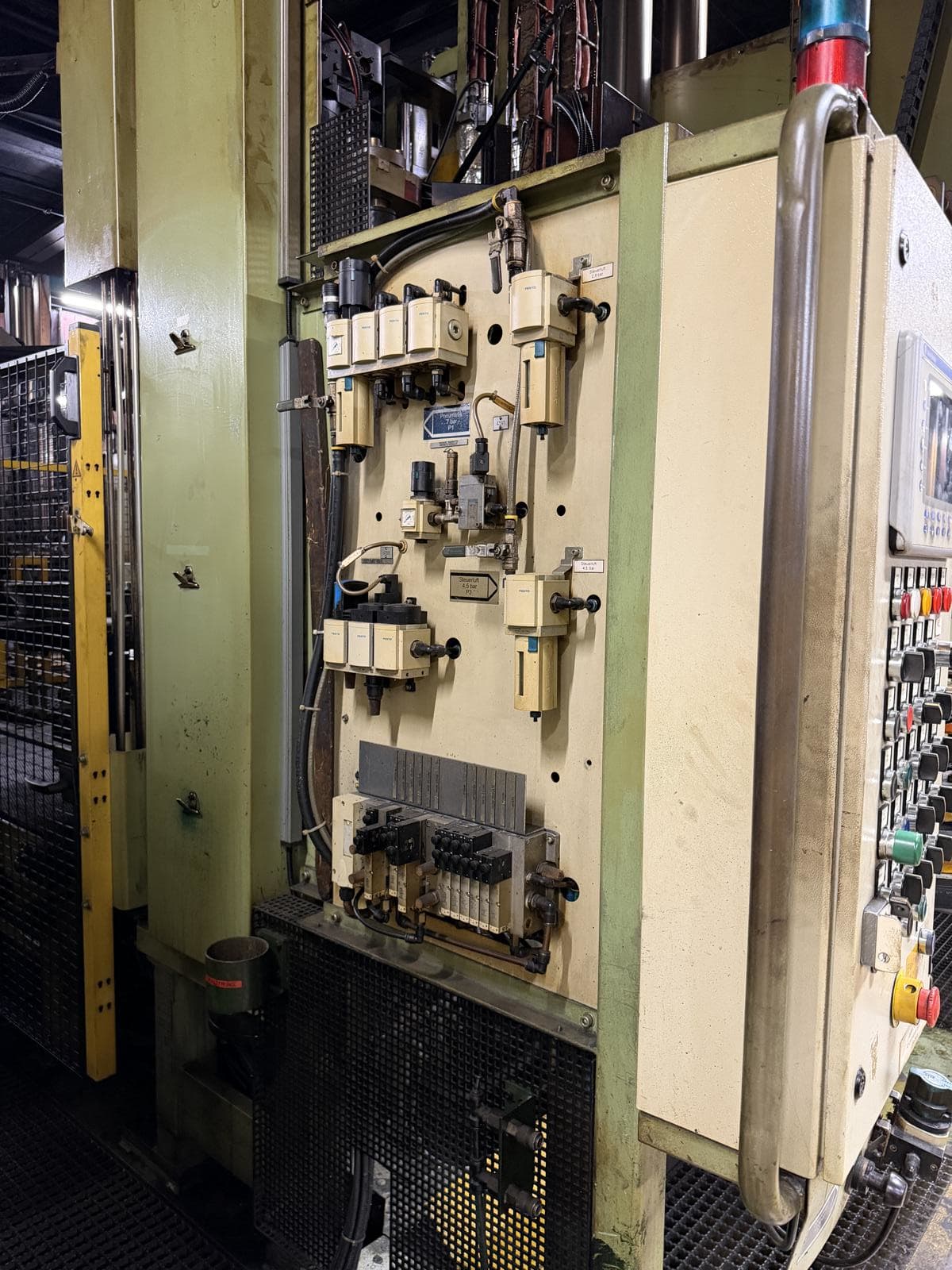

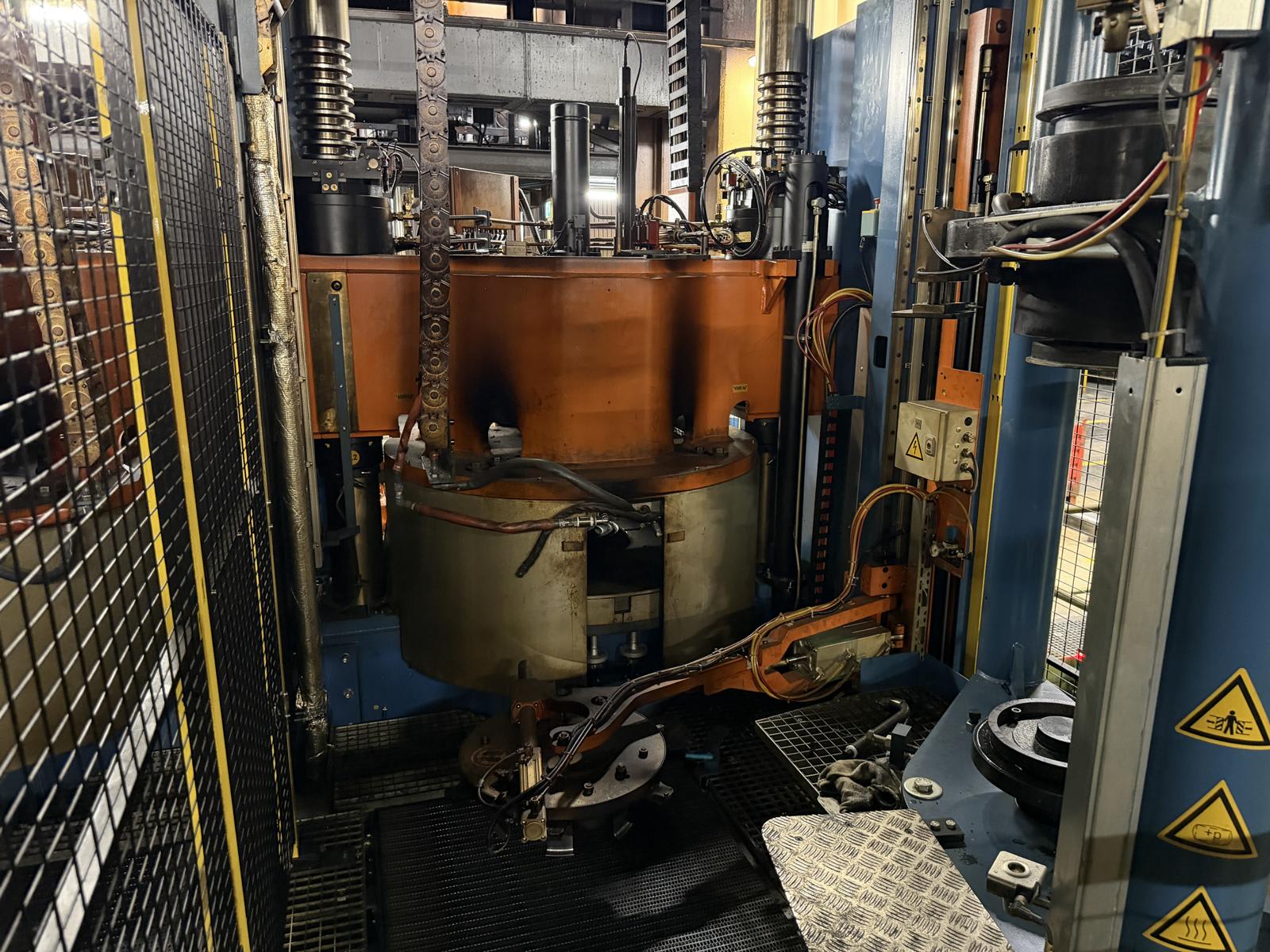

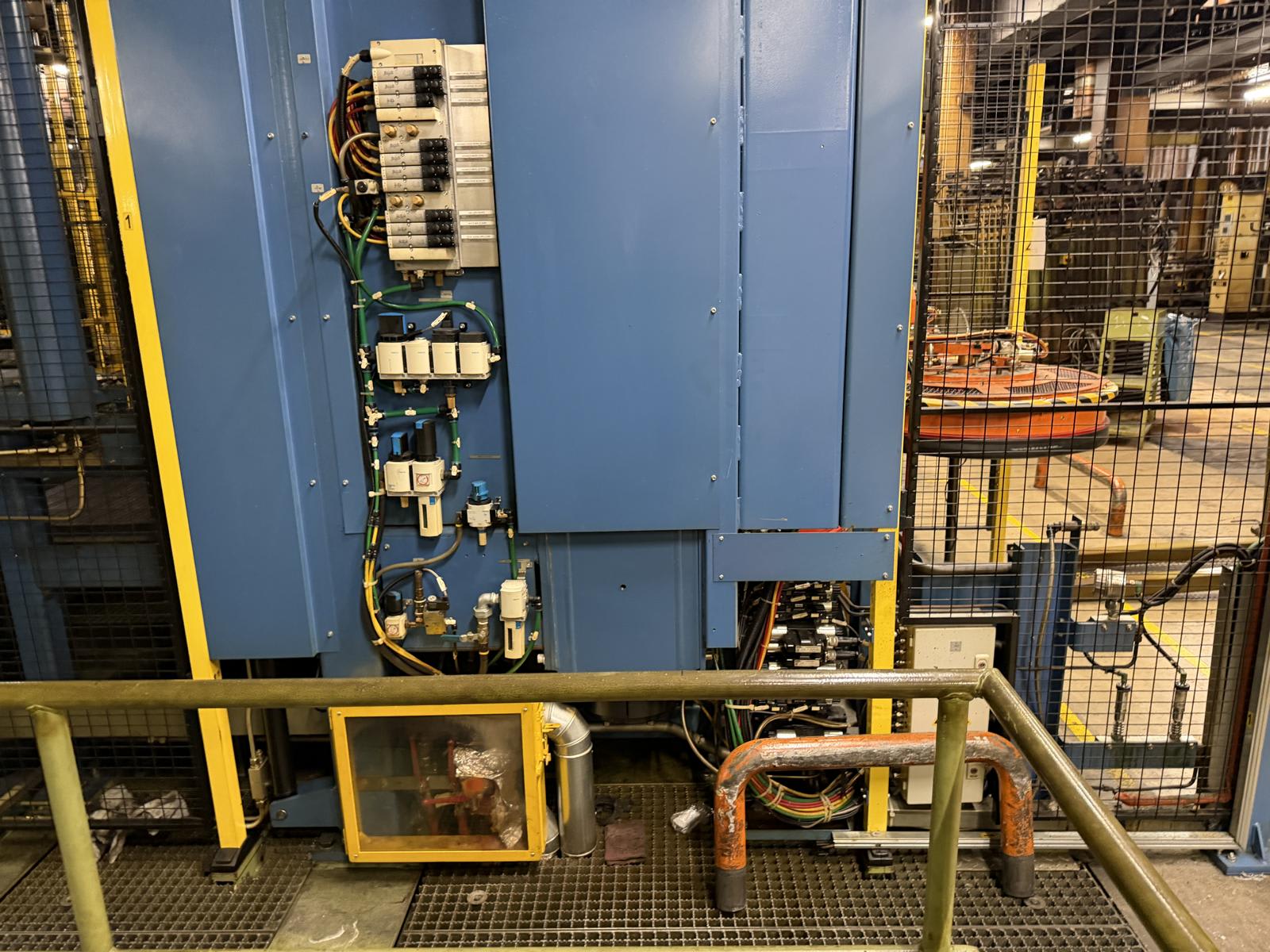

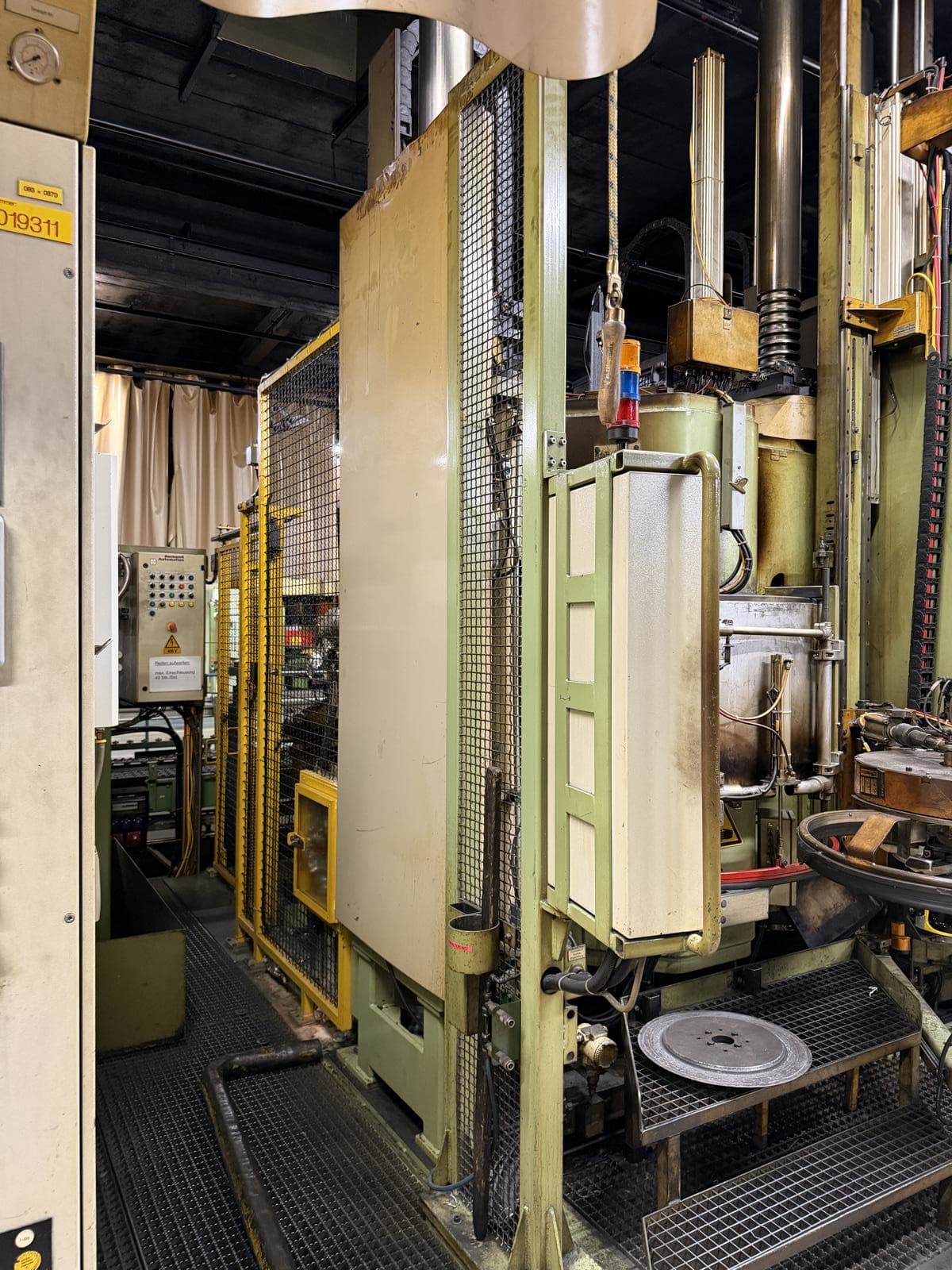

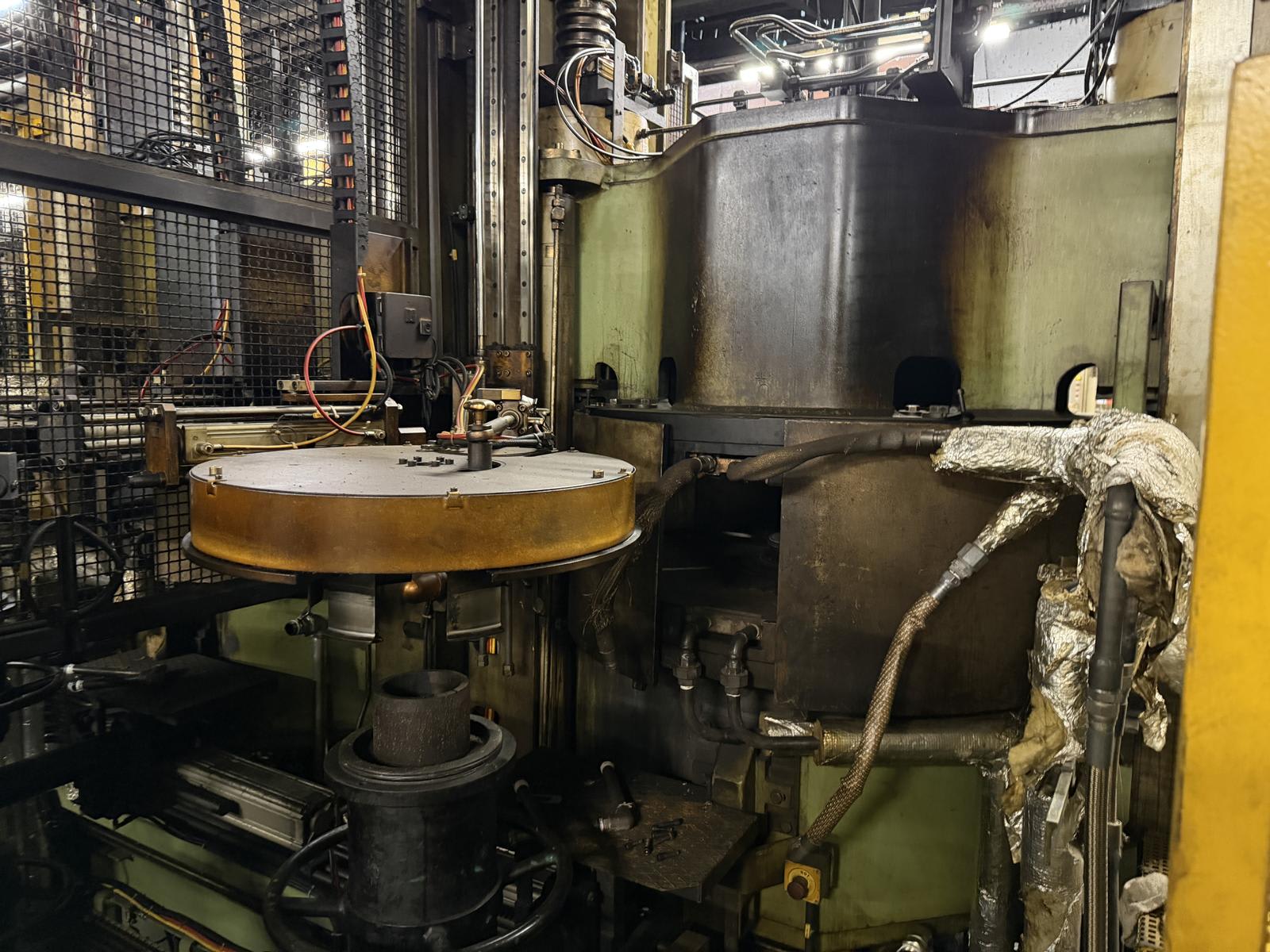

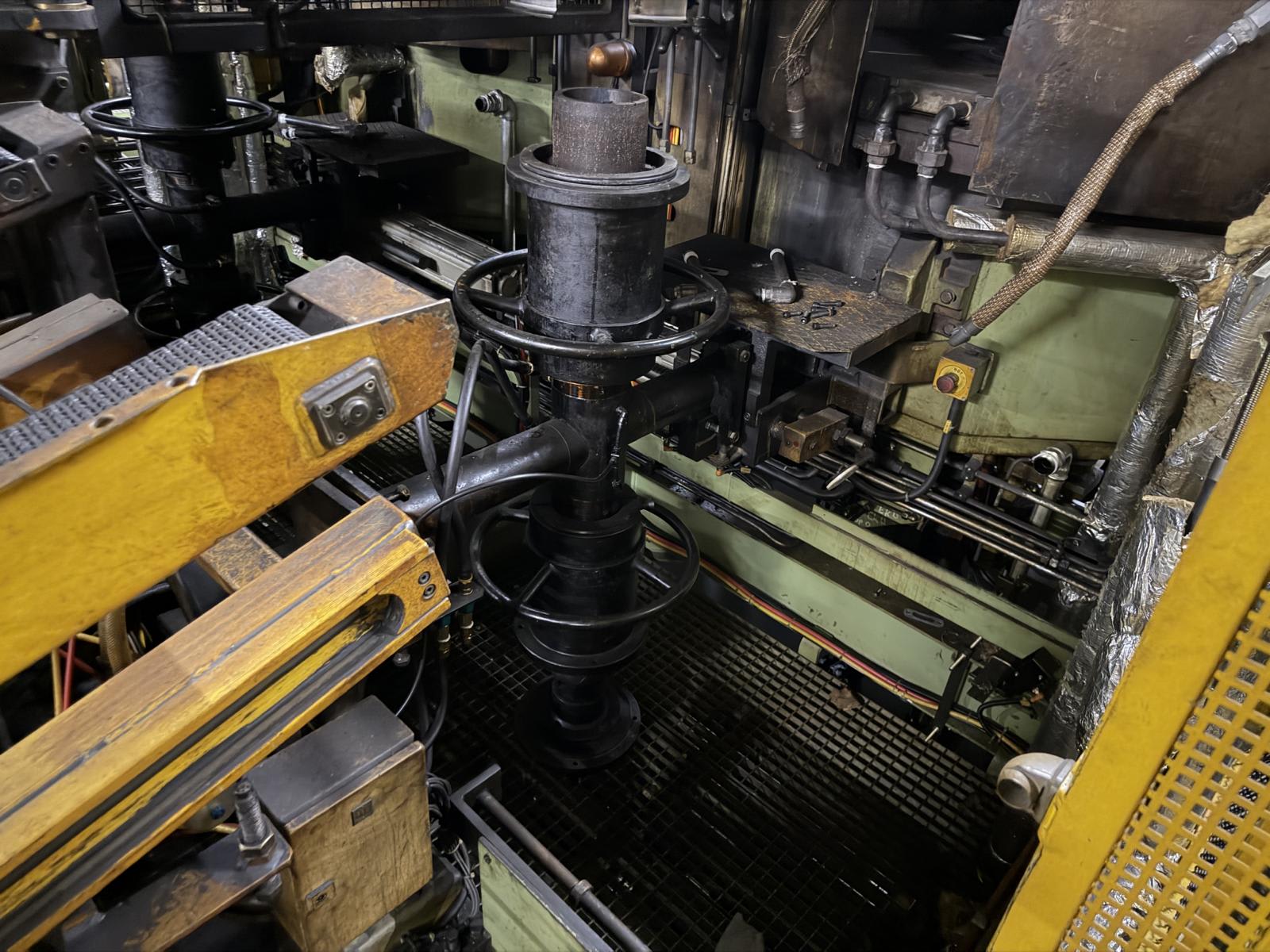

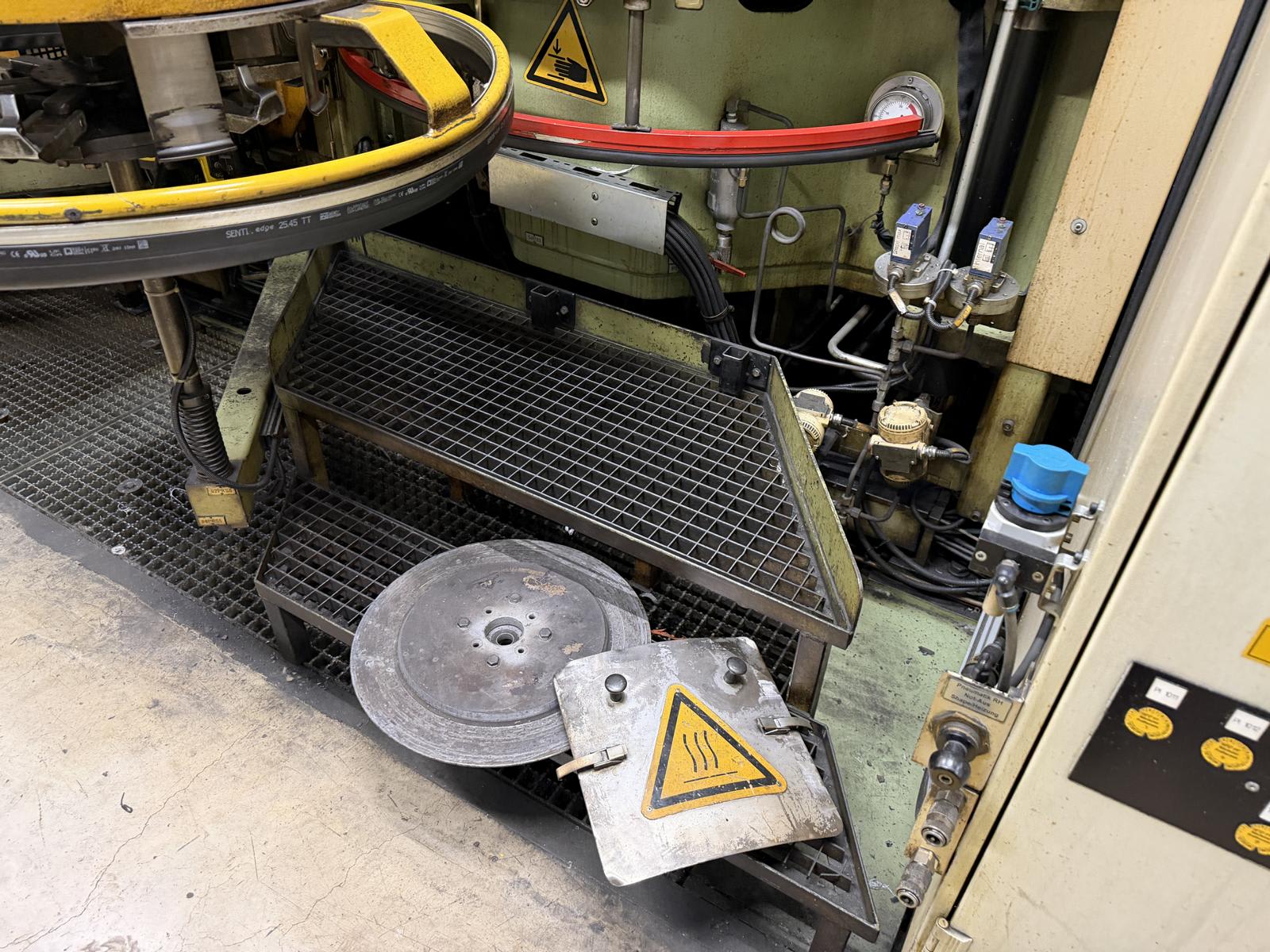

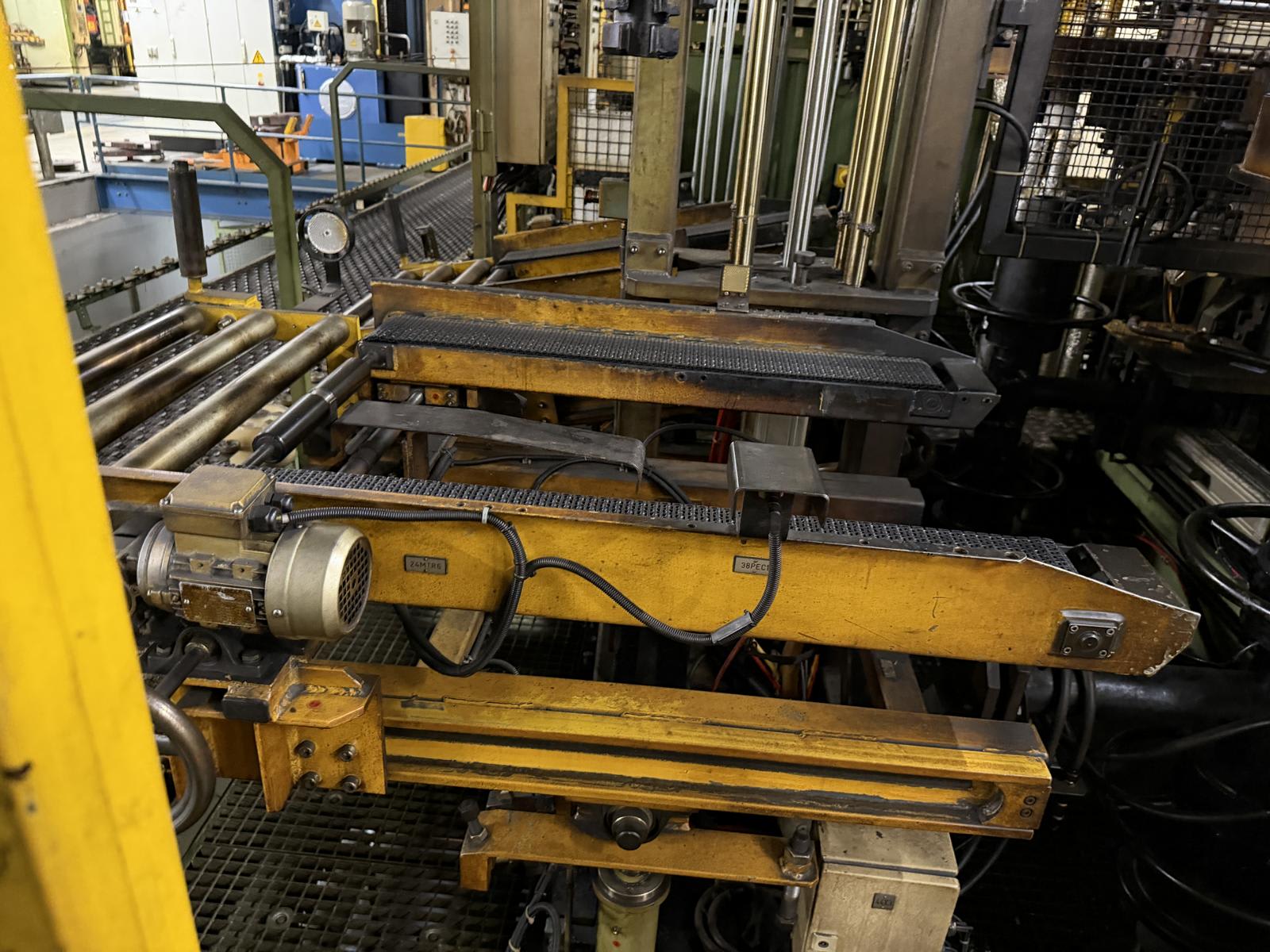

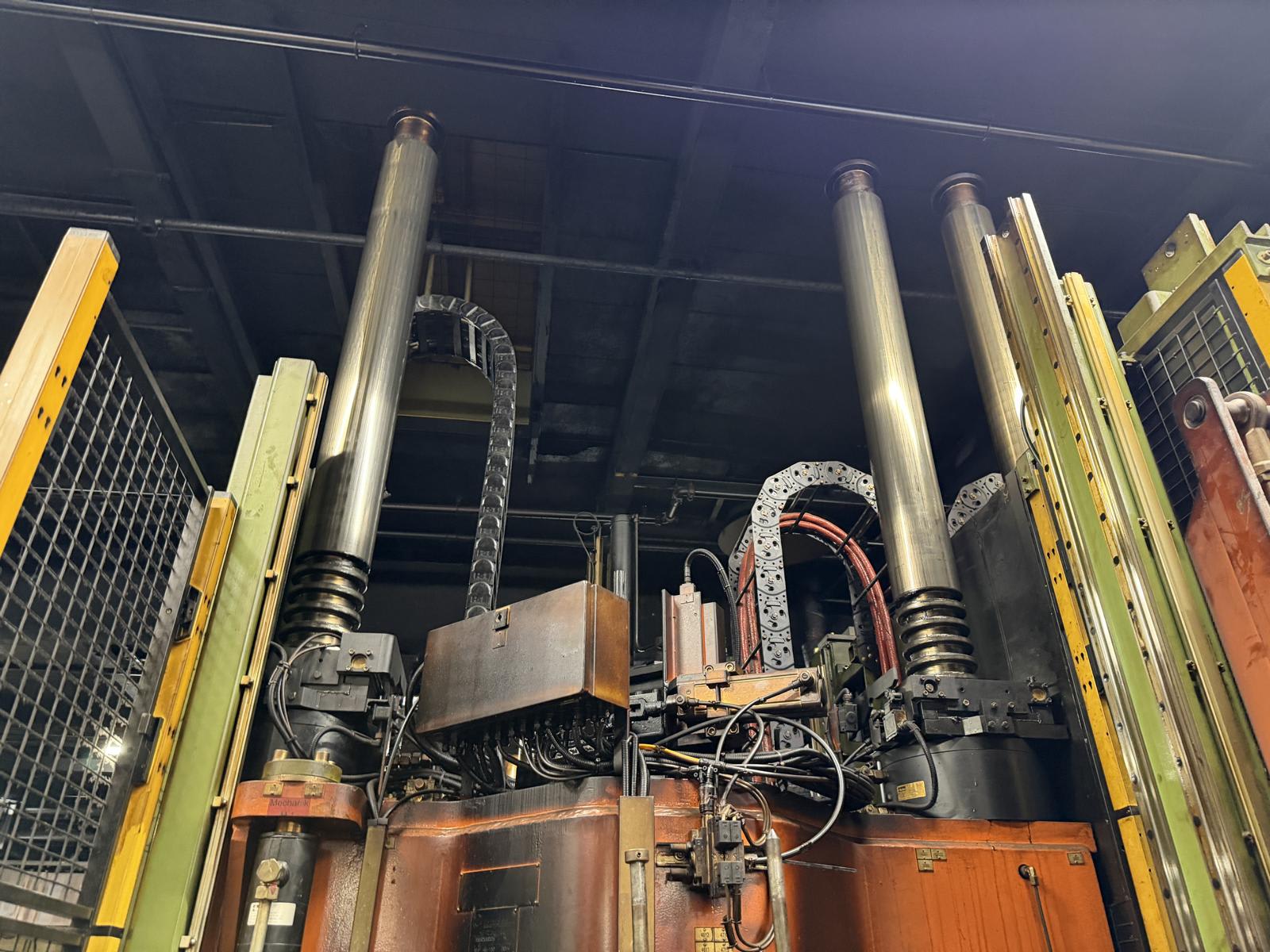

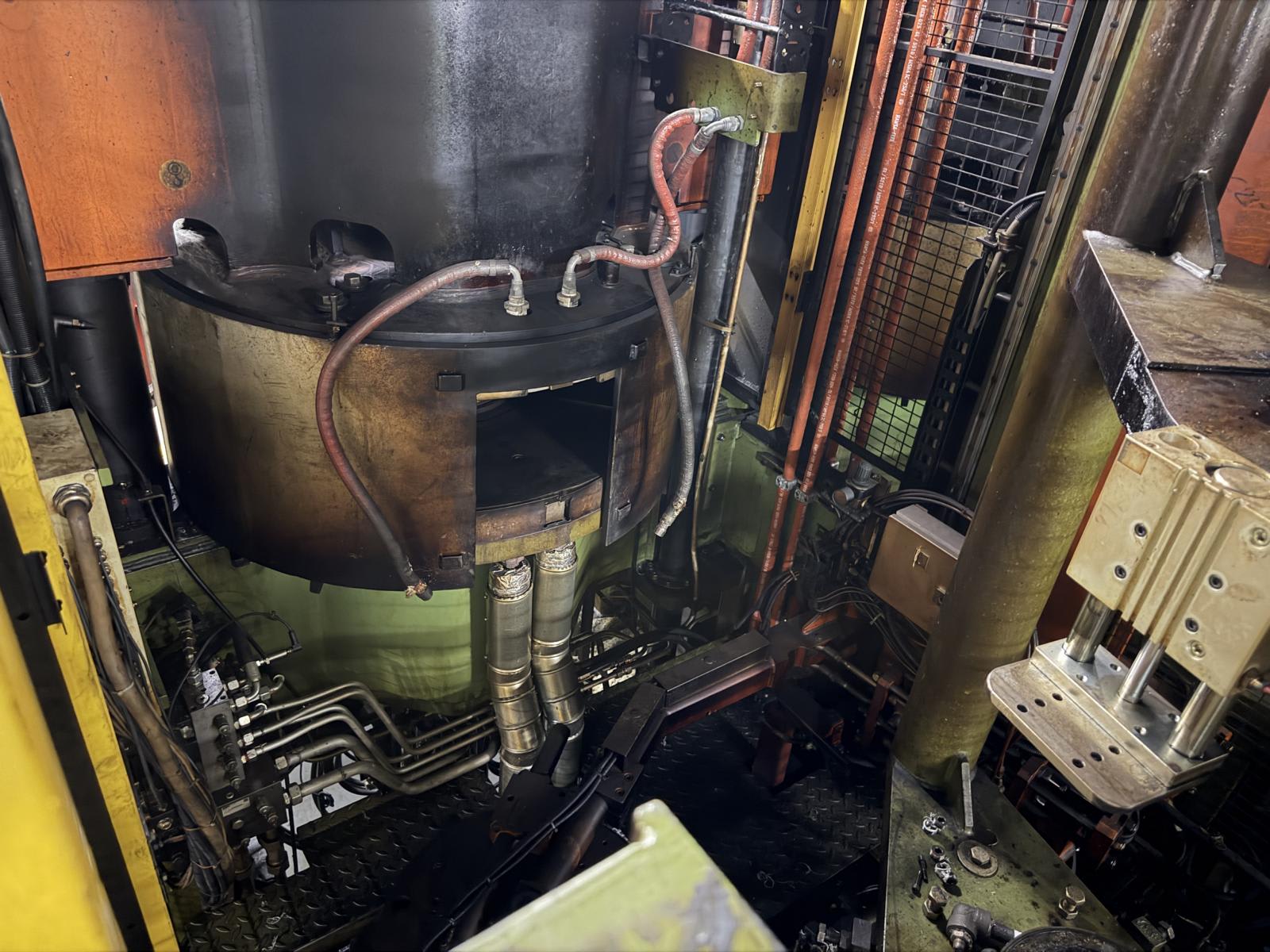

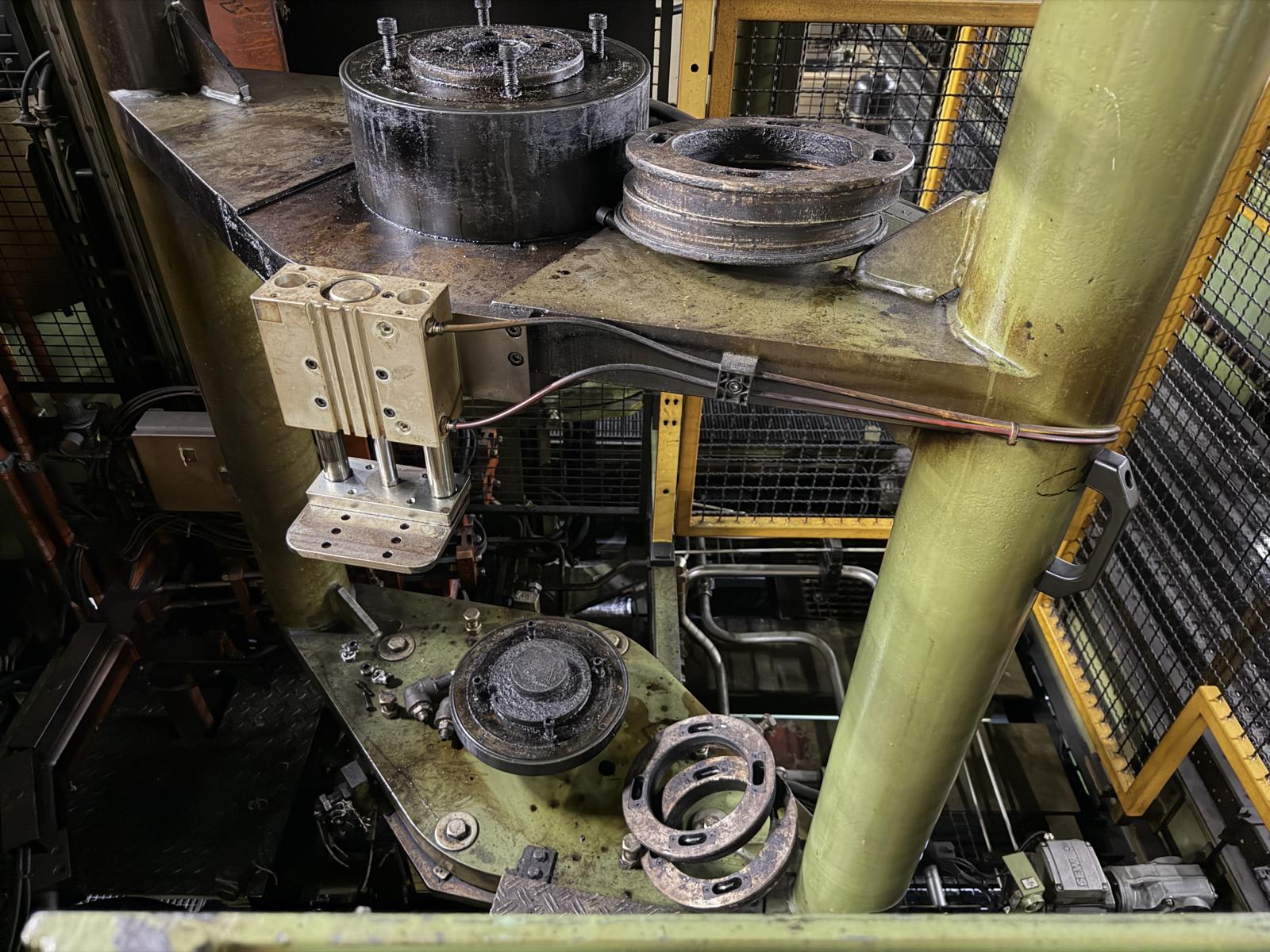

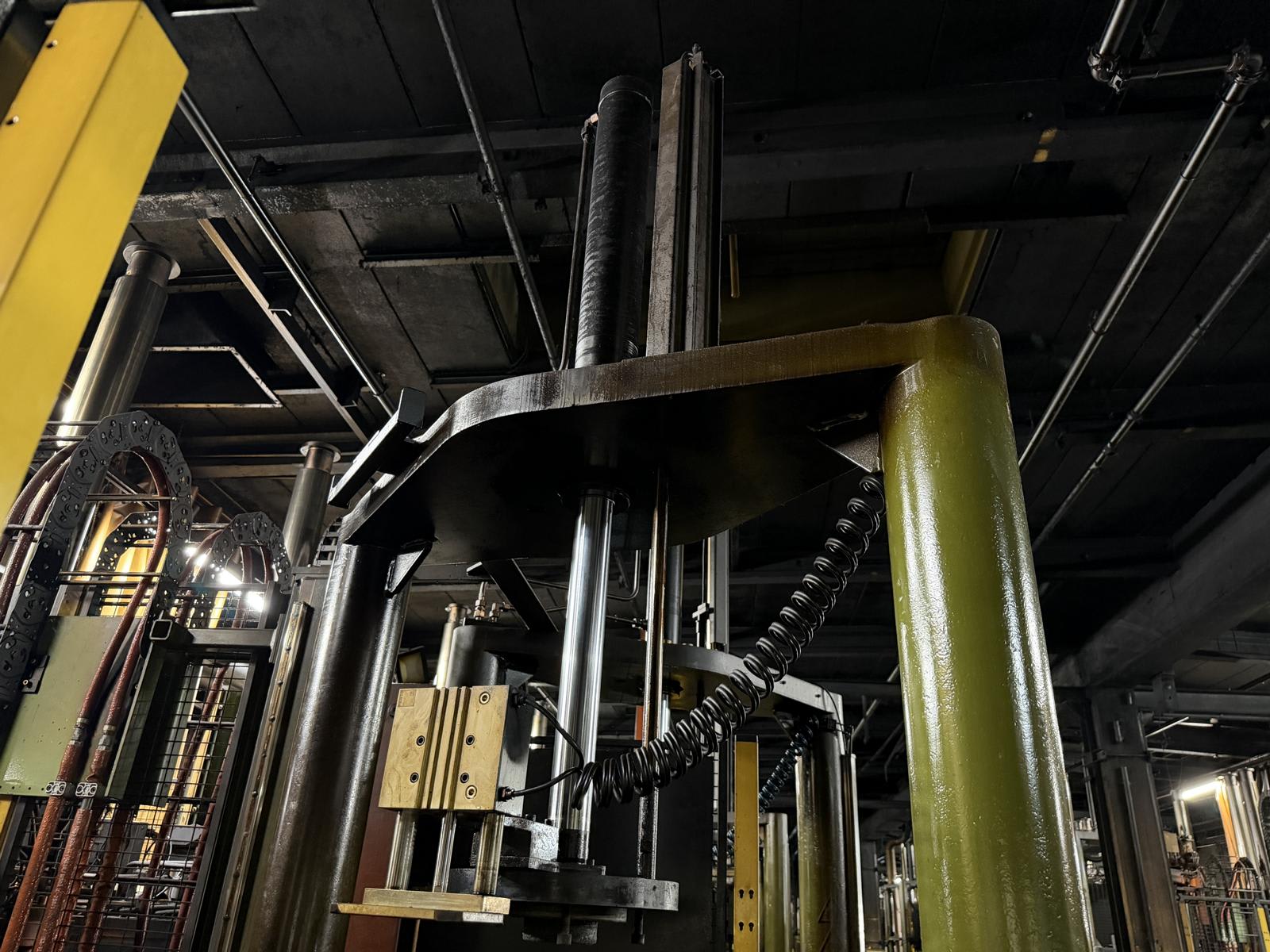

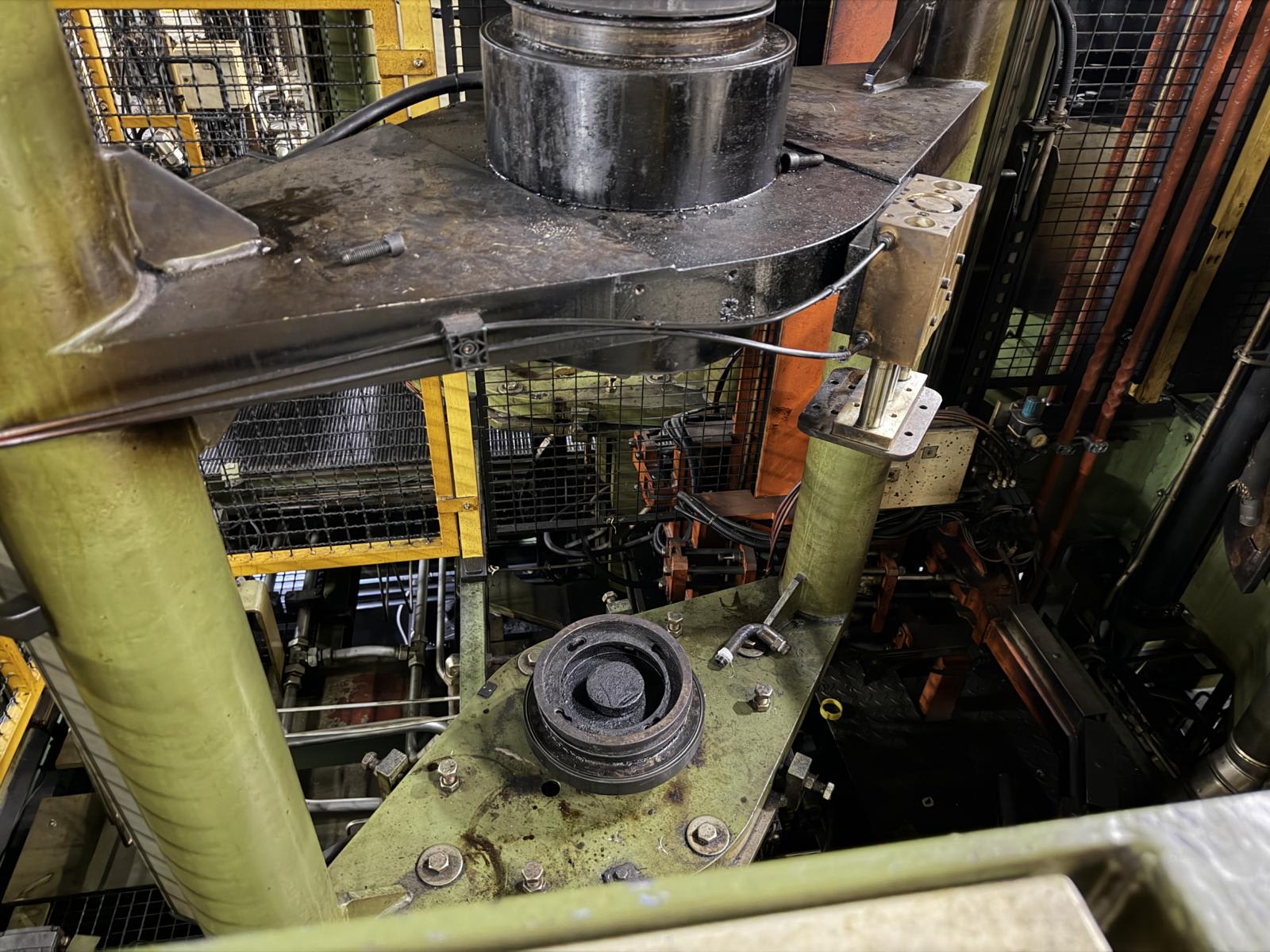

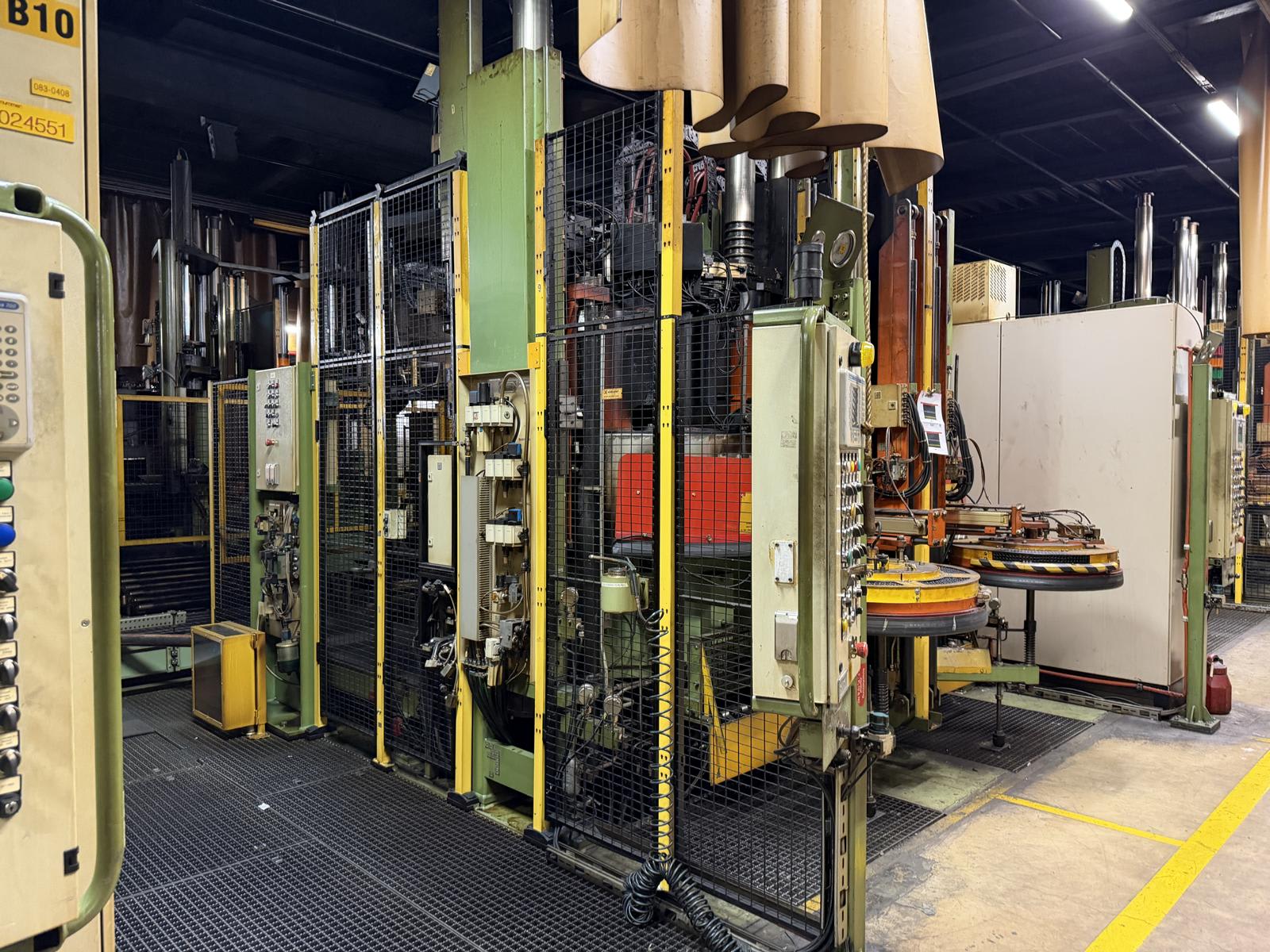

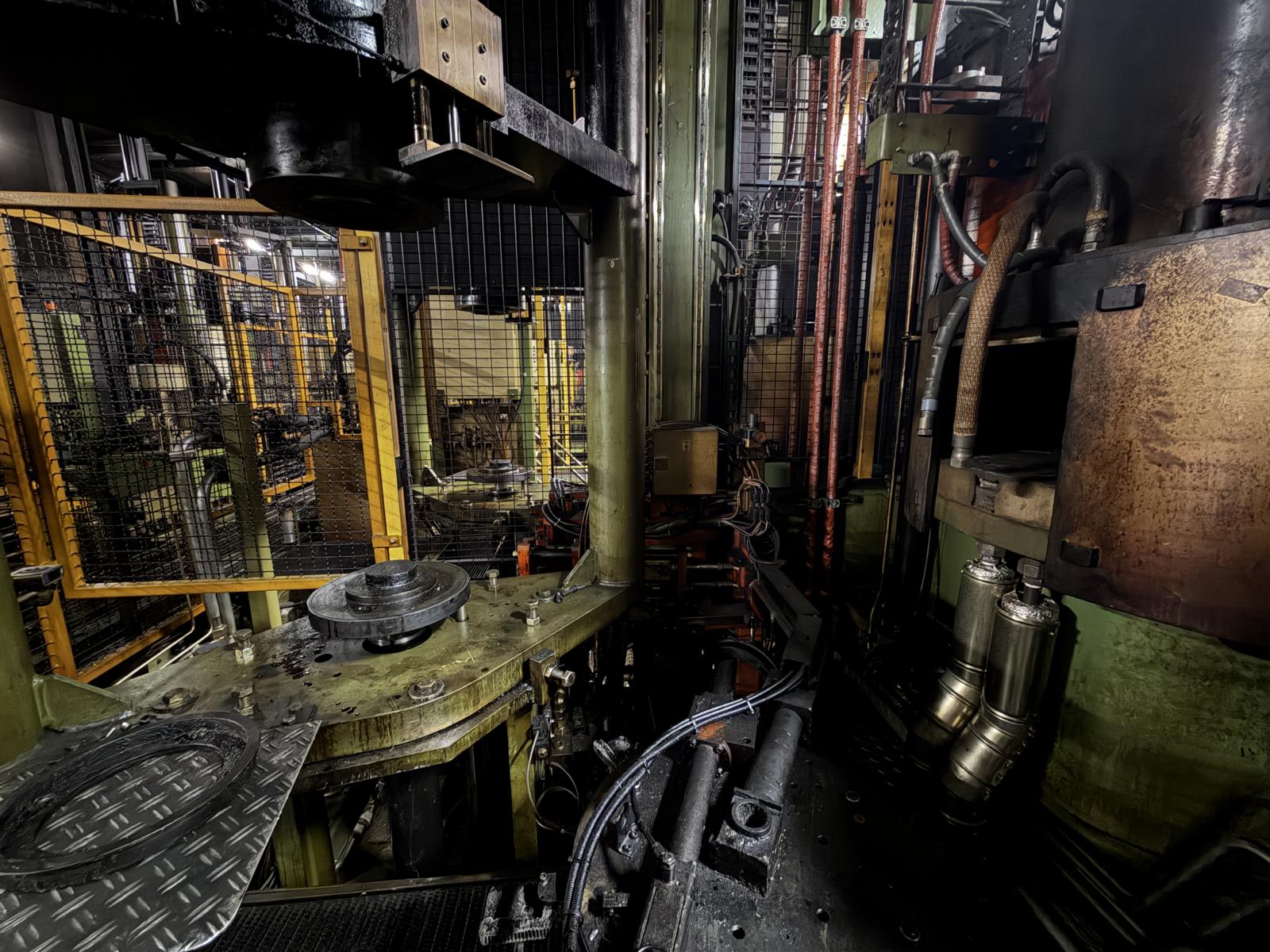

Banbury 2 Mixing Line Kobelco DEFU-BB270 Mixer (NP/P) | 1973-2022

Binding Handling & Service Fee:

132500 € (EURO)

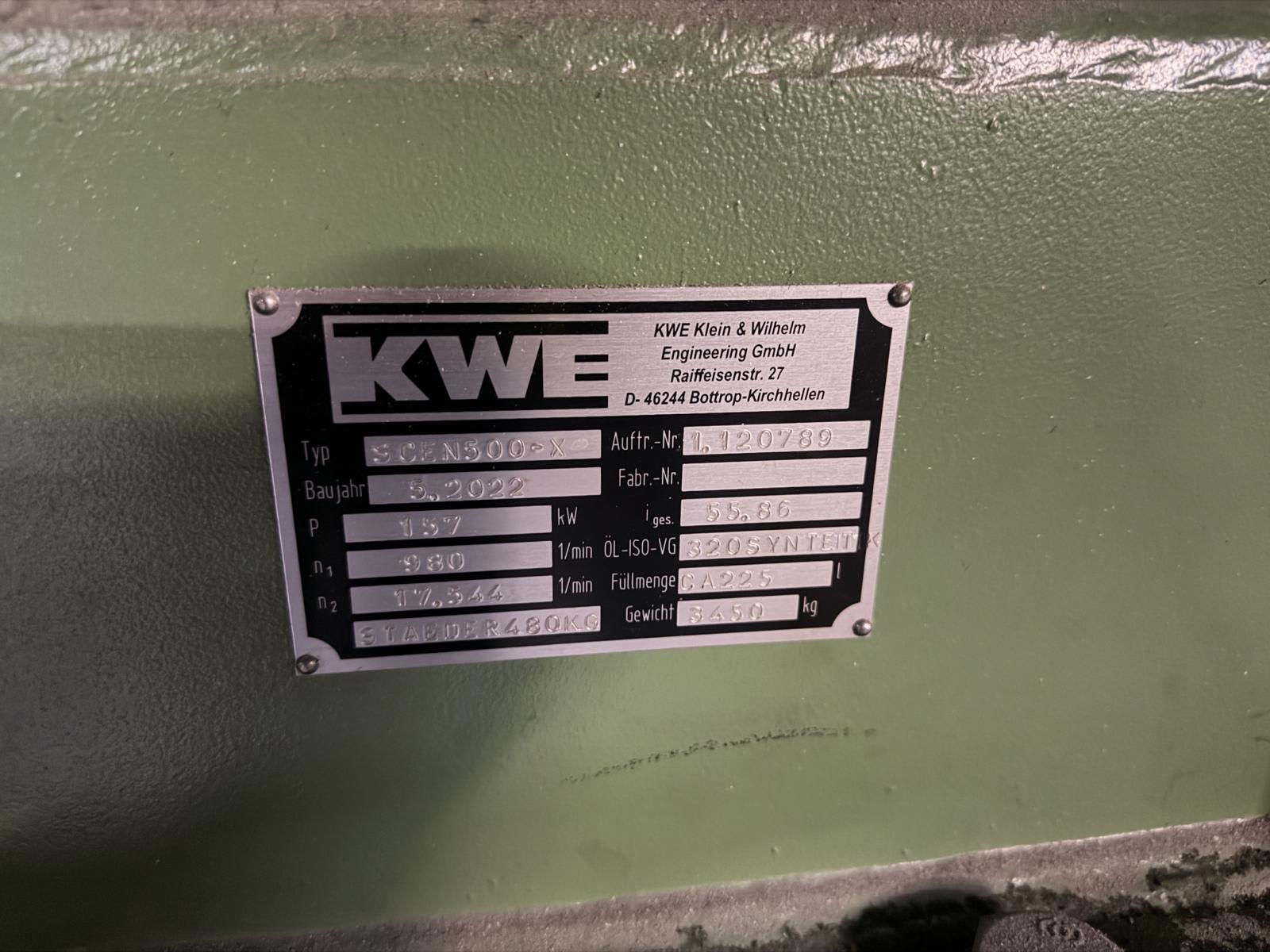

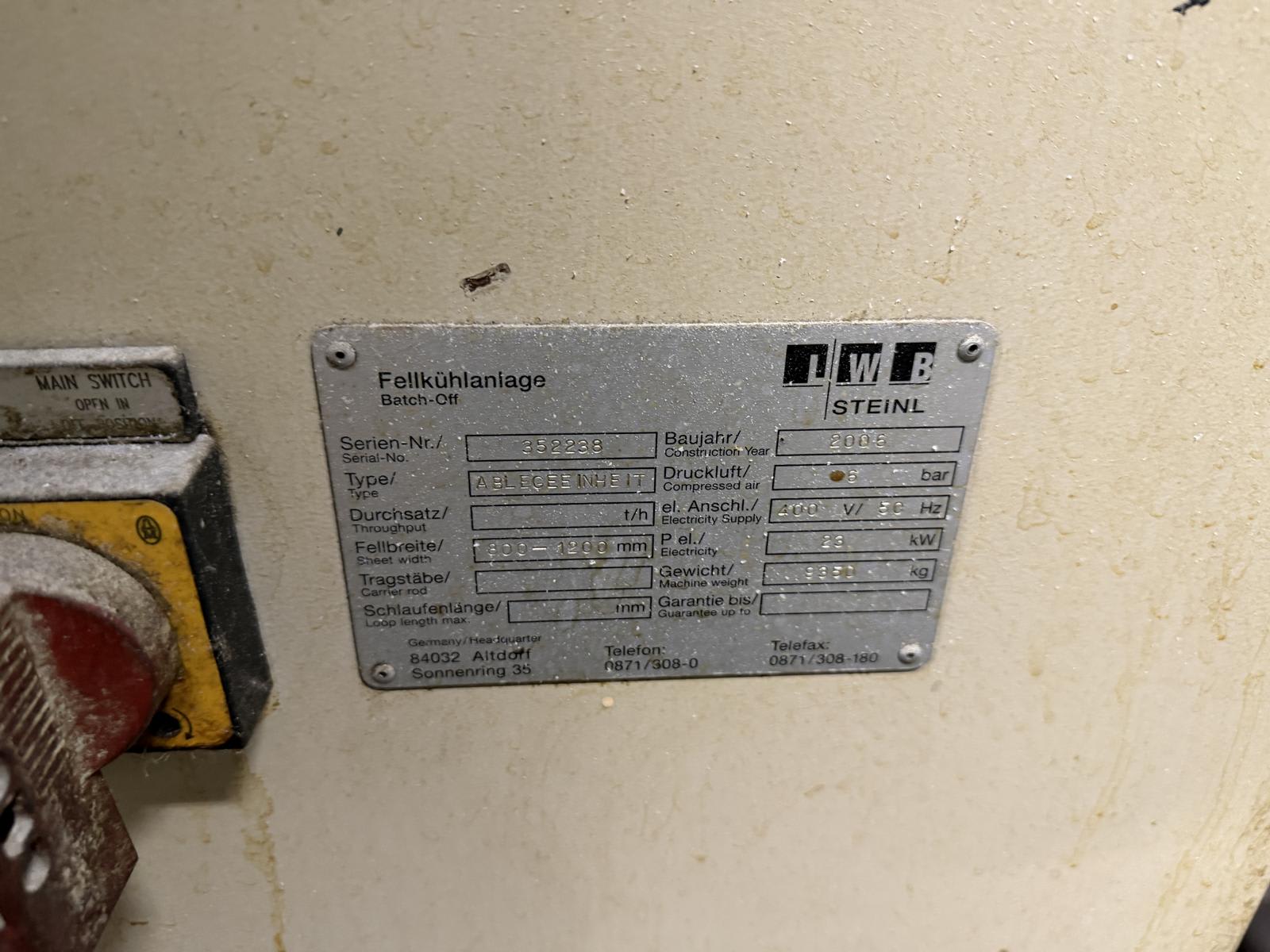

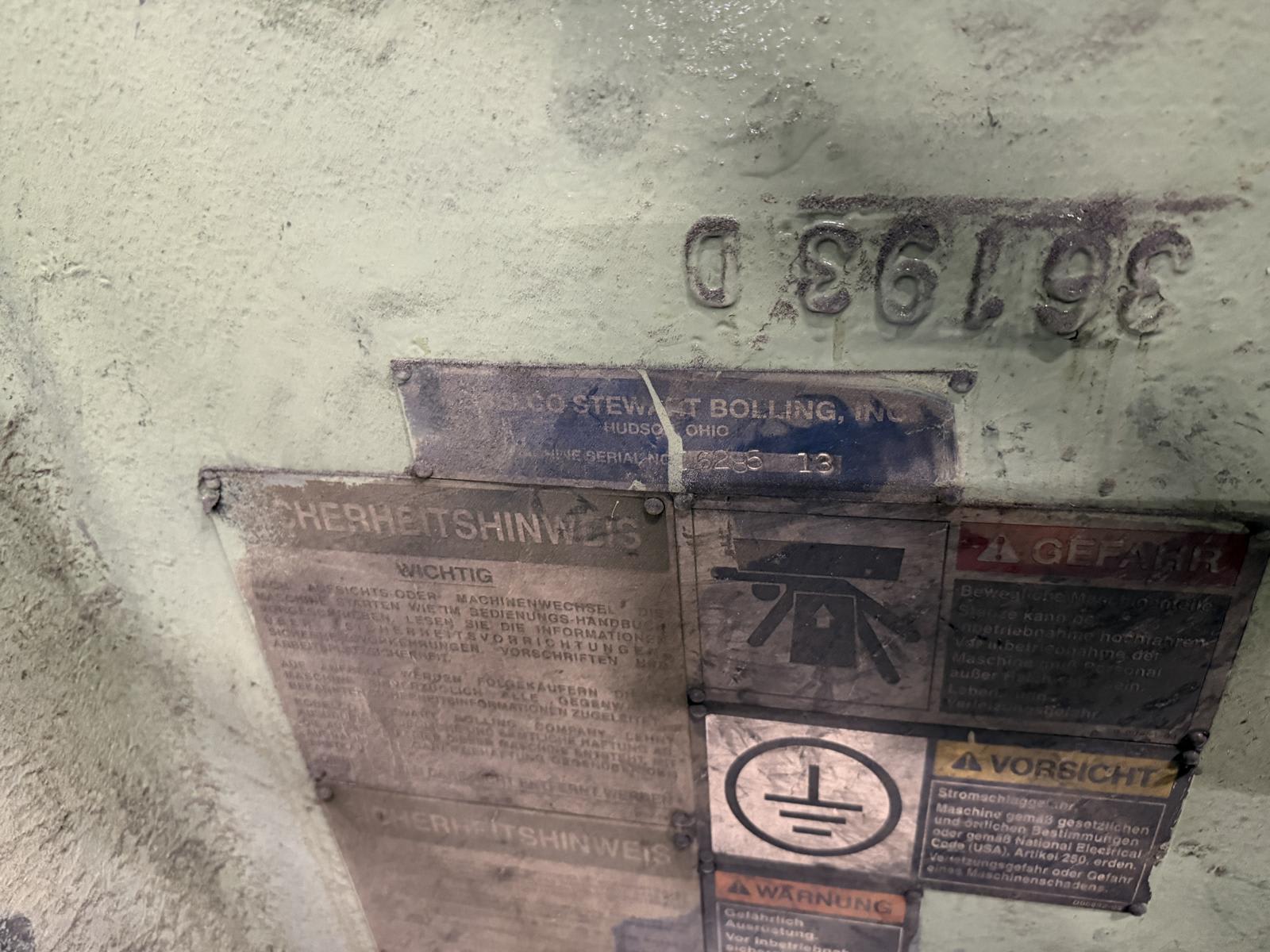

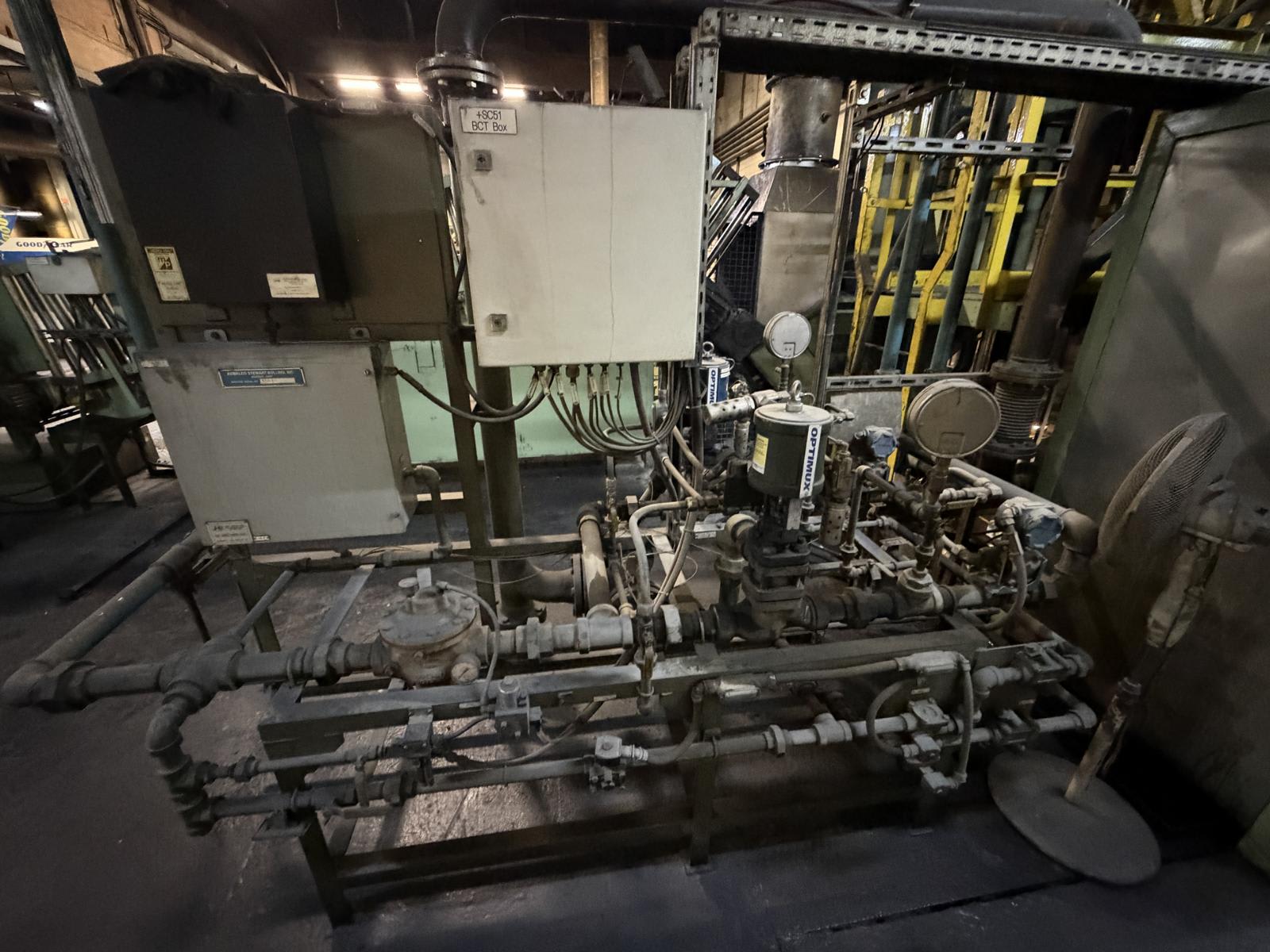

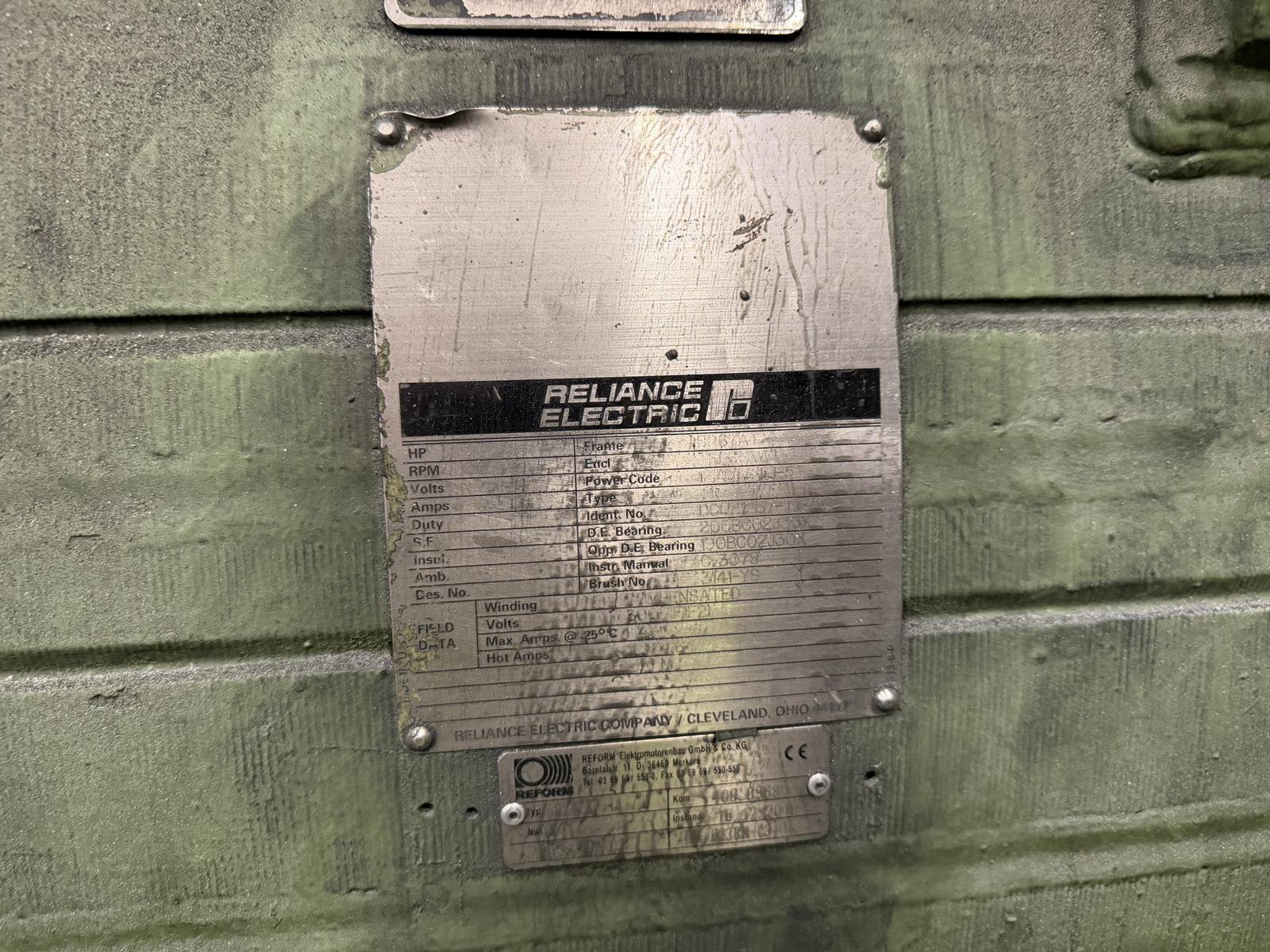

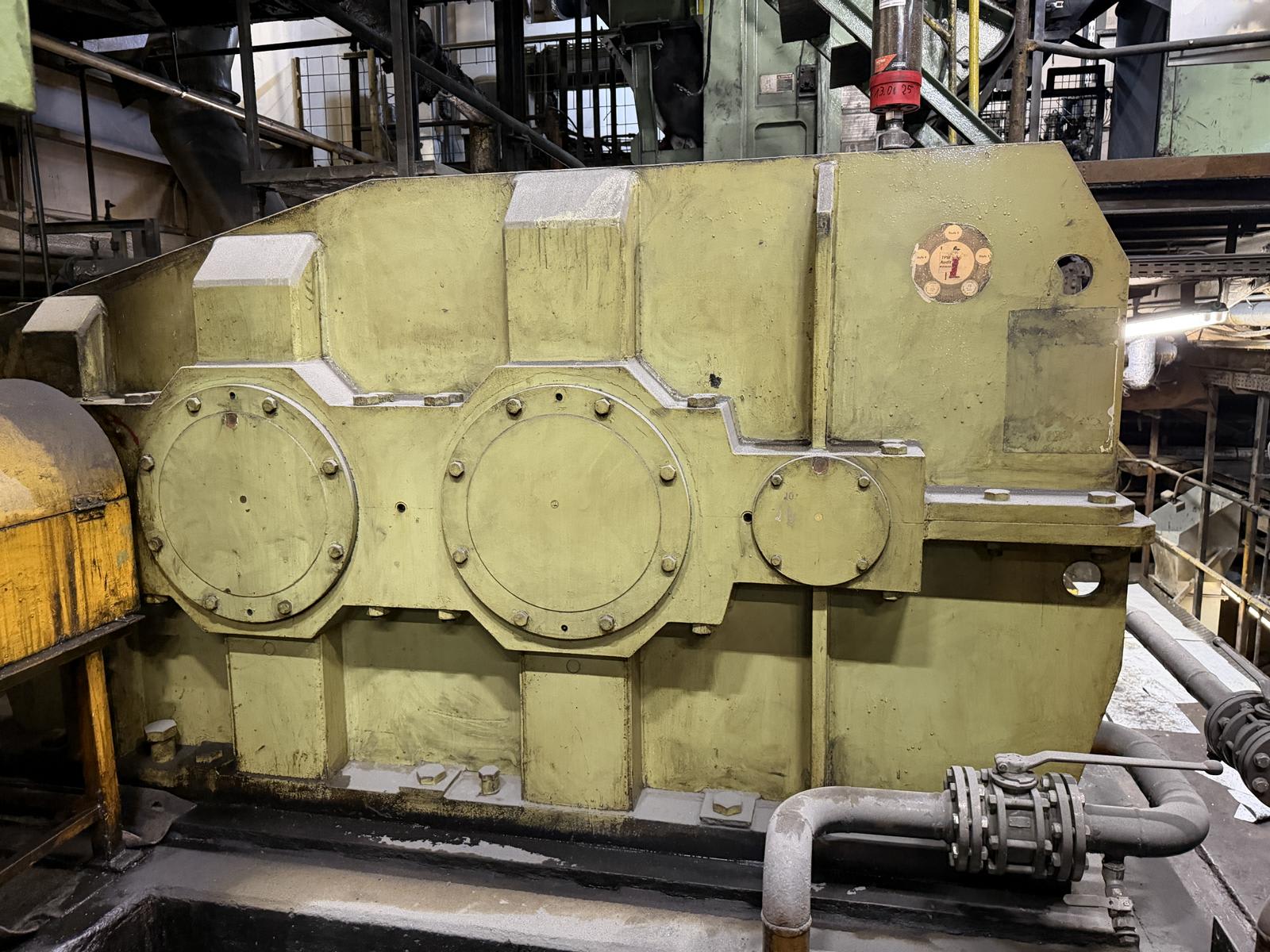

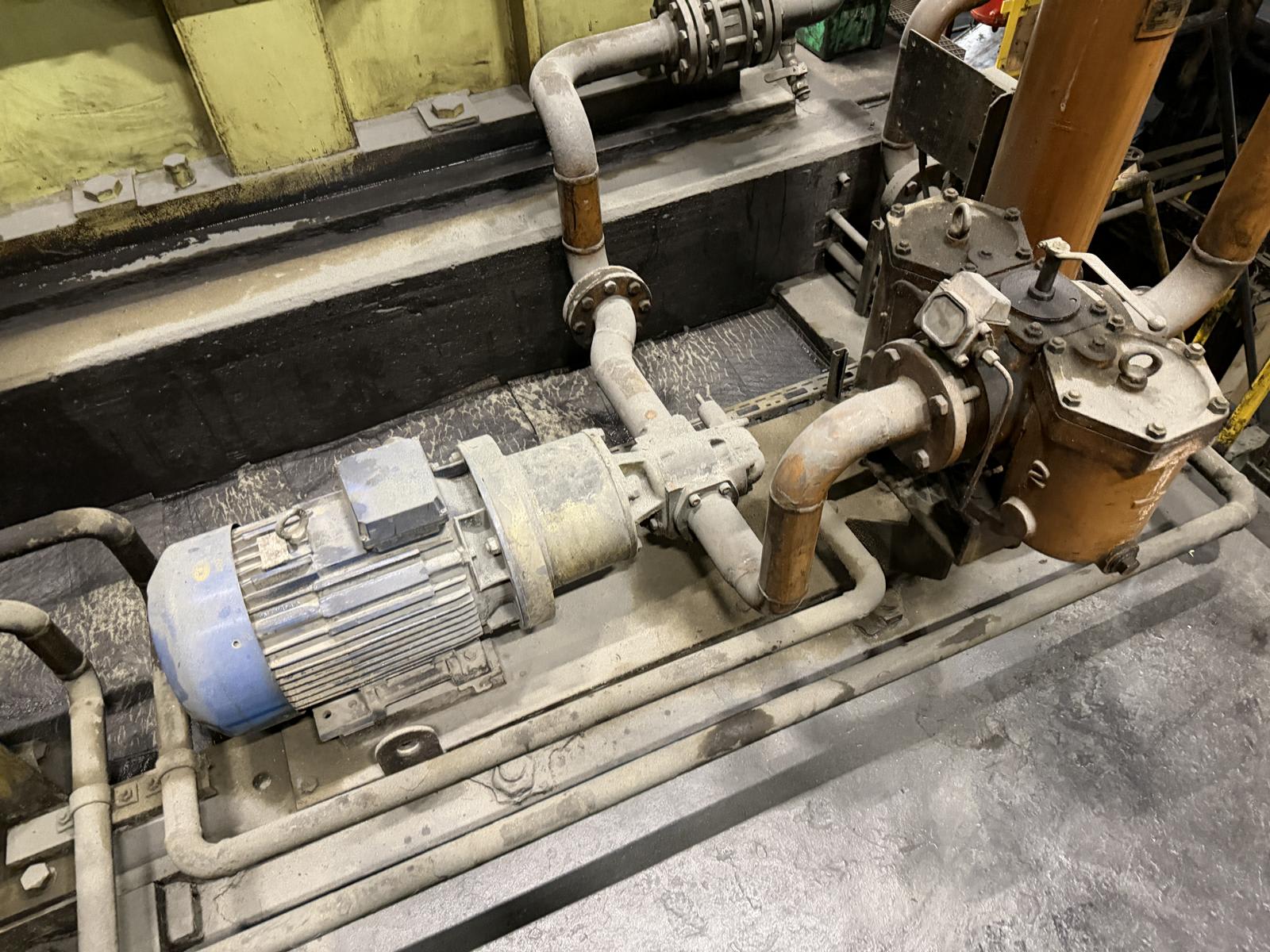

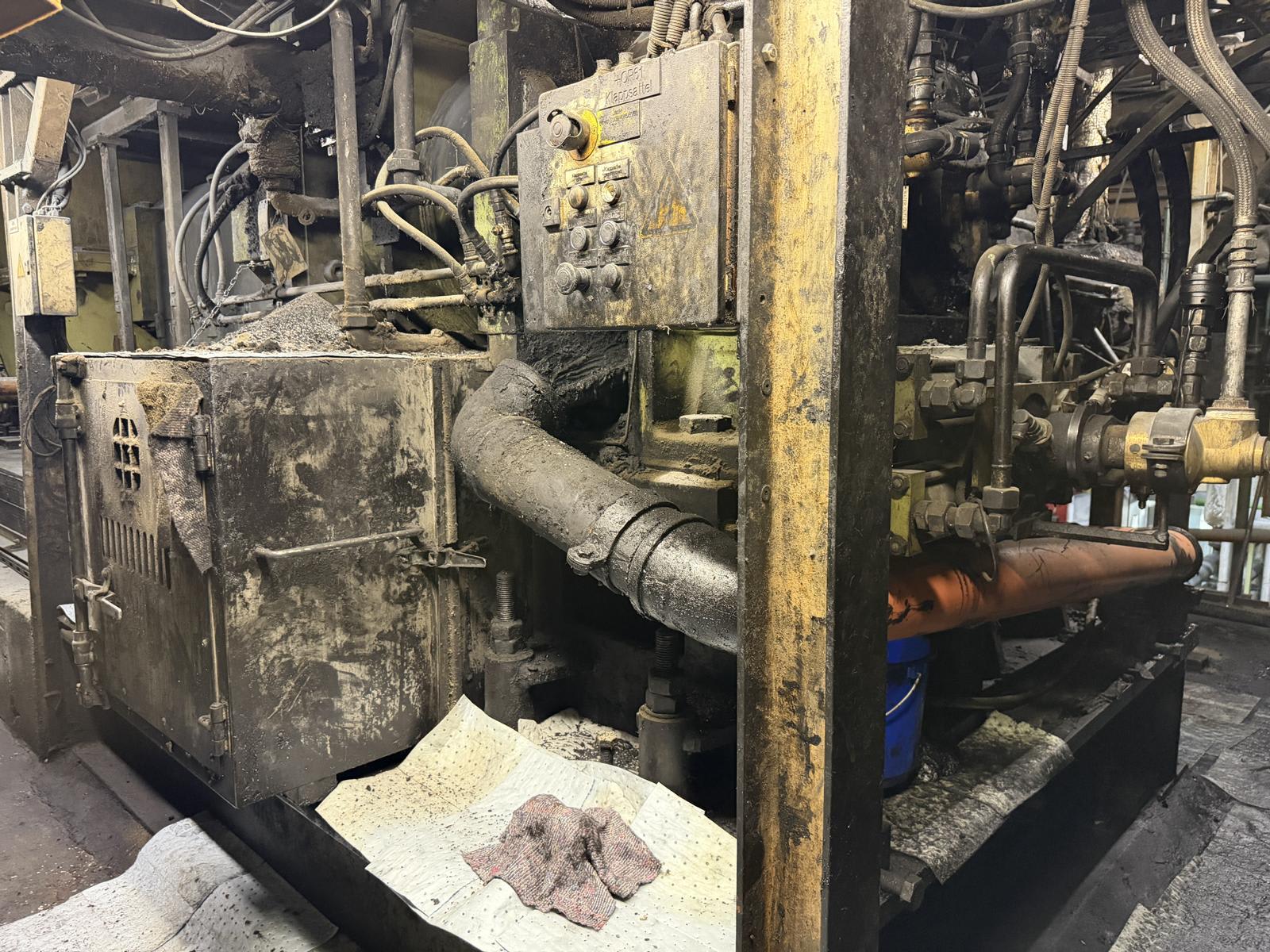

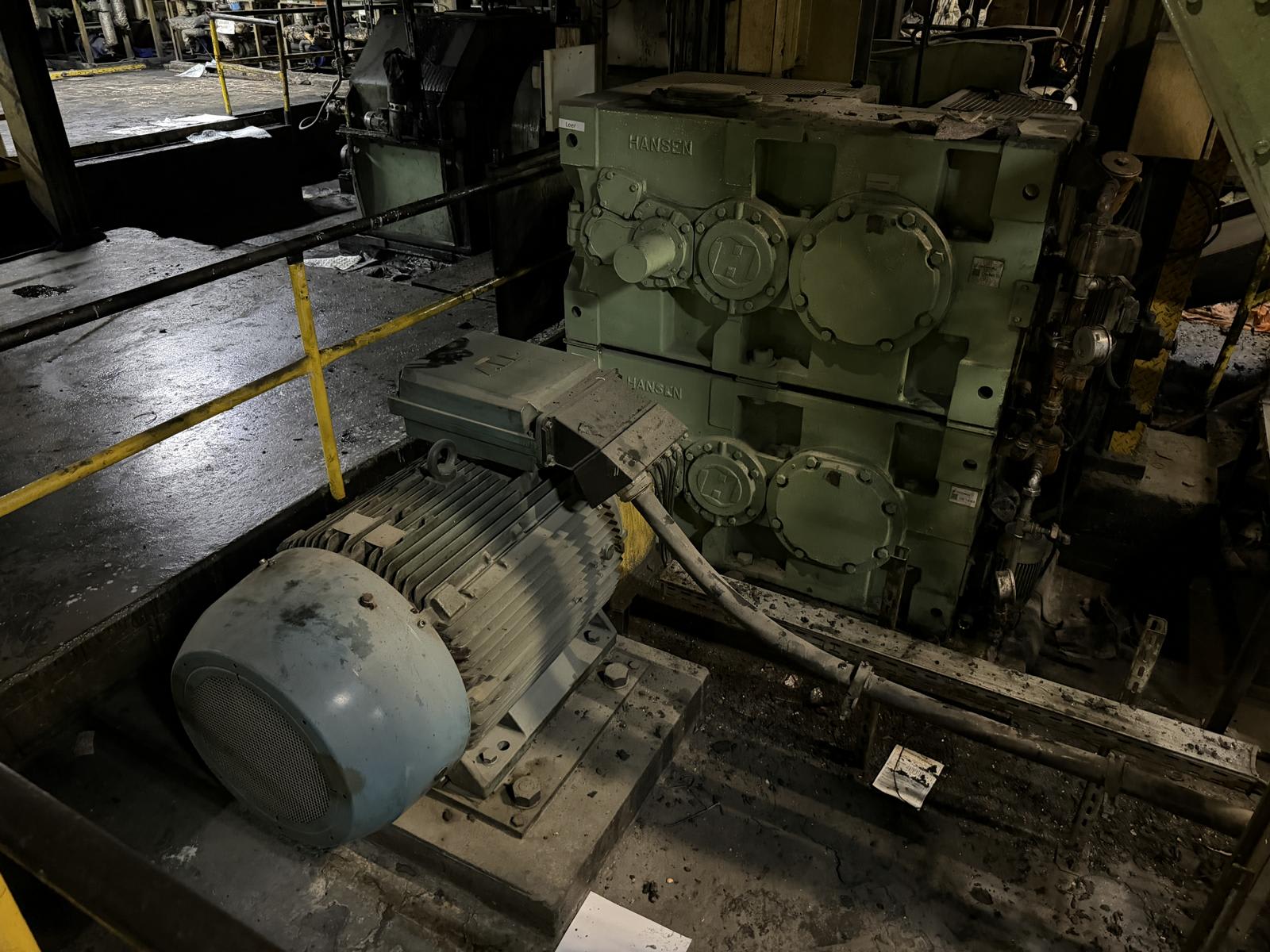

Banbury Kneader / Mixer #2 with peripheral equipment Documented modifications / upgrades: Year Modification / Upgrade 1973 Installation of 2 × 38" ASM Batch-Off units – Banbury II 1979 Beth filter for Kneader II 1981 Exhaust system for solvent tank Kneader 2 1985 Temperature control unit Kneader 2 1994 Automatic laydown system for Mixer #2 2008 Vibration measurement system Mixer II 2008 Demag Manipulator Mixer I (2x) 2009 Measuring device – Power Quality Interface for Kneader 2009 Ergonomic upgrade Rubber splitter 2010 CMS system for Mixer II 2010 Upgrade TCU for Mixer II 2014 BB 270-6W Mixer Head Transfer Unit (HTU) for Kneader II 2015 Monitoring system (Kneaders I–III) for CMS Kneader II 2015 Replacement of obsolete computer and UPS for Mixer 2 2015 Installation Autorelease Terminals Mixer II 2017 Hopper for Mixer #2 2018 Mixer 2 MS Version 4 2018 Slab feeder Mixer 2 2021 Replacement Mixer Body / Serial no. 16439 2022 Mill gearbox Kneader 2 Control system: CMS system, TCU upgrade, Computer & UPS replaced Maintenance / condition: Regular modernizations and upgrades documented (1973–2022) Accessories / options: Batch-Off units, Slab feeder, Hopper, Drop Door Box, Roller Head with Conveyor, Mill, Dip Tank, Cooling Line, Lay Down - LISTING 2760003

![Deutsch]()

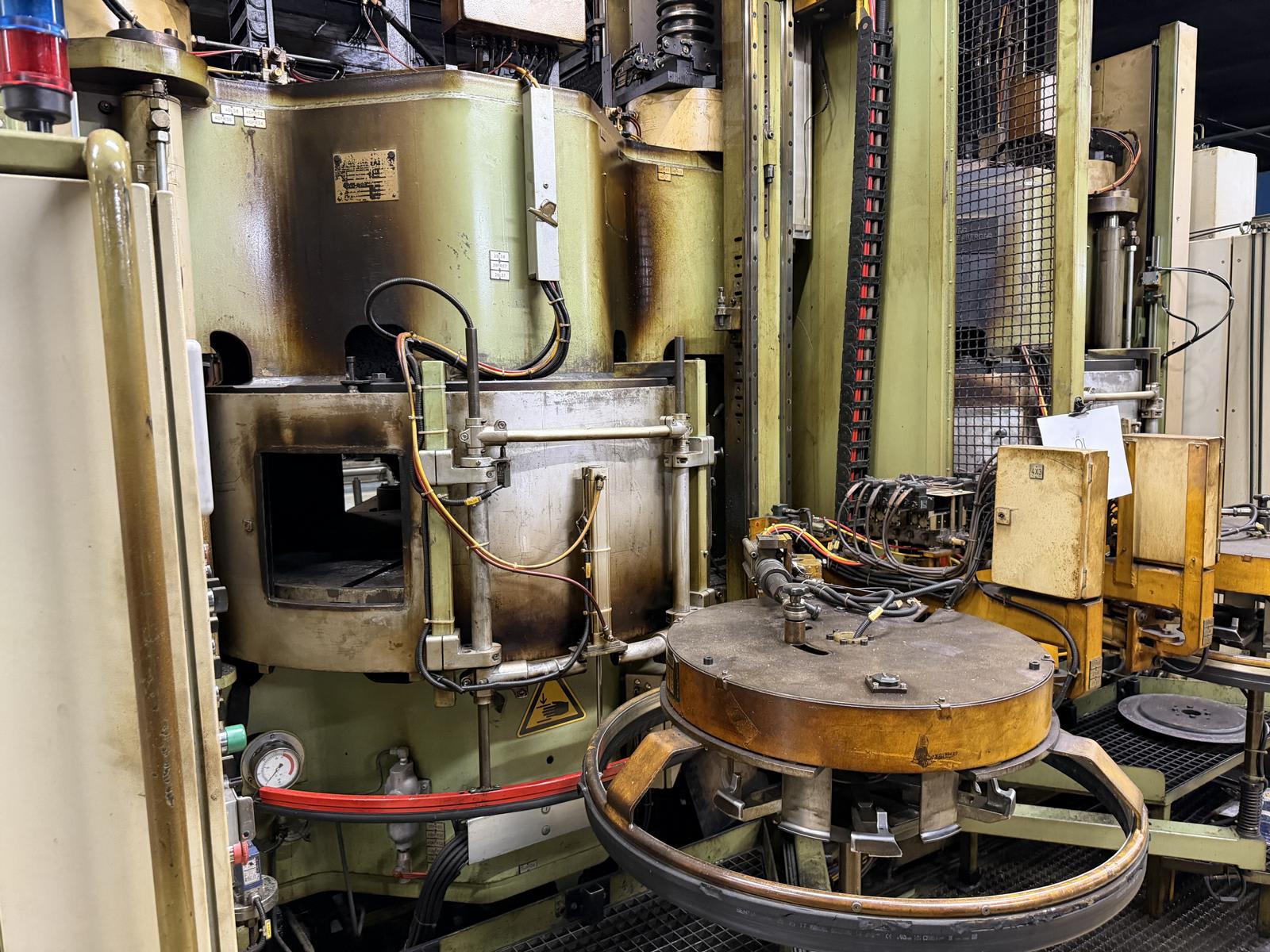

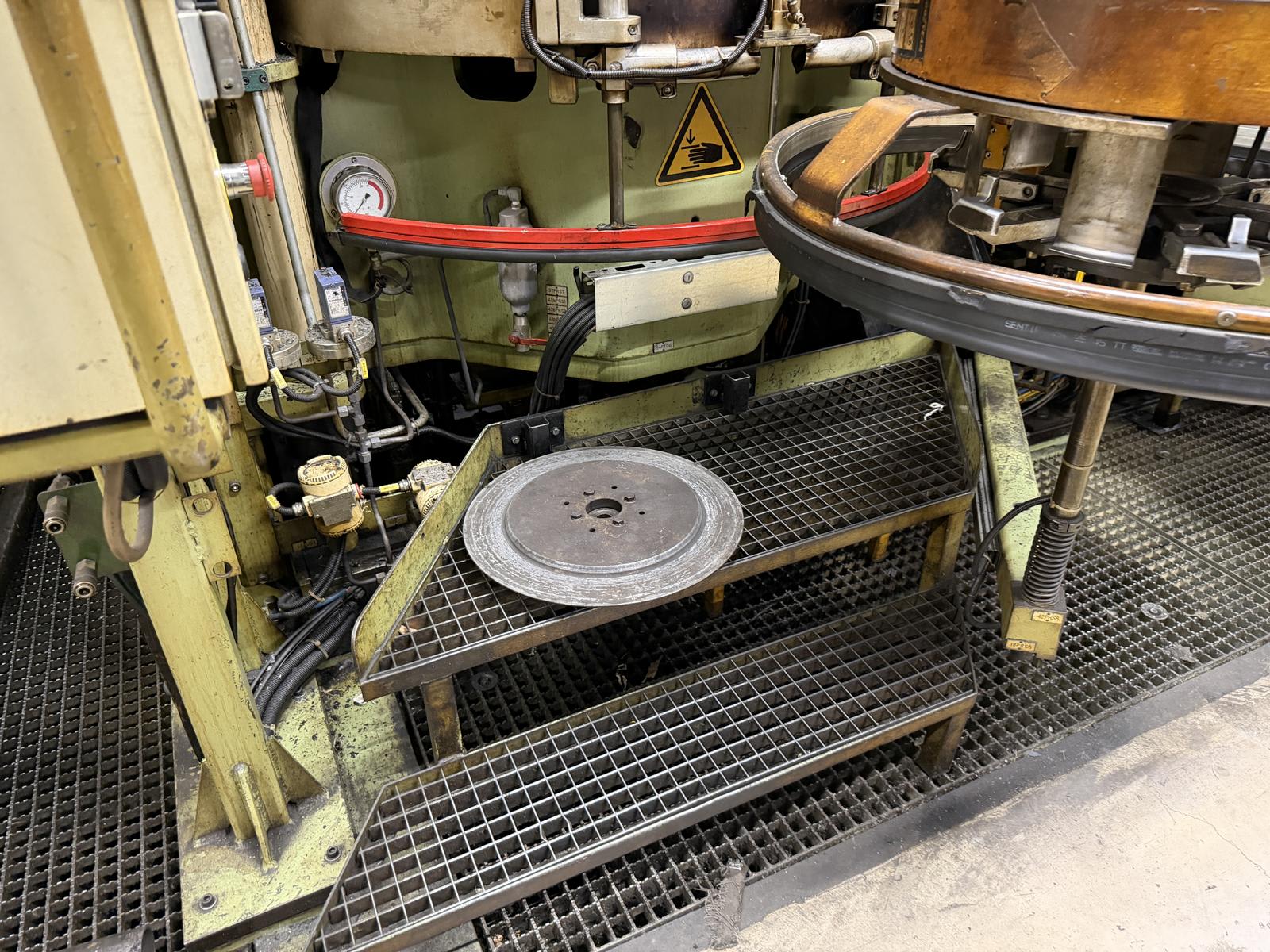

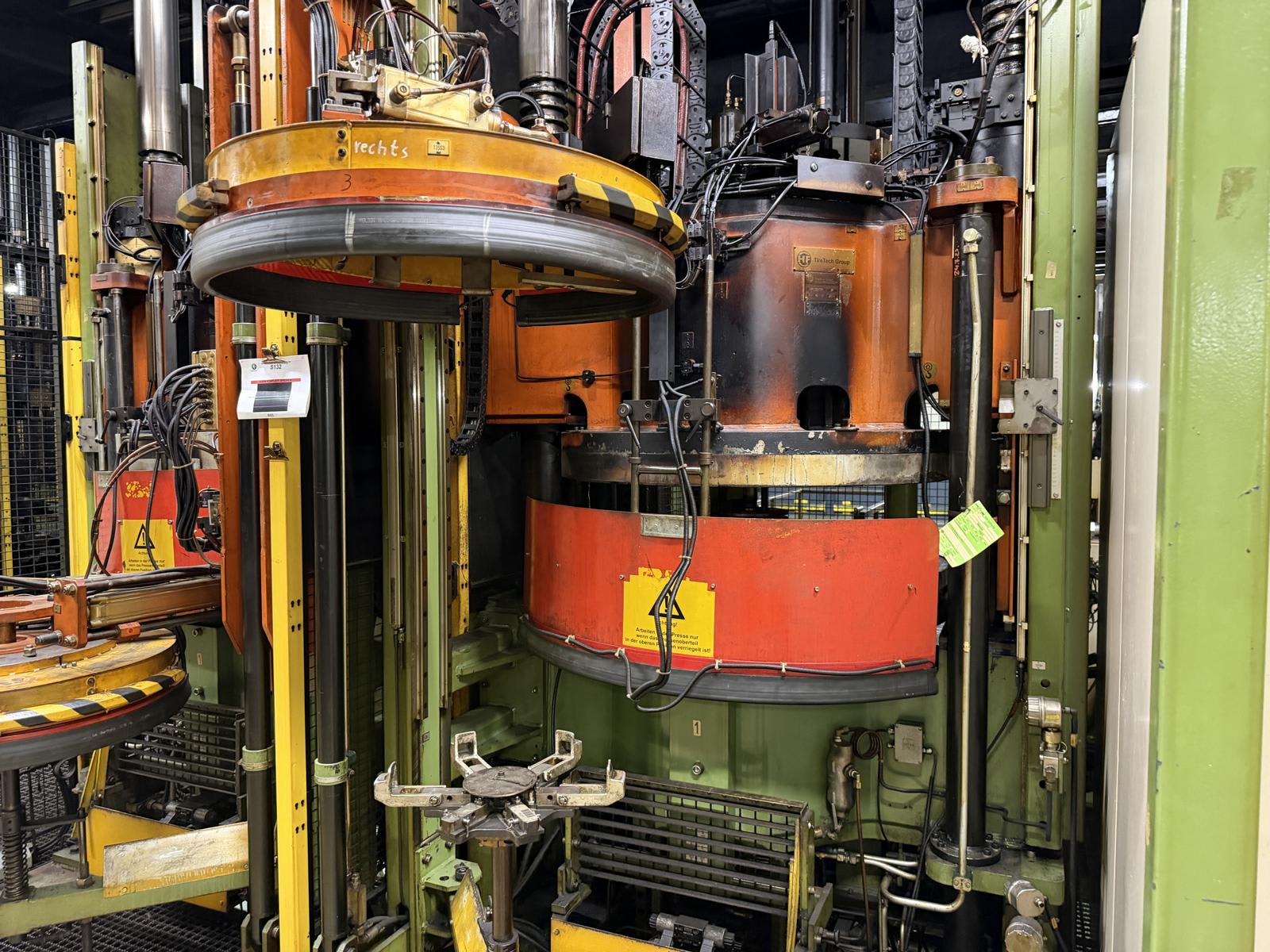

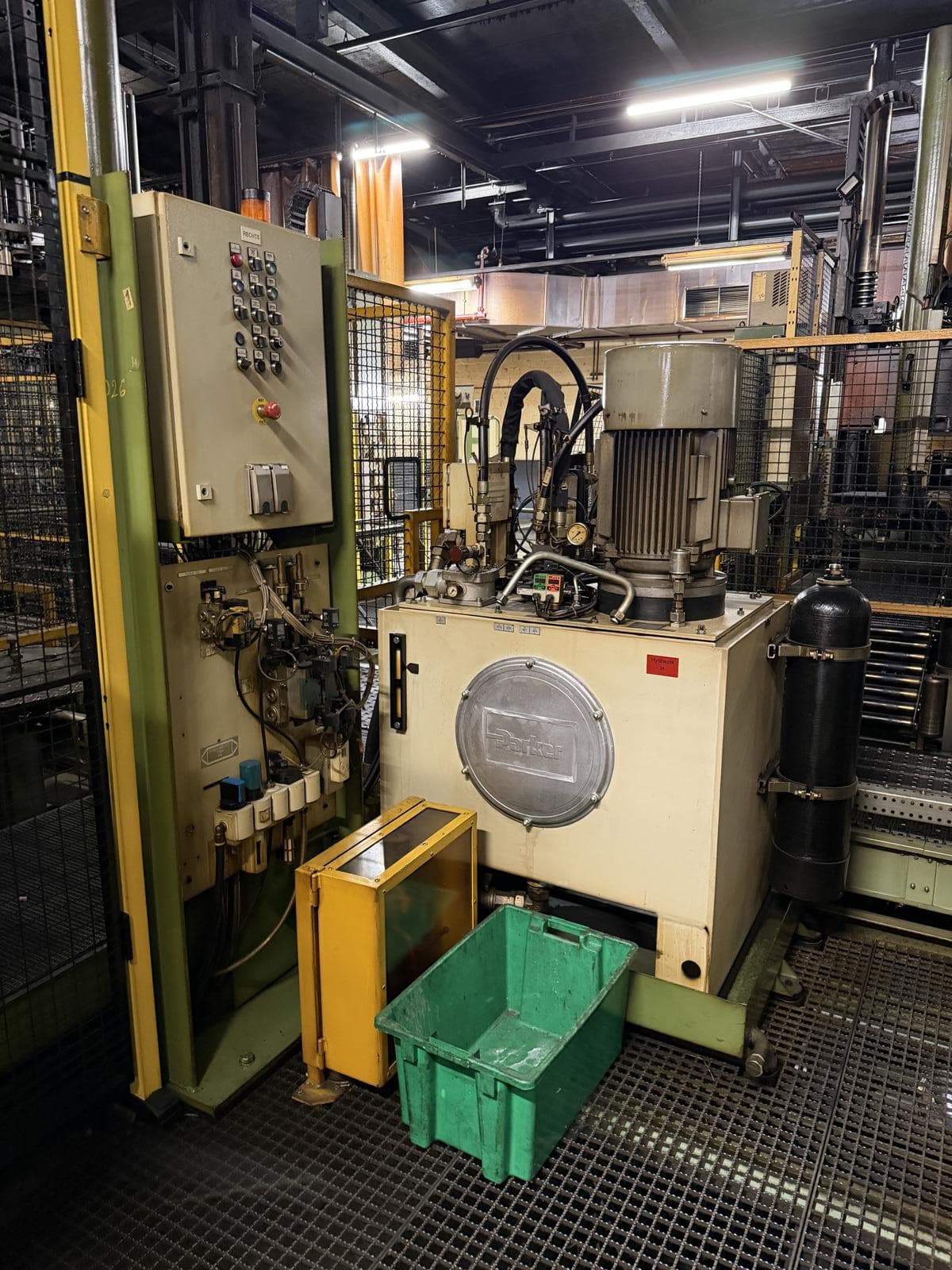

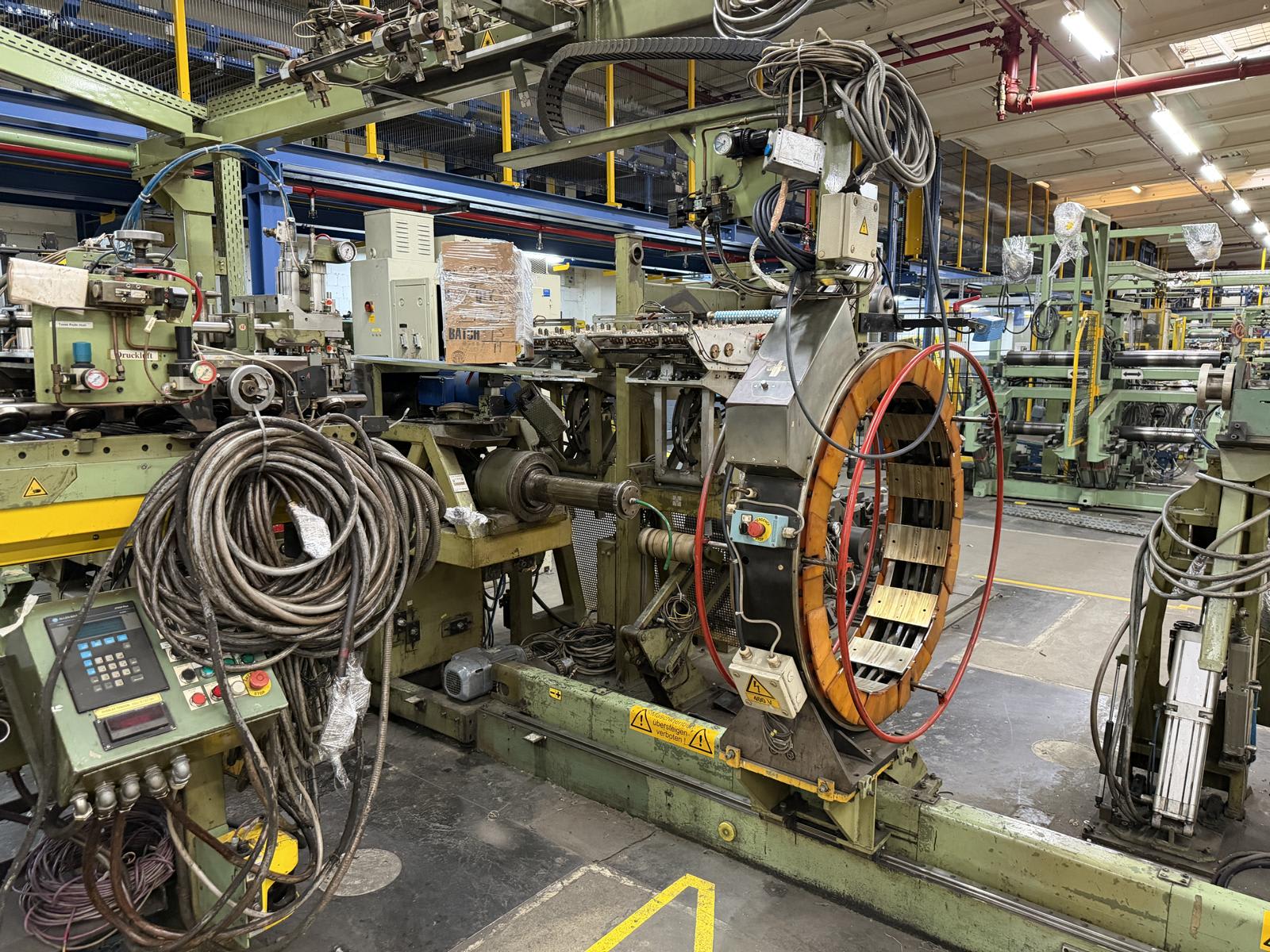

Banbury 3 Mixing Line Kobelco DEFU-BB270 Mixer (NP/P) [hybrid / productive and non productive] | 1962-2023

Binding Handling & Service Fee:

132500 € (EURO)

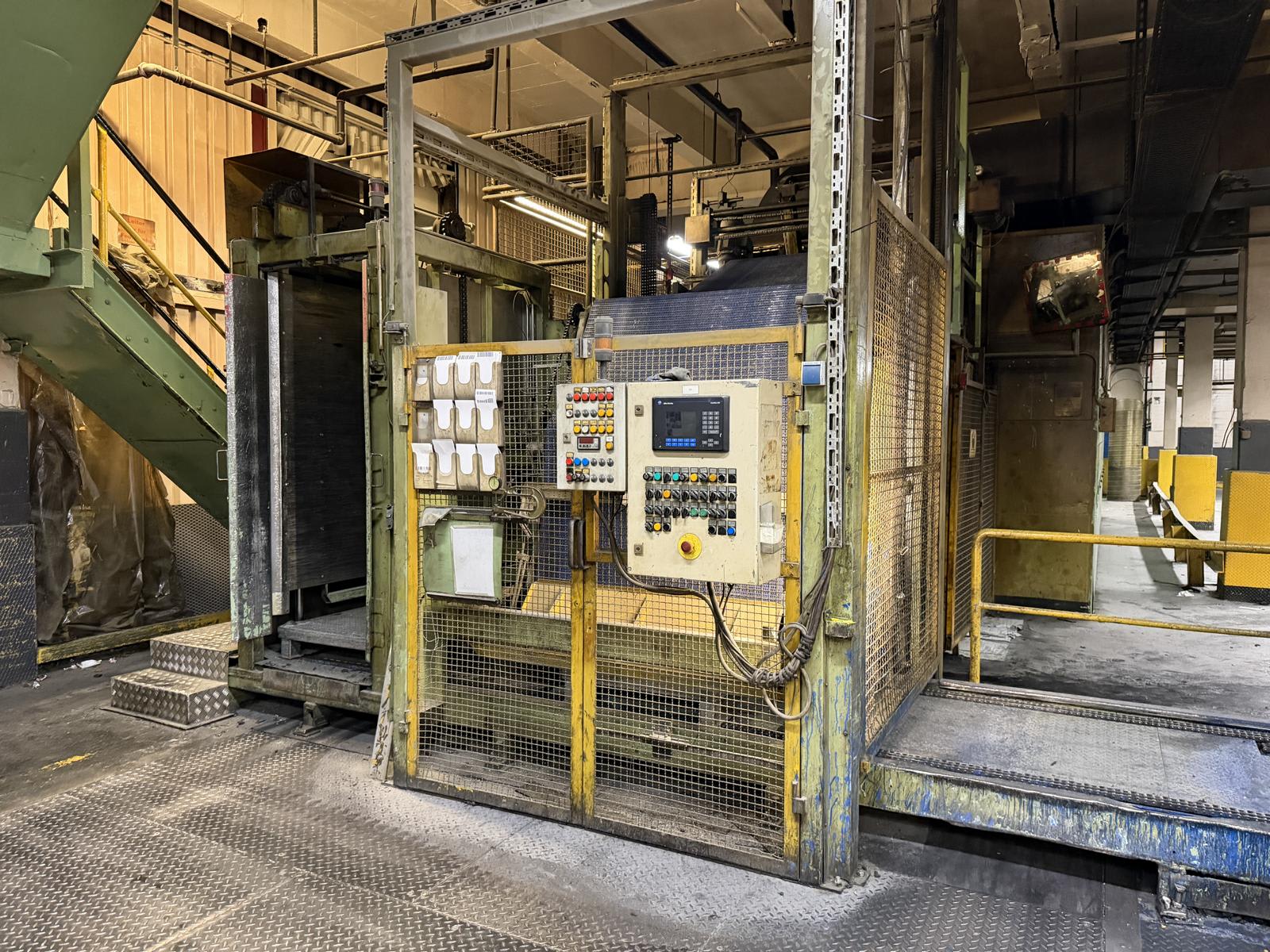

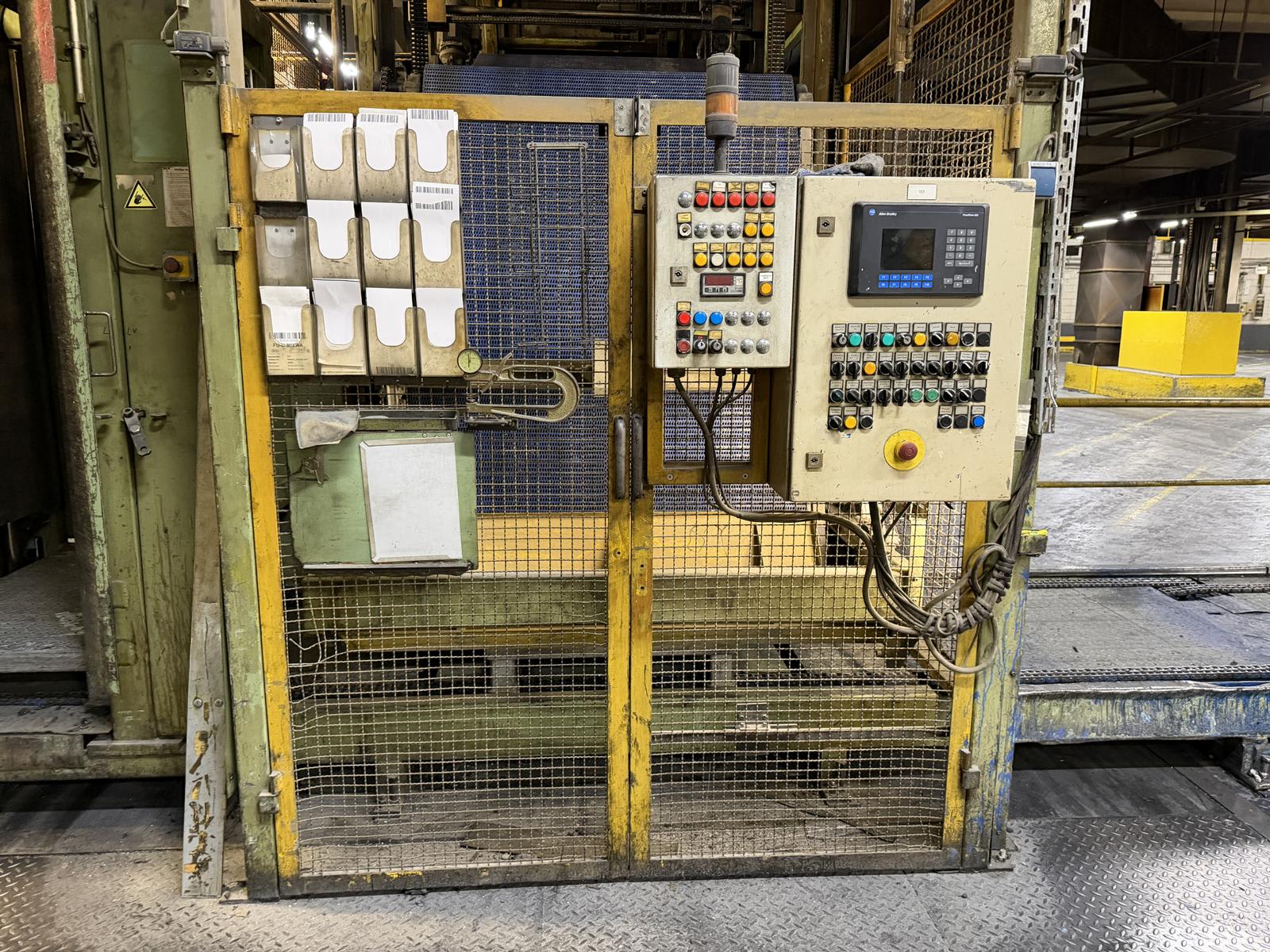

Banbury Kneader / Mixer #3 with peripheral equipment

Documented modifications / upgrades:

Year Modification / Upgrade

1962 Gearbox upgrade Kneader III

1973 Carbon black weighing & charging system for Kneader III

1981 Exhaust system for Kneader III

1985 Batch-Off machine Kneader 3

1985 Temperature control unit Kneader 3

1995 DC motor 1500 HP, 1700 V, 1678 A

1996 Upgrade to KSBI-L270 Kneader III

2007 Hose scale for Kneader #3

2008 Vibration measurement system Mixer III

2008 Column slewing crane for bale handling Mixer III

2009 Vacuum hoist system Kneader III

2010 CMS system for Mixer III

2013 Long-strip cutting device for Kneader III

2014 Slab feeder for Kneader III

2014 Overnose conveyor Kneader III

2014 2 × floor scales for Kneader III

2014 New controls for Kneader III

2014 Cooling register MUAFAN 1+2 – cooling line mill Kneader 2+3

2015 Monitoring system (Kneaders I–III) for CMS Kneader III

2017 Mixer body Kneader III (replacement)

2023 Rubber kneader III KSBI-L270

Control system: New controls 2014, CMS system 2010, DC Drive / Automax, PLC Batch-Off & Conveyor, AC Drives documented

Maintenance / condition: Regular modernizations and upgrades documented 1962–2023

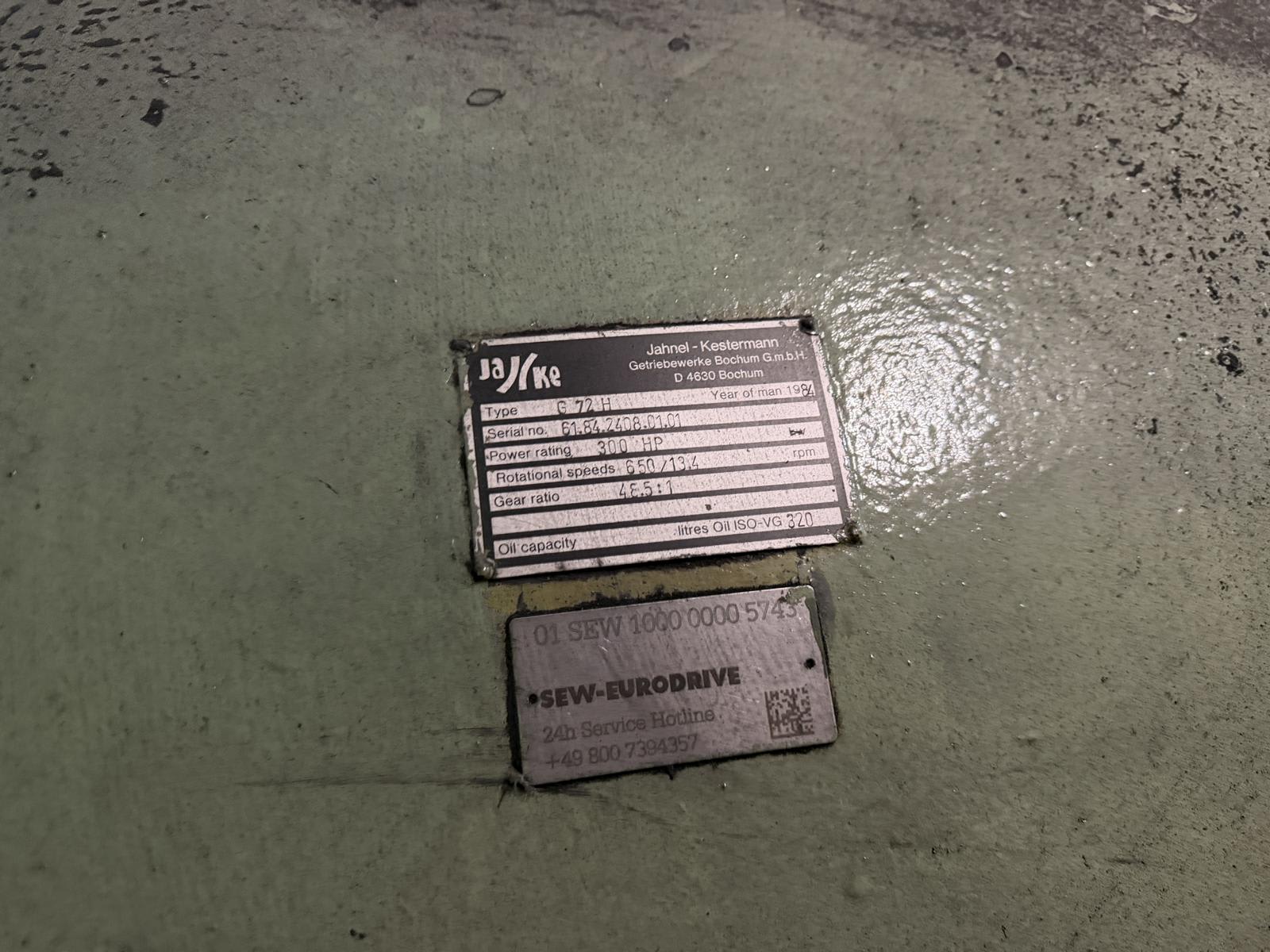

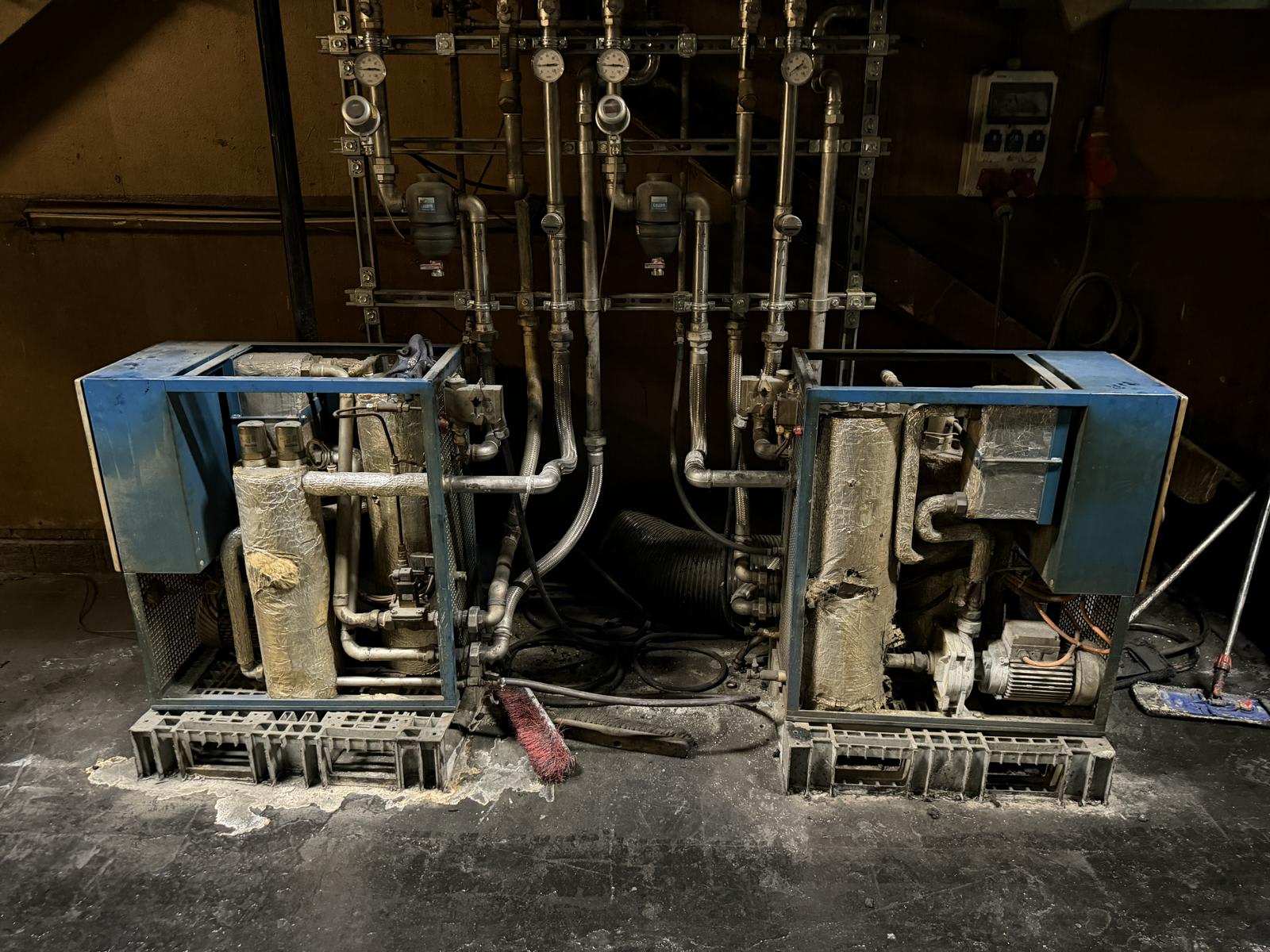

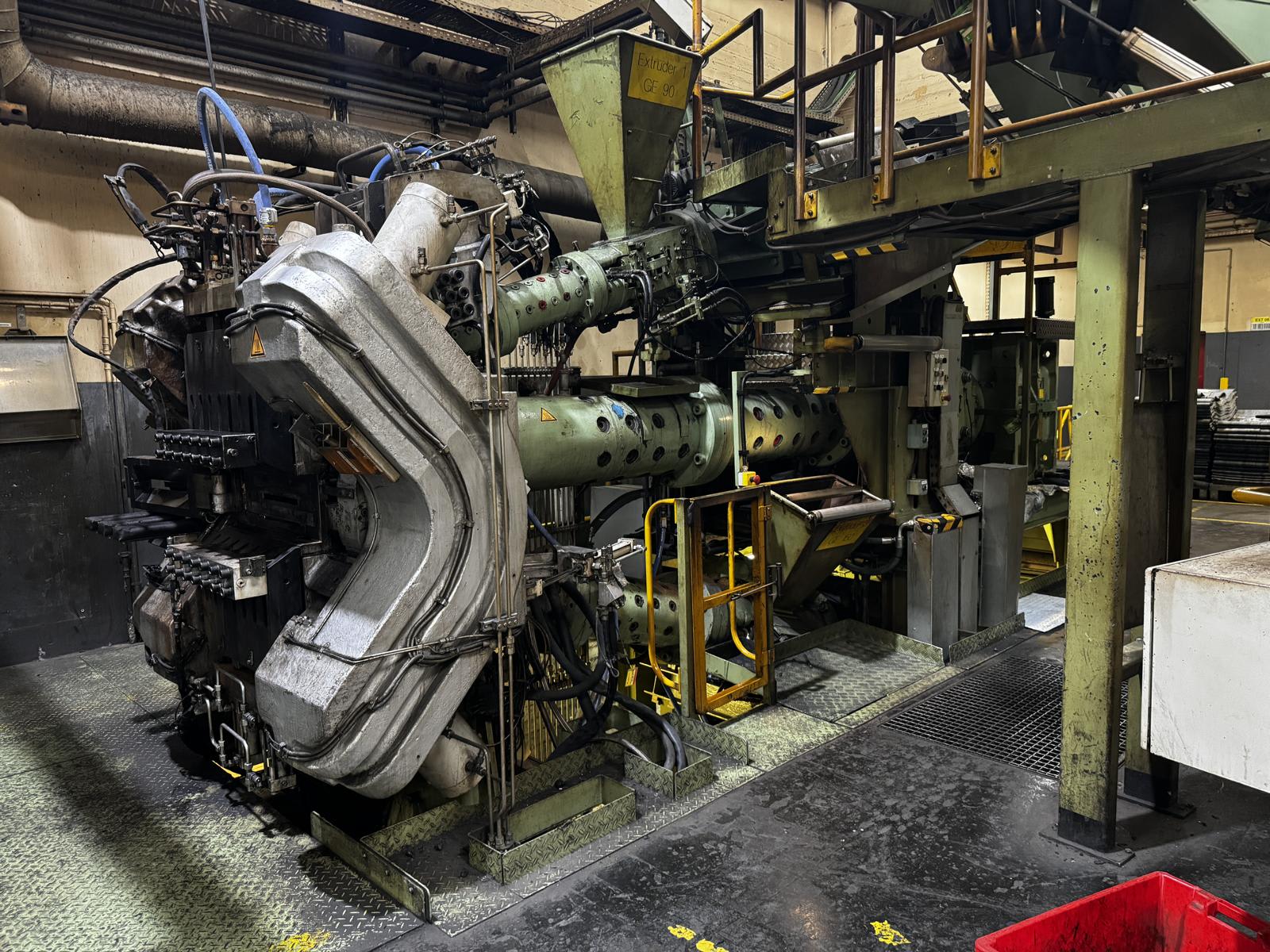

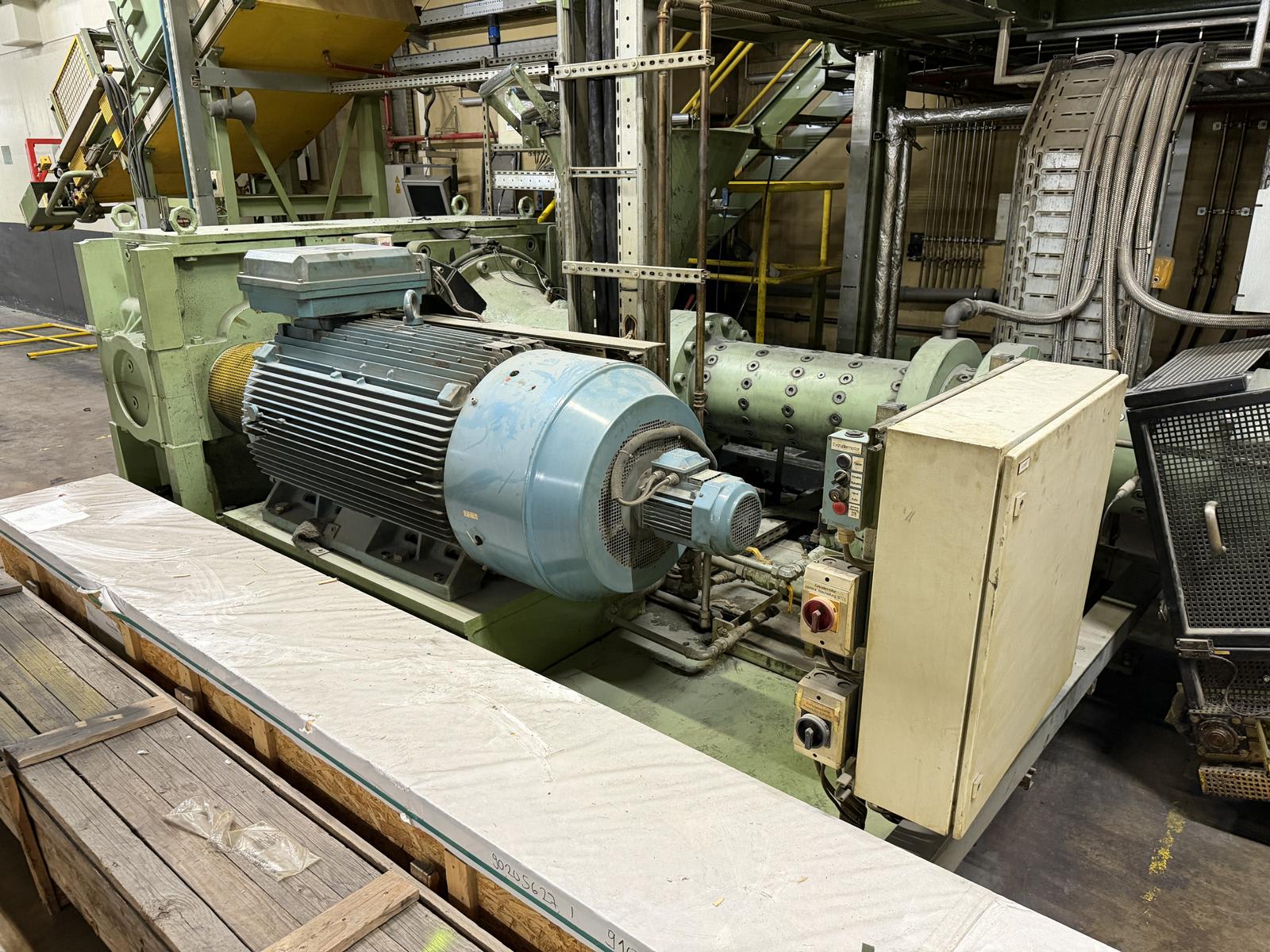

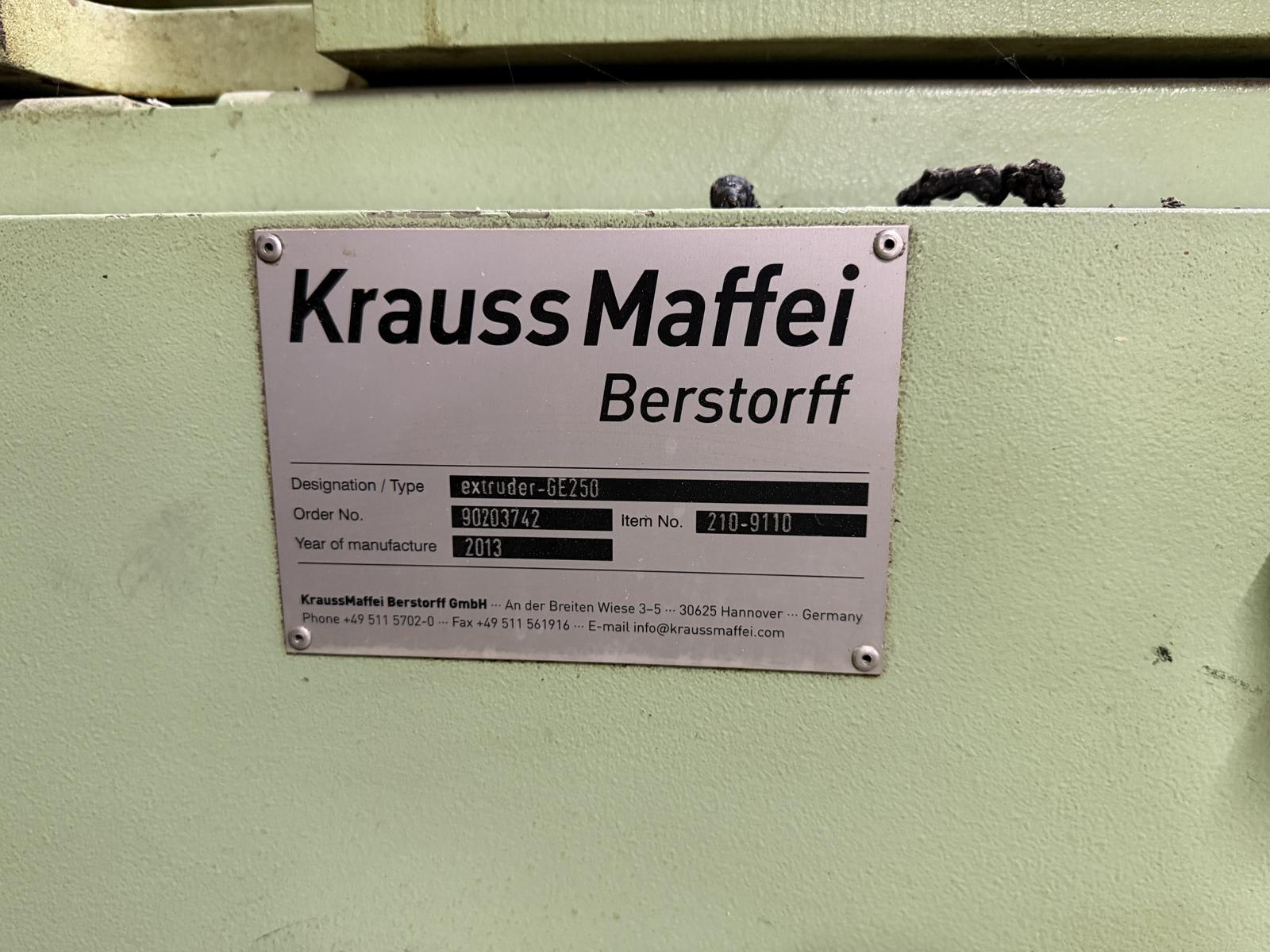

Accessories / options: Batch-Off machine, Slab feeder, Put Up conveyor, Long-strip cutter, Floor scales, Bale handling crane, Vacuum hoist system, Carbon black silos & weighing system, Extruder, Roller Die, Roller Head with conveyor, Cooling systems (Dip Tank, Cooling Line, Laydown), Control systems (DC Drive, AC Drive, Automax, PLC) - LISTING 2760004

![Deutsch]()

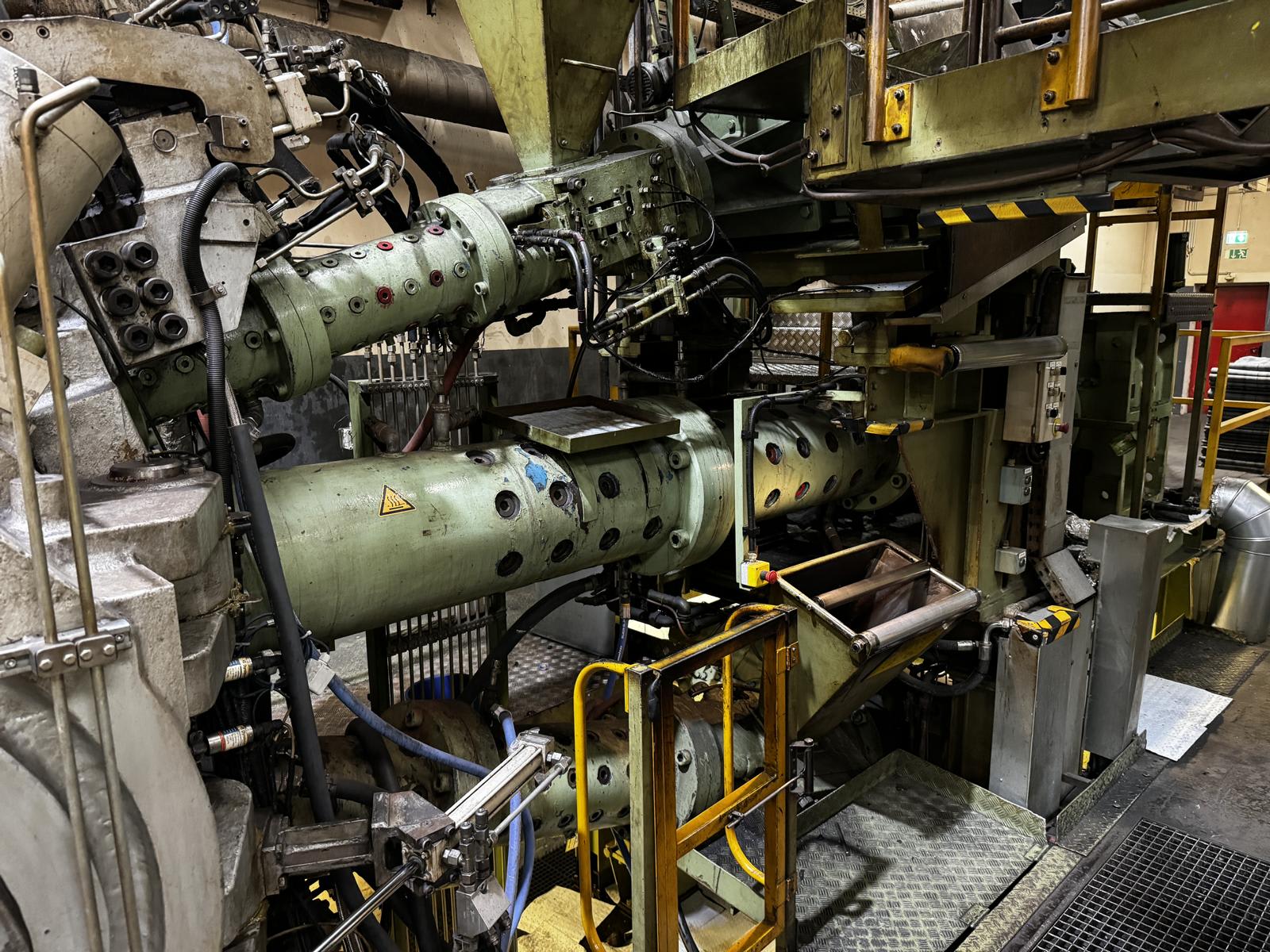

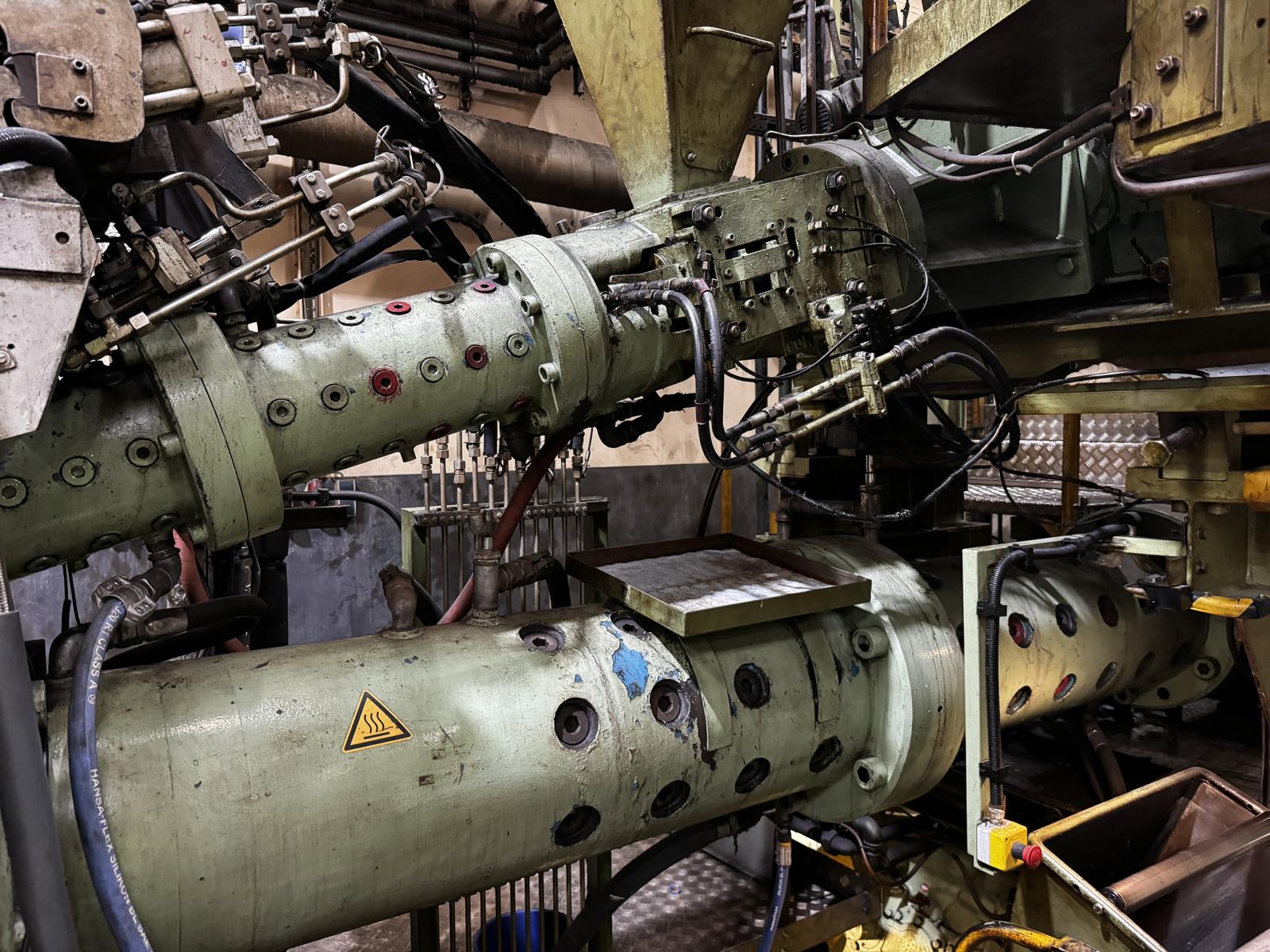

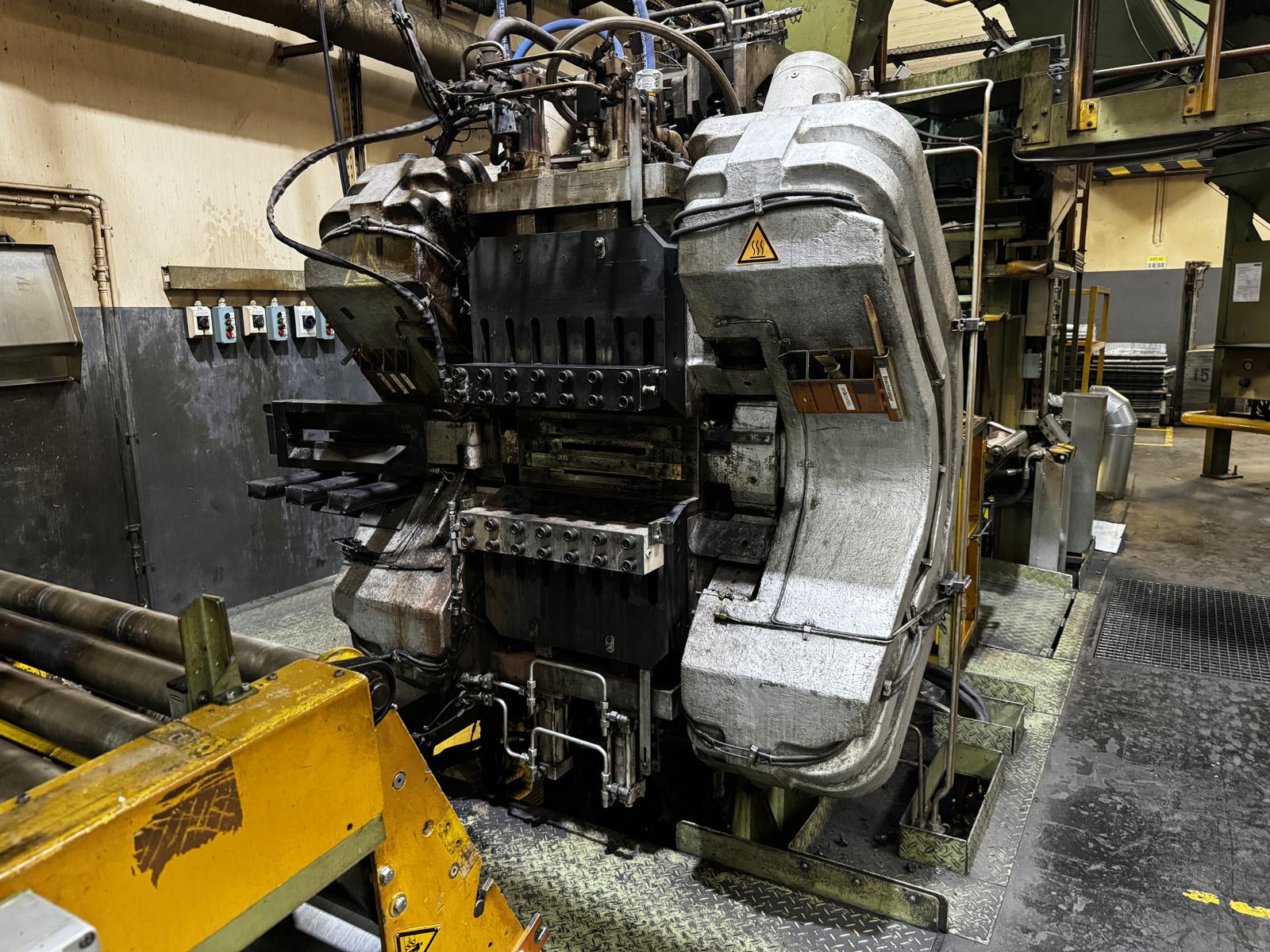

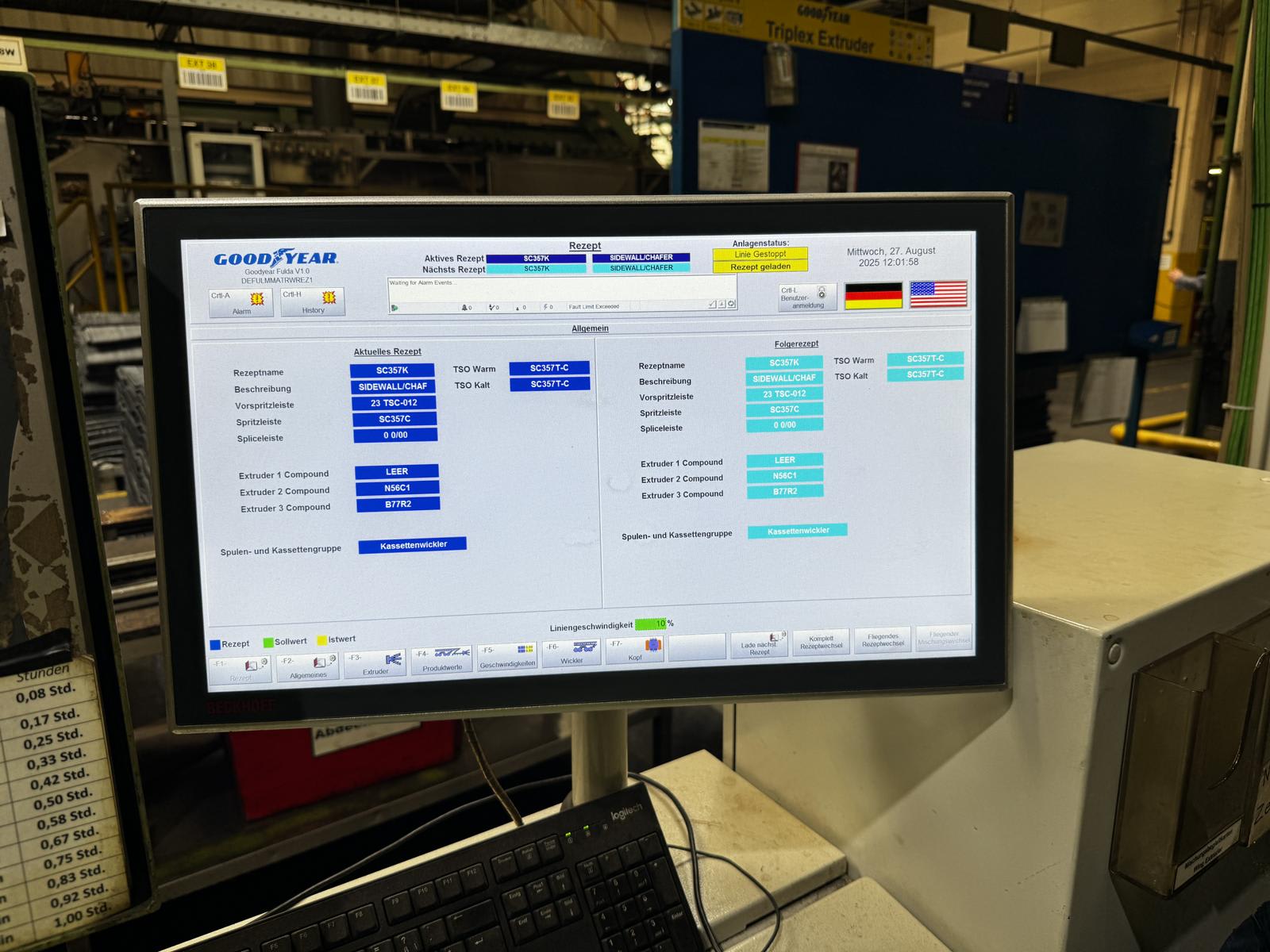

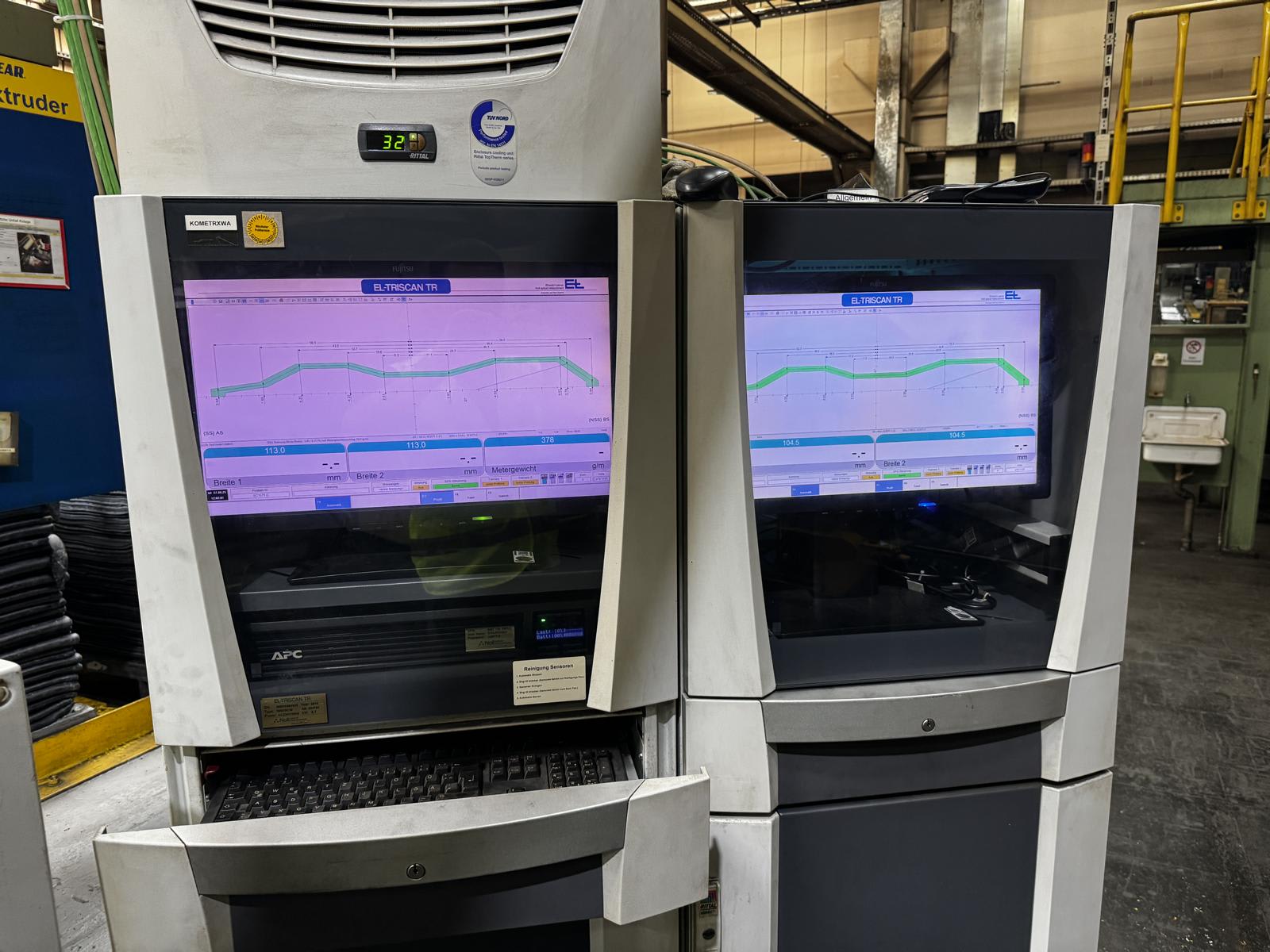

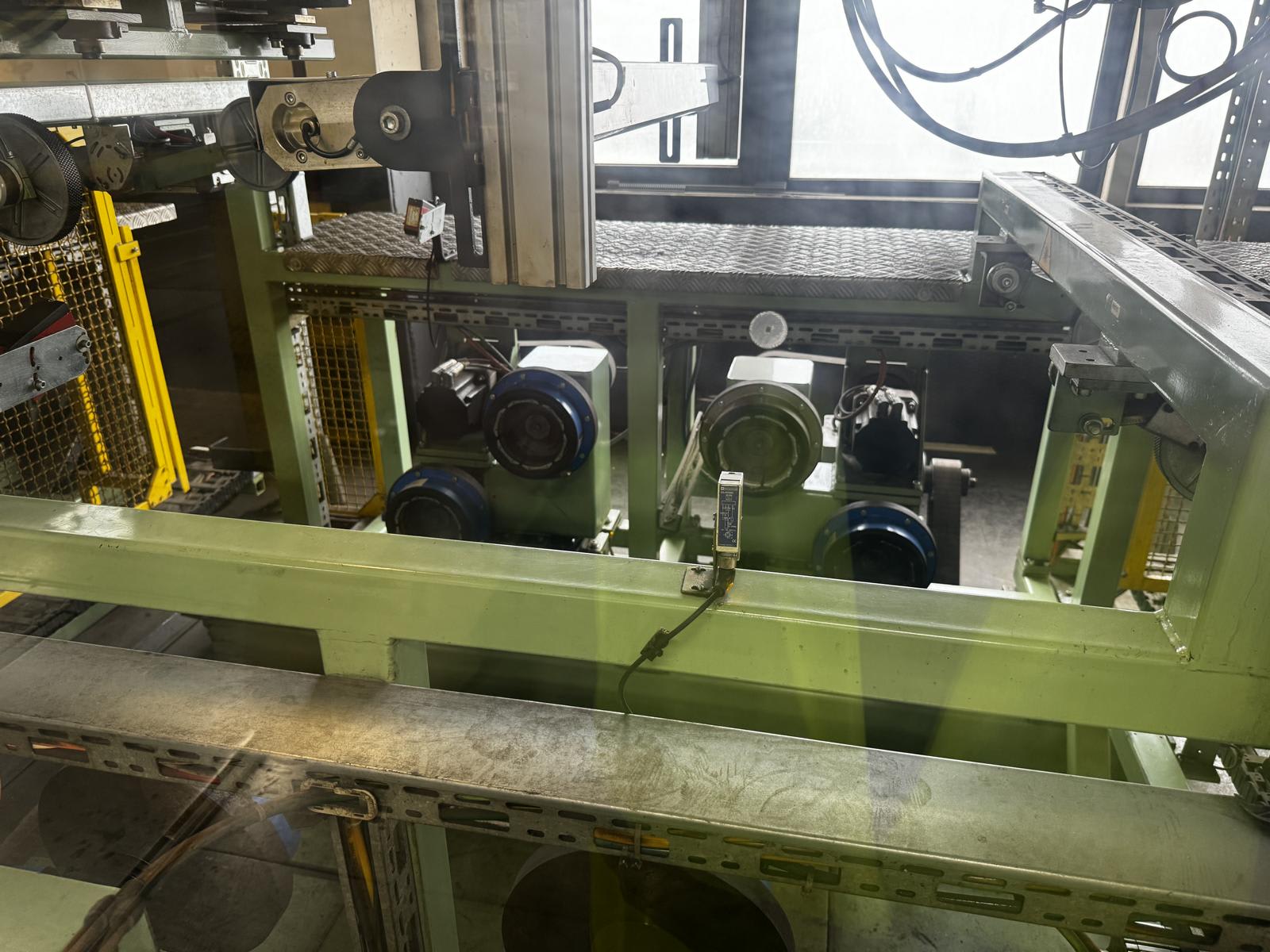

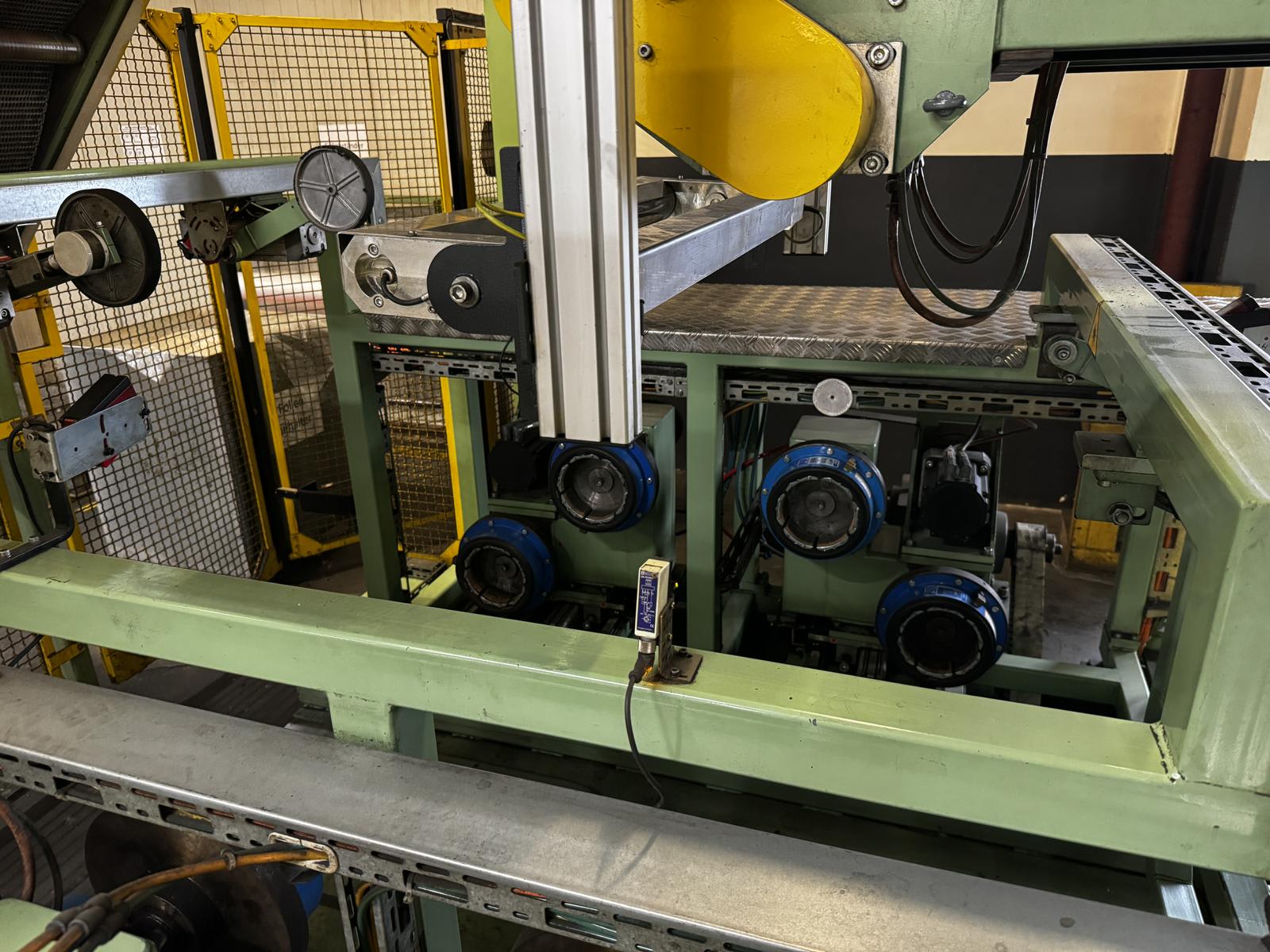

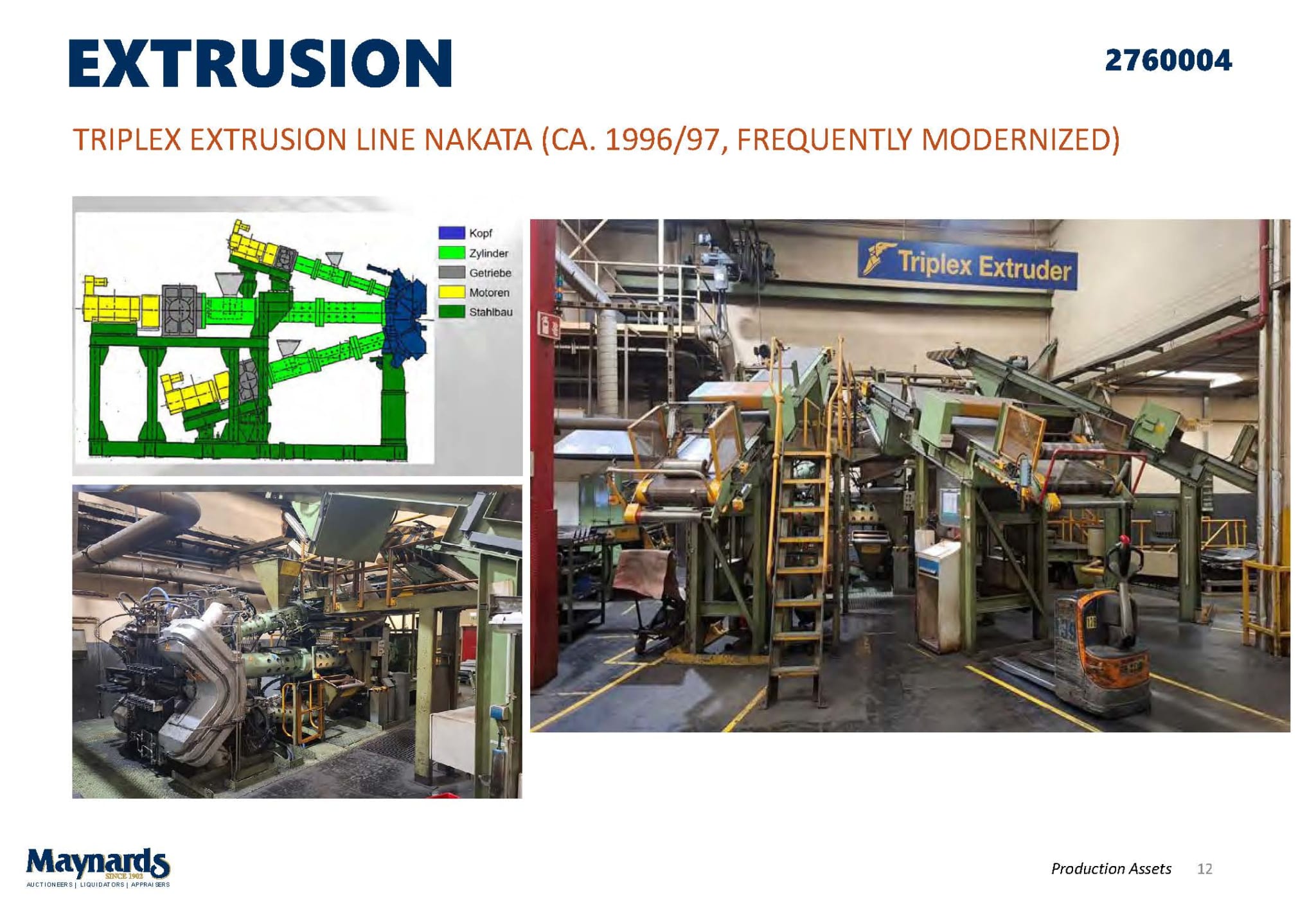

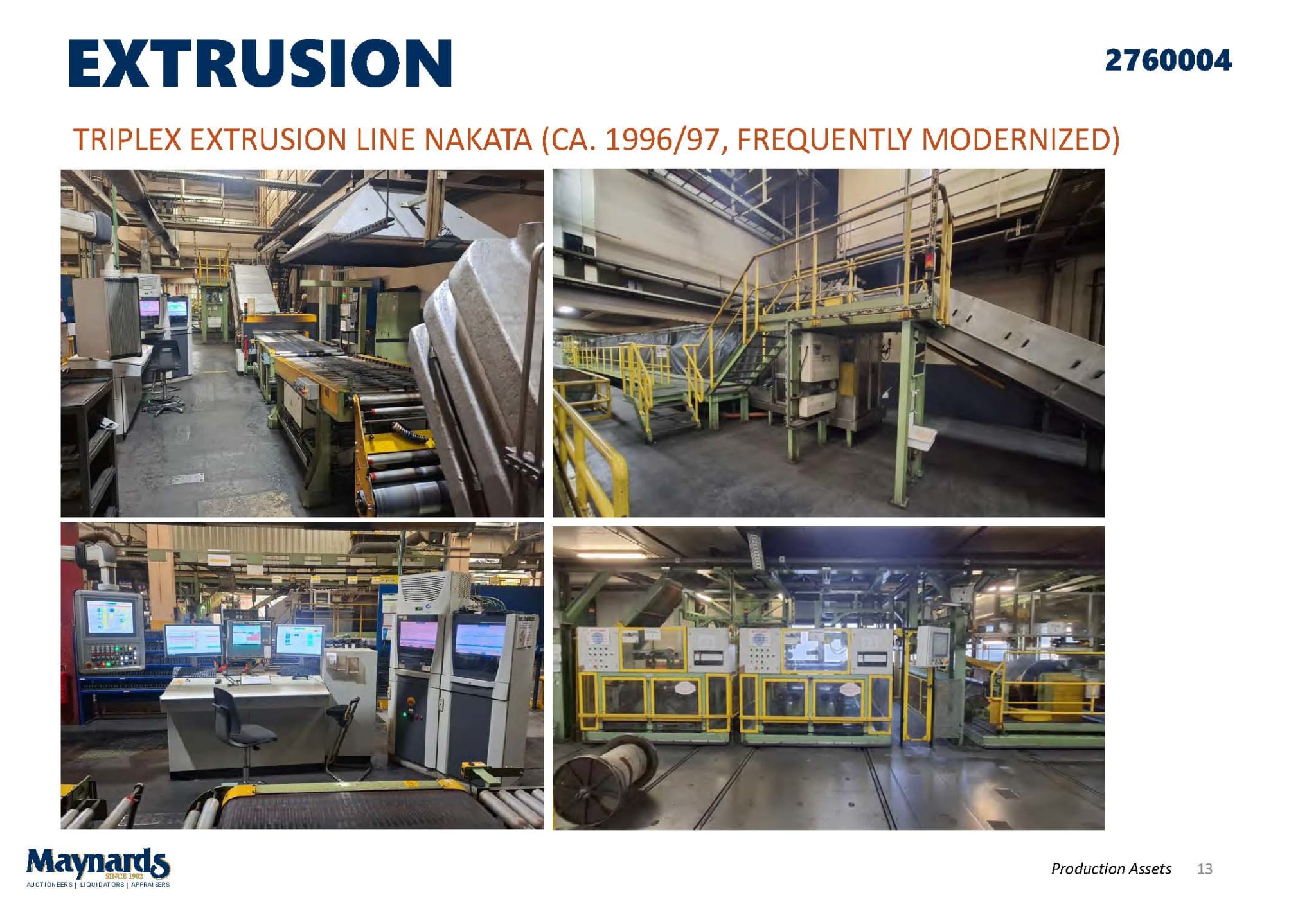

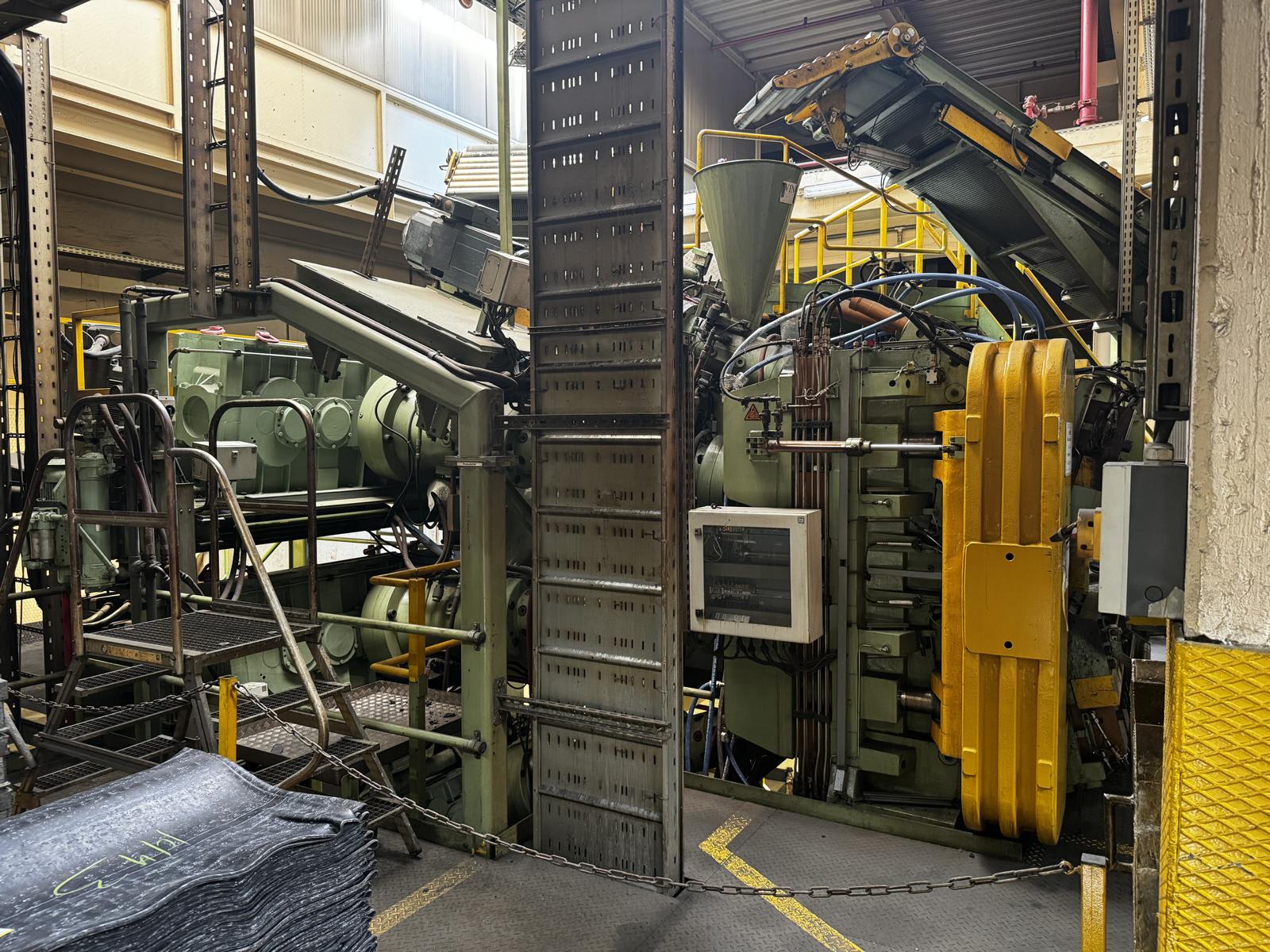

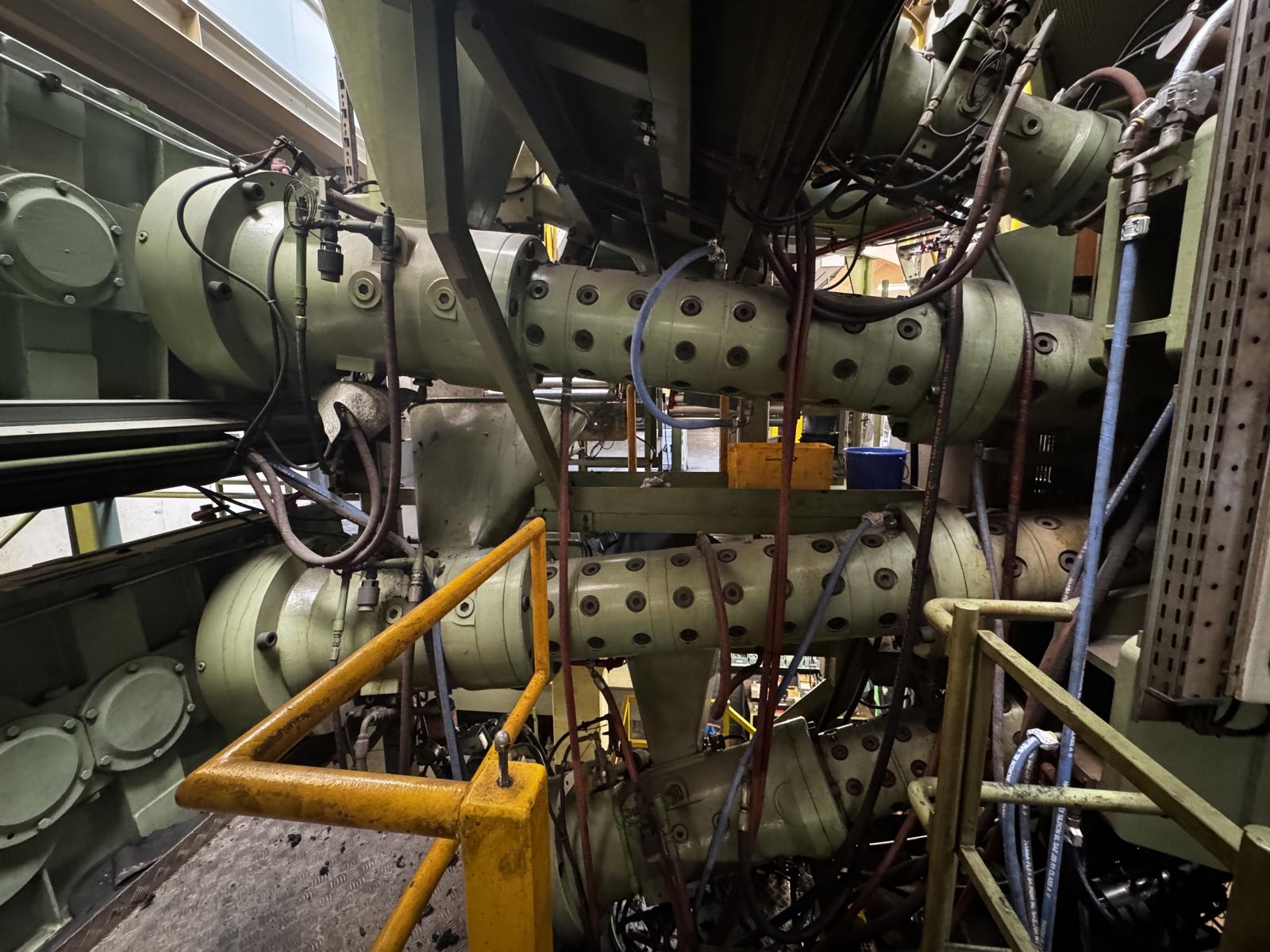

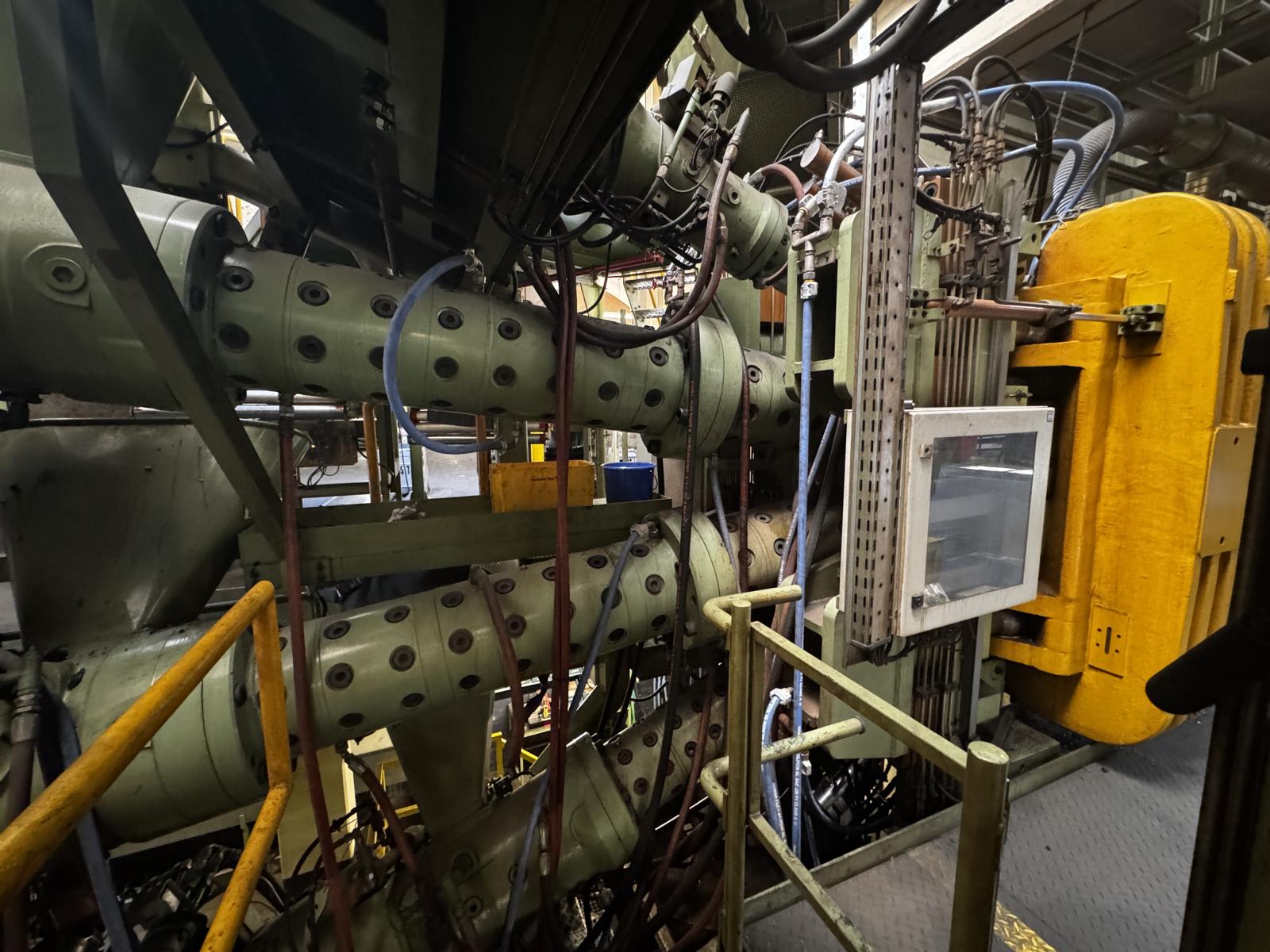

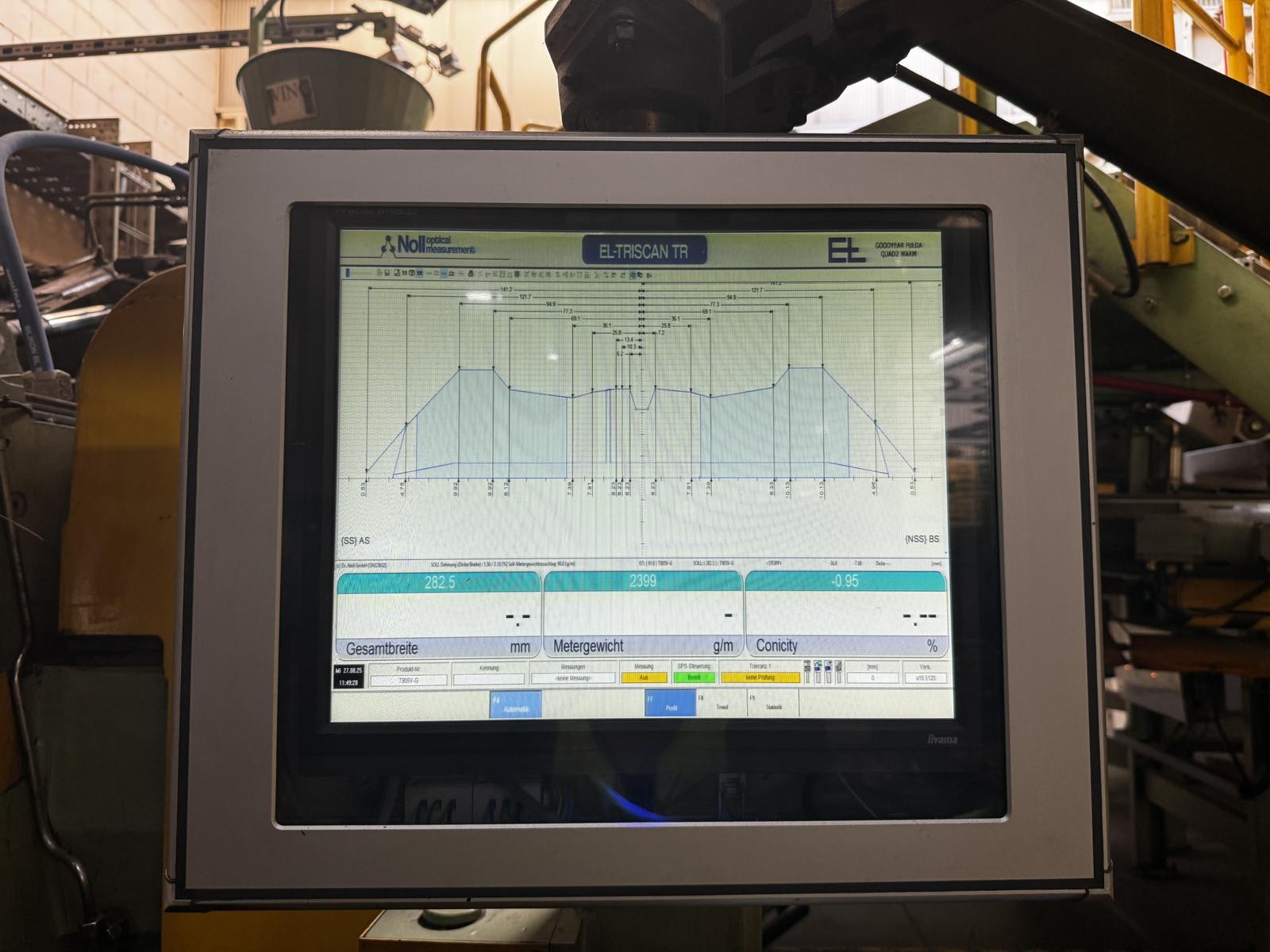

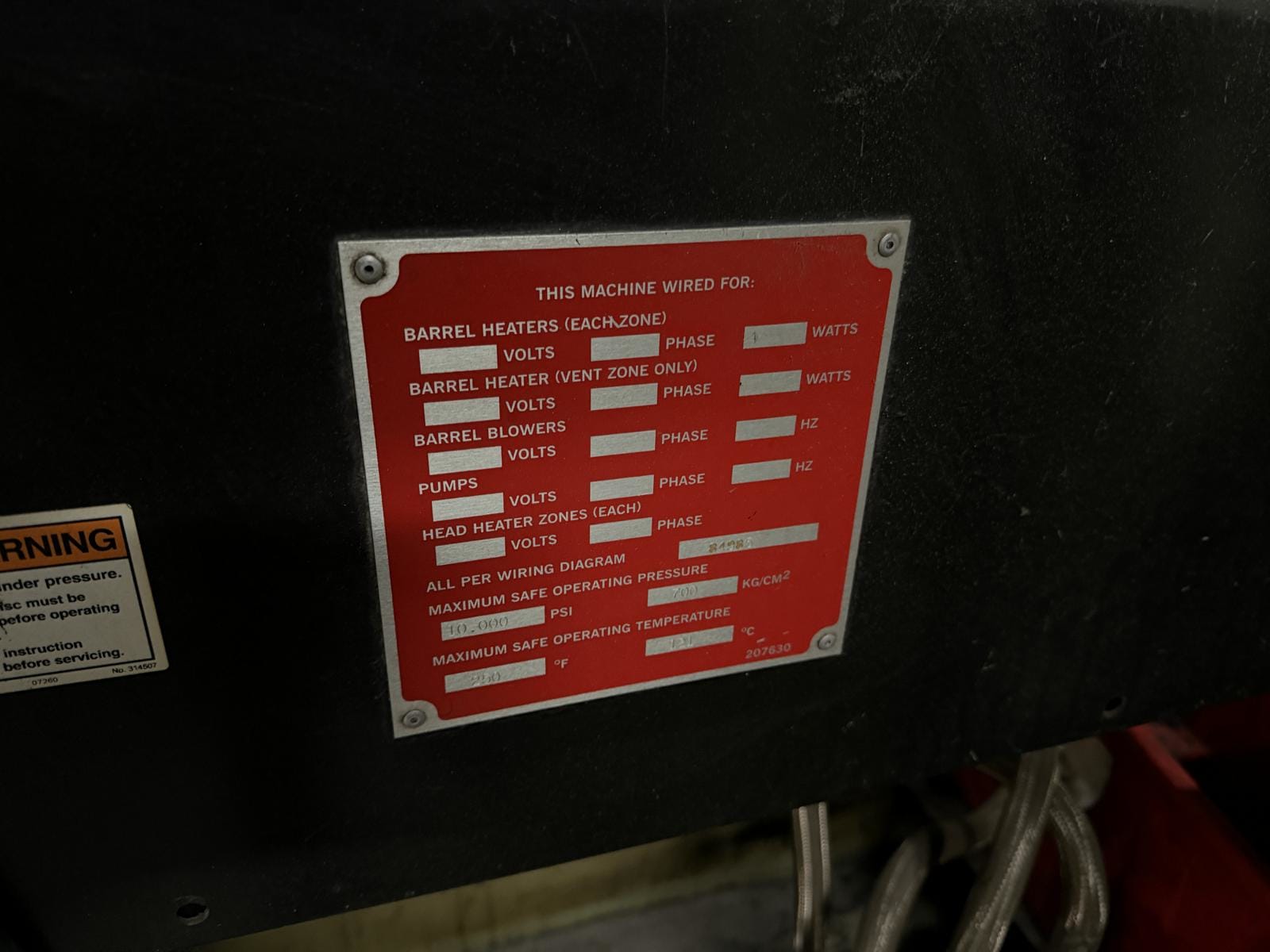

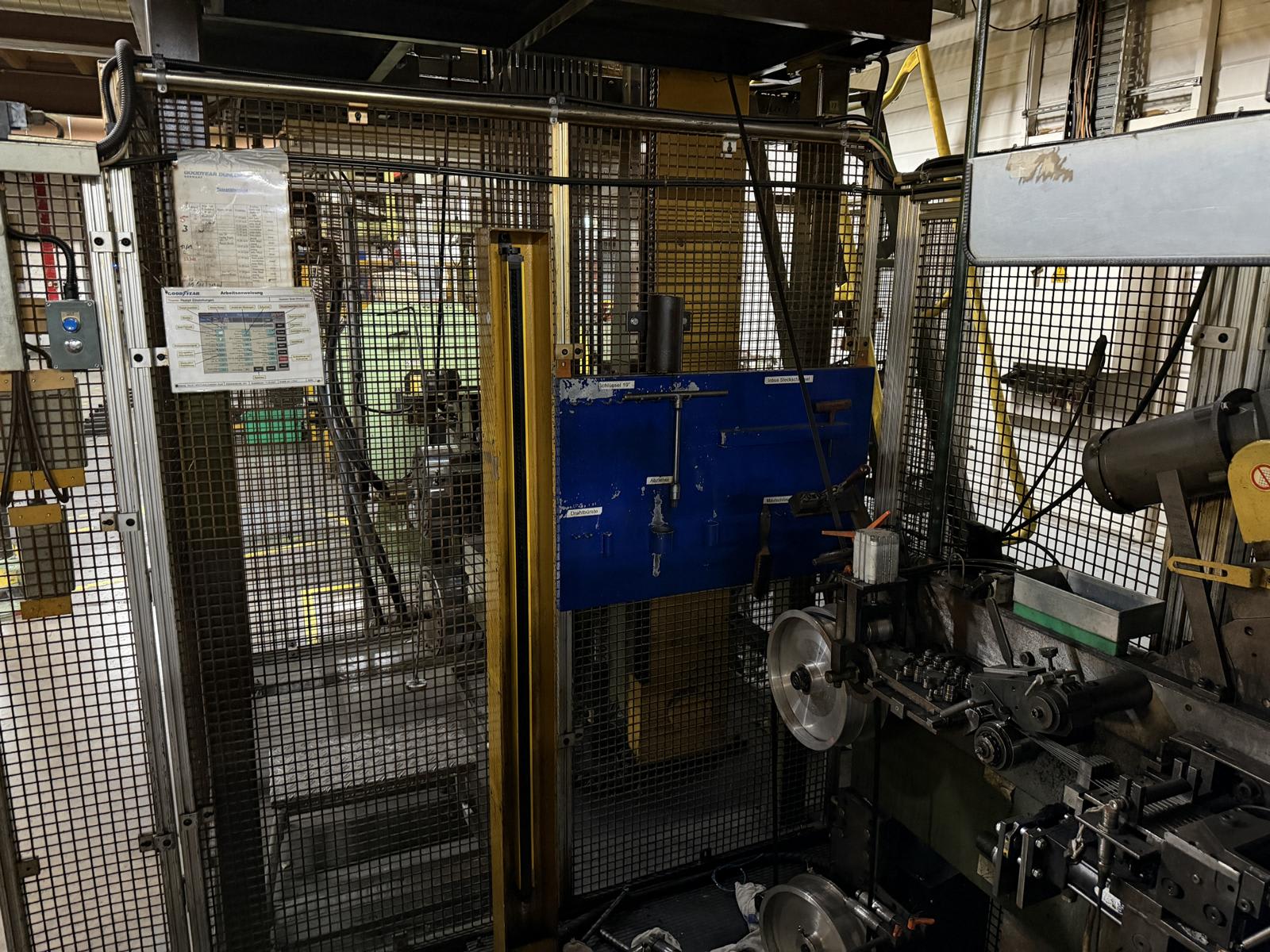

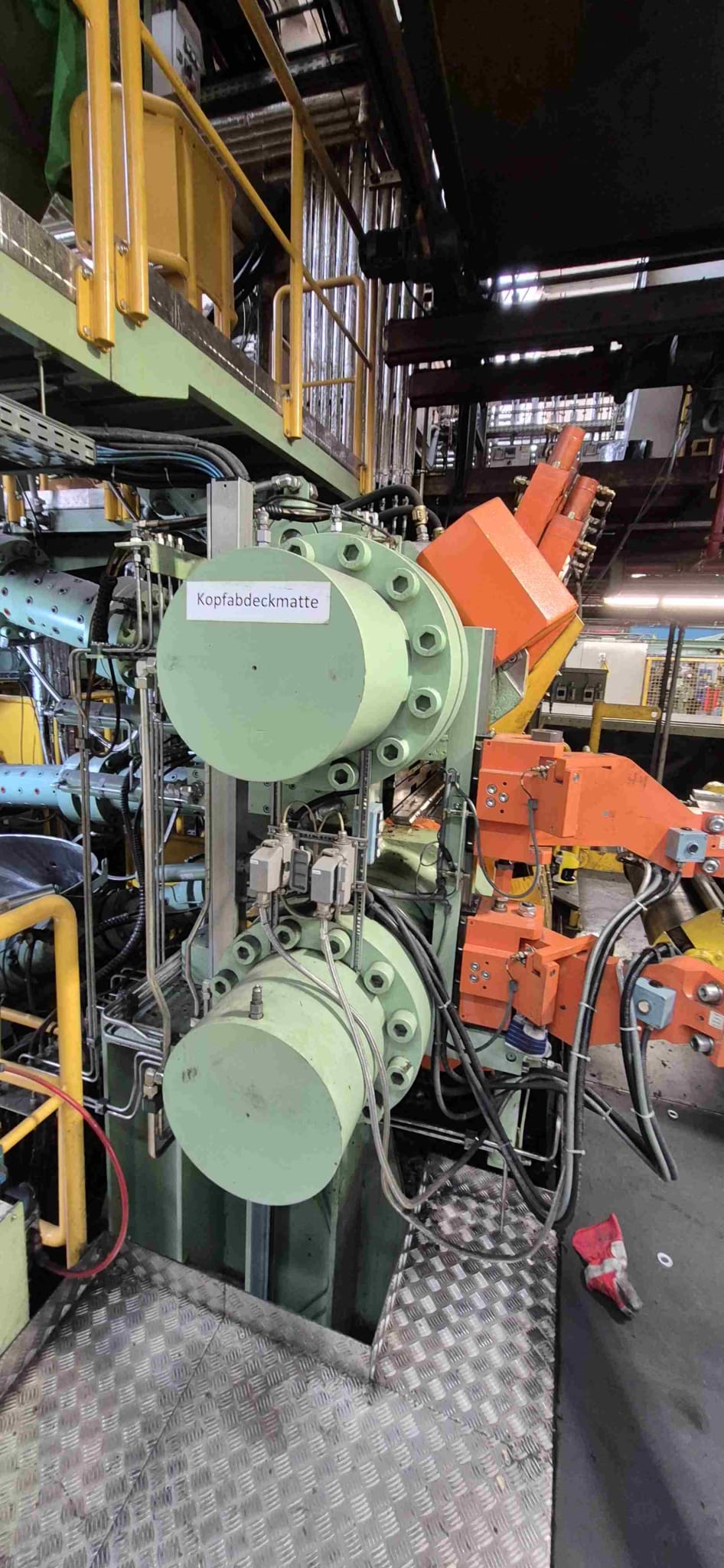

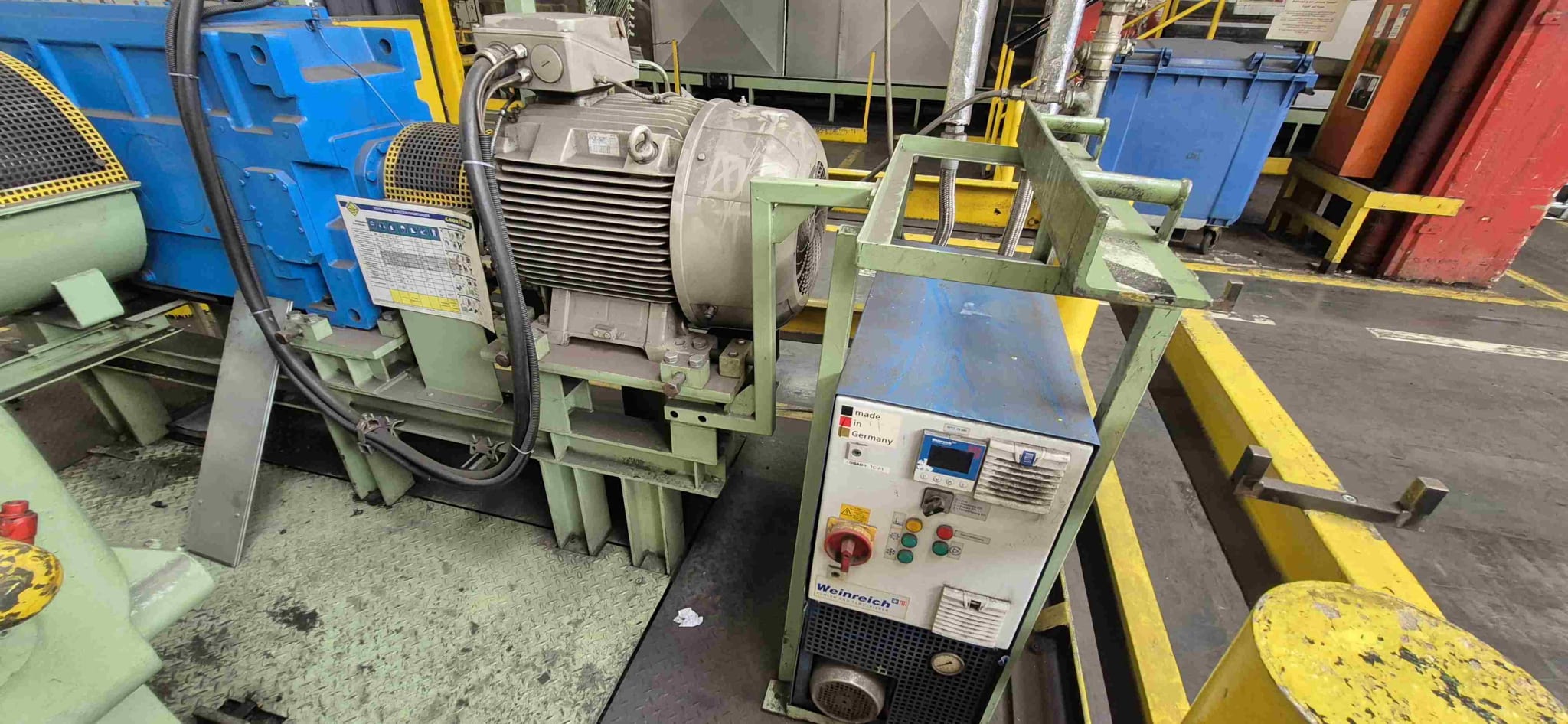

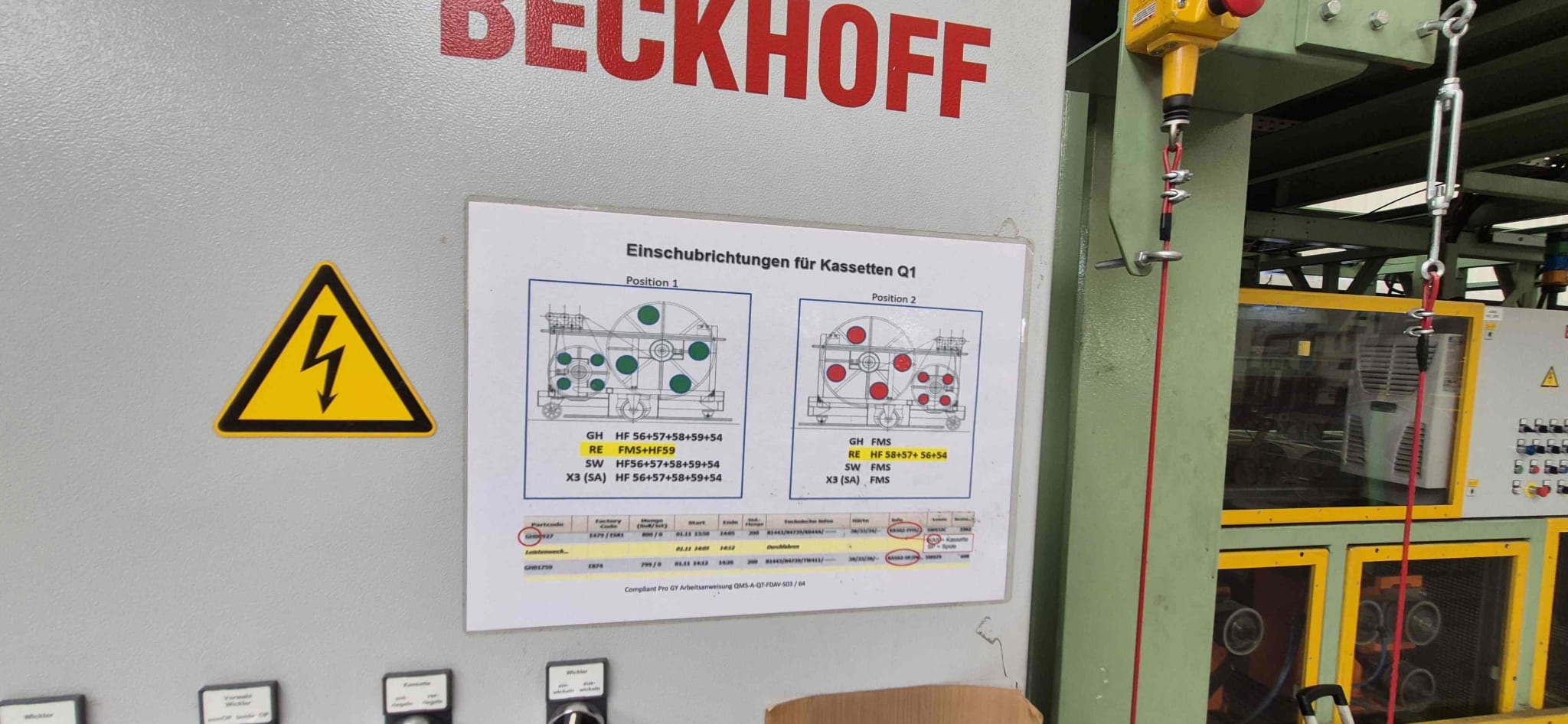

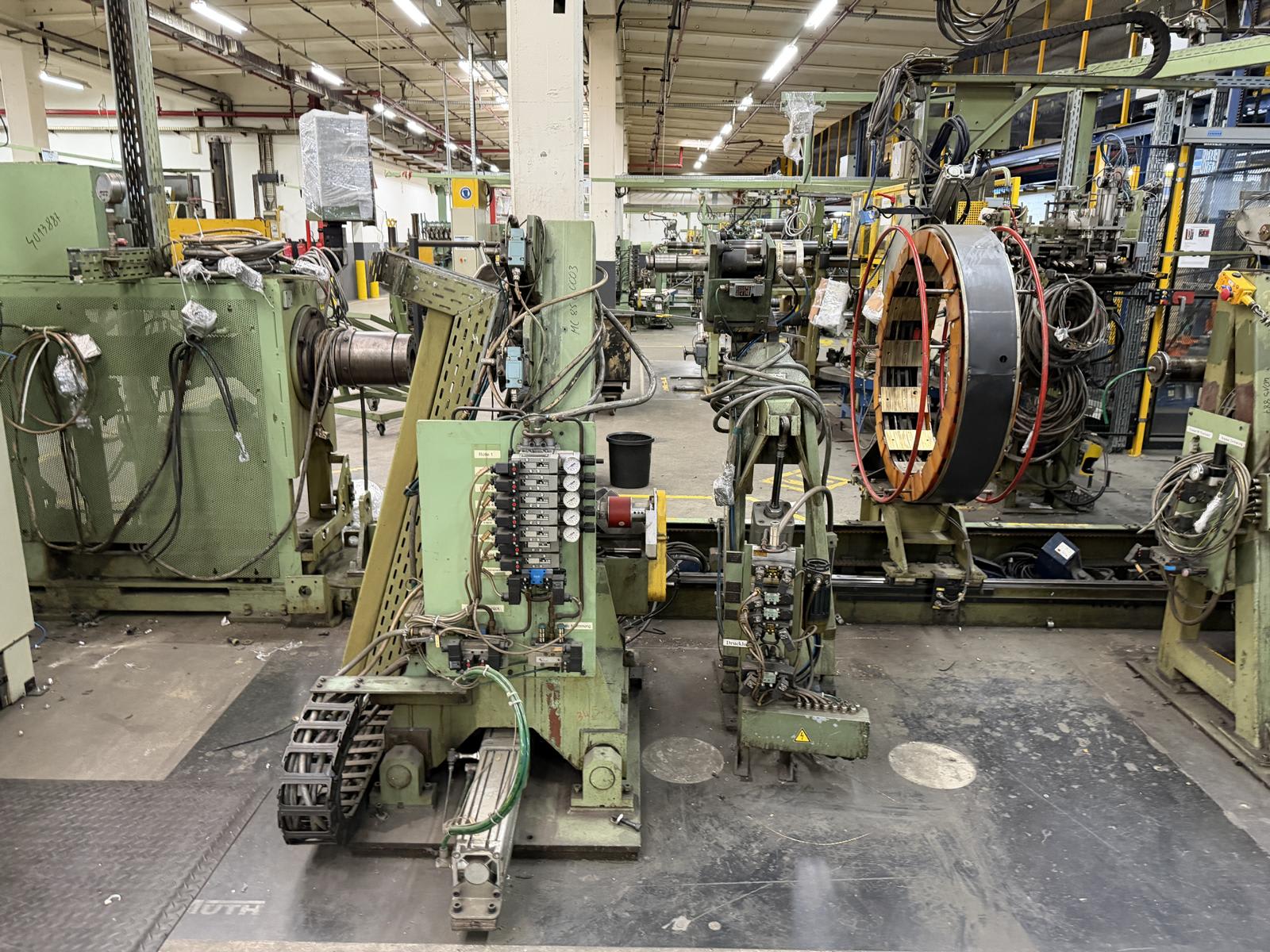

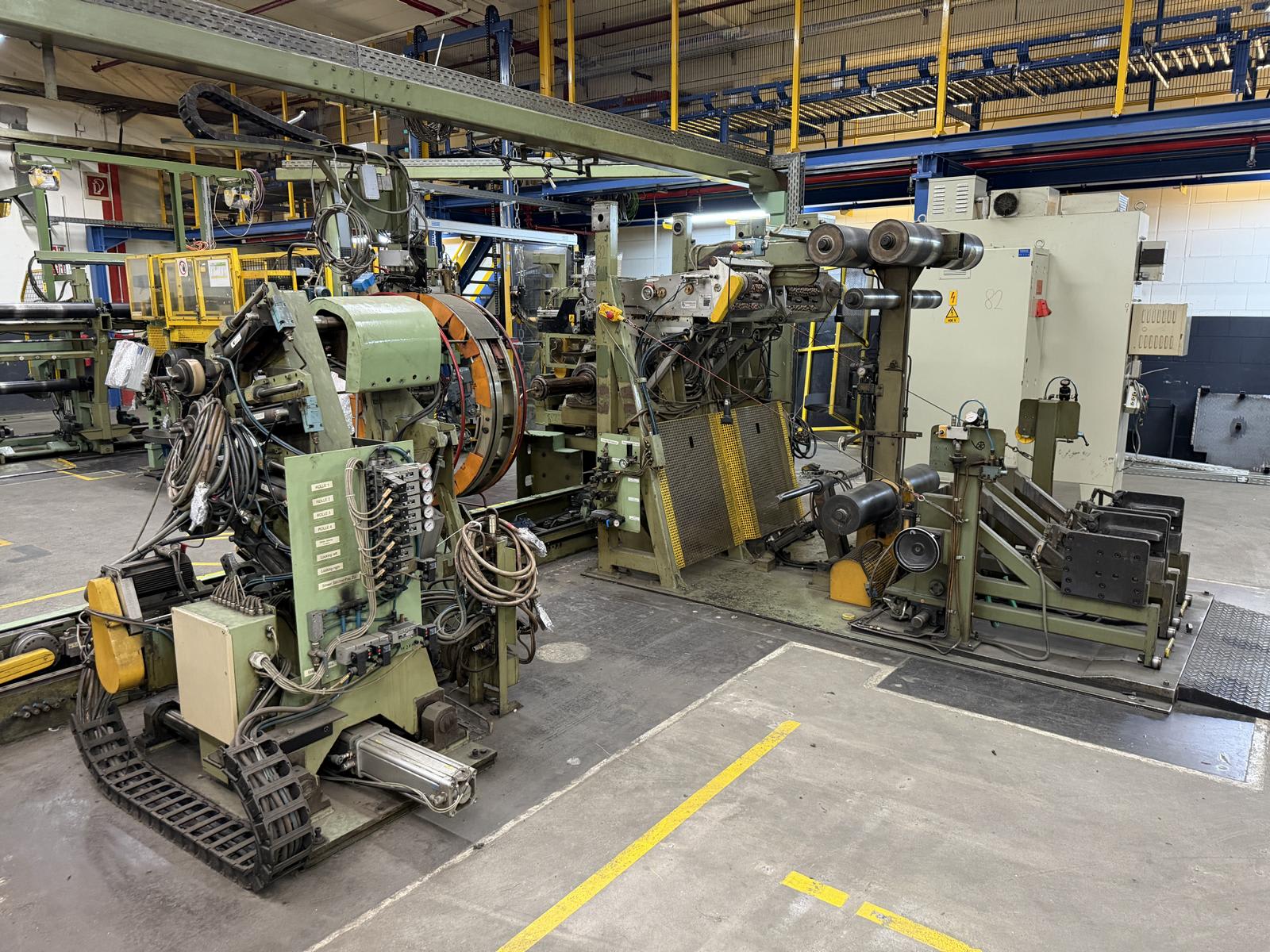

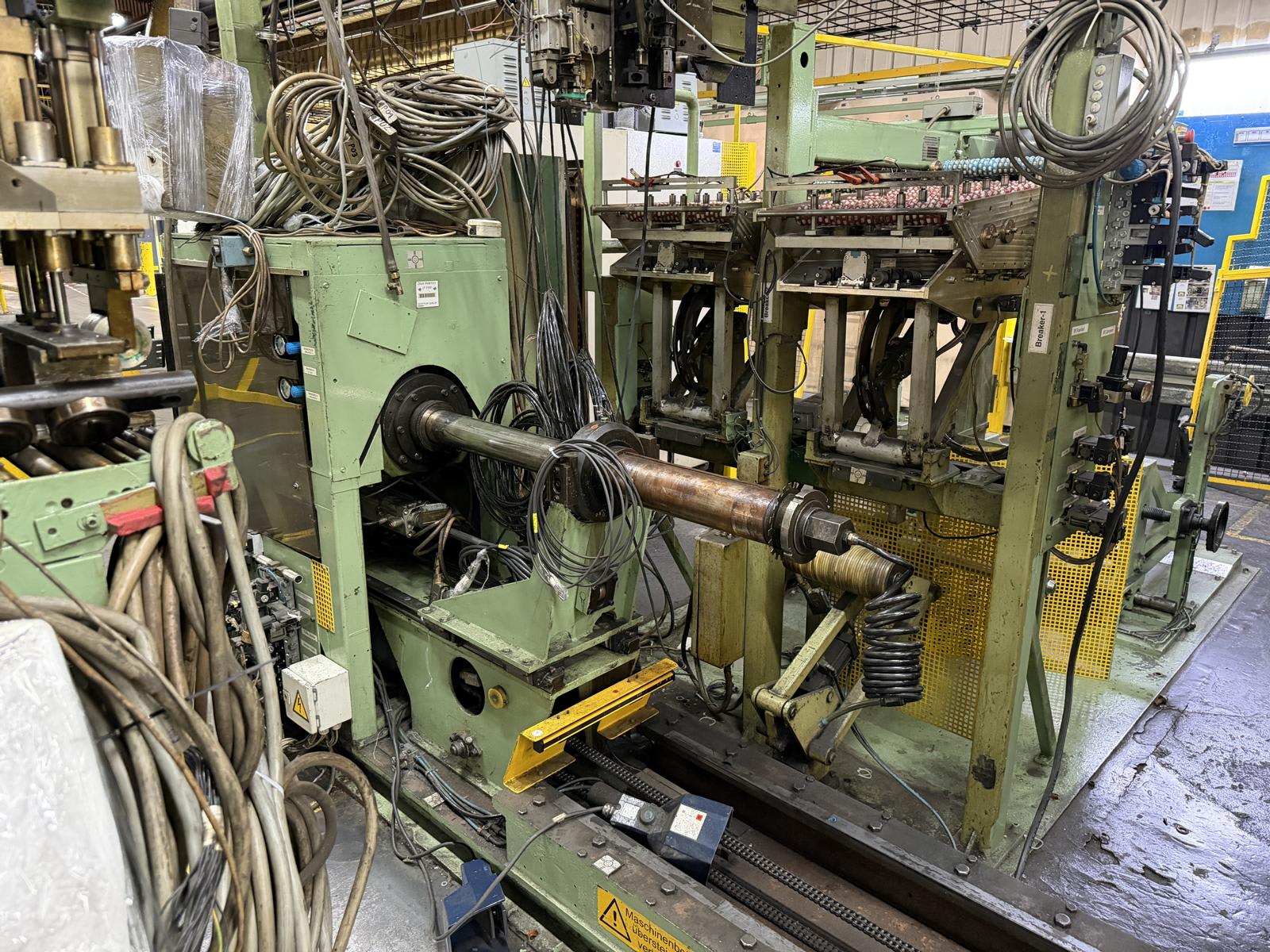

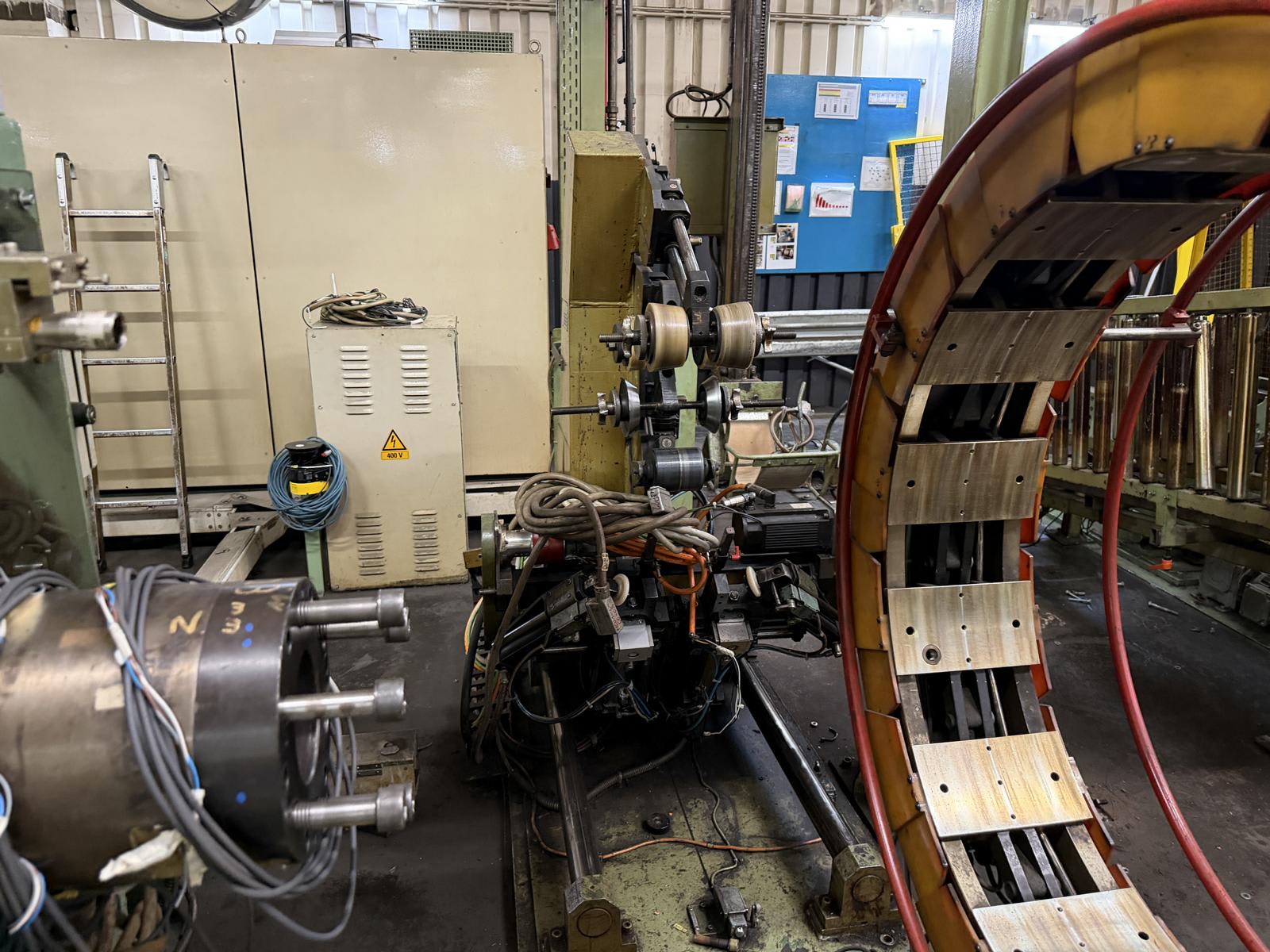

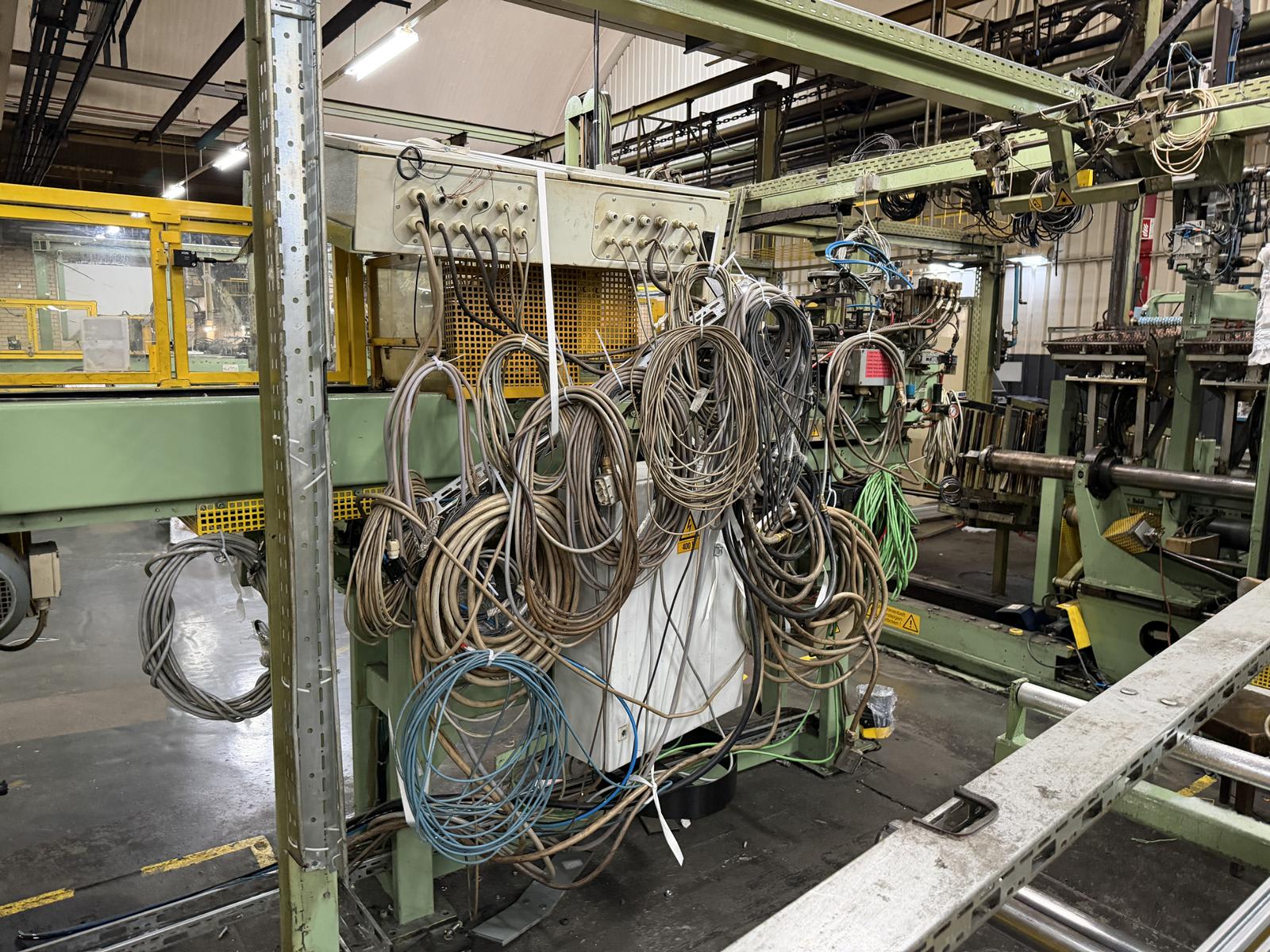

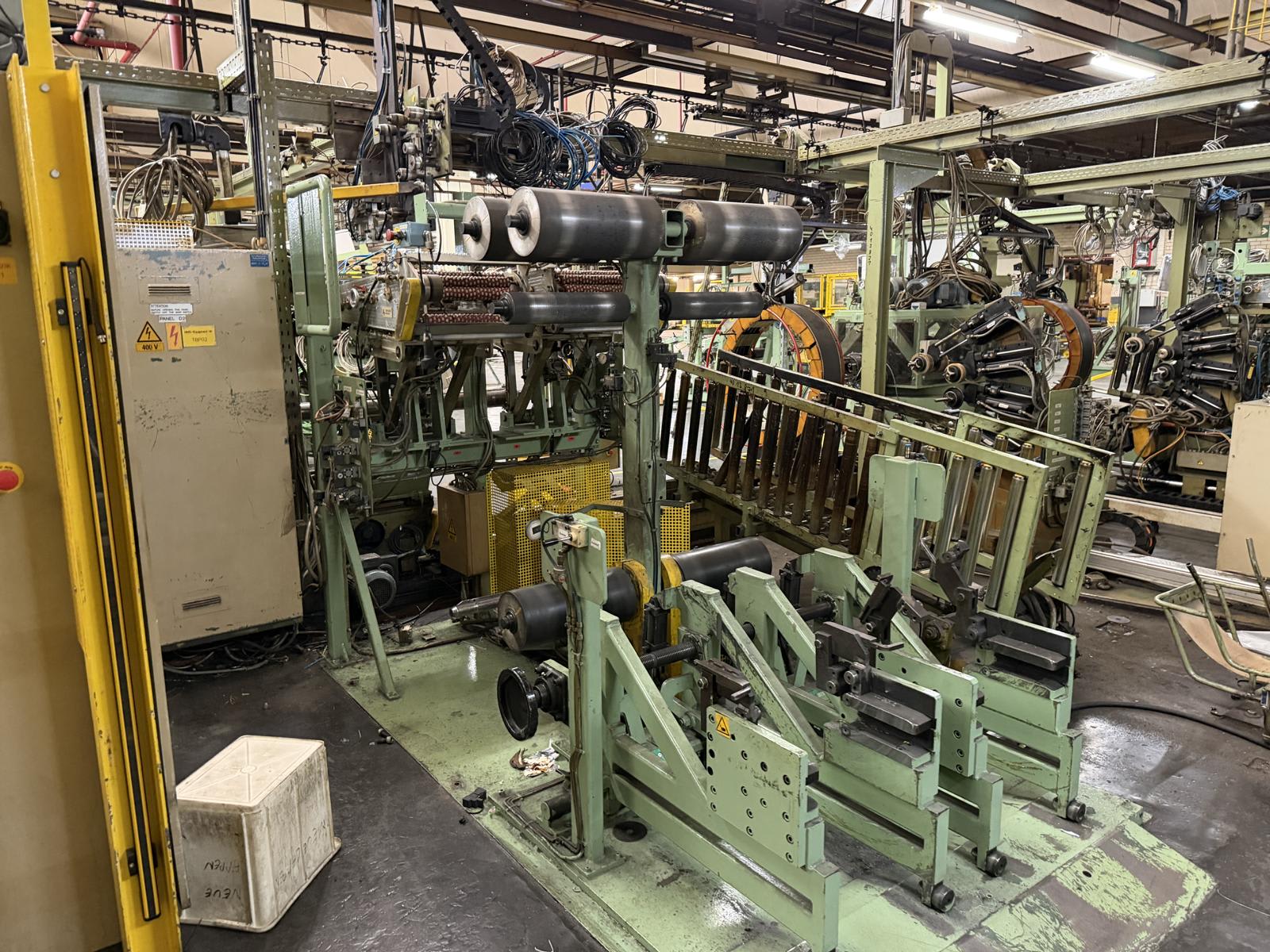

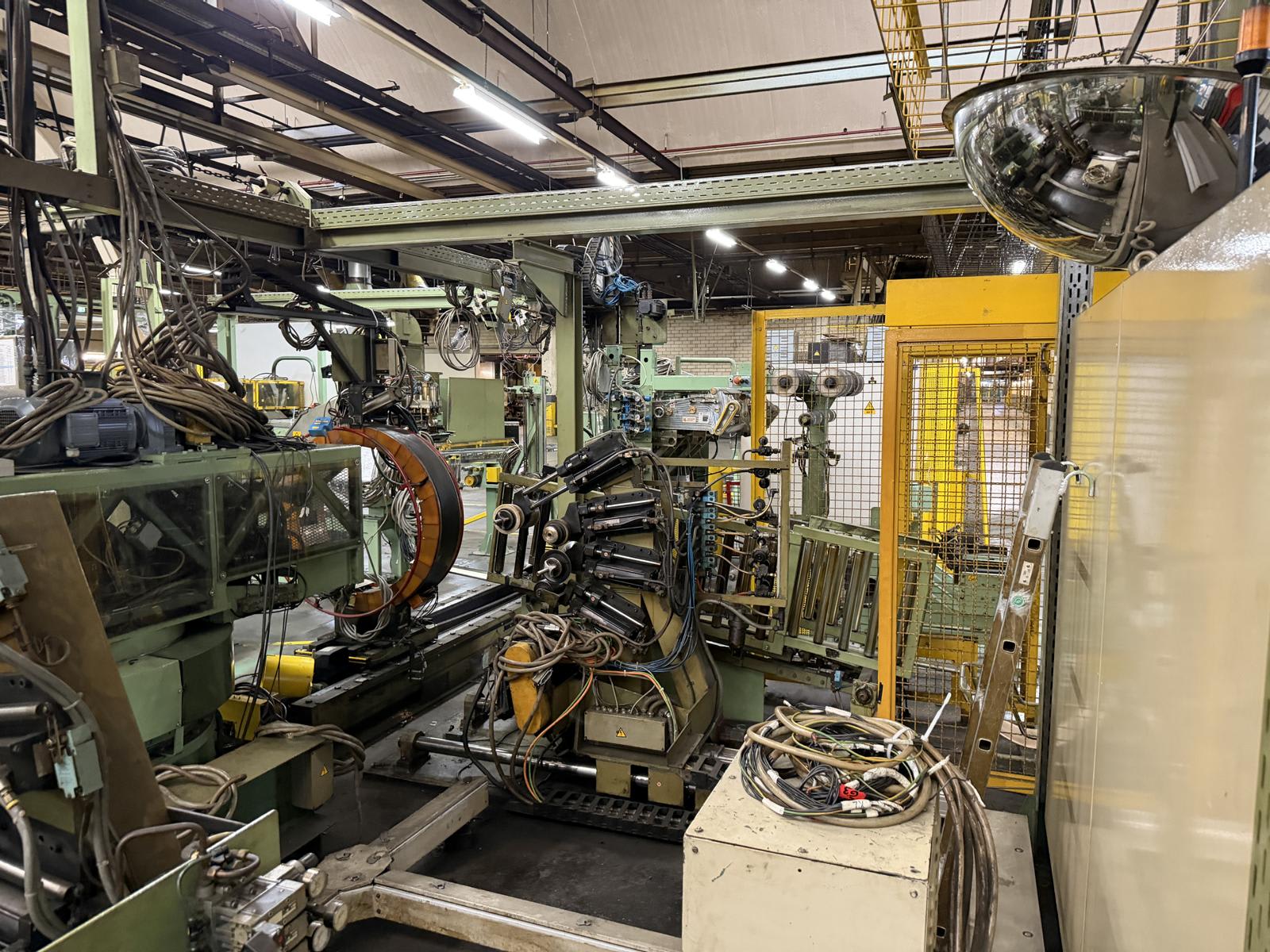

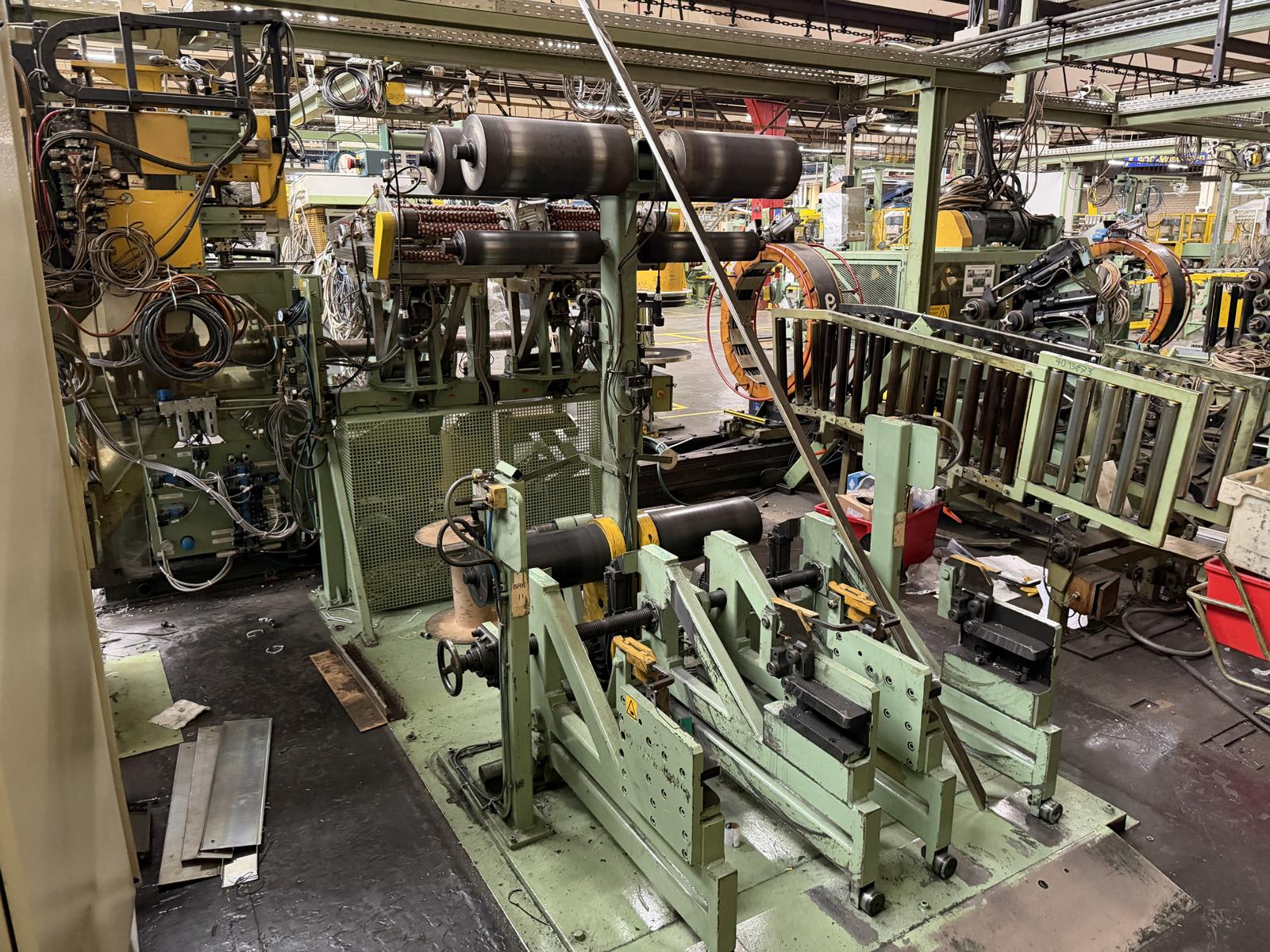

Triplex Extrusion Line Nakata | ca. 1996/97 (overhauled 2012/13)

Binding Handling & Service Fee:

68900 € (EURO)

Documented notes: Line has been frequently modernized since commissioning Line setup according to diagram: • Head • Cylinder • Gearbox • Motors • Steel frame • Triplex extruder configuration • Control system with Beckhoff interface • Operator screens displaying extrusion parameters • Winder units labeled “Wickler” • Emergency stop button present • Industrial electrical control cabinets installed - LISTING 2760005

![Deutsch]()

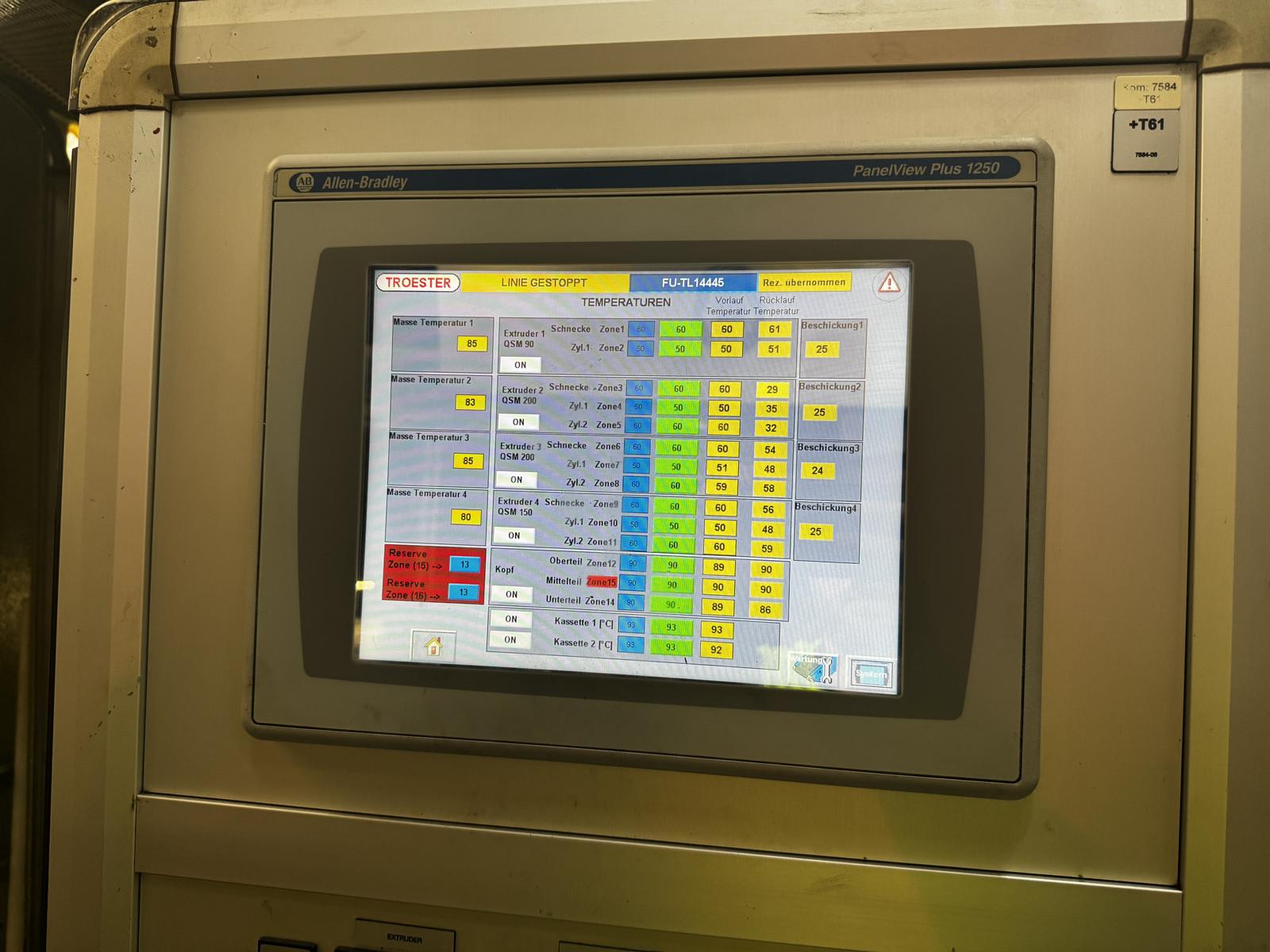

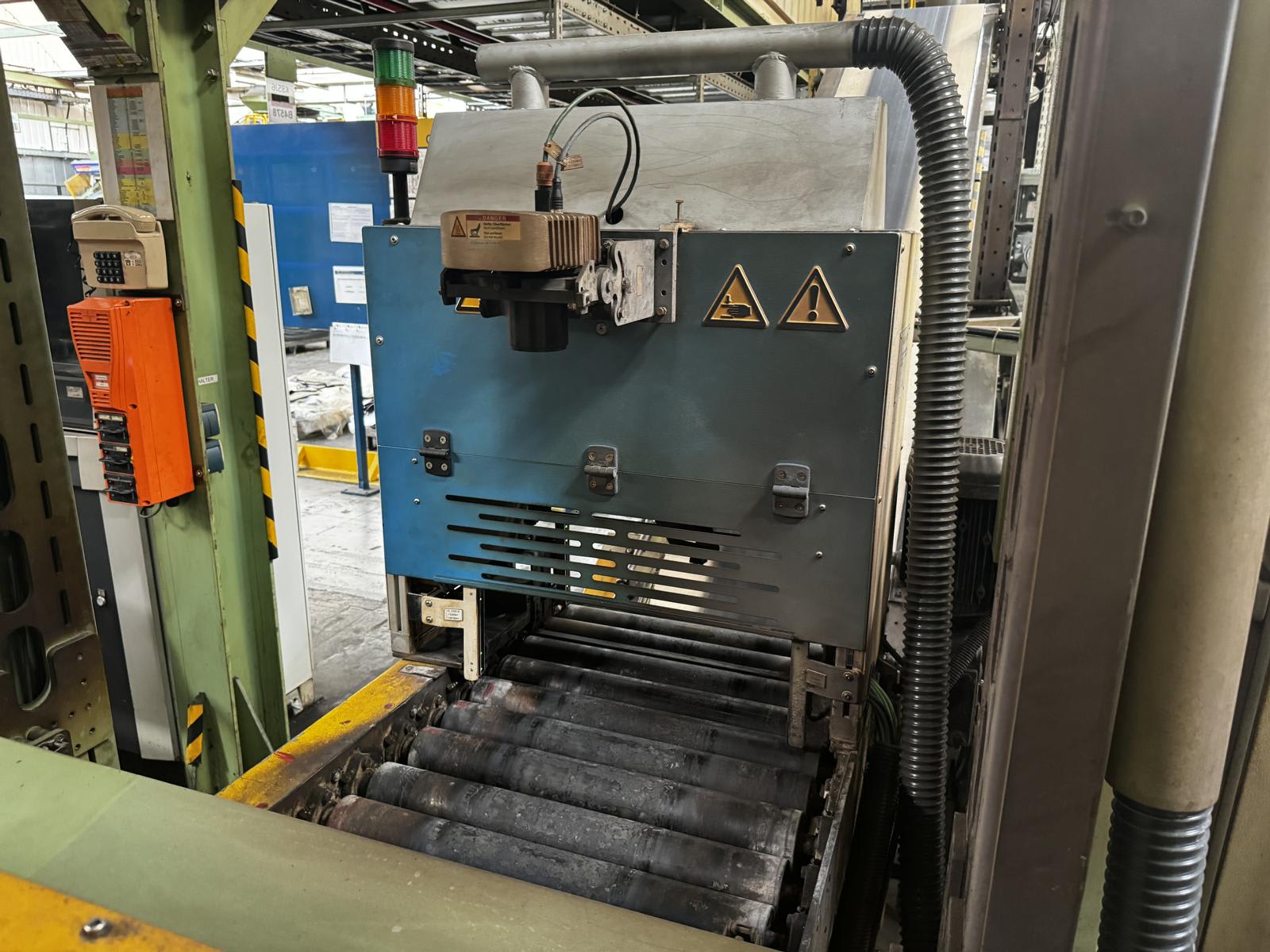

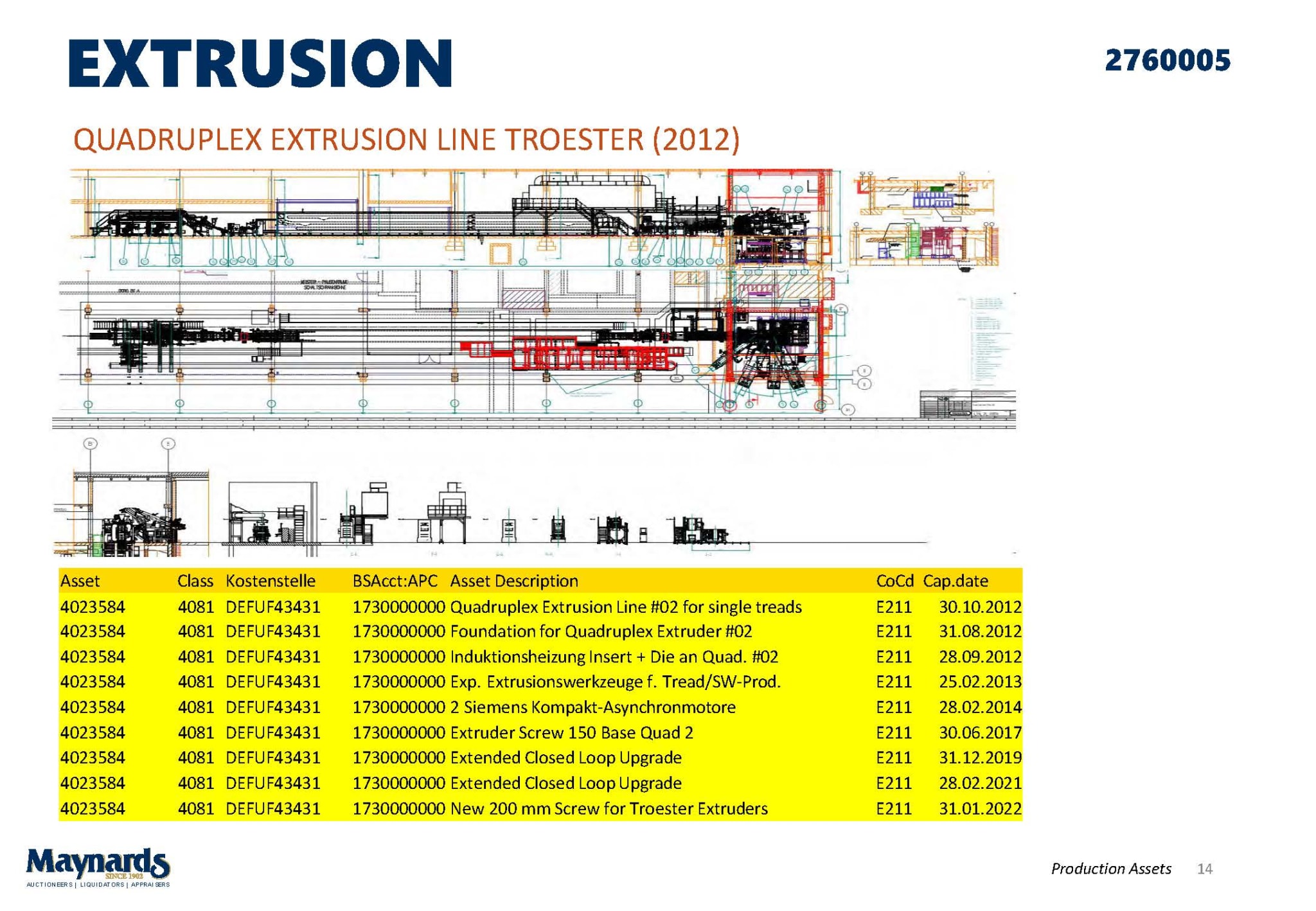

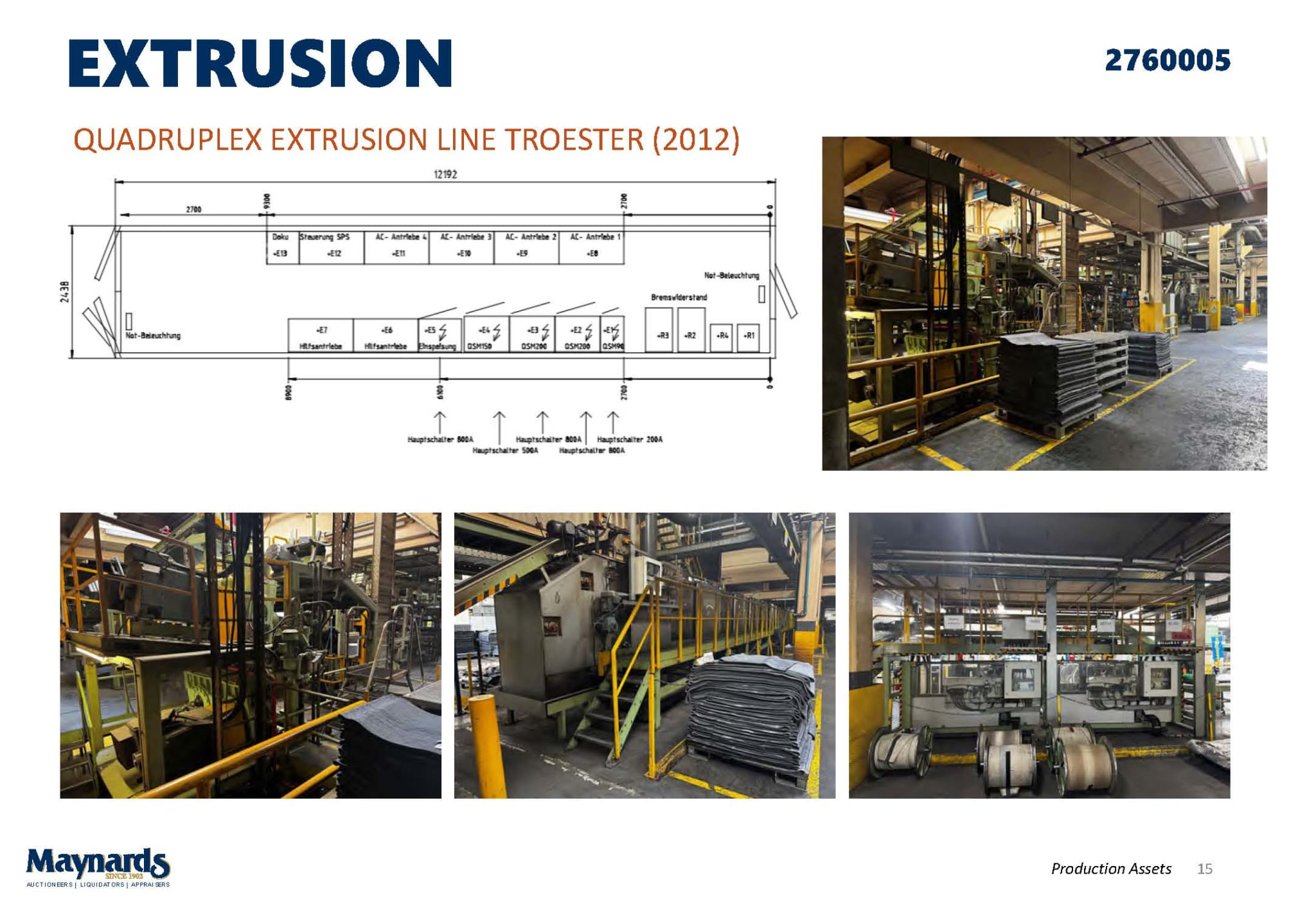

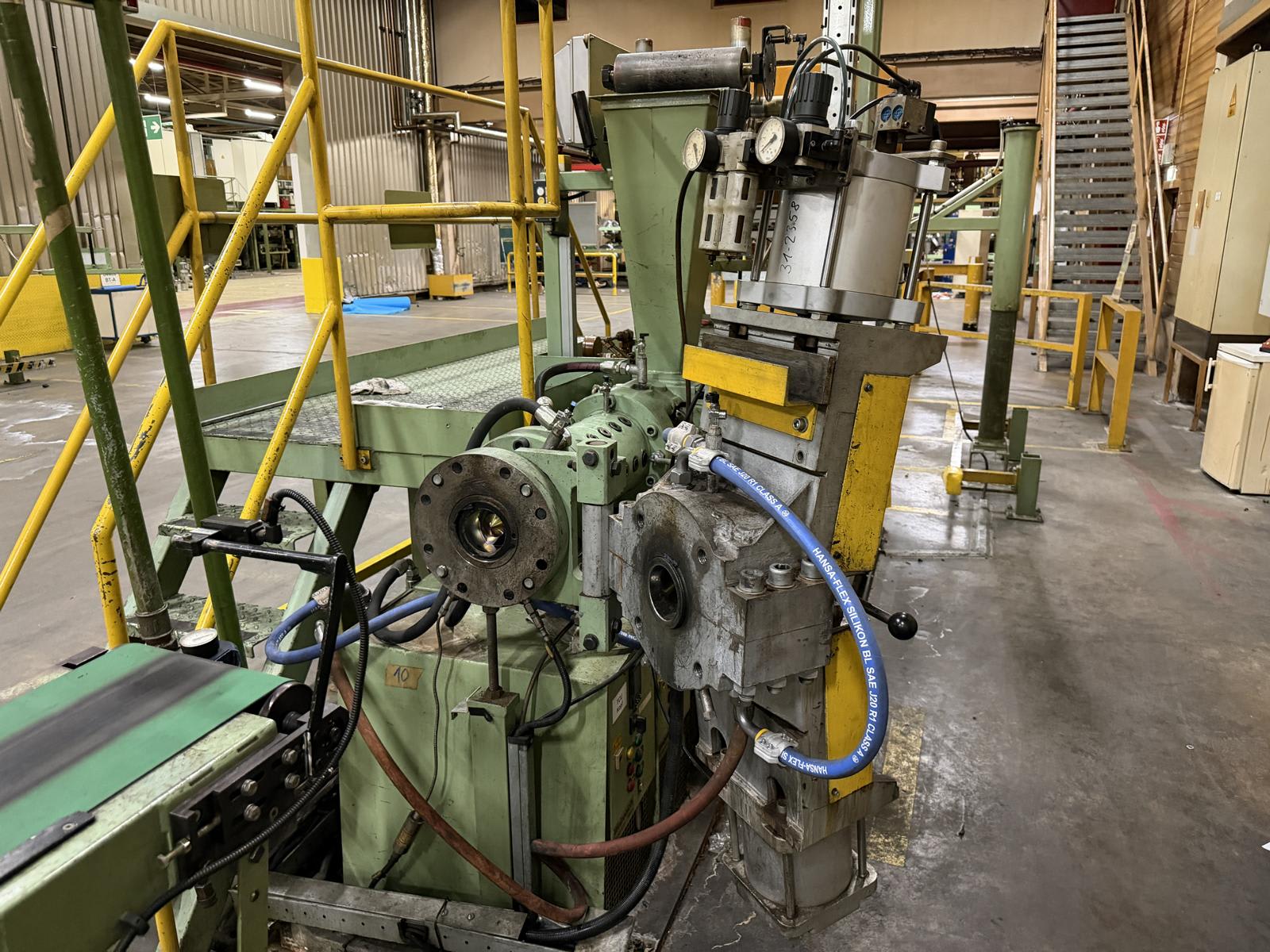

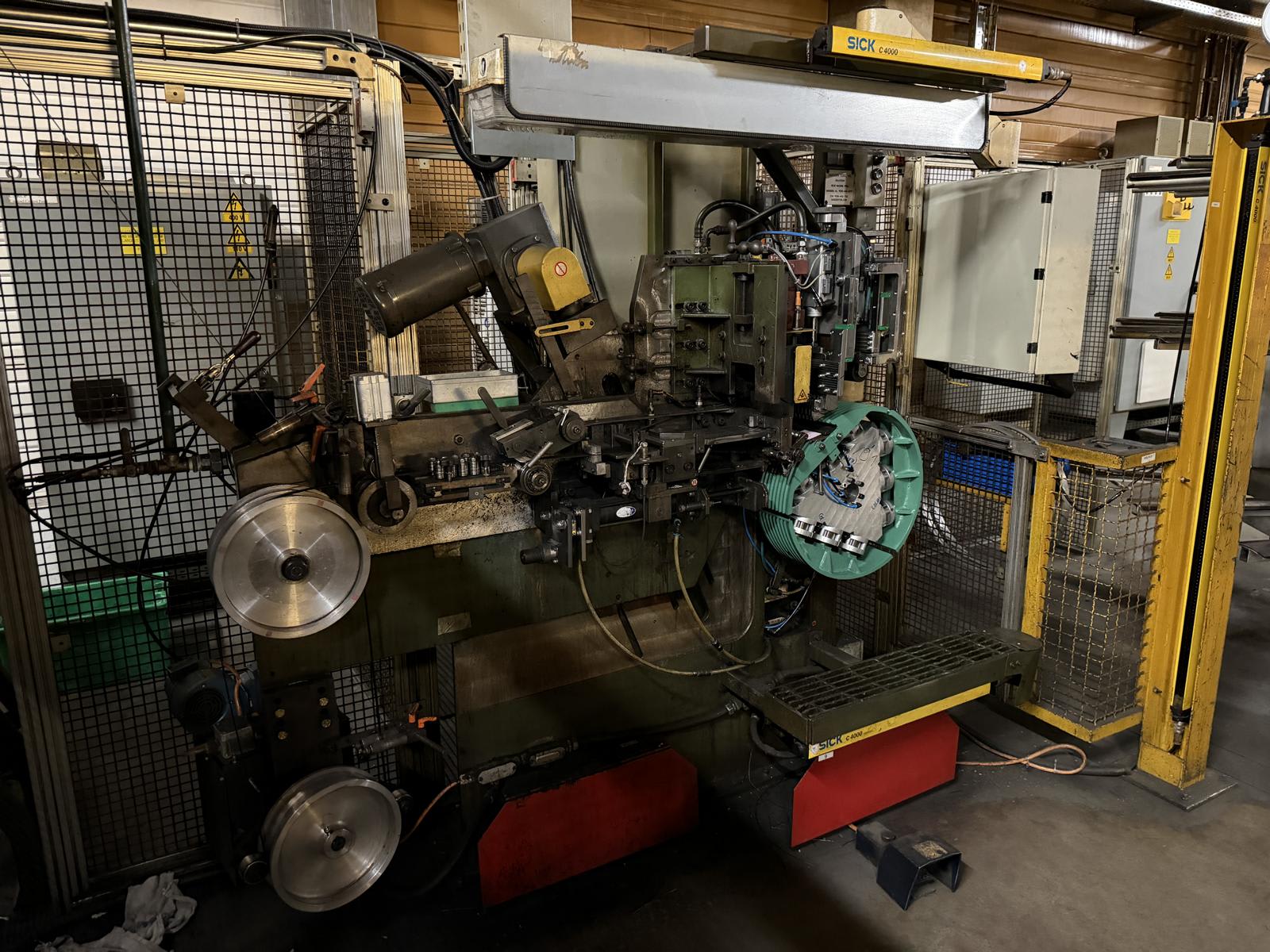

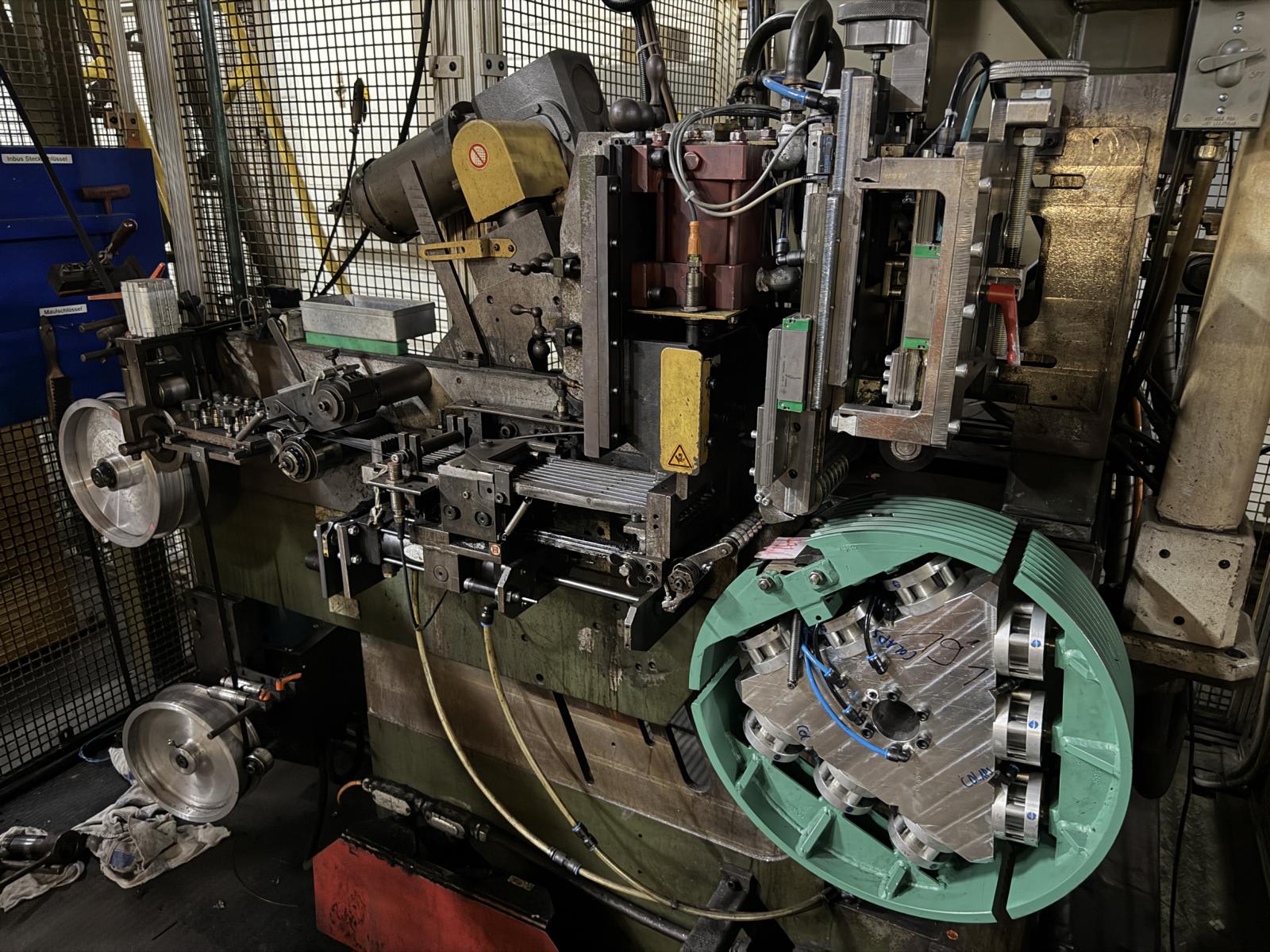

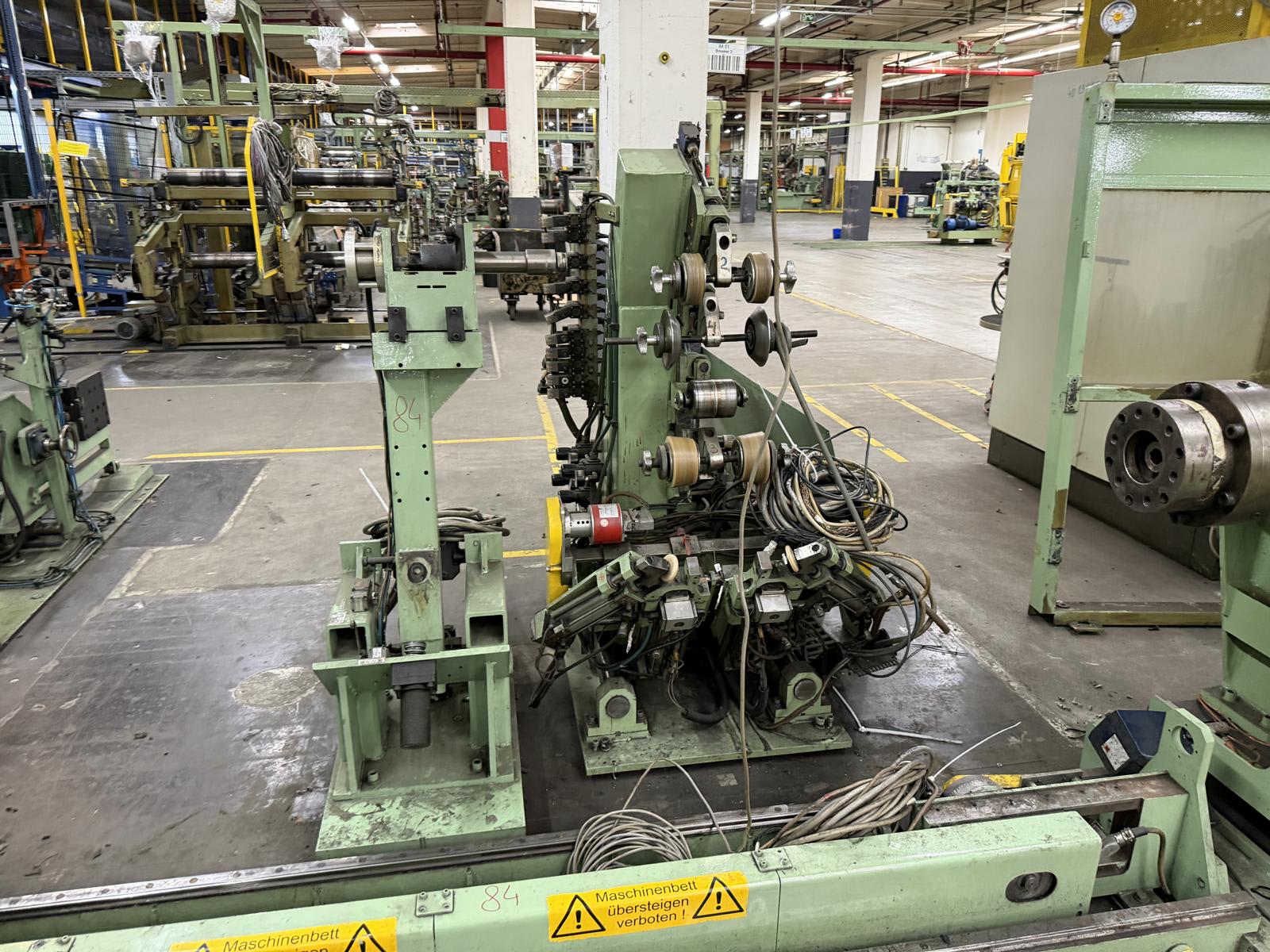

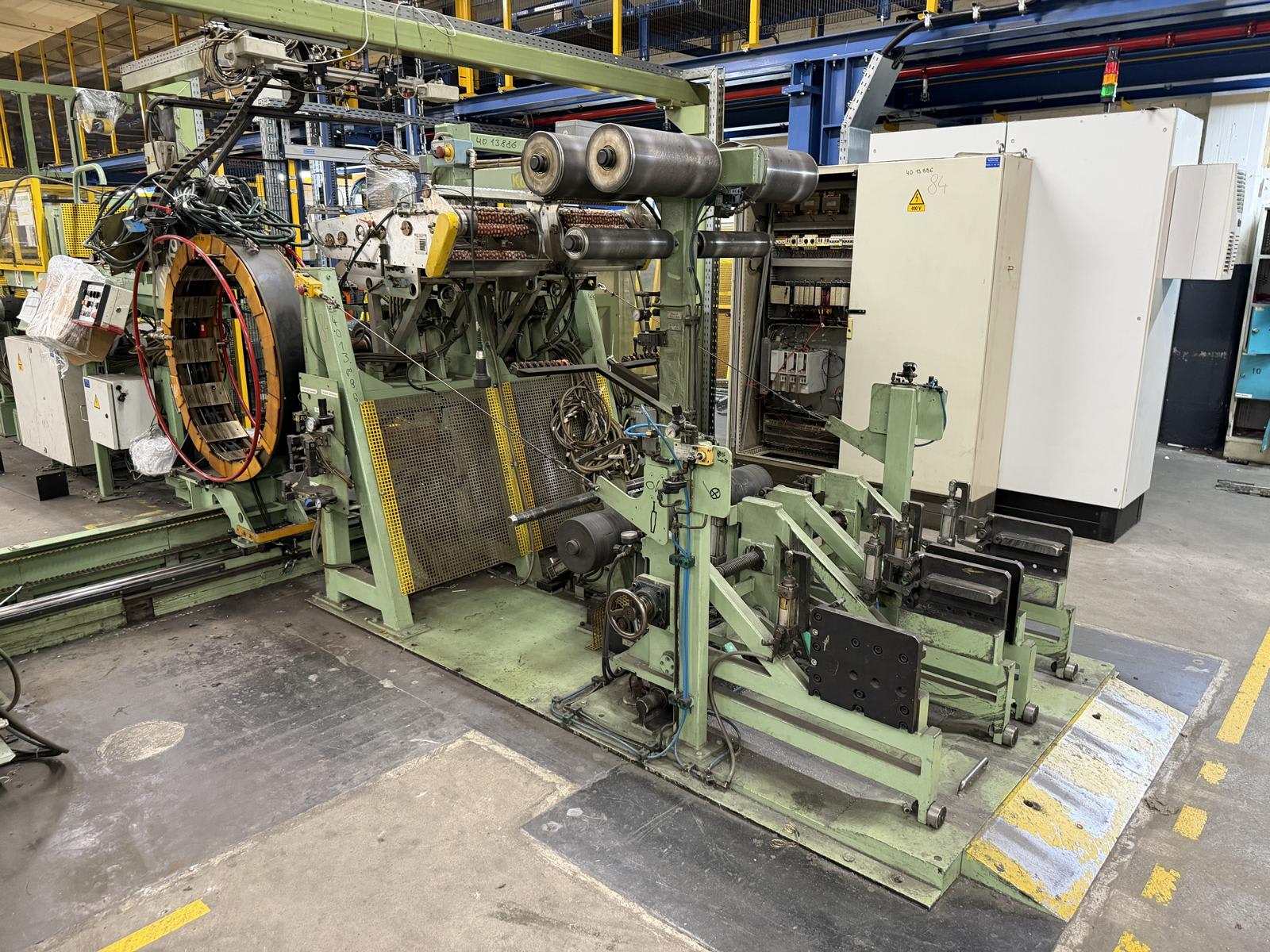

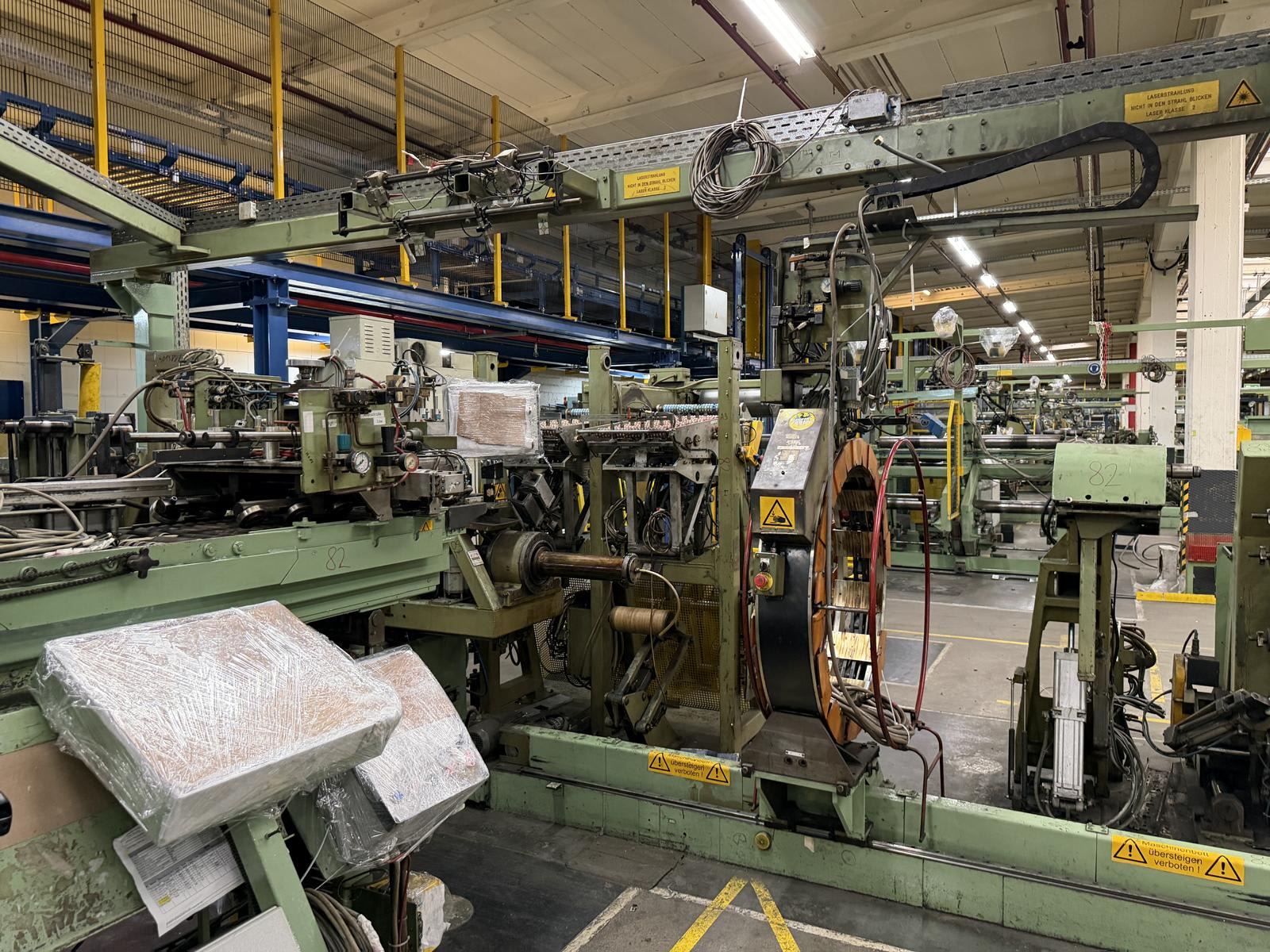

Quadruplex Extruder Troester | 2012

Binding Handling & Service Fee:

55700 € (EURO)

Documented modifications / upgrades: Year Modification / Upgrade 2012 Installation Quadruplex Extrusion Line #02 for single treads 2012 Foundation for Quadruplex Extruder #02 2012 Induction heating insert + die on Quad. #02 2013 Expansion of extrusion tools for tread/SW production 2014 2 Siemens compact asynchronous motors 2017 Extruder screw 150 base Quad 2 2019 Extended closed loop upgrade 2021 Extended closed loop upgrade 2022 New 200 mm screw for Troester extruders Control system: Modern control and visualization units (control desks, operator panels) Technical data: • Extruder screws up to 200 mm (2022) • Base screw 150 mm (2017) • Siemens asynchronous motors (2014) Maintenance / condition: Regularly modernized and upgraded 2012–2022 Accessories / options: Conveyor systems, heating and cooling units, monitoring and measuring stations, winding equipment - LISTING 2760006

![Deutsch]()

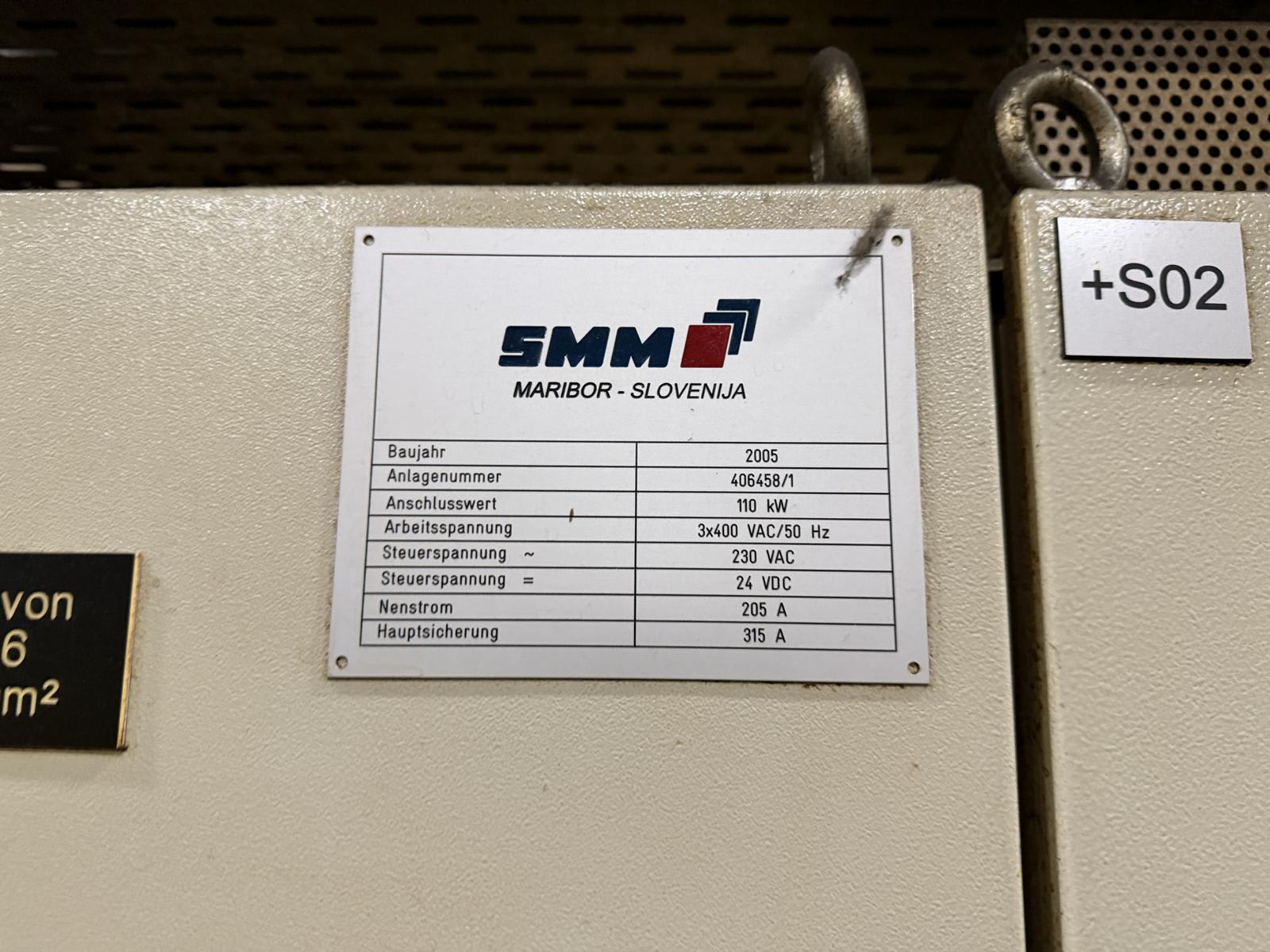

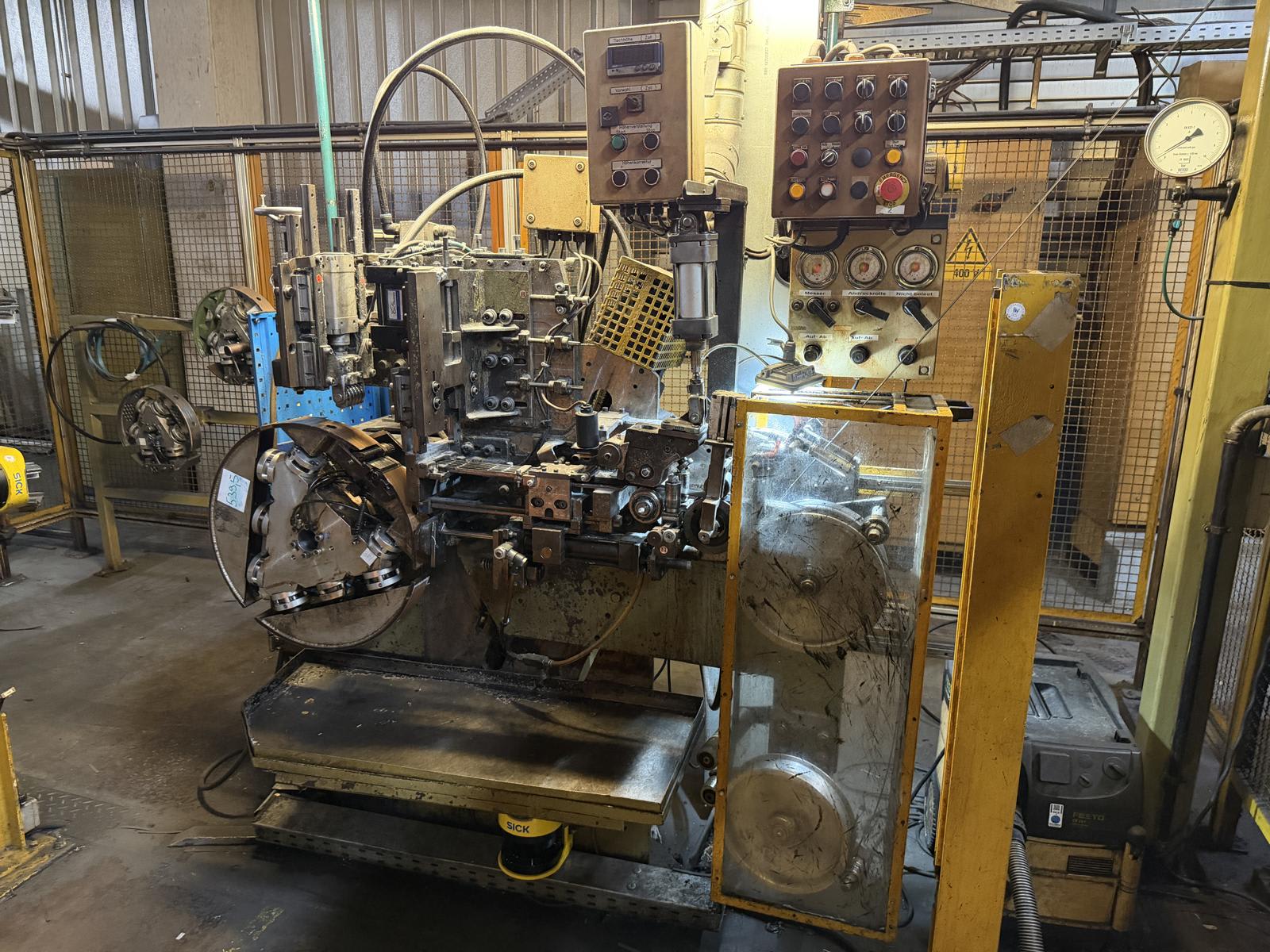

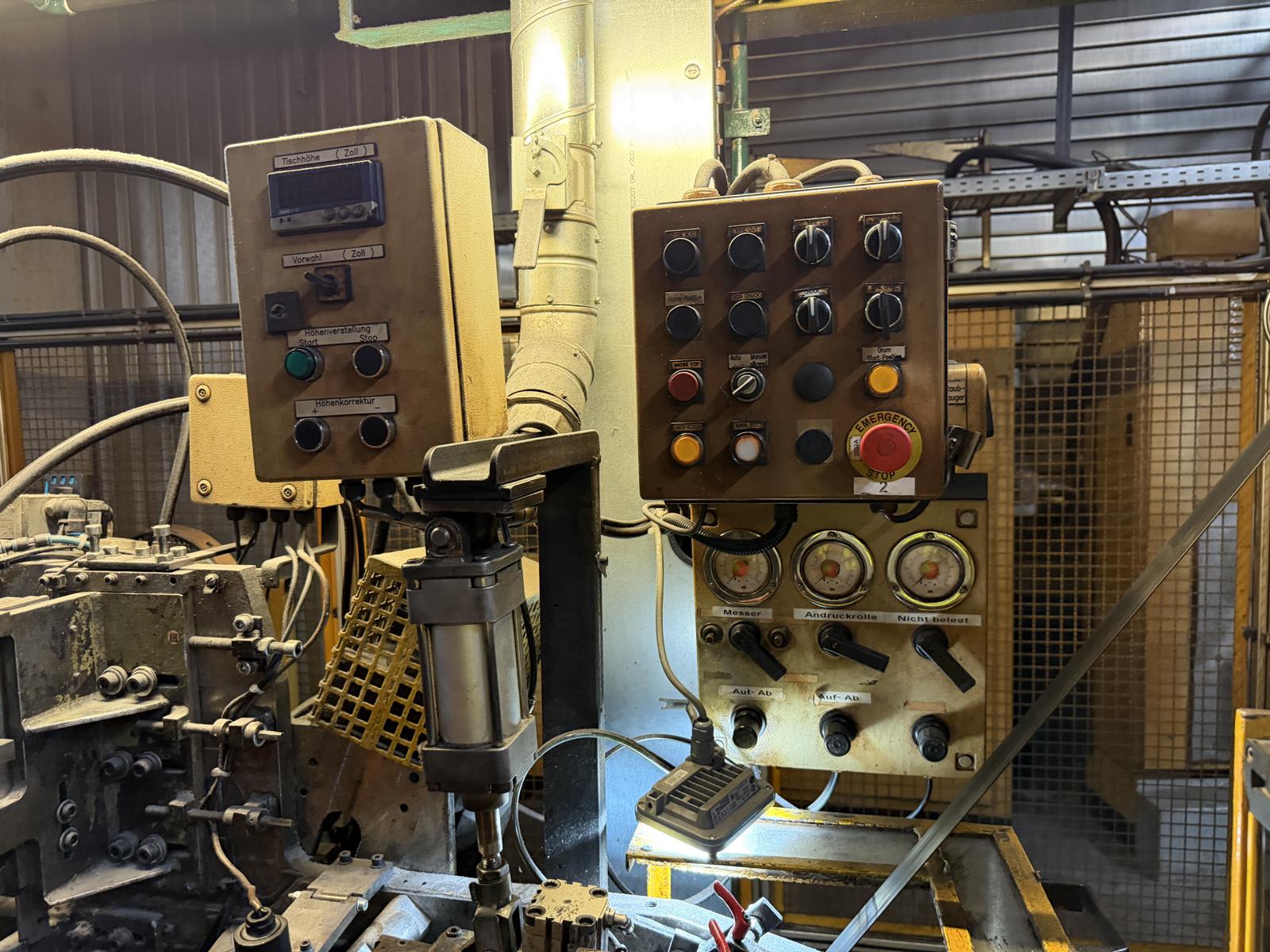

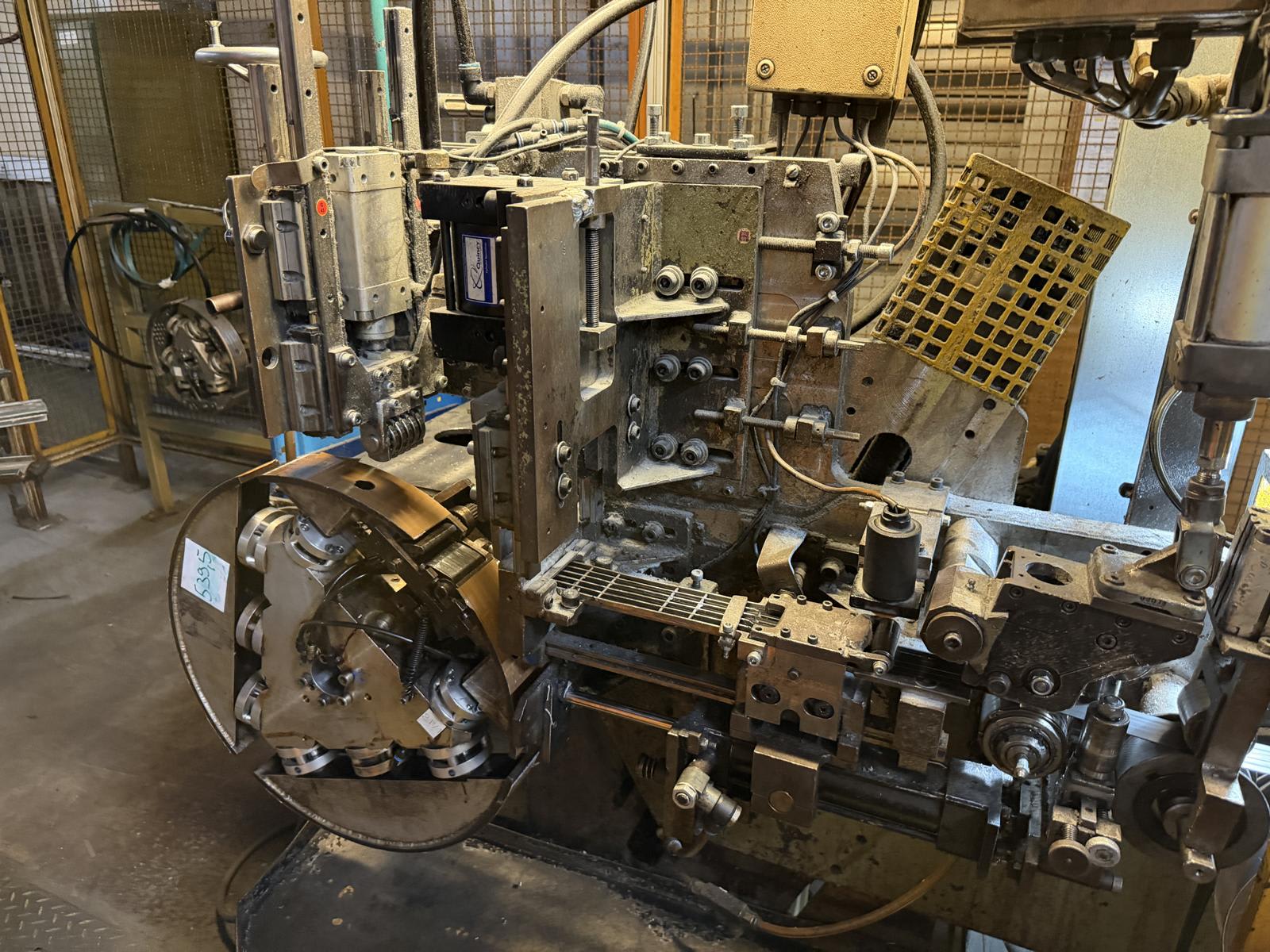

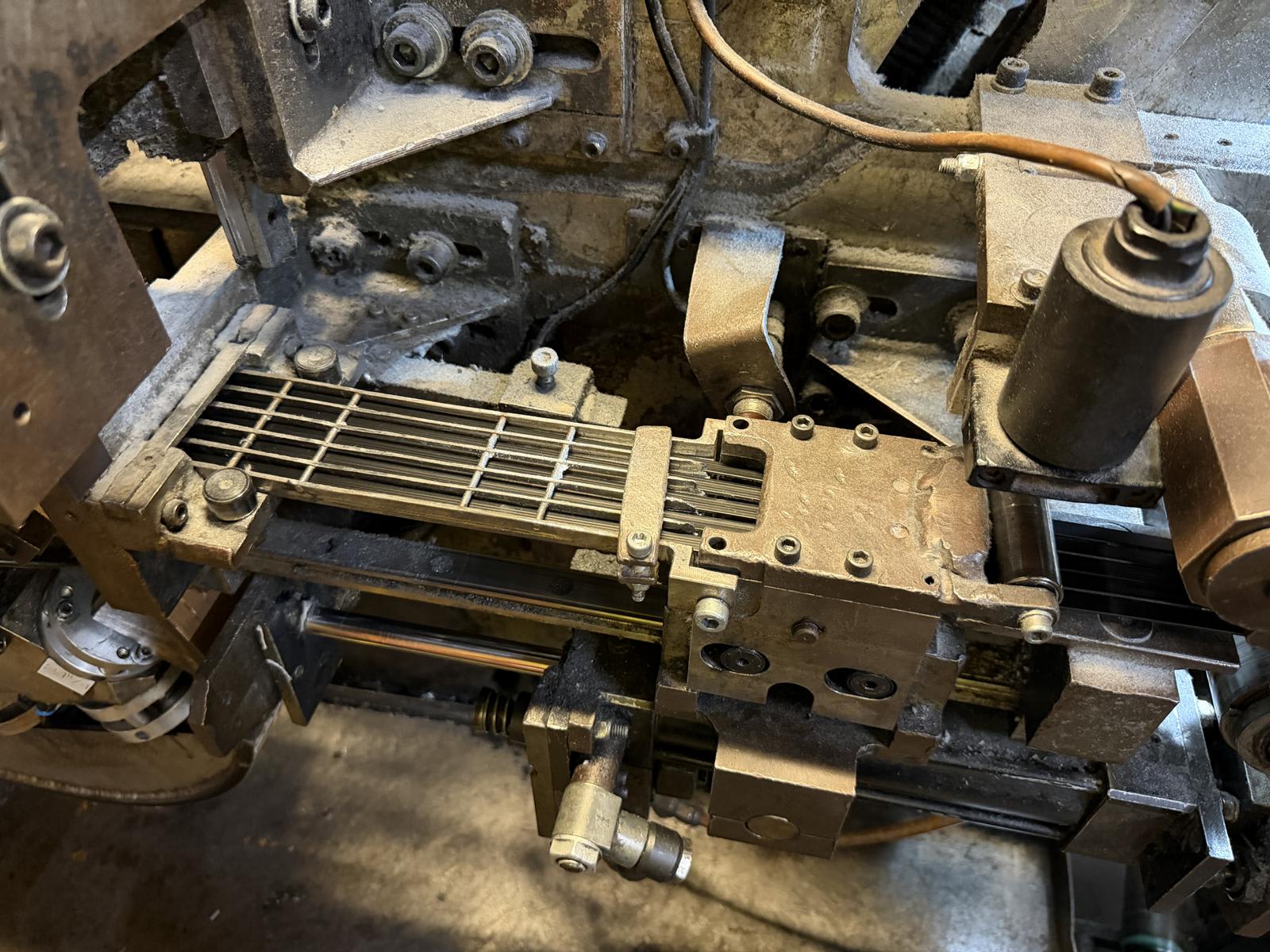

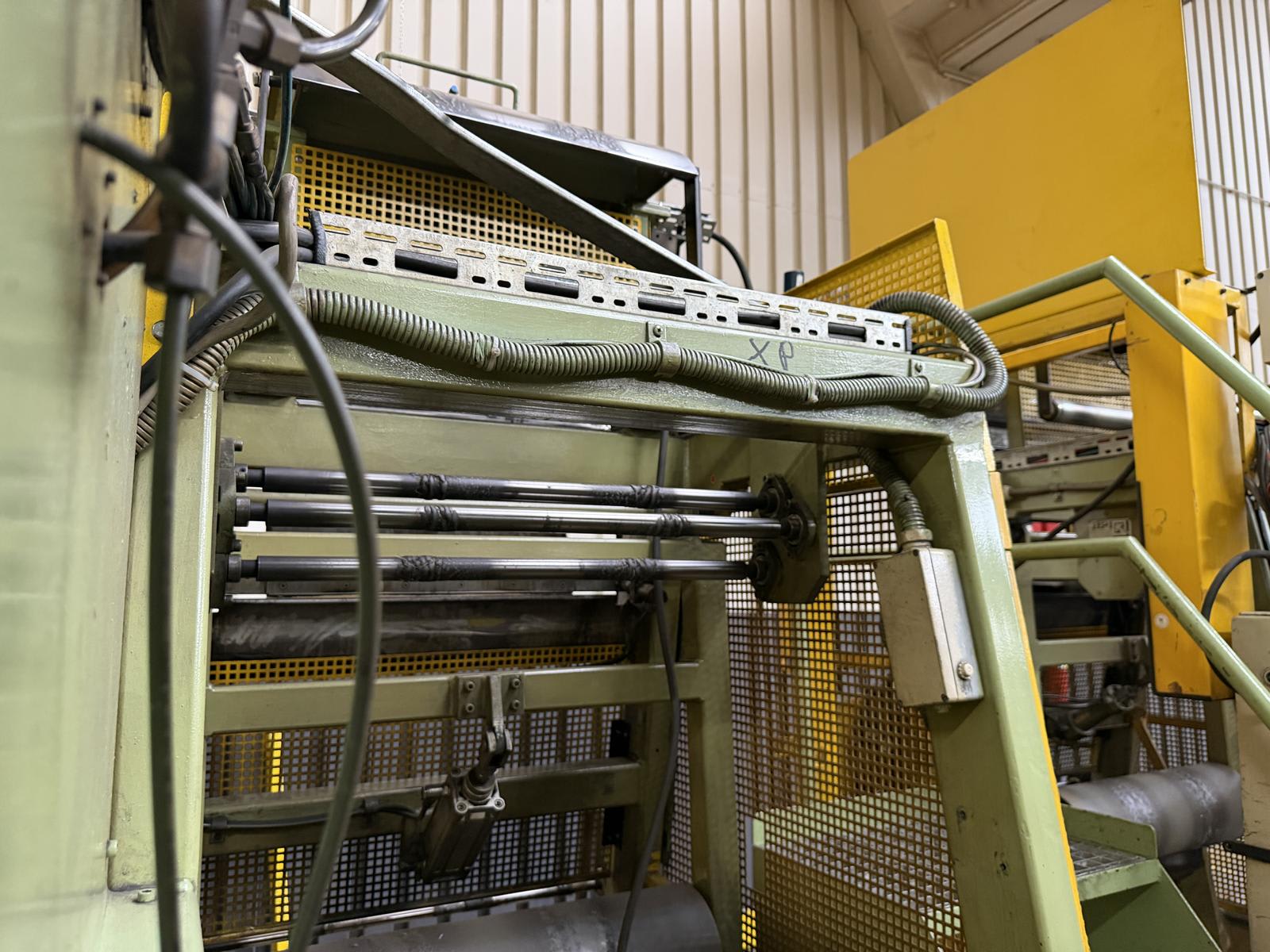

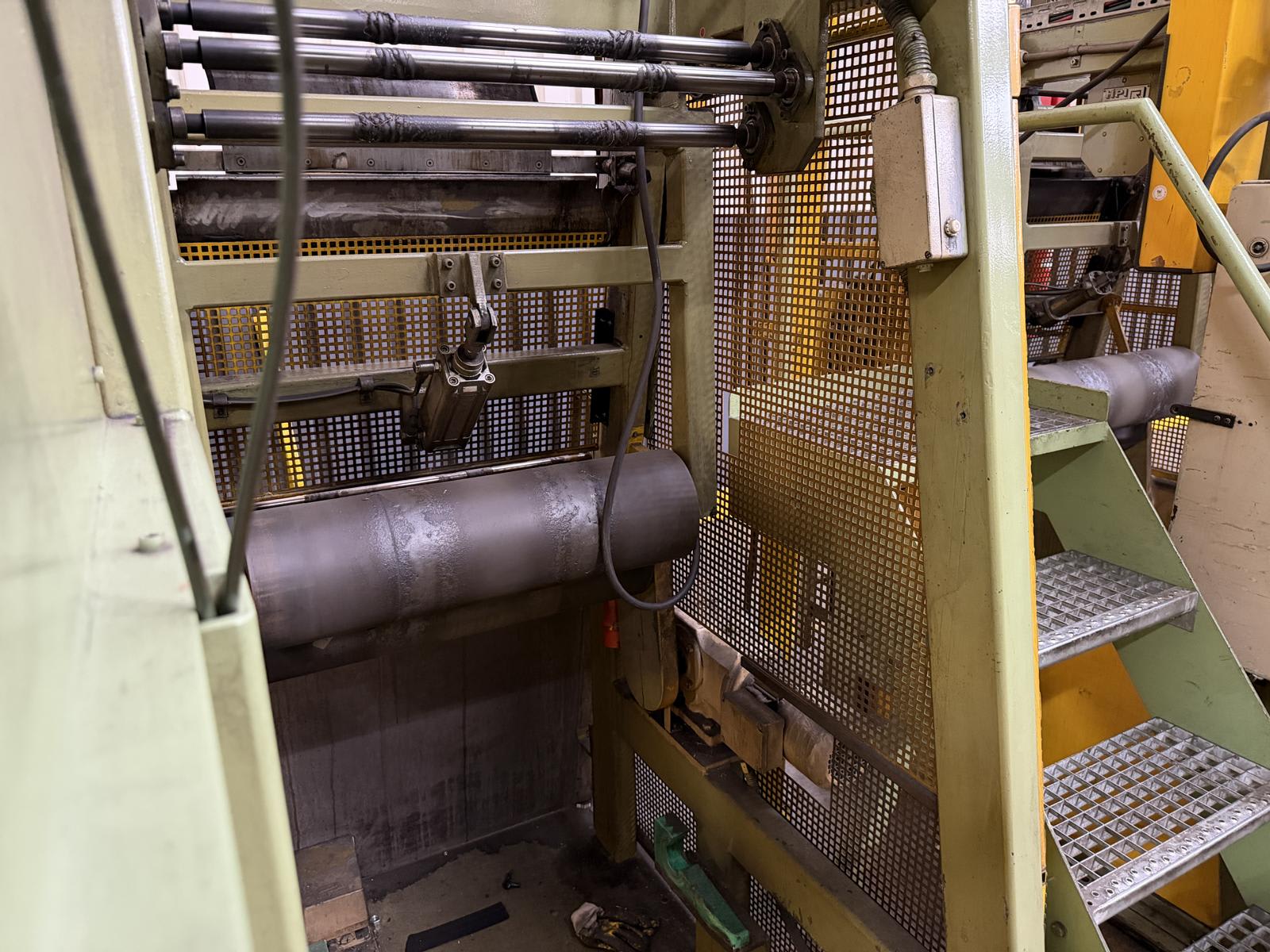

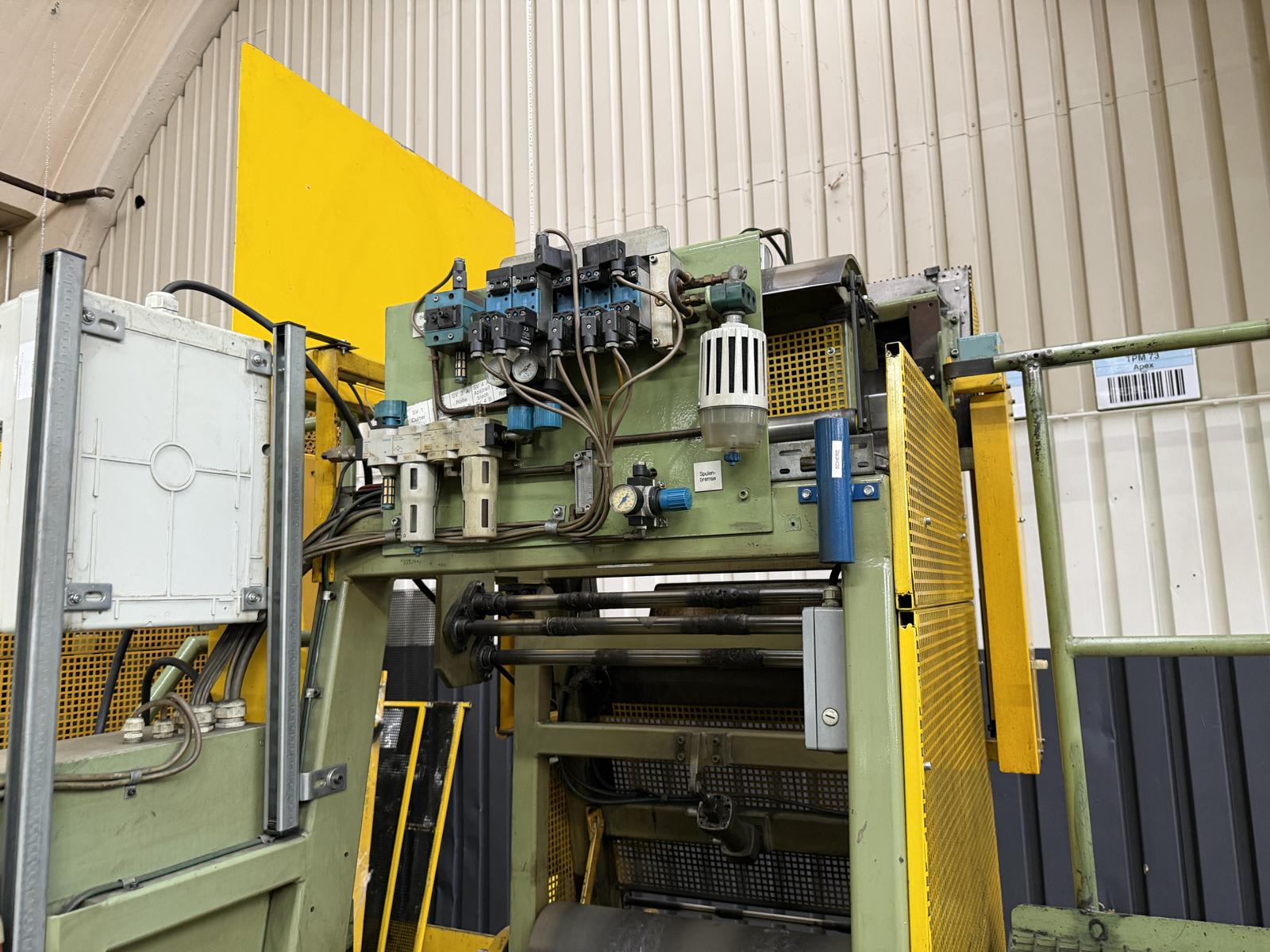

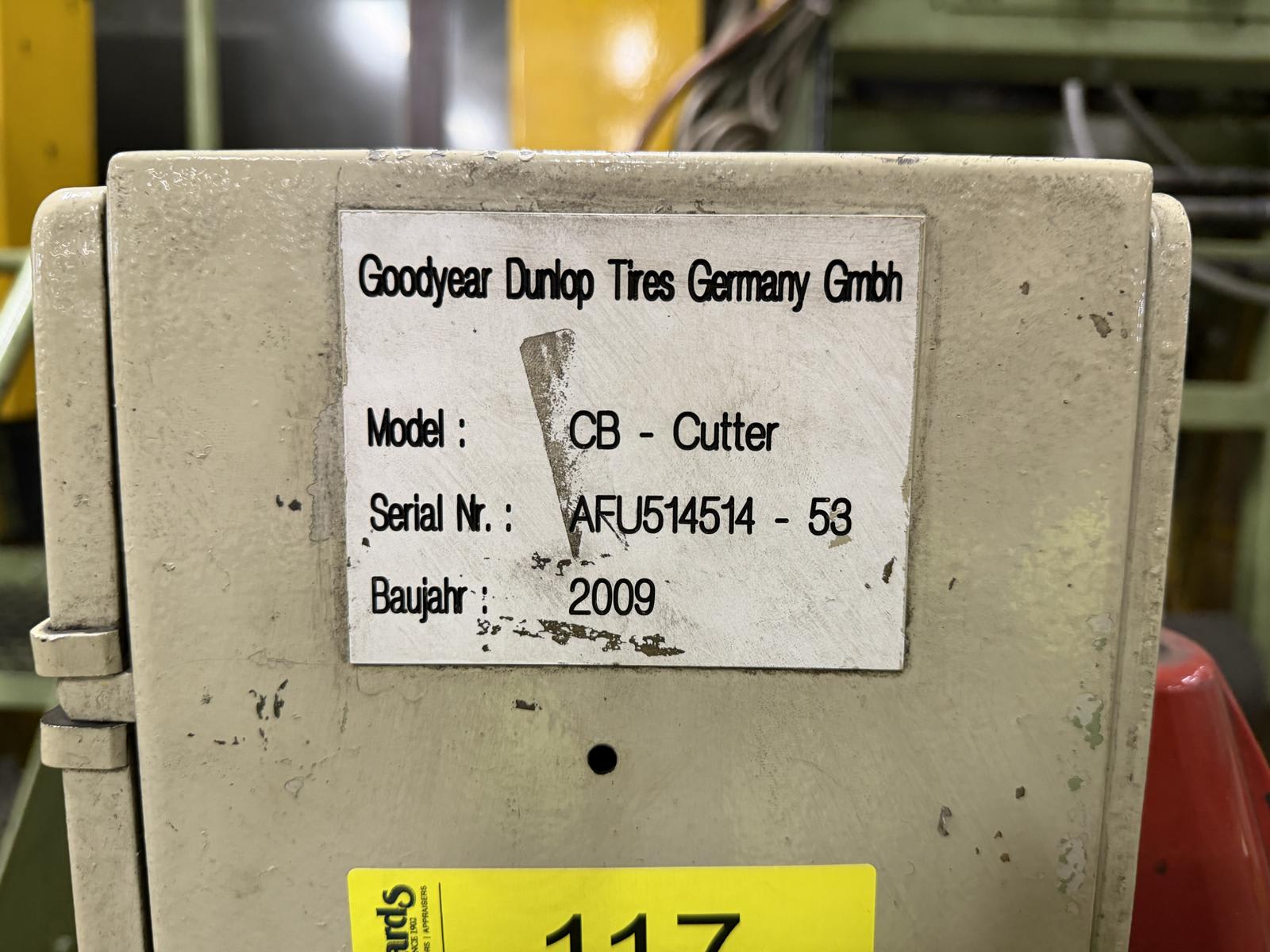

Bead Apexing Line (1) SMM d.o.o. Bead Apexing Line 1 // Apex 14"-24" | 2005

Binding Handling & Service Fee:

12200 € (EURO) - LISTING 2760007

![Deutsch]()

Liquid Polymer Weighing and Dosing System MEYER PLANTTEC / PLANER Systemtechnik Verwiegung Ricon 603 | 2020

Binding Handling & Service Fee:

700 € (EURO)

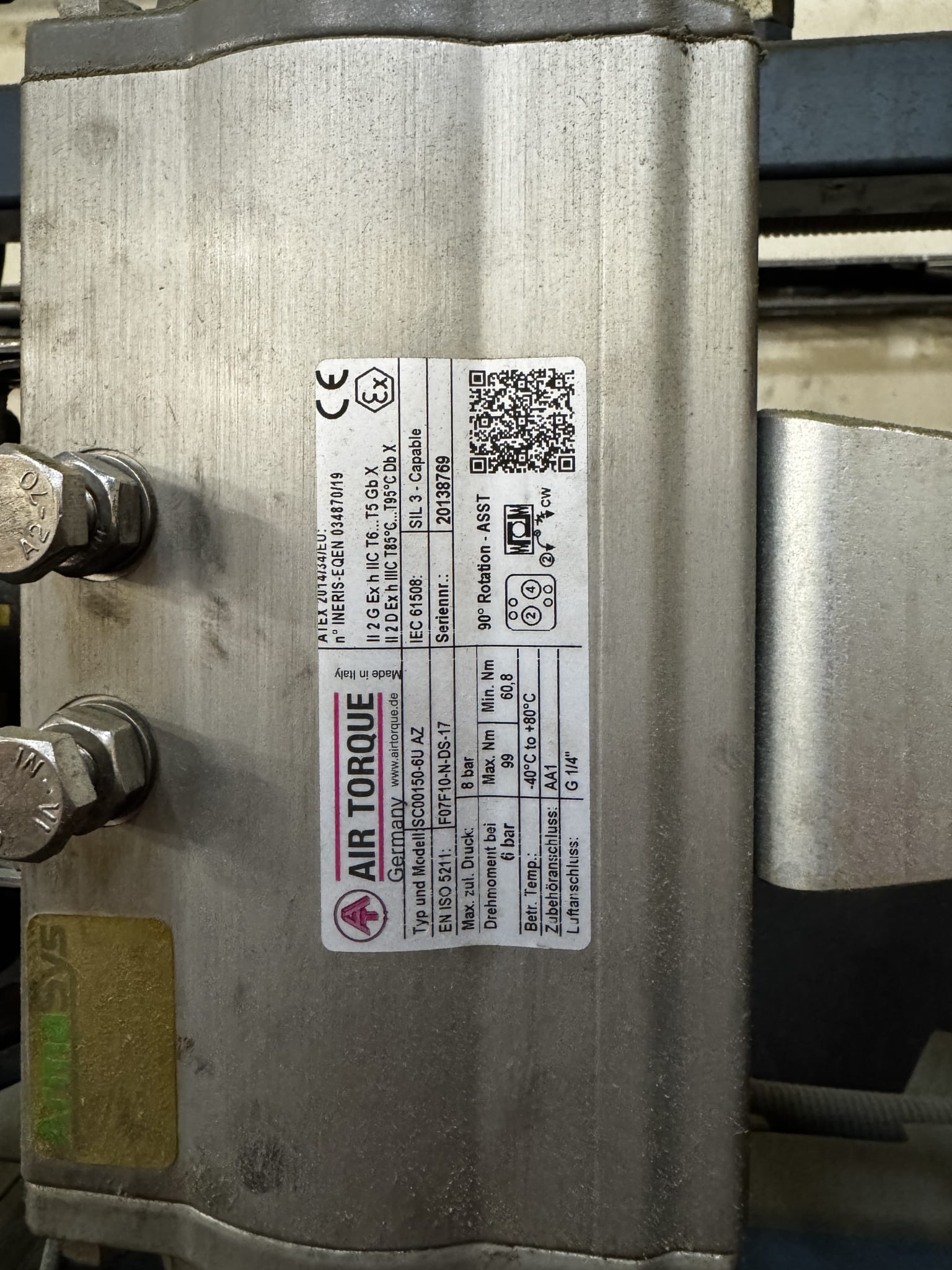

Manufacturer: • MEYER PLANTTEC • PLANER Systemtechnik Model / Designation: Verwiegung Ricon 603 Control Cabinet Type: 2005767 = P1 Power Supply: 400 VAC / 50 Hz Control Voltage: 24 VDC Maximum Fuse Rating: 25 A Rated Current: 8 A Total Weight: 60 kg Serial Number: 2005767-1 Year of Manufacture: 2020 PST Drawing Number: 161-10-760-02 2. System Overview (Visible Components) 2.1 Structural Frame • Welded steel frame with grated working platform • Integrated drum support area • Mounted linear guiding rails and table elements • Lower grid section for drainage or spill collection 2.2 Pump and Mixing Section Mounted on the left side: • Vertical motor-driven pump assembly, equipped with INVEOR motor controller • Pump intake connected to a chemical drum positioned on the system frame • Stainless-steel piping connected to the valve block and dosing line 2.3 Valve and Actuator Unit • Stainless steel valve block with flanged connections • Pneumatic rotary actuator: AIR TORQUE Germany Type / Model: SC0050-AJZ Series: FGF-010-S-17 Pressure range: Max. 10 bar Torque values: 29 Nm (min) / 60 Nm (max) Temperature range: –40 °C to +180 °C Connections: 1/4" Certification: CE, ATEX (EX II 2 G Ex h IIC T6 Gb X / Ex h IIIC T85°C Db X) Year Code: 20138769 - LISTING 2760008

![Deutsch]()

Bead Apexing Line (2) SMM d.o.o. Bead Apexing Line 2 // Apex 14"-24" | 2005

Binding Handling & Service Fee:

12200 € (EURO) - LISTING 2760009

![Deutsch]()

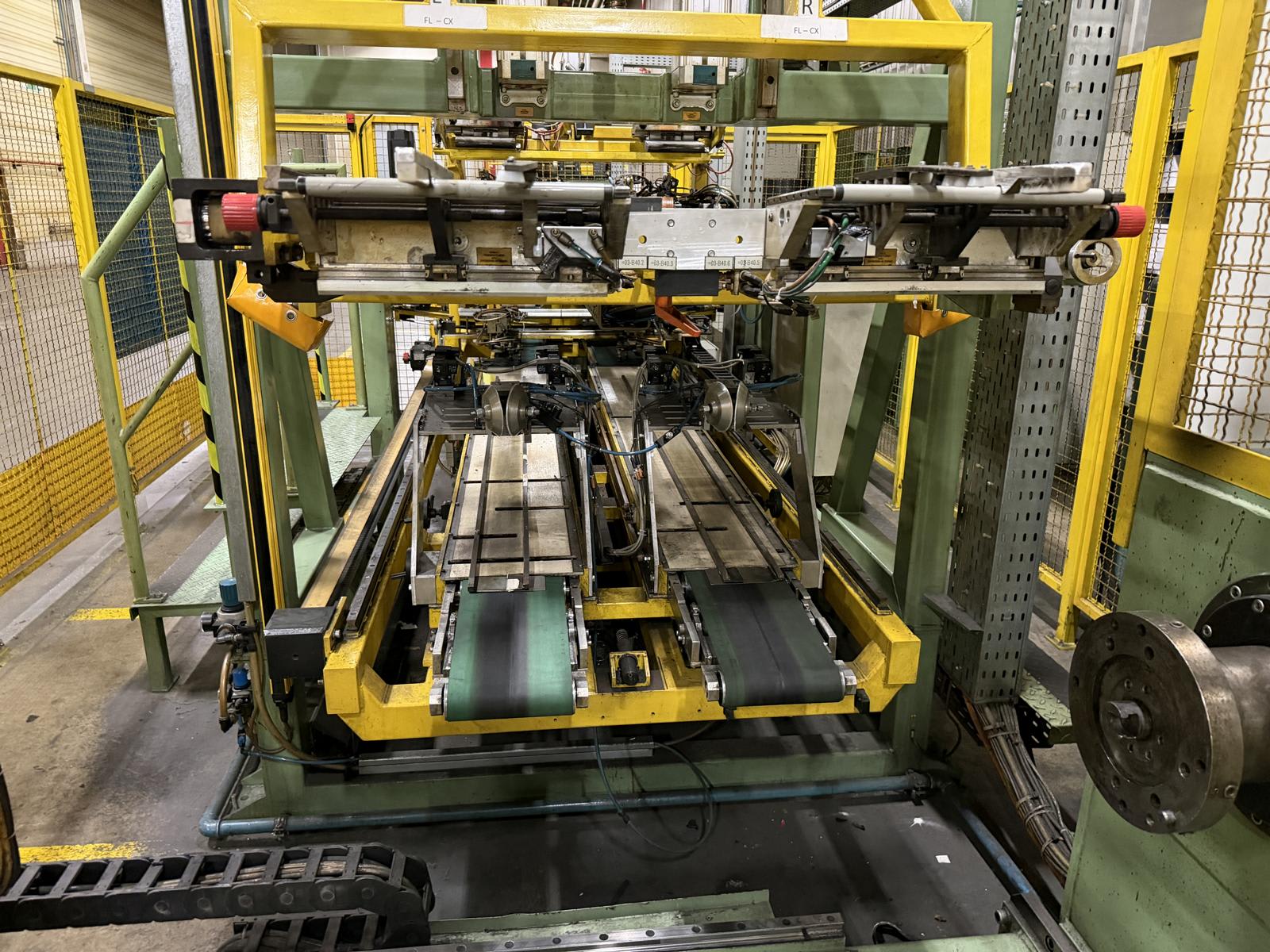

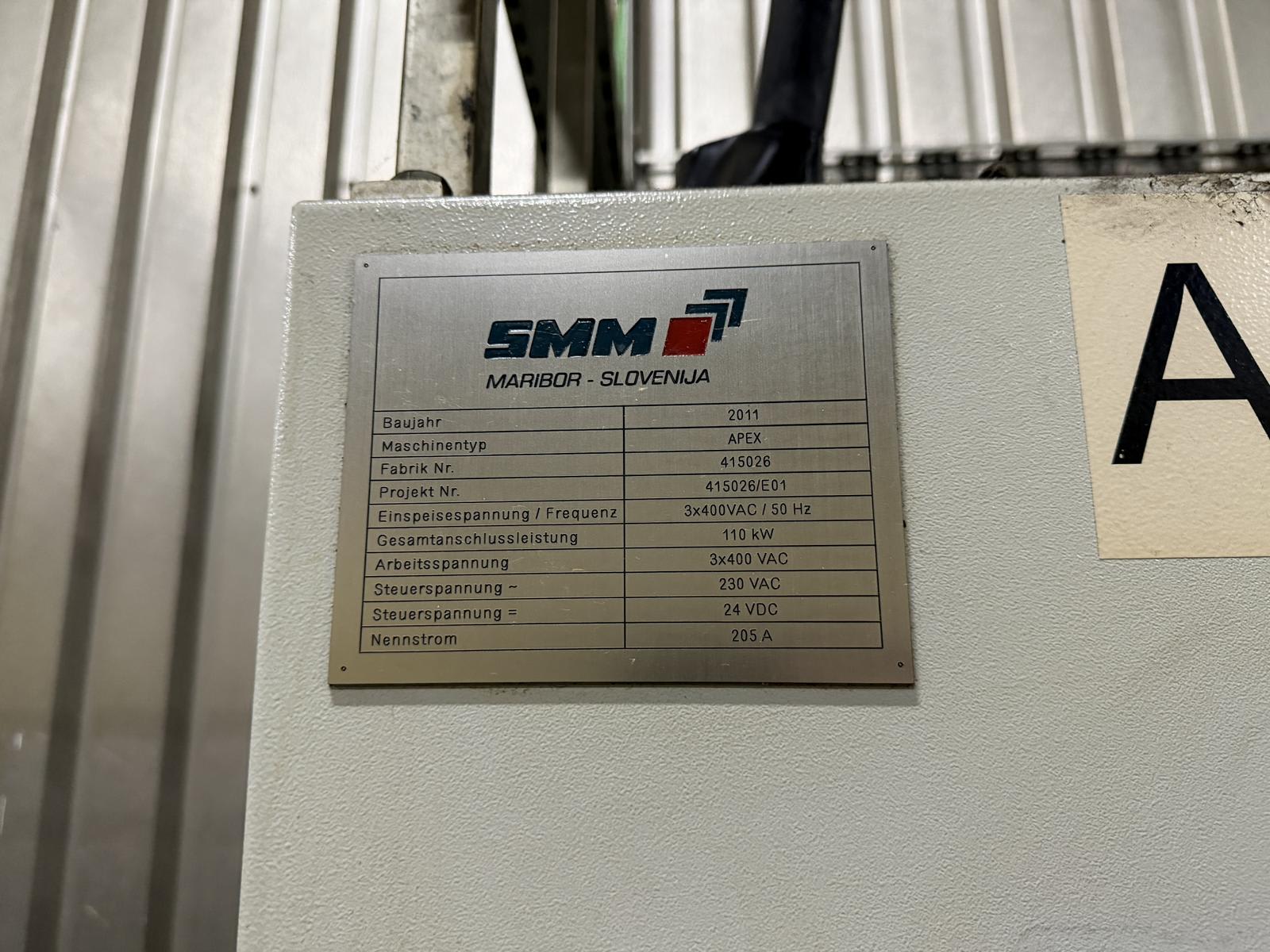

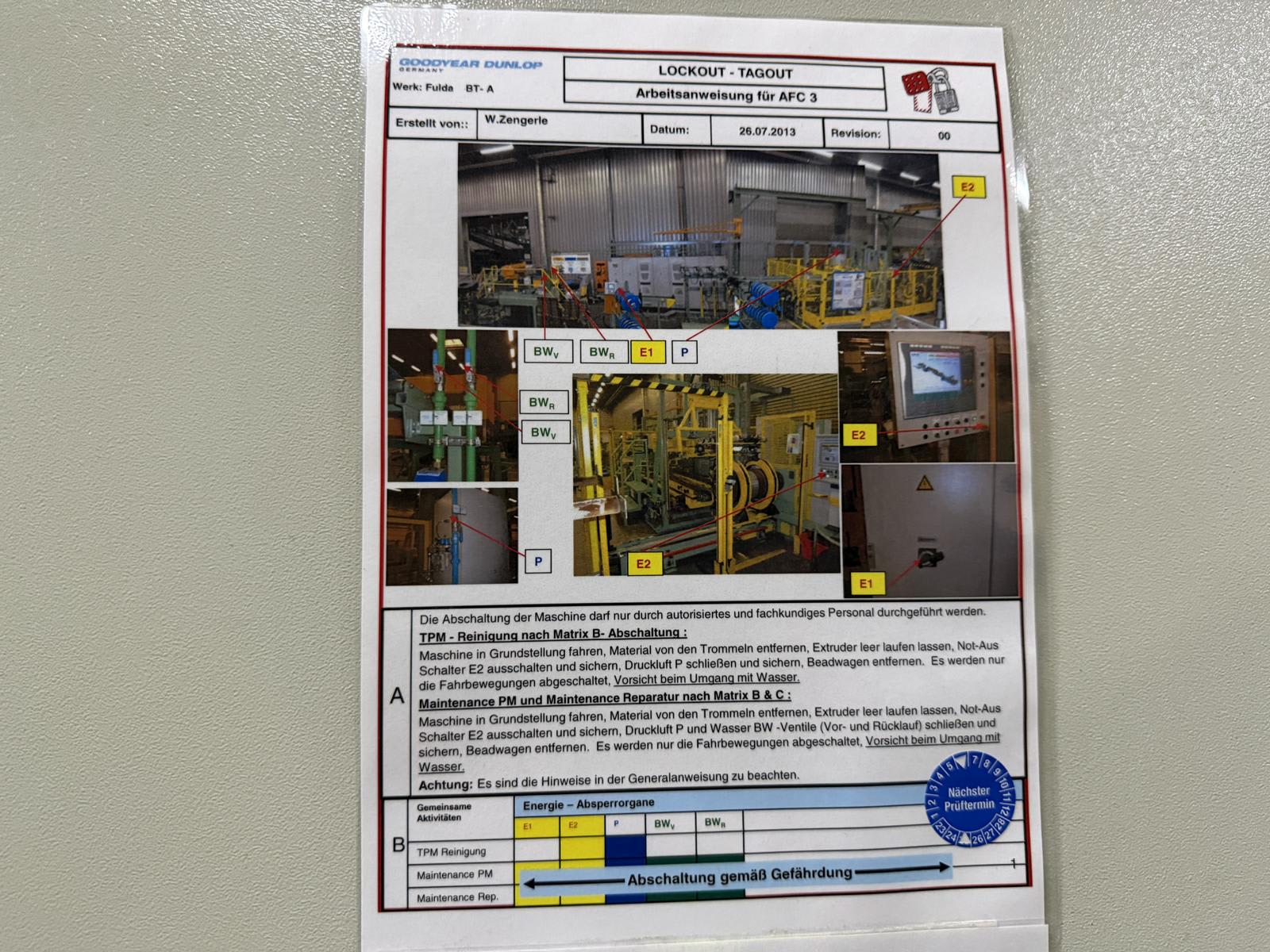

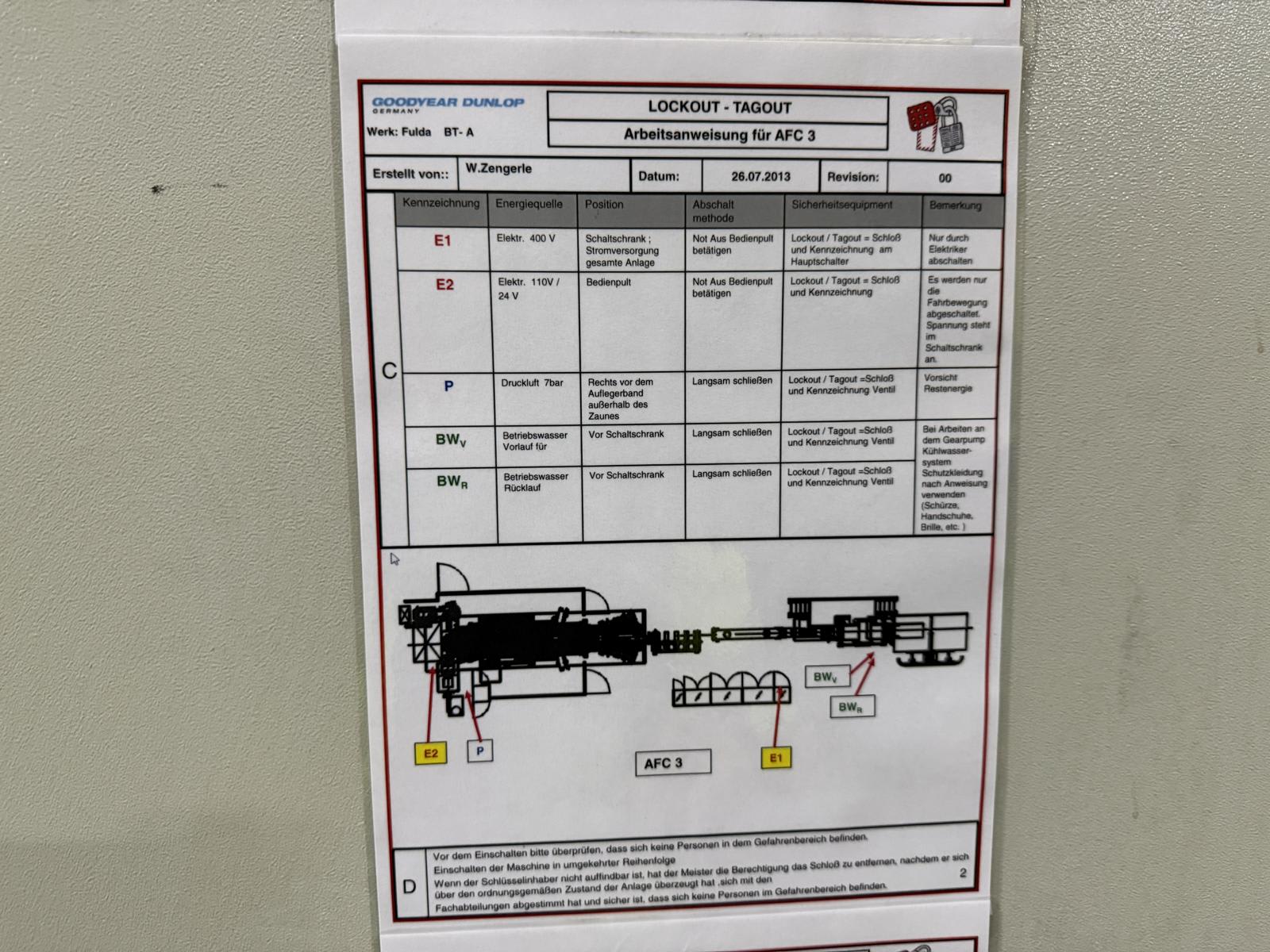

Bead Apexing Line (3) SMM d.o.o. Bead Apexing Line 3 // Apex 14"-24" | 2011

Binding Handling & Service Fee:

14400 € (EURO) - LISTING 2760010

![Deutsch]()

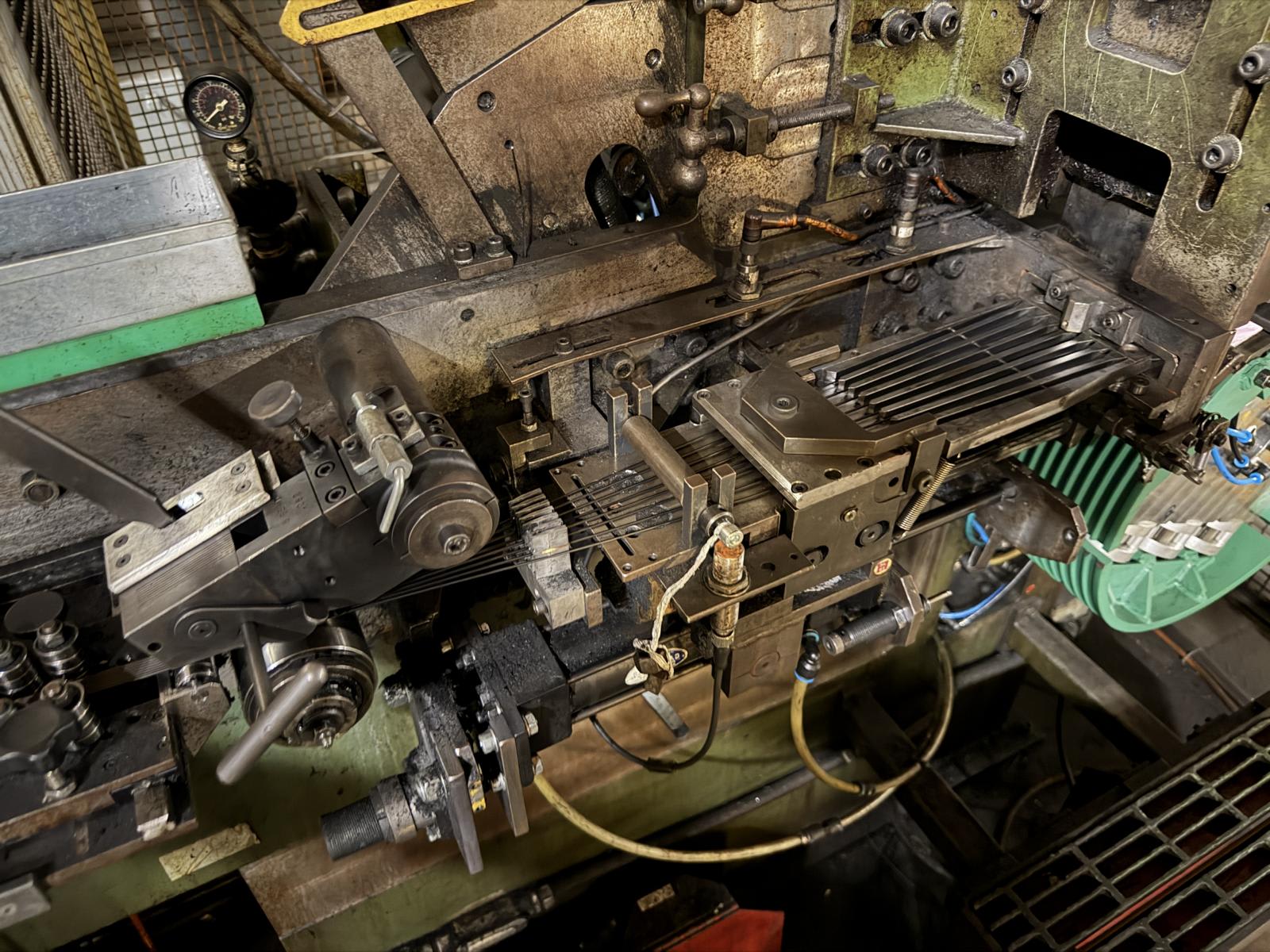

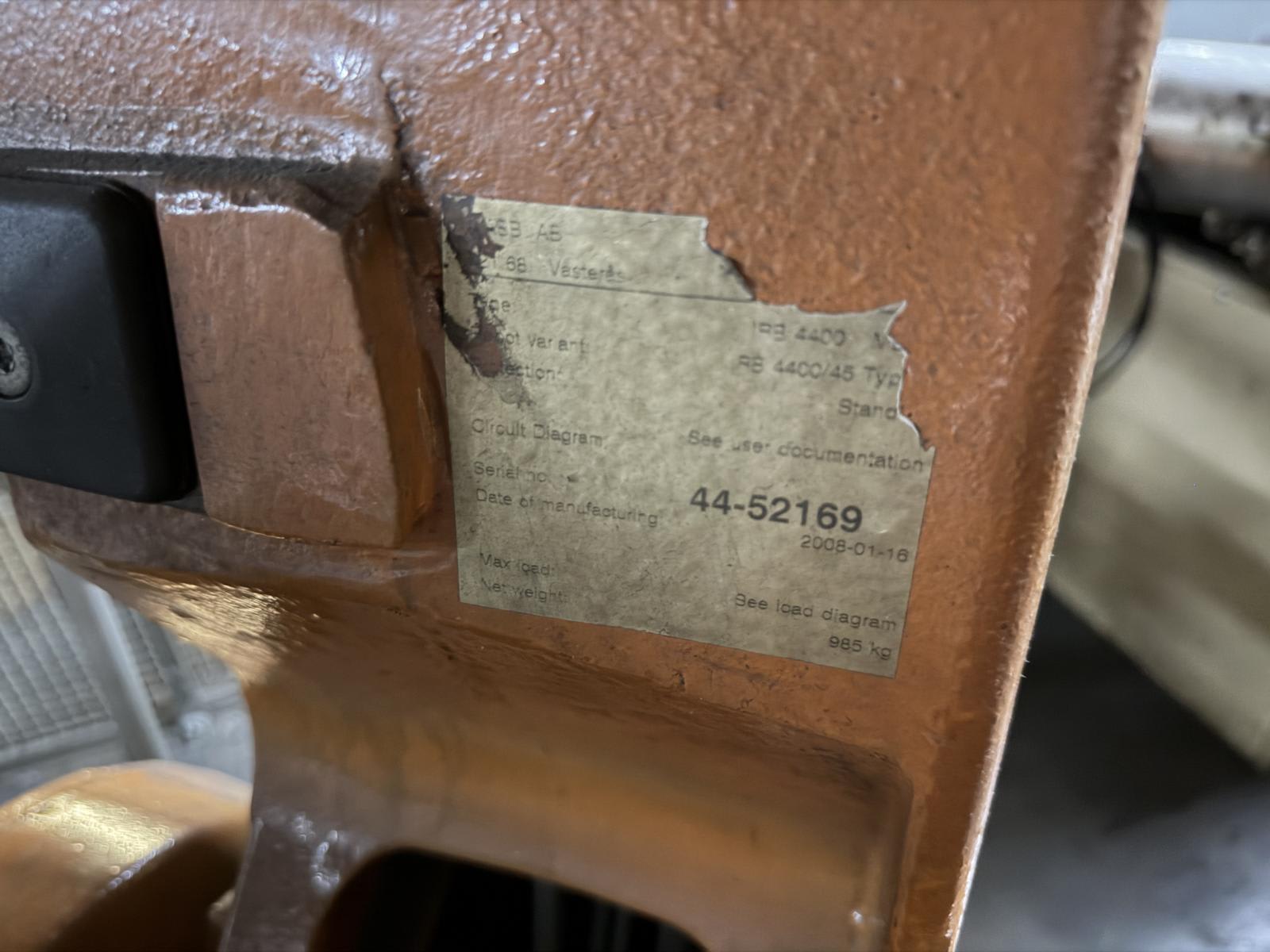

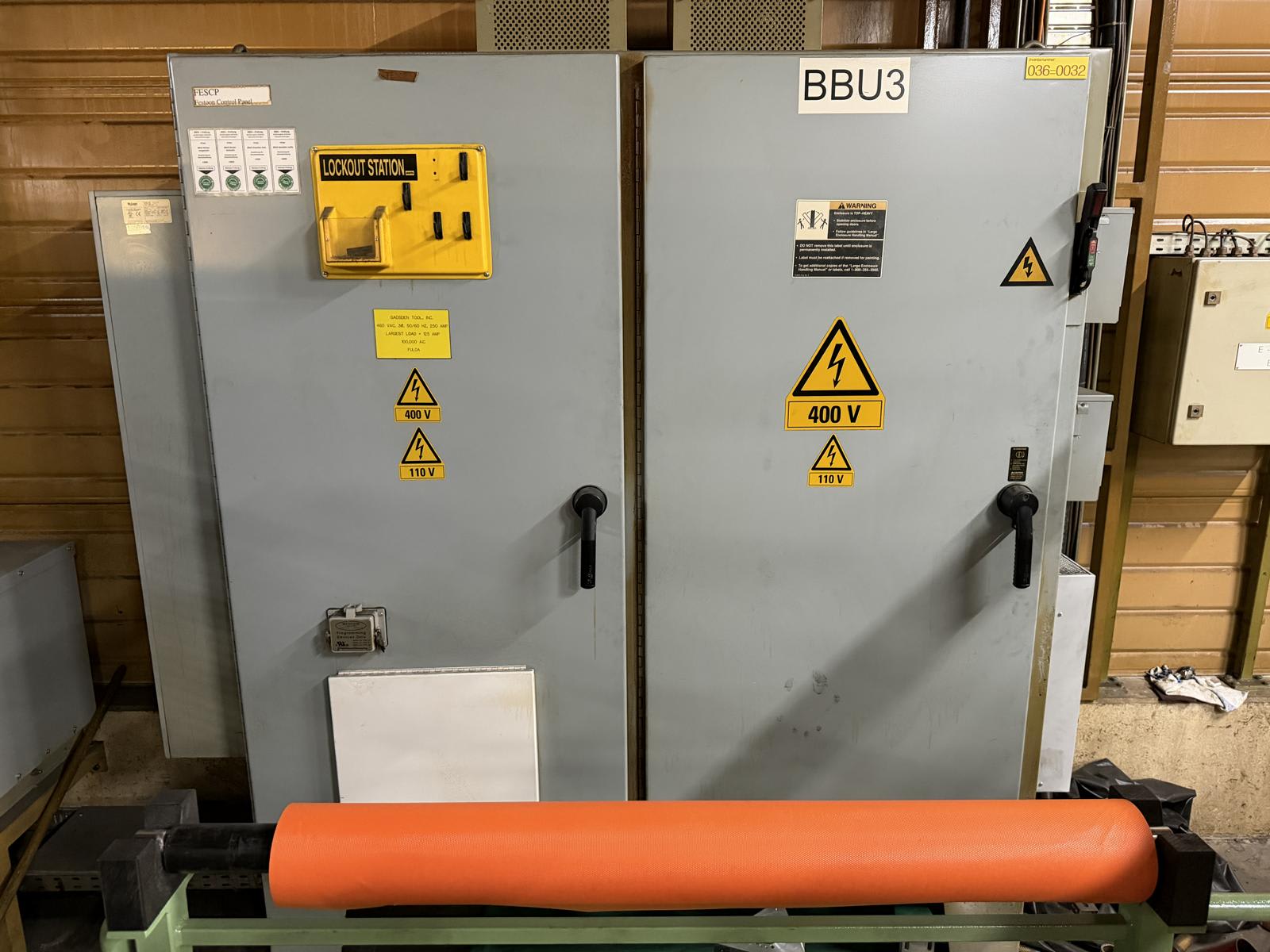

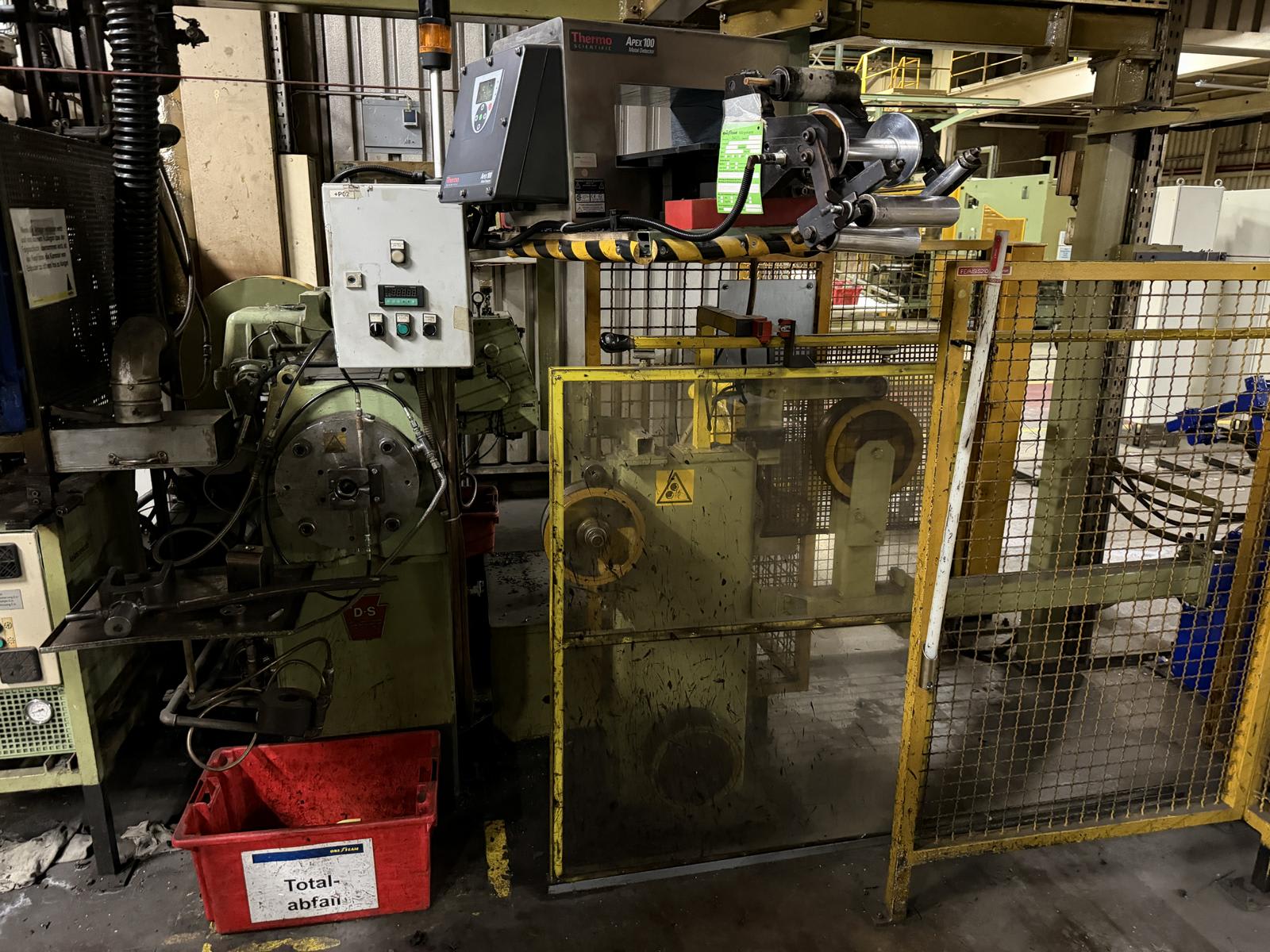

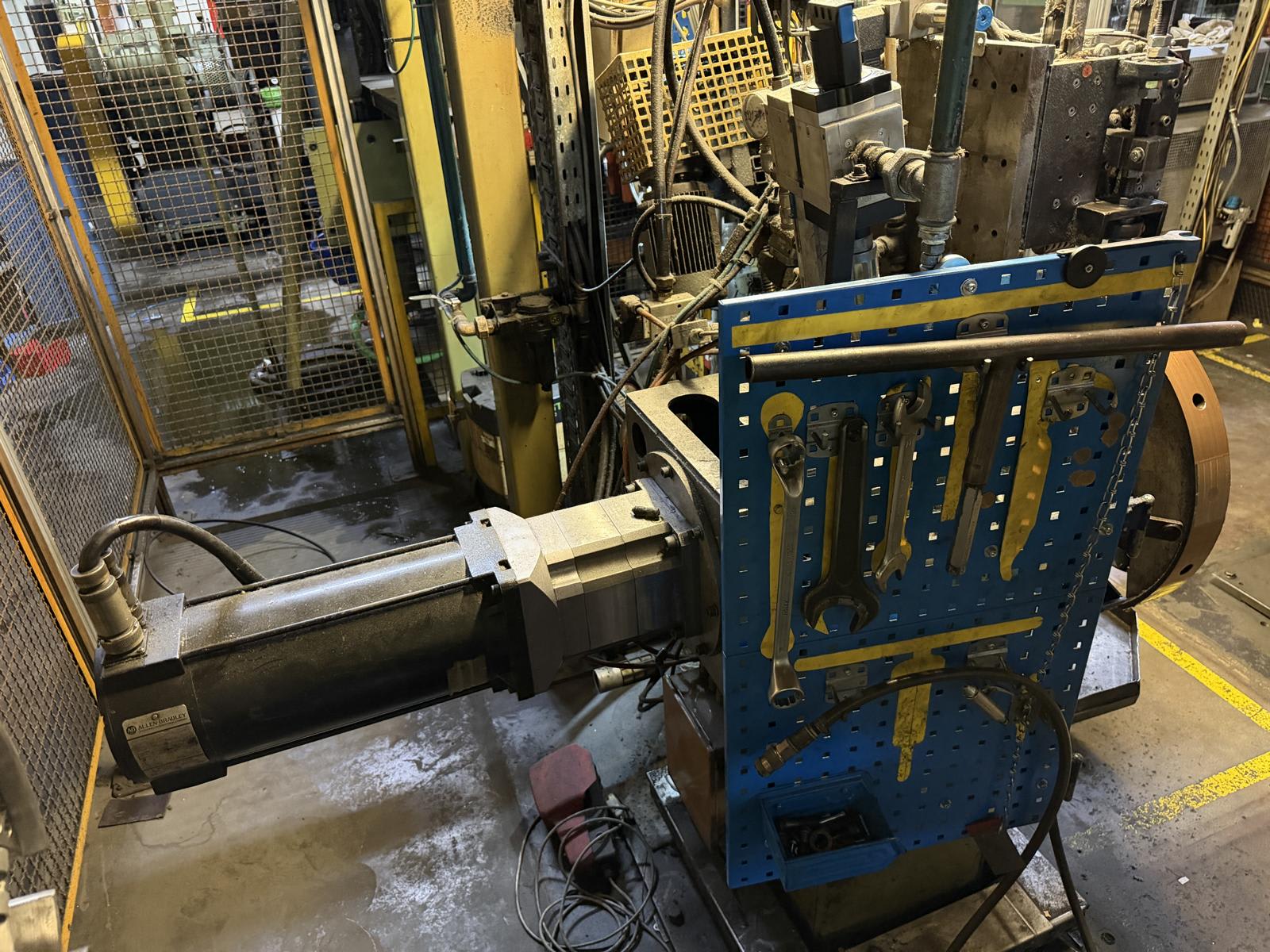

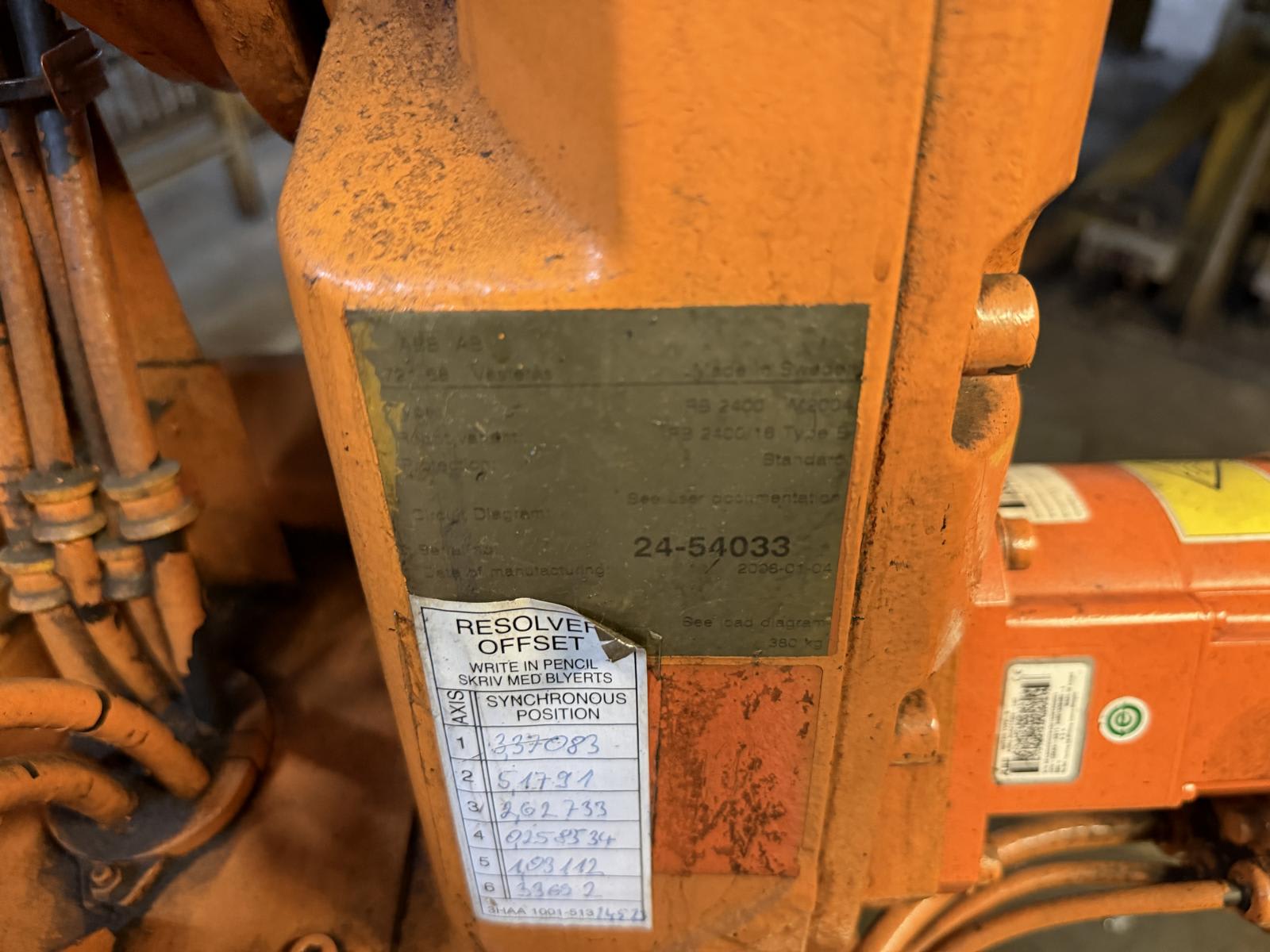

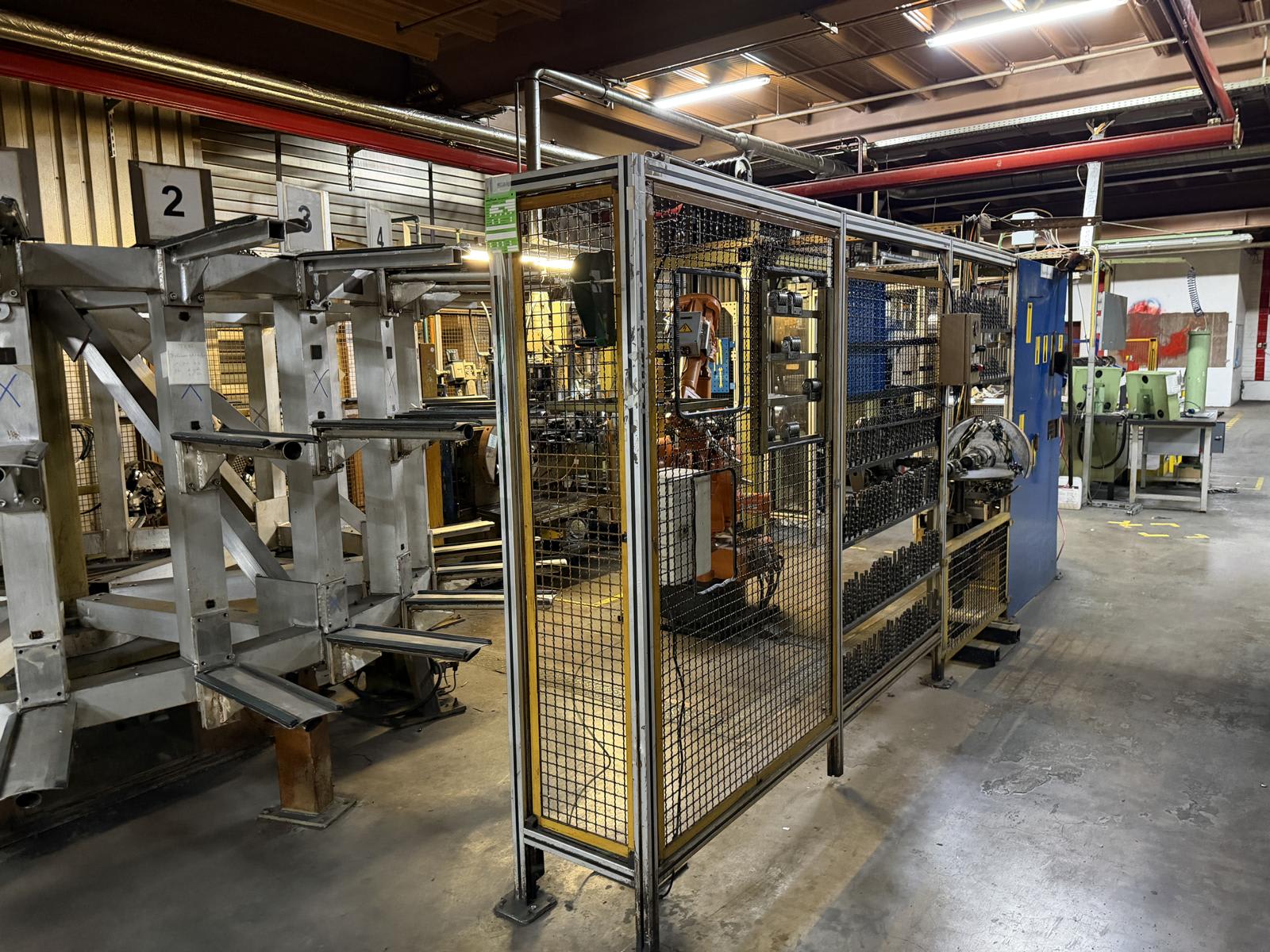

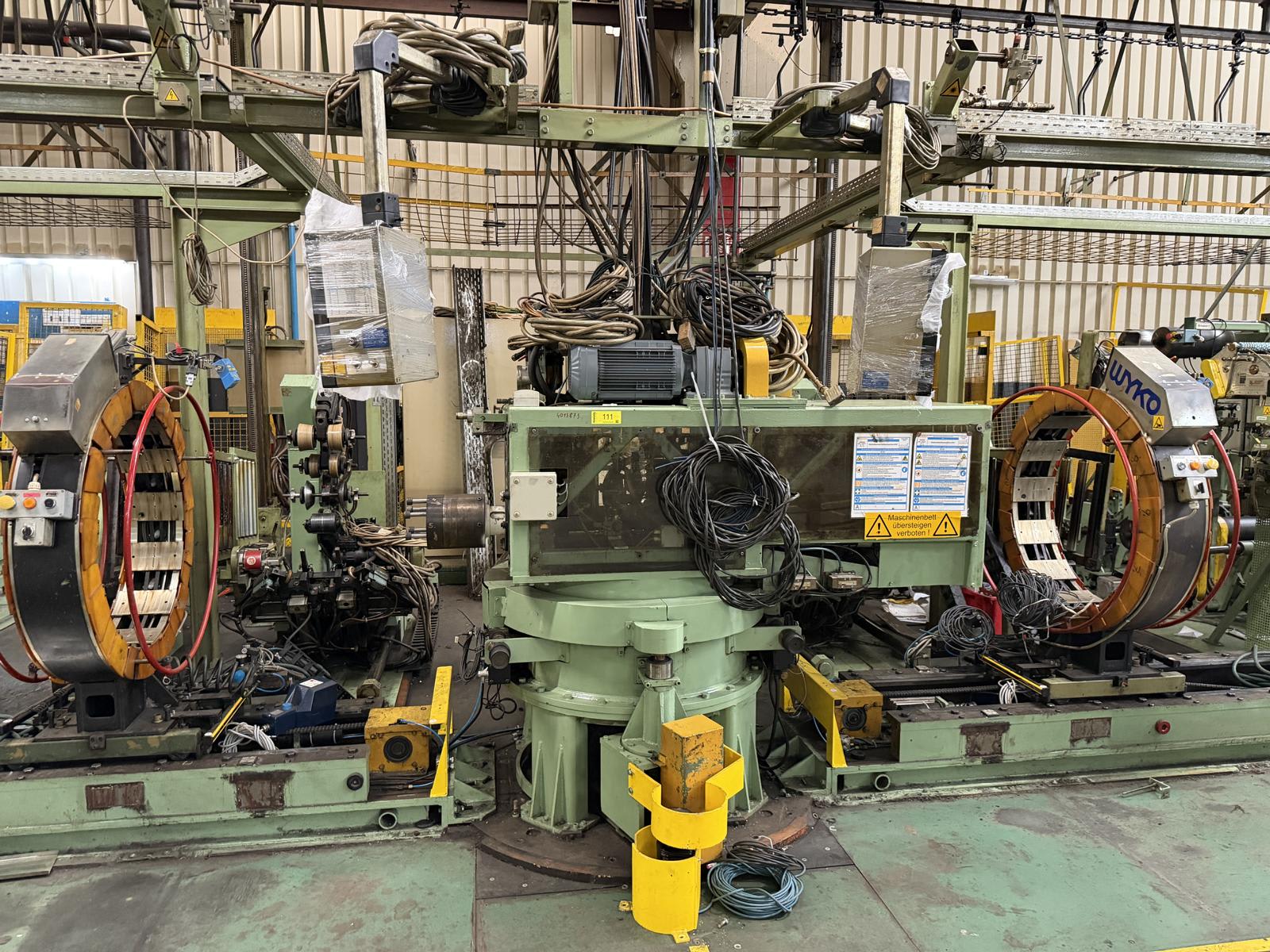

Hexagonal Bead Winding Line (1) Gadsden, Davis, ABB | 2001-2008

Binding Handling & Service Fee:

7200 € (EURO)

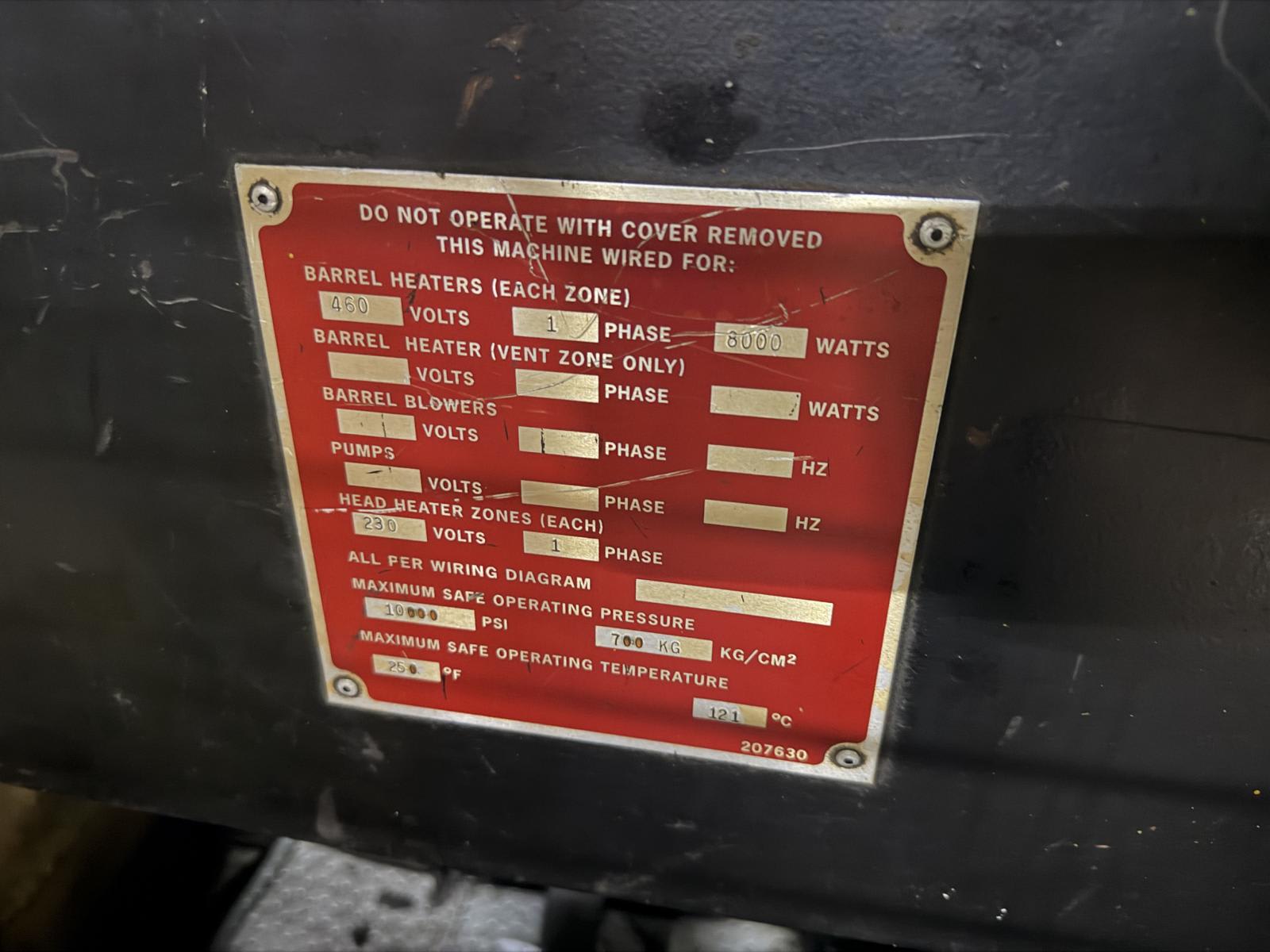

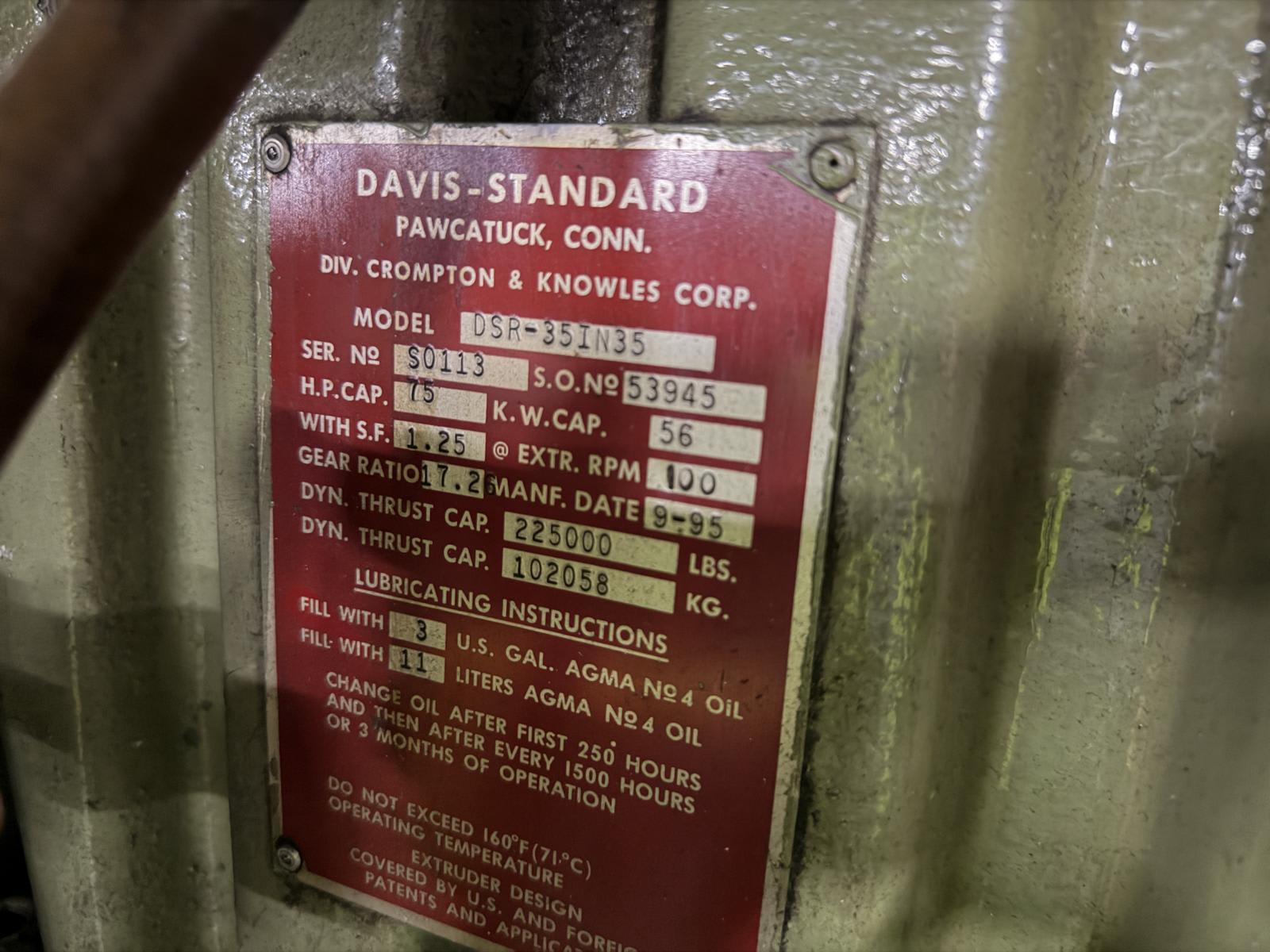

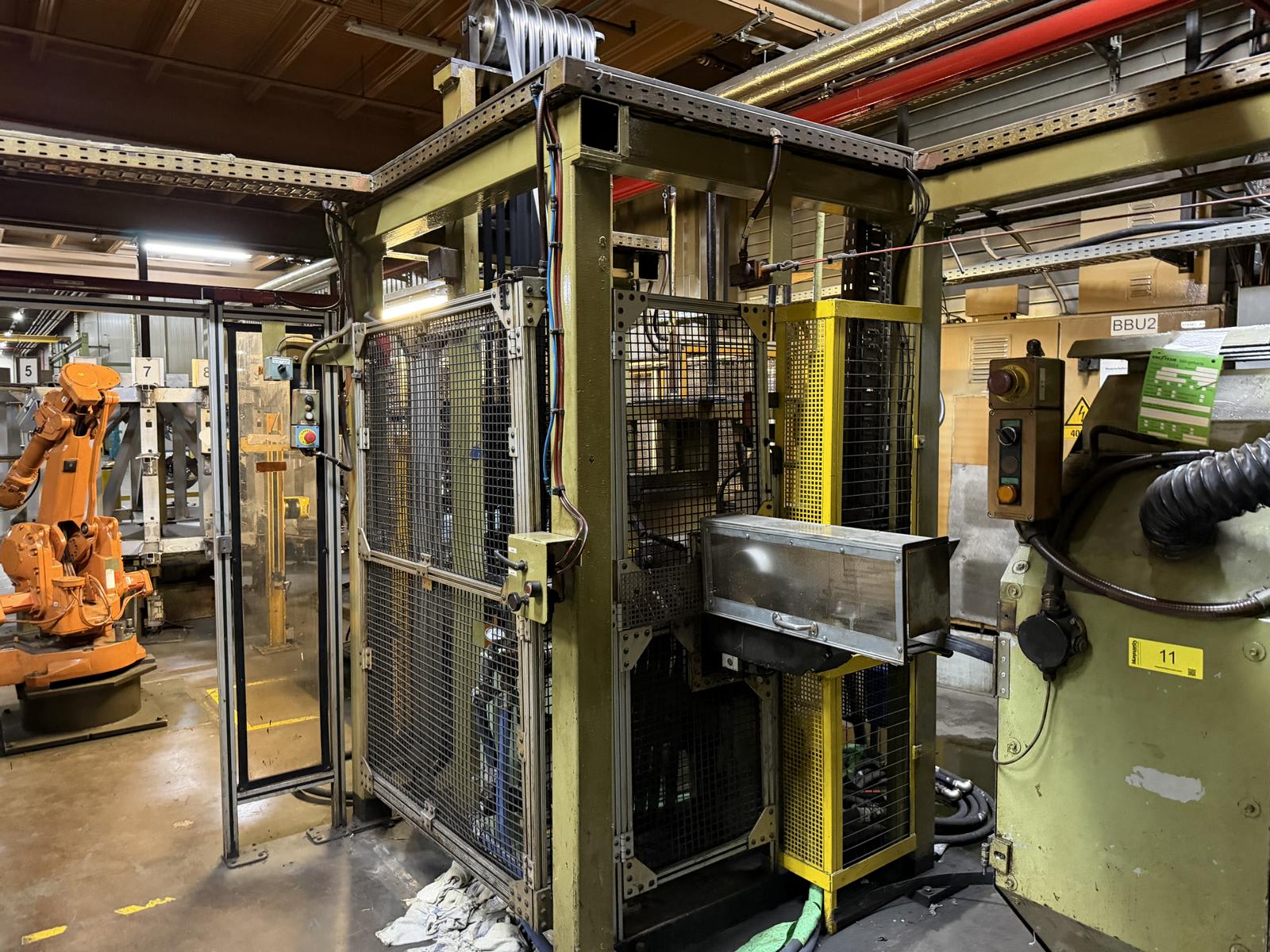

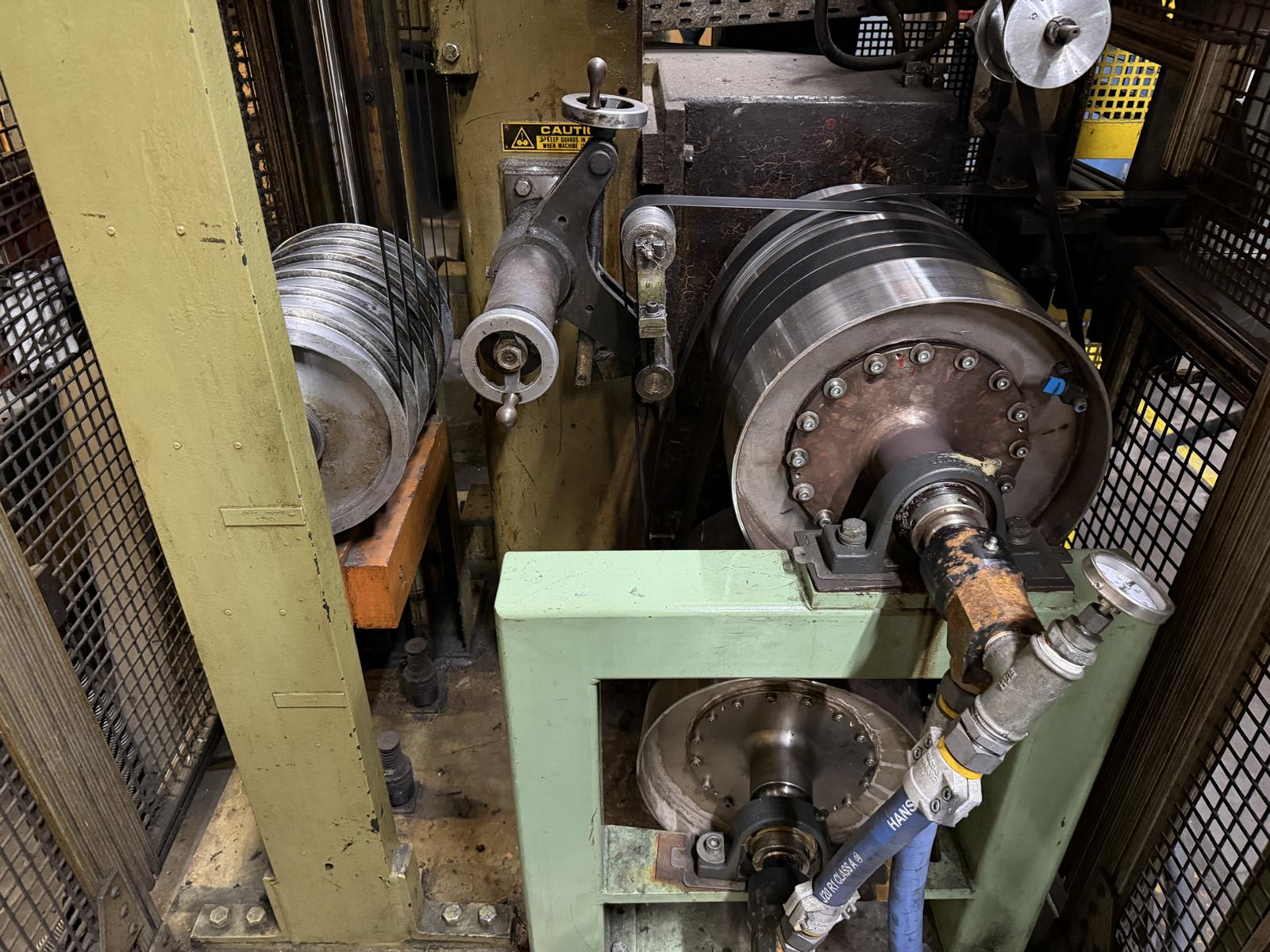

1. Bead Winder – Gadsden • Enclosed winding machines with yellow safety guarding • Multiple rotating winding discs and wire guides • Integrated operator control panels with pushbuttons, indicator lights, and emergency stop • Mechanical winding stations mounted on heavy steel frames • Wire feed paths and guiding elements visible 2. Bead Extruder – Davis • Extruder assemblies with screw and barrel sections • Downstream guiding and forming components • Control cabinets and local operator panels • Ancillary equipment including heating/control units and material handling components • Safety guarding integrated into the line 3. Carousel and Loader Robot • ABB Industrial articulated robot arm (orange) • Rotary carousel stations with multiple indexed holders • Safety fencing enclosing robot work areas • Integrated control panels adjacent to robot cell 4. Coil Winding Equipment • Multiple wire payoff and take-up reels arranged in series • Tensioning and guiding rollers • Winding stations mounted on steel frames • Clearly separated parallel winding positions - LISTING 2760011

![Deutsch]()

Square Bead Winding Line (2) Gadsden, Davis, ABB | 1995-2006

Binding Handling & Service Fee:

7200 € (EURO)

1. Bead Winder – Gadsden • Enclosed winding machines with yellow safety guarding • Multiple rotating winding discs and wire guides • Integrated operator control panels with pushbuttons, indicator lights, and emergency stop • Mechanical winding stations mounted on heavy steel frames • Wire feed paths and guiding elements visible 2. Bead Extruder – Davis • Extruder assemblies with screw and barrel sections • Downstream guiding and forming components • Control cabinets and local operator panels • Ancillary equipment including heating/control units and material handling components • Safety guarding integrated into the line 3. Carousel and Loader Robot • ABB Industrial articulated robot arm (orange) • Rotary carousel stations with multiple indexed holders • Safety fencing enclosing robot work areas • Integrated control panels adjacent to robot cell 4. Coil Winding Equipment • Multiple wire payoff and take-up reels arranged in series • Tensioning and guiding rollers • Winding stations mounted on steel frames • Clearly separated parallel winding positions - LISTING 2760012

![Deutsch]()

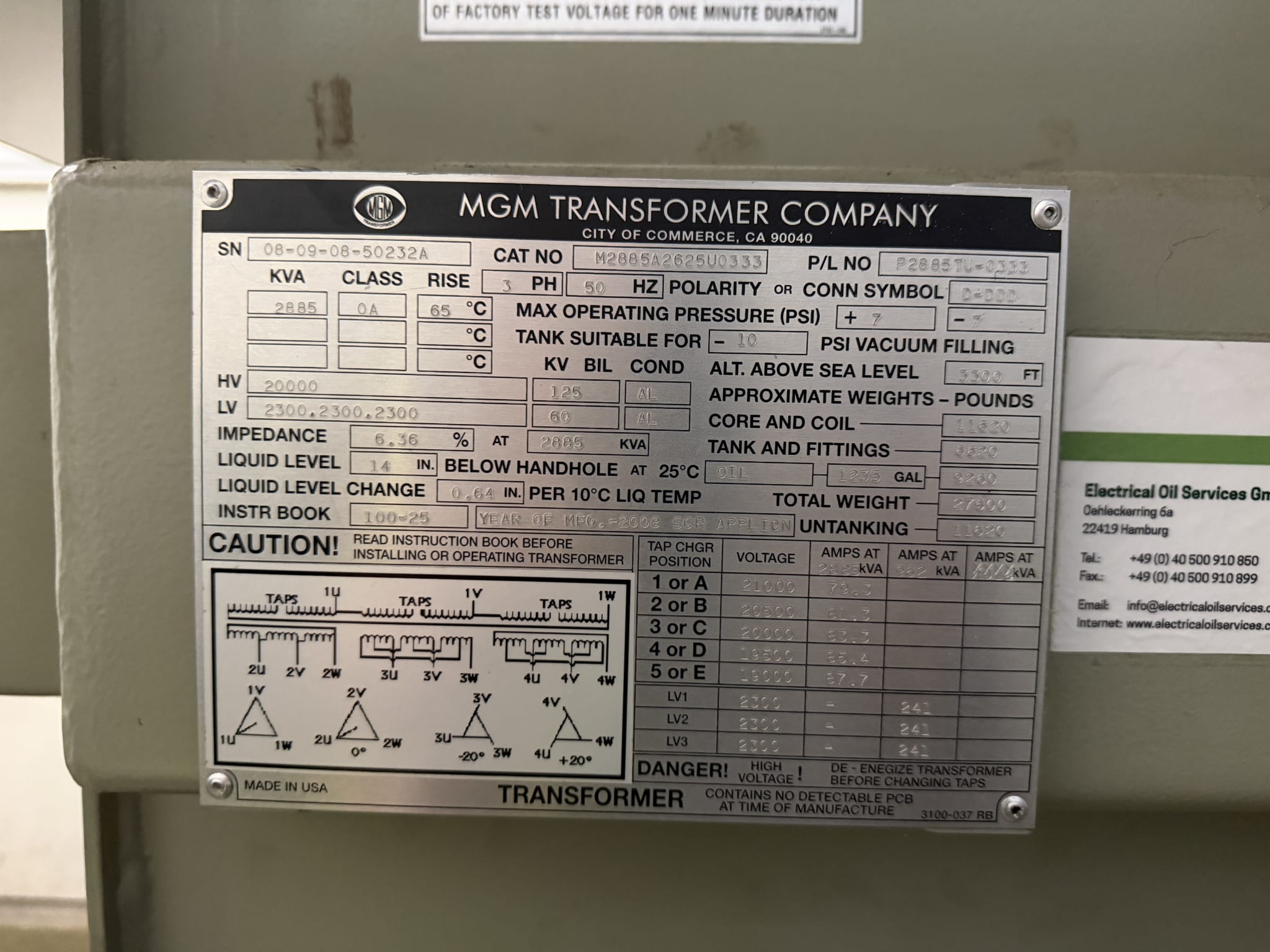

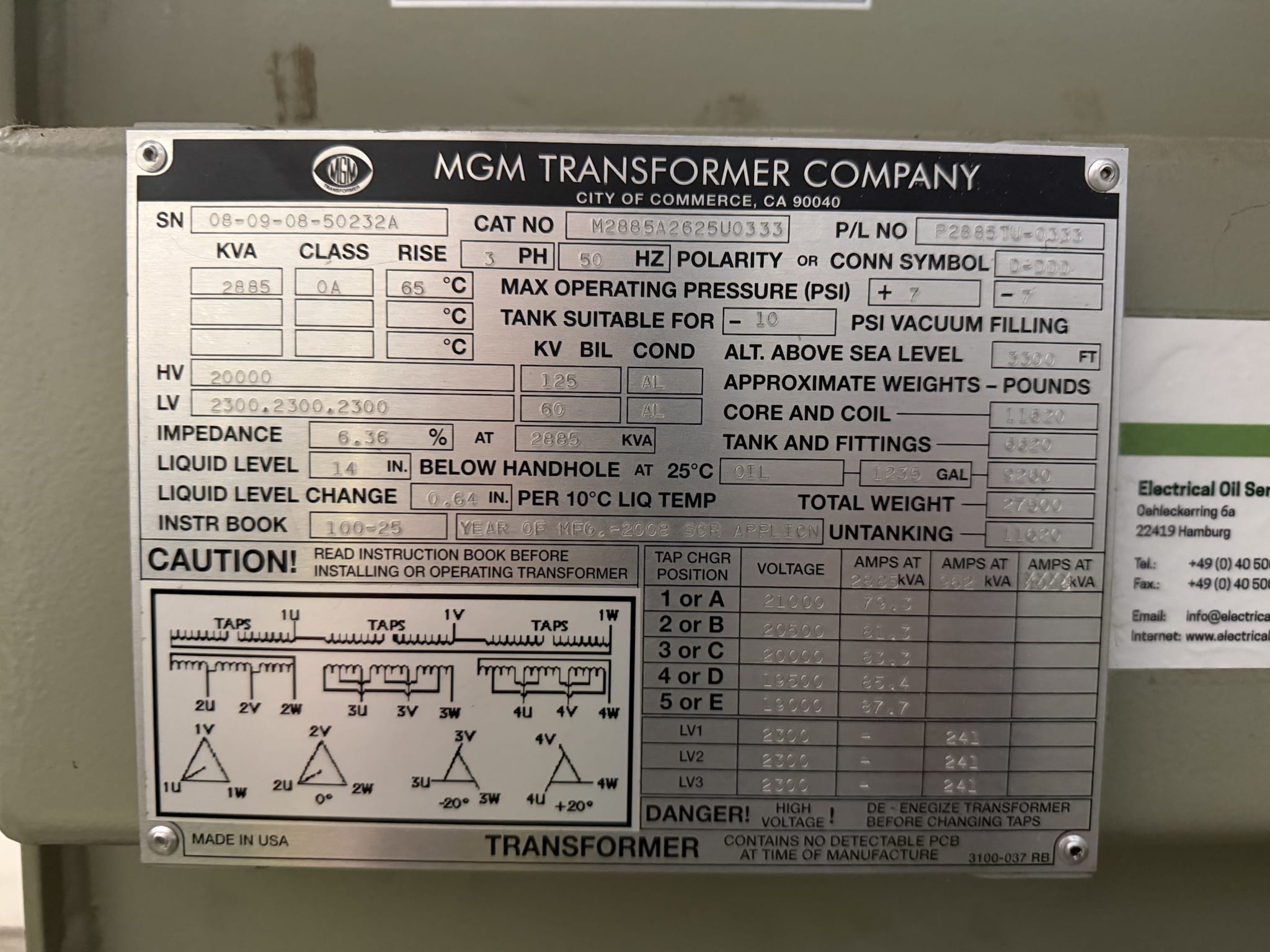

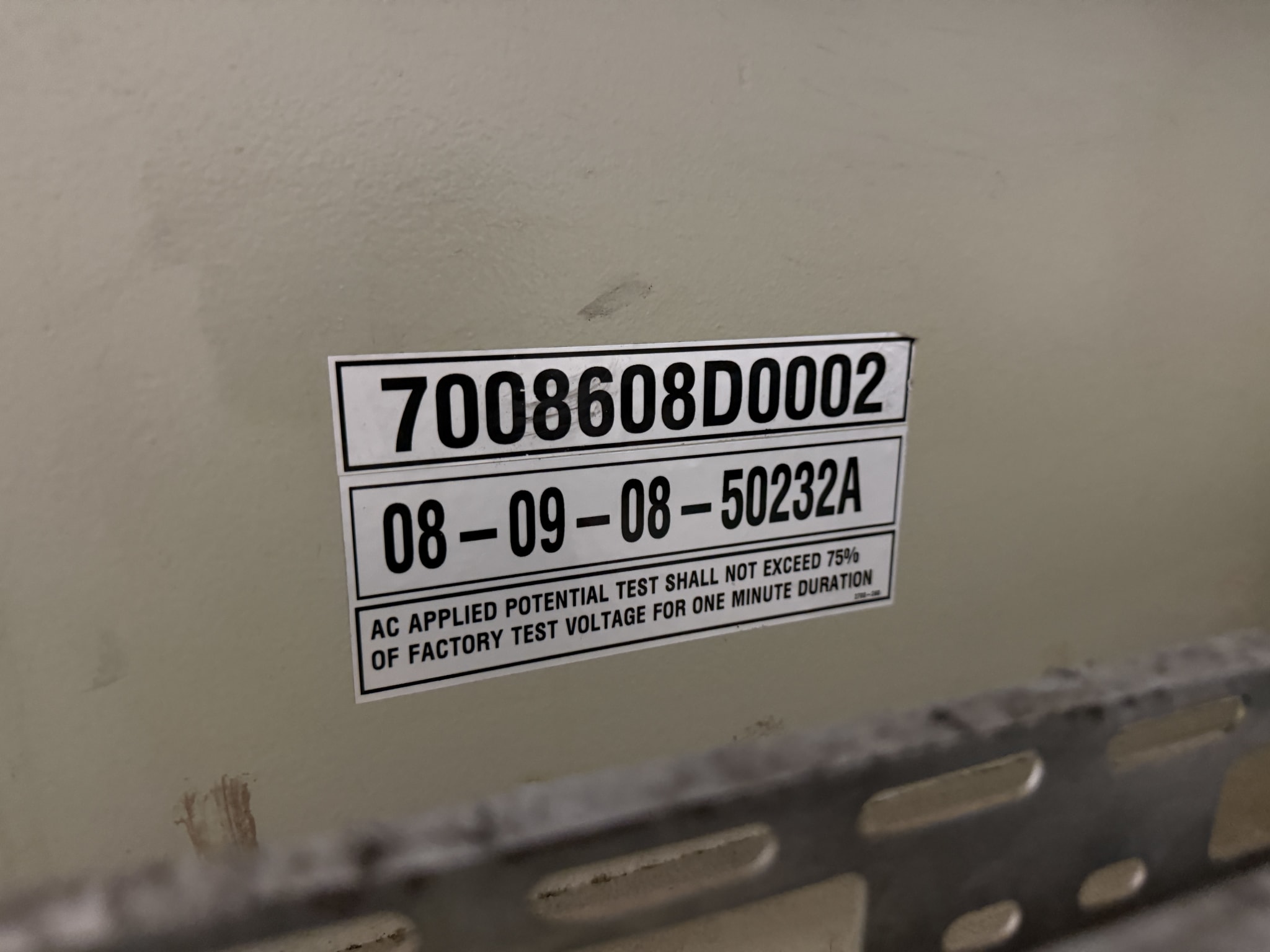

Oil-filled Power Transformer MGM Transformer Company | 2008

Binding Handling & Service Fee:

on Request

General Information • Equipment type: Oil-filled power transformer • Installation type: Stationary, floor-mounted • Application context (visual): Industrial power supply for production machinery Manufacturer • Manufacturer (nameplate): MGM Transformer Company • Manufacturer location (nameplate): City of Commerce, CA 90040, USA • Country of manufacture: United States (explicitly stated: “Made in USA”) Identification • Manufacturer serial number (SN): 08-09-08-50232A • Additional identification marking: 7008608D0002 • Catalog number (CAT NO): M2885A2625U0333 • P/L No.: P2885TU-0333 Electrical Characteristics (Nameplate) • Rated power: 2885 kVA • Phase: 3 PH • Frequency: 50 Hz • High voltage (HV): 20,000 V • Low voltage (LV): 2300 / 2300 / 2300 V • Impedance: 6.36 % at 2885 kVA • Insulation class: OA • Temperature rise: 65 °C Insulation / Dielectric Data • HV BIL: 125 kV • LV BIL: 60 kV • Cooling medium: Oil • Liquid level reference: – 14 in. below handhole at 25 °C – Liquid level change: 0.64 in. per 10 °C Mechanical / Tank Data • Tank vacuum suitability: −10 PSI (vacuum filling) • Maximum operating pressure: +7 PSI • Altitude rating: Up to 3300 ft above sea level Weight Data (Nameplate, approximate) • Core and coil weight: 11,820 lb • Tank and fittings: 8,320 lb • Oil quantity: 1,235 gal • Total weight: 27,500 lb • Untanking weight: 11,820 lb Tap Changer Information (Nameplate) • Tap positions: 1 (A) to 5 (E) • HV tap voltages: – 21,000 V – 20,500 V – 20,000 V – 19,500 V – 19,000 V - LISTING 2760018

![Deutsch]()

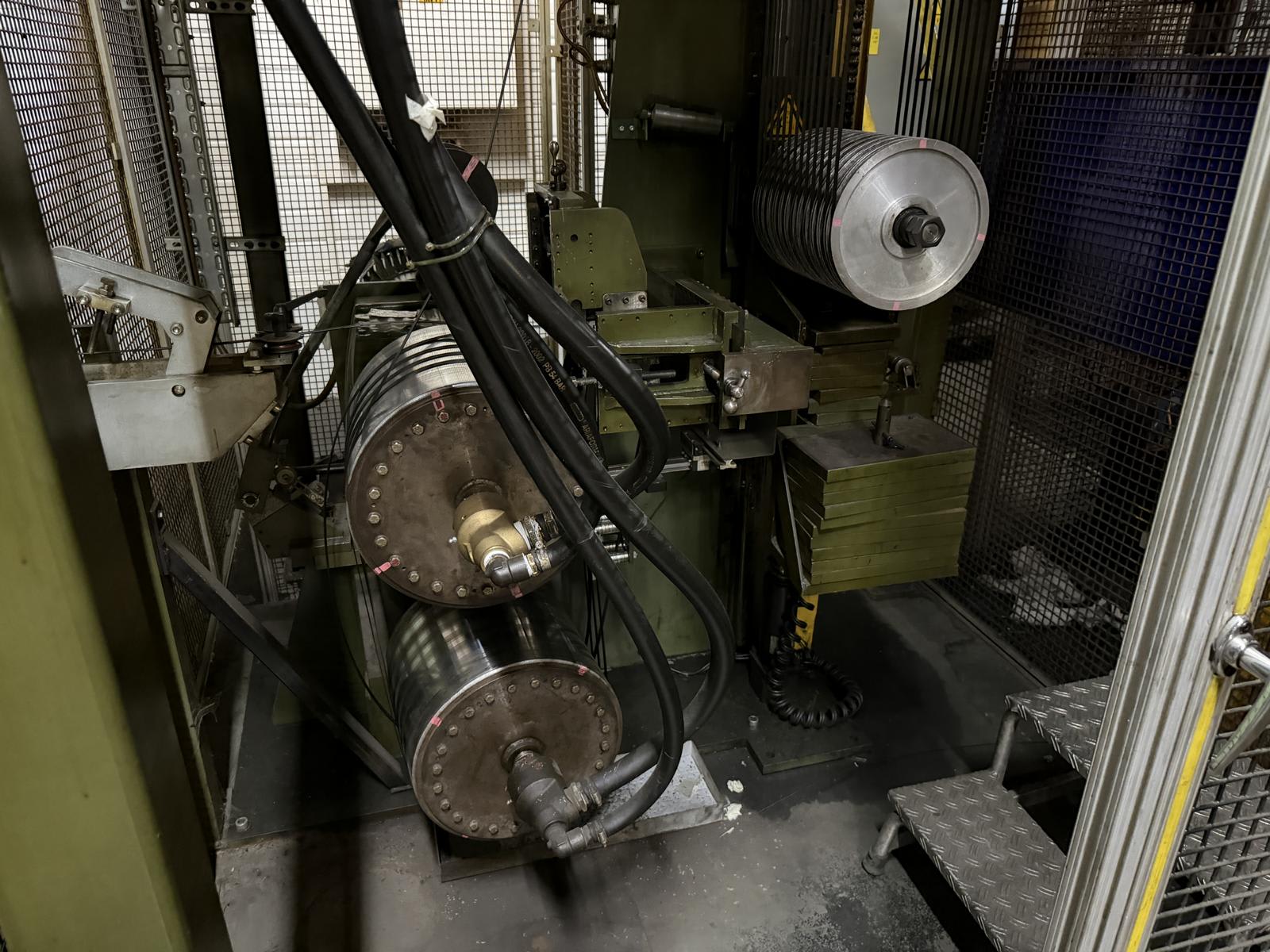

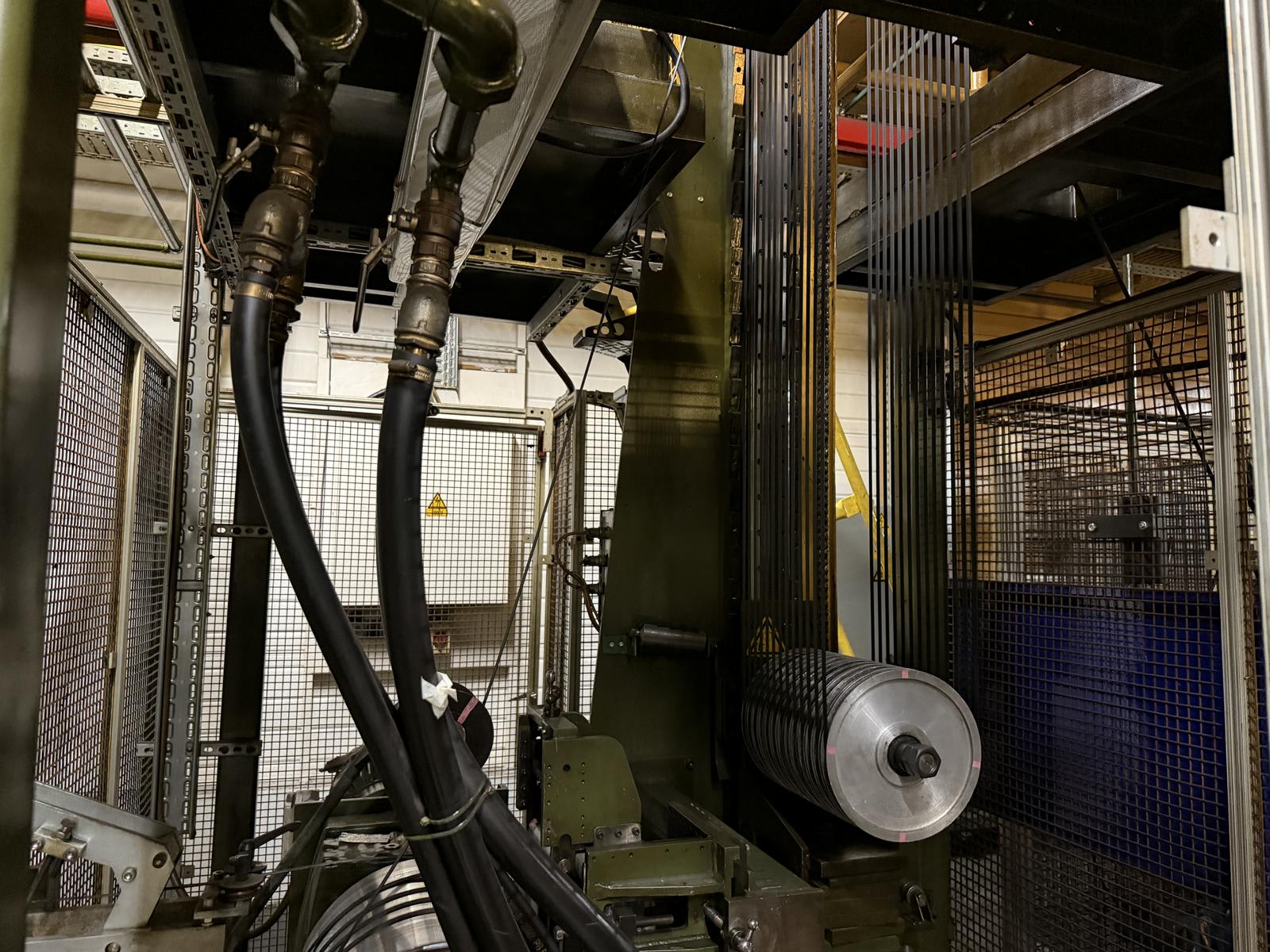

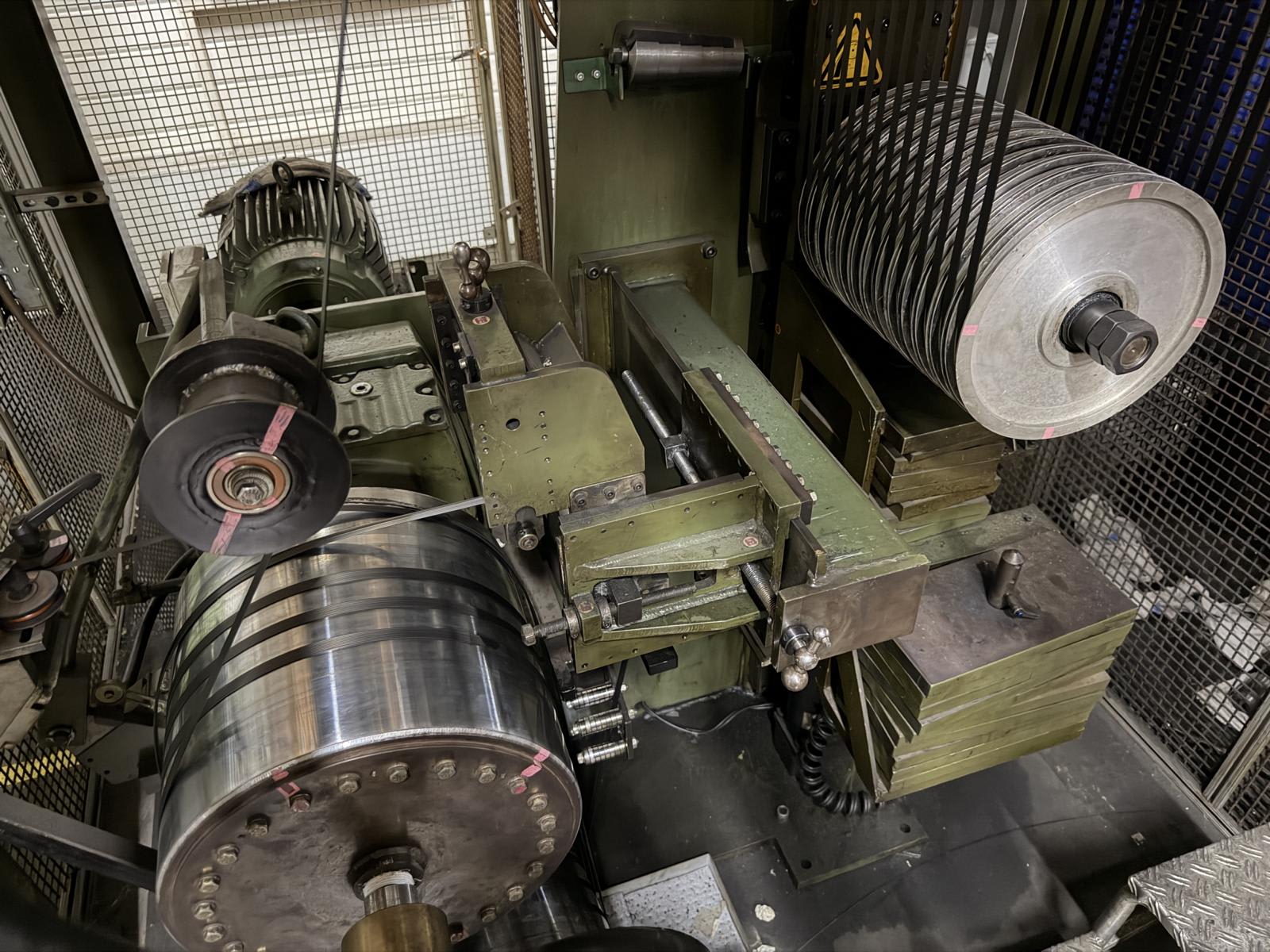

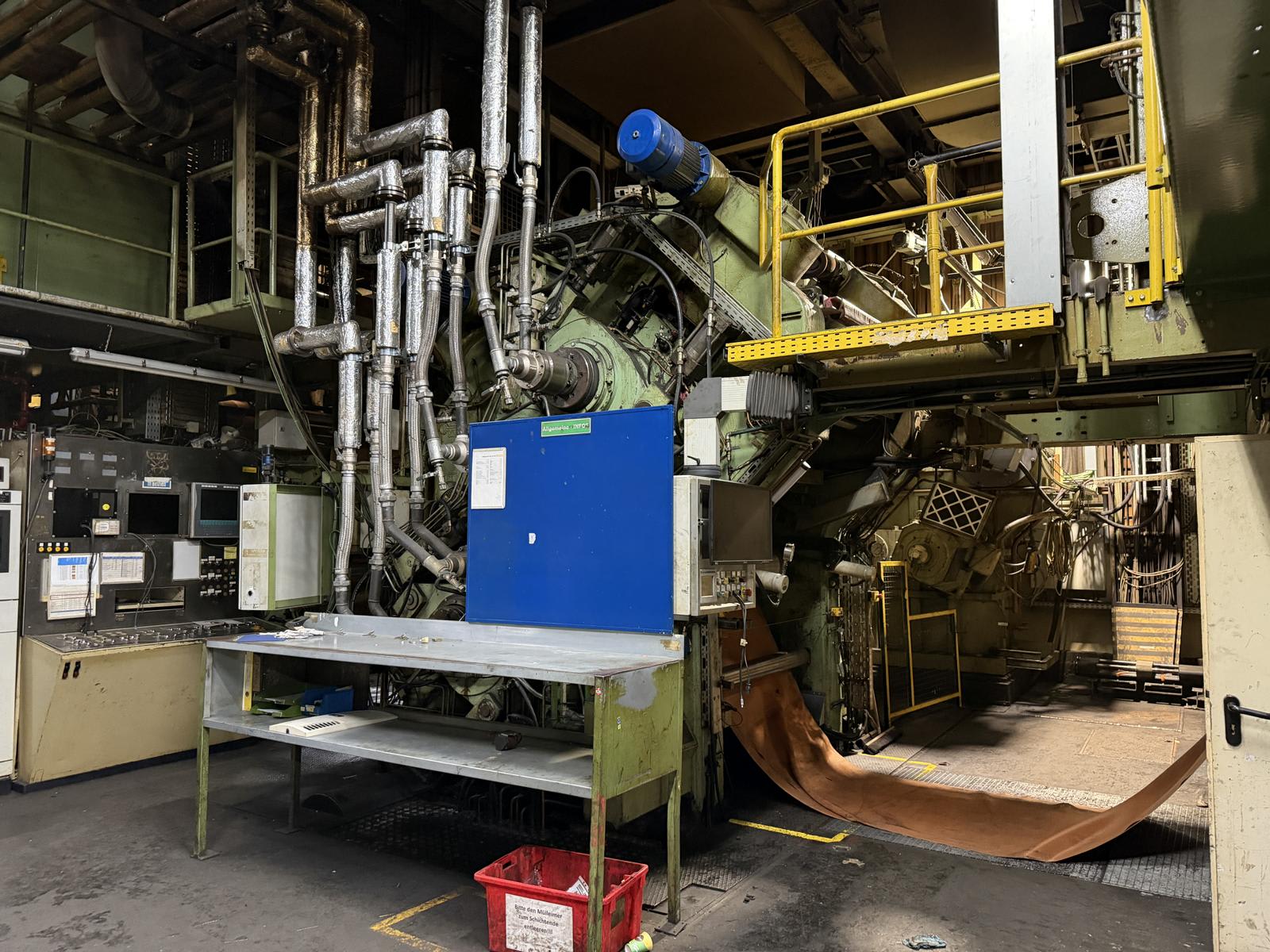

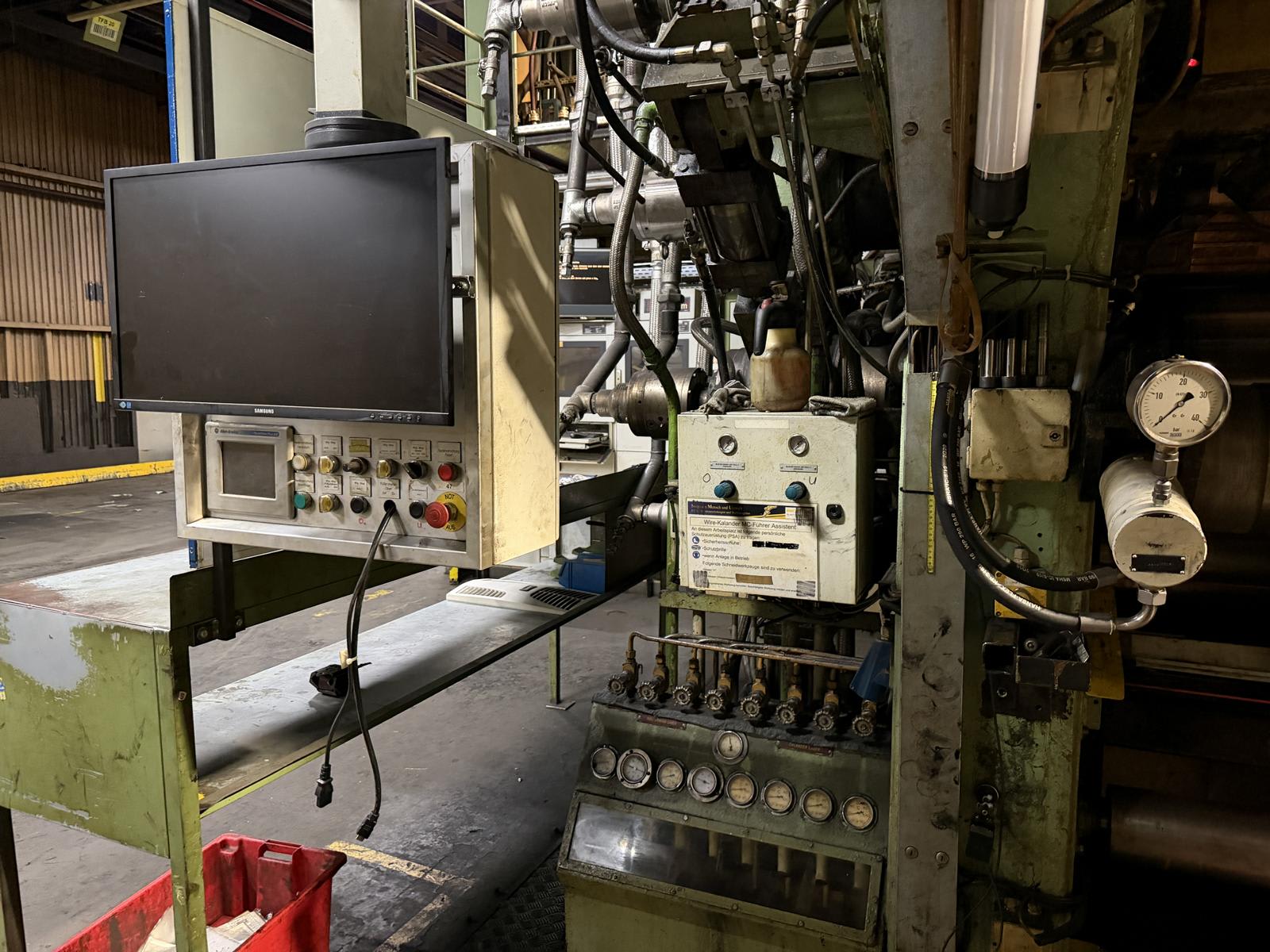

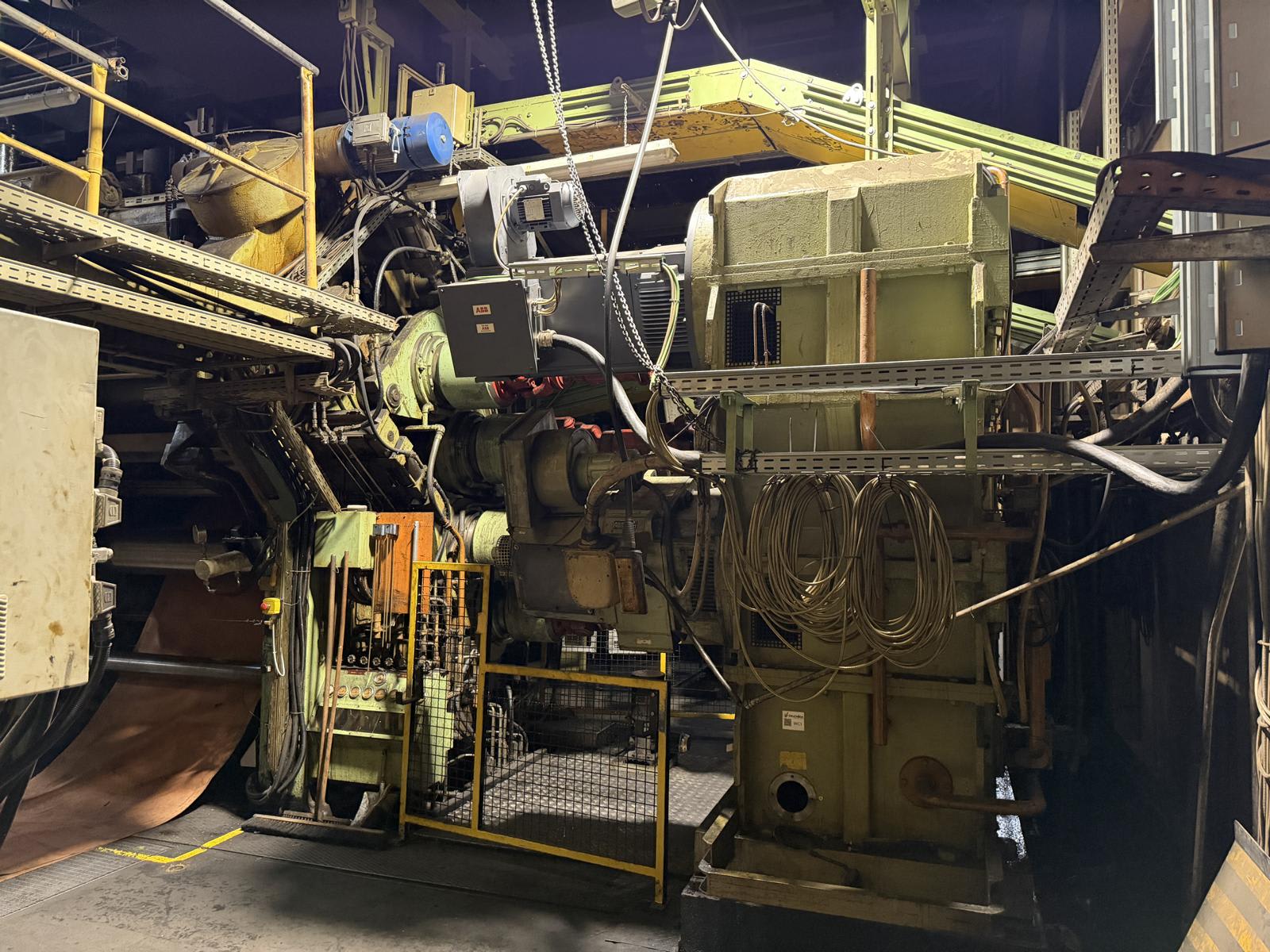

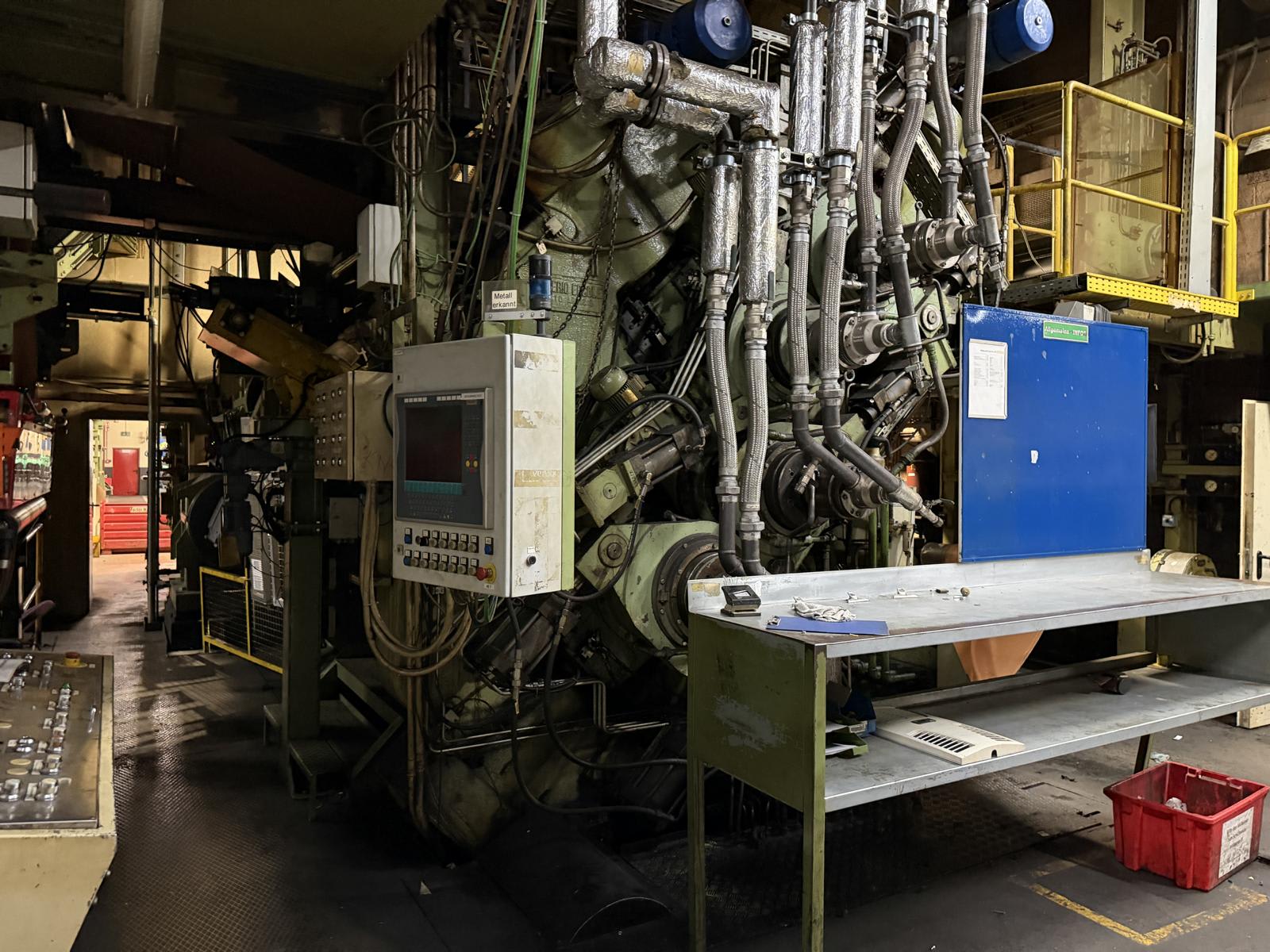

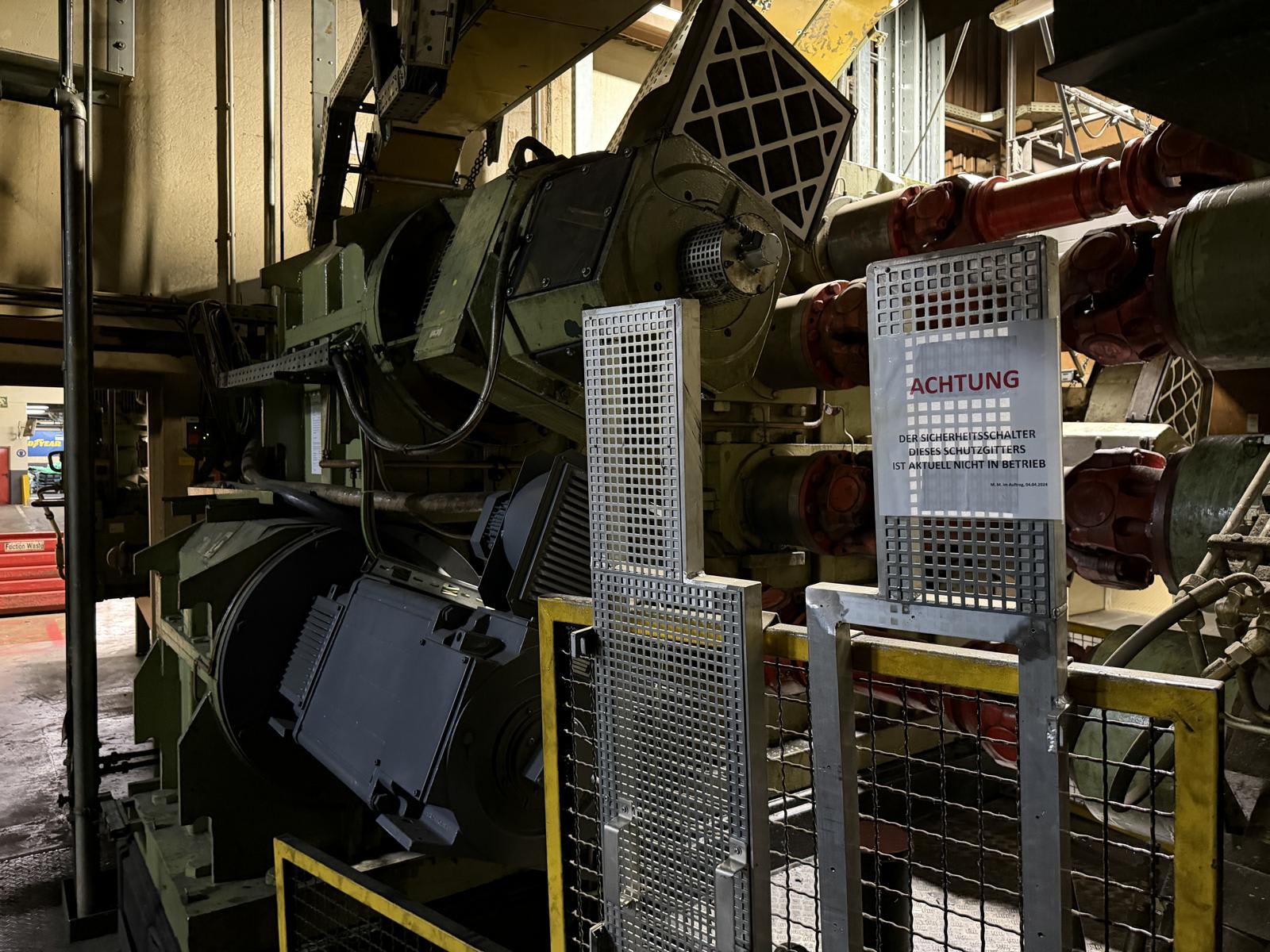

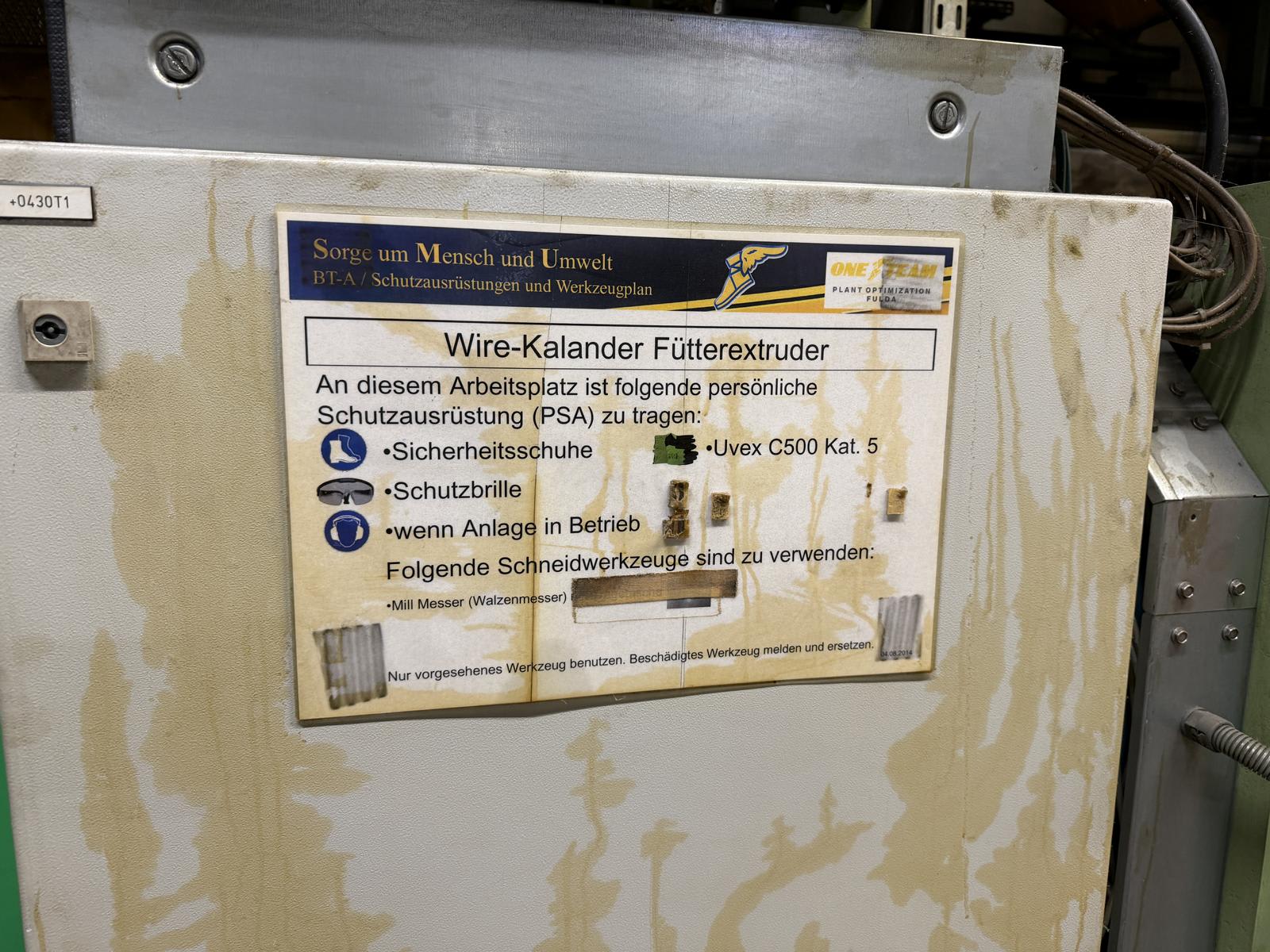

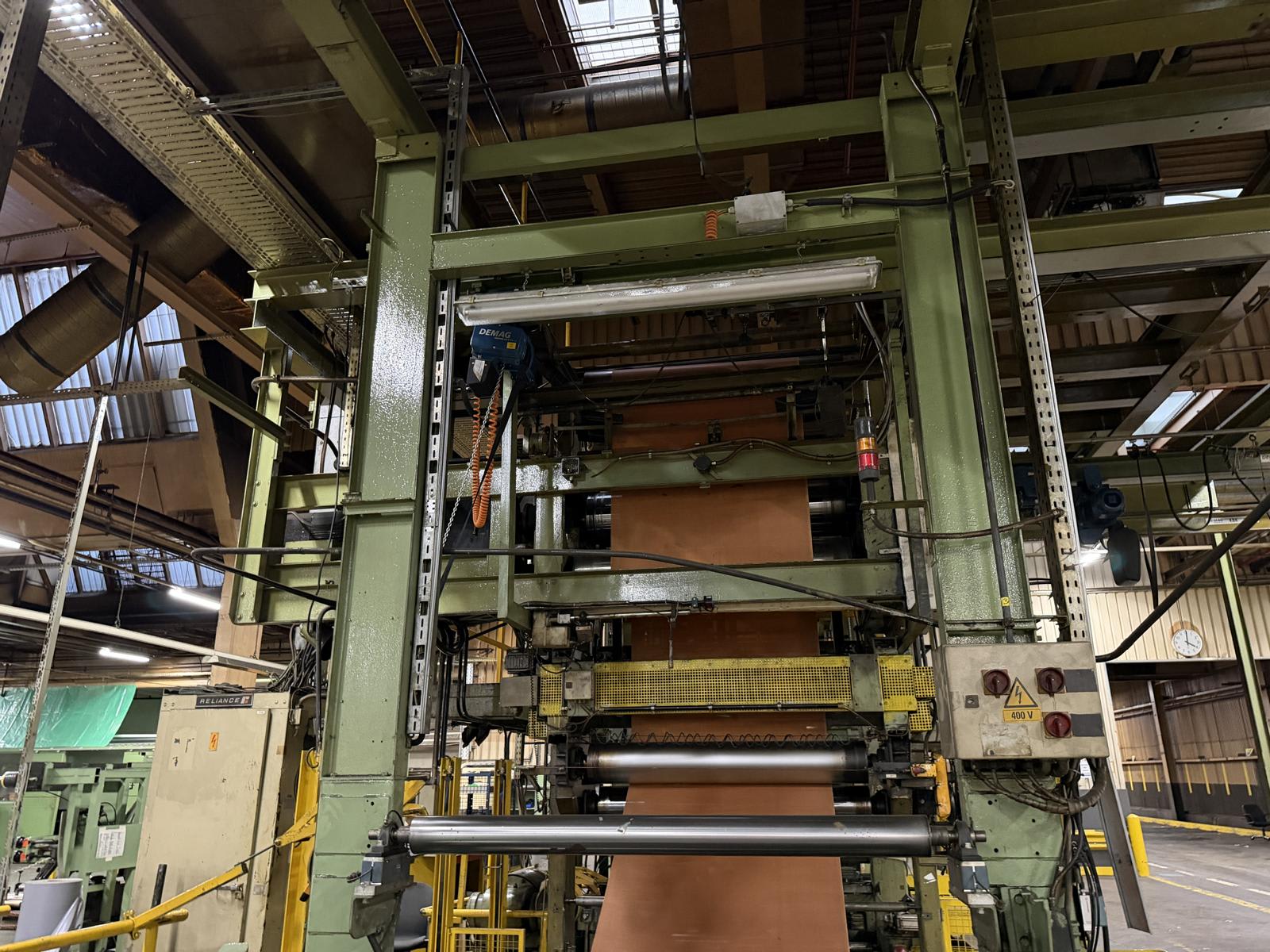

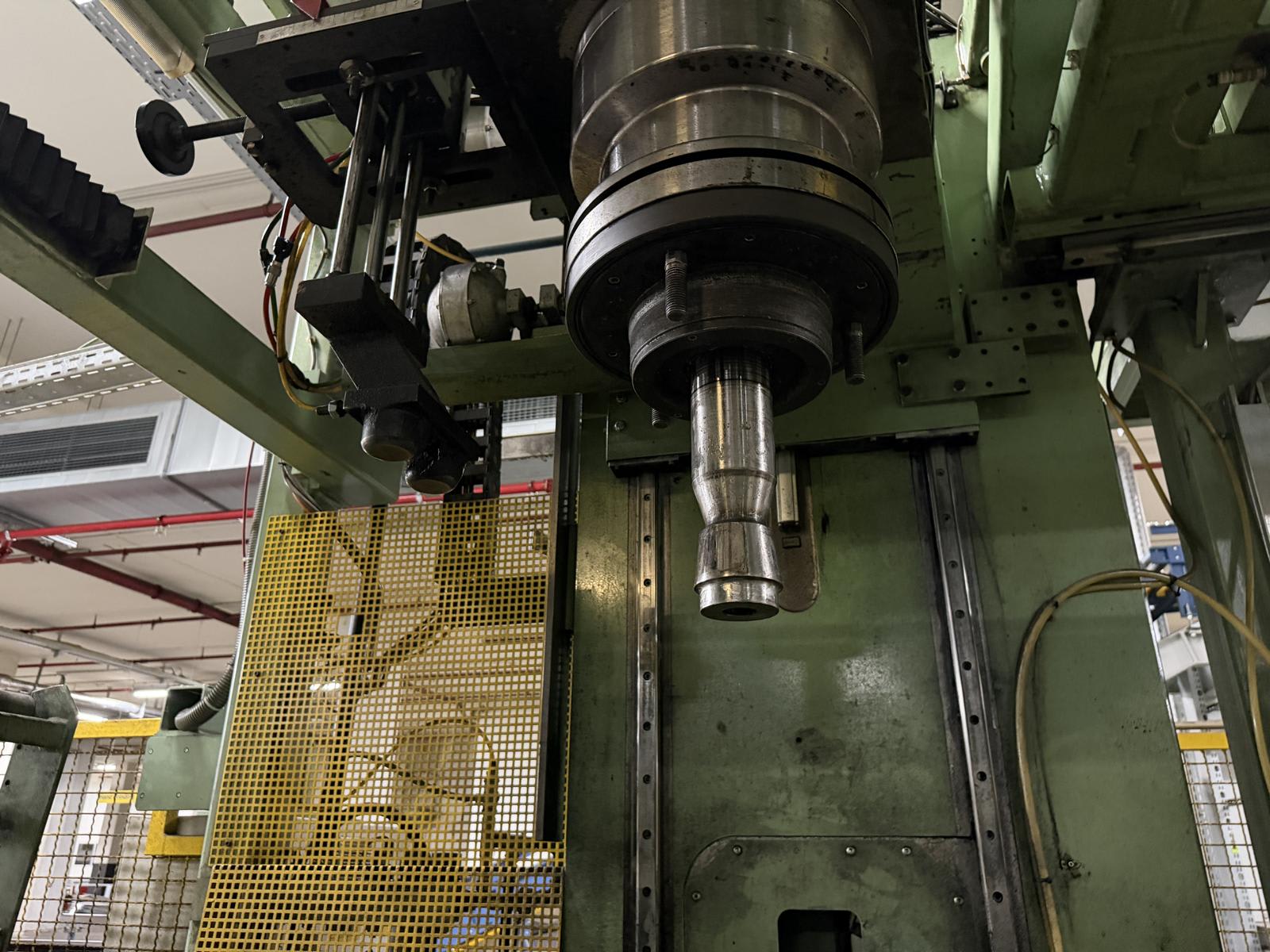

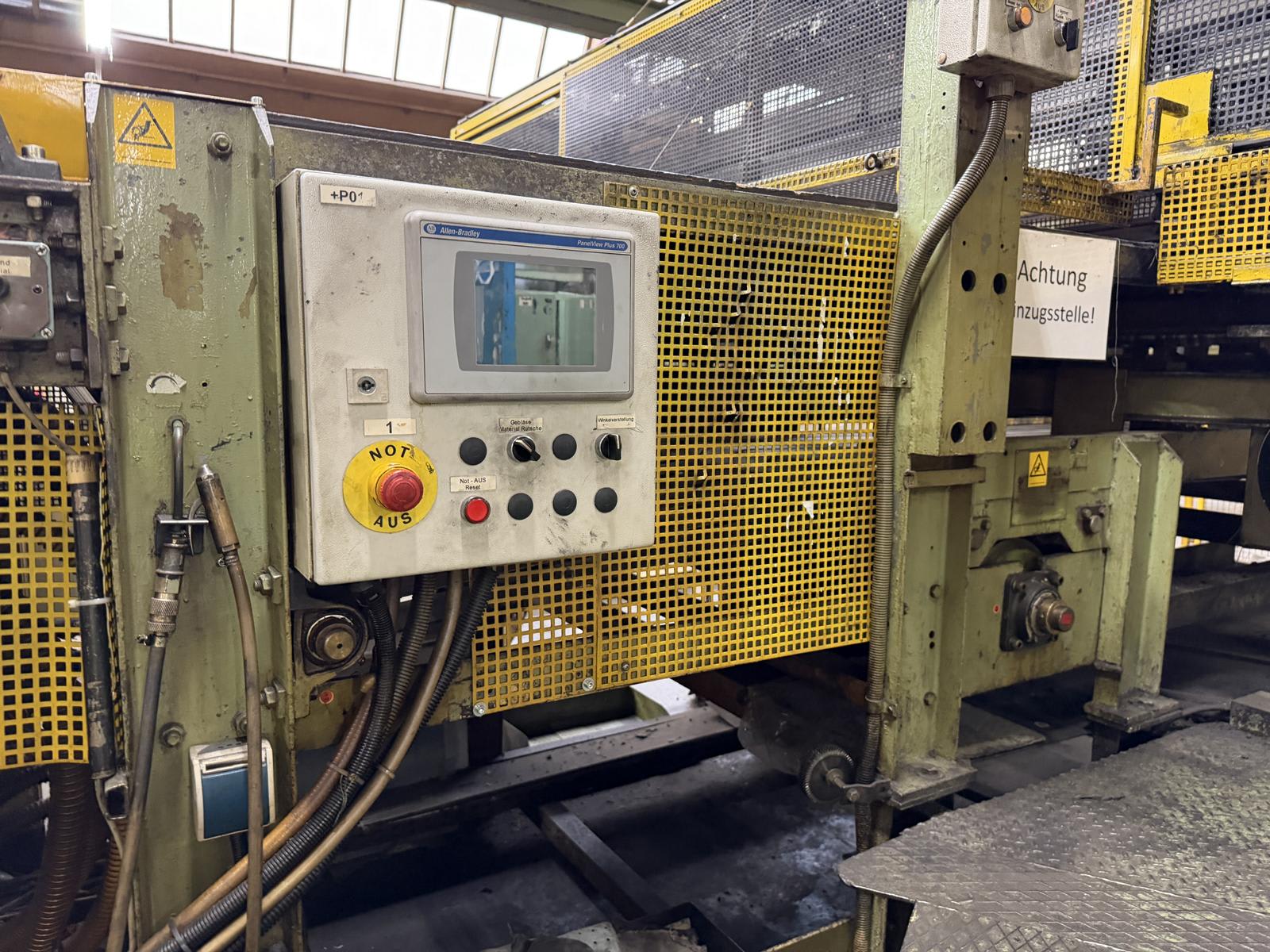

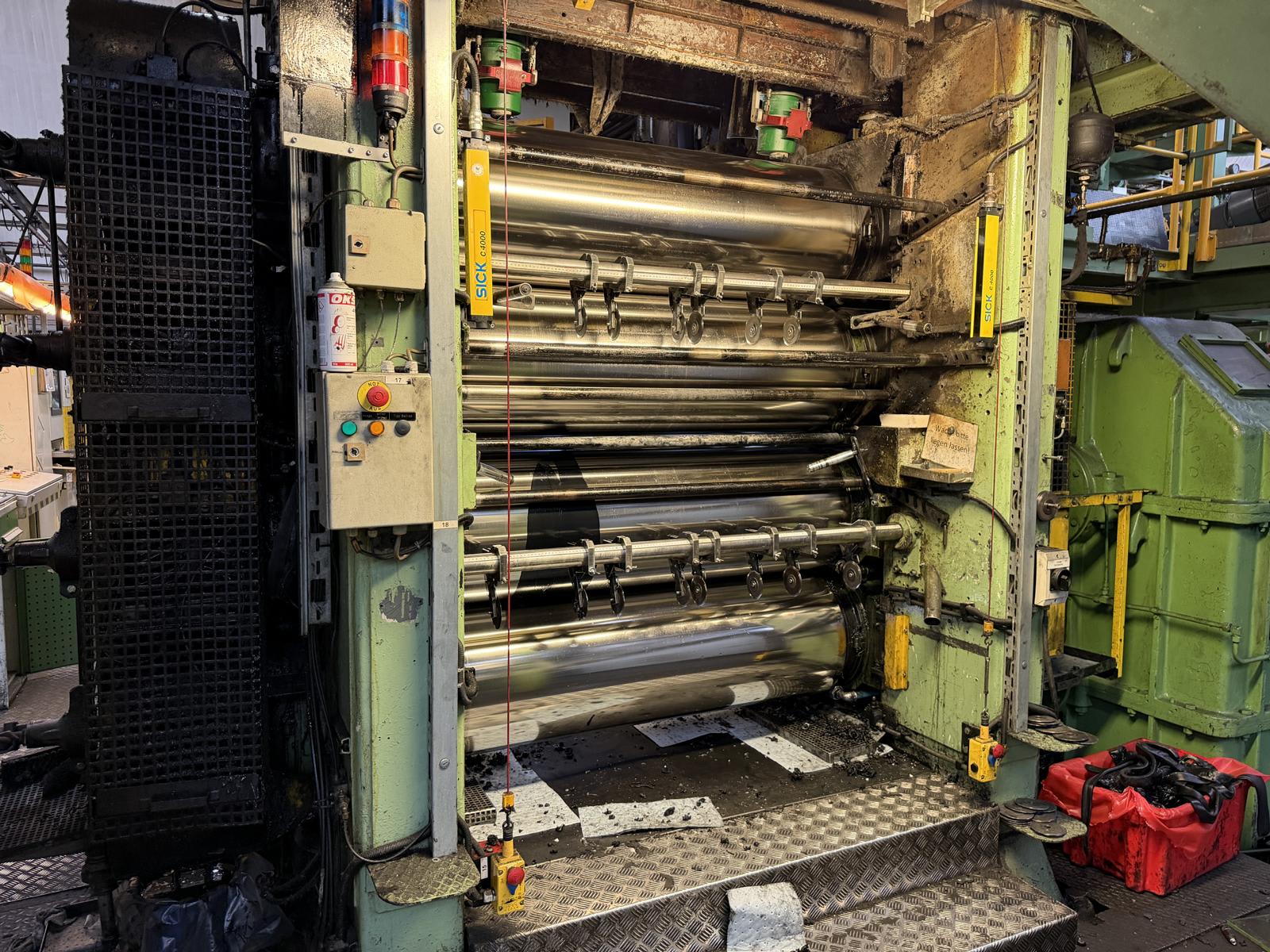

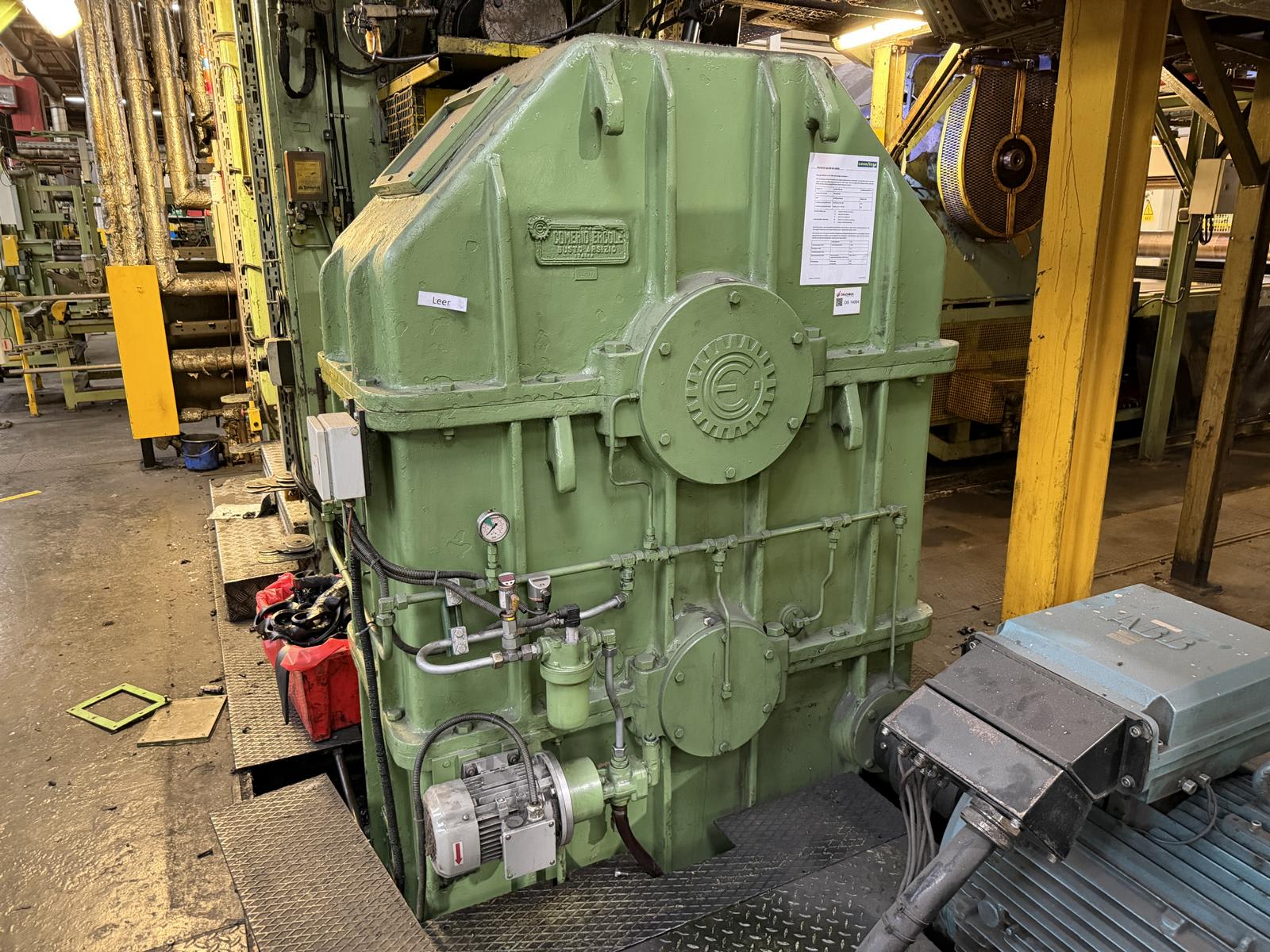

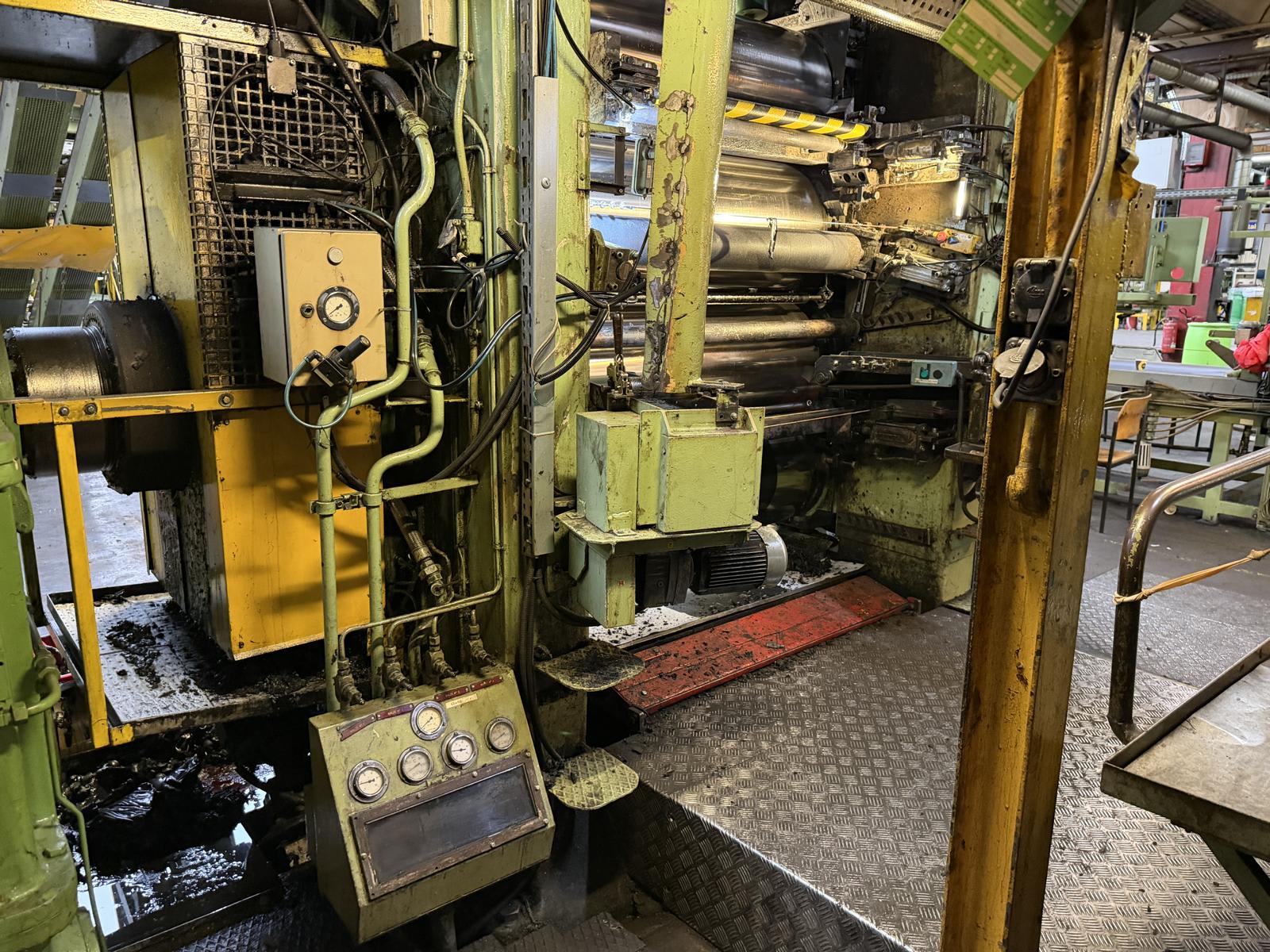

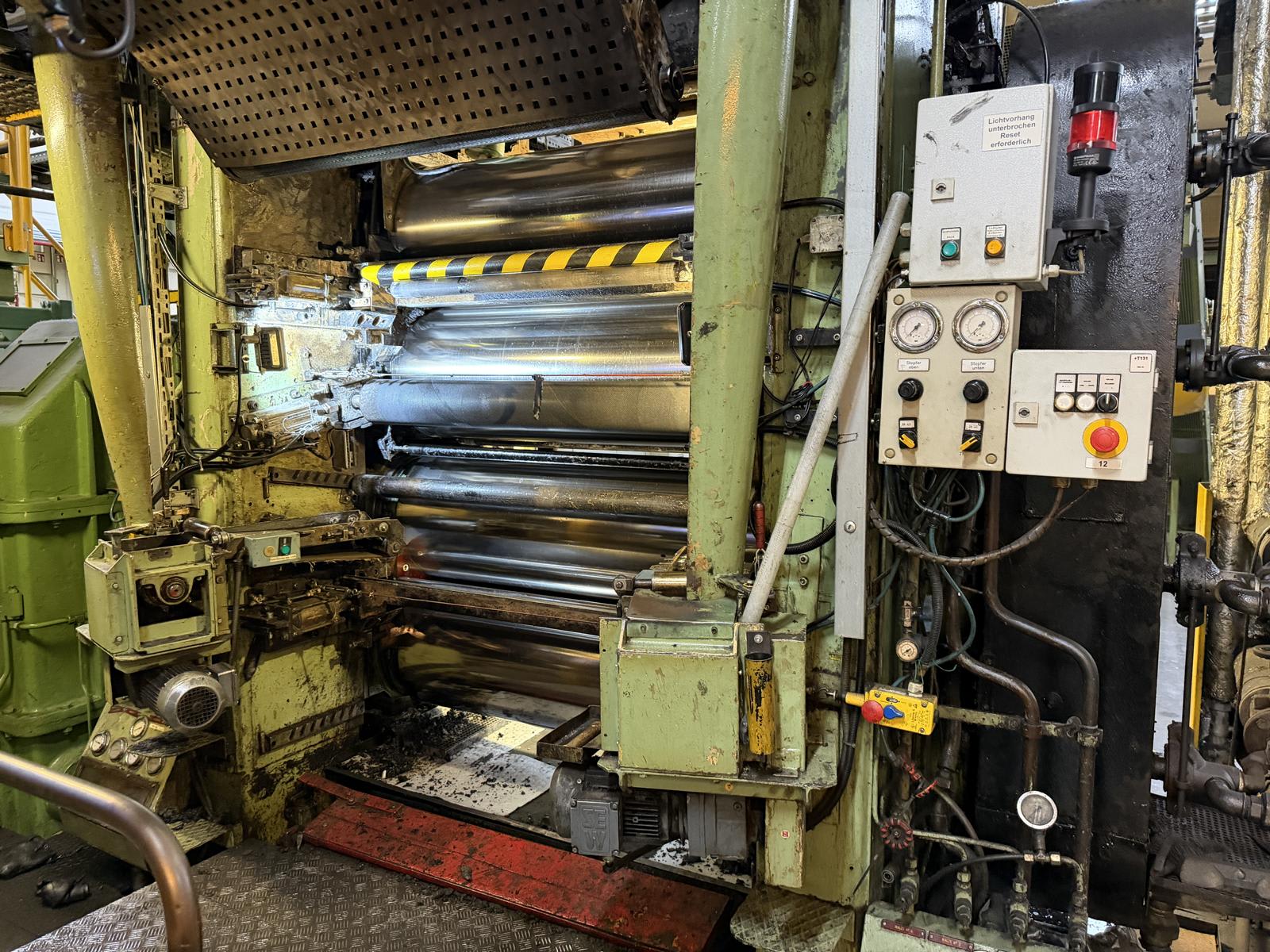

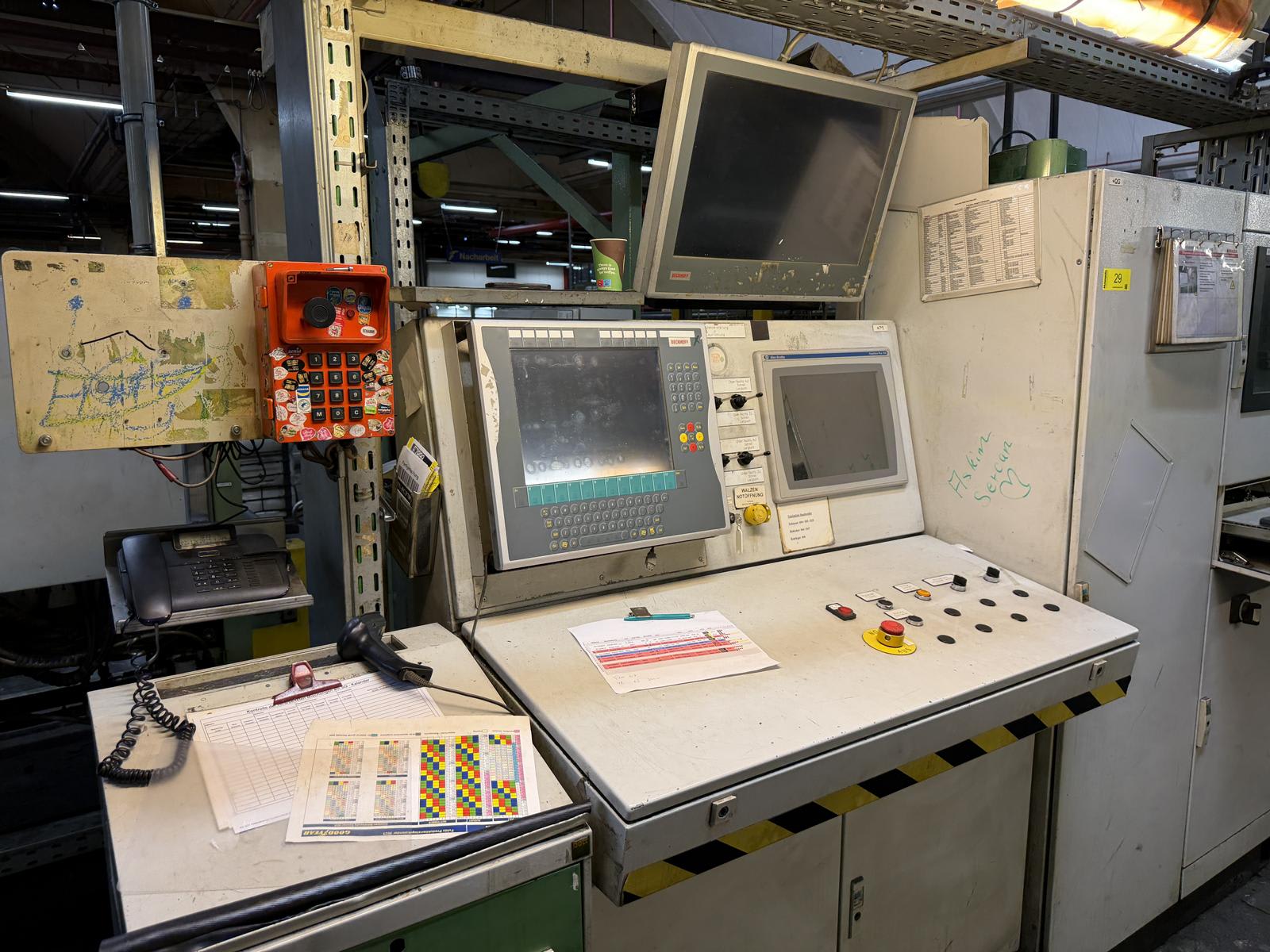

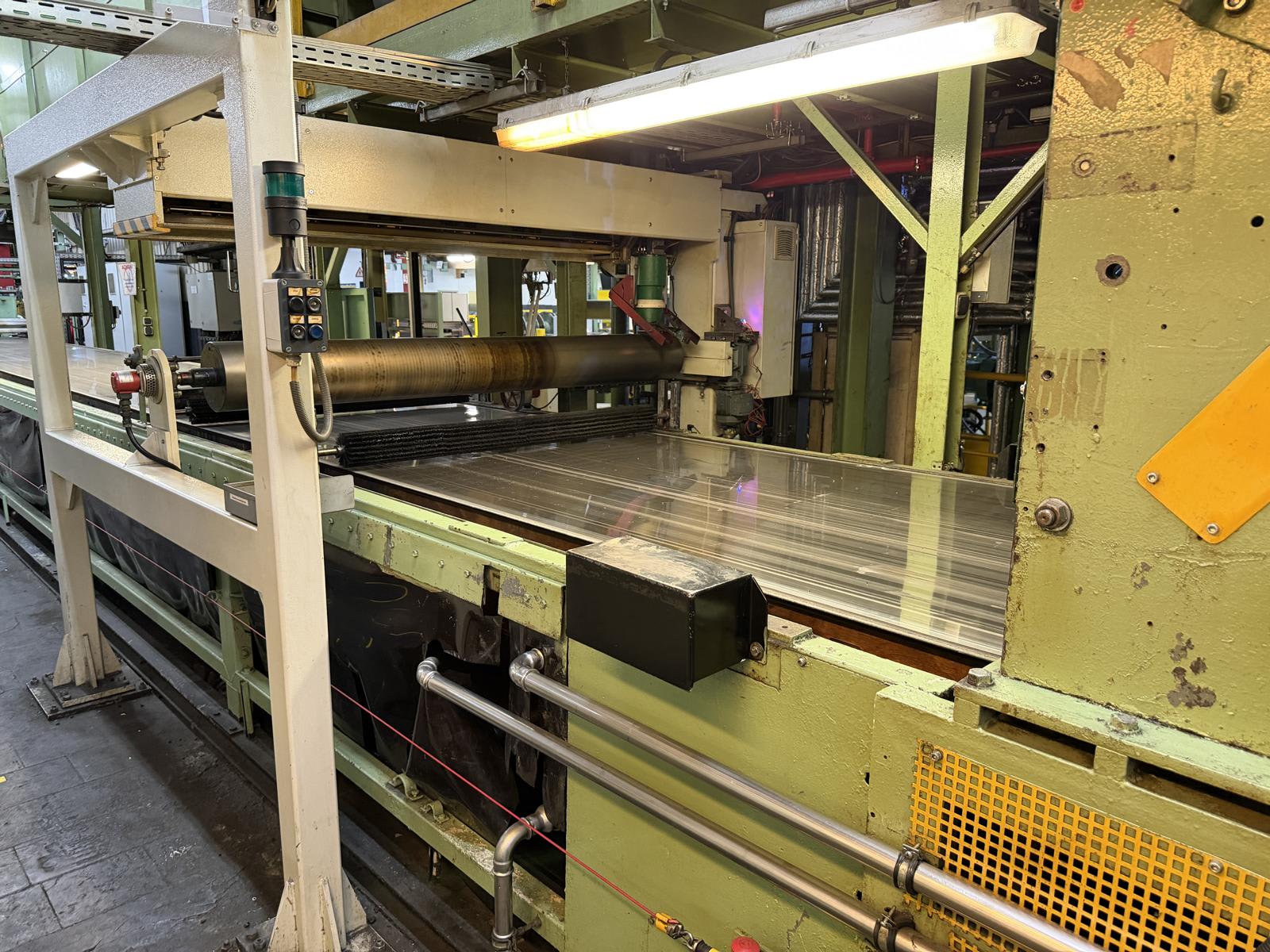

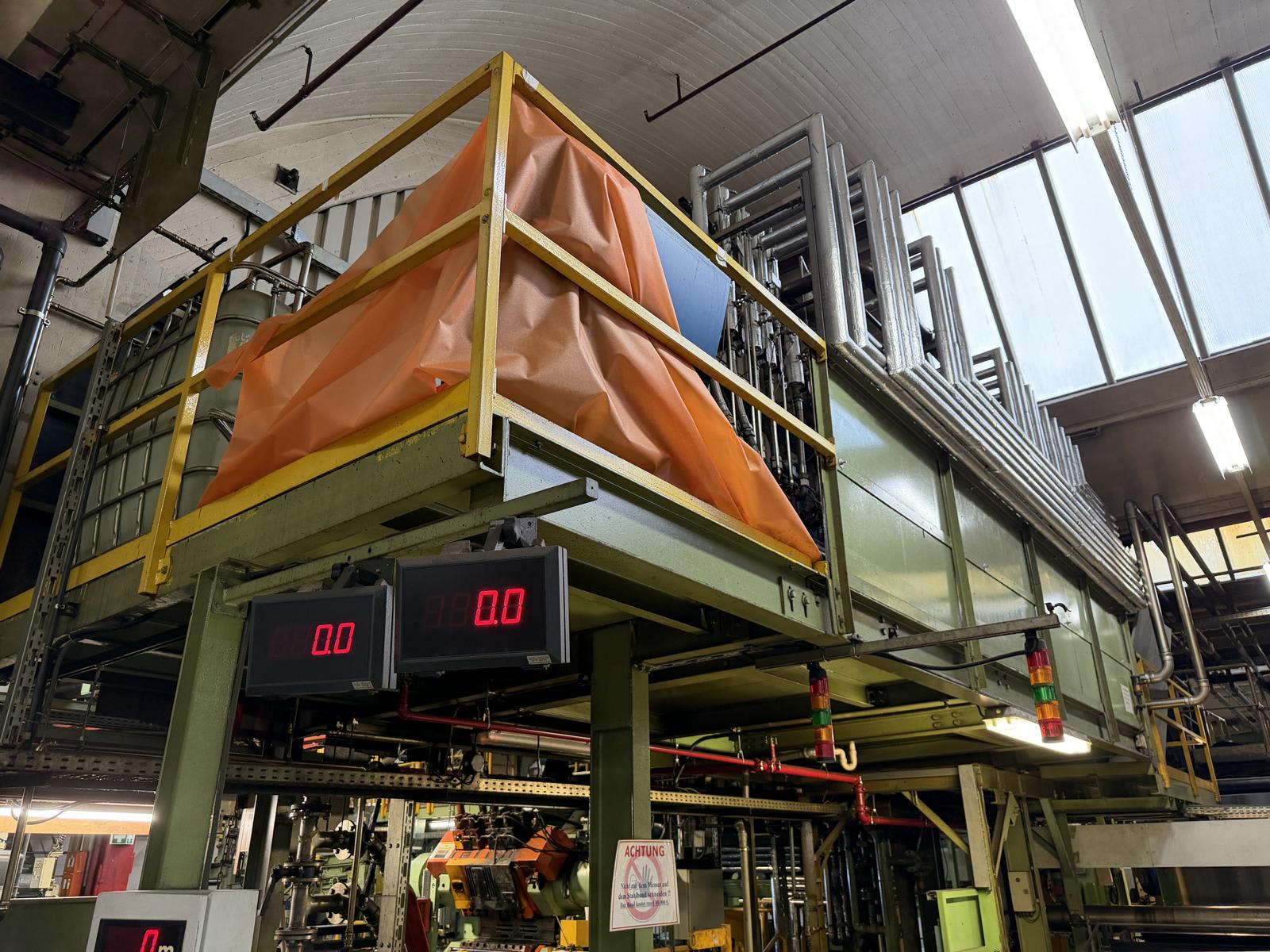

4-Roller Wire Calender Line Comerio | 1973-2024

Binding Handling & Service Fee:

62300 € (EURO)

• 4-roller configuration • Asset description text: “4-WALZEN-Z-KALANDER” • Multiple documented upgrades and overhauls listed (hydraulic overhaul, electronic systems update, control upgrade, pre-warming system, bubble piercing unit, etc.) with cap. dates shown - LISTING 2760022

![Deutsch]()

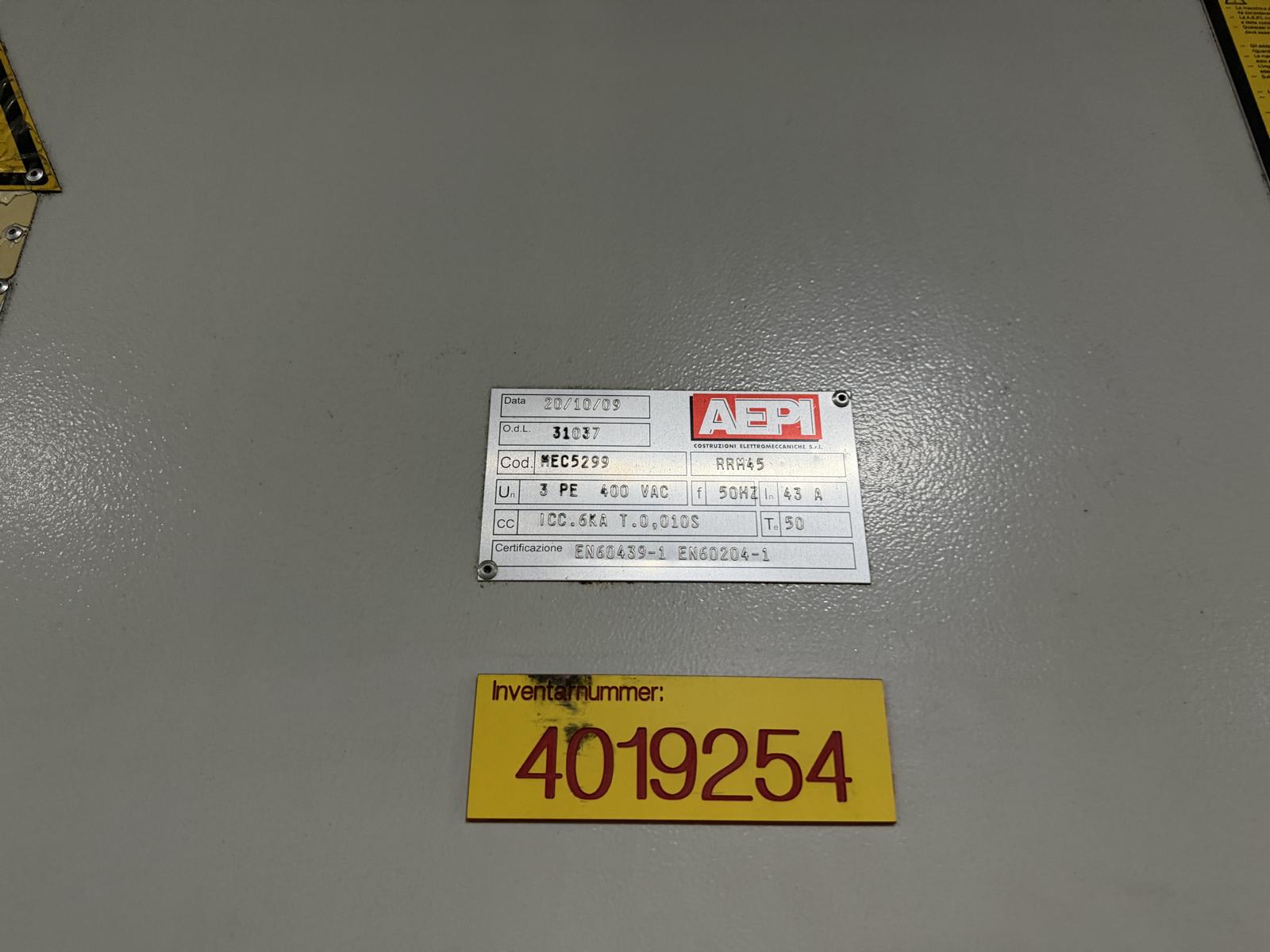

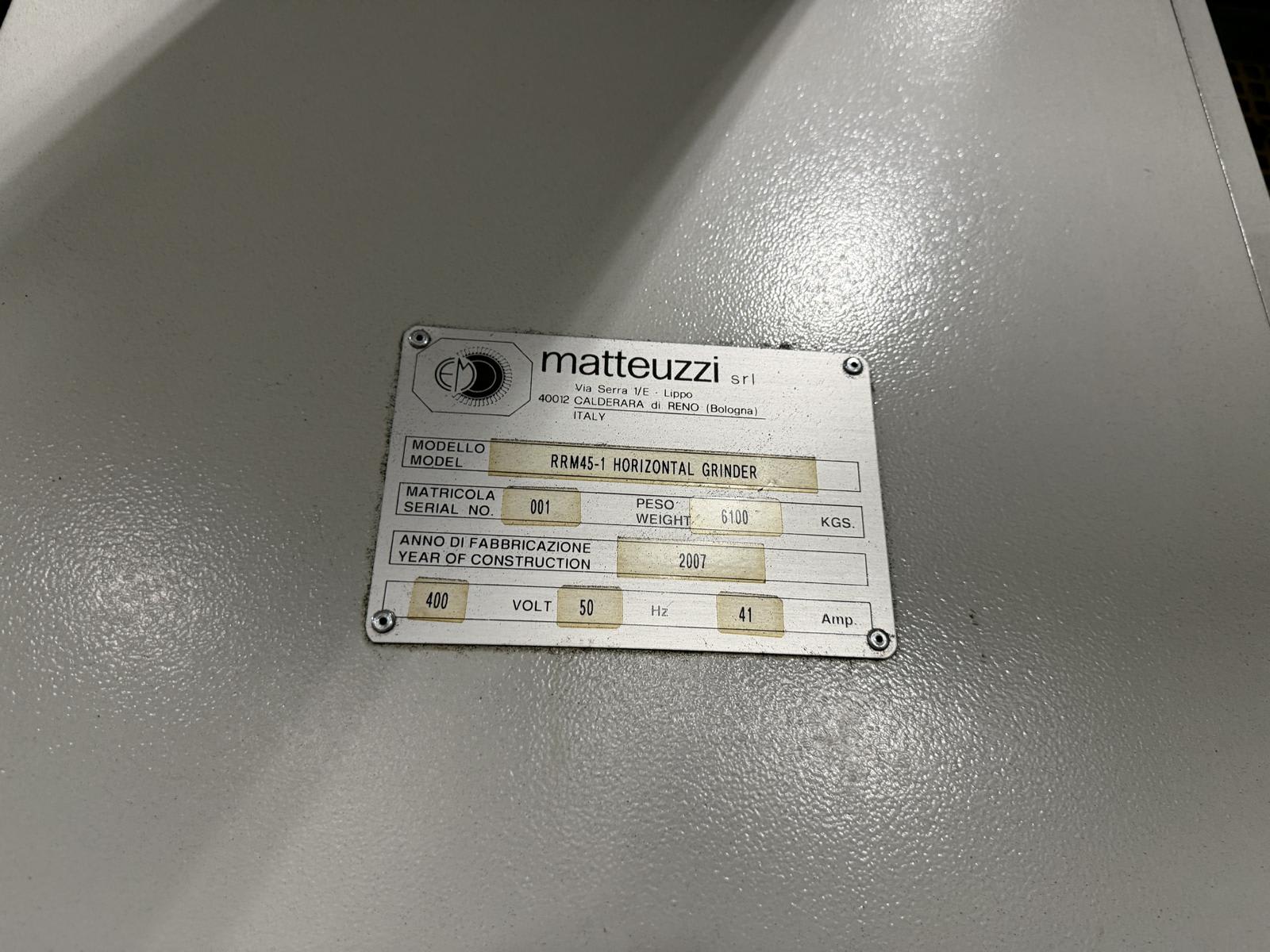

Automatic Horizontal Tire Grinding Machine Matteuzzi RRM45-1 | 2007

Binding Handling & Service Fee:

4600 € (EURO)

Weight: 6,100 kg | Power Supply: 400 V / 50 Hz / 41 A | Control Unit: Allen-Bradley PanelView Plus 1000 | Workholding: Horizontal rotating chuck | Conveyor System: Integrated roller conveyor (in-feed/out-feed) - LISTING 2760023

![Deutsch]()

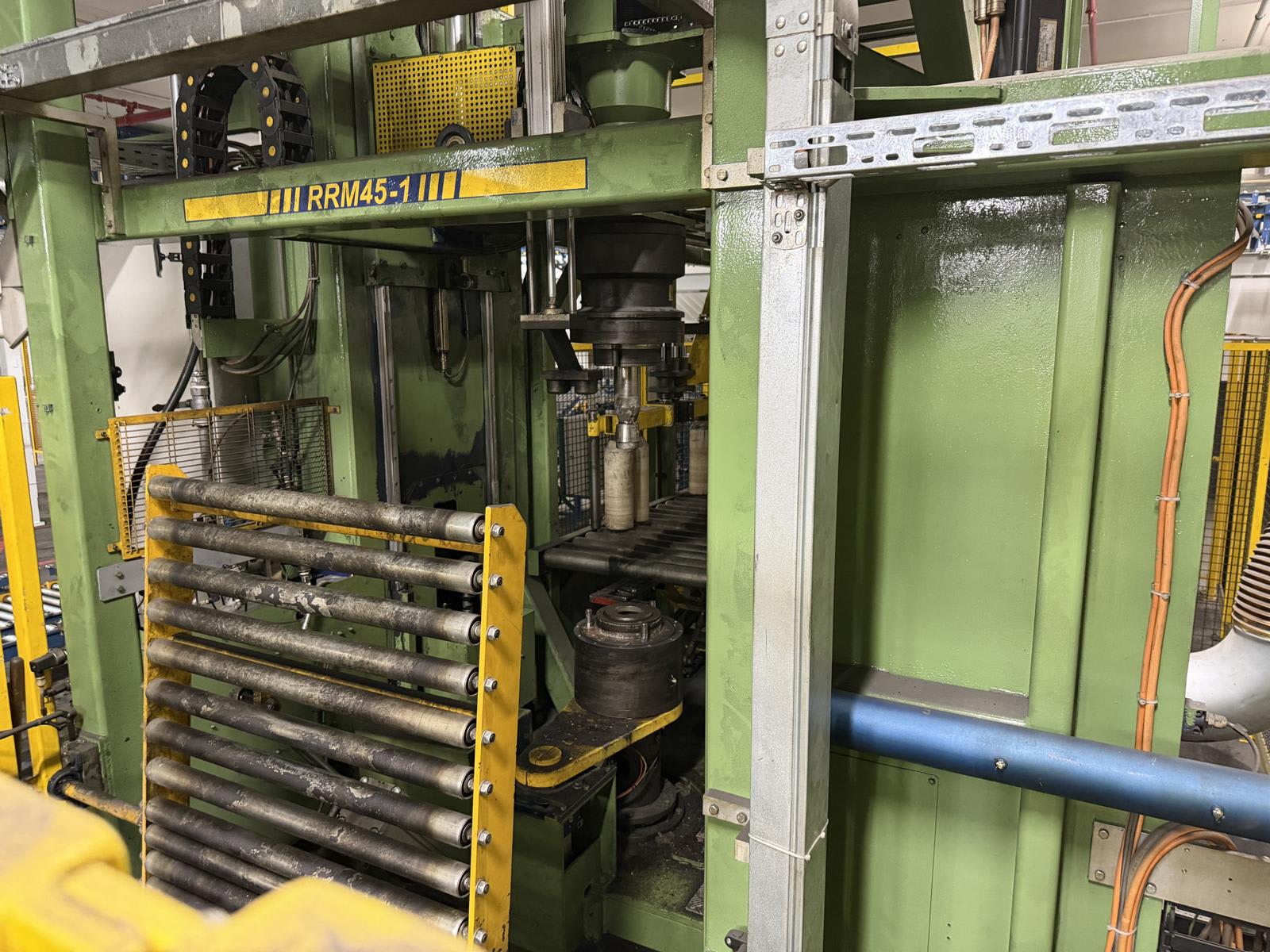

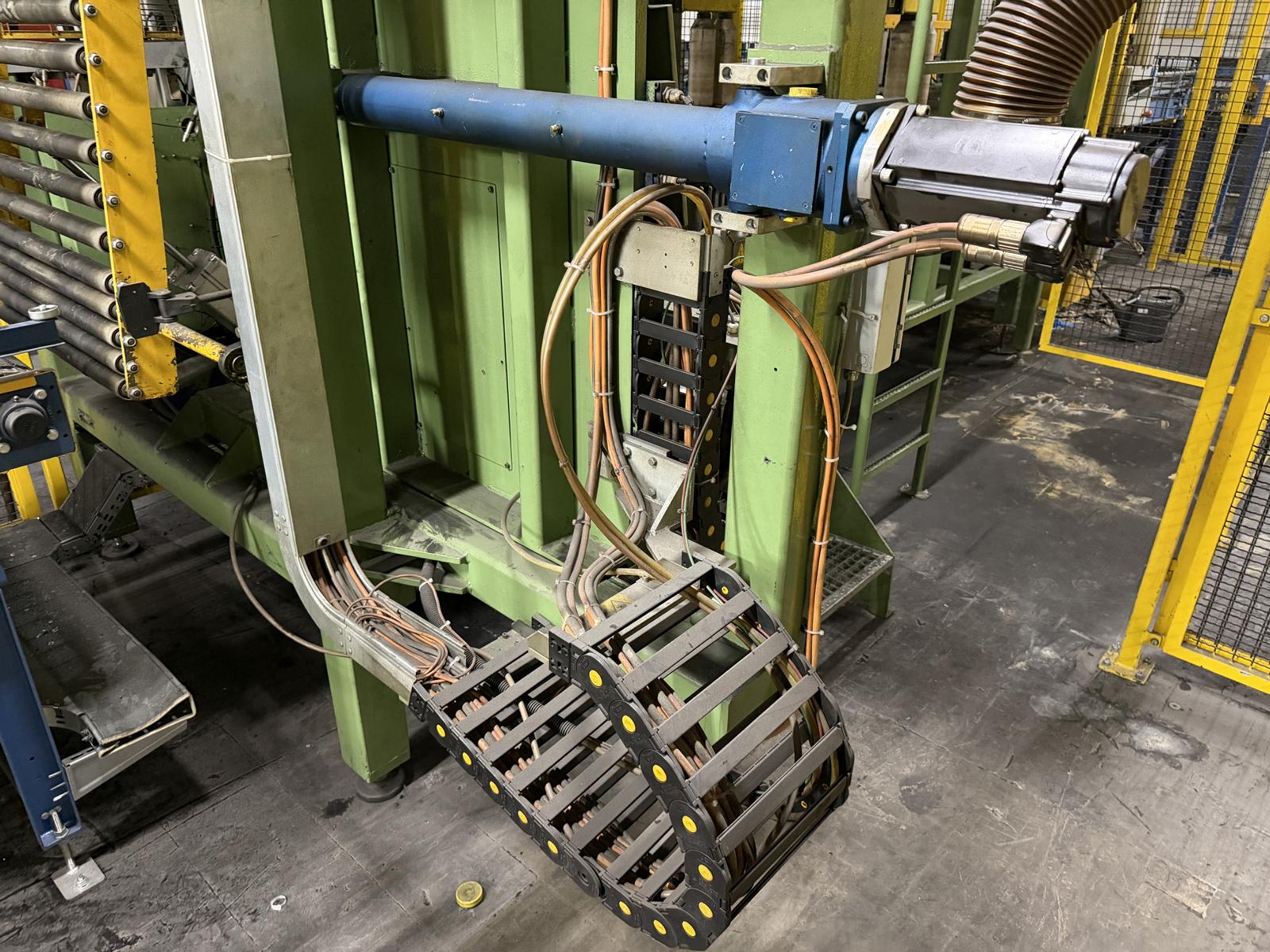

Automatic Horizontal Tire Grinding Machine Matteuzzi RRM45/1 | 2009

Binding Handling & Service Fee:

4600 € (EURO)

Weight: 6,100 kg Power Supply: 400 V / 50 Hz / 39 A Control Unit: Allen-Bradley PanelView Plus 1000 Touchscreen Workholding: Horizontal rotating chuck/clamping system Material Handling: Integrated roller conveyor with vertical centering rollers - LISTING 2760024

![Deutsch]()

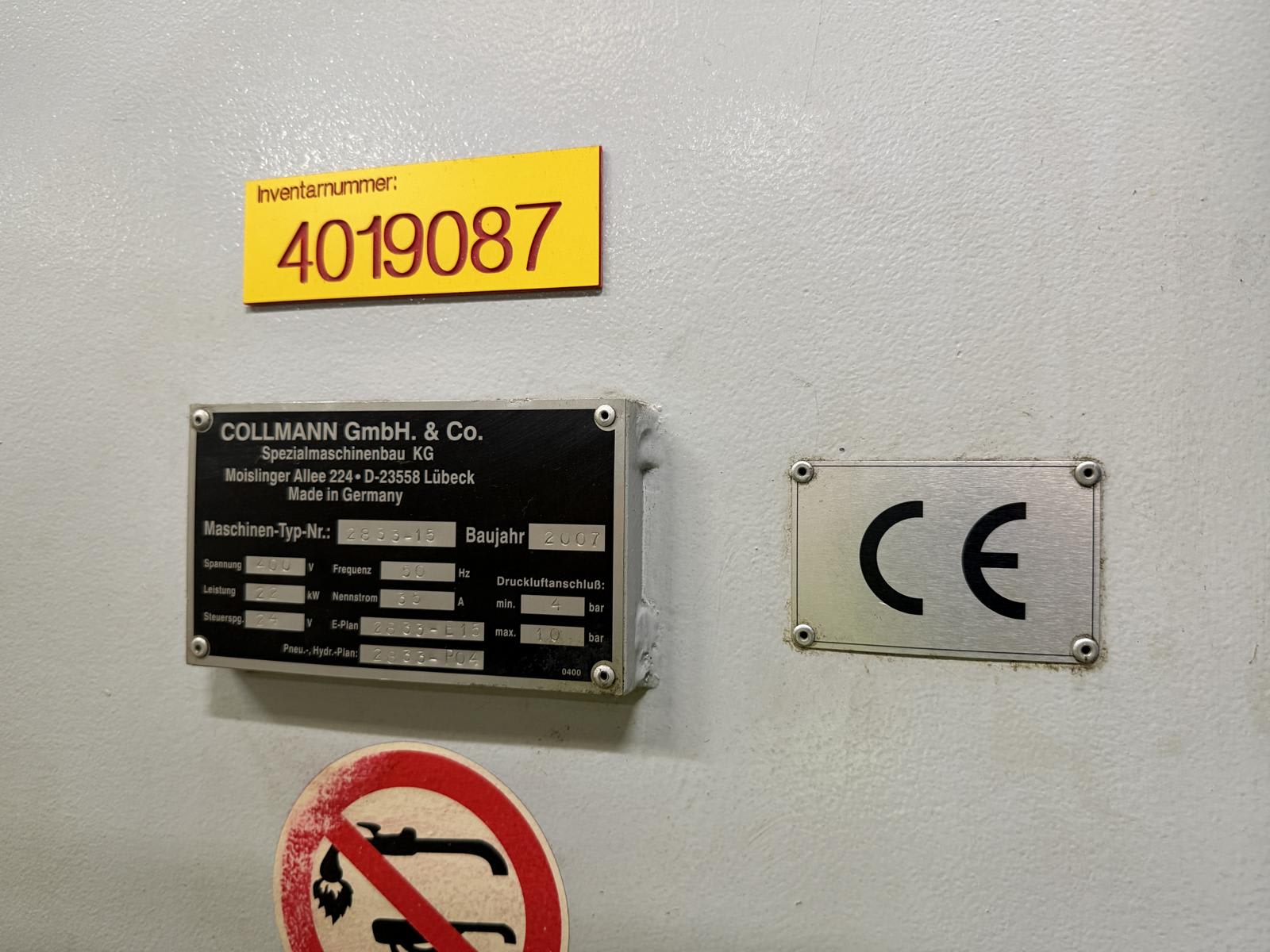

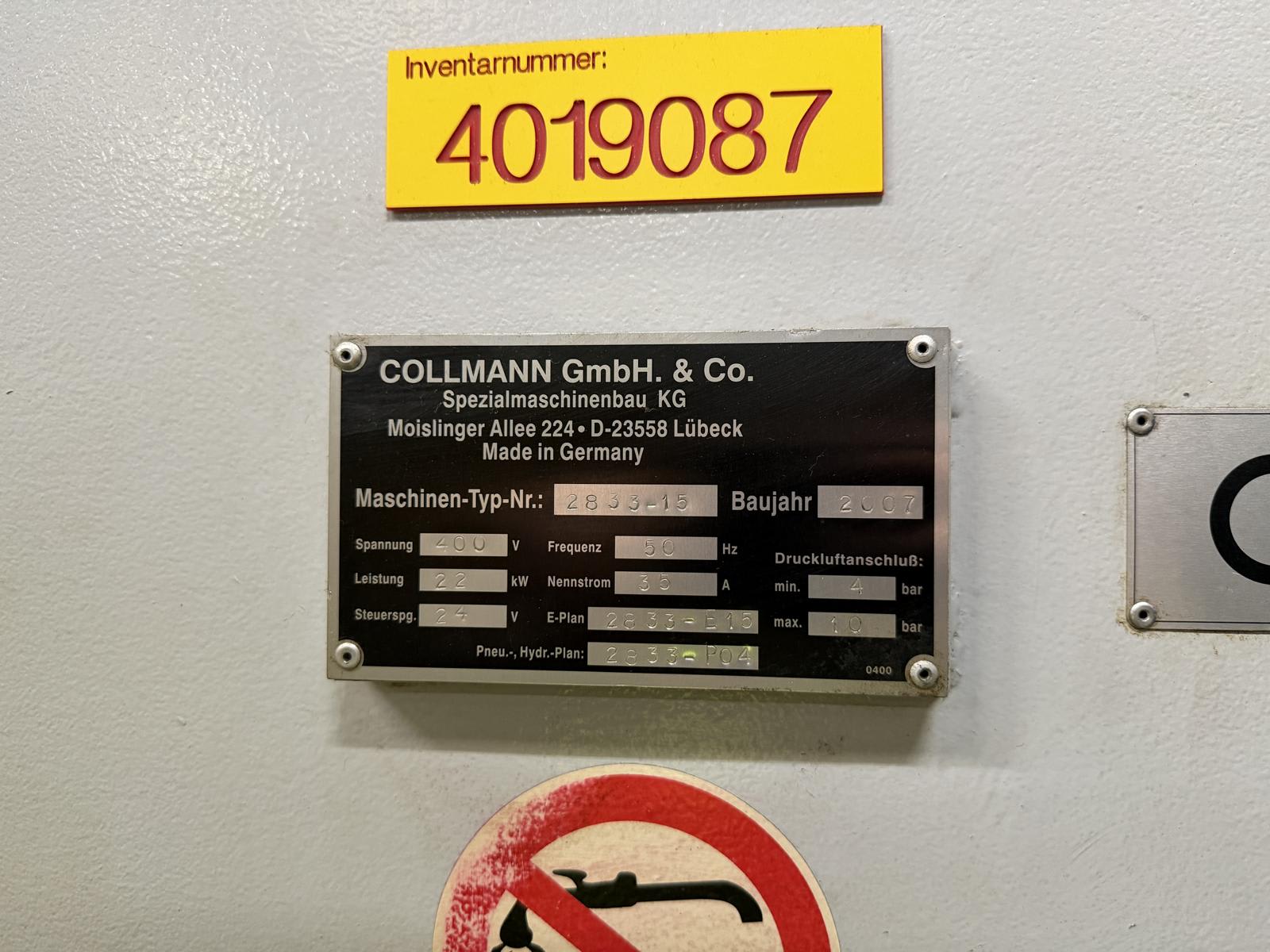

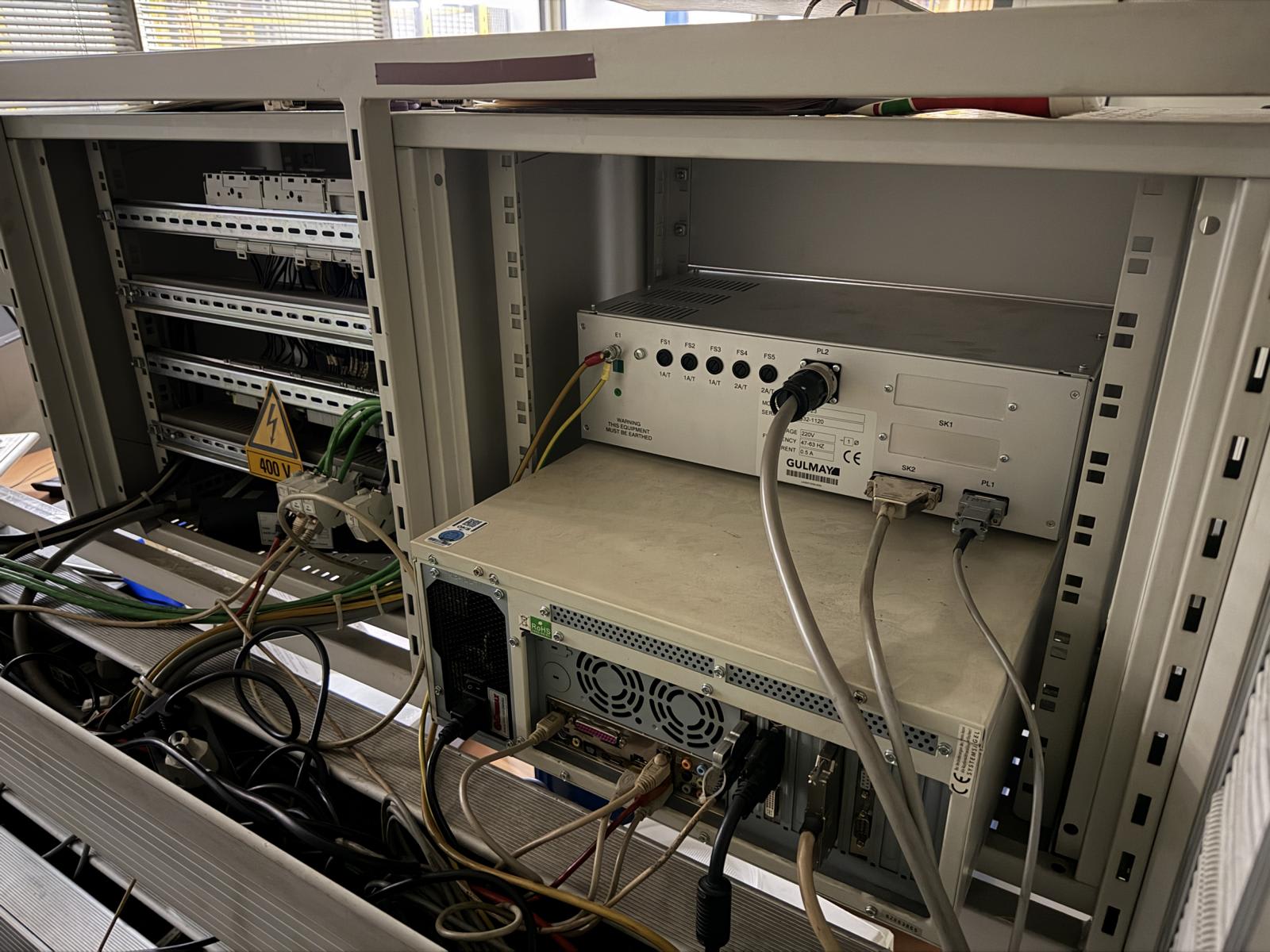

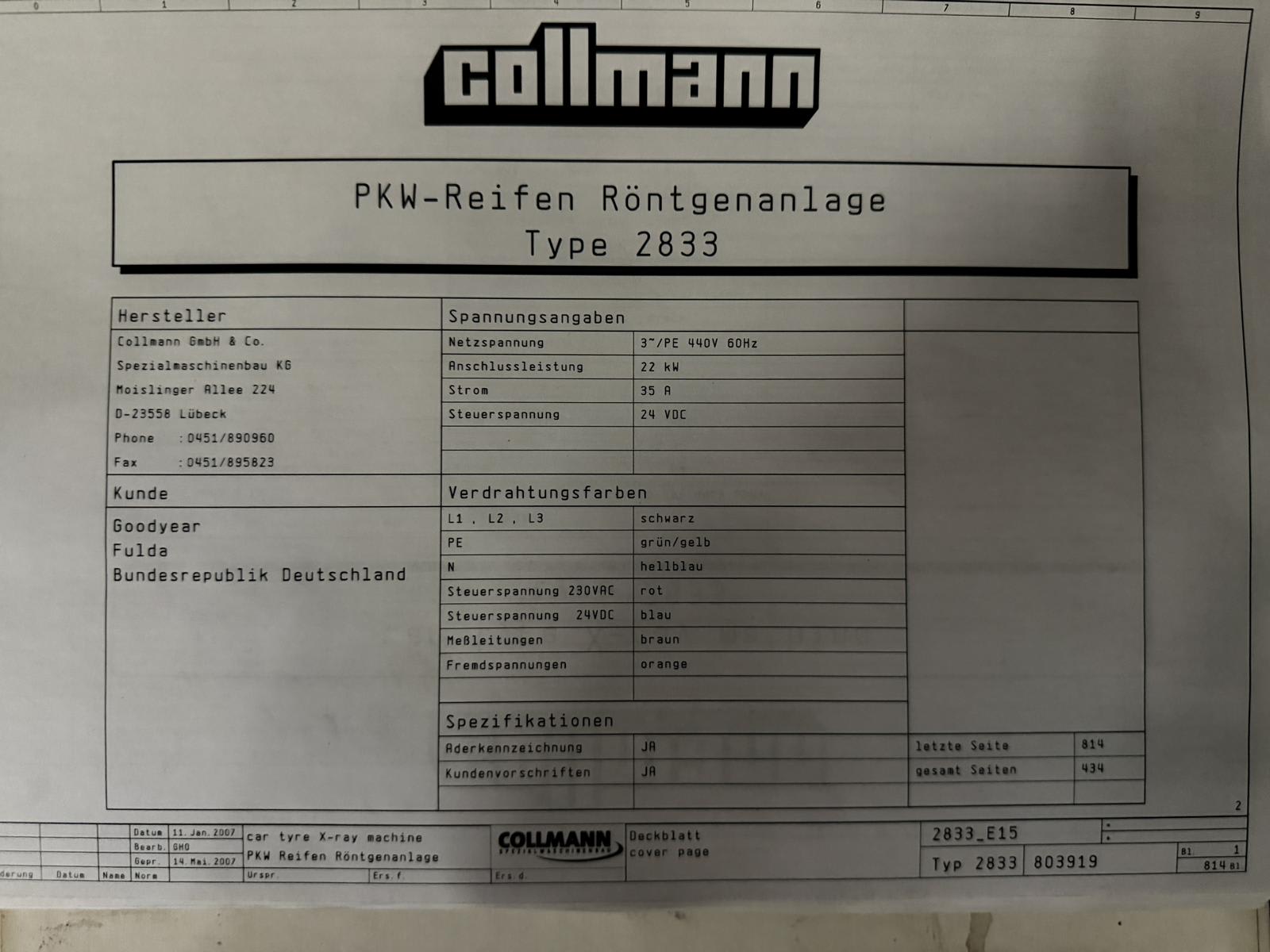

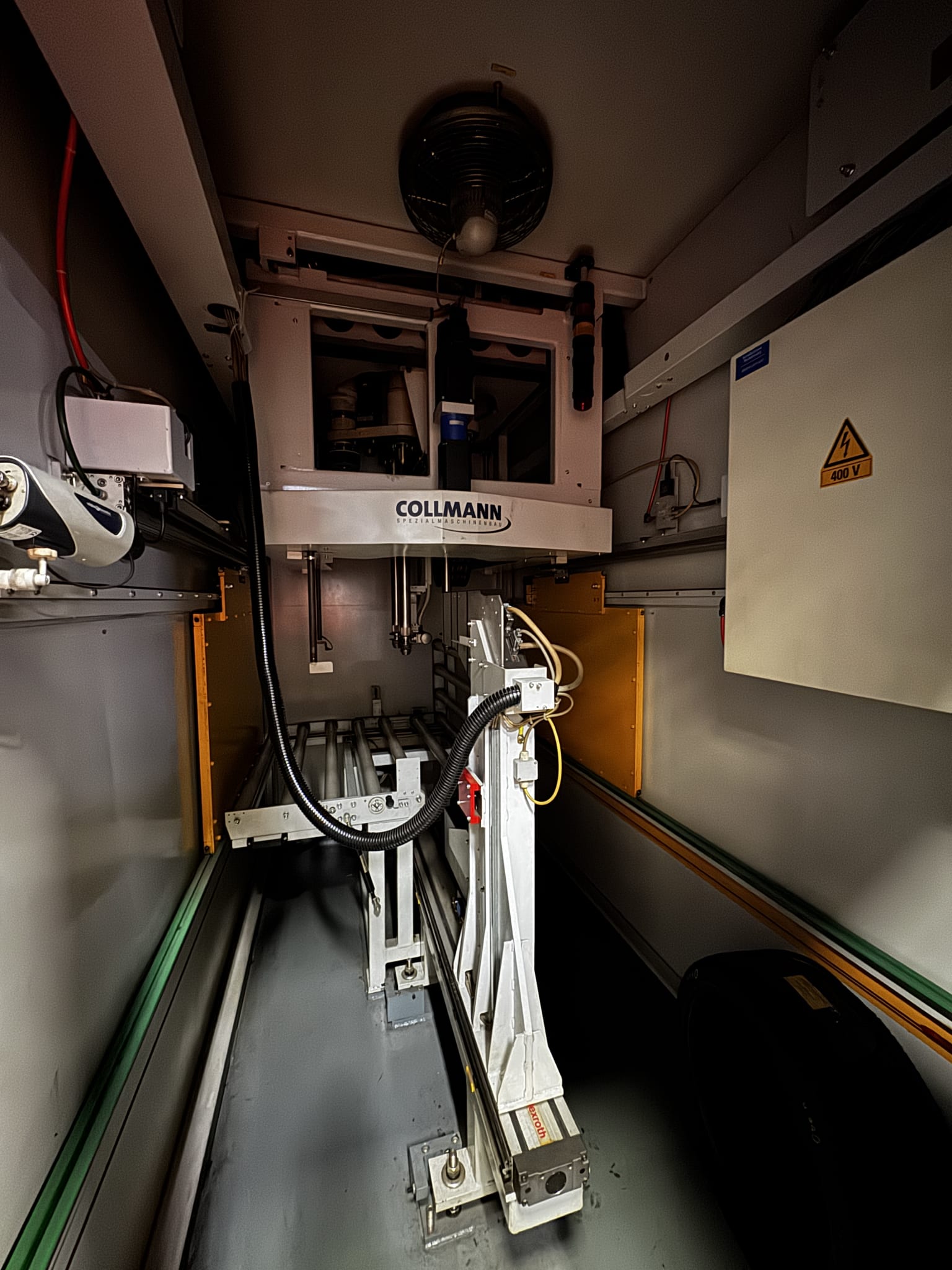

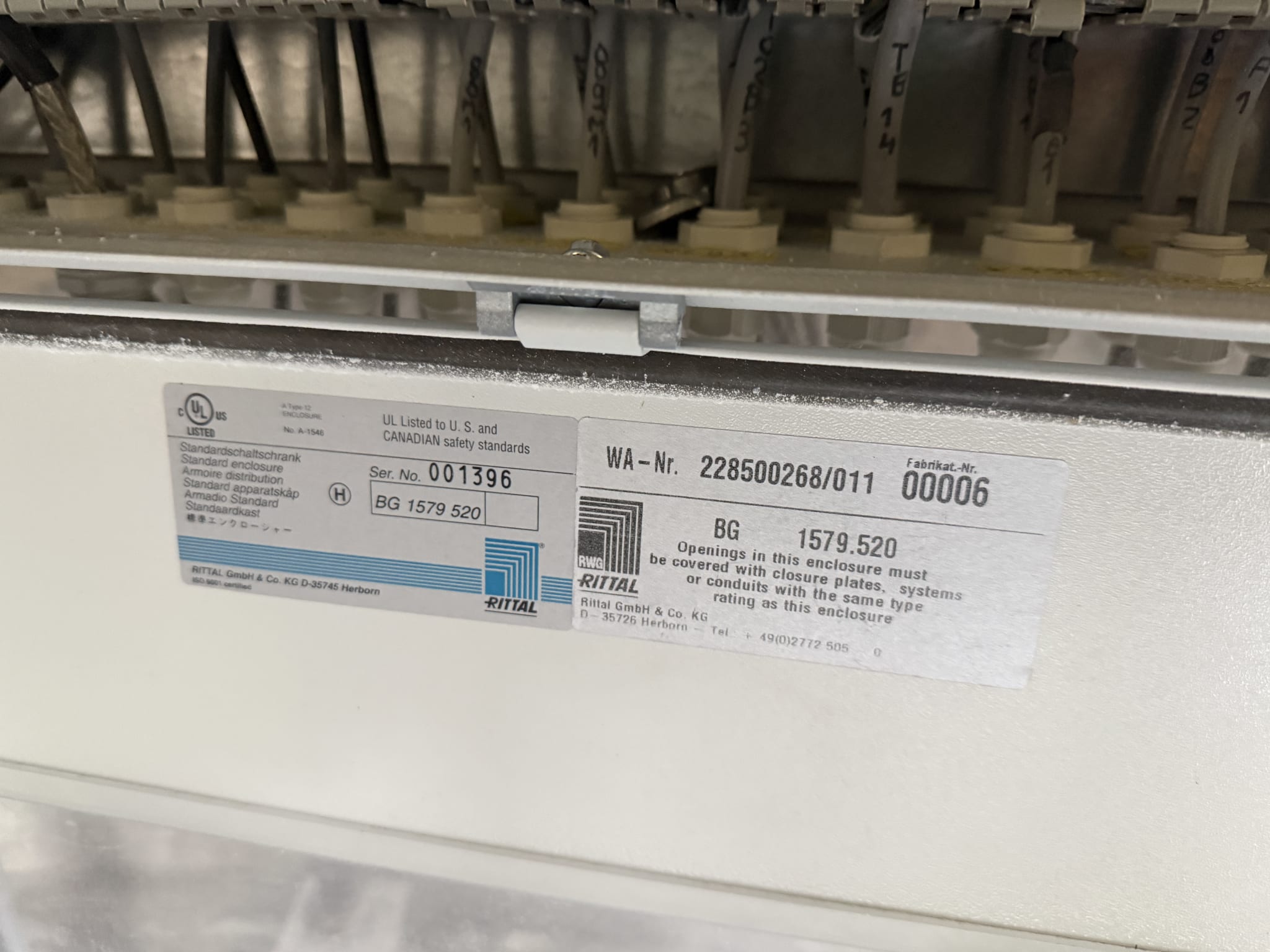

X-Ray Tire Inspection Machine Collmann Inspektomat | 2007

Binding Handling & Service Fee:

3500 € (EURO)

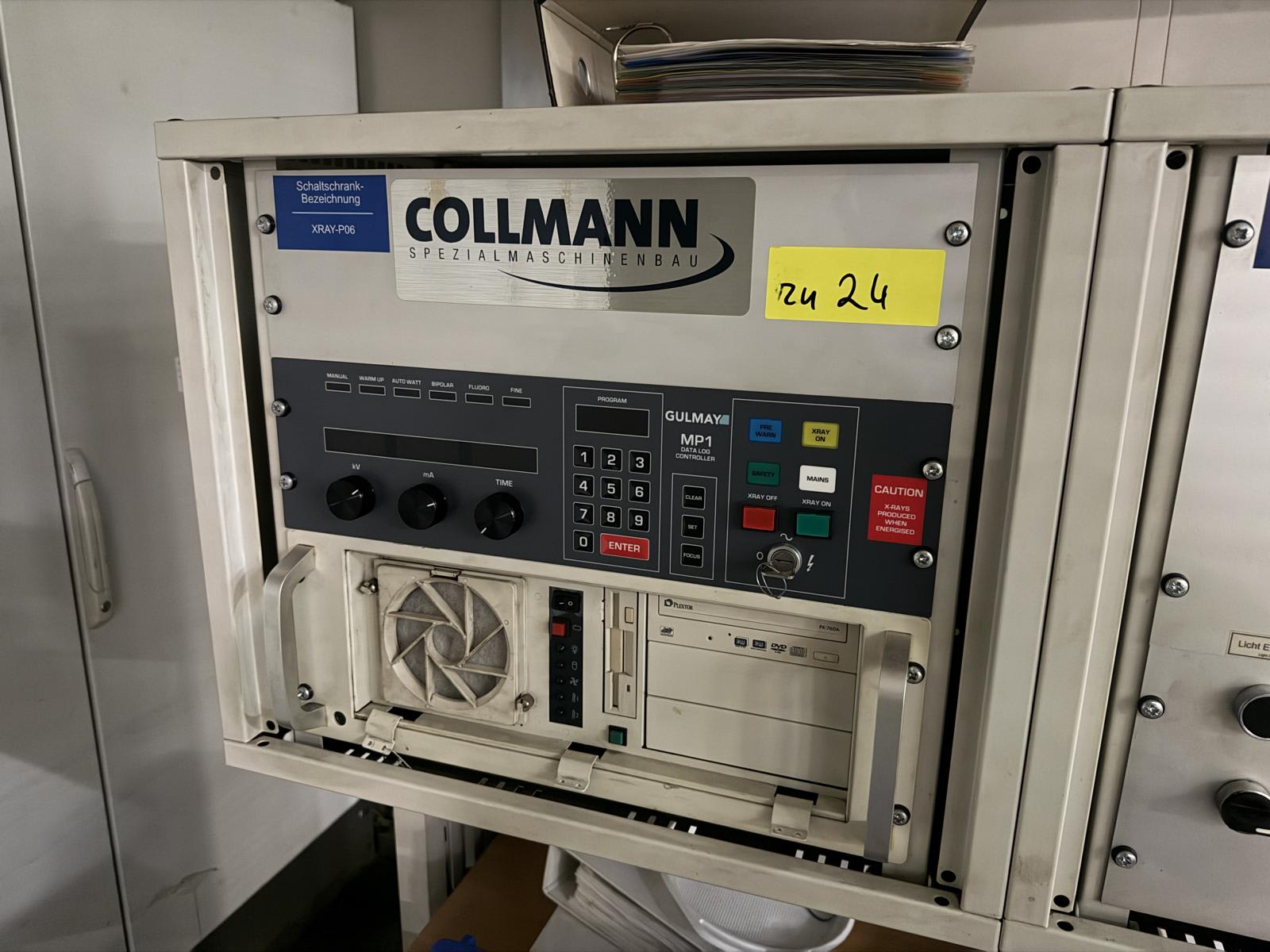

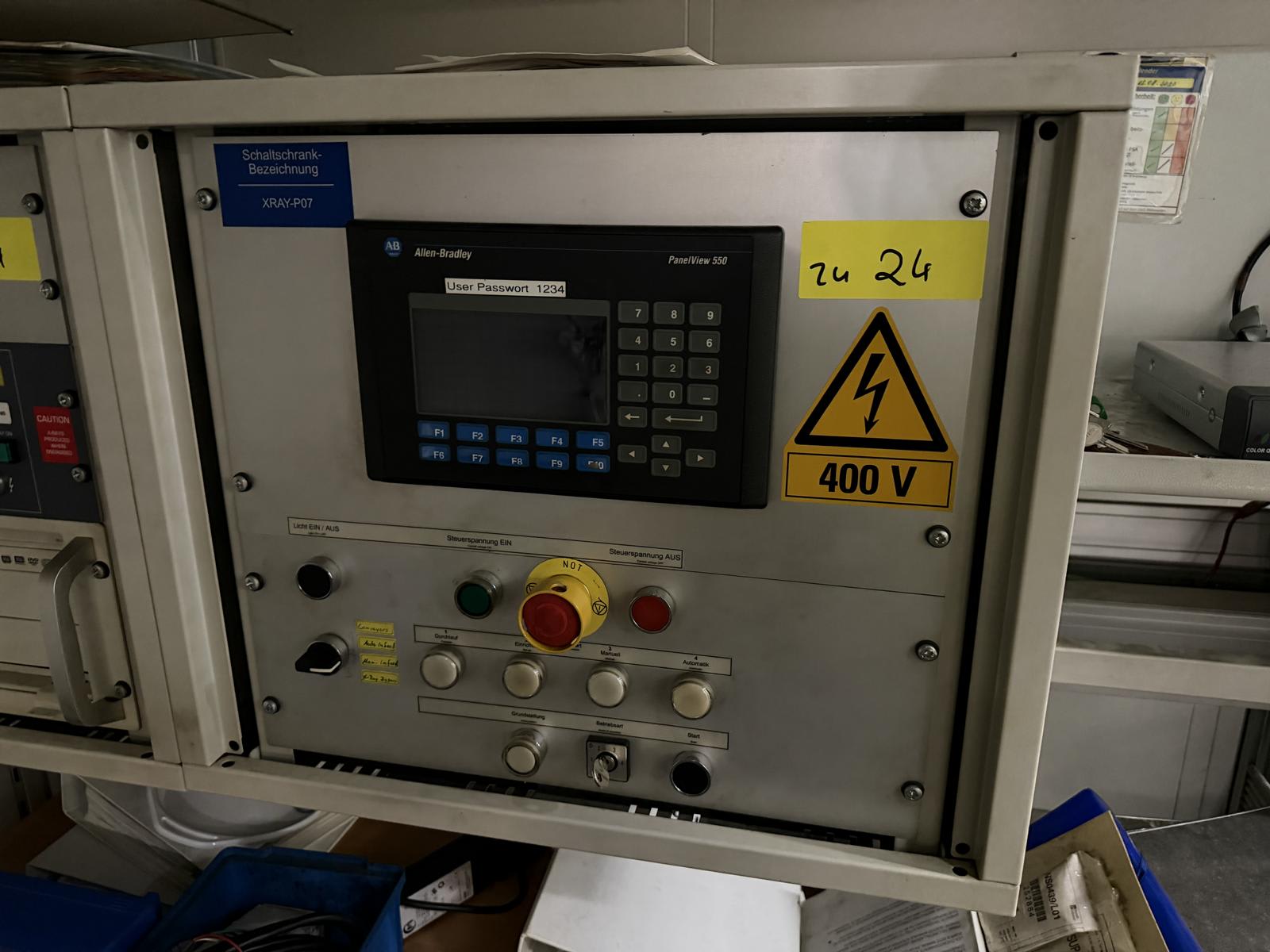

1. Electrical and Power Data • Rated power: 22 kW • Power supply: 400 V / 50 Hz • Rated current: 35 A 2. Pneumatic System • Operating pressure range: 4 – 10 bar 3. Control and Operating System • Control unit (HMI): Allen-Bradley PanelView 550 • X-ray controller: Gulmay MP1 Data Log Controller 4. X-Ray Generation System • High-voltage generator: Gulmay FC160-1/2 • Execution: Mobile unit • Country of manufacture: England 5. Housing and Safety Equipment • Fully enclosed, radiation-shielded cabin • Cabin colour: white / blue • Integrated safety interlock system 6. Material Handling System • Integrated motorized roller conveyor • Conveyor configured for both in-feed and out-feed of material 7. Electrical Installation • External electrical cabinet system • Multi-door cabinet bank • Cabinet manufacturer: Rittal - LISTING 2760027

![Deutsch]()

High Table Cutter BIAS 66 | 1971-1992

Binding Handling & Service Fee:

1400 € (EURO)

1. Machine Classification • Machine type: Rubber ply / tread servicer and winding line • Component designation: “R-Wickler 1” (R-Winder 1) 2. Functional Description • Conveying of rubber sheet material • Controlled let-off of rubber compounds and auxiliary liner or interleaf materials • Winding of processed rubber components into rolls suitable for downstream tire production processes 3. Mechanical Structure • Heavy-duty steel frame construction • Surface finish: industrial green paint 4. Conveyor and Material Handling Systems • Wide flat-belt conveyor system for rubber sheet transport • Overhead mounting points for liner and interleaf material rolls 5. Safety Equipment • Yellow perimeter safety fencing surrounding the operating area • Emergency stop push-buttons accessible to the operator 6. Control and Operating Interface • Local operator control panel • Integrated display screen • Physical push-button controls • Integrated communication handset Some Pictures show the Machine in the Situation when it was still used, those are only for Presentation Purposes - LISTING 2760028

![Deutsch]()

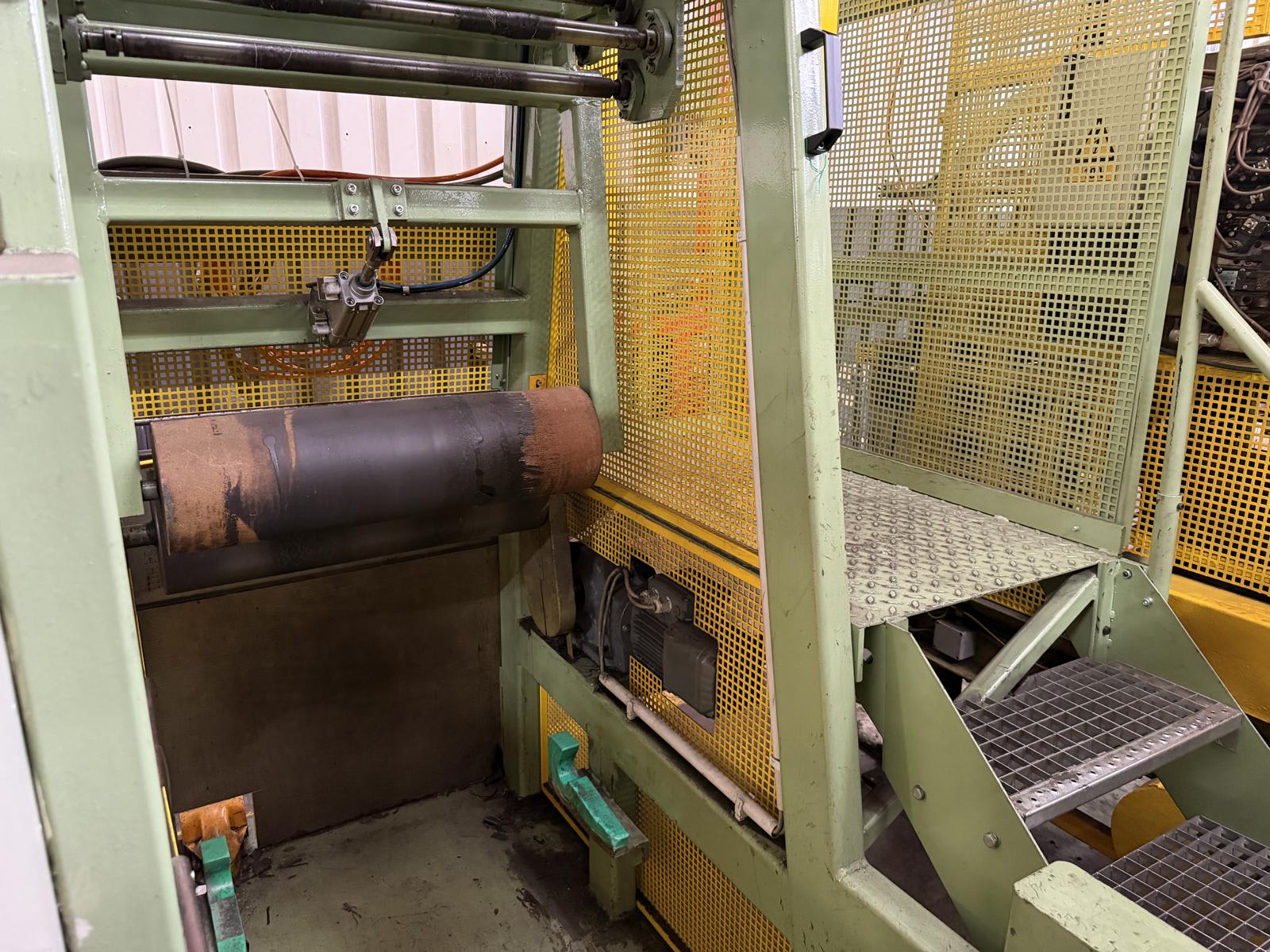

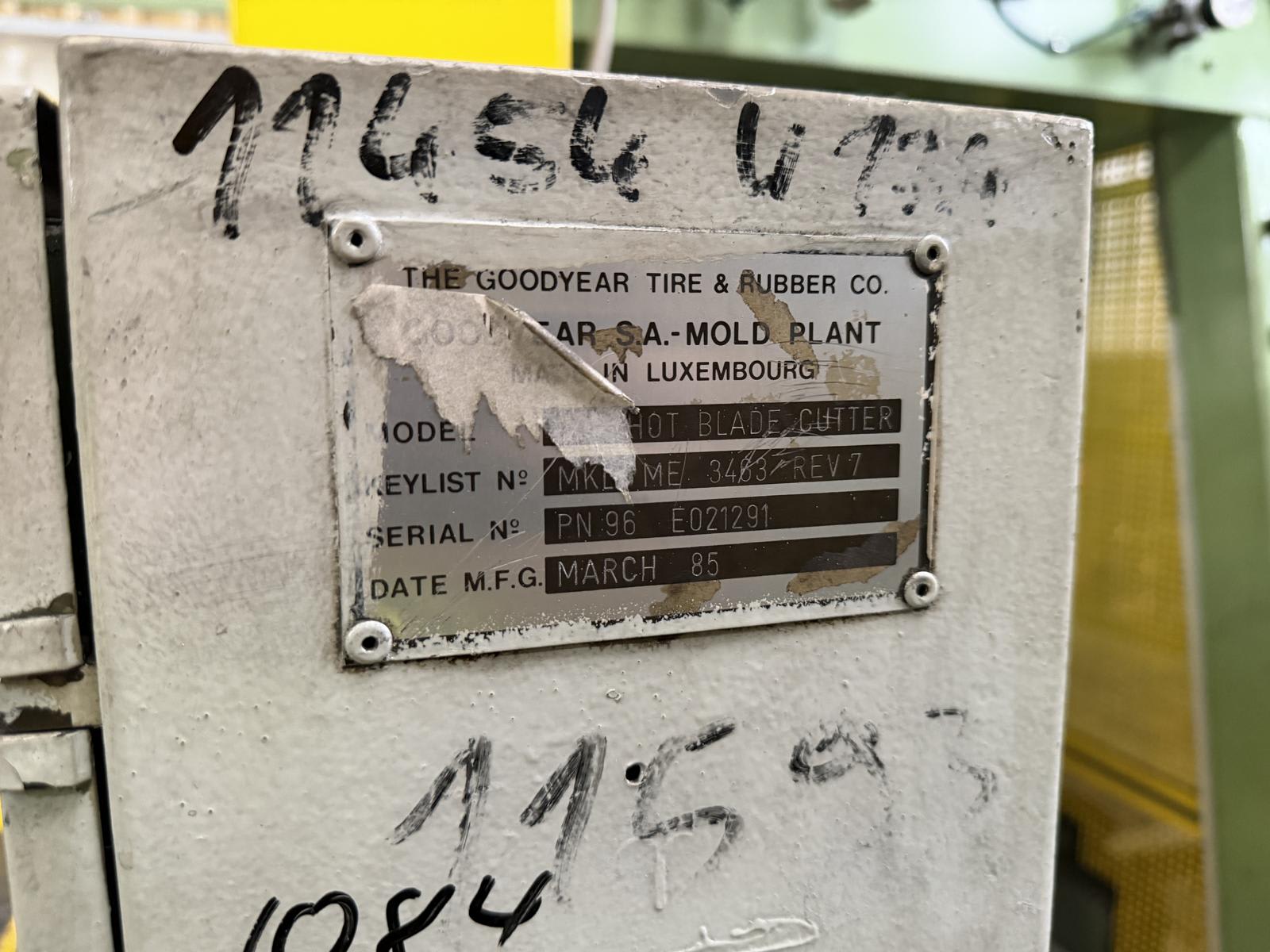

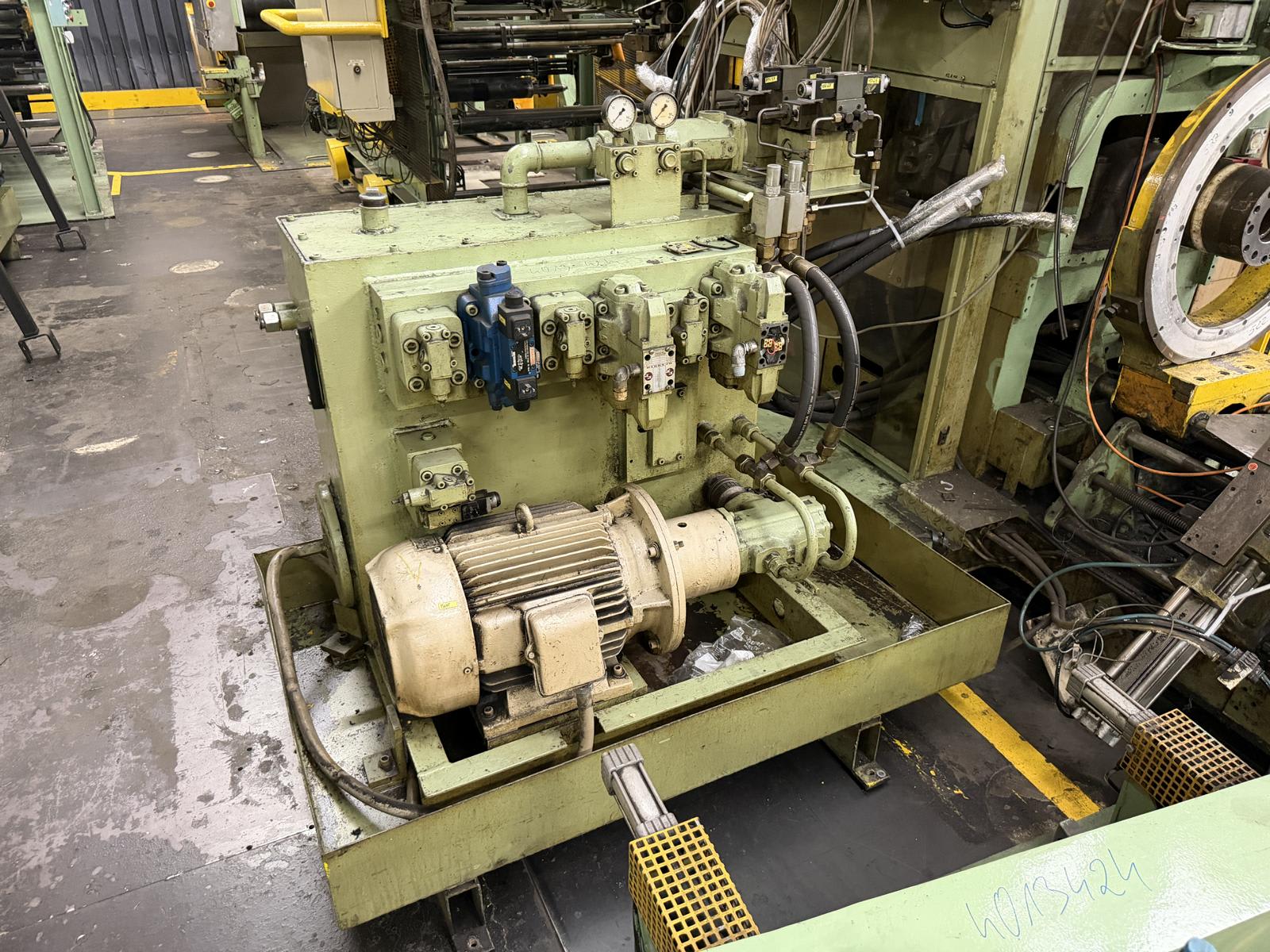

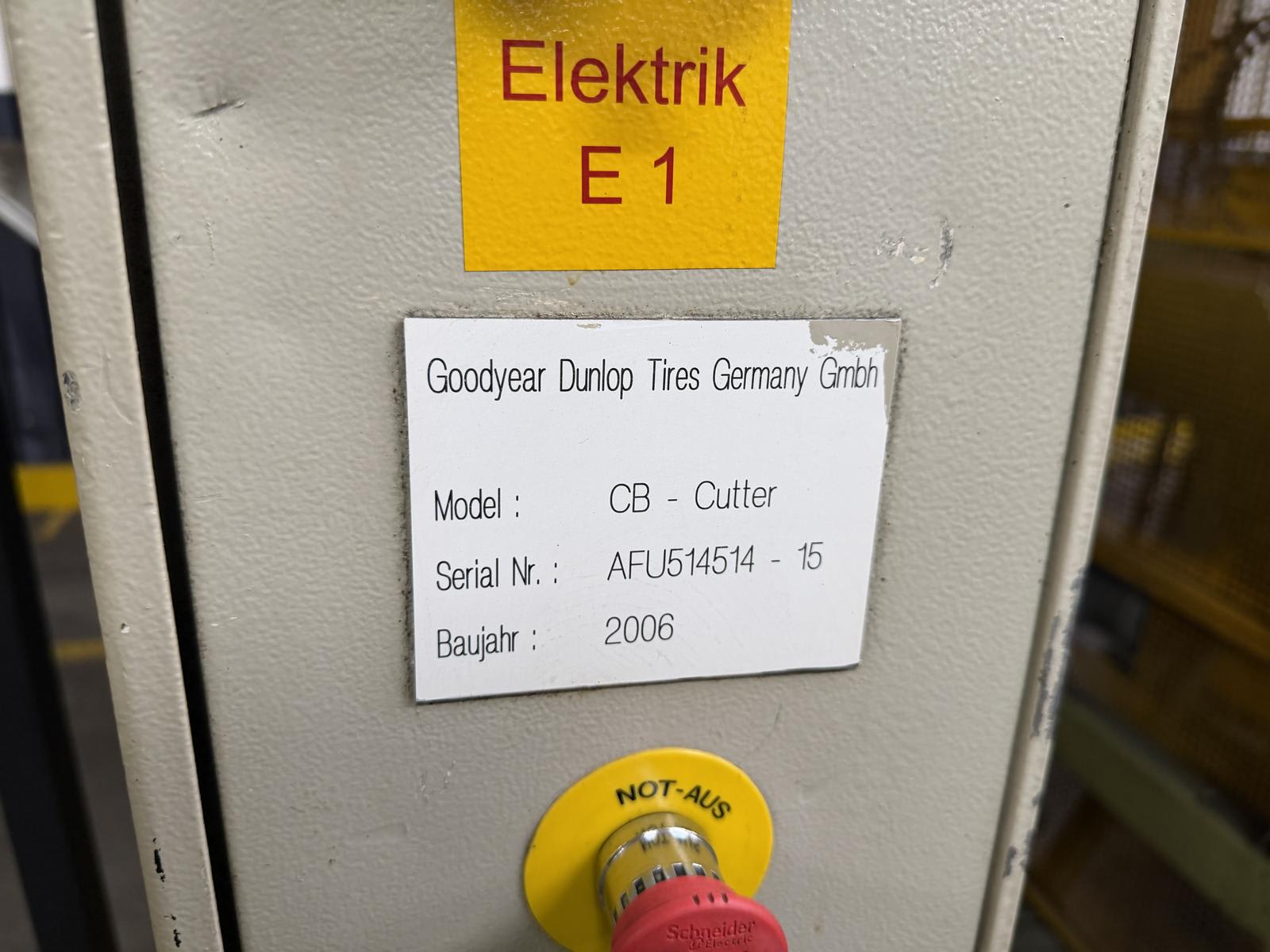

Gum Strip Application Ply Cutter Karl Eugen Fischer GmbH HTBC | 2005-2015

Binding Handling & Service Fee:

10100 € (EURO)

1. Manufacturer • Manufacturer: Karl Eugen Fischer GmbH 2. Machine Identification • Machine type: Gum strip application ply cutter • Model: HTBC • Year of construction: 2005–2015 (series production range) 3. Intended Use • Cutting and application of gum strips and/or ply material • Designed for use in tire manufacturing and rubber processing operations 4. Mechanical Construction • Heavy-duty steel frame construction • Industrial green painted finish • Elevated operator platform with integrated access stairs 5. Conveying and Material Handling • Wide flat-belt conveyor system for continuous rubber sheet transport • Conveyor integrated into the cutting and application process 6. Winding and Let-Off System • Overhead and lower roller stations • Designed for liner and ply material handling • Configured for controlled let-off and wind-up operations 7. Electrical Equipment • Electrical supply: 400 V / 50 Hz • Electrical cabinets: – Large standalone grey cabinet bank – Integrated climate control system 8. Safety Equipment • Yellow perimeter safety fencing • Mechanical guarding of hazardous areas - LISTING 2760029

![Deutsch]()

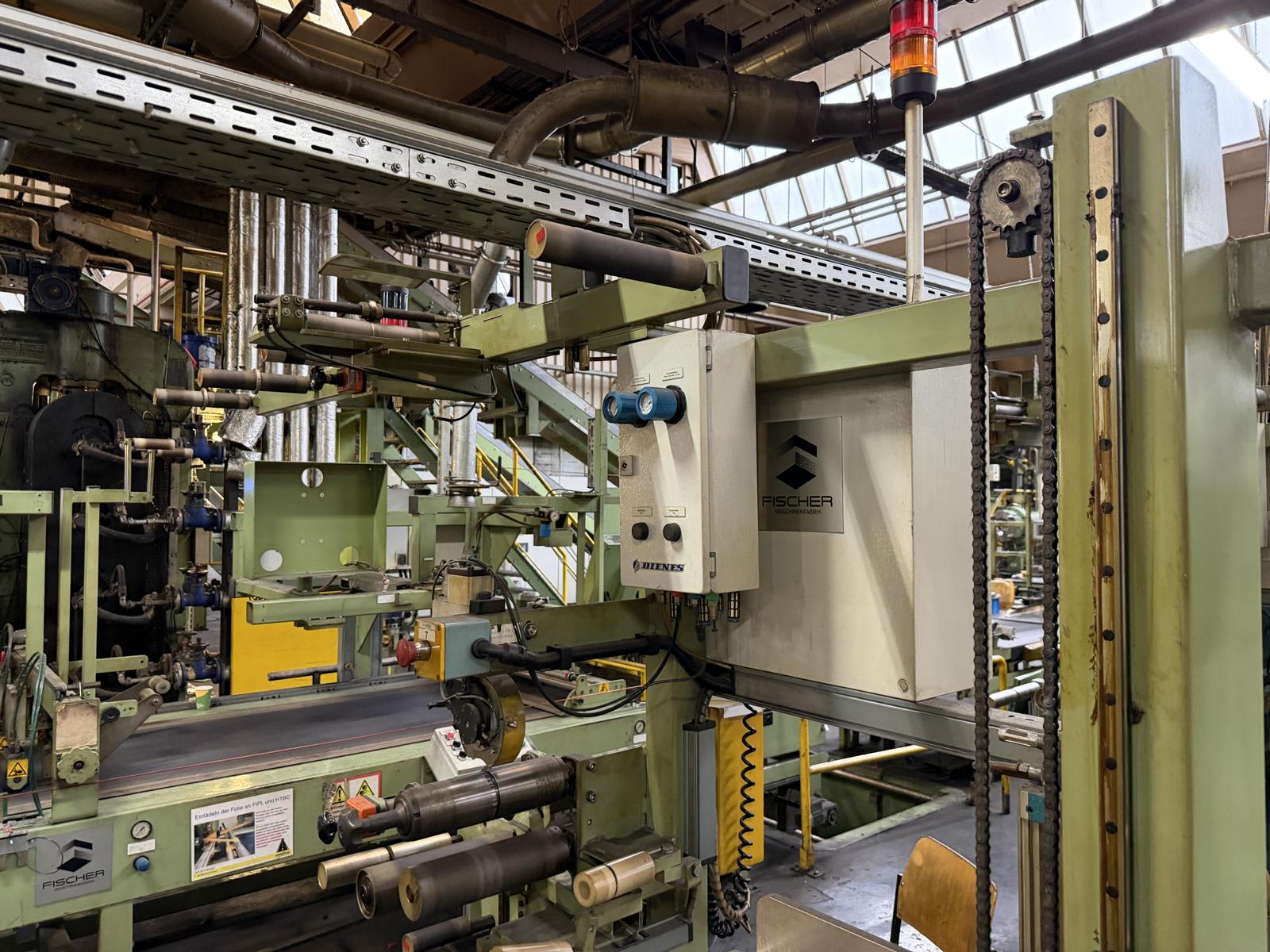

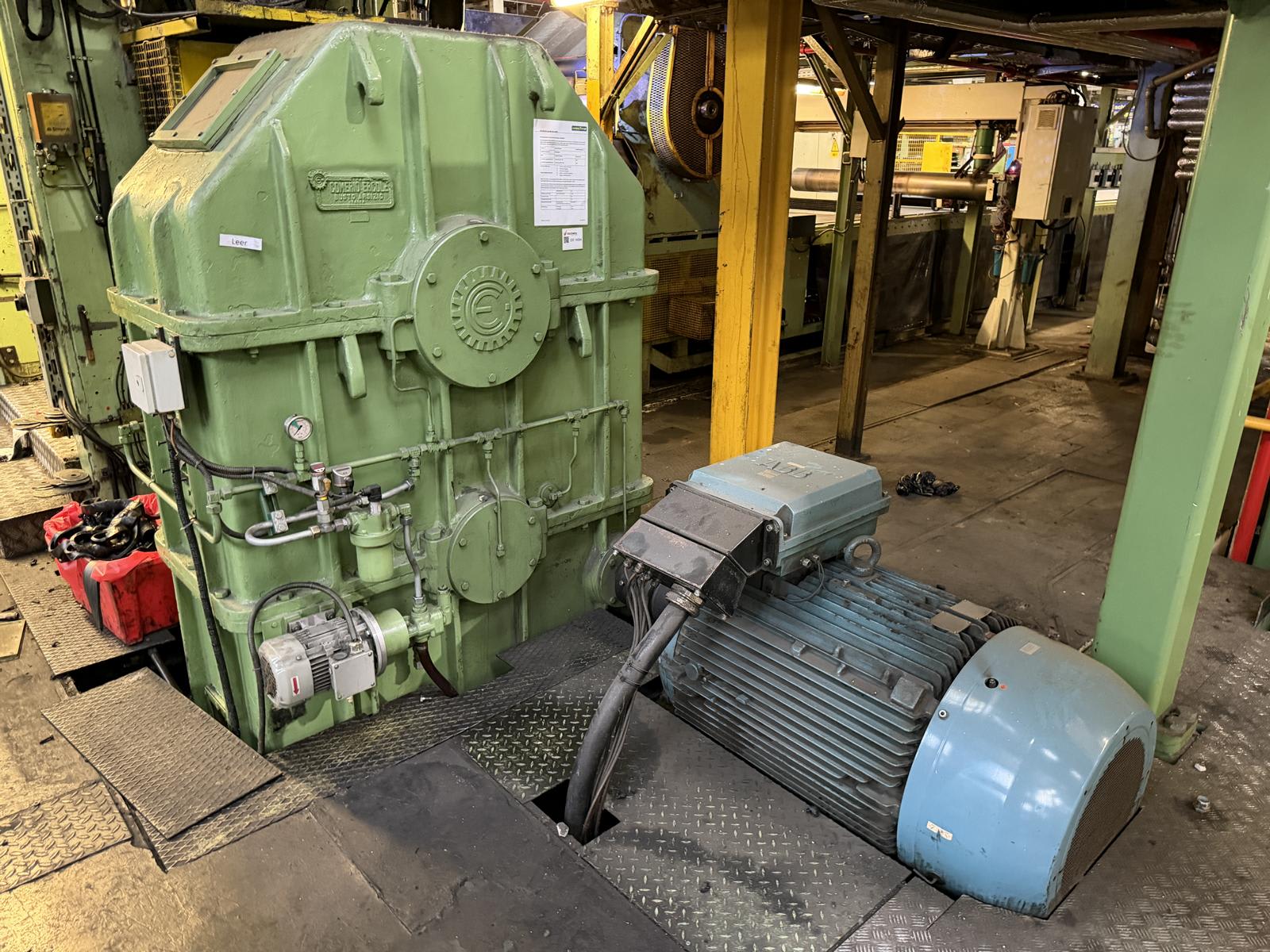

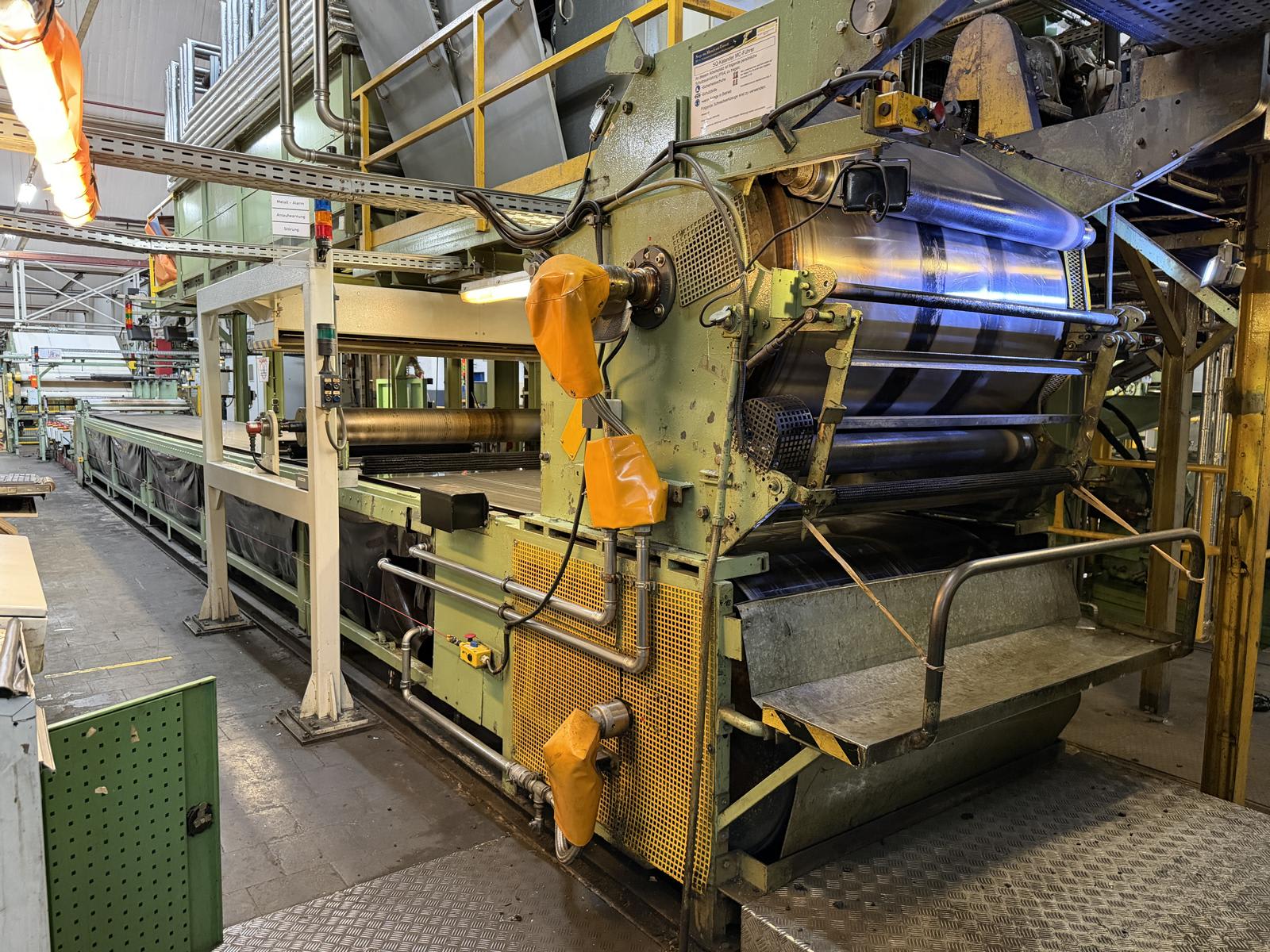

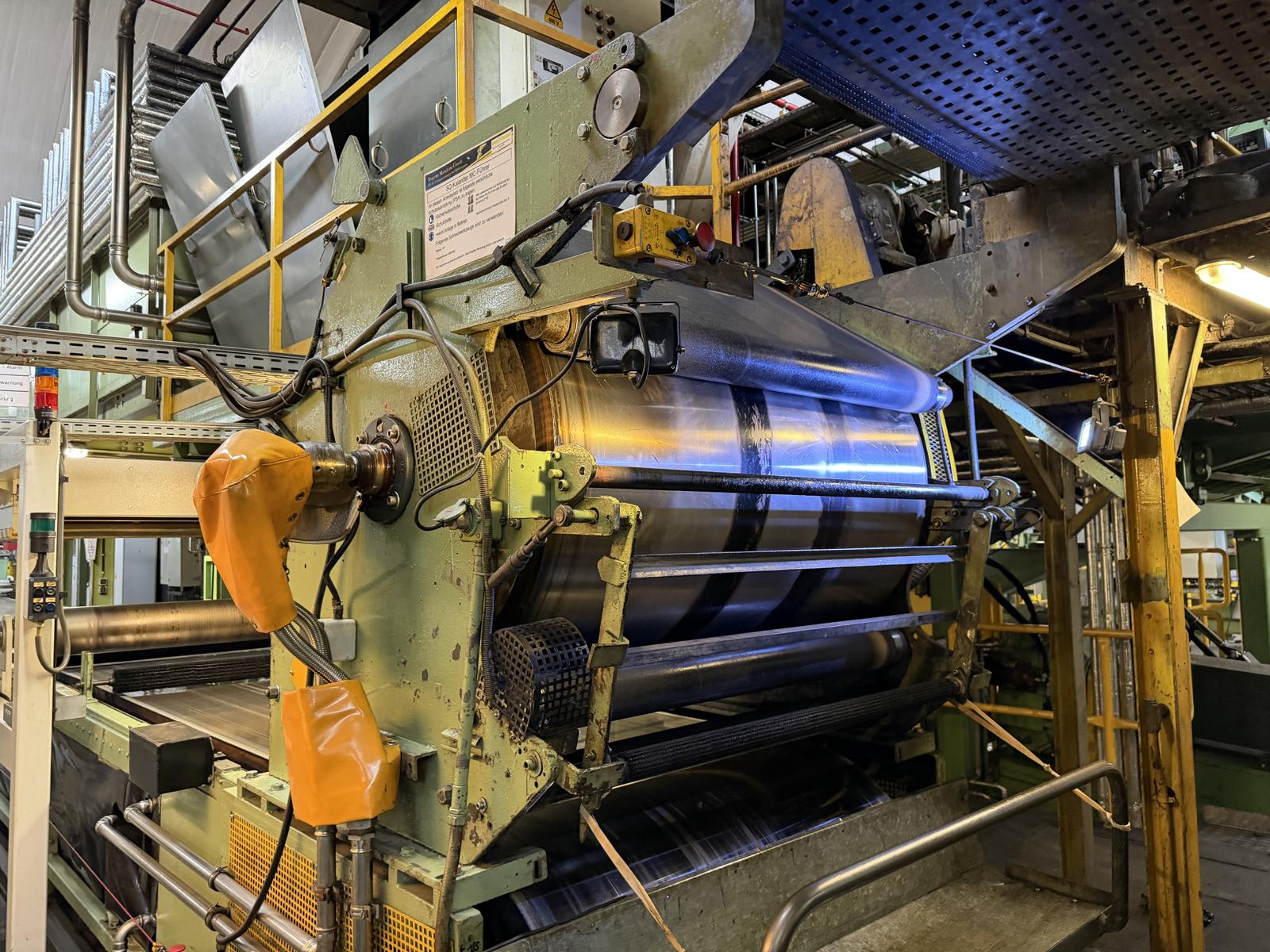

4-Roller Gum-Calender Comerio 18x54 | 1971-2018

Binding Handling & Service Fee:

10400 € (EURO)

4-Roller Gum Calender 1. Manufacturer • Manufacturer: Comerio Ercole 2. Machine Identification • Machine type: 4-roller gum calender • Roll dimensions: 18" × 54" – Roll diameter: 18 inches – Roll length: 54 inches 3. Year of Construction and Modernization • Original year of construction: 1971 • Modernization history: Machine regularly modernized up to 2018 4. Intended Use • Calendering of rubber compounds (gum) • Designed for continuous processing within tire and rubber manufacturing lines 5. Control and Automation • Upgraded control system implemented in 2012 • MMI system installed in 2001 • Control panel equipped with Beckhoff components 6. Mechanical and Process Upgrades Mechanical upgrades • Installation of new calender rolls (2018) • Spool winder optimization (2014) • Cooling line overhaul (2013) Process-related upgrades • Gauge measurement system installed (2012) • Material width measuring system SQ1 installed (2009) • Cassette wind-up systems with dedicated control cabinets installed (2009) 7. Drive System • Large industrial electric motor manufactured by ABB • Drive system coupled with Comerio Ercole gearbox 8. Line Configuration • Integrated feed extruder adaptation (installed 2012) • Cooling line included in the system • Multiple winding stations integrated into the calender line - LISTING 2760031

![Deutsch]()

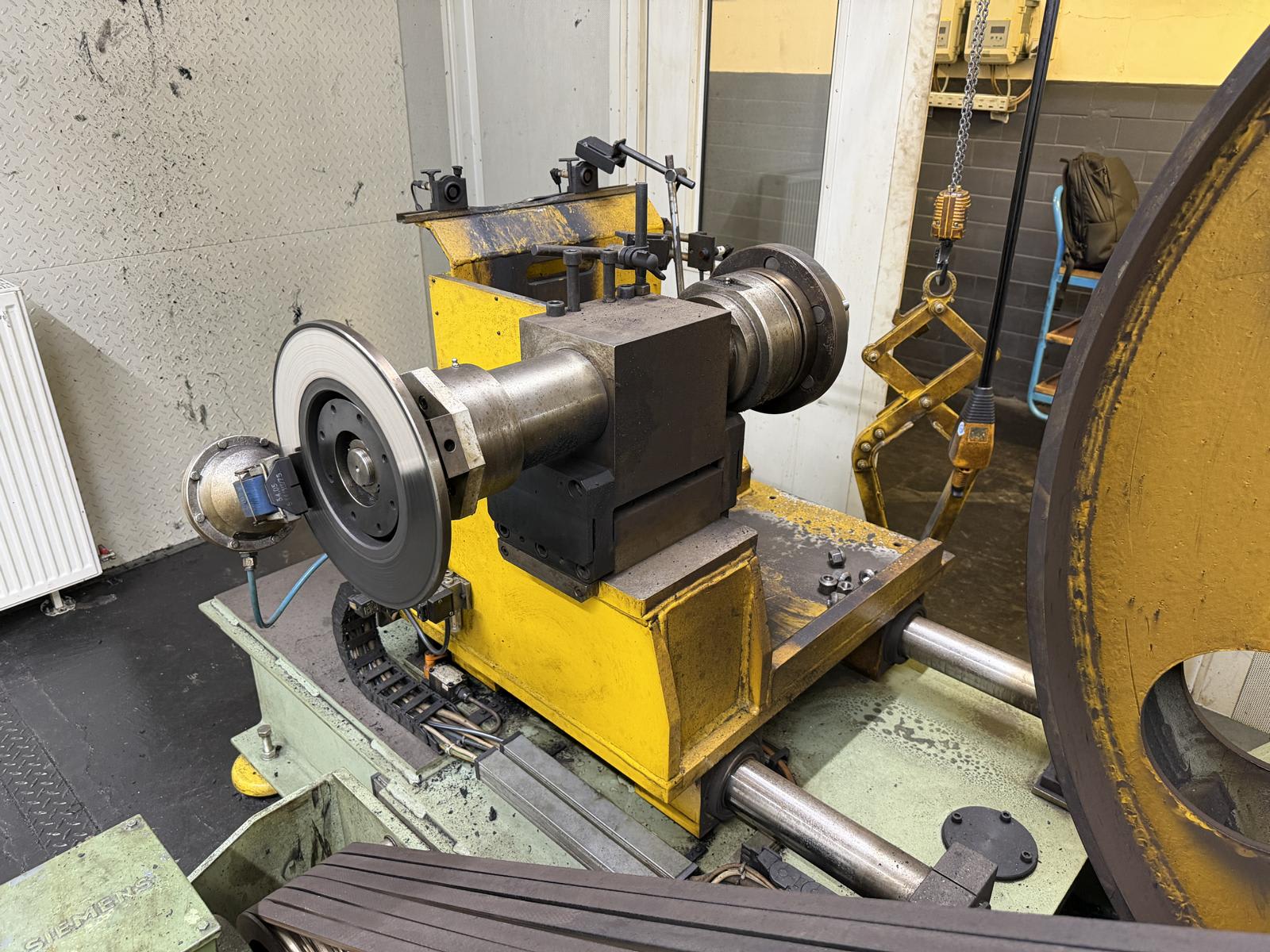

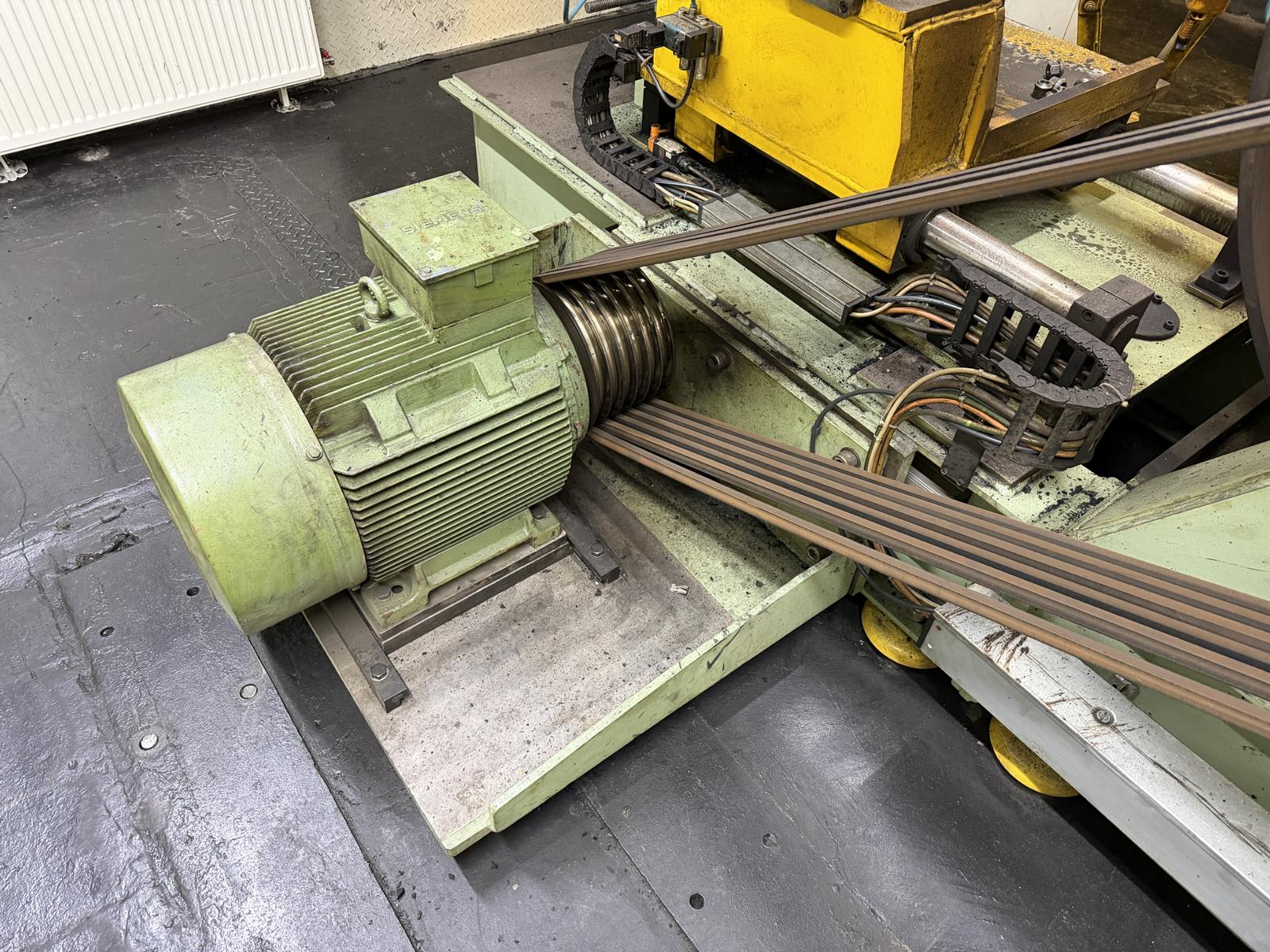

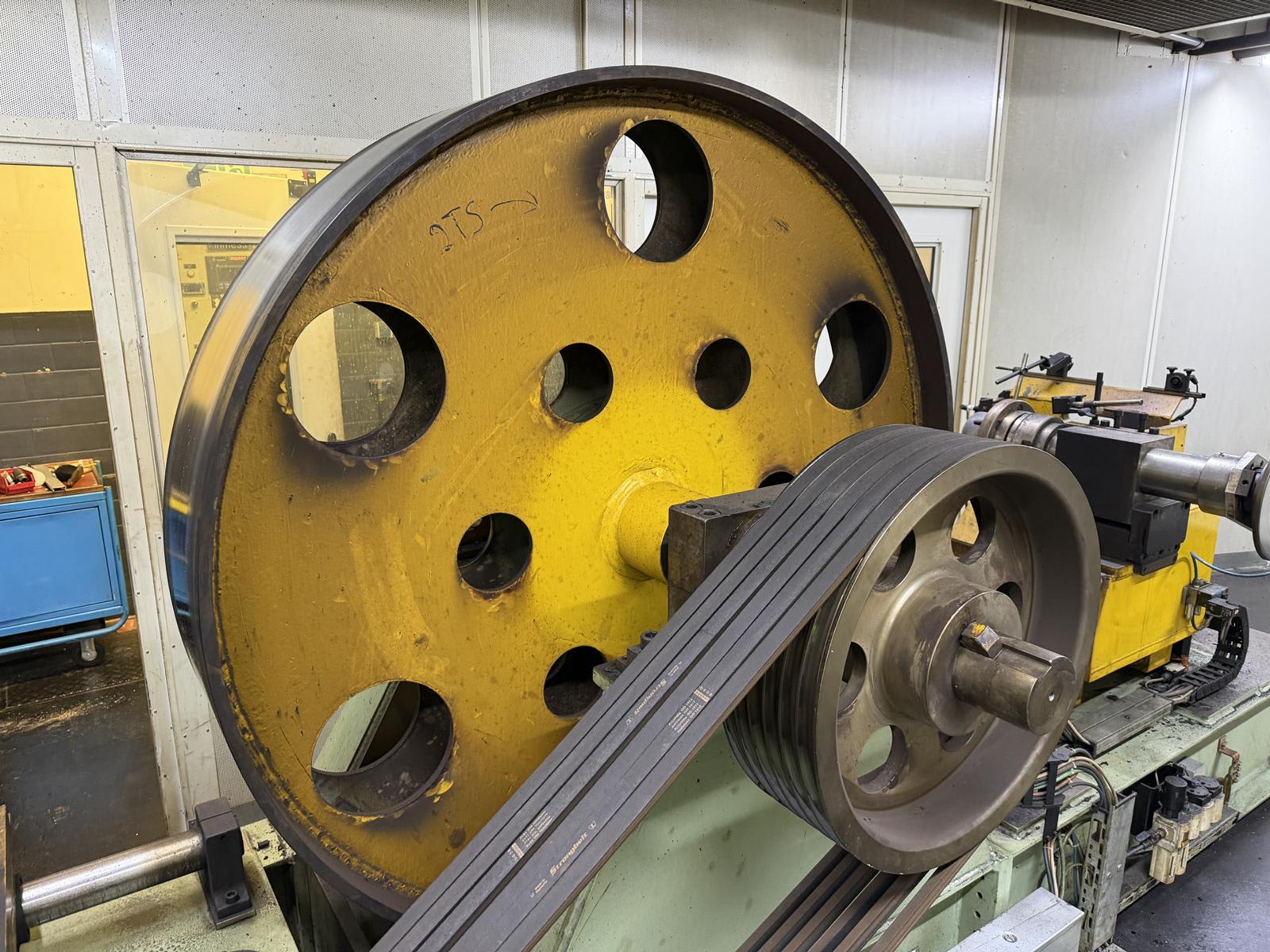

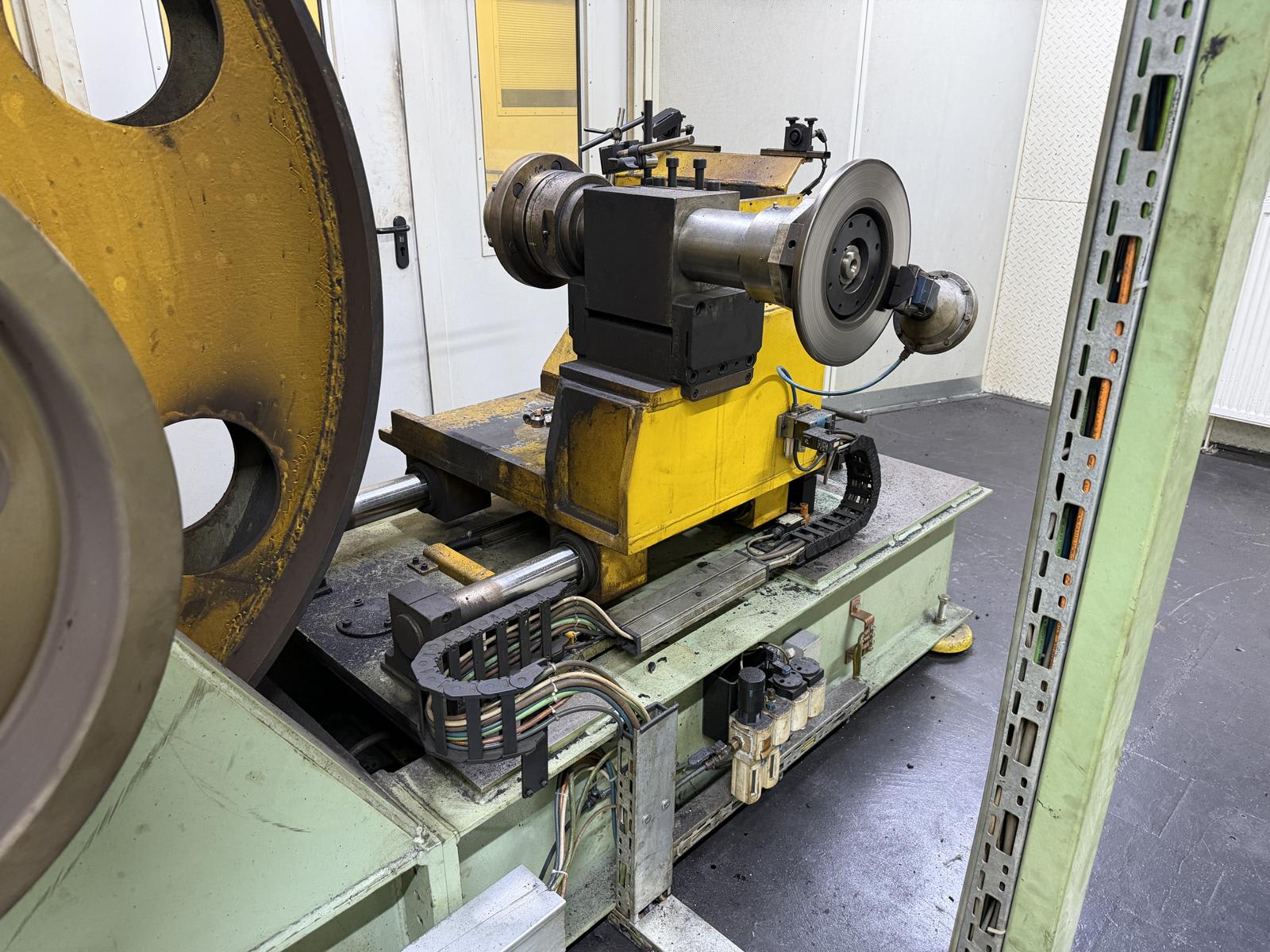

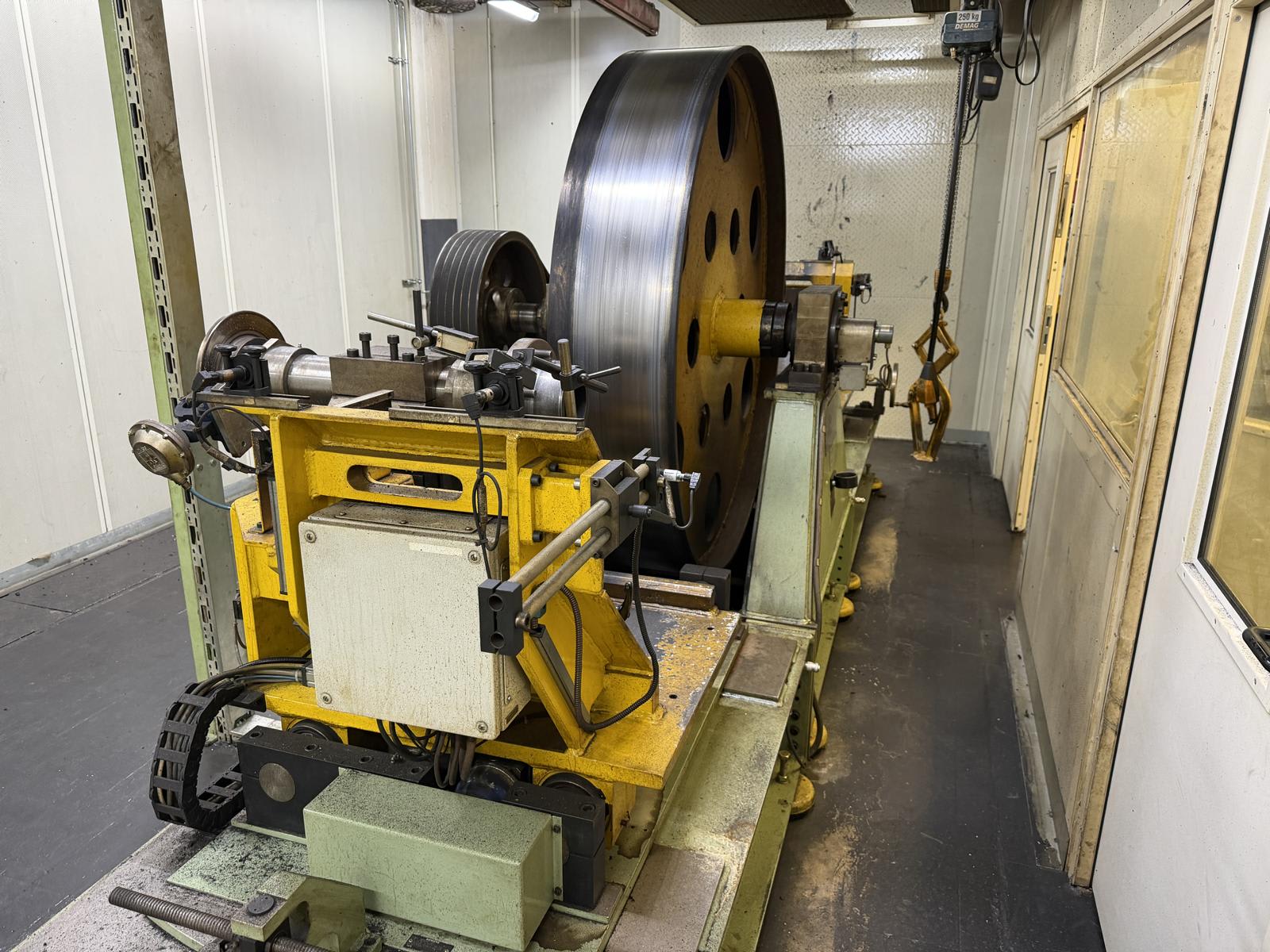

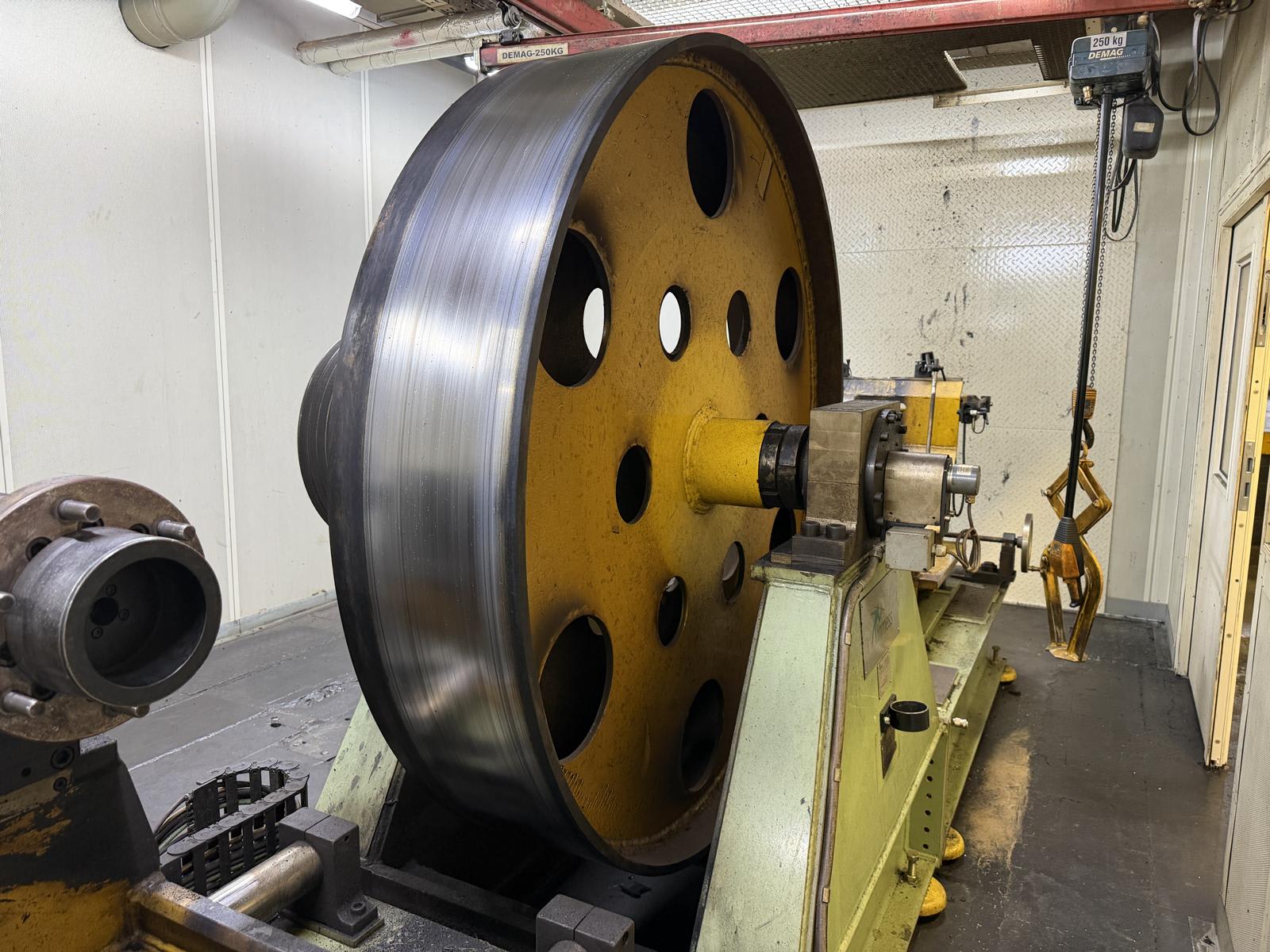

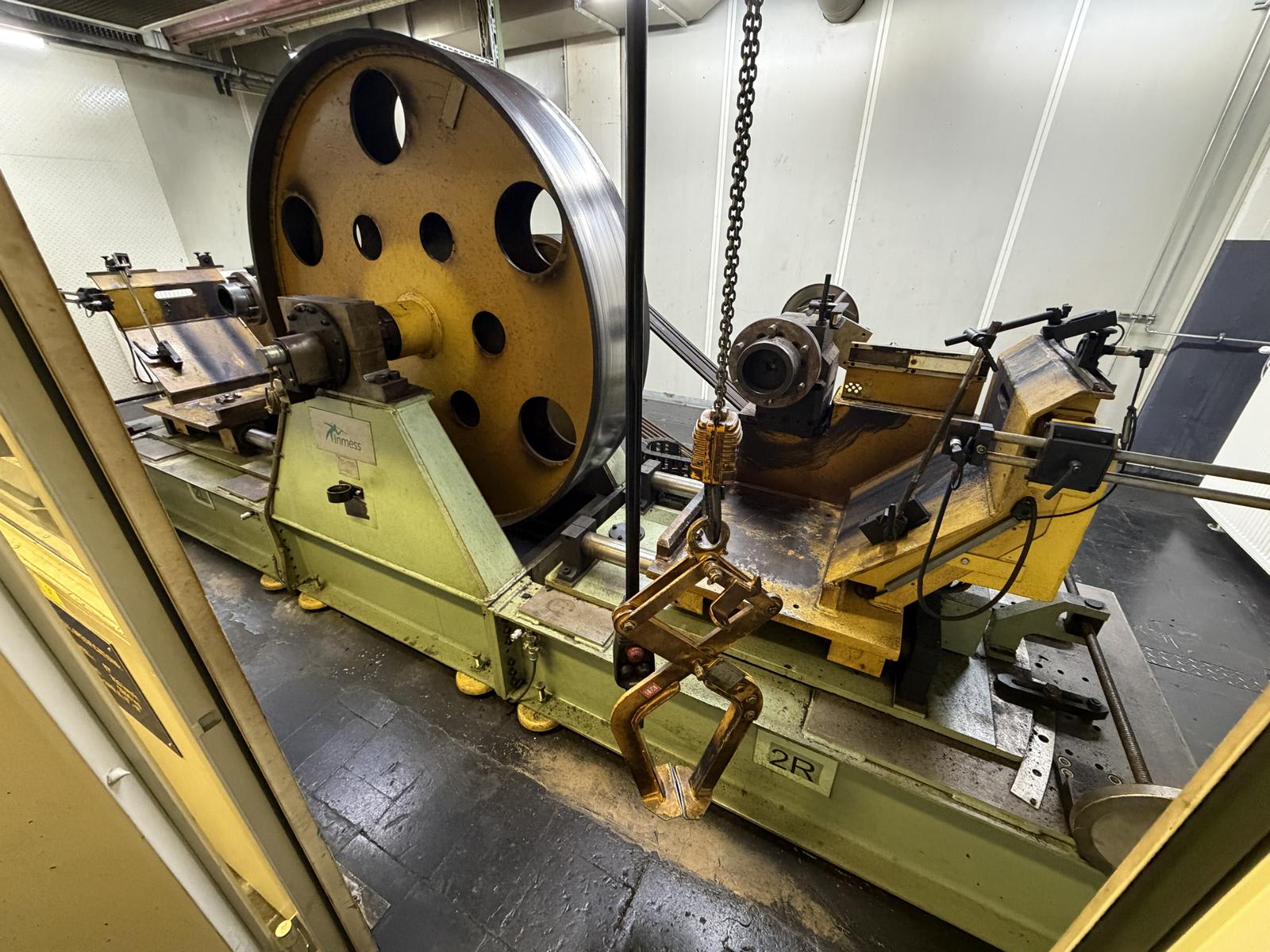

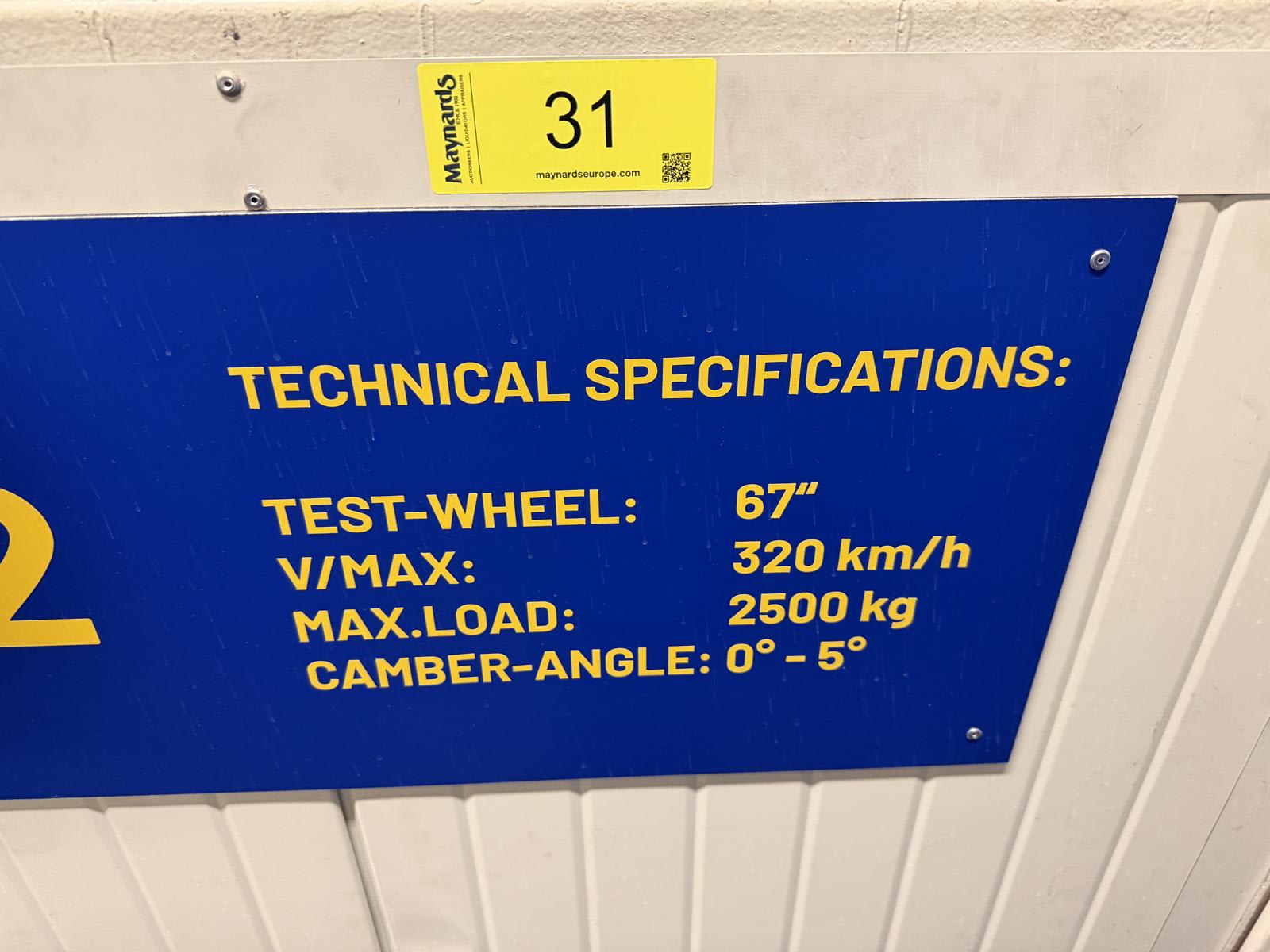

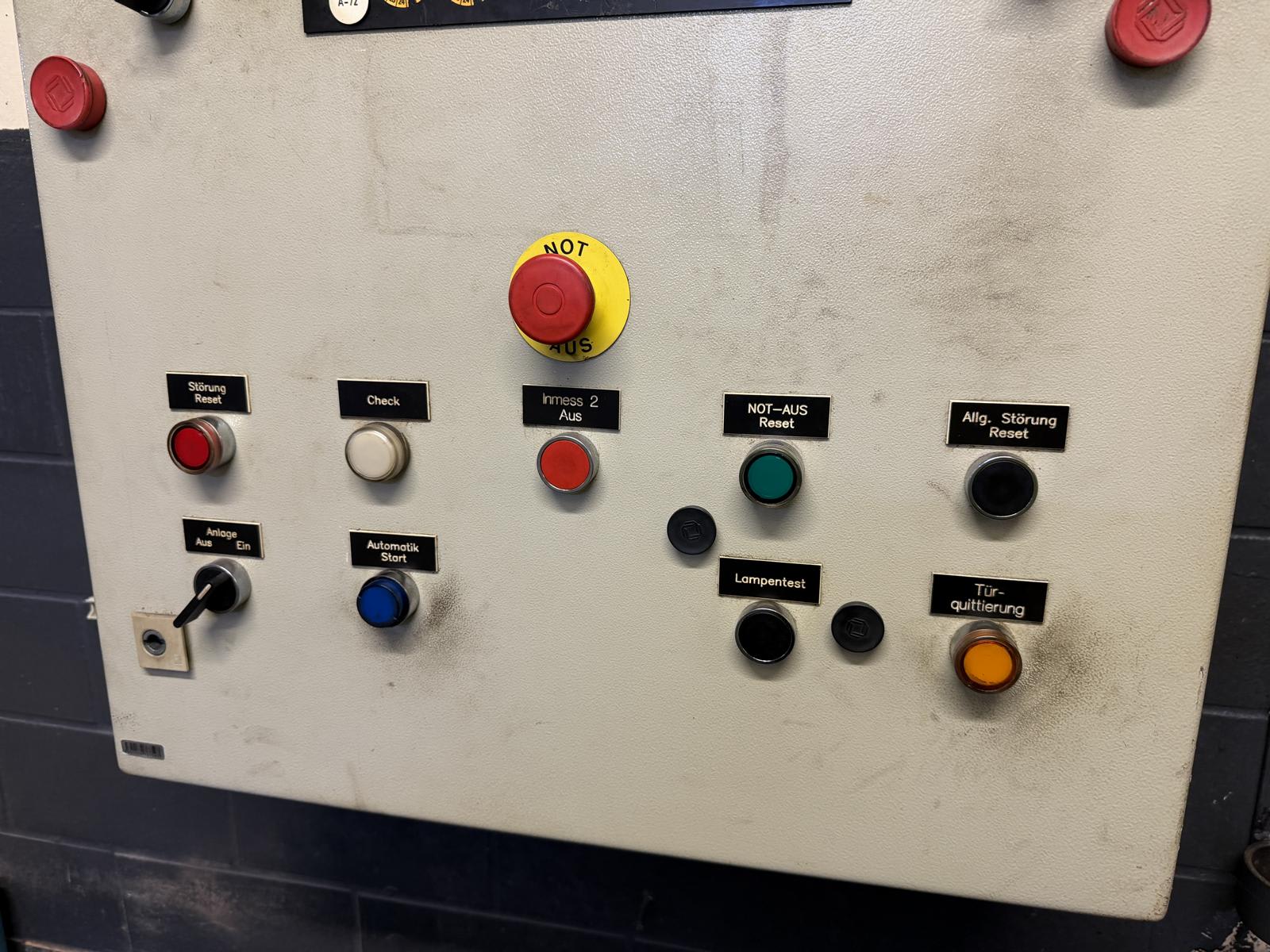

Tire Durability Testing Machine Inmess RRT | 2005

Binding Handling & Service Fee:

1900 € (EURO)

1. Manufacturer • Manufacturer: inmess Gesellschaft für Industrie- und Messtechnik mbH 2. Machine Identification • Model: RRT (Rolling Resistance Tester) • Machine number: 05-U-RRT-08 • Year of construction: 2005 3. Physical Data • Machine weight: 6,200 kg • Execution: Heavy industrial construction • Finish: Yellow / green 4. Test and Performance Parameters • Test wheel diameter: 67 inches (approx. 1.70 m) • Maximum test speed (V_max): 320 km/h • Maximum test load: 2,500 kg • Camber angle adjustment range: 0° – 5° 5. Drive System • Heavy-duty electric drive motor • Multi-belt transmission system 6. Control and Instrumentation • Control unit (HMI): Allen-Bradley PanelView 550 • Instrumentation: – Digital display units JUMO di 308 – Used for pressure and load monitoring 7. Electrical Equipment • Standalone electrical cabinet • Integrated active cooling unit - LISTING 2760032

![Deutsch]()

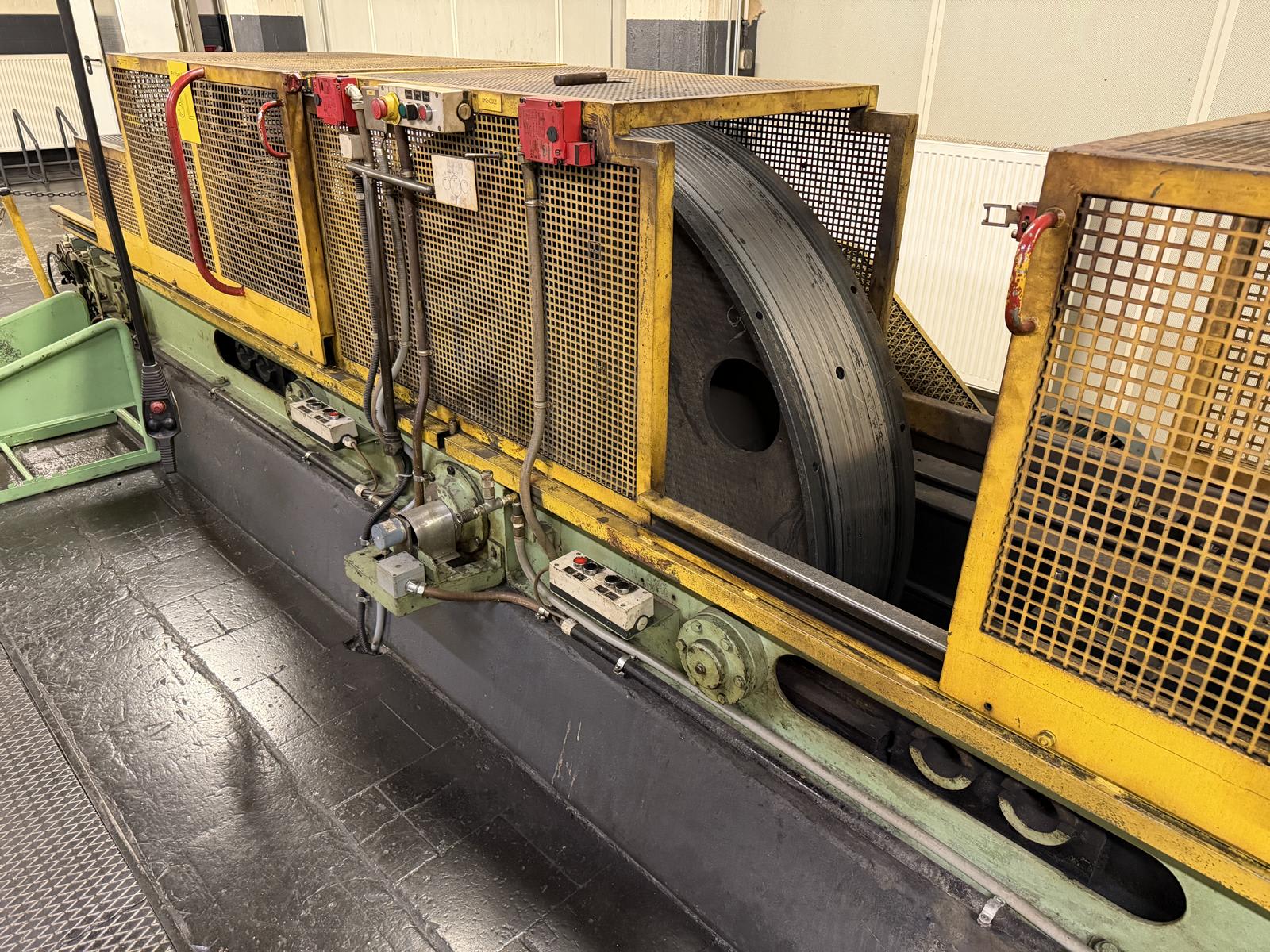

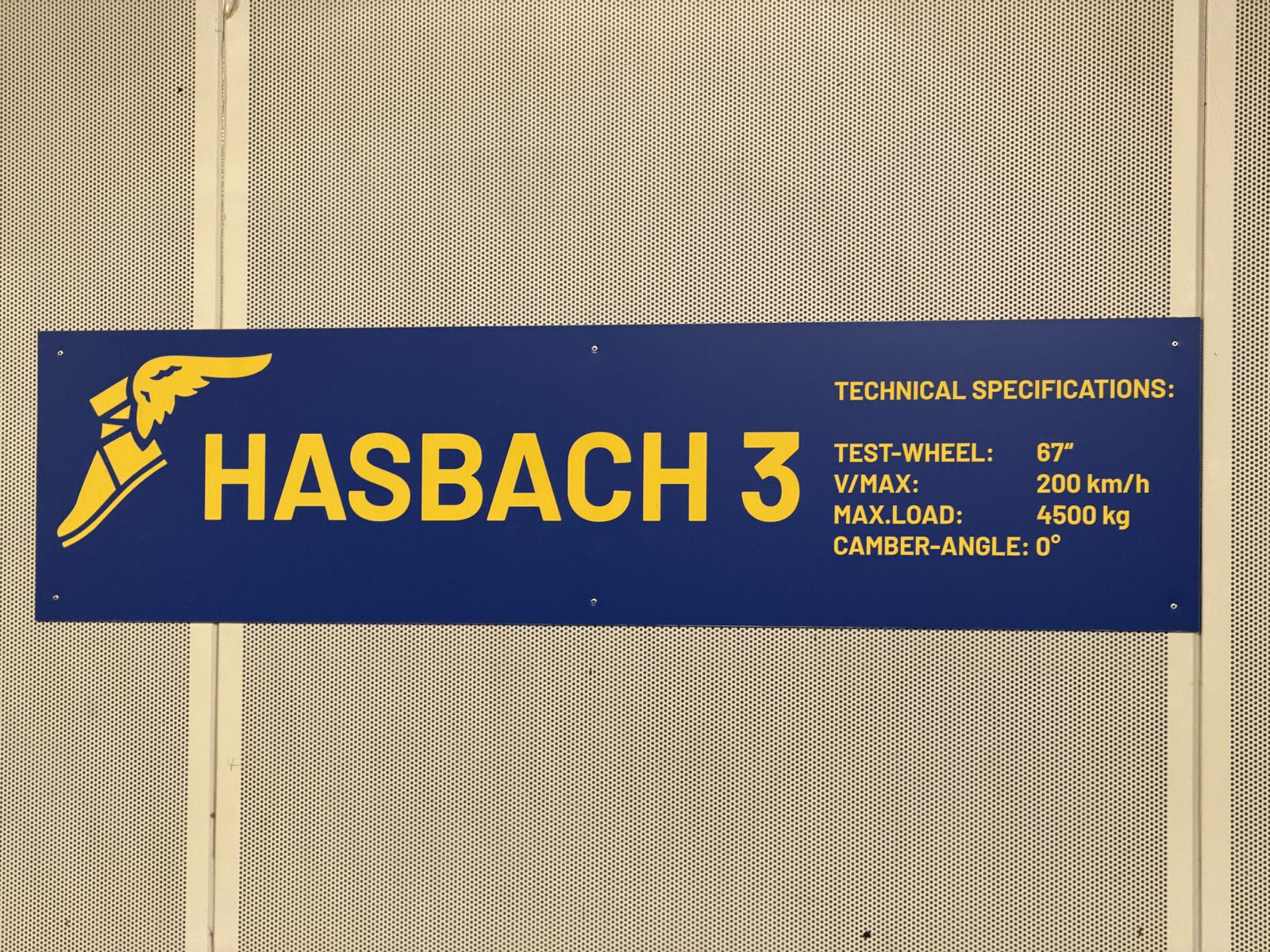

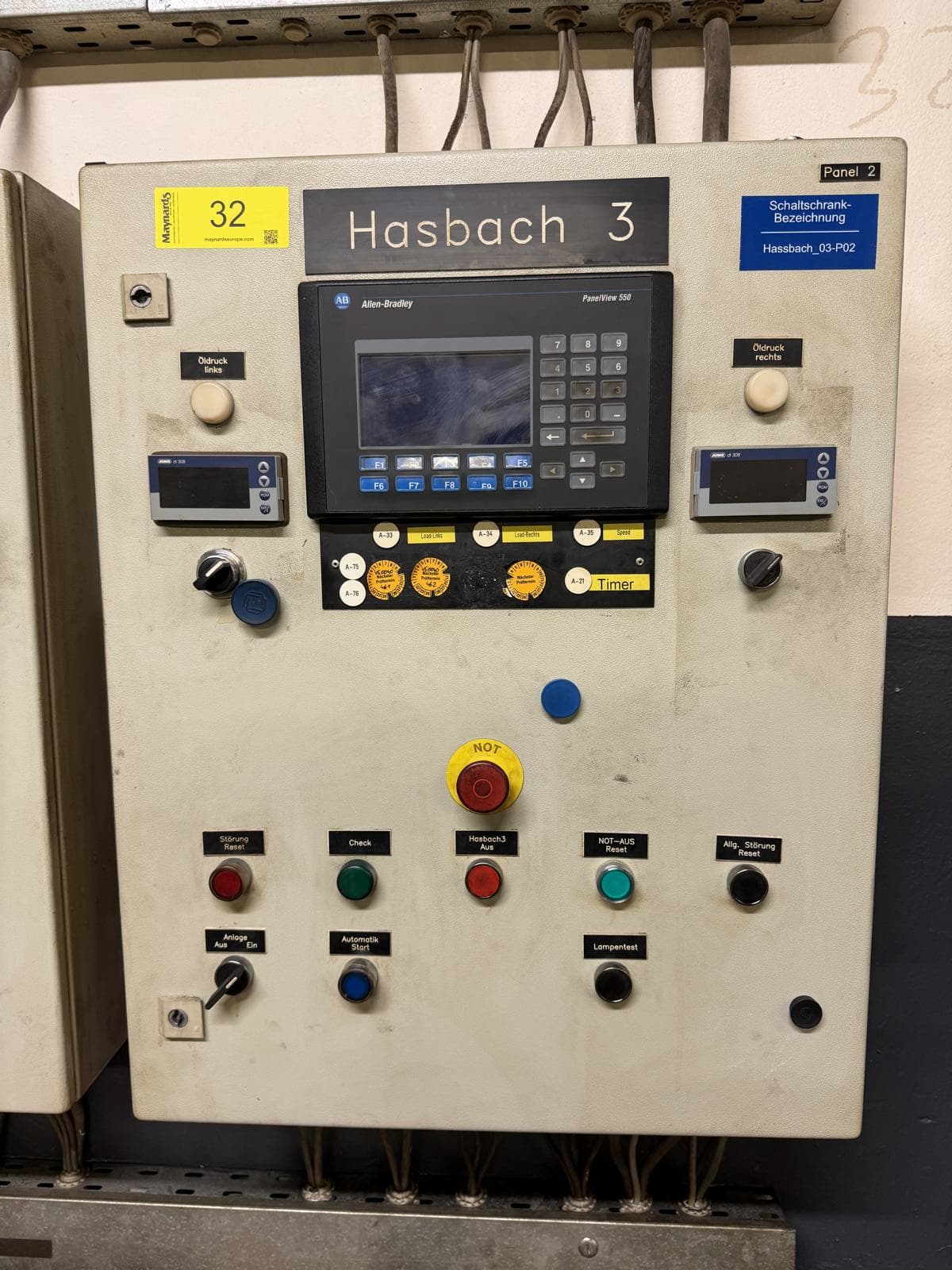

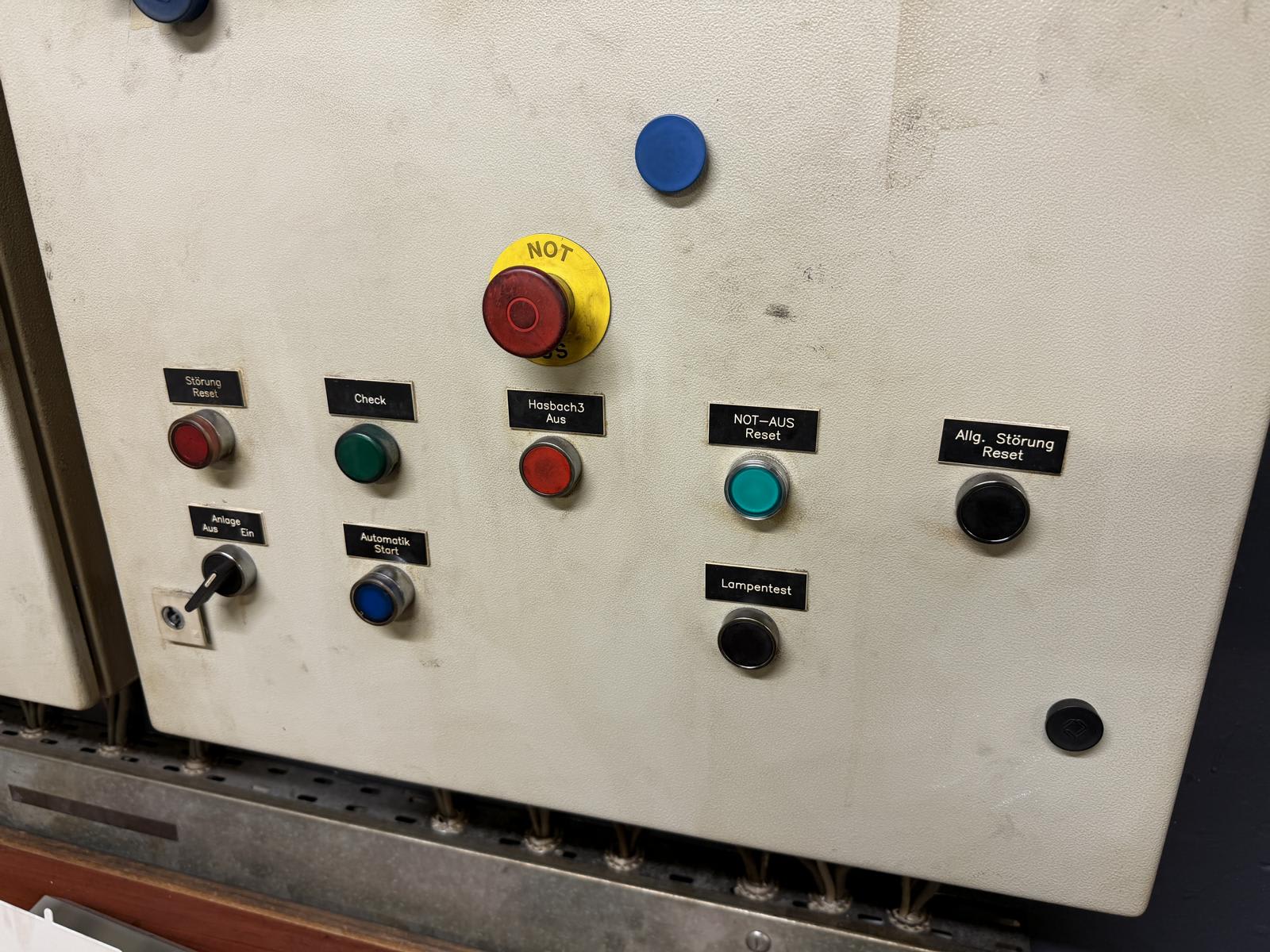

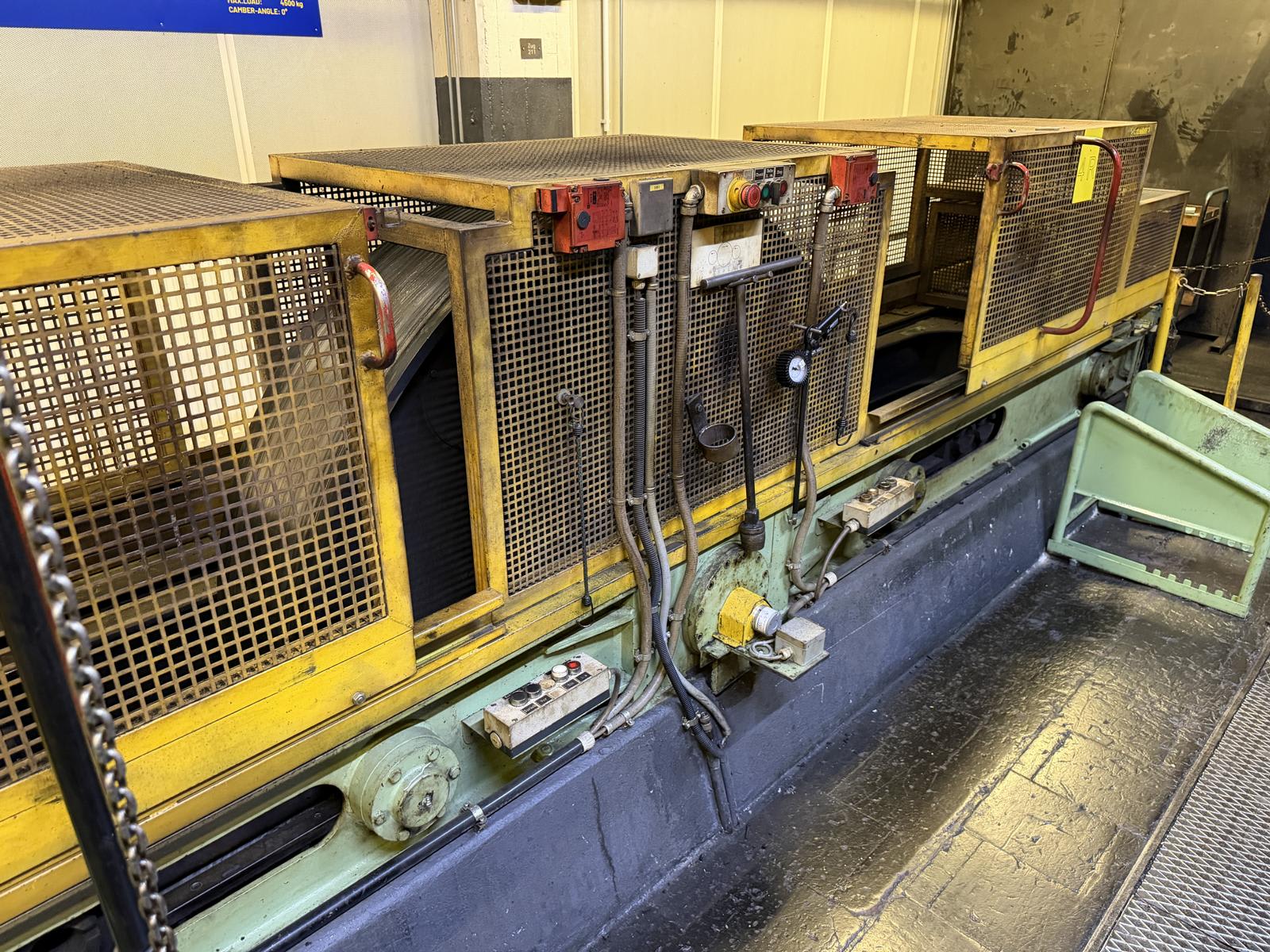

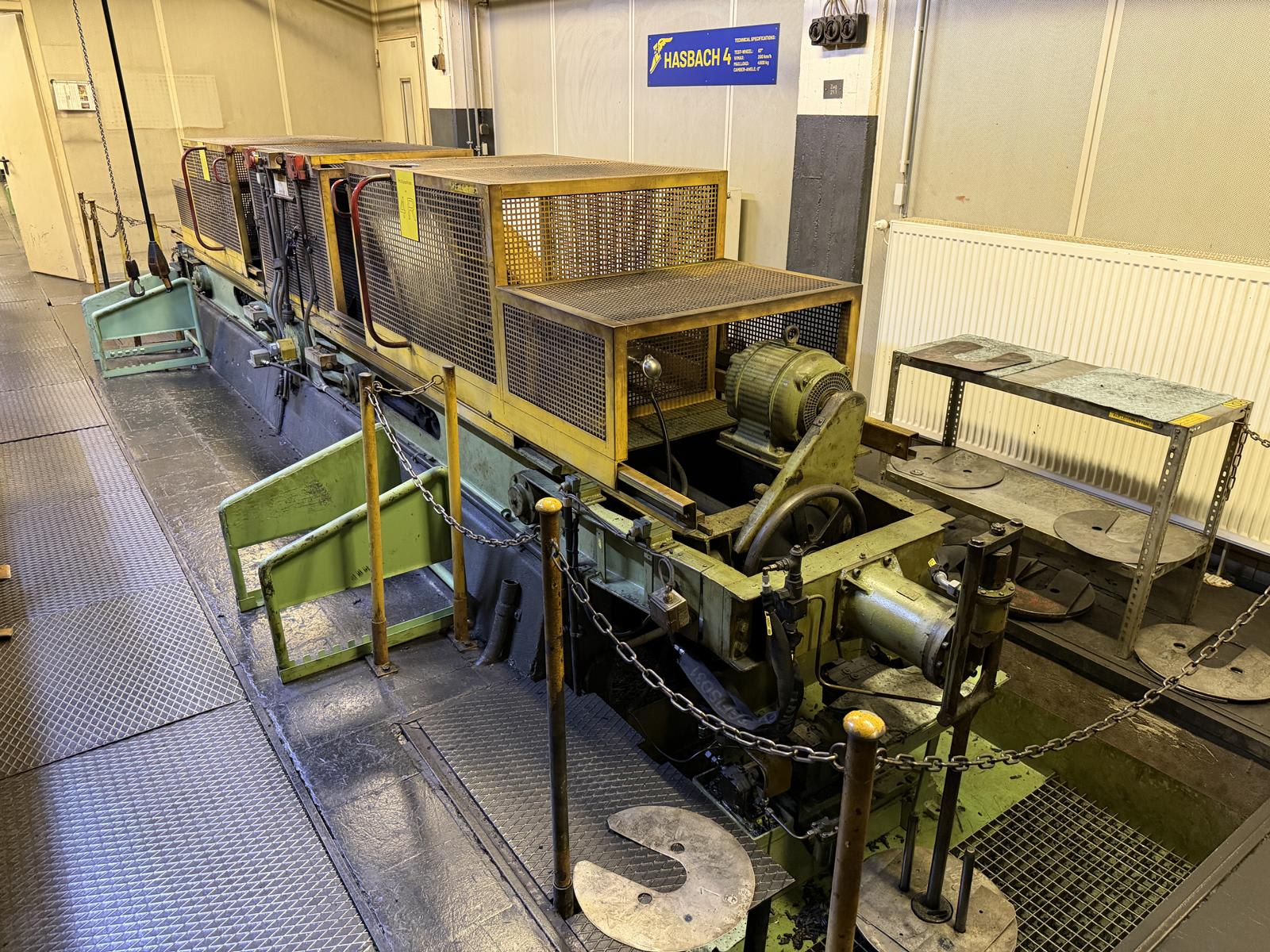

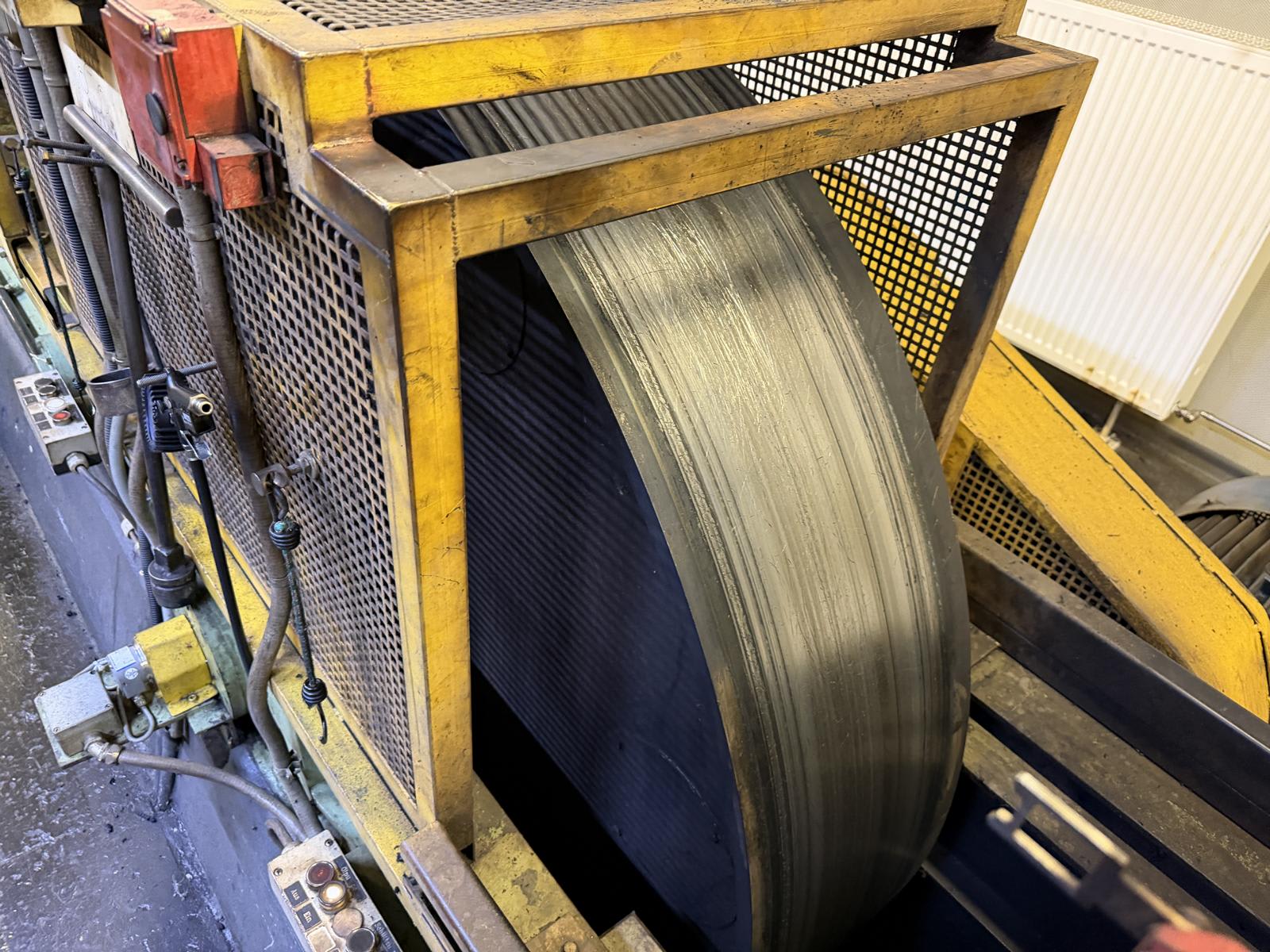

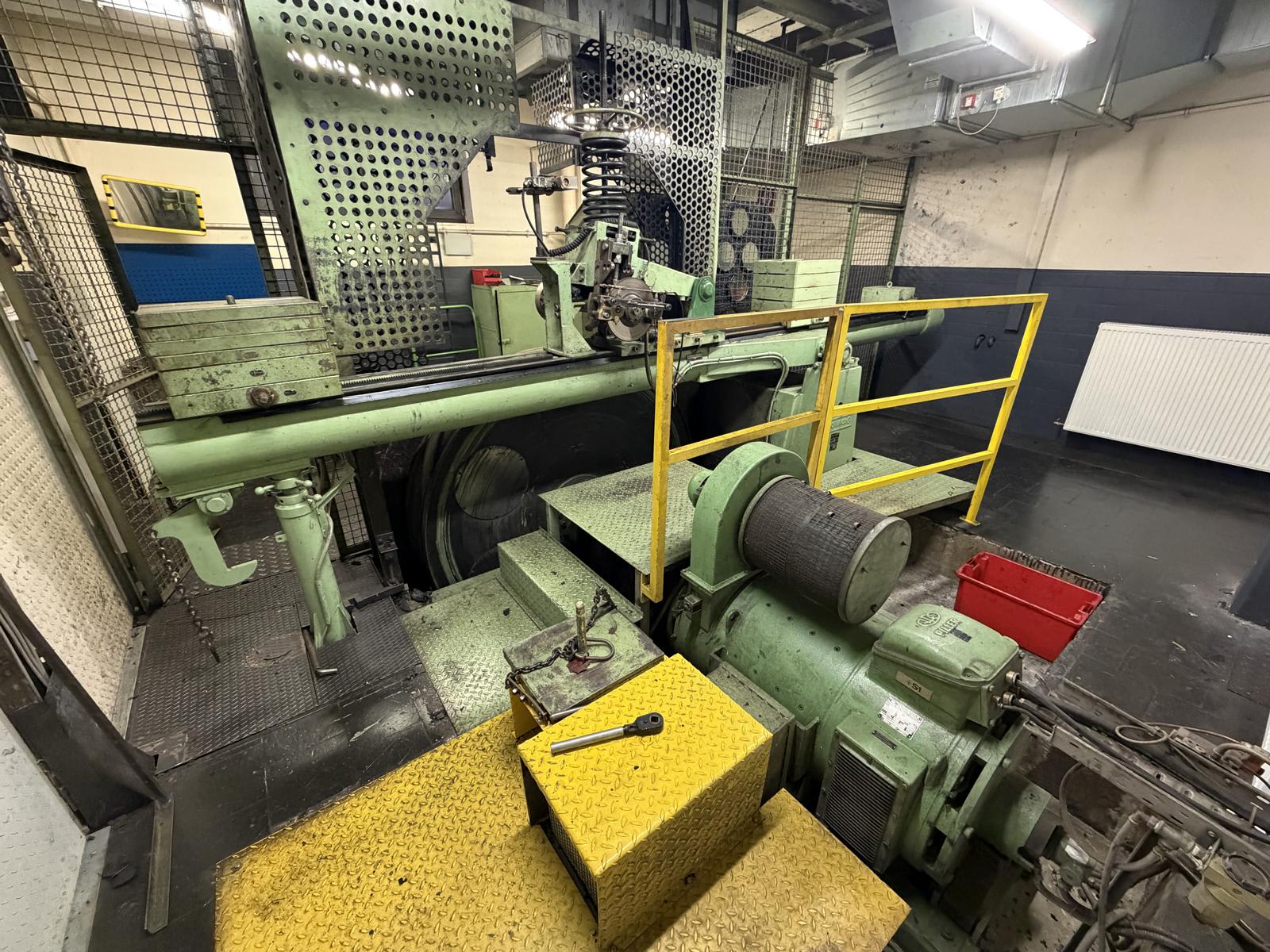

Tire Durability Testing Machine Hasbach | 1962

Binding Handling & Service Fee:

1900 € (EURO)

1. Manufacturer • Manufacturer: Hasbach 2. Machine Identification • Machine identification: Hasbach 3 • Machine type: Tire endurance / rolling resistance test rig 3. Intended Use • Endurance and rolling resistance testing of tires • Designed for industrial and laboratory tire testing applications 4. Mechanical and Performance Data • Test wheel diameter: 67 inches (approx. 1.70 meters) • Maximum speed (V/MAX): 200 km/h • Maximum test load: 4,500 kg • Camber angle: 0° (fixed) 5. Drive System • Large industrial electric motor • Multi-belt transmission system • Integrated flywheel for rotational inertia 6. Control System • Control unit (HMI): Allen-Bradley PanelView 550 7. Mechanical Construction and Installation • Heavy-duty steel frame construction • Frame colour: green • Yellow safety mesh guarding installed around hazardous areas • Installation type: pit-mounted configuration 8. Electrical Equipment • Standalone electrical cabinet bank • Cabinet colour: beige • Integrated cabinet cooling units - LISTING 2760033

![Deutsch]()

Tire Durability Testing Machine Hasbach | 1962

Binding Handling & Service Fee:

1900 € (EURO)

Tire Endurance / Rolling Resistance Test Rig 1. Manufacturer • Manufacturer: Hasbach 2. Machine Identification • Machine identification: Hasbach 4 • Machine type: Tire endurance / rolling resistance test rig 3. Intended Use • Endurance and rolling resistance testing of tires • Designed for industrial and laboratory tire testing applications 4. Mechanical and Performance Data • Test wheel diameter: 67 inches (approx. 1.70 meters) • Maximum speed (V/MAX): 200 km/h • Maximum test load: 4,500 kg • Camber angle: 0° (fixed) 5. Drive System • Large industrial electric motor (blue) • Belt-driven transmission system • Integrated flywheel for rotational inertia 6. Control and Instrumentation • Control unit (HMI): Allen-Bradley PanelView 550 • Instrumentation: – Digital controllers JUMO di 308 7. Safety and Installation • Yellow wire mesh safety cages providing perimeter guarding • Installation type: pit-mounted configuration - LISTING 2760034

![Deutsch]()

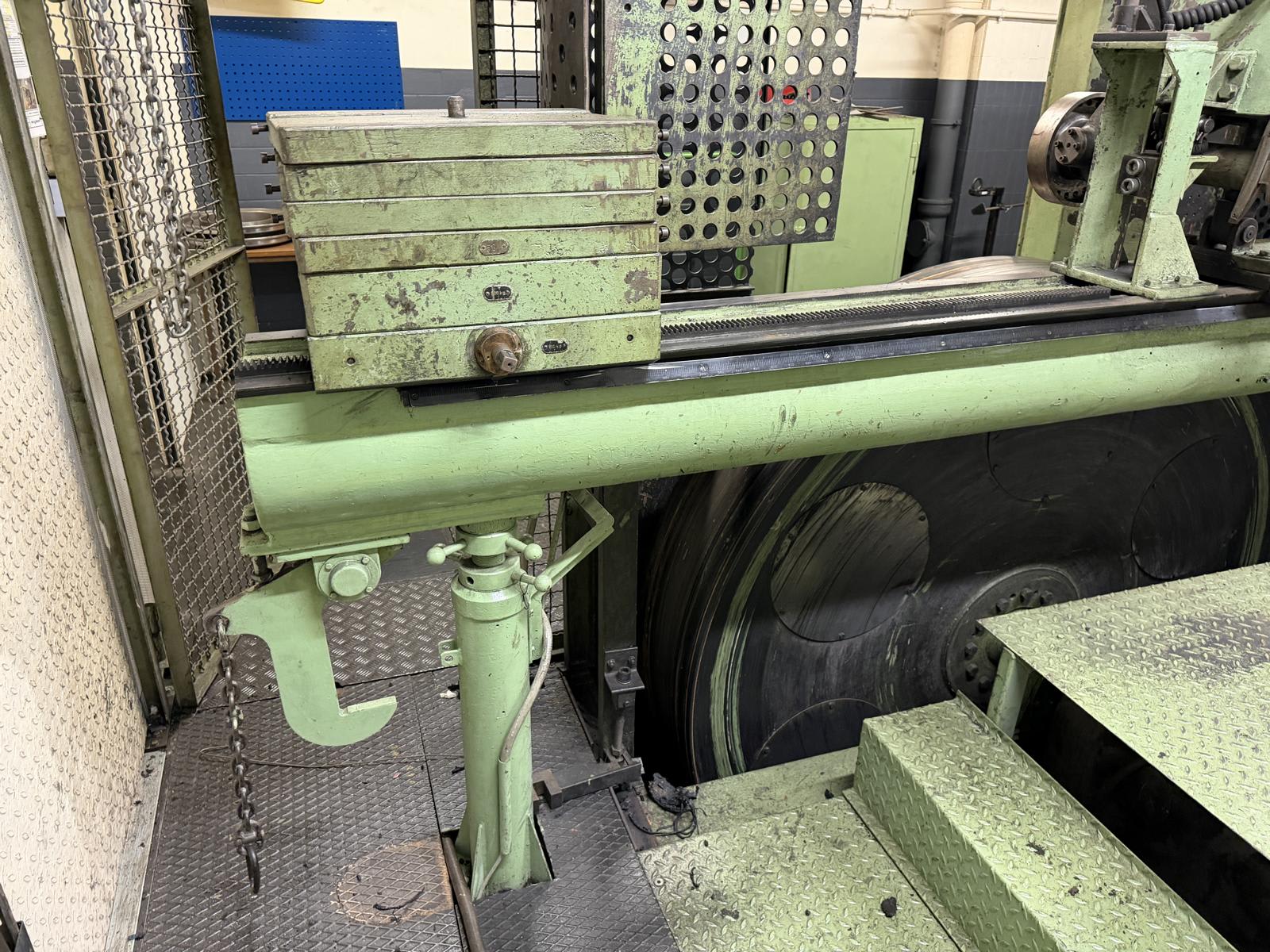

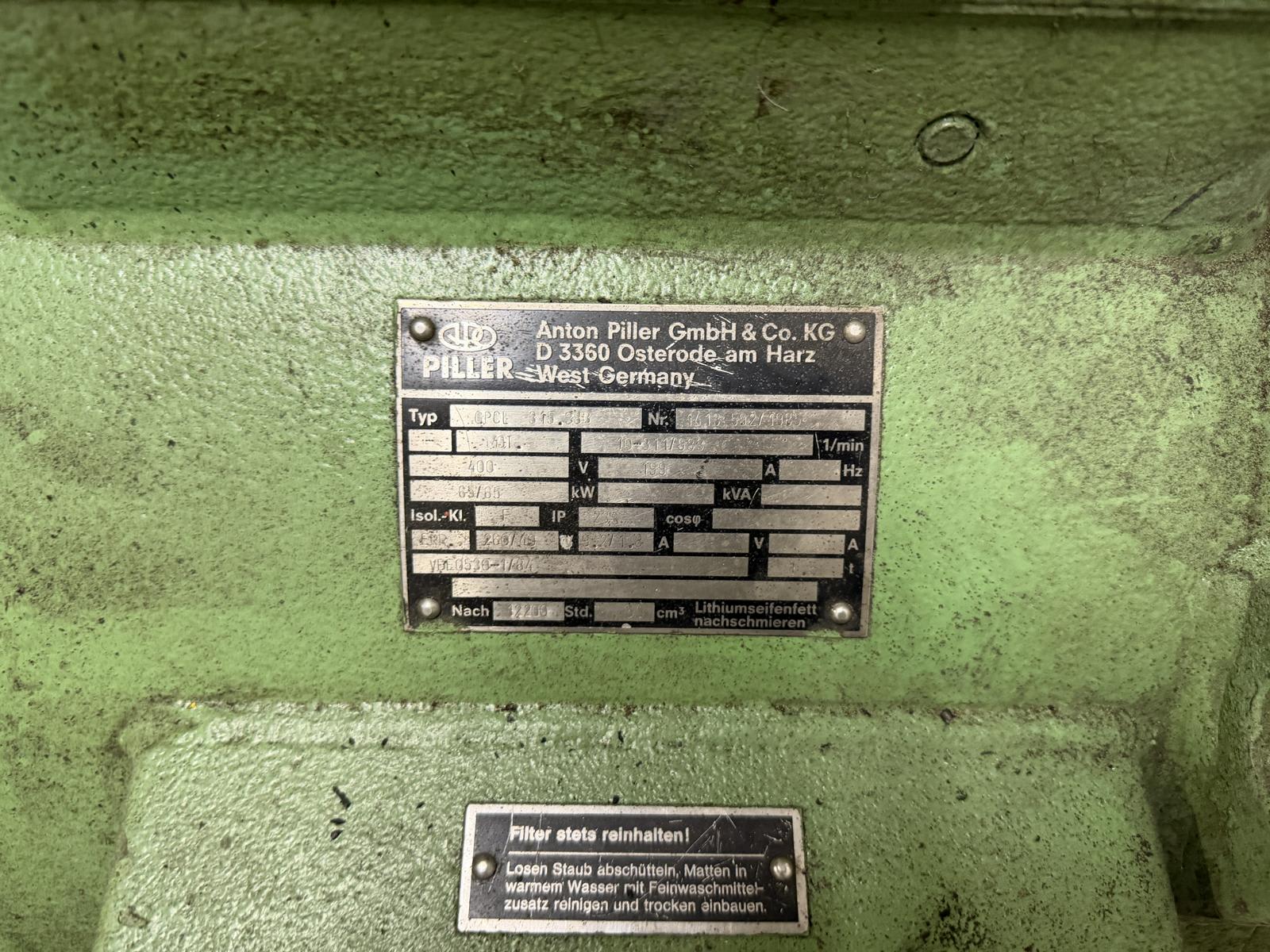

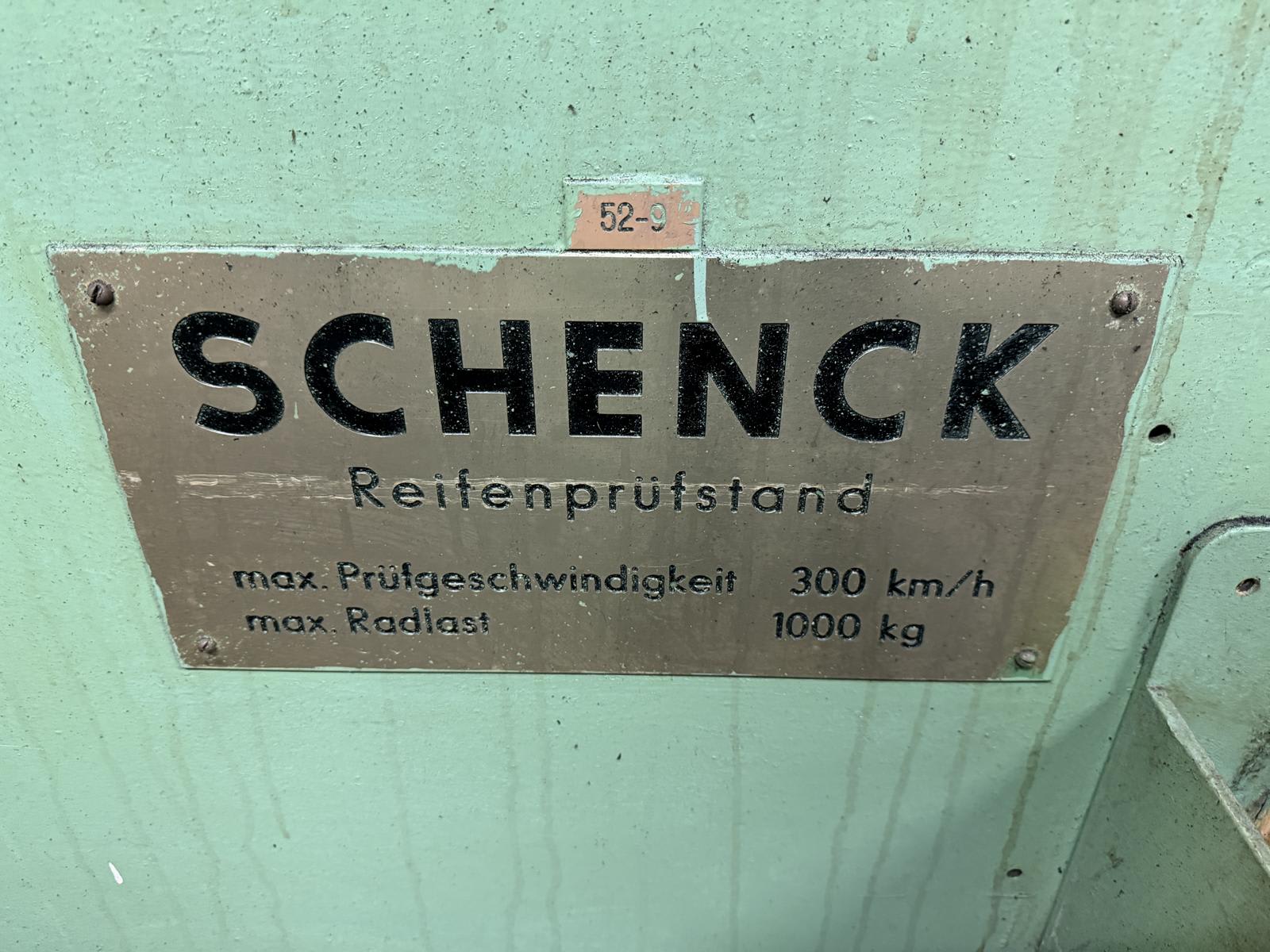

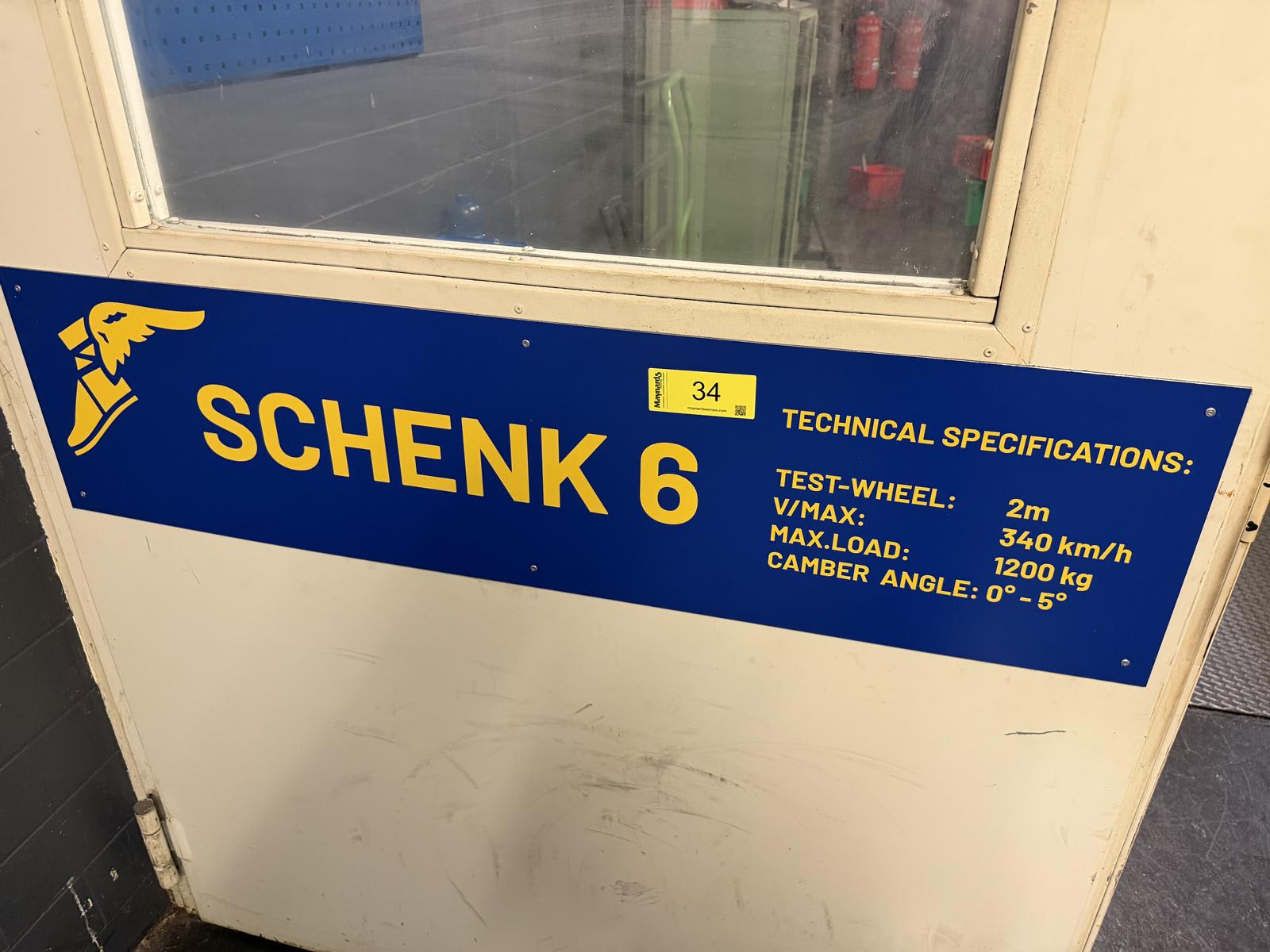

Tire Durability Testing Machine Schenk GPCL 316.388 | 1957 (1985)

Binding Handling & Service Fee:

1900 € (EURO)

High-Speed Tire Test Rig (Reifenprüfstand) 1. Manufacturer • Manufacturer: Carl Schenck Maschinenfabrik GmbH • Location: Darmstadt, Germany 2. Machine Identification • Machine identification: Schenck 6 • Machine type: High-speed tire test rig (Reifenprüfstand) 3. Year of Construction and Modernization Status • Original year of construction (mechanical chassis): 1957 • Condition: Vintage mechanical structure with subsequently retrofitted modern control technology 4. Intended Use • High-speed endurance and performance testing of tires • Designed for controlled laboratory and industrial testing under elevated rotational speeds 5. Mechanical and Performance Data • Test wheel diameter: 2.0 meters • Maximum speed (V/MAX): 340 km/h (upgrade specification) • Maximum test load: 1,200 kg • Camber angle adjustment range: 0° to 5° 6. Mechanical Construction • Heavy-duty cast steel frame construction • Frame finish: green • Large flywheels and rotating drums integrated into the mechanical structure 7. Drive System • Large industrial electric motor • Power transmission via belt drive 8. Control and Automation • Control unit (HMI): Allen-Bradley PanelView 550 • Modernized control architecture integrated with the original mechanical platform 9. Safety Equipment • Fully enclosed metal safety housing • Circular inspection windows integrated into the enclosure 10. Electrical Equipment • Standalone electrical cabinet • Cabinet finish: grey • Integrated active cooling system • Electrical equipment modernized relative to original mechanical design - LISTING 2760035

![Deutsch]()

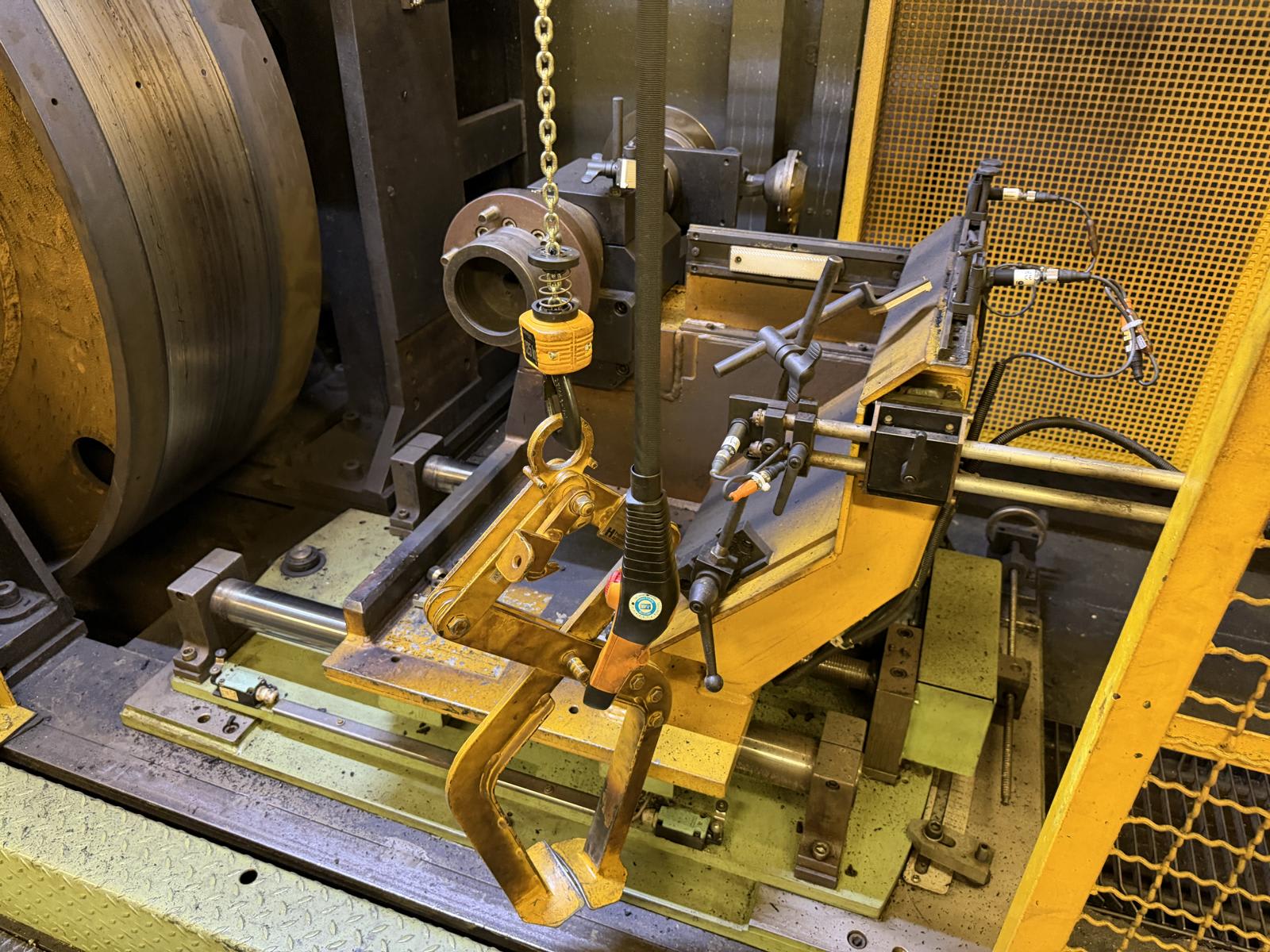

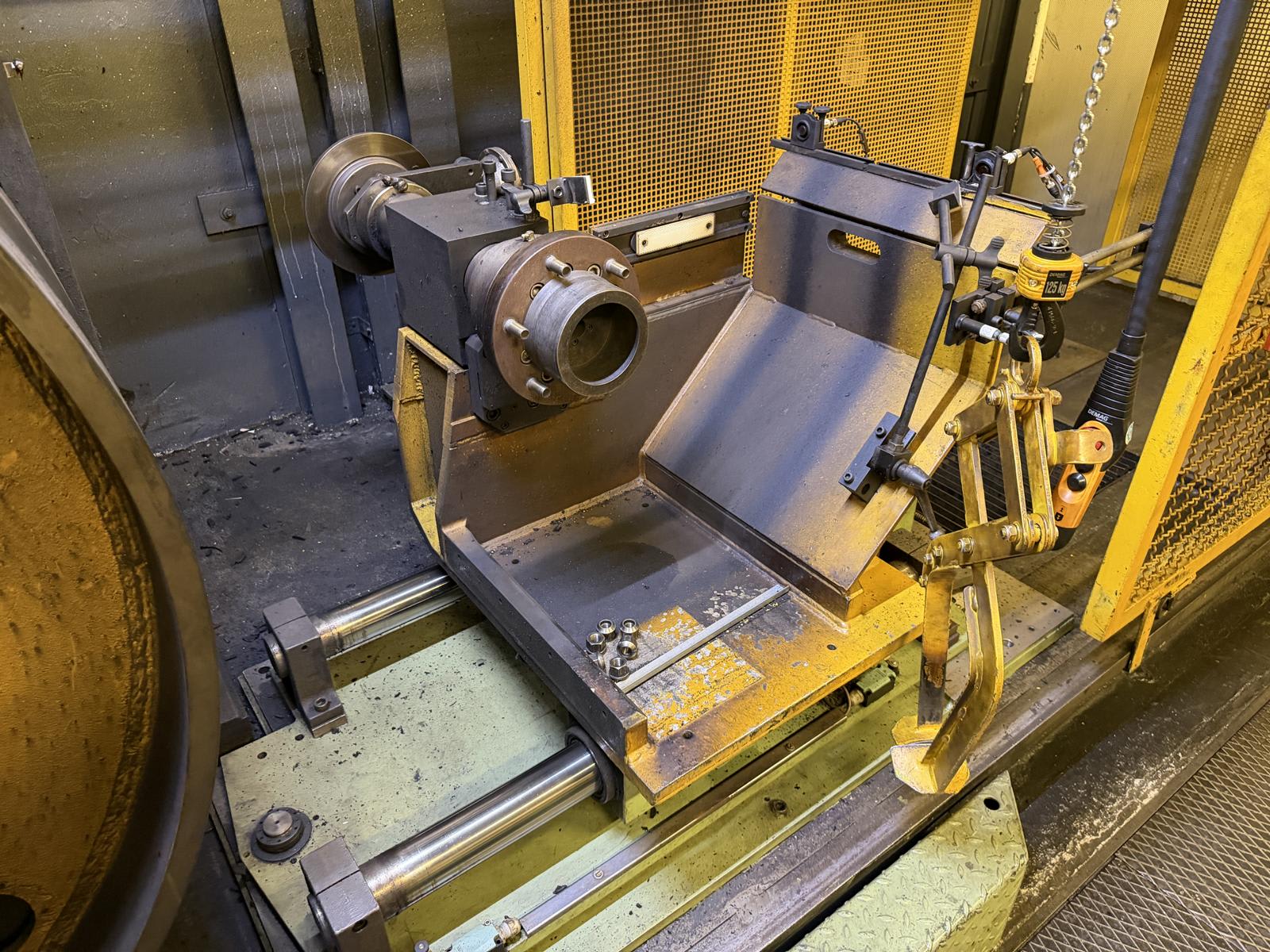

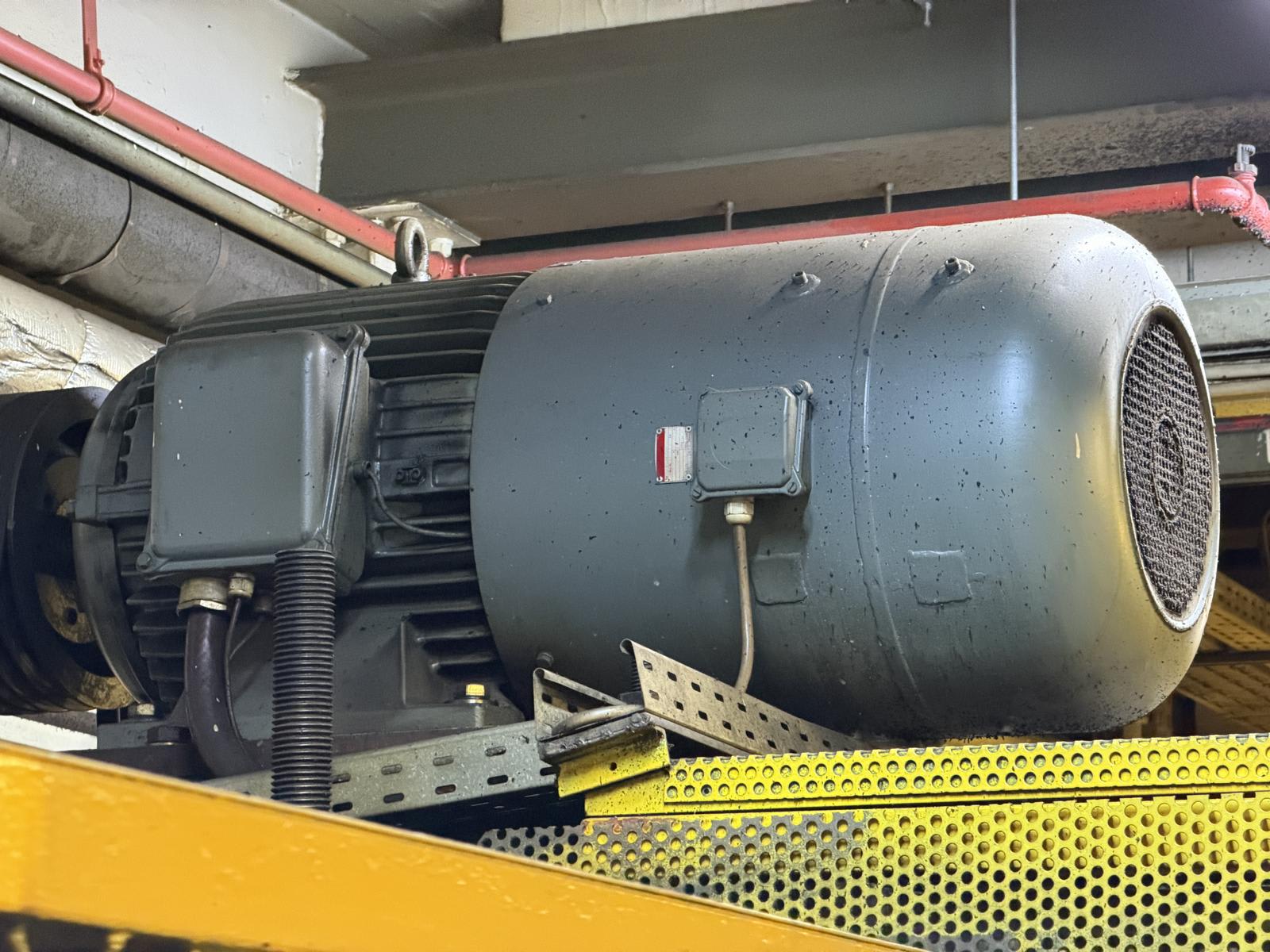

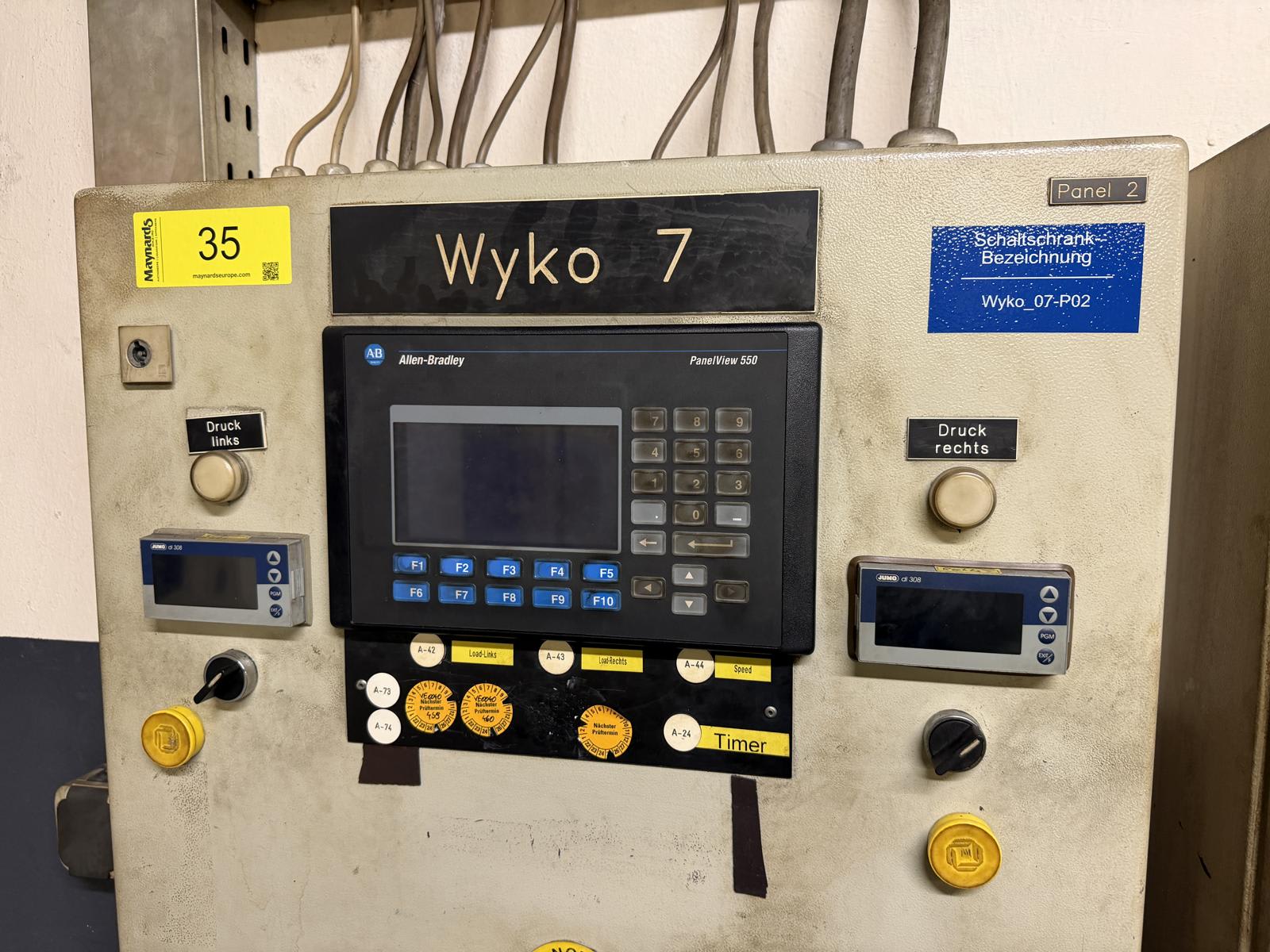

Tire Durability Testing Machine WYKO (7) | 1975

Binding Handling & Service Fee:

1900 € (EURO)

1. Manufacturer • Manufacturer: Wyko 2. Machine Identification • Machine identification: Wyko 7 • Internal equipment number: PRS07 • Machine type: High-speed tire test rig 3. Intended Use • High-speed and endurance testing of tires • Designed for controlled industrial tire testing operations 4. Mechanical and Performance Data • Test wheel diameter: 67 inches (approx. 1.70 meters) • Maximum speed (V/MAX): 300 km/h • Maximum test load: 2,500 kg • Camber angle adjustment range: 0° to 5° 5. Drive System • Large top-mounted industrial electric motor • Belt-driven power transmission 6. Control System • Control unit (HMI): Allen-Bradley PanelView 550 7. Loading and Handling Equipment • Integrated overhead Demag chain hoist • Tire grabber / manipulator for tire handling and positioning 8. Safety Equipment • Full perimeter yellow wire mesh safety cage • Safety interlocks integrated into enclosure 9. Electrical Equipment • Standalone electrical cabinet • Integrated active cooling unit - LISTING 2760036

![Deutsch]()

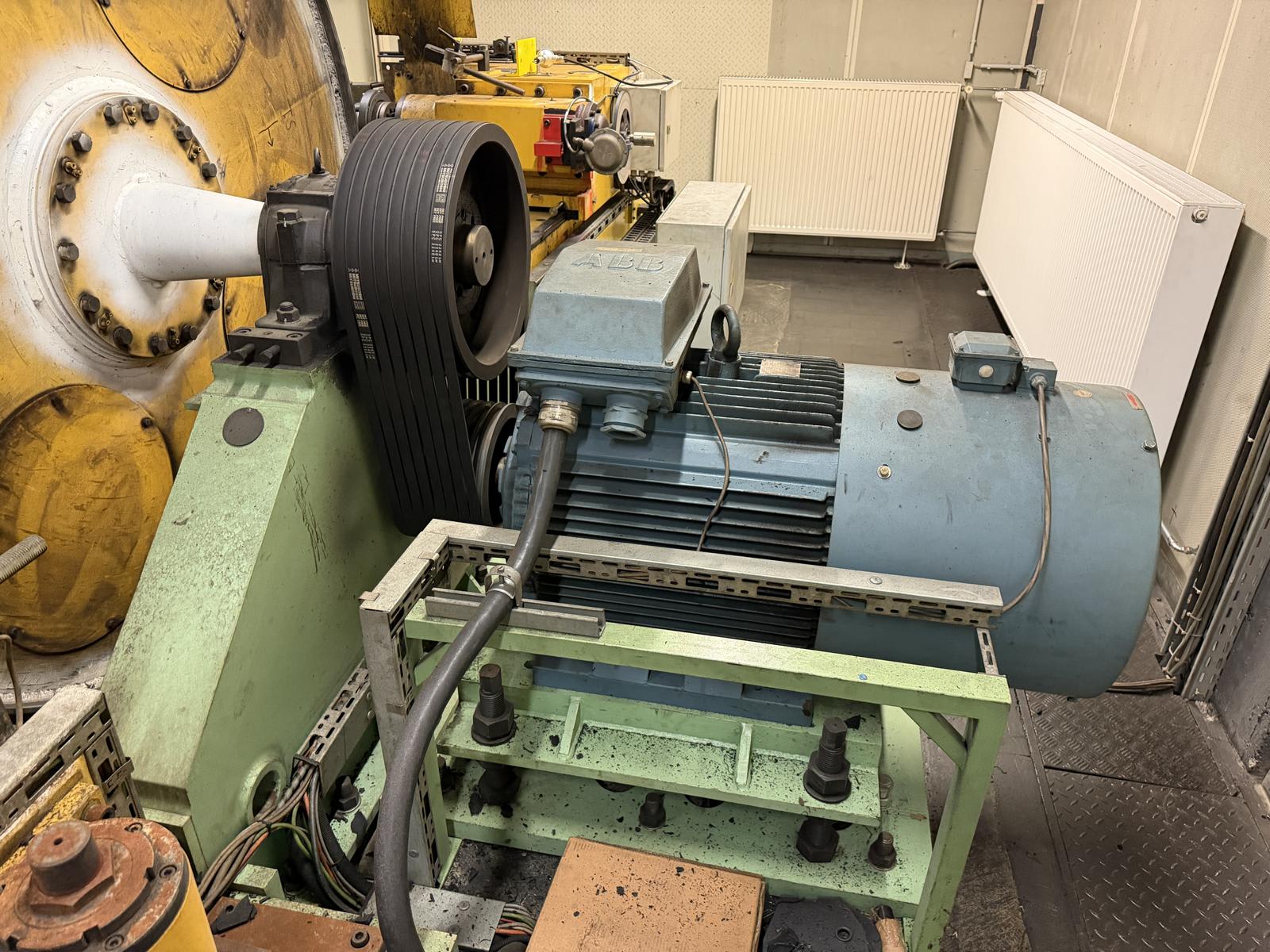

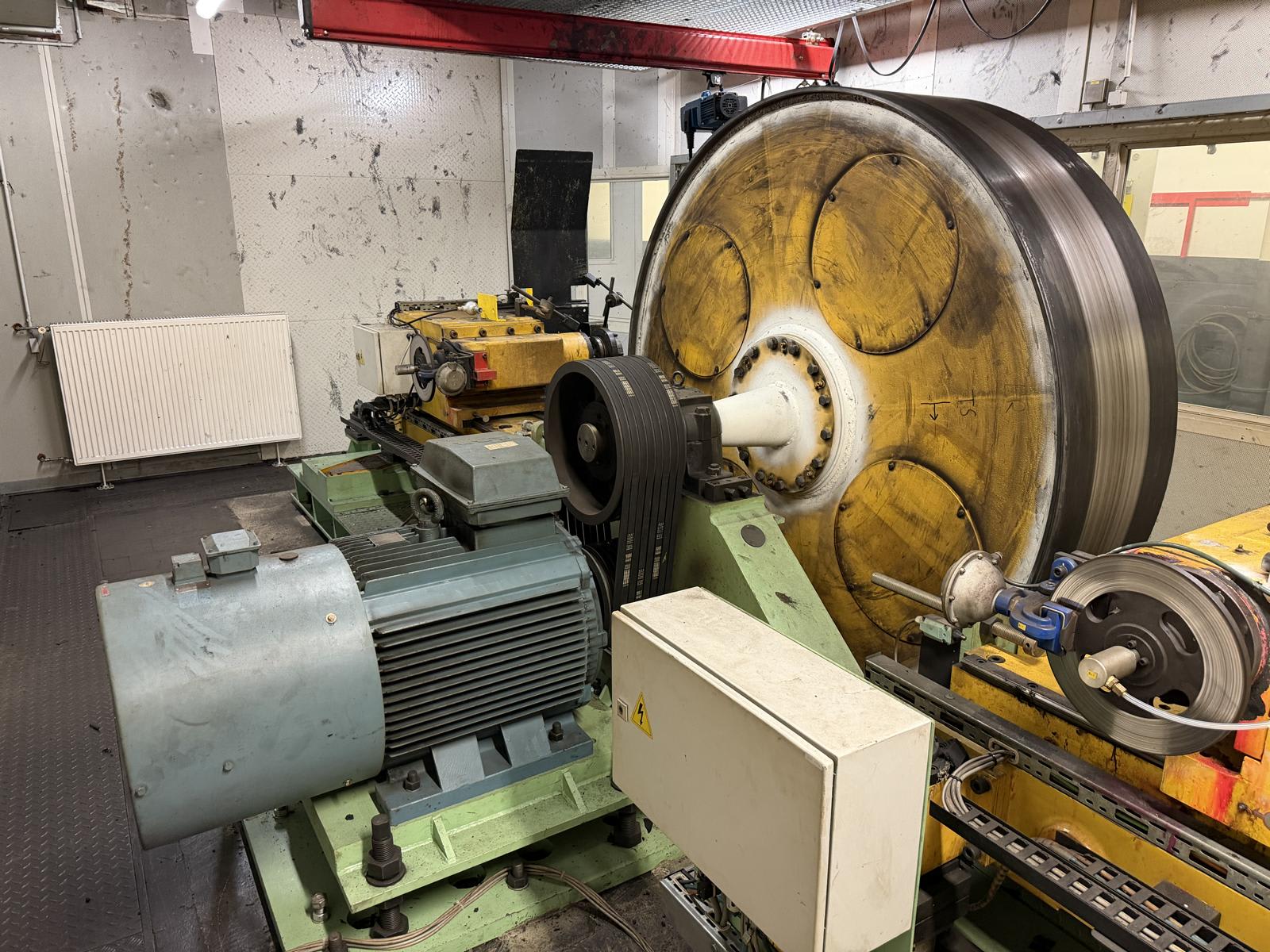

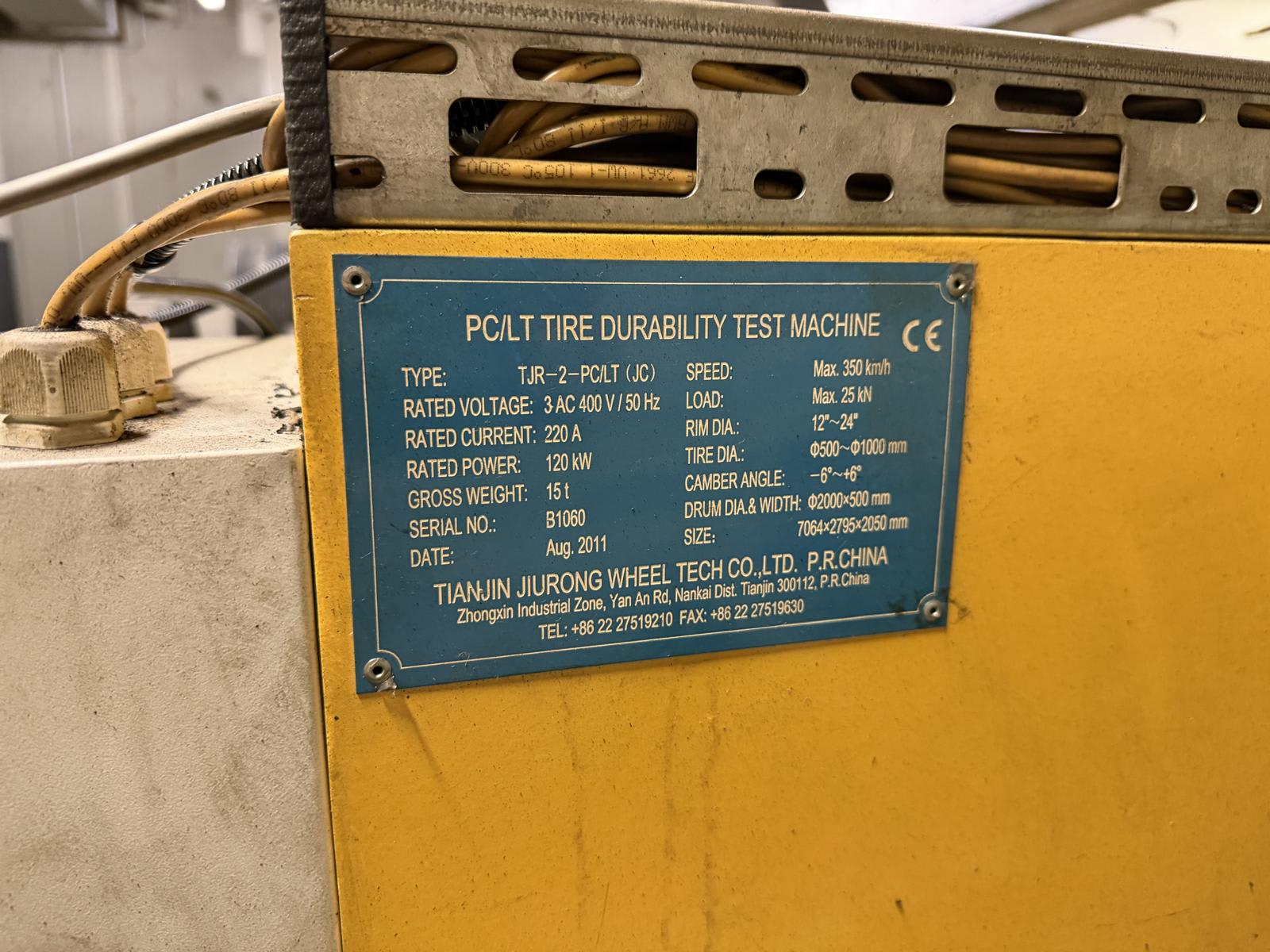

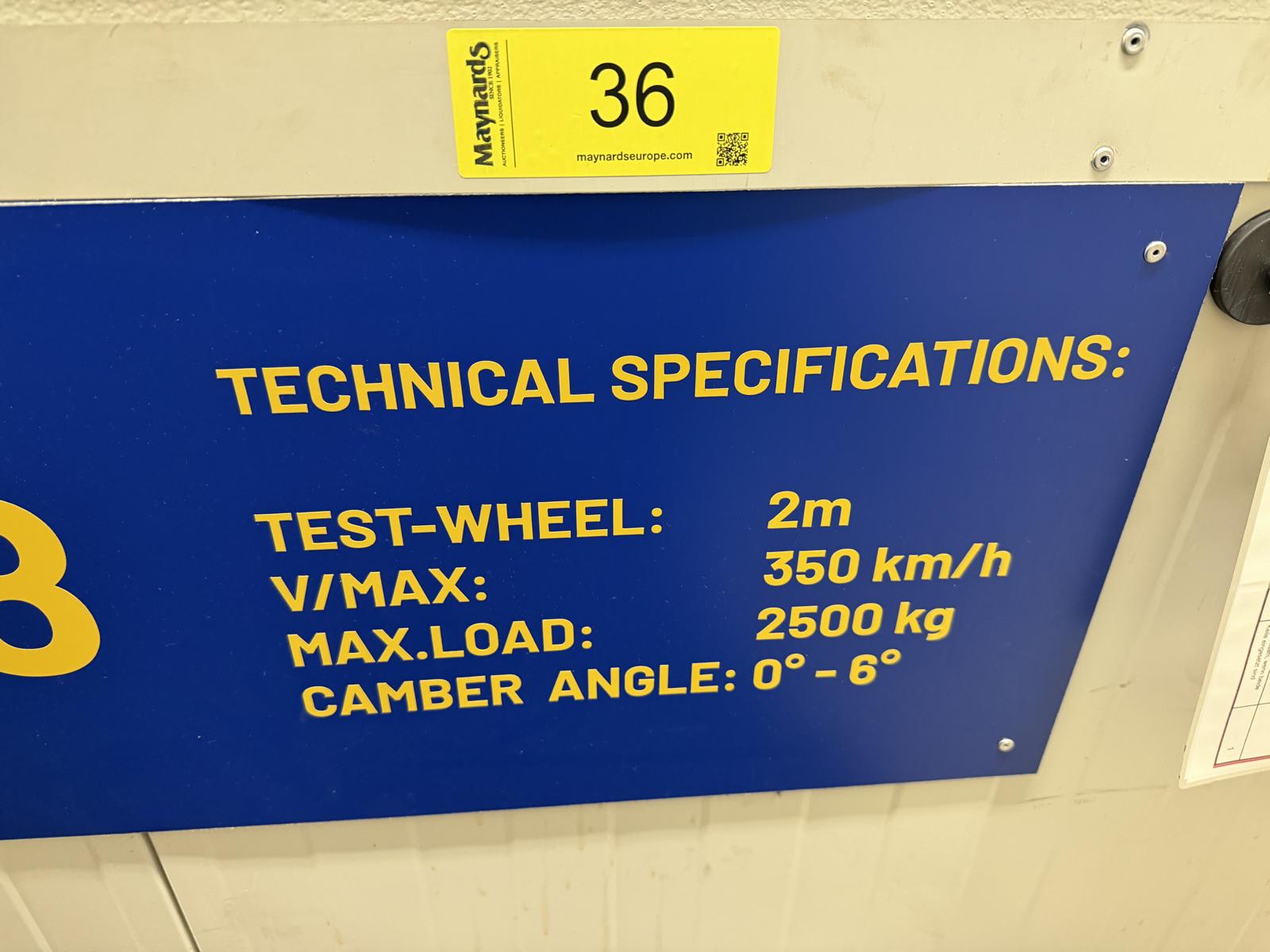

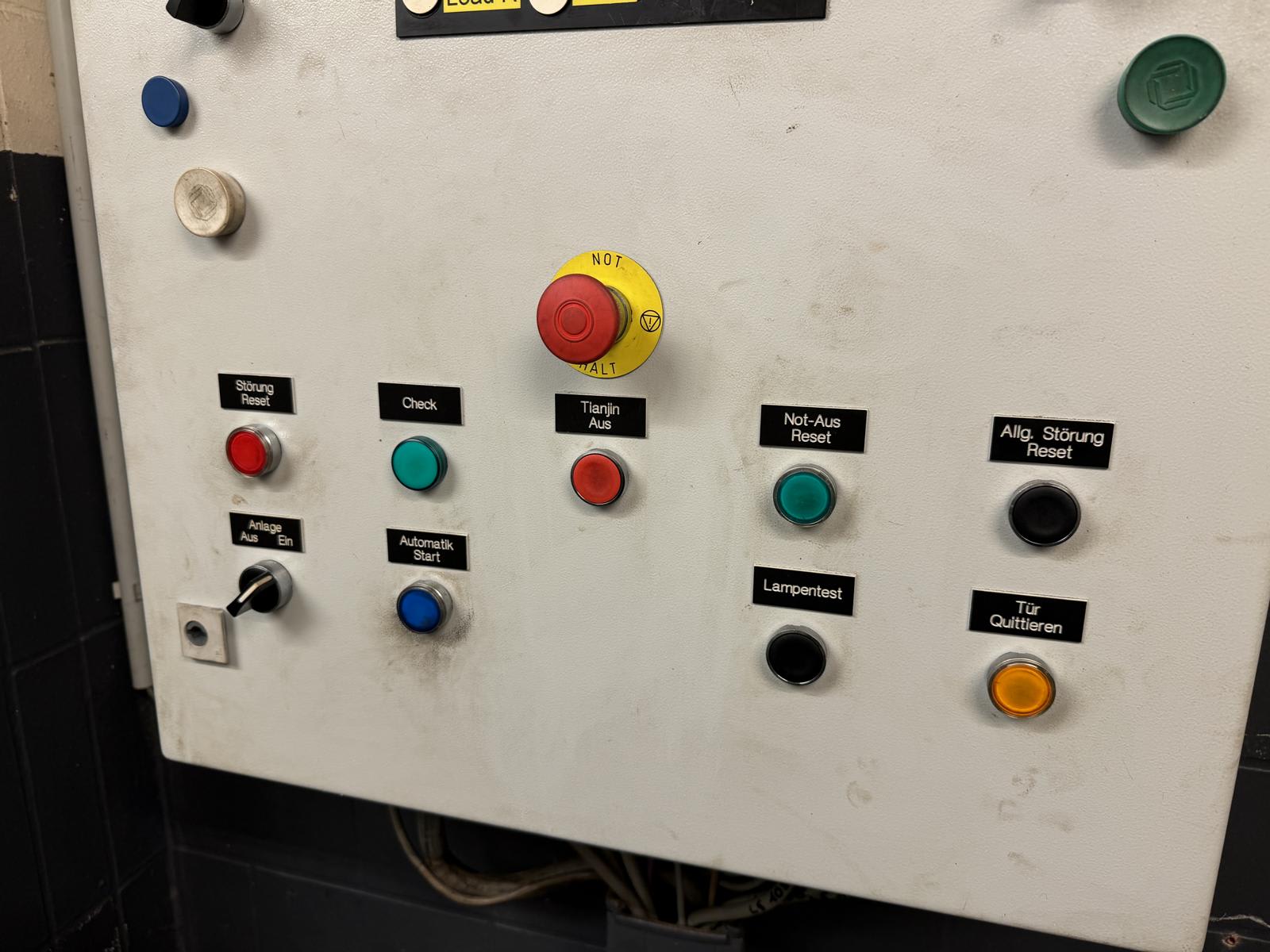

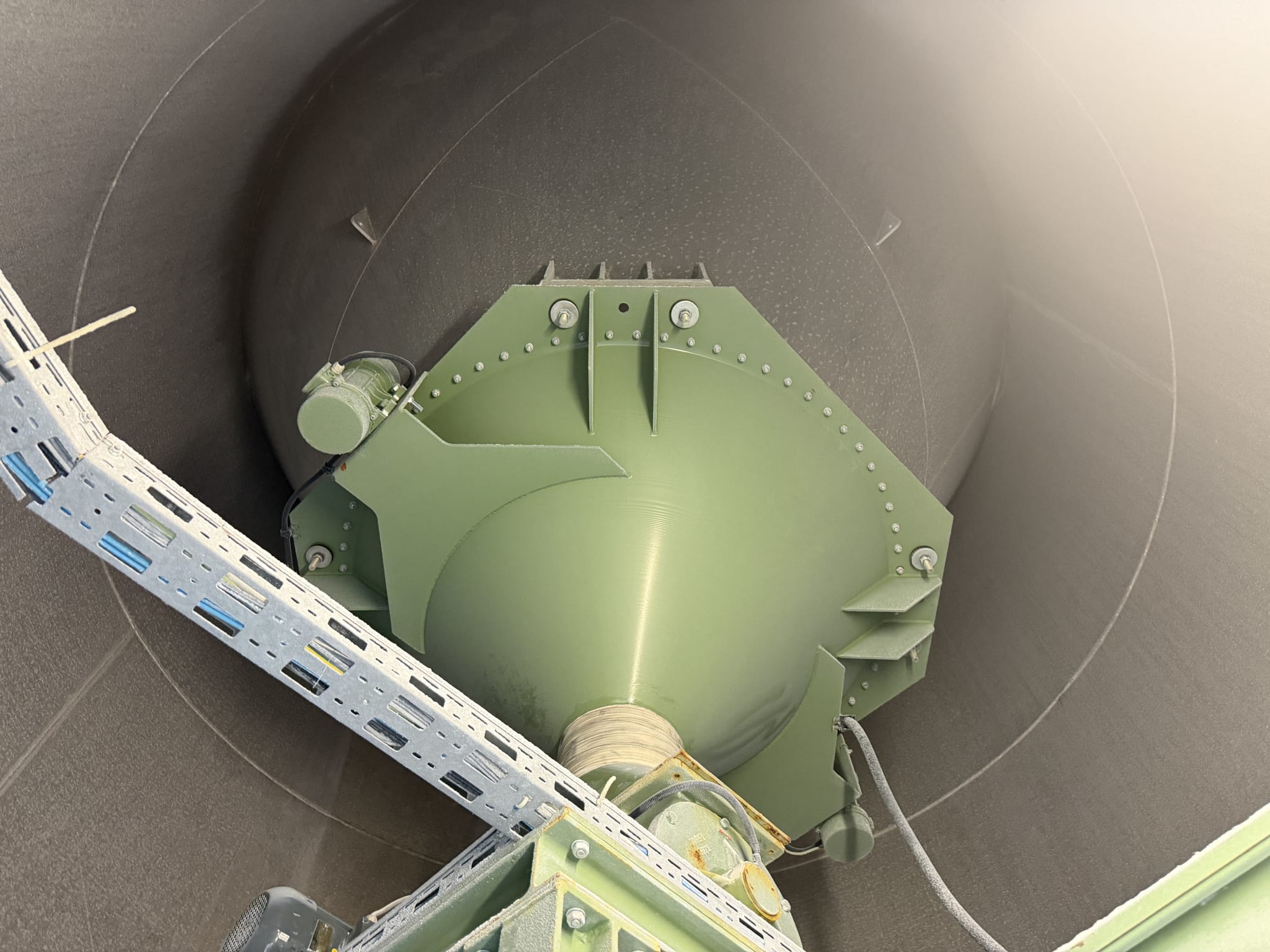

Tire Durability Testing Machine Tianjin Jiurong Wheel Tech TJR-2-PC/LT (JC) | 2011

Binding Handling & Service Fee:

1900 € (EURO)

PC/LT Tire Durability Test Machine 1. Manufacturer • Manufacturer: Tianjin Jiurong Wheel Tech Co., Ltd. • Country of manufacture: People’s Republic of China 2. Machine Identification • Model: TJR-2-PC/LT (JC) • Machine type: PC/LT tire durability test machine • Internal identification: “Tianjin 8” • Serial number: B1060 • Year of construction: August 2011 3. Intended Use • Durability and endurance testing of passenger car (PC) and light truck (LT) tires • Designed for high-speed and load-controlled tire testing applications 4. Test Drum and Capacity • Test drum diameter: 2,000 mm • Test drum width: 500 mm • Tire diameter range: 500 – 1,000 mm • Rim diameter range: 12" – 24" 5. Mechanical and Performance Data • Maximum speed (V/MAX): 350 km/h • Maximum test load: 25 kN (approx. 2,500 kg) • Camber angle adjustment range: –6° to +6° 6. Drive System • Large AC electric drive motor • Power transmission via multi-belt drive system 7. Electrical and Power Data • Rated power: 120 kW • Electrical connection: 400 V / 50 Hz • Rated current: 220 A 8. Control and Automation • Control unit (HMI): Allen-Bradley PanelView 550 9. Electrical Equipment • Standalone electrical cabinet • Cabinet manufacturer: Rittal • Integrated active cooling unit 10. Physical Data • Machine weight: 15,000 kg • Overall dimensions (L × W × H): – 7,064 × 2,795 × 2,050 mm - LISTING 2760043

![Deutsch]()

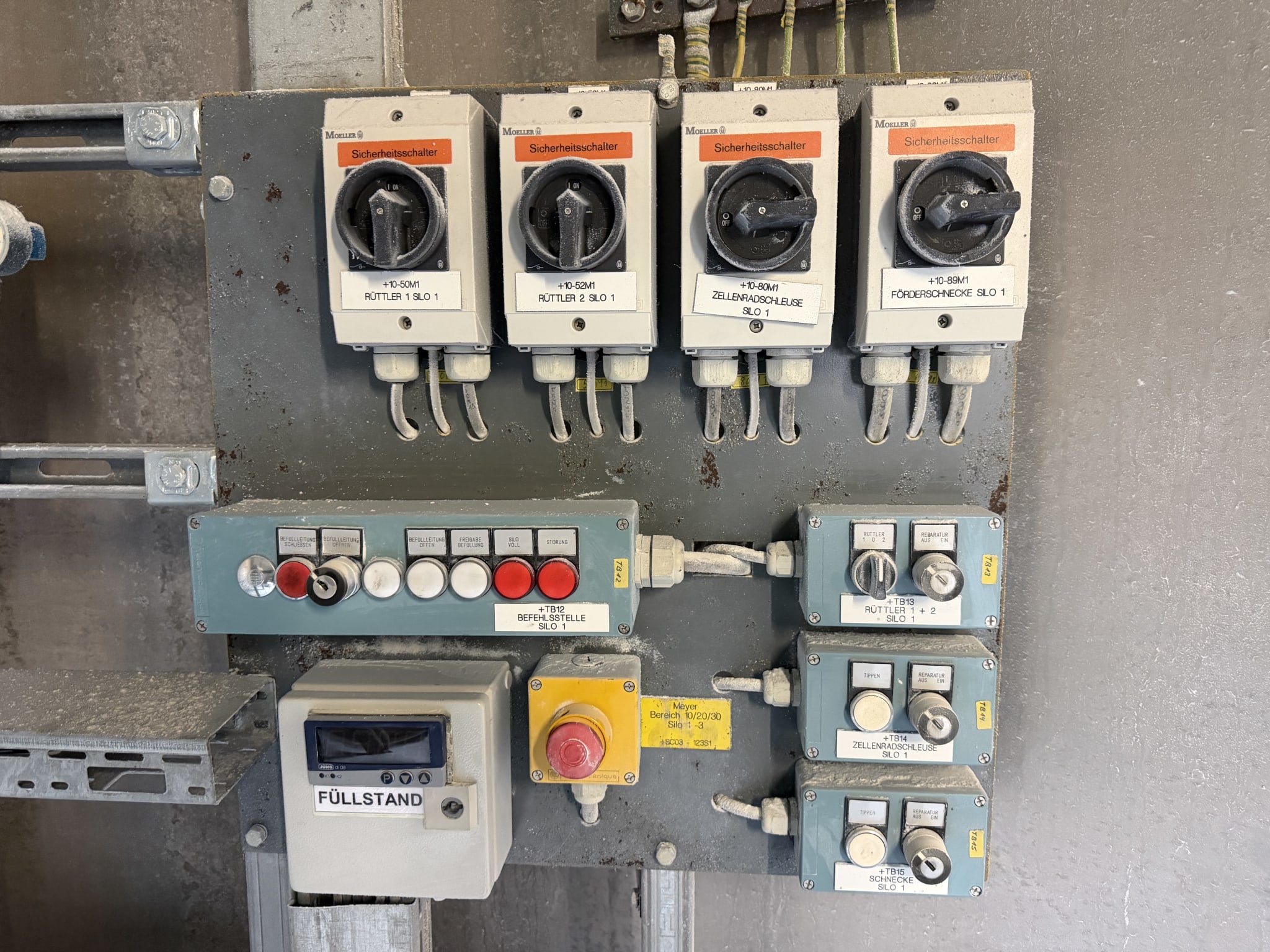

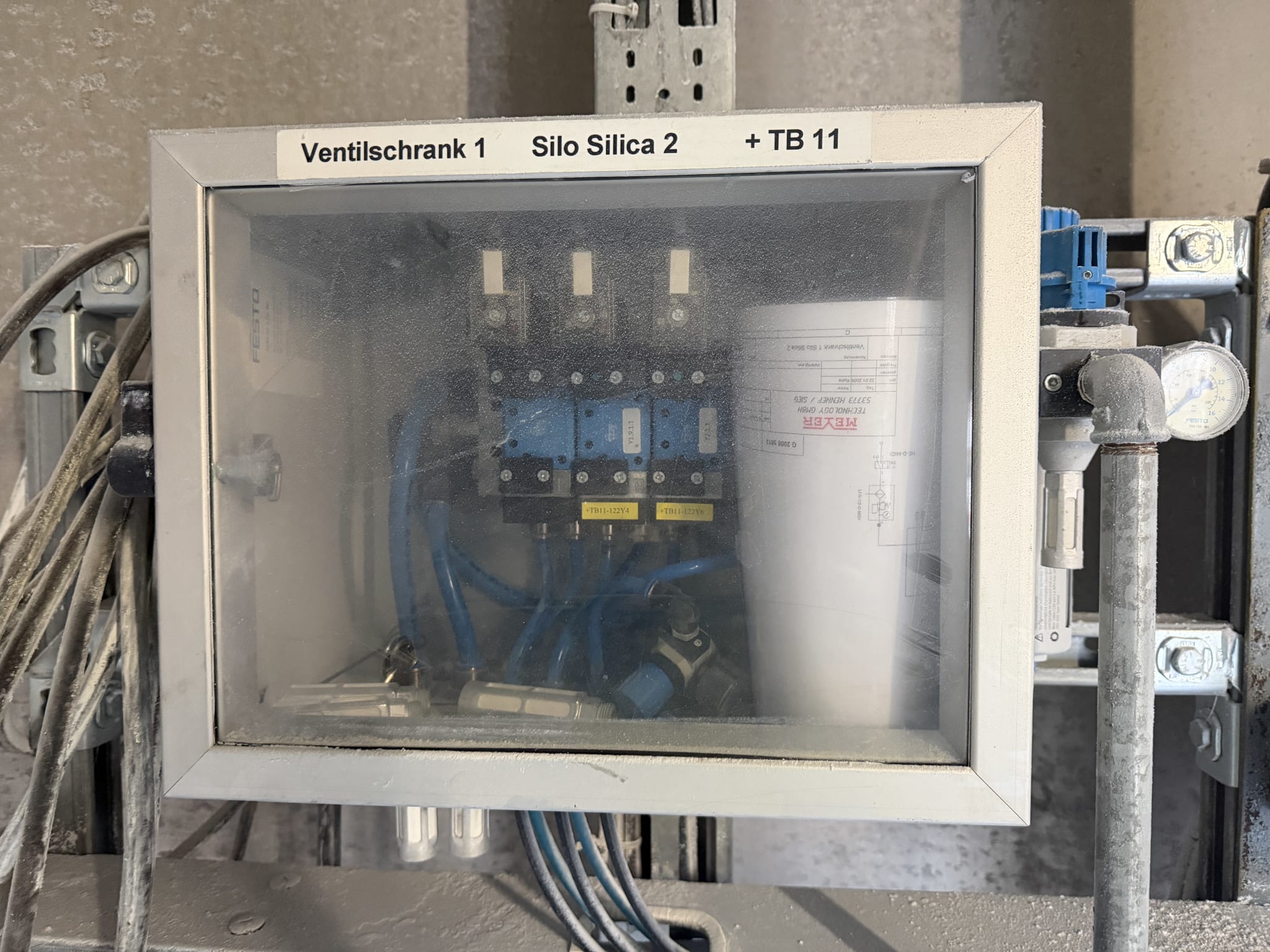

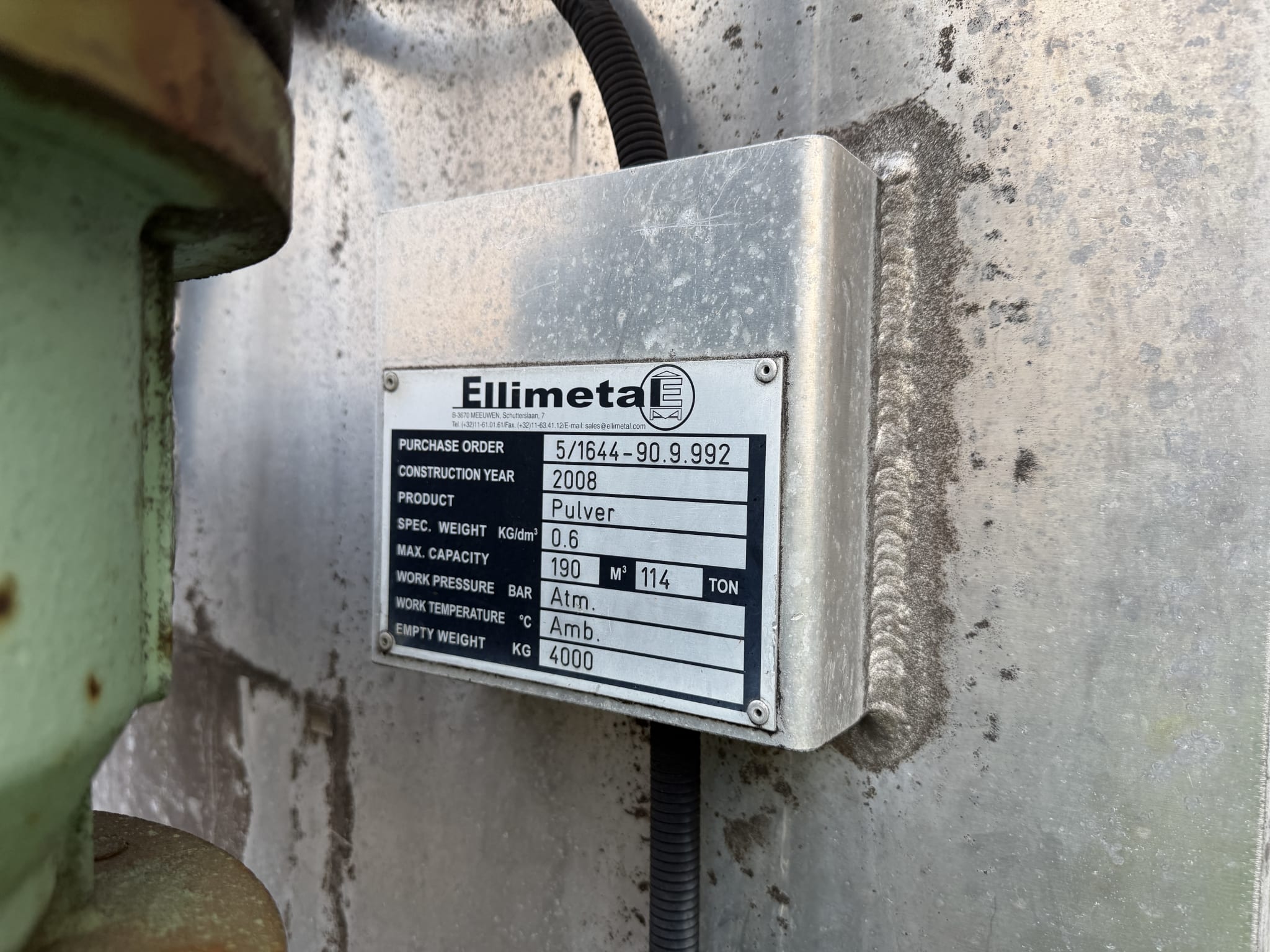

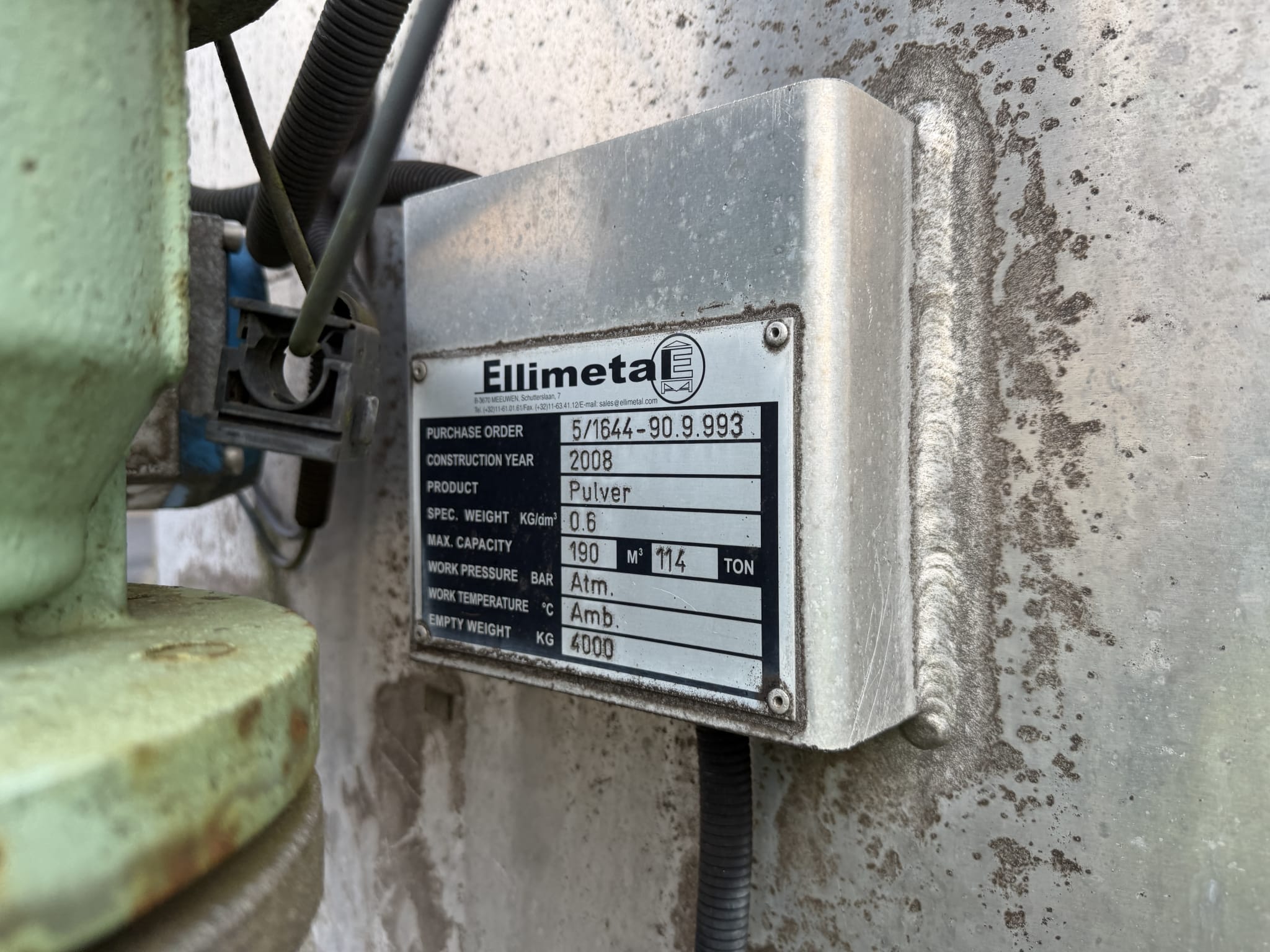

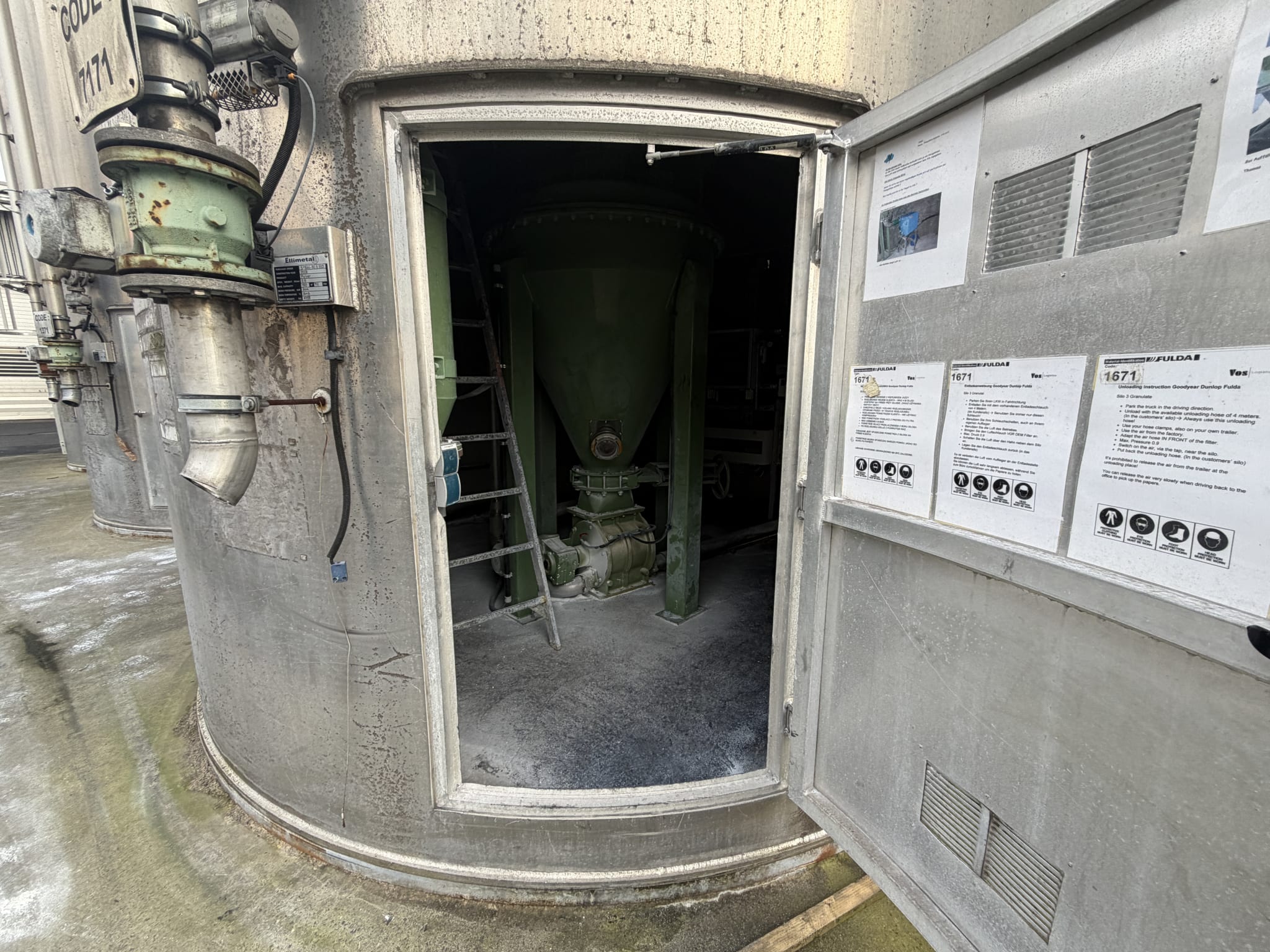

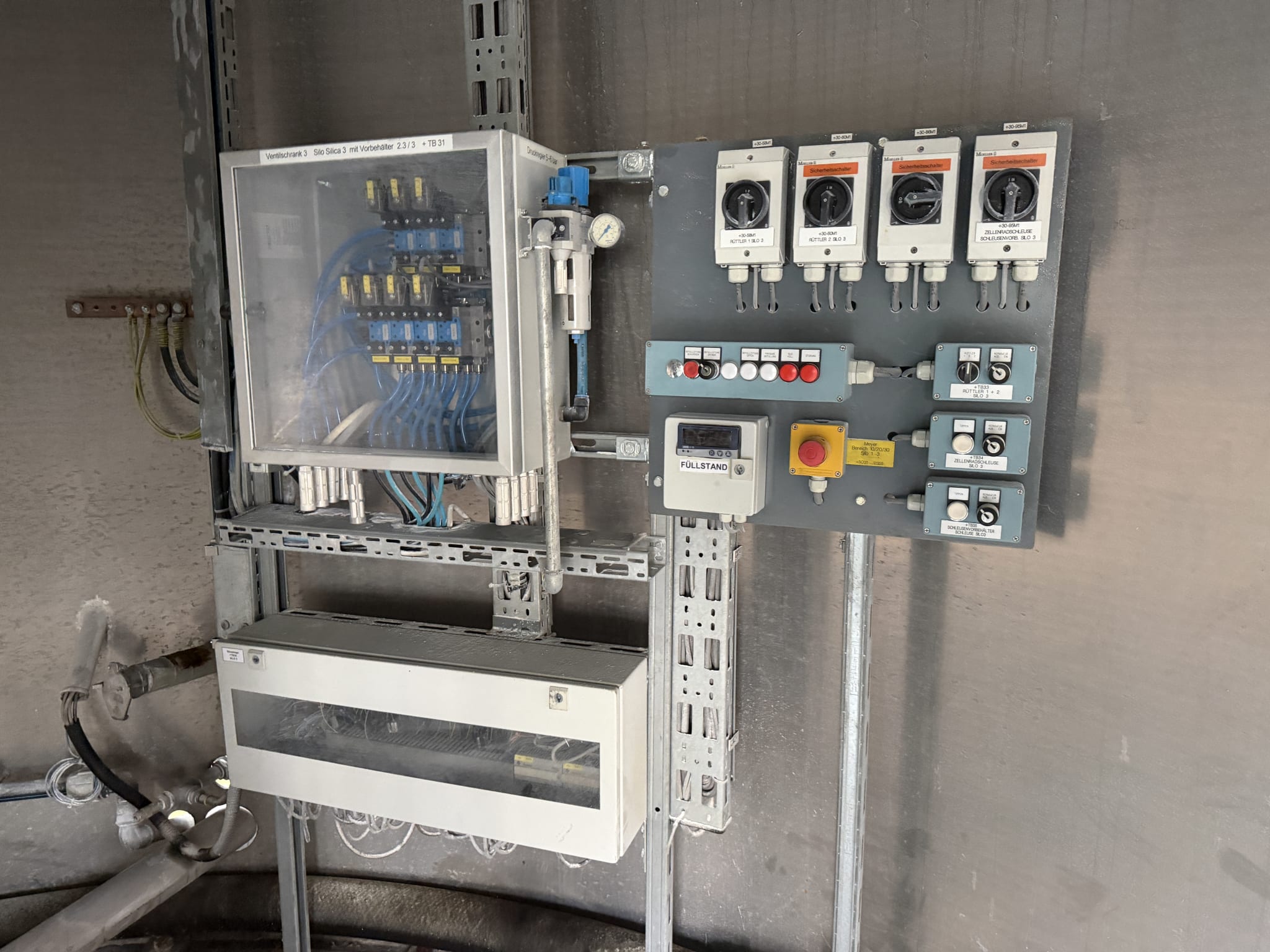

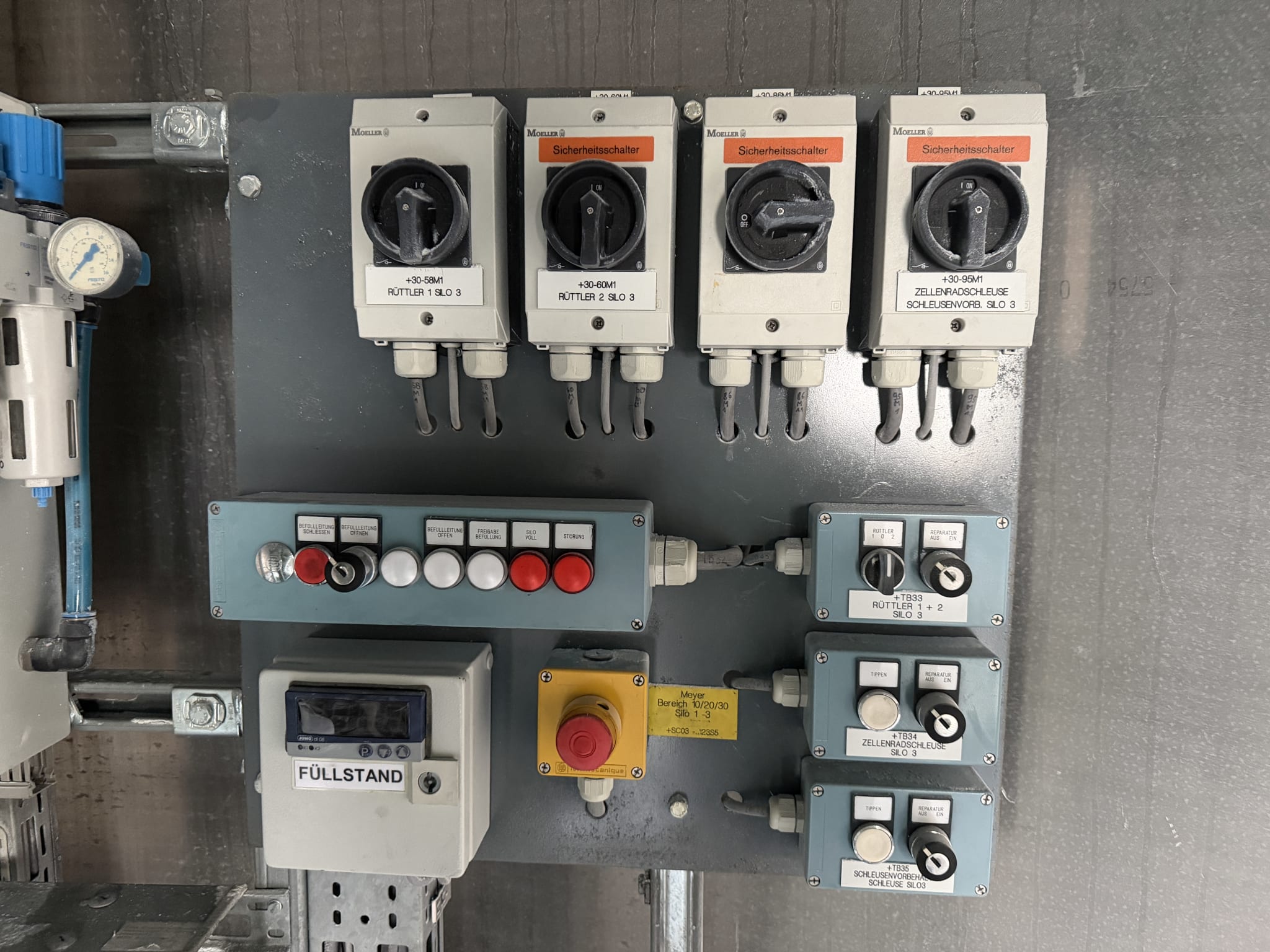

(3) Bulk Storage Silo System – Silica Ellimetal N.V. | 2008

Binding Handling & Service Fee:

9100 € (EURO)

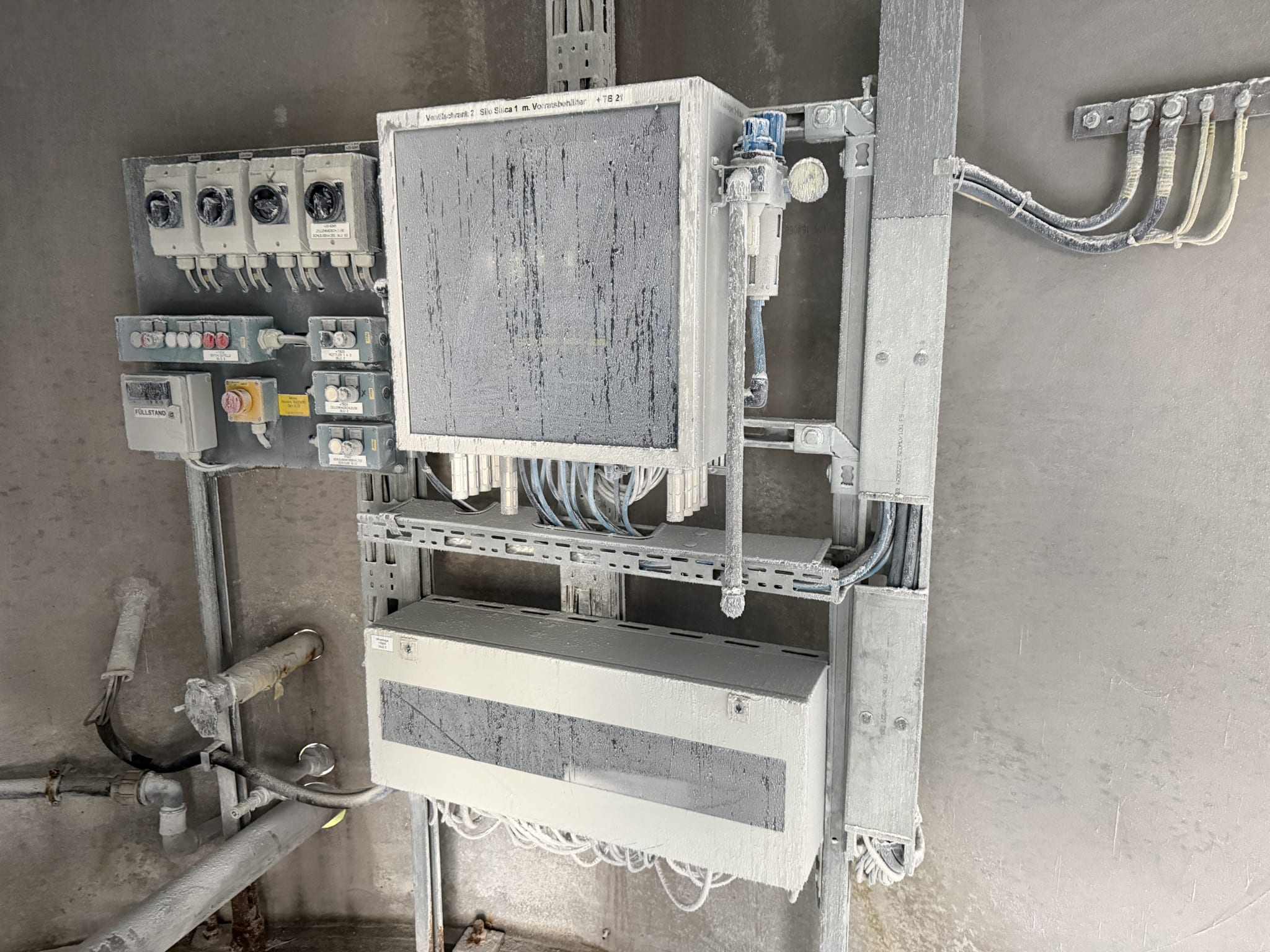

1. Manufacturer • Manufacturer: Ellimetal N.V. • Country of manufacture: Belgium 2. System Identification • System type: Bulk storage silo system • Configuration: Group of three (3) vertical silos • Application: Storage and handling of powder / silica (“Pulver”) 3. Year of Construction • Year of construction: 2008 4. Capacity and Design Data • Maximum storage volume: 190 m³ per silo • Design specific weight: 0.6 kg/dm³ • Empty weight: 4,000 kg per silo • Working pressure: Atmospheric 5. Structural Design • Vertical cylindrical steel silos • Cone-shaped discharge bottoms • External vertical access ladders with safety cages 6. Discharge and Dosing Equipment • Cone bottom discharge system • Integrated vibrating bin activators (“Rüttler”) • Rotary valve / airlock (“Zellenradschleuse”) for controlled discharge 7. Conveying Technology • Integrated screw conveyor / auger system • Conveyor components painted green 8. Control and Operation • Local control panels assigned to: – Silo Silica 1 – Silo Silica 2 – Silo Silica 3 • Control functions provided for: – Vibrating bin activators – Rotary valves / airlocks - LISTING 2760045

![Deutsch]()

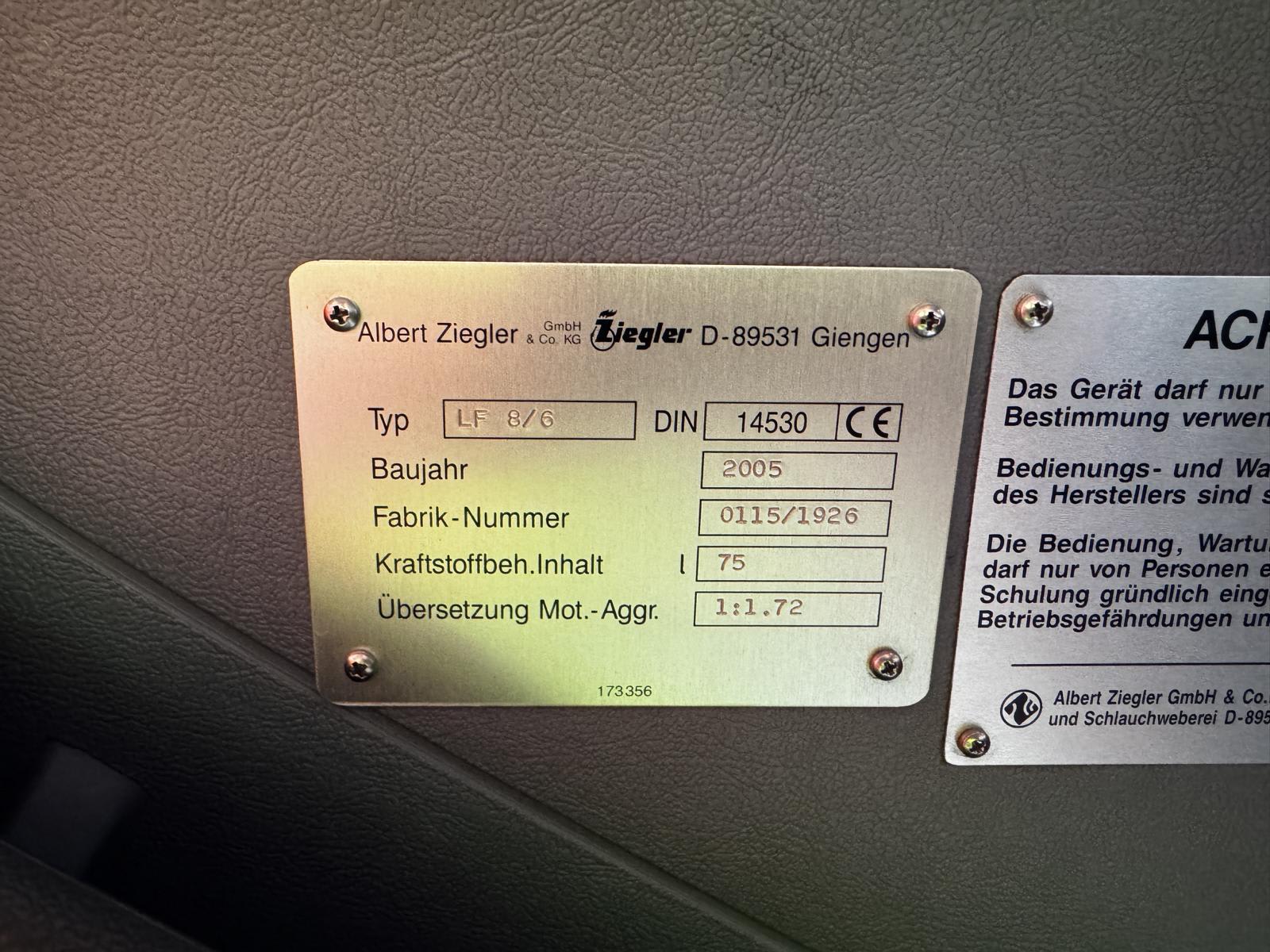

Fire Truck LF 20/6 FD-WF-305 Daimler/Ziegler LF 8/6 | 2005

Binding Handling & Service Fee:

30 € (EURO)

Only available for Pick-Up late March 2026 Fire Fighting Truck LF 8/6 (Löschgruppenfahrzeug) 1. Vehicle Classification • Vehicle type: Fire fighting truck LF 8/6 (Löschgruppenfahrzeug) • Applicable standard: DIN 14530 2. Manufacturer and Chassis • Body manufacturer: Albert Ziegler GmbH & Co. KG, Giengen, Germany • Chassis manufacturer: Mercedes-Benz • Chassis series: Atego 3. Identification and Production Data • Year of construction: 2005 • Factory number: 0115/1926 4. Previous Use • Formerly operated by the plant fire department (“Werkfeuerwehr Goodyear Fulda”) 5. Cab and Crew Configuration • Double crew cab • Integrated breathing apparatus holders installed in the seat backs 6. Powertrain • Transmission: Manual gearbox • Fuel tank capacity: 75 liters 7. Superstructure • Ziegler fire-fighting body • Aluminum roller shutters on equipment compartments • Roof-mounted storage area 8. Visible Equipment (As Installed) 8.1 Driver Side Equipment • Suction hoses • Pressure hoses • Fire nozzles • Yellow fuel canisters • Honda-powered aggregate 8.2 Passenger Side Equipment • Submersible pump TP 4-1 • Blue hose reel • Traffic cones • Floodlights • Tripods • Toolboxes - LISTING 2760046

![Deutsch]()

Fire Truck TSF VW/IVECO Magirus TSF | 2000

Binding Handling & Service Fee:

30 € (EURO)

Only available for Pick-Up late March 2026 Current mileage: approx. 17.500 Kilometers (17.12.2025) Fire Fighting Vehicle TSF (Tragkraftspritzenfahrzeug) 1. Vehicle Classification • Vehicle type: Fire fighting vehicle TSF (Tragkraftspritzenfahrzeug) • Applicable standard: DIN 14530 T 16 2. Manufacturer and Chassis • Body manufacturer: IVECO Brandschutztechnik Görlitz GmbH (Magirus) • Chassis manufacturer: Volkswagen • Chassis type: LT 35 3. Identification and Production Data • Year of construction: 2000 • Factory number: 0887 • Internal call sign: 80/59/1 4. Previous Use • Formerly operated by the plant fire department (“Werkfeuerwehr Goodyear Fulda”) 5. Powertrain • Transmission: Manual gearbox 6. Equipment Configuration (As Installed) 6.1 Equipment Compartment G1 (Driver Side) • Holmatro hydraulic rescue equipment, comprising: – Hydraulic power unit – Hydraulic spreader – Hydraulic cutter • Traffic cones • Medical backpack 6.2 Equipment Compartment G2 (Passenger Side) • Chainsaw (Stihl) • Breathing apparatus holders (Dräger) • Toolboxes • Chemical spill absorbent material 6.3 Equipment Compartment GR (Rear) • Slide-out tray for portable fire pump (TS) • Hose reel • Spine board • Stretcher - LISTING 2760047

![Deutsch]()

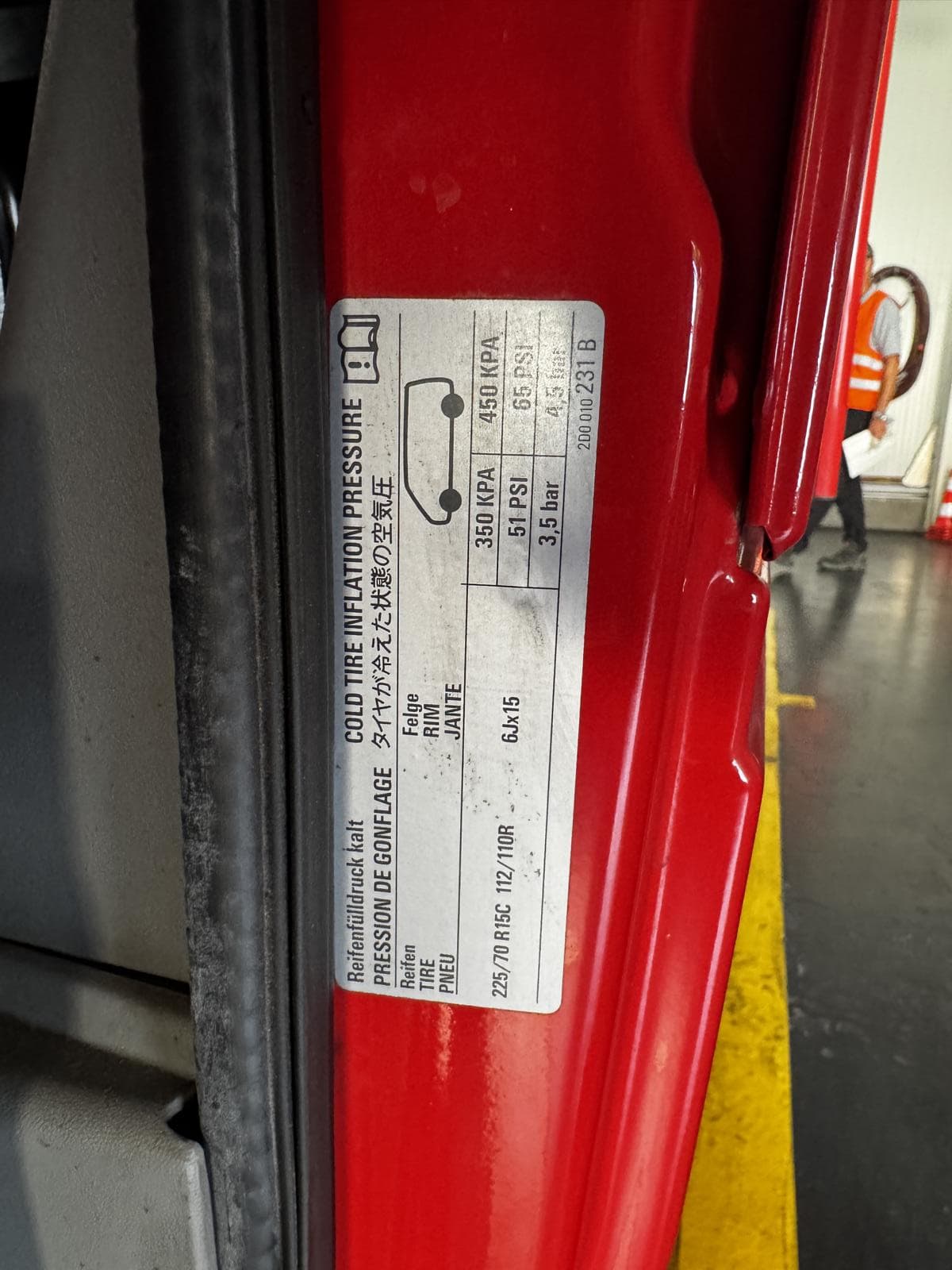

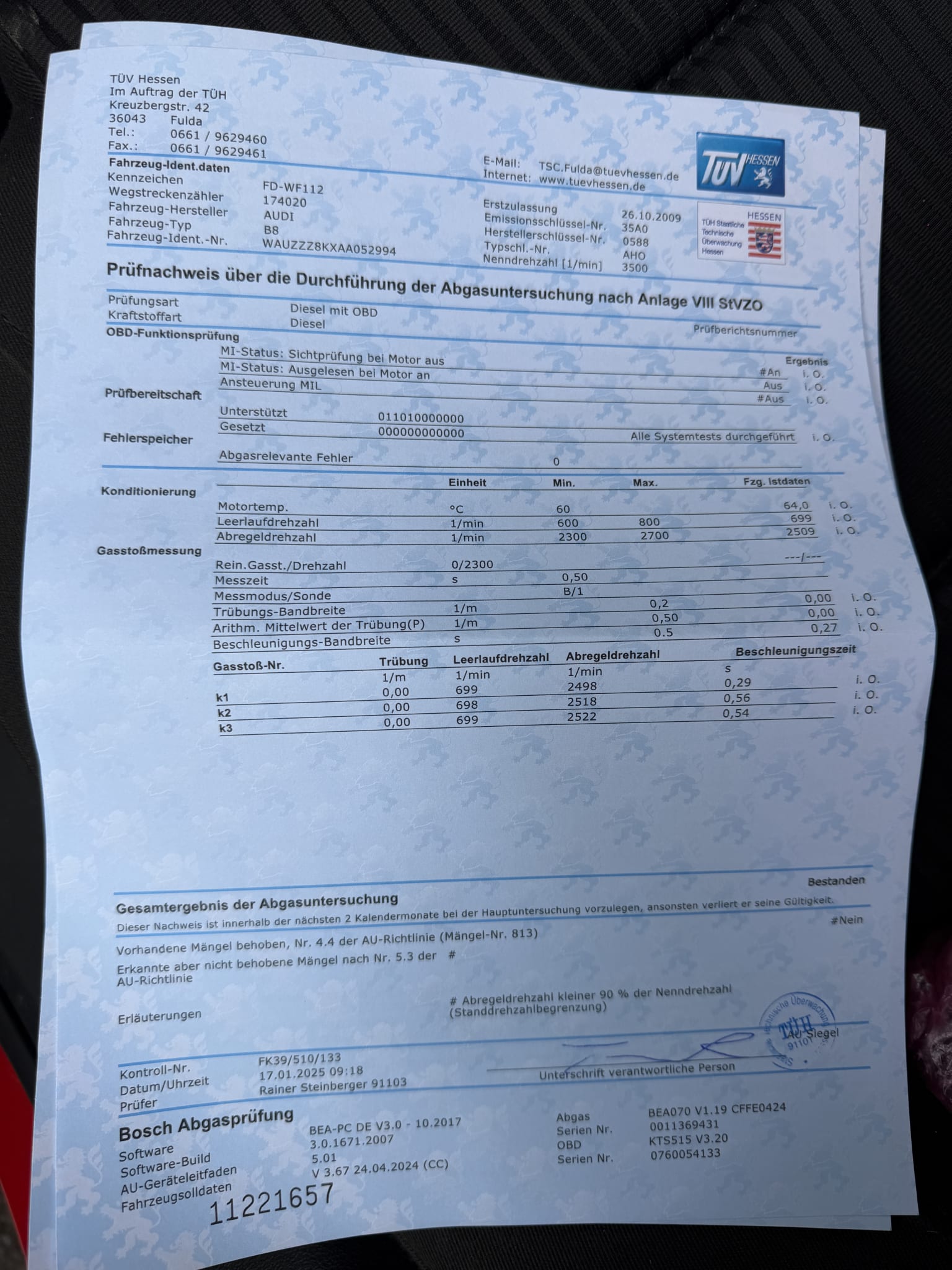

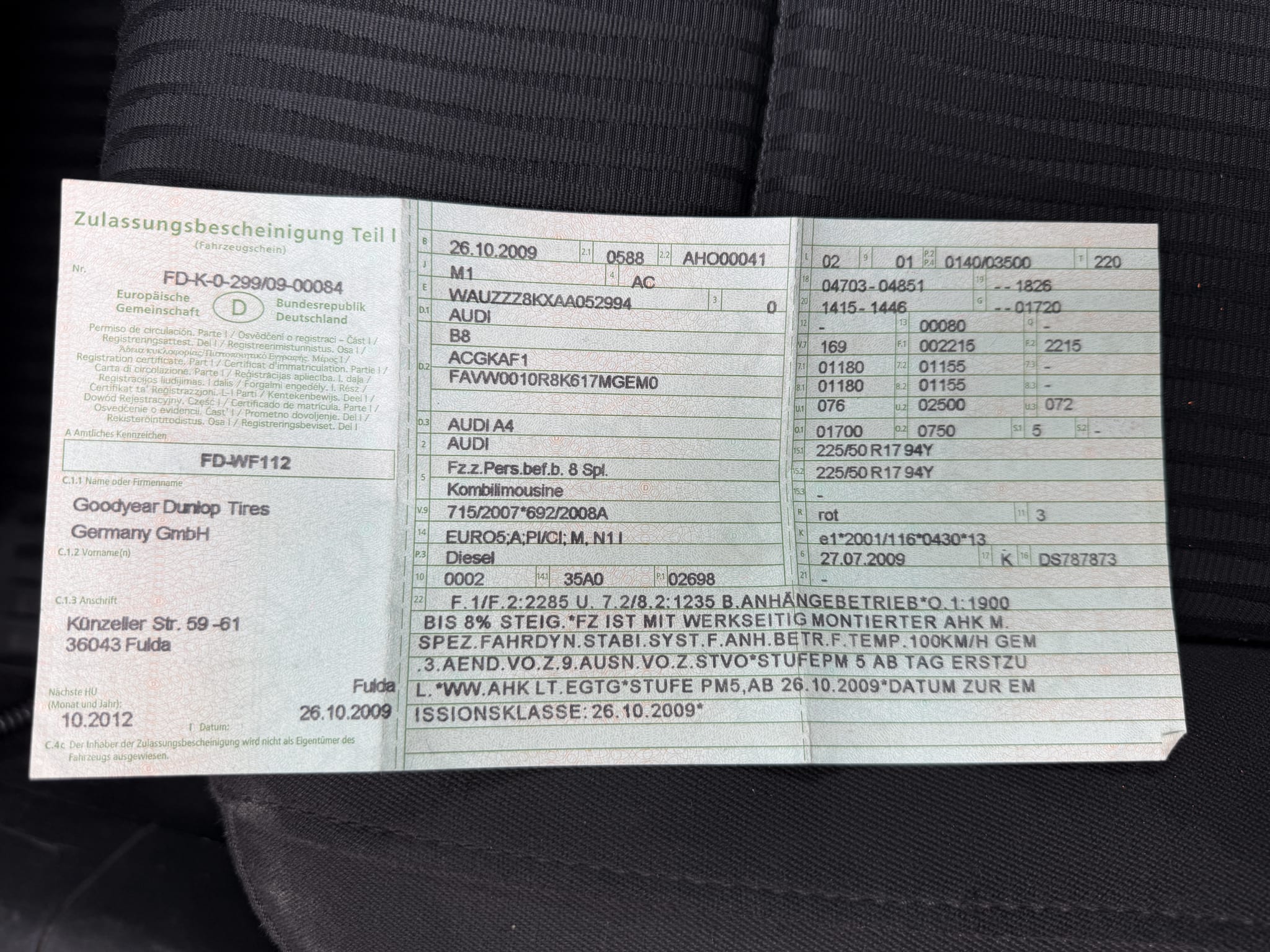

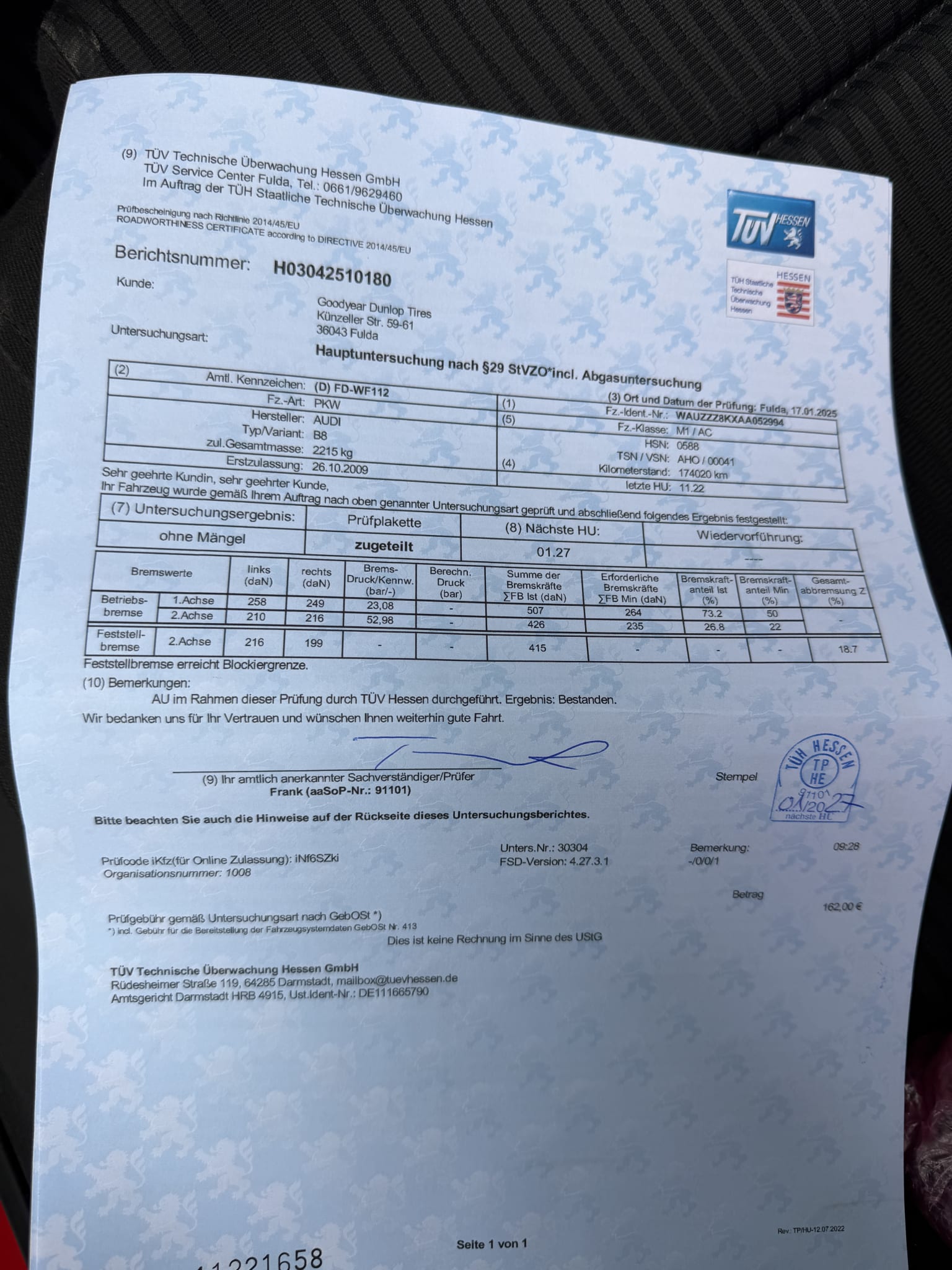

Commando Car Audi A4 | 2016

Binding Handling & Service Fee:

30 € (EURO)

Only available for Pick-Up late March 2026 Audi A4 Avant 2.0 TDI (“Werkfeuerwehr”) 1. Manufacturer and Model • Manufacturer: Audi AG • Model: Audi A4 Avant 2.0 TDI • Body type: Station wagon (“Kombilimousine”) 2. Identification Data • Vehicle Identification Number (VIN): WAUZZZ8KXAA052994 • License plate: FD-WF 112 • First registration: 26 October 2009 3. Mileage • Mileage: 174,522 km • Mileage reading date: 15 December 2025 4. Powertrain • Engine type: Diesel • Displacement: 1,968 ccm • Engine output: 105 kW (143 HP) • Transmission: Manual gearbox 5. Previous Use • Formerly operated as a command and service vehicle of the plant fire department (“Werkfeuerwehr Goodyear Fulda”) 6. Exterior and Interior • Exterior color: Red (“Rot”) • Interior: Grey cloth upholstery • Radio handset installed in the rear • Dashboard-mounted holder present 7. Wheels and Tires • Tire size: 225/50 R17 94Y 8. Equipment (As Stated) • Roof rails • Cargo barrier net • Rubber floor mats • Factory-installed detachable tow bar (AHK), as mentioned in vehicle documents - LISTING 2760053

![Deutsch]()

Hydraulic Pallet Turner Kaup Aschaffenburg | 2017

Binding Handling & Service Fee:

1600 € (EURO)

1. Manufacturer • Manufacturer: Kaup GmbH & Co. KG 2. Machine Identification • Model: 1.6T451W/099 (Clamp Unit) • Machine type: Stationary hydraulic bale clamp / opening station • Year of construction: 2011 • Serial number: 671426 3. Load and Hydraulic Data • Rated capacity: 1,500 kg at 600 mm load center • Maximum hydraulic pressure: 150 bar 4. Mechanical Construction • Blue hydraulic clamp unit • Mounted on a stationary lifting frame 5. Control System • Local control panel • Siemens hour meter installed • Physical push-buttons for operation 6. Safety Equipment • Full perimeter safety fencing • Fence color scheme: black / yellow • Light curtain protection integrated - LISTING 2760054

![Deutsch]()

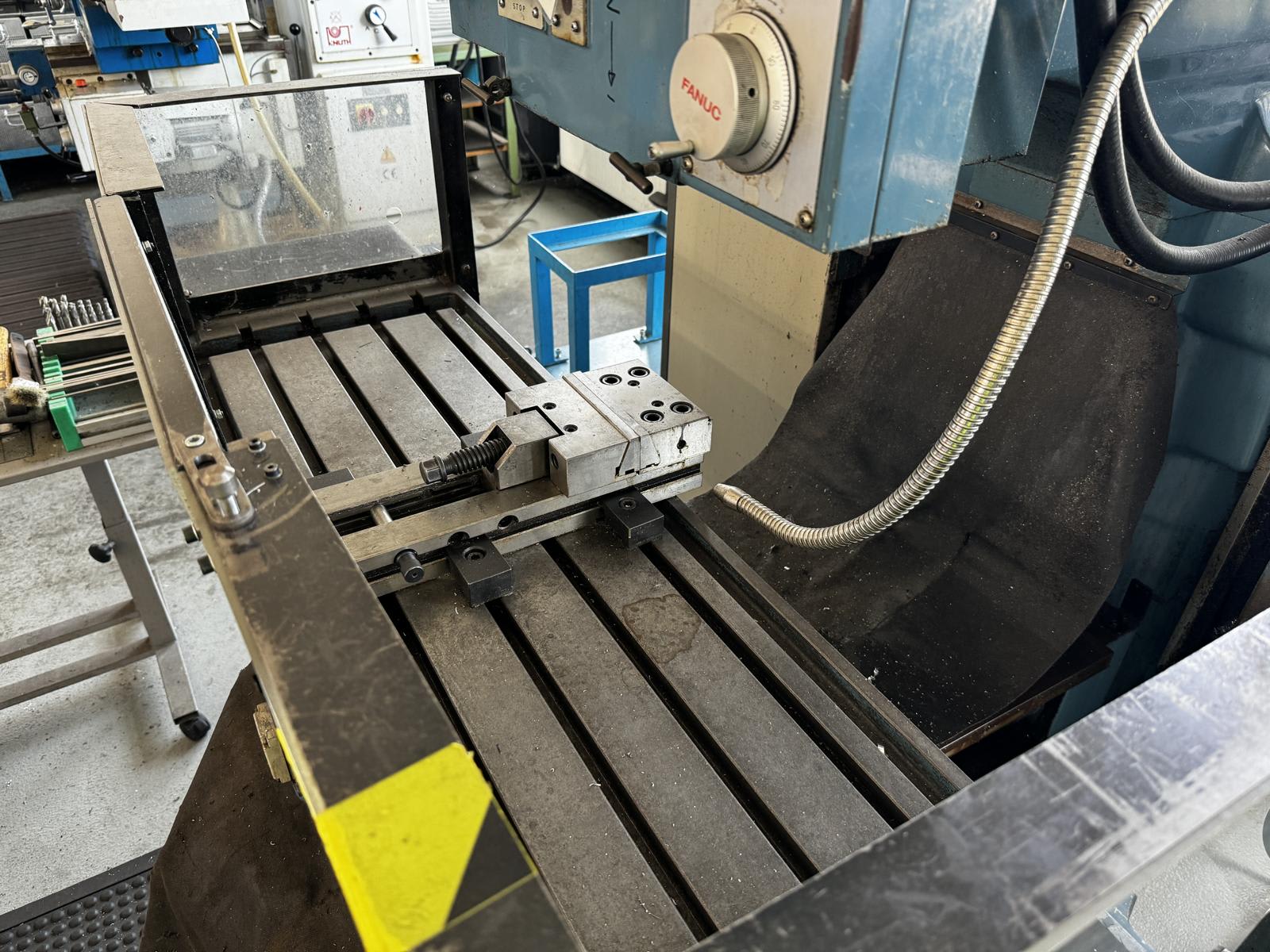

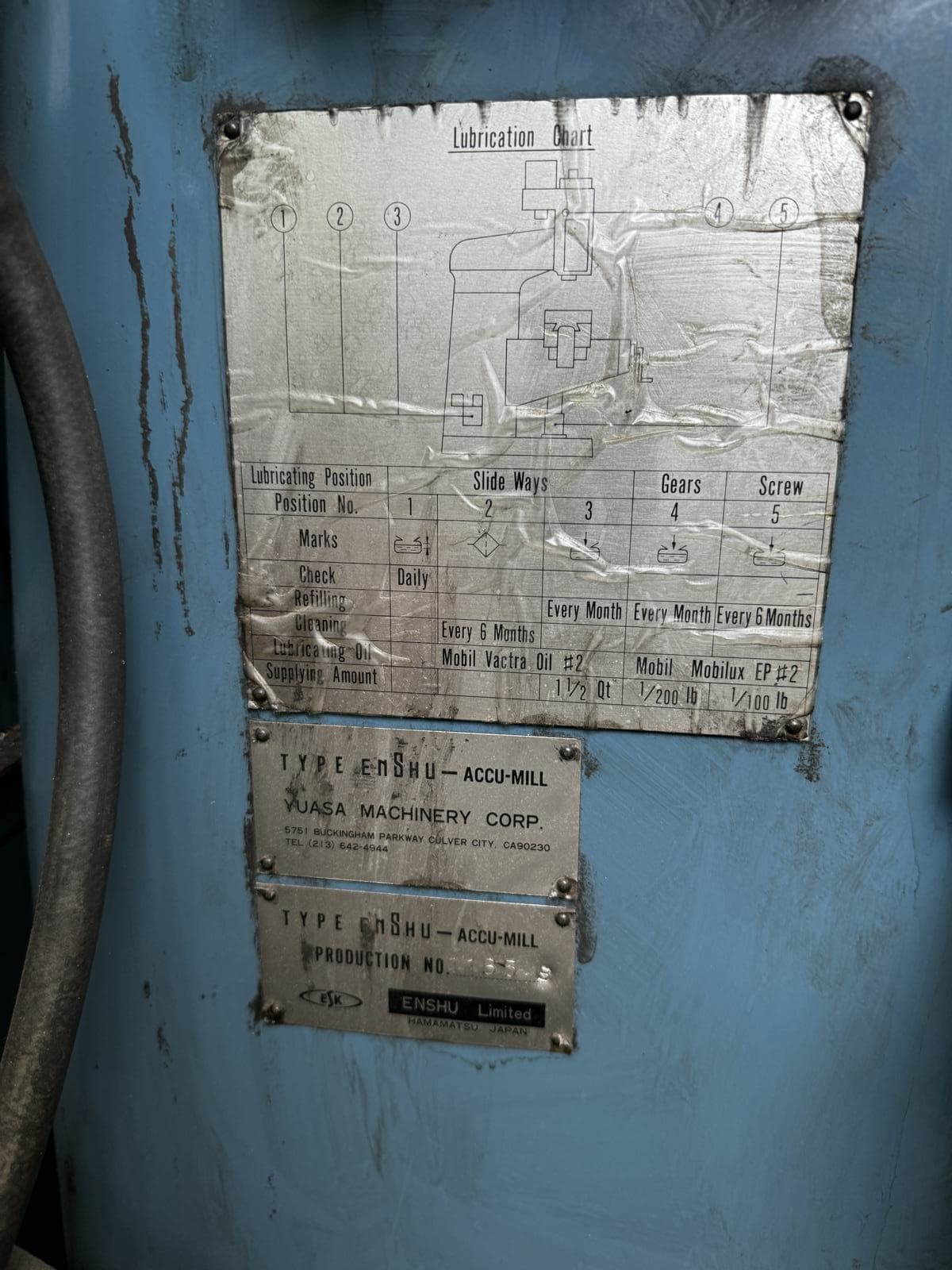

CNC Milling Machine Enshu ACCU-Mill AM-1547 | 1983

Binding Handling & Service Fee:

900 € (EURO)

CNC Milling Machine – Enshu Accu-Mill 1. Manufacturer • Manufacturer: Enshu Limited, Japan • Distribution / Affiliation: Yuasa Machinery Corp. 2. Machine Identification • Model: Accu-Mill • Machine type: Vertical CNC bed milling machine 3. Control System • CNC control unit: Fanuc System 6M 4. Spindle System • Vertical spindle head • Variable speed drive 5. Working Table • T-slot working table • Machine vise installed on the table 6. Lubrication System • Manual lubrication system • Automatic way lubrication system • Specified lubricant: Mobil Vactra Oil No. 2 - LISTING 2760055

![Deutsch]()

NC Milling Machine Knuth UMWF 4 | 2013

Binding Handling & Service Fee:

800 € (EURO)

Universal Milling Machine 1. Manufacturer • Manufacturer: KNUTH Werkzeugmaschinen GmbH 2. Machine Identification • Model: UWF 4 • Machine type: Universal milling machine (Universal-Fräsmaschine) • Year of construction: 2013 • Serial number: 156811 3. Electrical Data • Rated power: 7.5 kW • Electrical connection: 400 V / 50 Hz / 3-phase 4. Control and Measurement • Digital readout (DRO): Knuth X.pos 3.1 • Axis coverage: 3-axis 5. Spindle and Head Configuration • Universal swivel head (Huron system) • Additional horizontal spindle 6. Feed System • Automatic servo feed on X-, Y-, and Z-axes 7. Working Table • Large clamping table • Equipped with T-slots 8. Accessories • Machine vise • Coolant system • Integrated work light - LISTING 2760056

![Deutsch]()

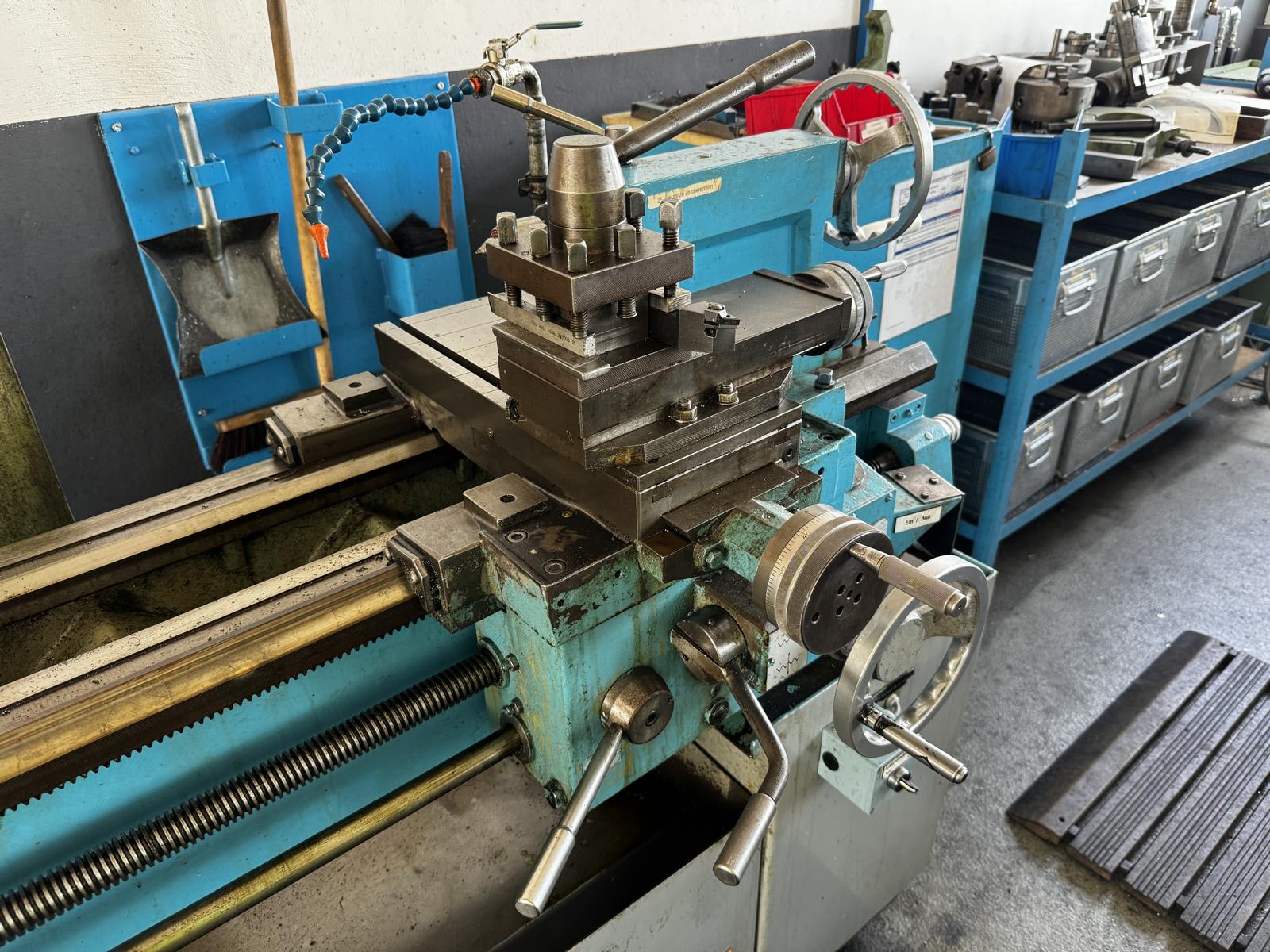

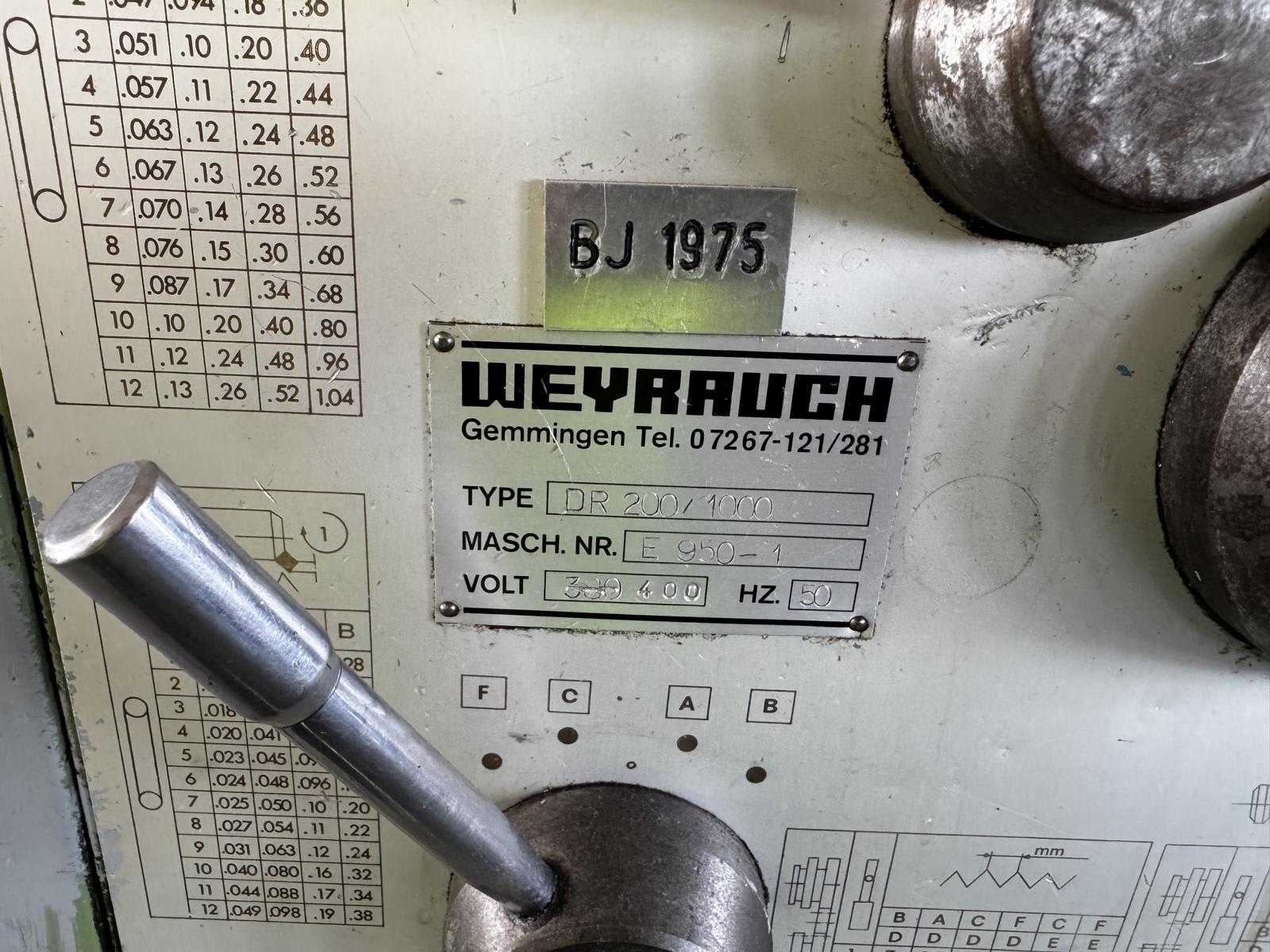

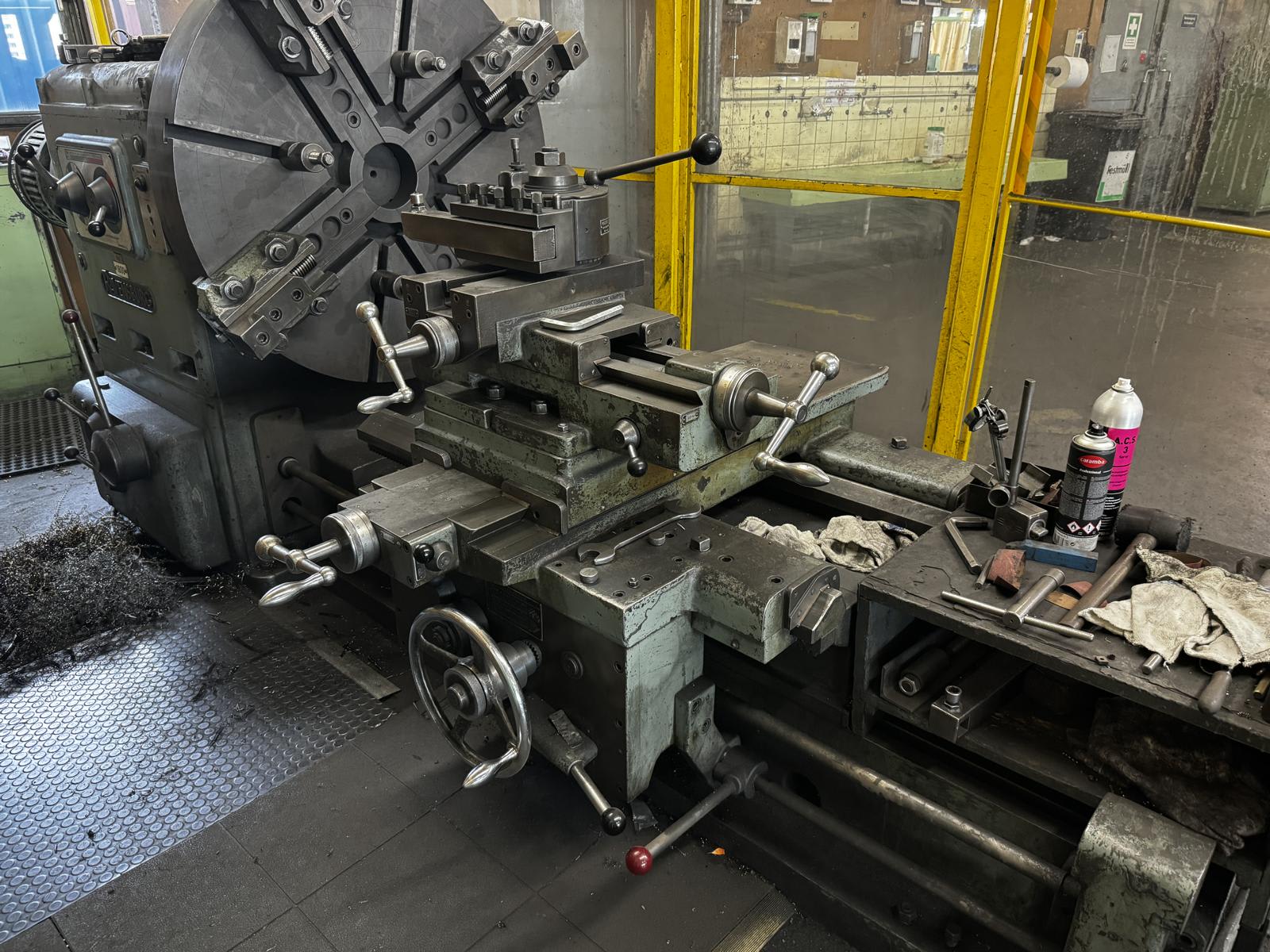

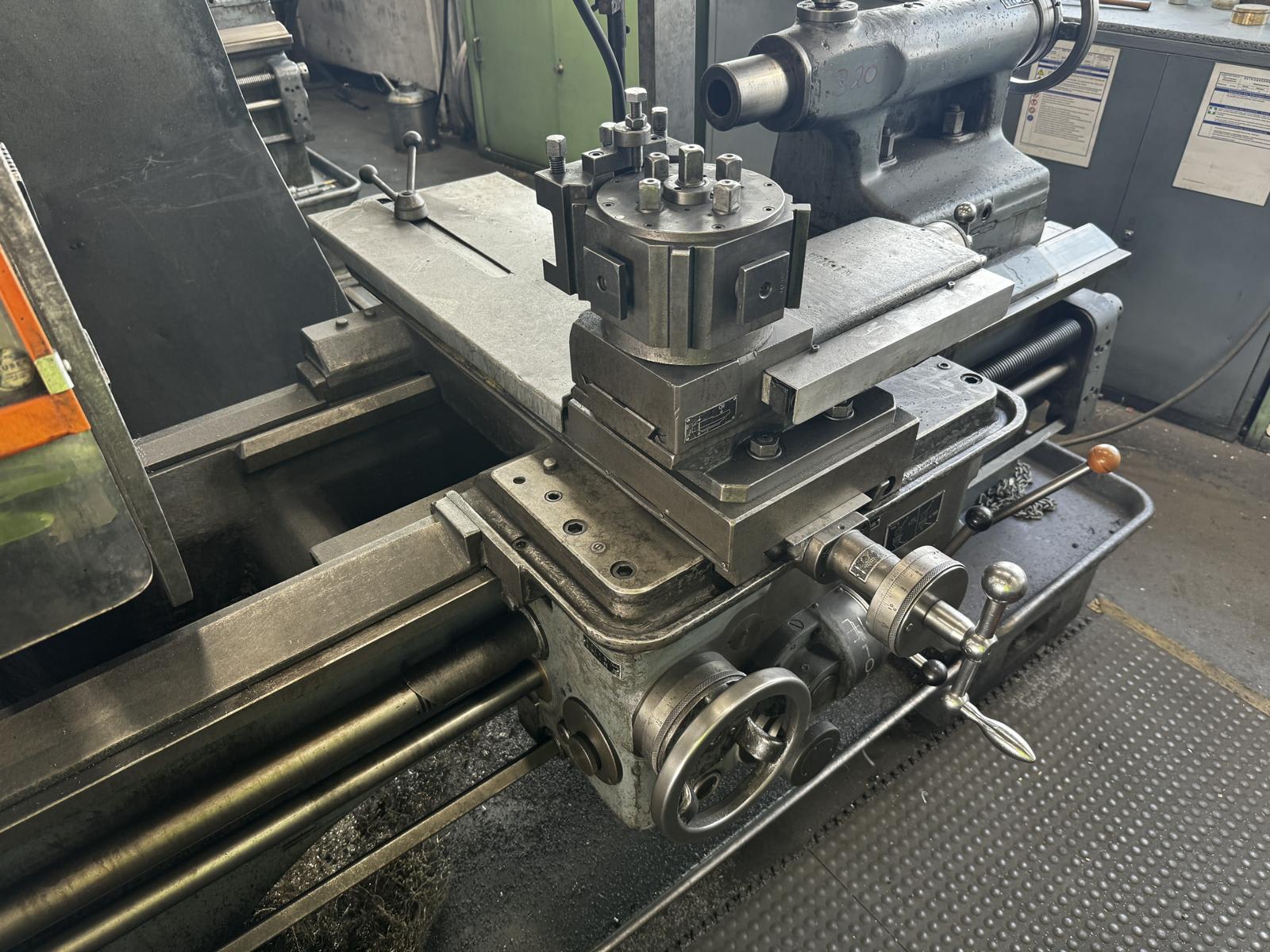

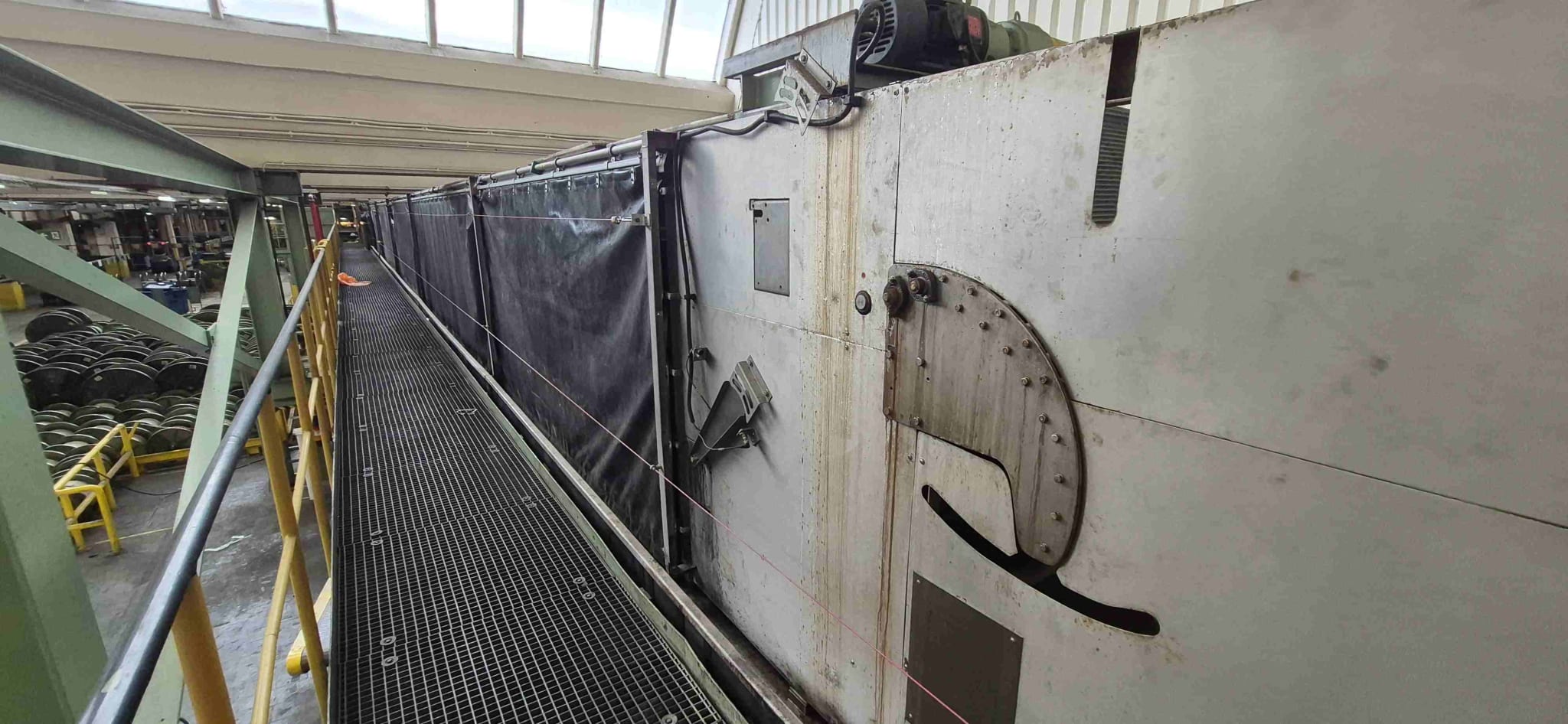

Lathe Weyrauch DR 200/1000 | 1975

Binding Handling & Service Fee:

500 € (EURO)

Manufacturer and Identification • Manufacturer: GDW Werkzeugmaschinen Herzogenaurach GmbH • Model: LZ 400 S • Machine Type: Precision Lead and Feed Spindle Lathe • Year of Construction: 2002 • Serial Number: 180327 • Country of Manufacture: Germany Main Dimensions and Capacity • Center distance: 1,000 mm • Center height: 200 mm Drive and Electrical Data • Rated power: 16 kVA • Nominal current: 25 A Control and Measuring Equipment • Digital readout (DRO): Heidenhain digital readout system Spindle and Clamping System • Chuck: 3-jaw chuck, Röhm - LISTING 2760057

![Deutsch]()

- LISTING 2760058

![Deutsch]()

Folding Machine Hera UIII | ca. 1970

Binding Handling & Service Fee:

300 € (EURO)

1. Manufacturer • Manufacturer: Maschinenfabrik H. Raffetsiefer • Brand name: HERA • Manufacturer location: Marienheide, Rheinland (Germany) 2. Machine Identification • Machine number (Maschine Nr.): 1640 • Machine type (Typ): U III 3. Technical Data (According to Nameplate) • Working width (Durchgang): 2,520 mm • Bending capacity at 40 kg/mm²: – 3.0 mm sheet thickness • Bending capacity at 55 kg/mm²: – 2.0 mm sheet thickness 4. Tool Openings (According to Nameplate) • Upper beam opening (Öffnung Oberwange): 350 mm • Lower beam opening (Öffnung Unterwange): 125 mm • Bending beam opening (Öffnung Biegewange): 125 mm - LISTING 2760059

![Deutsch]()

- LISTING 2760060

![Deutsch]()

Lathe Ferdinand C. Weipert W 500e | 1961

Binding Handling & Service Fee:

900 € (EURO)

Machine Description • Manufacturer: Ferdinand C. Weipert • Manufacturer Location: Heilbronn am Neckar, Germany • Machine Type: Conventional Engine Lathe • Model: W 500e • Year of Construction: 1961 (as stated on the nameplate) • Factory / Commission Number: 16 735 (as stated on the nameplate) Machine Construction and Design • Heavy-duty one-piece cast iron machine body with grey finish • Classic lathe bed design with continuous machine bed • Headstock with mechanically shifted gearbox • Tailstock with manually operated quill, longitudinally adjustable • Designed for large-diameter workpieces; oversized faceplate/chuck installed • Transparent semi-circular spindle guard with orange frame • Mechanical safety enclosure in the working area with yellow framing elements Spindle and Clamping System • Large-diameter chuck with multiple adjustable jaws installed • Mechanical jaw adjustment system visible • Fixed spindle safety guard installed • Spindle speed selection via mechanical levers on the headstock Carriage and Slide System • Manually operated longitudinal and cross slide • Swiveling compound slide • Four-position tool post installed • Manual handwheels with graduated scales • Feed and threading gearbox with selector charts mounted on the front of the machine Controls and Operation • Fully conventional manual operation • Mechanical levers for speed and feed selection • Front-mounted threading and feed tables • Additional emergency stop pushbutton mounted on the machine front Measuring Equipment and Accessories • Digital readout (DRO) installed in the carriage/tailstock area • Separate display unit with keypad visible • Work light mounted at the machine bed - LISTING 2760061

![Deutsch]()

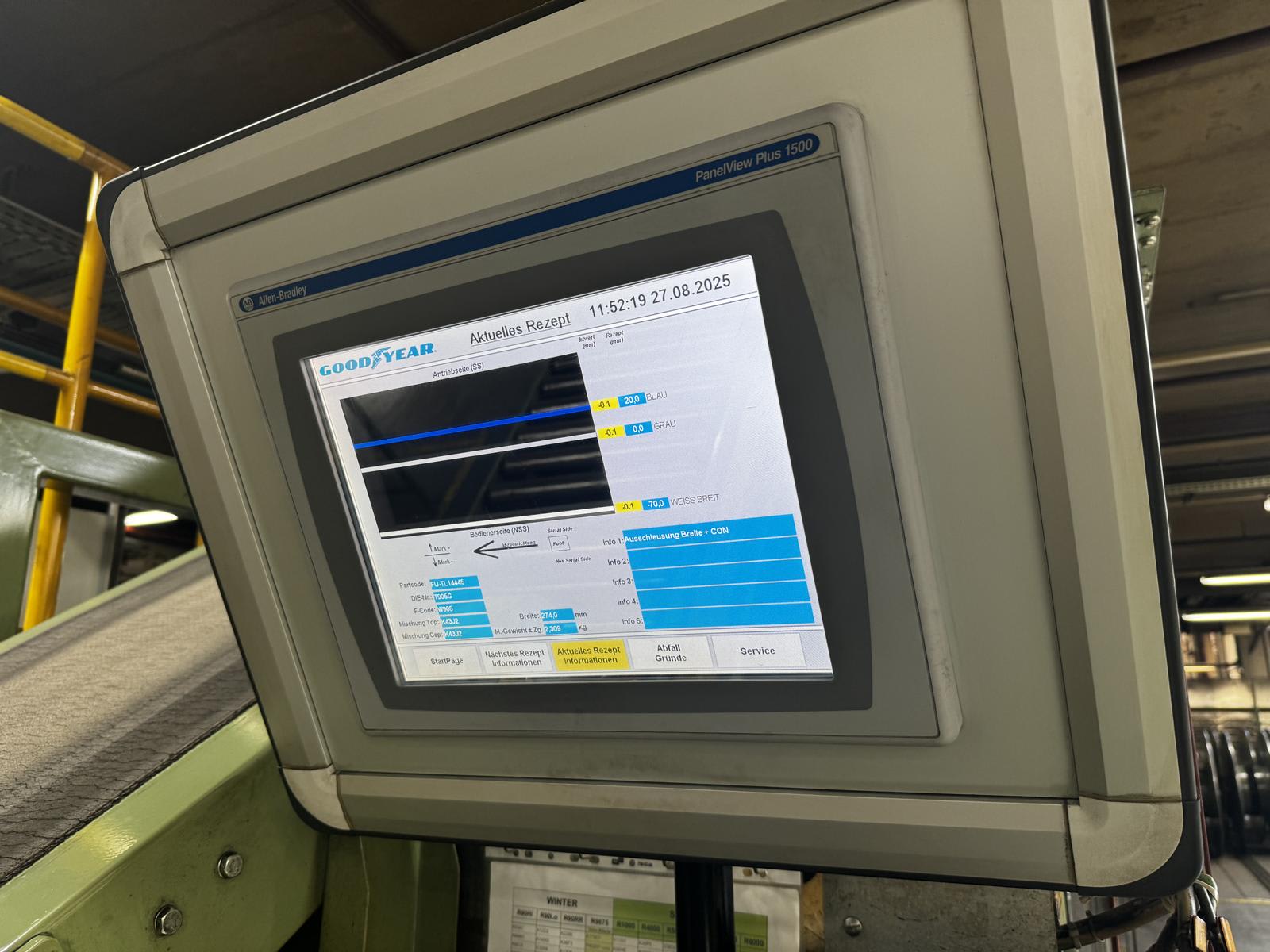

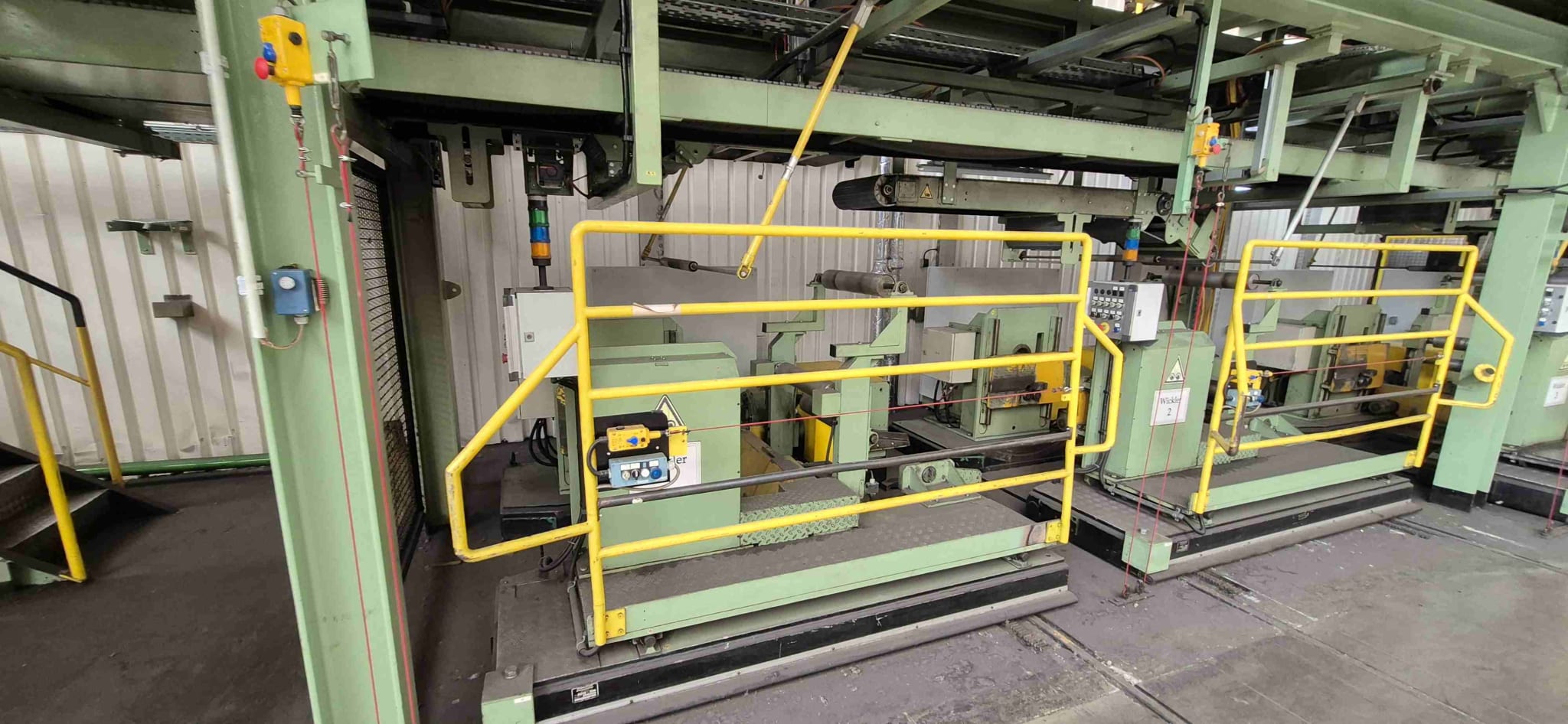

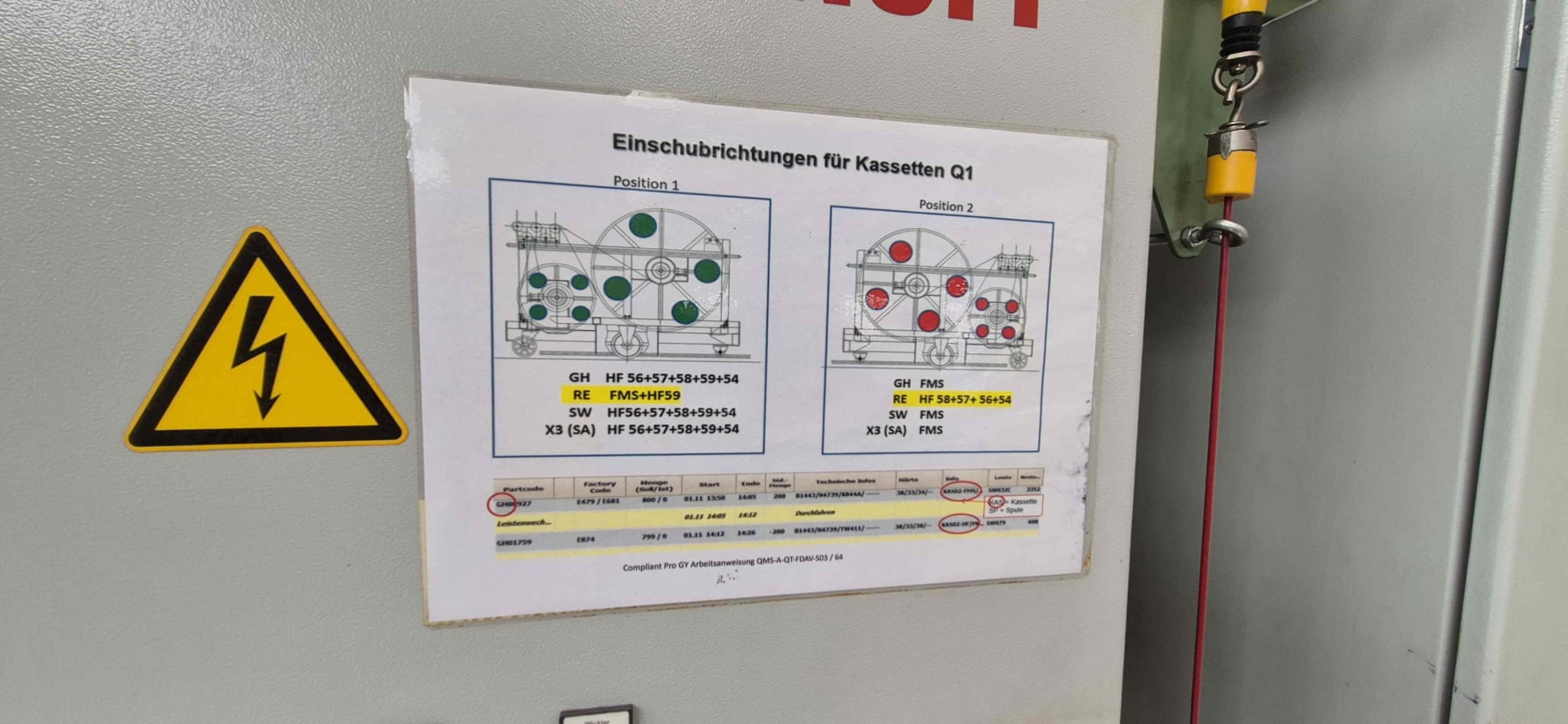

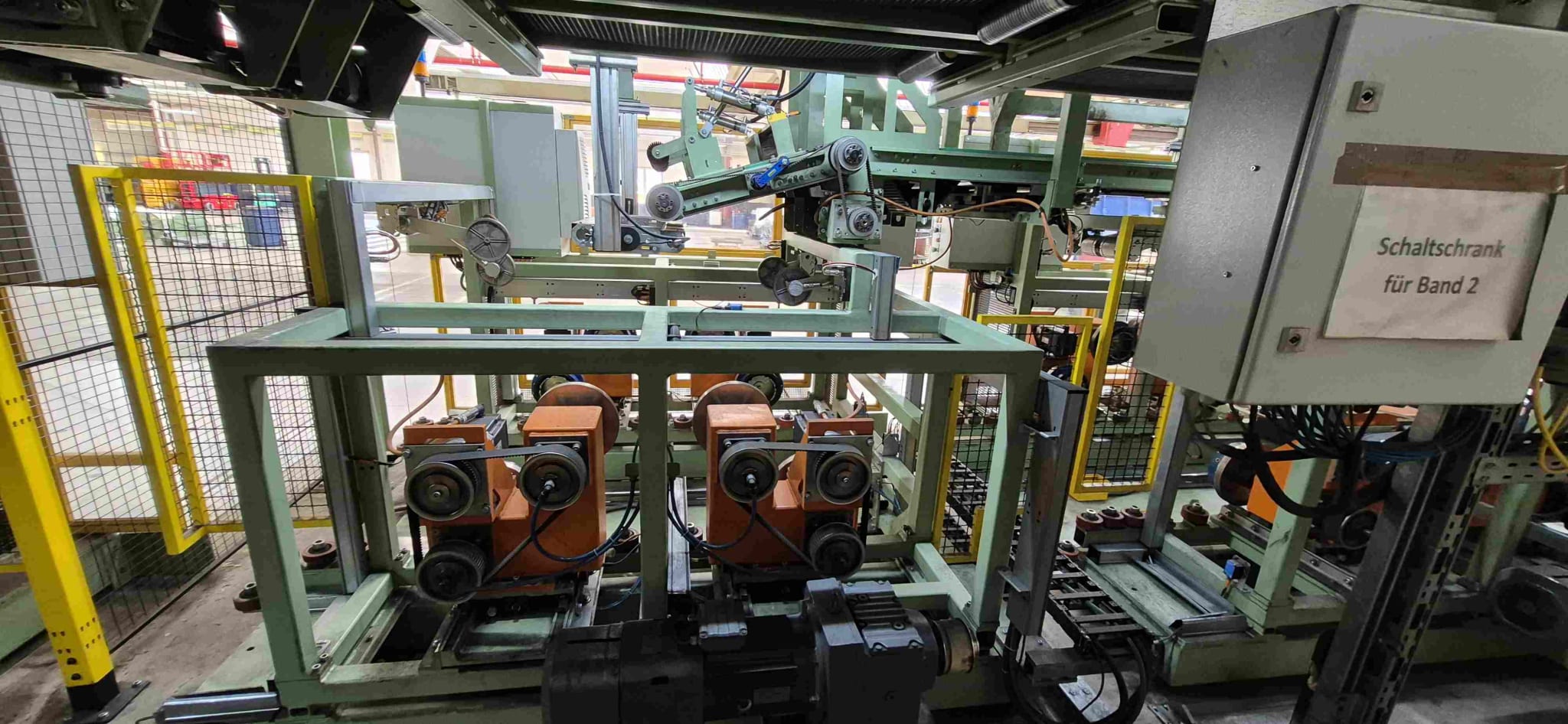

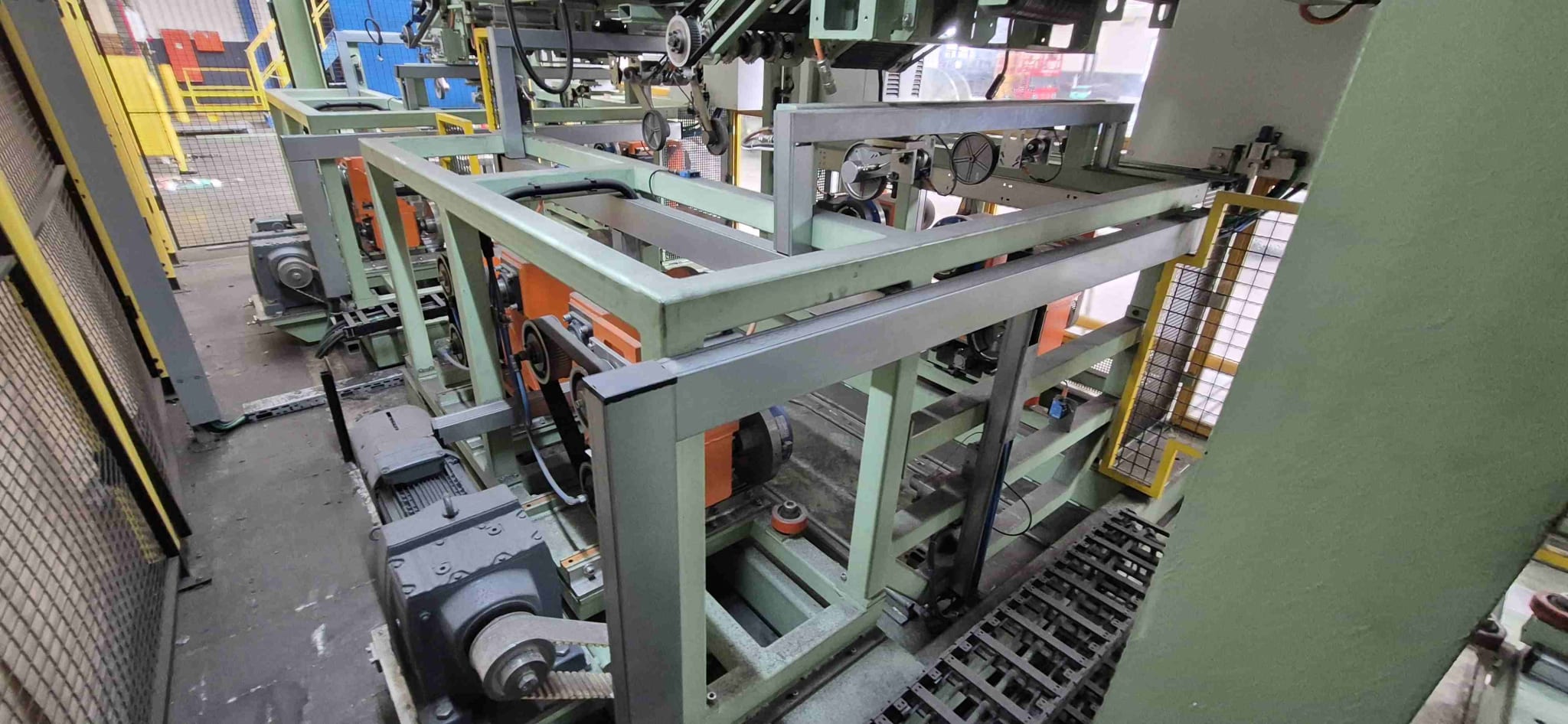

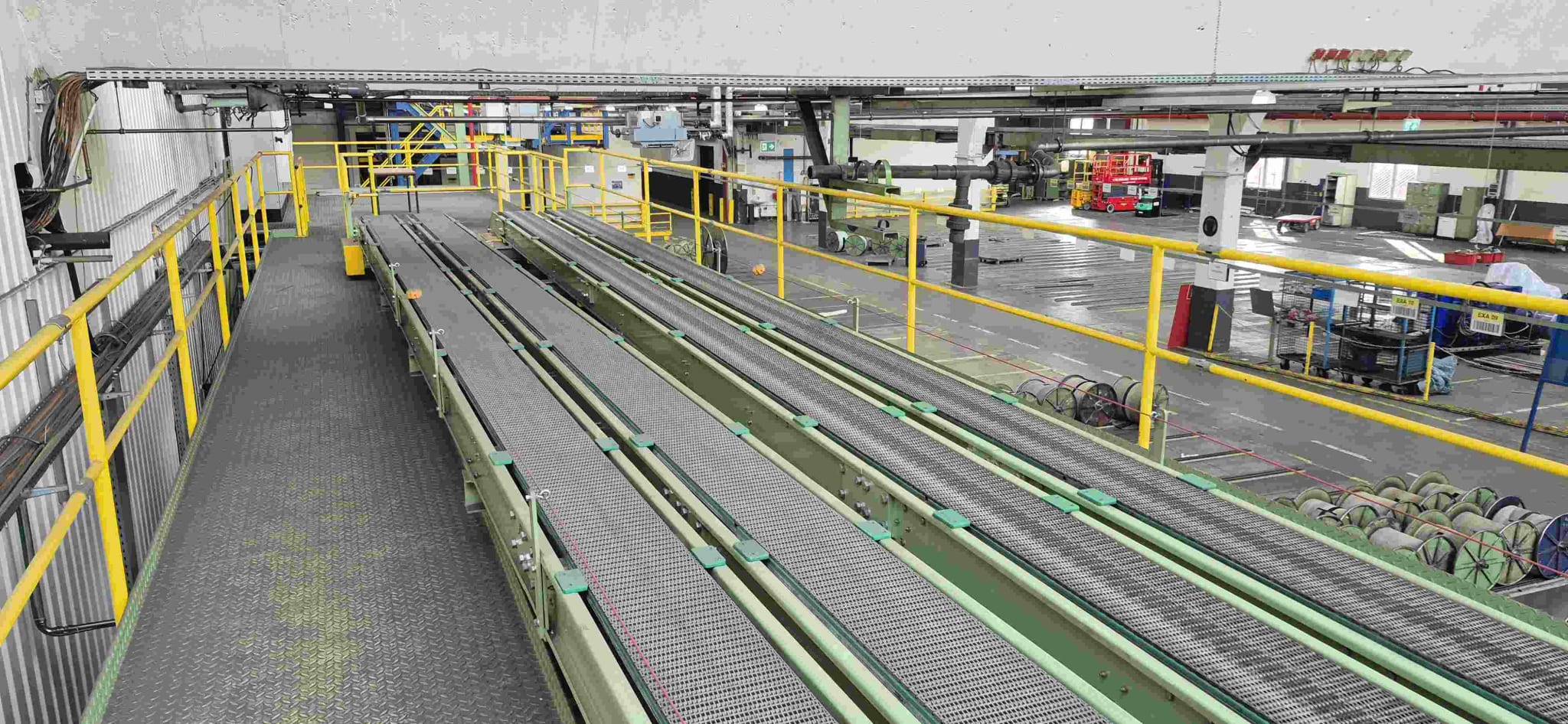

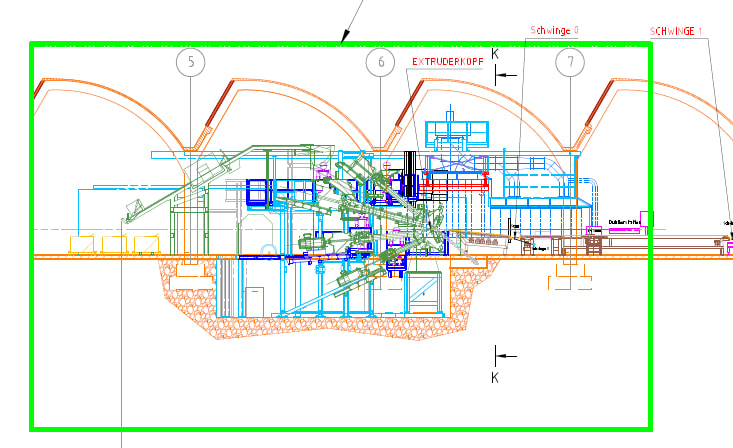

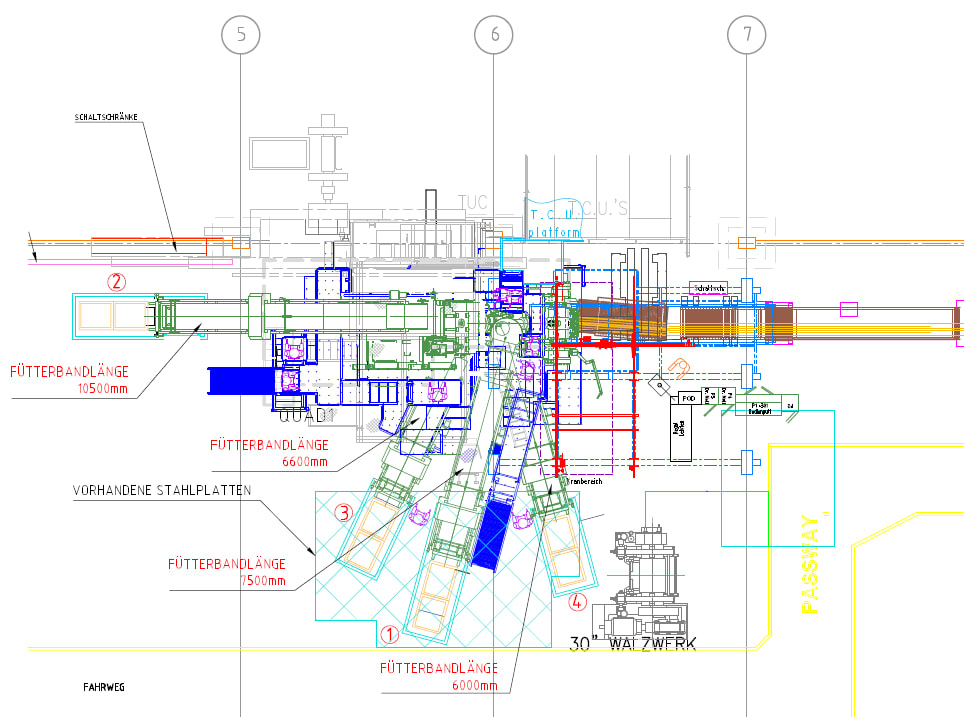

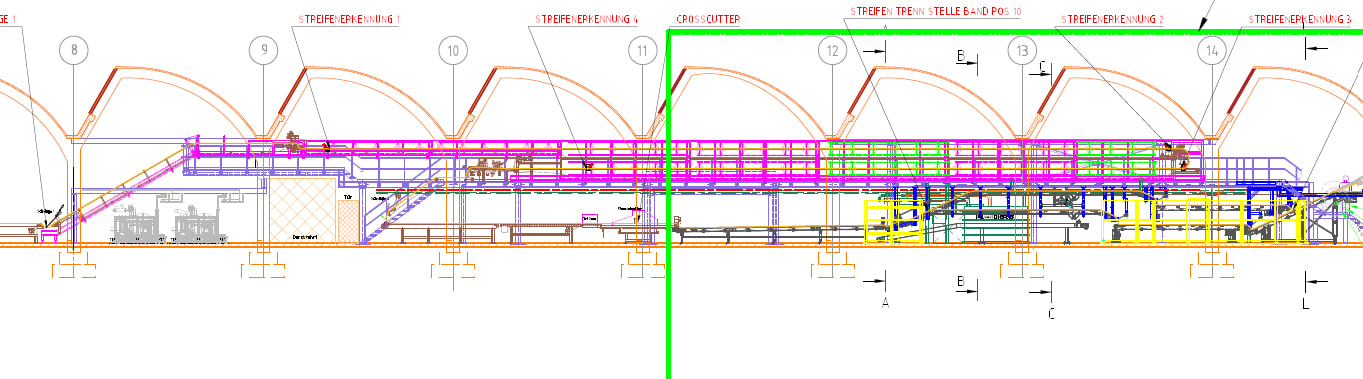

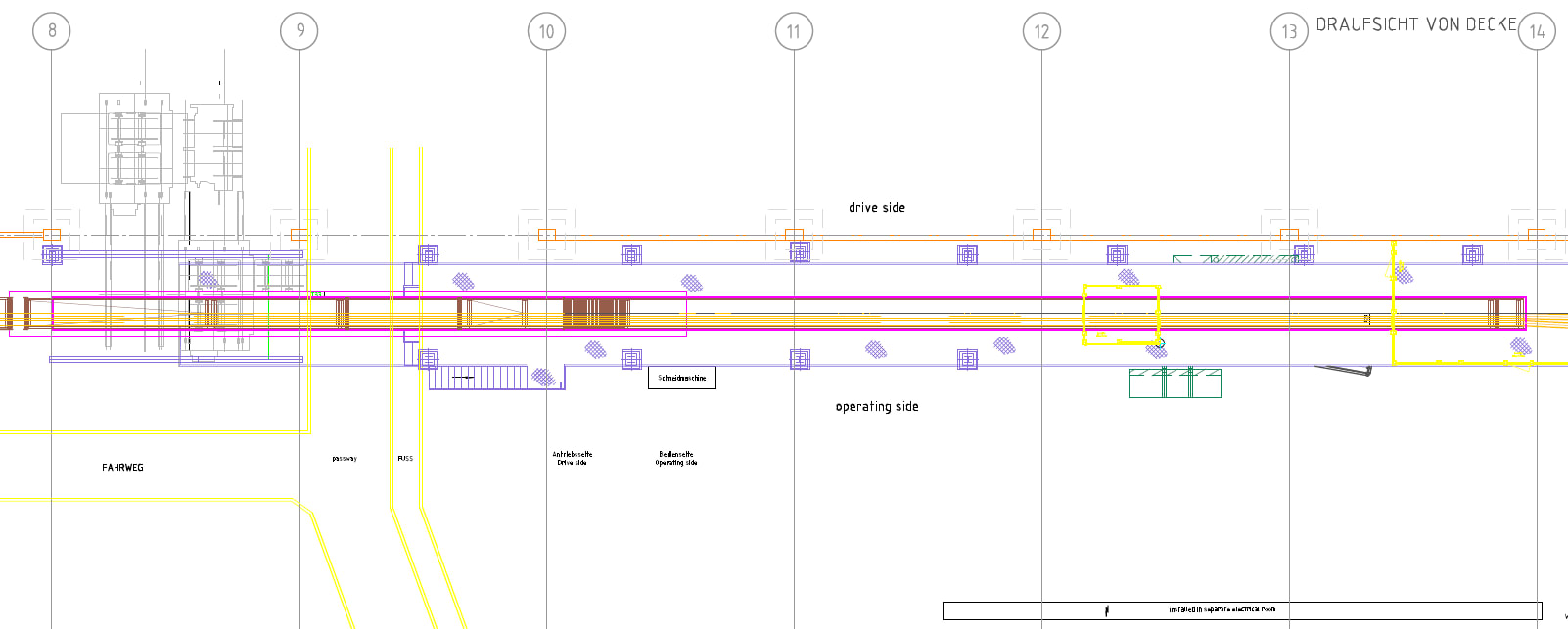

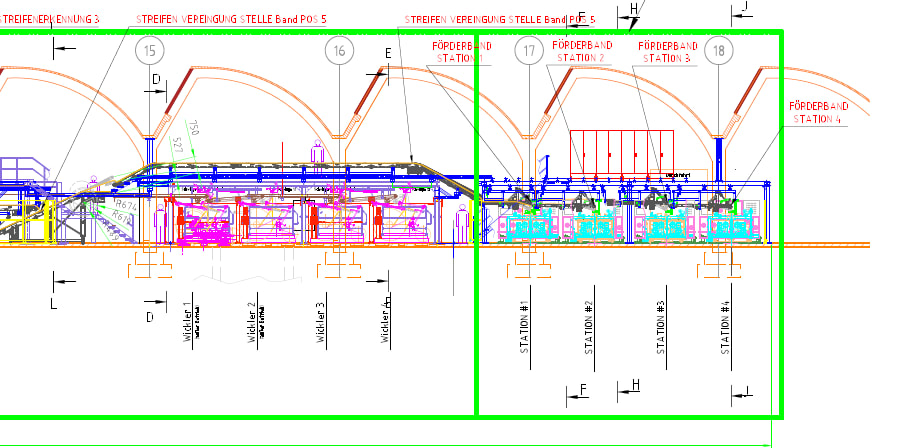

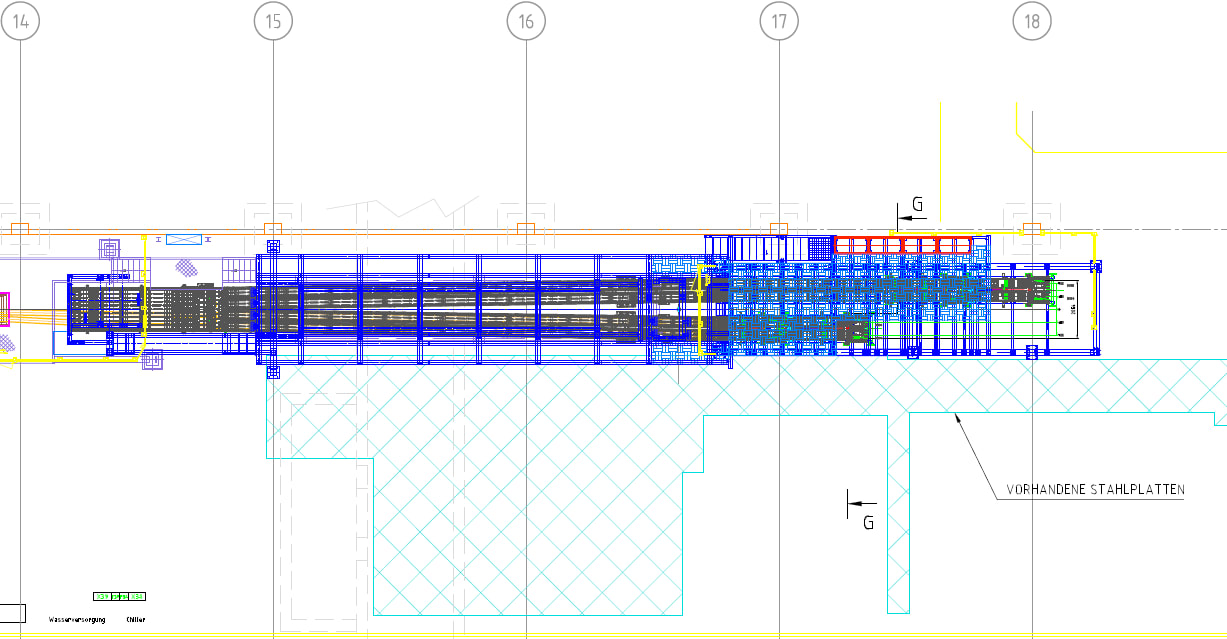

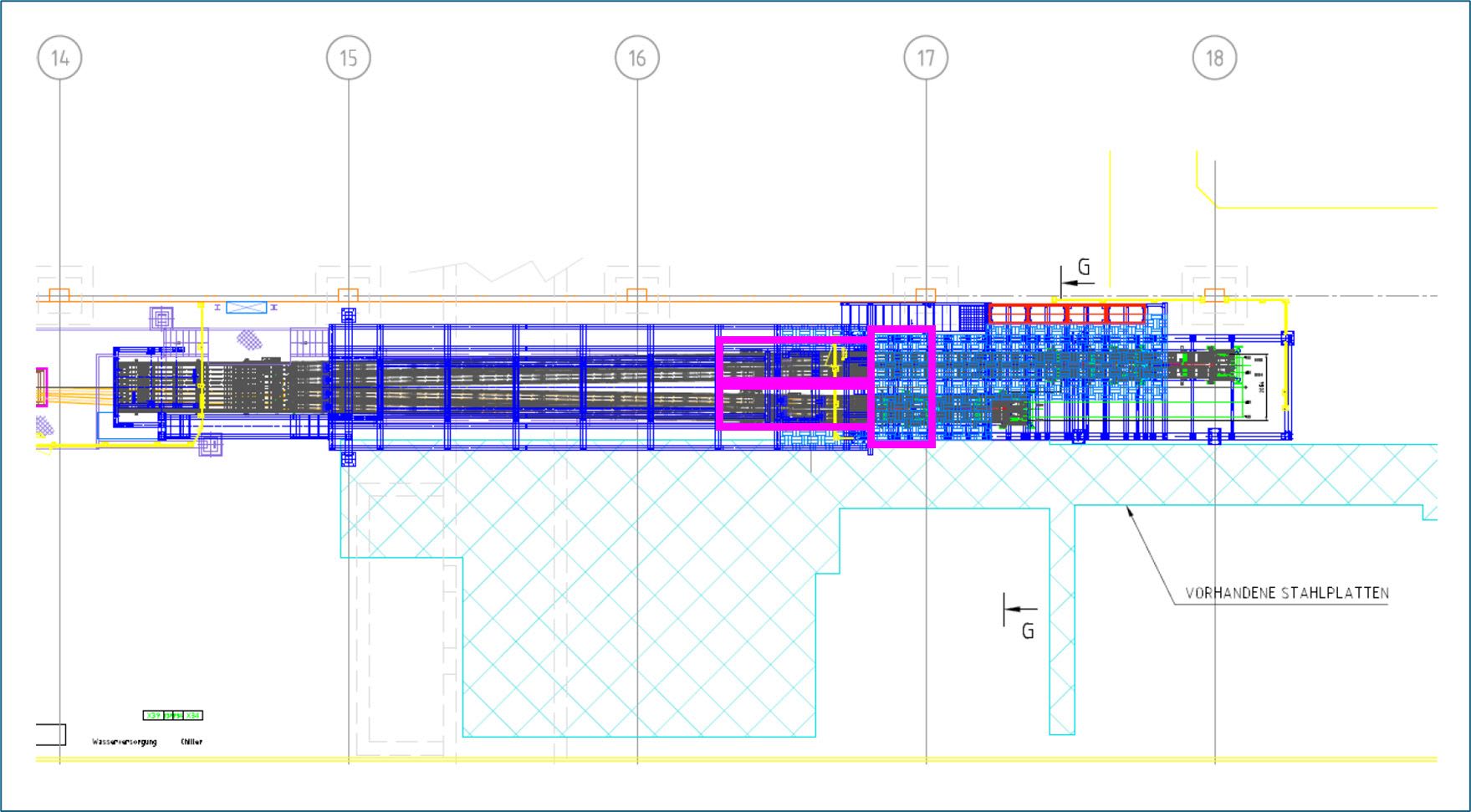

Quadruplex Extrusion Line Krauss Maffei Quadruplex | 2016

Binding Handling & Service Fee:

68900 € (EURO)

1. General Designation Machine Name: QUADRUPLEX-EXTRUDER #1 REF No.: FU-FPs 647 2. Functional Scope and System Components The overview represents the complete production line associated with the Quadruplex extruder, including material transport, strip guidance, strip scanning, acceleration zones, cross-cutting, and cassette winding stations. 2.1 Main Assemblies Extruder head Multiple “Schwingen” (swing arms), numbered 0 through 13 Strip scanning systems (“Scan 1”, “Tri Scan”, Streifenerkennung 1–4) Cross-cutting unit (“Querschneider”) Schneidmaschine (cutting machine) “Schneidtisch” (cutting table) Conveyor belts labelled BAND 1, BAND 2, BAND 3 Winding section: Cassettenwickler 1–4 Winding stations labelled “Wickler 1–4” Note: Wickler 1 and Wickler 2 marked “außer Betrieb” (not in operation) Cooling water tank (“Kühlwasserbehälter”) Chiller Electrical peripherals, TCU units (temperature control), switch cabinets (“Schaltschrank”, “Schaltsch.”) Structural steel platforms (“Bühne”, Kühlstreckenbühne) 3. Operating Parameters 3.1 Production Speed 0–30 m/min (stated production speed range) 3.2 Acceleration Section (Beschleunigungsgeschwindigkeit Q1) From the provided calculations: Base production speed: 30 m/min = 0.5 m/s Wippe cycle time: 4 sec Belt shifting cycle time: 4 sec Gap length: 2 m Acceleration length: 8 m Acceleration time: 16 sec Speed differential: 2 m/s = 7.5 m/min Resulting acceleration speed: 37.5 m/min 4. Strip (Material) Specifications 4.1 Strip Dimensions Strip width: 20 mm – 220 mm Strip height: 1.5 mm – 16 mm Strip temperature: 10 °C – 45 °C Strip weight: 0.02 kg/m – 2 kg/m 4.2 Strip Lengths Along the Line (Exact lengths between defined mechanical and sensor points) Extruder head → Schwinge 0: 3997 mm Schwinge 0 → Schwinge 1: 10279 mm Schwinge 1 → Streifenerkennung 1: 14400 mm Streifenerkennung 1 → Streifenerkennung 2: 39159 mm Streifenerkennung 2 → Streifenerkennung 3: 1812 mm Streifenerkennung 3 → Streifenerkennung 4: 27702 mm Streifenerkennung 4 → Crosscutter: 22032 mm Crosscutter → Zuführband Pos. 10: 13956 mm Further split and merge sections: From separation point Pos. 10.1 → Wippe Pos. 5: 17545 mm From separation point Pos. 10.2 → Wippe Pos. 5: 17542 mm From merging point Pos. 10 → Band split point Pos. 1–4: 17827 mm Final path lengths to winding stations: Band Position To Cassette Station – Band End Position 1 6050 mm Position 2 9072 mm Position 3 12376 mm Position 4 15393 mm To Spool Core (Innenkern) Position 1 6844 mm Position 2 10004 mm Position 3 13346 mm Position 4 16325 mm 5. Installed and Referenced Equipment The document lists a long chain of equipment references that the Quadruplex-Extruder line is “derived from” or “includes,” such as: FU-FPs 648 – Cassette Winder FU-FPs 649 – Conveyor modifications FU-FPs 650 – Extruder modifications Legacy equipment from Berstorff (1995–1996) Triplex winding equipment Steel structure foundations (2005, 2019) Control stands for conveyor belts (Erhardt + Leimer, 2019) Schutzzaun (safety fence) by Axelent Various structural and civil engineering modifications (2018–2019) The two marked top conveyors and a winding station for two cassettes, including the associated control cabinets on the platform as described in the drawing shown in the last picture of this lot are not included. The Cassette Winders are GoddYear specific, and the cassettes themselves are a proprietary design. The common winding system - Winding Stations by spools - remains part of the system. - LISTING 2760062

![Deutsch]()

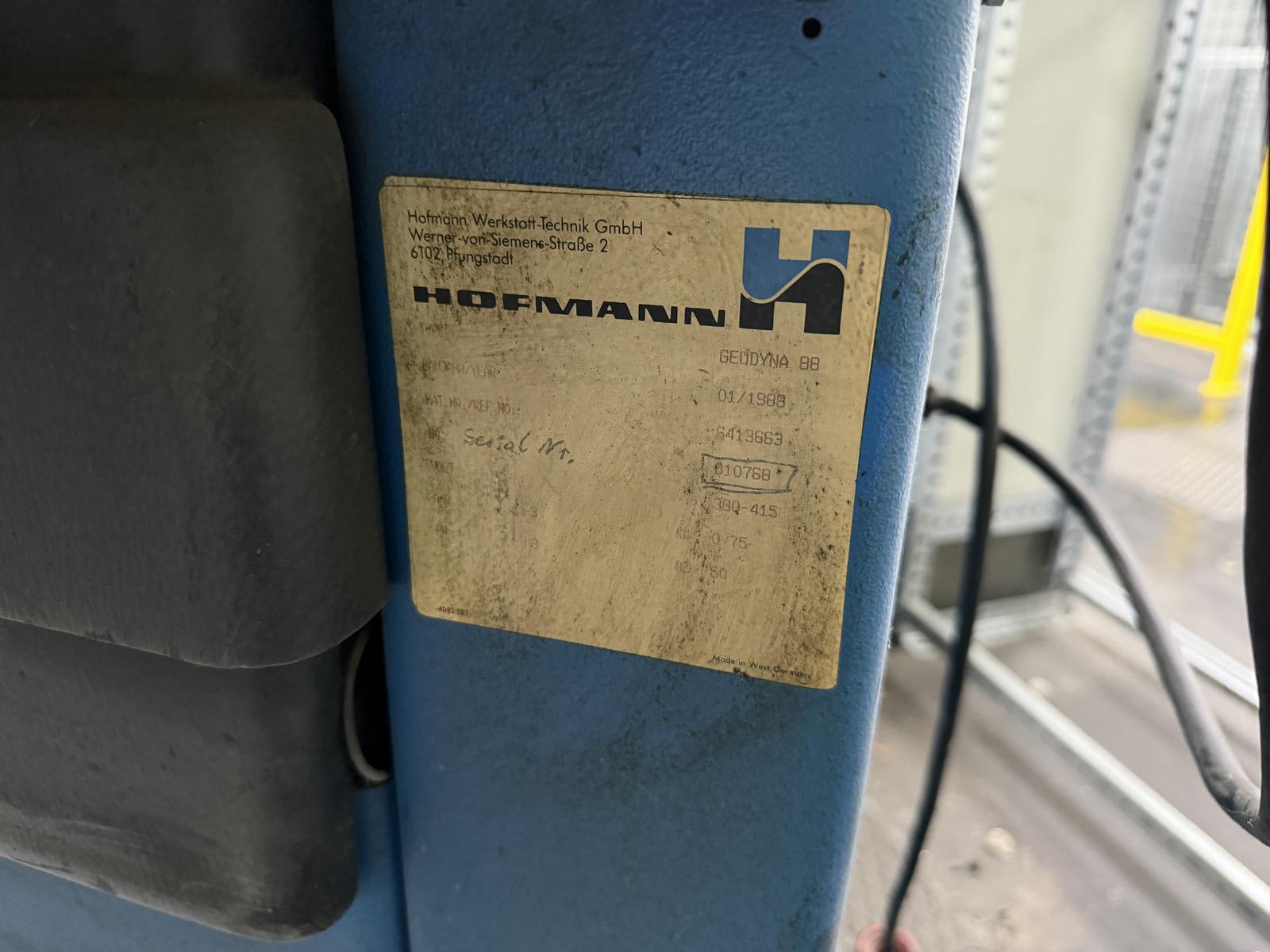

Tire Balancing Machine Hofmann Geodyna 88 | 1989

Binding Handling & Service Fee:

80 € (EURO)

Machine Description Manufacturer • Manufacturer: Hofmann Werkstatt-Technik GmbH • Address (as stated on rating plate): Werner-von-Siemens-Straße 2, 6102 Pfungstadt, Germany • Country of manufacture: West Germany (as stated on rating plate) Machine Identification • Brand: Hofmann • Model: Geodyna 88 • Machine type: Wheel Balancing Machine • Year of manufacture: January 1988 (01/1988) • Serial number: Marked on rating plate (partially legible; stamped number visible but not fully readable from image) Construction and Design • Design: Free-standing workshop wheel balancing unit • Housing: Blue steel base cabinet with grey protective balancing hood • Protective equipment: Hinged safety hood covering the balancing shaft • Control layout: Integrated front control console with keypad, display panel, and indicator lamps Control and Operation • Control system: Integrated electronic balancing control (model-specific to Geodyna 88 series) • User interface: Digital display panel Numeric keypad Function and indicator buttons - LISTING 2760063

![Deutsch]()

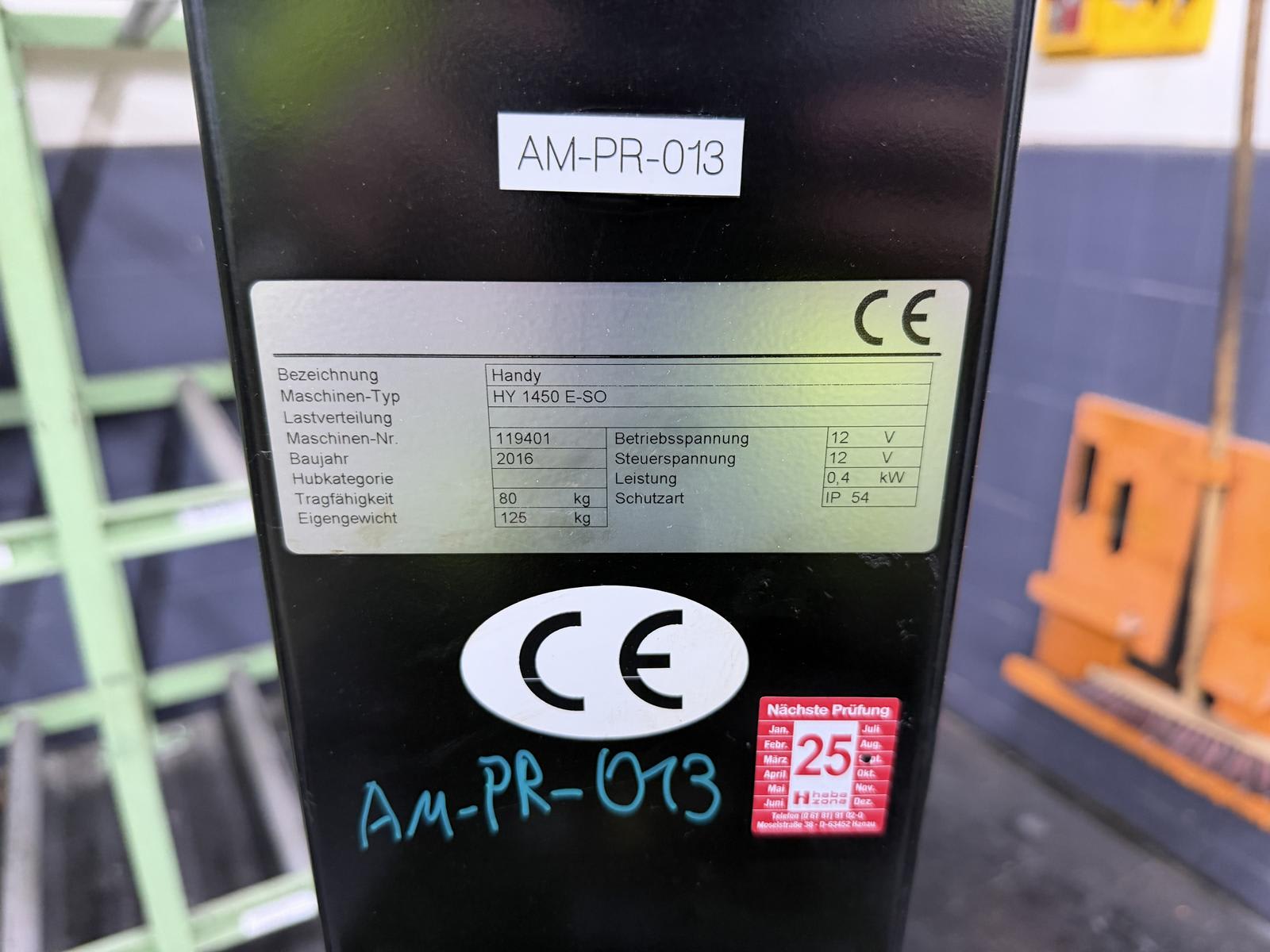

Electric Lifting Device (Handy) Hebe Zone HY 1450 E-SO | 2016

Binding Handling & Service Fee:

30 € (EURO)

General Information • Designation: Handy • Machine type: HY 1450 E-SO • CE marked: Yes • Internal identification marking: AM-PR-013 Manufacturer / Branding • Manufacturer name: Hebe Zone Identification Data • Machine number: 119401 • Year of manufacture: 2016 Load and Weight Data • Load category: Hubkategorie (exact category not specified) • Load capacity: 80 kg • Dead weight (own weight): 125 kg Electrical Data • Operating voltage: 12 V • Control voltage: 12 V • Power rating: 0.4 kW Protection and Safety • Degree of protection: IP 54 - LISTING 2760064

![Deutsch]()

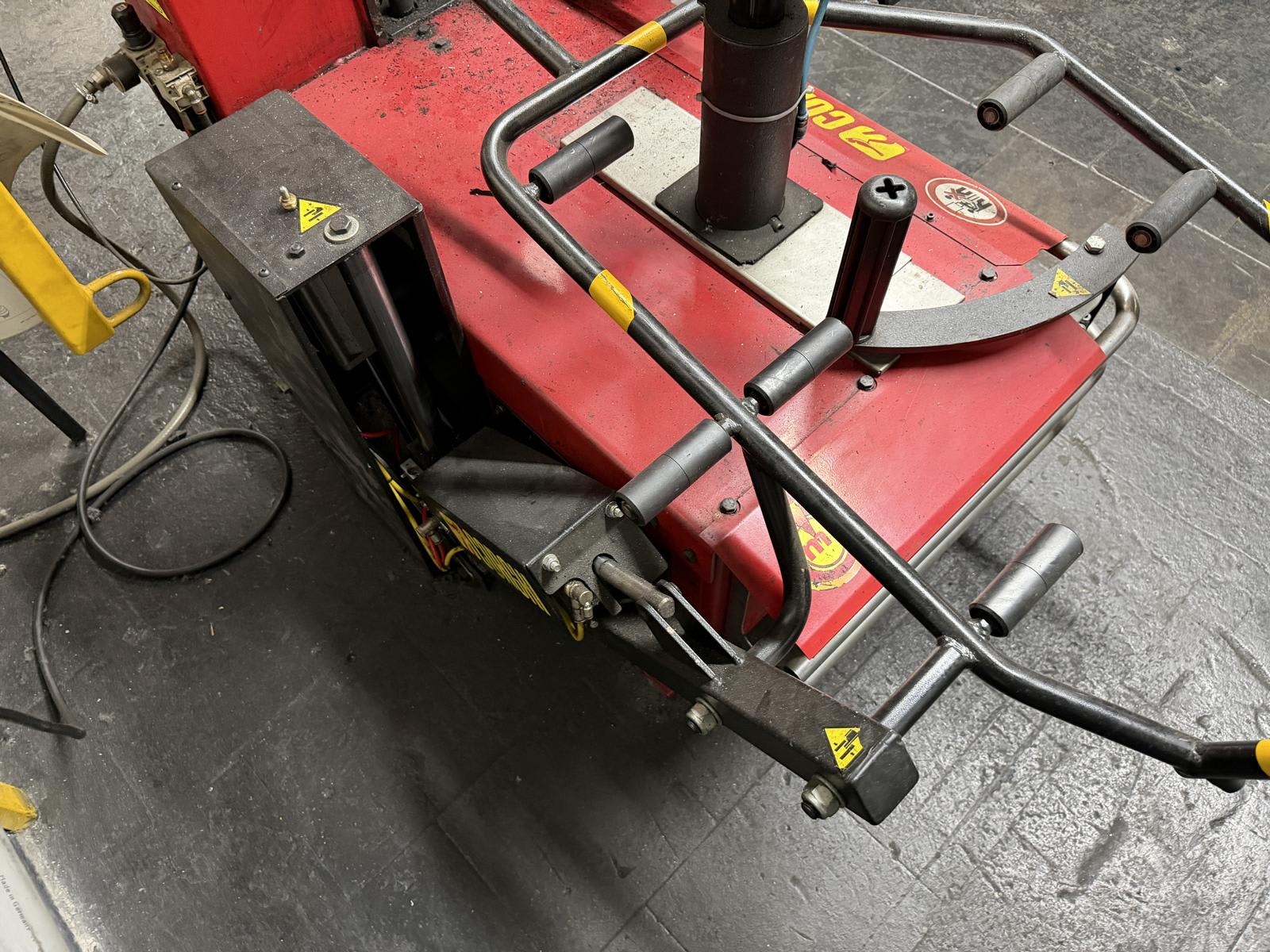

Tire Mounting Machine Corghi Master 26M | 2010

Binding Handling & Service Fee:

60 € (EURO)

Corghi Master 26M Tire Changer Manufacturer: Corghi Model: Master 26M Branding on housing: "Artiglio Master 26" Year of Manufacture: 2010 Serial Number: 0-11103612/0000 - 16 Code: CGF044898 Technical Specifications: Power Supply: 230 V AC / 16 A / 1 Phase / 50/60 Hz Power Rating: 1 kW Operating Pressure: 10 bar / 145 psi Weight: 465 kg Lifting Capacity (Sticker): Label reads "MAX. Hubkraft 65 kg" Key Components (Visual): Equipped with WIKA analog pressure gauge and digital display panel Control pedestal featuring joystick and button operation Pneumatic bead breaker and mounting tool assembly Integrated wheel lift system with roller platform Observed Condition (Visual Only): CE Marking present on type plate Multilingual safety warning stickers applied to the main column - LISTING 2760065

![Deutsch]()

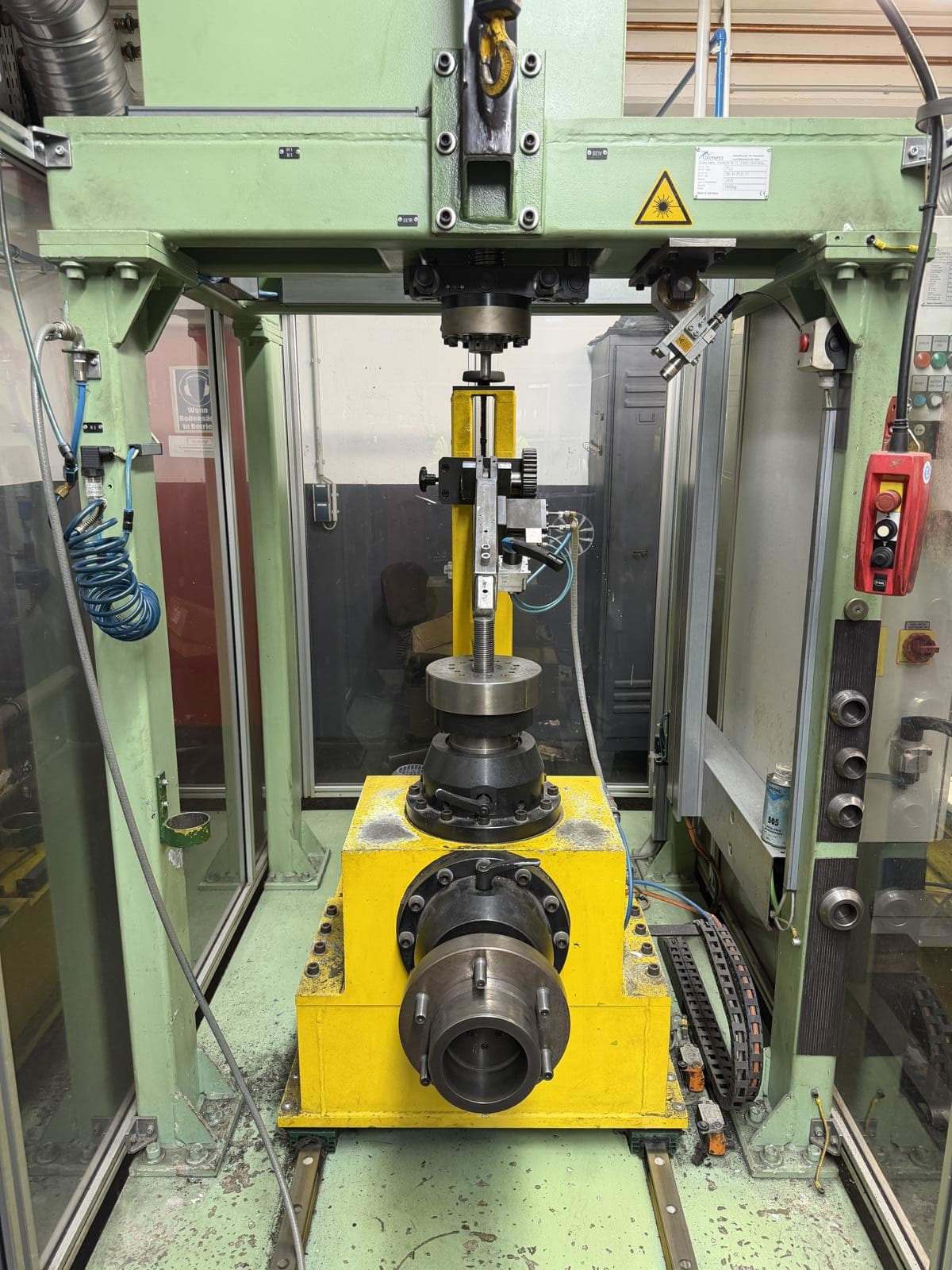

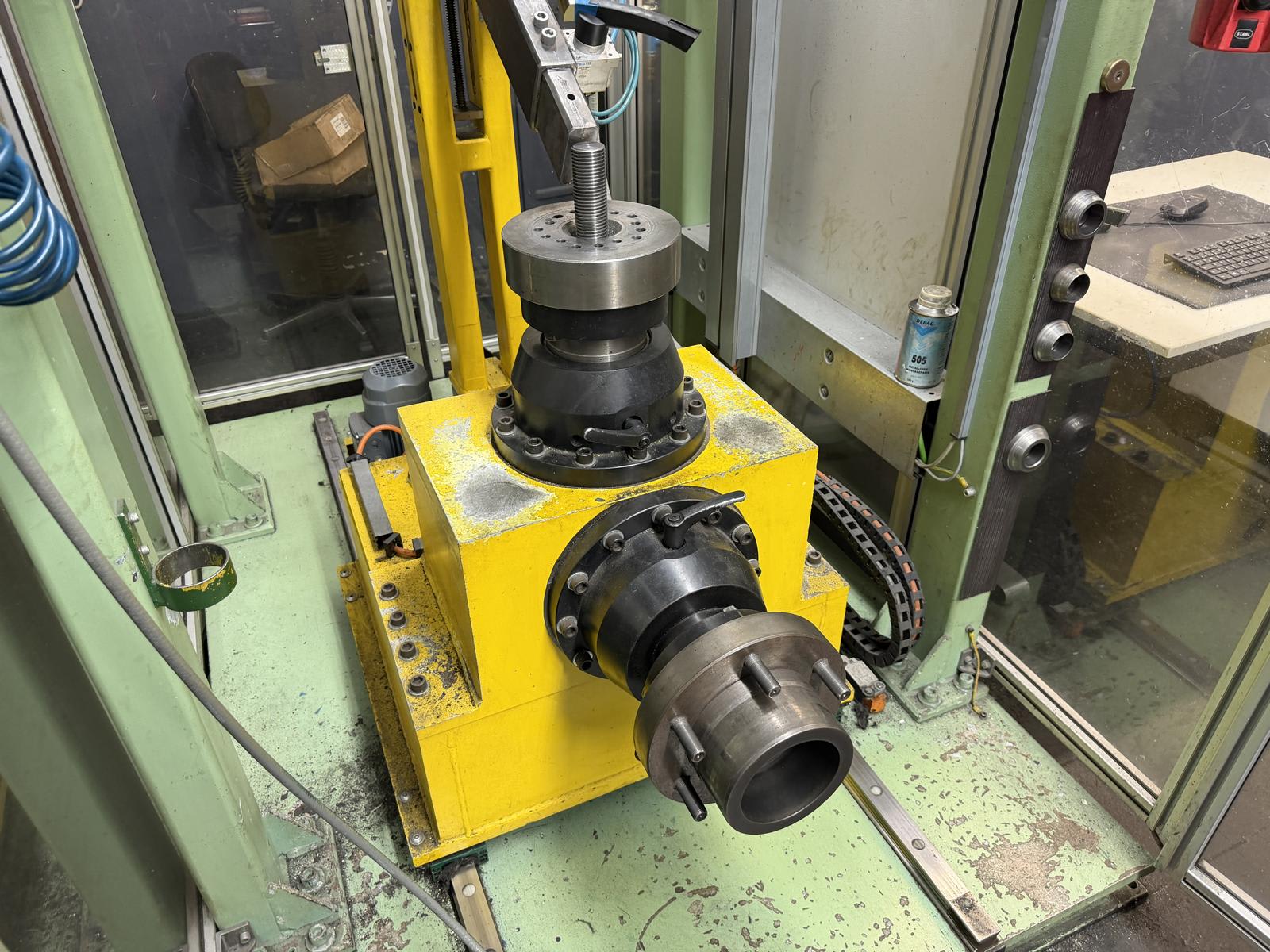

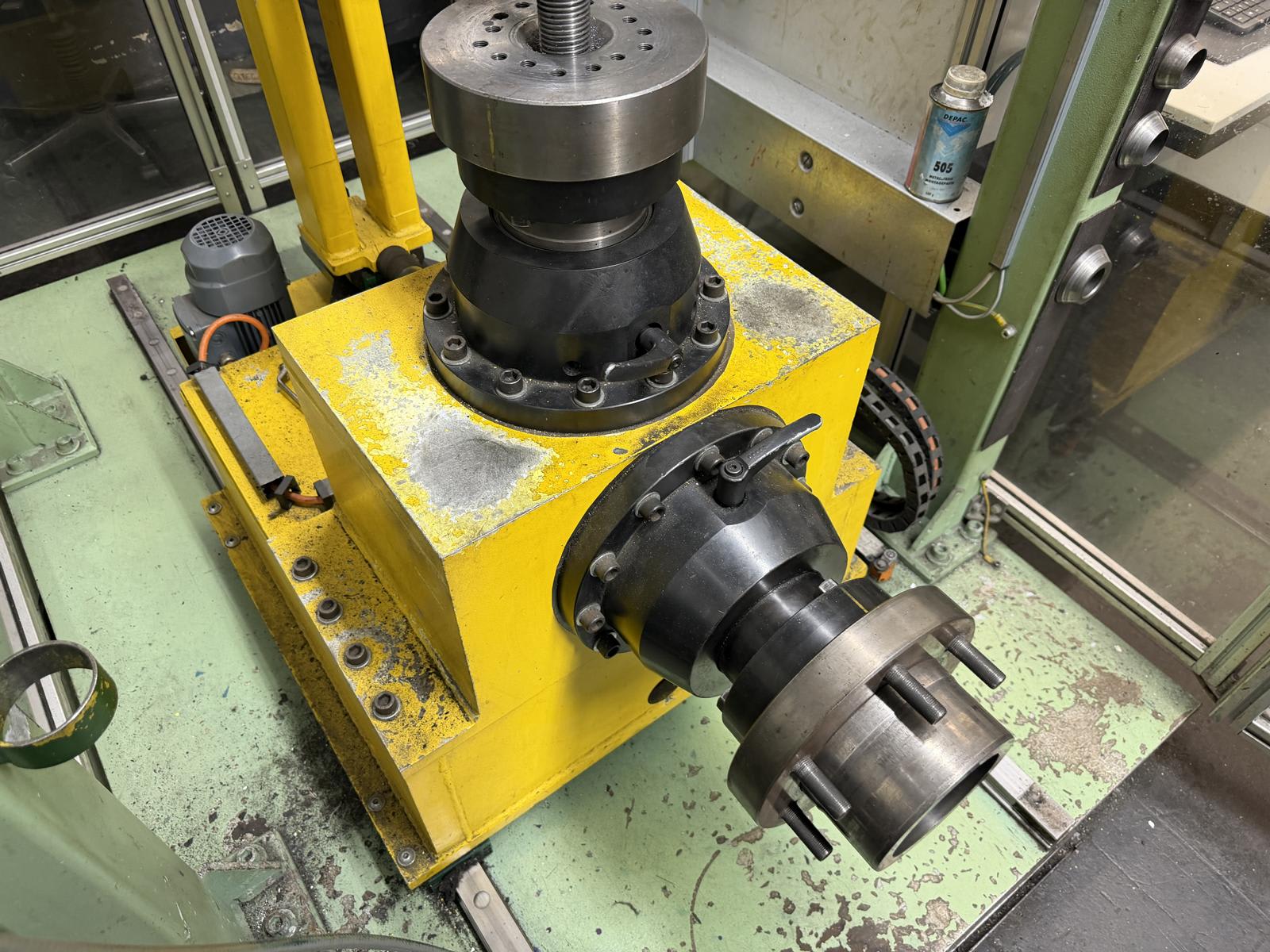

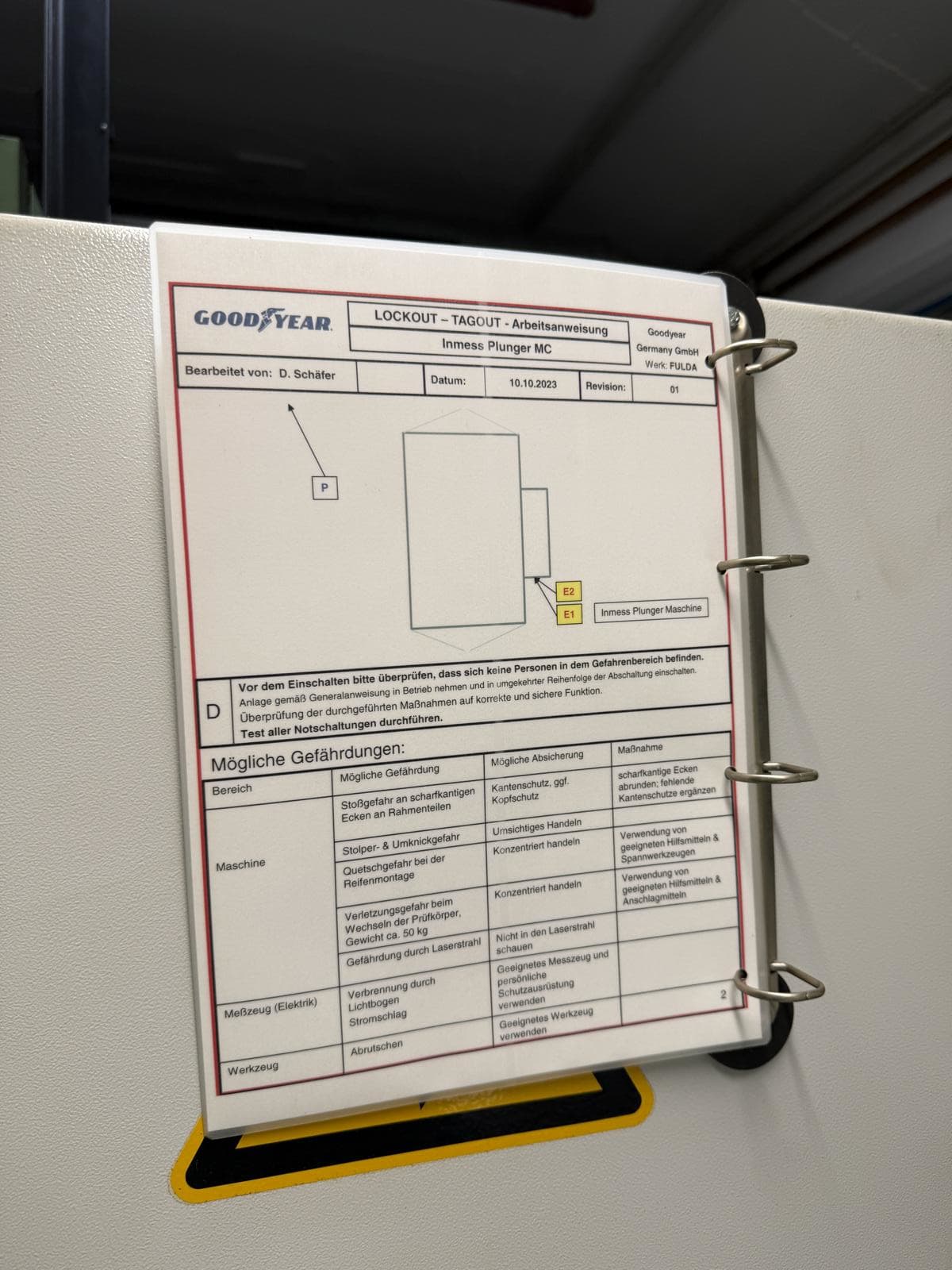

Tire Testing Machine Inmess PLU (08-M-PLU-01) | 2008

Binding Handling & Service Fee:

800 € (EURO)

General Information • Manufacturer: inmess Gesellschaft für Industrie- und Messtechnik mbH • Manufacturer address (as stated on nameplate): Frankfurter Str. 74, D-64521 Groß-Gerau, Germany • CE marked: Yes • Country of manufacture: Germany Machine Identification • Machine type (M/C Type): PLU • Machine number (M/C No.): 08-M-PLU-01 • Year of manufacture: 2008 Electrical Data (Control Cabinet Nameplate) • Incoming supply: 3 × 400 V, 50 Hz • Control voltage: 24 V DC • Rated current: 12 A • Main fuse: 35 A • Connected load / power: 6 kVA Weight • Machine weight (as stated on machine nameplate): 1,900 kg Construction and Design (Visible and Verifiable) • Enclosed machine housing with transparent safety panels • Integrated control cabinet mounted on the machine frame • Main control panel with push buttons, selector switches, and emergency stop • Additional emergency stop button visible on the control cabinet • Mechanical working area fully enclosed by safety guarding • Central horizontal spindle unit mounted on a rigid yellow machine base • Opposing spindle / support unit visible on the same axis • Linear guide rails visible on the machine bed • Pneumatic lines present within the working area • Cable drag chain installed for protected cable routing Safety and Warning Markings • CE conformity marking present • Laser warning symbol affixed to the machine frame • Emergency stop markings visible • Lockout / Tagout work instruction folder mounted on the machine - LISTING 2760066

![Deutsch]()

Lot of Various Testing Wheel Rims BBS and more

Binding Handling & Service Fee:

200 € (EURO)

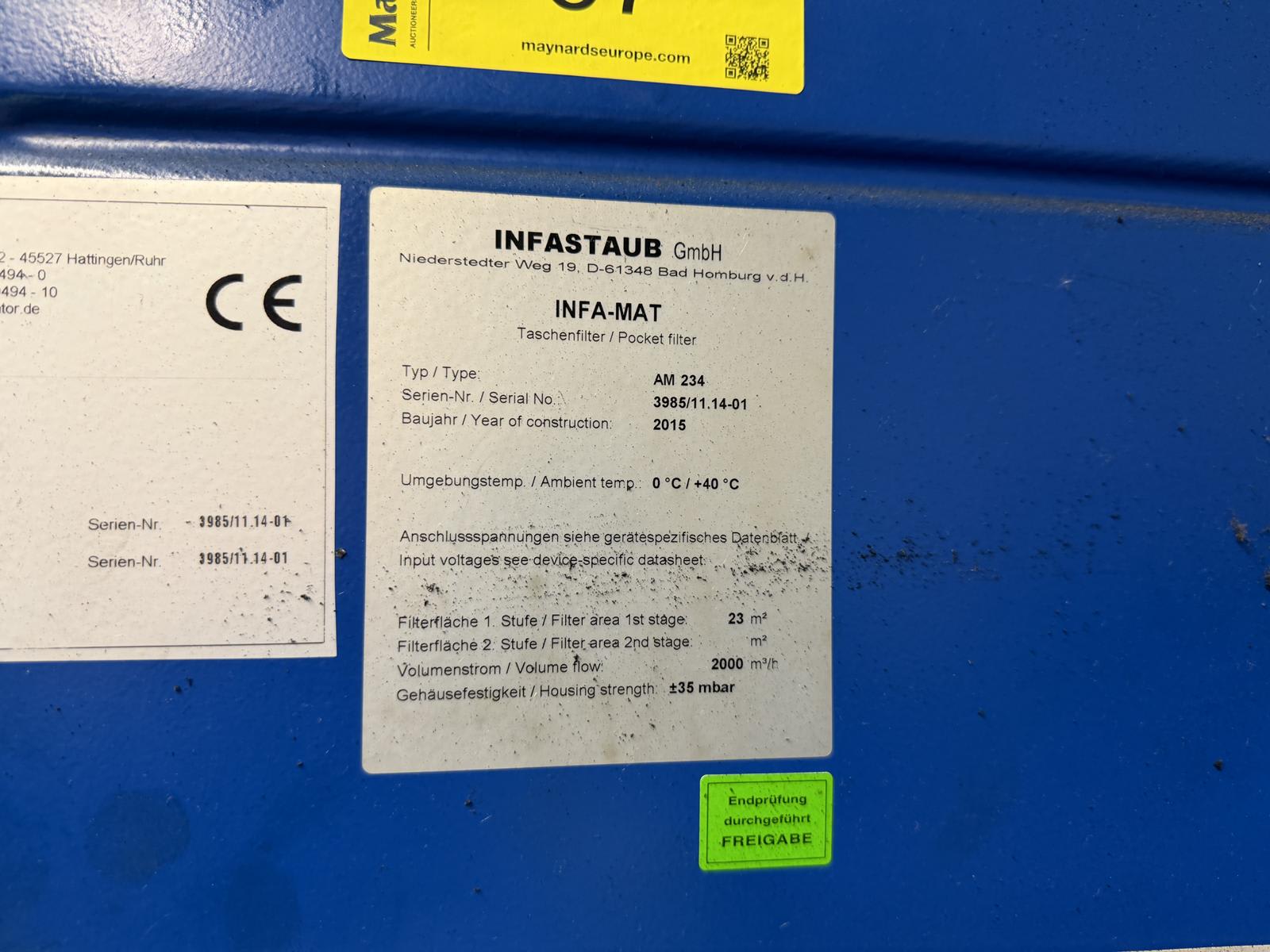

General Information • System type: Dust extraction and filtration system • CE marked: Yes Filter Unit Manufacturer • Manufacturer: INFASTAUB GmbH • Address (as stated): Niederstedter Weg 19, D-61348 Bad Homburg v. d. H., Germany Designation • Product name: INFA-MAT • Filter type: Pocket filter (Taschenfilter) Identification • Type: AM 234 • Serial number: 3985/11.14-01 • Year of construction: 2015 Technical Data (as stated on nameplate) • Ambient temperature range: 0 °C to +40 °C • Filter area, 1st stage: 23 m² • Filter area, 2nd stage: not specified • Volume flow: 2,000 m³/h • Housing strength: ±35 mbar • Input voltages: see device-specific datasheet (no values stated on nameplate) - LISTING 2760067

![Deutsch]()

Dust Extraction System Lohtor / Infastaub AM234 / INFA-MAT | 2015

Binding Handling & Service Fee:

200 € (EURO)

General Information • Machine type: Refrigerated compressed air dryer • Product designation: FD 2400 VSD • CE marked: Yes (CE 0038) Manufacturer • Manufacturer: Atlas Copco Airpower n.v. • Place of manufacture: Wilrijk, Belgium • Brand name on housing: Atlas Copco Identification • Type: FD 2400 VSD • Serial number: AIF125258 • Year of construction: 2007 Electrical Data • Supply voltage: 400 V • Frequency: 50 Hz • Electrical power: 3.5 kW • Phase: as stated on nameplate (Ph, exact number not specified) Operating Data • Maximum compressed air pressure (Pmax): 13 bar(e) • Maximum air temperature (Tmax): 55 °C • Ambient temperature range: Max: 45 °C Min: 3 °C Refrigeration System • Refrigerant type: R404A • Refrigerant charge: 15 kg • Refrigerant maximum pressure (high side): 29 bar • Refrigerant low-side pressure: not specified Weight • Machine weight: 1,180 kg Control and Interface • Control system: Elektronikon® (as labeled on control panel) • Integrated display and membrane keypad on front door - LISTING 2760068

![Deutsch]()

Refrigerated Air Dryer Atlas Copco FD 2400 VSD W | 2007

Binding Handling & Service Fee:

500 € (EURO)

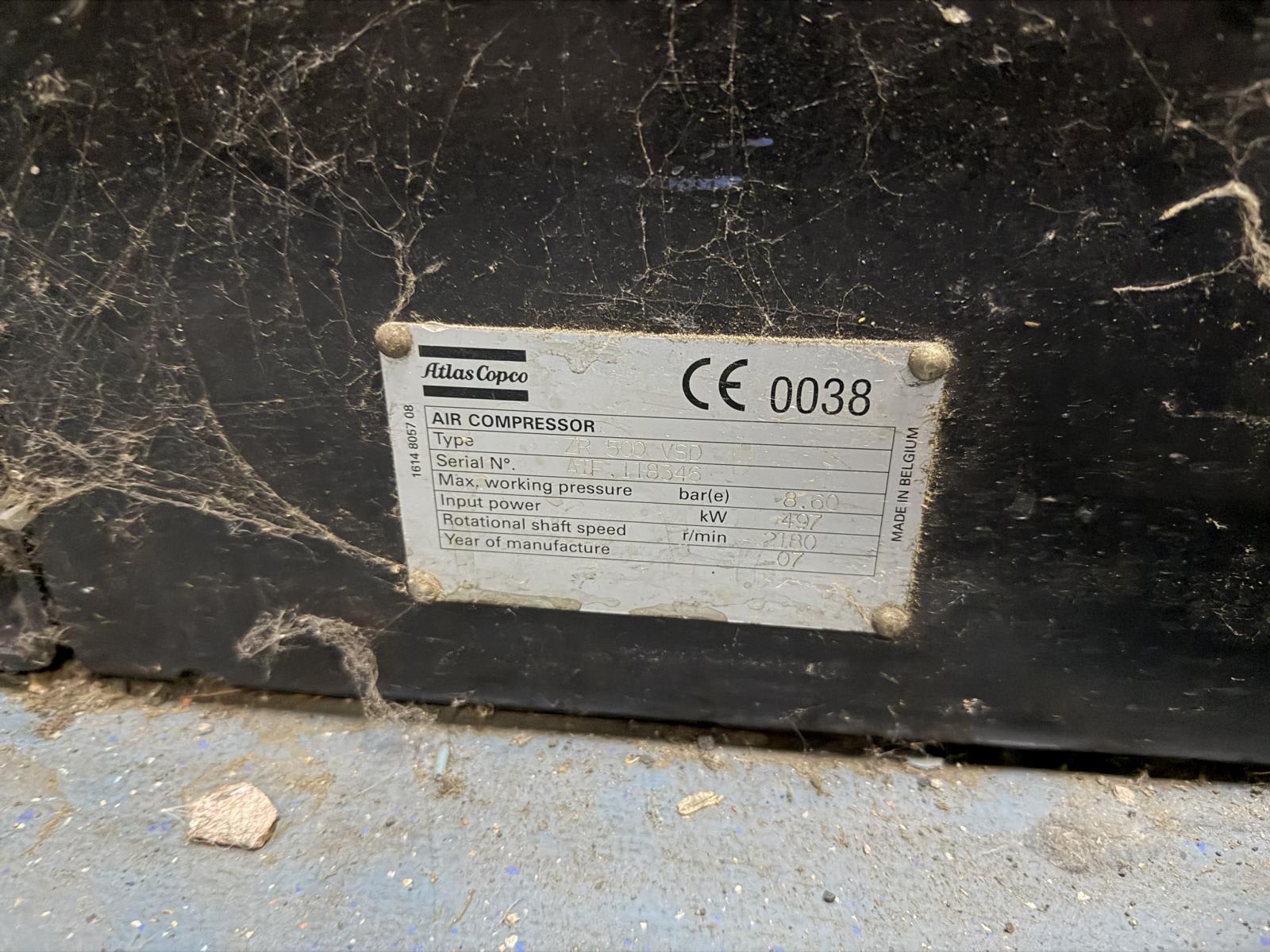

General Information • Machine type: Oil-free Air Compressor • Product designation: ZR 500 VSD • CE marked: Yes (CE 0038) Manufacturer • Manufacturer: Atlas Copco • Manufacturing origin (as stated on nameplate): Made in Belgium Identification • Type: ZR 500 VSD • Serial number: AIF118346 • Year of manufacture: 2007 Technical Data (Nameplate) • Maximum working pressure: 8.60 bar(e) • Input power: 497 kW • Rotational shaft speed: 2,180 r/min Control and Operation • Control system: Elektronikon® (as labeled on control panel) • Integrated display with membrane keypad • Emergency stop push-button mounted on front panel - LISTING 2760069

![Deutsch]()

Oil-free Air Compressor Atlas Copco ZR 500 VSD | 2007

Binding Handling & Service Fee:

700 € (EURO)

General Information • Machine type: Refrigerated compressed air dryer • Product designation: FD 2400 VSD • CE marked: Yes (CE 0038) Manufacturer • Manufacturer: Atlas Copco Airpower n.v. • Place of manufacture (as stated on nameplate): Wilrijk, Belgium Identification • Type: FD 2400 VSD • Serial number: AIF125259 • Year of construction: 2007 Electrical Data (Nameplate) • Supply voltage: 400 V • Frequency: 50 Hz • Electrical power: 3.5 kW • Phase: stated as “Ph” (exact phase number not specified on nameplate) Operating Data • Maximum compressed air pressure (Pmax): 13 bar(e) • Maximum air temperature (Tmax): 55 °C • Ambient temperature range: Max: 45 °C Min: 3 °C Refrigeration System • Refrigerant type: R404A • Refrigerant charge: 15 kg • Refrigerant maximum pressure (high side): 29 bar • Refrigerant low-side pressure: not specified Weight • Machine weight: 1,180 kg Control and Interface • Control system: Elektronikon® (as labeled on the control panel) • Integrated display and membrane keypad on front door - LISTING 2760070

![Deutsch]()

Refrigerated Air Dryer Atlas Copco FD 2400 VSD W | 2007

Binding Handling & Service Fee:

500 € (EURO)

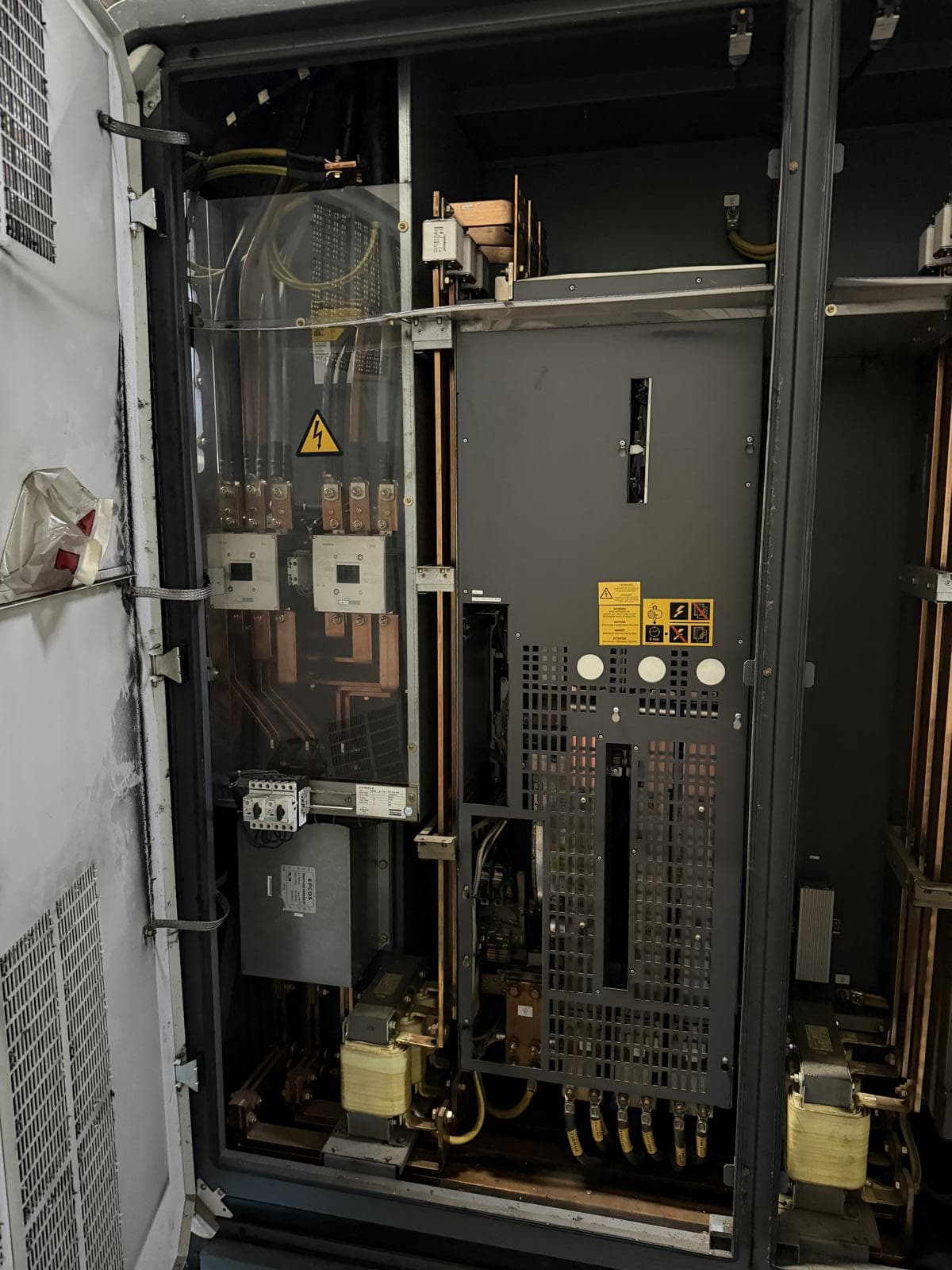

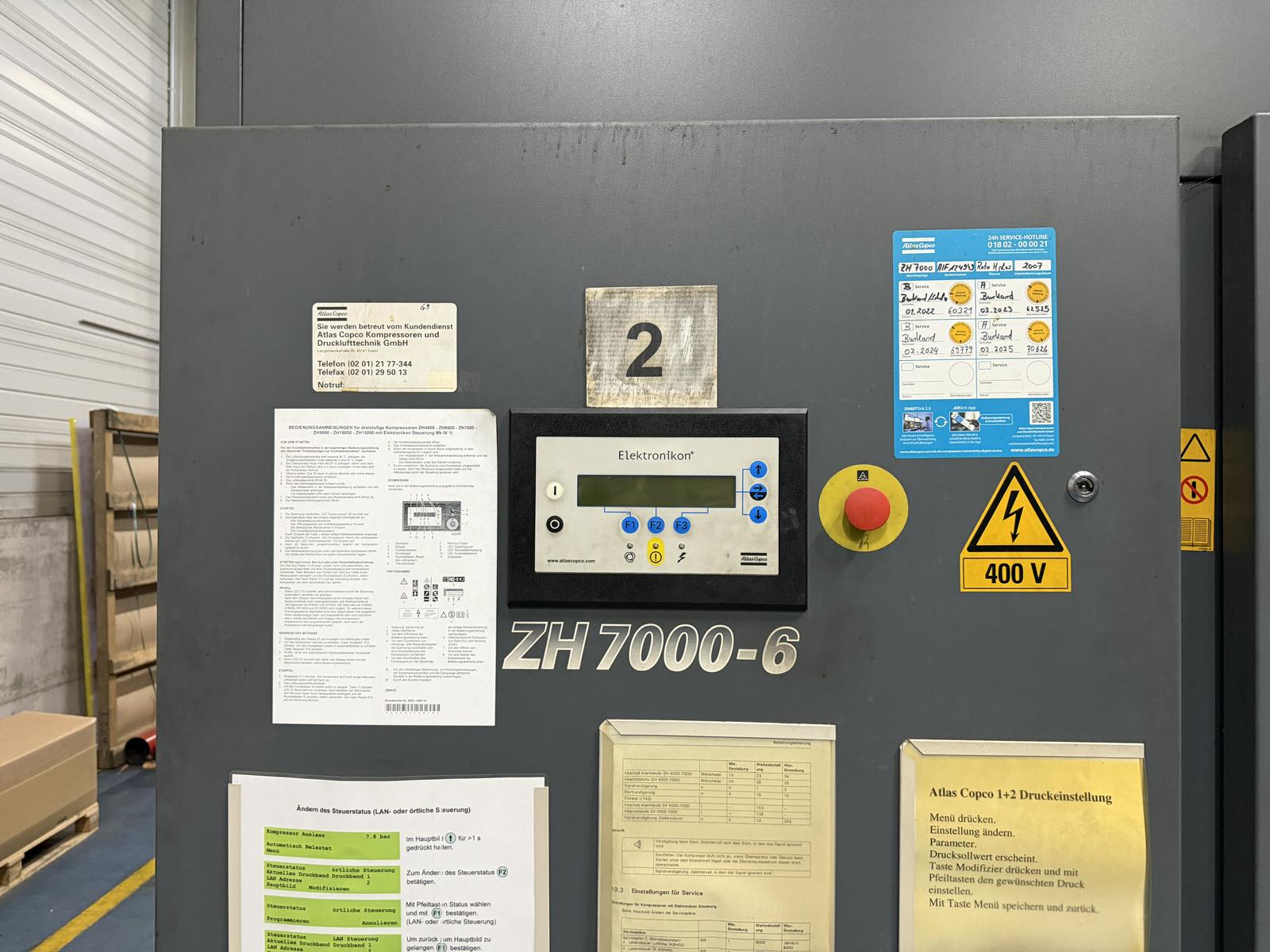

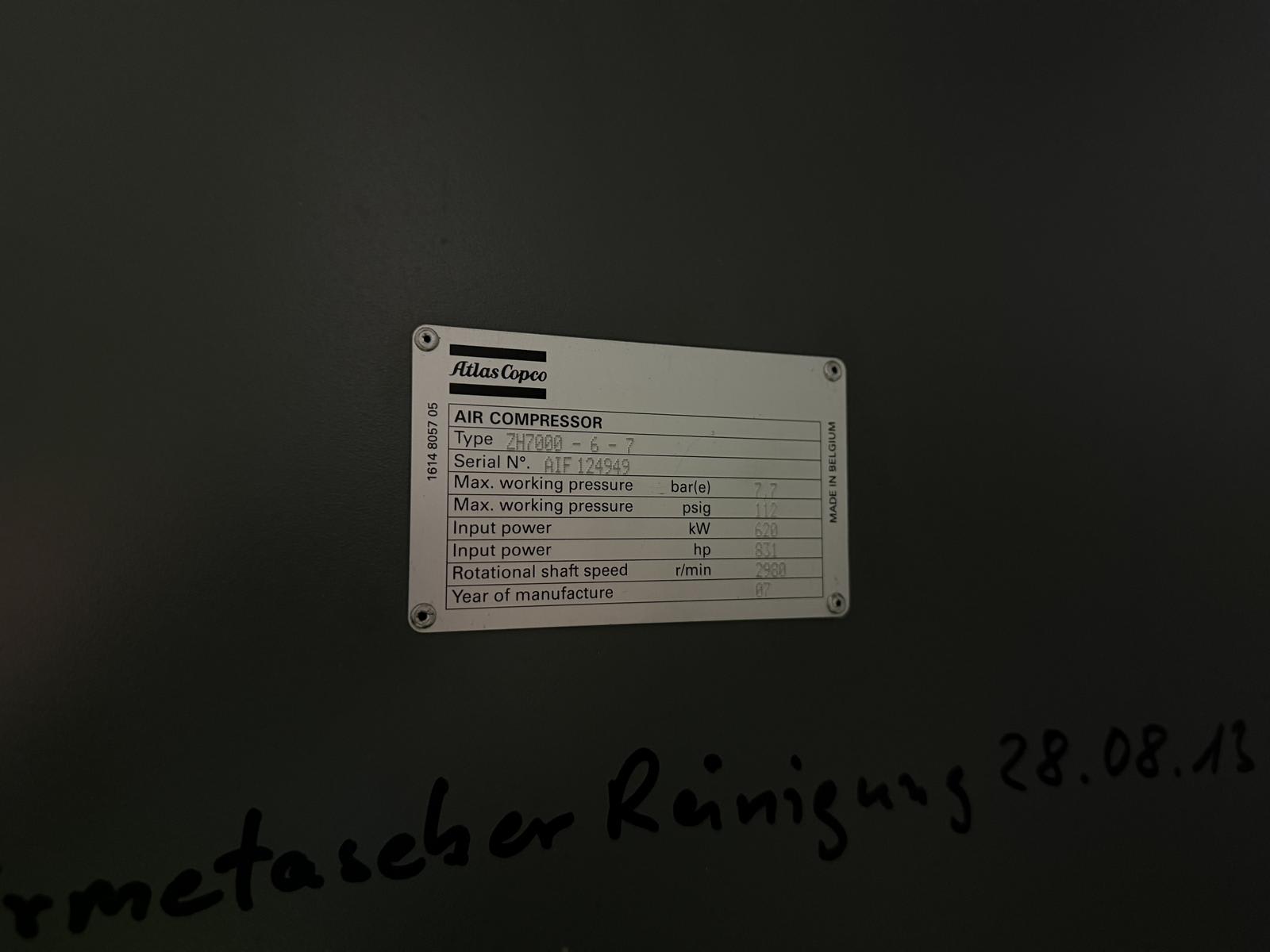

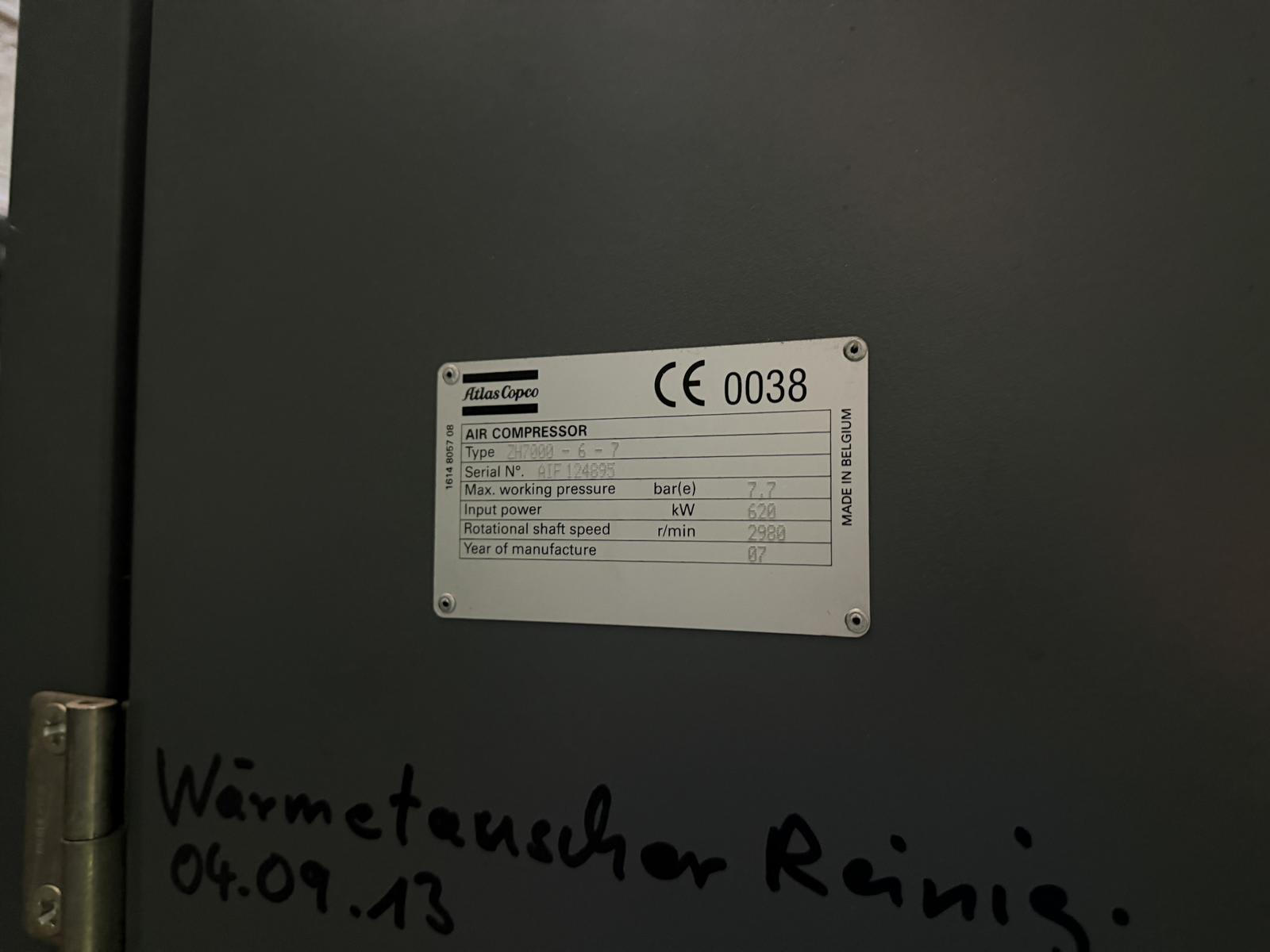

General Information • Machine type: Oil-free Air Compressor • Product designation: ZH 7000-6 • CE marked: Yes Manufacturer • Manufacturer: Atlas Copco • Country of manufacture (as stated on nameplate): Belgium Identification • Type: ZH7000-6-7 • Serial number: AIF124949 • Year of manufacture: 2007 Technical Data (Nameplate) • Maximum working pressure: 7.7 bar(e) 112 psig • Input power: 620 kW 831 hp • Rotational shaft speed: 2,980 r/min Control and Operation • Control system: Elektronikon® • Integrated display with membrane keypad • Emergency stop push-button mounted on front panel - LISTING 2760071

![Deutsch]()

Oil-free Air Compressor Atlas Copco ZH7000-6-7 | 2007

Binding Handling & Service Fee:

700 € (EURO)

General Information • Machine type: Refrigerated Air Dryer • Product designation: FD 2400 VSD • CE marked: Yes (CE 0038) Manufacturer • Manufacturer: Atlas Copco Airpower n.v. • Place of manufacture (as stated on nameplate): Wilrijk, Belgium Identification • Type: FD 2400 VSD W • Serial number: AIF125669 • Year of construction: 2007 Electrical Data (Nameplate) • Supply voltage: 400 V • Frequency: 50 Hz • Electrical power: 3.5 kW • Phase: indicated as “Ph” (exact phase number not specified on nameplate) Operating Data • Maximum compressed air pressure (Pmax): 13 bar(e) • Maximum air temperature (Tmax): 55 °C • Ambient temperature range: Max: 45 °C Min: 3 °C Refrigeration System • Refrigerant type: R404A • Refrigerant charge: 15 kg • Refrigerant maximum pressure (high side): 29 bar • Refrigerant low-side pressure: not specified Weight • Machine weight: 1,180 kg Control and Interface • Control system: Elektronikon® (as labeled on the control panel) • Integrated display with membrane keypad mounted on the front door - LISTING 2760072

![Deutsch]()

Refrigerated Air Dryer Atlas Copco FD 2400 VSD W | 2007

Binding Handling & Service Fee:

500 € (EURO)

General Information • Machine type: Air Compressor • Product designation: ZH7000-6-7 • CE marked: Yes (CE 0038) Manufacturer • Manufacturer: Atlas Copco • Place of manufacture (as stated on nameplate): Belgium (Made in Belgium) Identification • Type: ZH7000-6-7 • Serial number: AIF124895 • Year of construction: 2007 Electrical / Drive Data (Nameplate) • Input power: 520 kW • Rotational shaft speed: 2,980 r/min Operating Data • Maximum working pressure: 7.7 bar(e) Design and Execution (Visible) • Stationary industrial compressor in enclosed sound-insulated housing • Multi-door cabinet design with ventilation openings • Side-mounted piping connections • Marked as “Oil-free Air” on the housing Control and Interface (Visible) • Front-mounted control and display panel • Additional operating and safety documentation mounted on the cabinet • Exact control system designation not specified on the visible labels - LISTING 2760073

![Deutsch]()

Oil-free Air Compressor Atlas Copco ZH7000-6-7 | 2007

Binding Handling & Service Fee:

700 € (EURO)

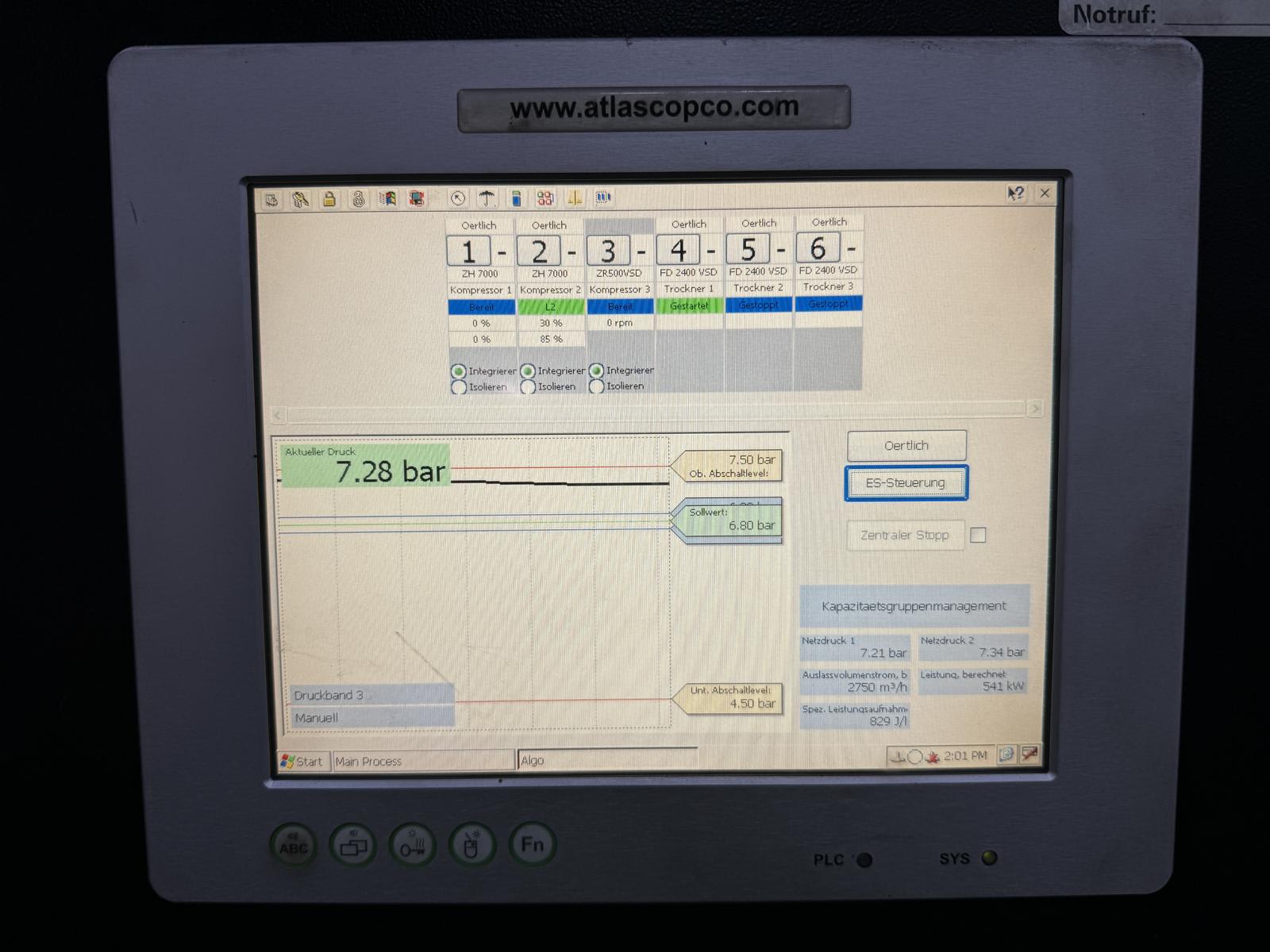

General Information • Machine type: Central compressor control system • Product designation: ES 130 Manufacturer • Manufacturer: Atlas Copco • Service provider (as stated on label): Atlas Copco Kompressoren und Drucklufttechnik GmbH Identification • Type: ES 130 • Serial number: Not specified on visible labels • Year of construction: Not specified Control System • Control system designation: ES 130 • Function (as visible on display): Central control and capacity group management for multiple compressors and dryers • Controlled units (visible on screen): ZH 7000 – Compressor 1 ZH 7000 – Compressor 2 ZR 500 VSD – Compressor 3 FD 2400 VSD – Dryer 1 FD 2400 VSD – Dryer 2 FD 2400 VSD – Dryer 3 Display and Interface • Integrated color display with graphical process visualization • Display shows operating states such as “Bereit”, “Gestartet”, “Gestoppt” • On-screen pressure visualization with setpoints and thresholds • Front-mounted membrane keys and function buttons • Status indicators labeled PLC and SYS Operating Data (Visible on Screen at Time of Recording) • Current system pressure: 7.28 bar • Upper shutdown limit: 7.50 bar • Setpoint: 6.80 bar • Lower shutdown limit: 4.50 bar System Monitoring (Visible) • Network pressure 1: 7.21 bar • Network pressure 2: 7.34 bar • Calculated air flow: 2,750 m³/h • Calculated power: 541 kW • Specific power consumption: 829 J/l - LISTING 2760074

![Deutsch]()

Compressor Control System Atlas Copco ES 130 | 2007

Binding Handling & Service Fee:

80 € (EURO)

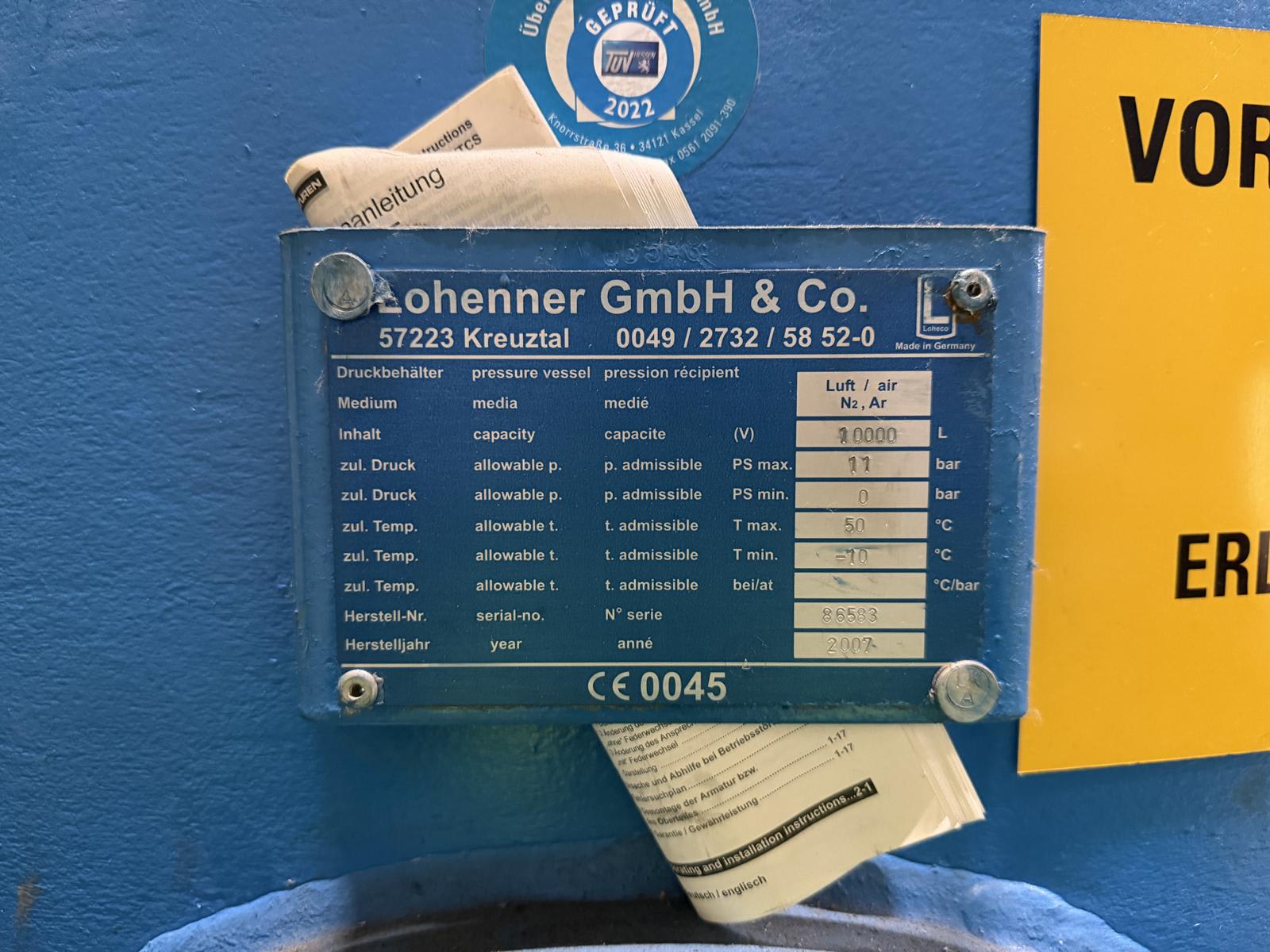

General Information • Machine type: Pressure vessel (compressed air receiver) • Product designation: Pressure vessel • CE marked: Yes (CE 0045) Manufacturer • Manufacturer: Hohener GmbH & Co. • Place of manufacture (as stated on nameplate): Germany Identification • Type: Pressure vessel • Serial number: 86583 • Year of construction: 2007 Medium • Permitted medium: Air Nitrogen (N₂) Argon (Ar) Capacity • Vessel volume: 10,000 L Pressure Data (Nameplate) • Maximum allowable pressure (PS max): 11 bar • Minimum allowable pressure (PS min): 0 bar Temperature Data (Nameplate) • Maximum allowable temperature (T max): 50 °C • Minimum allowable temperature (T min): −10 °C - LISTING 2760075

![Deutsch]()

Pressure Air Tank Lohenner Gmbh | 2007

Binding Handling & Service Fee:

300 € (EURO)

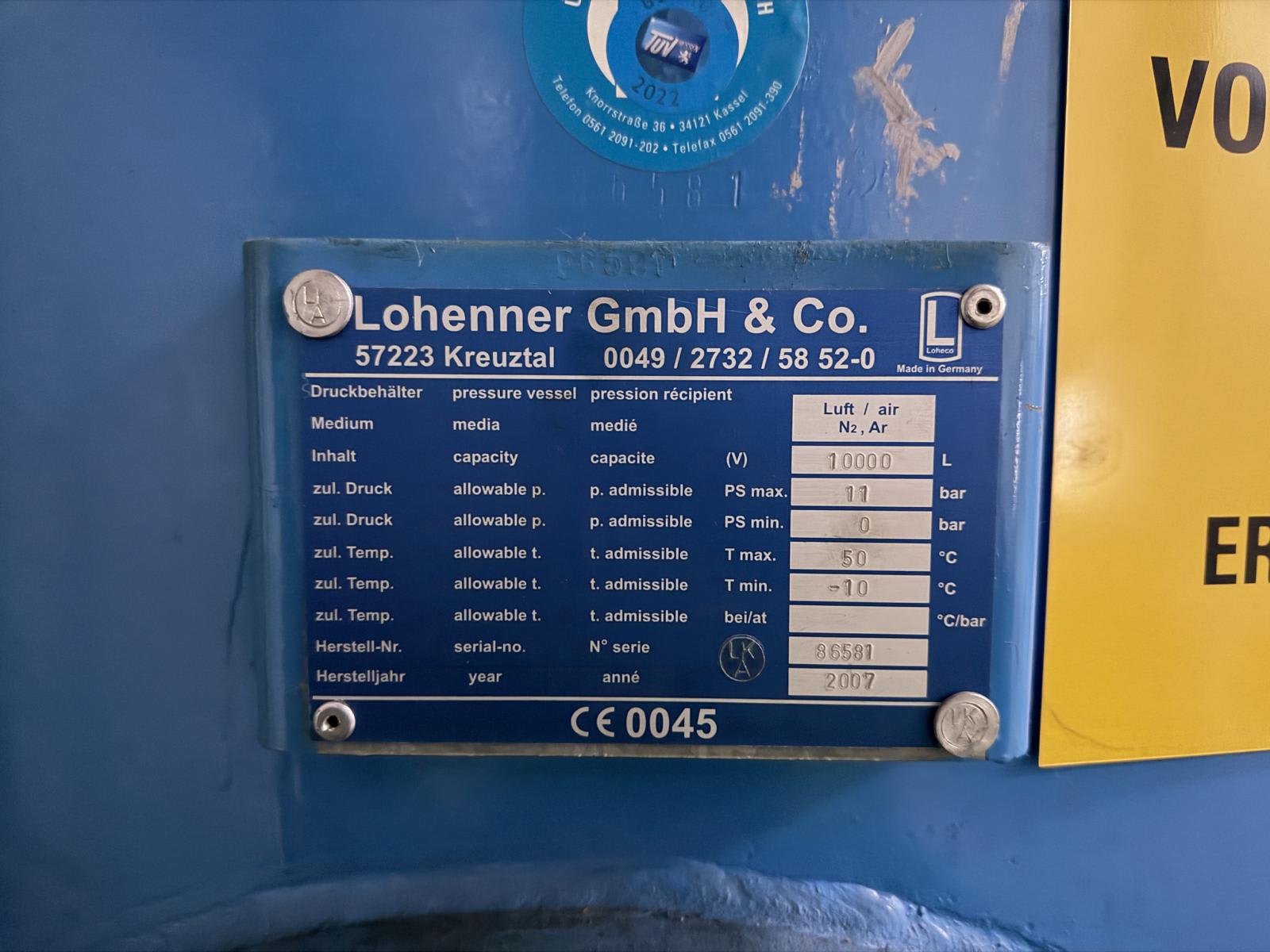

General Information • Machine type: Pressure vessel (compressed air receiver) • Product designation: Pressure vessel • CE marked: Yes (CE 0045) Manufacturer • Manufacturer: Hohenner GmbH & Co. • Place of manufacture (as stated on nameplate): Germany Identification • Type: Pressure vessel • Serial number: 86581 • Year of construction: 2007 Medium • Permitted medium: Air Nitrogen (N₂) Argon (Ar) Capacity • Vessel volume: 10,000 L Pressure Data (Nameplate) • Maximum allowable pressure (PS max): 11 bar • Minimum allowable pressure (PS min): 0 bar Temperature Data (Nameplate) • Maximum allowable temperature (T max): 50 °C • Minimum allowable temperature (T min): −10 °C - LISTING 2760076

![Deutsch]()

- LISTING 2760077

![Deutsch]()

- LISTING 2760078

![Deutsch]()

- LISTING 2760079

![Deutsch]()

6 KV Transfomer Mocotech

Binding Handling & Service Fee:

1300 € (EURO)

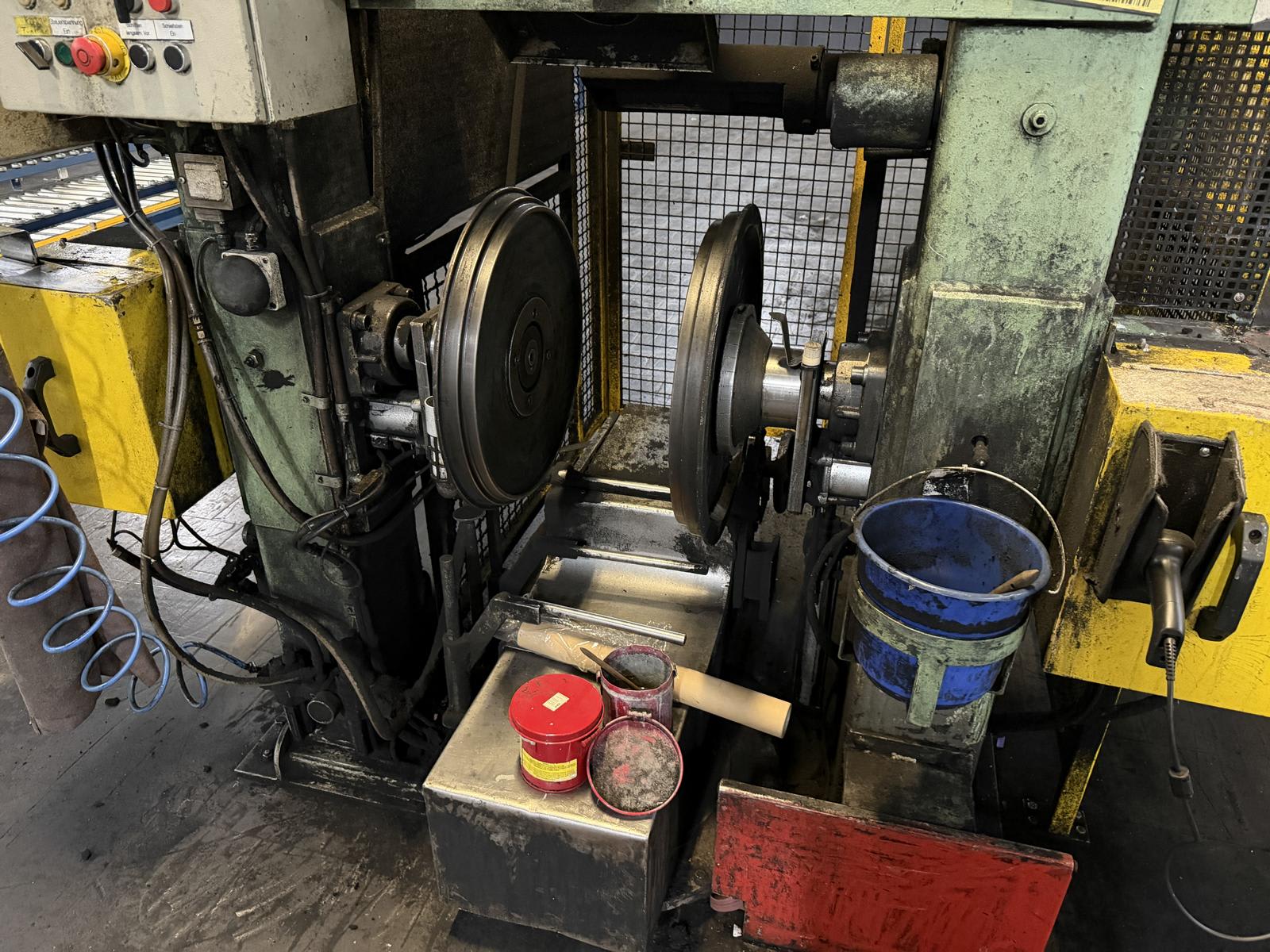

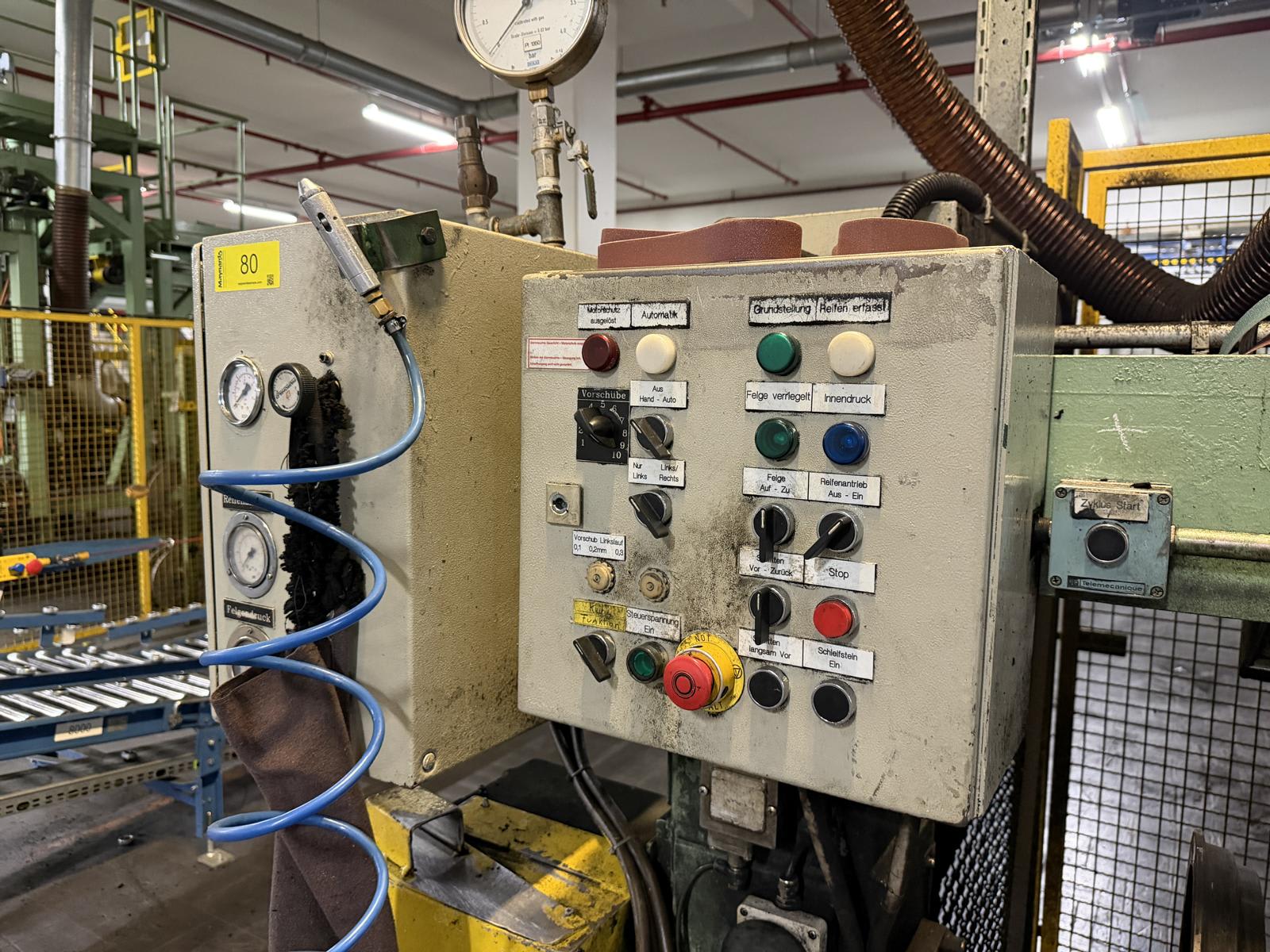

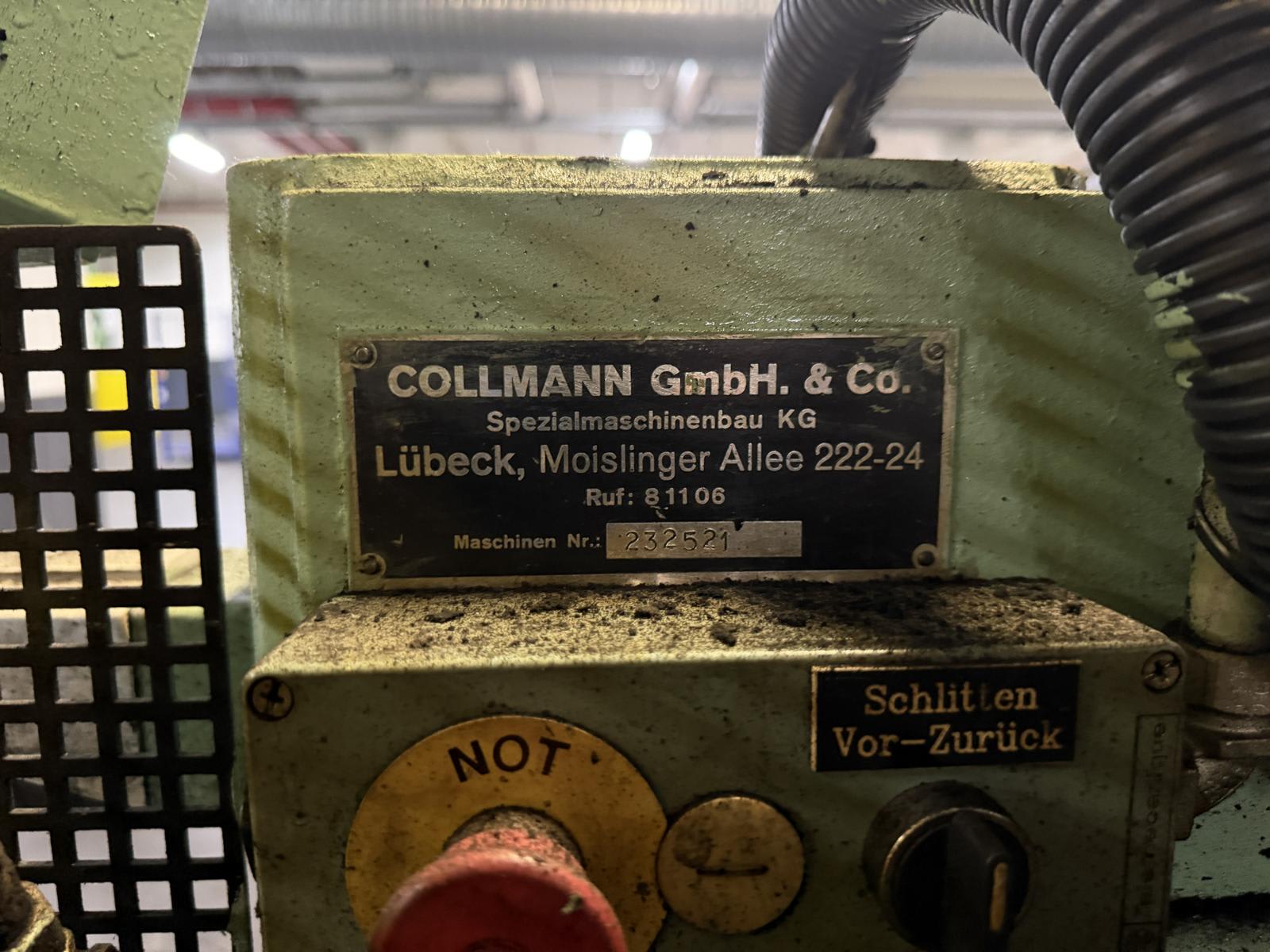

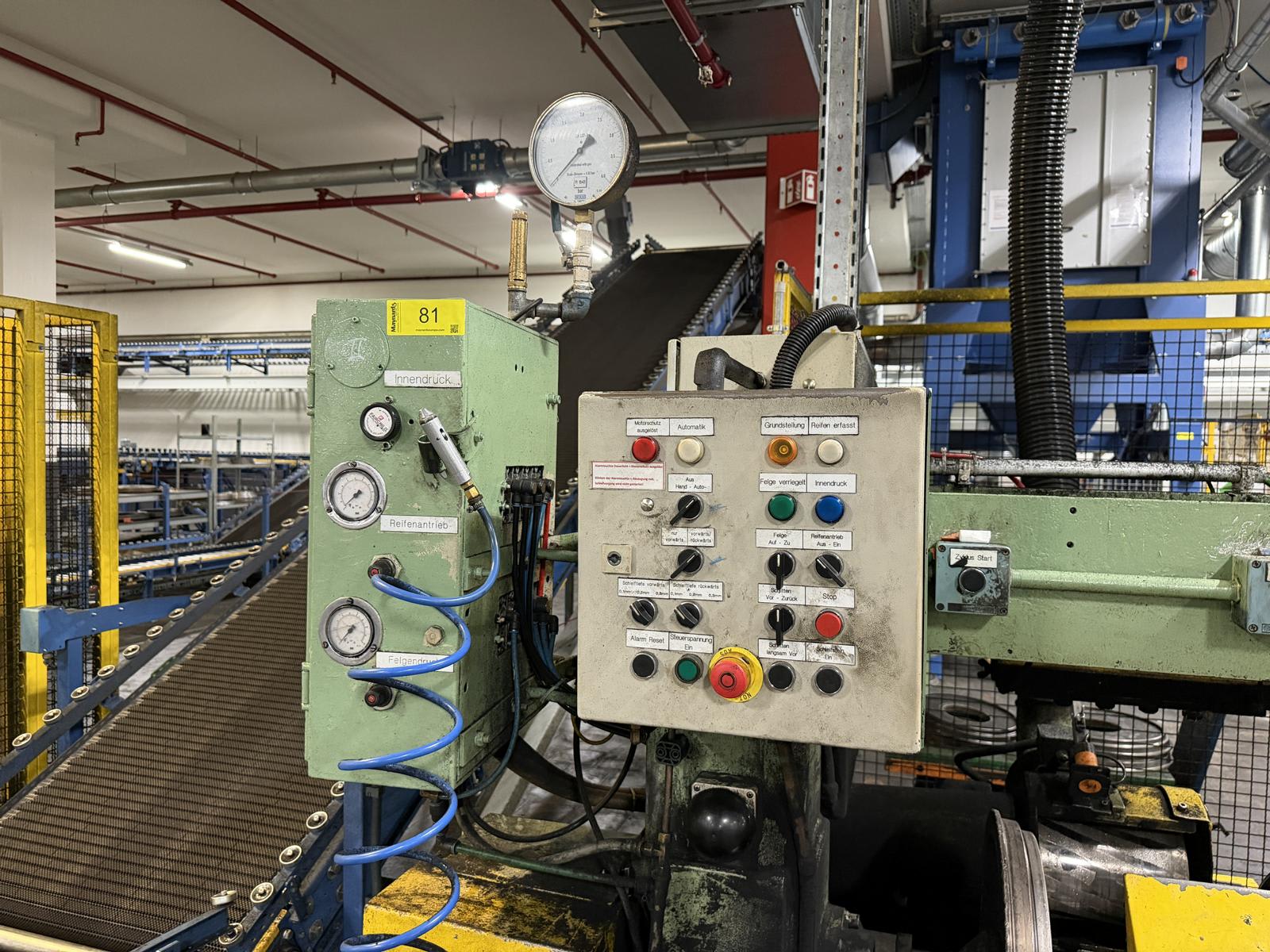

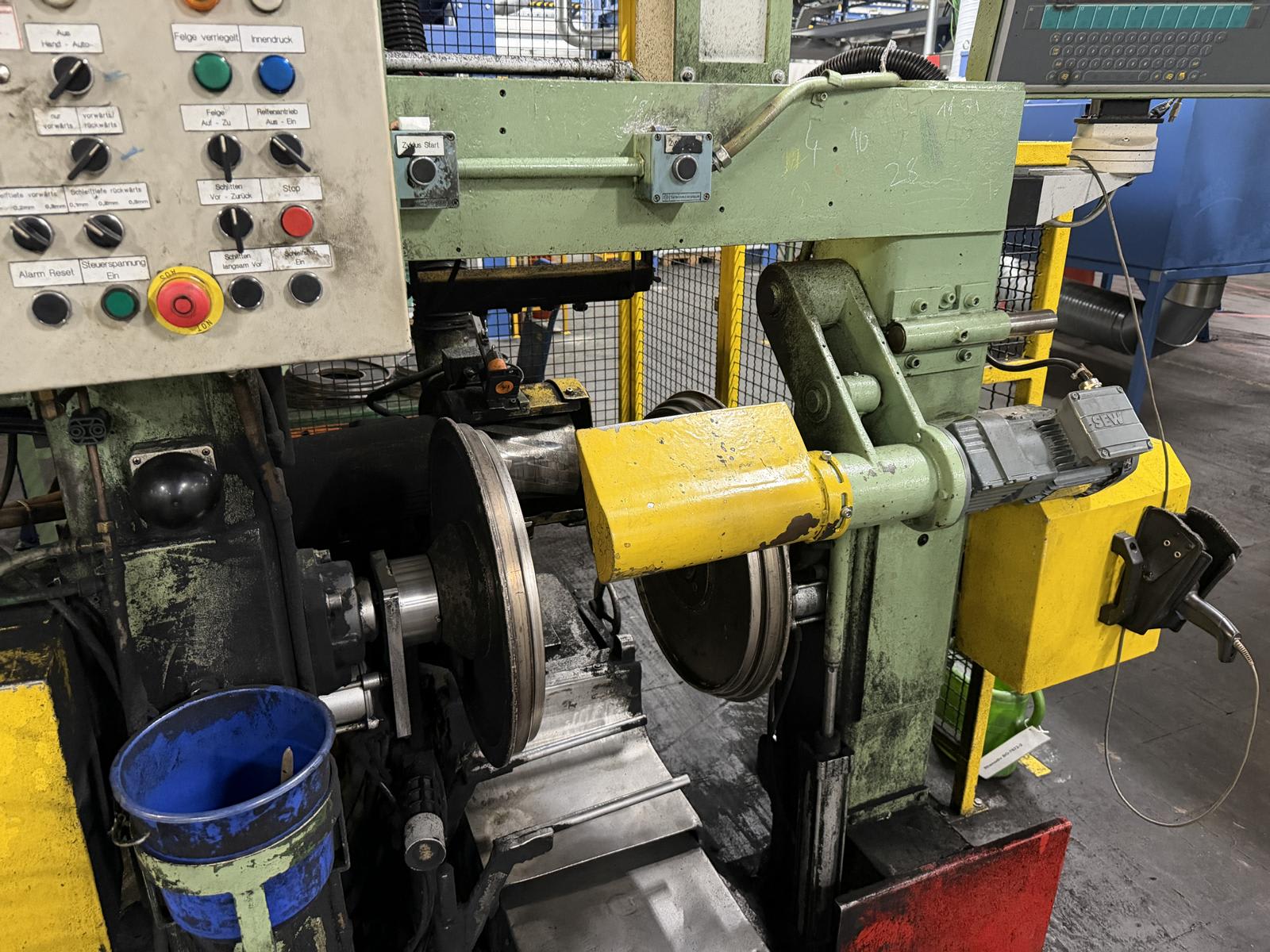

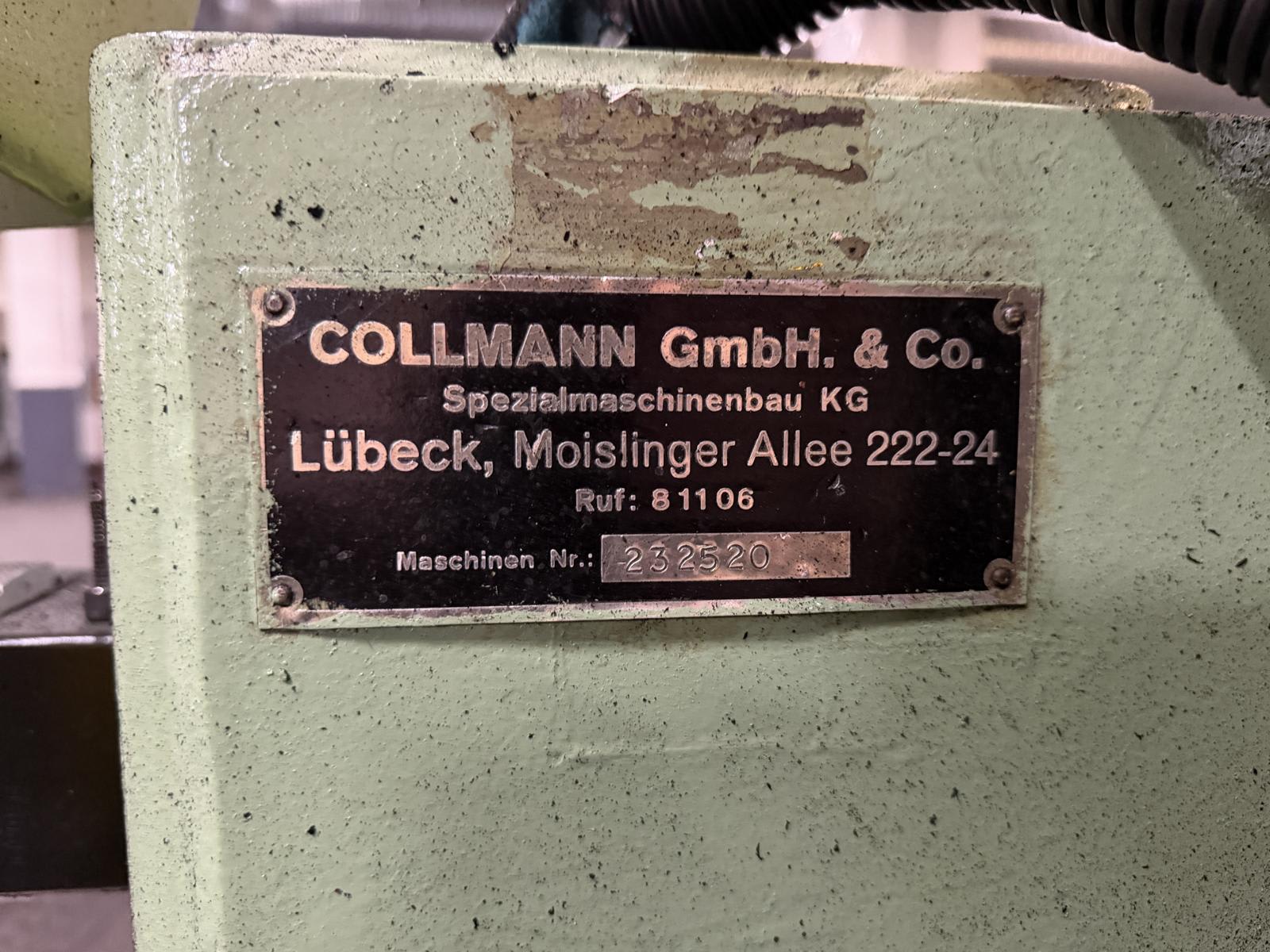

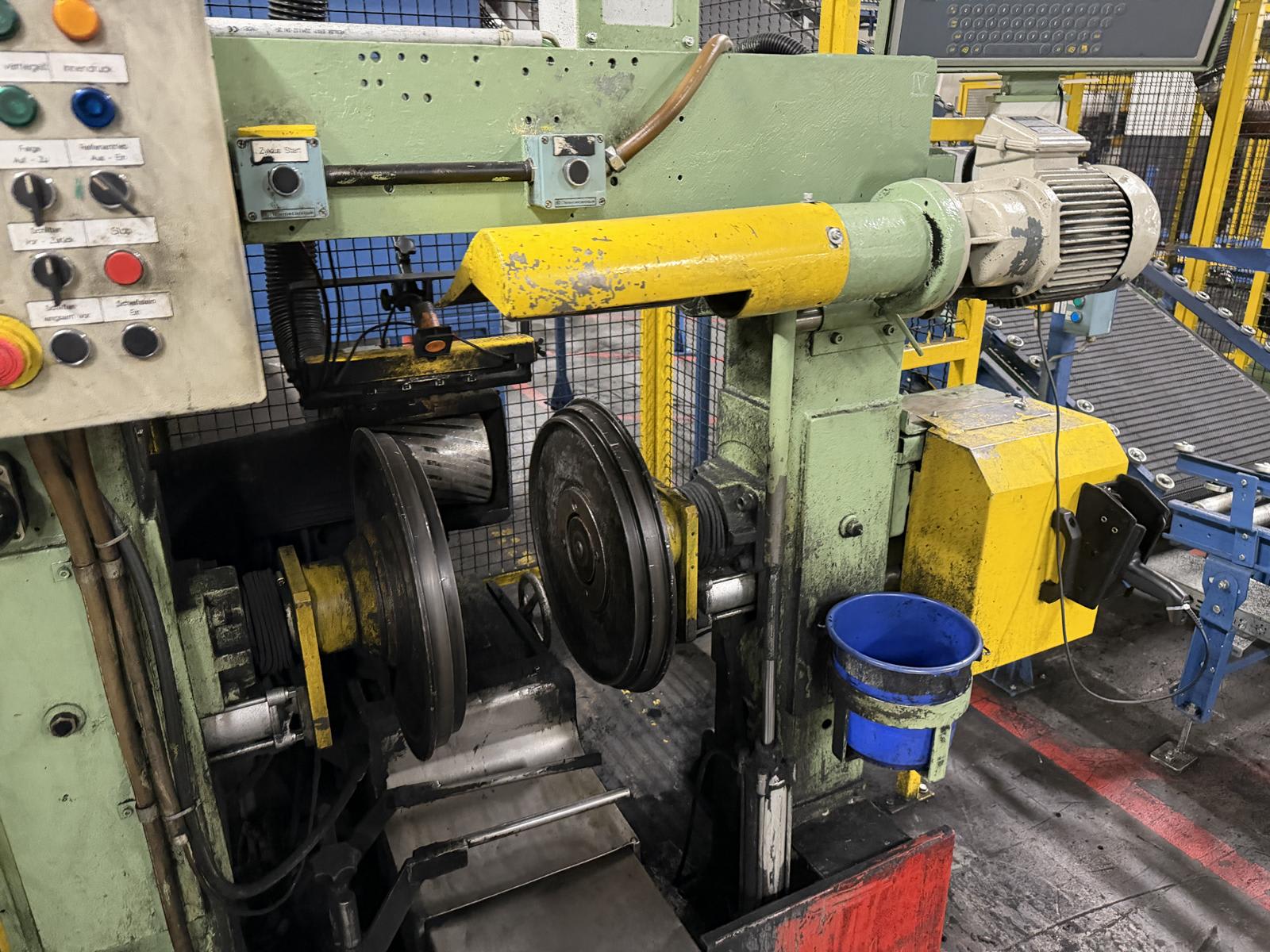

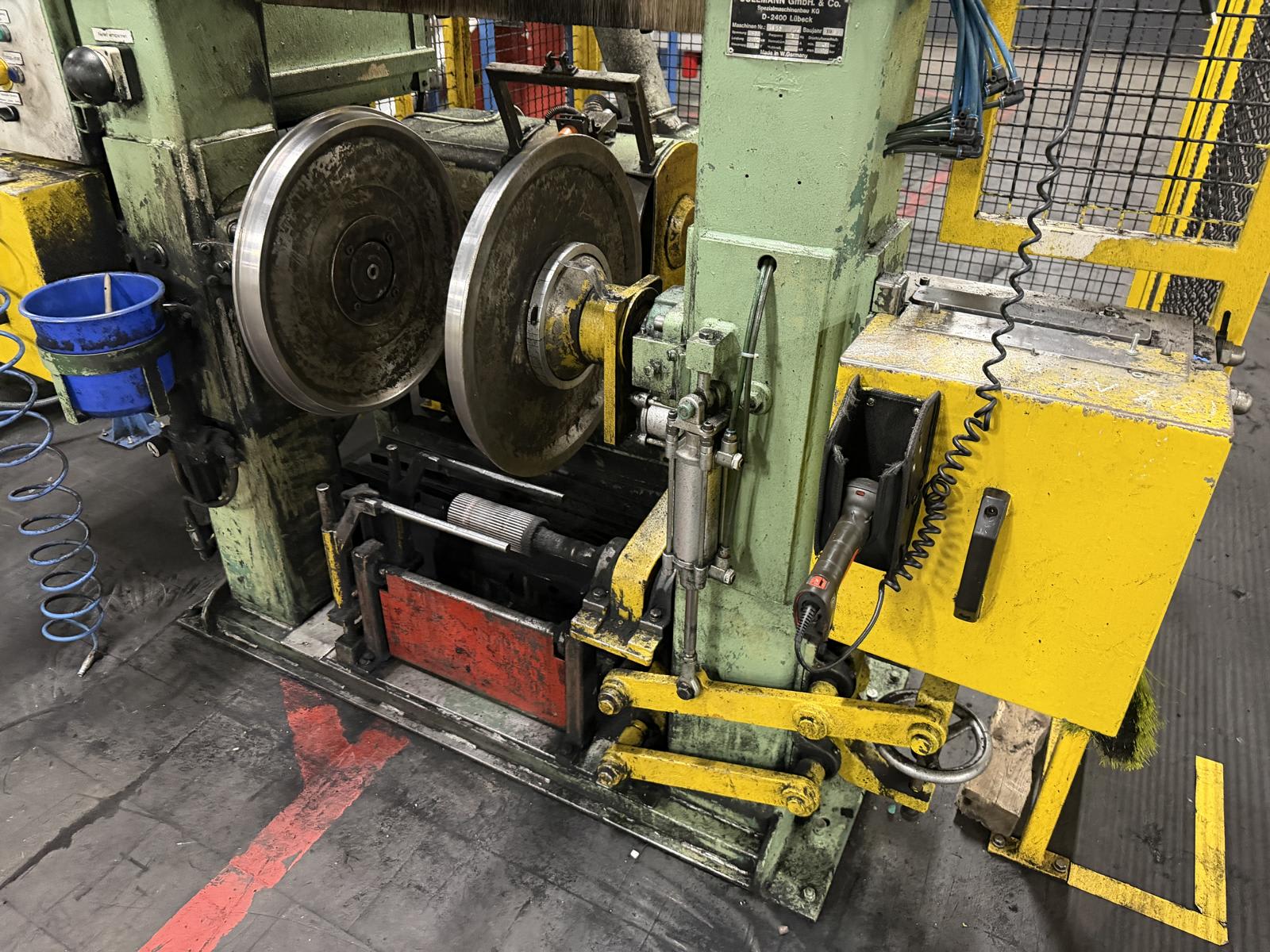

General Information Manufacturer • Manufacturer: COLLMANN GmbH & Co. Spezialmaschinenbau KG • Manufacturer address (as stated on nameplate): Lübeck, Moislinger Allee 222–224, Germany Identification • Machine number: 232521 • Type: Special-purpose grinding machine - LISTING 2760080

![Deutsch]()

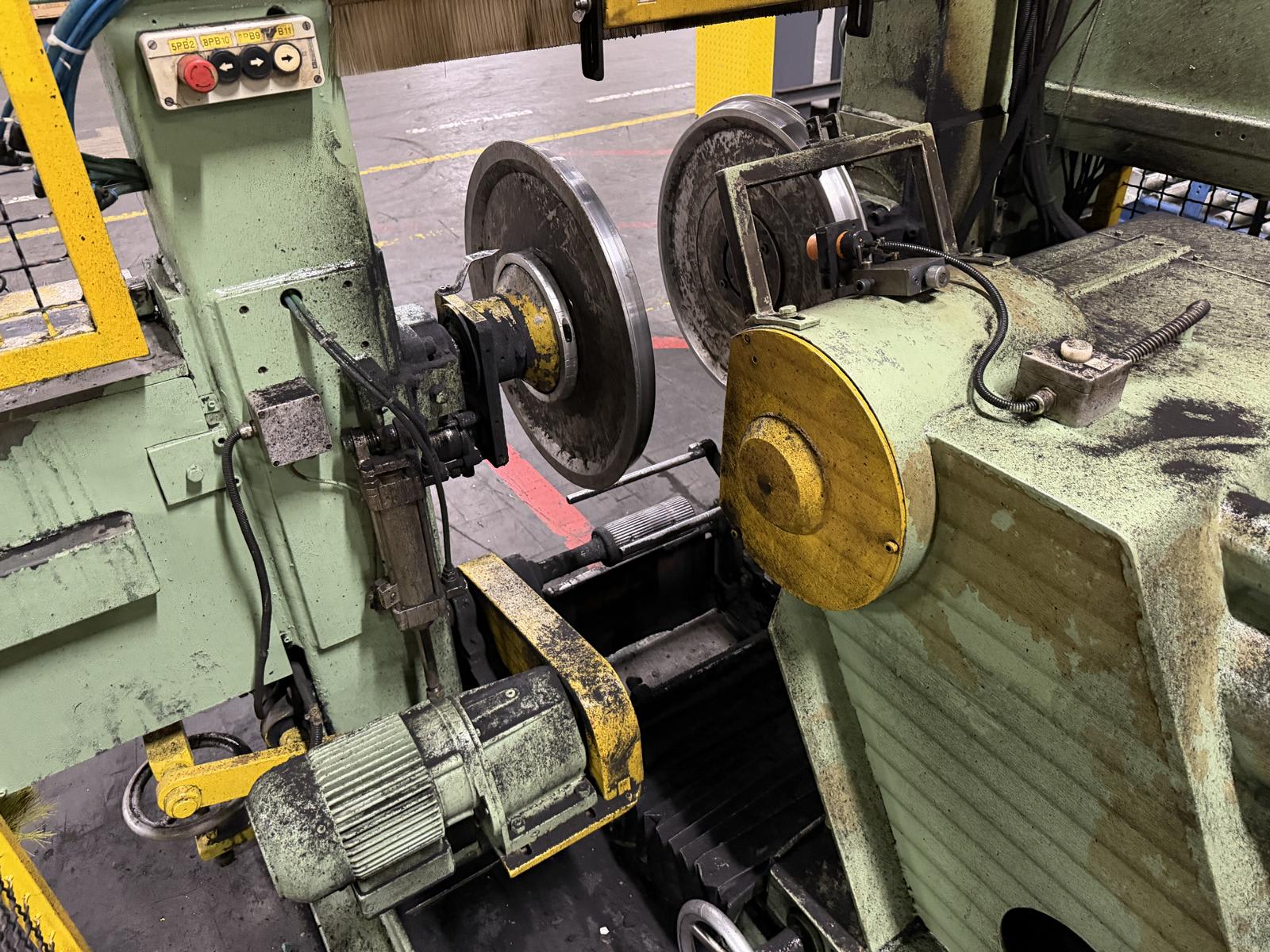

Manual Tire Grinding Machine Collmann

Binding Handling & Service Fee:

600 € (EURO)

General Information Manufacturer • Manufacturer: COLLMANN GmbH & Co. Spezialmaschinenbau KG • Manufacturer address (as stated on nameplate): Lübeck, Moislinger Allee 222–224, Germany Identification • Machine number: 232520 • Type: Special-purpose grinding machine - LISTING 2760081

![Deutsch]()

Manual Tire Grinding Machine Collmann

Binding Handling & Service Fee:

600 € (EURO)

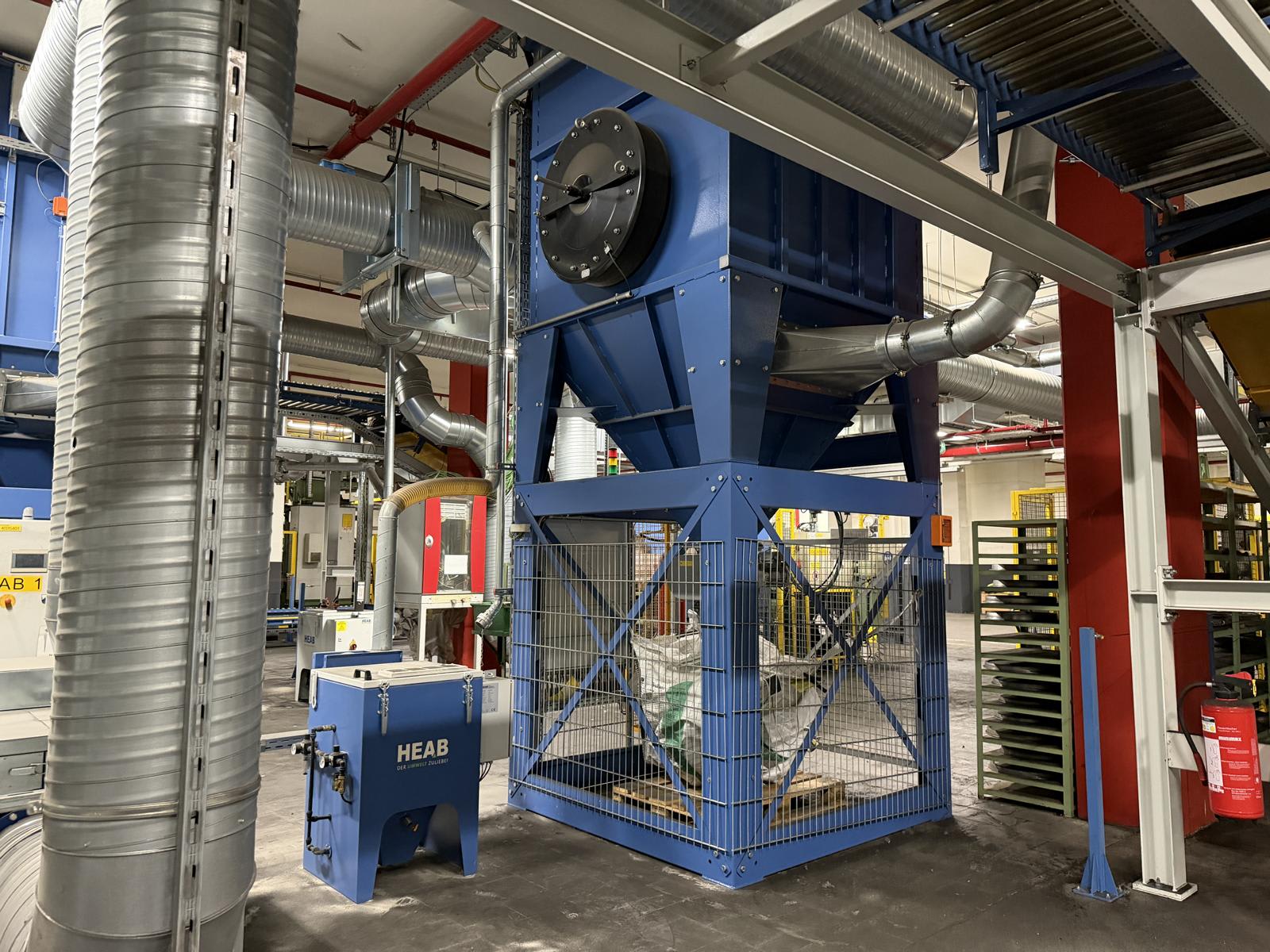

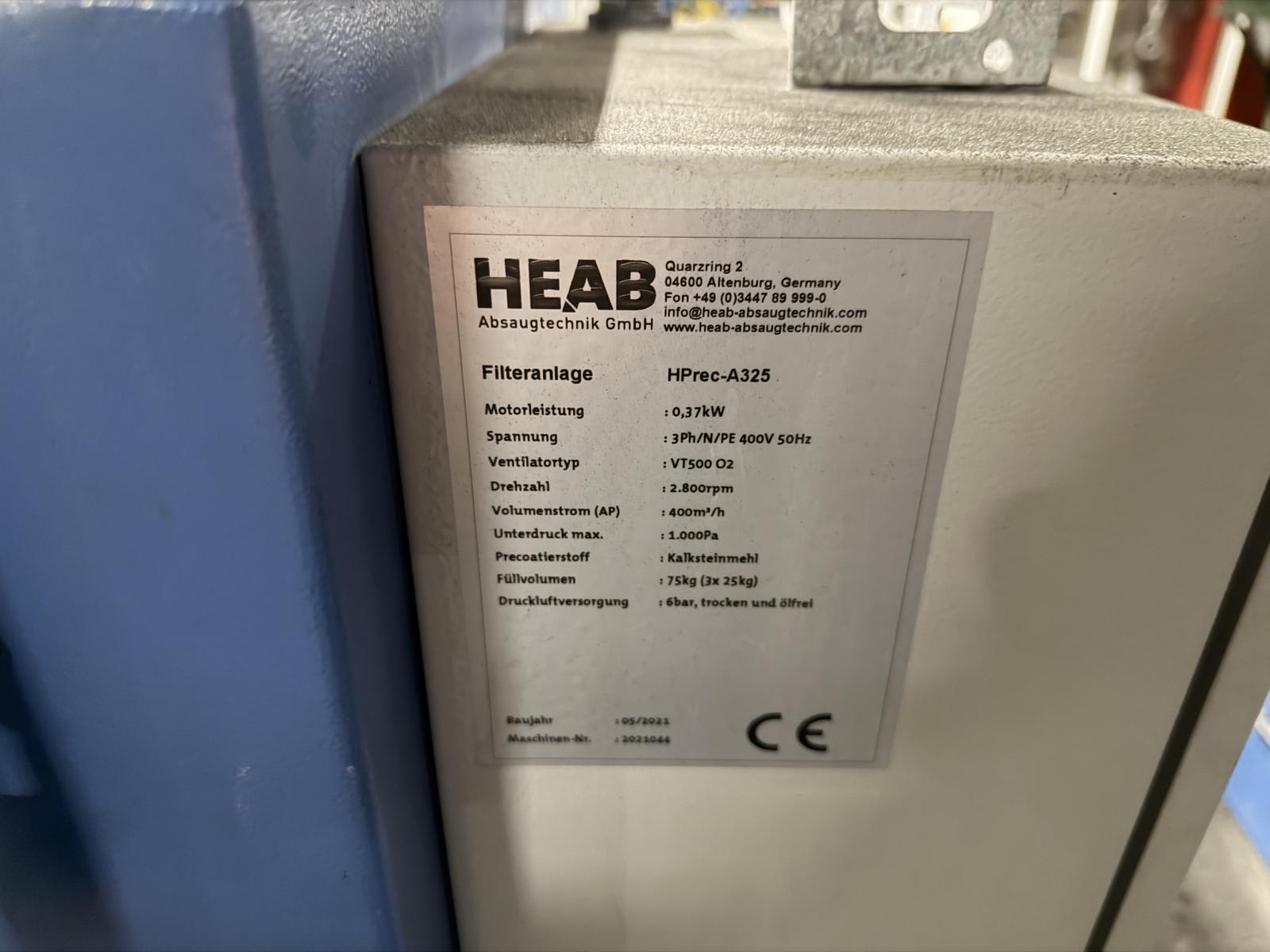

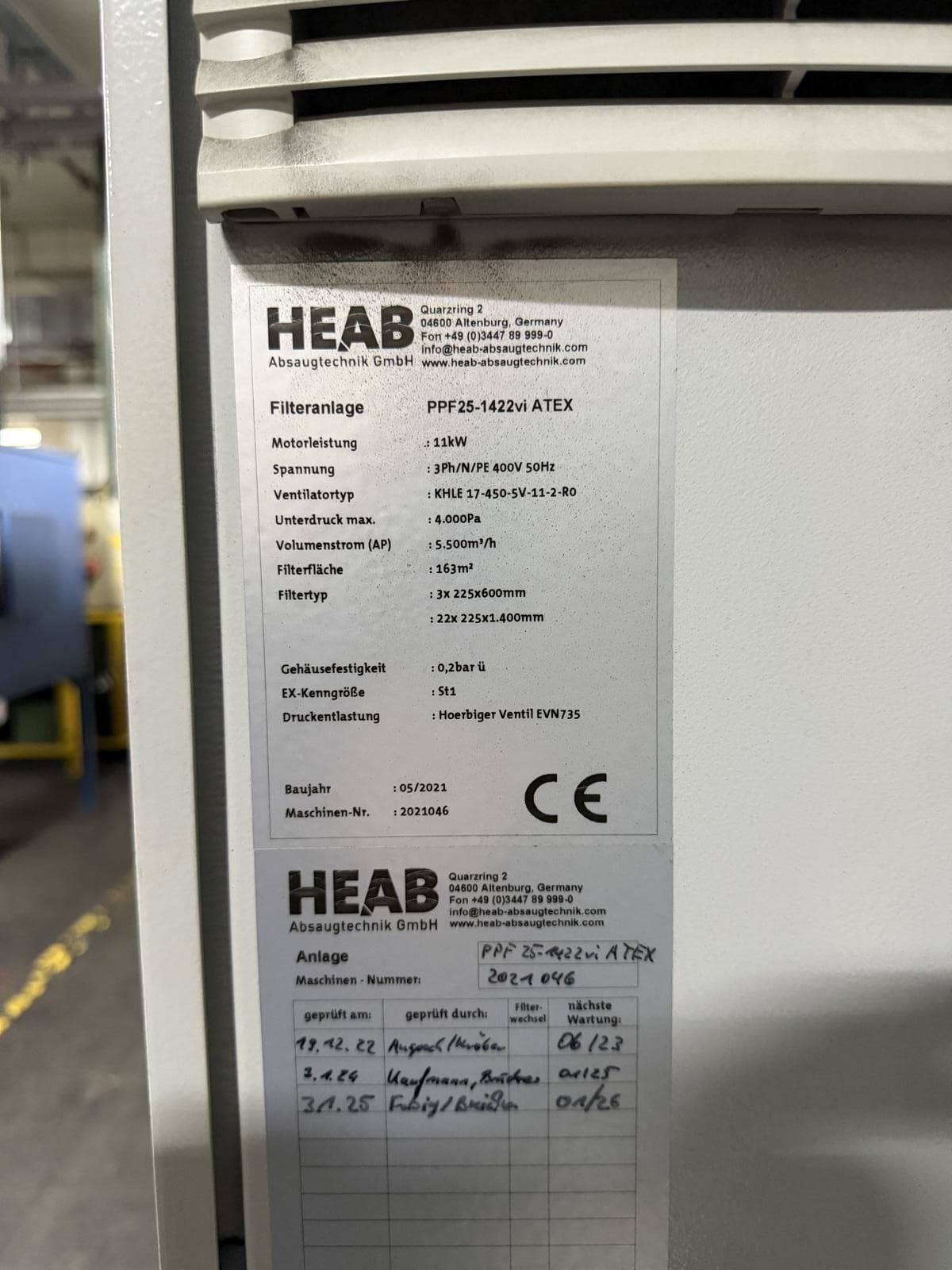

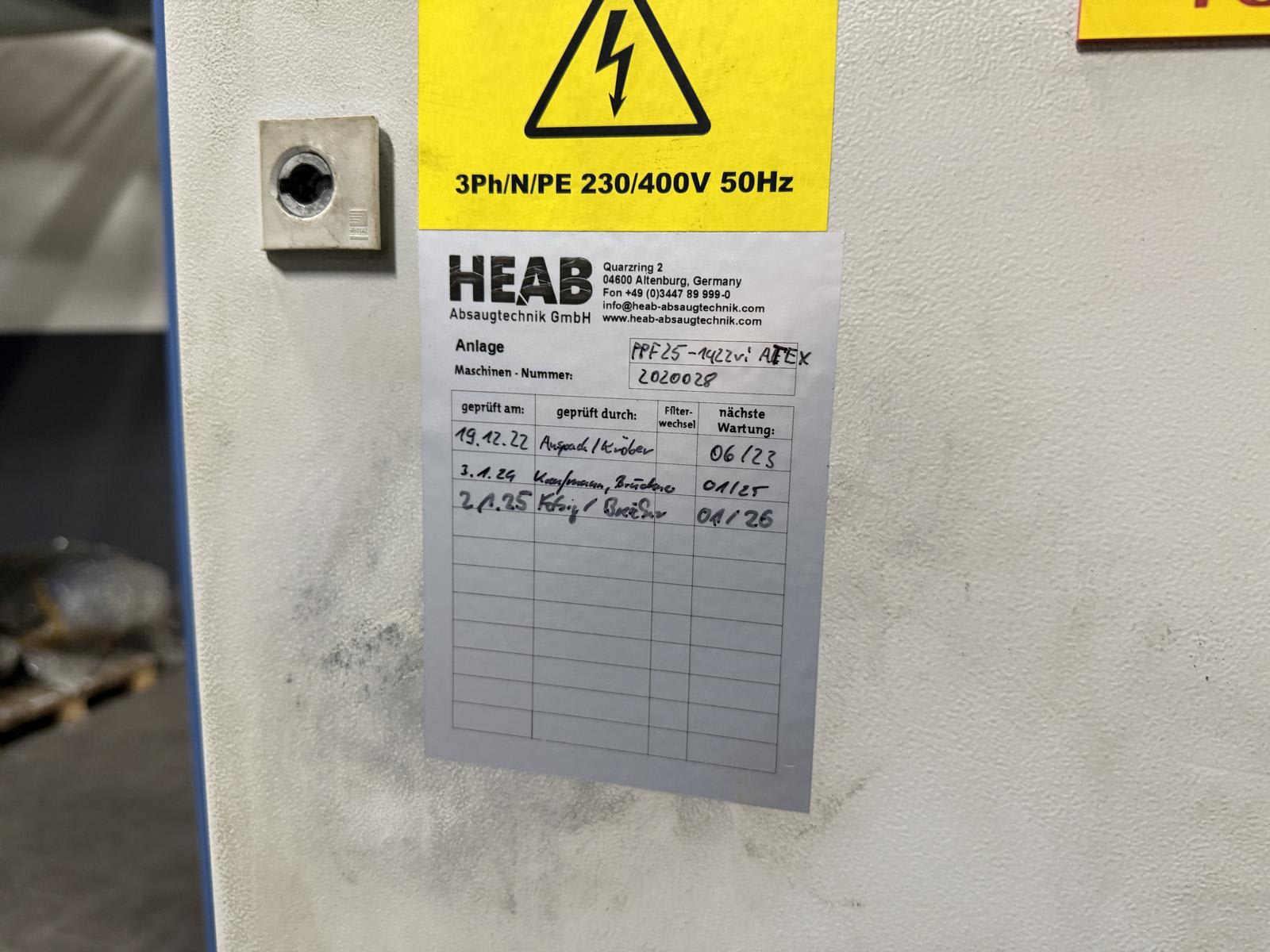

General Information • Machine type: Industrial filter and extraction system • Product designation: Filteranlage PPF25-1422vi ATEX & HPRec-A325 • CE marked: Yes (CE marking visible on nameplate) Manufacturer • Manufacturer: HEAB Absaugtechnik GmbH • Manufacturer address (as stated on nameplate): Quarzring 2, 04600 Altenburg, Germany Part 1: Identification • Type designation: PPF25-1422W ATEX • Machine number: 2021046 • Year of construction: 2021 (05/2021) Electrical Data (Nameplate) • Motor power: 11 kW • Supply voltage: 3Ph / N / PE, 400 V • Frequency: 50 Hz Fan and Performance Data (Nameplate) • Fan type: KHLE 17-450-5V-11-2-R0 • Air volume flow (AP): 4,000 m³/h • Maximum negative pressure: 1,500 Pa Filtration System (Nameplate) • Filter surface area: 163 m² • Filter type: 3 × 225 × 600 mm 22 × 225 × 1,400 mm Explosion Protection (Nameplate) • ATEX classification: ATEX • Explosion protection marking: Ex • Maximum housing overpressure: 0.2 bar (ü) • Explosion pressure relief device: Type: High-speed vent VN735 Part 2: Model: HPrec-A325 Machine Type: Filteranlage (Filter Unit) Year of Manufacture: 05/2021 Machine Number: 2021044 Technical Data / Specifications Motor Power: 0.37 kW Electrical Connection: 400 V / 50 Hz / 3 Ph / N / PE Fan Type: VT500 O2 Rotation Speed: 2,800 rpm Volume Flow (AP): 400 m³/h Max. Negative Pressure: 1,000 Pa Filtration Media: Precoat Material: Kalksteinmehl (Limestone powder) Filling Volume: 75 kg (3 x 25 kg) Compressed Air Supply: 6 bar (dry and oil-free) - LISTING 2760082

![Deutsch]()

Industrial Filter and Extraction System HEAB PPF25-1422vi ATEX & HPRec-A325 | 2021

Binding Handling & Service Fee:

1400 € (EURO)

General Information Manufacturer • Manufacturer: COLLMANN GmbH & Co. Spezialmaschinenbau KG • Manufacturer address (as stated on nameplate): Lübeck, Moislinger Allee 222–224, Germany Identification • Machine number: 232568 • Type: Special-purpose grinding machine - LISTING 2760083

![Deutsch]()

Manual Tire Grinding Machine Collmann

Binding Handling & Service Fee:

600 € (EURO)

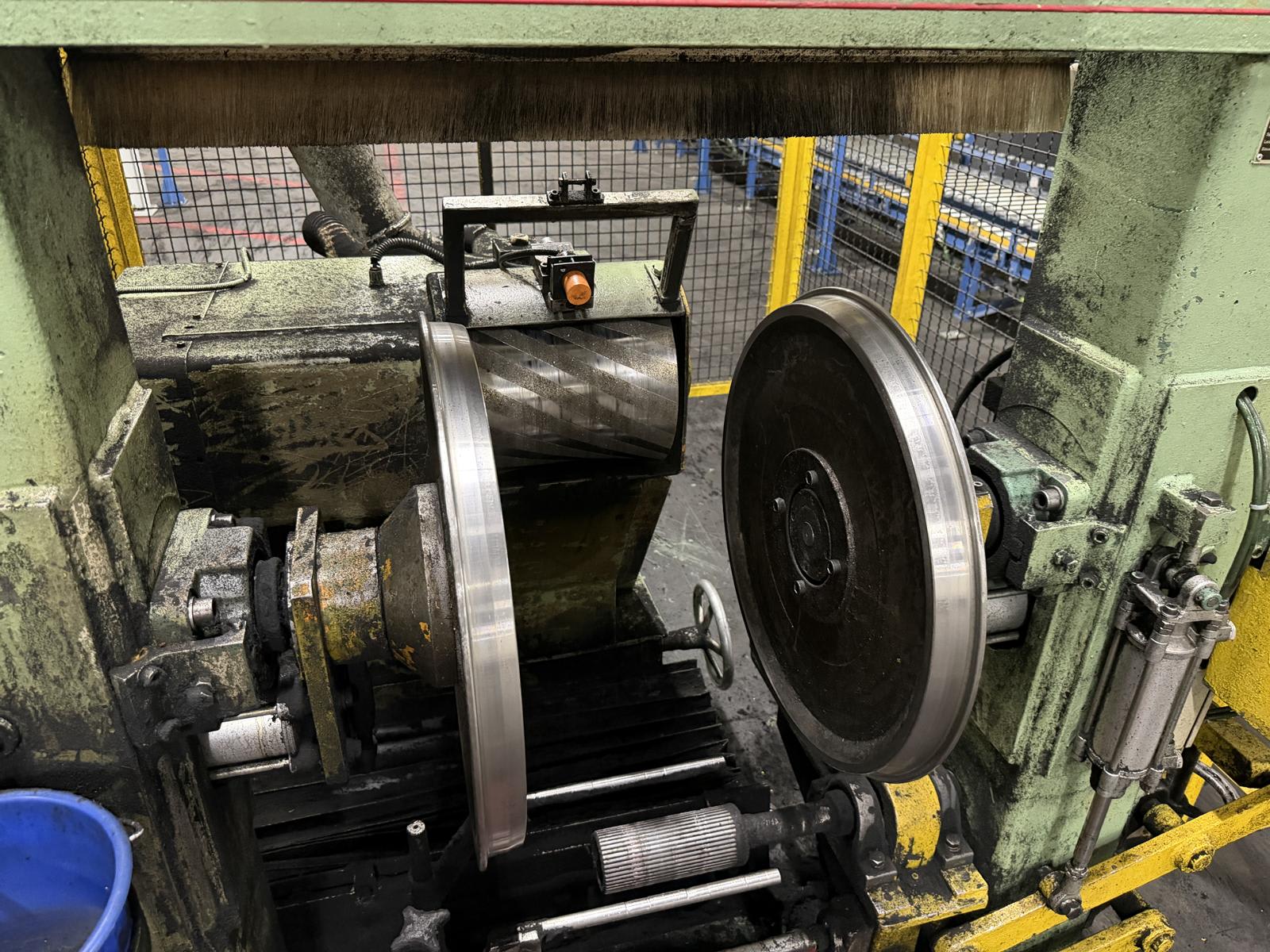

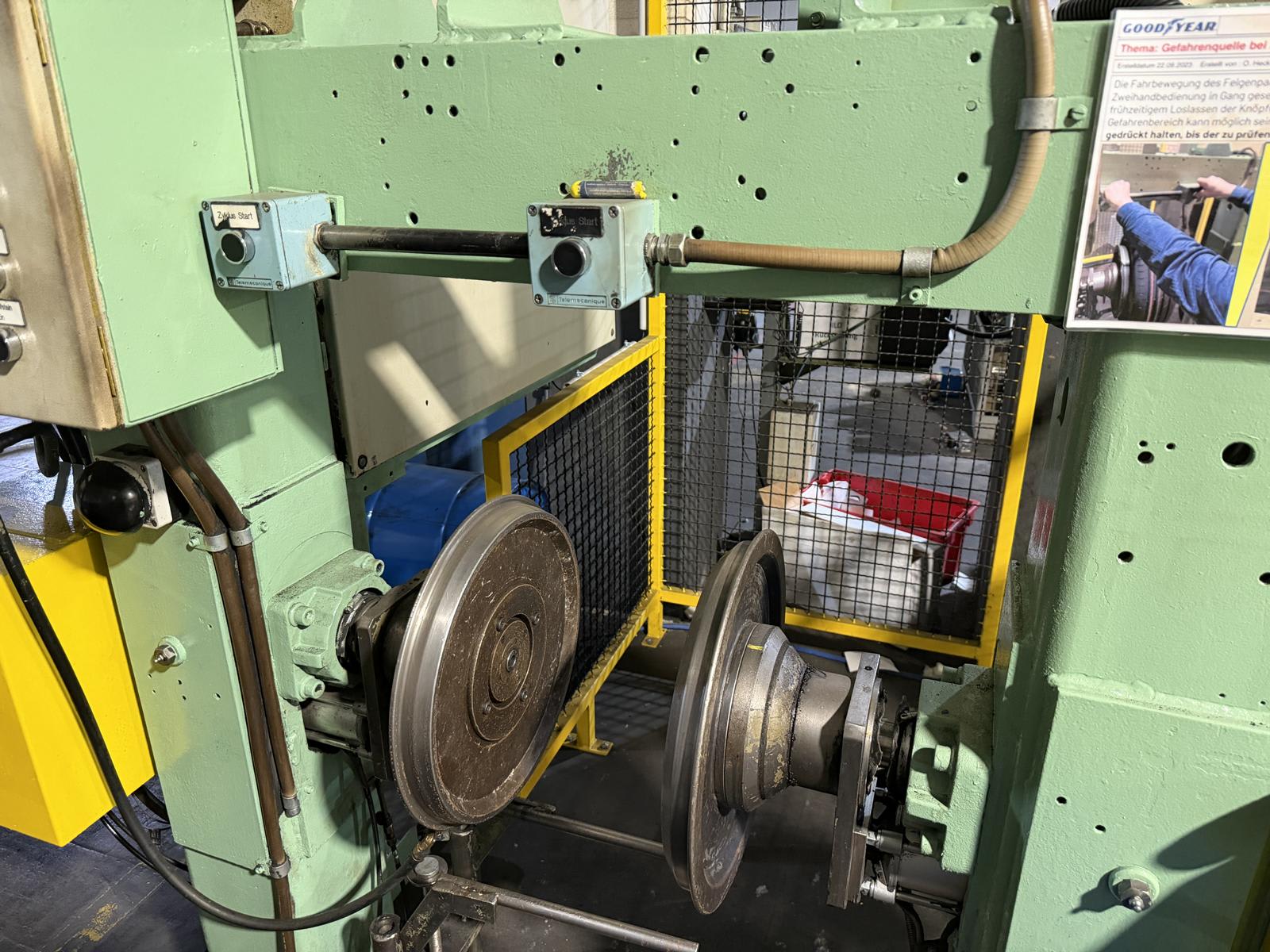

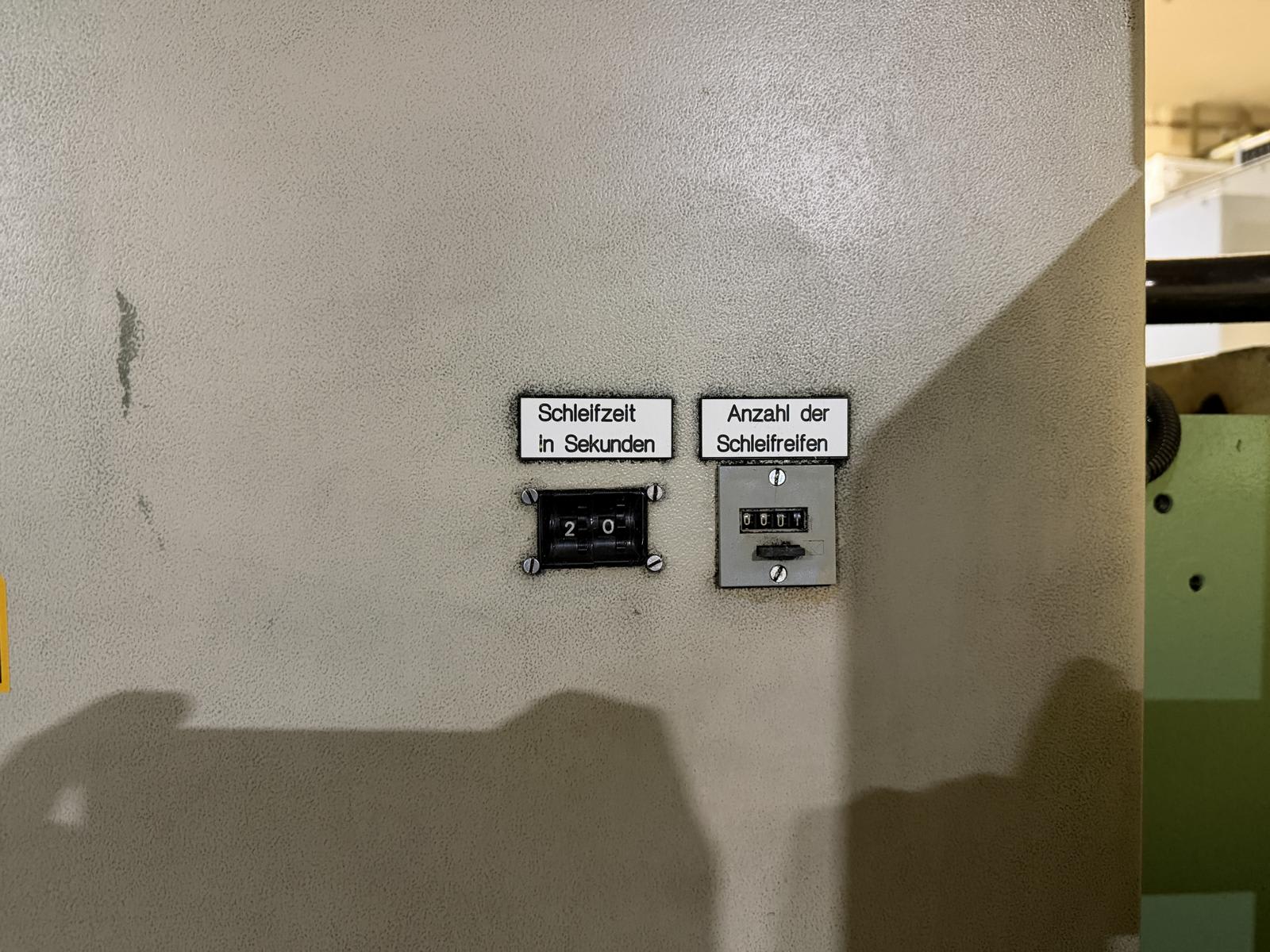

General Designation Machine Name: Special Purpose Grinding Machine / Automatic Grinder General Information Manufacturer: COLLMANN GmbH. & Co. Spezialmaschinenbau KG Location of Manufacture: D-2400 Lübeck, West Germany Machine Number: 2325149 Year of Manufacture: 1988 Control Interface: Beckhoff Industrial PC with physical keyboard and function keys Technical Data / Specifications Voltage: 380 V Frequency: 50 Hz Power Rating: 14 kW Control Voltage: 24 V Pneumatic Connection (Min): 8 bar Pneumatic Connection (Max): 10 bar Tooling: Dual abrasive grinding wheels mounted on opposing spindles Safety Infrastructure: Full perimeter yellow safety cage with wire mesh panels - LISTING 2760084

![Deutsch]()

Manual Tire Grinding Machine Collmann | 1988

Binding Handling & Service Fee:

600 € (EURO)

General Information Manufacturer: HEAB Absaugtechnik GmbH (Altenburg, Germany) Model: PPF25-1422vi ATEX Year of Manufacture: 04/2020 Machine Number: 2020028 Application: Industrial dust extraction with ATEX compliance Technical Data / Specifications Motor Power: 11 kW Electrical Supply: 3Ph / N / PE 400V 50Hz Volume Flow (AP): 7.500 m³/h Max. Negative Pressure (Vacuum): 3.955 Pa Filter Surface Area: 163 m² Filter Configuration: 3 x Elements (225 x 600 mm) 22 x Elements (225 x 1.400 mm) Fan Type: KHLE 15-566-5V-11-2-R Housing Strength: 0,2 bar ü Explosion Protection (ATEX): EX-Characteristic: St1 Pressure Relief System: Hoerbiger Valve EVN735 Discharge System: Funnel with "Big Bag" collection station below unit Observed Condition Maintenance Status: Sticker indicates last check on 03.01.24; next check due 01/25. Control Interface: Integrated control cabinet with touchscreen display (Siemens Simatic HMI visible) and physical emergency stop. Peripheral Equipment: Includes separate white dosing/precoat unit labeled "HEAB" positioned next to the main tower. Safety: Fire suppression/spark detection piping connected to inlet ducts. - LISTING 2760085

![Deutsch]()

Industrial Filter and Extraction System HEAB PPF25-1422vi ATEX | 2020

Binding Handling & Service Fee:

1400 € (EURO)

General Information Manufacturer • Manufacturer: COLLMANN GmbH & Co. Spezialmaschinenbau KG • Manufacturer address (as stated on nameplate): Lübeck, Moislinger Allee 222–224, Germany Identification • Machine number: 232571 • Type: Special-purpose grinding machine - LISTING 2760086

![Deutsch]()

Manual Tire Grinding Machine Collmann

Binding Handling & Service Fee:

600 € (EURO)

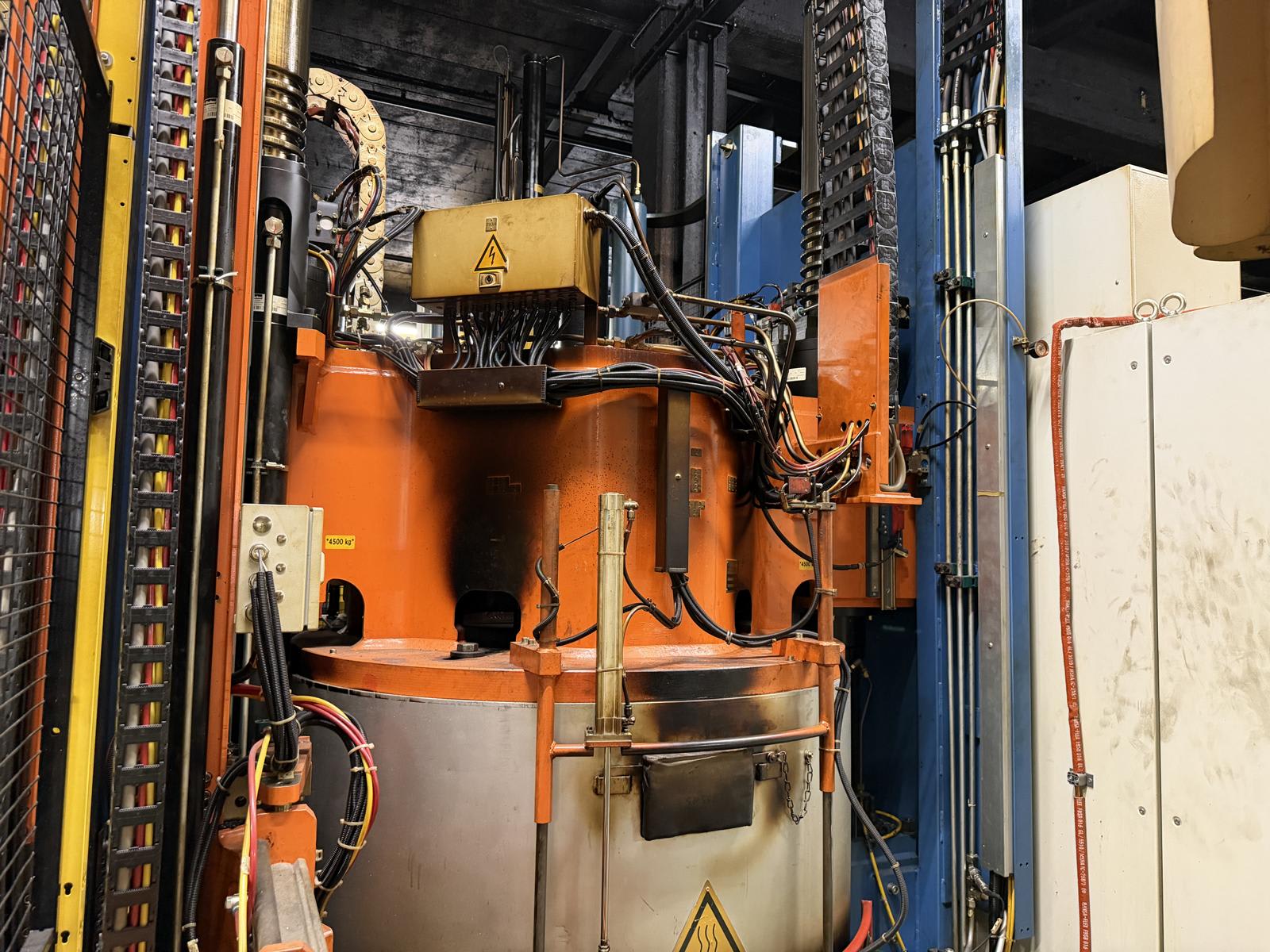

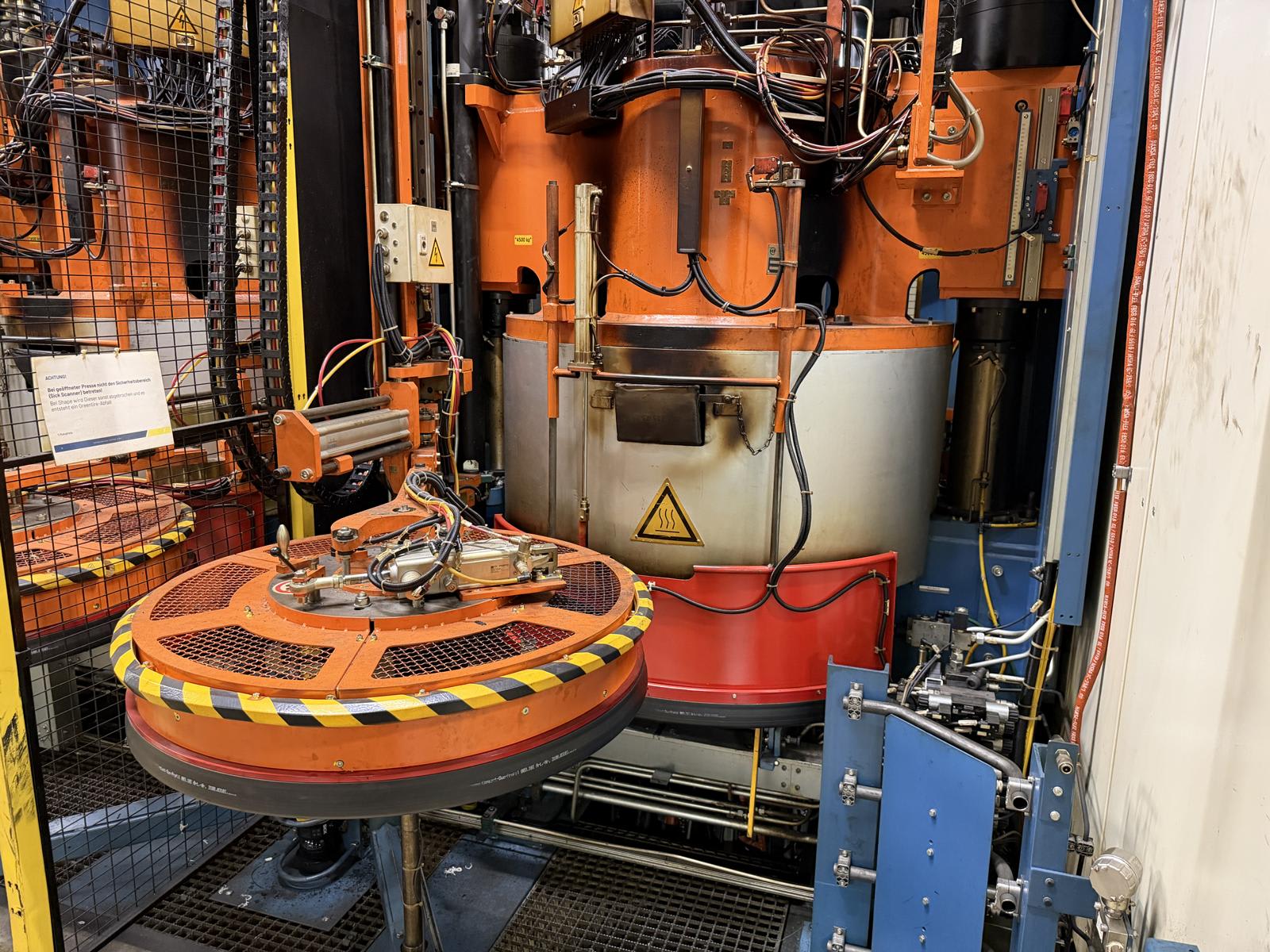

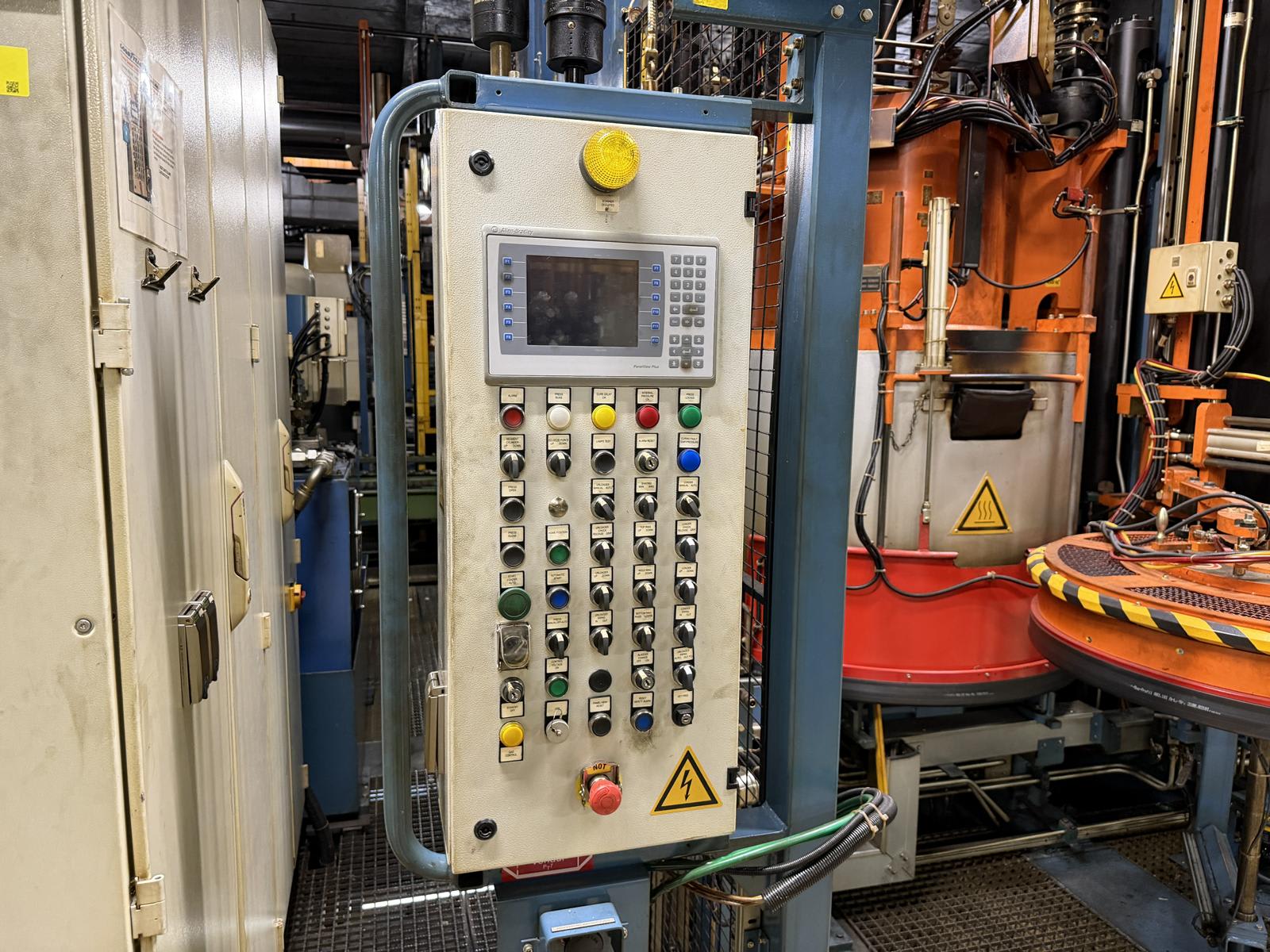

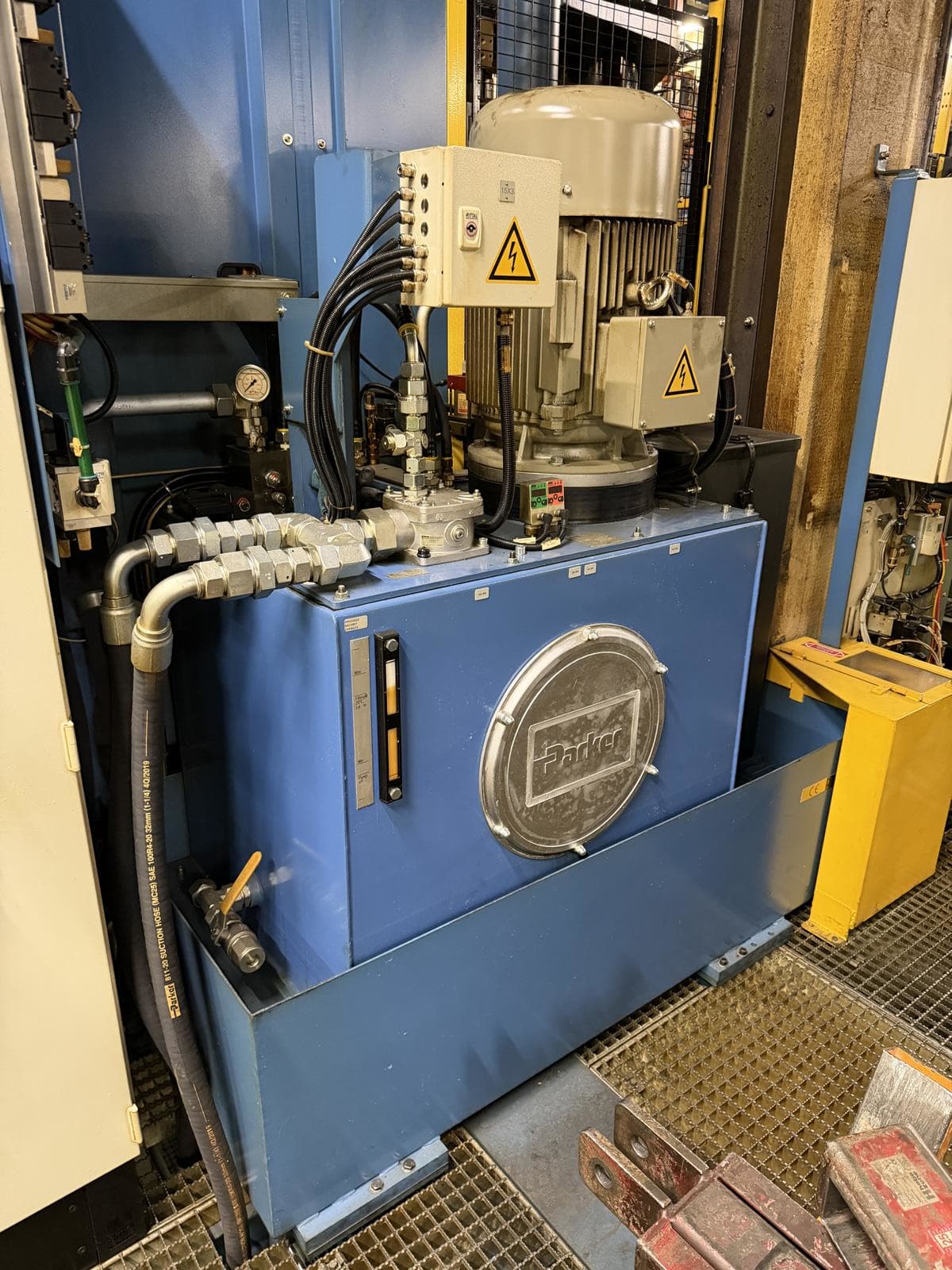

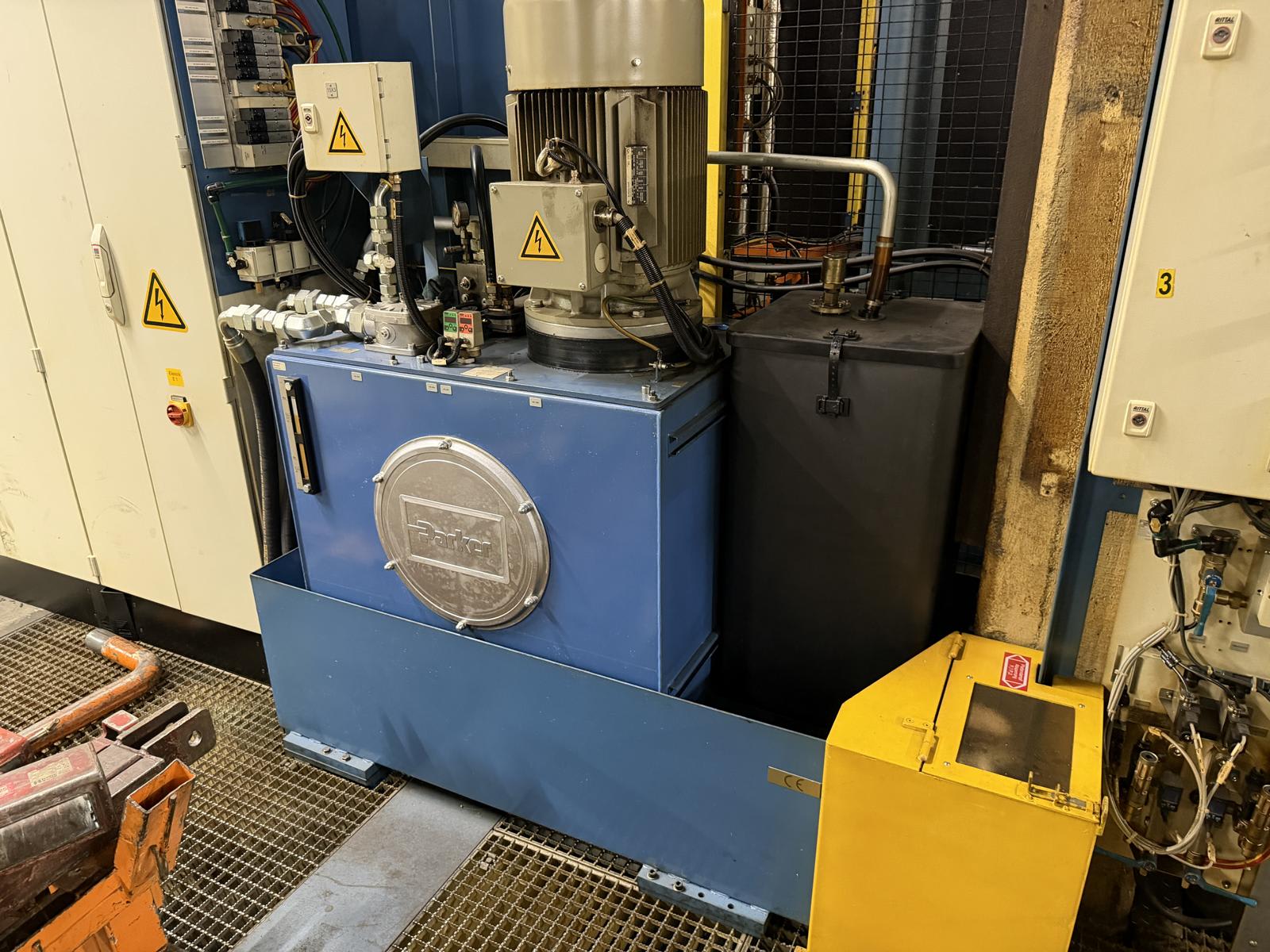

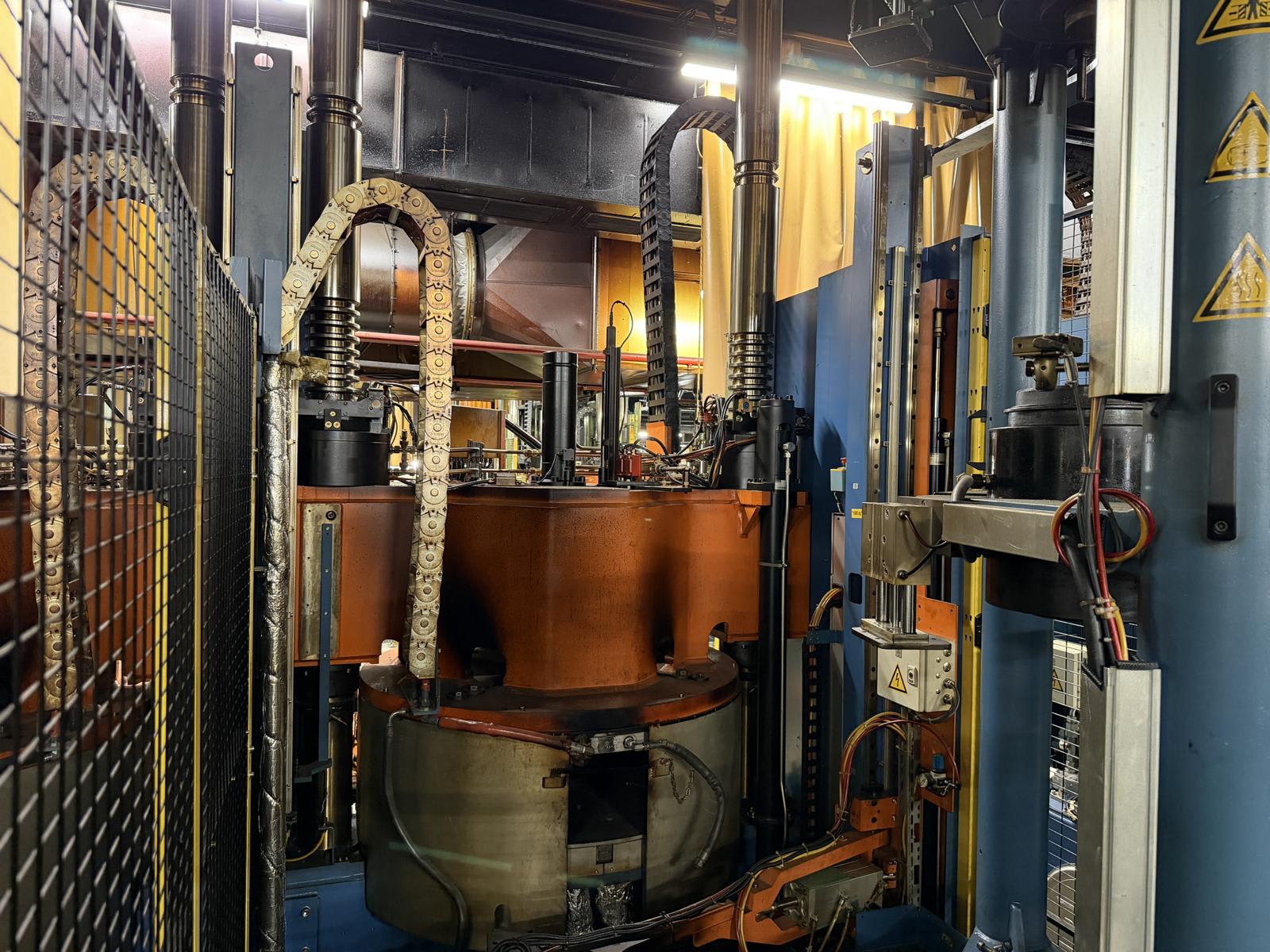

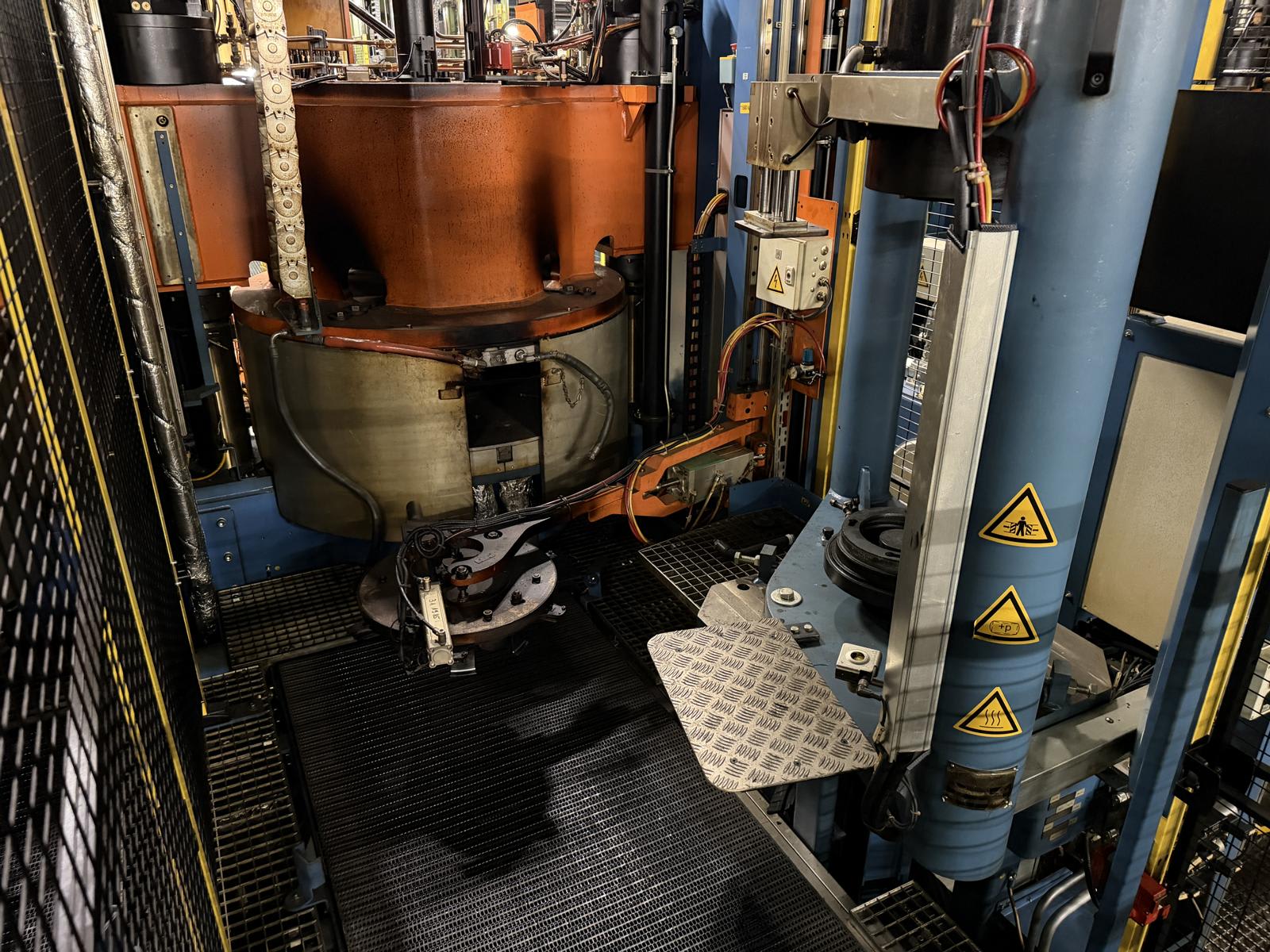

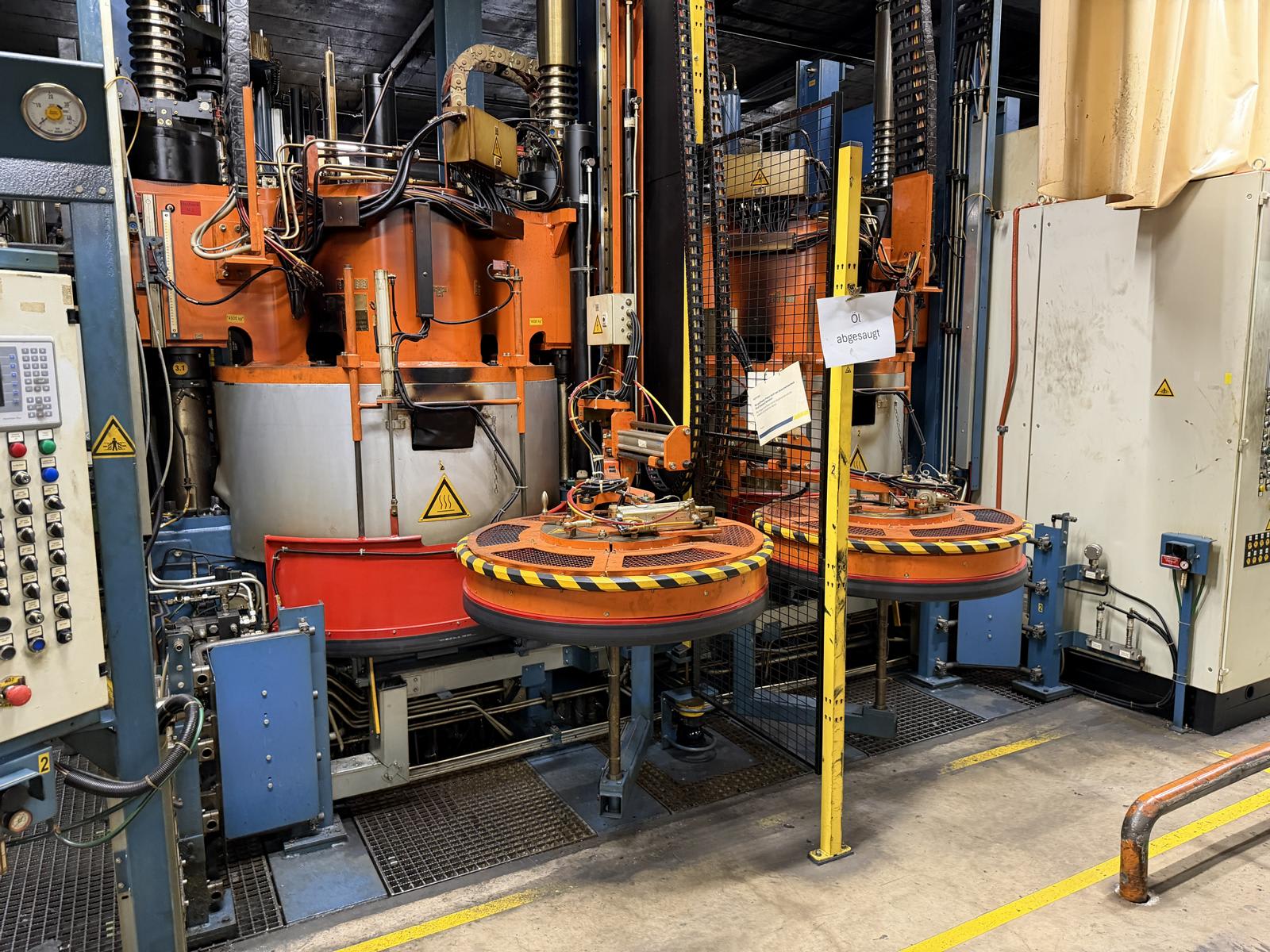

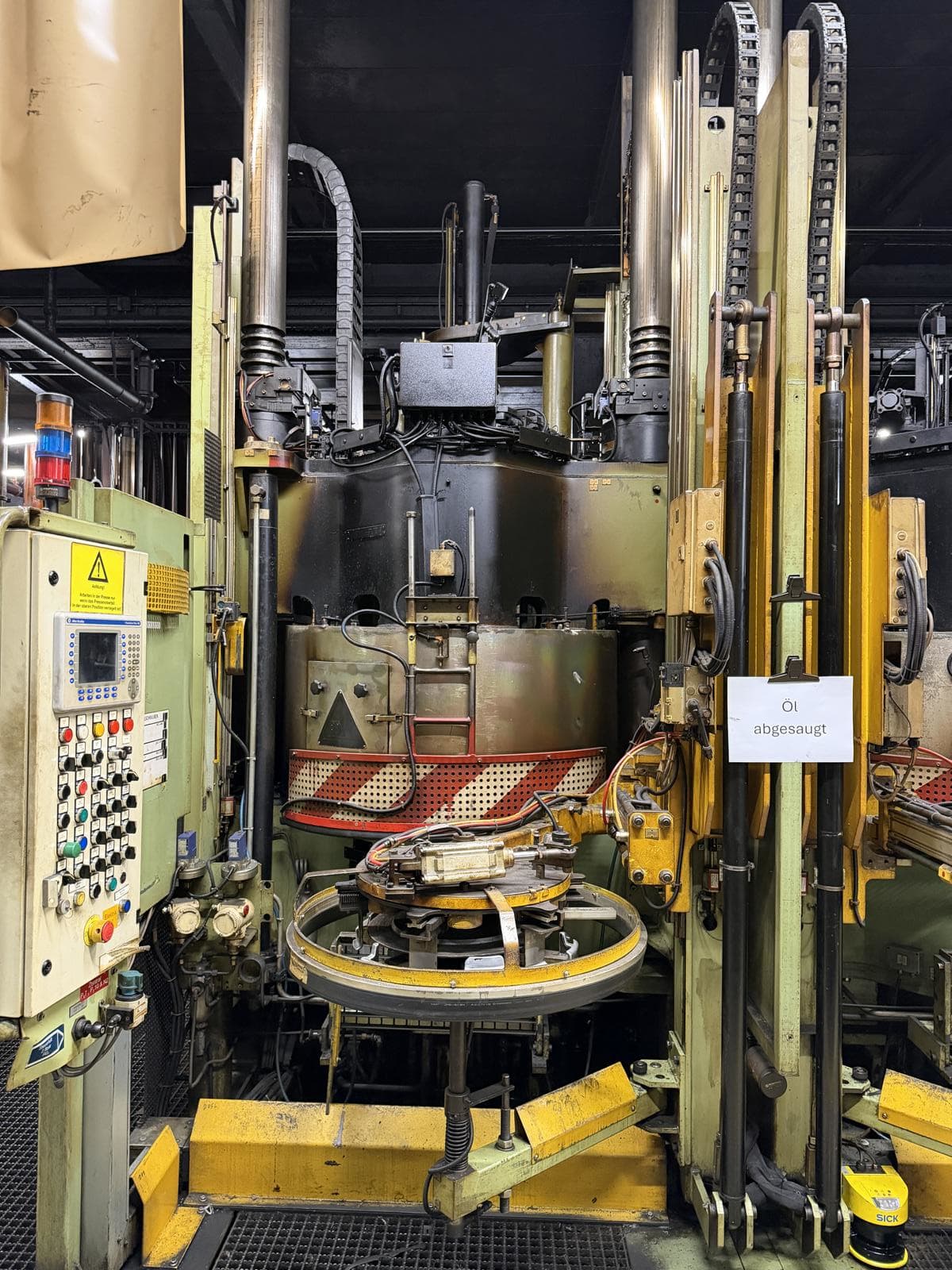

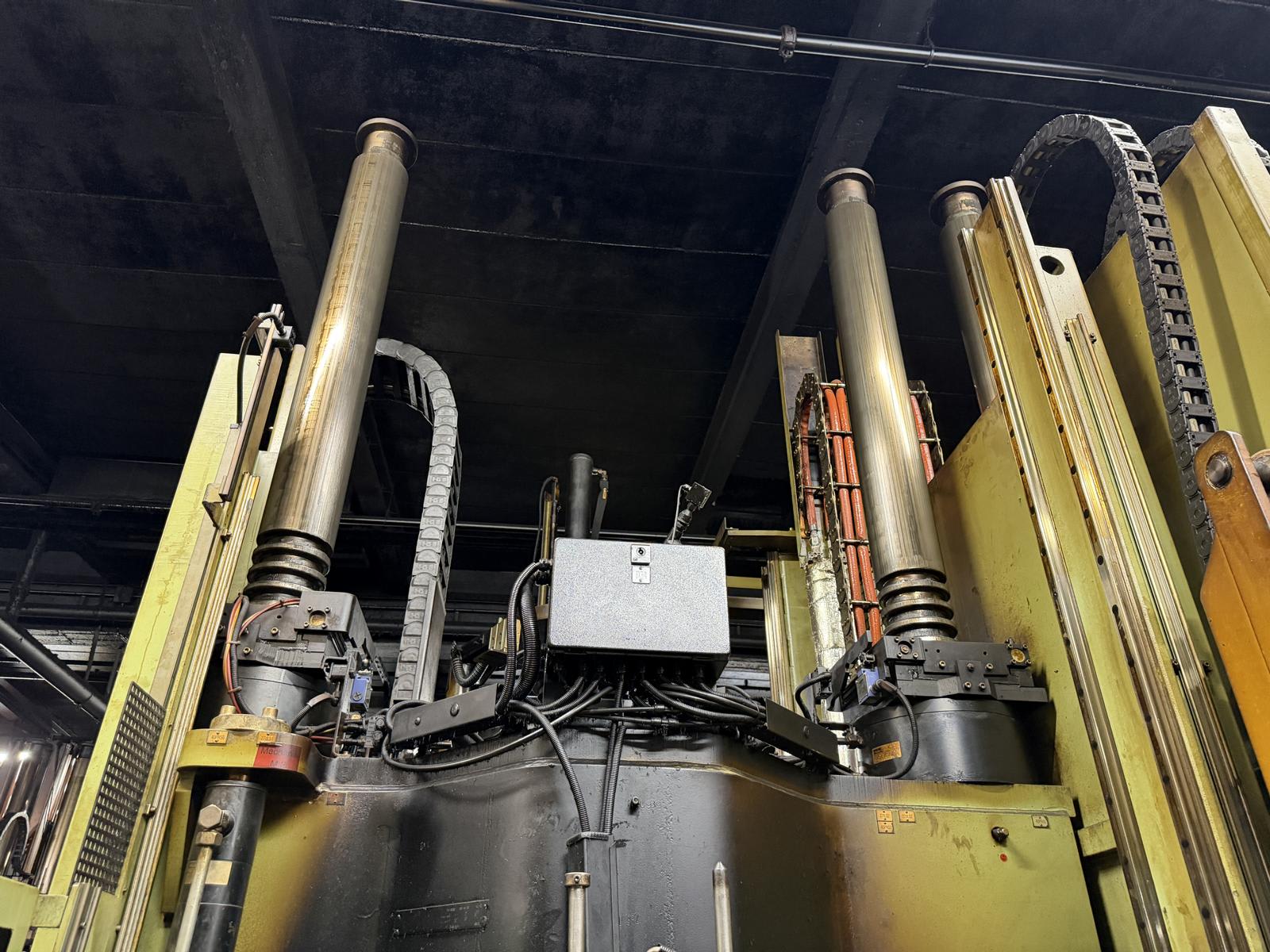

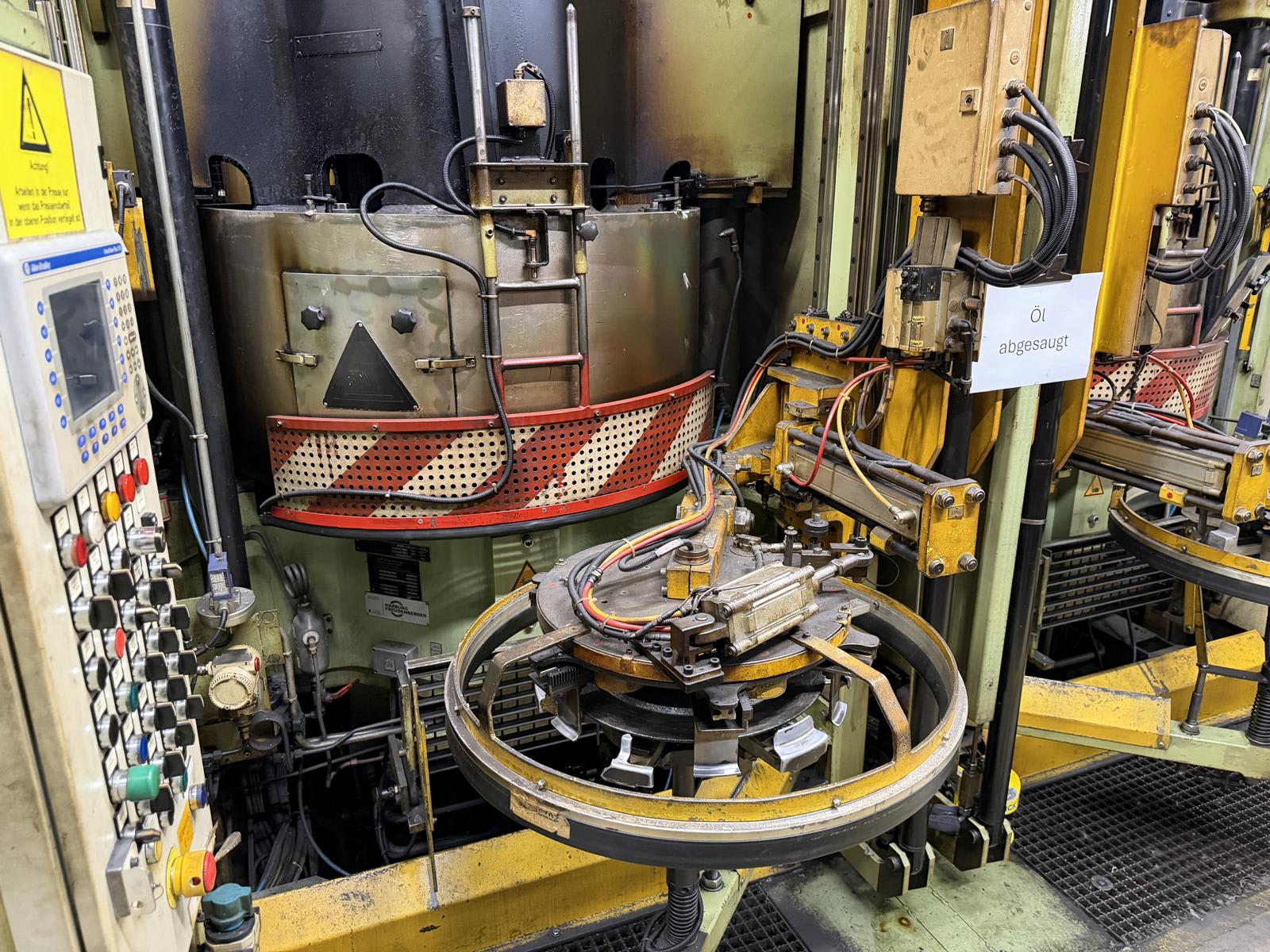

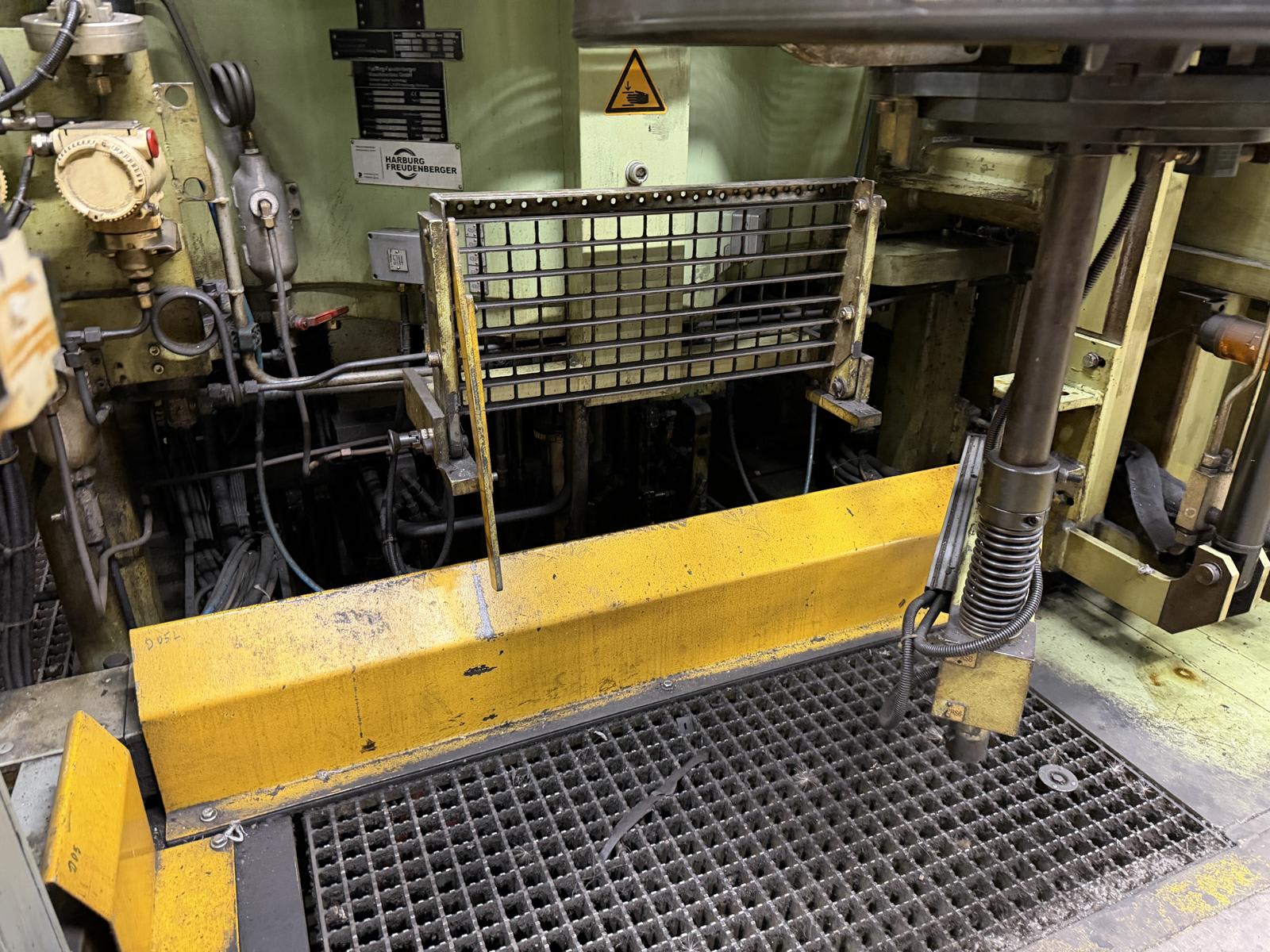

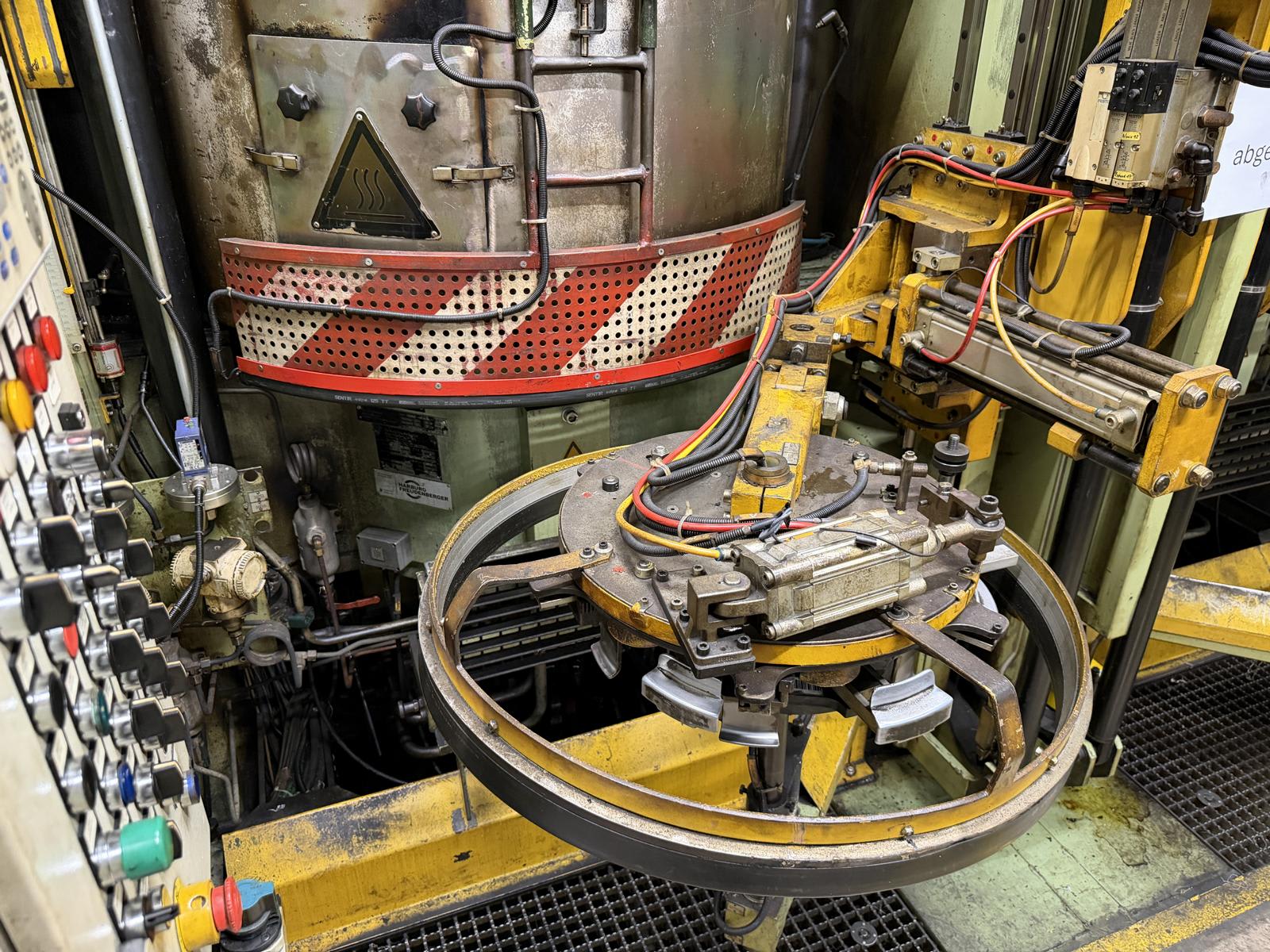

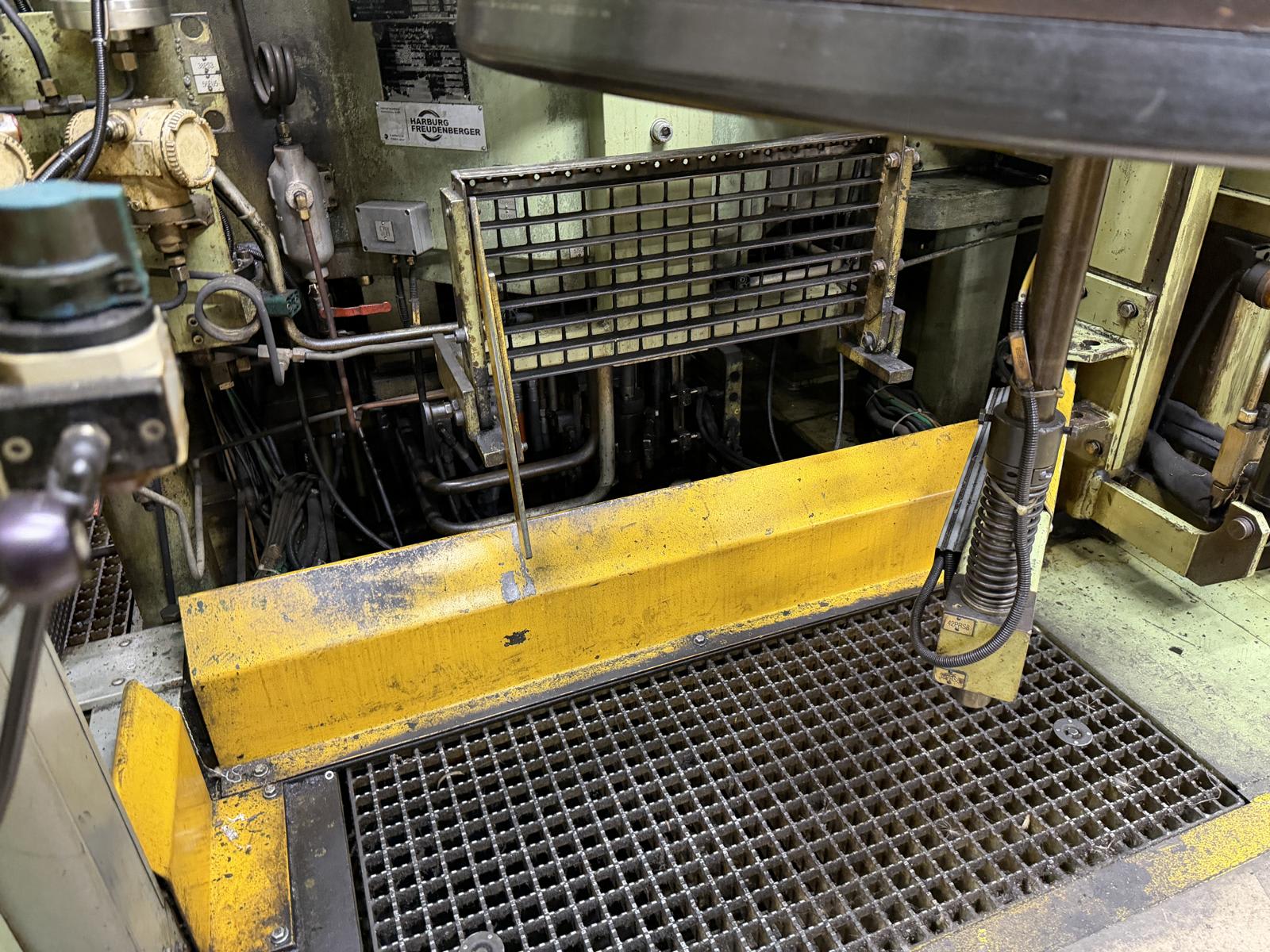

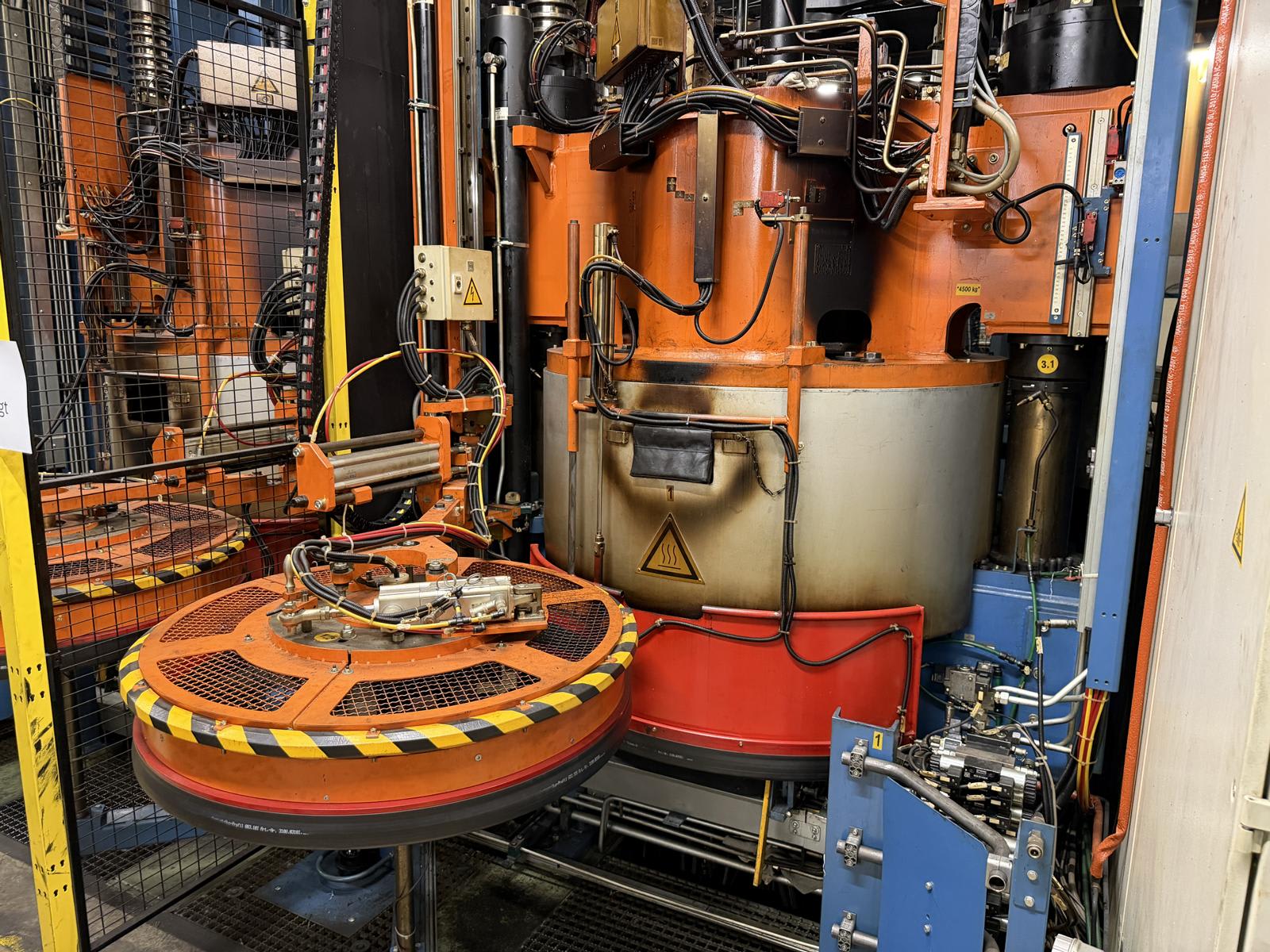

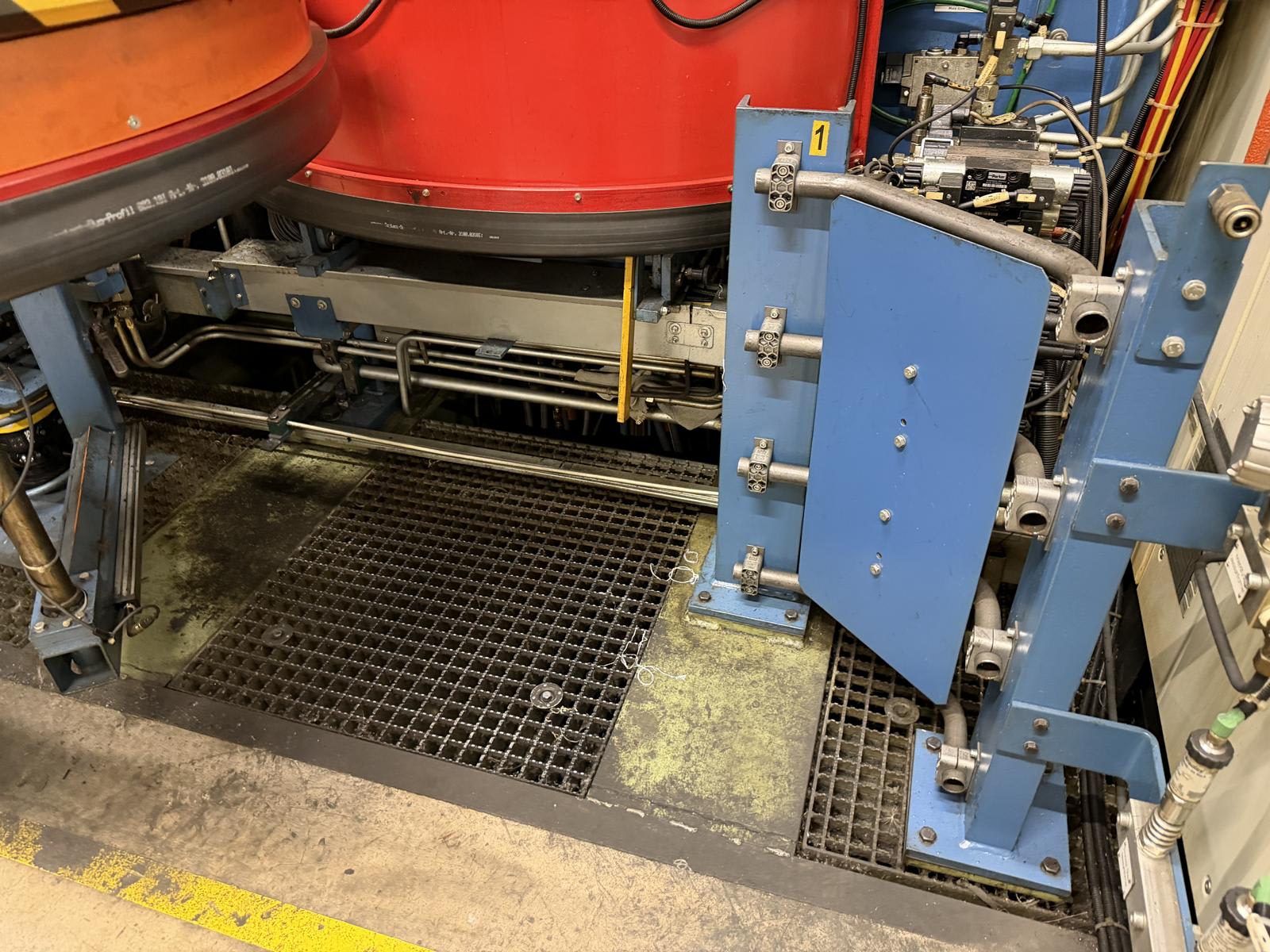

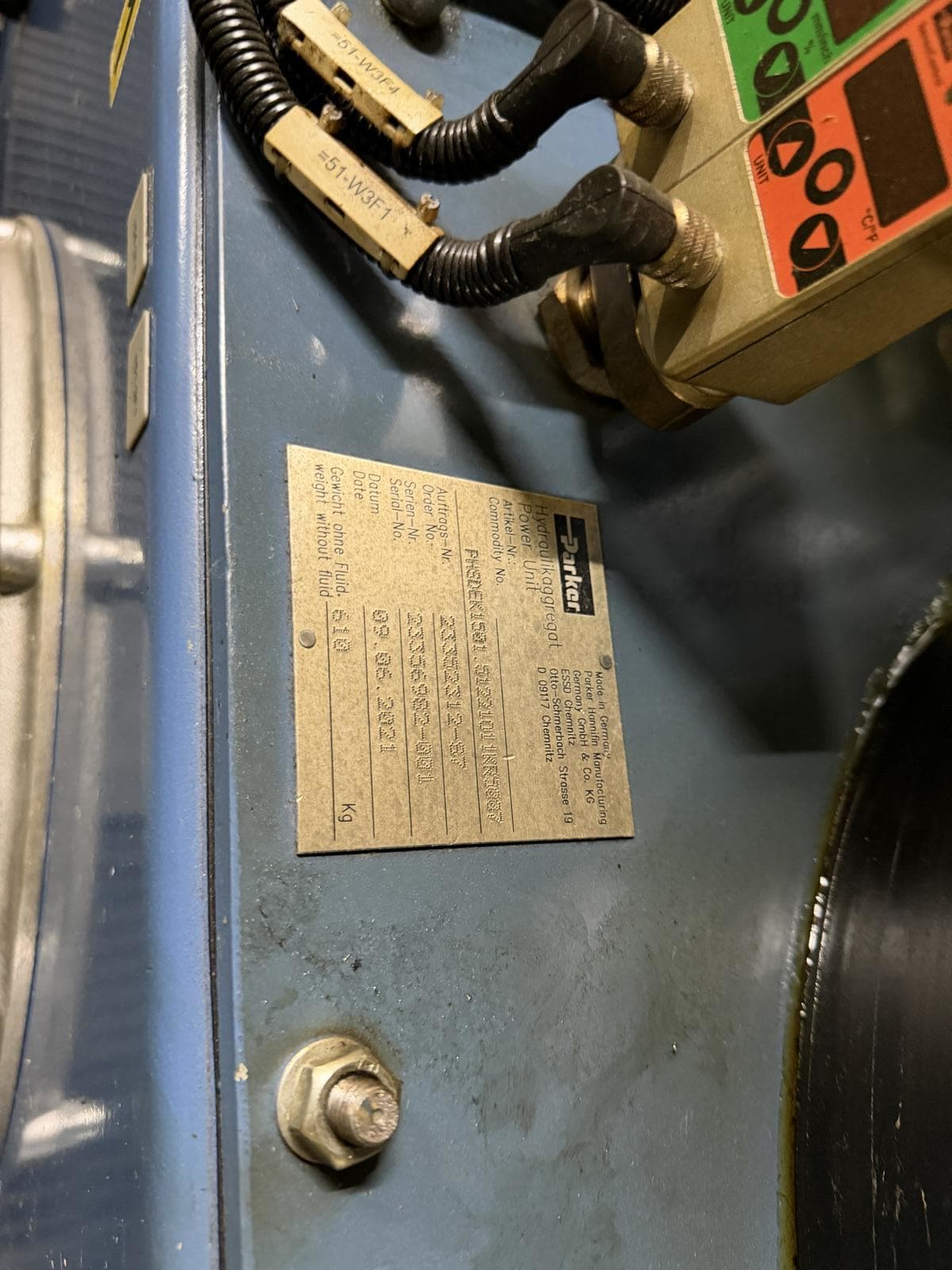

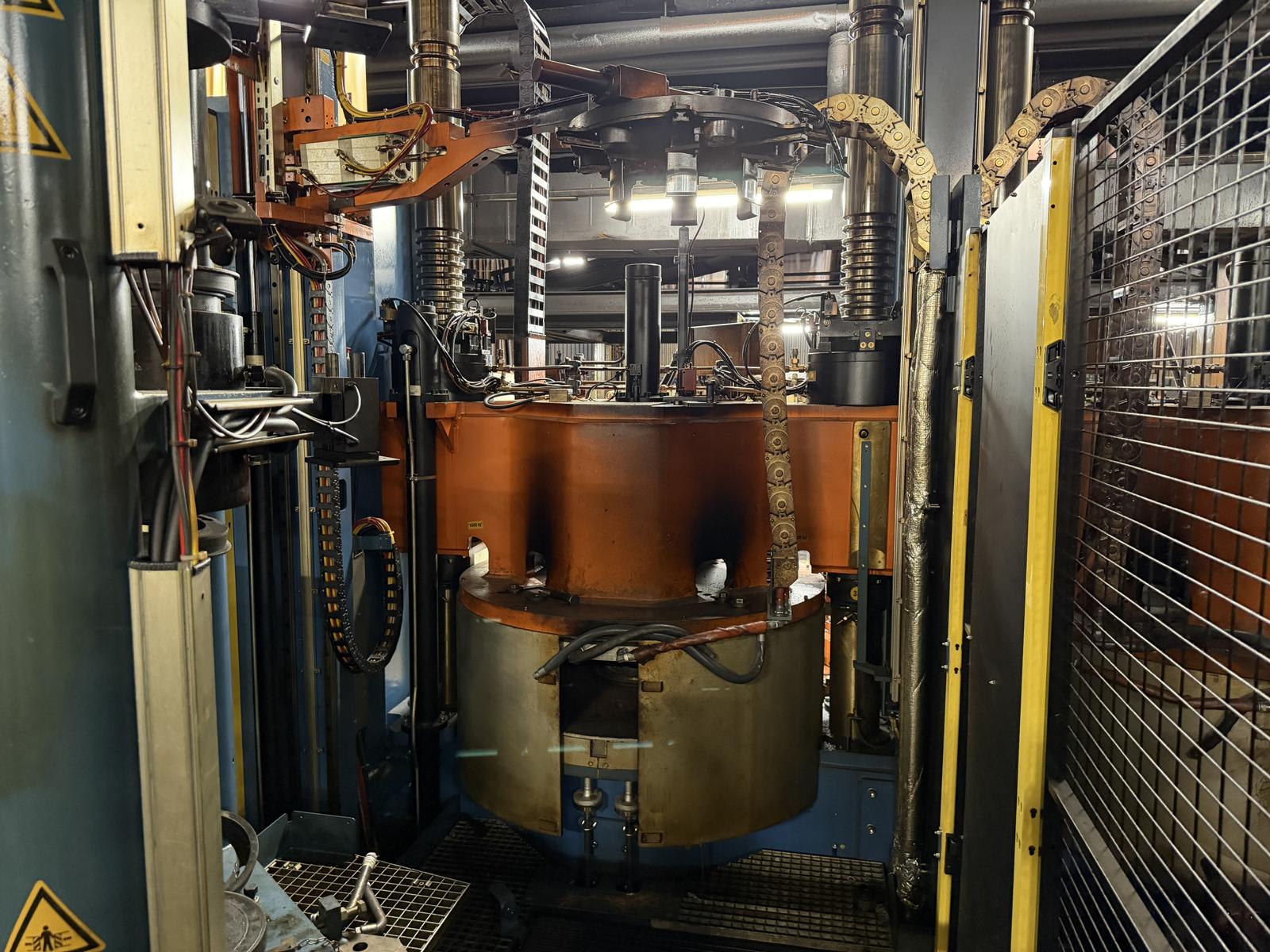

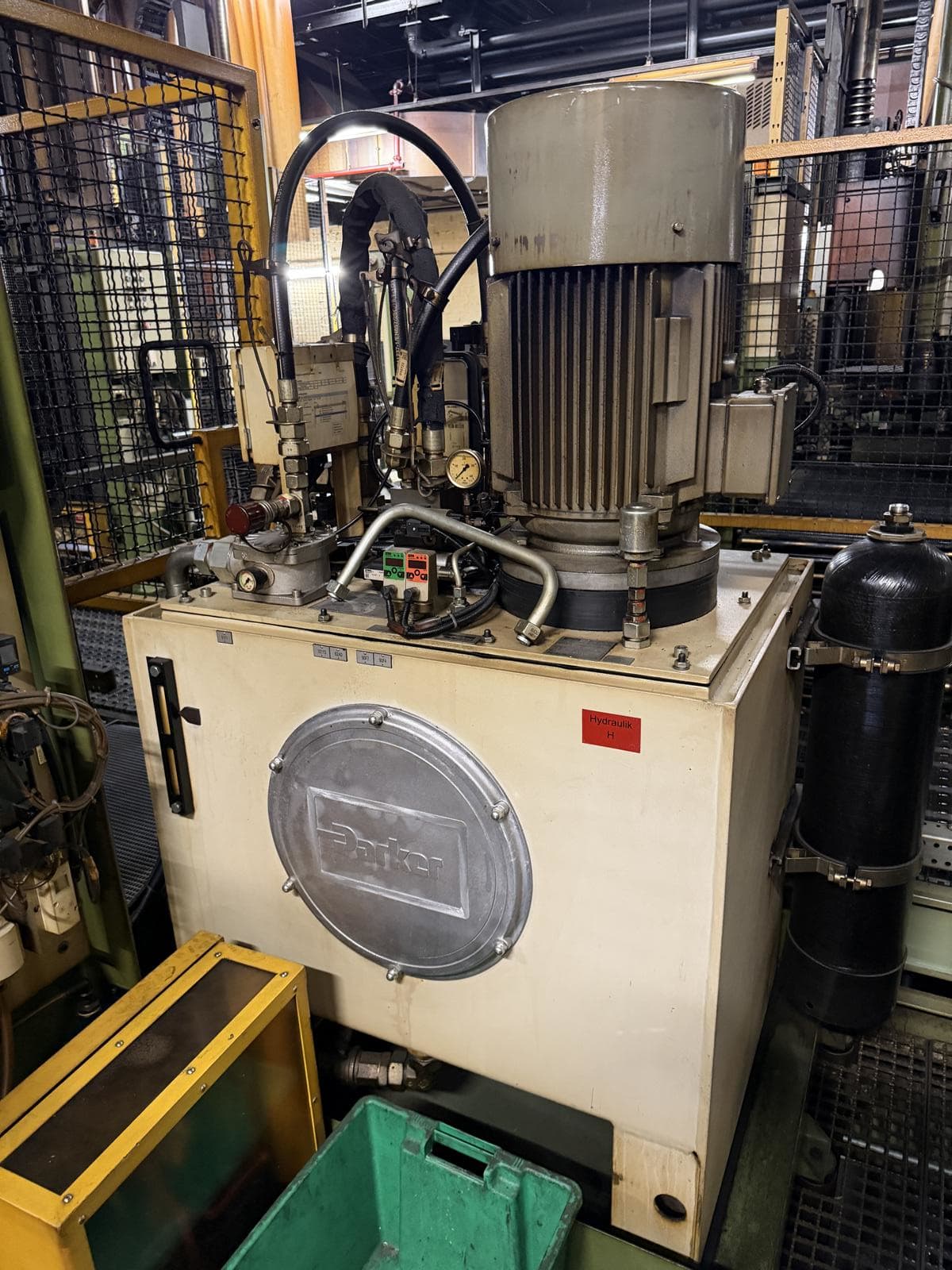

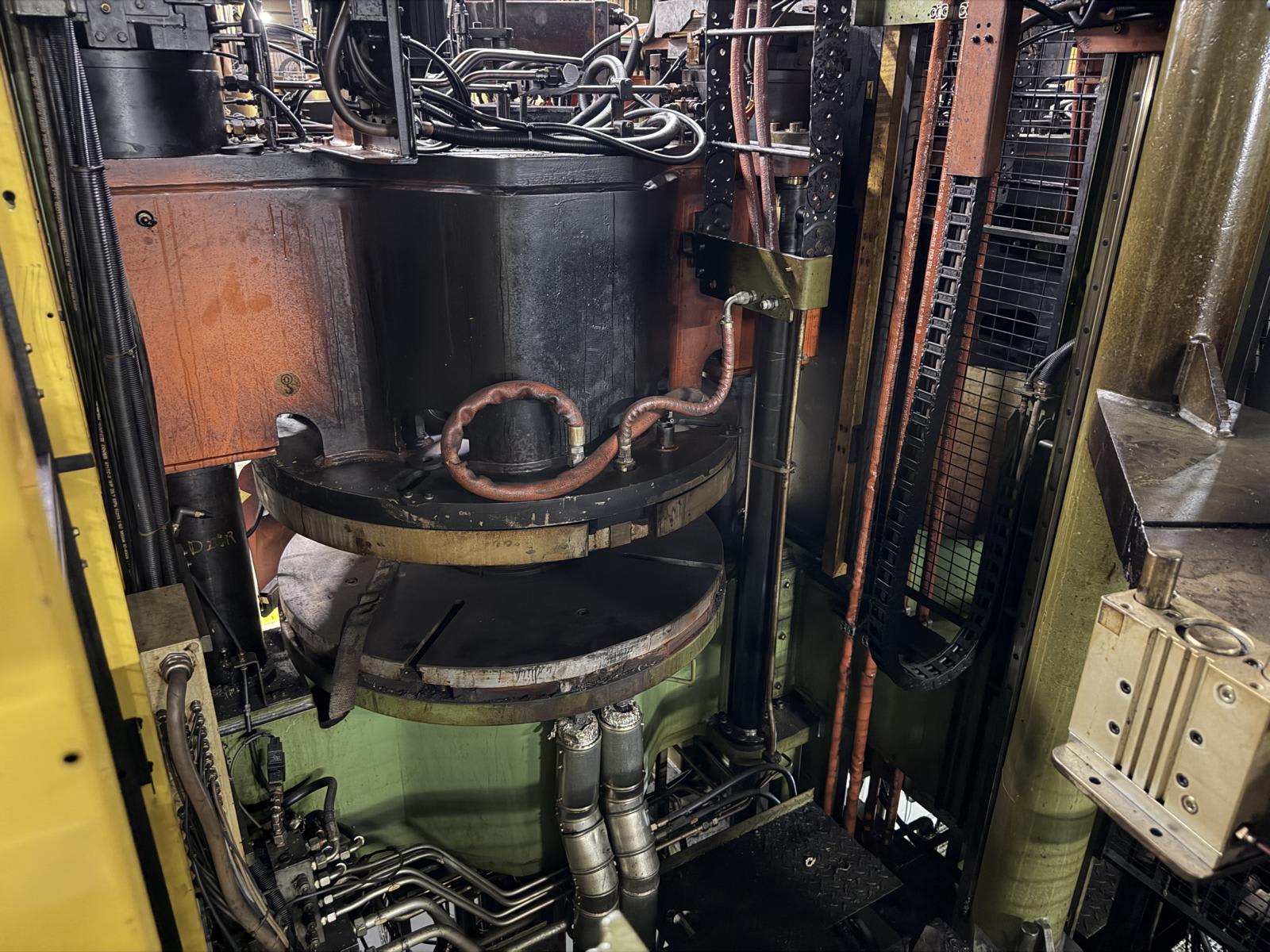

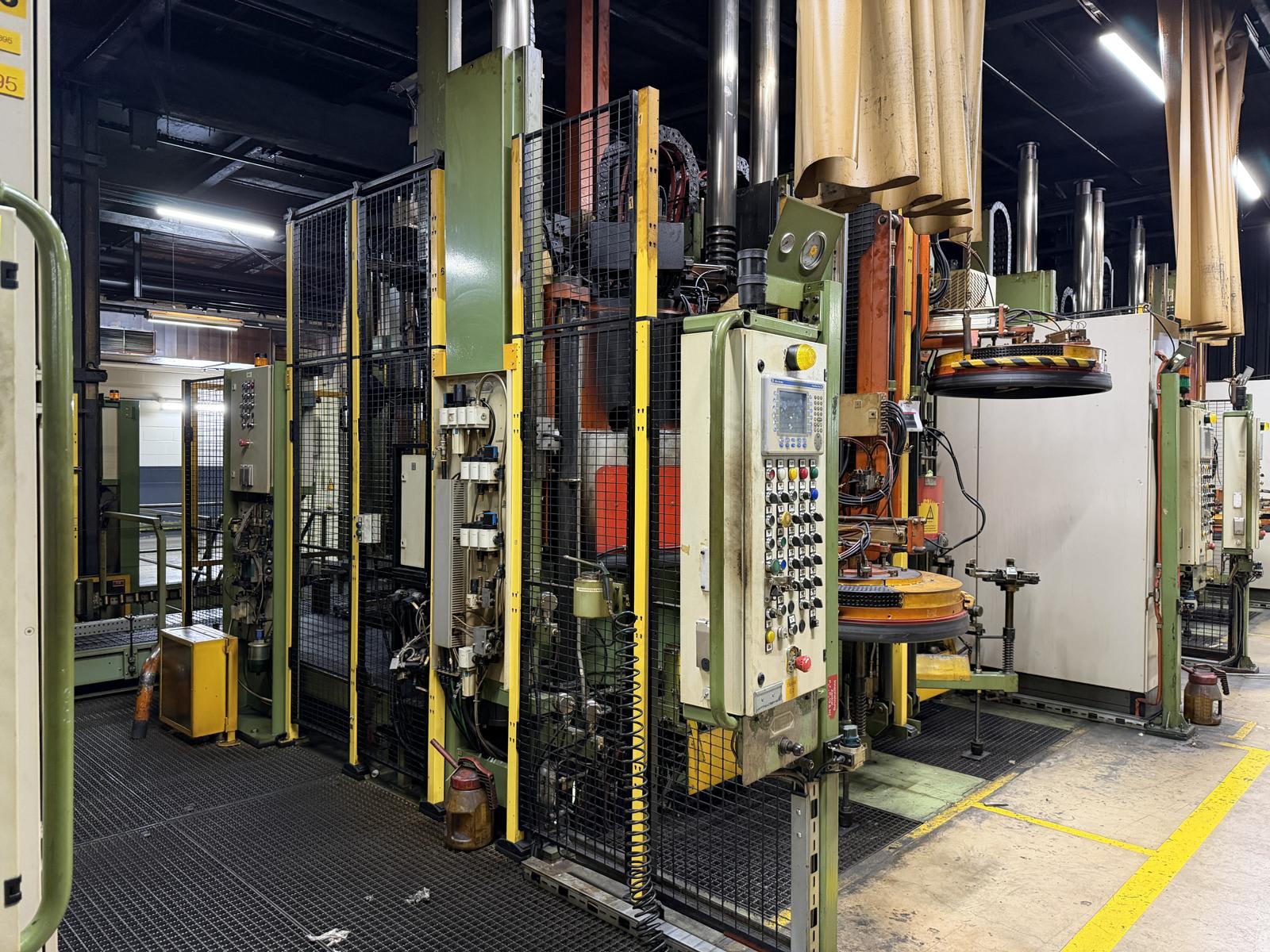

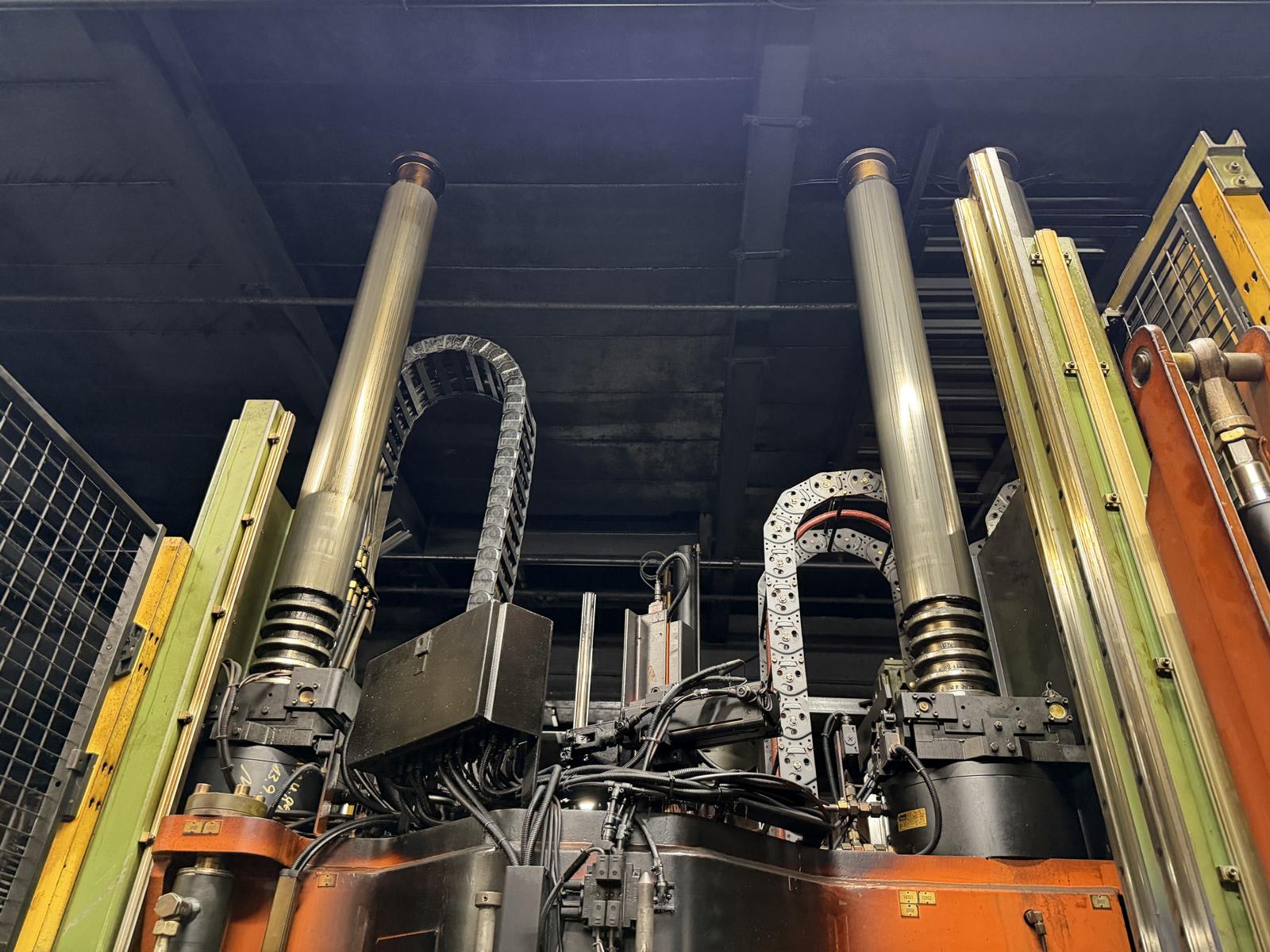

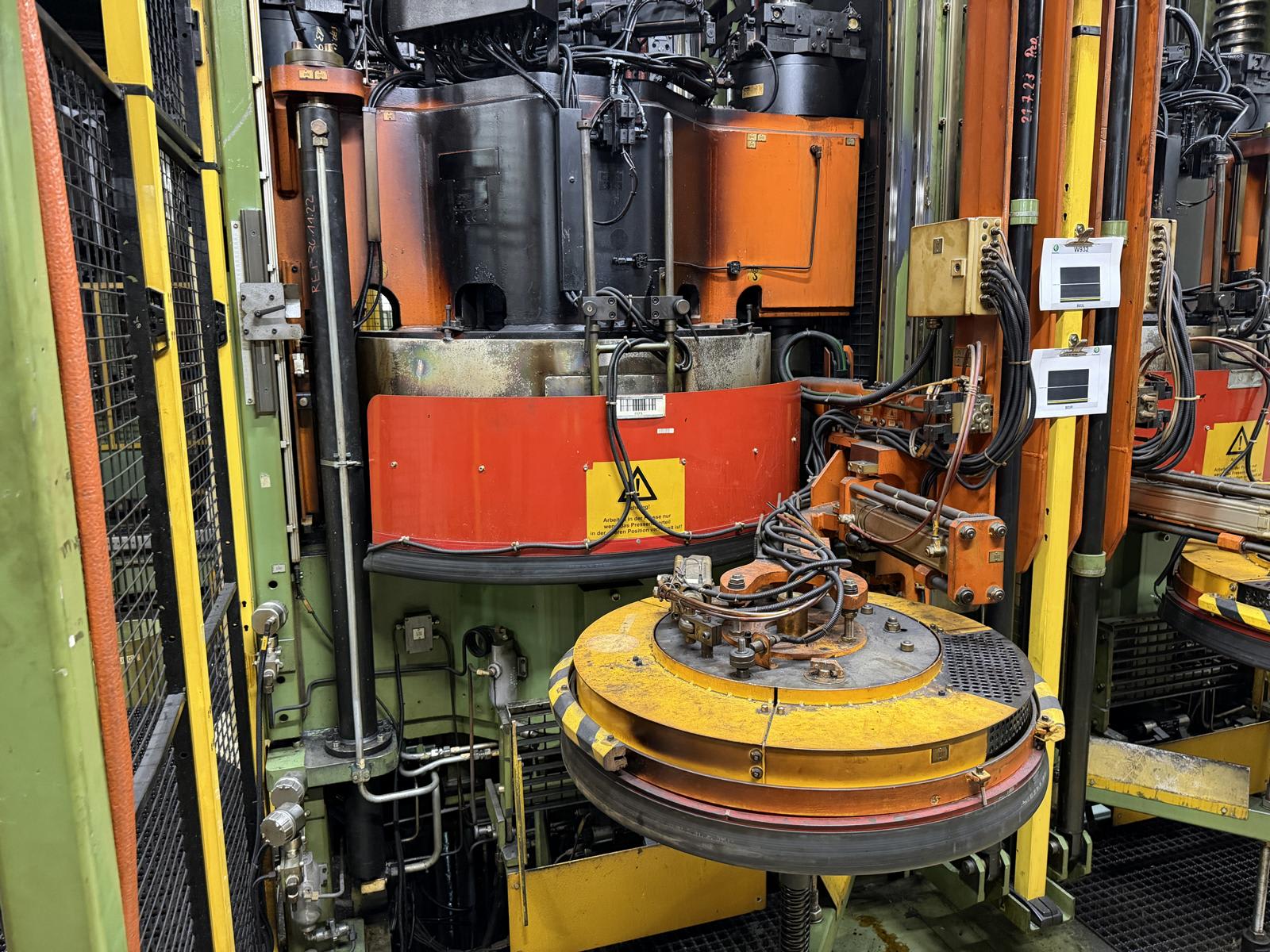

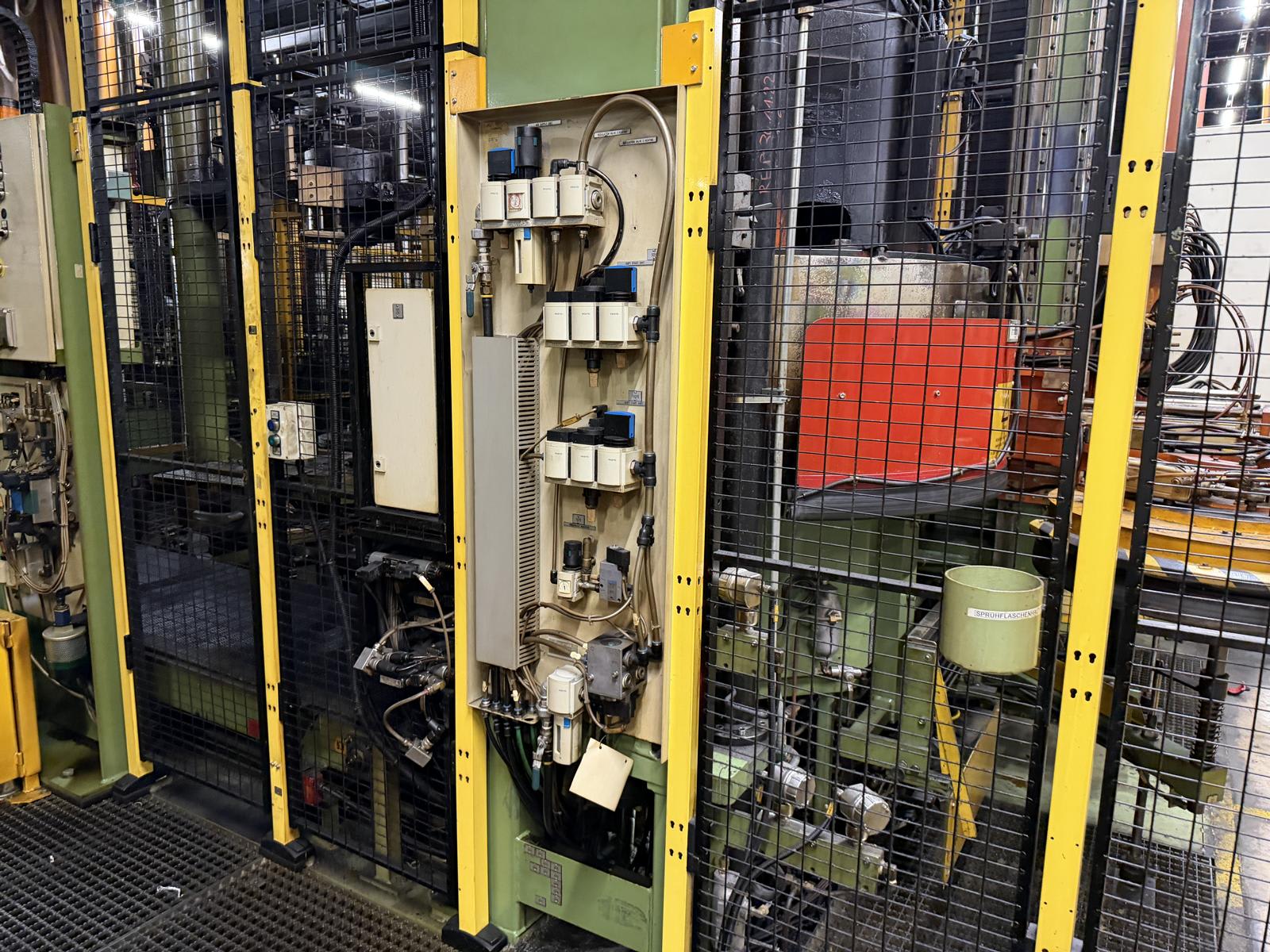

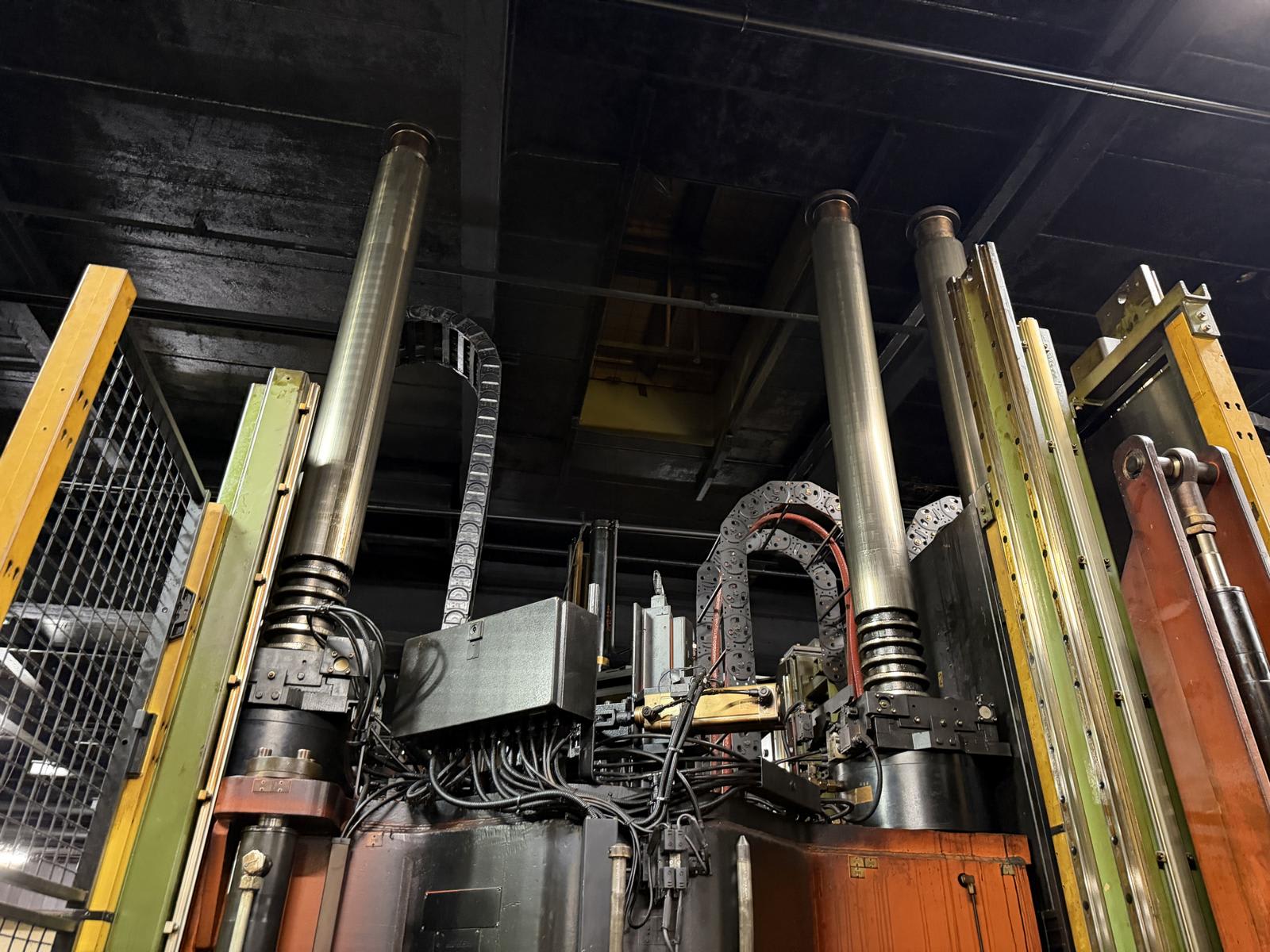

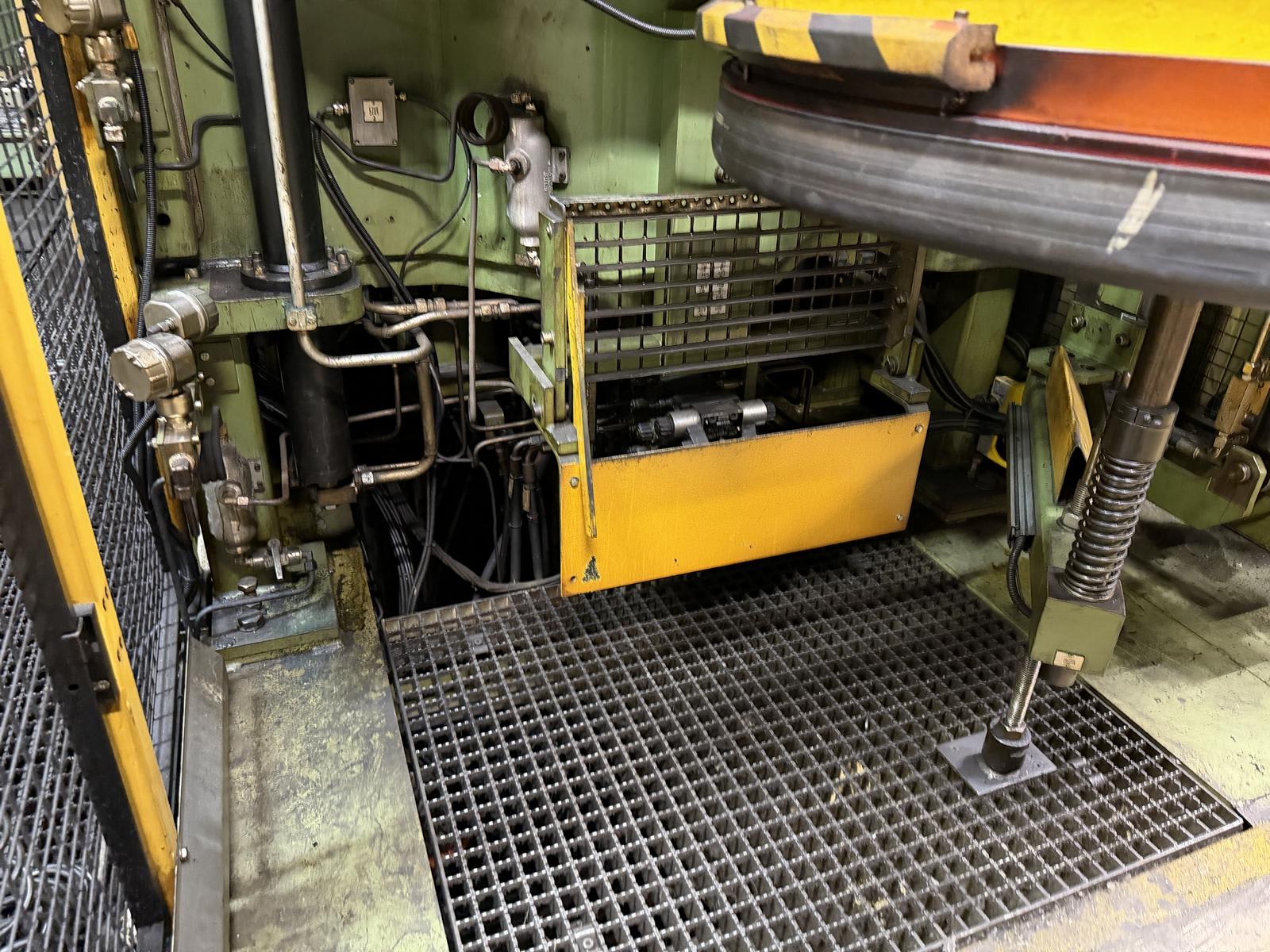

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: MCP 52-180IC Year of Manufacture: 2021 Order Number: 7782500896 Station Identification: Left Station Fact No.: 3L Right Station Fact No.: 3R Asset Number: "C10" Control Interface: Allen-Bradley PanelView Plus (Touchscreen with physical control array) Technical Data / Specifications Configuration: Twin-cavity vertical press system Hydraulic Unit: Manufacturer: Parker Components: Integrated blue hydraulic reservoir with level gauge and motor/pump assembly Electrical Cabinet: Identification: Cabinet C10 Branding: HF TireTech Group - LISTING 2760087

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH MCP 52-180IC | 2021

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: MCP 52-180IC Year of Manufacture: 2021 Order Number: 7782500896 Station Identification: Left Station Fact No.: 2L Right Station Fact No.: 2R Asset Number: "C09" Control Interface: Allen-Bradley PanelView Plus terminal with manual override switches Technical Data / Specifications Configuration: Vertical twin-cavity curing system Hydraulic System: Unit Manufacturer: Parker Motor: Electric drive motor mounted on top of blue reservoir Reservoir: Blue steel tank with integrated level monitoring Loading System: Automatic green tire loading mechanism with front-facing chucks - LISTING 2760088

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH MCP 52-180IC | 2021

Binding Handling & Service Fee:

19700 € (EURO)

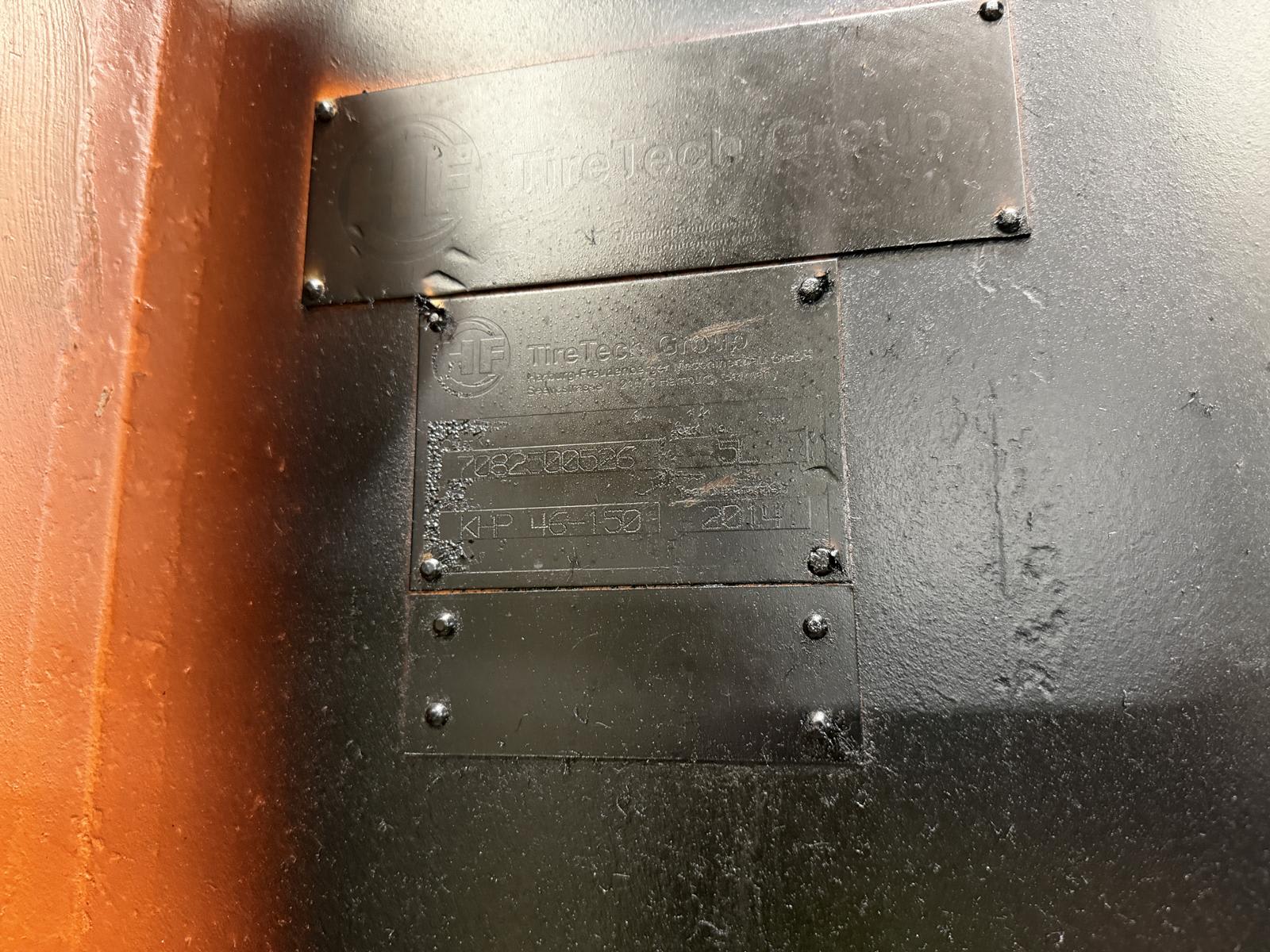

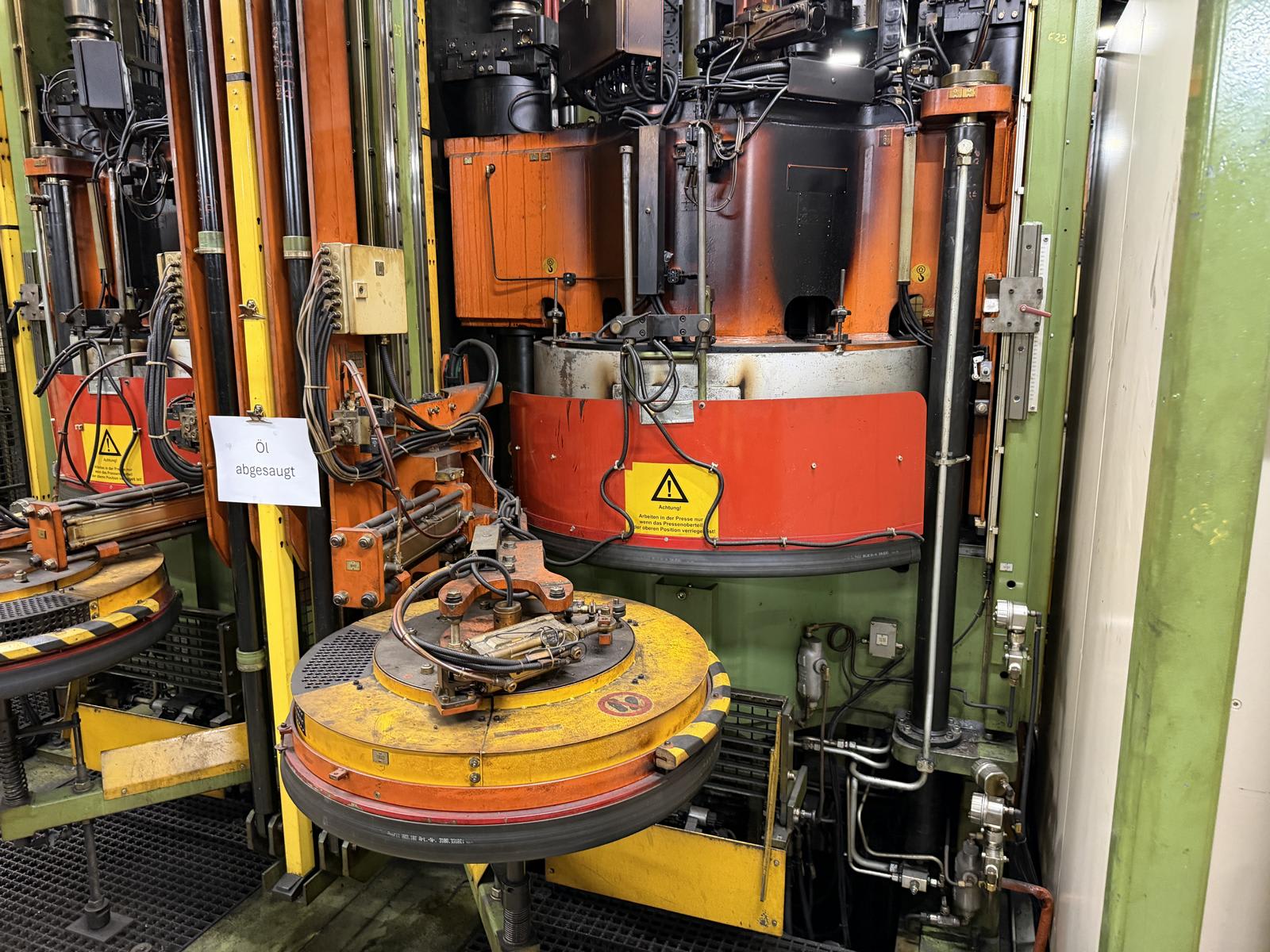

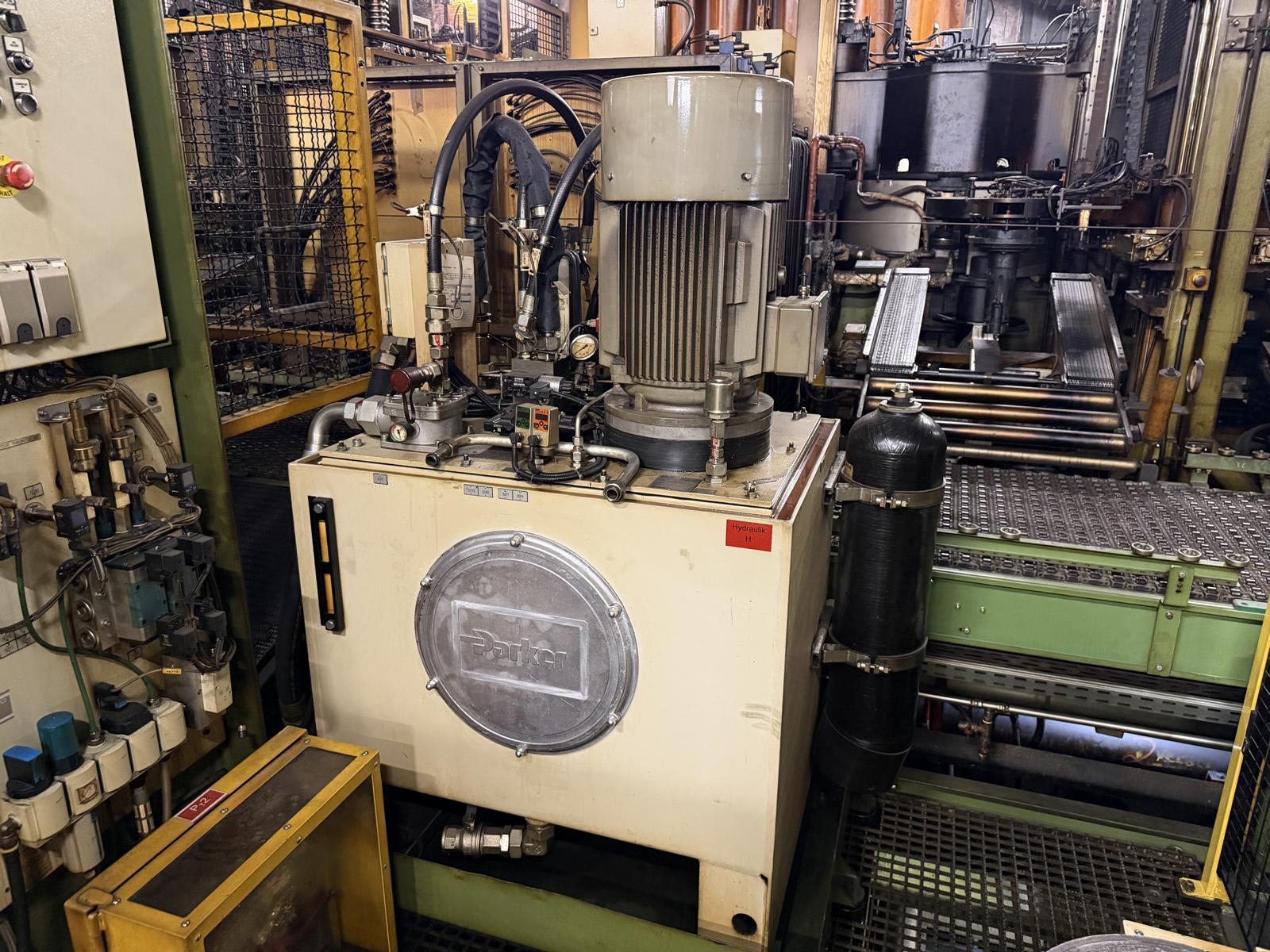

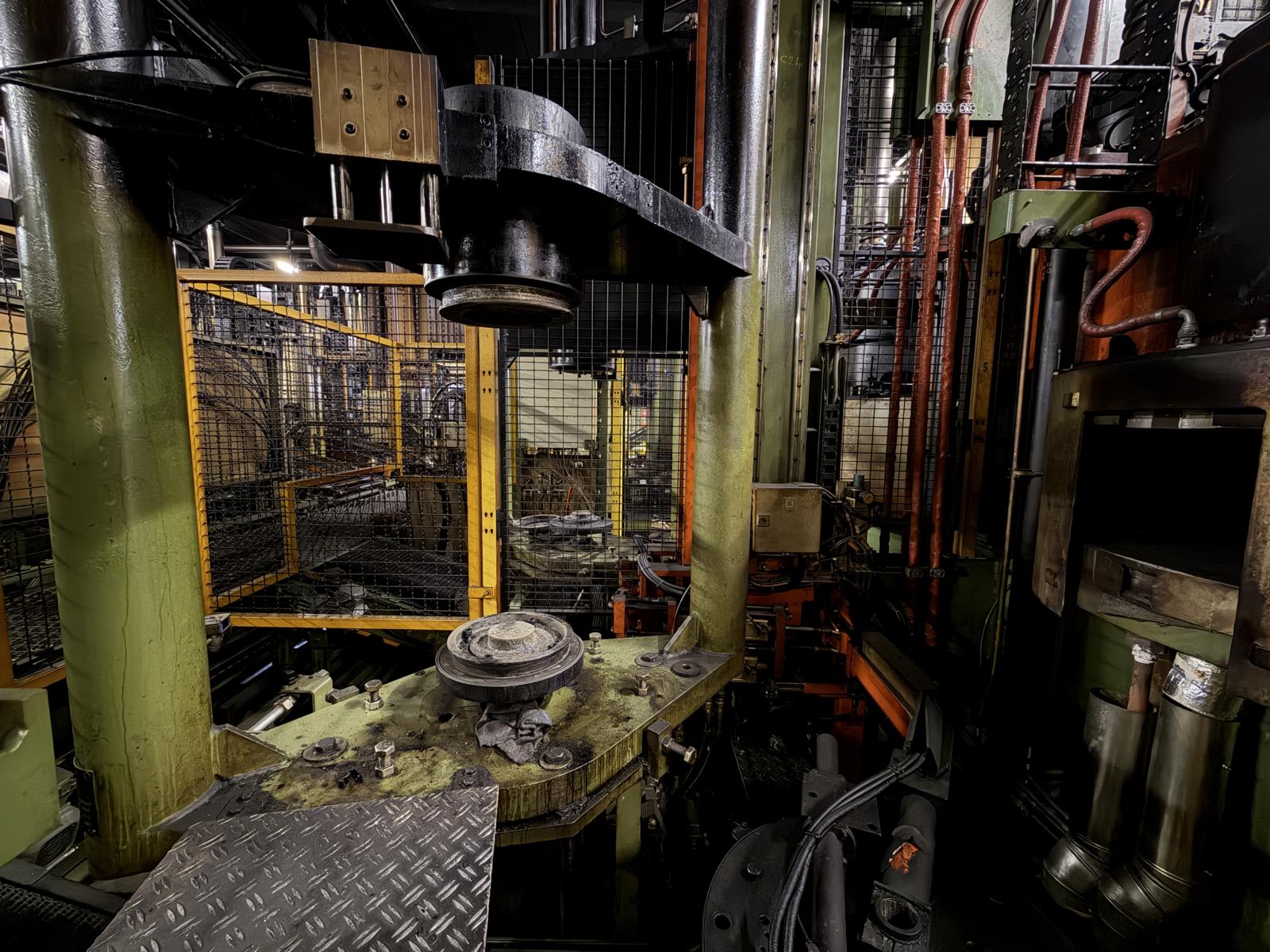

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: KHP 46-150 Year of Manufacture: 2014 Order Number: 7082500526 Station Identification: Left Station Fact No.: 6L Right Station Fact No.: 6R Asset Number: Sticker "D01" Control Interface: Allen-Bradley PanelView Plus 700 Technical Data / Specifications Configuration: Twin-cavity vertical press system Electrical Cabinet: Identification: Cabinet D01 Hydraulic System: Unit Manufacturer: Parker Reservoir Color: Cream/Beige (distinct from previous lots) Loading Mechanism: Automatic green tire loading arms - LISTING 2760089

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2014

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: KHP 46-150 Year of Manufacture: 2014 Order Number: 7082500526 Station Identification: Left Station Fact No.: 5L Right Station Fact No.: 5R Asset Number: Sticker "90" Control Interface: Allen-Bradley PanelView Plus 700 with physical button array Technical Data / Specifications Configuration: Vertical twin-cavity curing press Electrical Cabinet: Identification: Cabinet D02 Hydraulic System: Unit Manufacturer: Parker Reservoir Color: Cream/Beige (Consistent with 2014 models) Motor Configuration: Vertical mount electric motor on tank top Loading Mechanism: Automatic green tire loader with expanding chucks - LISTING 2760090

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2014

Binding Handling & Service Fee:

19700 € (EURO)

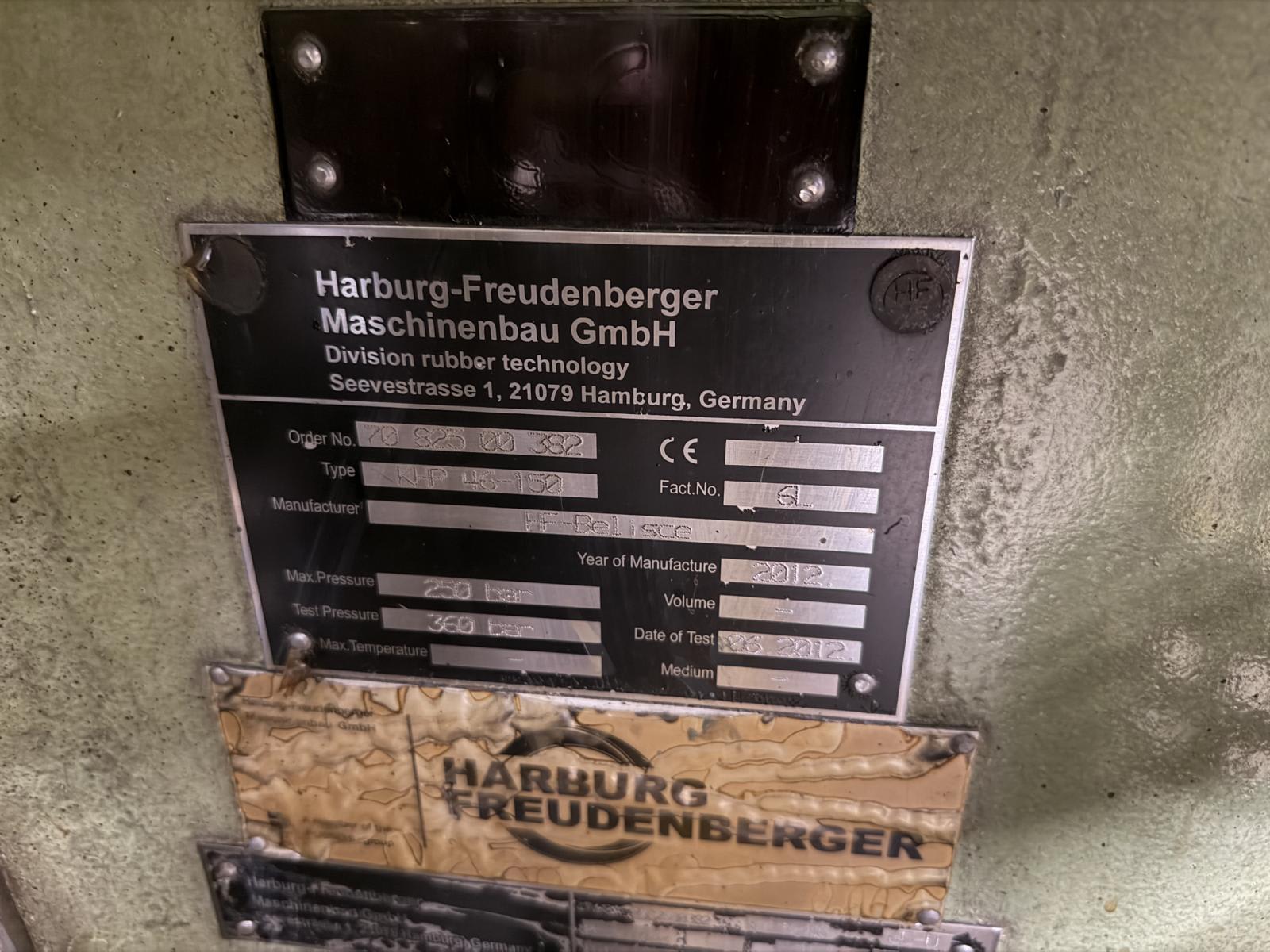

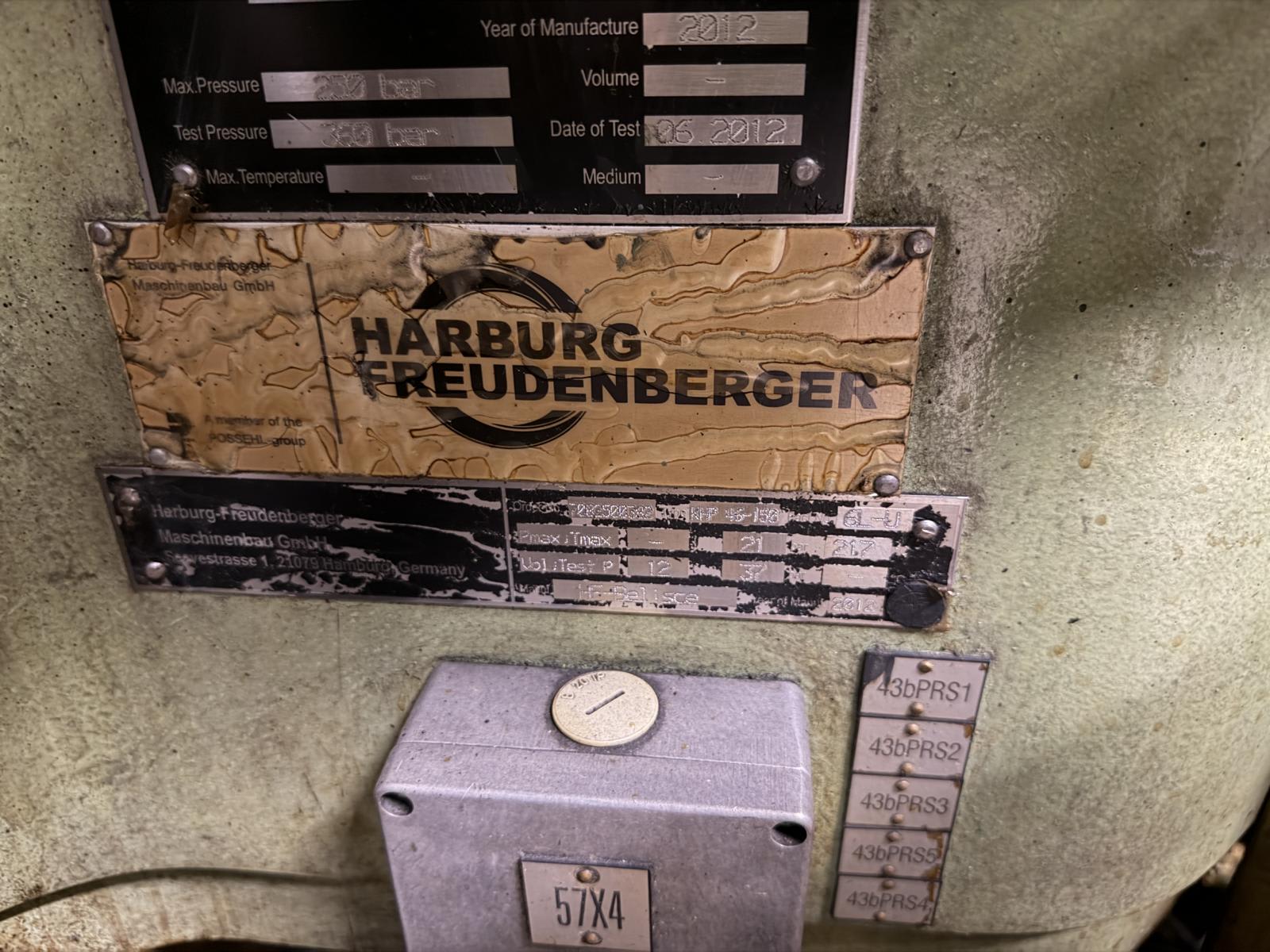

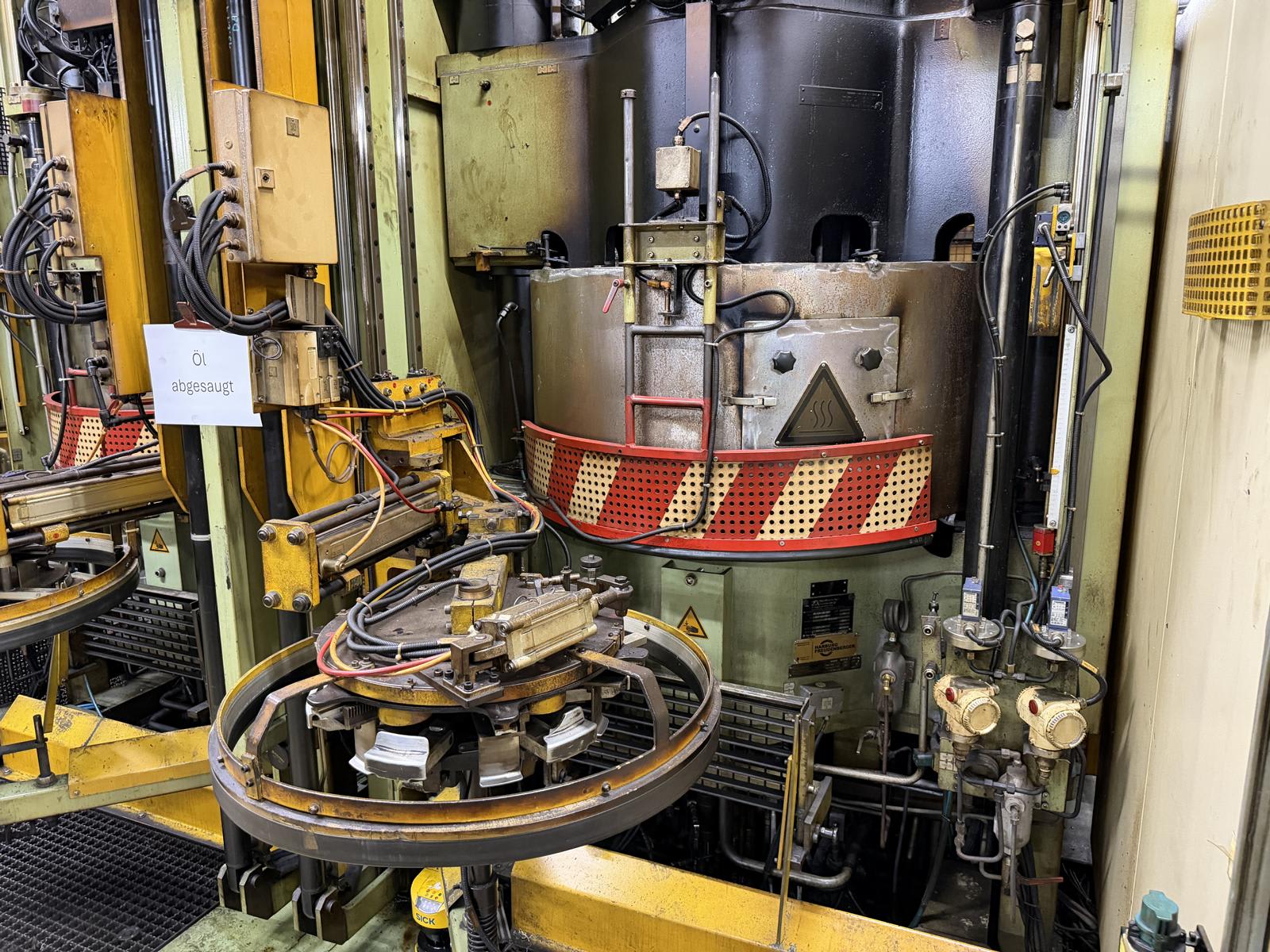

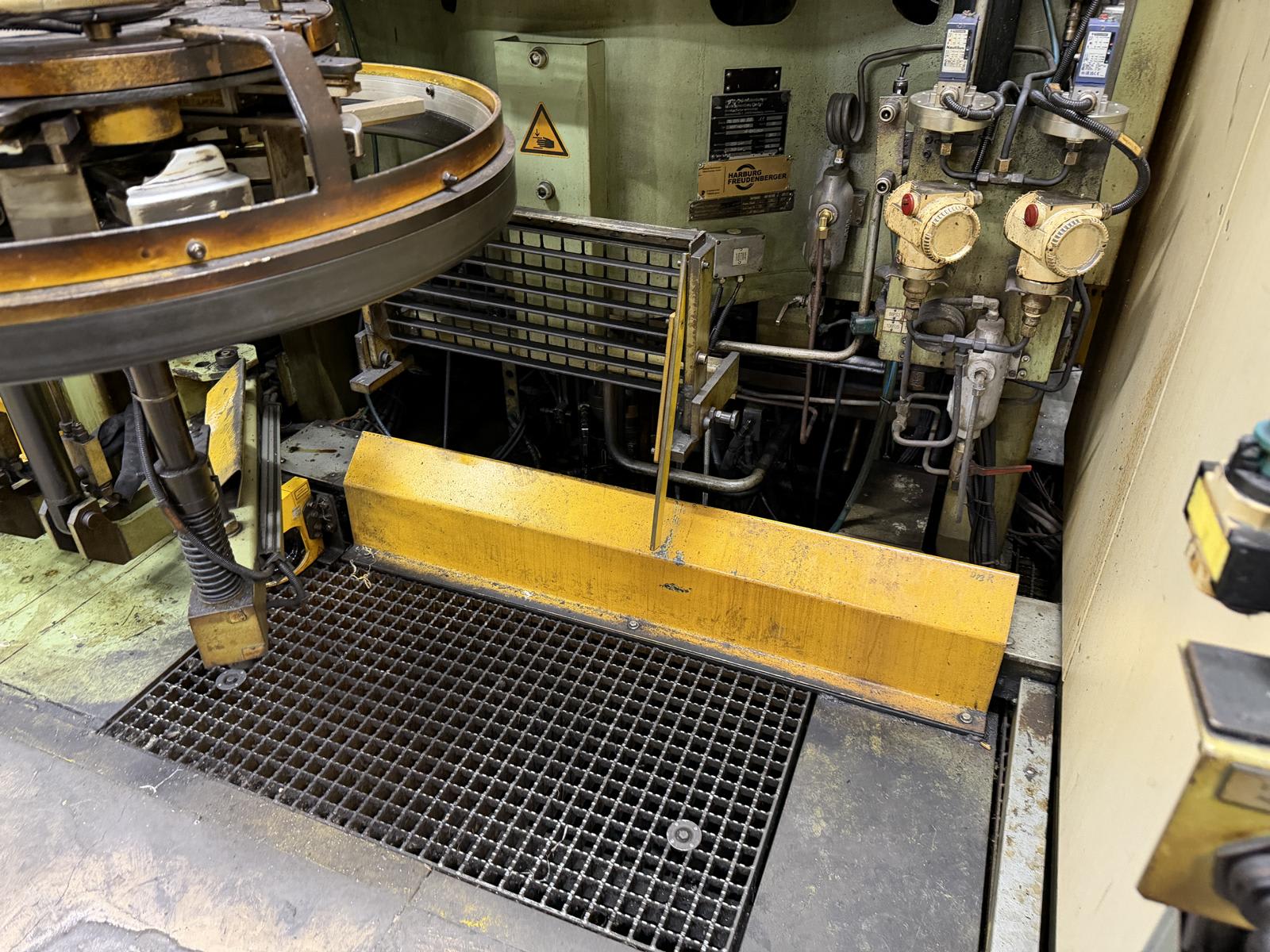

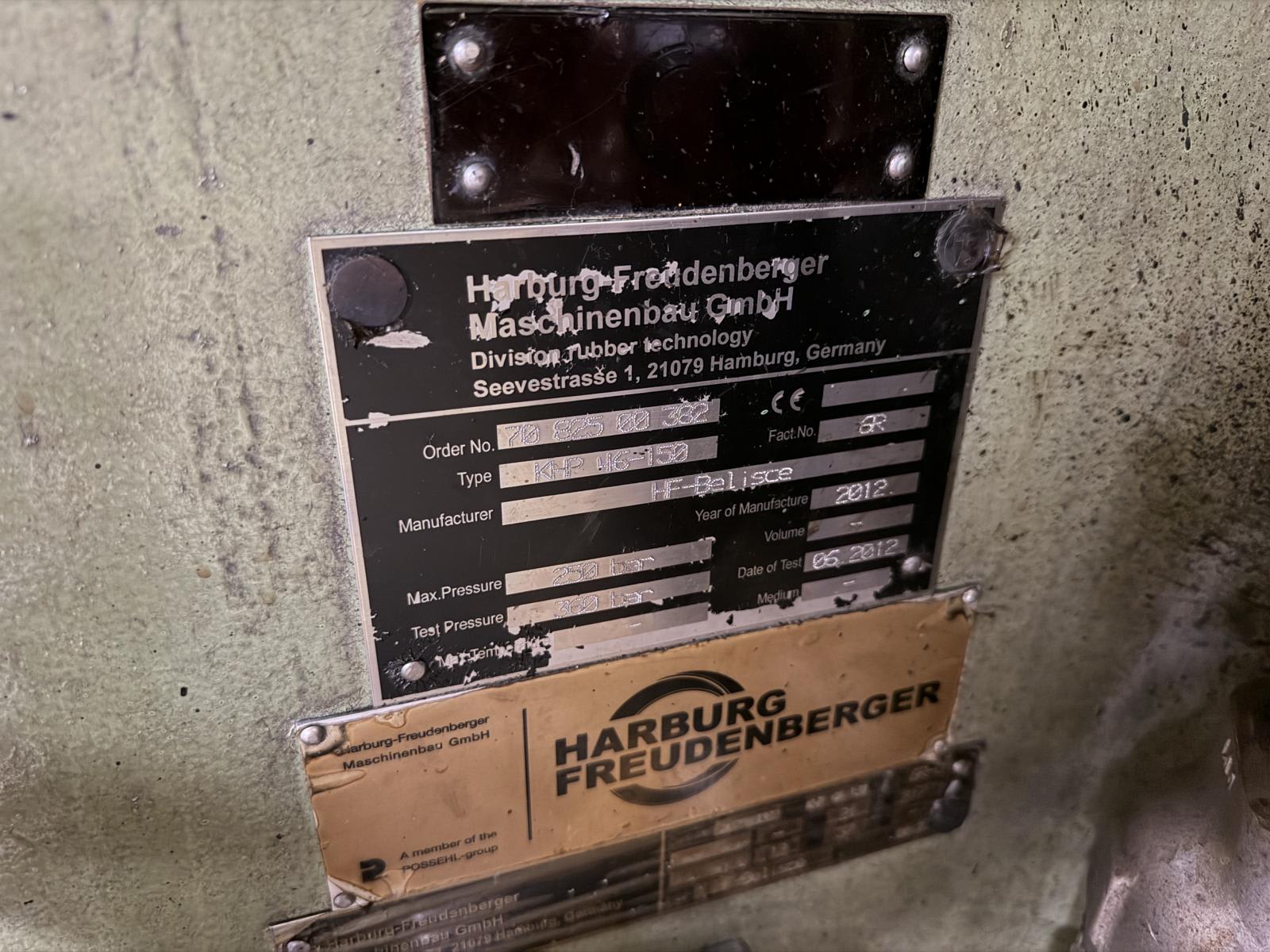

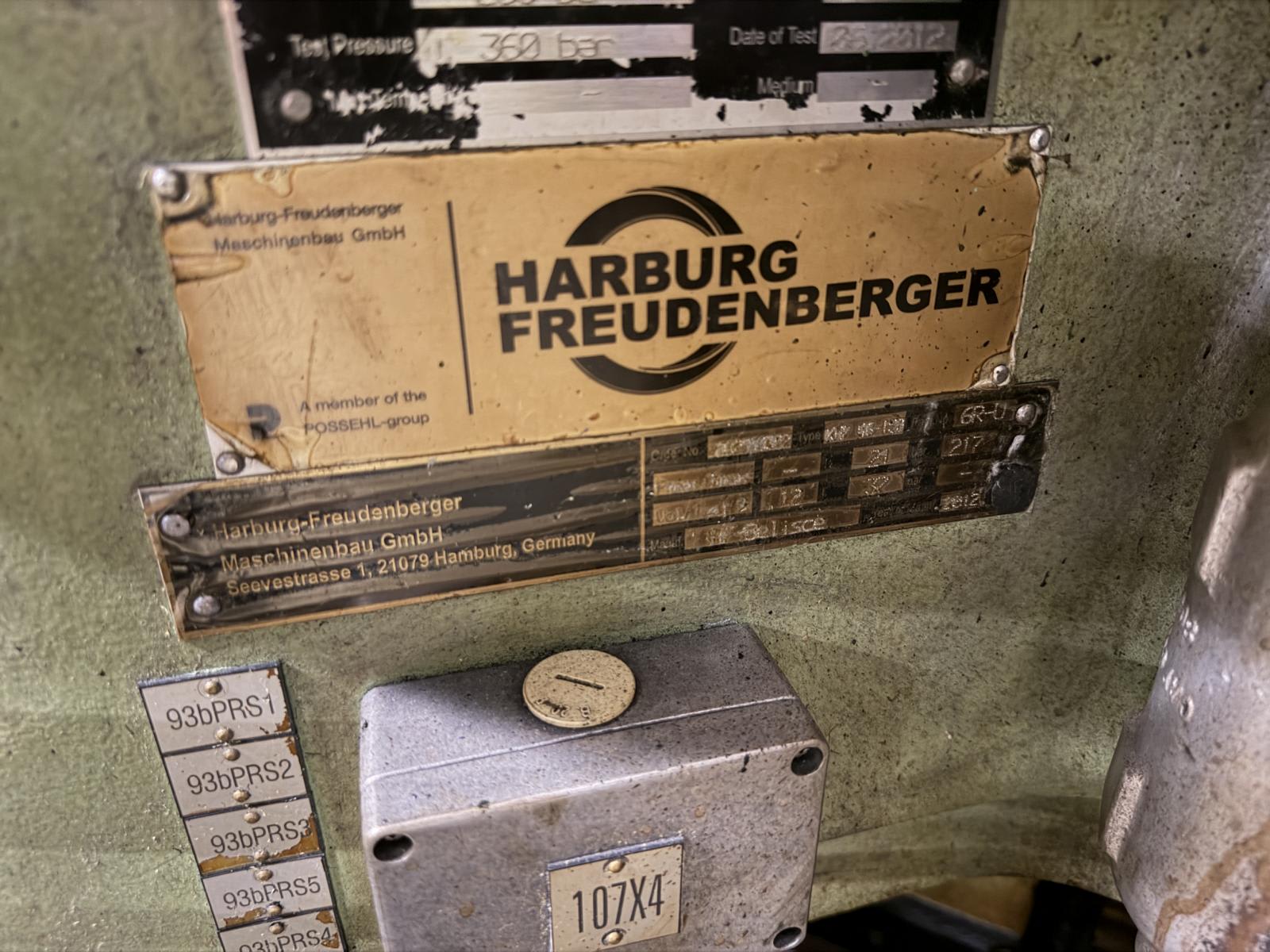

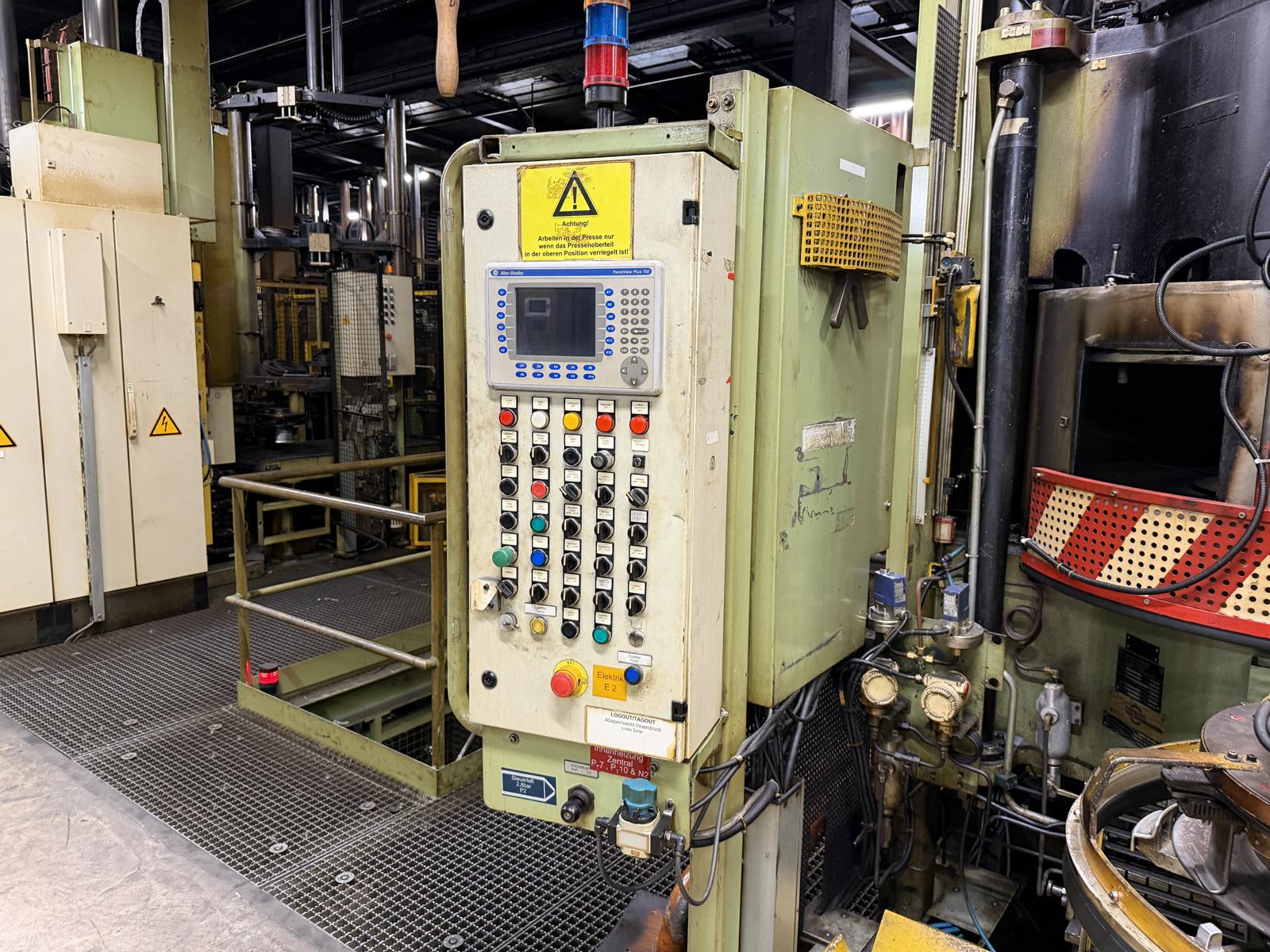

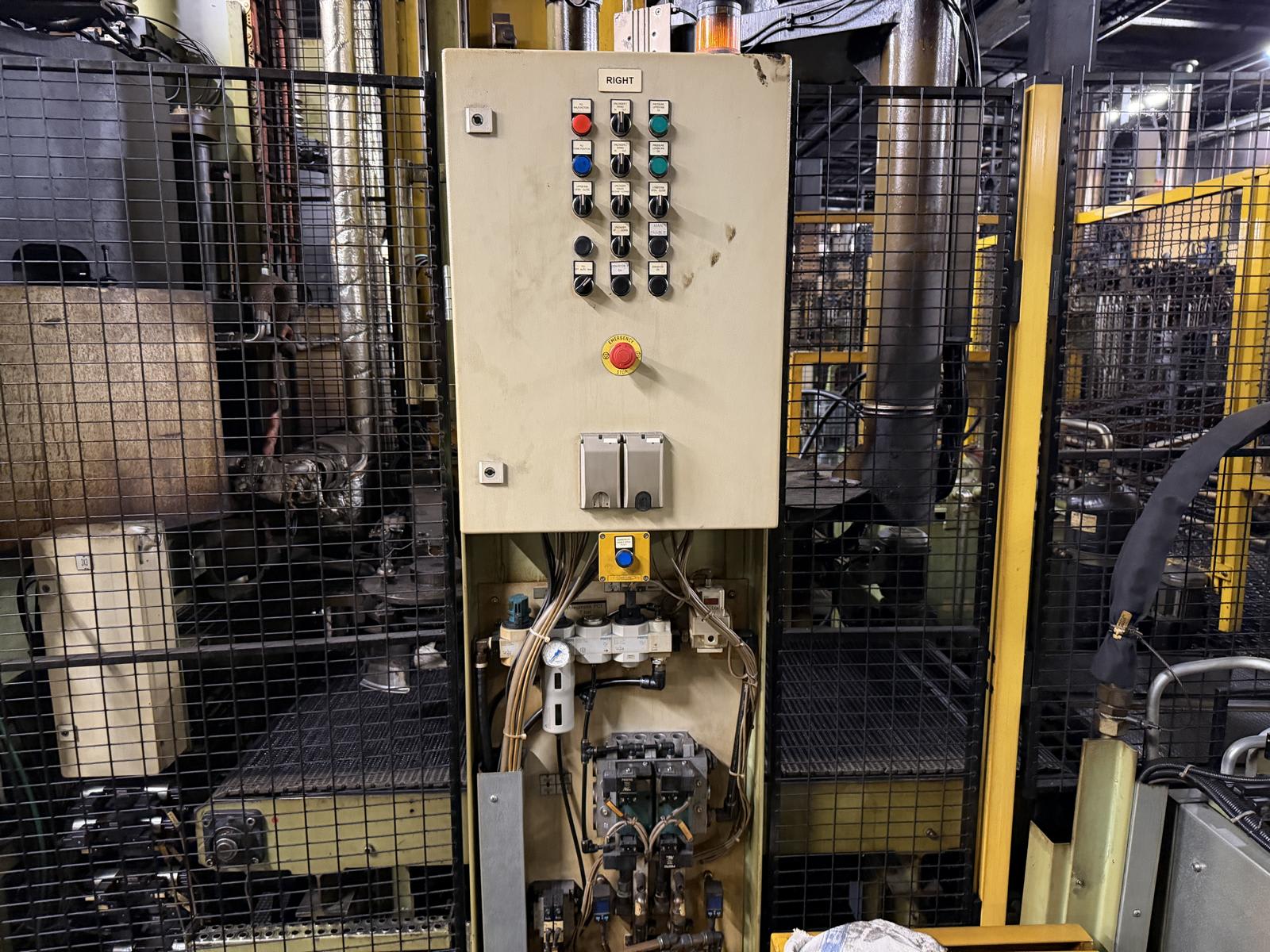

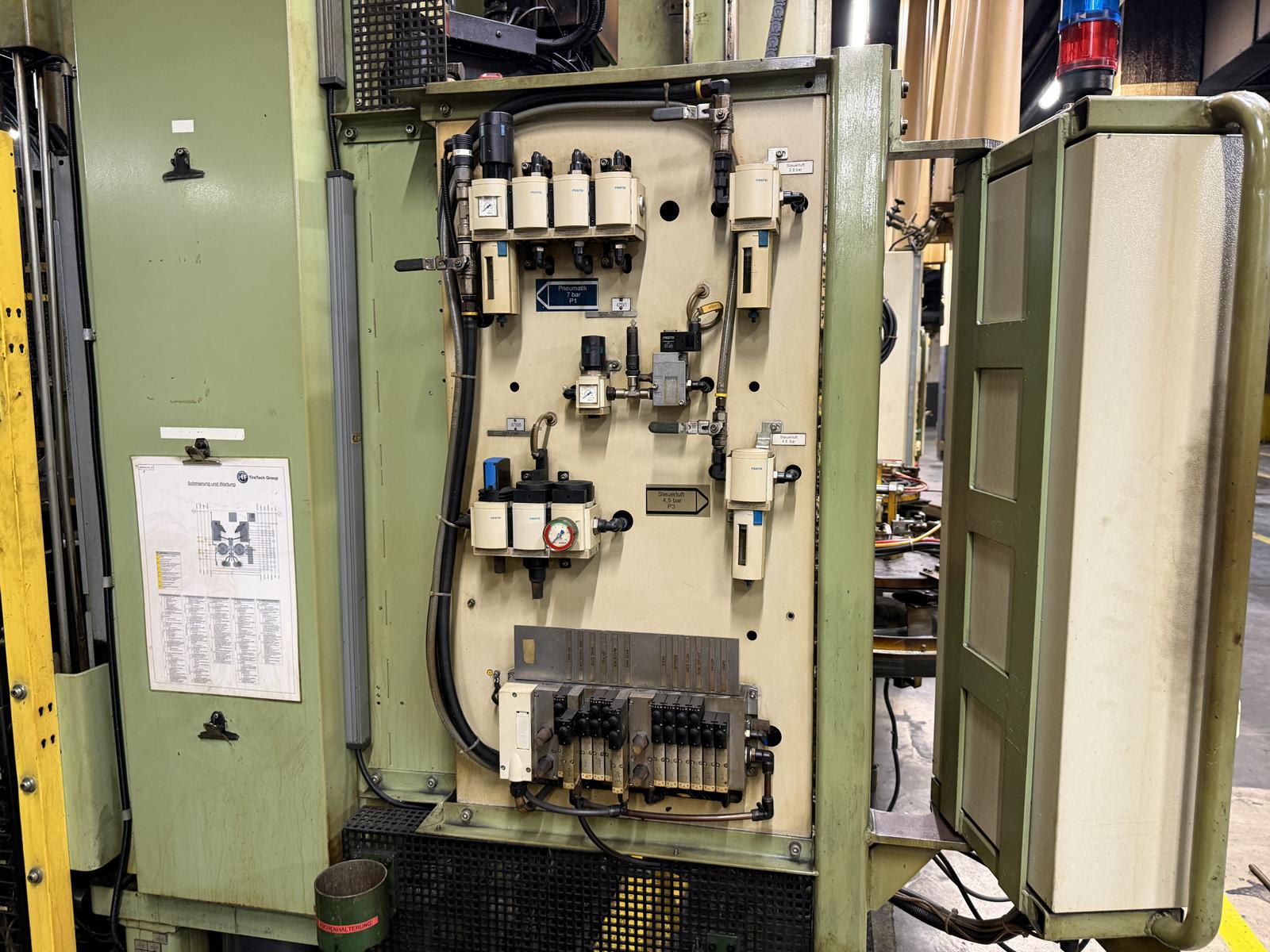

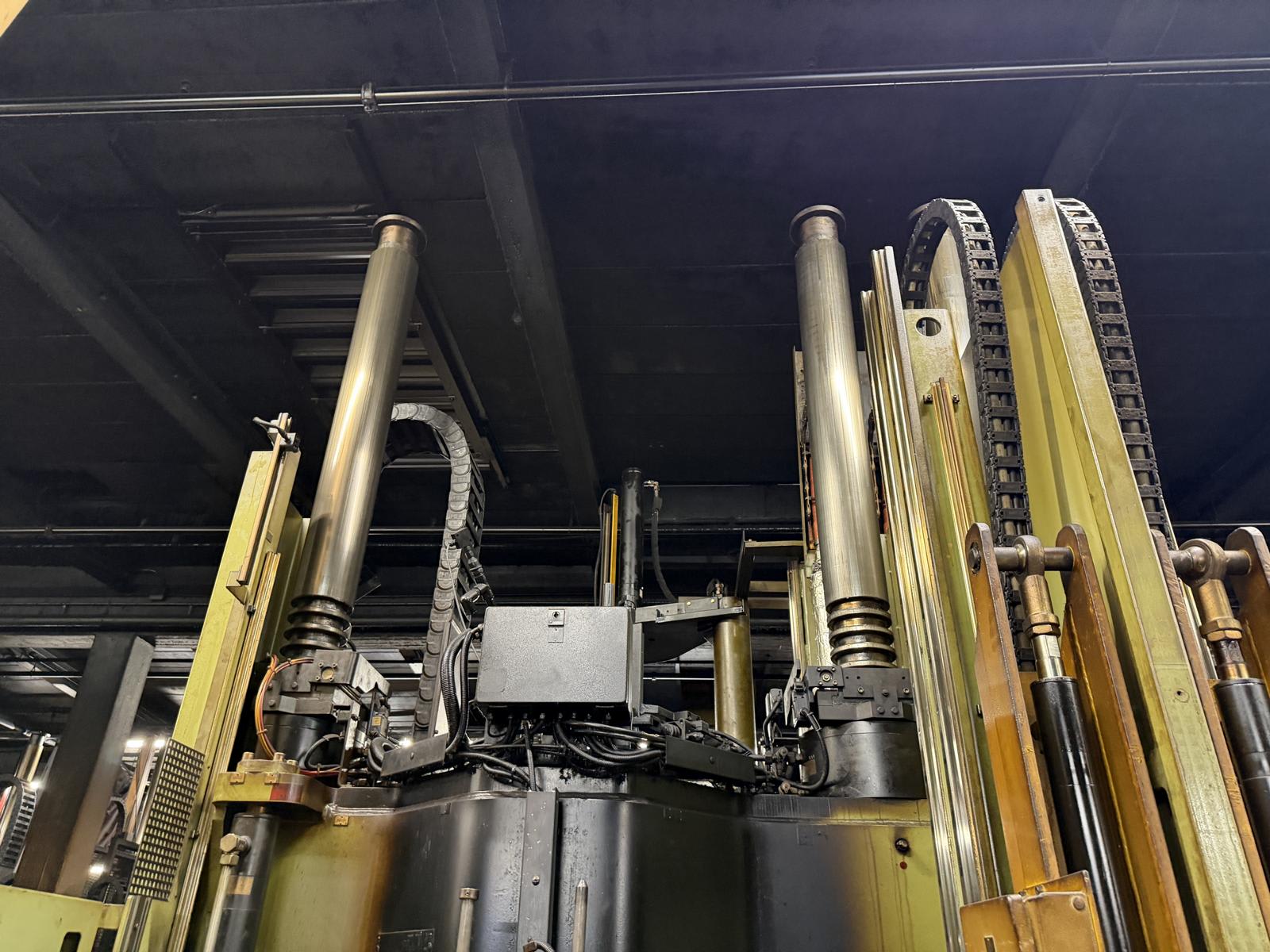

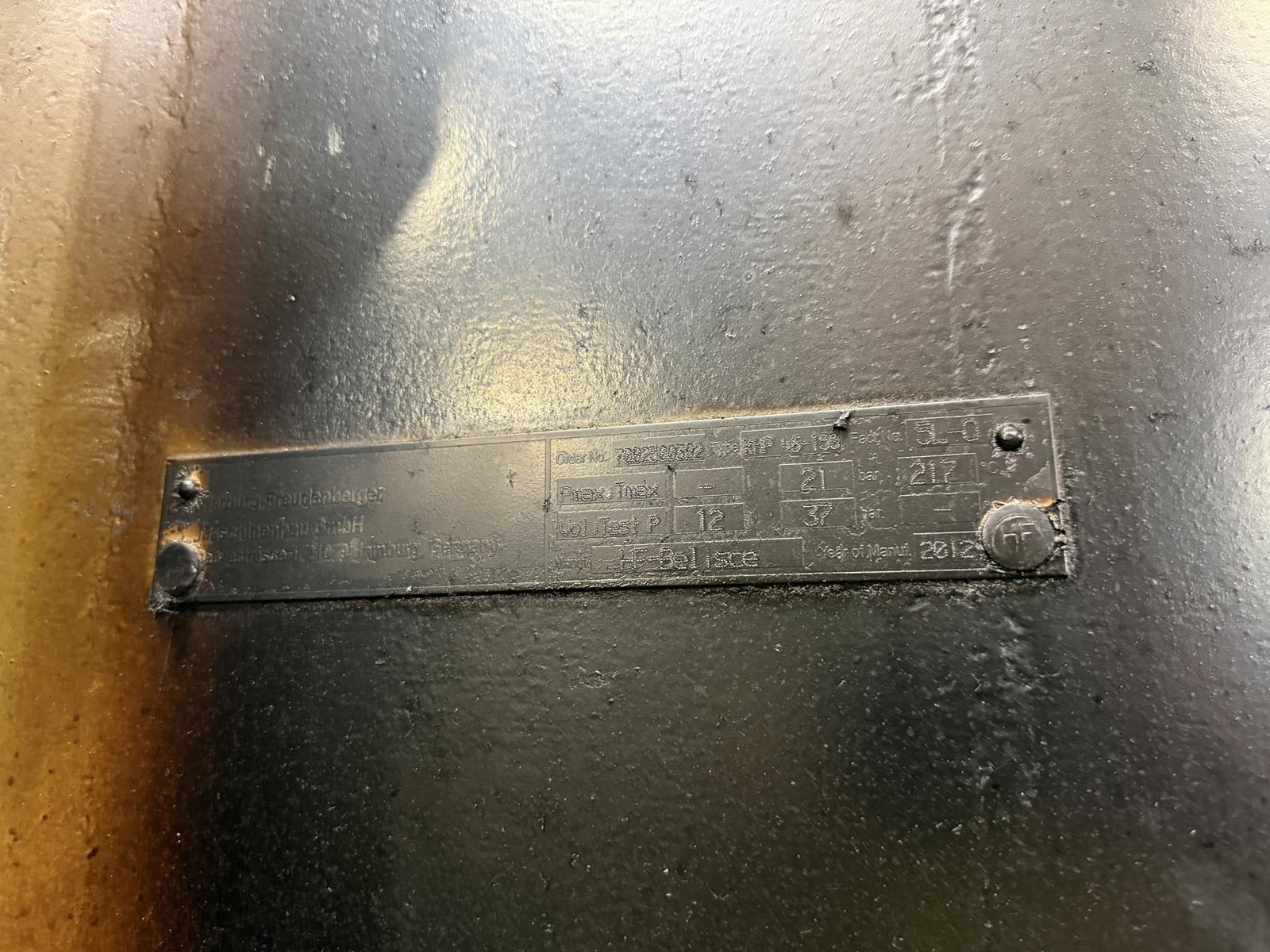

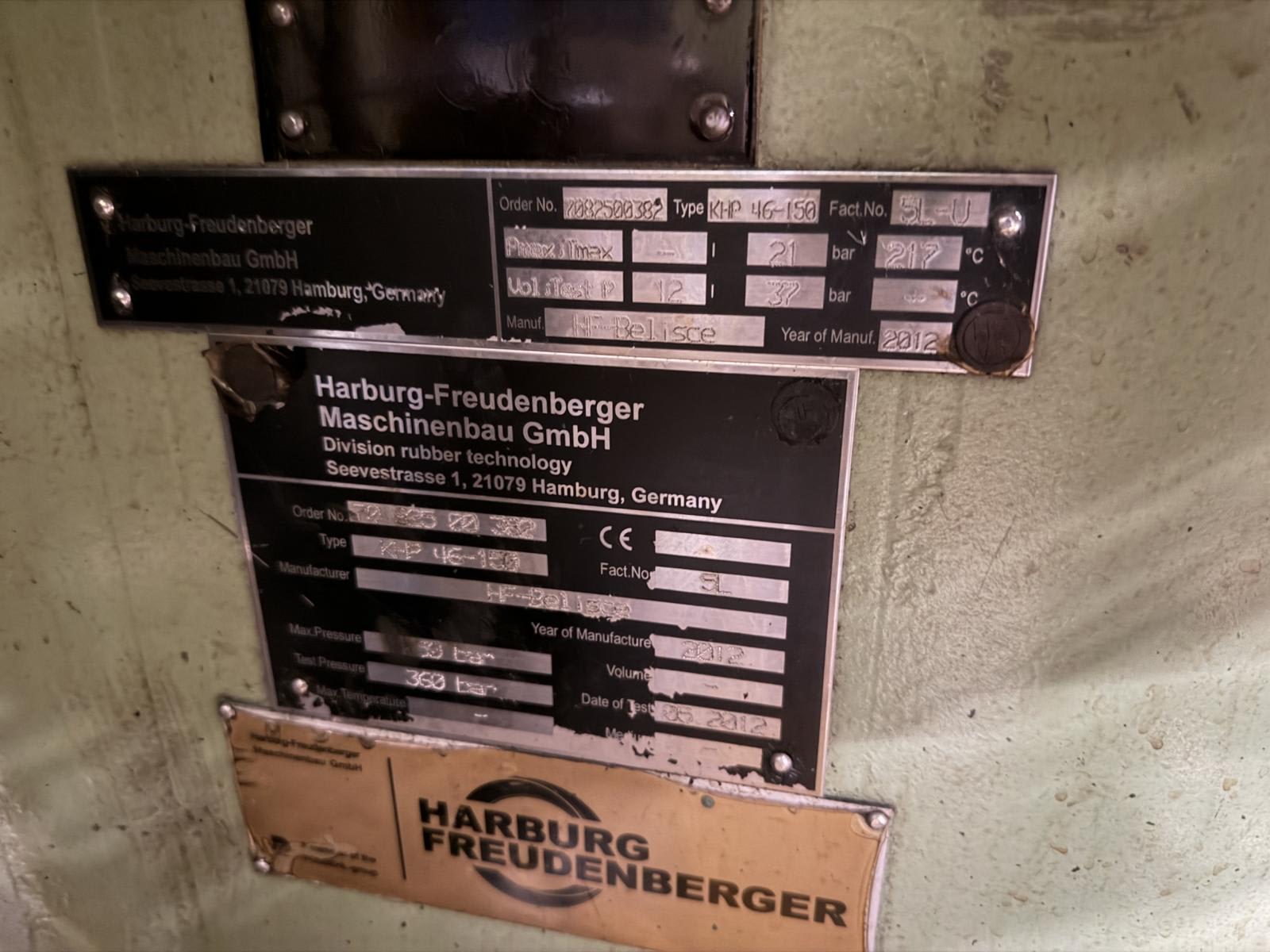

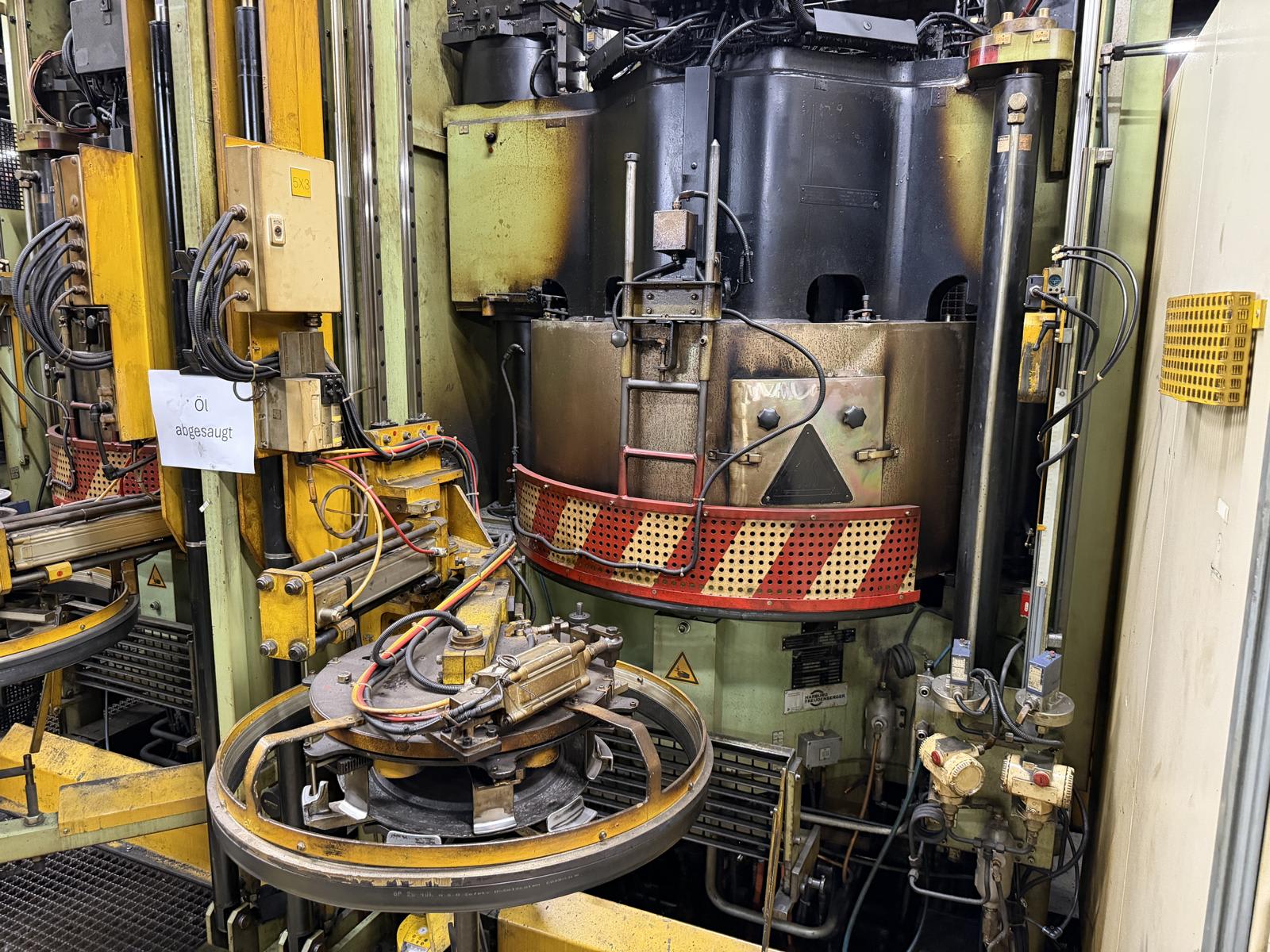

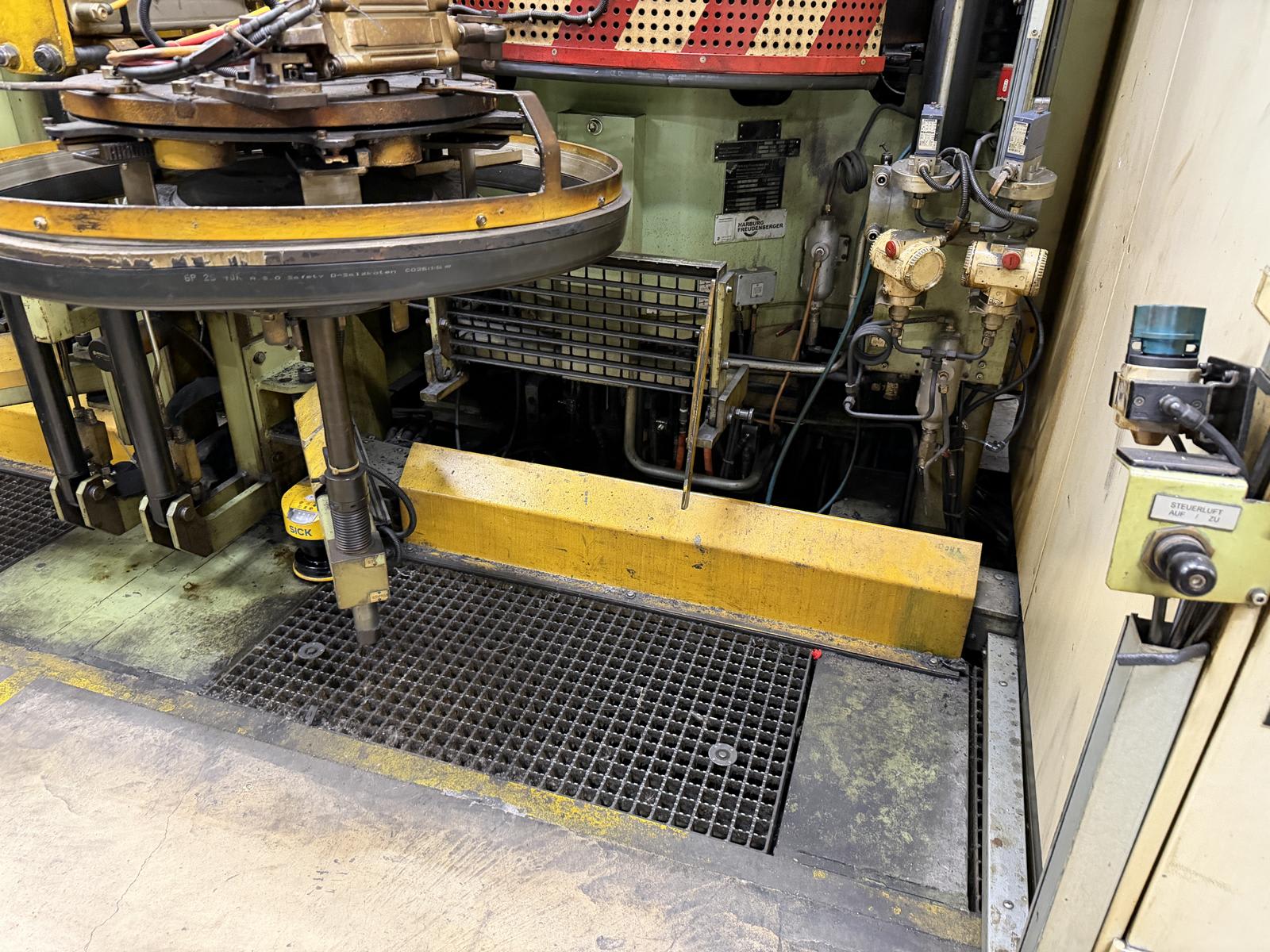

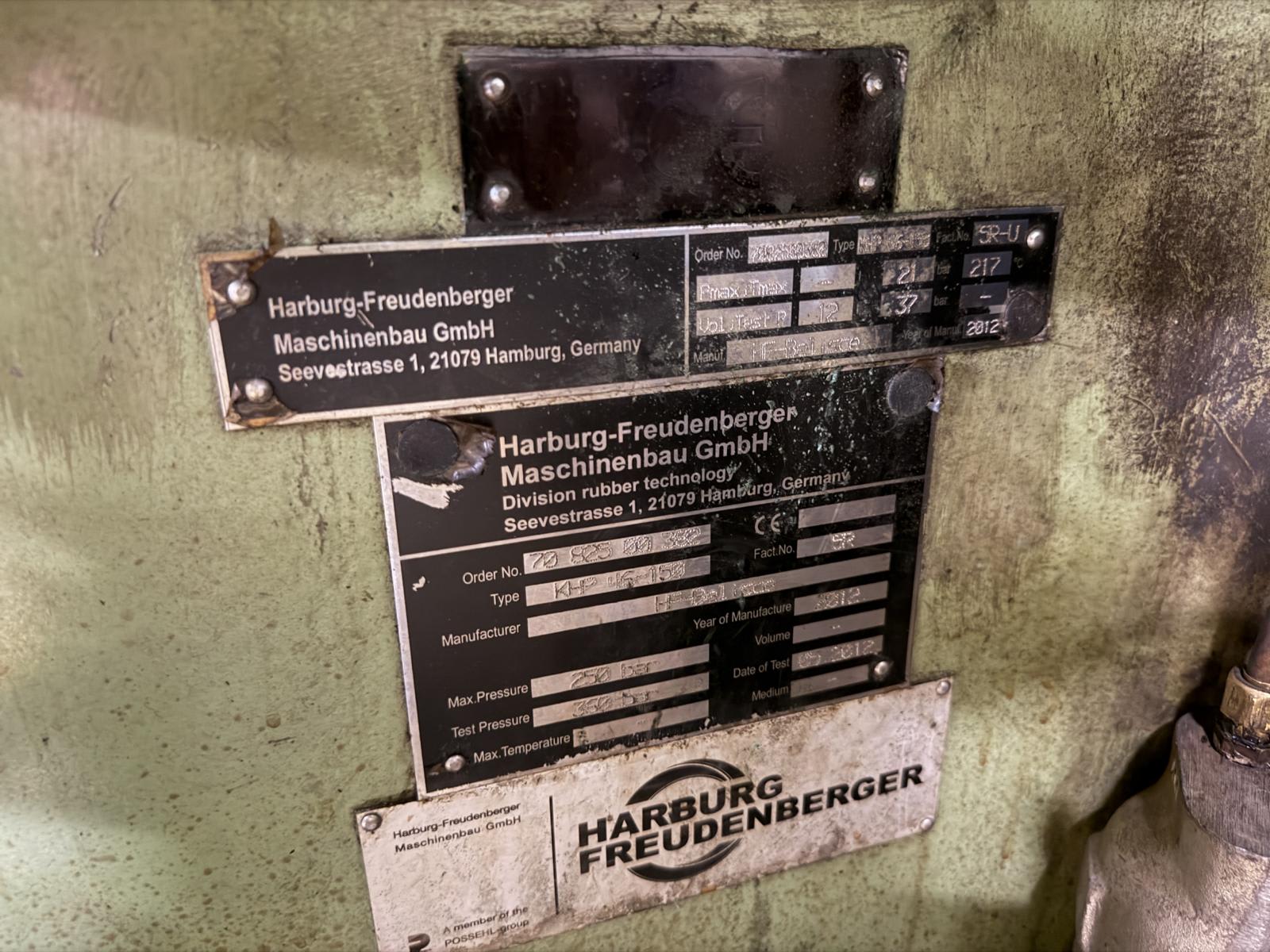

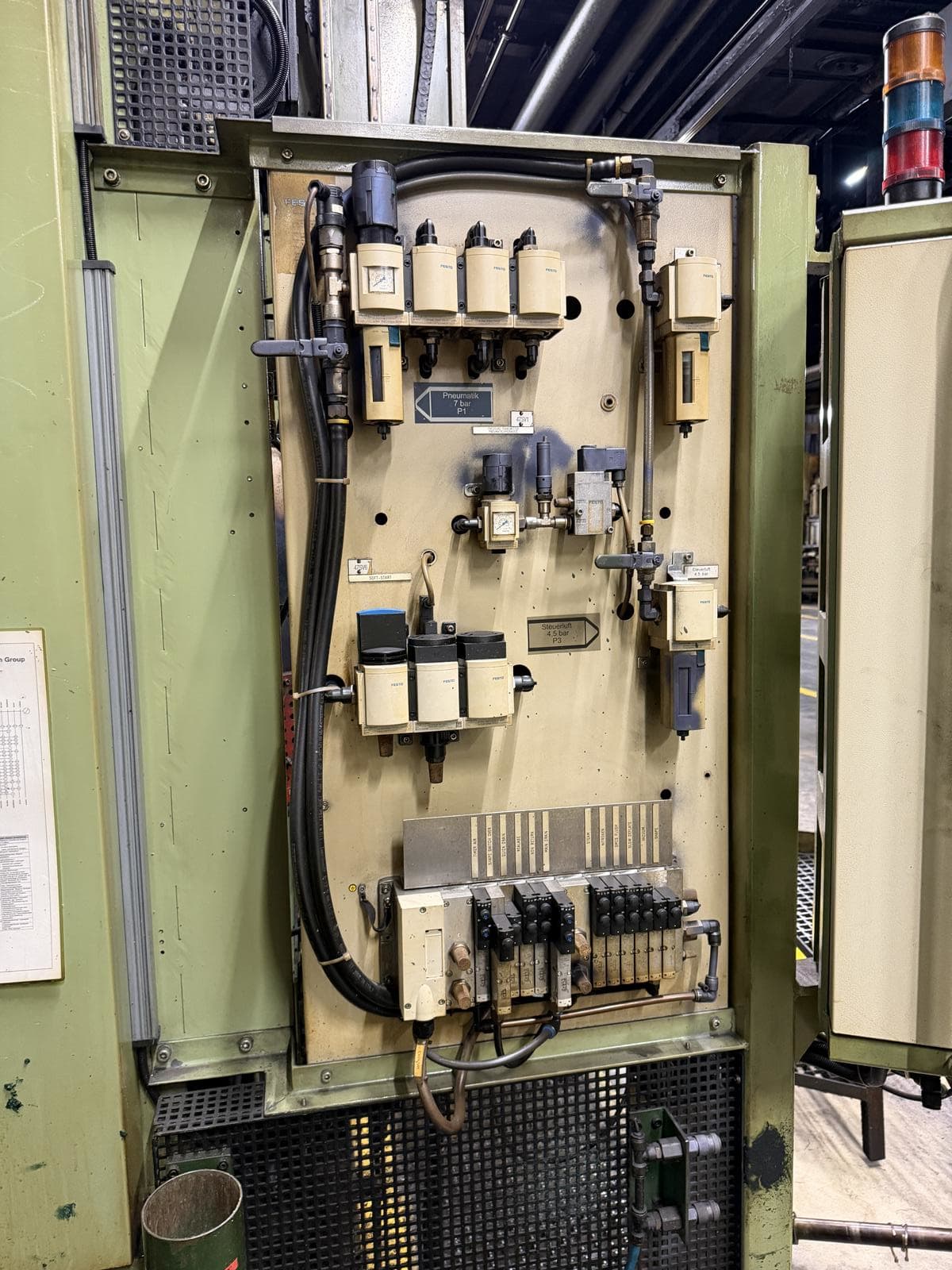

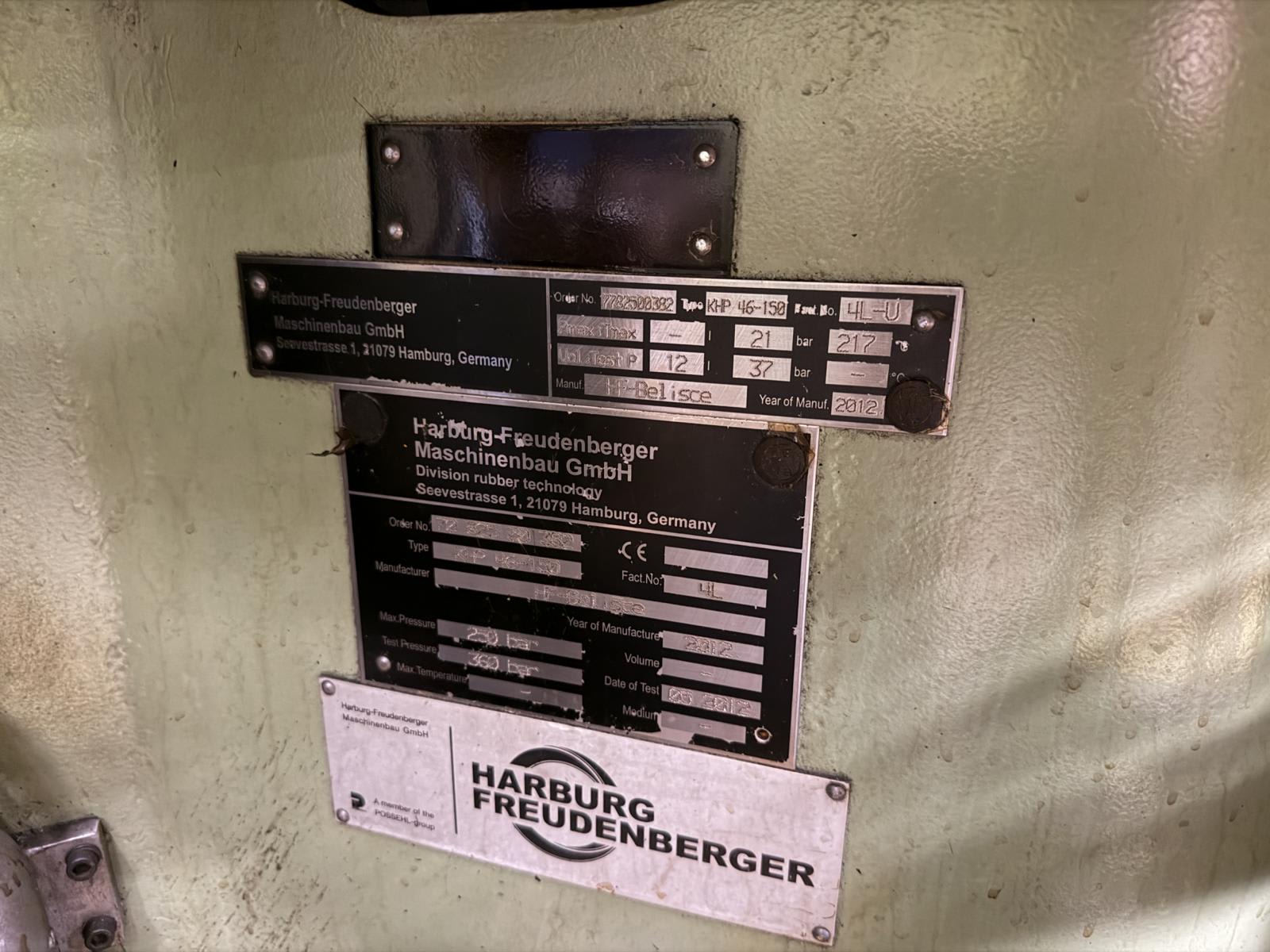

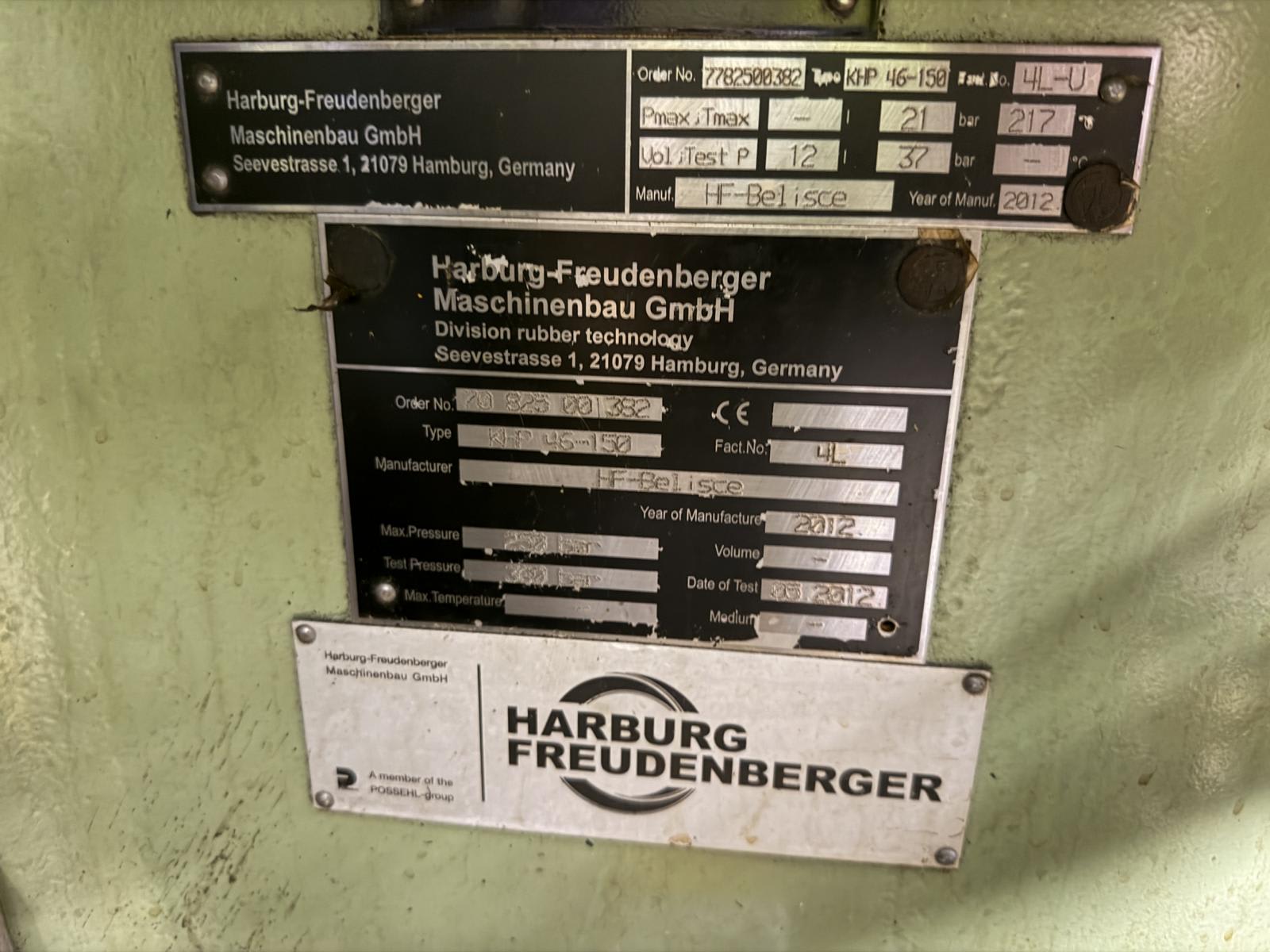

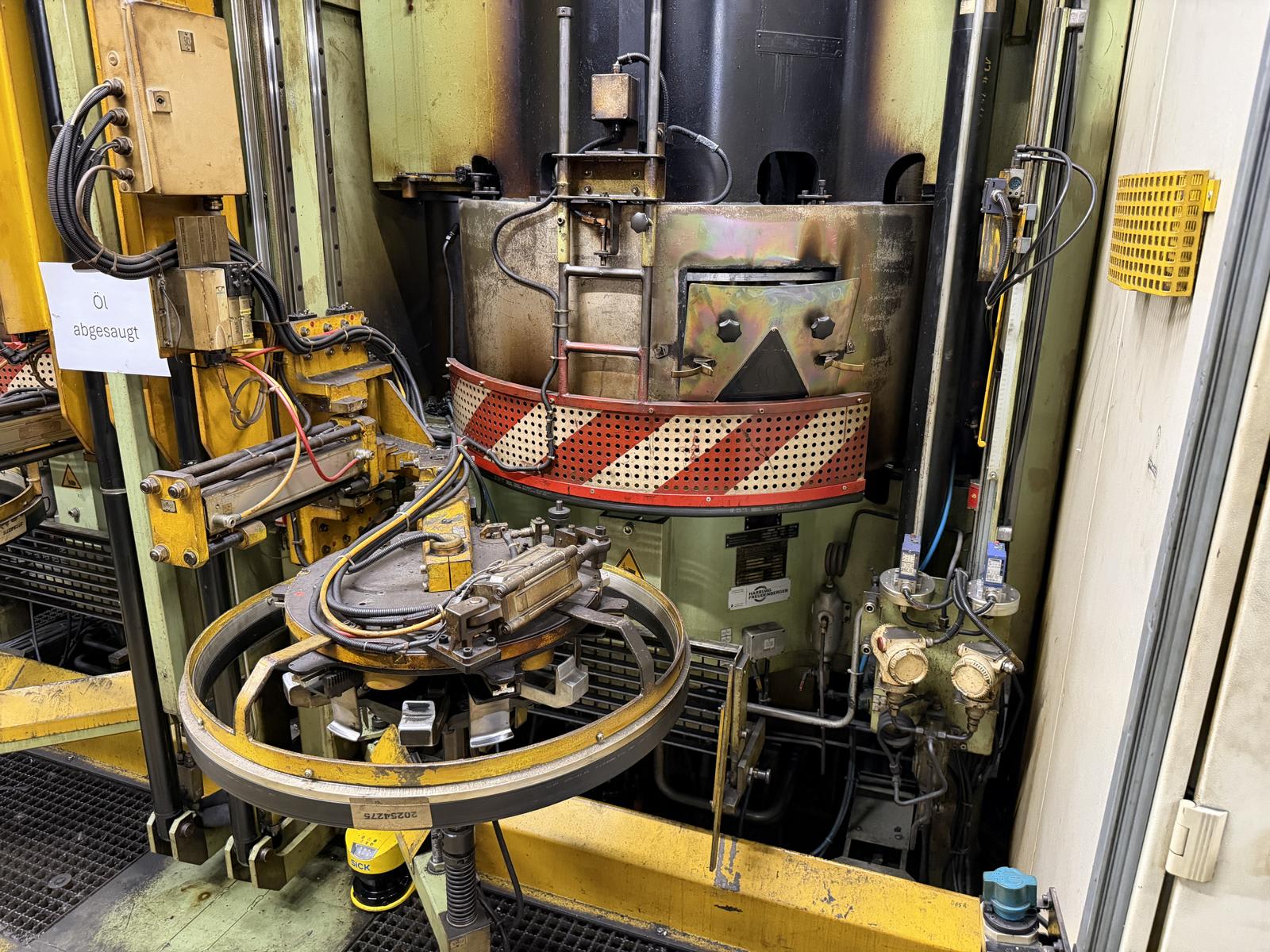

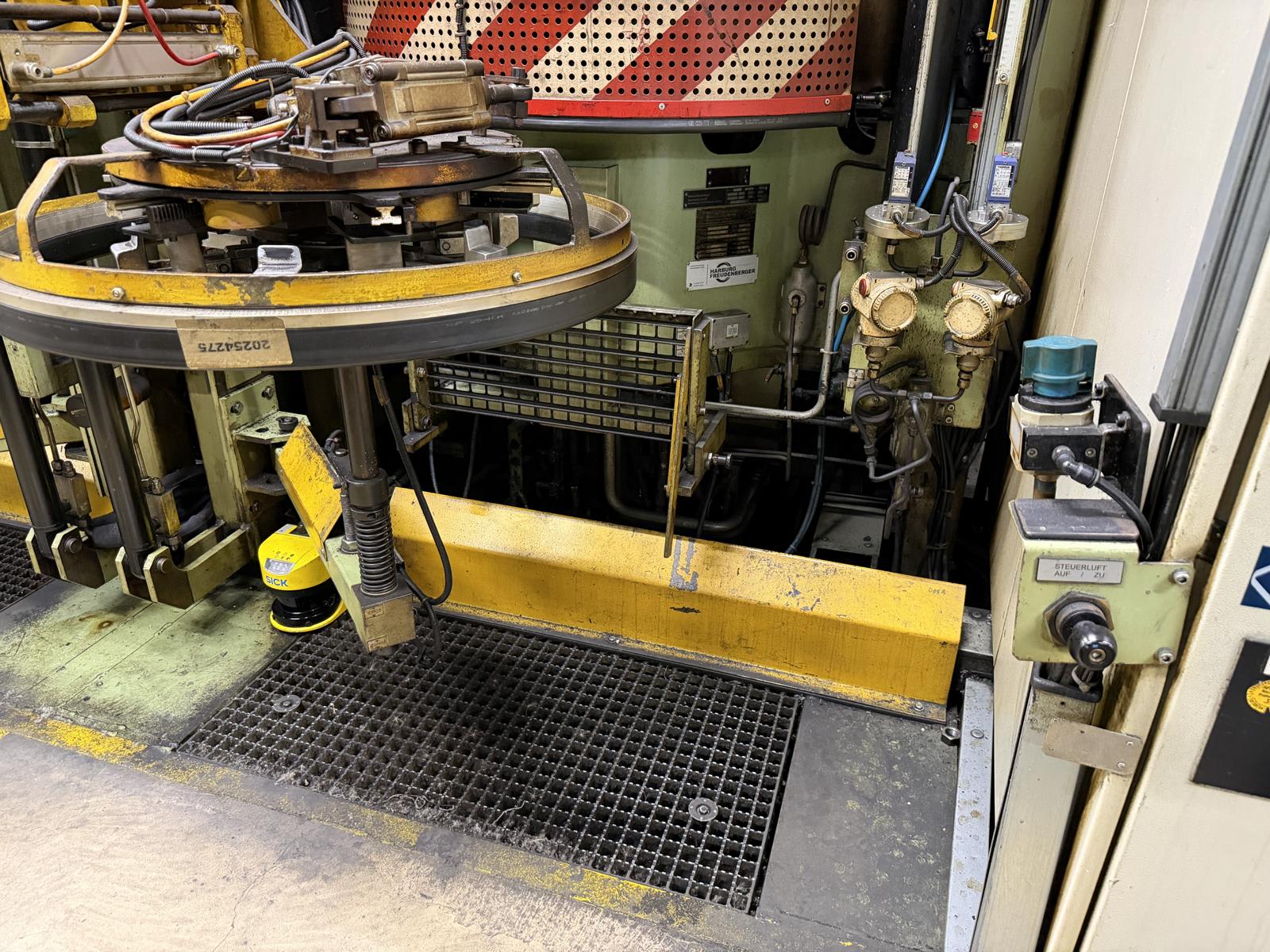

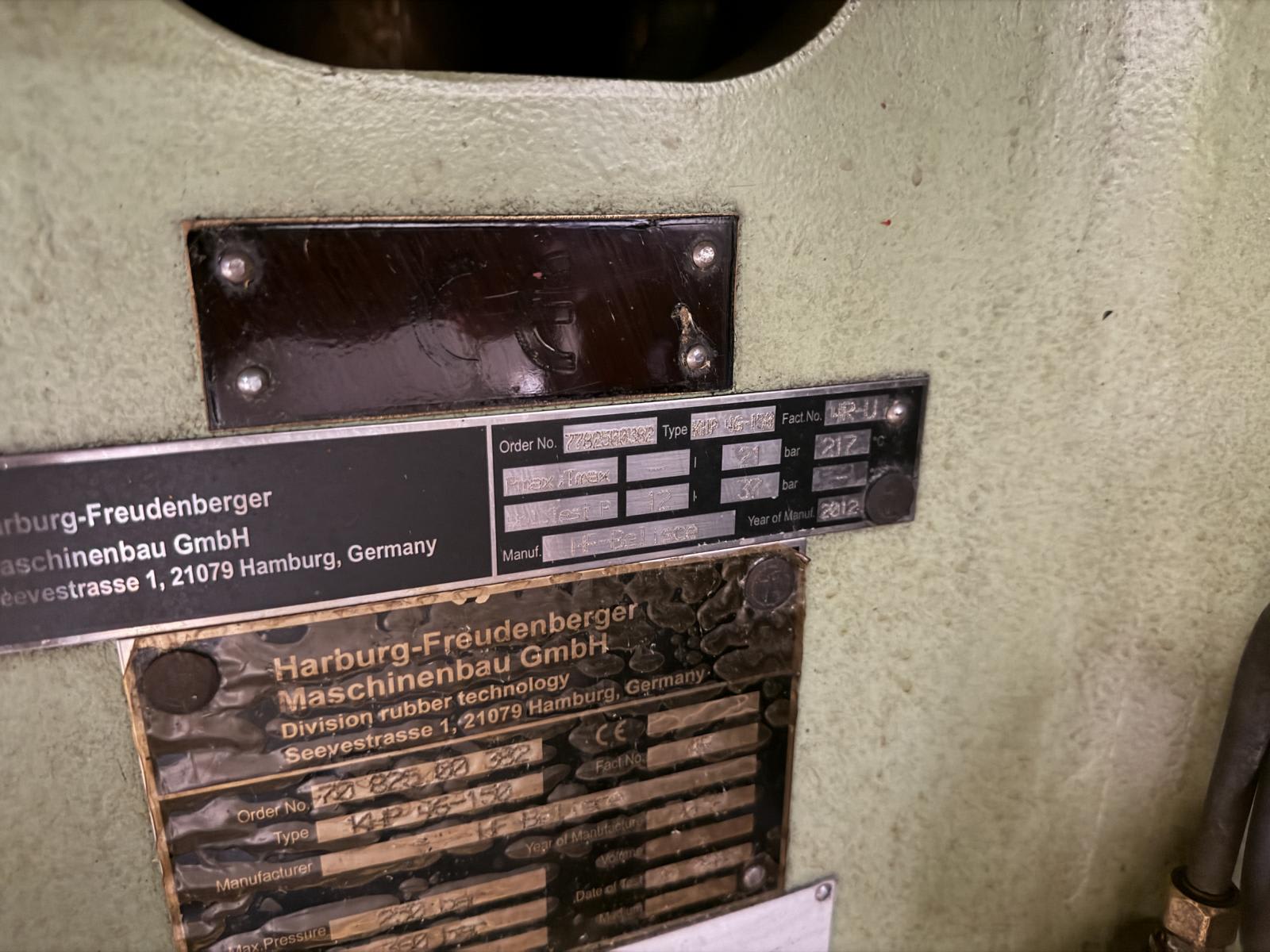

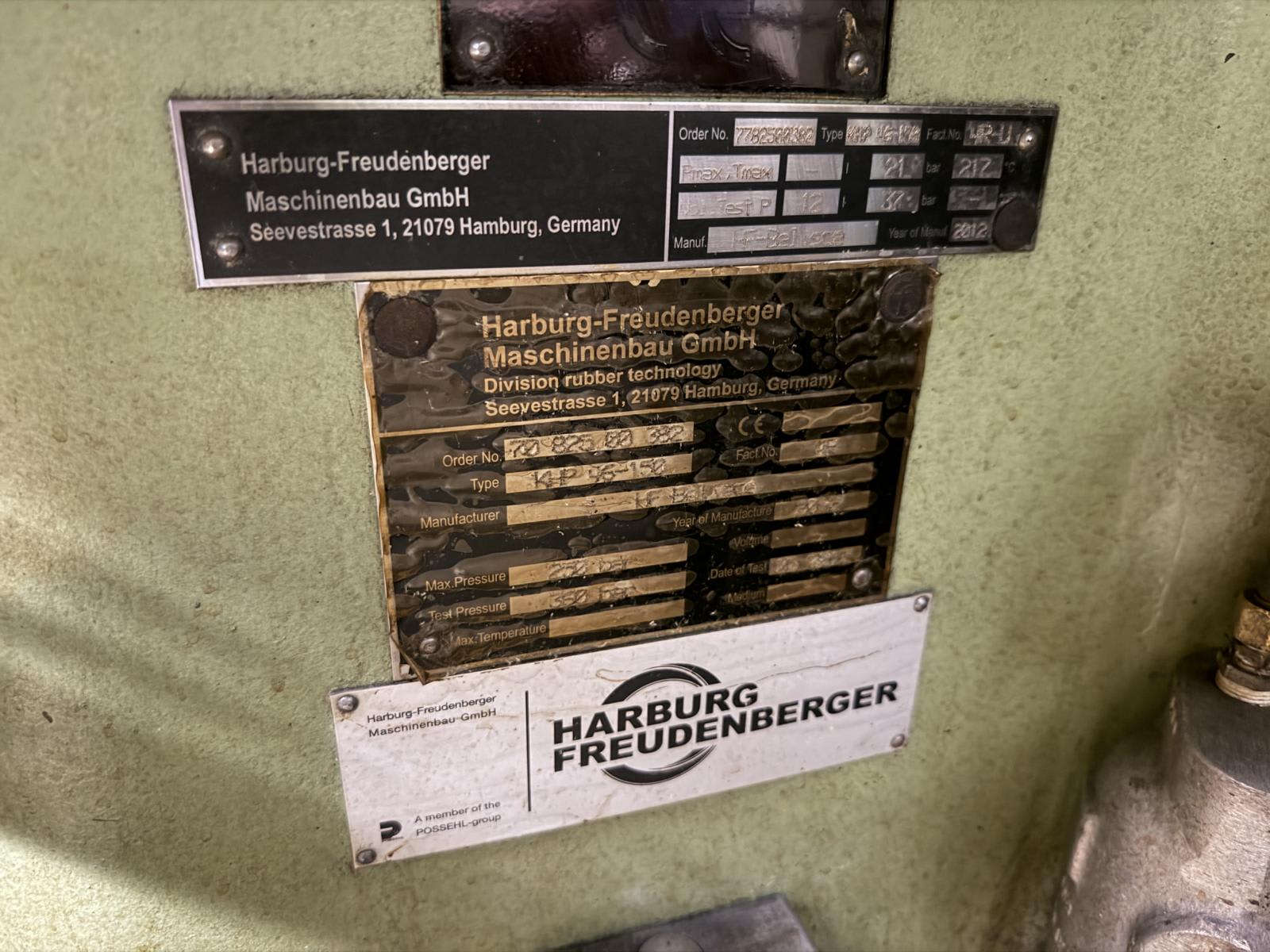

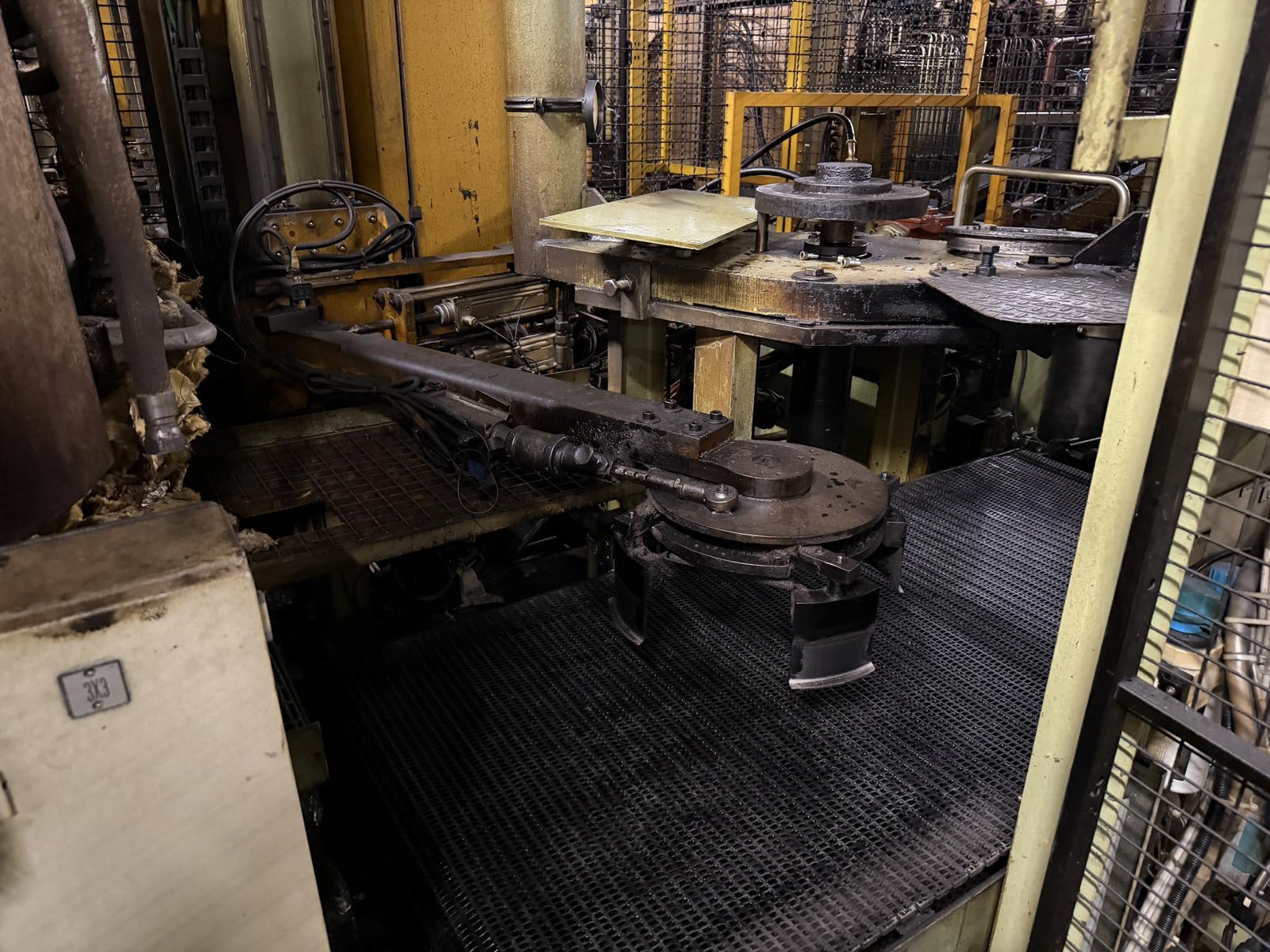

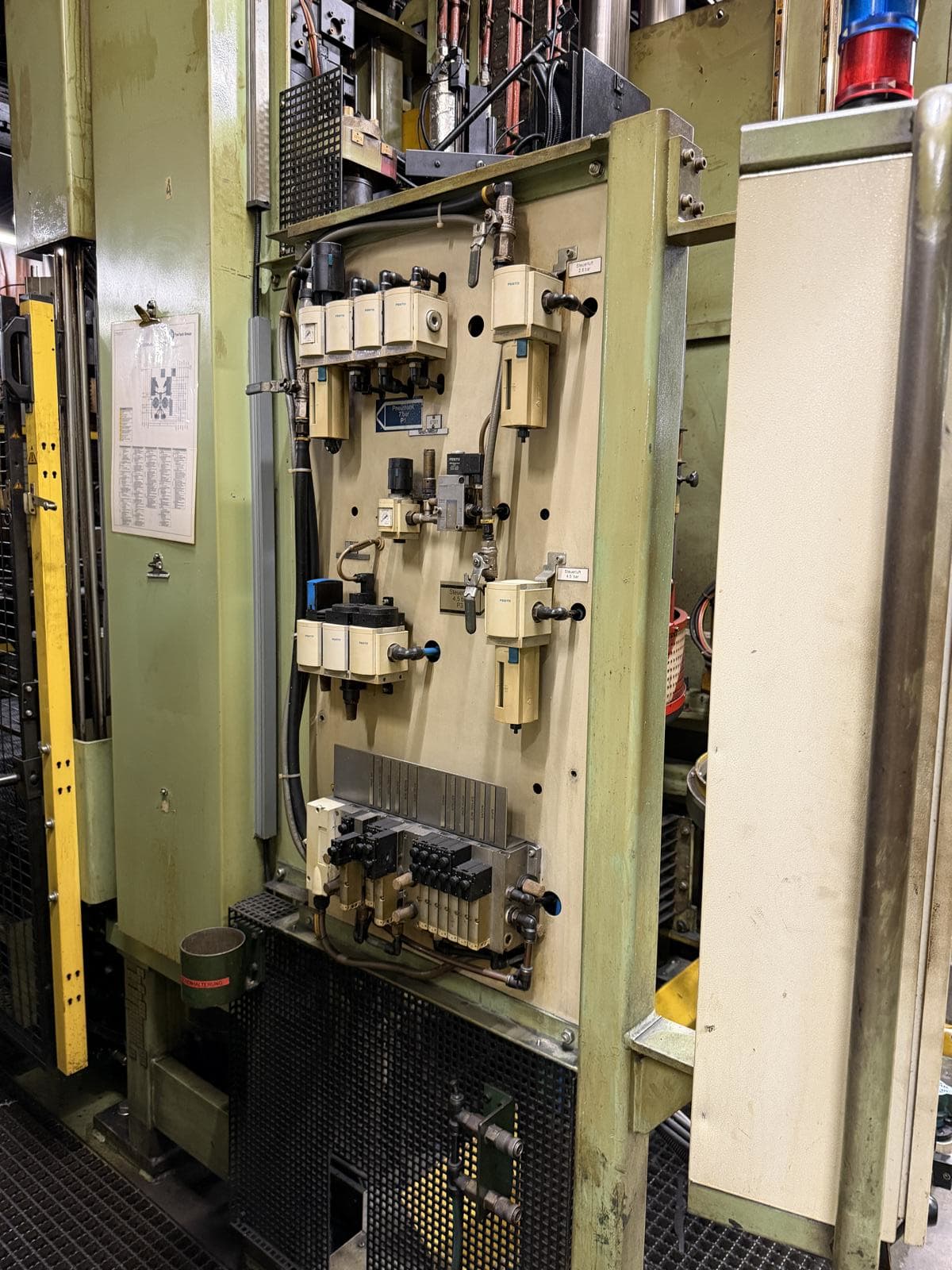

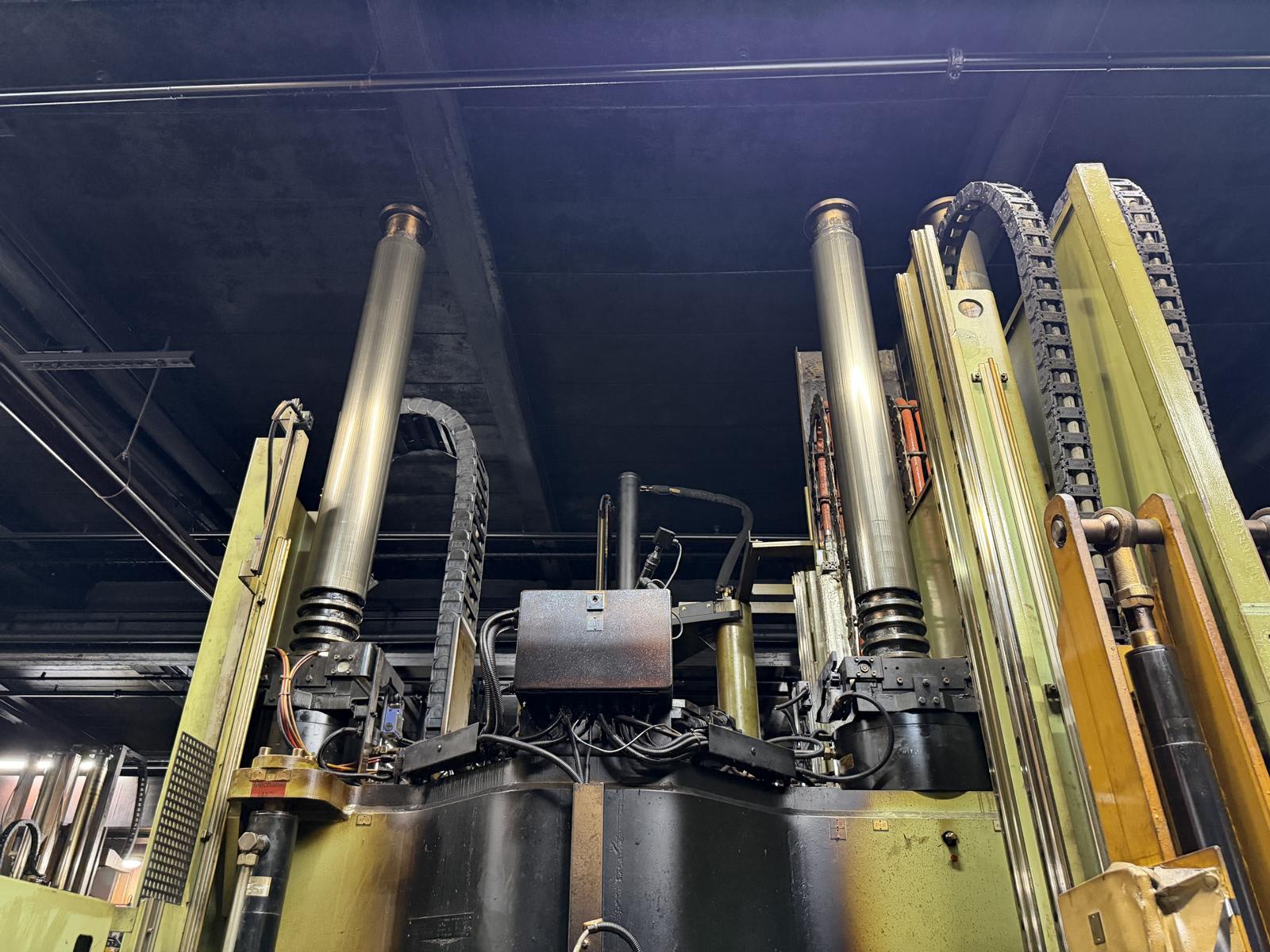

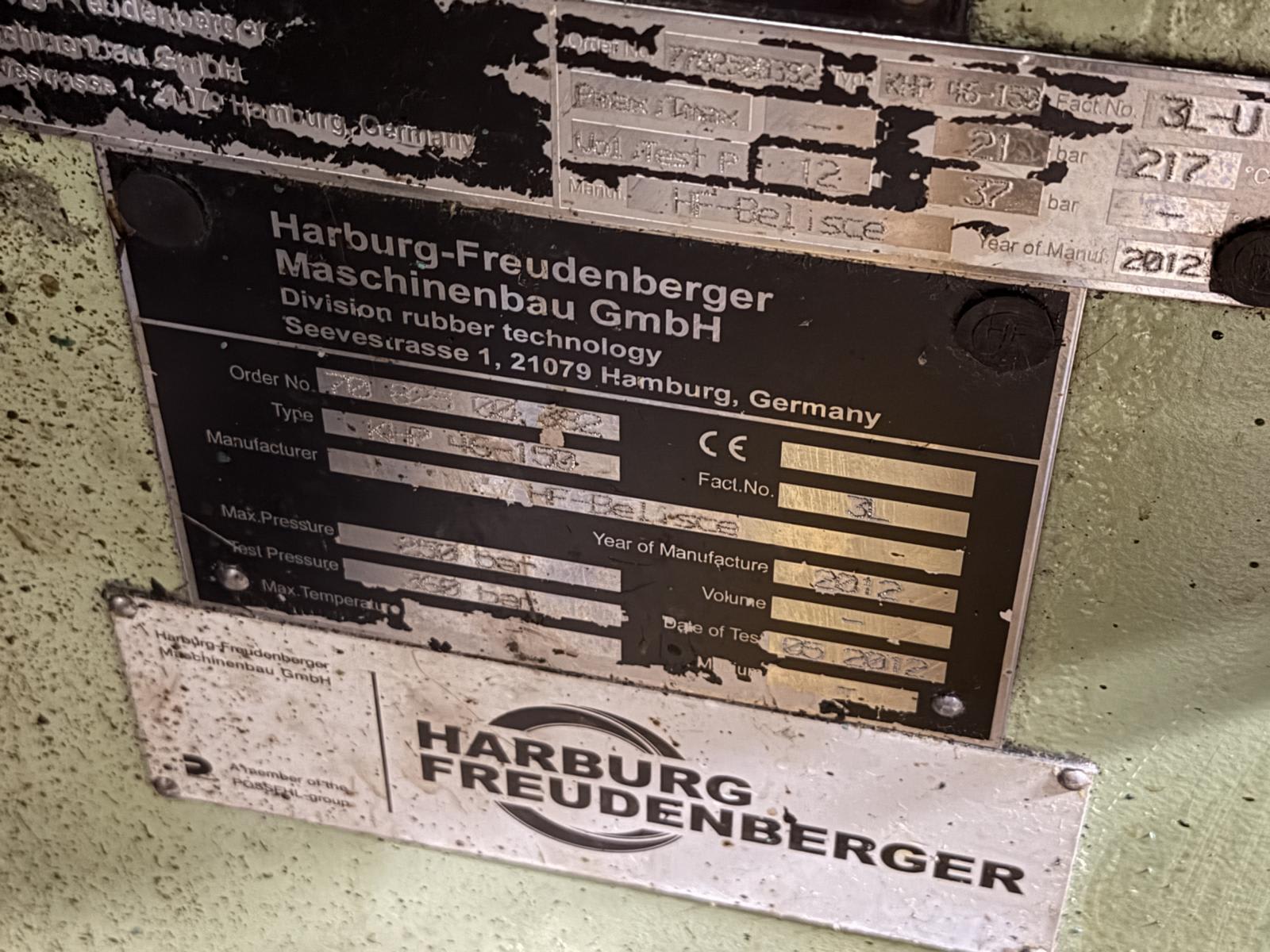

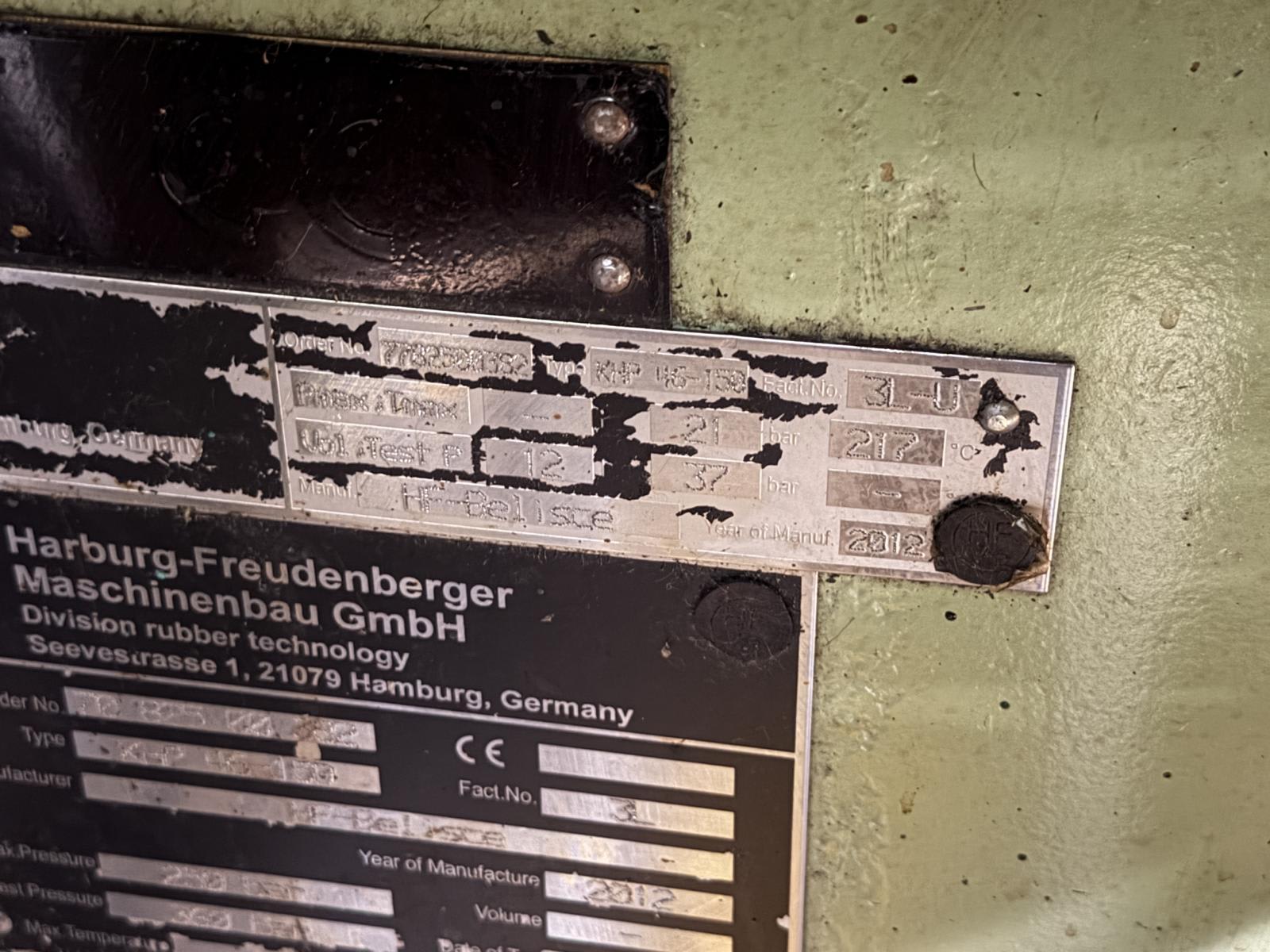

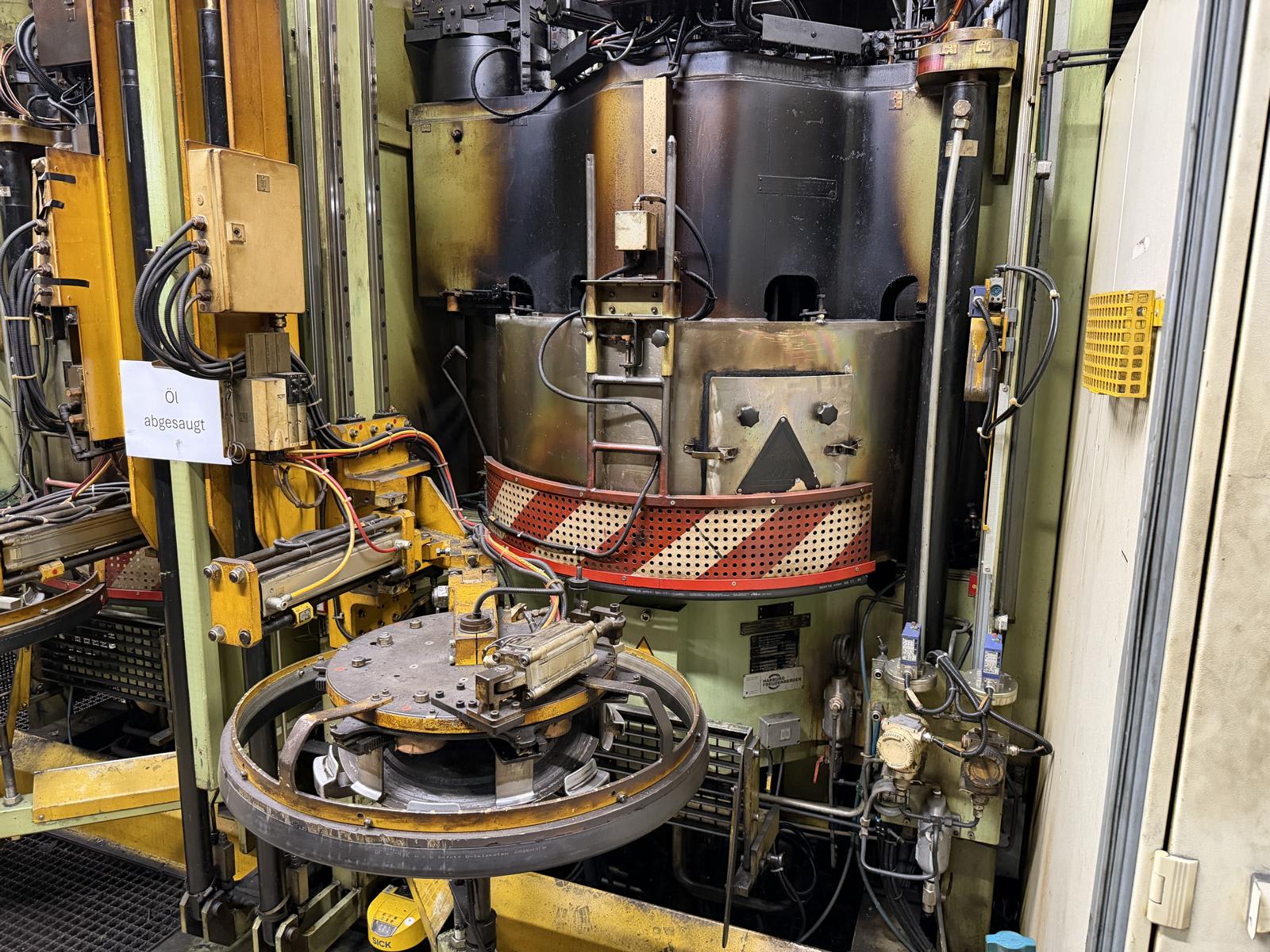

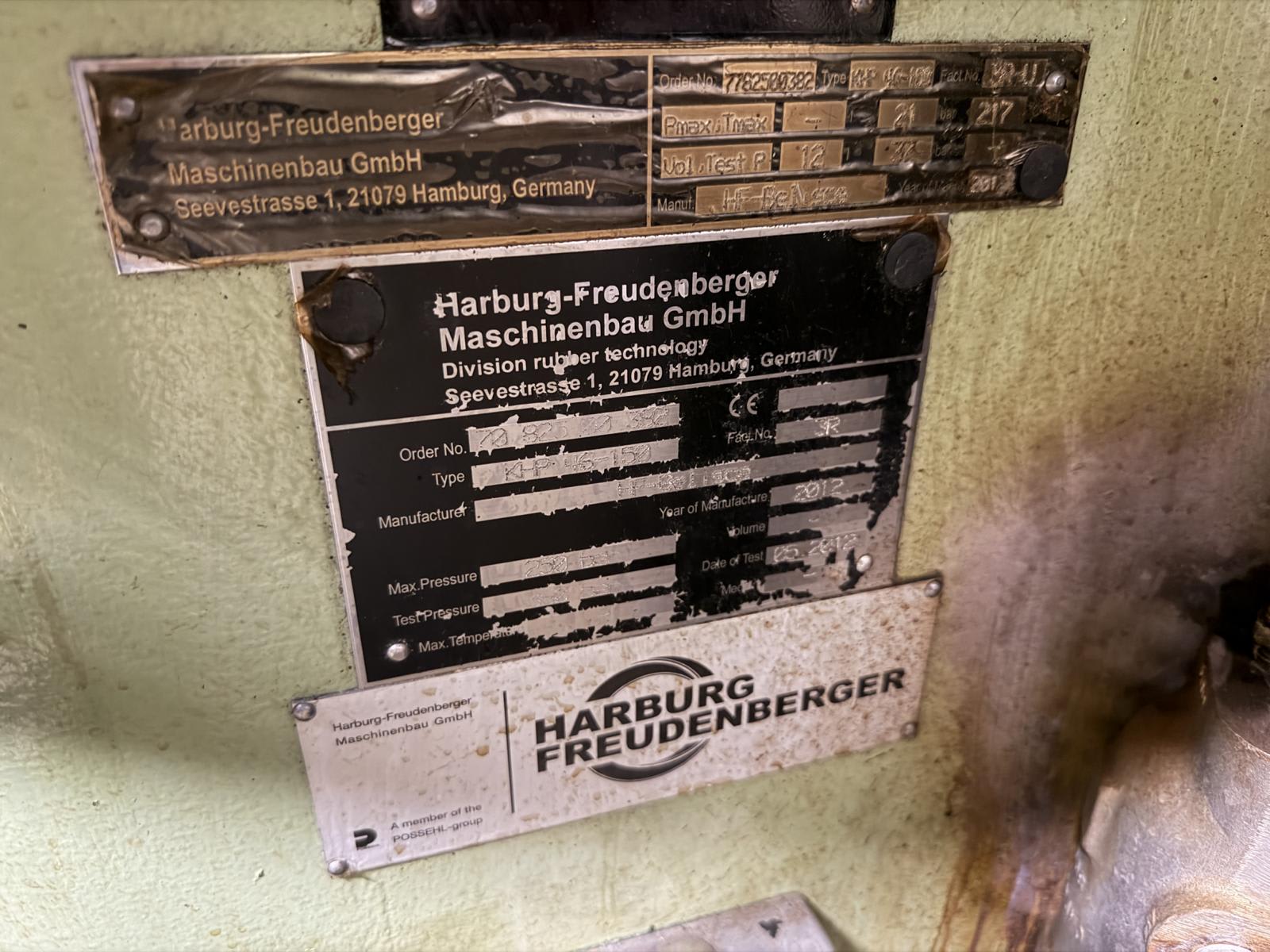

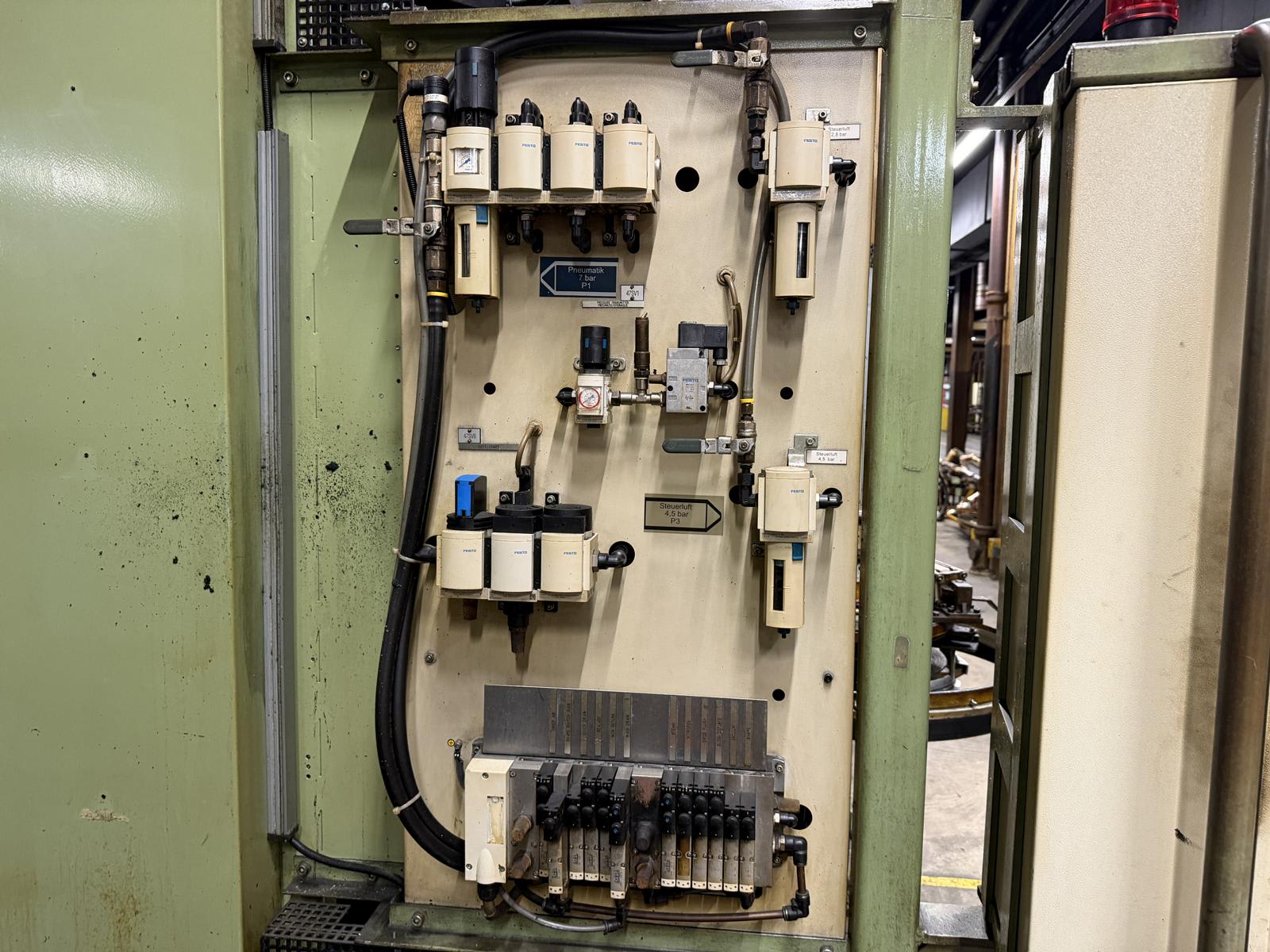

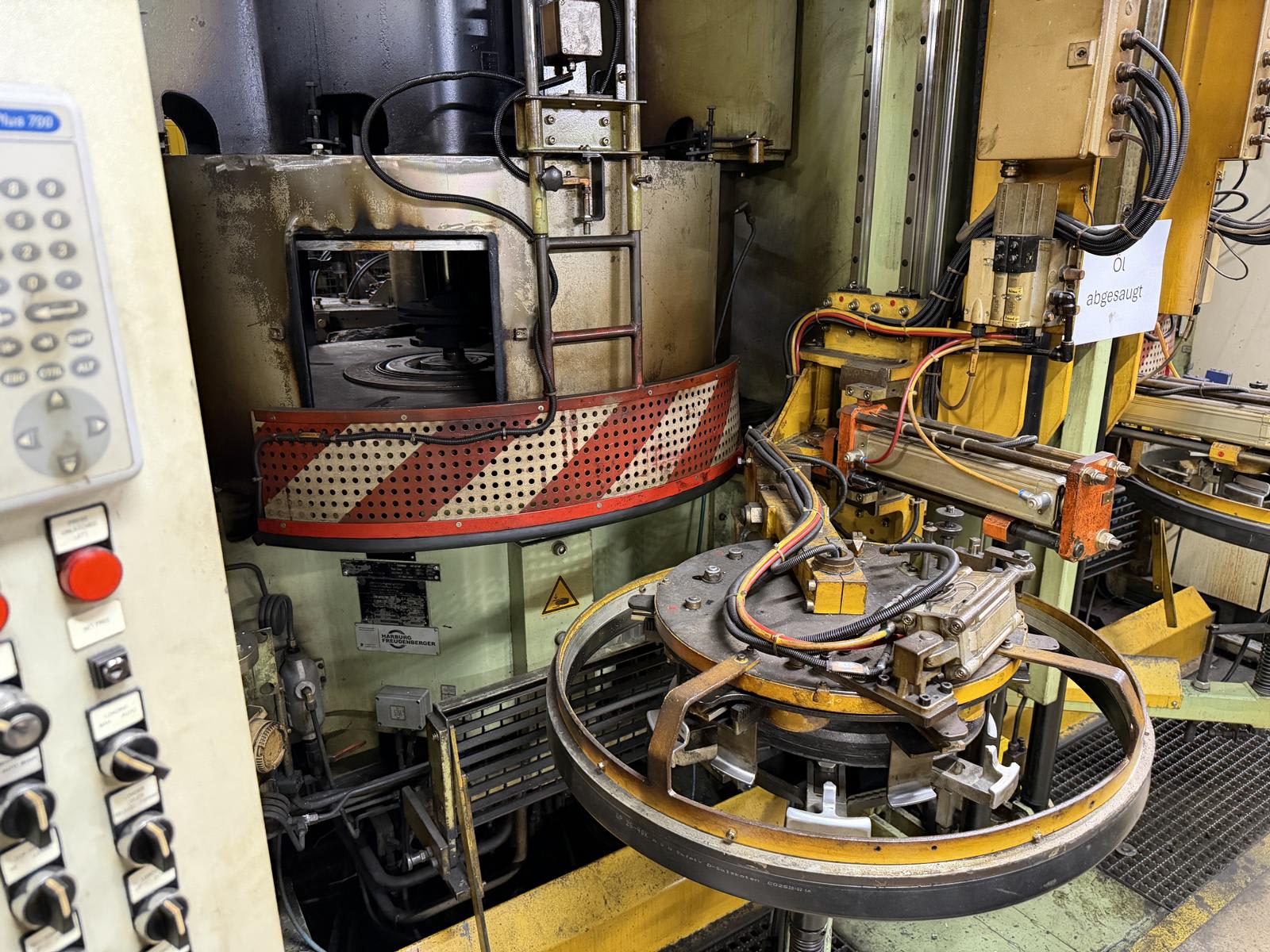

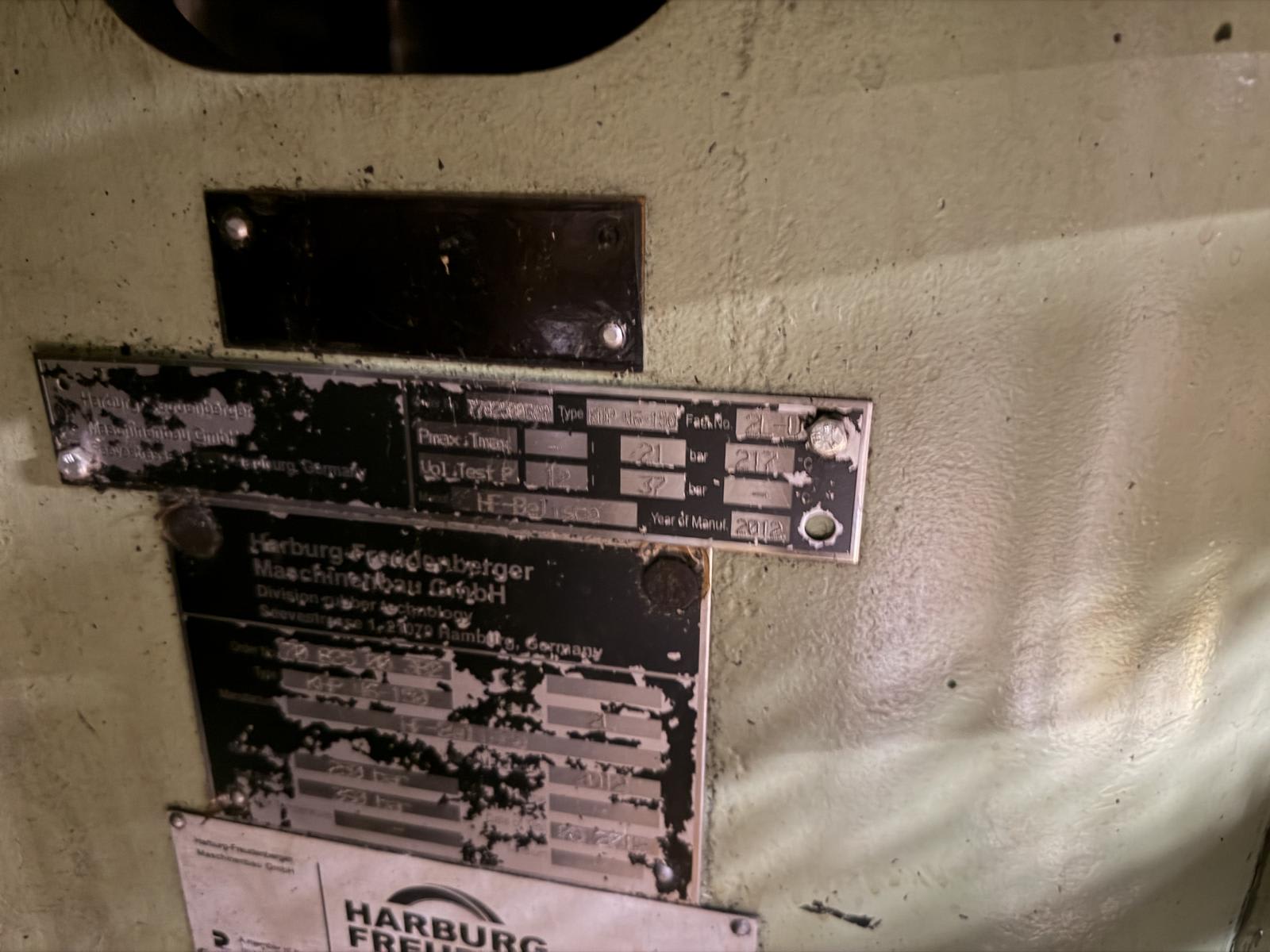

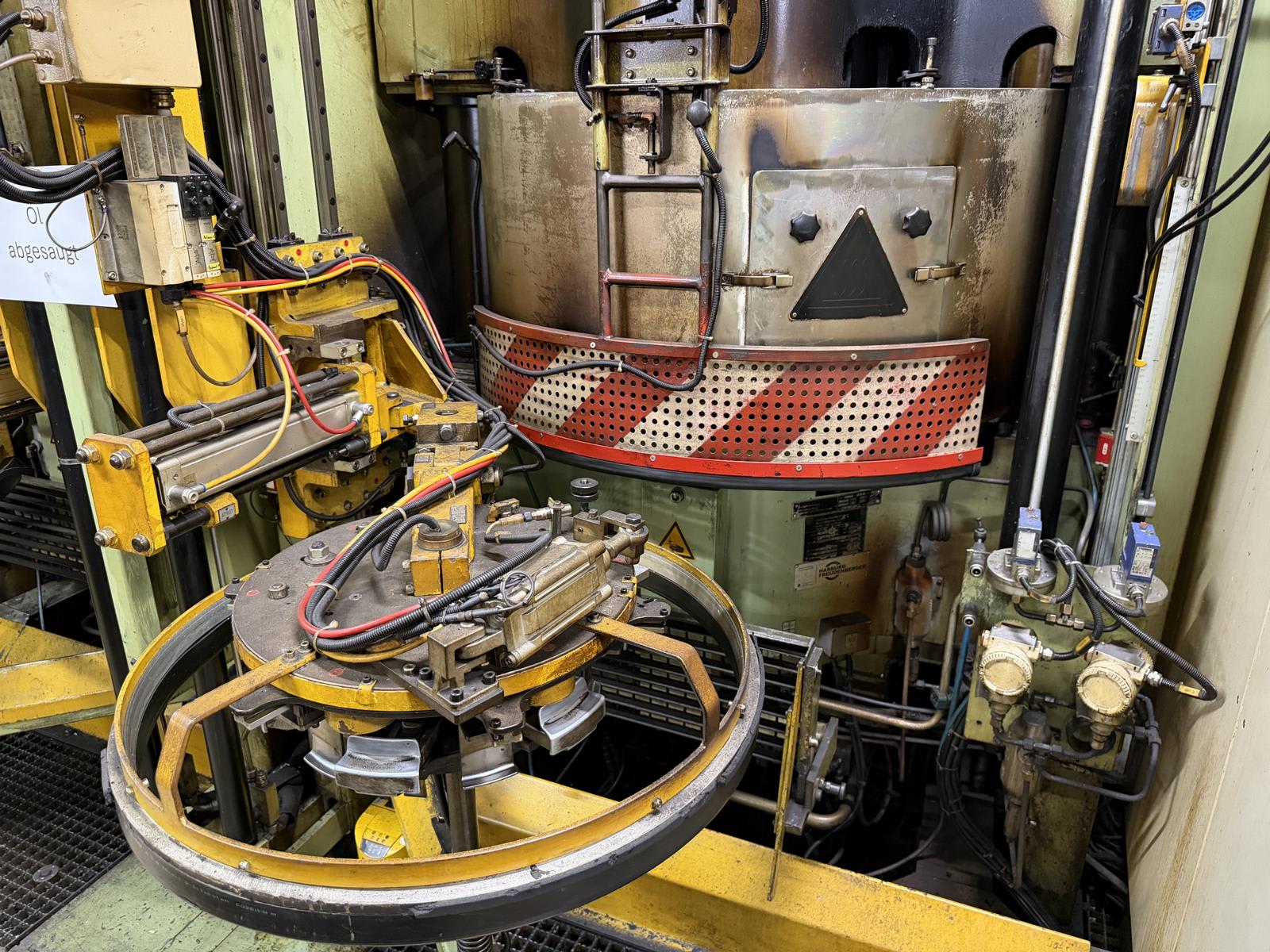

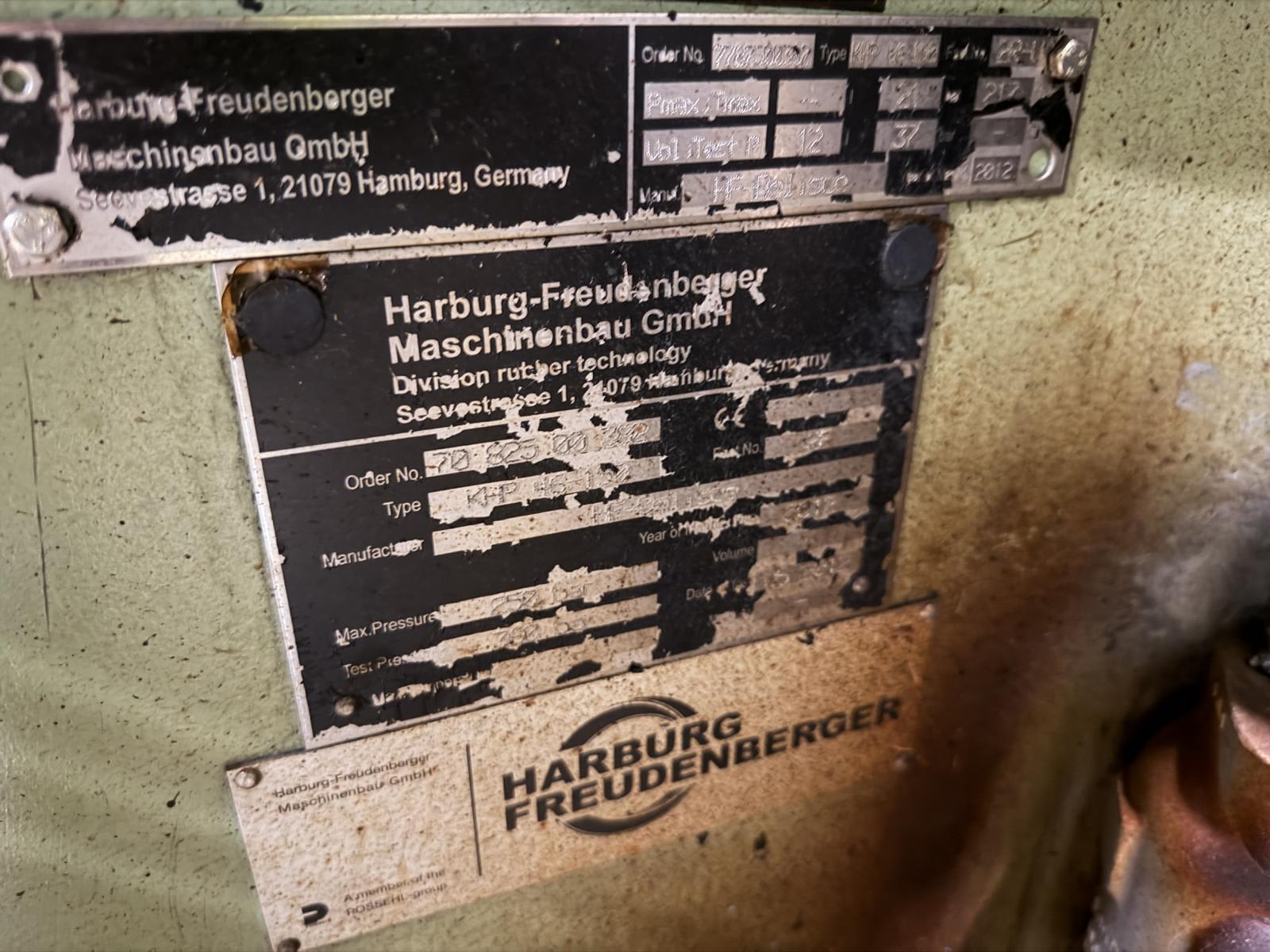

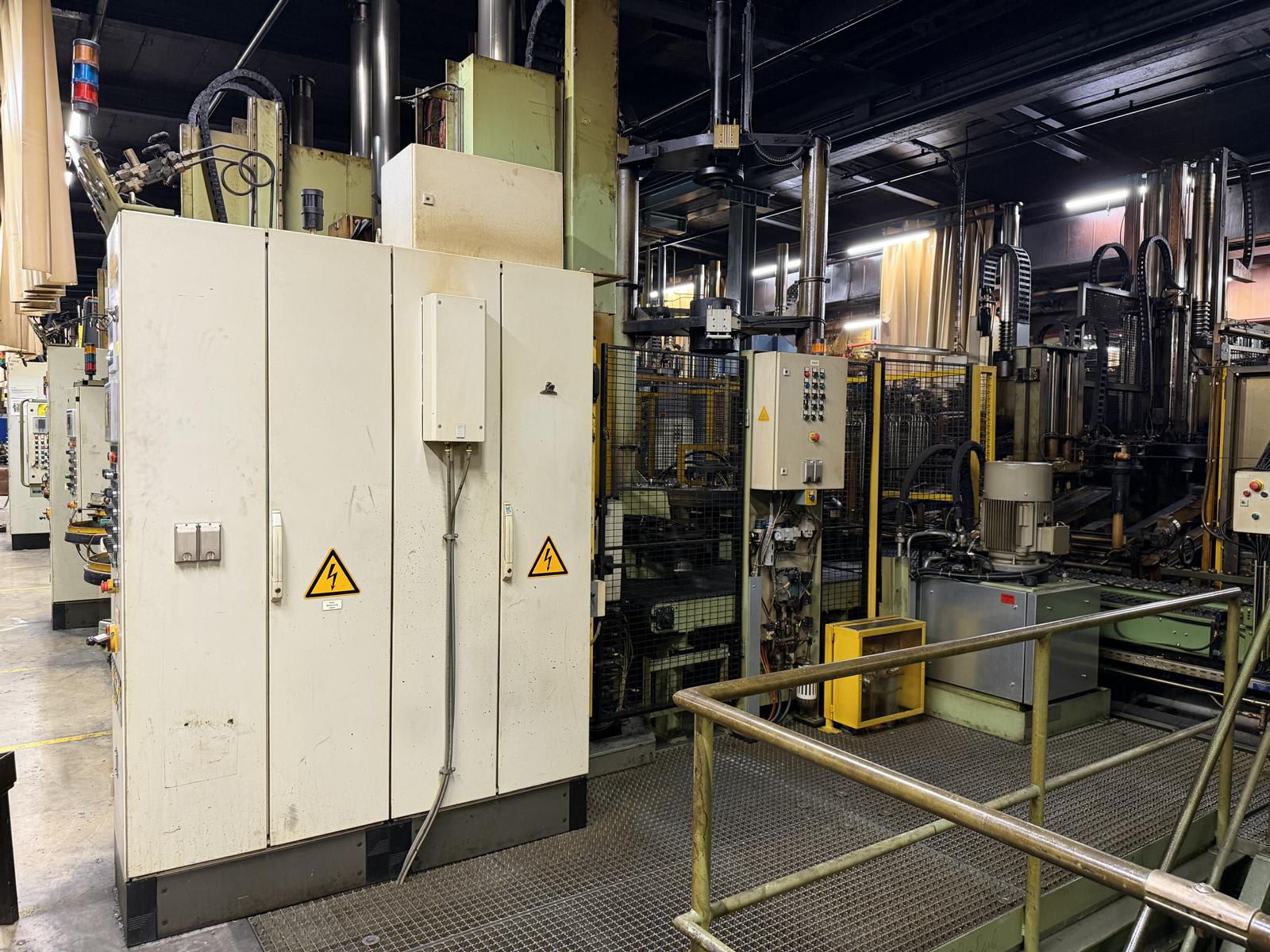

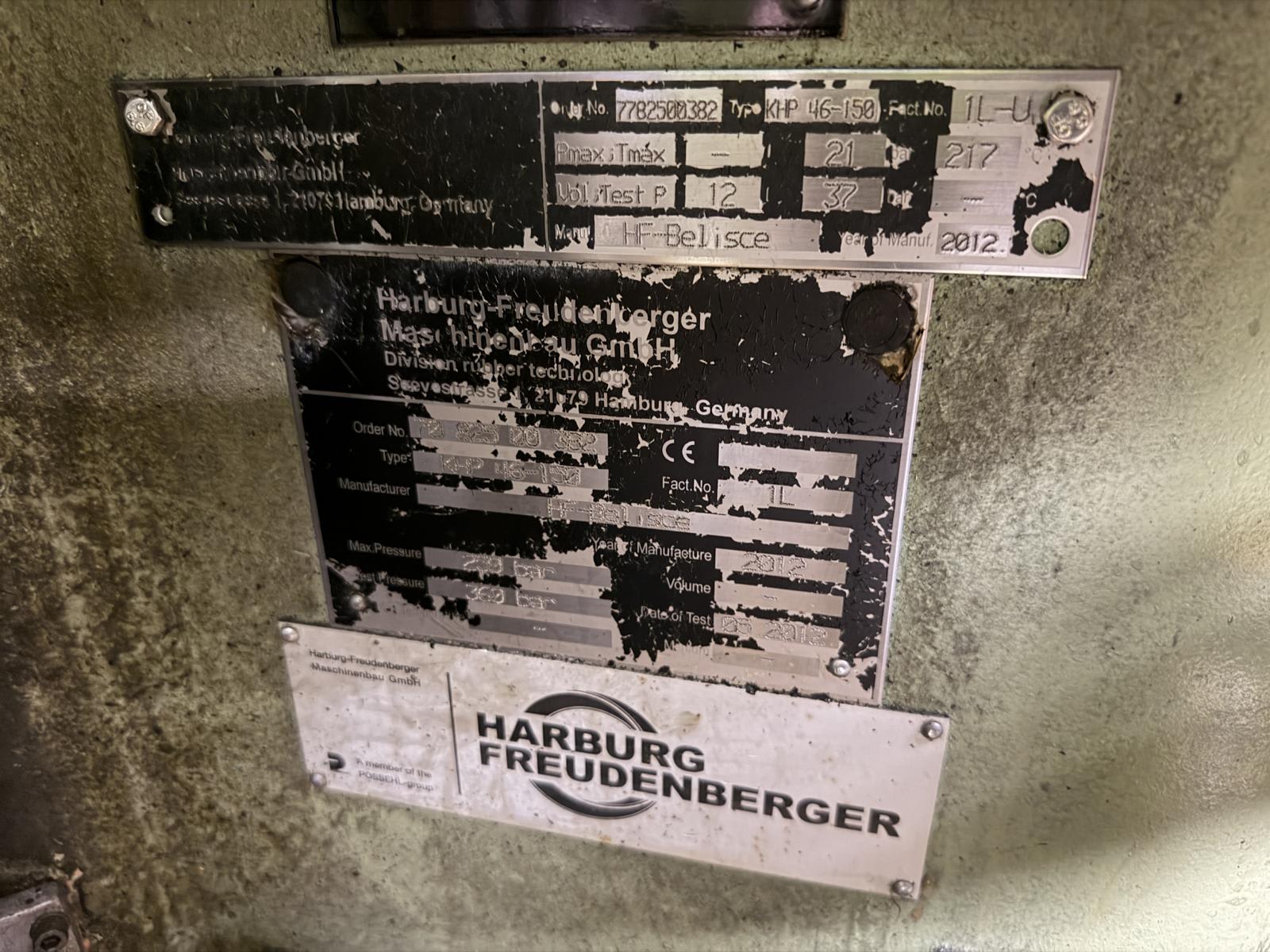

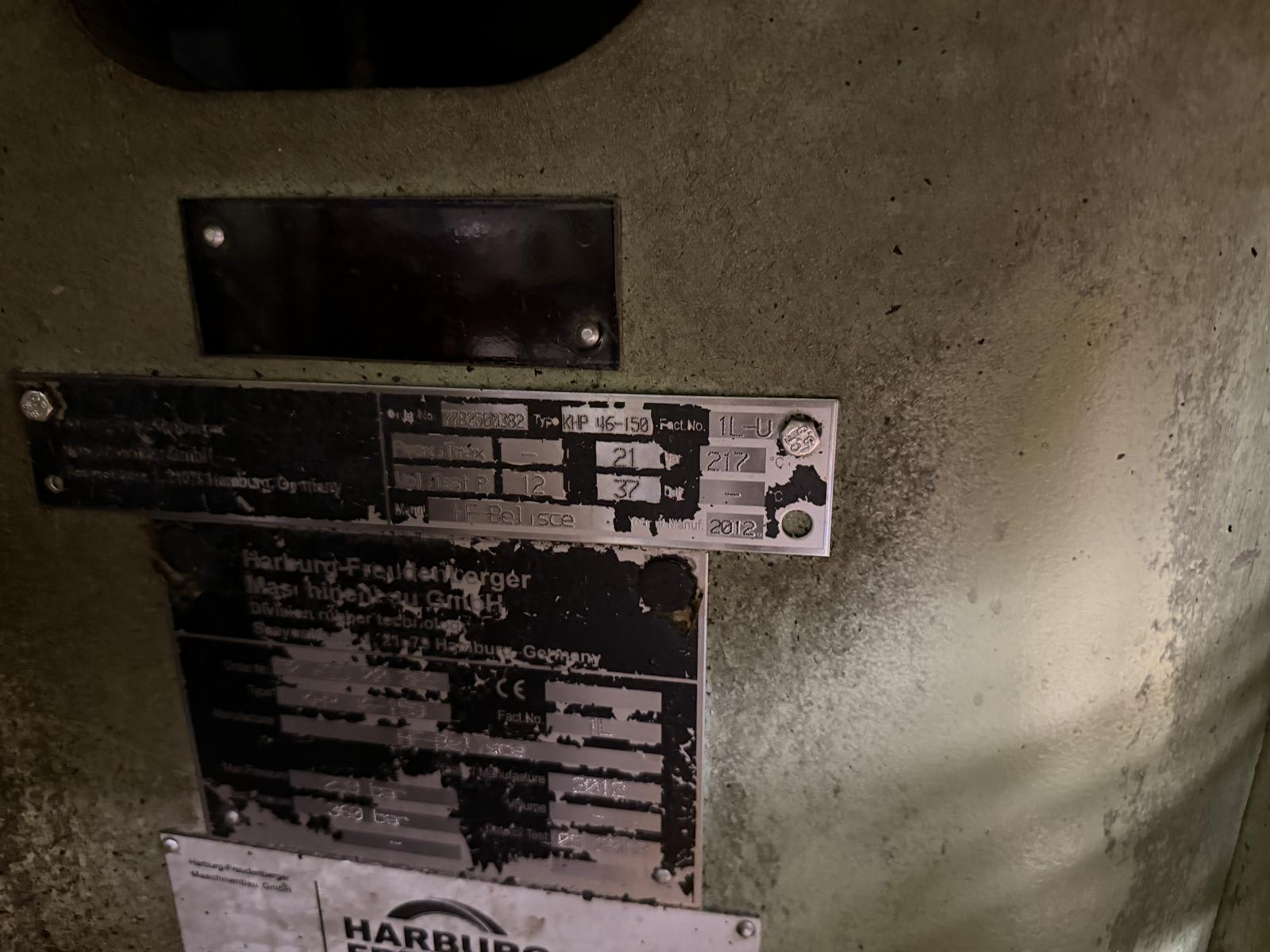

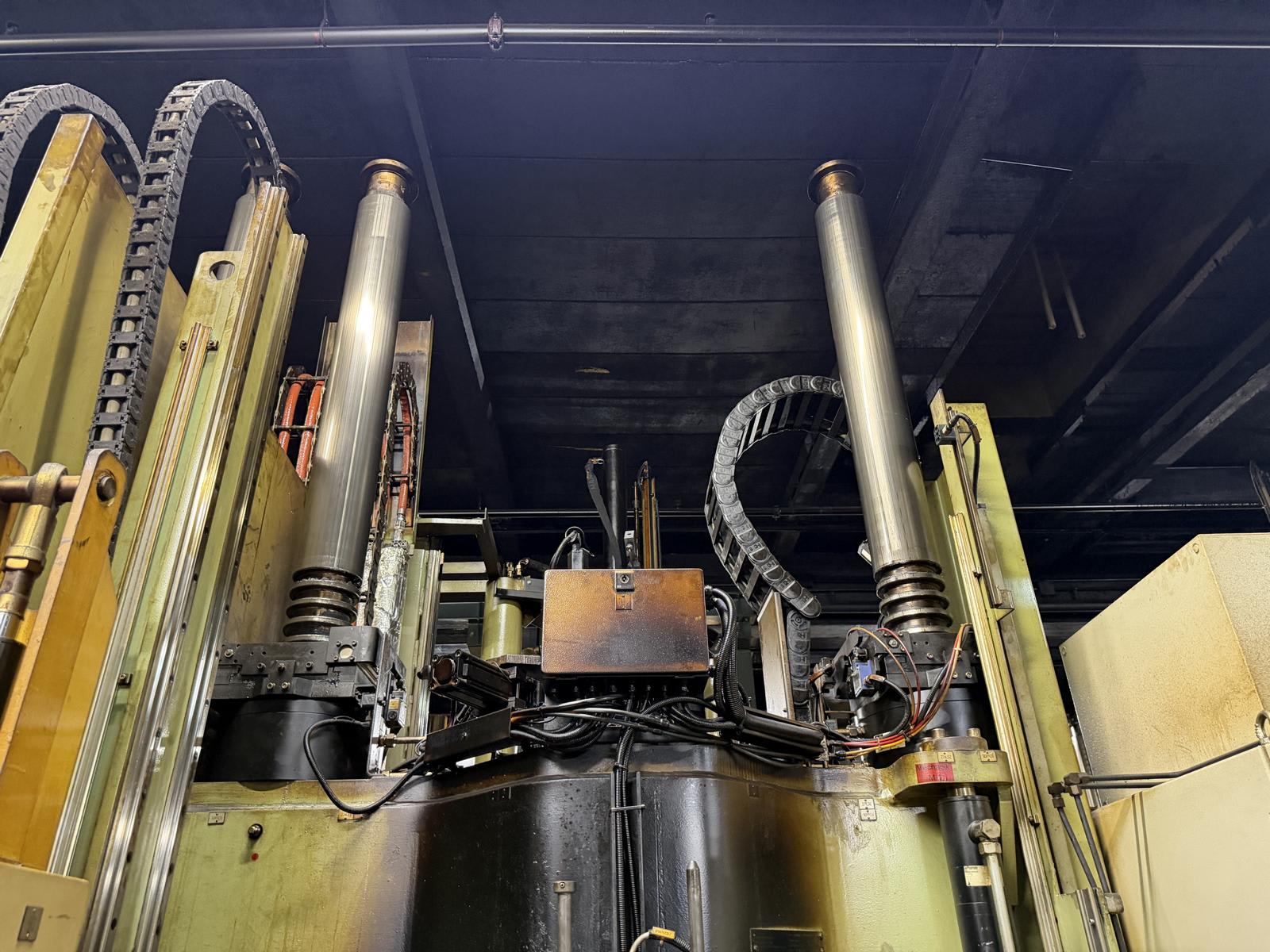

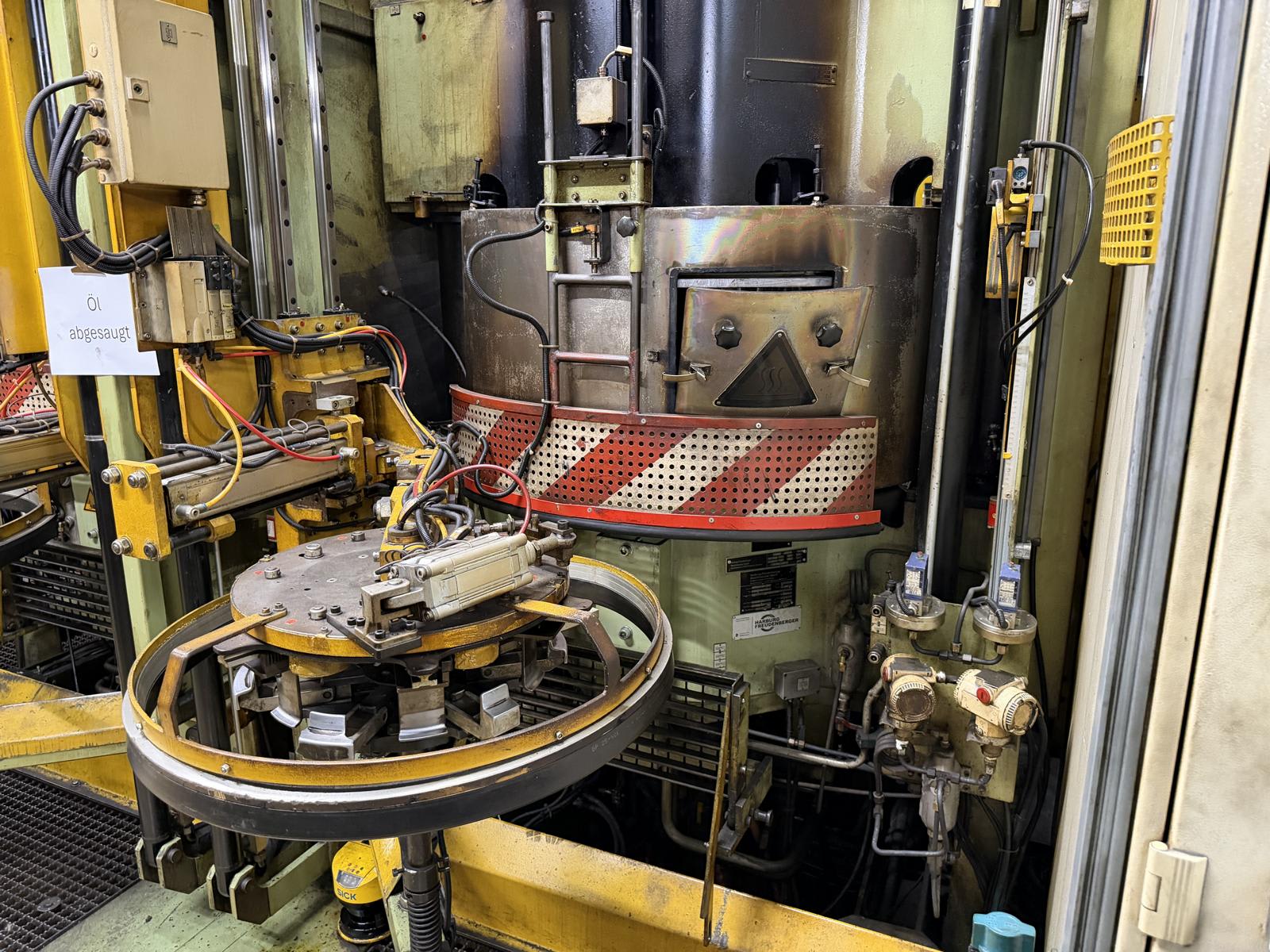

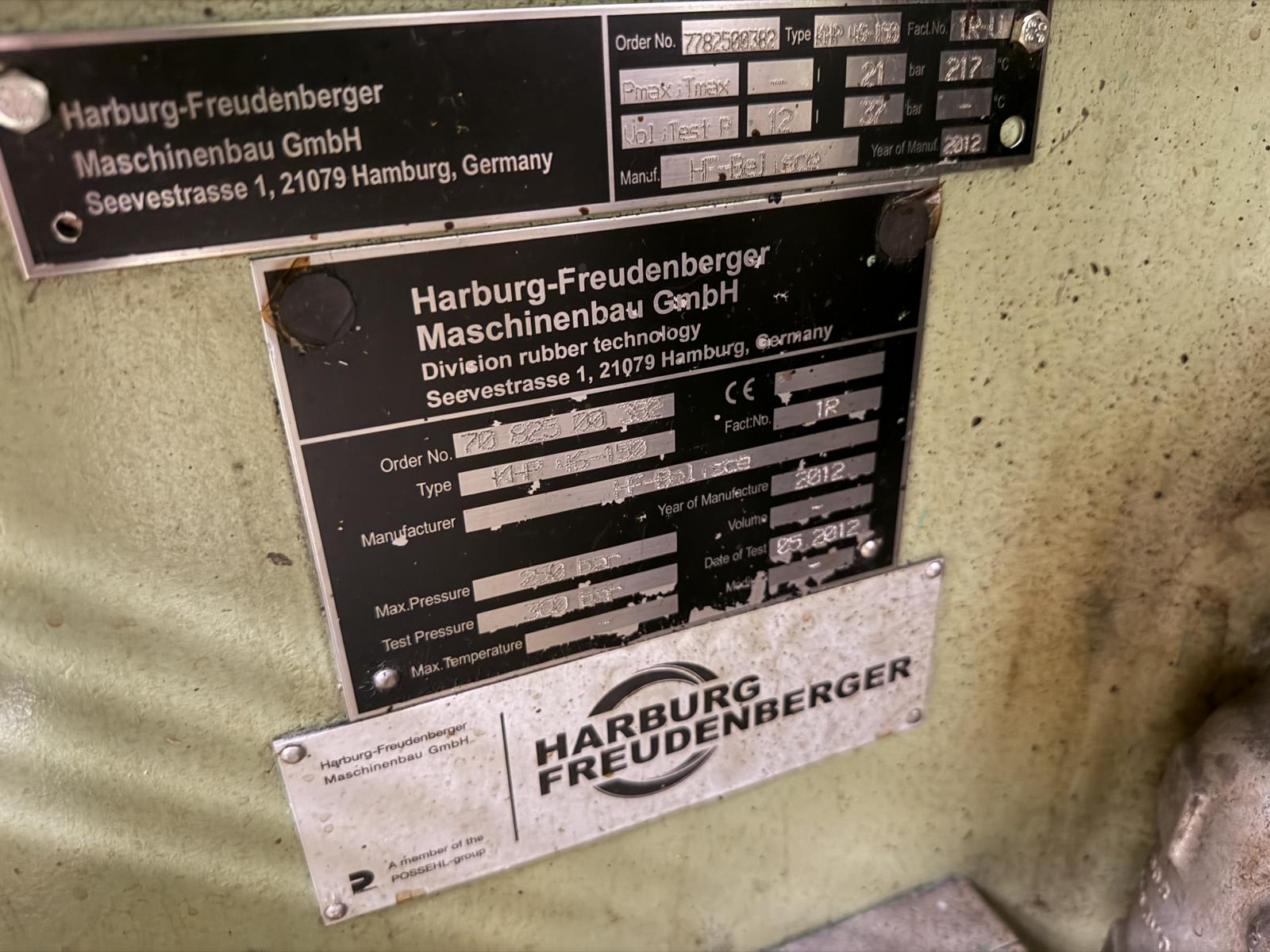

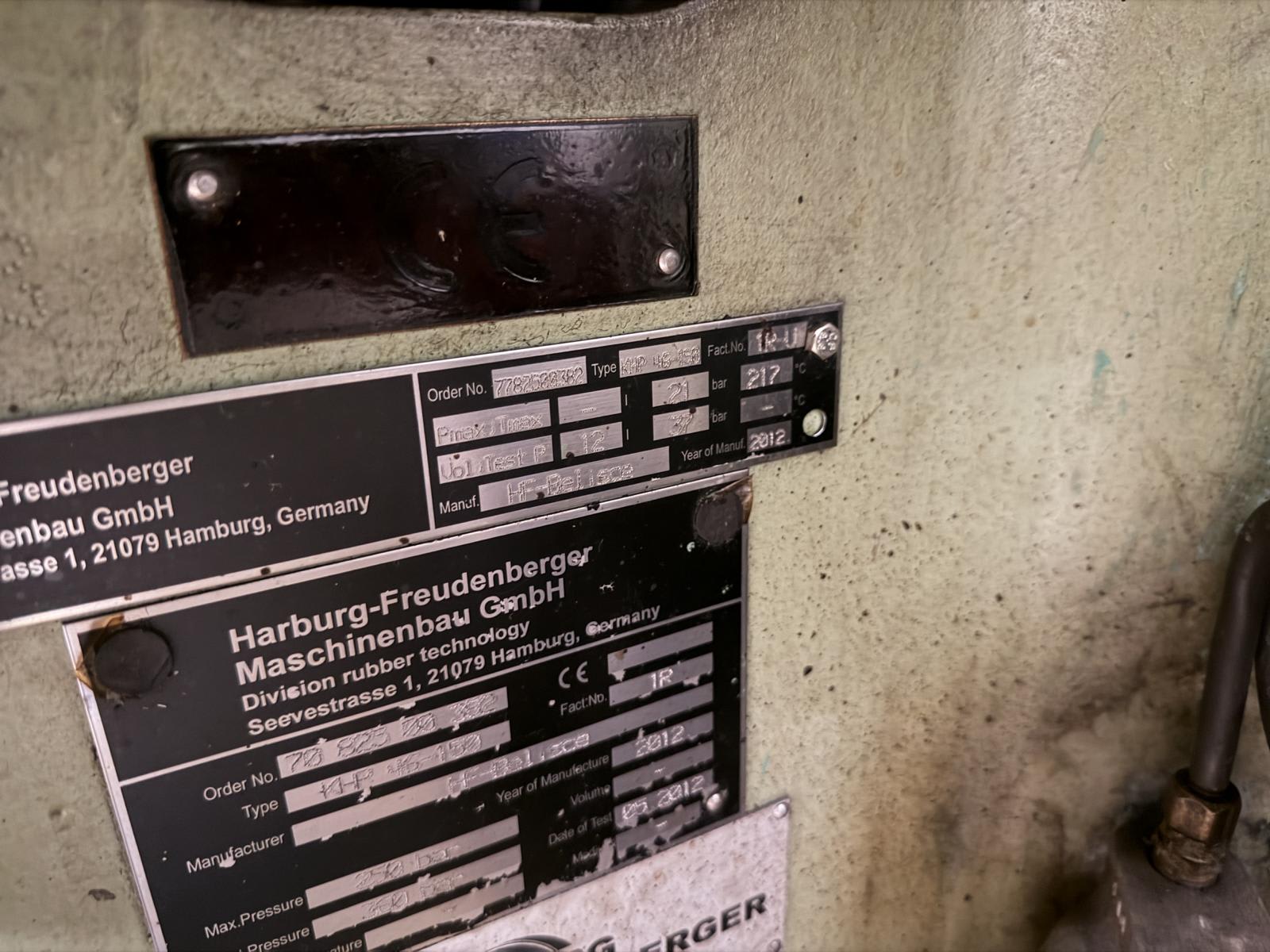

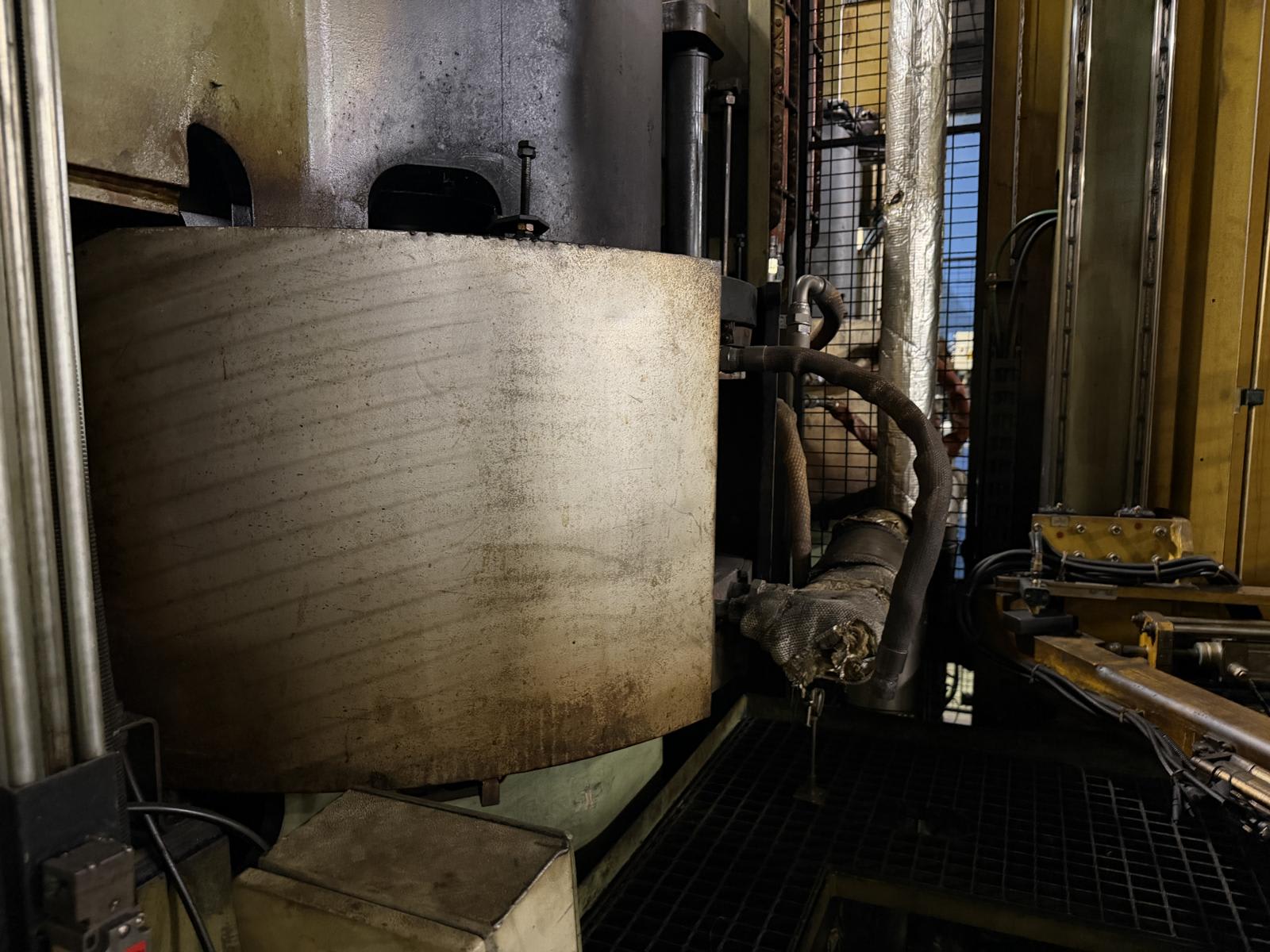

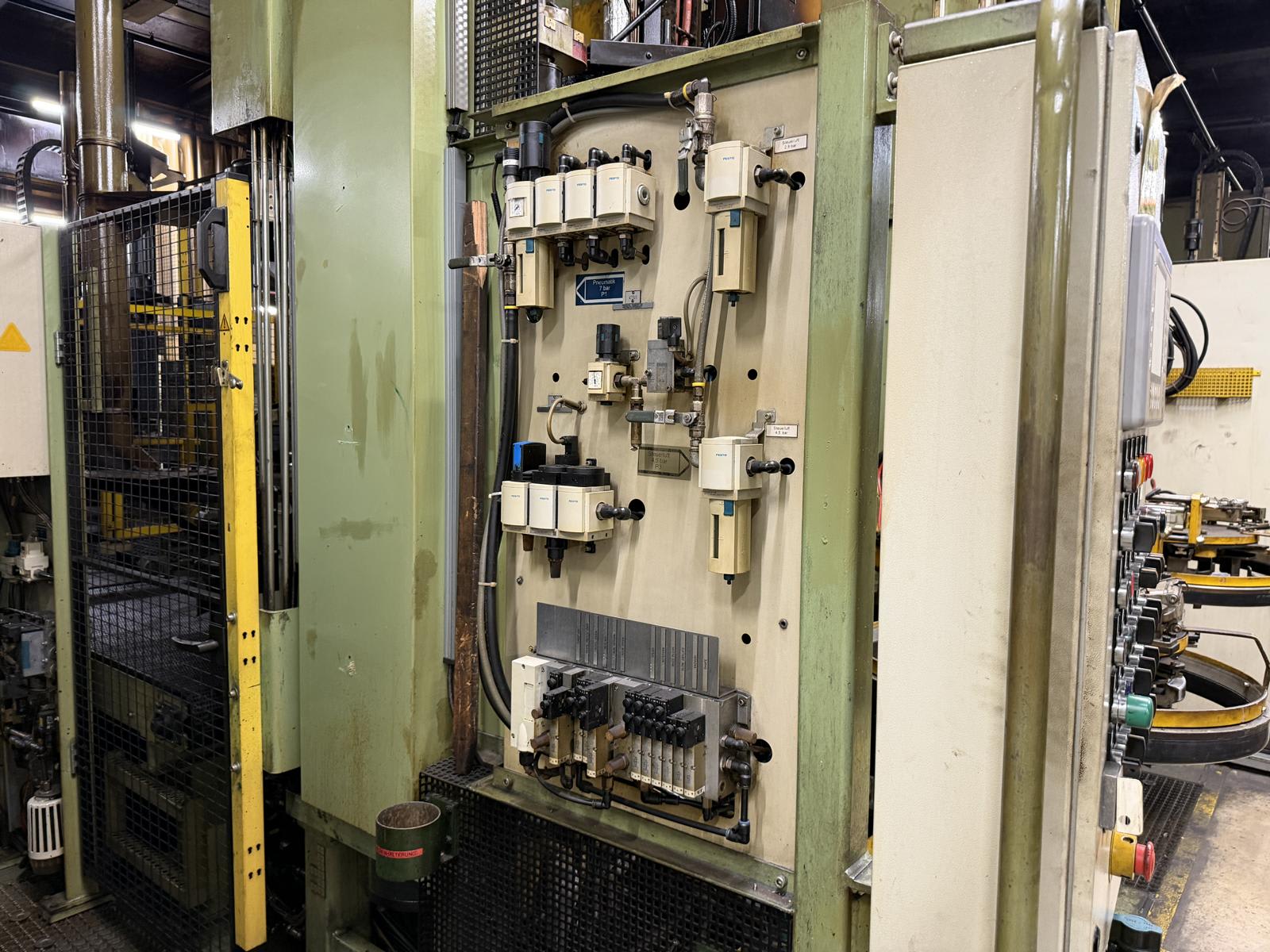

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: Harburg-Freudenberger Maschinenbau GmbH (Division Rubber Technology) Model / Type: KHP 46-150 Year of Manufacture: 2012 Order Number: 70 825 00 382 Station Identification: Left Station Fact No.: 6L Right Station Fact No.: 6R Asset Number: "D03" Control Interface: Allen-Bradley PanelView Plus 700 with integrated push-button module Technical Data / Specifications Configuration: Vertical twin-cavity curing press Pressure Ratings: Max. Pressure: 250 bar Test Pressure: 360 bar Electrical Cabinet: Identification: Cabinet D03 Inventory Label: "4023489" / "91" Hydraulic System: Unit Manufacturer: Parker / Harburg-Freudenberger Tank Manufacture: HF-Belisce (Date of Test: 06.2012) Motor: Electric drive motor mounted vertically on tank Loading Mechanism: Automatic green tire loading arms with expanding chucks - LISTING 2760091

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2012

Binding Handling & Service Fee:

19700 € (EURO)

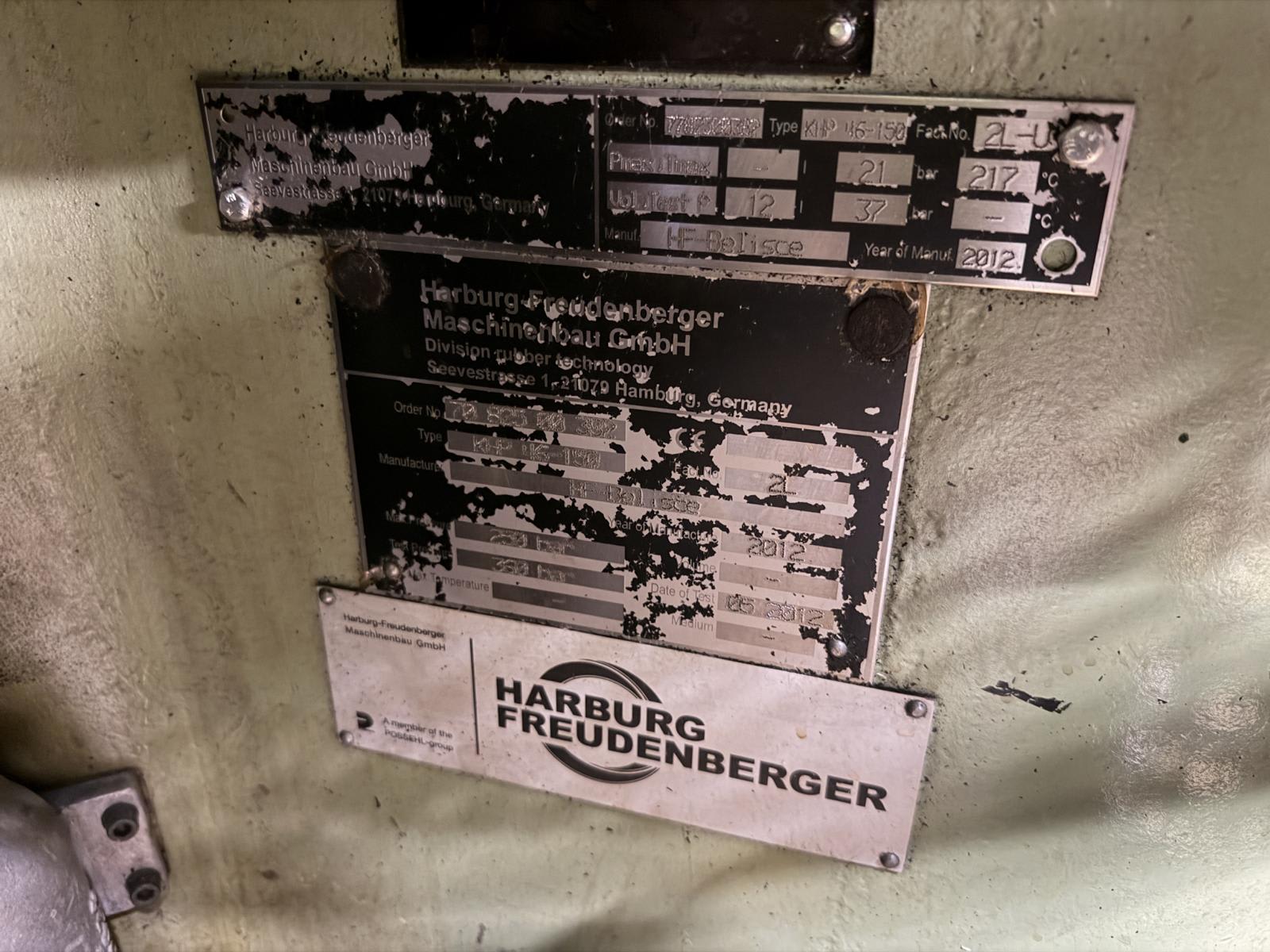

General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: Harburg-Freudenberger Maschinenbau GmbH (Division Rubber Technology) Model / Type: KHP 46-150 Year of Manufacture: 2012 Order Number: 70 825 00 382 Station Identification: Left Station Fact No.: 5L Right Station Fact No.: 5R Asset Number: "D04" Control Interface: Allen-Bradley PanelView Plus 700 Technical Data / Specifications Configuration: Vertical twin-cavity curing press Pressure Ratings: Max. Pressure: 250 bar Test Pressure: 360 bar Electrical Cabinet: Identification: Cabinet D04 Inventory Label: "4023488" / "92" Hydraulic System: Unit Manufacturer: Harburg-Freudenberger Tank Manufacture Date: 06.2012 Pump/Motor: Vertical mount electric motor configuration Loading Mechanism: Automatic green tire loading arms - LISTING 2760092

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2012

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: Harburg-Freudenberger Maschinenbau GmbH (Division Rubber Technology) Model / Type: KHP 46-150 Year of Manufacture: 2012 Order Number: 70 825 00 382 Station Identification: Left Station Fact No.: 4L Right Station Fact No.: 4R Asset Number: "D05" Control Interface: Allen-Bradley PanelView Plus 700 with push-button module Technical Data / Specifications Configuration: Vertical twin-cavity curing press Pressure Ratings: Max. Pressure: 250 bar Test Pressure: 360 bar Electrical Cabinet: Identification: Cabinet D05 Inventory Label: "4023487" / "93" Hydraulic System: Unit Manufacturer: Harburg-Freudenberger Tank Manufacture Date: 06.2012 Motor Configuration: Vertical electric motor mounted on tank Loading Mechanism: Automatic green tire loading arms - LISTING 2760093

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2012

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: Harburg-Freudenberger Maschinenbau GmbH (Division Rubber Technology) Model / Type: KHP 46-150 Year of Manufacture: 2012 Order Number: 70 825 00 382 Station Identification: Left Station Fact No.: 3L Right Station Fact No.: 3R Asset Number: Sticker "D06" Control Interface: Allen-Bradley PanelView Plus 700 with physical button array Technical Data / Specifications Configuration: Vertical twin-cavity curing press Pressure Ratings: Max. Pressure: 250 bar Test Pressure: 360 bar Electrical Cabinet: Identification: Cabinet D06 Inventory Label: "4023486" / "94" Hydraulic System: Unit Manufacturer: Harburg-Freudenberger Tank Manufacture Date: 06.2012 Pump/Motor: Vertical mount configuration Loading Mechanism: Automatic green tire loading arms - LISTING 2760094

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2012

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: Harburg-Freudenberger Maschinenbau GmbH (Division Rubber Technology) Model / Type: KHP 46-150 Year of Manufacture: 2012 Order Number: 70 825 00 382 Station Identification: Left Station Fact No.: 2L Right Station Fact No.: 2R Asset Number: "D07" Control Interface: Allen-Bradley PanelView Plus 700 with physical button module Technical Data / Specifications Configuration: Vertical twin-cavity curing press Pressure Ratings: Max. Pressure: 250 bar Test Pressure: 360 bar Electrical Cabinet: Identification: Cabinet D07 Inventory Label: "4023485" / "95" Hydraulic System: Unit Manufacturer: Harburg-Freudenberger Tank Manufacture Date: 06.2012 Pump/Motor: Vertical mount electric motor configuration Loading Mechanism: Automatic green tire loading arms - LISTING 2760095

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2012

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: Harburg-Freudenberger Maschinenbau GmbH (Division Rubber Technology) Model / Type: KHP 46-150 Year of Manufacture: 2012 Order Number: 70 825 00 382 Station Identification: Left Station Fact No.: 1L Right Station Fact No.: 1R Asset Number: Sticker "D08" Control Interface: Allen-Bradley PanelView Plus 700 with physical button module Technical Data / Specifications Configuration: Vertical twin-cavity curing press Pressure Ratings: Max. Pressure: 250 bar Test Pressure: 360 bar Electrical Cabinet: Identification: Cabinet D08 Inventory Label: "4023484" / "96" Hydraulic System: Unit Manufacturer: Harburg-Freudenberger Tank Manufacture Date: 06.2012 Pump/Motor: Vertical mount electric motor configuration Loading Mechanism: Automatic green tire loading arms - LISTING 2760096

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2012

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: MCP 52-180IC Year of Manufacture: 2021 Order Number: 7782500896 Station Identification: Left Station Fact No.: 1L Right Station Fact No.: 1R Asset Number: "D09" Control Interface: Allen-Bradley PanelView Plus terminal with manual override switches Technical Data / Specifications Configuration: Vertical twin-cavity curing system Hydraulic System: Unit Manufacturer: Parker Motor: Electric drive motor mounted on top of blue reservoir Reservoir: Blue steel tank with integrated level monitoring Loading System: Automatic green tire loading mechanism with front-facing chucks - LISTING 2760097

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH MCP 52-180IC | 2021

Binding Handling & Service Fee:

19700 € (EURO)

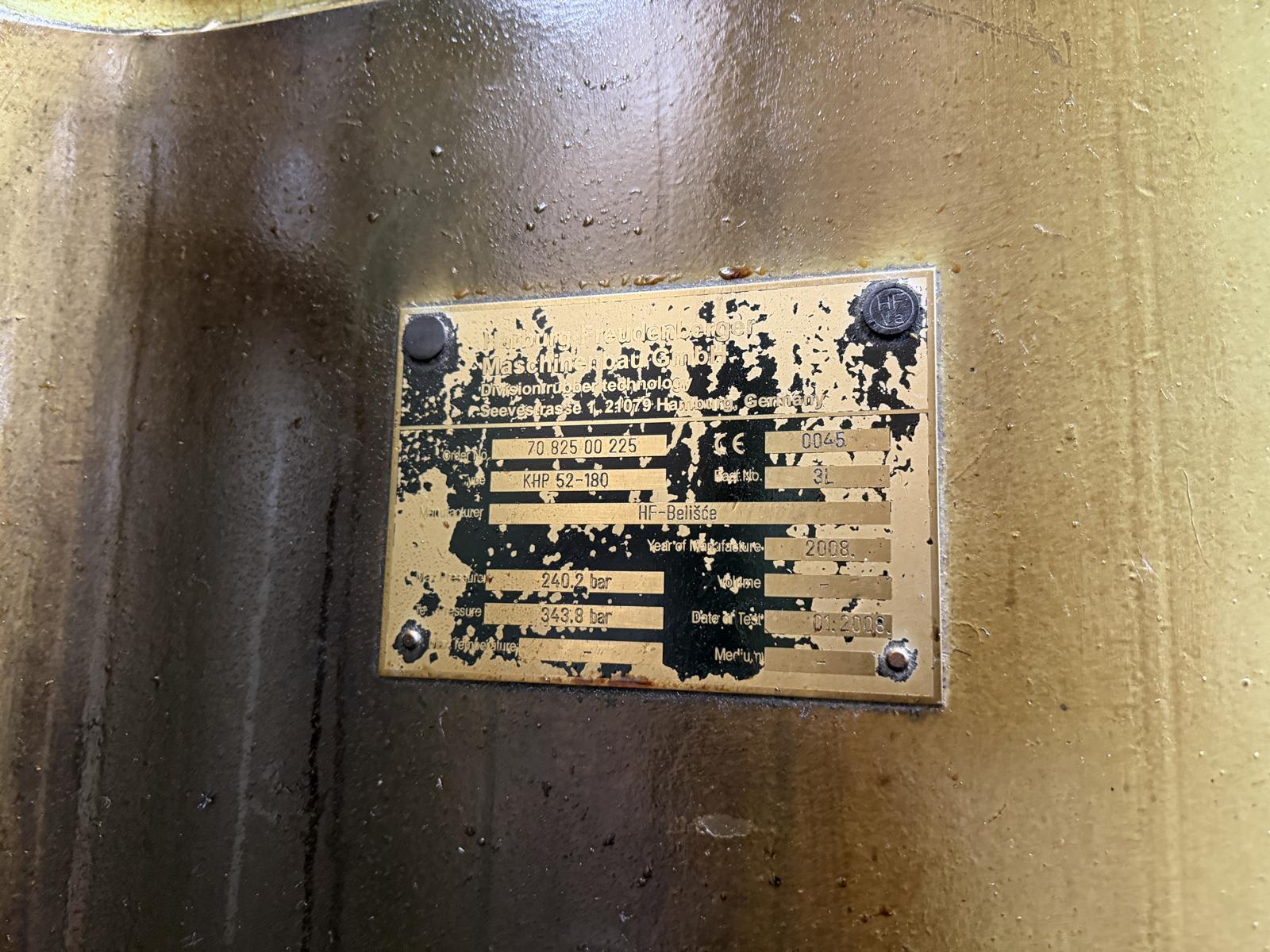

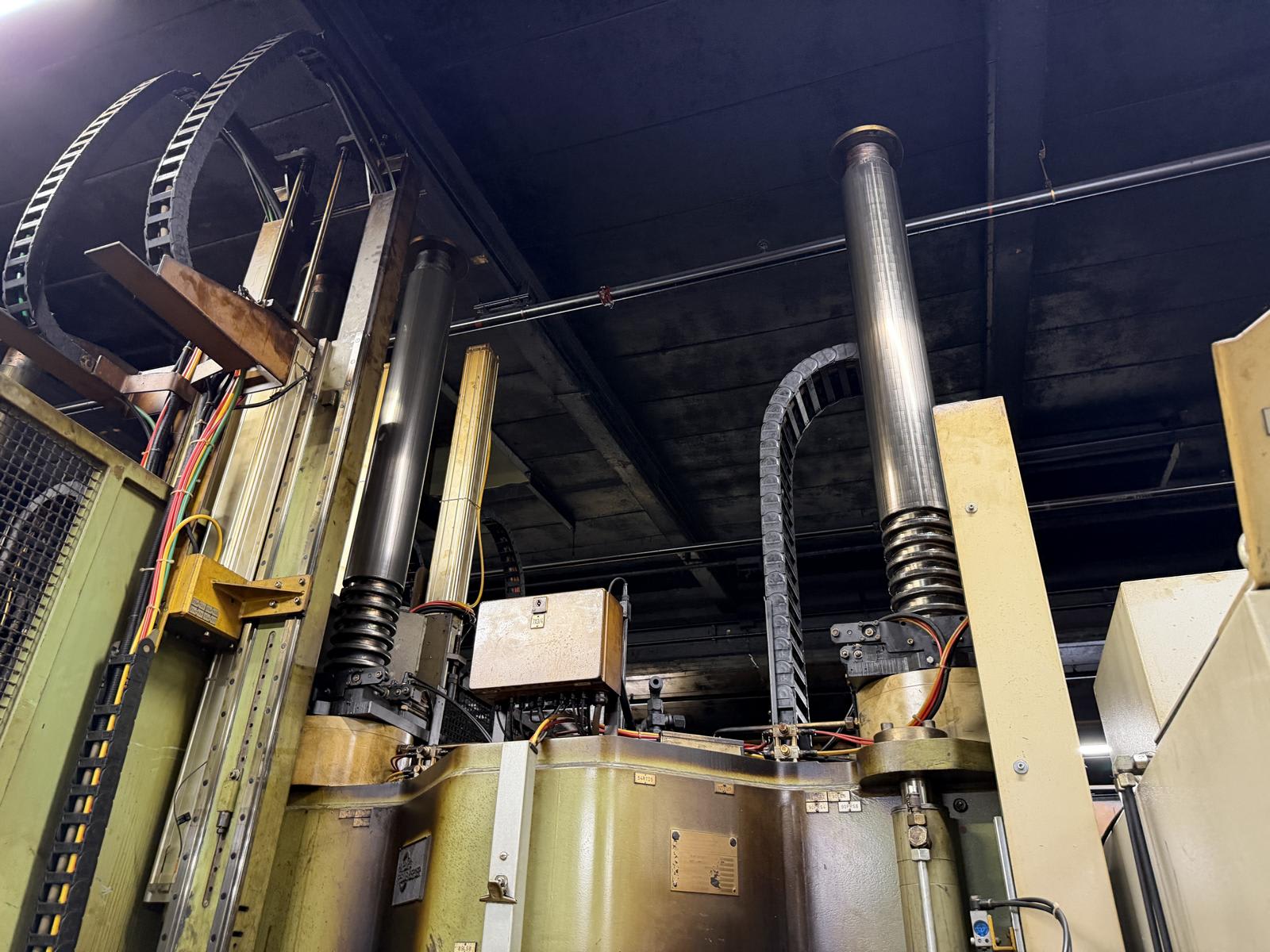

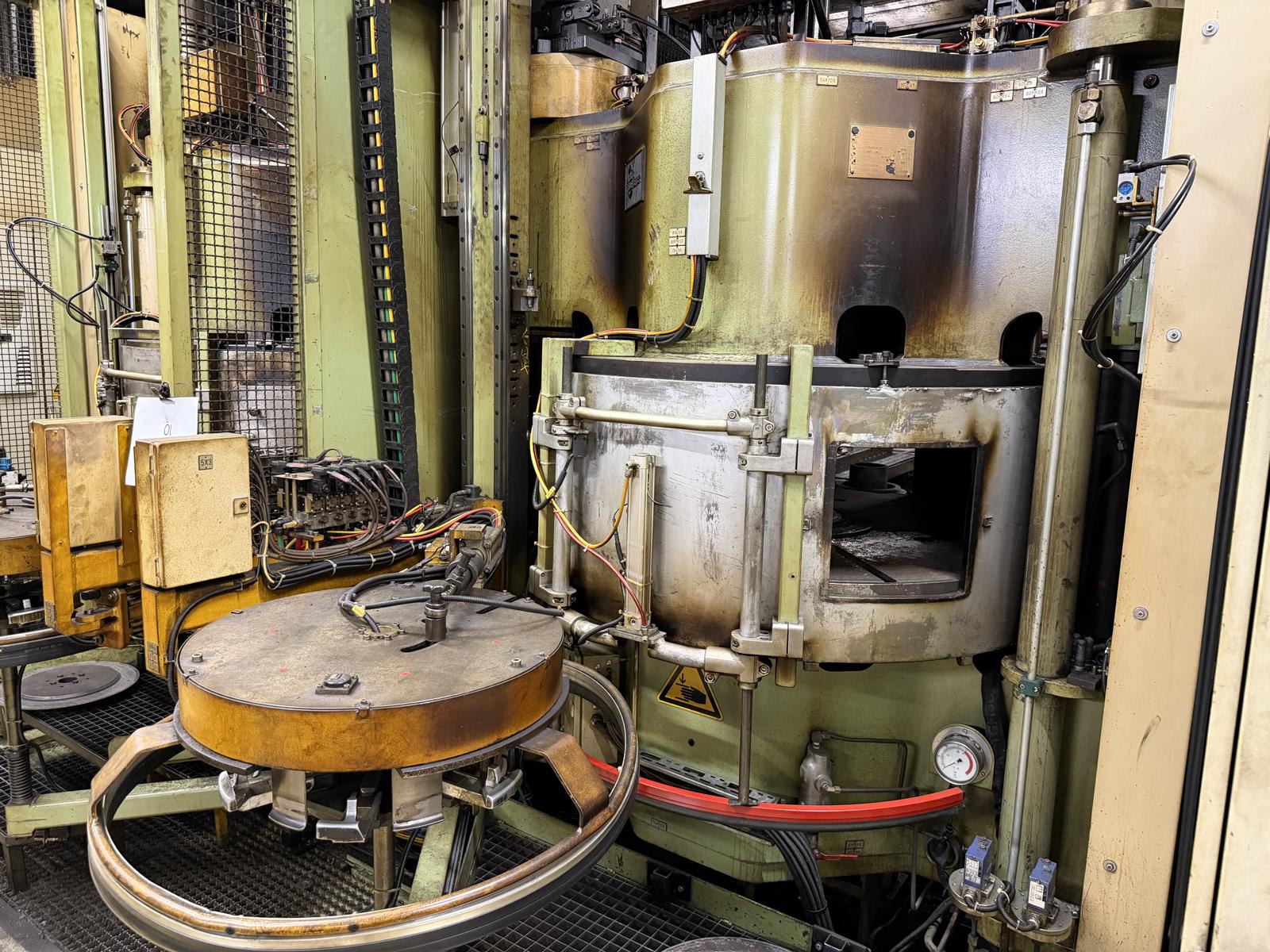

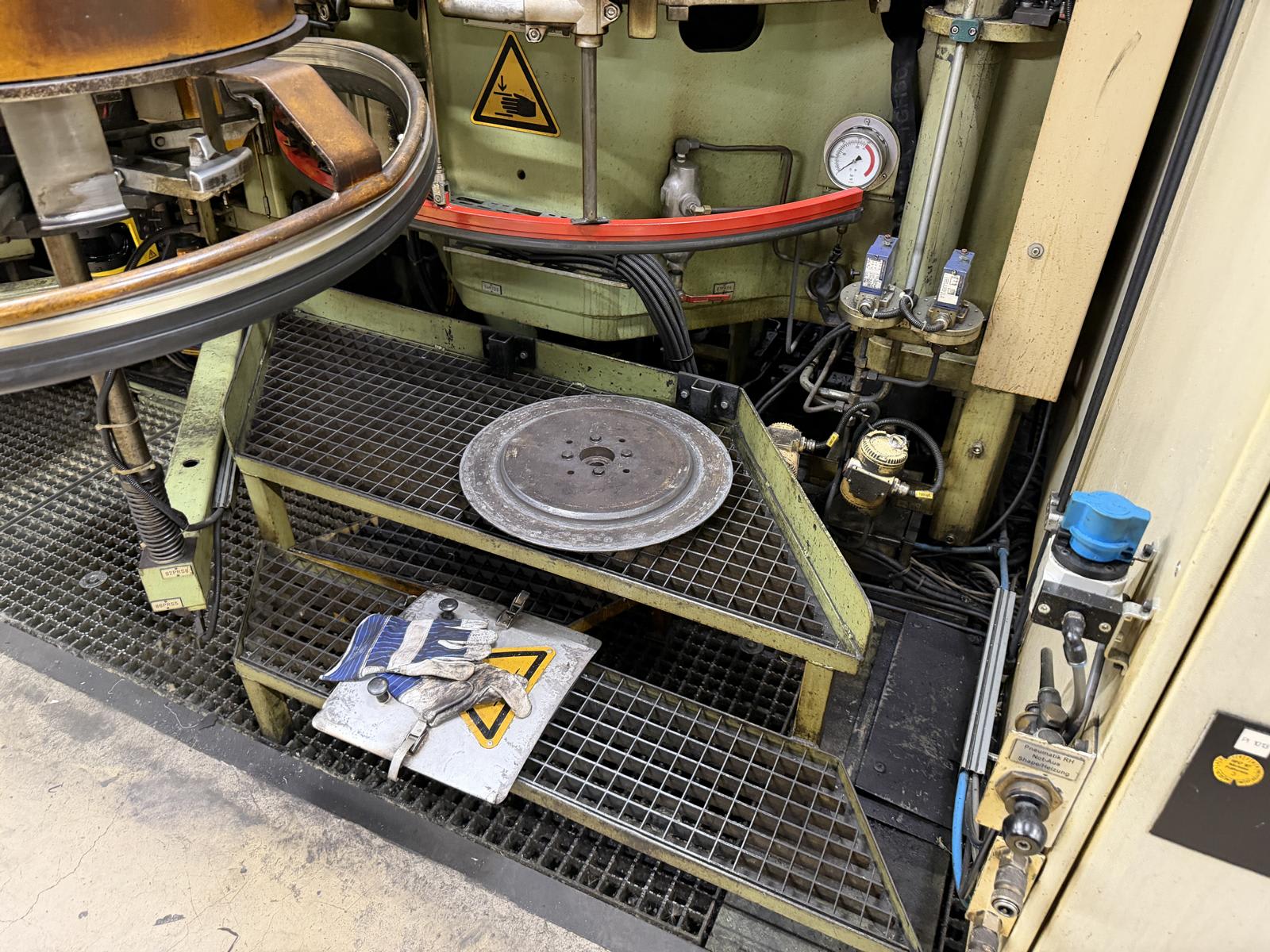

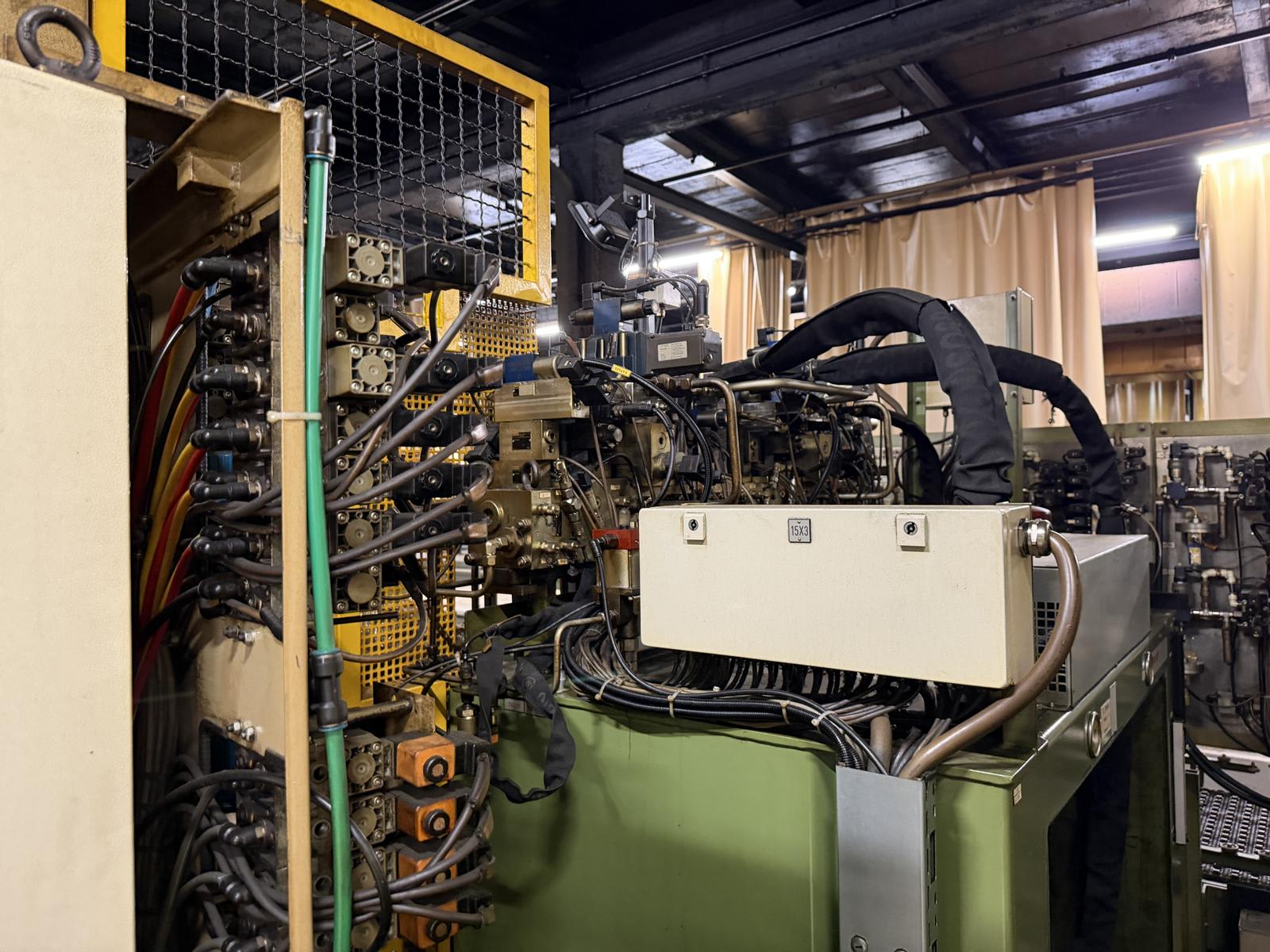

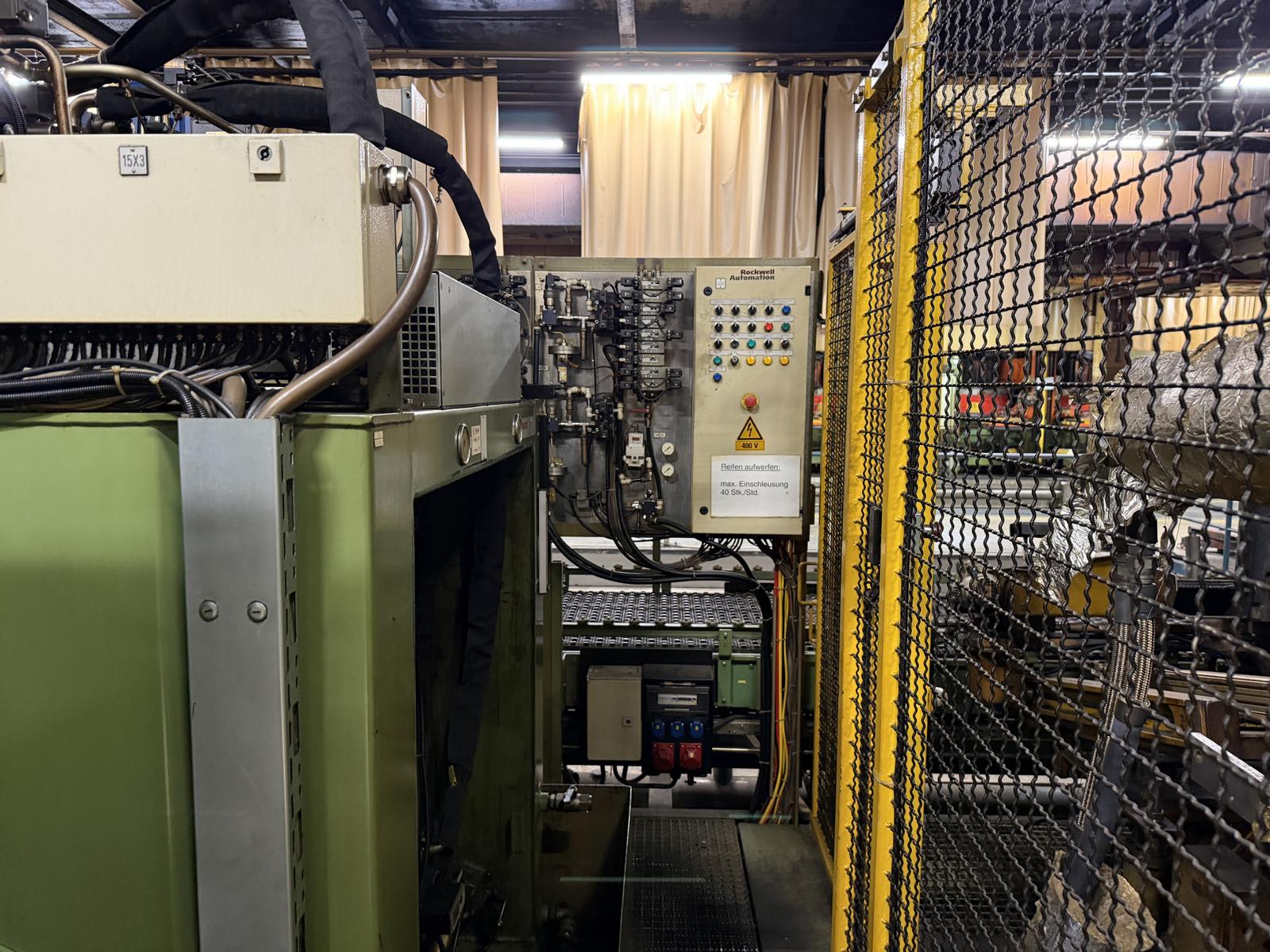

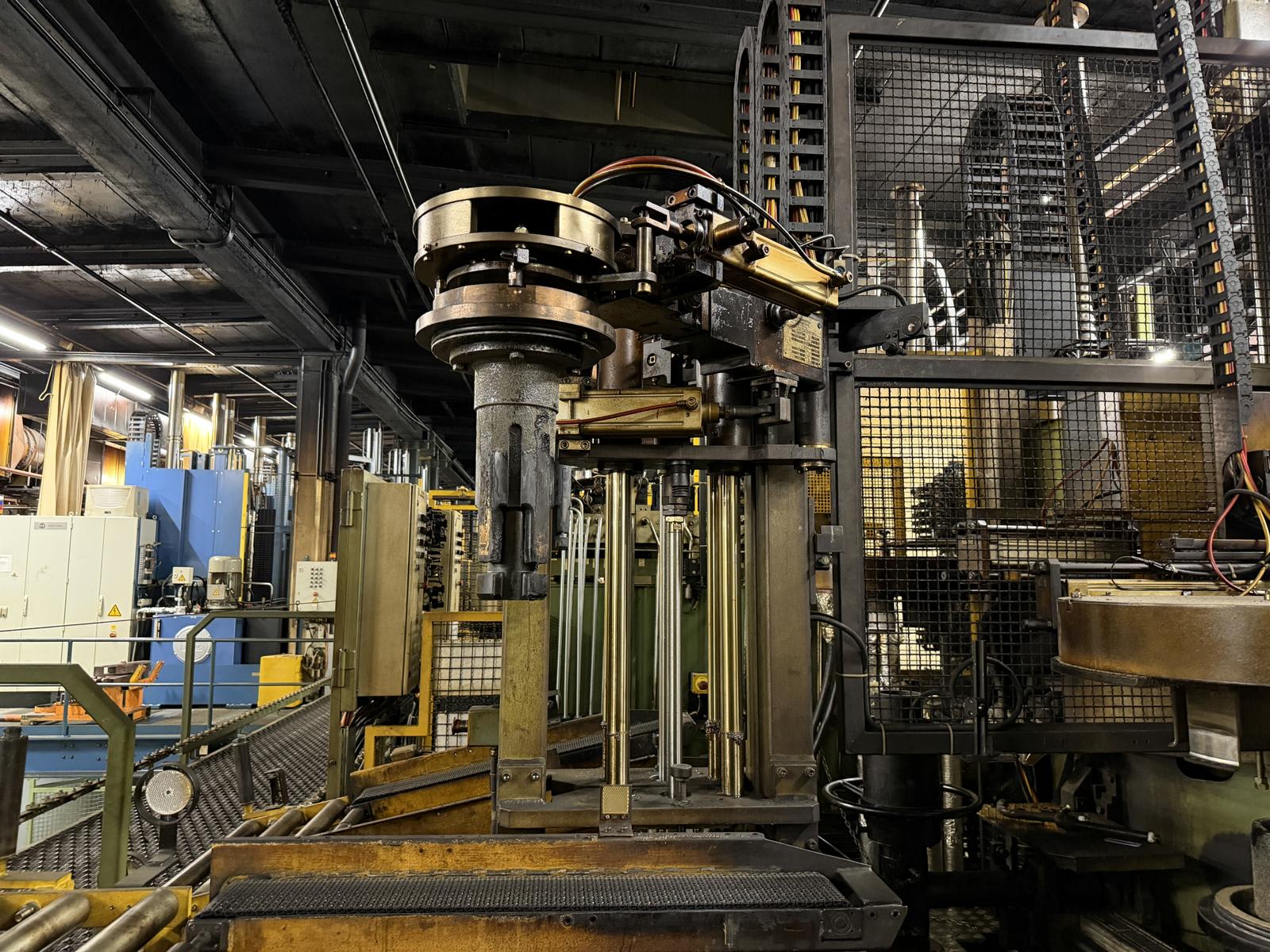

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press 2. General Information Manufacturer: Harburg-Freudenberger Maschinenbau GmbH (Division Rubber Technology) Model / Type: KHP 52-180 Year of Manufacture: 2008 Order Number: 70 825 00 225 Station Identification Left Station (Factory No.): 3L Right Station (Factory No.): 3R Control Interface System: Rockwell Automation / Allen-Bradley PanelView Plus 700 Operator Controls: Integrated physical push-button and selector switch array 3. Technical Data / Specifications Configuration: Vertical twin-cavity hydraulic curing press Pressure Ratings Maximum Pressure: 240.2 bar Test Pressure: 343.8 bar Test Date: January 2008 Electrical Cabinet Identification: Cabinet D10 Inventory Labels: “4019310” / “98” Hydraulic System Unit Manufacturer / Components: Rexroth (visible on green hydraulic unit) Pump / Motor: Rear-mounted electric motor drive configuration Loading Mechanism System: Automatic green tire loading system Mold Handling: Segmented mold operators - LISTING 2760098

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 52-180 | 2008

Binding Handling & Service Fee:

19700 € (EURO)

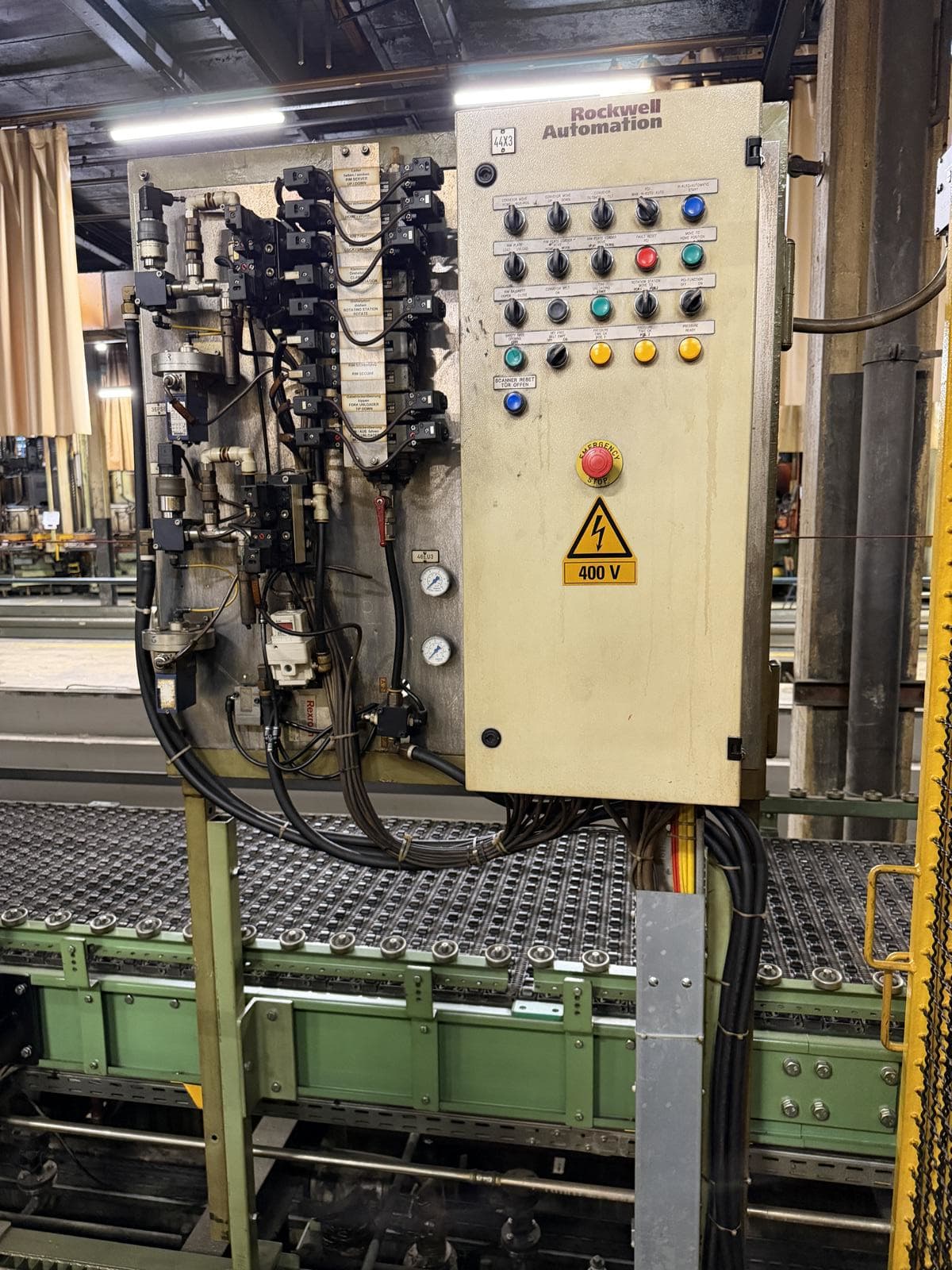

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press 2. General Information Manufacturer: Harburg-Freudenberger Maschinenbau GmbH (Division Rubber Technology) Model / Type: KHP 52-180 Year of Manufacture: 2008 Order Number: 70 825 00 225 Station Identification Left Station (Factory No.): 4L Right Station (Factory No.): 4R Control Interface System: Rockwell Automation / Allen-Bradley PanelView Plus 700 Operator Controls: Integrated physical push-button array 3. Technical Data / Specifications Configuration: Vertical twin-cavity hydraulic curing press Pressure Ratings Maximum Pressure: 240.2 bar Test Pressure: 343.8 bar Test Date: January 2008 Electrical Cabinet Identification: Cabinet D11 Inventory Labels: “4019311” / “99” Hydraulic System Unit Configuration: Rear-mounted green hydraulic tank and manifold system Components: Rexroth hydraulic valves and pressure gauges (visibly installed) Loading Mechanism System: Automatic green tire loading system Mold Handling: Segmented mold operators Auxiliary Control System Control Panel: Secondary pneumatic/hydraulic valve control panel Manufacturer: Rockwell Automation Installation Location: Mounted on conveyor in-feed - LISTING 2760099

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 52-180 | 2008

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press 2. General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: KHP 46-150 Year of Manufacture: 2014 Order Number: 7282500526 Station Identification Left Station (Factory No.): 4L Right Station (Factory No.): 4R Control Interface System: Rockwell Automation / Allen-Bradley PanelView Plus 700 Operator Controls: Integrated physical push-button array 3. Technical Data / Specifications Configuration: Vertical twin-cavity hydraulic curing press Pressure Ratings Maximum Pressure: Not explicitly legible on the installed nameplate; consistent with KHP 46-150 series design parameters (typically approx. 250 bar based on model specification). Electrical Cabinet Identification: Cabinet B01 Inventory Labels: “024398” / “100” Hydraulic System Unit Manufacturer: Parker Tank / Components: Branded hydraulic reservoir and system components Pump / Motor: Vertical-mounted electric motor on white/beige hydraulic tank Loading Mechanism System: Automatic green tire loading system Mold Handling: Segmented mold operators Pneumatic Control System Control Panel: Dedicated pneumatic control panel (Pneumatik PC) Equipment: Pressure regulators and solenoid valves - LISTING 2760100

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2014

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press 2. General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: KHP 46-150 Year of Manufacture: 2014 Order Number: 70 825 00 526 Station Identification Left Station (Factory No.): 3L Right Station (Factory No.): 3R Control Interface System: Rockwell Automation / Allen-Bradley PanelView Plus 700 Operator Controls: Integrated physical push-button array 3. Technical Data / Specifications Configuration: Vertical twin-cavity hydraulic curing press Electrical Cabinet Identification: Cabinet B02 Inventory Labels: “4024396” / “101” Hydraulic System Unit Manufacturer: Parker Tank / Components: Branded hydraulic reservoir and system components Pump / Motor Configuration: Vertical-mounted electric motor on beige/white hydraulic tank Loading Mechanism System: Automatic green tire loading system Mold Handling: Segmented mold operators Pneumatic Control System Control Type: Integrated pneumatic valve terminal Equipment: Pressure regulation and solenoid valve controls - LISTING 2760101

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2014

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press 2. General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: KHP 46-150 Year of Manufacture: 2014 Order Number: 70 825 00 526 Station Identification Left Station (Factory No.): 2L Right Station (Factory No.): 2R Control Interface System: Rockwell Automation / Allen-Bradley PanelView Plus 700 Operator Controls: Integrated physical push-button array 3. Technical Data / Specifications Configuration: Vertical twin-cavity hydraulic curing press Electrical Cabinet Identification: Cabinet B03 Inventory Labels: “4024395” / “102” Hydraulic System Unit Manufacturer: Parker Tank / Components: Branded hydraulic reservoir and system components Pump / Motor Configuration: Vertical-mounted electric motor on beige/white hydraulic tank Model Consistency: Configuration consistent with 2014 KHP 46-150 series specification Loading Mechanism System: Automatic green tire loading system Mold Handling: Segmented mold operators Pneumatic Control System Control Type: Integrated pneumatic valve terminal (Pneumatik PC) Functionality: Pressure regulation and solenoid valve control - LISTING 2760102

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2014

Binding Handling & Service Fee:

19700 € (EURO)

1. General Designation Machine Name: Dual Station Hydraulic Tire Curing Press Asset Number: Sticker “103” (observed on Electrical Cabinet B04) 2. General Information Manufacturer: HF TireTech Group (Harburg-Freudenberger Maschinenbau GmbH) Model / Type: KHP 46-150 Year of Manufacture: 2014 Order Number: 70 825 00 526 Station Identification Left Station (Factory No.): 1L Right Station (Factory No.): 1R Control Interface System: Rockwell Automation / Allen-Bradley PanelView Plus 700 Operator Controls: Integrated physical push-button array 3. Technical Data / Specifications Configuration: Vertical twin-cavity hydraulic curing press Electrical Cabinet Identification: Cabinet B04 Inventory Labels: “4024397” / “103” Hydraulic System Unit Manufacturer: Parker Tank / Components: Branded hydraulic reservoir and system components Pump / Motor Configuration: Vertical-mounted electric motor on beige/white hydraulic tank Pneumatic Control System Control Type: Integrated pneumatic valve terminal (Pneumatik PC) Functionality: Pressure regulation and solenoid valve control - LISTING 2760103

![Deutsch]()

Dual Station Hydraulic Tire Curing Press Harburg-Freudenberger Maschinenbau GmbH KHP 46-150 | 2014

Binding Handling & Service Fee:

19700 € (EURO)

General Information • Machine type: Tire Building Machine (TBM) • Product designation: R 2.5 TBM • Application: Automated building of tire components into green tires Machine Configuration • Multi-station tire building machine with linear layout • Heavy-duty steel base frames (green painted) aligned in series • Central tire building drum station with horizontal spindle axis • Additional stations arranged before and after the drum station • Overhead gantry structure spanning the working area Tire Building and Handling Functions • Central building drum for cylindrical tire assembly • Automated application stations arranged along the machine axis • Rotating spindles for component positioning - LISTING 2760104

![Deutsch]()

Tire Building Machine R 2.5 TBM